Fluorocarbon spray coating and etching aluminum veneer and preparation process of fluorocarbon spray coating and etching aluminum veneer

A preparation process and a technology for etching aluminum, which is applied in the coating process of metal materials, processes used to produce decorative surface effects, coatings, etc., can solve the problem of insufficient bonding force between the coating and aluminum veneer, and the surface coating is resistant to atmospheric corrosion. Poor performance, inconvenience for daily maintenance and other problems, to achieve the effect of easy daily maintenance, reliable and easy process, and strong self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, a preparation process of fluorocarbon spraying and etching aluminum veneer: it comprises the following process steps:

[0057] A. Sheet metal processing: Select a 2mm thick aluminum alloy panel for sheet metal processing according to the design requirements;

[0058] B. Grinding: Use a pneumatic grinder and use 180# sandpaper to grind the surface of the aluminum plate to remove mechanical scratches on the surface of the aluminum plate due to the processing process.

[0059] C. Etched aluminum veneer:

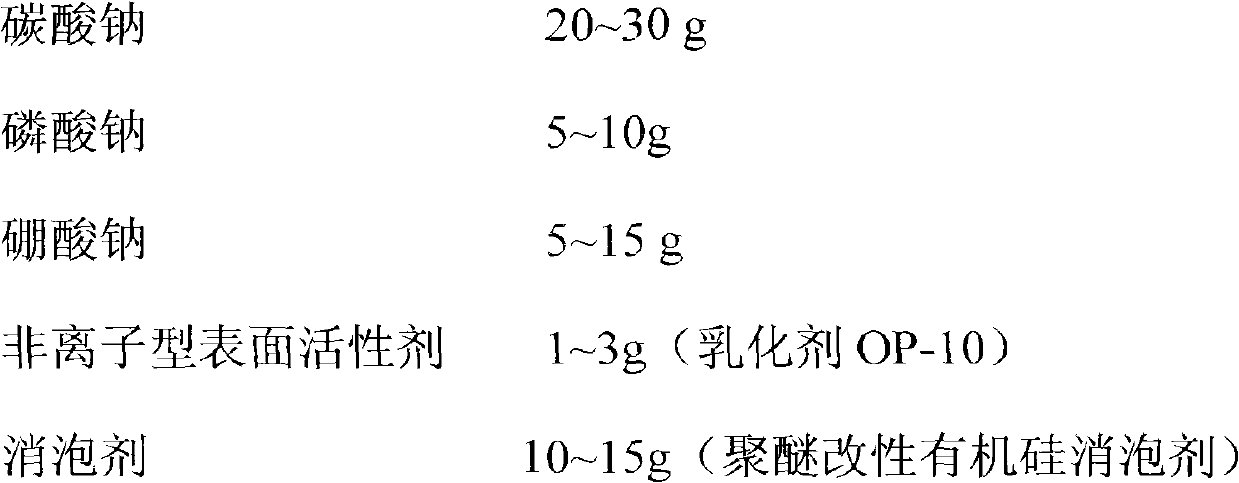

[0060] C1. Degreasing: degreasing the aluminum alloy panel obtained in step B for 10 minutes at 50°C with a degreasing solution, and each liter of the degreasing solution includes the following raw materials:

[0061]

[0062] C2, washing with water;

[0063] C3, drying;

[0064] C4. Pattern printing:

[0065] C4.1: According to the requirements of the pattern, make a standard pattern screen printing screen (choose 100 mesh stainless steel, polyester or...

Embodiment 2

[0090] Embodiment 2, a preparation process of fluorocarbon spraying and etching aluminum veneer: it includes the following process steps:

[0091] A. Sheet metal processing: Select a 4mm thick aluminum alloy panel for sheet metal processing according to the design requirements;

[0092] B. Grinding: Use a pneumatic grinder and use 180# sandpaper to grind the surface of the aluminum plate to remove mechanical scratches on the surface of the aluminum plate due to the processing process.

[0093] C. Etched aluminum veneer:

[0094] C1. Degreasing: The aluminum alloy panel obtained in step B is degreased at 80° C. for 1 minute with a degreasing solution, and each liter of the degreasing solution includes the following raw materials:

[0095]

[0096] C2, washing with water;

[0097] C3, drying;

[0098] C4. Pattern printing:

[0099] C4.1: According to the requirements of the pattern, make a standard pattern screen printing screen (select 250 mesh stainless steel, polyester...

Embodiment 3

[0124] Embodiment 3, a preparation process of fluorocarbon spraying and etching aluminum veneer: it includes the following process steps:

[0125] A. Sheet metal processing: Select a 3mm thick aluminum alloy panel for sheet metal processing according to the design requirements;

[0126] B. Grinding: Use a pneumatic grinder and use 180# sandpaper to grind the surface of the aluminum plate to remove mechanical scratches on the surface of the aluminum plate due to the processing process.

[0127] C. Etched aluminum veneer:

[0128] C1. Degreasing: degreasing the aluminum alloy panel obtained in step B for 8 minutes at 60° C., and each liter of degreasing liquid includes the following raw materials:

[0129]

[0130] C2, washing with water;

[0131] C3, drying:

[0132] C4. Pattern printing:

[0133] C4.1: According to the requirements of the pattern, make a standard pattern screen printing screen (choose 180 mesh stainless steel, polyester or nylon monofilament mesh). Und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com