Anodized aluminum plate and preparation technique thereof

An anodized aluminum, preparation technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of easy softening, peeling and falling off of the coating layer, and achieve reliable and easy process and impact resistance Good mechanical properties, improved wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

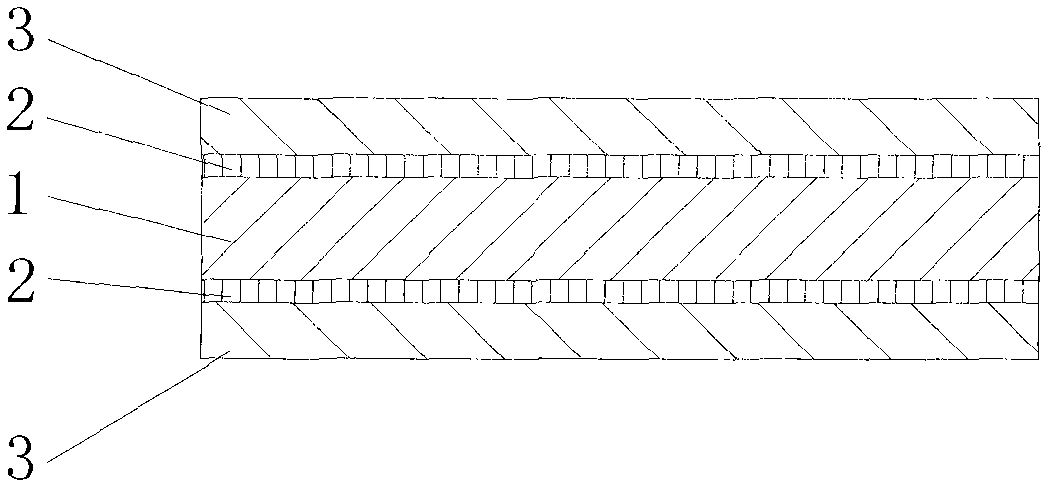

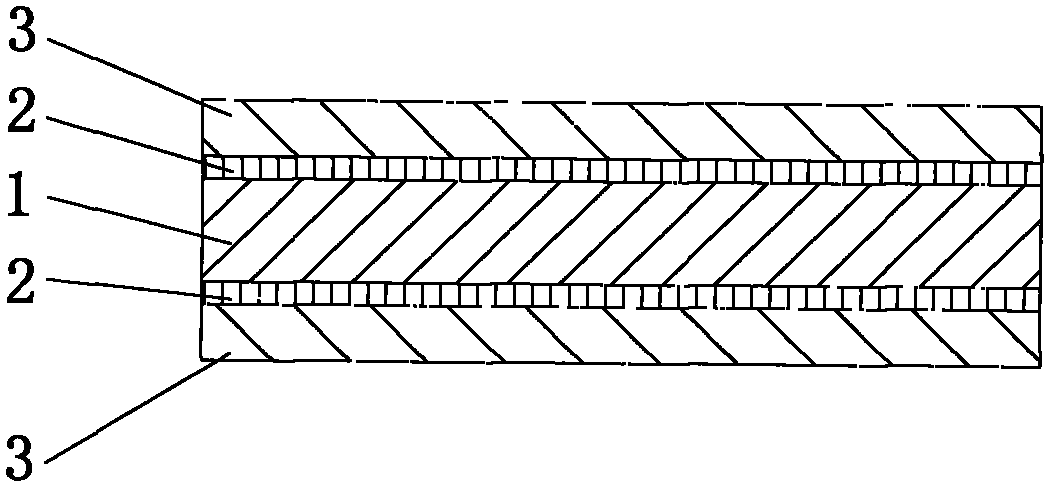

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of anodized aluminum plate, its preparation process comprises the following steps:

[0046] A. Sheet metal processing: select 1mm thick aluminum or aluminum alloy panels for sheet metal processing, so as to achieve the workpiece with the dimensional accuracy and shape accuracy specified in the design;

[0047] B. Hanging: Clamp the workpiece with an elastic fixture to ensure current flow, because an oxide film will be formed quickly on the surface of the fixture and the workpiece during anodic oxidation, and the contact point will be changed if the fixture and workpiece are slightly loose during the process position, which hinders the flow of current, so the workpiece must be clamped with an elastic clamp to avoid burning the workpiece due to heat generated by poor contact;

[0048] C. Anodizing:

[0049] C1, chemical degreasing: the workpiece obtained in step A is alkaline-washed for 1 minute at 50° C. with an alkaline lotion to remove organic gre...

Embodiment 2

[0072] Embodiment 2: a kind of anodized aluminum plate, its preparation process comprises the following steps:

[0073] A. Sheet metal processing: Select a 4mm thick aluminum or aluminum alloy panel for sheet metal processing, so as to achieve the workpiece with the dimensional accuracy and shape accuracy specified in the design;

[0074] B. Hanging: Clamp the workpiece with an elastic fixture to ensure current flow, because an oxide film will be formed quickly on the surface of the fixture and the workpiece during anodic oxidation, and the contact point will be changed if the fixture and workpiece are slightly loose during the process position, which hinders the flow of current, so the workpiece must be clamped with an elastic clamp to avoid burning the workpiece due to heat generated by poor contact;

[0075] C. Anodizing:

[0076] C1, chemical degreasing: the workpiece obtained in step A is alkaline-washed at 65° C. for 5 minutes with alkaline washing solution to remove or...

Embodiment 3

[0099] Embodiment 3: a kind of anodized aluminum plate, its preparation process comprises the following steps:

[0100] A. Sheet metal processing: Select a 6mm thick aluminum or aluminum alloy panel for sheet metal processing, so as to achieve the workpiece with the dimensional accuracy and shape accuracy specified in the design;

[0101] B. Hanging: Clamp the workpiece with an elastic fixture to ensure current flow, because an oxide film will be formed quickly on the surface of the fixture and the workpiece during anodic oxidation, and the contact point will be changed if the fixture and workpiece are slightly loose during the process position, which hinders the flow of current, so the workpiece must be clamped with an elastic clamp to avoid burning the workpiece due to heat generated by poor contact;

[0102] C. Anodizing:

[0103] C1, chemical degreasing: the workpiece obtained in step A is washed with alkaline washing solution for 10 minutes at 80°C to remove organic grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com