Ceramic aluminum single sheet and preparation process thereof

An aluminum veneer and production process technology, applied in the field of building materials, can solve the problems of insufficient bonding force between the coating and the aluminum veneer, poor atmospheric corrosion resistance of the surface coating, inconvenience for daily maintenance, etc. Reliable and easy process, strong self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

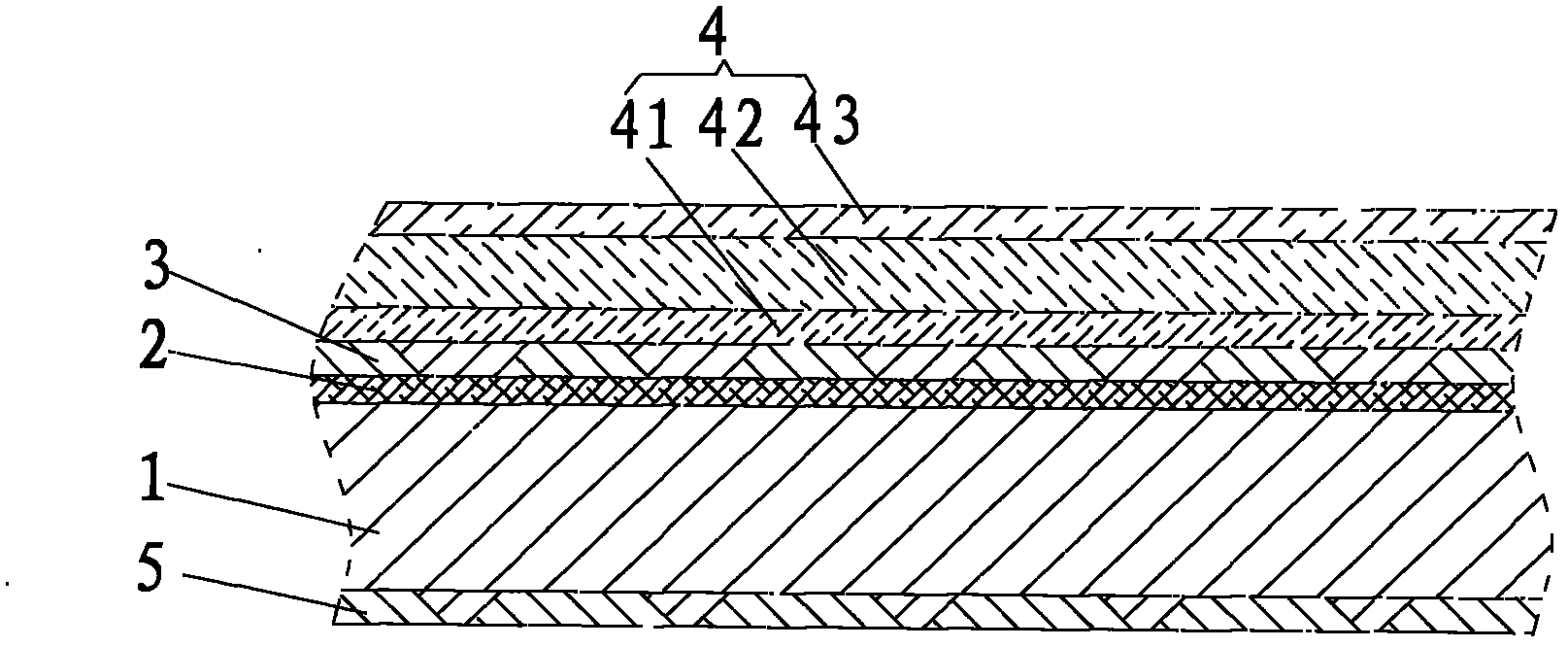

Image

Examples

Embodiment 1

[0041] Embodiment 1, a preparation process of a ceramic aluminum veneer: it includes the following process steps:

[0042] A. Sheet metal processing: select aluminum alloy panels composed of 2mm thick aluminum or alloy plates for sheet metal processing. Sheet metal processing includes process design, cutting, forming, welding, nailing, installation of reinforcing ribs, installation of corner codes, and grinding ;

[0043] B. Sand blasting treatment: spray emery on the outside of the aluminum alloy panel to form a sand blast passivation layer, generally use 60# emery, carry out at room temperature in summer, and preheat the base material in winter (preheat temperature 25 ~ 30 ℃) . Adjust the surface roughness of the workpiece by adjusting the spray angle, pressure, and distance, and the surface roughness should reach Ra3 level;

[0044] C. Pretreatment:

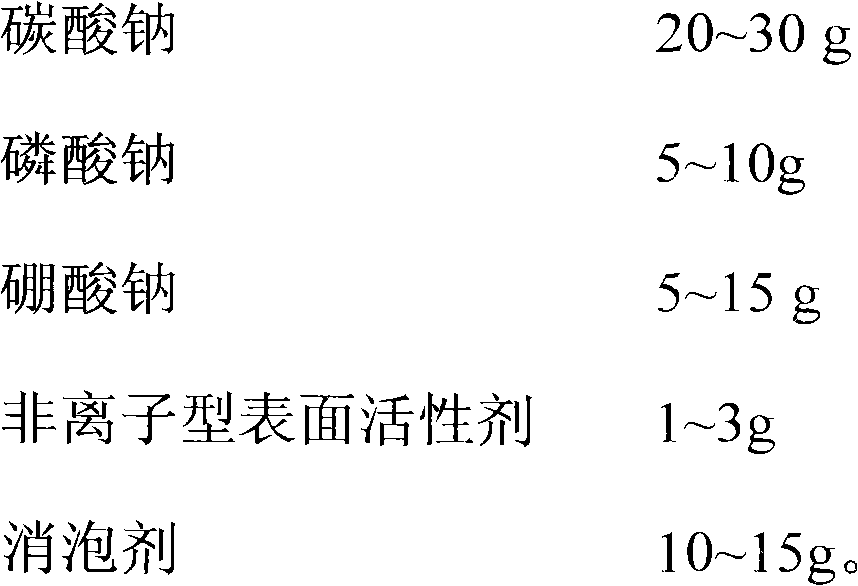

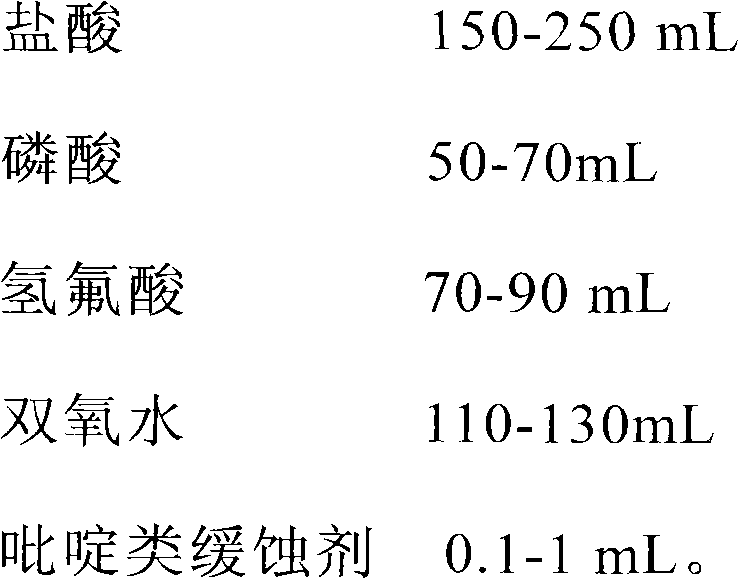

[0045] C1. Degreasing: degreasing the aluminum alloy panel obtained in step A for 10 minutes at 50° C., and each liter of...

Embodiment 2

[0063] Embodiment 2, a preparation process of a ceramic aluminum veneer: it includes the following process steps:

[0064]A. Sheet metal processing: Select aluminum alloy panels made of 4mm thick aluminum or alloy plates for sheet metal processing. Sheet metal processing includes process design, cutting, forming, welding, nailing, installation of reinforcing ribs, installation of corner codes, and grinding ;

[0065] B. Sandblasting treatment: Spray emery on the outside of the aluminum alloy panel to form a passivation layer for sandblasting, generally use 80# emery, carry out at room temperature in summer, and preheat the base material in winter (preheating temperature 25-30°C) . Adjust the surface roughness of the workpiece by adjusting the spray angle, pressure, and distance, and the surface roughness should reach Ra3 level;

[0066] C. Pretreatment:

[0067] C1. Degreasing: The aluminum alloy panel obtained in step A is degreased at 80° C. for 1 minute with a degreasing...

Embodiment 3

[0086] Embodiment 3, a preparation process of a ceramic aluminum veneer: it includes the following process steps:

[0087] A. Sheet metal processing: Select aluminum alloy panels made of 3mm thick aluminum or alloy plates for sheet metal processing. Sheet metal processing includes process design, cutting, forming, welding, nailing, installation of reinforcing ribs, installation of corner codes, and grinding ;

[0088] B. Sand blasting treatment: spray emery on the outside of the aluminum alloy panel to form a sand blast passivation layer, generally use 70# emery, carry out at room temperature in summer, and preheat the base material in winter (preheat temperature 25 ~ 30 ℃) . Adjust the surface roughness of the workpiece by adjusting the spray angle, pressure, and distance, and the surface roughness should reach Ra3 level;

[0089] C. Pretreatment:

[0090] C1. Degreasing: degreasing the aluminum alloy panel obtained in step A for 1-10 minutes at 70° C., and each liter of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com