High-corrosion-resistance gas protection welding wire

A gas shielded welding wire, high corrosion resistance technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve excellent welding process performance, good atmospheric corrosion resistance, and beautiful shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

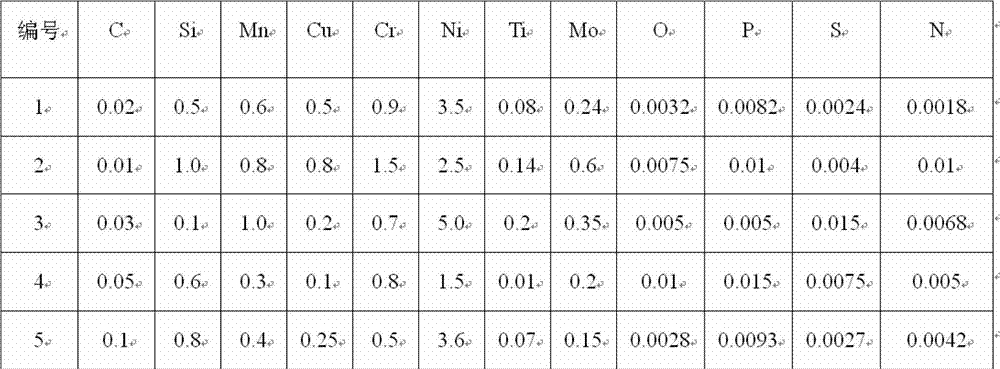

[0030] Below, the present invention will be further described in detail in conjunction with examples.

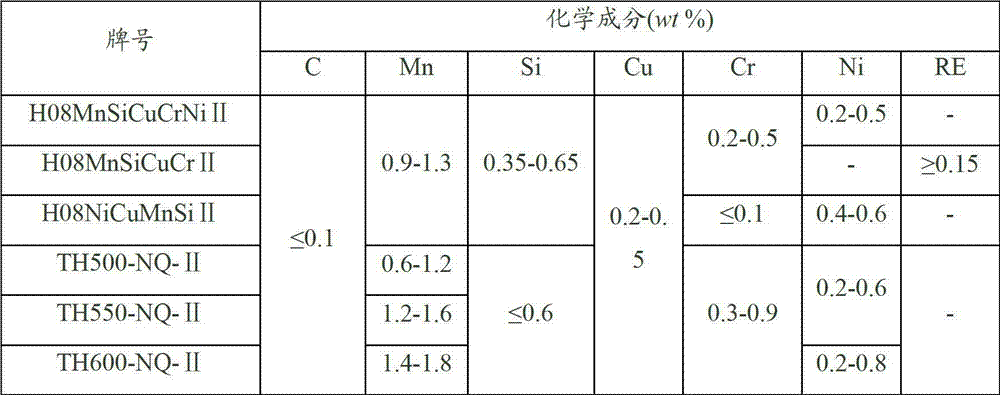

[0031] Within the scope of the chemical composition of the welding wire of the present invention, control smelting is carried out according to the specific chemical composition of each embodiment in Table 4. Then, the smelted steel ingot is rolled into a φ8 wire rod, followed by heat treatment and drawing, and finally a φ1.2 welding wire is obtained.

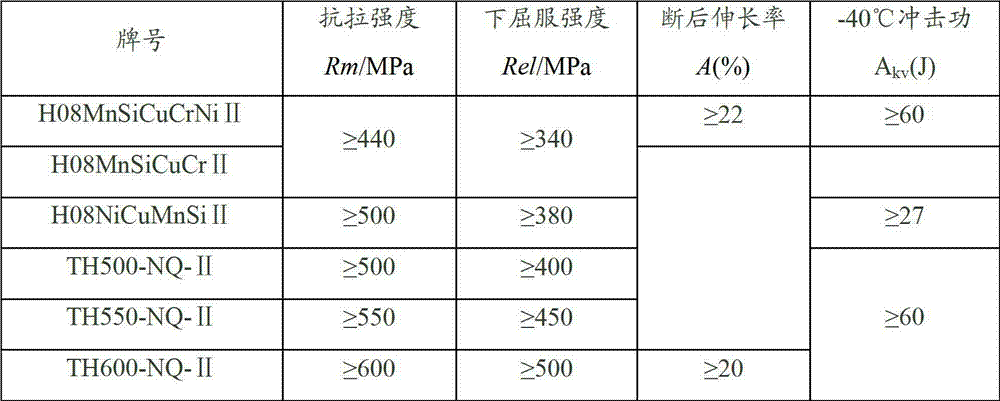

[0032] Using the welding wire of the present invention, with 80%Ar+20%CO 2 The gas is used for the performance test of the deposited metal. Among them, the thickness of the welding test plate is 20mm, the groove form is 45° single-sided V-shaped butt joint, and the bottom surface gap is 12mm. The specific welding specifications are: welding current 260A, arc voltage 29V, welding speed 38cm / min, layer temperature 150°C. After welding, the tensile samples and impact samples of deposited metal were taken for mechanical perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com