Patents

Literature

108results about How to "Improved arc erosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Submicron particle reinforced Ag-based electrical contact material and preparation method thereof

ActiveCN101651050AImprove welding resistanceImprove arc ablation resistanceContactsCopperFusion welding

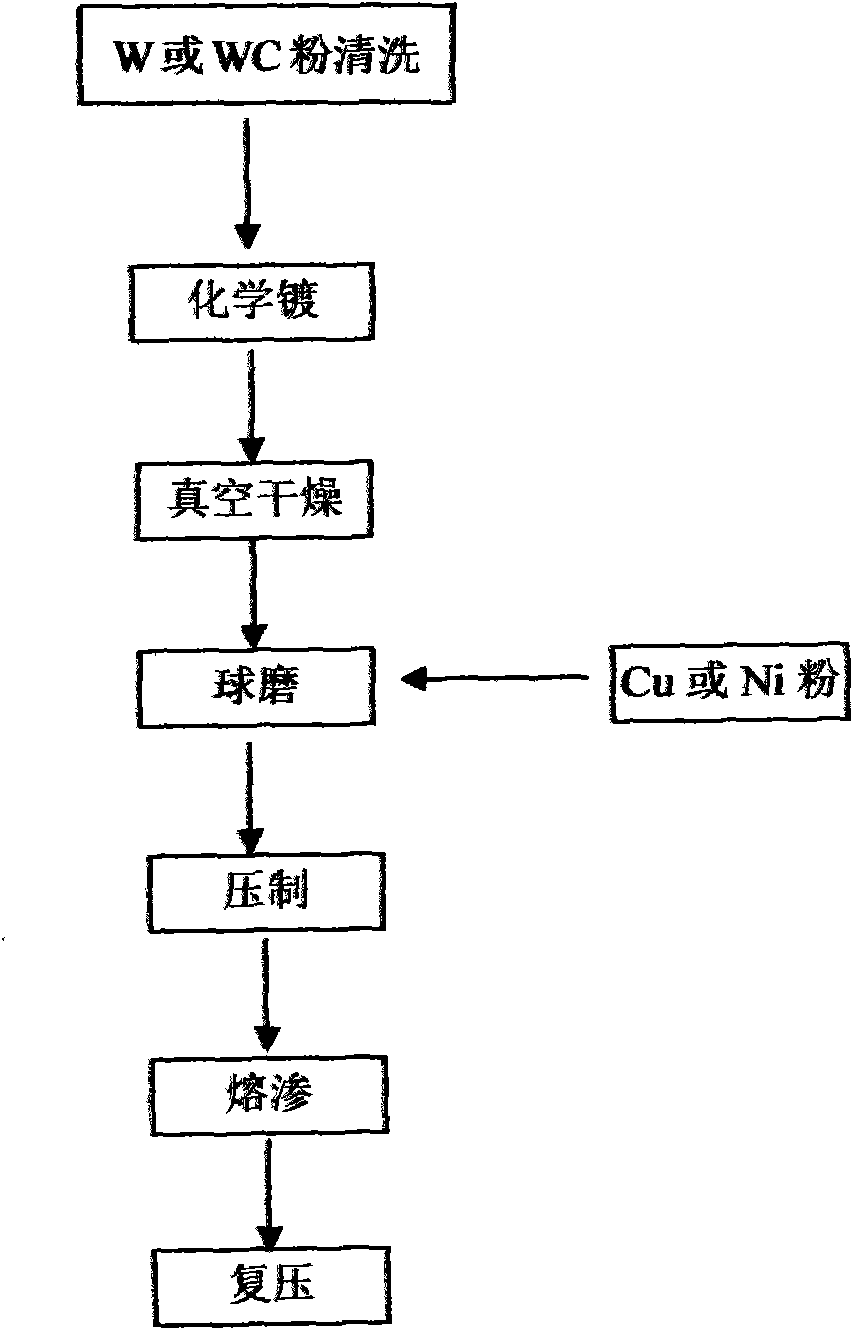

The invention discloses a submicron particle reinforced Ag-based electrical contact material and a preparation method thereof. The method comprises the following steps: adopting chemical plating method to coat silver on the surface of submicron W particles or WC particles, and then adopting pressing infiltration method to prepare dense micron particle reinforced Ag-based composite material. The material comprises the following components by weight percent: 0.1%<=Ni<=2%, 0.1%<=Cu<=2%, 30%<=W(or WC)<=80% and the balance Ag, wherein the grain size of W or WC powder is 0.01-1mu m. The material ofthe invention has good mechanical and physical properties and the reinforced phase particles are dispersed evenly. Compared with the traditional Ag-W material or Ag-WC material, the material has better fusion welding resistance, lower electric arc burning loss resistance and longer electrical life as the tiny high melting point reinforced phase is distributed evenly in the material substrate in dispersion manner.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Preparation method of fine-particle stannic oxide reinforced Ag-based electrical contact material

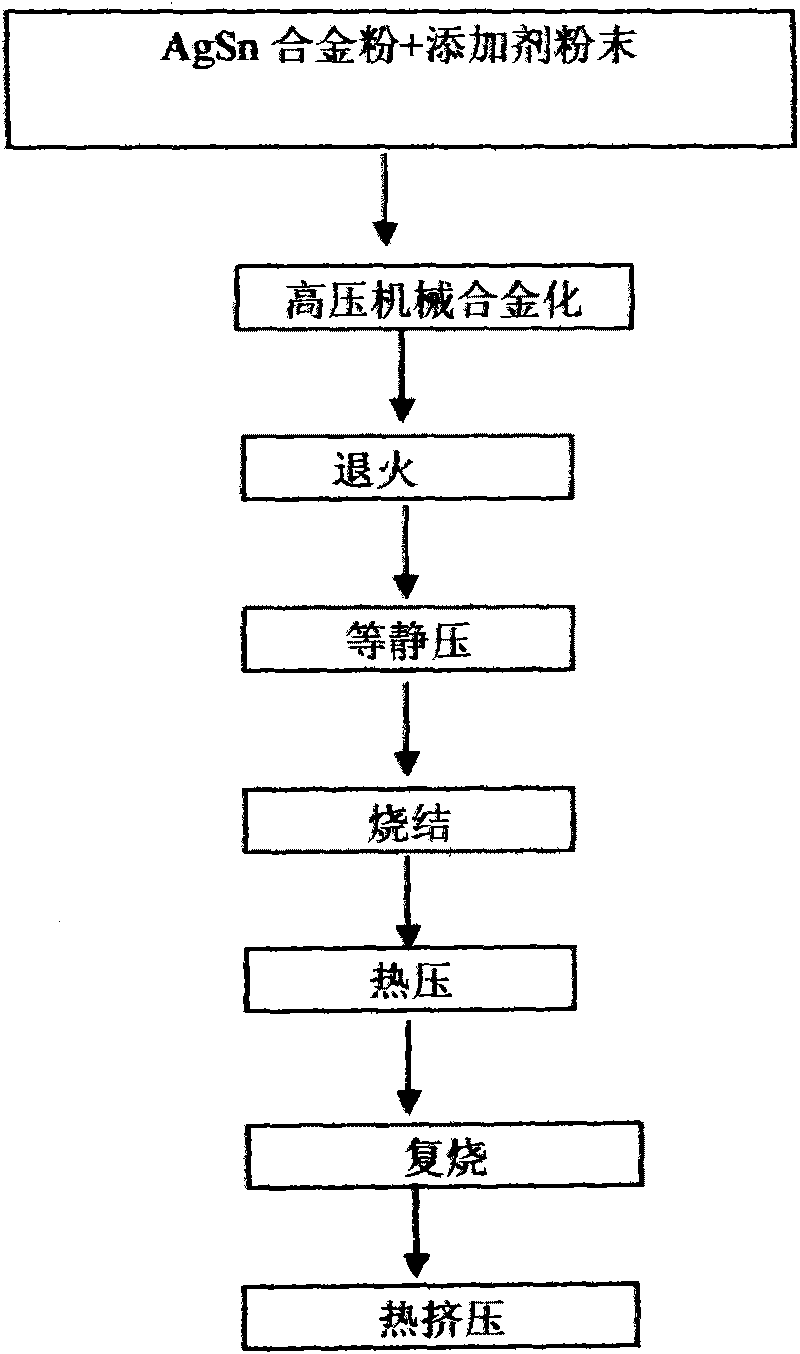

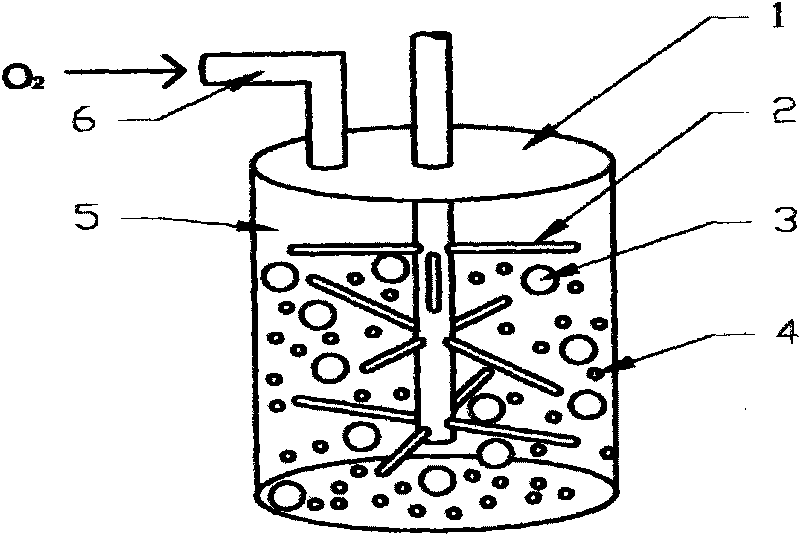

The invention discloses a preparation method of fine-particle stannic oxide reinforced Ag-based electrical contact material, which adopts AgSn alloy powder to be mixed and collide mutually in the ball milling process, and keeps high-pressure oxidative atmosphere in the ball milling process simultaneously to lead the pre-oxidation of the AgSn alloy powder and the ball milling dispersing process to be conducted synchronously, thus greatly shortening the pre-oxidation time of the AgSn alloy, avoiding high-temperature oxidation and improving SnO2 distribution condition. The method has the characteristic of simple and flexible operation, and the silver tin oxide prepared by the method has the ideal structure of submicron or nanometer SnO2 particle reinforced phase dispersed distribution, thus leading the material to have high strength, high electrical conductivity and excellent electrical properties.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

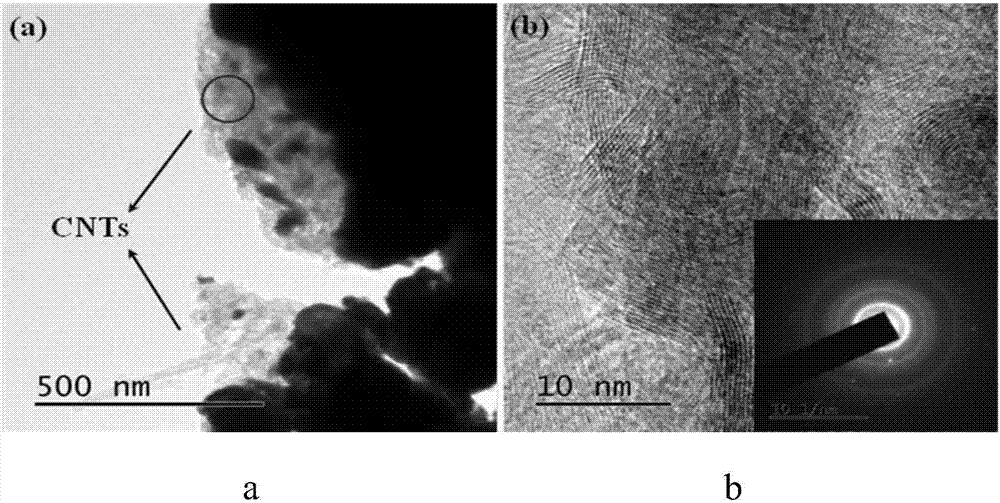

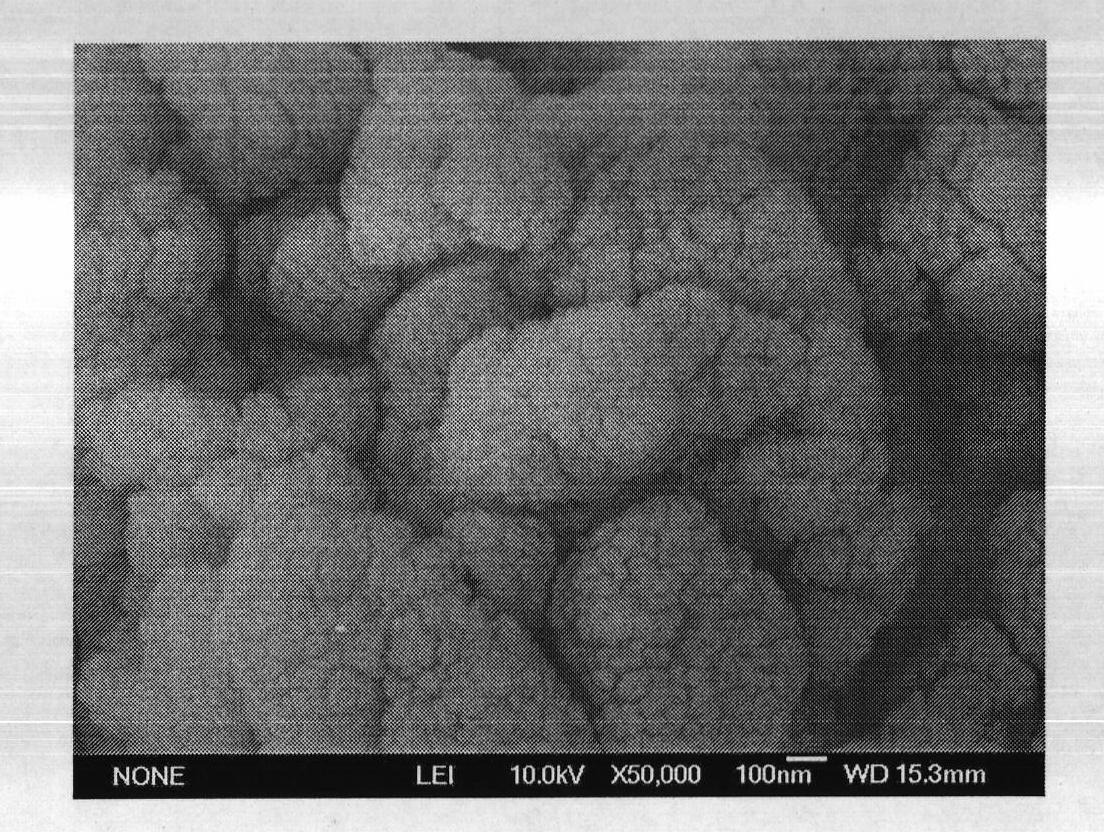

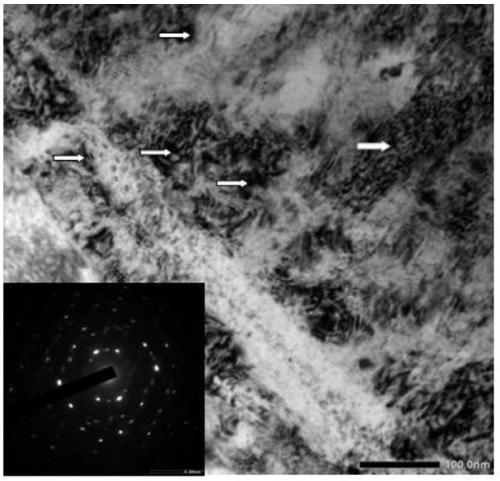

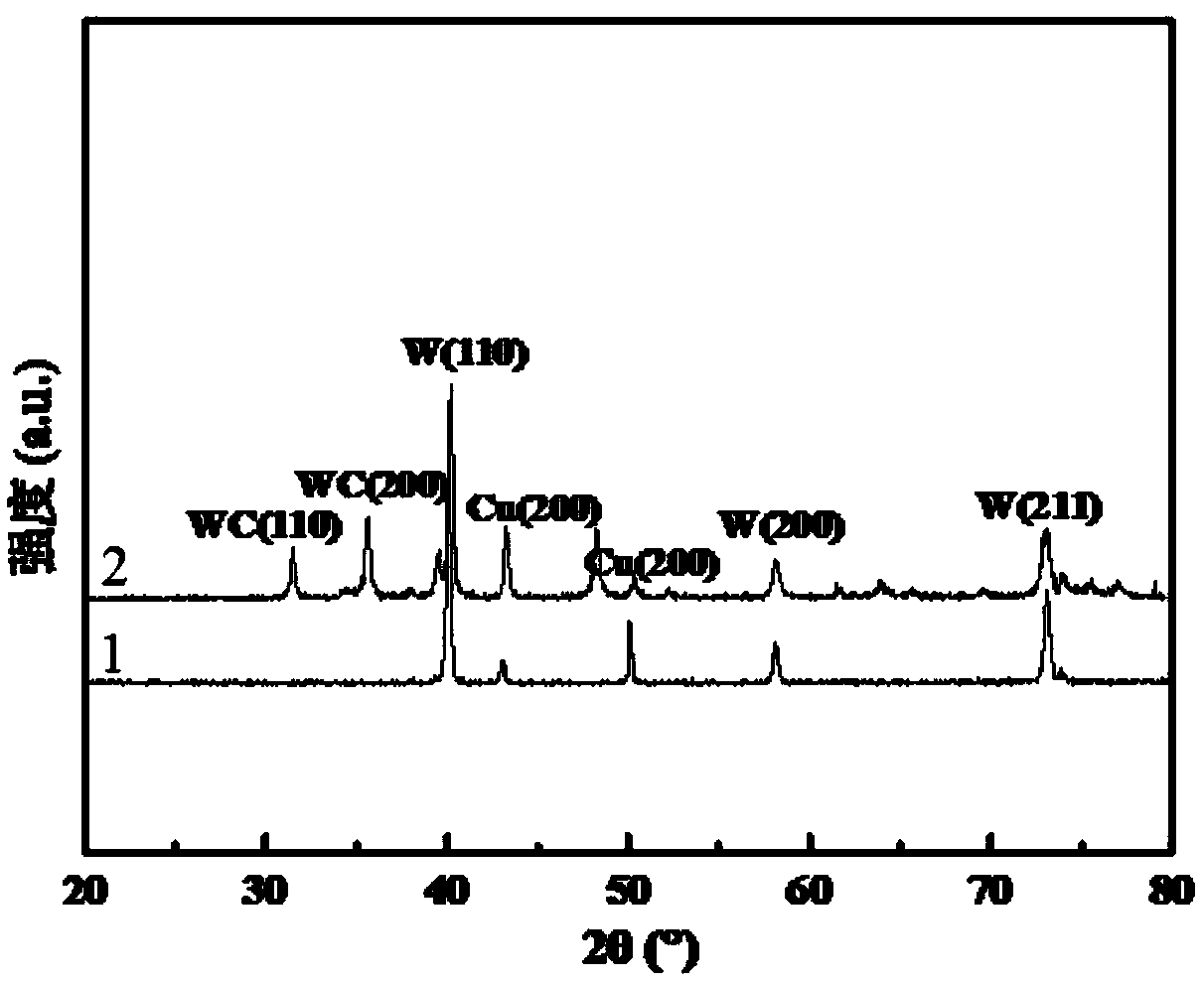

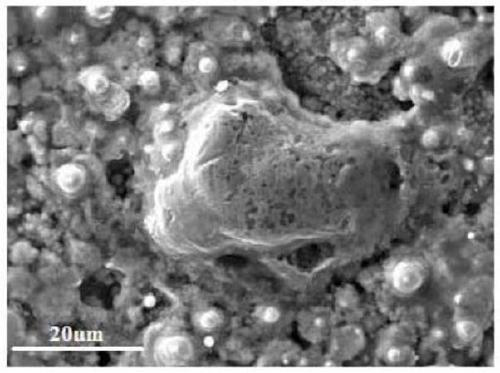

Preparing method of carbon nanometer tube reinforced tungsten copper composite material

ActiveCN107130126APlay a self-lubricating roleImproved arc erosion resistanceHigh energyHydrogen atmosphere

The invention provides a preparing method of a carbon nanometer tube reinforced tungsten copper composite material. The preparing method comprises the specific steps that at first, tungsten powder, copper powder and carbon nanometer tubes are added into a high-energy ball mill according to the proportion to be subjected to ball milling and mixed uniformly, and WCu mixed powder with the CNTs dispersed and distributed is obtained; then the mixed powder is pressed to obtain a composite material green body; and finally, the composite material green body is subjected to liquid phase sintering and infiltration in a high-temperature hydrogen atmosphere sintering furnace, and then the carbon nanometer tubes and the in-situ synthesis tungsten carbide mingled reinforced tungsten copper composite material are obtained. According to the preparing method, by means of the high-energy ball milling technology, the CNTs are dispersed and distributed on the surfaces of tungsten particles and copper particles, by means of high-temperature sintering, carbon sources of the surfaces of the tungsten particles and tungsten are subjected to an in-situ reaction to generate WC phases or W2C phases, the carbon sources of the surfaces of the copper particles will be dispersed and distributed in the copper phases, and then electric arc ablation resistant performance, wear resistance, high-temperature strength and the like of the WCu composite material are improved.

Owner:XIAN UNIV OF TECH

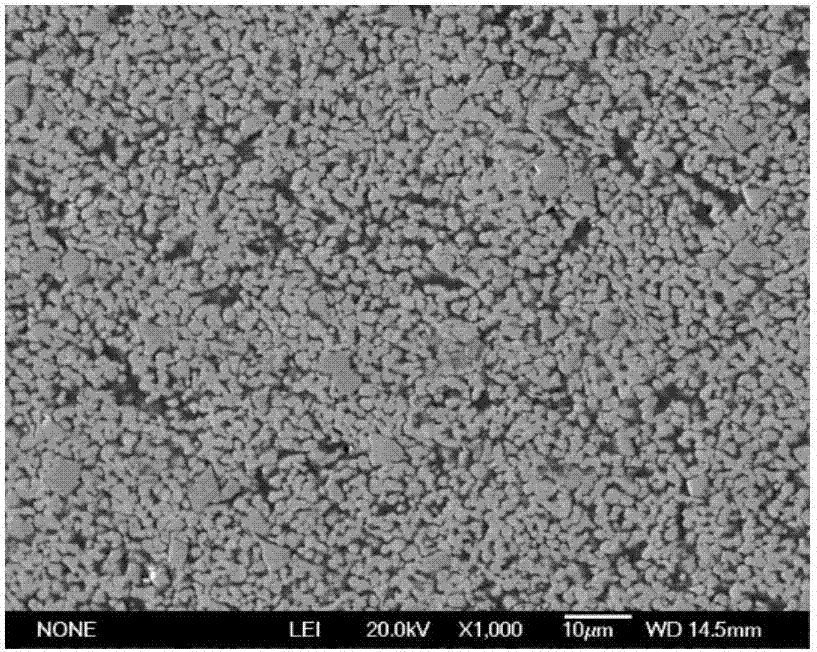

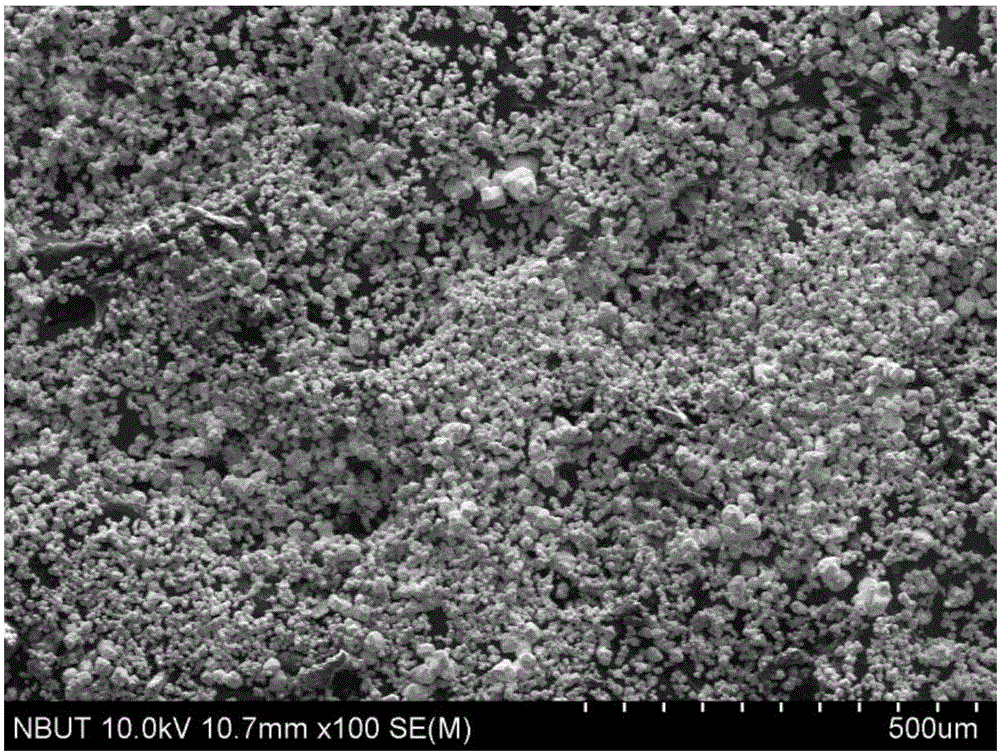

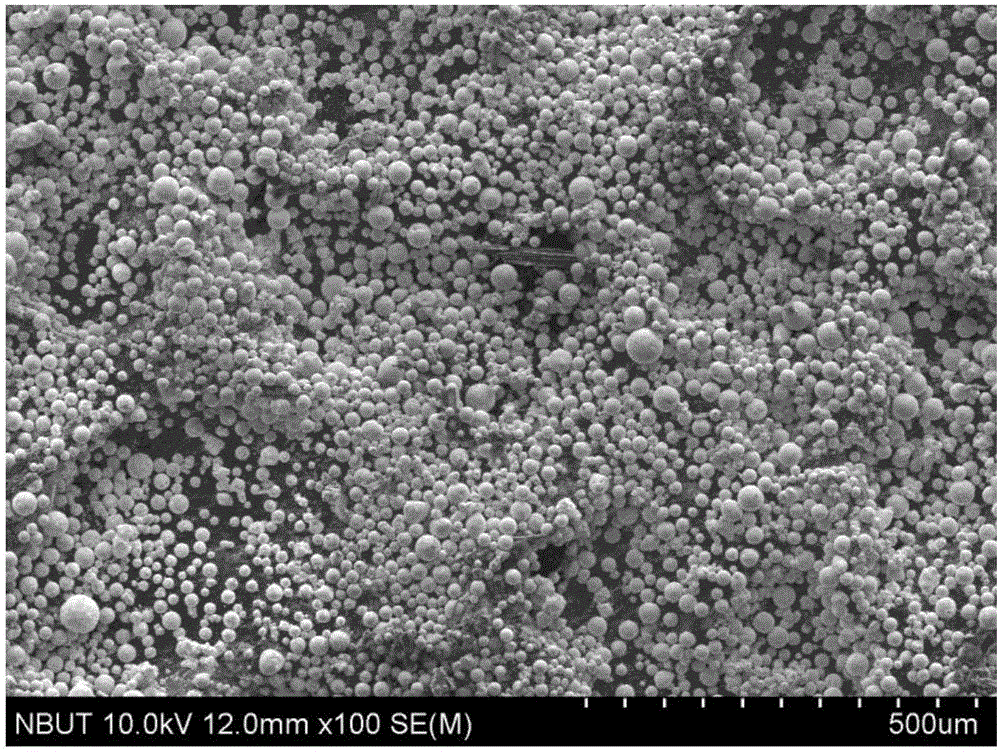

Tungsten-copper alloy and production method thereof

ActiveCN106435319AGood dispersionReduce clumpingTransportation and packagingMetal-working apparatusDispersityCompression molding

The invention belongs to the field of alloy material production, and particularly relates to tungsten-copper alloy and a production method thereof. The tungsten-copper alloy and the production method thereof aim to solve the problem that alloy structures are not uniform because of two-phase segregation of tungsten and copper in tungsten-copper alloy produced through existing methods. According to the production method, after tungsten powder undergoes plasma spheroidization, copper powder serves as an inducer for chemical copper plating, then compression molding, pre-sintering and tungsten-copper infiltration are carried out, and finally the tungsten-copper alloy with uniform structures can be obtained. According to the method, the shape of the tungsten powder is changed into a spherical shape from a polygonal shape, the dispersity is improved, and uniform distribution of the tungsten and the copper in the chemical copper plating process is guaranteed. According to the produced alloy material, two-phase composition segregation of the tungsten and the copper can be effectively prevented, the thermal conductivity, the electrical conductivity, the arc ablation resistance, the high temperature performance, the plasticity and the machinability of the alloy material are greatly improved, and the alloy material can be widely applied to heat sink materials, encapsulating materials and high explosive anti-tank cartridge liner materials.

Owner:四川恒珲新材料科技有限公司

Silver-graphite electrical contact material and preparation method thereof

The invention relates to a silver-graphite electrical contact material and a preparation method thereof. The electrical contact material contains the main components of 1-8 wt% of graphite, 0.5-2 wt % of ternary layered metal ceramic, 0.1-1 wt% of lanthanum and / or cerium, not greater than 0.1 wt% of impurities and the balance of silver. The preparation method comprises the following steps of: A, atomizing a mixture of the molten silver and the molten lanthanum and / or the molten cerium into silver alloy powder; B, mixing and activating graphite powder and ceramic powder; C, preparing graphite-ceramic composite powder, a reducing agent and deionized water into a granular concentration reducing suspension; D, dropwise adding ammonia water in a silver-ammonia solution prepared in a silver nitrate solution, slowly adding the reducing suspension during severely stirring and then reducing and plating the silver on the surface of the composite powder so that composite powder of silver-plated graphite powder and metal ceramic powder is obtained through precipitation and drying; and E, mixing and sintering the equivalent silver-rare earth alloy powder and silver-plated graphite and metal ceramic powder so that the silver-graphite electrical contact material is obtained. The electrical contact material has the advantages of favorable compactness, high electrical conductivity, high hardness and high electrical wear resistance and arc erosion resistance.

Owner:桂林金格电工电子材料科技有限公司

Method for preparing TiC/CuW alloy contact material

Owner:XIAN UNIV OF TECH

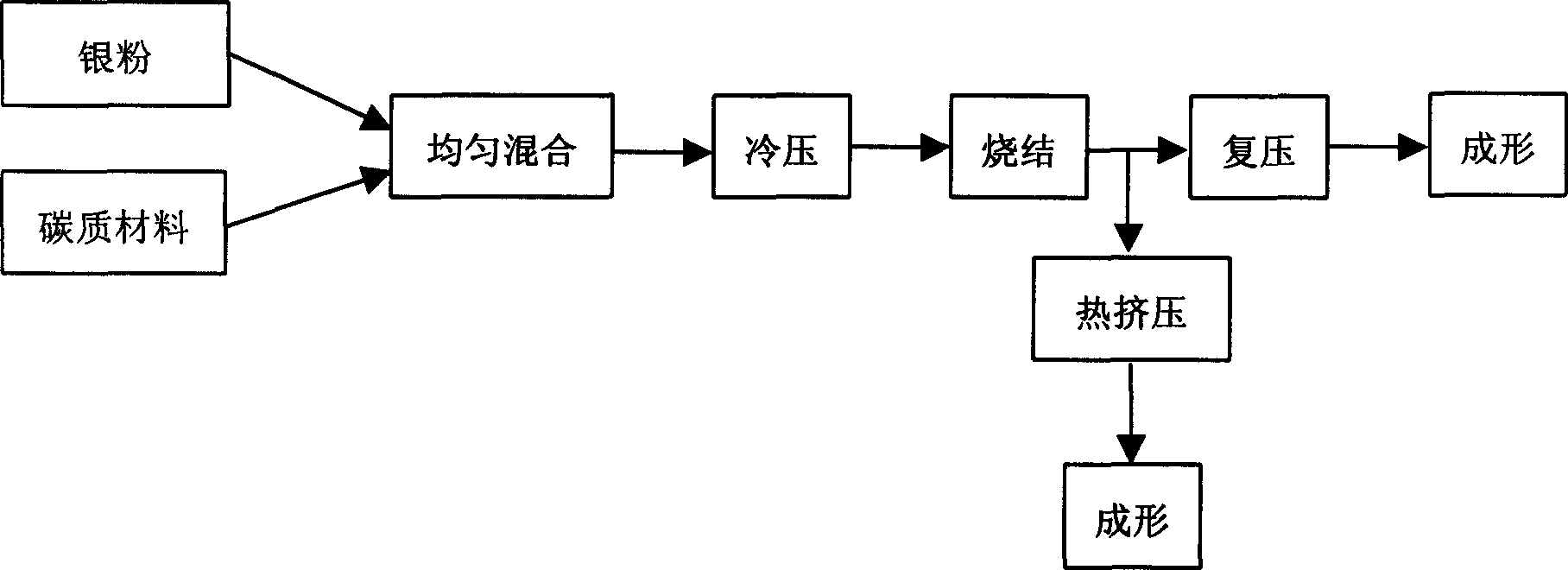

Method for preparing silver-based electrical contact material with fibrous structure

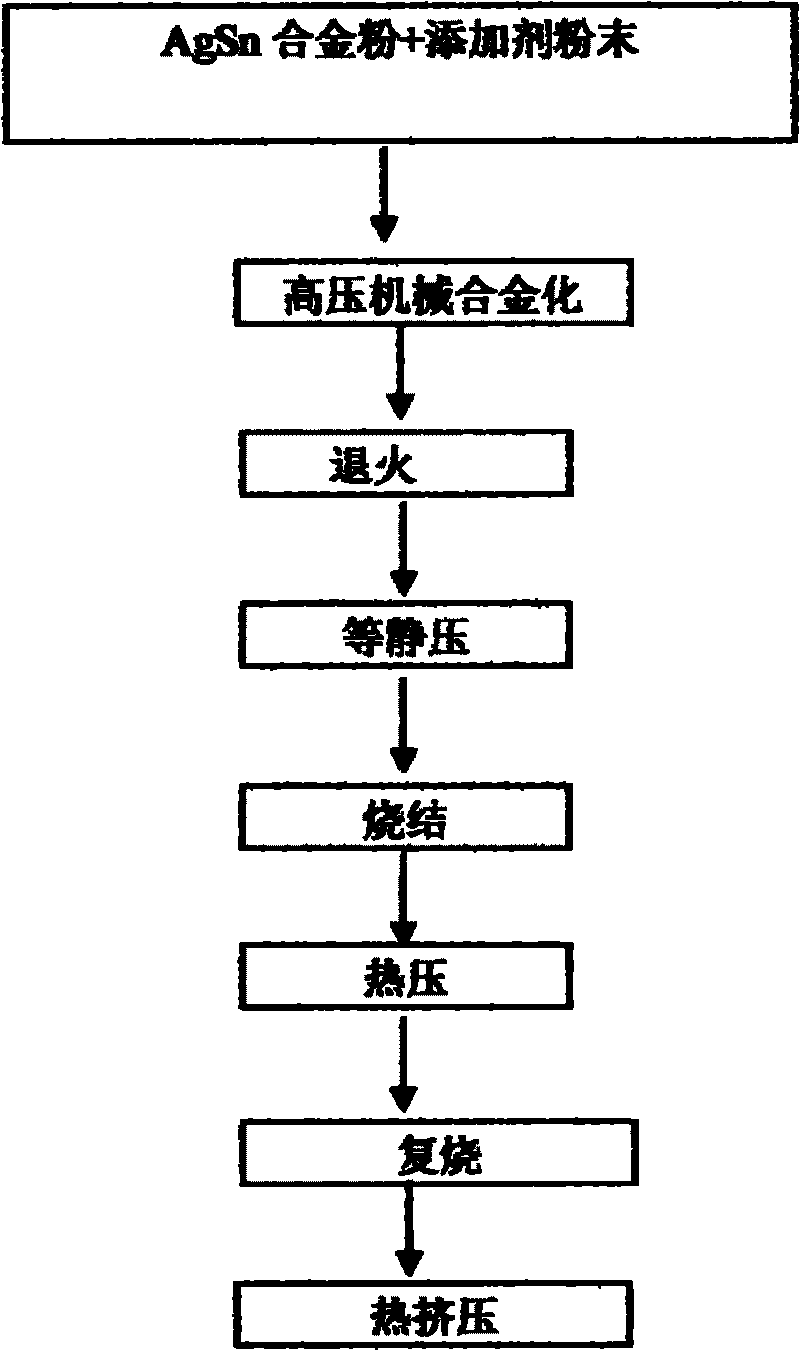

ActiveCN102002651AImproved arc erosion resistanceImprove conductivityContactsFusion weldingElectrical resistivity and conductivity

The invention discloses a method for preparing a silver-based electrical contact material with a fibrous structure, which comprises the following steps: 1, uniformly mixing reinforcing-phase material powder with substrate silver powder uniformly, and ball milling; 2, feeding the obtained mixed powder and substrate silver powder into a powder mixer for mixing powder; 3, performing isostatic cool pressing; 4, sintering; 5, performing hot pressing; and 6, performing hot extrusion and obtaining the silver-based electrical contact material. The method of the invention can prepare the sliver-based electrical contact material with an obvious fibrous structure regardless the processing deformation amount and the levels of the plasticity and ductility of a reinforcing phase; and in the method, theprocess is simple, it is convenient to operate, the cost is low, and special requirements on equipment are avoided. The fusion welding resistance, arc erosion resistance and conductivity of the material prepared by the method are all improved greatly, and the processing performance of the material is high.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

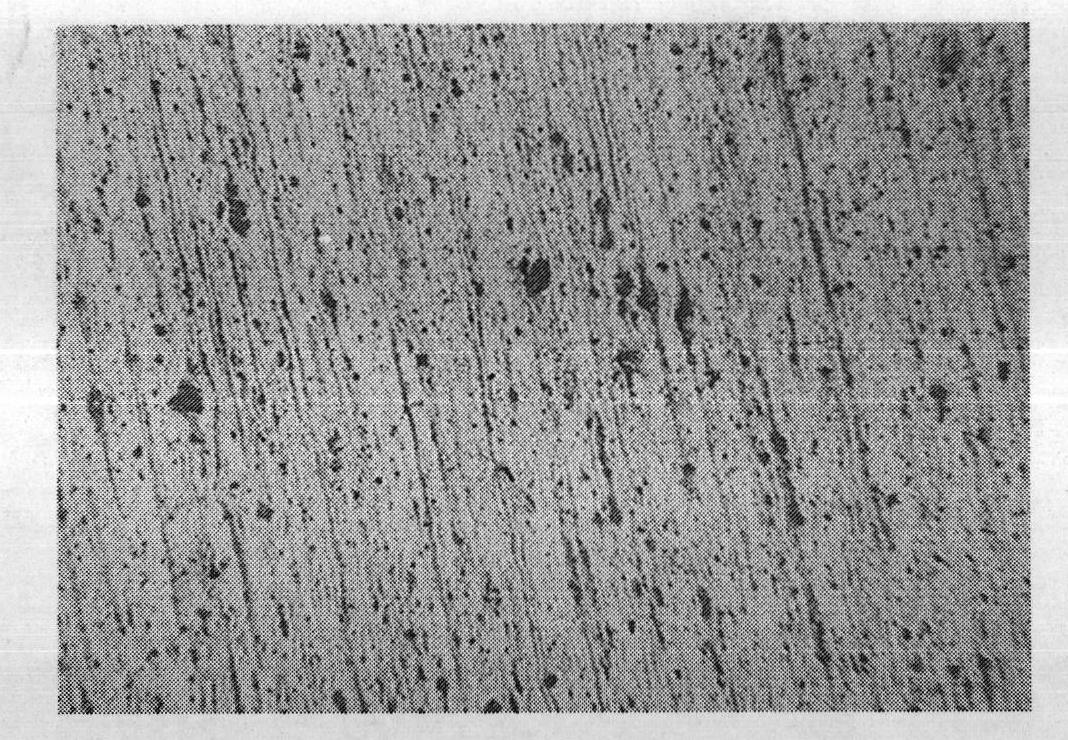

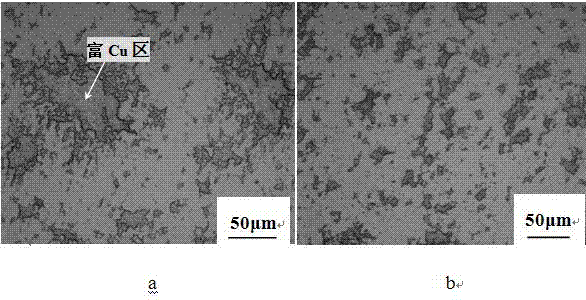

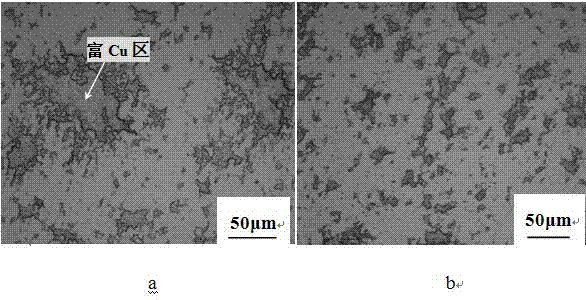

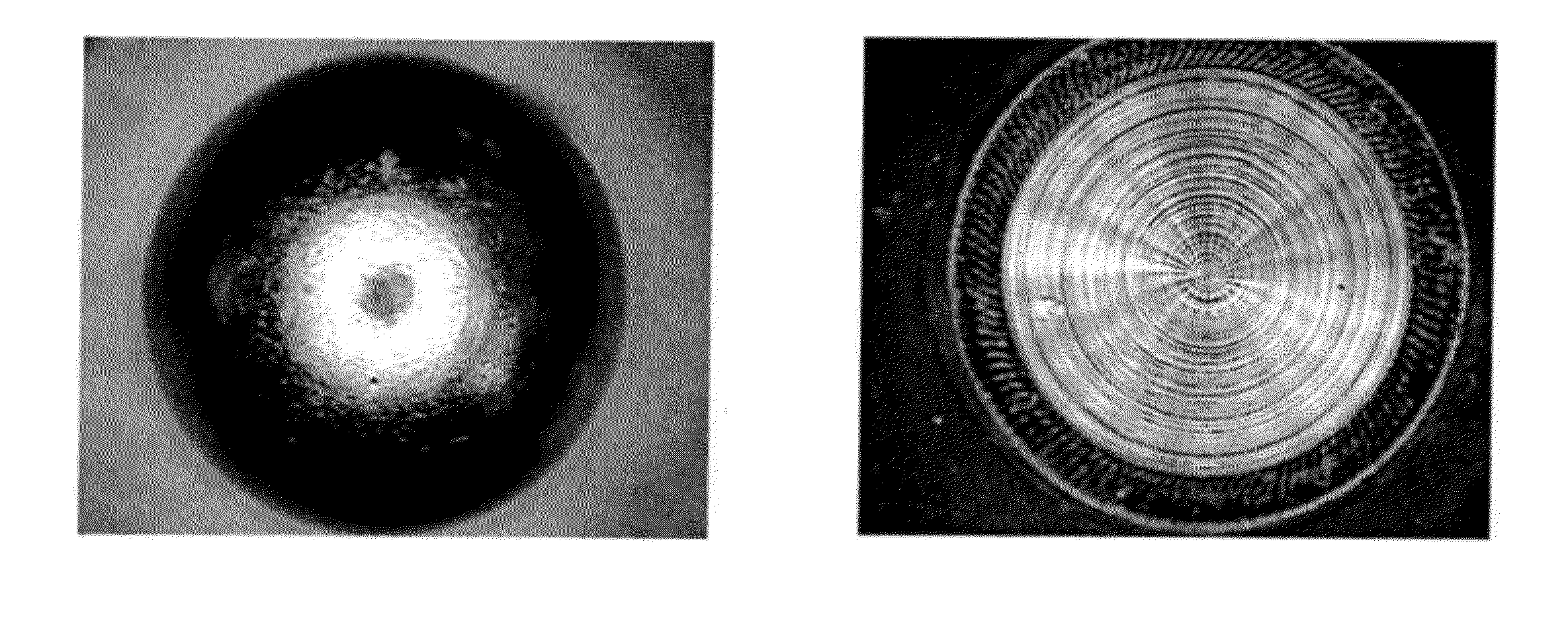

Preparation method of CuW70 contact material

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

Preparing method for silver plating graphene enhanced copper-based electric contact material

ActiveCN105950904AGood electrical and thermal conductivityImprove welding resistanceTransportation and packagingMetal-working apparatusSilver plateChemical plating

The invention relates to a copper-based electric contact material used in a middle-low-voltage electric appliance switch, in particular to a preparing method for a silver plating graphene enhanced copper-based electric contact composite material. The copper-based composite material comprises, 0.5 wt.%-4 wt.% of bismuth, 0.05 wt.%-0.5 wt.% of yttrium, 0.1 wt.%-0.5 wt.% of graphene (silver plating), 1wt.%-5wt. / % of silver and the balance copper and other inevitable impurities. Copper-yttrium alloy powder is prepared and subjected to chemical silver plating, the copper-yttrium alloy powder and graphene subjected to silver plating treatment are subjected to ball milling and mixed evenly, and the electric contact material is finally prepared through pressing and sintering. The surface of copper powder is subjected to silver plating so that the anti-oxidation performance of the material can be improved, the graphene is subjected to silver plating treatment so that combination between the graphene and a copper base body can be enhanced, and therefore the comprehensive performance of the material is improved, and the copper-based electric contact material good in electric conductivity, resistant to electric arc erosion and excellent in welding resistance is finally obtained.

Owner:UNIV OF JINAN

Method for synergistically improving arc ablation performance of CuW contact material

ActiveCN108950279AImproved arc ablation performanceImprove protectionContactsElectrolysisMaterials science

The invention discloses a method for synergistically improving the arc ablation performance of a CuW contact material. The method comprises the steps that firstly, spherical electrolytic copper powderis rolled into a sheet, then reduced tungsten powder is added for ball milling, even mixing is conducted, and tungsten-copper modified mixed powder is obtained; secondly, expanded graphite is sequentially subjected to low temperature intercalation oxidation, medium temperature intercalation oxidation and high temperature intercalation oxidation, and graphene oxide is obtained; thirdly, the tungsten-copper mixed powder and the graphene oxide are added into an ethanol-water mixed solution to be mixed evenly, drying is conducted, graphene oxide / tungsten-copper composite powder is obtained and then subjected to low-temperature thermal reduction, and reduced graphene oxide / tungsten-copper composite powder is obtained; and fourthly, the reduced graphene oxide / tungsten-copper composite powder issubjected to discharge plasma liquid phase sintering, and the CuW contact material is obtained. The graphene oxide is added into the tungsten-copper modified mixed powder, thermal reduction is conducted at first, the reduced graphene oxide is obtained, then discharge plasma liquid phase sintering is conducted, tungsten carbide nanoparticles are generated, and the arc ablation performance and mechanical performance of the CuW contact material are synergistically strengthened through the reduced graphene oxide and the tungsten carbide nanoparticles.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Transition metal oxide carried graphene enhanced copper-based composite electrocontact material and preparation method thereof

The invention relates to a graphene enhanced copper-based composite electrocontact material and a preparation method thereof, in particular to a transition metal oxide carried graphene enhanced copper-based composite electrocontact material and a preparation method thereof. The transition metal oxide carried graphene enhanced copper-based composite electrocontact material is composed of transition metal oxide carried graphene and copper, and the transition metal oxide refers to a mixture or one of SnO2, ZnO, Fe3O4, CuO, NiO, MnO and Co3O4. The preparation method includes: well mixing transition metal oxide / graphene powder and copper powder, and performing dispersive mixing to obtain mixed powder; putting the mixed powder into a grinding tool, pressing to obtain billets, and subjecting the billets to vacuum sintering to obtain the transition metal oxide carried graphene enhanced copper-based composite electrocontact material which can be used for manufacturing of electrical contact elements. The problems of poor abrasion resistance and poor arc ablation resistance of existing graphene enhanced copper-based composite materials are solved.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Silver-base electric contact head materials

InactiveCN1552926AImprove performanceReduce electrical erosion rateContact materialsElectricityWear resistant

A durable wear-resistant and arc erosion-resistant silver based electric contact material consists of carbon material 0.5-20wt% and balanced of silver. One dimension nano carbon material replaces, partially or completely, graphite to be added into the silver based material to form one dimension nano carbon / silver composite material as electric contact material. It has higher electric and heat conductivities, higher strength and better self-lubrication, reduces losses by wear or arc erosion, and can replace graphite silver contact material completely.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

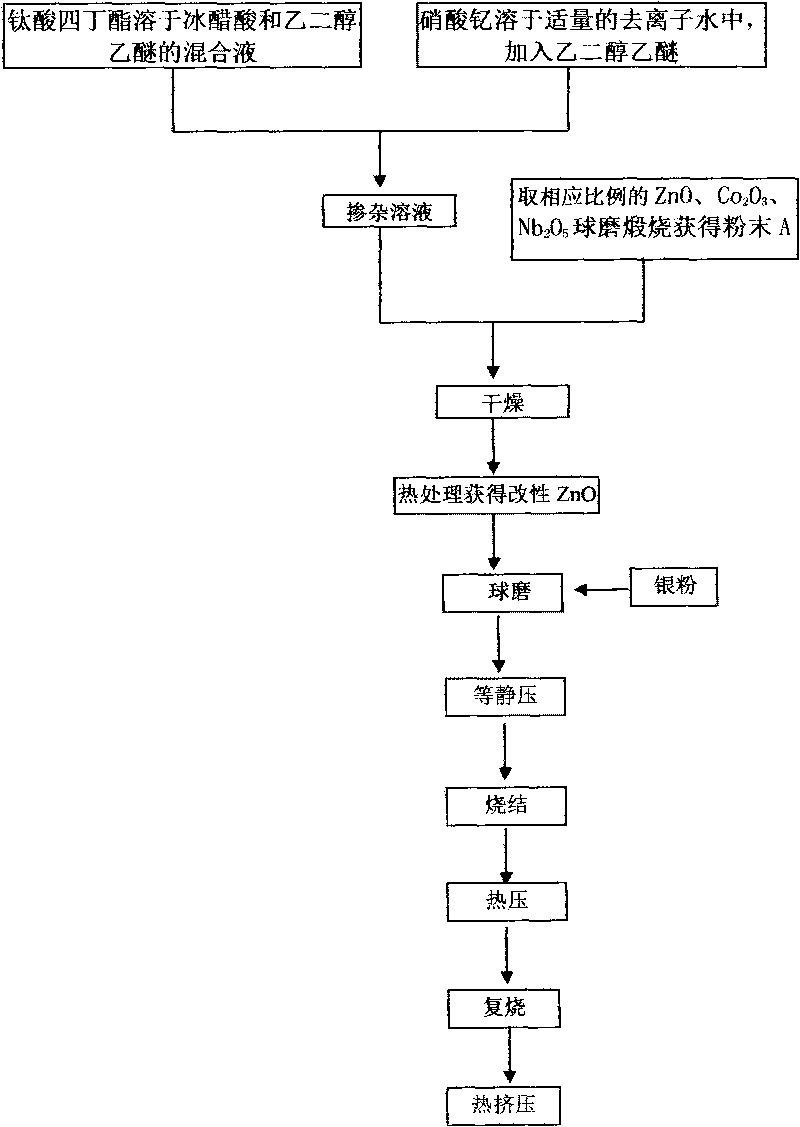

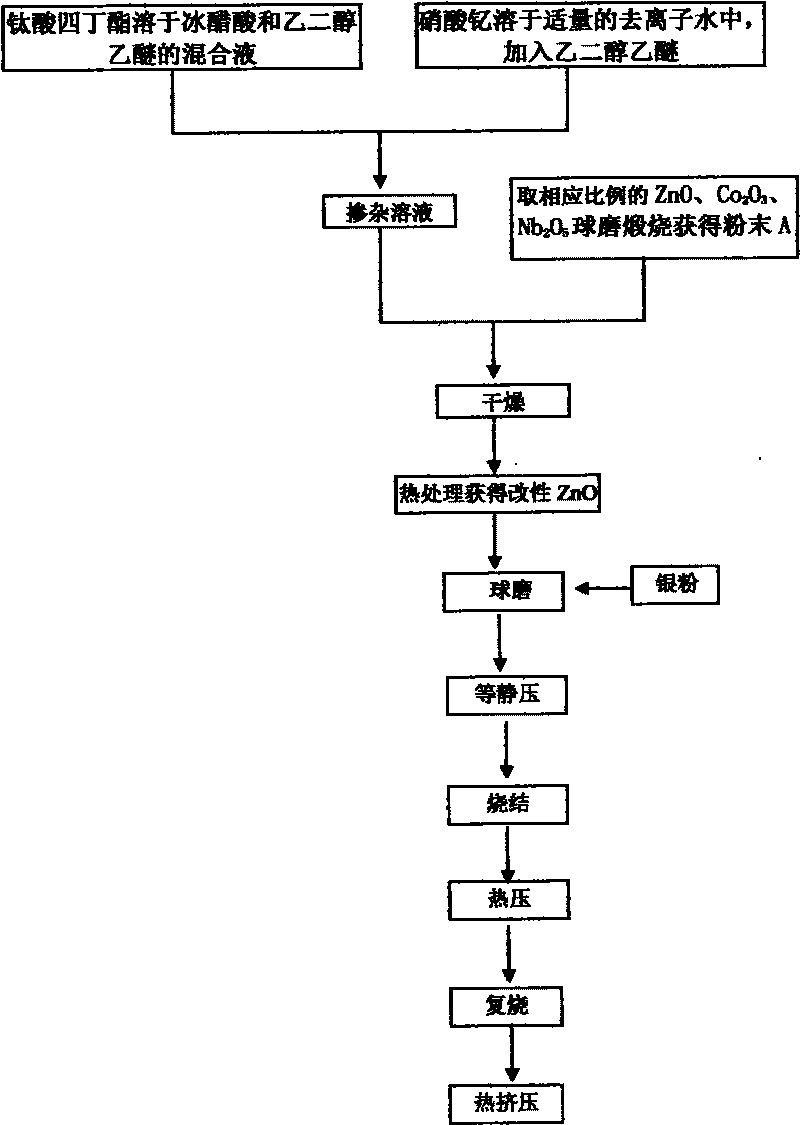

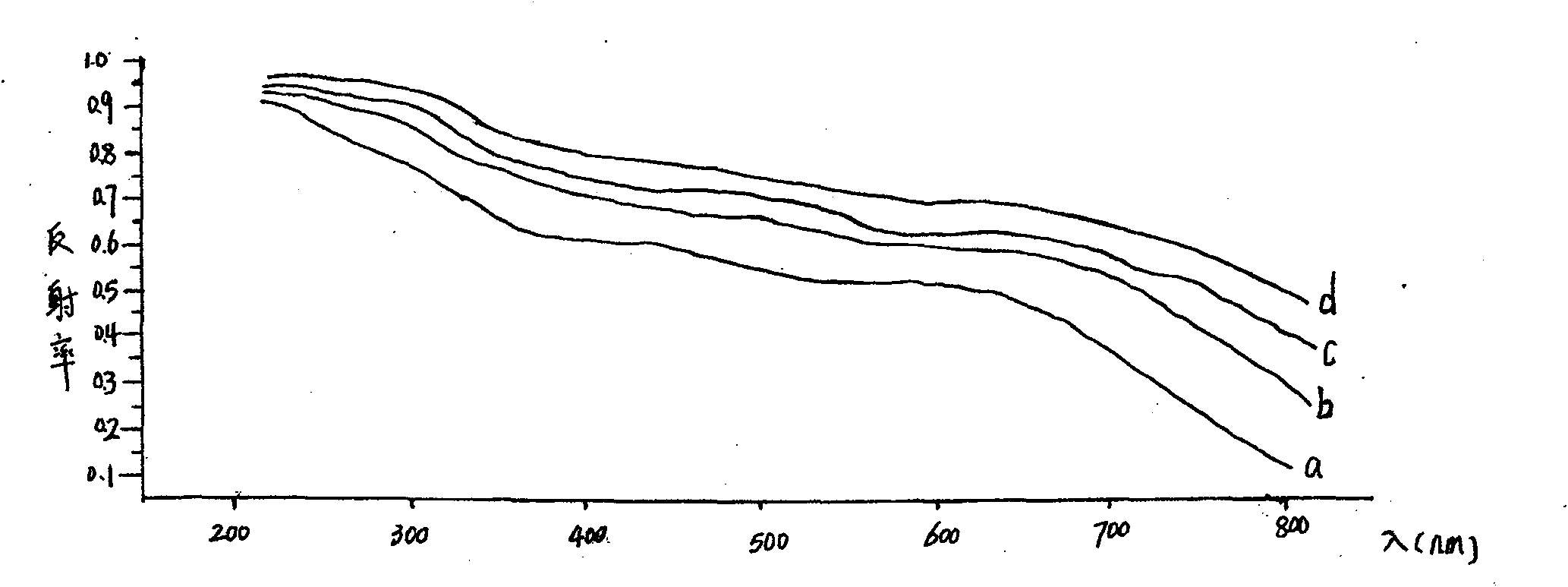

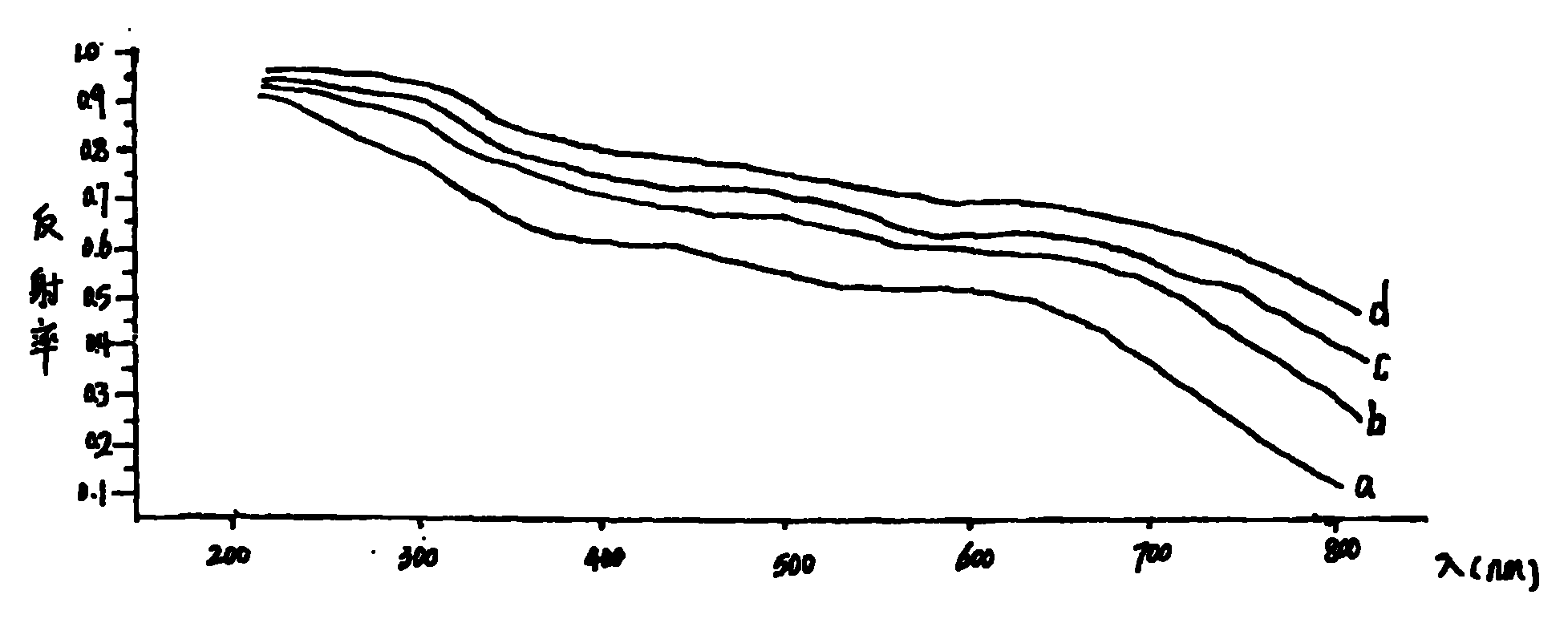

Method for preparing Ag-ZnO-doped electrical contact material

ActiveCN101707156AAdd nonlinearityLow resistivityElectric switchesElectrical resistance and conductanceContact resistance

The invention discloses a method for preparing an Ag-ZnO-doped electrical contact material, comprising the following steps: obtaining modified ZnO particles by adopting a sol-gel method, improving the electrical conductivity of the ZnO particles and then preparing a dispersed composite material with compact distribution from modified ZnO used as raw material and Ag powder by the process flow of ball milling, pressing, sintering, hot extrusion and the like. Since the electrical conductivity of the ZnO particles is improved, the problems of contact resistance and overhigh temperature rise of the material in the use process are solved, thereby widening the use range of the Ag-ZnO material and improving the electrical contact performance of the material.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Method for manufacturing nozzle for circuit breaker

The invention discloses a method for manufacturing a nozzle for a circuit breaker. Inorganic materials such as boron nitride and the like are added based on a pure polytetrafluoroethylene (PTFE) material of the nozzle in the prior art, so the light reflectivity of the nozzle is greatly improved, the ablation caused by electric arc radiation to the nozzle is reduced, serious decomposition and internal explosion due to that the nozzle is subjected to optothermal and electric arc radiation are avoided, and electric arc ablation resistance of the nozzle is greatly improved.

Owner:江苏常新密封材料有限公司

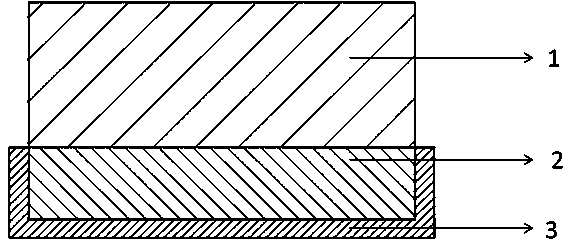

Plated switch contact and preparing method thereof

ActiveCN104112607AImproved arc erosion resistanceImprove reliabilityLiquid/solution decomposition chemical coatingContactsKey pressingVulcanization

The invention discloses a plated switch contact and a preparing method thereof. The switch contact is a combined body with a three-layer structure, the first layer is a hydrophobic rubber layer, the second layer is a sheet metal layer, the third layer is a plated layer, and a combination body of the first layer and the second layer is soaked in a chemical plating solution with a soluble gold compound and gold or gold alloy is selectively deposited on the surface of sheet metal in the combination body by a chemical deposit method to form the plated layer. According to the plated switch contact and the preparing method thereof, the prepared switch contact is suitable for heat vulcanization bonding and forming with rubber, and thereby, a rubber press key with the switch contact can be produced. The switch contact has the advantages that the resistance to atmospheric corrosion, contact chatter and arc erosion is good, the surface contact resistance is low, the service life is long, and the like.

Owner:NANTONG MEMTECH TECH

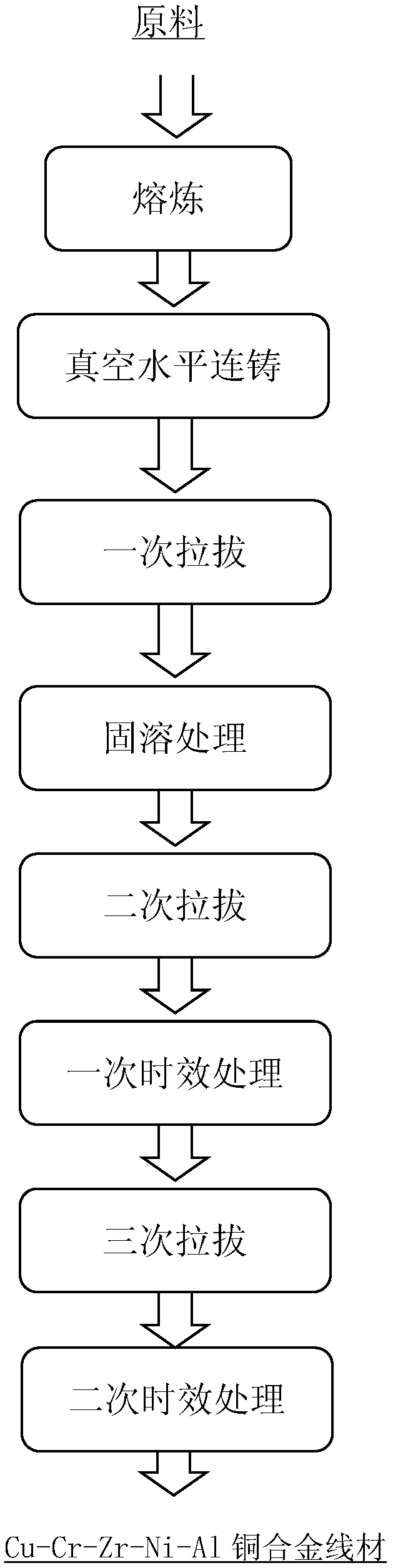

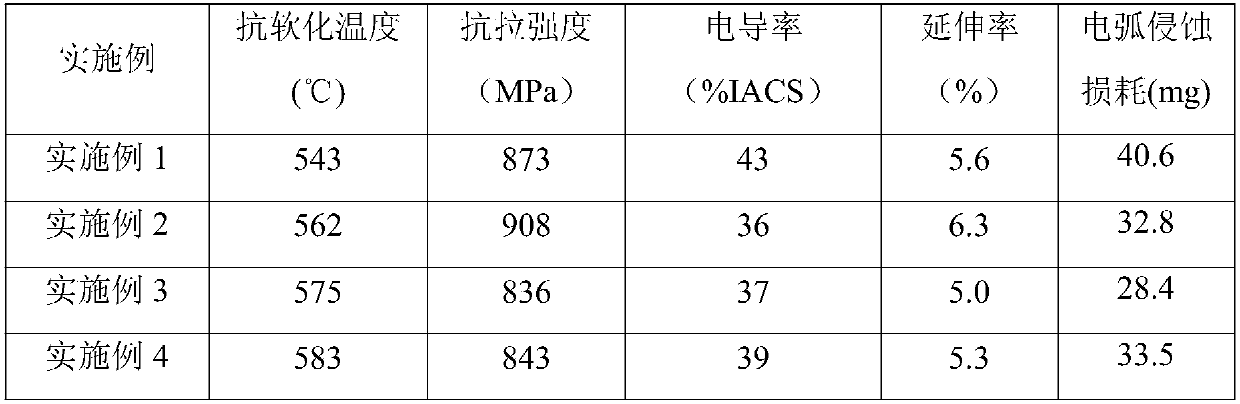

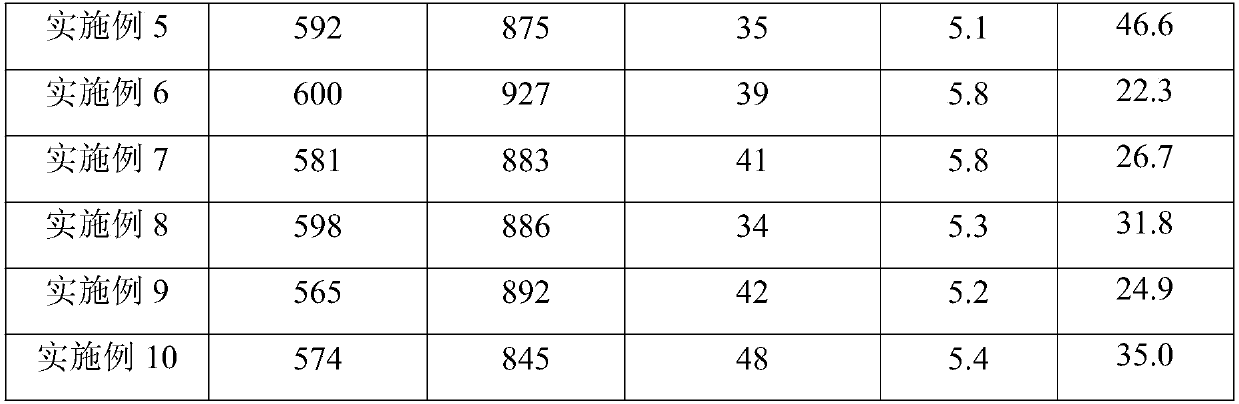

Cu-Cr-Zr-Ni-Al copper alloy, Cu-Cr-Zr-Ni-Al copper alloy wire rod and preparation method thereof

The invention provides a Cu-Cr-Zr-Ni-Al copper alloy. The Cu-Cr-Zr-Ni-Al copper alloy comprises, by mass, 0.10%-0.70% of Cr, 0,05%-0.50% of Zr, 0.50%-2.00% of Ni, 0.10%-0.50% of A1, the balance Cu andinevitable impurities. The invention further discloses a Cu-Cr-Zr-Ni-Al copper alloy wire rod. The invention further discloses a preparation method of the Cr-Zr-Ni-A1 copper alloy wire rod. The tensile strength of the copper alloy wire rod can reach 800MPa-950MPa, the elongation rate is larger than 5%, the electrical conductivity is 34%-48% IACS, the softening temperature is 550 DEG C-600 DEG C,and the electric arc erosion loss is within 50 mg.

Owner:JIANGXI UNIV OF SCI & TECH

Method for preparing submicron silver-tin dioxide electrical contact material

InactiveCN1595568AImprove mechanical propertiesImproved arc erosion resistanceContact materialsTin dioxideBall mill

Disclosed is a manufacture method for electric contact material of submicron silver-stannic oxide material which belongs to electric material technical field. Its characteristics is that the following steps are included silver of 12~94.9%, stannic oxide of 5~20% and cerium oxide or lanthanum oxide powder of 1.0-8% are added according to weight ratio into stainless steel high speed ball grinder, and dispersion agent of triethanolamine and protective agent of acetone solution are added to form mixed powder of 350-400nm which then will be changed into rivet-typed electric contact material of submicron silver-stannic oxide material through pressing, sinter, hot extrusion and cold-finish drawing. It has the advantage of simple manufacture technique, low cost and suitable for production of larger scale, the contact material has high electric conductivity ,symmetric tissue, excellent tensile strength, resistance to fusion welding and electric arc burnt.

Owner:TIANJIN UNIV

Preparation method of tin oxide fiber reinforced silver-based electric contact alloy

InactiveCN105908108AImprove conductivityImproved arc erosion resistanceElectric switchesFiberElectrical resistance and conductance

The invention provides a preparation method of a tin oxide fiber reinforced silver-based electric contact alloy. The method specifically includes: firstly preparing a Sb element doped tin oxide precursor gel, adding the gel into a fiber forming agent to prepare a spinning solution, and conducting electrostatic spinning to obtain Sb element doped SnO2 fiber; then subjecting the fiber and silver powder to mechanical mixing, and carrying out pressing-sintering-extrusion on a silver-tin oxide fiber mixture by a traditional process, thus obtaining the tin oxide fiber reinforced silver-based electric contact alloy. The method provided by the invention improves the electroconductivity of tin oxide through effective doping of the Sb element, reduces the resistance of a contact alloy body, at the same time enables fibrous distribution of a second phase oxide and reinforcement of the oxide in a silver matrix, solves the problems of large contact resistance, high temperature rise and large oxide loss in traditional oxide particle reinforced silver-based electric contact materials during arc erosion, improves the arc erosion resistance of silver-based oxide electric contact alloy, and also expands the application scope of the silver-based oxide electric contact alloy.

Owner:XI'AN POLYTECHNIC UNIVERSITY

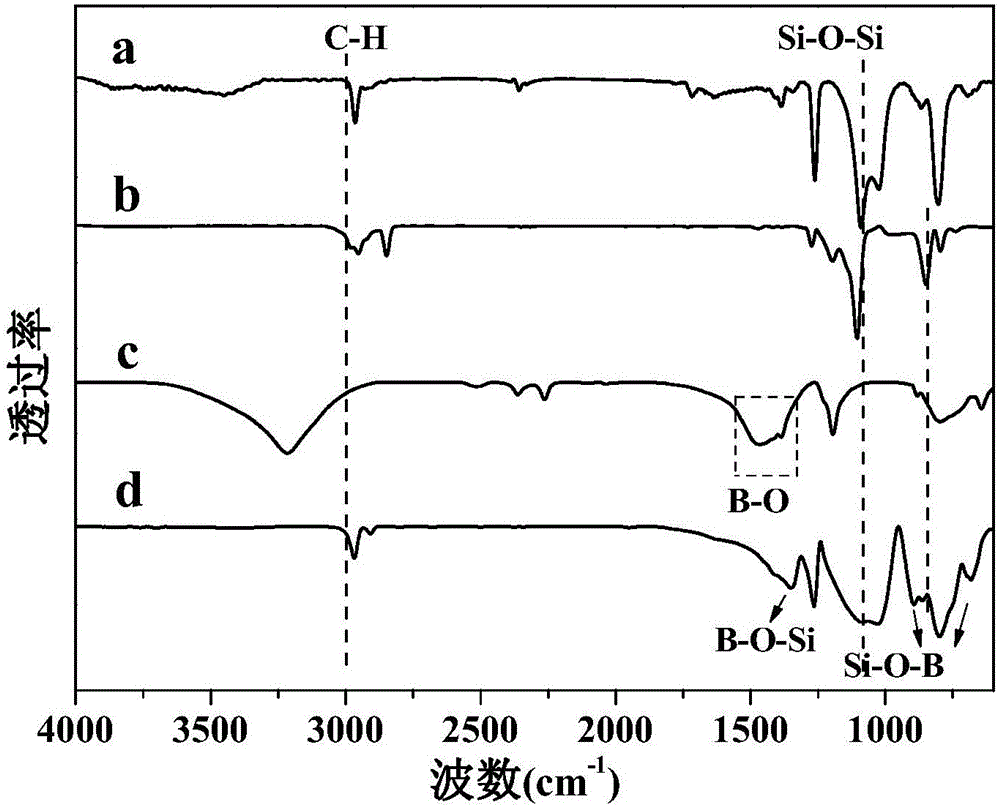

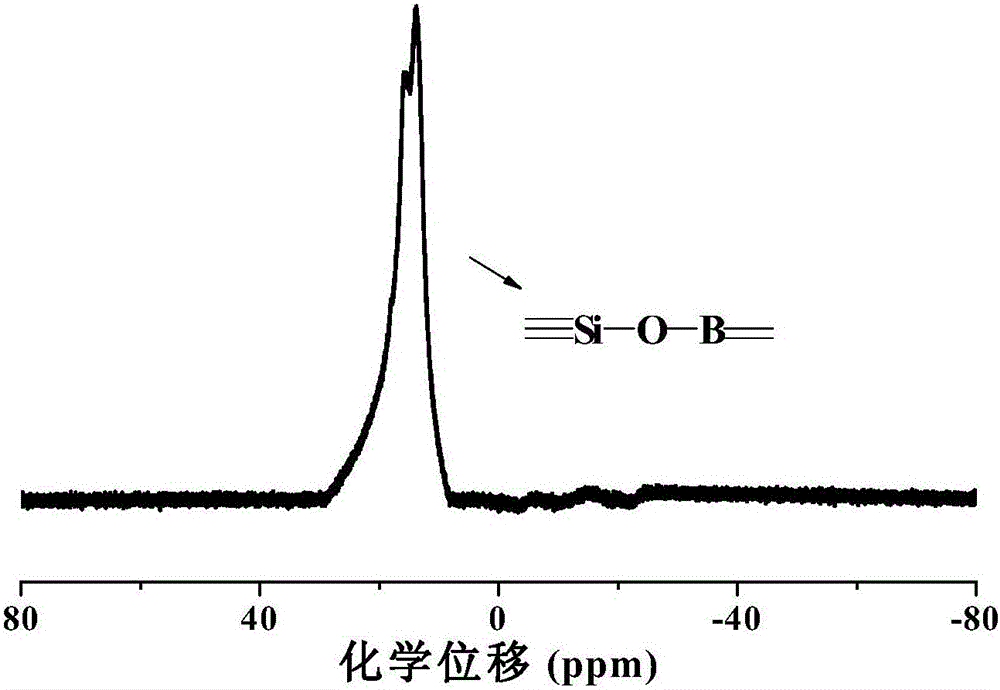

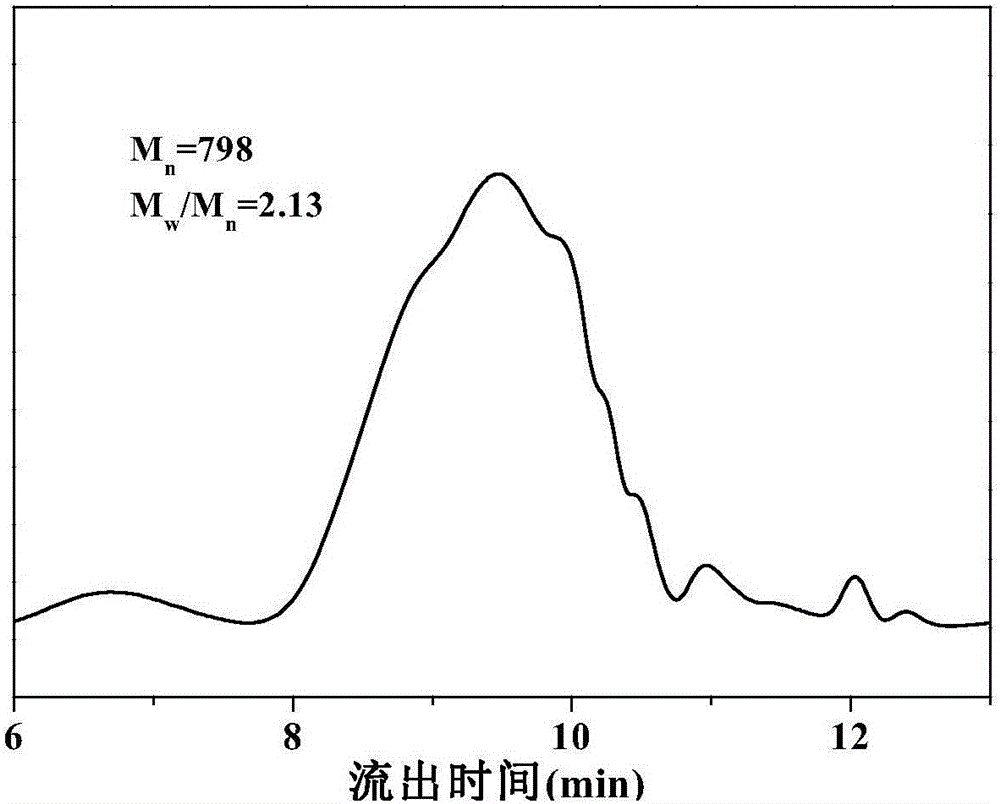

Organic silicon-boron ceramic precursor as well as preparation method and application thereof

ActiveCN105153708AControllable boron contentGood compatibilitySilicon organic compoundsAviationFire resistance

The invention discloses an organic silicon-boron ceramic precursor as well as a preparation method and an application thereof. The preparation method comprises steps as follows: cyclotetrasiloxane, trifunctional siloxane and boric acid are stirred at the temperature of 25-35 DEG C for 10-20 min under the action of an acid catalyst, then heated to the temperature of 80-100 DEG C for a polycondensation reaction and finally heated to the temperature of 120-150 DEG C for a continuous reaction, and the organic silicon-boron ceramic precursor is obtained through after-treatment. The prepared ceramic precursor has the controllable boron content, is high in thermal stability and has good compatibility with silicone rubber, the preparation method is simple and environment-friendly, the heat resistance and the arc firing resistance of the additional liquid silicone rubber can be substantially improved through addition of only 1.0 part of the organic silicon-boron ceramic precursor by mass, and the organic silicon-boron ceramic precursor has the important application prospect in fields of aviation and aerospace, high-voltage and extra-high-voltage power transmission and transformation and the like.

Owner:SOUTH CHINA UNIV OF TECH

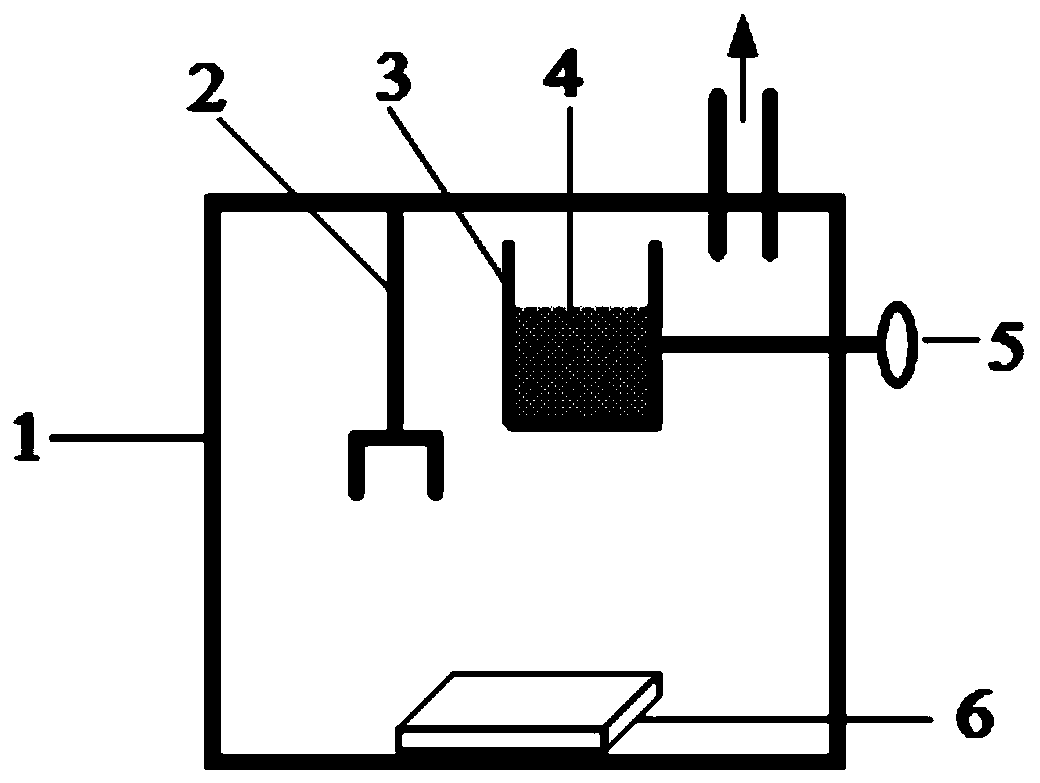

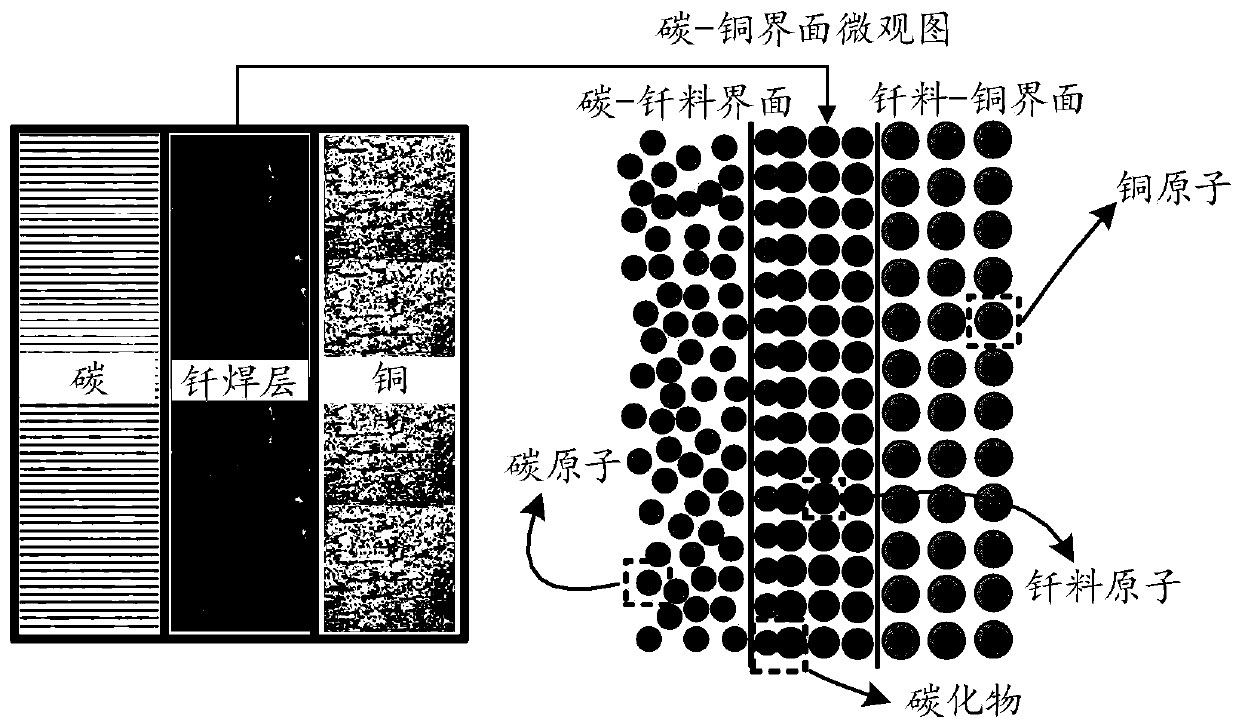

High-electric-conductivity carbon pantograph pan and preparation method thereof

ActiveCN110436926AImprove conductivityEvenly distributedCarbon preparation/purificationElectric vehicle charging technologyElectricityUltimate tensile strength

The invention discloses a high-electric-conductivity carbon pantograph pan and a preparation method thereof. A pore forming substance is added in a powder mixing stage in a carbon pan preparation process to obtain the carbon pan having communicated pores, thus increasing the electric conductivity of the carbon pan. A brazing alloy and copper metal are melted and mixed, and the mixture is adopted to impregnate the carbon pantograph pan so that the copper, the brazing alloy and carbon which are three materials are tightly bonded, thus increasing the bonding force of a copper-carbon interface. Anexternal strong magnetic field is applied in during impregnation to drive the melted copper alloy to be uniformly dispersed in pores of a carbon pantograph pan blank, thus increasing the impregnationefficiency and further improving mechanical strength and arc ablation resistance of the carbon pan. Through addition of the pore forming substance and the brazing alloy and through application of theexternal strong magnetic field, a problem that carbon pantograph pans are low in electric conductivity, low in mechanical strength, poor in arc ablation resistance can be effectively solved, and a new ideal is provided for preparation of carbon pantograph pans with high performance.

Owner:SOUTHWEST JIAOTONG UNIV

Electrical contact material of silver matrix capable of resisting arc erosion and containing no cadmium-composite

ActiveUS20120132869A1High hardnessImproved arc erosion resistanceContact with seperate bridge contactLegendsAmpereCadmium Cation

In an electric contact material of silver matrix capable of resisting arc erosion and containing no cadmium-composite, an Ag—(SnO2+In2O3) composite containing 9˜11% of (SnO2+In2O3) or an Ag—Cu oxide, composite containing 15˜25% of Cu oxide is used. The electrical contact material has a contact resistance of 5˜60 milliohms (mohm) and an arc erosion resistance capability up to 2*103˜10*103 times provided that the Vickers hardness (Hv) of the material is 100˜150, the measured current is 1˜5 amperes, and the measured voltage is 10˜20 volts. Two electrical contacts maintain an arc erosion resisting capability at the condition of a low contact resistance when the electrical contact material is formed on a surface of a metal substrate of an electric connector.

Owner:C C P CONTACT PROBES

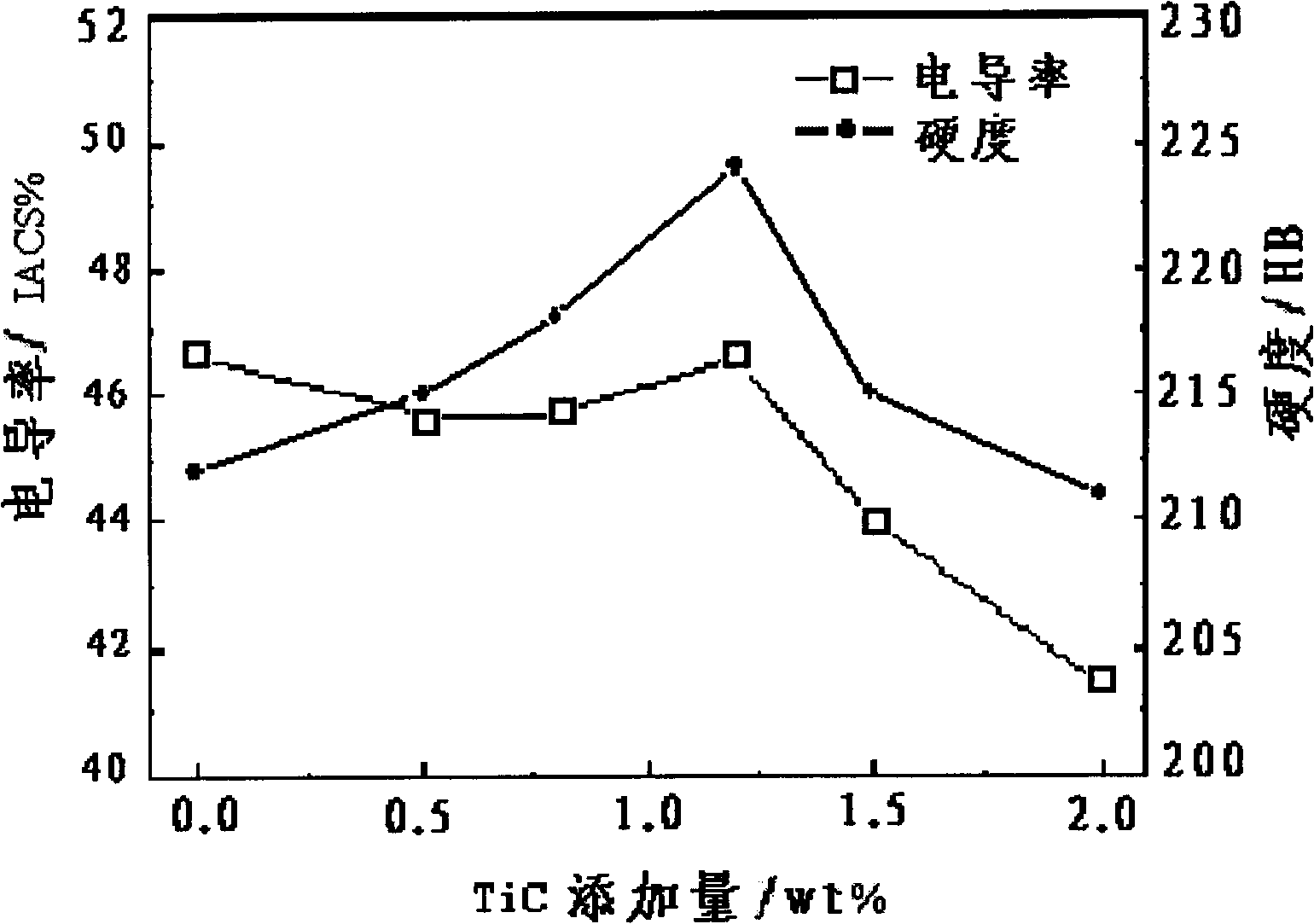

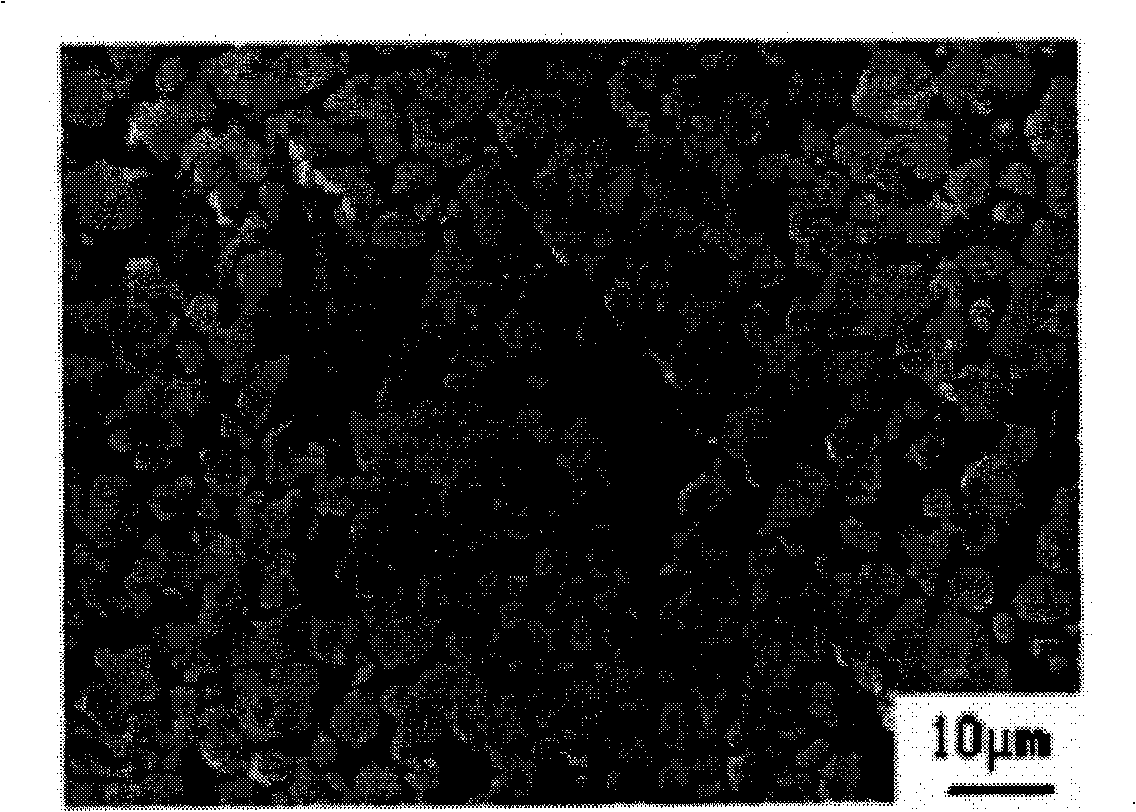

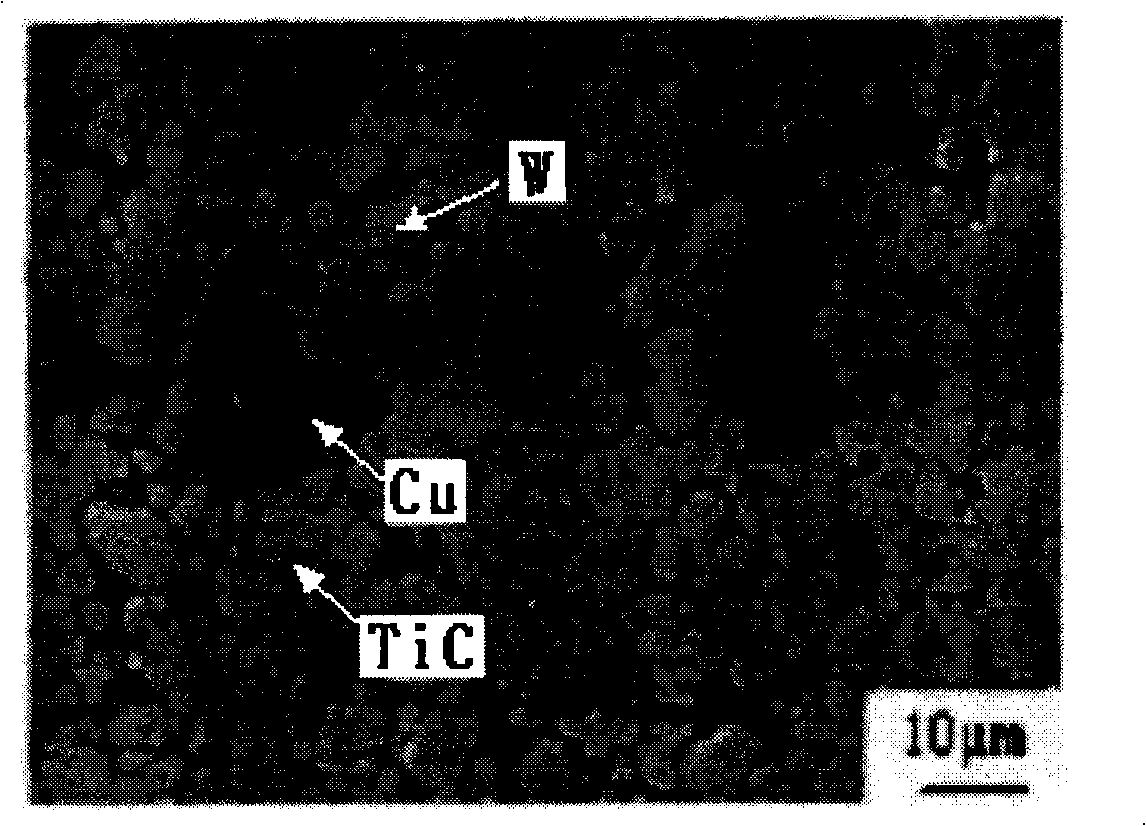

Copper-based contact material applied to lower-voltage apparatus and preparation method of copper-based contact material

InactiveCN104064253AImprove antioxidant capacityNot prone to oxidative denaturationMetal/alloy conductorsCable/conductor manufactureTitanium carbideOxide

The invention provides a copper-based contact material applied to a lower-voltage apparatus and a preparation method of the copper-based contact material. The copper-based contact material comprises, by weight, 1%-40% of titanium carbide and the balance copper; or 1%-40% of titanium carbide, 0.01%-5% of carbon and the balance copper; or 1%-40% of titanium carbide, 0.01%-8% of rare earth oxide and the balance copper; or 1%-40% of titanium carbide, 0.01%-8% of rare earth oxide, 0.01%-5% of carbon and the balance copper. The preparation method of the copper-based contact material includes the following steps that copper powder and titanium carbide powder are mixed in proportion; cold isostatic pressing is conducted on the evenly mixed powder to obtain a cylindrical pressure ingot; the pressure ingot is sintered in vacuum or under atmosphere protection; hot extrusion is conducted on the sintered pressure ingot to obtain a plate; finally, the plate is rolled to the specified thickness in a cold mode; the plate is cut into the specified dimension. According to the copper-based contact material, under the condition of long-term use, contact resistance between contacts is low, and temperature rising is low and stable.

Owner:哈尔滨东大高新材料股份有限公司

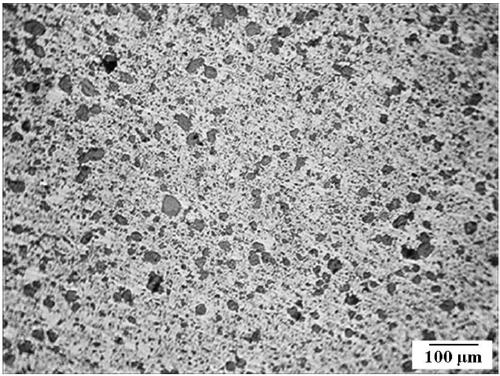

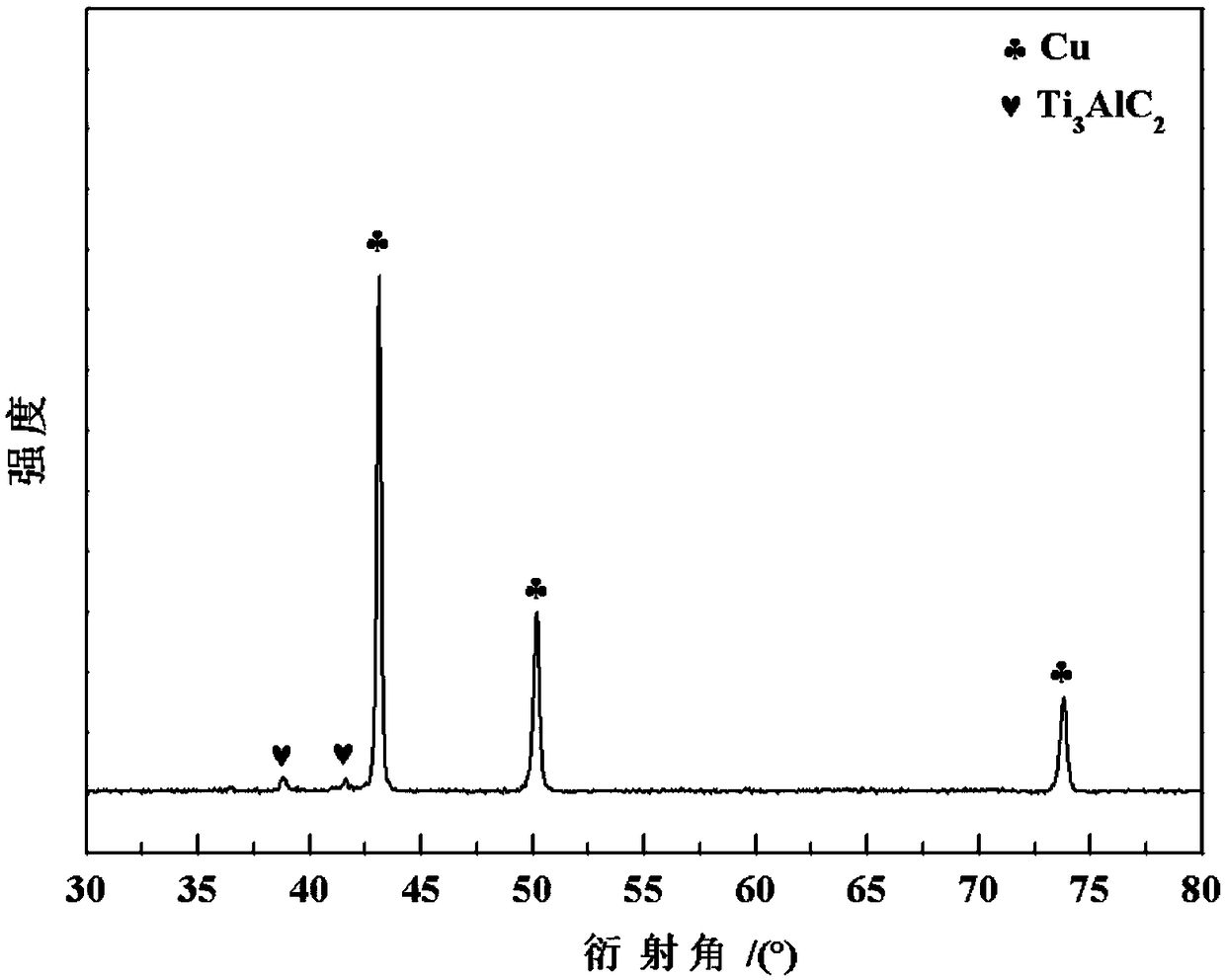

Cu-Ti3AlC2 composite material and preparation method thereof

The invention relates to the technical field of metal matrix composite materials, in particular to a Cu-Ti3AlC2 composite material and a preparation method thereof. Metal copper powder is used as a matrix phase, ceramic phase Ti3AlC2 is used as a reinforcing phase, and the volume percentage of the metal copper powder in the composite material is 60%; and the Cu-Ti3AlC2 composite material is prepared from the metal copper powder and Ti3AlC2 powder through the initial pressure, sintering and re-pressing processes. By means of the Cu-Ti3AlC2 composite material, the electric conduction and thermalconduction performance of the material can be maintained as high as possible while the hardness and strength of metal Cu are improved, and application of modern industrial electrical contact elementsis achieved.

Owner:BENGBU COLLEGE

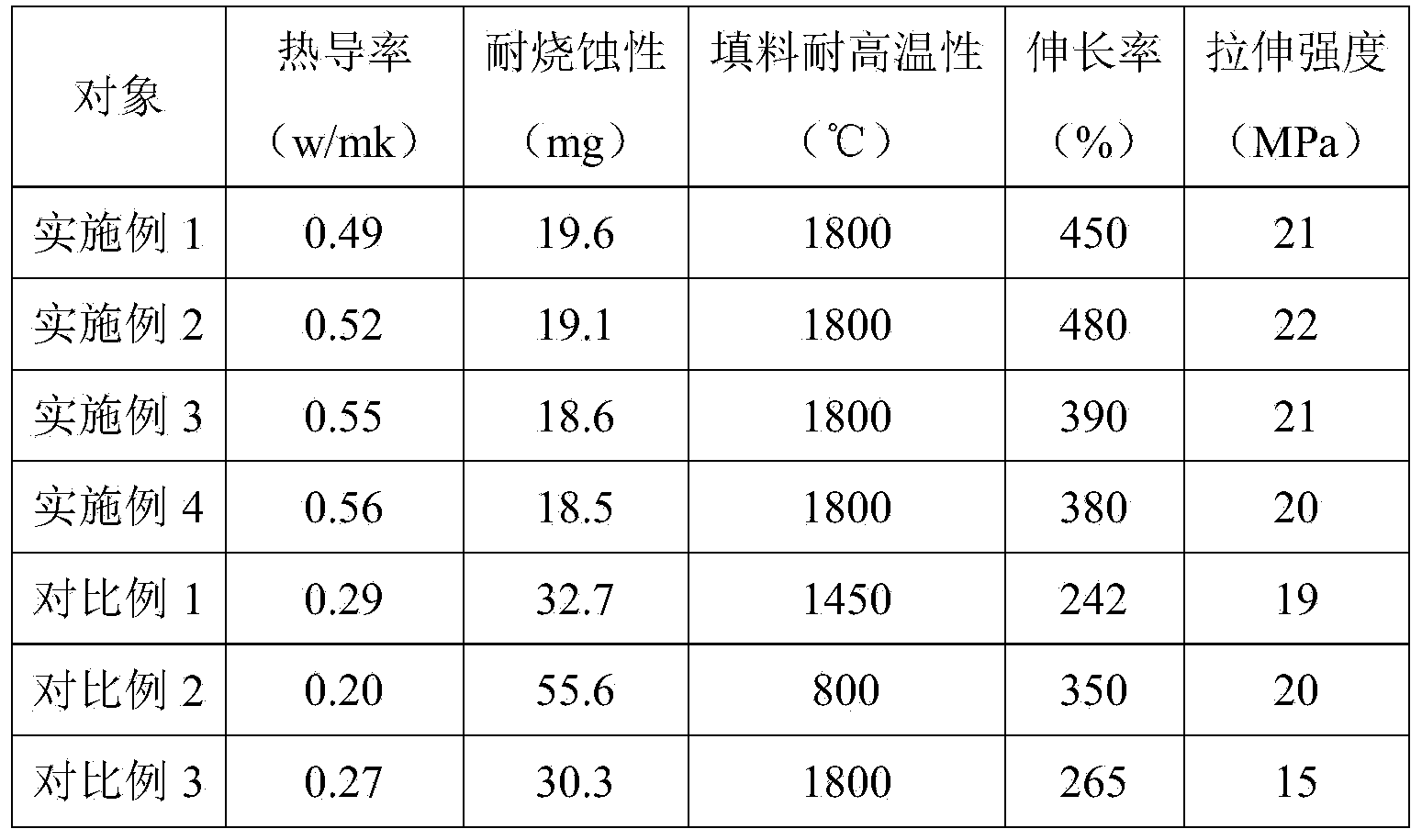

Arc extinction nozzle for high-voltage breaker and preparation method thereof

ActiveCN104387709AImprove breaking capacityImproved arc erosion resistanceCircuit-breaking switch detailsEmergency protective device manufactureBoron nitrideHigh pressure

The invention discloses an arc extinction nozzle for a high-voltage breaker and a preparation method thereof. The arc extinction nozzle comprises the following components in percentage by weight: 5%-10% of aluminum nitride, 1%-15% of boron nitride and the balance of polytetrafluoroethylene resin. According to the arc extinction nozzle disclosed by the invention, inorganic fillers of the aluminum nitride and the boron nitride are compounded and stuffed in composite polytetrafluoroethylene materials, and the stuffing proportion is reasonably allocated, so that the heat conductivity of nozzle materials is obviously improved, the electric arc erosion resistance of the materials is improved, and moreover, the arc extinction nozzle has an excellent mechanical property and a high temperature resistant property. The arc extinction nozzle is used for arc extinguish chambers of an open type breaker, a pot type breaker and a breaker of an all-metal closed type combined electric appliance, and the breaking-closing property of the breaker is improved, so that the operating stability of high-voltage switch equipment is improved.

Owner:HENAN PINGGAO ELECTRIC +3

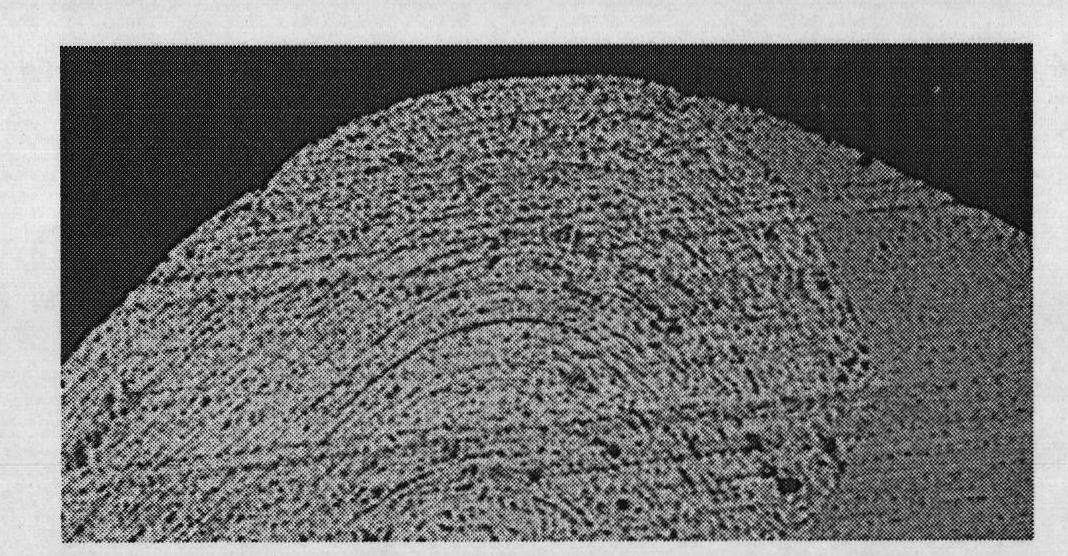

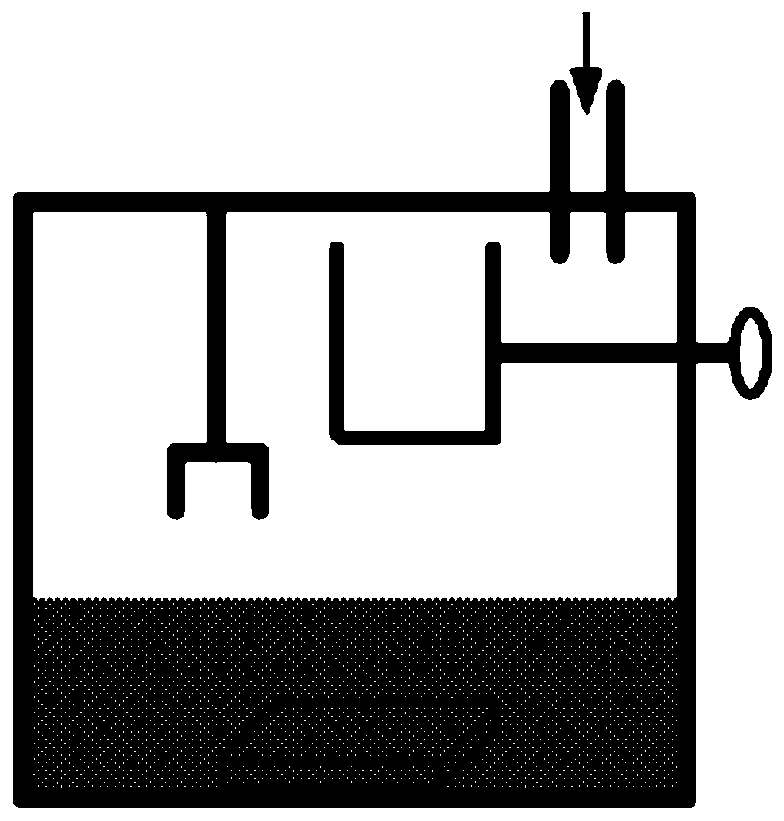

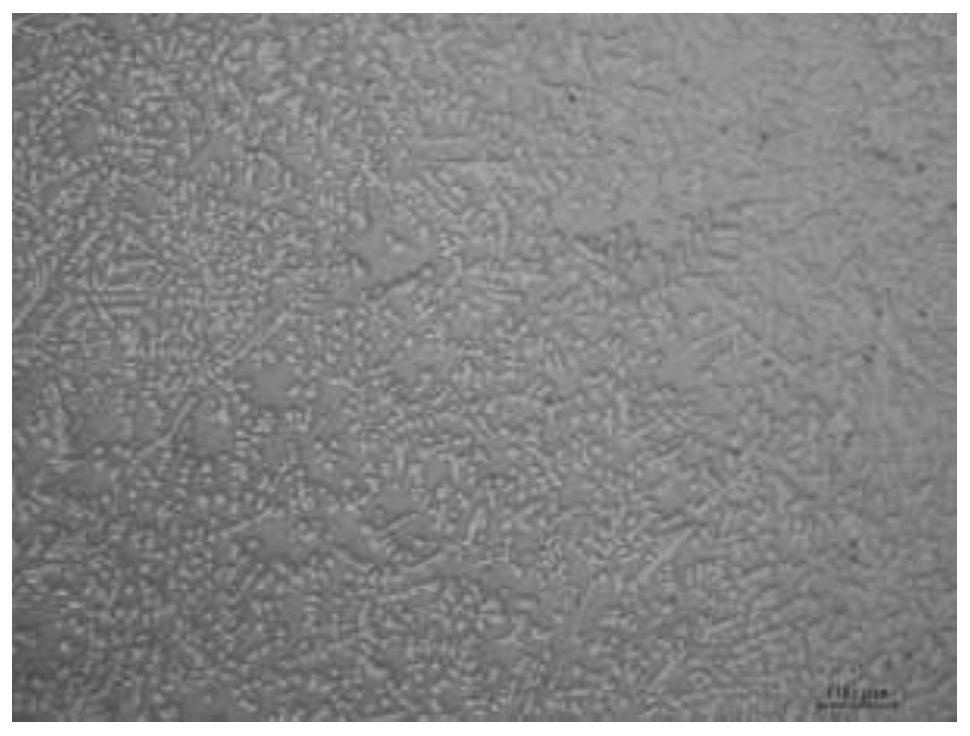

Structure optimization method for vacuum consumable electric arc smelting copper-chromium contact material

PendingCN113293309AImprove defectsImprove cooling efficiencyProcess efficiency improvementContactsAlloyCopper

The invention discloses a structure optimization method for a vacuum consumable electric arc smelting copper-chromium contact material. The method comprises the steps of S1, burdening, wherein copper powder and chromium powder are weighed; S2, sintering, wherein firstly, the copper powder and the chromium powder are fully mixed to be uniform, vacuum compaction sintering treatment is carried out, an intermediate alloy is obtained, then, the intermediate alloy is subjected to smelting and atomization powder making treatment, alloy powder is obtained, and finally, the alloy powder is sintered to obtain a consumable electrode bar; and S3, vacuum consumable smelting, wherein the consumable electrode bar is smelted in a vacuum consumable electric arc smelting furnace, and the copper-chromium contact material is obtained after cooling. The copper-chromium contact material prepared through the method is uniform in metallographic structure, and the fusion welding resistance and the segmentation capacity of the contact material are further improved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Preparation method of fibriform metal copper oxide enhanced silver-based electric contact material

The invention relates to a preparation method of a fibriform metal copper oxide enhanced silver-based electric contact material, which is used for preparing the silver copper oxide electric contact material (wires) by taking silver powder and silver and copper alloy powder as raw materials, adding a small number of tungsten and molybdenum elements as performance adjusting elements, taking the silver oxides as a reactant and adopting the steps of mixing, press forming, solid phase in-situ sintering, extruding and drawing. The invention is characterized in that: (1) the formation of the copper oxide and the fibrosis of the copper oxide are finished at a time in the preparation and machining processes; (2) the fibriform distribution of the copper oxide forms a microstructural characteristic with a certain orientation relation to make the metal oxide rooted in a silver matrix, thereby solving the problem of the metal oxide loss of the traditional particle metal oxide in electrical arc corrosion, improving the electrical arc corrosion resistance of the metal oxide and also broadening the application range of the silver metal oxide electric contact material; and (3) the preparation method has the advantages of short flow, low production cost and easy industrialization.

Owner:KUNMING UNIV OF SCI & TECH

Nitride enhanced copper-based electrical contact composite material

InactiveCN105140057AHigh densityExcellent mechanical properties and electrical propertiesContactsContactorYttrium

The invention relates to a nitride enhanced copper-based electrical contact composite material, which comprises the following components in percentage by weight: 0.5 to 4 percent by nitride, 0.5 to 4 percent of bismuth, 0.1 to 0.6 percent of rare earth yttrium, 0.5 to 2.5 percent of yttrium oxide, and the rest is copper and other unavoidable impurities, wherein the nitride is titanium nitride or aluminum nitride. The material provided by the invention is made by a preparation method comprising the steps of preparing powder by atomization, proportioning, mixing and vacuum hot pressed sintering. The composite material takes copper as a base body, the main raw materials are rich in resources, the nitride is distributed in the copper base material uniformly and dispersedly in an enhanced phase mode, and the fineness degree of an internal organizational structure of the material is improved. The composite material not only has good electrical conductivity, thermal conductivity, welding resistance and arc ablation resistance, but also is excellent in mechanical property and abrasion resistance, can meet basic requirements of workpieces such as an electrical contact and the like for materials, and can be applied to low-voltage electrical apparatuses such as medium and low electrical-load power switches, relays, DC contactors, air switches and the like. Compared with a silver-based electrical contact material, the nitride enhanced copper-based electrical contact composite material is more advantageous in price-to-performance ratio.

Owner:UNIV OF JINAN

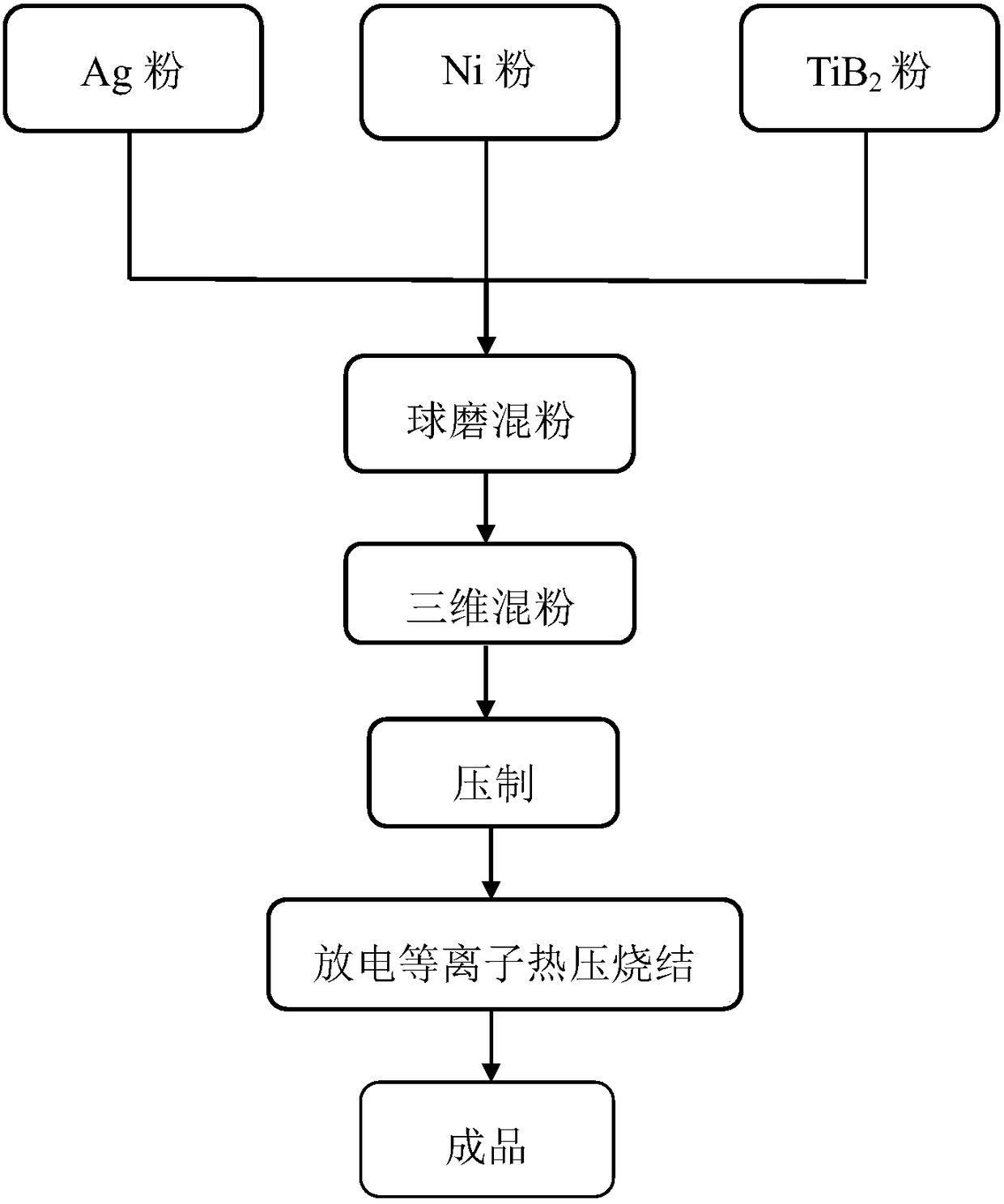

Silver-based contact material with high fusion welding resistance and preparation method of silver-based contact material

ActiveCN108251683AImproved arc erosion resistanceImprove the problem of poor welding resistanceMetallurgyFusion welding

The invention discloses a silver-based contact material with high fusion welding resistance. The silver-based contact material comprises, by weight percentage, 2%-15% of Ag powder, 2%-8% of Ni powderand 77%-96% of TiB2 powder; the sum of the weight percentages of the components is 100%. The invention also discloses a preparation method of a silver-based electrical contact material with fusion welding resistance, wherein the preparation method comprises the following steps: pre-mixing the Ni powder, the TiB2 powder and the Ag powder weighed in proportion for 4-8 h; then, continuing to mix thepowder in a three-dimensional motion power mixing machine for 2-6 h; and then compressing the mixed powder into a compressed blank and sintering to obtain an AgNi-TiB2 electrical contact material. TheAgNi-TiB2 electrical contact material prepared in the invention significantly solves a problem of poor fusion welding resistance of an AgNi contact material by introducing TiB2 particles into the AgNi contact material, and has the advantages of excellent electrical properties and low silver content.

Owner:XIAN UNIV OF TECH

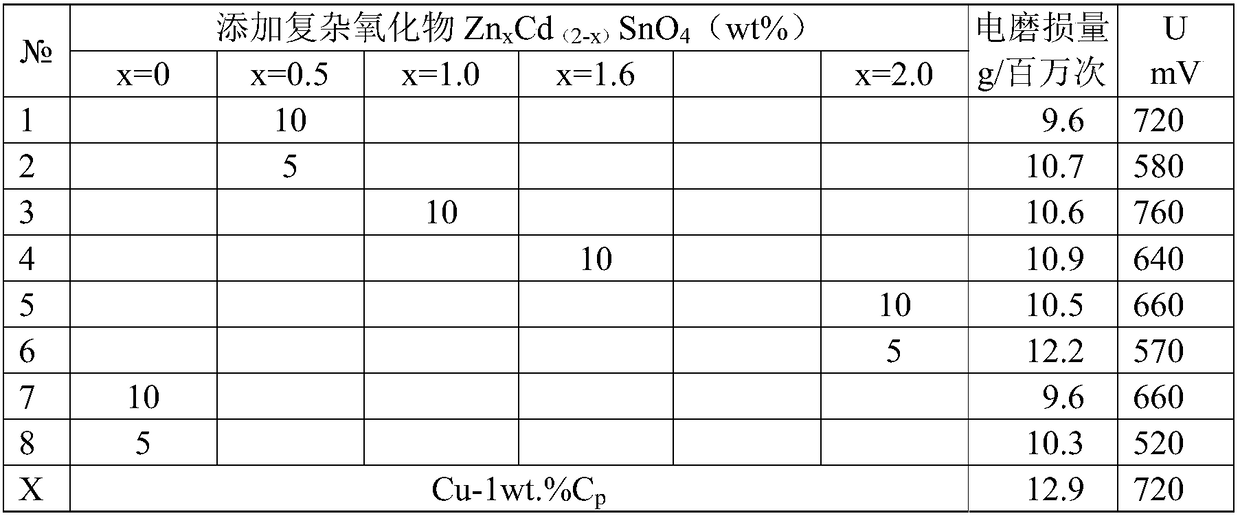

Complex conductive oxide-modified copper-based electric contact material and preparation method thereof

InactiveCN108690920AImproved arc erosion resistanceLow and stable contact resistanceContactsLow voltageLanthanum

The invention discloses a complex conductive oxide-modified copper-based electric contact material and a preparation method thereof, and relates to a copper-based electric contact material and a preparation method thereof. The invention aims at solving the problem of short life of a break contact of a low-voltage electrical appliance switch. The complex conductive oxide-modified copper-based electric contact material is composed of complex conductive oxide, lanthanum, zirconium and the balance copper in percentage by mass; and the molecular formula of the complex conductive oxide is ZnxCd(2-x)SnO4, and x in the molecular formula is 0-2. The preparation method comprises the following steps: weighing cadmium acetate dihydrate, dihydrate dihydrate, tin chloride pentahydrate and copper alloy powder, and dissolving the raw materials into distilled water separately and stirring to obtain a suspension, adjusting the pH value to obtain precipitates, washing, carrying out vacuum drying, calcining, sieving, carrying out cold-pressing molding, sintering, and extruding or rolling. The contact part prepared from the material disclosed by the invention is high in contact conducting capacity, self-arc-extinguishing capacity, matrix wettability and arc erosion resistance. The preparation method disclosed by the invention is applicable to preparation for the copper-based electric contact material.

Owner:HARBIN INST OF TECH

Copper-based electrical contact composite material and discharge plasma sintering process thereof

The invention relates to a copper-based electrical contact composite material for middle and low voltage appliance switches, in particular to a method for preparing the copper-based electrical contact composite material through a discharge plasma sintering process. The copper-based composite material is composed of, by weight, 0.5%-4% of bismuth, 0.05%-0.4% of lanthanum, 0.05%-0.3% of a carbon nano tube (nickelized), and the balance copper and unavoidable impurities. The copper-based composite material is prepared through the preparation method of alloy powder preparation, burdening, ball milling and discharge plasma sintering; the discharge plasma sintering process is adopted and has the characteristics of being high in heating speed, short in sintering time, high in density of an obtained material, good in property and the like, so that the discharge plasma sintering process is important to realizing material preparation with high quality, high efficiency, low consumption and low cost. The copper serves as a substrate, so that the main raw material is abundant in resource, and the electrical and thermal conductibility, electric erosive resistance, oxidation resistance and the like of the material are comparable to those of a silver-based electrical contact material, and the essential requirements of electrical contact and the like for the material by workpieces can be met.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com