Patents

Literature

66 results about "Sb element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional particle electrode loaded with catalyst active carbon and preparation method thereof

ActiveCN103663631AIncrease productionImprove structural stabilityWater contaminantsWater/sewage treatmentThree dimensional electrodeSolid solution

The invention discloses a three-dimensional particle electrode loaded with catalyst active carbon and a preparation method thereof. The electrode consists of particle active carbon and a TiO2 solid solution compound catalyst which is loaded on the particle active carbon and is doped with Sn and Sb elements. The method comprises the steps of particle active carbon pretreatment, catalyst preparation, soaking for aging, drying and roasting for activating. The three-dimensional particle electrode loaded with the catalyst active carbon prepared with the method has the characteristics of high pollutant removing rate, high electrocatalytic activity, high yield of hydroxyl radicals, little loss of a catalyst and the like; moreover, the preparation method is simple, noble metal catalysts are not used, used raw materials are widely available, the manufacturing cost is low, and secondary pollution is avoided. When the three-dimensional particle electrode loaded with the catalyst active carbon prepared with the method is applied to a three-dimensional electrode reactor, non-biodegradable organic waste water can be treated efficiently.

Owner:TSINGHUA UNIV

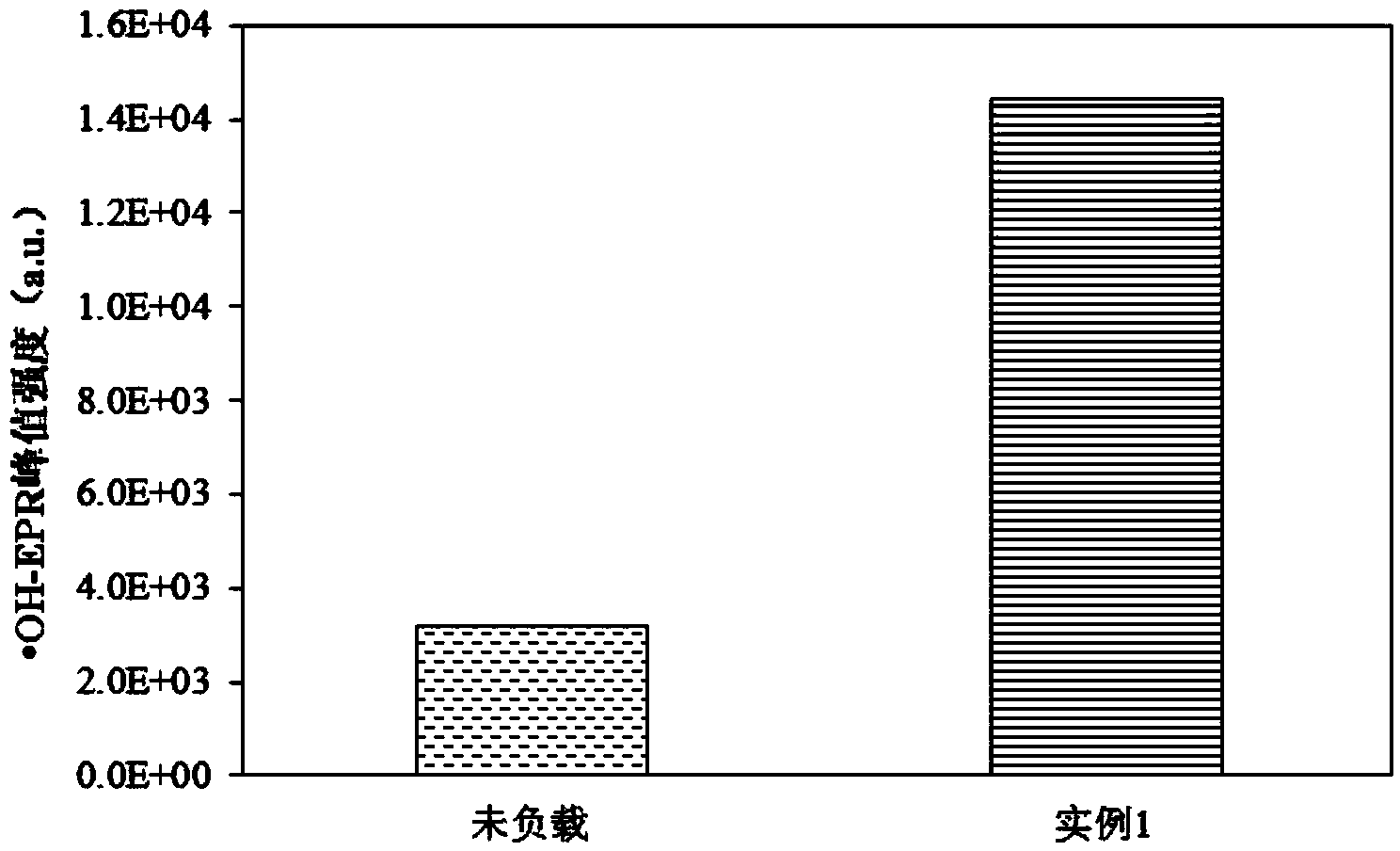

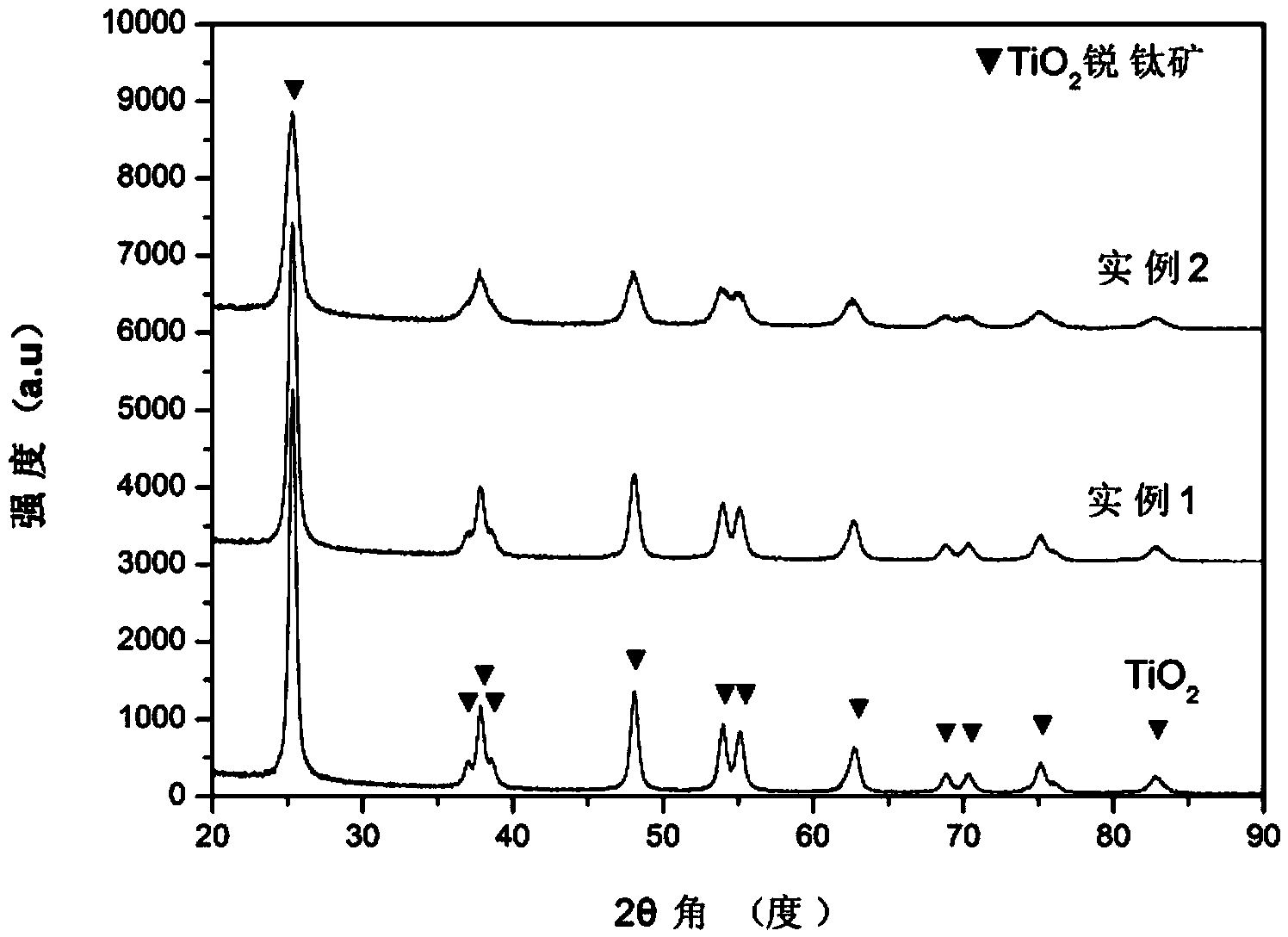

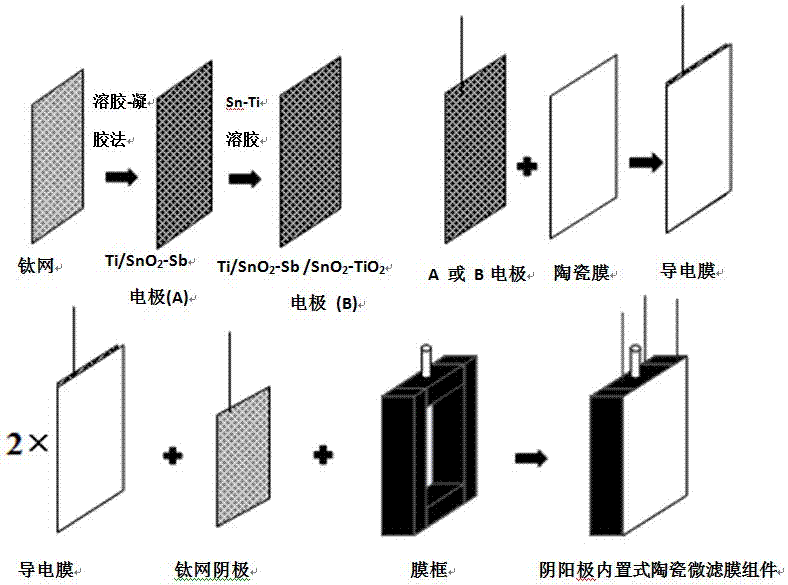

Cathode and anode built-in ceramic micro-filtration membrane reactor suitable for removing pollutant in source water

ActiveCN107162118AExtended service lifeHigh removal rateSpecific water treatment objectivesWater contaminantsFiltration membraneWater source

The invention relates to a cathode and anode built-in ceramic micro-filtration membrane reactor suitable for removing pollutant in source water. According to the invention, titanium mesh is taken as cathode, an Sb element-doped titanium-based SnO2 coating A electrode or a mixed coating B electrode with TiO2 and SnO2 loaded on the basis of the A electrode serves as an anode, and the cathode faces to two sheets of anodes and is placed into a micro-filtration membrane module. The reactor applies extra electric field by constant voltage DC source, and operates under a continuous flow mode, the particles and colloid in source water can be filtered by the ceramic micro-filtration membrane with the aperture of 0.1-0.4 [mu]m, under electrocatalysis effect, a lot of substances with strong oxidizability is generated in water, and removal of the organic pollutants which are difficultly degraded is realized. doping of Sb can obviously increase the conductivity of SnO2, the coating of the electrode has physical sorption effect on HO., and has important effect for degrading an intermediate. According to the invention, TiO2 cavity loaded on the surface of the electrode provides more places for H2O for forming HO. with an adsorption state and organic matter molecules in a solution on the anode through discharging, so that the catalytic oxidation effect of the electrode is enhanced.

Owner:TONGJI UNIV

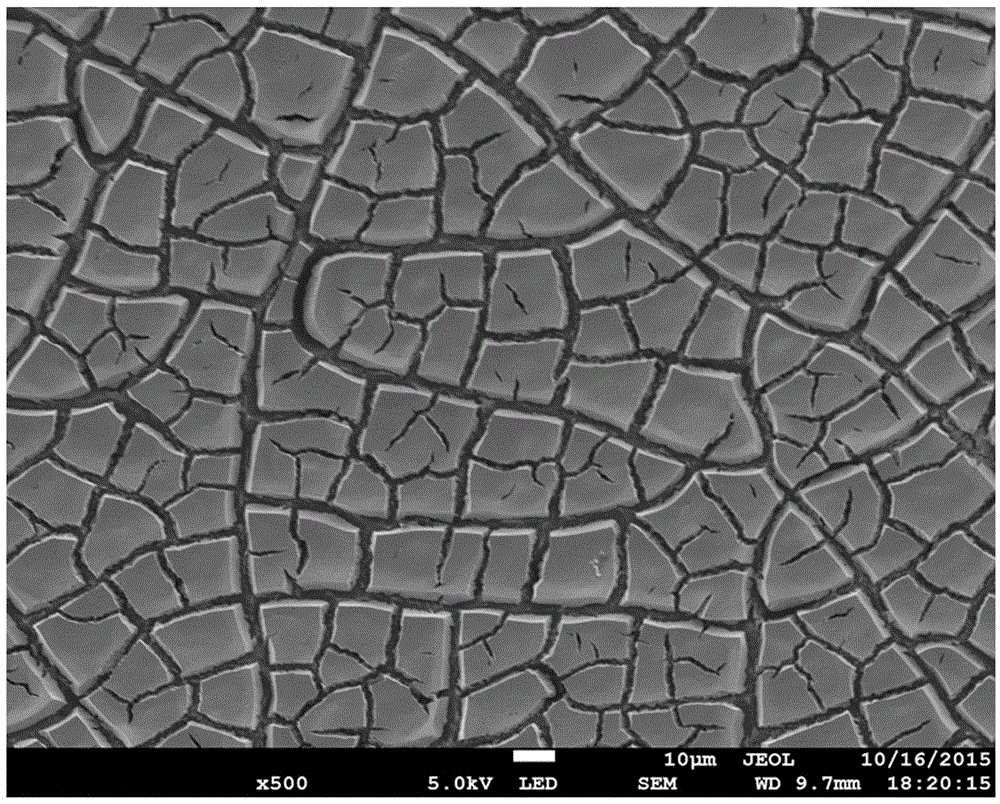

Manufacturing method for nodular cast iron used for crankshaft

The invention discloses a manufacturing method for nodular cast iron used for a crankshaft. Waste steel, pig iron, coke, melted-down waste iron, tin slag and iron-ore slag are selected as raw materials. The manufacturing method includes the five steps of raw material melting, spheroidizing, primary inoculation, secondary inoculation and pouring. Compared with the prior art, the manufacturing method has the beneficial effects that the silicon content is reduced, the recovery rate can be increased, and the production cost can be reduced; as Sb elements and Re elements are additionally arranged in the nodular cast iron, the abrasion resistance, the corrosion resistance and the tensile strength of the nodular cast iron are improved on the original basis; timely slag raking is carried out after spheroidizing to remove impurities in molten iron, slag raking is carried out again after two times of inoculation are carried out under the corresponding conditions, impurities are reduced, the quality of materials is improved accordingly, and the tenacity of the nodular cast iron is guaranteed; and the content of Nb elements and the content of Mo elements are increased, and as the thermal expansion coefficient of the Nb elements and the thermal expansion coefficient of the Mo elements are small, the heat resistance and the abrasion resistance of the nodular cast iron are improved.

Owner:HEFEI CITY TENVER PRECISION CASTING

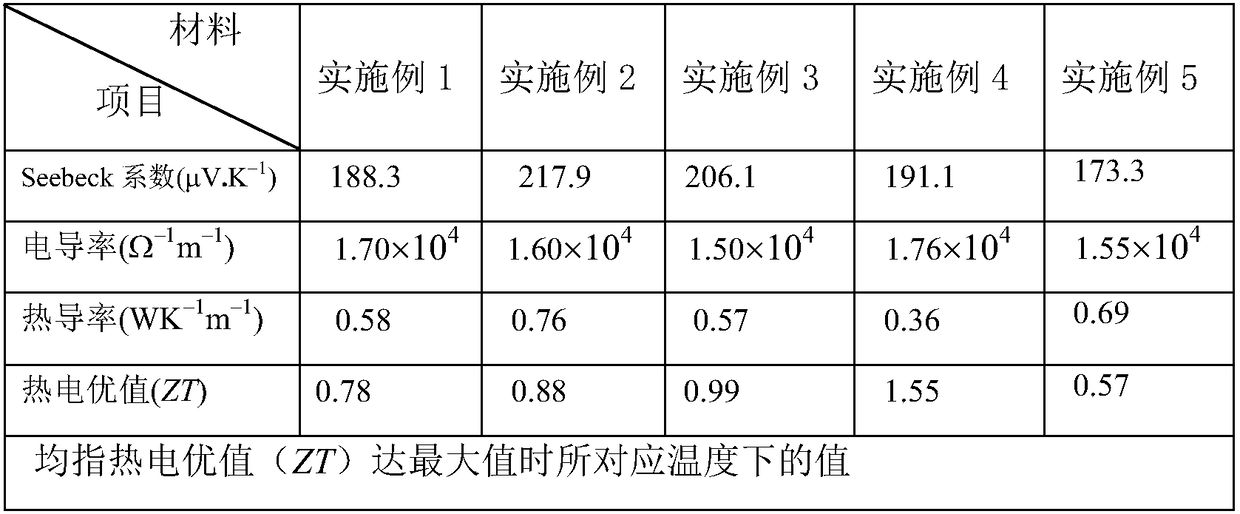

Composite nanometer ZnSb-based thermoelectric material and preparation thereof

InactiveCN101275192AImprove Seebeck coefficientImprove thermoelectric performanceThermoelectric device junction materialsThermoelectric materialsHigh energy

A composite nanometer Znsb group thermoelectric material and a manufacturing method thereof are disclosed, the composite nanometer Znsb base thermoelectric material is manufactured by the following method, high pure Zn powder, Sb powder and nanometer Zn powder which is 0.5-30% of mass number of Zn and Sb powder, nanometer Sb powder or Zn, Sb nanometer lines; high energy ball milling is carried out under an inert atmosphere to obtain the powder of Znsb group compound, eventually, the powder is cool-pressed to formation and densified under the pressure of 1-8GPa and at 10-30 DEG C, wherein mol ratio of Zn element to Sb element is 4-2: 3. The material of the invention includes lower heat conduction coefficient, and higher thermoelectric conversion rate.

Owner:SNTO TECH GRP

Sb-containing magnesium alloy sacrificial anode material

The invention discloses a Sb-containing magnesium alloy sacrificial anode material. The magnesium alloy sacrificial anode material comprises, by mass, 5.0-5.2% of Al, 0.6-0.8% of Zn, 0.1-0.3% of Sb, and the balance Mg and inevitable impurities. The alloy components of the Sb-containing magnesium alloy sacrificial anode material include Mg-Al-Zn-Sb. On the basis of combined use of Zn and Al, by adding the Sb elements, grains are refined, and the structure is improved, so that the anode material is uniform in consumption, longer in service life and suitable for cathode protection under the corrosion environments such as soil, seawater and water heaters, and has wide application prospects.

Owner:LUOYANG INST OF SCI & TECH

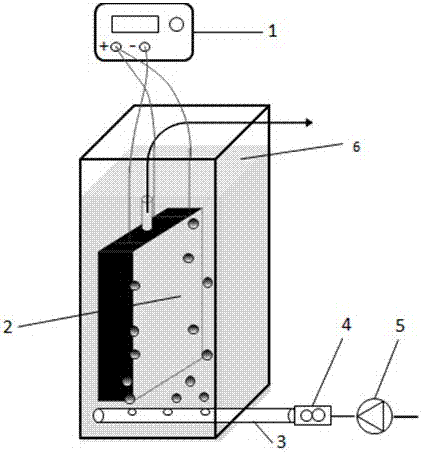

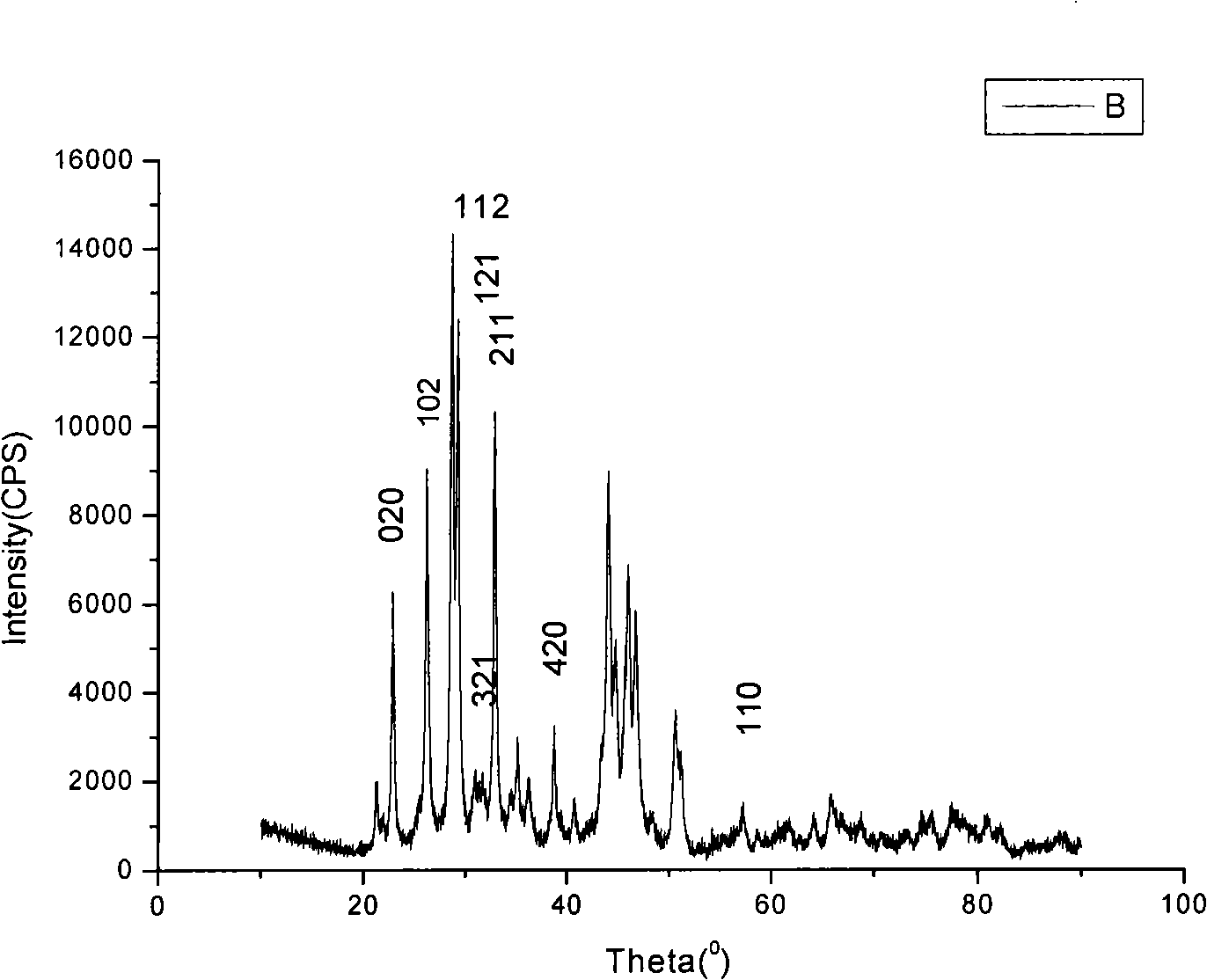

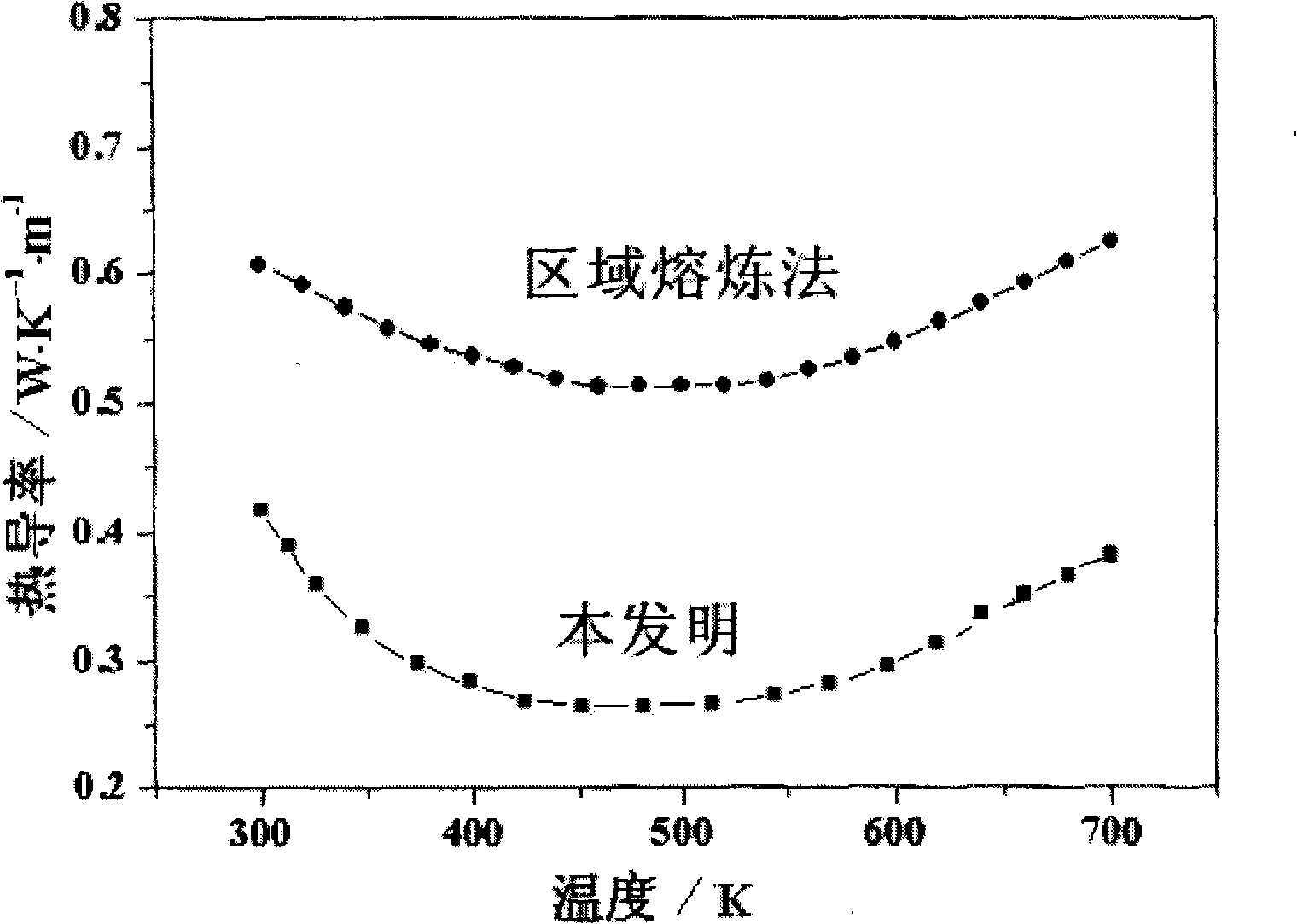

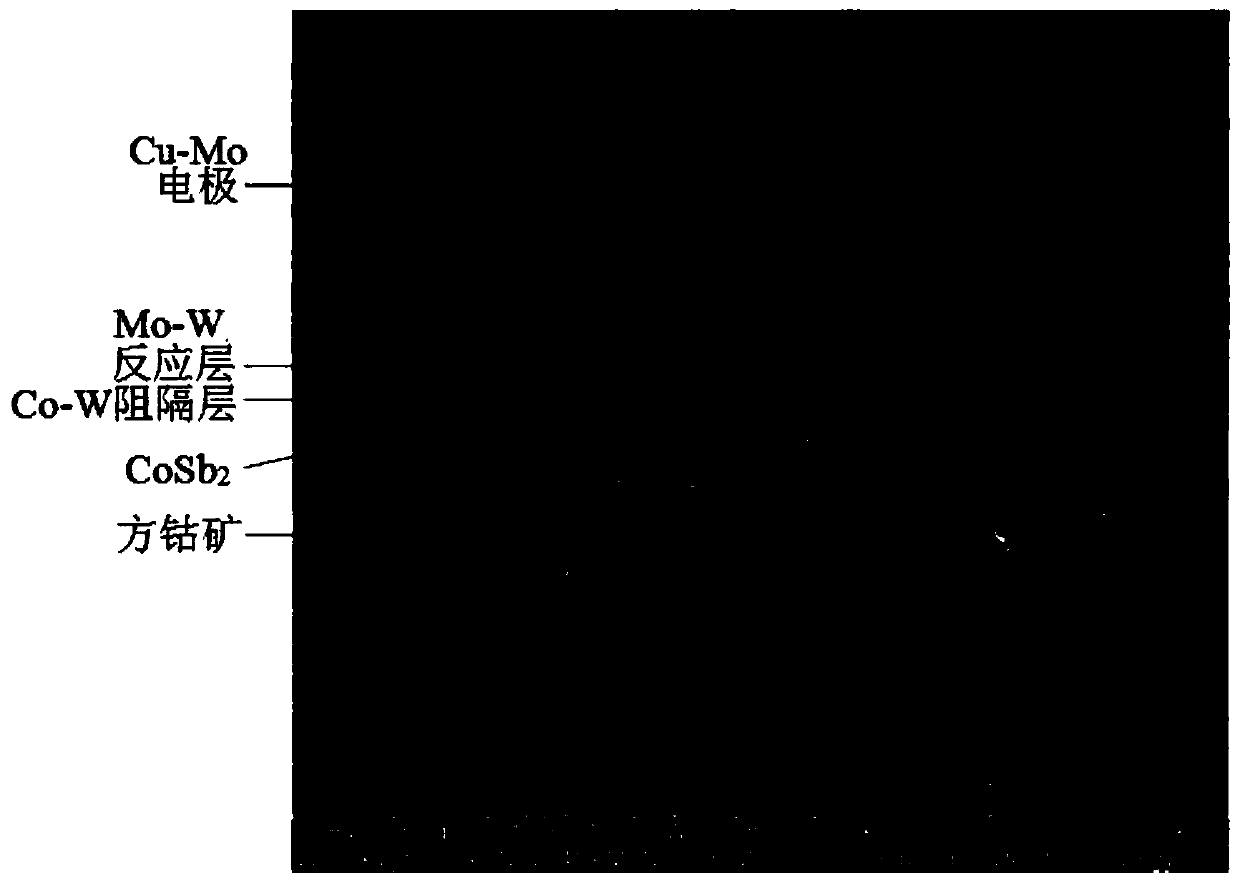

Rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929AImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusSkutteruditeElectroplating

The invention discloses a rapid diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The method aims to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with an electrode. The method comprises the steps of takingan electrode, cleaning a to-be-welded surface, electroplating an alloy barrier layer on the surface of the to-be-welded surface of the electrode, cleaning the to-be-welded surface of the skutteruditethermoelectric material, and performing diffusion welding. The barrier layer is prepared on the electrode side through an electroplating method, diffusion welding is achieved between the barrier layerand the skutterudite thermoelectric material under the relatively low pressure and at the relatively low temperature, element diffusion of weld joint elements and skutterudite does not exist in the process, and Sb element volatilization and element diffusion can be prevented. The method is suitable for welding the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

Preparation method of tin oxide fiber reinforced silver-based electric contact alloy

InactiveCN105908108AImprove conductivityImproved arc erosion resistanceElectric switchesFiberElectrical resistance and conductance

The invention provides a preparation method of a tin oxide fiber reinforced silver-based electric contact alloy. The method specifically includes: firstly preparing a Sb element doped tin oxide precursor gel, adding the gel into a fiber forming agent to prepare a spinning solution, and conducting electrostatic spinning to obtain Sb element doped SnO2 fiber; then subjecting the fiber and silver powder to mechanical mixing, and carrying out pressing-sintering-extrusion on a silver-tin oxide fiber mixture by a traditional process, thus obtaining the tin oxide fiber reinforced silver-based electric contact alloy. The method provided by the invention improves the electroconductivity of tin oxide through effective doping of the Sb element, reduces the resistance of a contact alloy body, at the same time enables fibrous distribution of a second phase oxide and reinforcement of the oxide in a silver matrix, solves the problems of large contact resistance, high temperature rise and large oxide loss in traditional oxide particle reinforced silver-based electric contact materials during arc erosion, improves the arc erosion resistance of silver-based oxide electric contact alloy, and also expands the application scope of the silver-based oxide electric contact alloy.

Owner:XI'AN POLYTECHNIC UNIVERSITY

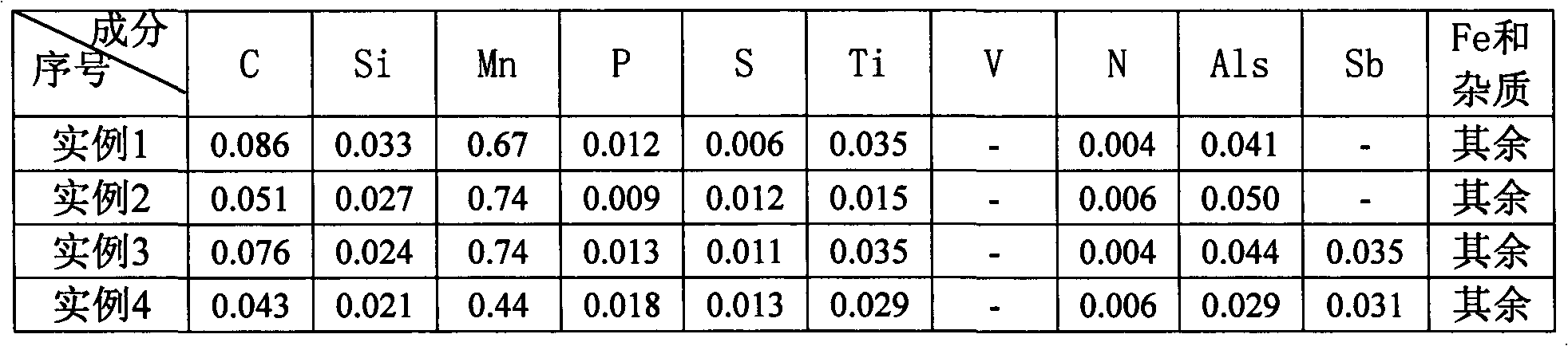

Hot rolled steel plate for double-faced enamel and production method thereof

InactiveCN102653847AReduce the risk of fish scale chipping defectsReduce the amount addedTemperature control deviceSteelmakingDetonation

The invention relates to a hot rolled steel plate for double-faced enamel and a production method of the hot rolled steel plate and belongs to the technical field of iron-base alloy. The production method of the hot rolled steel plate comprises the steps of: controlling the ingredients and mass percents of the hot rolled steel plate as follows: 0.02-0.1% of C, not larger than 0.1% of Si, 0.2-1.0% of Mn, not larger than 0.02% of P, 0.005-0.035% of S, 0.01-0.1% of Als, 0.002-0.01% of N, 0.01-0.1% of Ti, 0.01-0.05% of Sb, and the balance of ferrum and inevitable impurities; and simultaneously controlling the heating temperature of the continuous casting slab of the hot rolled steel plate to be 1150-1230 DEG C, controlling the temperature of a precise rolling inlet to be 1020+ / -20 DEG C, controlling the precise rolling ending temperature to be 840-920 DEG C, and controlling the coiling temperature after the precise rolling operation to be 550-650 DEG C. The hot rolled steel plate and the production method of the hot rolled steel plate fully utilize the inevitable products C, S and N elements of steelmaking production to replace the function of the Ti element to reduce the dosage of the Ti element; and a proper dosage of Sb element is added to prevent the scales detonation of the enamel and reduce the steelmaking cost, and the hot rolled steel plate with good double-faced enamel processing performance and small strength performance change after enamel is obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for preparing high magnetic induction oriented silicon steel

InactiveCN110791635AImprove the pass rate of magnetic propertiesIncrease magnetic sensitivitySiliconCasting

The invention relates to a method for preparing high magnetic induction oriented silicon steel. The method for preparing the high magnetic induction oriented silicon steel includes the steps: adding Sb element in ingredients of silicon steel, meanwhile adding a small amount of Cu, setting the drawing velocity at 0.8-1.0m / min, and setting the thickness of a casting blank at 200-250min; setting heating temperature of the casting blank at 1180-1220 DEG C, and setting heating time at 180-240min; performing the normalizing process by adopting two-step normalizing; performing the nitriding treatmentprocess by adopting NH3 nitriding in a mixture containing 75% of H2 and 25% of N2; performing high temperature annealing, wherein first raising temperature to 600-650 DEG C at the velocity of 50-100DEG C / h under N2 atmosphere, then keeping the temperature at 600-650 DEG C for 5-10h under protective atmosphere containing 75% of H2 and 25% of N2 by volume fraction, and then raising the temperatureto 1200 DEG C at the velocity of 15-20 DEG C; and after coating the silicon steel with an insulating layer, drying the insulating layer under the temperature of 500 DEG C, and performing annealing after levelling the silicon steel by stretching the silicon steel at the elongation of 0.25%-0.75% under the temperature about 800-900 DEG C. The method for preparing the high magnetic induction oriented silicon steel improves induction value of the oriented silicon steel, and improves performance qualification rate of the oriented silicon steel by 15-25%.

Owner:ANGANG STEEL CO LTD

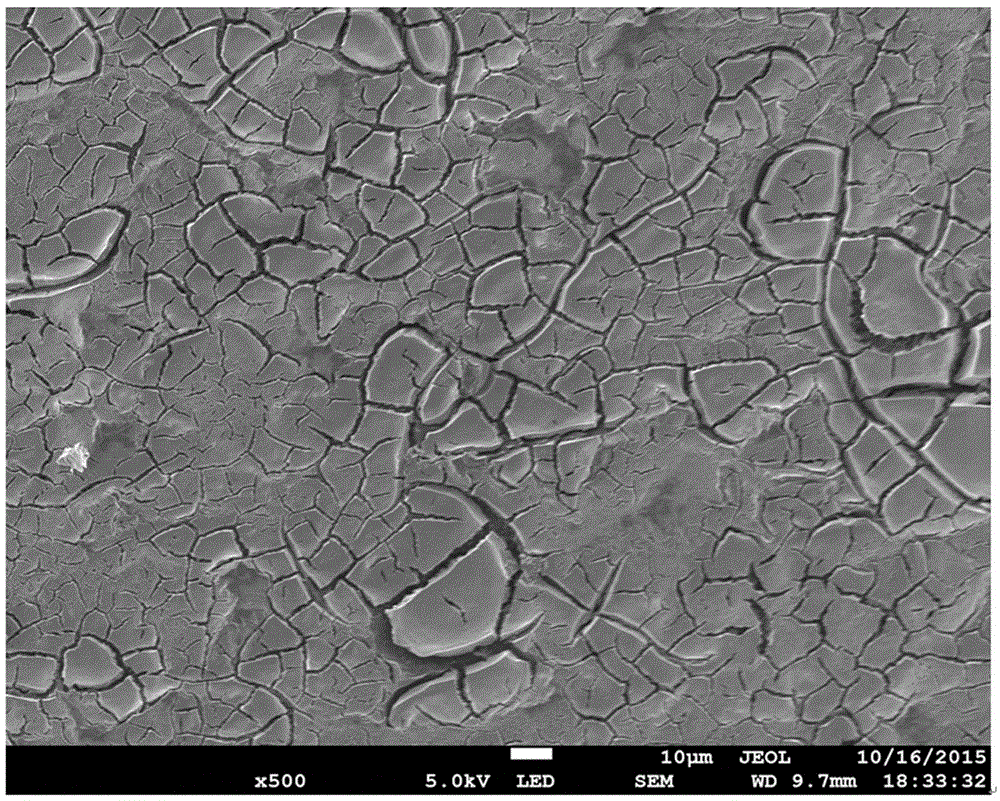

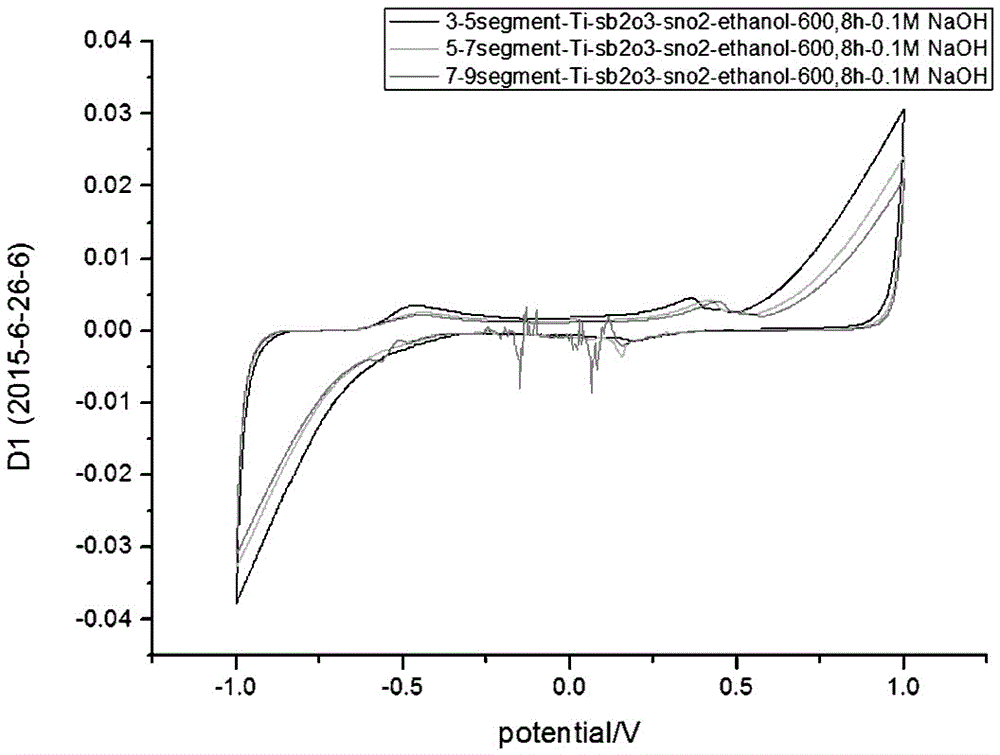

Preparation method of high-mechanical strength Ti-based double-interlayer anode

InactiveCN105800741AAcid-resistant and corrosion-resistantLow priceWater treatment compoundsWater contaminantsEtchingSolvent

The invention relates to a preparation method of a high-mechanical strength Ti-based double-interlayer anode; the preparation method is characterized in that a pure Ti plate or a Ti alloy plate is taken as an electrode substrate, a mixed alcohol solution of Sn salt is taken as an impregnation solution, and the electrode substrate and the impregnation solution are doped with Sb elements at the same time, so that a Ti-Sb2O3-SnO2 compound catalytic anode is obtained; after the Ti-Sb2O3-SnO2 compound catalytic anode is prepared, a yellow conductive layer TiO is slowly formed in a water solution, and the Ti-TiO / Sb2O3-SnO2 anode having double interlayers of TiO / Sb2O3 is finally formed; the method takes the mixed alcohol solution as a solvent so as to enable a surface layer of an electrode to be evenly and firmly coated; TiO is good in electrical conductivity; the binding force between the TiO and SnO2 is higher than that between pure Ti and the SnO2, so that the mechanical strength of the coated electrode is further improved. The method adopts the pure Ti plate or the Ti alloy plate as the substrate, thus having the advantages of being low in price, acid-resistant, corrosion-resistant and stable in mechanical properties; furthermore, a large specific surface area is obtained by oxalic acid etching, so that a material guarantee is provided for preparing the electrode with high mechanical strength.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

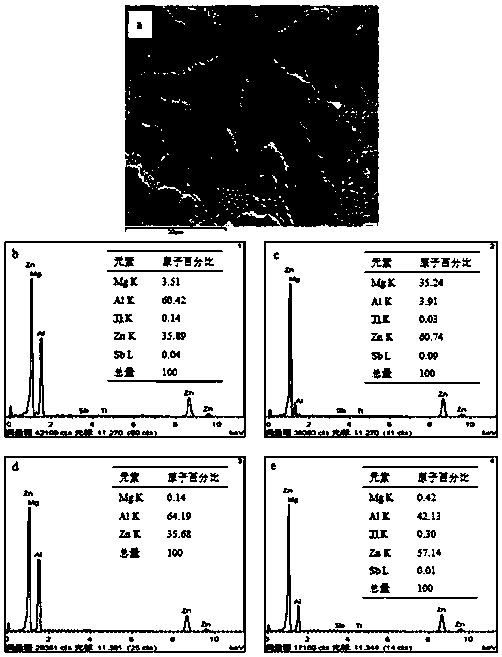

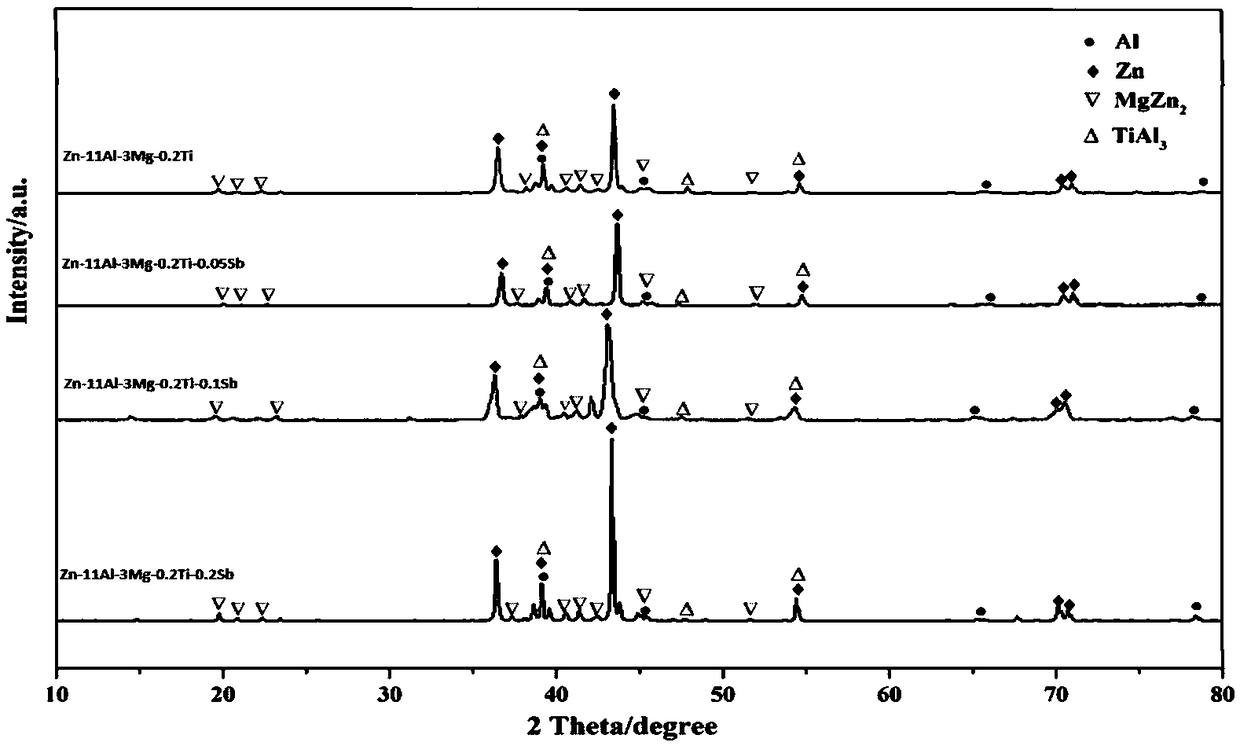

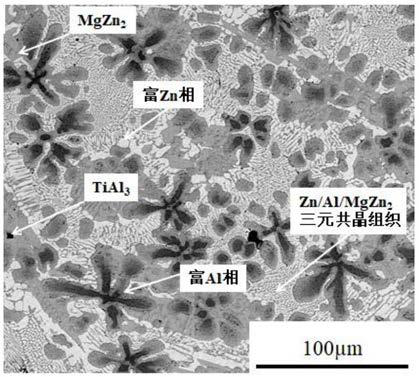

Titanium and antimony-containing hot dipping zinc plating aluminum magnesium alloy and preparation method thereof

ActiveCN108977695AReduce lossIncrease nucleation pointHot-dipping/immersion processesTitaniumNucleation

The invention relates to the field of anticorrosion of steel and iron materials, in particular to a titanium and antimony-containing hot dipping zinc plating aluminum magnesium alloy and a preparationmethod thereof. The alloy is prepared from Zn, Al, Mg, Ti and Sb elements in percentage by mass: 10.0 to 12.0 weight percent of Al, 2.5 to 3.5 weight percent of Mg, 0.1 to 0.2 weight percent of Ti, 0.1 to 0.2 weight percent of Sb and the balance of Zn. Through the addition of Ti and Sb elements in the zinc aluminum magnesium alloy, the flowability of the zinc liquid is enhanced; the zinc loss isreduced; meanwhile, the nucleation points of an aluminum-rich phase are increased; the aluminum-rich dendrite arm length is shortened, so that the crystal grain tissues of the aluminum-rich phase arerefined; the layer sheet space of the eutectic tissues is reduced, so that the eutectic tissues become fine and compact; the comprehensive performance of the alloy is effectively improved; the anti-scratch performance and anti-corrosion performance of the hot dipping zinc plating aluminum magnesium alloy are finally improved; meanwhile, big zinc patterns can be promoted to be formed on the surfaceof the plating layer; the appearance decorative performance of the plating layer is improved.

Owner:UNIV OF JINAN

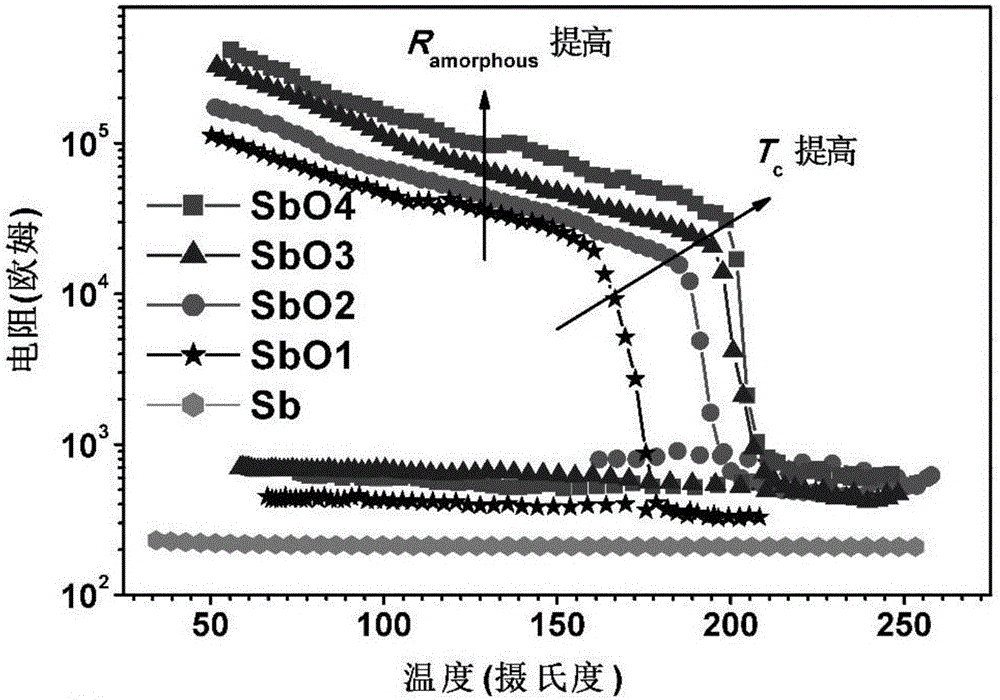

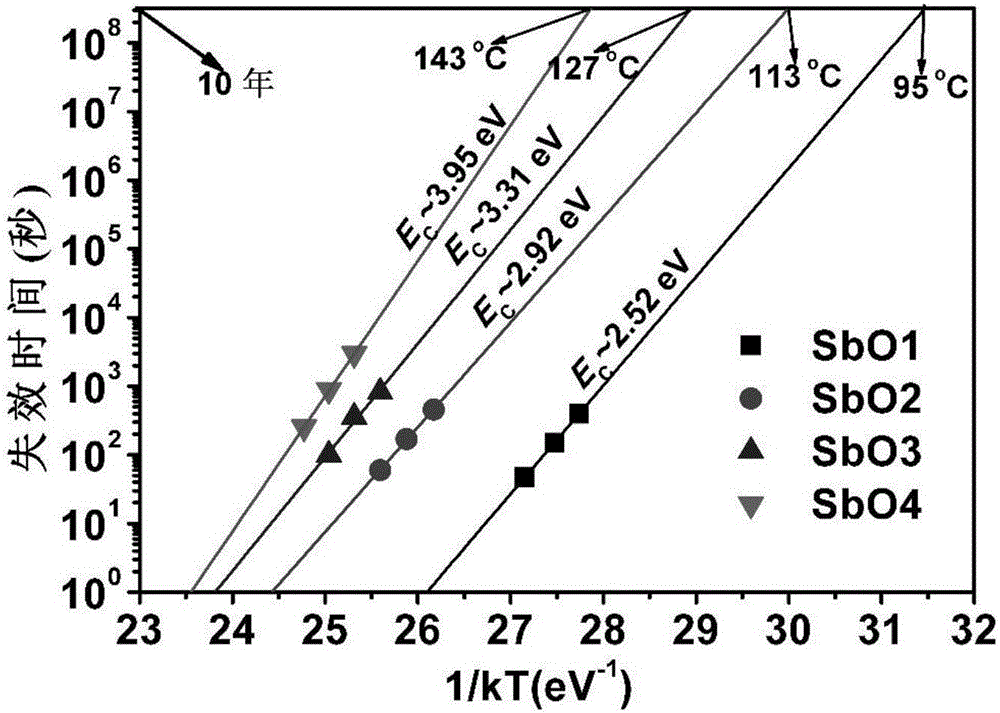

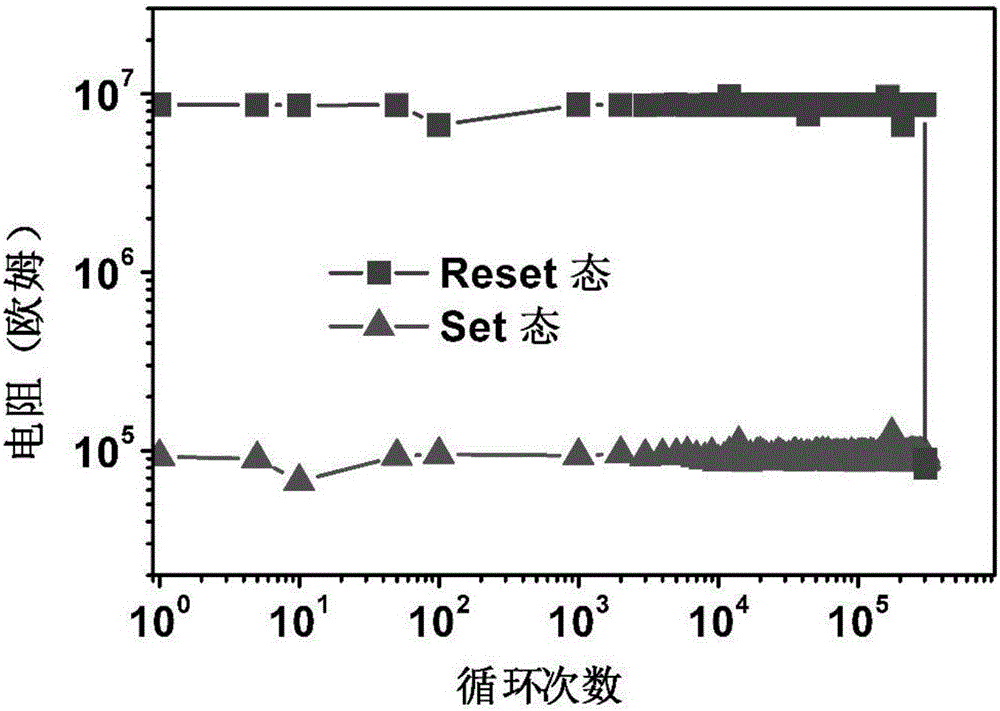

Oxygen-doped Sb nanometer phase change thin-film materials and preparation method thereof and application thereof

InactiveCN106410025AFast crystallization rateRaise the crystallization temperatureMaterial nanotechnologyElectrical apparatusSemiconductor materialsMetallurgy

The present invention belongs to the semiconductor material field, and discloses the oxygen-doped Sb nanometer phase change thin-film materials. The chemical composition general formula is expressed by SbOx, wherein the Sb represents the Sb element, the O represents the nitrogen atom, the x represents different oxygen doping amount marks, and x=1,2,3 or 4. A magnetron sputtering method is employed for preparation, the substrate employs SiO2 / Si(100) substrate, the target of sputter is the Sb target, the sputtering gas is high-purity Ar gas and the high-purity O2 gas, and the total flow of the argon and the oxygen is maintained to 30 sccm in the sputtering process. The oxygen-doped Sb materials can solve the defects and deficiencies of the pure Sb materials. Different oxygen atoms are doped to allow the Sb crystallization temperature to be obviously improved, the data maintenance capacity is enhanced, and the stability is improved. The RESET power consumption is reduced while the crystalline state resistance is improved.

Owner:JIANGSU UNIV OF TECH

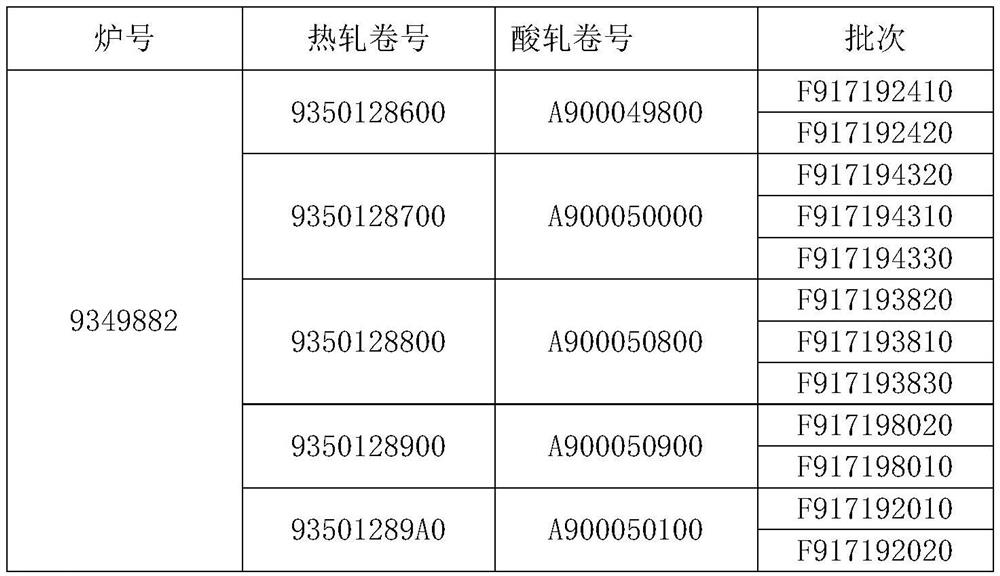

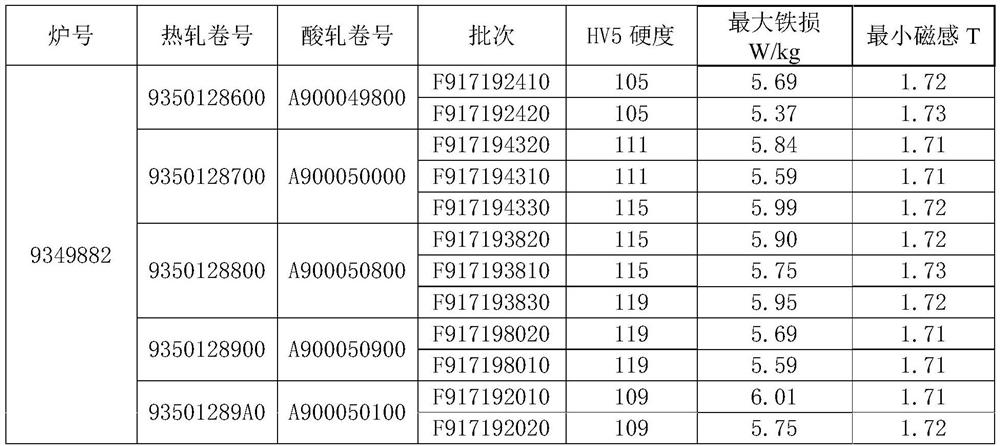

Low-hardness 50W800 electrical steel and production method

The invention provides low-hardness 50W800 electrical steel which consists of the following elements in percentage by mass: less than or equal to 0.005% of C, greater than or equal to 0.45% and less than or equal to 0.60% of Si, greater than or equal to 0.25% and less than or equal to 0.40% of Mn, greater than or equal to 0.15% and less than or equal to 0.35% of Al, greater than or equal to 0.03%and less than or equal to 0.05% of P, less than or equal to 0.06% of S, greater than or equal to 0.045% and less than or equal to 0.060% of Sb, less than or equal to 0.0030% of N, less than or equal to 0.0030% of Ti, and the balance of iron and inevitable impurity elements. Through reasonable component designs, micro-alloy Sb element is added while content of Si and Al is regulated, a corresponding cover type furnace annealing temperature and corresponding annealing time can be matched to realize equiaxial annealing of crystalline grains, so that electrical steel is reduced to reasonable hardness, hardness and magnetic performance requirements of full-process electrical steel products are met, and therefore, the all-process non-oriented electrical steel is produced through the cover type annealing process.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Ge-Se-Sb composite material, 1S1R phase change memory unit and preparation method thereof

InactiveCN108922960ALow reversible conversion capabilityFeatures Transition Over Threshold (OTS)Electrical apparatusDielectricHigh resistance

The invention provides a Ge-Se-Sb composite material, a 1S1R phase change memory unit and a preparation method thereof. The composite material has the chemical formula of GexSeySb100-x-y, wherein x and y are both atomic percentage of elements, and a formula which is as shown in the specification is met. When the material is used as a gate device material dielectric, the atomic percentage of Sb element satisfies a formula which is as shown in the specification, and the threshold value conversion unit has the advantages of low threshold voltage, high switching ratio and the like; when the material is used as an energy storage material dielectric, the atomic percentage of Sb element satisfies a formula which is as shown in the specification, and the material is high in crystallization temperature and the phase change storage unit has relatively high data retention. The Ge-Se-Sb composite material has the threshold value transformation (OTS) characteristic as well as phase change storage (OMS) characteristic, and has the reversible conversion capability between high resistance and low resistance under the effect of an electric signal.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

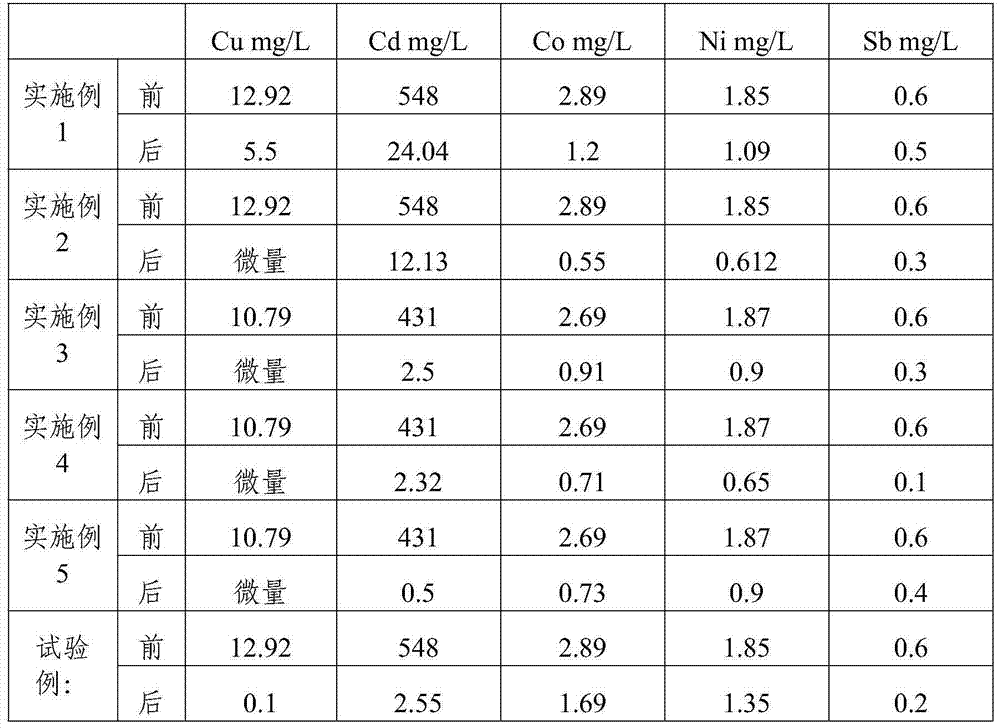

Method for reducing content of Cu, Cd, Ni, Co and Sb in zinc hydrometallurgy zinc sulfate solution

InactiveCN104711423AHigh purityReduce contentProcess efficiency improvementSulfate zincHydrometallurgy

The invention relates to the technical field of hydrometallurgy, and especially relates to a method for reducing the content of Cu, Cd, Ni, Co and Sb in a zinc hydrometallurgy zinc sulfate solution. The method comprises the following steps: detecting and recording the content of components in the zinc sulfate solution, and adjusting the pH value of the zinc sulfate solution to 2.5-3.5 to make zinc sulfate meet condition requirement in subsequent purifying technologies, improves the removal rate of Cu, Cd, Ni, Co and Sb elements in zinc sulfate and improve the purity of the zinc sulfate solution; adding a cobalt removal agent in the treatment process, stirring, adding zinc powder, stirring, and filtering to simultaneously remove Cu, Cd, Ni, Co and Sb elements from zinc sulfate in order to reduce the content of impurity elements in zinc sulfate, improve the purity of zinc sulfate, complete the purification process at 50-60DEG C and reduce the energy consumption in the purification process.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

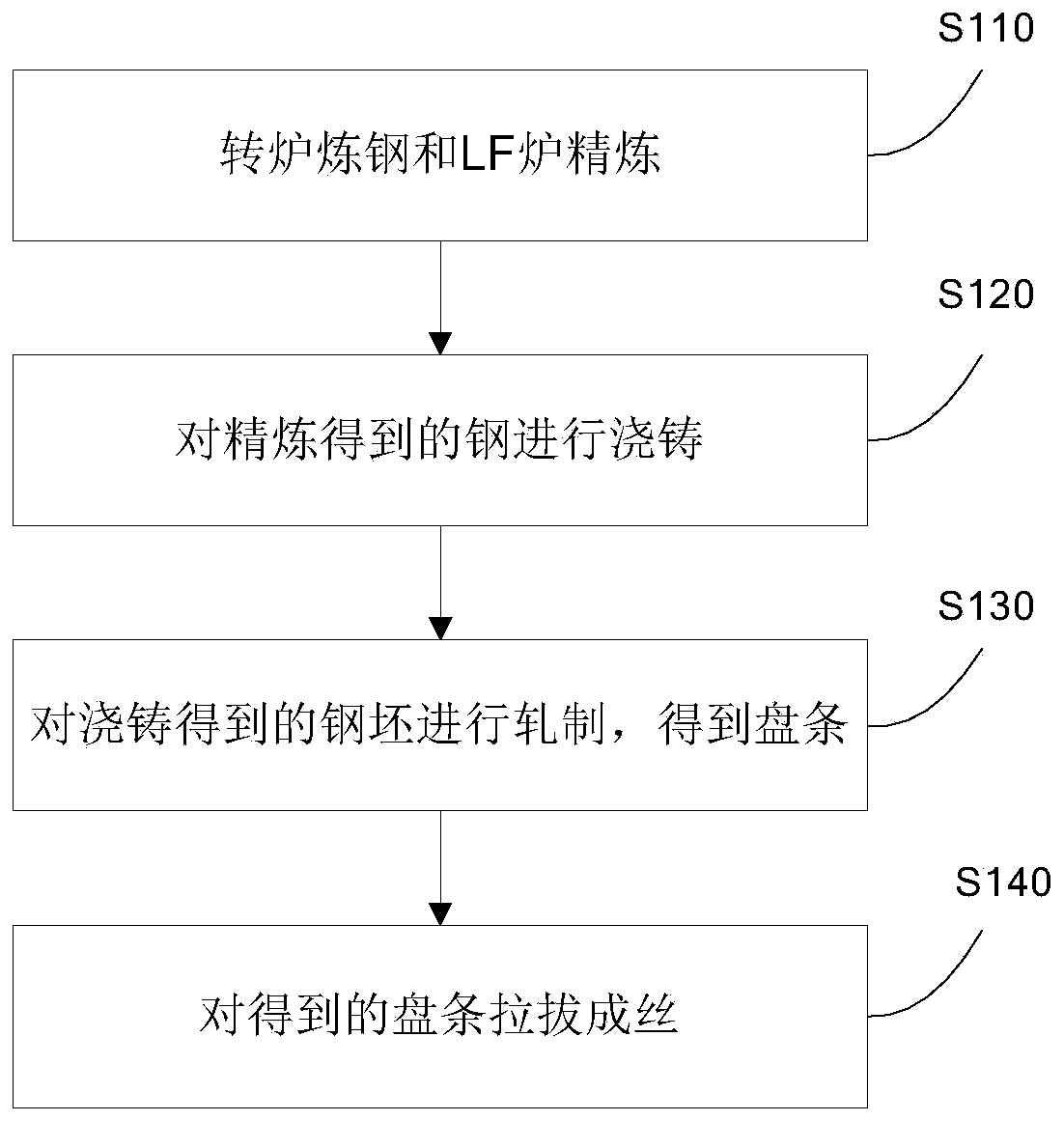

High-impact-toughness solid weld wire resisting acid liquid corrosion and preparation method thereof

InactiveCN109877487AReduced cold crack susceptibilityImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaSulfurEquivalent carbon content

The invention discloses a high-impact-toughness solid weld wire resisting acid liquid corrosion and a preparation method thereof. Ultra-low carbon is adopted, the equivalent carbon content is reduced,thus cold crack sensitivity of weld seam metal is reduced, and meanwhile, low-temperature impact toughness is improved beneficially. Meanwhile, with suitable content of Si, Mn, Cu and Cr, the strength of the weld seam metal can be ensured. With high Ni content, the low-temperature impact toughness of the weld seam metal can be improved. In addition, by adding a certain amount of Sb element, the sulfur and hydrochloric salt corrosion resisting performance of the weld seam metal can be ensured, and thus the technical problem that in the prior art, high sulfur and hydrochloric salt corrosion resisting performance and low-temperature impact toughness cannot be possessed at the same time is solved.

Owner:SHOUGANG CORPORATION

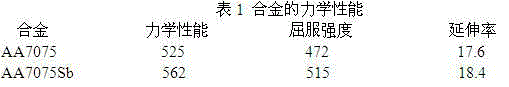

Method for improving overall performance of AA7075 aluminum alloy by adding rare earth Sb

InactiveCN105274371AThe tensile strength optimization effect is obviousHigh tensile strengthRare-earth elementAluminium alloy

In order to refine crystalline grains of AA7075 aluminum alloy and improving the mechanical property of the AA7075 aluminum alloy, the invention discloses a method for improving the overall performance of the AA7075 aluminum alloy by adding rare earth Sb. The rare earth Sb element is added to the as-cast-condition AA7075 aluminum alloy with the temperature of 720 DEG C. The rare earth Sb element accounts for, by mass, 0.3%. The AA7075 aluminum alloy is smelted through a conventional melting mode.

Owner:王晓芳

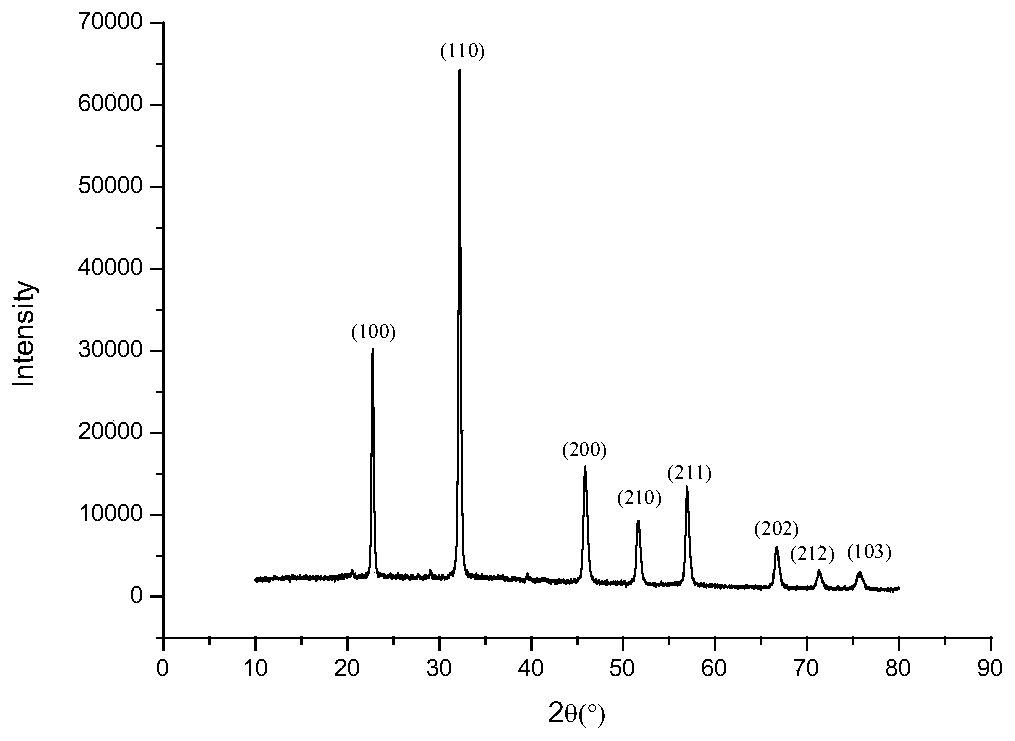

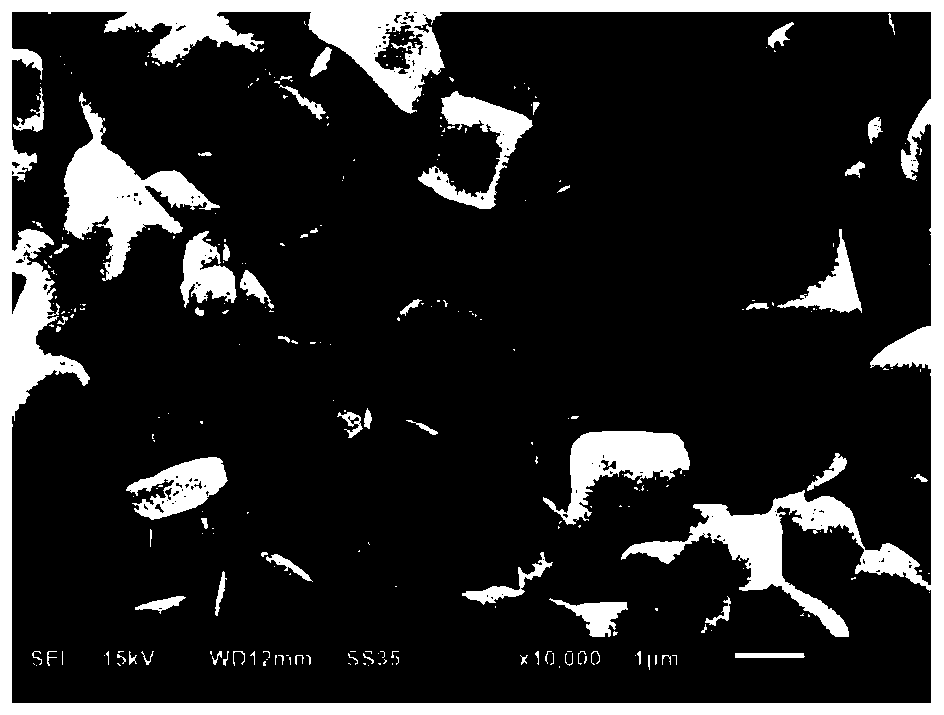

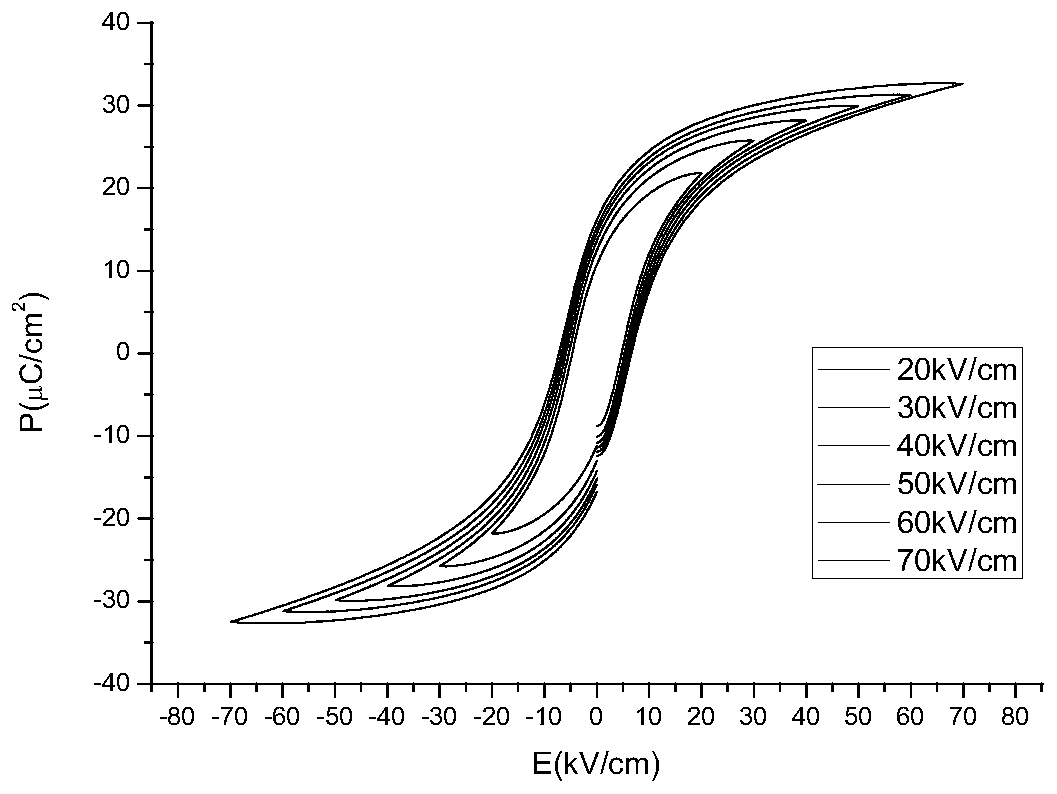

Potassium sodium niobate-based piezoelectric ceramic, and preparation method and application thereof

ActiveCN110835266AImprove compactnessNot susceptible to moisturePiezoelectric/electrostrictive device manufacture/assemblyManganese oxideMaterials science

The invention provides a potassium sodium niobate-based piezoelectric ceramic, and a preparation method and an application thereof, and belongs to the technical field of piezoelectric ceramics. The general formula of the potassium sodium niobate-based piezoelectric ceramic is K0.48Na0.52Sb0.10Nb0.90-xMnO2, x is greater than or equal to 0.2 and less than or equal to 0.8, and x is a mass fraction. Aspecific amount of manganese oxide added as a sintering aid effectively reduces the volatilization amounts of Na2O and K2O in the sintering process, so that the prepared potassium sodium niobate-based piezoelectric ceramic has good compactness and is not prone to damp, and the technical defect of poor compactness of potassium sodium niobate-based piezoelectric ceramics doped with the Sb element in the prior art is overcome. Results of the embodiment show that the strain of the potassium sodium niobate-based piezoelectric ceramic prepared in the invention reaches 0.15% in a 40 kV / cm electric field, and reaches 0.23% in a 70 kV / cm electric field, and the density reaches 98%.

Owner:CHIZHOU UNIV

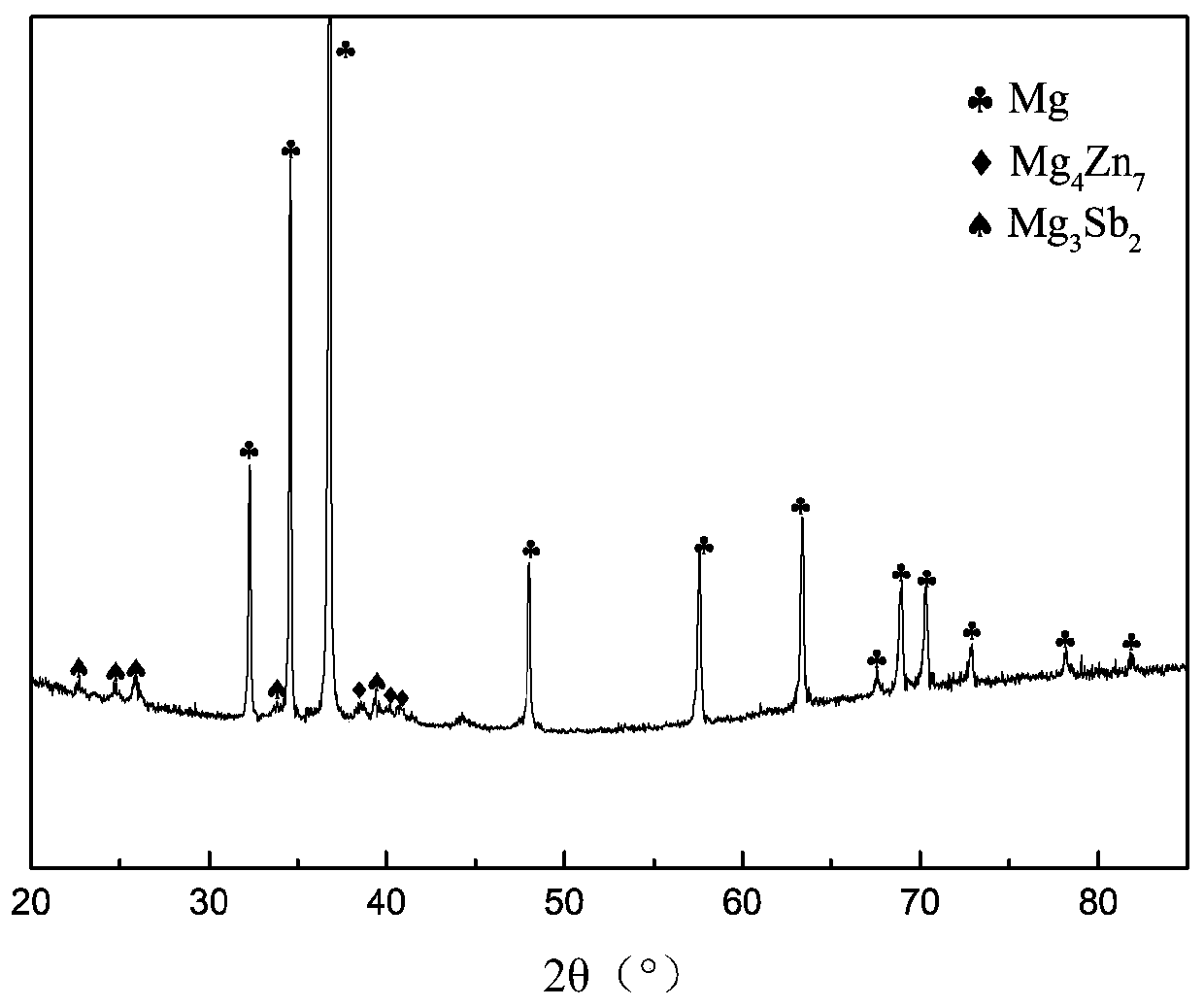

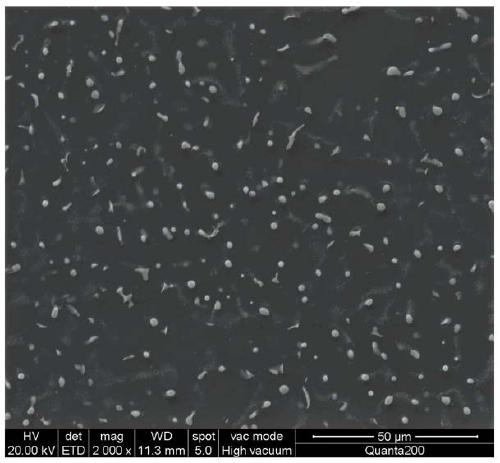

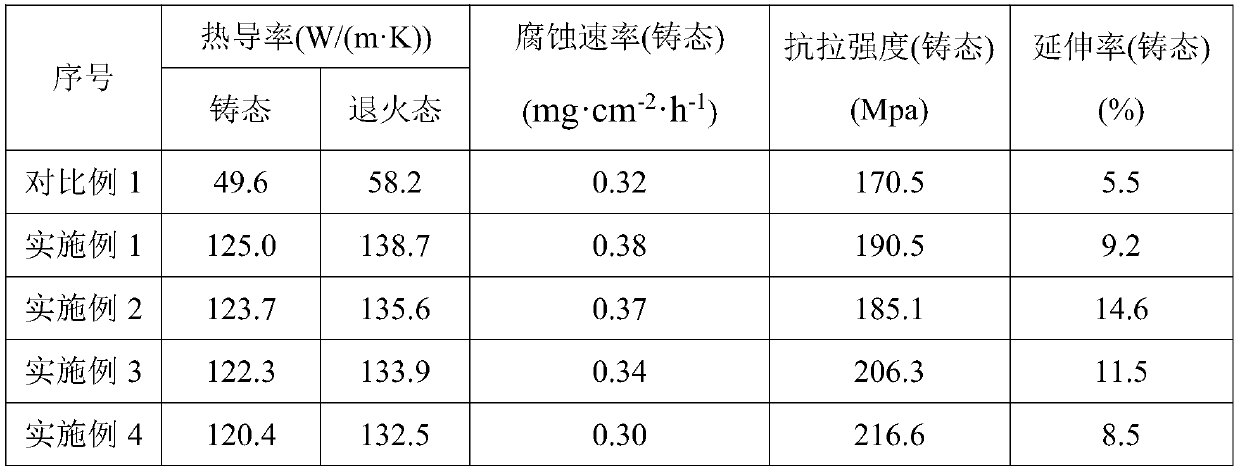

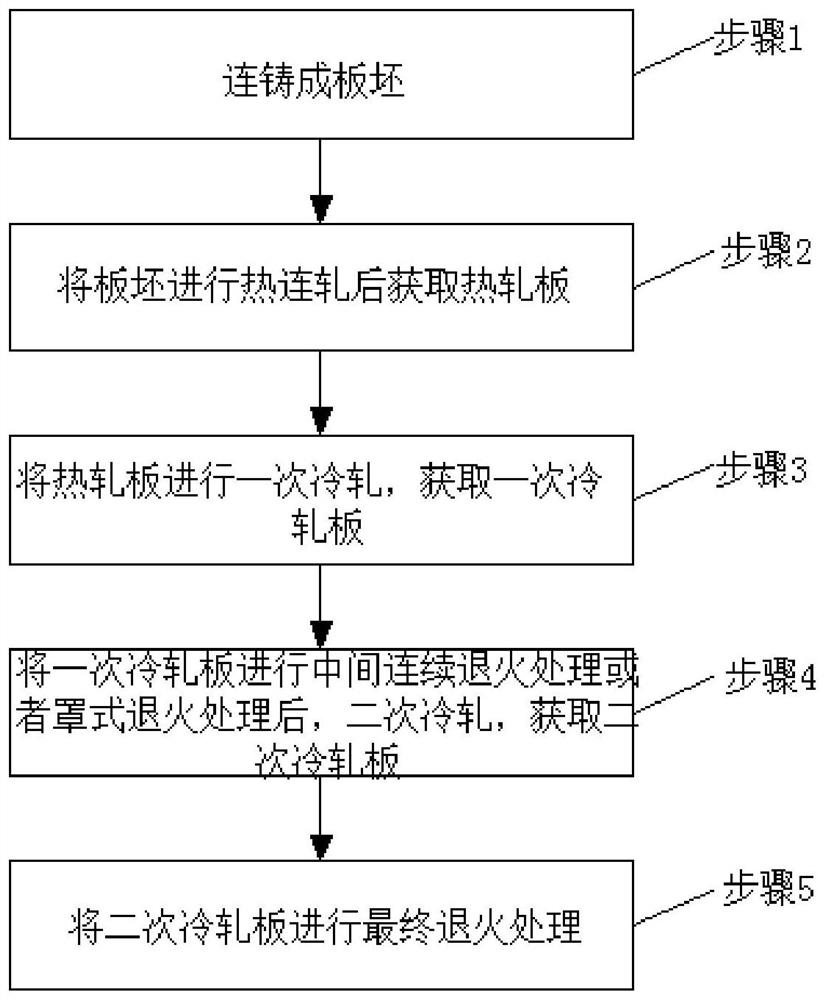

High thermal conductivity magnesium alloy and preparation method thereof

InactiveCN111455246AImprove thermal conductivityImprove mechanical propertiesHeat exchange apparatusMetallurgyCe element

The invention belongs to the technical field of magnesium alloys, and discloses a high thermal conductivity magnesium alloy and a preparation method thereof. The high thermal conductivity magnesium alloy contains the following components by weight percentages of Zn 4% to 6%, Sb 0.5% to 1.2%, Al 0.1% to 0.3%, Mn 0.1% to 0.3%, Ce 0.2% to 0.5%, and the balance is Mg. The invention also discloses a preparation method of the high thermal conductivity magnesium alloy. The invention gives full play to the synergistic effect of Sb element alloying and Al / Mn / Ce element microalloying, so that the magnesium alloy has very excellent thermal conductivity, high mechanical properties and good corrosion resistance, and shows an excellent comprehensive performance. The preparation process of the high thermal conductivity magnesium alloy disclosed by the invention has simple and convenient technology, low raw material cost, easy control of the added amount, remarkable effect and low industrial production cost, and has wide applicability.

Owner:SOUTH CHINA UNIV OF TECH

Thin-gauge non-oriented silicon steel 35BW440 and production method thereof

InactiveCN113502433AIncrease magnetic inductionImprove surface qualityContinuous annealingUltimate tensile strength

The invention relates to thin-gauge non-oriented silicon steel 35BW440. The non-oriented silicon steel 35BW440 comprises the following elements including, by mass, less than or equal to 0.003% of C, 0.8%-2.0% of Si, 0.4%-1.2% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.25%-0.6% of Als, less than or equal to 0.003% of N, 0.04%-0.1% of Sb, less than or equal to 0.0025% of O and the balance Fe and inevitable impurities. On the premise that no electromagnetic stirring equipment is used for increasing the magnetic induction intensity of the non-oriented silicon steel, the electromagnetic performance is improved by adding the Sb element and increasing {110} and {100} texture components beneficial to the electromagnetic performance, and the surface quality of the non-oriented silicon steel is improved by adopting the processes of secondary cold rolling and intermediate continuous annealing.

Owner:BENGANG STEEL PLATES

High-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy and preparation method thereof

The invention relates to the technical field of magnesium alloy materials, in particular to a high-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy and a preparation method thereof. The high-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy comprises the following components: 2-4 wt.% of Zn, 2-4 wt.% of Al, 0.5-2 wt.% of Y, 0.2-1 wt.% of Sb, the total quantity of impurity elements Si, Fe, Cu and Ni less than 0.02 wt.%, and the balance of Mg. The preparation method of the high-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy comprises two processes of smelting and heat treatment, wherein the smelting process comprises the steps of material baking, Mg smelting, Zn and Al adding, Y adding, Sb adding, refining and casting; and the heat treatment process comprises solid solution treatment and aging. The Sb elements with a certain mass are added in a Mg-Zn-Al-Y alloy, so that the casting structure of the alloy is effectively improved, and grains are refined; anda compact second phase with high melting point and high heat stability is formed, so that the room-temperature and high-temperature mechanical performances of the alloy are improved.

Owner:JIANGSU UNIV OF TECH

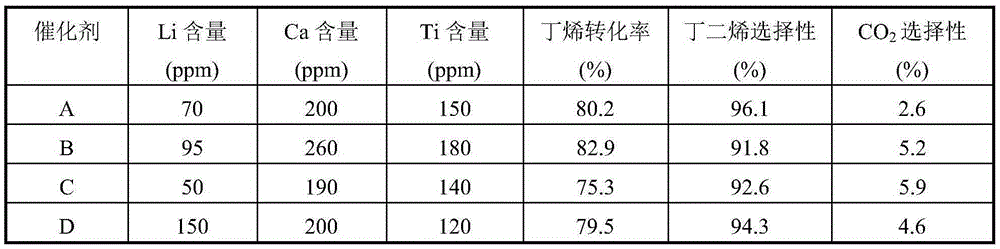

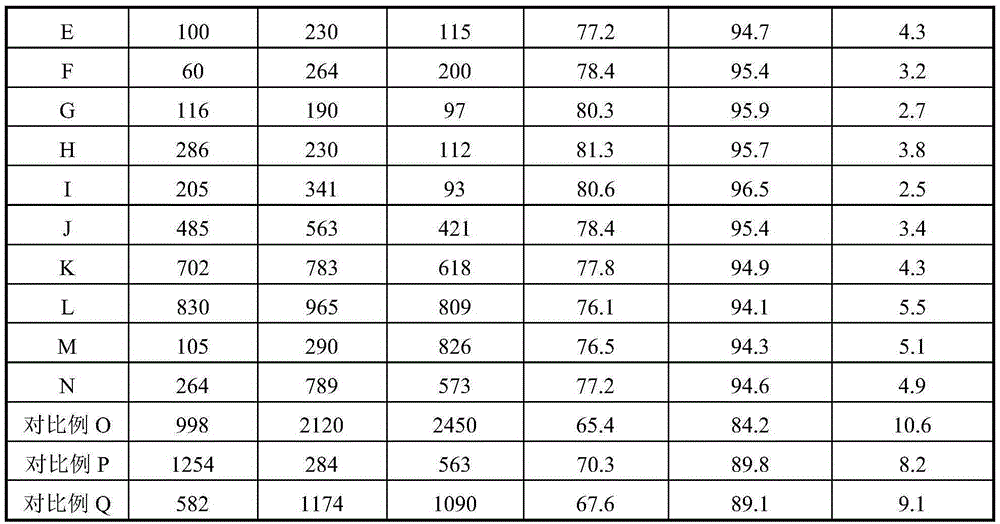

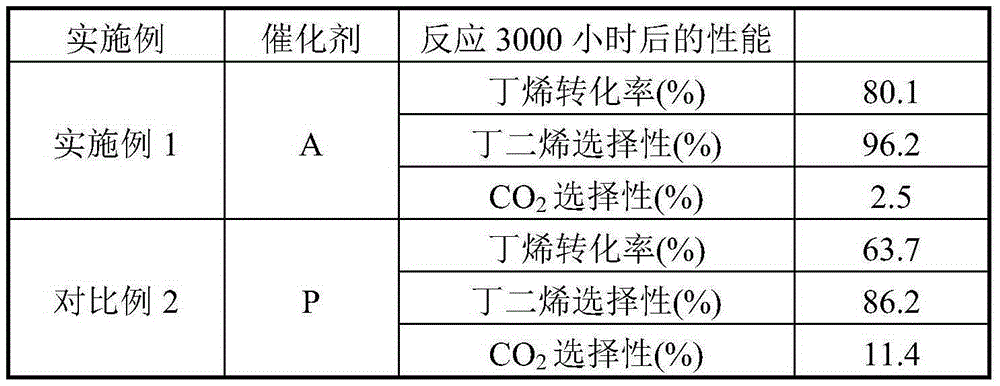

Catalyst for butene oxidative dehydrogenation preparation of butadiene and preparation method thereof

The invention relates to a catalyst for butene oxidative dehydrogenation preparation of butadiene and a preparation method thereof. The catalyst mainly solves the problem that the existing catalyst for butene oxidative dehydrogenation preparation of butadiene has low selectivity to butadiene and produces more deep oxidative products. The catalyst component comprises Fe<3+> and Sb elements, Fe<3+> exists in at least one form of Fe2O3 and Fe2O4<2->, Li mass content of the catalyst is less than 900ppm, Ca mass content of the catalyst is less than 900ppm and Ti mass content of the catalyst is less than 900ppm. The catalyst solves the problem, realizes efficient and stable preparation of a butadiene product, reduces deep oxidative product CO2 and can be used for industrial production of butadiene through butene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steel material and preparing method thereof

The invention provides a steel material. The steel material comprises components including smaller than or equal to 0.12wt% of C, smaller than or equal to 0.75 wt% of Si, smaller than or equal to 1.5wt% of Mn, smaller than or equal to 0.02 wt% of P, smaller than or equal to 0.008 wt% of S, 0.2-0.55 wt% of Cu, 0.3-1.25 wt% of Cr, 0.12-0.65 wt% of Ni, smaller than or equal to 0.1 wt% of V, smallerthan or equal to 0.1 wt% of Nb, 0.41-1 wt% of Sb and the balance Fe and inevitable impurities. The proper amount of Sb element is added in the provided steel material, oxidization is not likely to happen at the normal temperature, the anti-corrosion performance is high, the Sb element is prone to being dissolved in hot nitric acid, hydrous antimony oxide is formed and can be reacted with hot sulfuric acid, antimony sulfate is produced, and activity of acid and corrosion to the steel material can be reduced. The invention further provides a preparing method of the steel material.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

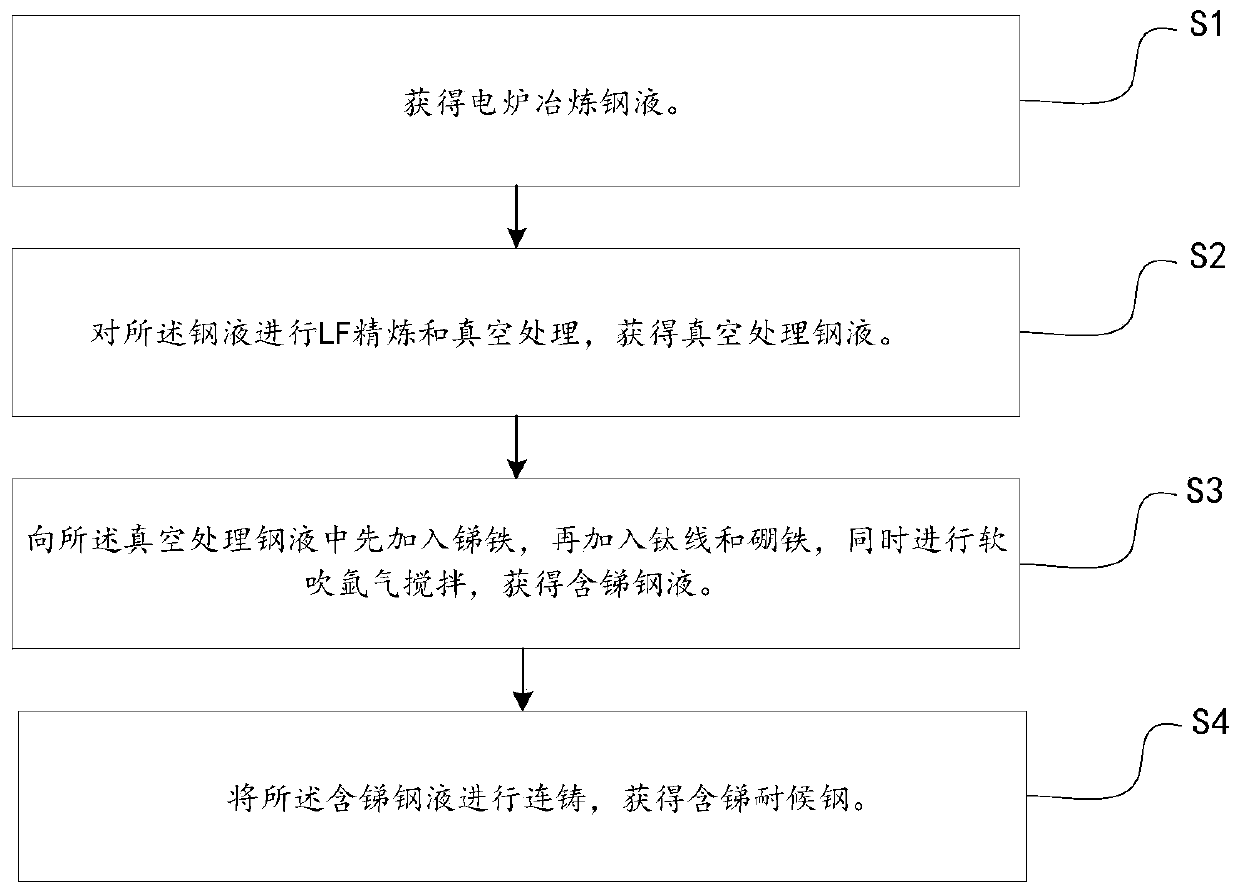

Antimony-containing weathering steel and smelting method and application thereof

The invention discloses antimony-containing weathering steel and a smelting method and application thereof. The method comprises the steps that electric furnace smelting molten steel is obtained; vacuum treatment is conducted on the electric furnace smelting molten steel, and vacuum treatment molten steel is obtained; the vacuum treatment pressure is smaller than or equal to 67Pa, and the temperature of the vacuum treatment molten steel ranges from 1635-1700 DEG C; and antimony iron is added into the vacuum treatment molten steel for component adjustment, and antimony-containing molten steel is obtained. By the adoption of the method, the components of the Sb element are uniform, the yield is 96% or above, cost is reduced, and the method is simple and easy to popularize.

Owner:SHOUGANG CORPORATION

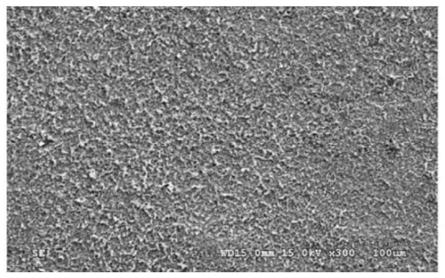

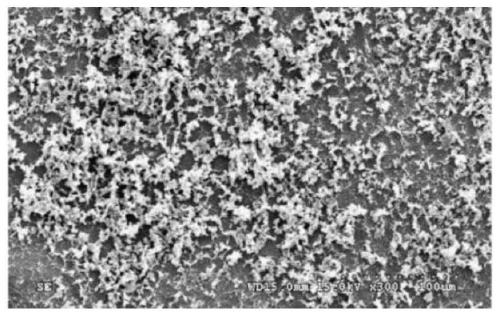

P-type Cu2.856In4Te8 base medium-high temperature thermoelectric material containing Sb and manufacturing technology thereof

ActiveCN108470817ANo noiseNo pollution in the processThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsManufacturing technology

The invention relates to P-type Cu2.856In4Te8 base medium-high temperature thermoelectric material containing Sb and manufacturing technology thereof. A design main point is characterized by directlyadding a Sb element with a molar fraction of 0.0388 to a Cu2.856In4Te8 alloy to form a Cu2.856In4Te8 base thermoelectric material containing Sb, wherein a chemical formula is Cu2.856Sb0.6In4Te8. The manufacturing technology comprises the following steps of weighing the corresponding amount of four elements of Cu, In, Sb, Te according to the chemical formula, and carrying out vacuum smelting at 800to 900 DEG C for 24 hours; after the melting is ended, cooling to 390 DEG C and annealing for 72 hours, smashing annealed ingot casting and carrying out ball milling, sintering and forming a powder after ball milling by discharge plasma sparks in a short time, and manufacturing and acquiring a Cu2.856Sb0.6In4Te8 thermoelectric material, wherein sintering time is 5 to 10 minutes, a sintering temperature is 600-700 DEG C and sintering pressure is 50-60MPa. The thermoelectric material is not polluted and there is no noise. The material can be used for manufacturing a medium-high temperature power generation component and has advantages that operation is reliable, a service life is long and the manufacturing technology is simple.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

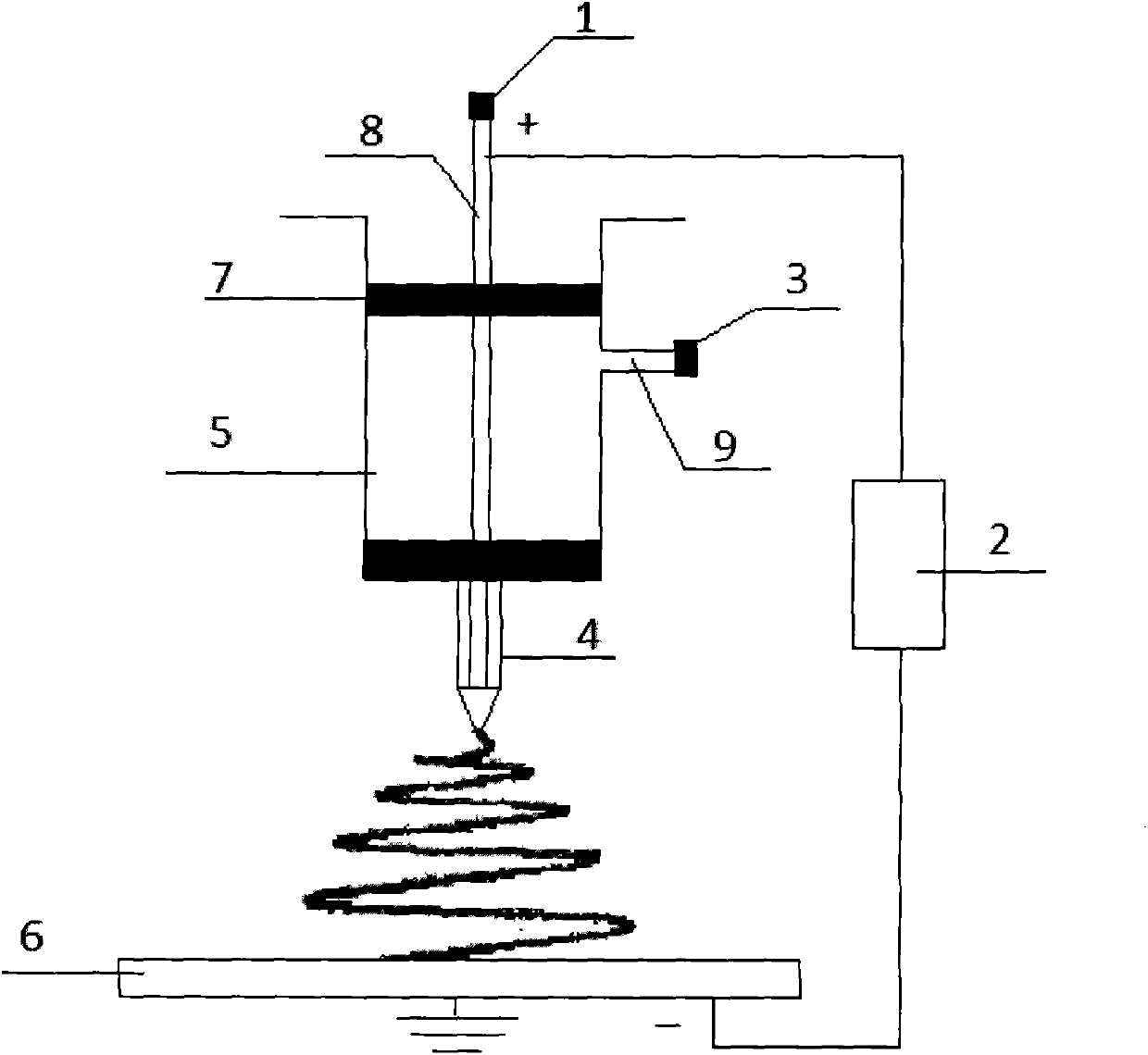

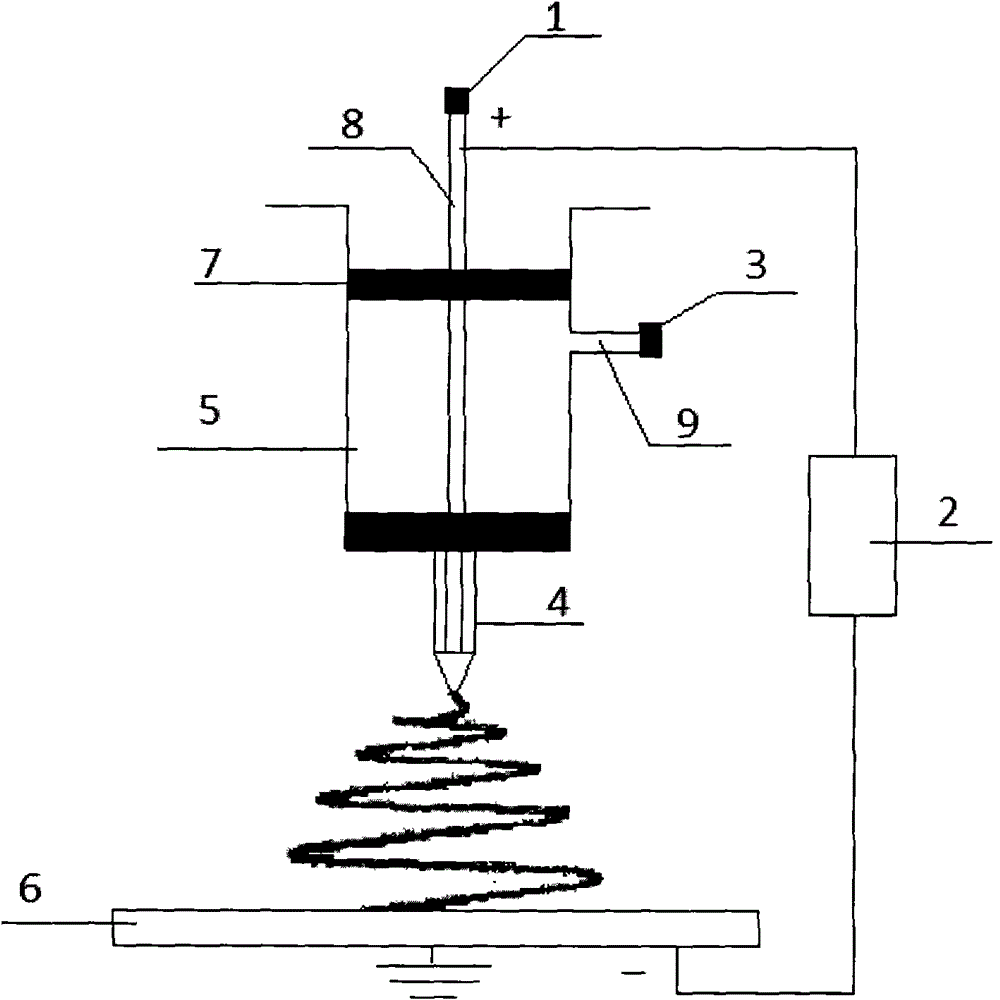

Nanofiber with specific surface area capable of being increased

ActiveCN103436991ALow costSimple manufacturing methodArtificial filament physical treatmentFilament/thread formingElectrospinningNanofiber

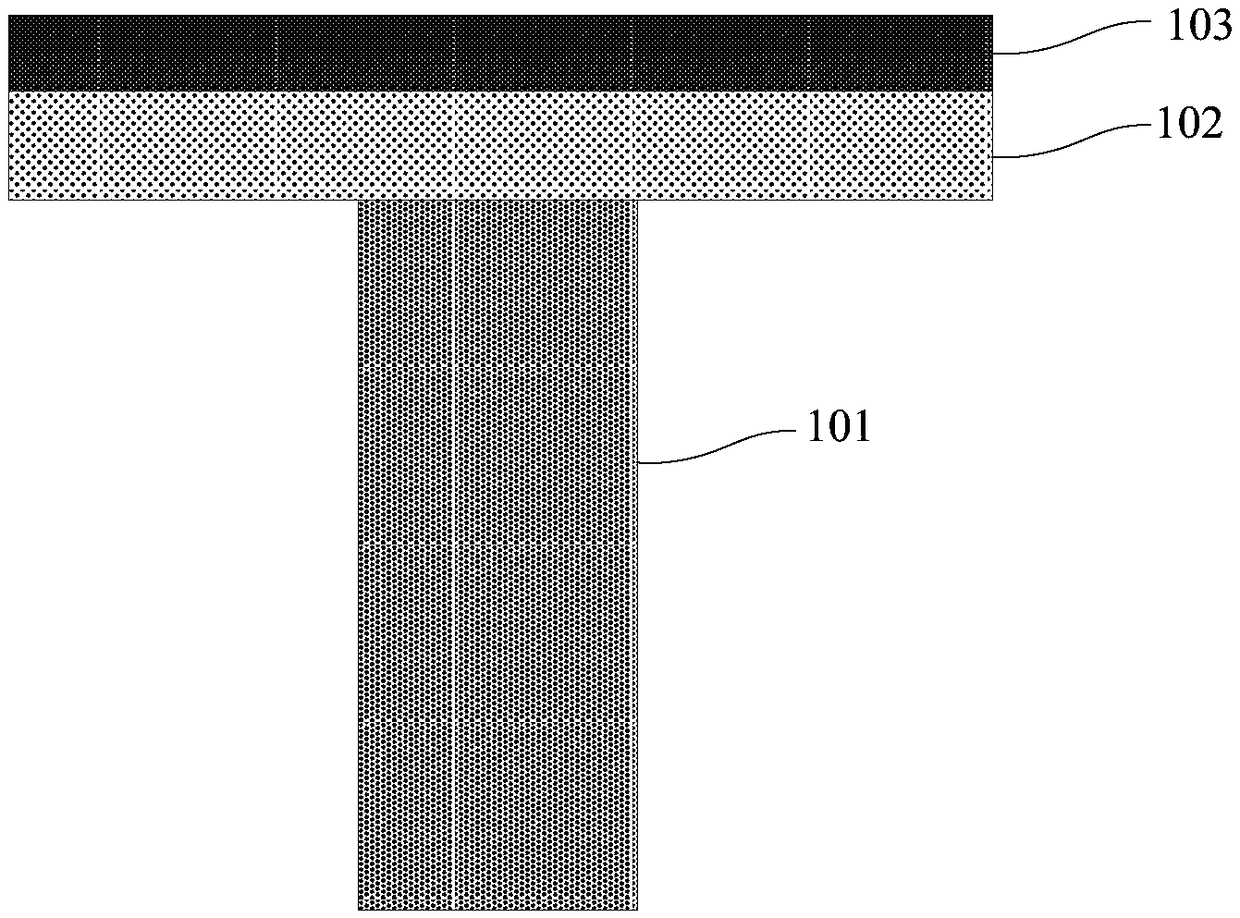

The invention relates to a nanofiber with the specific surface area capable of being increased. The high-surface-area nanofiber has a nuclear-shell structure, a nuclear layer is made of titanium dioxide (TiO2), a shell layer is made of antimony tin oxide (ATO), the antimony tin oxide in the shell layer is SnO2 doped with a Sb element, wherein the mass percentage of the Sb element is 20-80%; the fiber structure is of a nuclear-shell structure formed by the process that the titanium dioxide is coated with the antimony tin oxide, wherein the mass percentage of the TiO2 is 20-80%, the mass percentage of the ATO is 20-80%; the average diameter of the nanofiber which is of the nuclear-shell structure is 100-450nm. The nanofiber which is of the nuclear-shell structure is prepared by using an electrostatic spinning technique, the preparation method is simple and easy to implement, and according to the obtained nanofiber material, the cost of conductive materials is lowered, and the nanofiber has a great specific surface area.

Owner:高建华

Application of Sb element in high-strength nodular cast iron tile cover

The invention discloses application of an Sb element in a high-strength nodular cast iron tile cover. On the basis of the weight of the melt, 0.005-0.015% of stibium and 0.3-0.6% of manganese are added into the melt in a casting ladle. Compared with the traditional application of adding massive Cu, Cr and other alloy elements, copper, chrome and other alloy elements are substituted by stibium so that the consumption is obviously reduced, the pearlite content of the nodular cast iron is stabilized above 60%, and the pearlite distribution is uniform without segregation; and by using the stibium, the Si element content in the nodular cast iron is properly increased, the Si content range is widened, the boiling point of the stibium is much lower than that of copper and chrome, and the stibium waste is more beneficial to reutilization, thereby saving the resources.

Owner:西峡县众德汽车部件有限公司

A nanofiber that can increase the specific surface area

ActiveCN103436991BLow costSimple manufacturing methodArtificial filament physical treatmentFilament/thread formingCarbon nanofiberConductive materials

The invention relates to a nanofiber with the specific surface area capable of being increased. The high-surface-area nanofiber has a nuclear-shell structure, a nuclear layer is made of titanium dioxide (TiO2), a shell layer is made of antimony tin oxide (ATO), the antimony tin oxide in the shell layer is SnO2 doped with a Sb element, wherein the mass percentage of the Sb element is 20-80%; the fiber structure is of a nuclear-shell structure formed by the process that the titanium dioxide is coated with the antimony tin oxide, wherein the mass percentage of the TiO2 is 20-80%, the mass percentage of the ATO is 20-80%; the average diameter of the nanofiber which is of the nuclear-shell structure is 100-450nm. The nanofiber which is of the nuclear-shell structure is prepared by using an electrostatic spinning technique, the preparation method is simple and easy to implement, and according to the obtained nanofiber material, the cost of conductive materials is lowered, and the nanofiber has a great specific surface area.

Owner:高建华

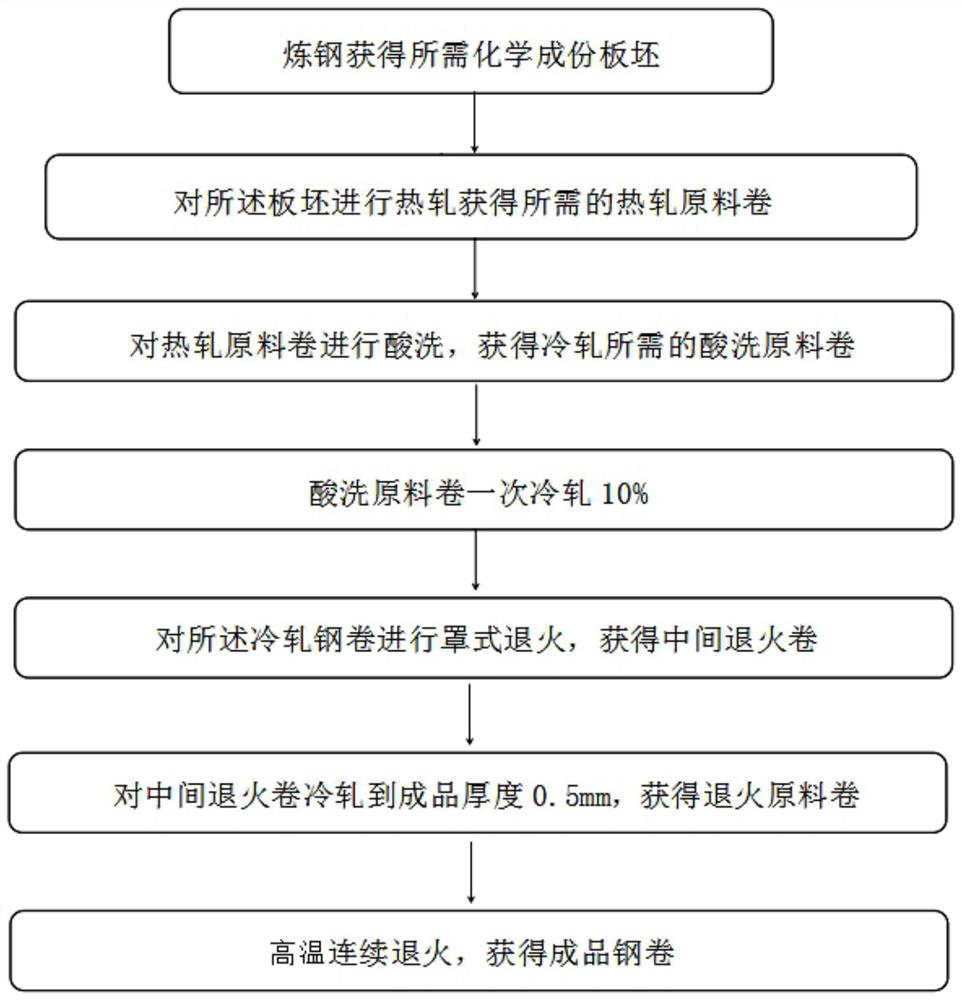

Production method of cover type intermediate annealing high-grade non-oriented silicon steel 50BW350

The invention relates to a production method of cover type intermediate annealing high-grade non-oriented silicon steel 50BW350. The production method comprises the steps of molten steel chemical component design, a hot rolling process, a cold rolling process, an annealing process and the like. The molten steel comprises the following chemical components: less than or equal to 0.004% of C, 1.80-2.1% of Si, 0.70-0.90% of Mn, 0.30-0.45% of Als, less than or equal to 0.015% of P, less than or equal to 0.0030% of S, less than or equal to 0.0020% of O, less than or equal to 0.0025% of N, 0.06-0.12% of Sb and the balance of Fe. The high-grade non-oriented silicon steel product without surface corrugation defects is obtained through special chemical design, Sb element addition, improvement of electromagnetic performance by optimizing the structure of the product, proper reduction of Si content, improvement of Mn element content and elimination of the influence of hot-rolled thick fiber tissues by a secondary cold rolling method. And compared with a traditional high-grade production method, the cost is low, and the produced silicon steel is excellent in electromagnetic performance.

Owner:BENGANG STEEL PLATES

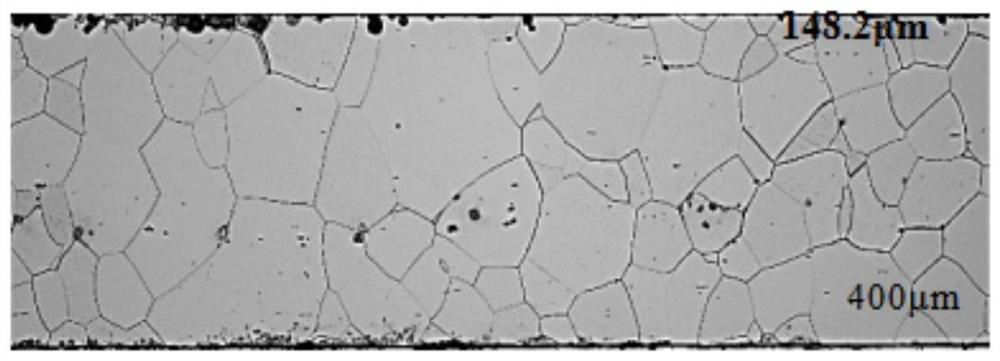

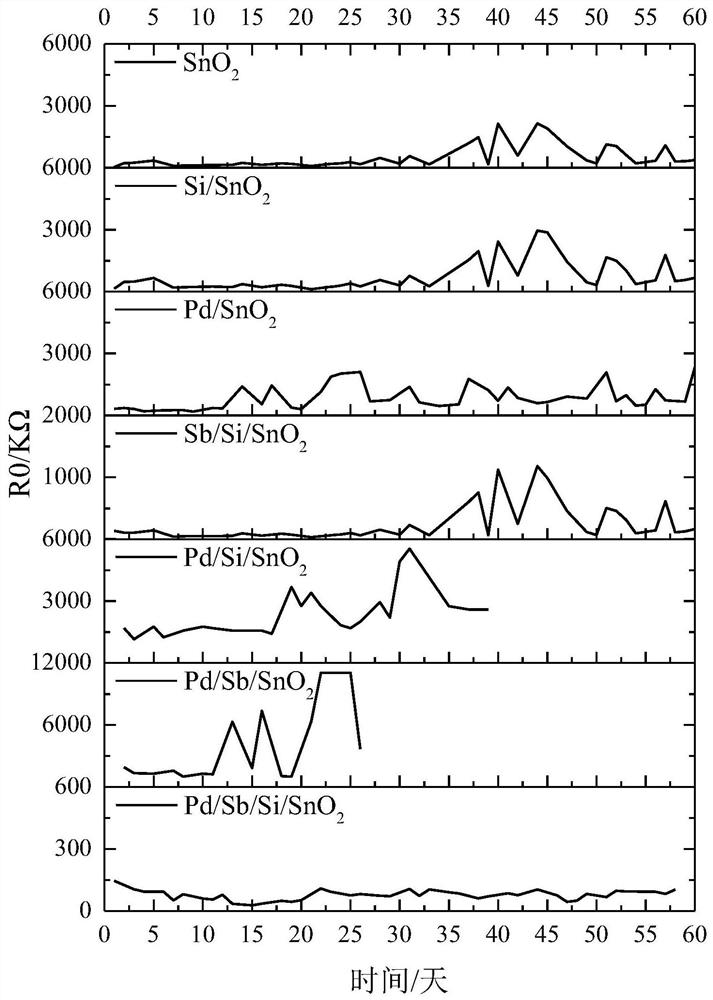

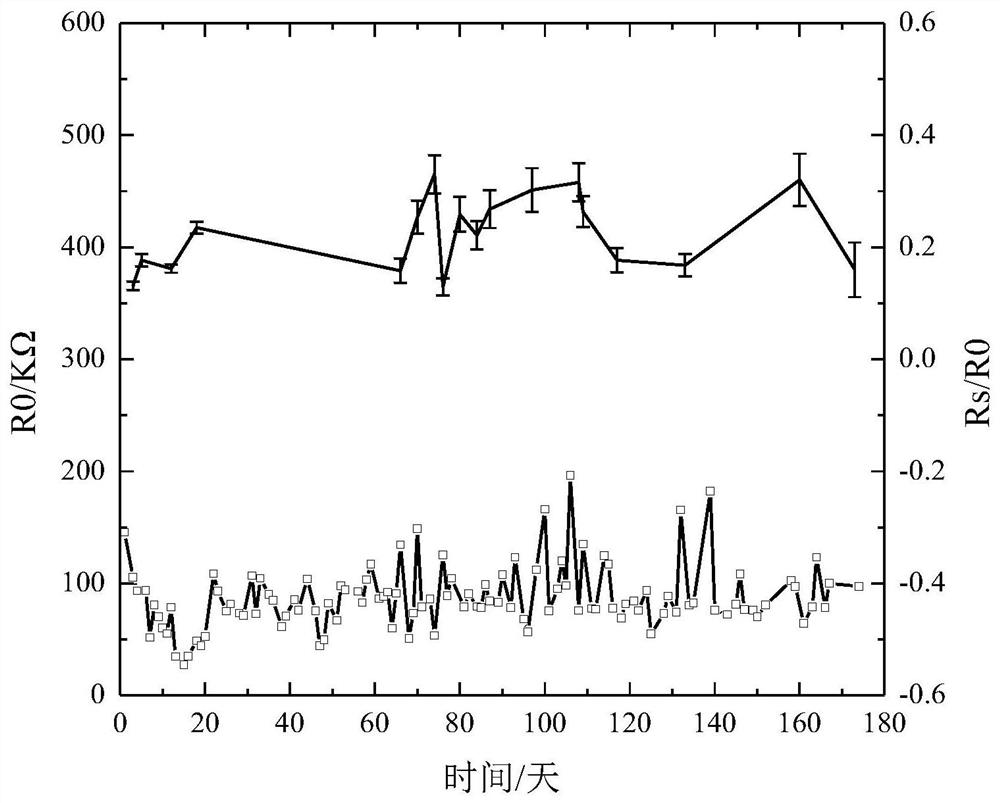

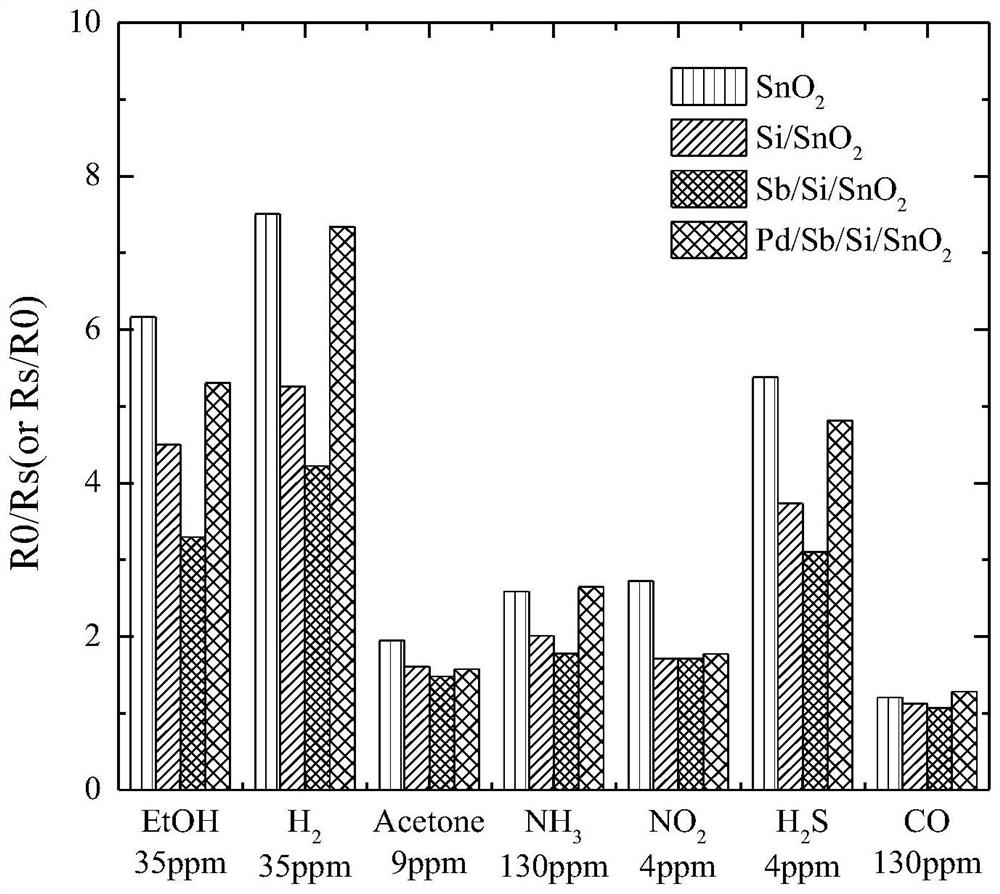

SnO2-based gas sensitive material, and preparation method and application of SnO2-based gas sensitive material

The invention discloses a SnO2-based gas sensitive material, and relates to the technical field of gas sensors. The gas sensor is doped with Pd, Si and Sb elements on the basis of SnO2. The inventionalso provides a preparation method of the SnO2-based gas sensitive material, a preparation method of the MEMS sensitive chip, the prepared MEMS sensitive chip, a preparation method of the MEMS gas sensor and the prepared MEMS gas sensor. The material has the beneficial effects that SnO2 is used as a base material, and Pd, Si and Sb elements are doped at the same time so that the stability of the sensor is remarkably improved, and meanwhile, relatively high sensitivity is maintained.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com