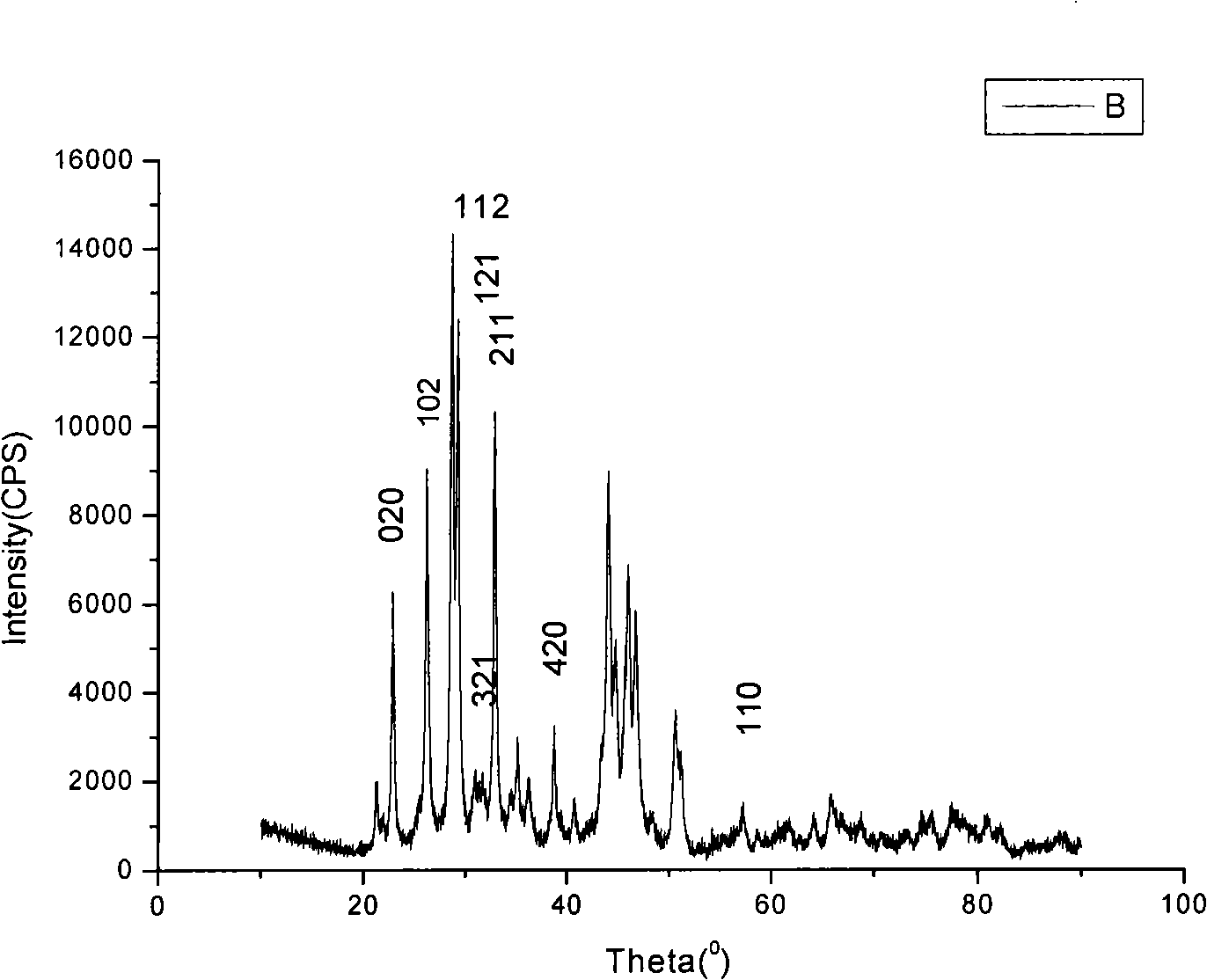

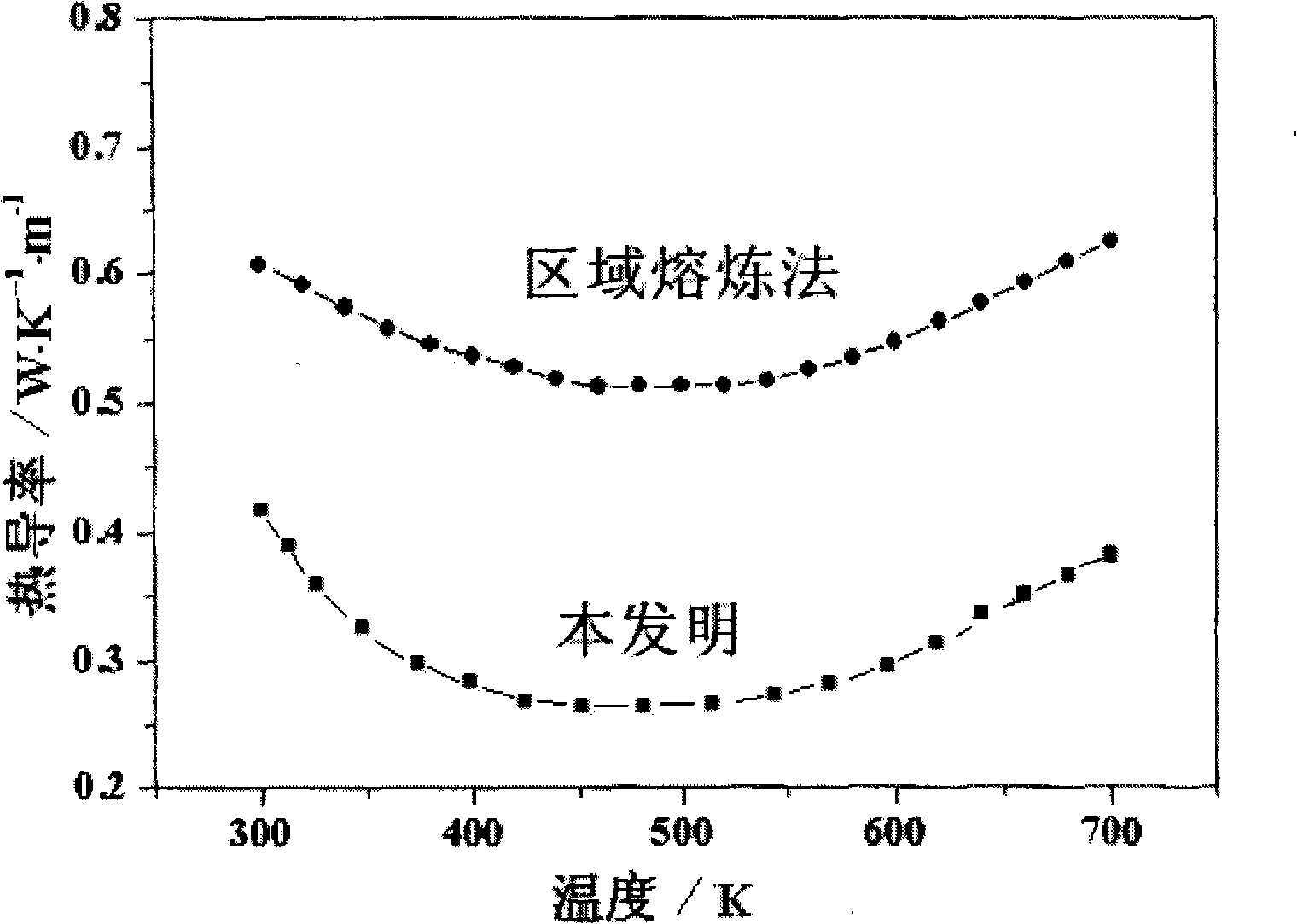

Composite nanometer ZnSb-based thermoelectric material and preparation thereof

A kind of thermoelectric material and nanotechnology, which is applied in the direction of thermoelectric device node lead wire materials, etc., can solve the problems affecting thermoelectric performance and application limitations, and achieve the effect of improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) According to the nominal composition, it is Zn 4 Sb 3 Stoichiometric ratio Weigh high-purity Zn powder 4.152g and Sb powder 5.800g, nano powder accounts for 0.5% by weight, weigh high-purity Zn nano powder 0.02g and Sb nano powder 0.03g, and after uniform mixing, ball mill jar The ratio of ball to material is 10:1, put it into a nylon ball mill tank, and after vacuuming, feed N 2 to slightly higher than 100kPa, install it in a planetary ball mill, adjust the rotating speed to 250 rpm, and grind for 12 hours at room temperature to obtain a composite nanopowder.

[0024] (2) Press the above powder at 30MPa for 15 minutes to make a green body with a diameter of 10mm and a thickness of 5mm. The green body is placed in an ultra-high pressure device and loaded at a pressure increase rate of 1.2GPa / min at room temperature To 3GPa, after maintaining the pressure for 10min, unload to normal pressure at the same depressurization rate to obtain a dense bulk thermoelectric ma...

Embodiment 2

[0028] (1) According to the nominal composition, it is Zn 4 Sb 3 Stoichiometric ratio Weigh high-purity Zn powder 4.131g and Sb powder 5.769g, nano powder accounts for 1% by weight, weigh high-purity Zn nano powder 0.04g and Sb nano powder 0.058g, and after uniform mixing, ball milling tank The ratio of ball to material is 10:1, put it into a nylon ball mill tank, and after vacuuming, feed N 2 to slightly higher than 100kPa, install it in a planetary ball mill, adjust the rotating speed to 250 rpm, and grind for 12 hours at room temperature to obtain a composite nanopowder. That is, the material of the present invention is obtained.

[0029] (2) Press the above powder at 30MPa for 15 minutes to make a green body with a diameter of 10mm and a thickness of 5mm. The green body is placed in an ultra-high pressure device and loaded at a pressure increase rate of 1.2GPa / min at room temperature To 3GPa, after maintaining the pressure for 10min, unload to normal pressure at the sam...

Embodiment 3

[0032] (1) According to the nominal composition, it is Zn 4 Sb 3 The stoichiometric ratio weighs 3.964g of high-purity Zn powder and 5.536g of Sb powder, and after uniform mixing, the ball-material ratio of the ball mill tank is 10:1, put them into the nylon ball mill tank, and after vacuuming, feed N 2 to slightly higher than 100kPa, install it in a planetary ball mill, adjust the speed at 250 rpm, and grind for 8 hours at room temperature;

[0033] (2) add and account for 5% nano-powder by weight in the ball mill tank, promptly take high-purity Zn nano-powder 0.209g and Sb nano-powder 0.291g, then vacuumize, pass into N 2 to slightly higher than 100kPa, and continue ball milling for 4 hours to obtain a composite nanopowder.

[0034] (3) Press the above powder at 30MPa for 15 minutes to make a green body with a diameter of 10mm and a thickness of 5mm. The green body is placed in an ultra-high pressure device and loaded at a pressure increase rate of 1.2GPa / min at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com