Patents

Literature

87results about How to "Improve Seebeck coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

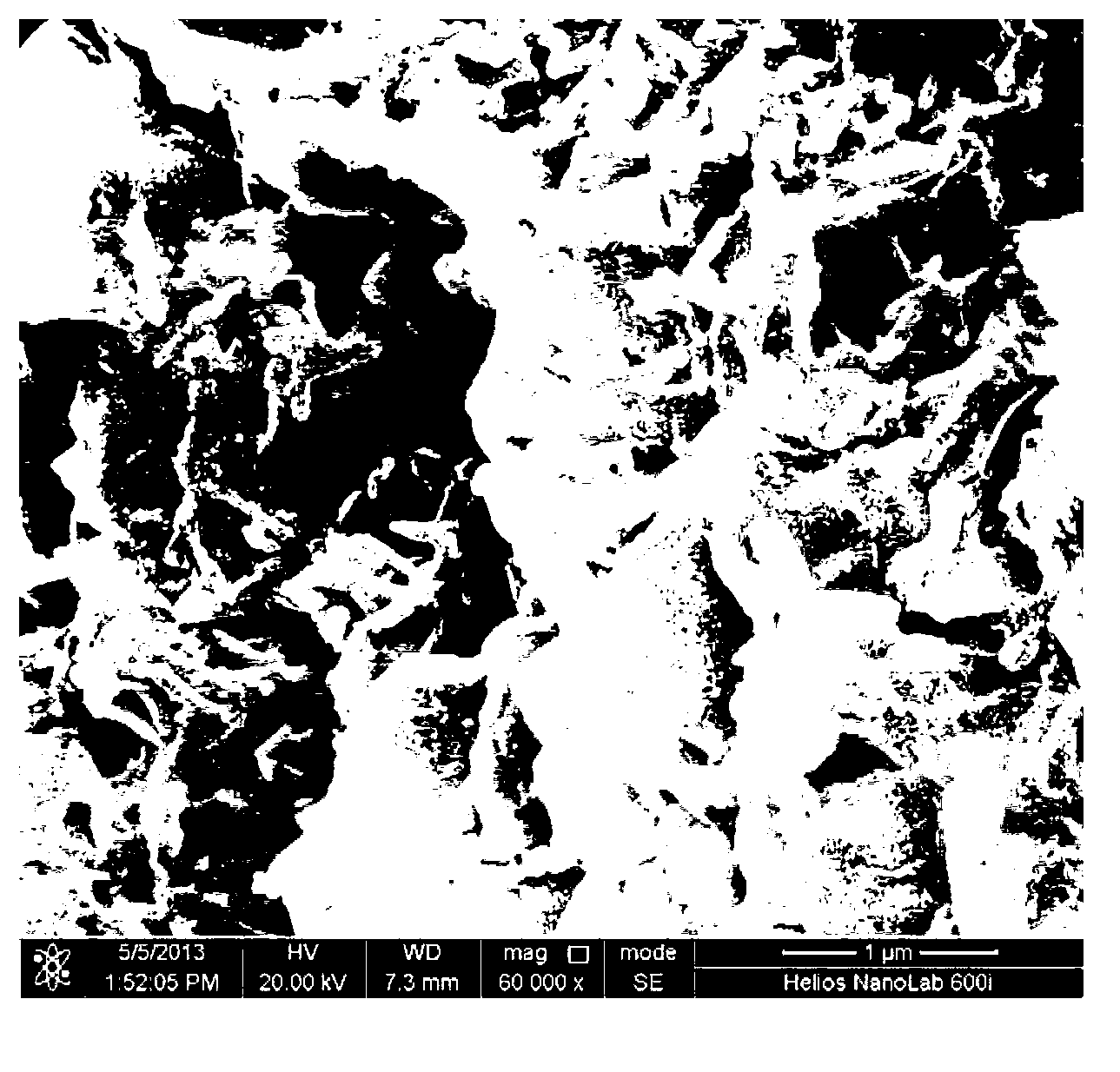

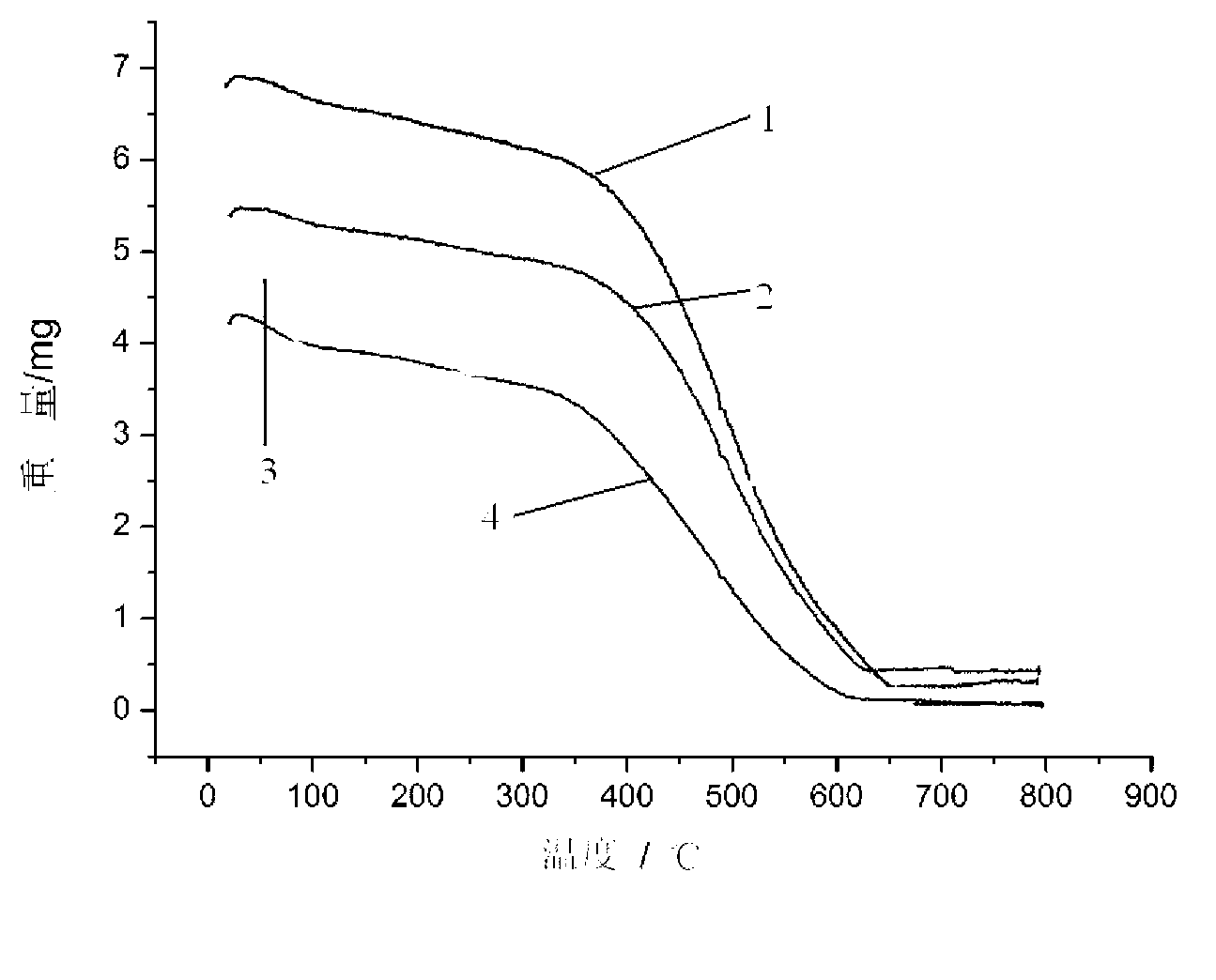

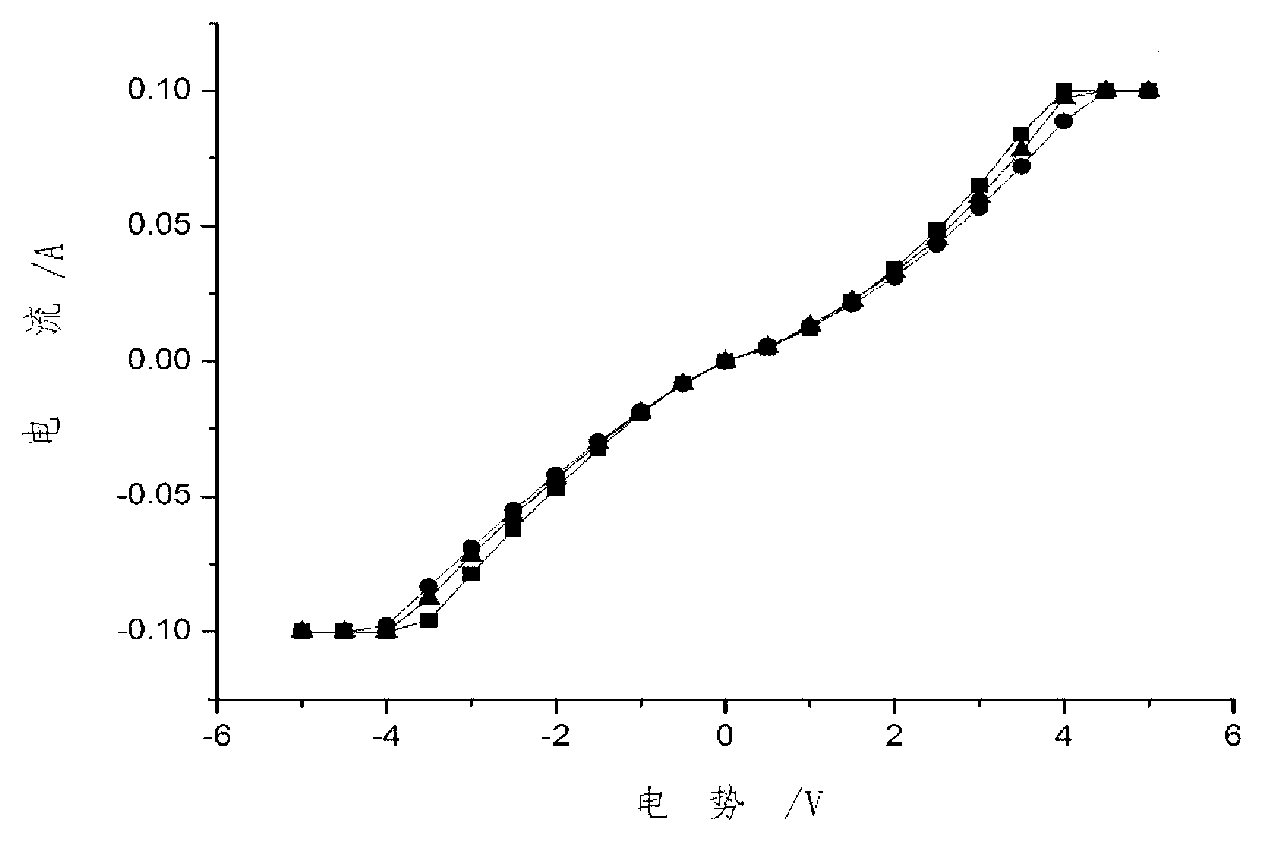

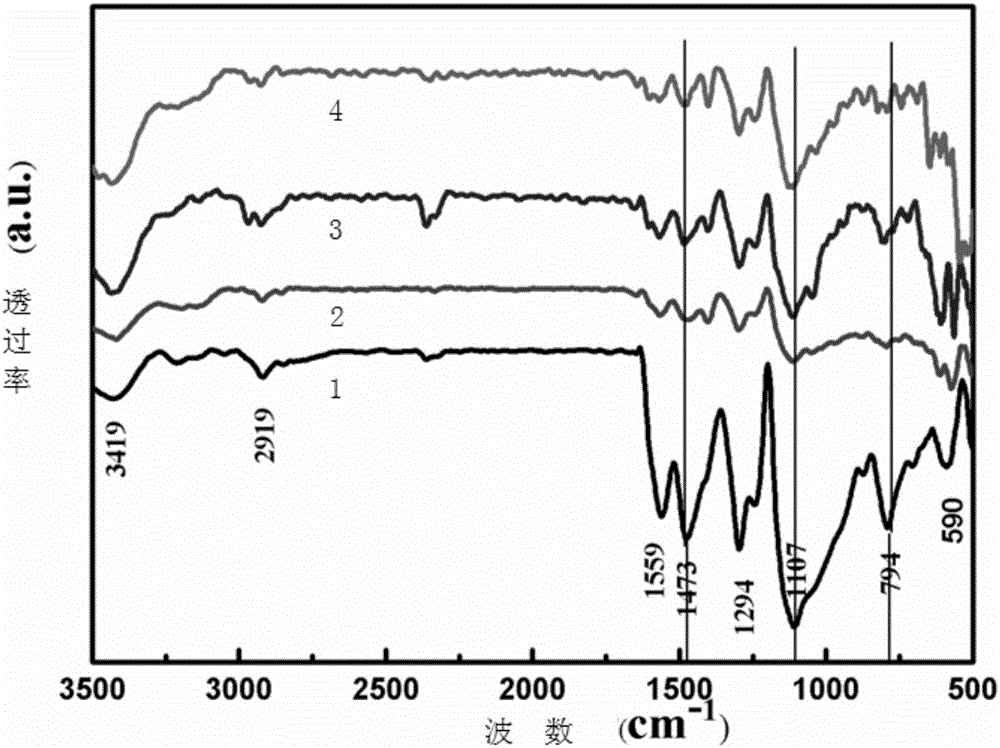

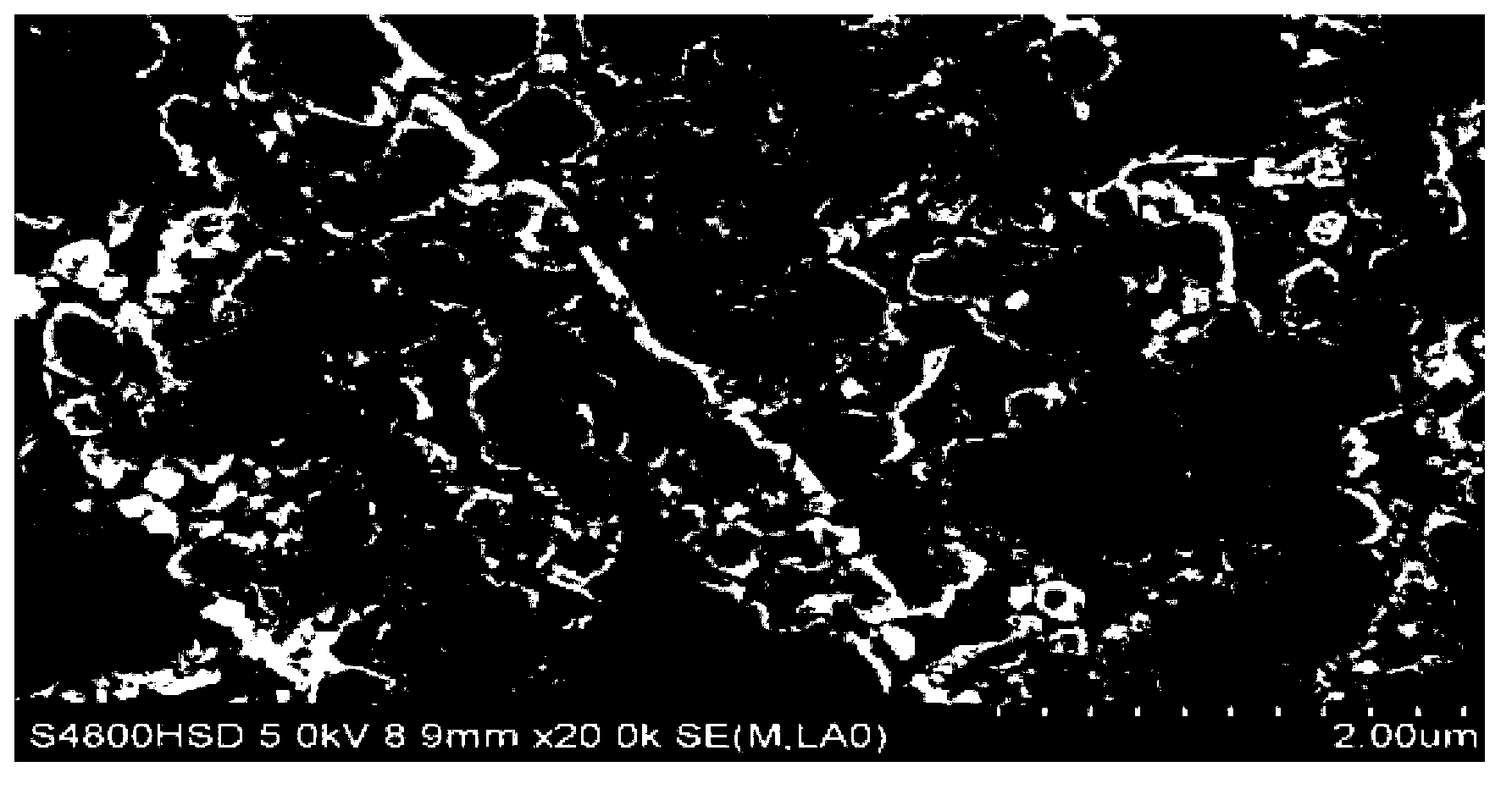

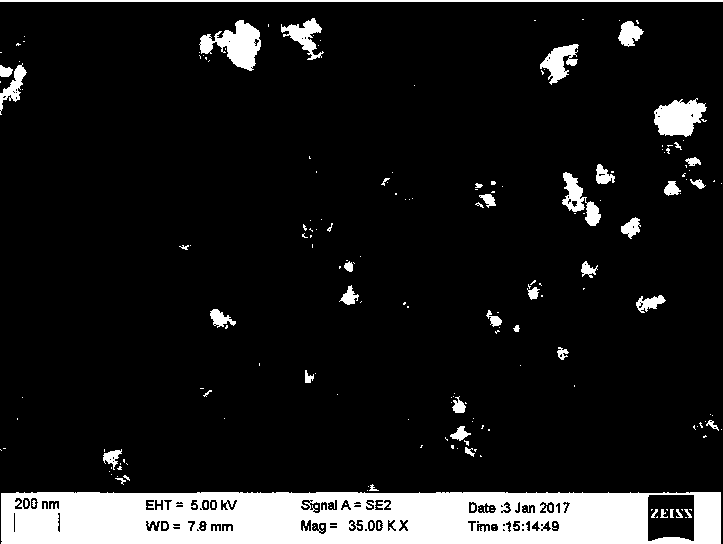

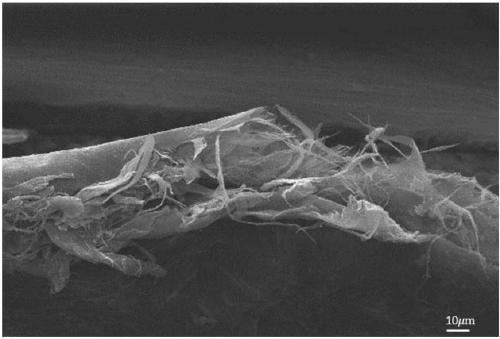

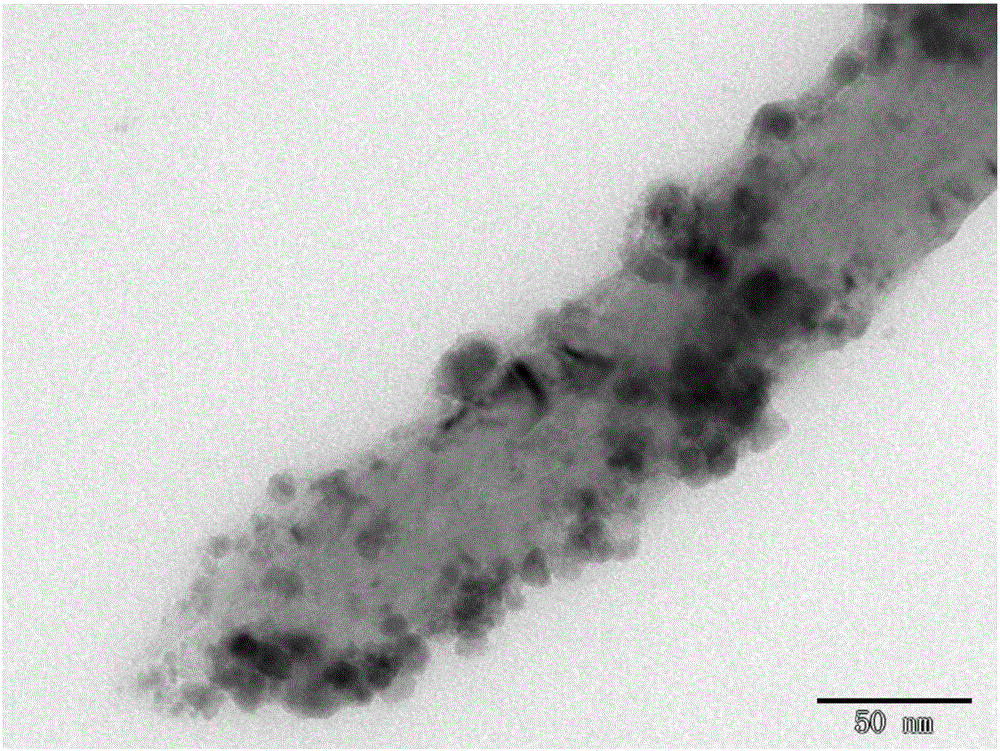

Method for preparing composite thermoelectric material of PPY cladding carbon nano tube

InactiveCN103840074AGood uniformity of component dispersionMild conditionsThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsEnvironmental resistance

The invention relates to a method for preparing a composite thermoelectric material of a PPY cladding carbon nano tube, in particular to a method according to which when ammonium persulfate serves as an oxidizing agent, pyrrole is used for carrying out cladding on the carbon nano tube through in-situ oxidative polymerization to form the composite thermoelectric material. According to the method for preparing the composite thermoelectric material, pyrrole monomers which are low in cost and easy to obtain and the carbon nano tube which is stable in property are used as raw materials, PSSNa serves as a surface activating agent, 1,5-naphthalene disulfonic acid serves as a doping agent, the ammonium persulfate serves as the oxidizing agent and water serves as a solvent, the composite thermoelectric material of the carbon nano tube and the PPY is synthesized with high efficiency by means of in-situ oxidative polymerization of the pyrrole under the room temperature. According to the method for preparing the composite thermoelectric material of the PPY cladding carbon nano tube, the defects of the low intrinsic conductivity of the pure-electricity-conducting macromolecule PPY, the high heat conducting rate of the carbon nano tube and the like are overcome, the features of the low heat conducting rate of the PPY and the high conductivity of the carbon nano tube are made full use of, the PPY and the carbon nano tube are organically combined, and therefore the method for preparing the high-thermoelectric-property composite material of the PPY cladding carbon nano tube is easy to operate, green, environmentally friendly, low in reaction temperature and good in dispersion uniformity of components.

Owner:INST OF CHEM CHINESE ACAD OF SCI

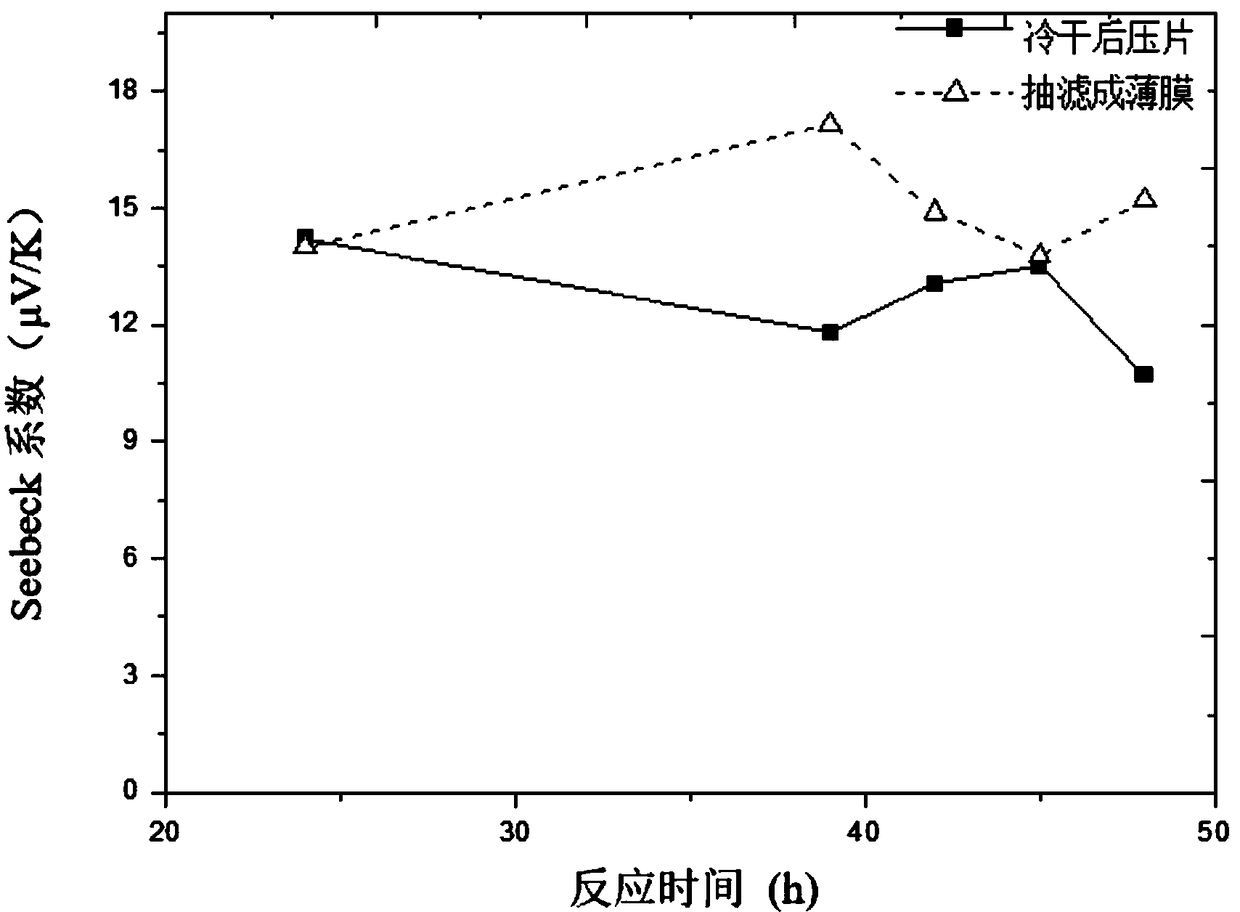

Method for manufacturing graphene/polyaniline thermoelectric thin film

ActiveCN103311428ALow costSimple processElectrolytic coatingsThermoelectric device manufacture/treatmentAnilineFigure of merit

The invention discloses a method for manufacturing a graphene / polyaniline thermoelectric thin film, and relates to a method for manufacturing a thermoelectric thin film. The method for manufacturing the graphene / polyaniline thermoelectric thin film includes firstly, manufacturing graphene oxide powder; secondly, manufacturing graphene oxide / aniline mixed solution; thirdly, manufacturing a graphene / polyaniline composite powder material; fourthly, manufacturing the thermoelectric thin film by means of oriented deposition. The method has the advantages that the technical problem of low thermoelectric conversion efficiency due to a low figure of merit (a ZT value) of an existing organic thermoelectric material is solved, and the method can be applied to industrial temperature differential power generation.

Owner:HARBIN INST OF TECH

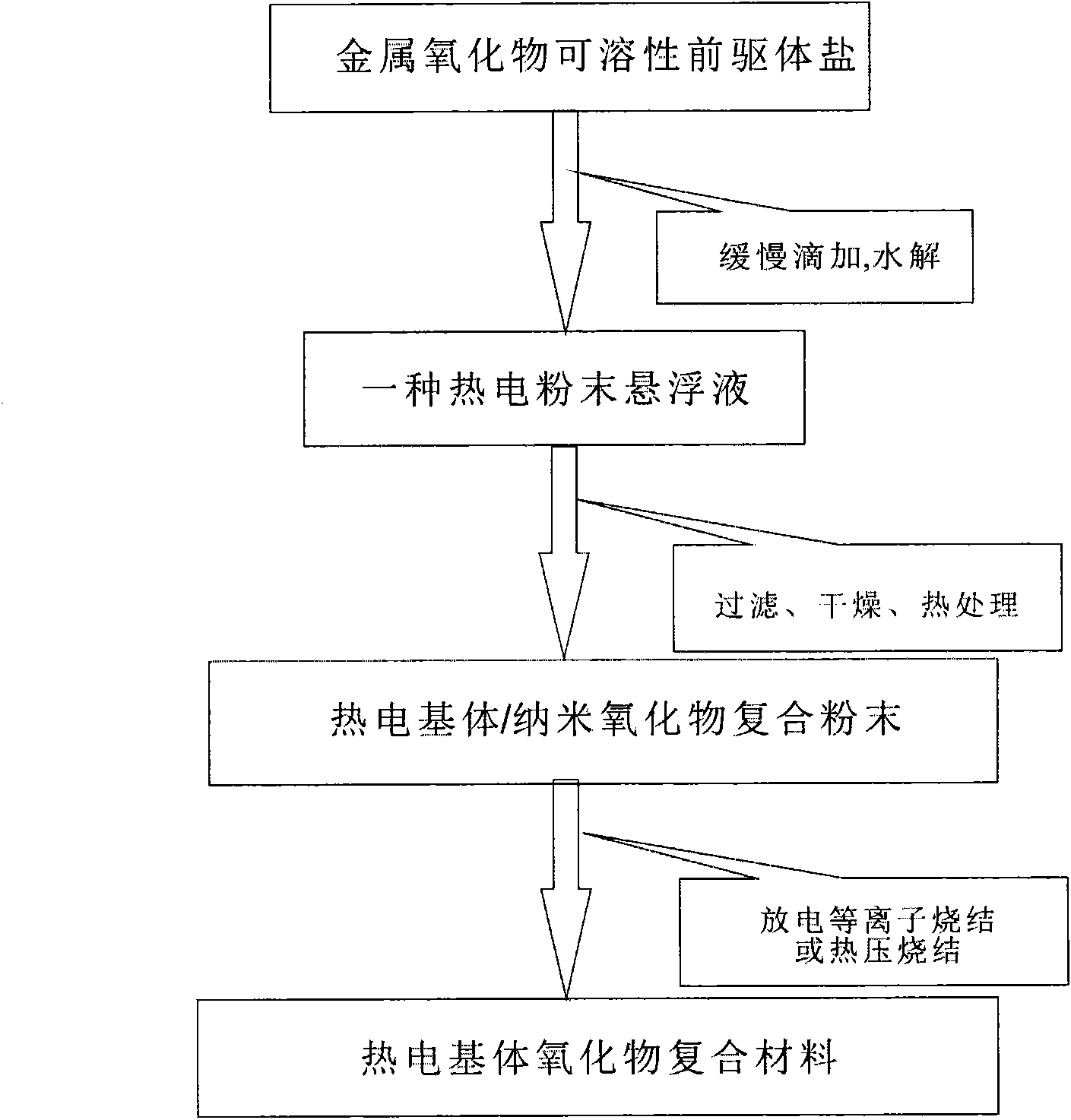

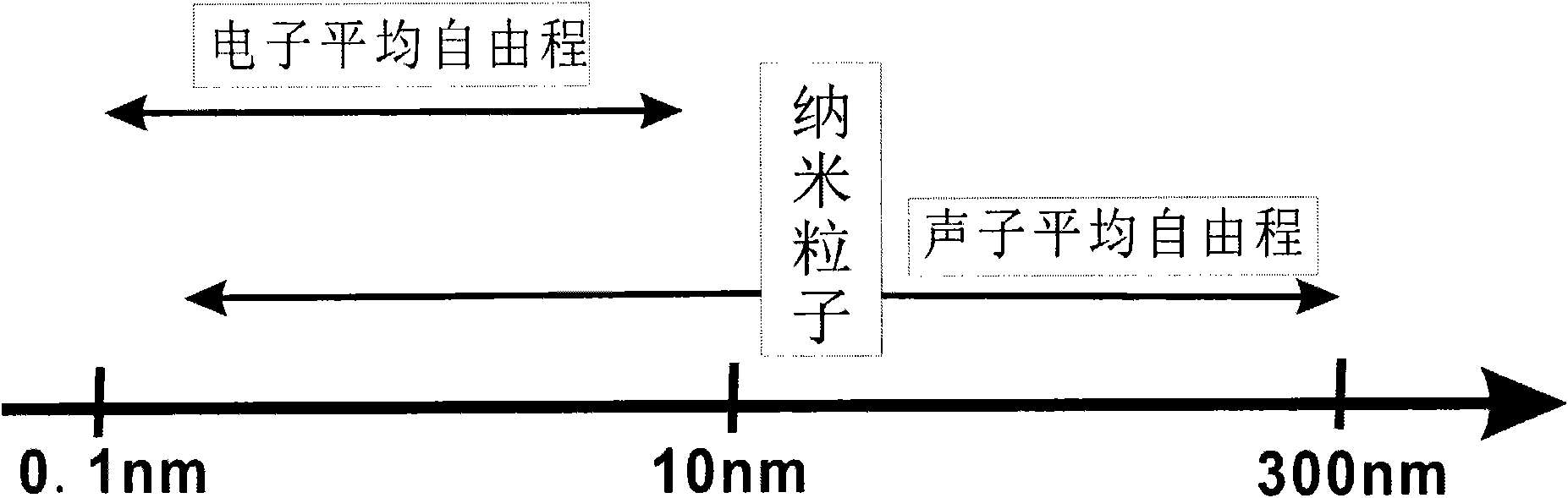

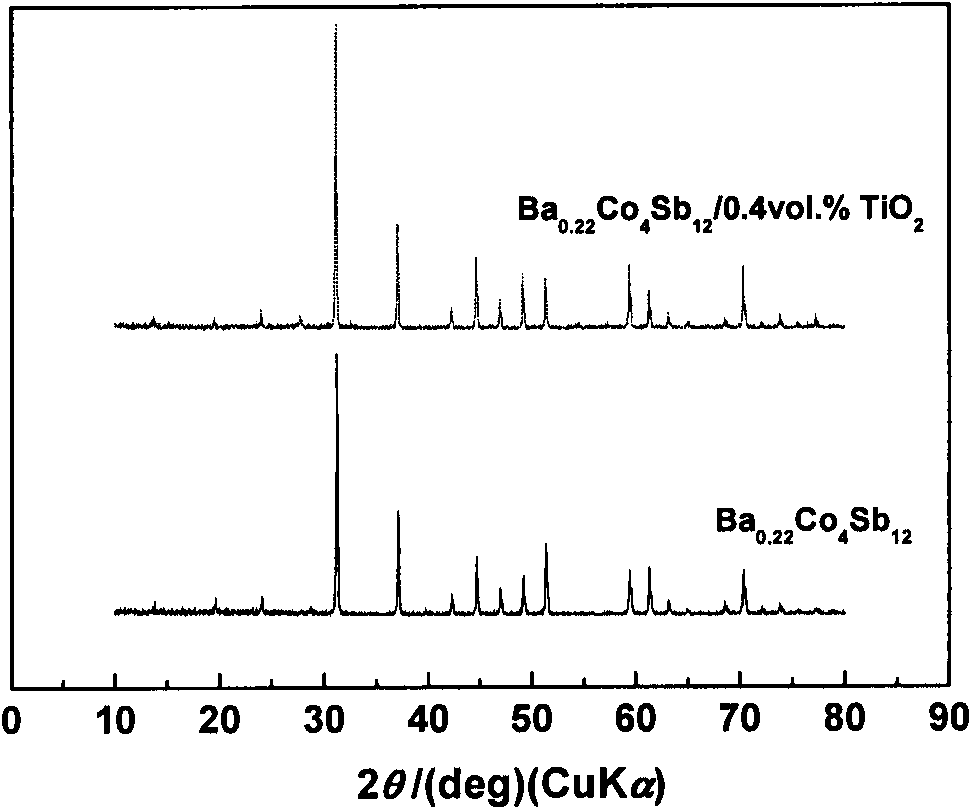

Thermoelectric composite and preparation method thereof

InactiveCN101942577ALower lattice thermal conductivityImprove thermoelectric performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentLiquid mediumSkutterudite

The invention provides a preparation method of a composite, comprising: providing a suspension of a solid thermoelectric material which disperses in a liquid medium, wherein the solid thermoelectric material is filled and / or doped with skutterudite, half-Heusler alloy, a cagelike material and other thermoelectric ordered alloy or thermoelectric disordered alloy or a thermoelectric intermetallic compound; contacting the suspension with a solution formed by dissolving a metallic oxide precursor into solvent to obtain a reaction mixture; forming a metallic oxide by hydrolyzing the metallic oxide precursor in the presence of water; obtaining the compound of the metallic oxide and the solid thermoelectric material which are evenly dispersed in liquid phase; and separating the compound of the metallic oxide and the solid thermoelectric material from the liquid phase to obtain the separated composite. The invention can dramatically improve the thermoelectric performance of the composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

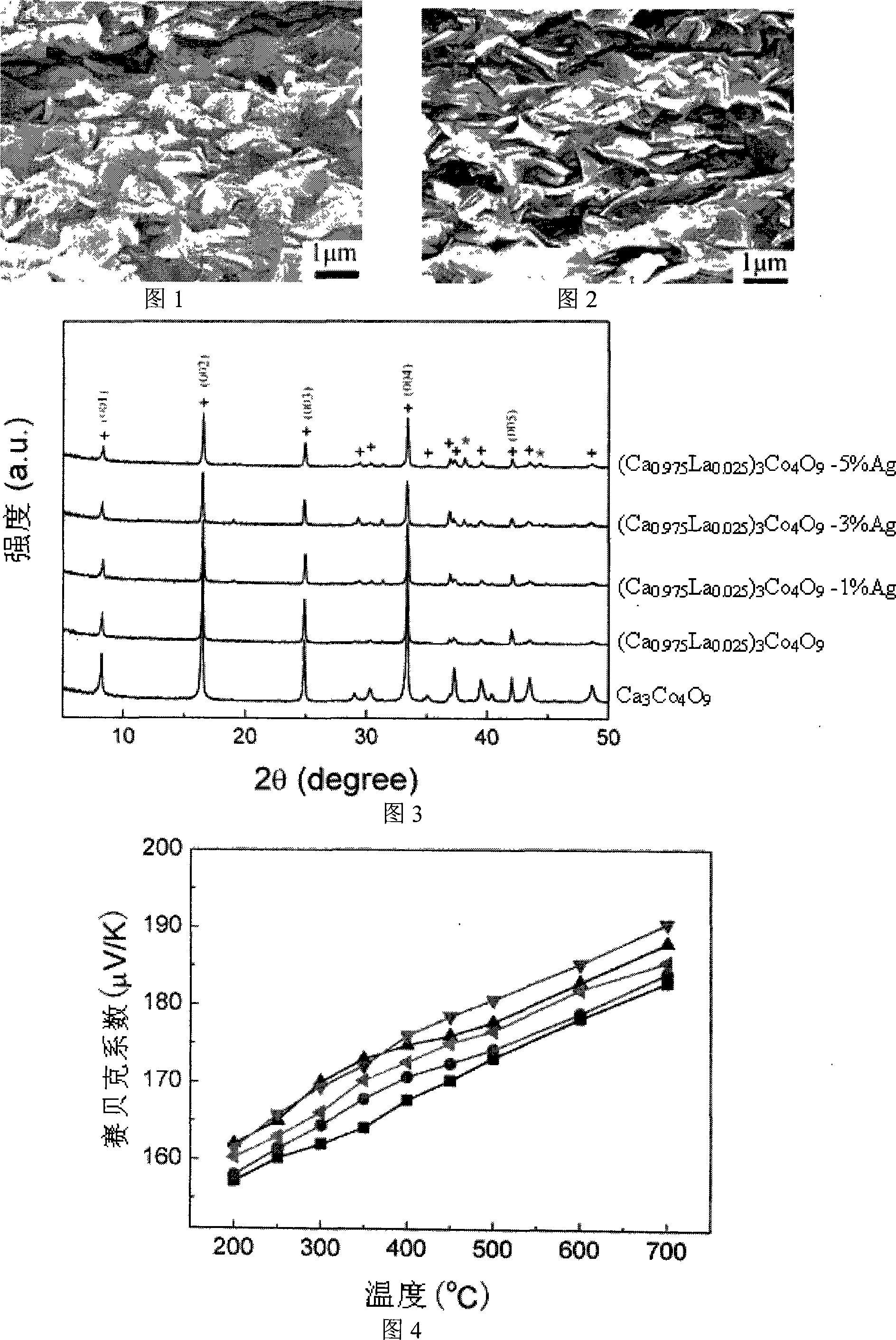

Method for preparing pyroelectric material Ag complex (Ca***La*)*Co*O

The invention discloses a preparation method of thermoelectric material Ag compound (Ca(1-X)LaX)3Co4O9, and relates to the preparation method of Ag compound oxide thermoelectric material. The invention resolves the problems that the distribution of Ag phases in an Ag compound Ca-Co-O-based oxide is not even, the size of Ag phase particles is large, thereby leading that current carrier transporting loop is formed between Ca-Co-O-based oxide crystal grains, and leading Seebeck coefficient of the Ag compound Ca-Co-O-based oxide to be reduced evidently, and the existence of lanthanon results in decreasing the electrical conductivity of the Ca-Co-O-based oxide. The preparation methods comprises that firstly, calcium nitrate, cobalt nitrate and lanthanum nitrate are dissolved in distilled water; secondly, citric acid is add; thirdly, silver nitrate is added; fourthly, organic monomers and network agent are added; fifthly, initiating agent is added; sixthly, microwave dry is performed; seventhly, calcination is operated; eighthly, the spark plasma sintering is performed. The distribution of Ag phases in Ag compound (Ca(1-X)LaX)3Co 4O9 prepared by the methods of the invention is even, the size of the Ag phase particles is smaller than 500 nm, and the current carrier transporting loop is not formed. The Seebeck coefficient of the Ag compound (Ca(1-X)LaX)3Co4O9improves 1.7 percent to 4.9 percent than that of the Ca3Co4O9, the electrical conductivity improves 13.3 percent to 38.9 percent, and the power factor improves 21.6 percent to 35.1 percent.

Owner:HARBIN INST OF TECH

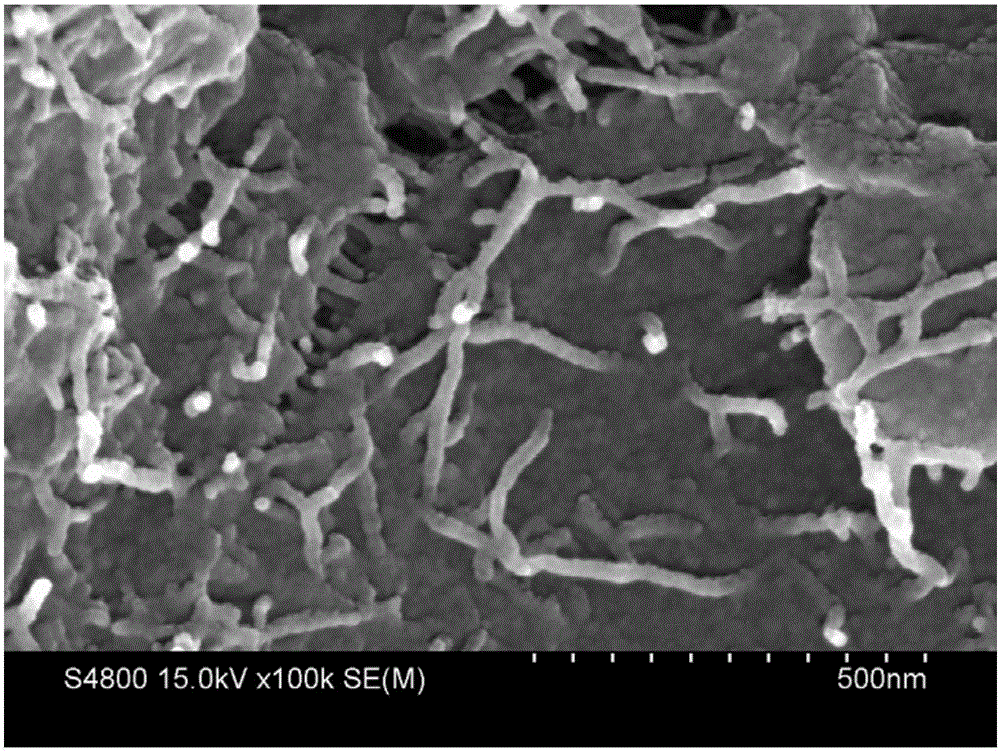

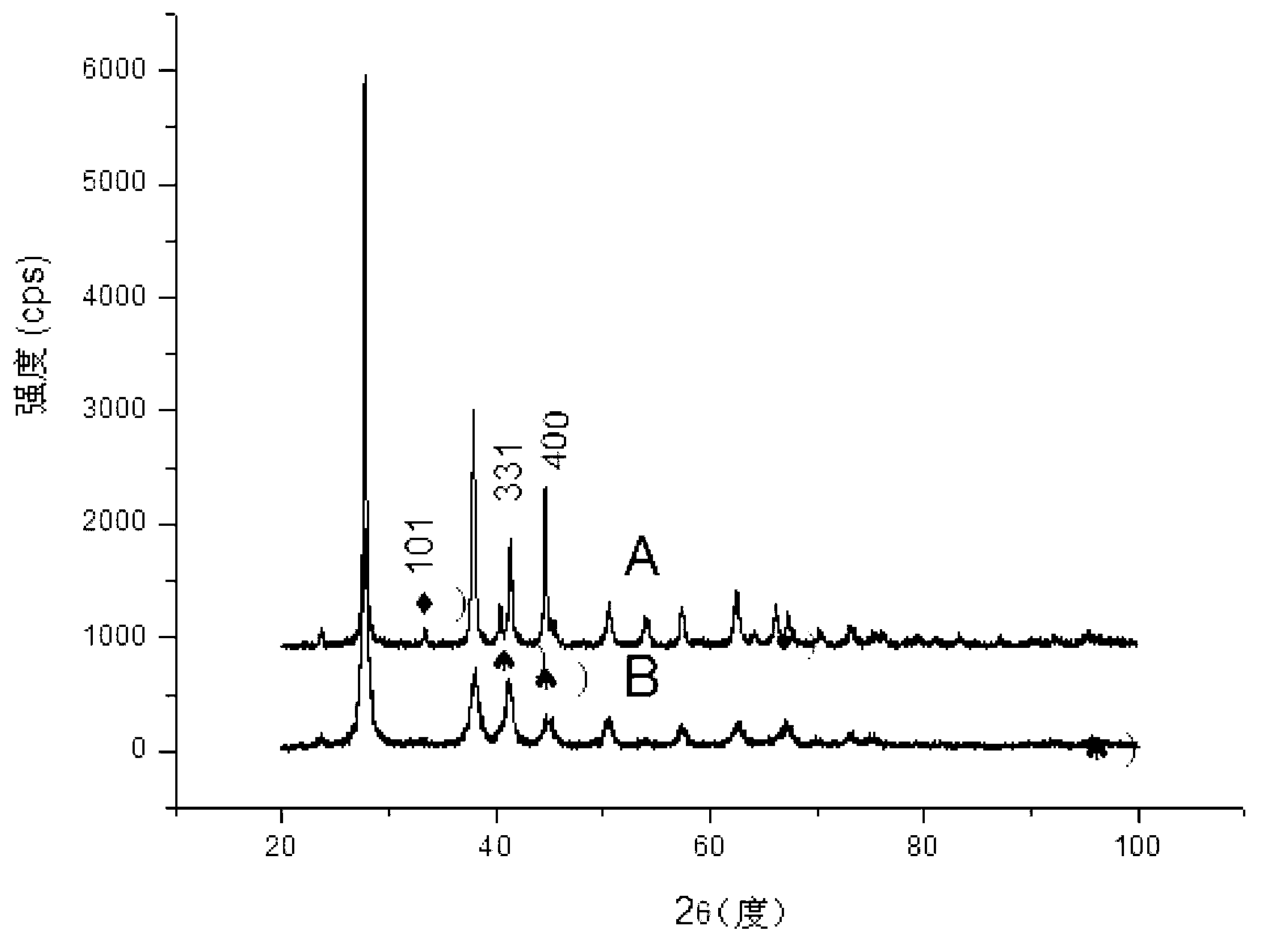

Composite material of skutterudite filling substrate and preparation method thereof

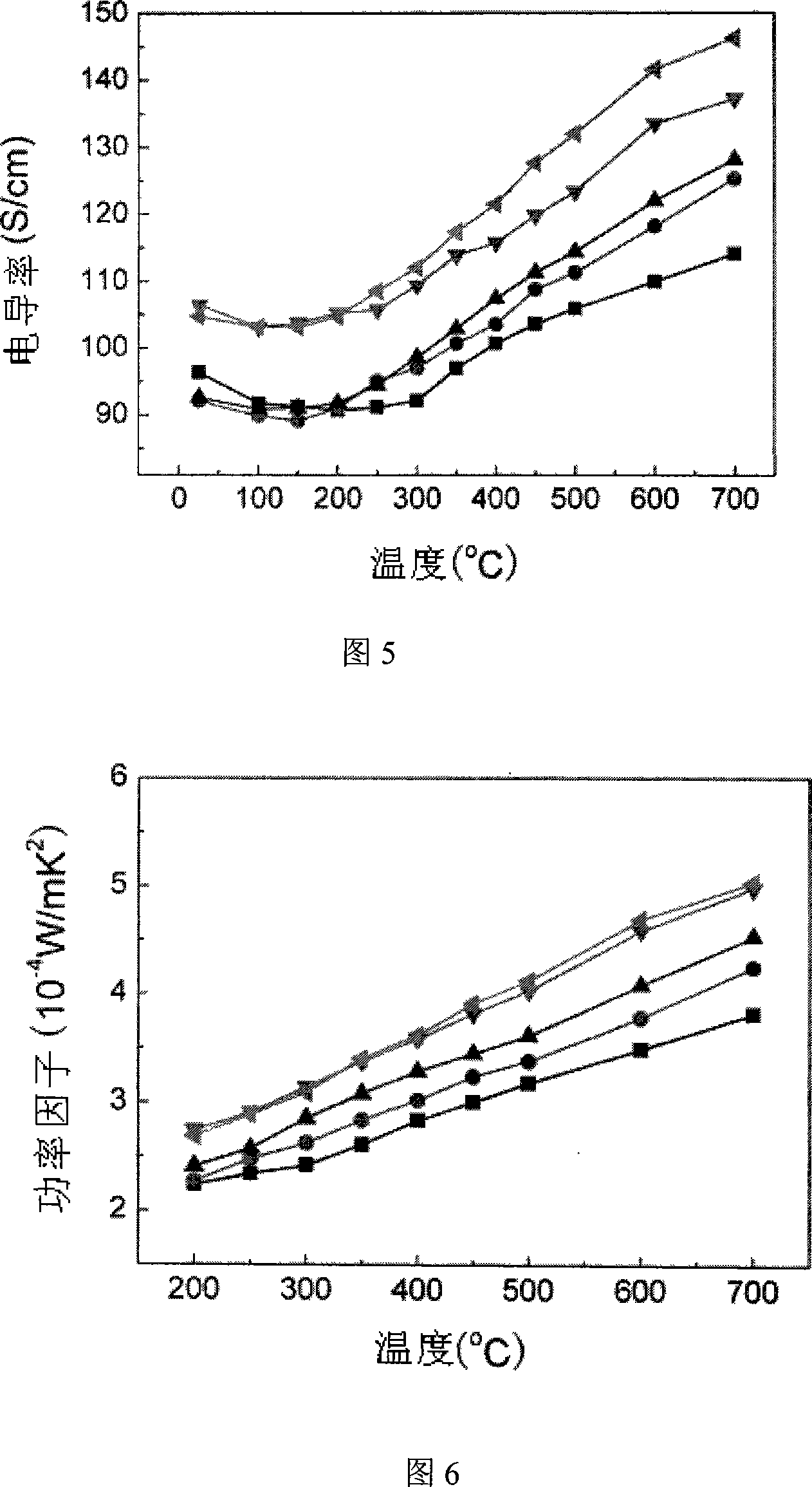

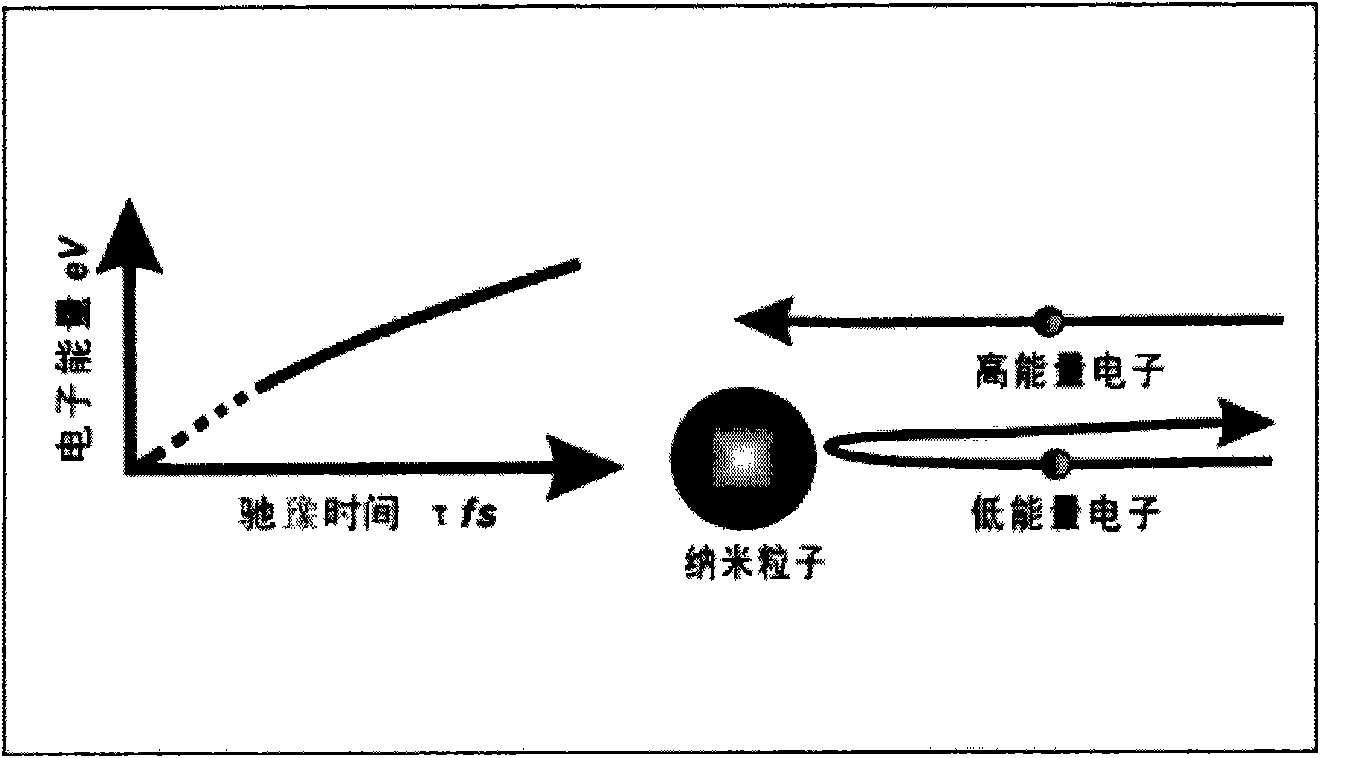

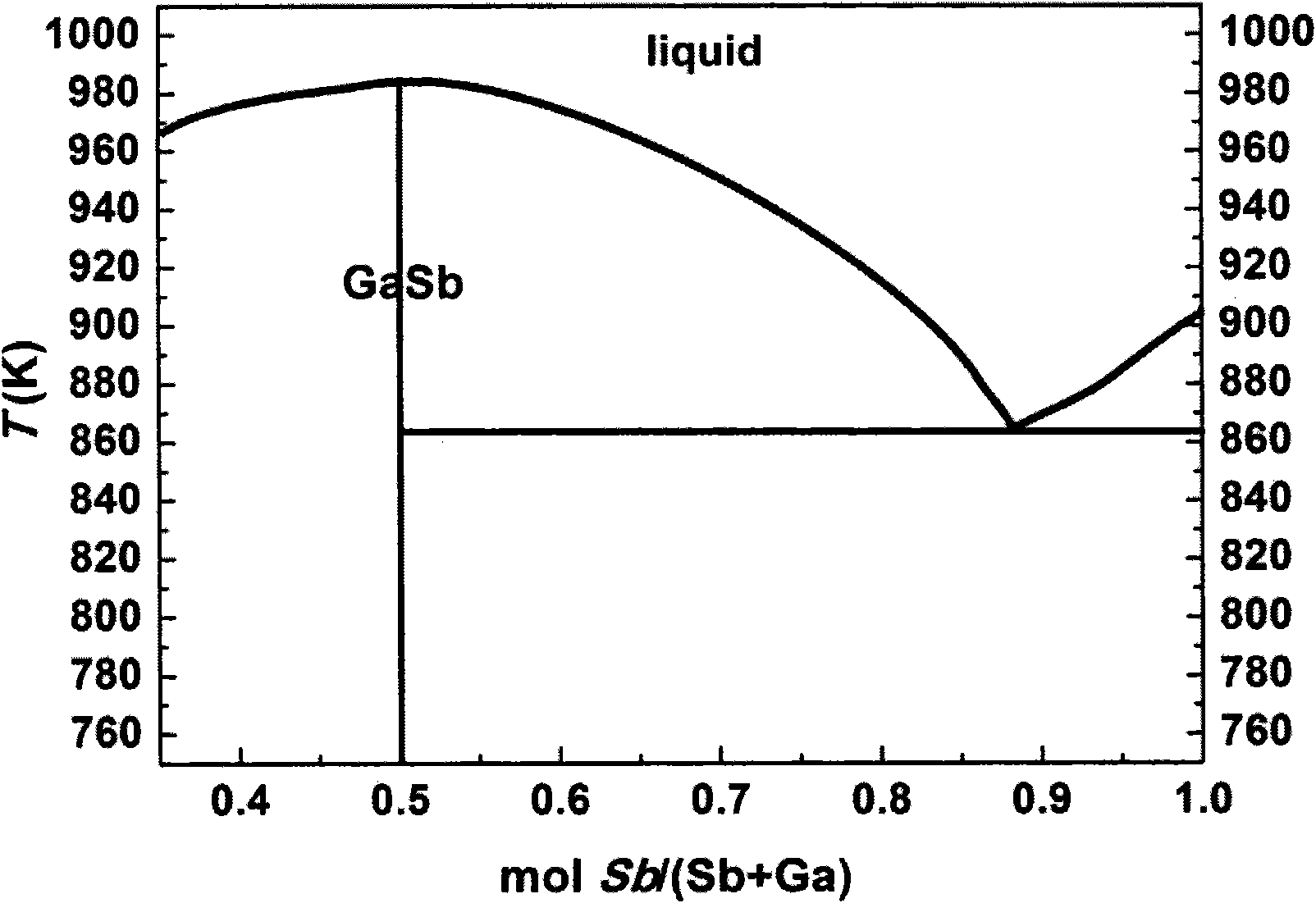

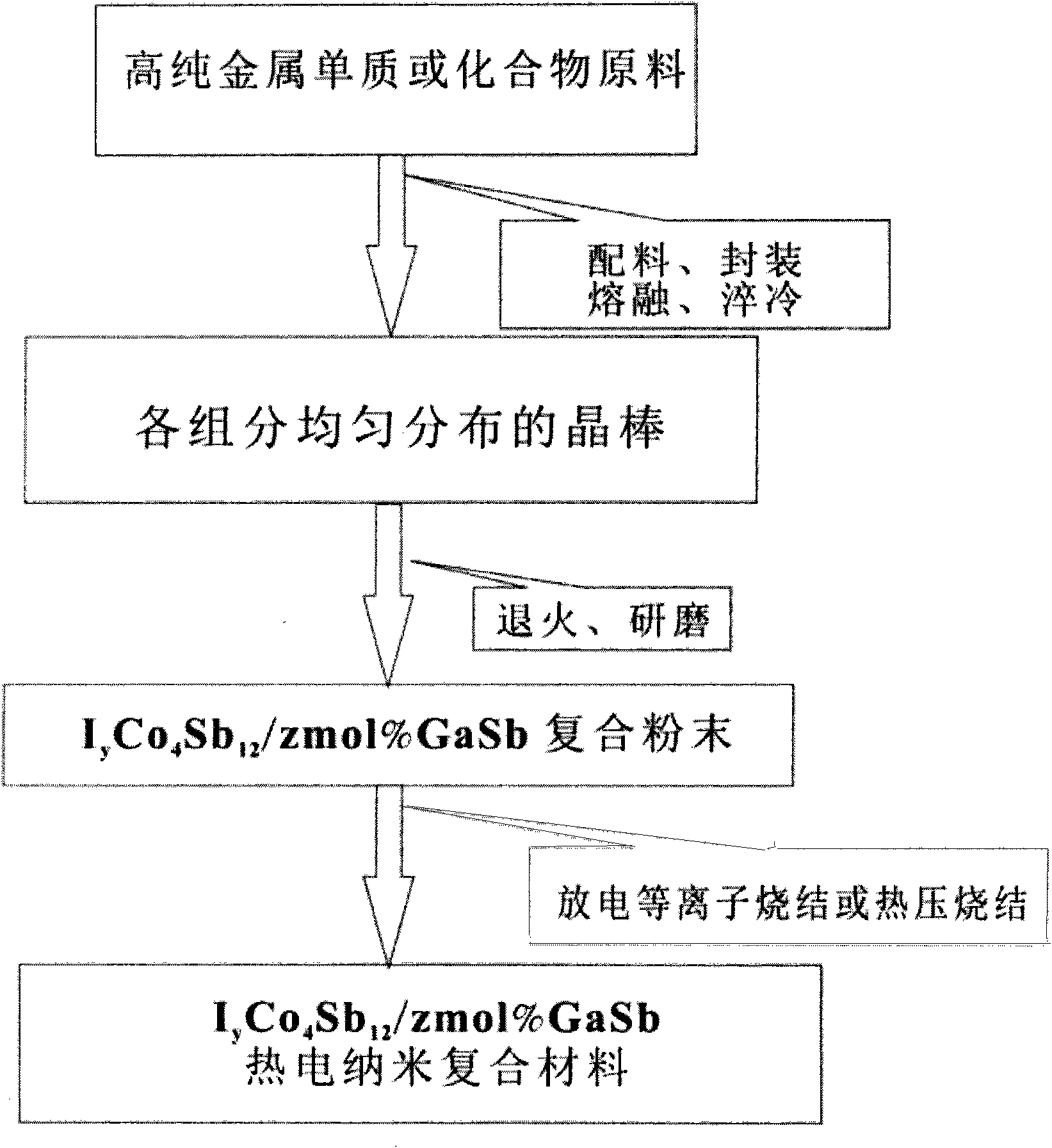

InactiveCN102031416AImprove Seebeck coefficientLow thermal conductivityMaterial nanotechnologyGallium/indium/thallium compoundsCompound aSkutterudite

The invention provides a composite material. The composite material comprises a skutterudite filling substrate shown as the following formula (I): IyCo4Sb12 (1), wherein I is at least one of Yb, Eu, Ce, La, Nd, Ba and Sr, and y is less than 1 and not more than 0.05. The composite material further comprises GaSb particles distributed in the skutterudite filling substrate, wherein the composite material contains 0.05-5 mol% GaSb particles. Compared with the thermoelectric material substrate without compounding a nanometer GaSb phase, the Seebeck coefficient of the composite material is improved to a large extent, the total heat conductivity is slightly reduced, the thermoelectric performance index ZT value is greatly increased in the whole high temperature and low temperature zone range, and the thermoelectric conversion efficiency of the material is greatly improved. The composite material has simple process and favorable industrialization prospect and is easy to control.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Carbon-coated class V-VI compound semiconductor nano sheet and preparation method thereof

InactiveCN103165810AImprove protectionImprove stabilityThermoelectric device junction materialsCarbon layerThermoelectric materials

The invention discloses a carbon-coated class V-VI compound semiconductor nano sheet and a preparation method thereof, and relates to a topological insulator and a thermoelectric material and a preparation method thereof. The method solves the problems that the conventional preparation method for the class V-VI compound topological insulator is complex and cannot be used for preparing bulk materials, the surface of the topological insulator is instable, unsymmetrical and high in roughness and the electric conductivity and the Seebeck coefficient of the topological insulator serving as the thermoelectric material cannot be simultaneously improved. The carbon-coated class V-VI compound semiconductor nano sheet consists of a nano sheet matrix and a carbon layer coated on the surface of the nano sheet matrix. The amorphous carbon-coated class V-VI compound semiconductor nano sheet is prepared through a one-step hydrothermal method; and a grapheme-coated class V-VI compound semiconductor nano sheet is prepared through a two-step hydrothermal method. The surface of the prepared nano sheet is stable, symmetrical and low in roughness, and the electric conductivity and the Seebeck coefficient of the nano sheet can be simultaneously improved. The invention is applied in the field of preparation of topological insulators and thermoelectric materials.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

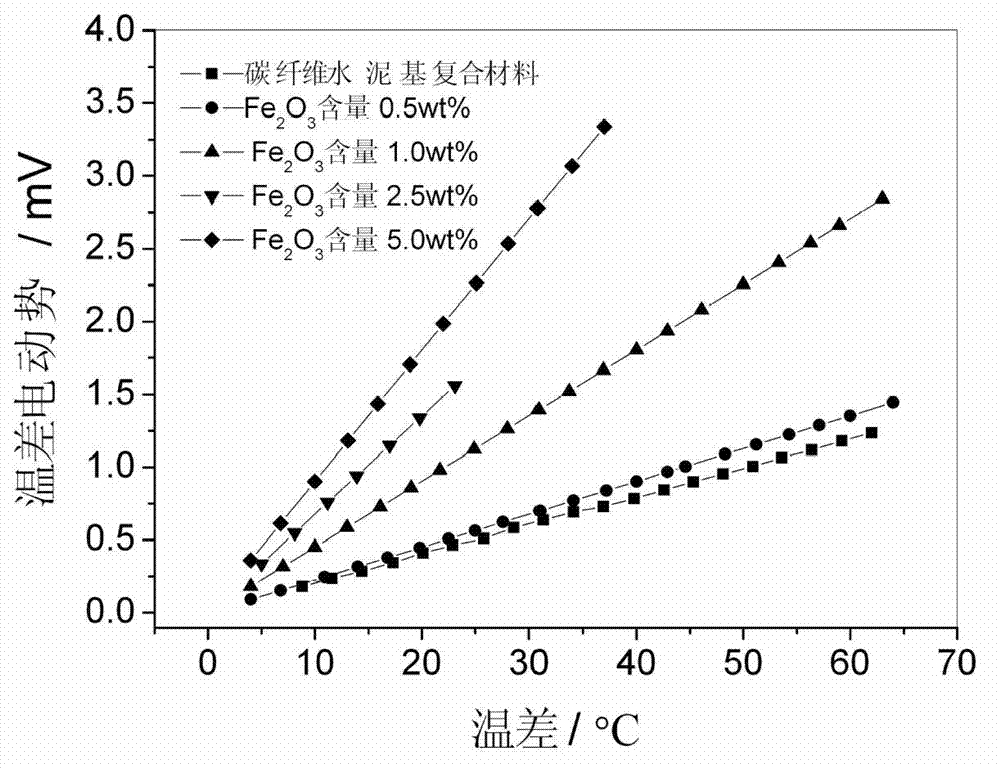

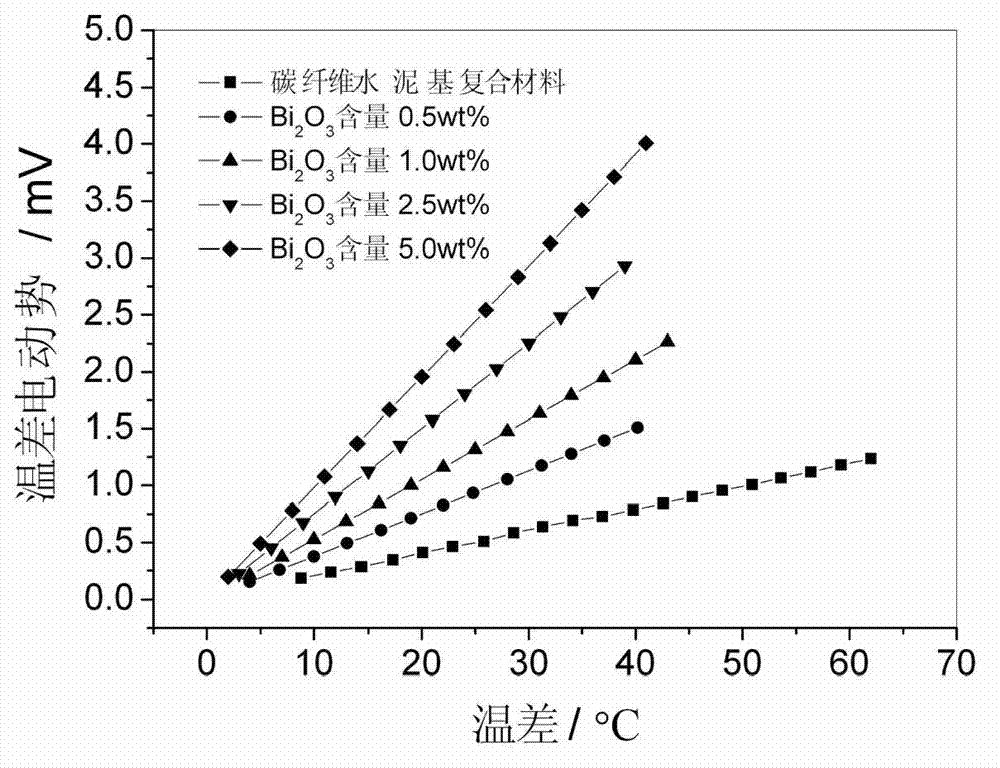

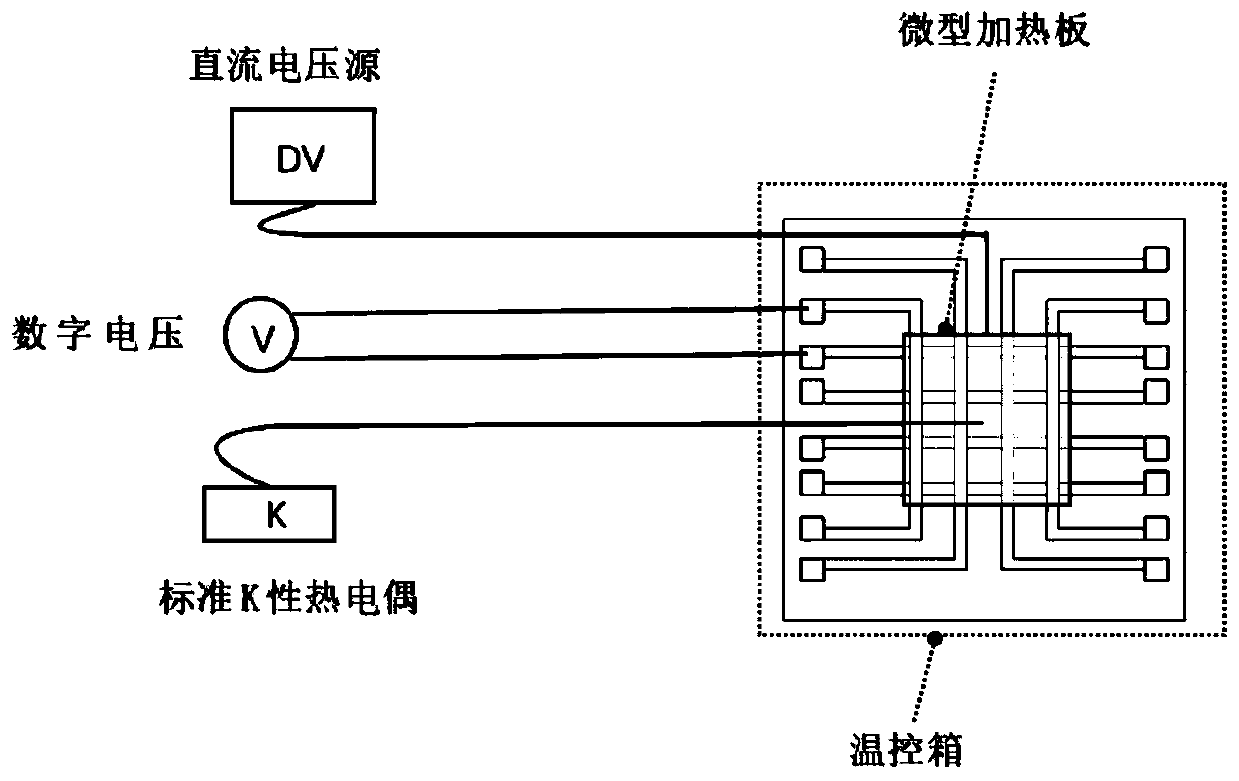

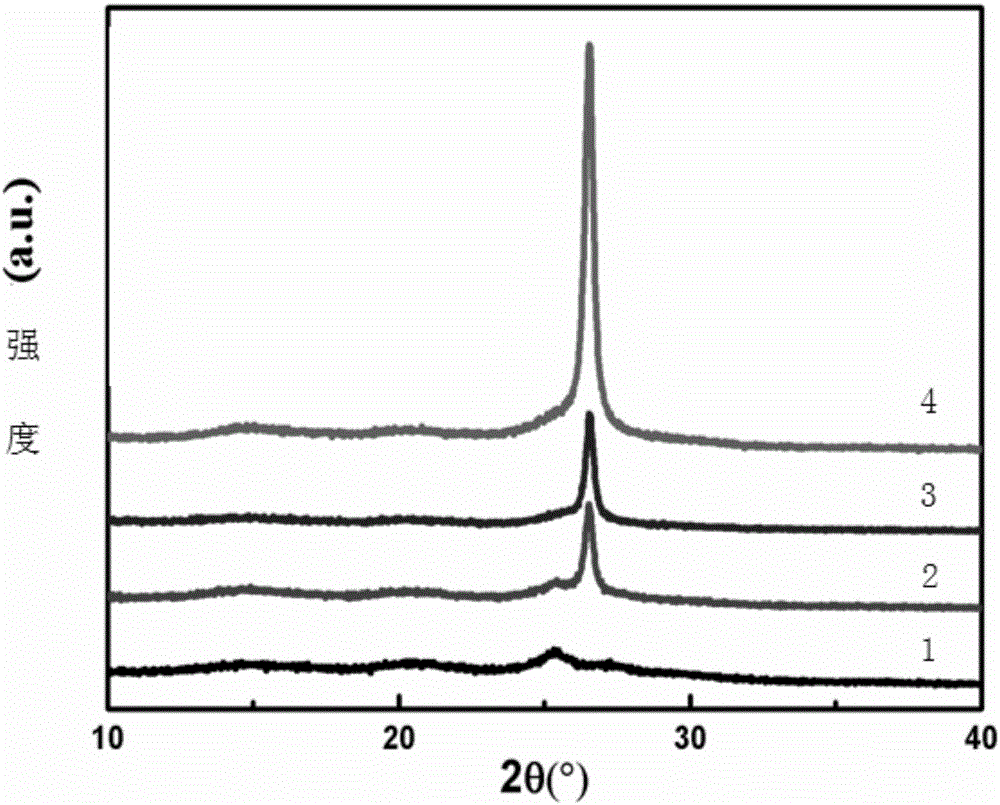

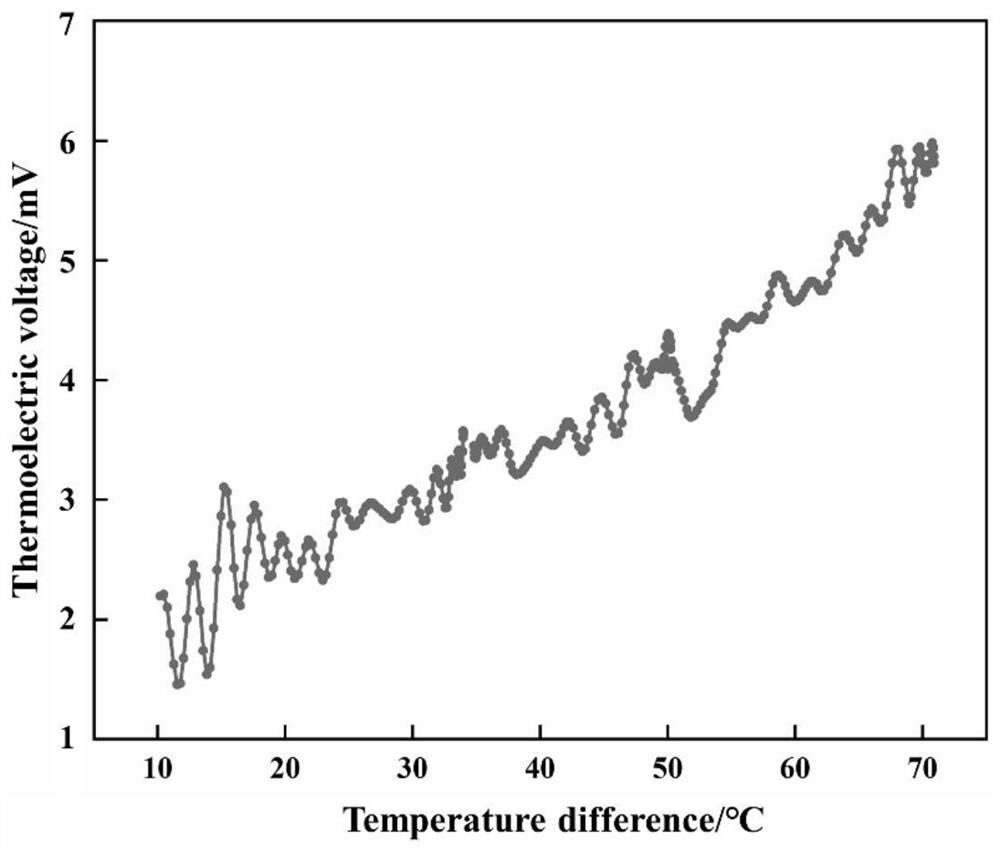

Method for improving Seebeck coefficient of carbon fiber cement-based composite material

The invention provides a method for improving Seebeck coefficient of a carbon fiber cement-based composite material. According to the method, Fe2O3 and / or Bi2O3 powders are added during preparing the carbon fiber cement-based composite material; a linear relation is generated between the thermoelectromotive force and the temperature difference of the carbon fiber cement-based composite material, and the Seebeck coefficient of the carbon fiber cement-based composite material is increased along with the increasing of the quantity of added Fe2O3 and / or Bi2O3 powders, so that the obtained carbon fiber cement-based composite material is high in Seebeck coefficient, stable in thermoelectric property, high in mechanical property, and simple in preparation technology, and avoids the problem that the Seebeck coefficient of the composite material is unstable due to the application of lightweight aggregate, steel slag or crystalline flake graphite; the carbon fiber is free from the technical processing of bromine intercalation, so that the problem due to environmental pollution caused by bromine vapor can be avoided, and the problem that the mechanical property of the cement-based composite material is reduced due to adoption of the lightweight aggregate, the steel slag or the intercalation crystalline flake graphite also can be avoided; and the cement-based composite material can be uniformly dispersed in a cement matrix.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

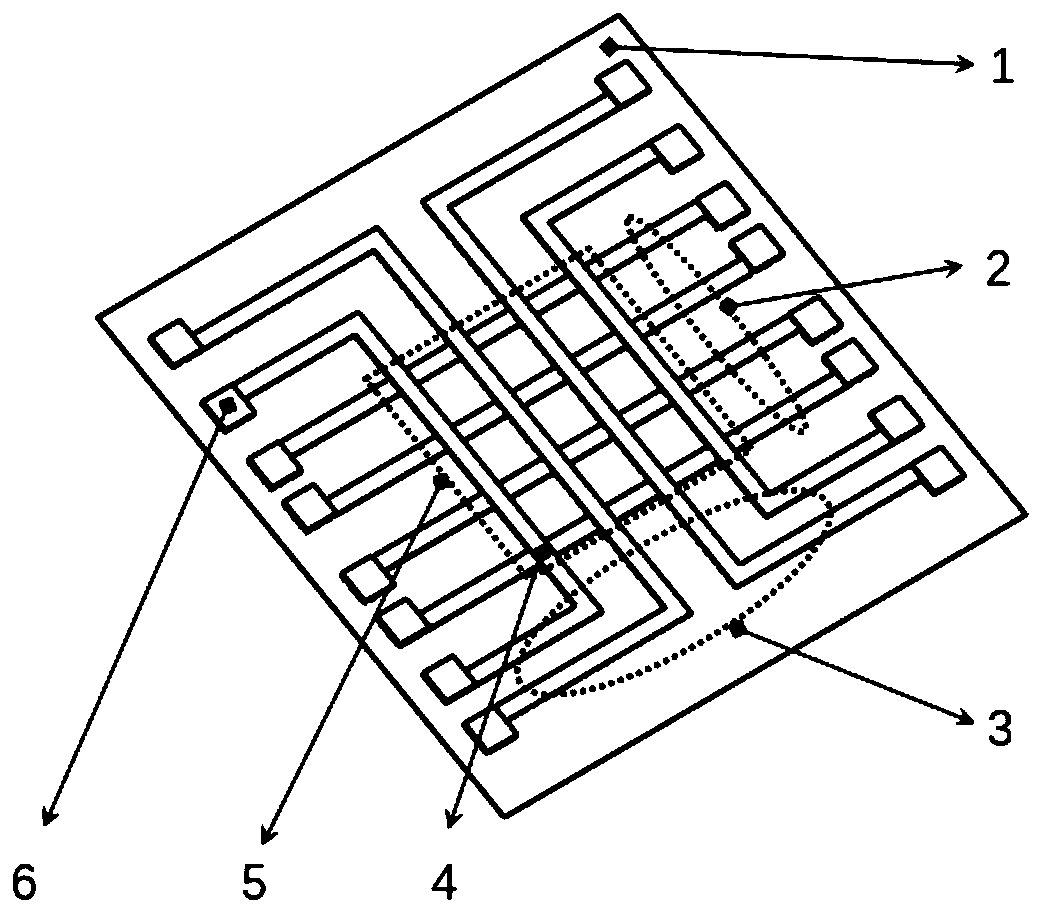

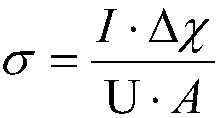

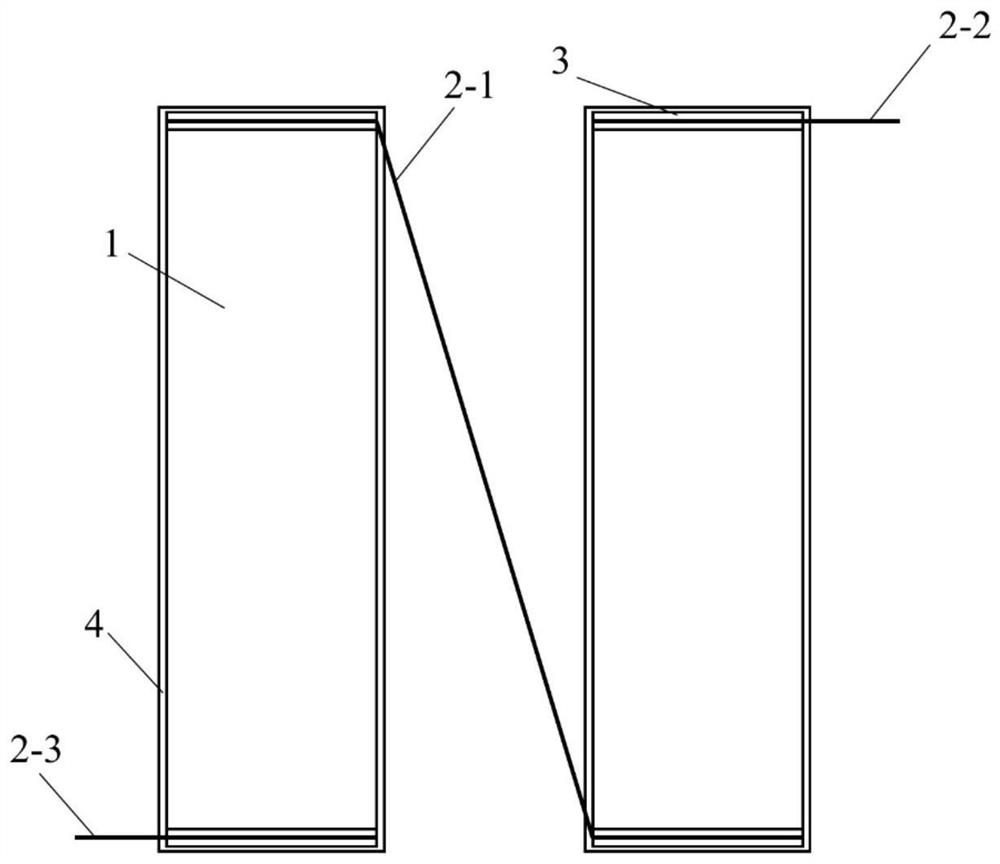

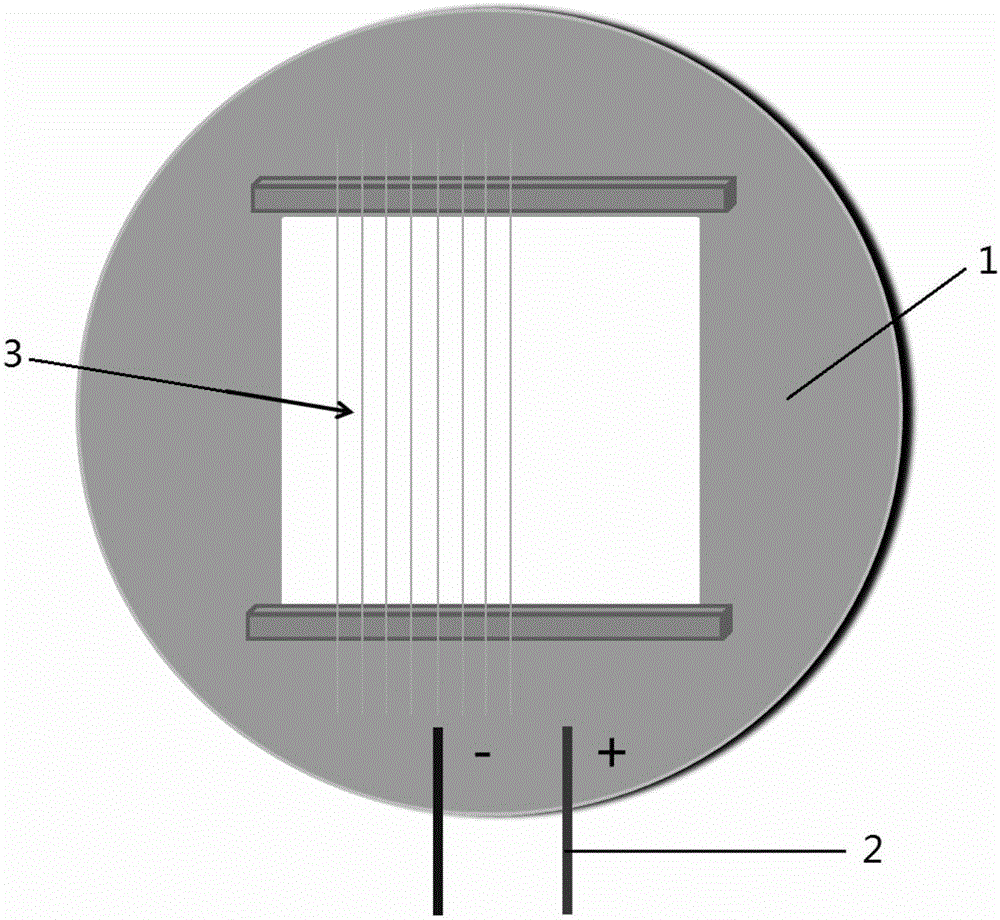

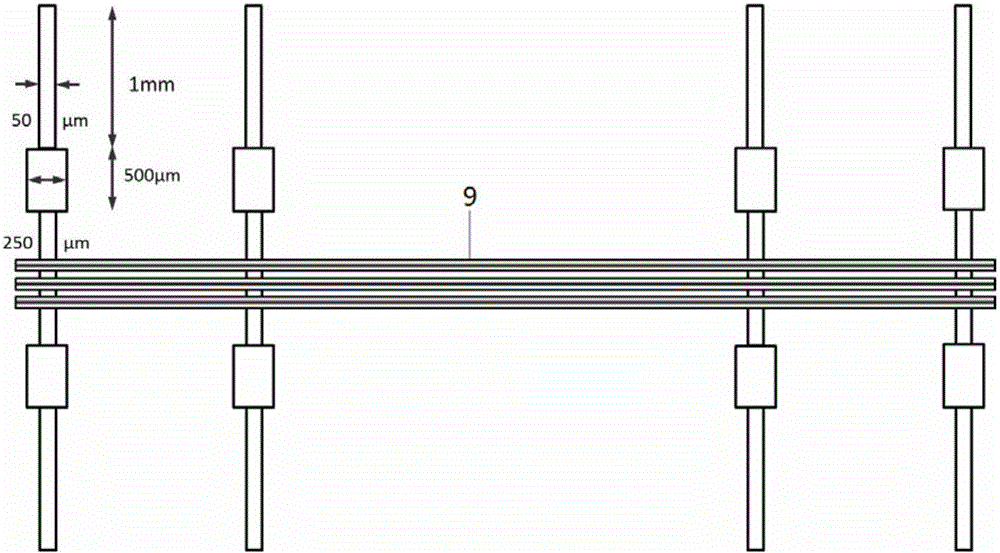

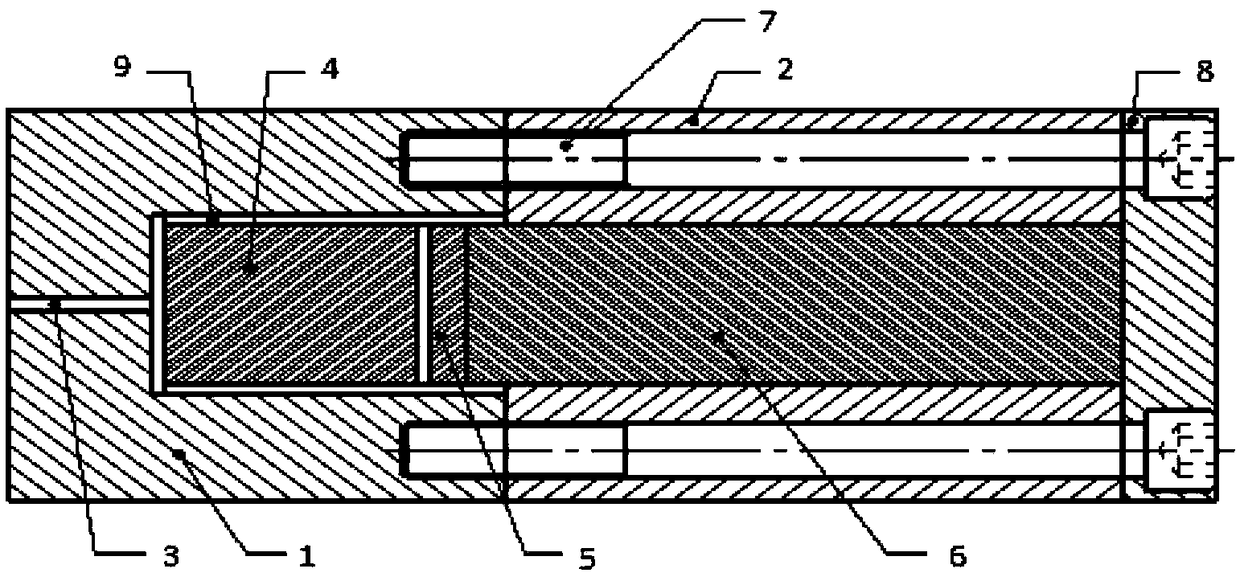

High-spatial resolution flexible film thermocouple temperature sensor

InactiveCN109781287AMeet all flexible requirementsEasy to measureThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesImage resolution

The invention discloses a high-spatial resolution flexible film thermocouple temperature sensor. The sensor comprises a flexible insulating substrate as well as a positive electrode thermocouple filmarray and a negative electrode thermocouple film array sequentially deposited on the surface of the flexible insulating substrate; the positive electrode thermocouple film array and the negative electrode thermocouple film array have a plurality of overlapping regions; the overlapping regions of the positive electrode thermocouple film array and the negative electrode thermocouple film array constitute thermal nodes; the surface of the flexible insulating substrate is divided into a sensitive region and a non-sensitive region; the thermal nodes are located in the sensitive region; the end portions of each positive electrode thermocouple film in the positive electrode thermocouple film array and the end portions of each negative electrode thermocouple film in the negative electrode thermocouple film array are connected with cold ends respectively; and the cold ends are located in a non-sensitive region. The sensor can accurately measure the temperature of a plurality of points to be measured under a condition that the number of sensors is not increased. The sensor has the advantages of simple structure, high reliability, high durability and low cost.

Owner:XI AN JIAOTONG UNIV

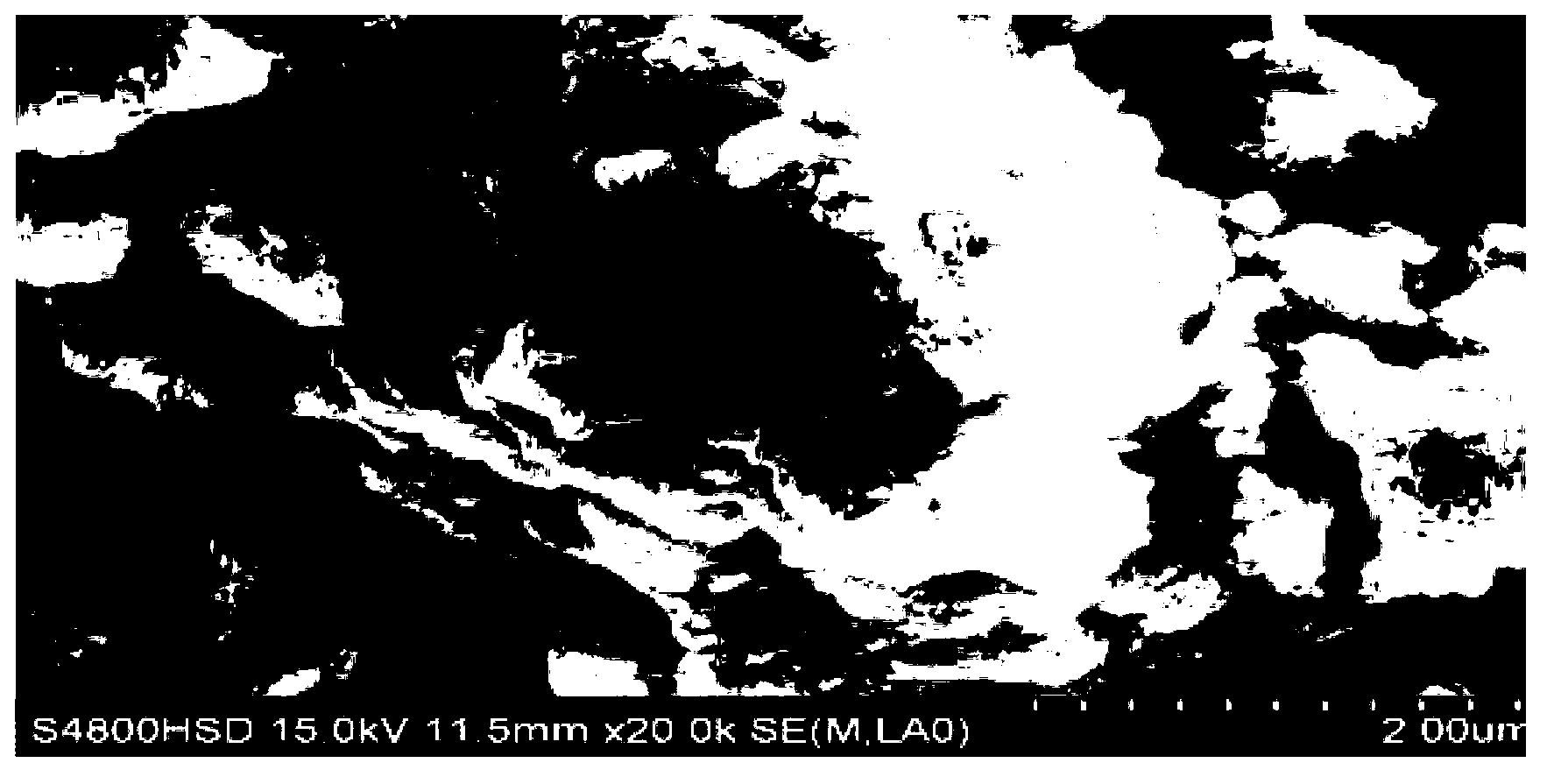

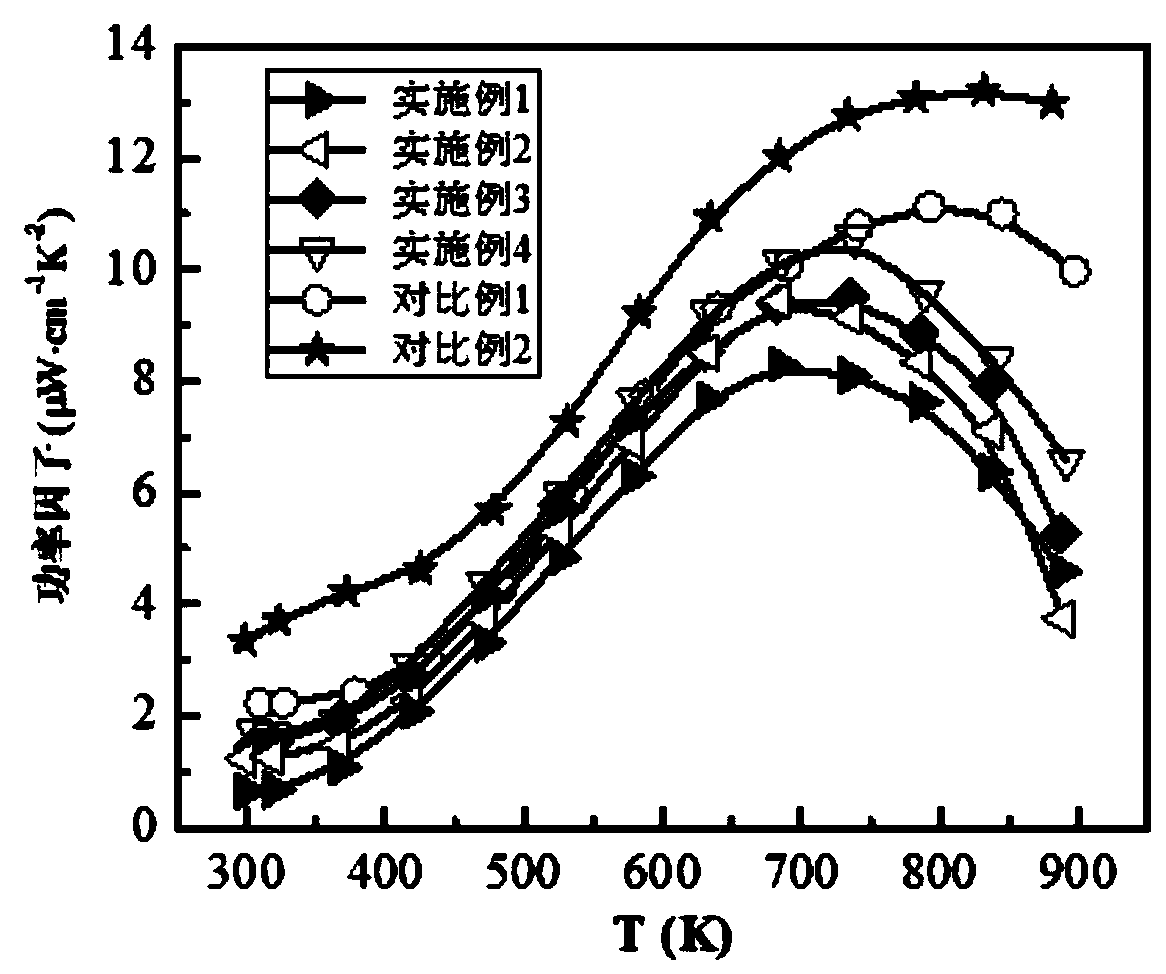

Preparation method for thermoelectric composite material of polyaniline in-situ polymerization clad PEDOT modified nano-carbon

ActiveCN105789423AImprove thermoelectric performanceLower percolation thresholdThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsPolymer science

The invention provides a preparation method for thermoelectric composite material of polyaniline in-situ polymerization clad PEDOT modified nano-carbon, belongs to the field of thermoelectric polymers, and aims at solving the problem of low thermoelectric performance of existing polyaniline thermoelectric polymer material. The preparation method comprises the steps that firstly, an organic solvent and nano-carbon material are added in a PEDOT:PSS solution, and acid is added and stirring is performed so that suspending liquid is obtained; secondly, aniline is added to the PEDOT modified nano-carbon material suspending liquid, and ultrasonic stirring reaction is performed under temperature of 0-30 DEG C so that the PEDOT modified nano-carbon material suspending liquid having aniline is obtained; and thirdly, a proton acid solution having an oxidizing agent is dropped in the suspending liquid, and compression molding is performed after stirring reaction so that the thermoelectric composite material is obtained. Preparation time of the thermoelectric composite material of polyaniline in-situ polymerization clad PEDOT modified nano-carbon is short, the PEDOT:PSS content is low, the percolation threshold of the nano-carbon particles in the base is low and the thermoelectric performance is great.

Owner:HARBIN INST OF TECH

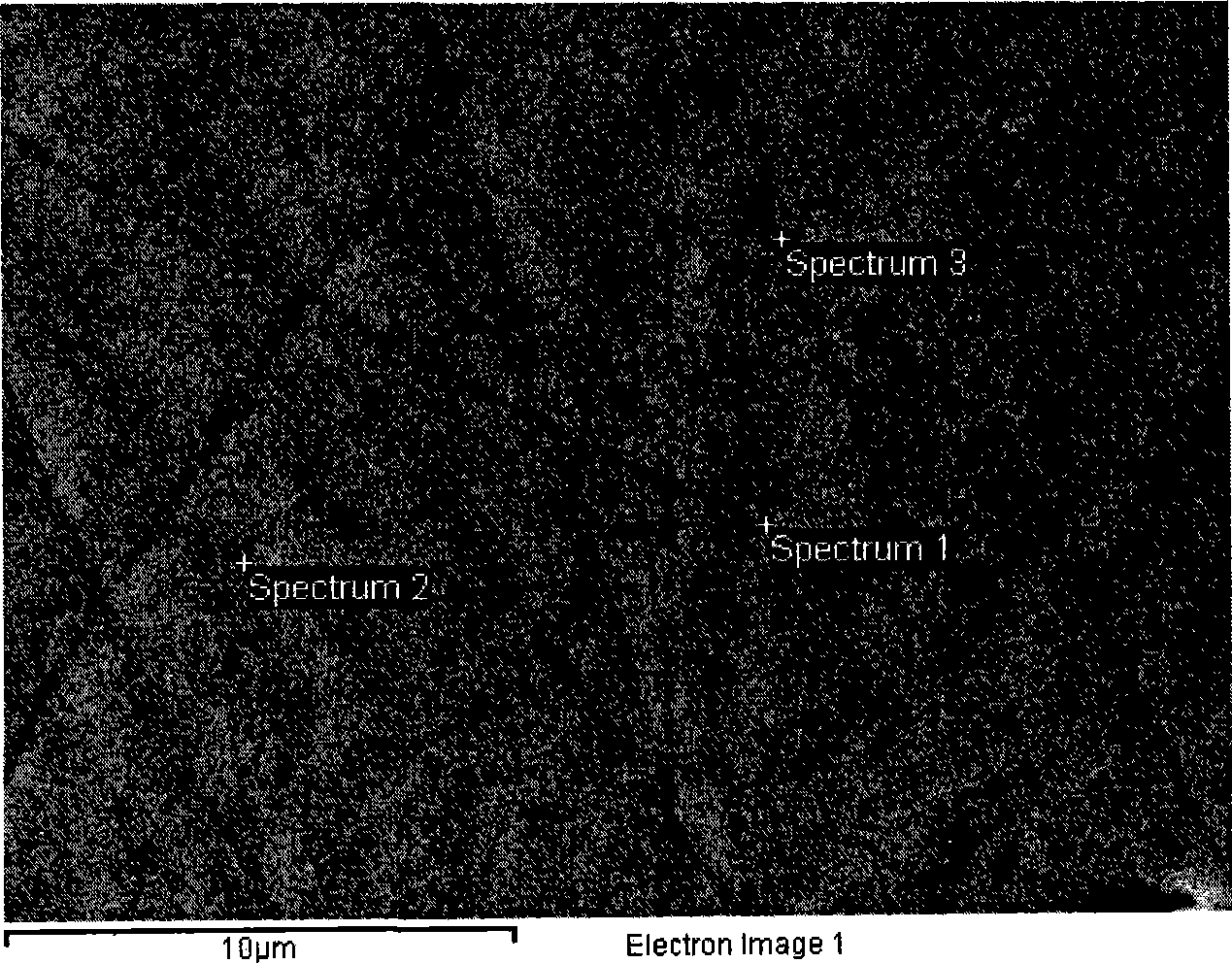

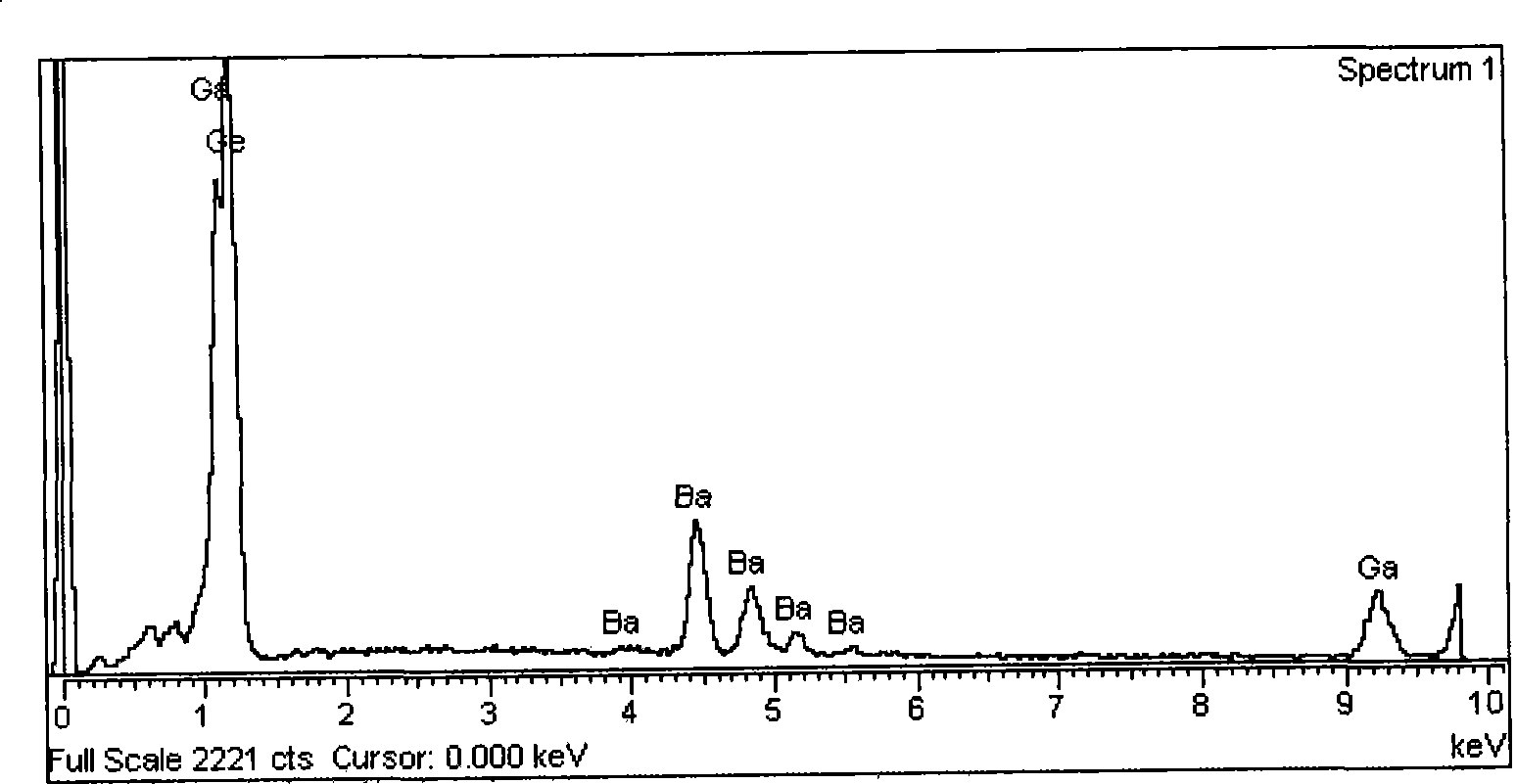

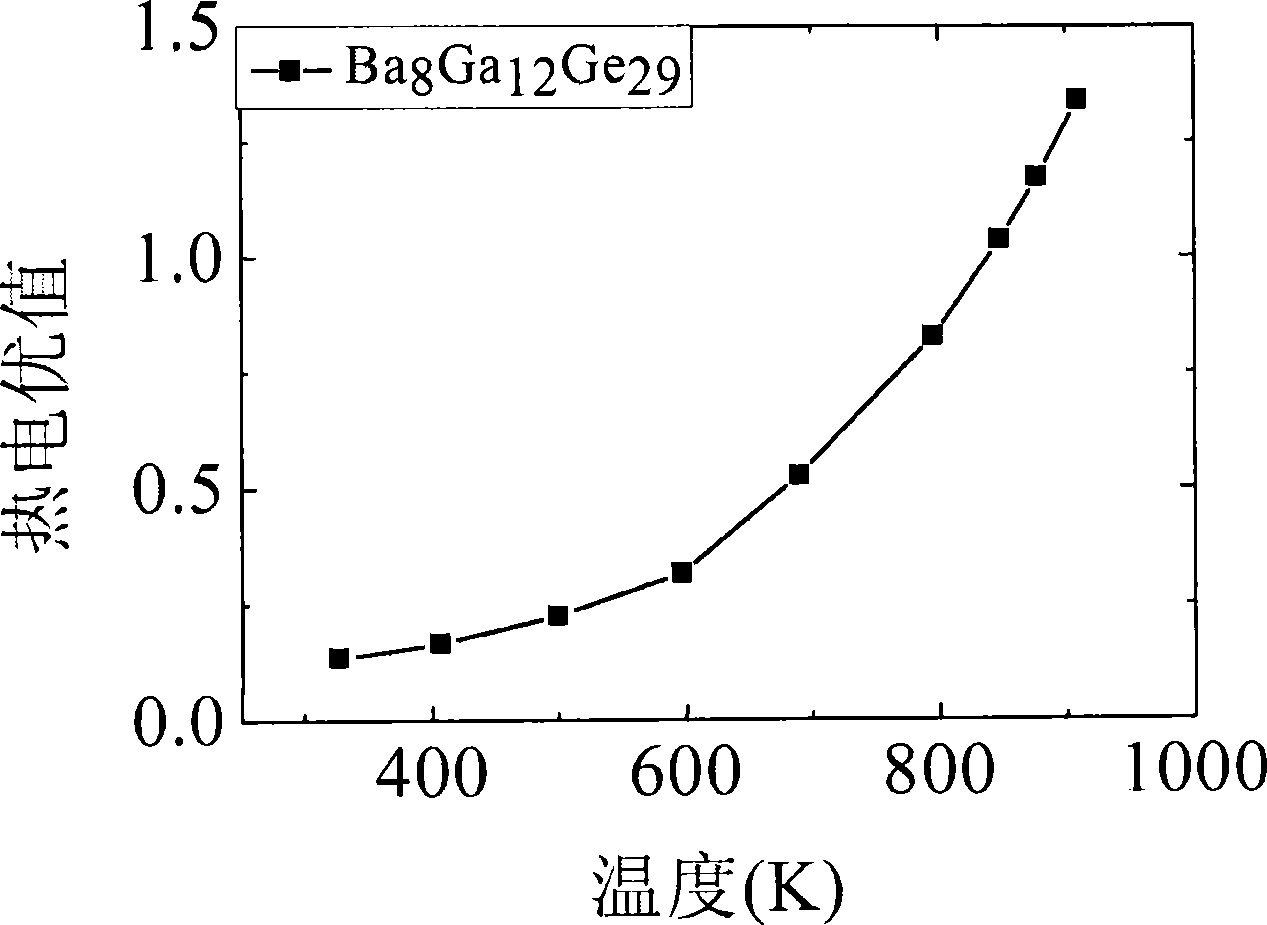

Cage type compound

InactiveCN101393959AImprove Seebeck coefficientImprove thermoelectric performanceThermoelectric device junction materialsAlkaline earth metalRare earth

The invention discloses a cage compound with the following formula 1: M8AxBy-x, wherein, M can be alkaline-earth metal, rare-earth metal, alkali metal, Cd atom or the combination thereof; A can be Ga, Al, In, Zn or the combination thereof; B can be Ge, Si, Sn, Ni or the combination thereof; and x is larger than or equal to 12 and smaller than or equal to 16, y is larger than or equal to 40 and smaller than or equal to 43, and x and y are integers or non-integers respectively. The invention provides the cage compound with better pyroelectricity and a preparation method thereof.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

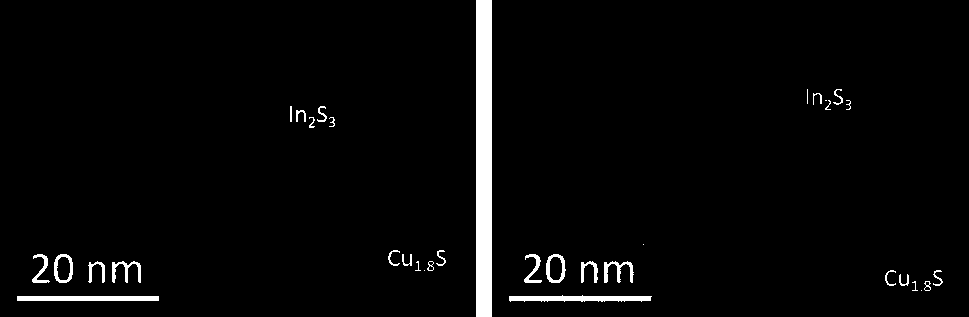

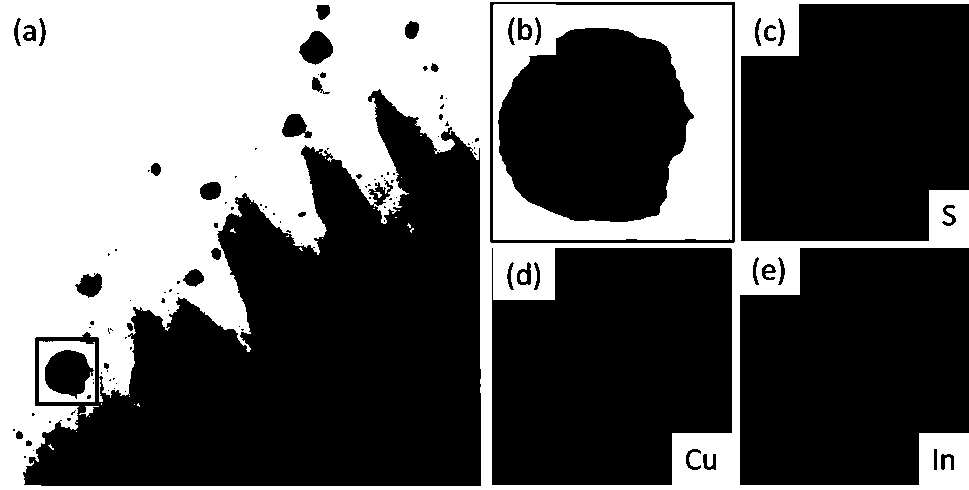

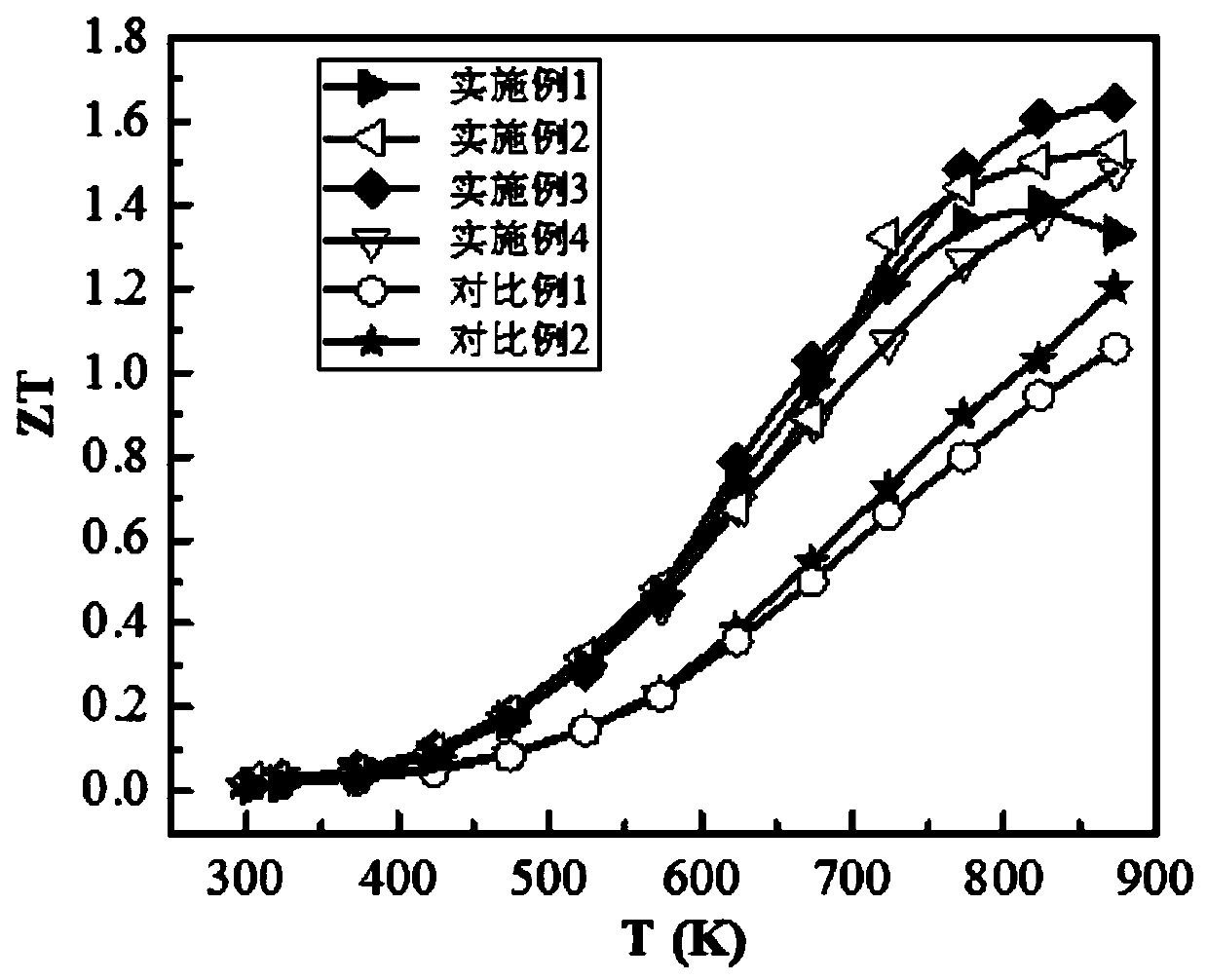

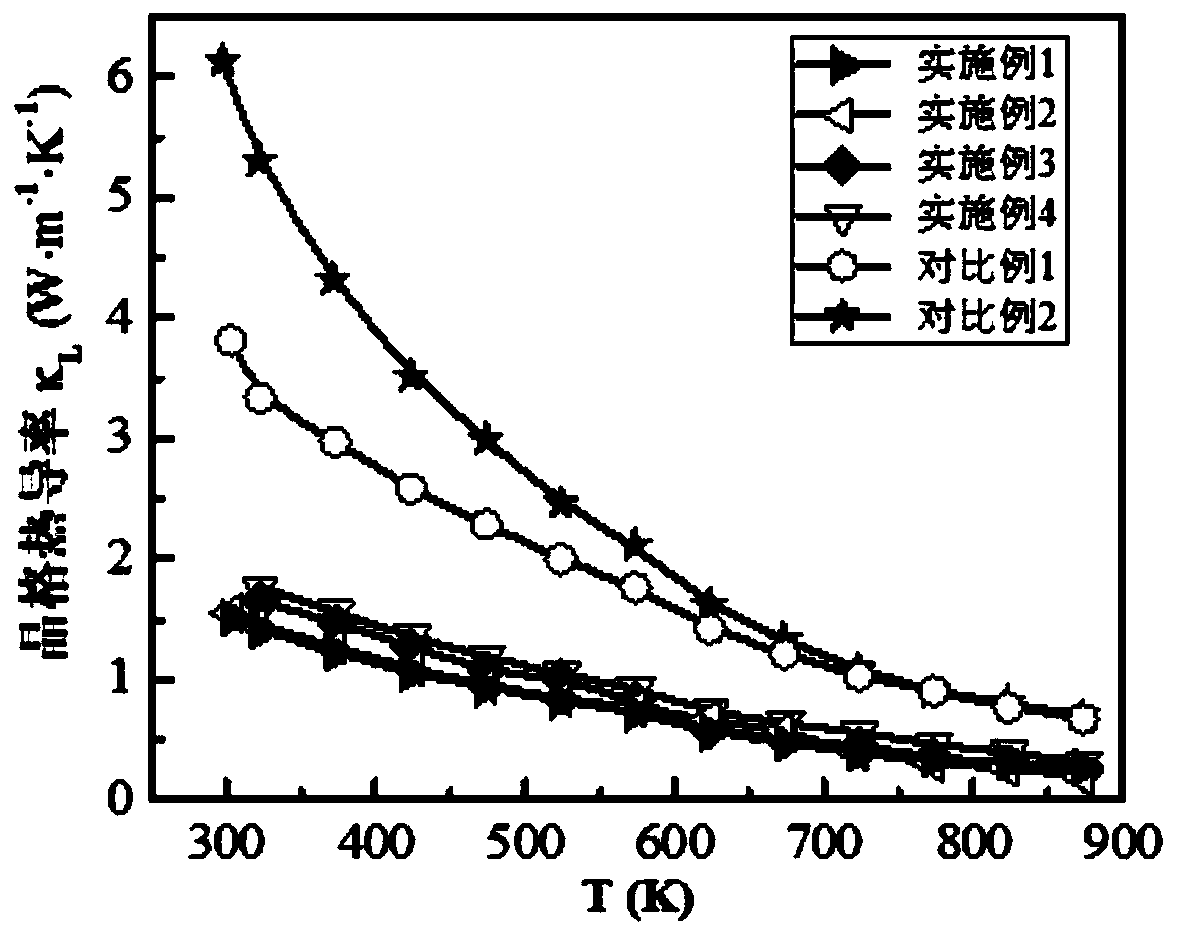

Cu1.8S-based polycrystalline block thermoelectric material and preparation method thereof

ActiveCN108383526AReduce concentrationReduced mean free pathMaterial nanotechnologyThermoelectric device junction materialsNano structuringPolymer science

The invention discloses a Cu1.8S-based polycrystalline block thermoelectric material and a preparation method thereof. The thermoelectric material is prepared from raw materials including Cu1.8S and adoping agent X2Y3, wherein the mol ratio of the Cu1.8S to the doping agent X2Y3 is 1 to (0.005 to 0.07). The thermoelectric material prepared by the preparation method has the advantages that on onehand, In is doped, electrons are introduced and the concentration of current carriers is optimized; point defects are introduced and scattering of short-wavelength phonons is remarkably enhanced, so that the high-temperature thermal conductivity is reduced; on the other hand, surplus In2S3 forms a special nano-structure, i.e., the surplus In2S3 is attached to the edge of an air hole; the thermal conductivity of the material can be greatly reduced by the structure and the thermoelectric performance of a Cu1.8S material is optimized. The preparation method of the Cu1.8S-based polycrystalline block thermoelectric material, disclosed by the invention, has the advantages of low cost of needed raw materials, simple equipment, easiness for operation and remarkable effect.

Owner:陕西天璇涂层科技有限公司

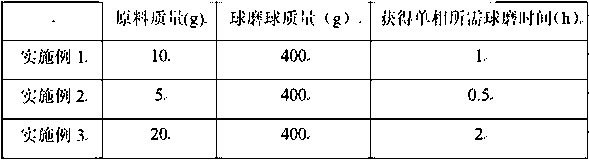

Method of preparing n-type counterfeit ternary erbium-doped thermoelectric material by utilizing mechanical alloying cold pressing sintering method

InactiveCN102925729AAchieve compoundImprove mechanical propertiesThermoelectric device manufacture/treatmentRare-earth elementThermoelectric materials

The invention discloses a method of preparing an n-type counterfeit ternary erbium-doped thermoelectric material by utilizing a mechanical alloying cold pressing sintering method, and relates to a method of preparing a thermoelectric material. The invention solves the technical problems of easiness in separation, poor mechanical property and high material cost of the conventional thermoelectric material. The method comprises the following steps of: 1, mixing a simple substance Bi, a simple substance Sb, a simple substance Te and a simple substance Se, adding a rare earth element Er, and ball-milling to obtain alloy powder; 2, cold-pressing the alloy powder to a block at room temperature; 3, placing the cold-pressing block obtained in the step 2 into a high-temperature-resistant glass tube, sintering, and cooling to room temperature along with a furnace so as to obtain the n-type counterfeit ternary erbium-doped thermoelectric material. The material, prepared by the method in the invention, has a thermoelectromotive force rate close to an oriented crystal, according to the national departmental standard, the Seebeck coefficient of the material is tested to reach 200 muVK<-1>, the conductivity is 55 omega<-1>cm<-1>, and a power factor is close to 2 muWcm<-1>K<-2>.

Owner:HARBIN NORMAL UNIVERSITY

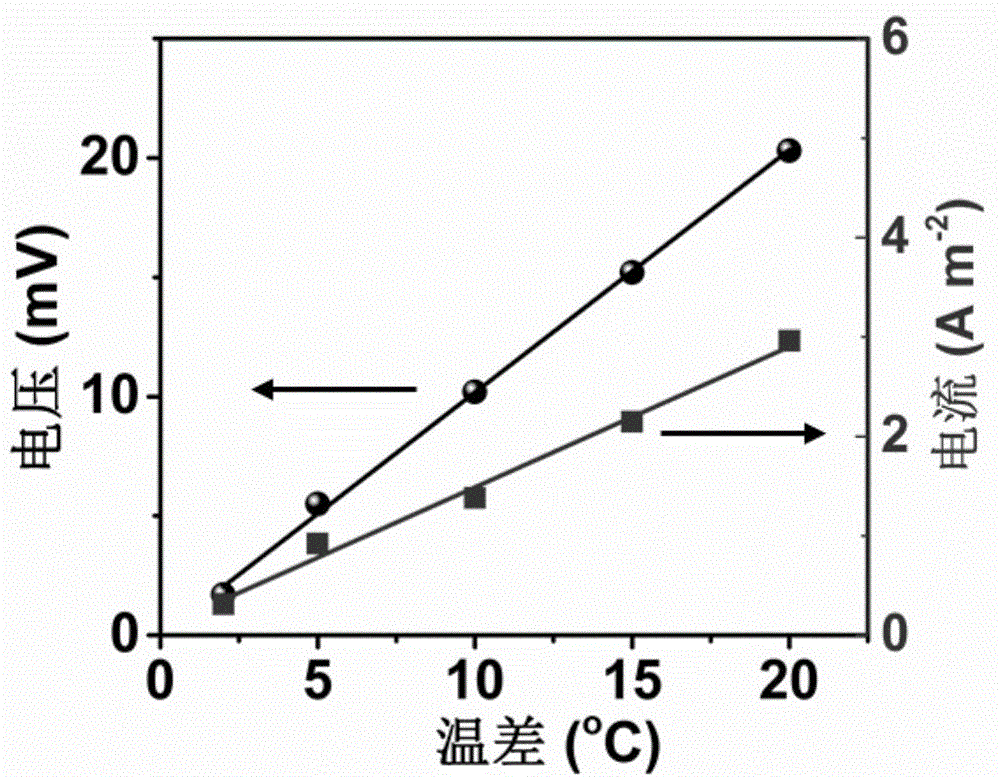

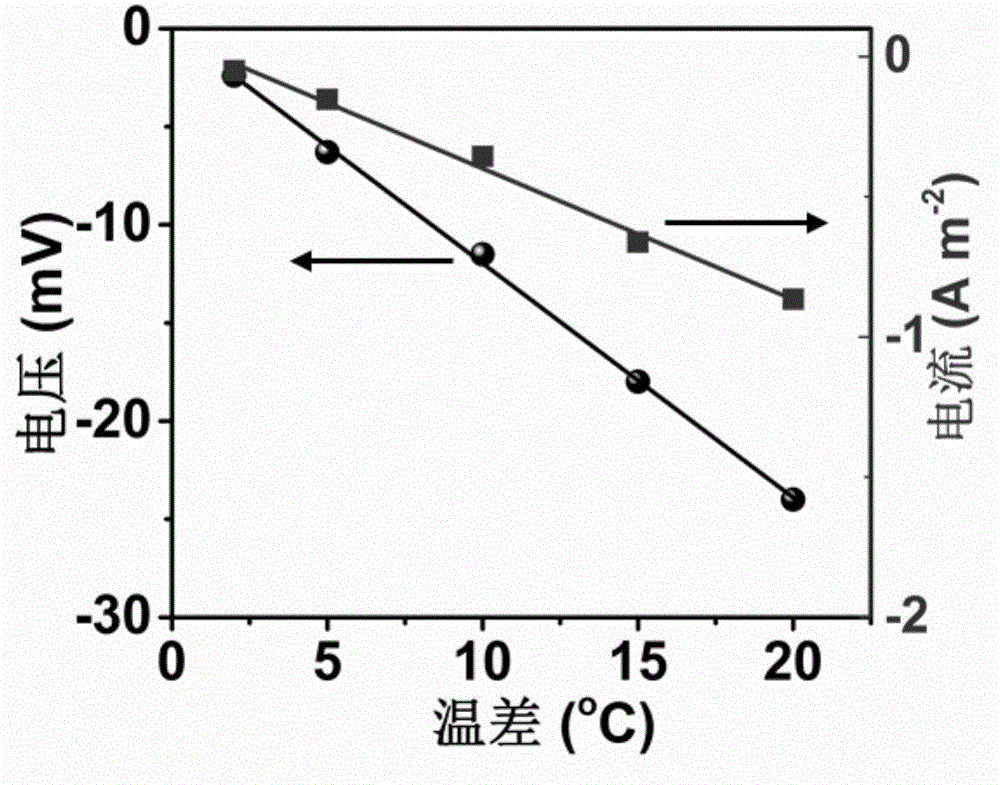

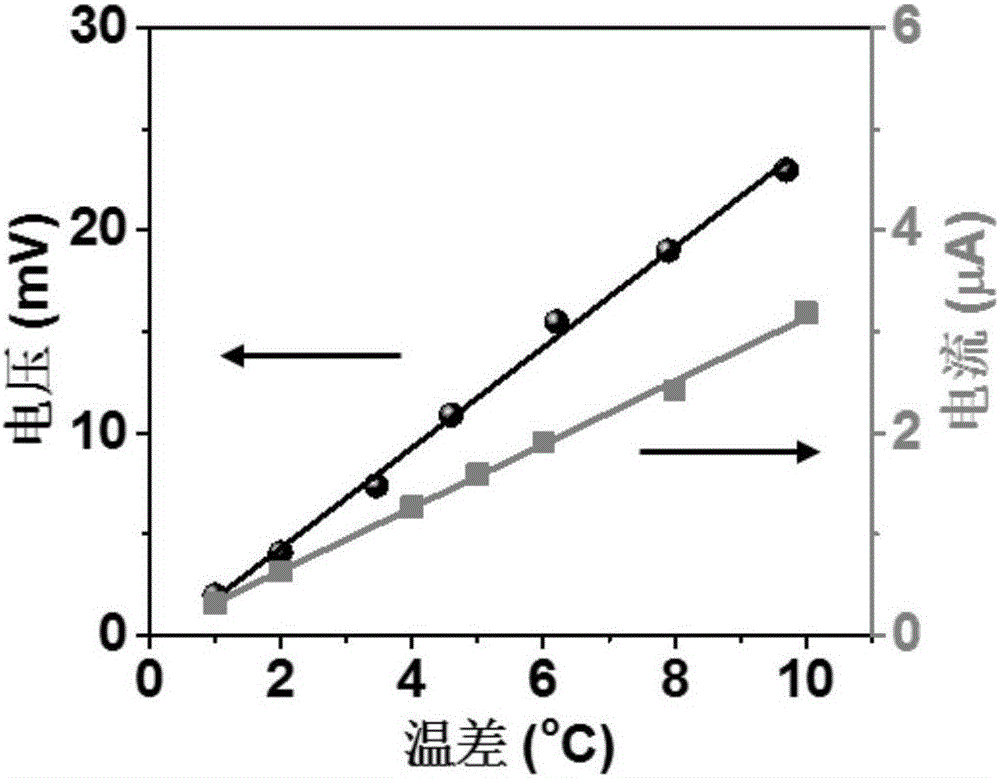

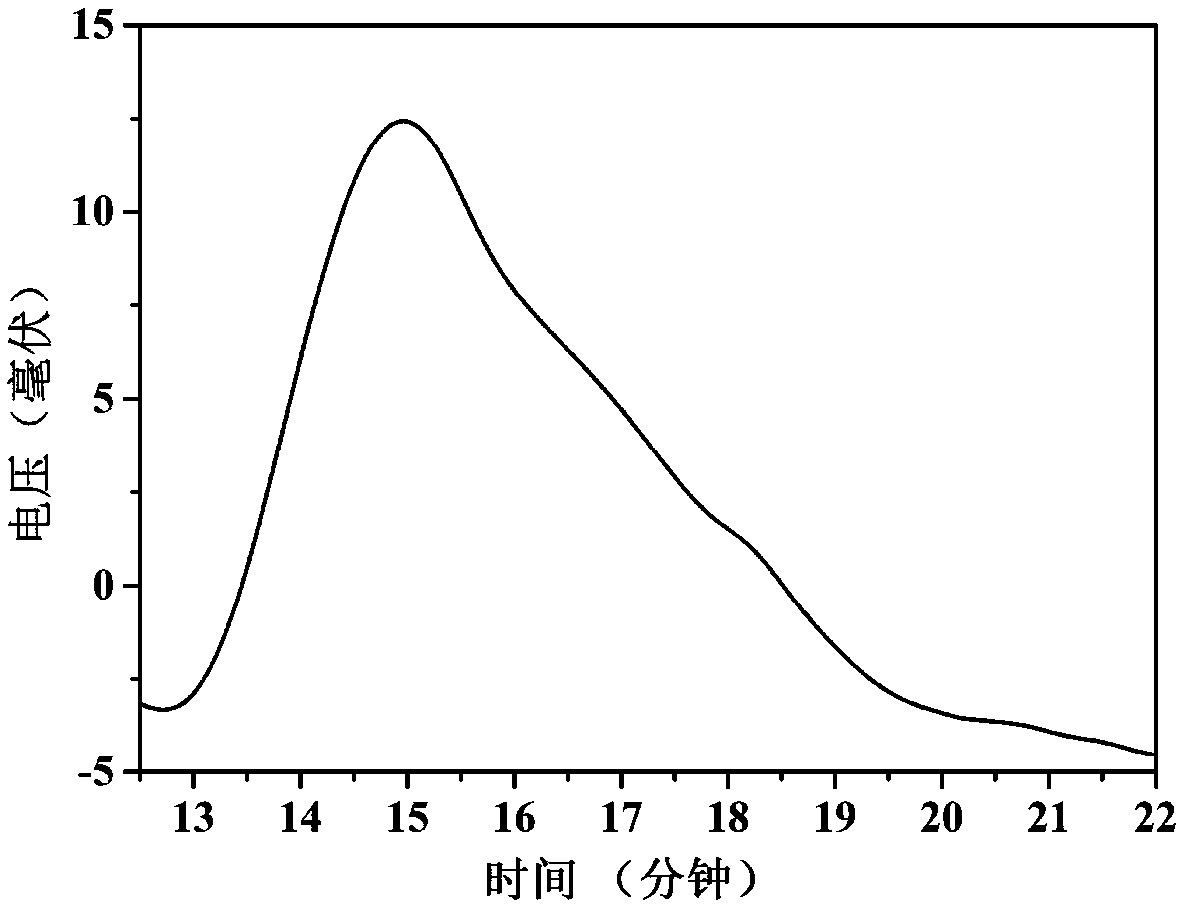

Preparation methods for thermoelectric colloid material and thermoelectric device, and product

InactiveCN106299102AEasy to packageImprove Seebeck coefficientThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentFlexible electronicsSolid-state

The invention discloses preparation methods for a thermoelectric colloid material and a thermoelectric device, and a product. After a polymer solution is mutually mixed with a redox electrolyte, a product is subjected to curing process to prepare the thermoelectric colloid; the thermoelectric colloid regulates and controls a thermoelectric-chemical Seebeck coefficient and thermoelectric output performance by changing the redox electrolyte; the thermoelectric colloid has flexible and tensile characteristics, so that the thermoelectric colloid can be prepared into a required solid-state shape through a mould; the solid-state thermoelectric colloid is applicable to large-area packaging and integrating; the thermoelectric device is prepared by packaging and integrating the thermoelectric colloid and electrodes; and by adoption of the thermoelectric device, low-dimension heat energy can be effectively converted into electric energy, so that the thermoelectric device has wide application prospect in flexible electronic devices and wearable equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

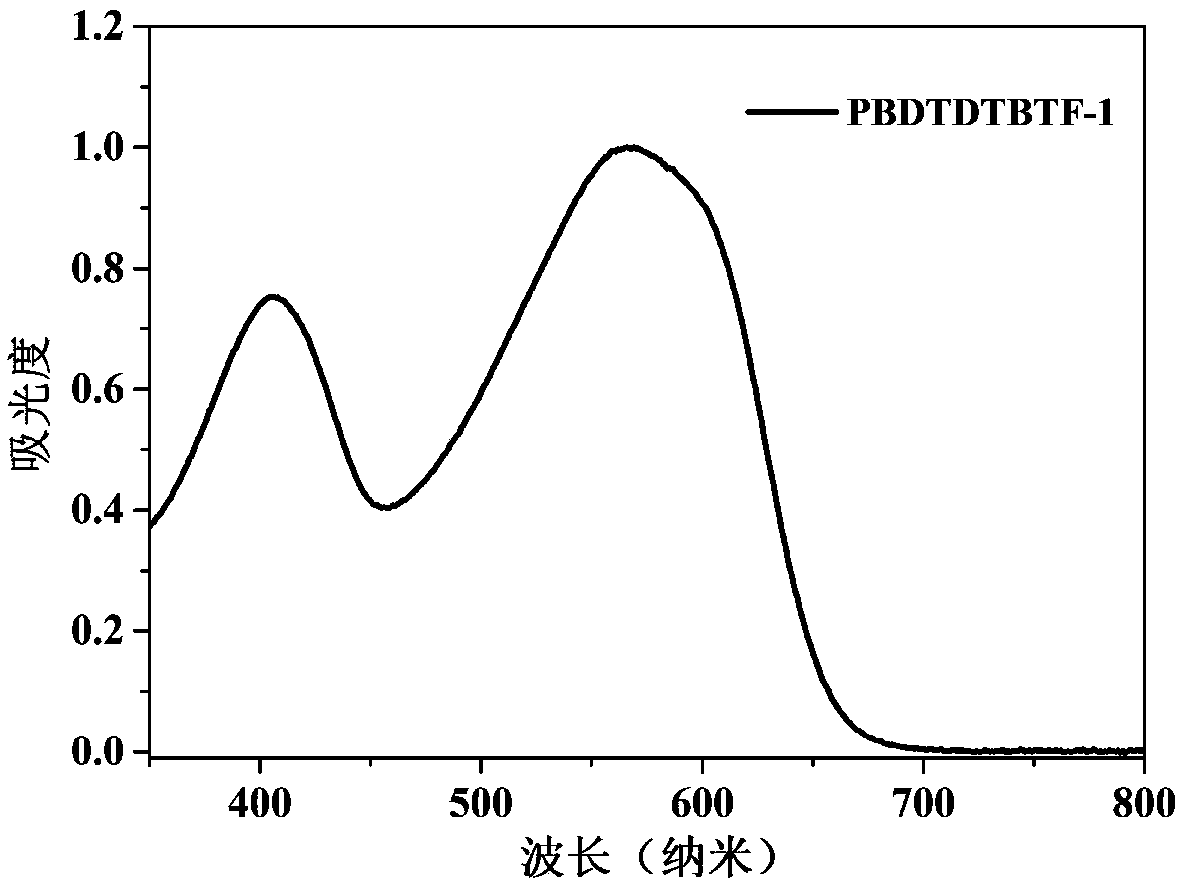

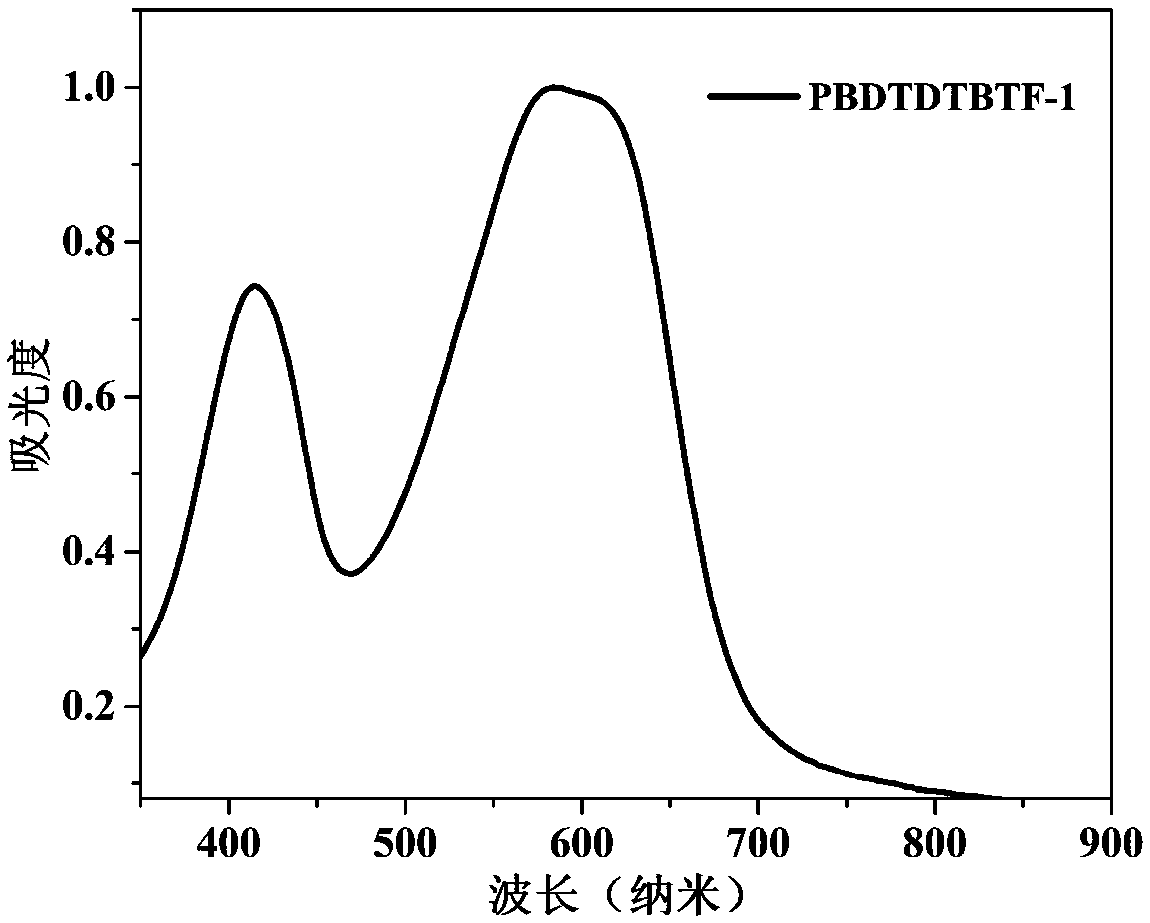

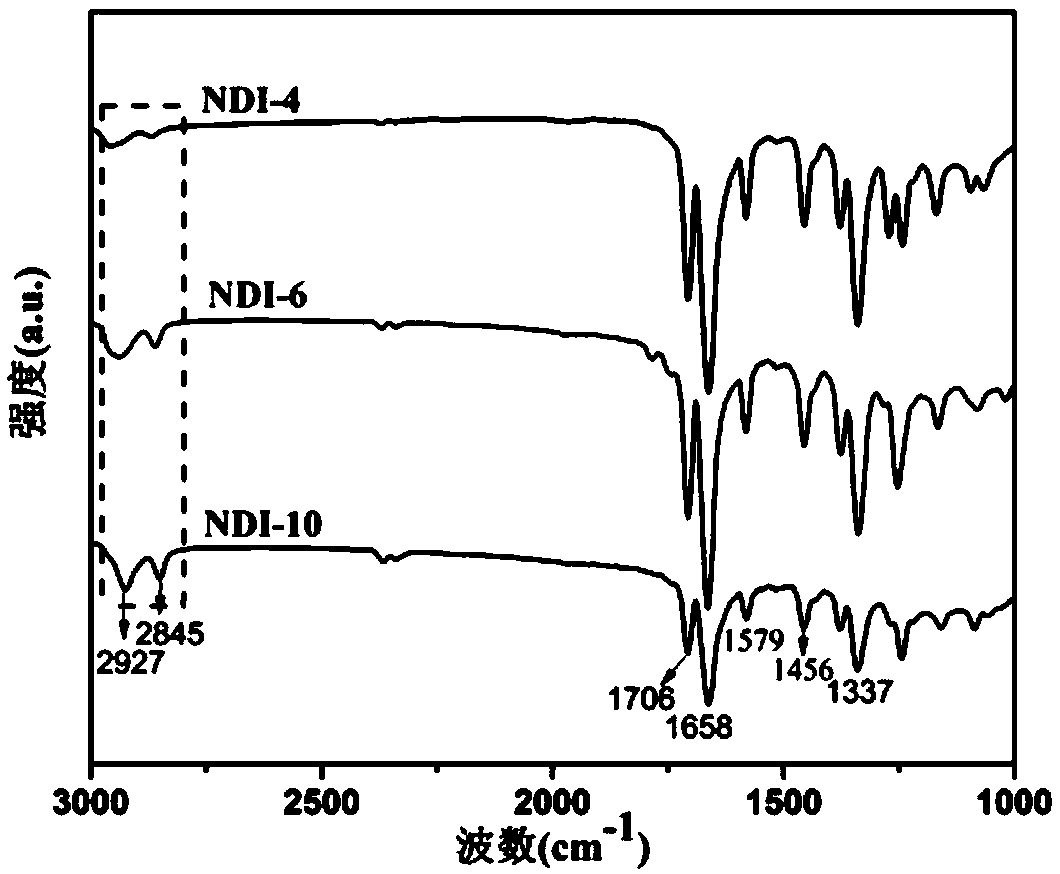

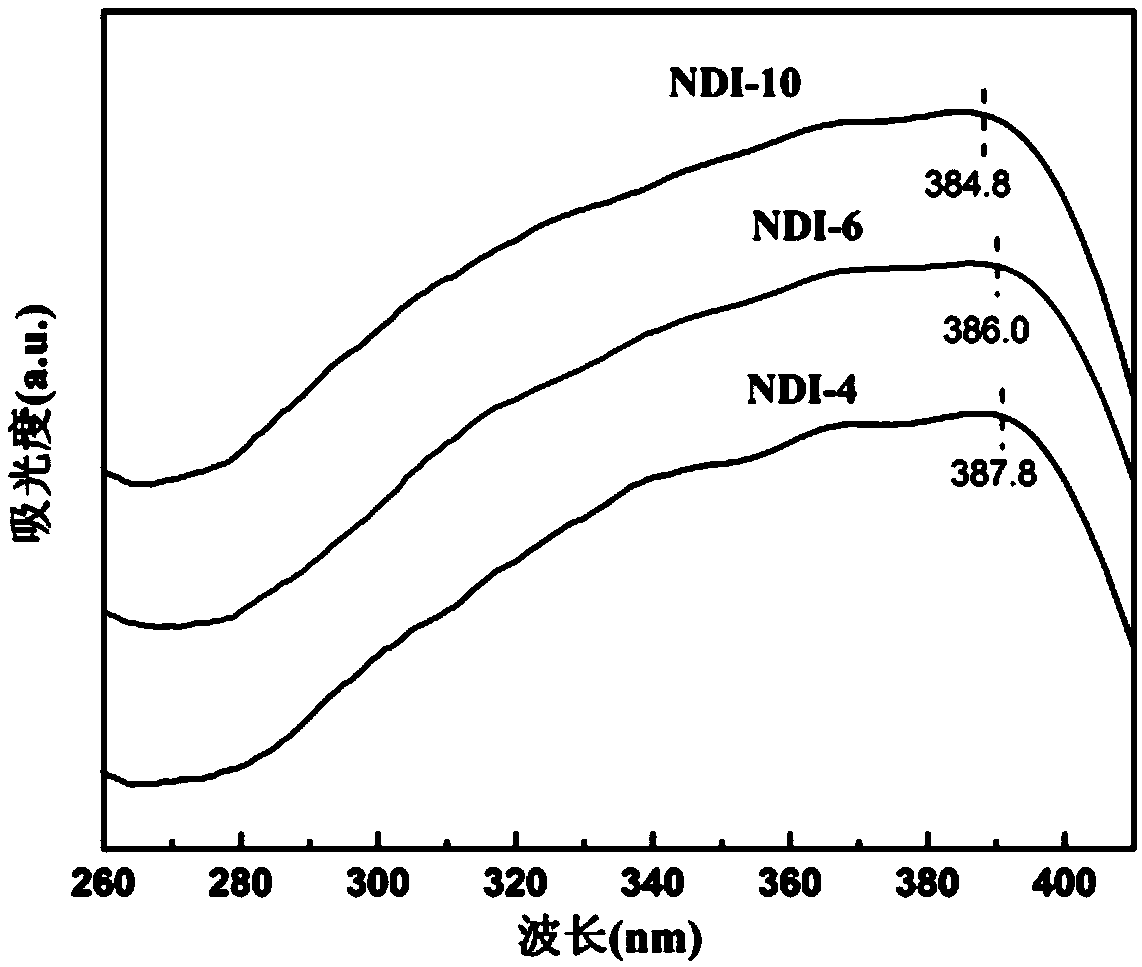

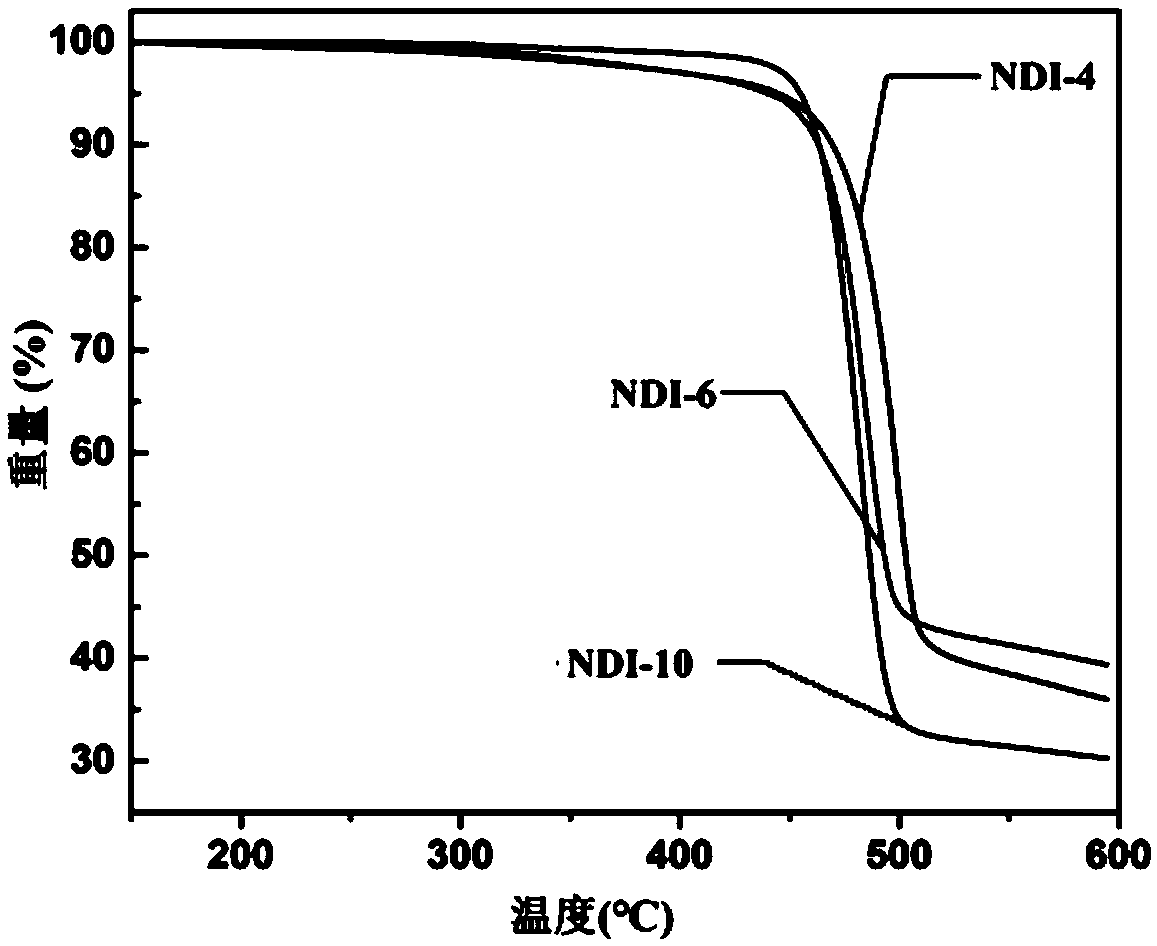

D-A type conjugated polymer organic thermoelectric thin film material and preparation method thereof

The invention discloses a D-A type conjugated polymer organic thermoelectric thin film material and a preparation method thereof. The chemical structural formula of the organic thermoelectric thin film material is as shown in specification, wherein X is one of oxygen atoms, thiophene and thienothiophene, and n is an integer from 40 to 70. The provided organic thermoelectric thin film material is easily dissolved in common organic solvents such as tetrahydrofuran, dichloromethane, trichloromethane and chlorobenzene, and therefore, the organic thermoelectric thin film material has good solutionmachinability. In addition, the D-A type conjugated polymer organic thermoelectric thin film material further has high Seebeck coefficients and thermoelectric property, and meanwhile also has good flexibility, and thus, the organic thermoelectric thin film material is expected to be used in flexible wearable thermoelectric equipment; and moreover, the preparation method of the D-A type conjugatedpolymer organic thermoelectric thin film material is simple and easy to implement, and the cost is low.

Owner:SHENZHEN UNIV

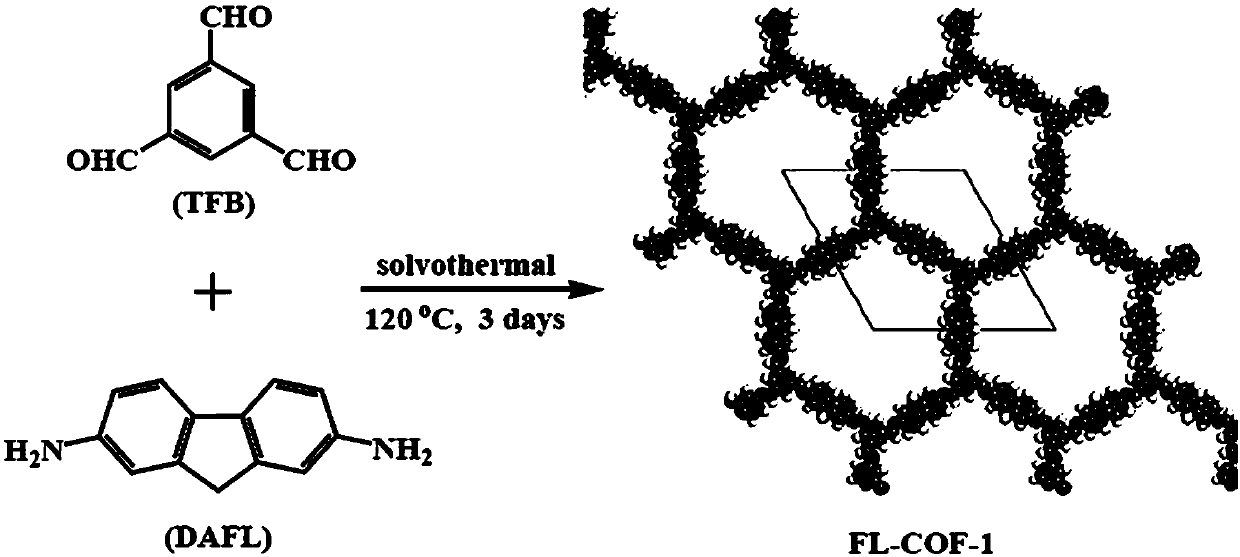

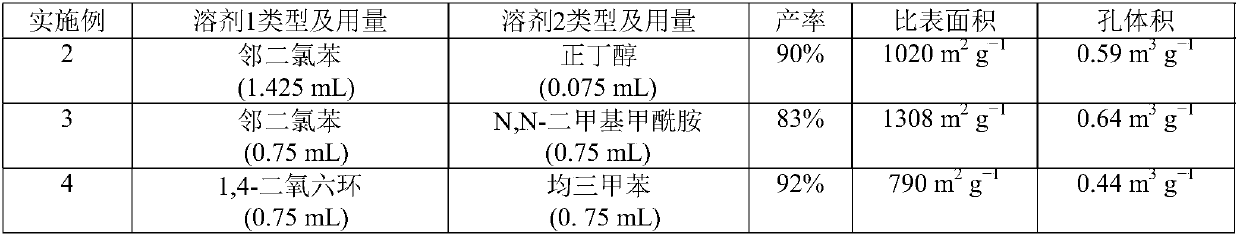

Fluorine-functionalized covalent organic framework material as well as preparation and thermoelectric application thereof

The invention discloses preparation of a fluorine-functionalized covalent organic framework material and an application technology of the material in the thermoelectric field. Organic micromolecular elements are polymerized orderly through a Schiff-base condensation reaction with a solvent synthesis method to form a covalent bond connected crystal structure material. The covalent organic frameworkpolymer is synthesized for the first time, and the material has the advantages that the material has permanent open pore structure and very good thermal stability, tolerates iodine doping, shows ultrahigh seebeck coefficients and good thermoelectric performance at the room temperature for the first time and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

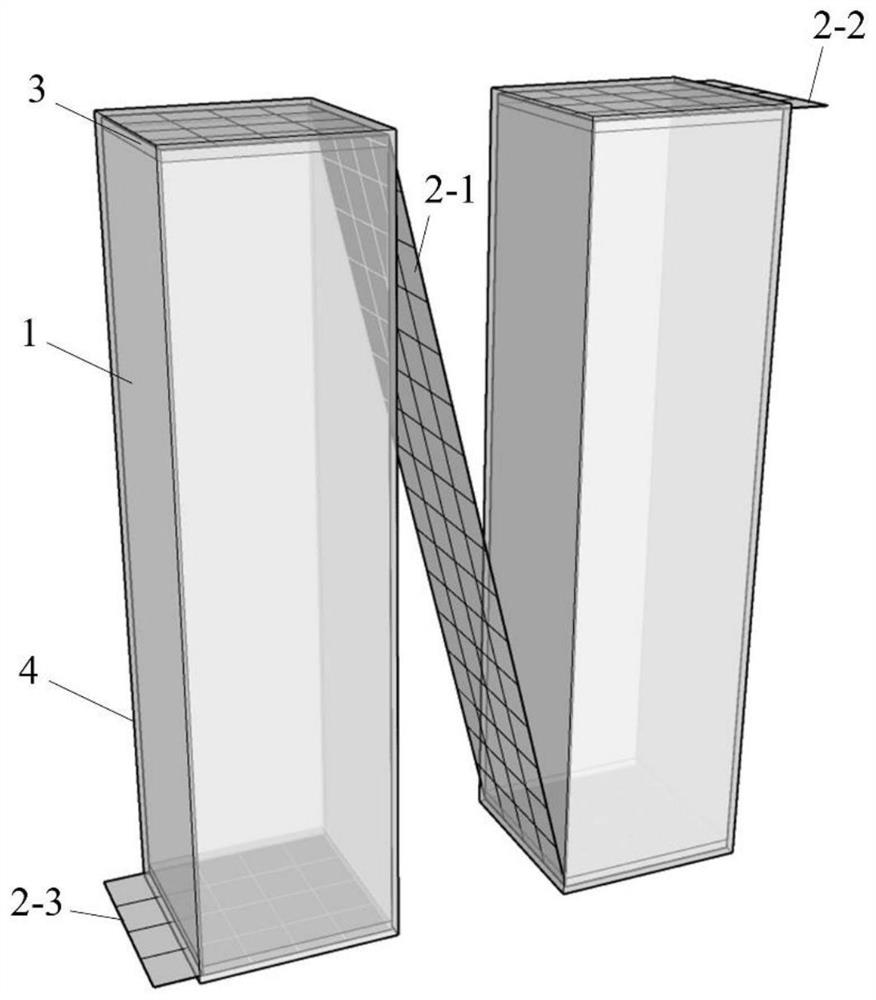

Cement concrete pavement energy conversion device and preparation method thereof

ActiveCN112047675ASignificant thermoelectric effectImprove Seebeck coefficientThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEpoxyHeat energy

A cement concrete pavement energy conversion device disclosed by the invention is based on a graphene reinforced cement-based composite material, can convert heat energy into electric energy under theaction of temperature difference by utilizing the thermo-electric effect of the graphene reinforced cement-based composite material, and is suitable for energy collection and conversion of cement concrete pavements. The invention further provides a preparation method of the cement concrete pavement energy conversion device, the dried graphene-reinforced cement-based composite material is used forprocessing and preparing the conversion units, the upper surfaces and the lower surfaces of the conversion units are coated with the conductive silver paste, and the conductive copper nets are inserted into the conversion units to prepare the electrodes; the positive conductive copper net and the negative conductive copper net are connected with the positive electrode and the negative electrode of an external circuit, and the outer surface of the structure is coated with epoxy resin by a roller to finish a anti-seepage treatment. Heat energy in the cement pavement slab can be converted into electric energy, so that energy conversion of the cement concrete pavement is achieved, and the device has the advantages of being high in Seebeck coefficient, stable in thermo-electric performance, simple in preparation process, expandable in structure and coordinated with deformation of the cement pavement slab.

Owner:TSINGHUA UNIV +1

Method for preparing SiGe thermoelectric material

InactiveCN108258110APrevent oxidationRapid alloyingThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsAlloy

The invention discloses a method for preparing a SiGe thermoelectric material. According to the method, Si powder, Ge powder, B powder or P blocks are mixed according to a determined molar ratio; obtained mixtures are loaded into hard steel ball mill tanks under the protection of an Ar inert atmosphere; ball-milling and alloying are performed on the mixtures through using a planetary ball mill, sothat single-phase SiGe thermoelectric material powder is obtained; the single-phase SiGe thermoelectric material powder is subjected to discharge plasma sintering at 1150 DEG C, so that dense blockscan be obtained. The P type and N type SiGe alloy prepared by the method for preparing the SiGe thermoelectric material of the present invention have high electrical conductivity, high Seebeck coefficients and high power factors. The method for preparing the SiGe thermoelectric material of the invention has the advantages of high synthesis speed, simplicity, convenience, high efficiency and wide application prospect.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Preparation method for composite aerogel thermoelectric material

ActiveCN109301060AIncreased energy filter effectRaise SeebeckThermoelectric device manufacture/treatmentThermoelectric materialsAqueous solution

The invention relates to a preparation method for a composite aerogel thermoelectric material. With the preparation method adopted, the technical problems of conductivity increase during the compounding of PEDOT, a carbon material and an inorganic material and the decrease of the overall conductivity of aerogel can be solved. The method includes following steps that: (1) bacterial cellulose and EDOT monomer are mixed in an aqueous solution at a mass ratio of 1: (9-11), and an obtained solution is fully stirred, and a 1.35 to 3.51 mmol of Fe<3+> aqueous solution is added into the solution, andthe solution is fully stirred for 24 to 48 hours, and is washed with HCL and deionized water, so that a composite material mixed liquid can be prepared; (2) the prepared solution is mixed with nano-conductive fillers with different proportions of content, stirring and ultrasonic treatment are carried out, so that an obtained solution is frozen at -10 to -50 DEG C, and the solution is subjected tovacuum freezing and drying, so that the aerogel can be obtained; and (3) the aerogel obtained in the step (2) is treated with a powder tableting machine, so that a BC-PEDOT multi-component composite sheet having a pore structure is obtained. The method of the invention is widely used in the field of thermoelectric material preparation.

Owner:BEIJING UNIV OF CHEM TECH

Thermoelectric material and preparation method thereof

ActiveCN110690341AIncrease powerImprove performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermodynamicsChalcopyrite

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

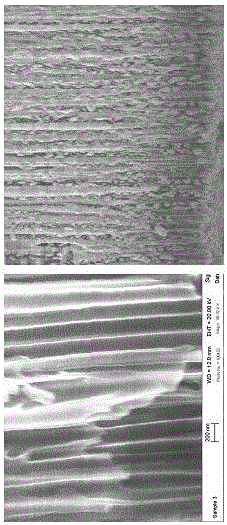

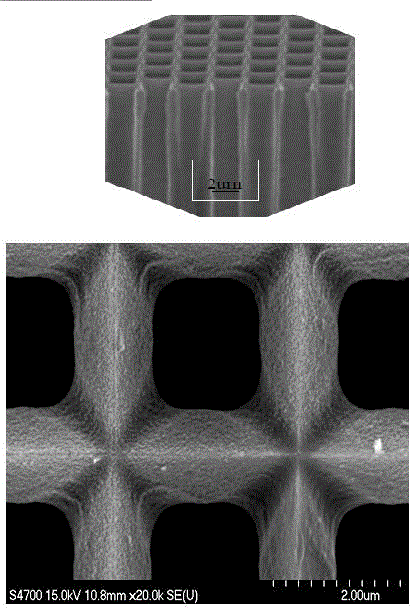

High-temperature quantum well super-lattice thick film thermoelectric material and production method thereof

InactiveCN106784287AImprove performanceHigh thermoelectric figure of meritMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsQuantum well

The invention discloses a production method for a high-temperature quantum well super-lattice thick film thermoelectric material. The production method comprises the following steps: growing a thermoelectric material on a porous silicon, porous aluminium oxide or doped silicon substrate through an atomic layer deposition method, wherein the thermoelectric material can grow from the inner walls of pores and then grow radially layer by layer to the centres of the pores so as to generate a thick film super-lattice thermoelectric material. A base thermoelectric material is SiGe. According to the production method for the high-temperature quantum well super-lattice thick film thermoelectric material, the super-lattice thermoelectric material which is applicable to high-temperature application is synthesized quickly through a chemical method by utilizing an atomic layer deposition method and taking a porous template as a substrate, so that high merit figure and high thermoelectric conversion efficiency are realized. The high-temperature thermoelectric material can be quickly produced on a doped or curved conductive substrate under a non-vacuum condition; the thermoelectric material has set thickness and a quantum well super-lattice structure, and is particularly suitable for high temperature, that is, the using temperature range is 700 to 1,100 DEG C.

Owner:滁州玛特智能新材料科技有限公司

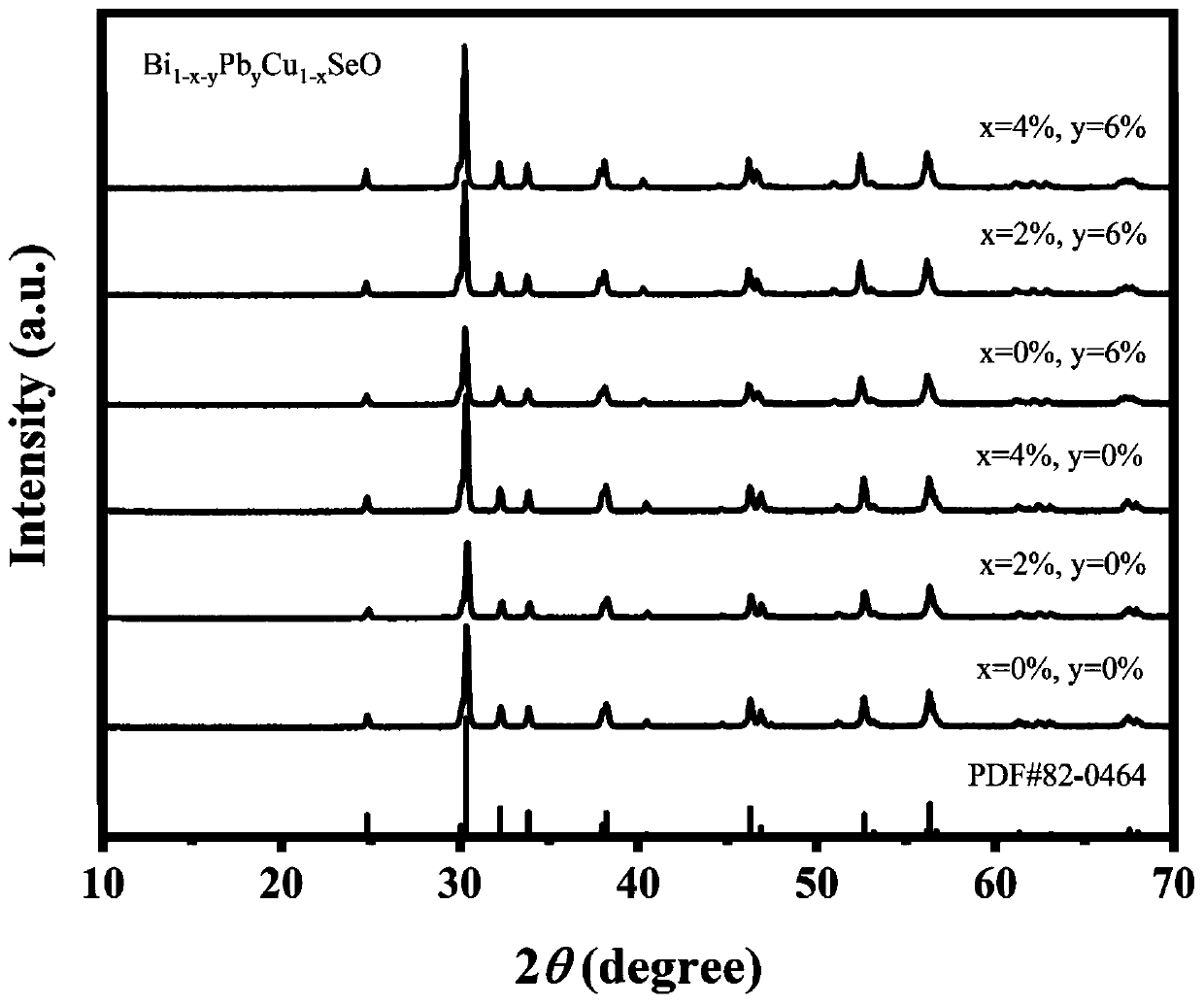

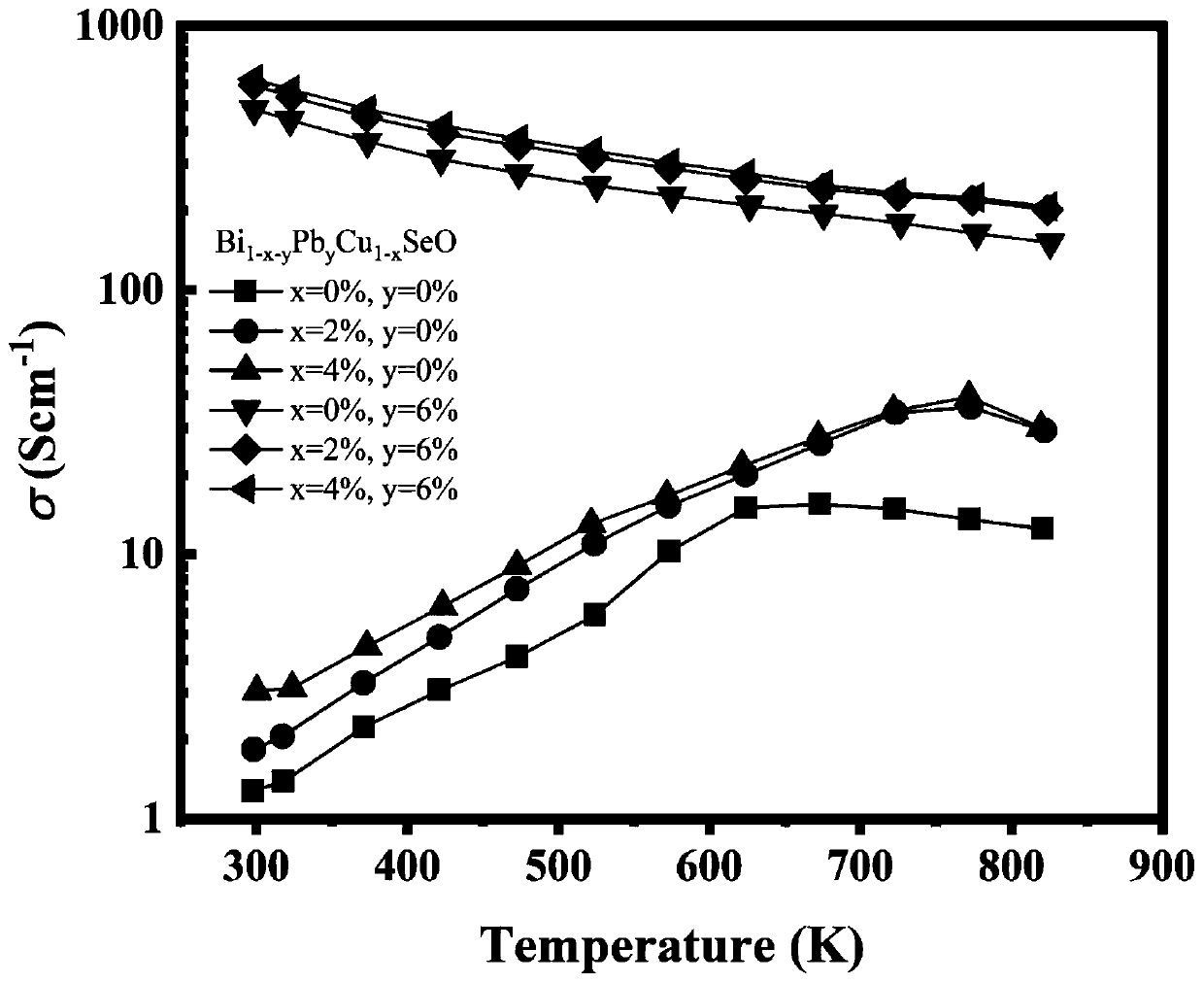

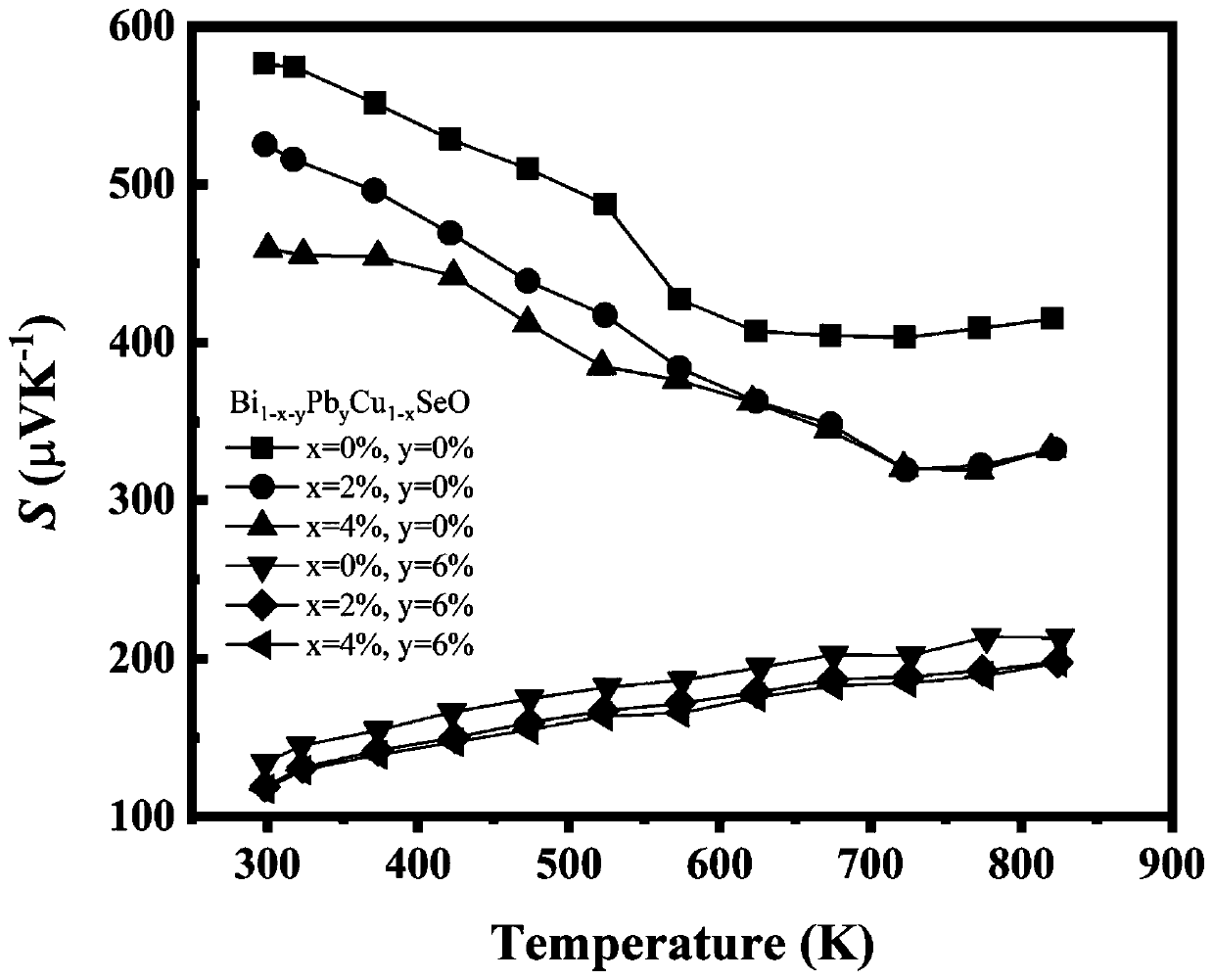

High-performance BiCuSeO-base thermoelectric material and preparation method thereof

ActiveCN110350074AImprove conductivityImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsMaterials scienceChemical formula

The invention provides a high-performance BiCuSeO-base thermoelectric material and a preparation method thereof. The thermoelectric material has a chemical formula I: Bi<1-x-Y>A<y>Cu<1-x>SeO, whereinA is selected from Ca, Sr, Ba or Pb0<x<=0.04, and 0<=y<=0.15. According to the thermoelectric material provided by the invention, Bi and Cu double vacancies are introduced, and then an interlayer charge transfer channel is constructed; after an element A (A is Ca, Sr, Ba or Pb) is doped into a Bi site, the conductivity of the material is remarkably improved by means of the interlayer charge transfer channel constructed by Bi / Cu double vacancies; meanwhile, a larger Seebeck coefficient is maintained, so that the thermoelectric performance of the material is improved.

Owner:UNIV OF SCI & TECH OF CHINA

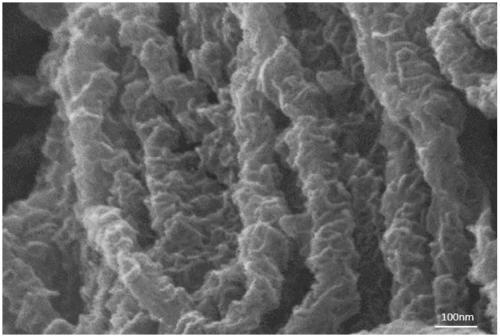

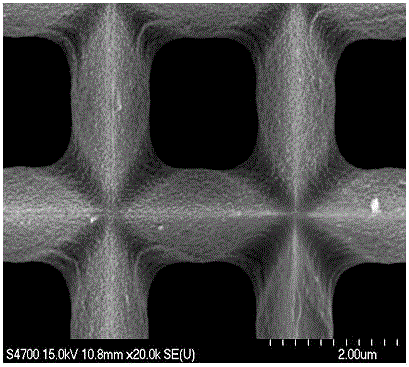

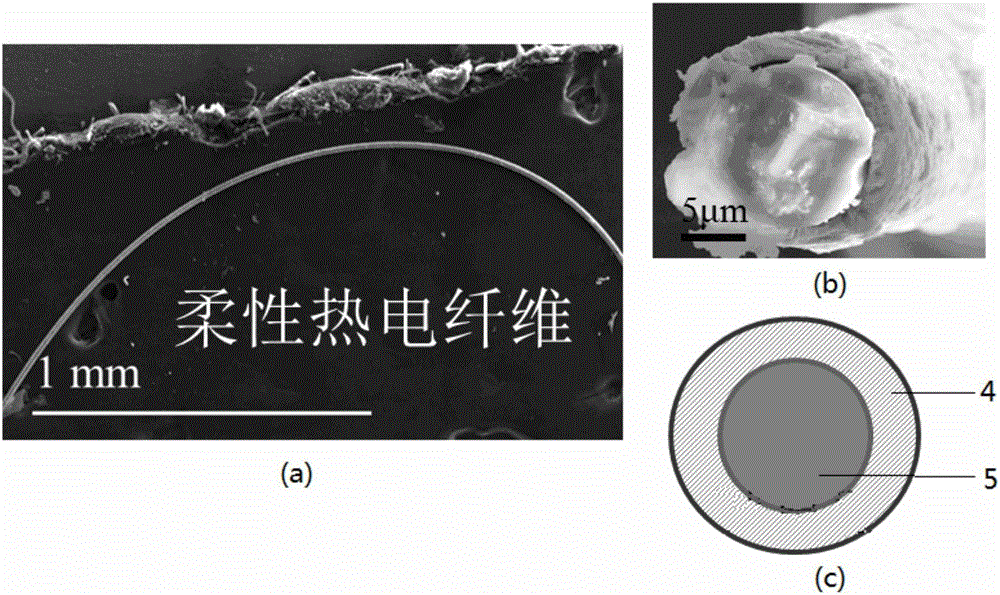

Glass fiber/Bi2Te3 thermoelectric thin-film composite material and preparation method thereof

InactiveCN105789424AImprove flexibilityImprove bending resistanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsCelluloseFiber

The invention relates to the field of composite materials, in particular to a glass fiber / Bi2Te3 thermoelectric thin-film composite material and a preparation method thereof. The composite material can be applied to the aspects of a flexible energy device, a miniature sensor and the like. The composite material comprises a glass fiber substrate and a Bi2Te3 thermoelectric thin-film layer, wherein the Bi2Te3 thermoelectric thin-film layer is evenly deposited on the surface of the cellulose paper substrate to form a core-shell structure; the diameters of glass fibers are 5-10 microns; the thickness of the Bi2Te3 thermoelectric thin-film layer is 1-2 microns; and the film layer is compact in structure and good in combination with the surfaces of the glass fibers. The glass fiber / Bi2Te3 thermoelectric thin-film composite material is prepared by an unbalanced magnetron deposition technology; a Bi2Te3 deposited layer has a compact structure of nanoscale grains and is uniform and adjustable in thickness; and the thermoelectric properties are close to those of a commercial block material. Due to the scale effect of the thin-film material, the fiber / thermoelectric composite material demonstrates good bending resistance and can be applied to the fields of the flexible energy device, the miniature sensor and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Five element n-type thermoelectric material realizing powder alloy sintering phase transformation based on crystal topology and preparation method thereof

ActiveCN108649115AMethod securityEasy to achieve high-volume industrial productionThermoelectric device manufacture/treatmentThermoelectric device junction materialsAlloyHigh conductivity

The invention relates to a five element n-type thermoelectric material realizing powder alloy sintering phase transformation based on crystal topology and a preparation method thereof. The chemical formula of the n-type thermoelectric material is Bi<2-x-y>Sb<x>S<y>Te<3-z>Se<z>, wherein the x is greater than or equal to 0.74 and less than or equal to 1.2, y is greater than or equal to 0.04 and lessthan or equal to 0.06, z is greater than or equal to 0.2 and less than or equal to 0.45. Compared with other n-type thermoelectric materials, the five element n-type thermoelectric material disclosedby the invention undergoes the transformation of p-type alloy to p-type powder alloy embryo material to n-type thermoelectric material in the preparation process, therefore, the finally obtained fiveelement n-type thermoelectric material has the advantages of high Seebeck coefficient, high conductivity, low thermal conductivity, high ZT value and excellent thermoelectric performance.

Owner:LEIZIG GUANGDONG THERMOELECTRIC TECH CO LTD

An organic composite thermoelectric film and a preparation method thereof

ActiveCN109244228AImprove Seebeck coefficientImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsMaterials scienceThermoelectric thin film

The invention discloses an organic composite thermoelectric film and a preparation method thereof, wherein the organic thermoelectric thin film comprises an organic thermoelectric material having thechemical formula (shown in the description), wherein n is 2, 3 or 5, and m is a natural number between 40 and 70; The organic thermoelectric material has high Seebeck coefficient and thermoelectric performance, and also has high carrier mobility, which makes the organic composite thermoelectric film prepared by the invention have excellent air stability and thermal stability; The preparation method provided by the invention is simple, easy to realize and low in cost.

Owner:SHENZHEN UNIV

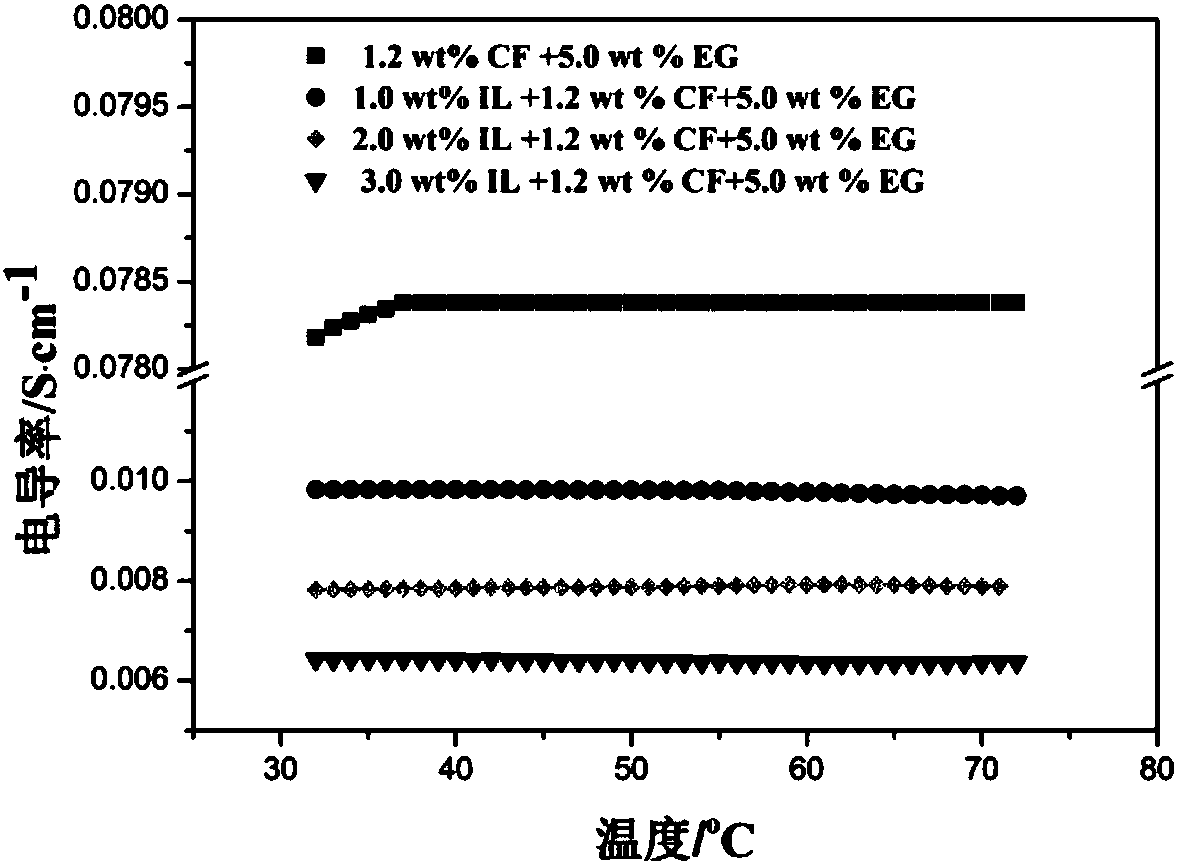

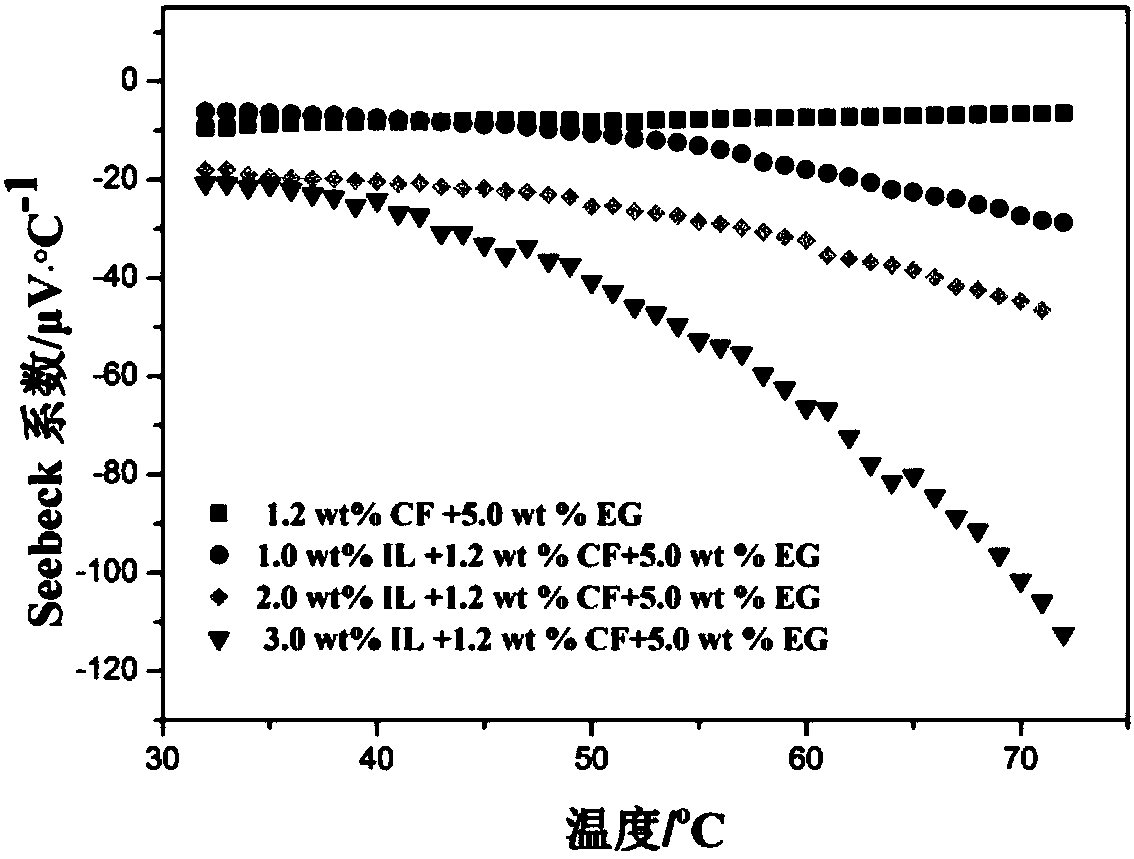

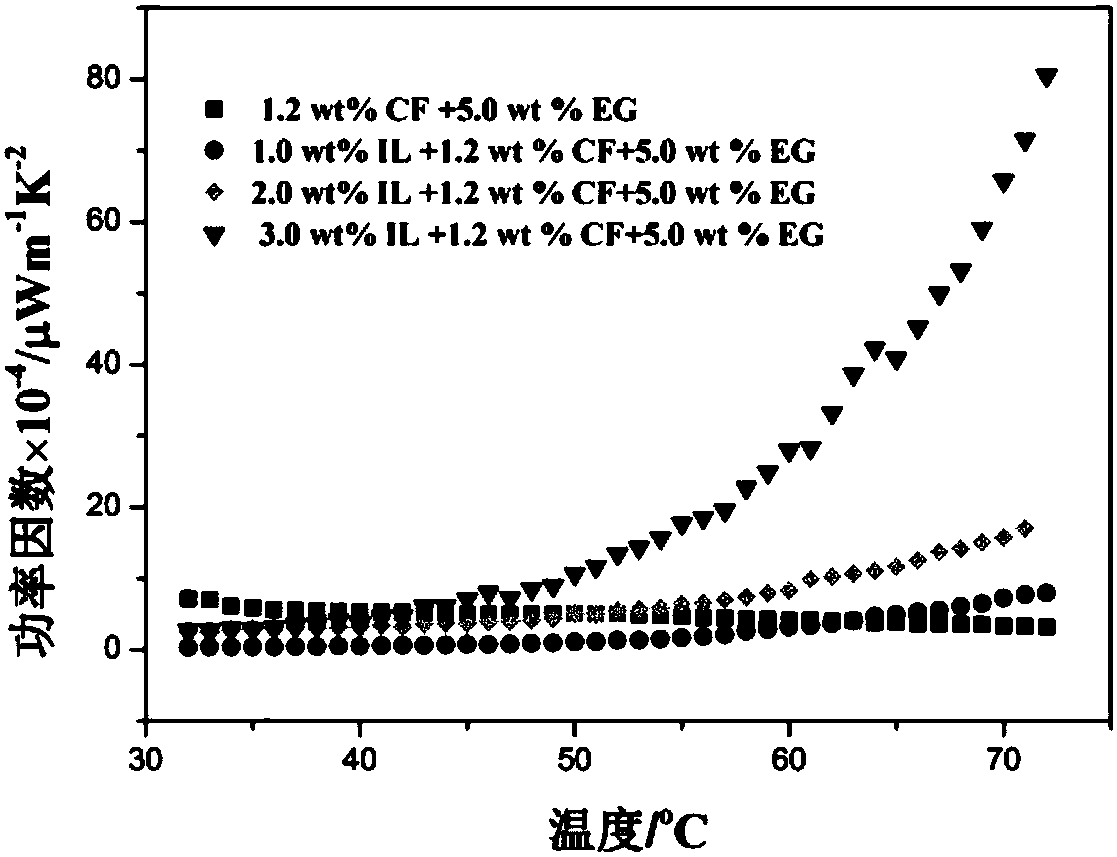

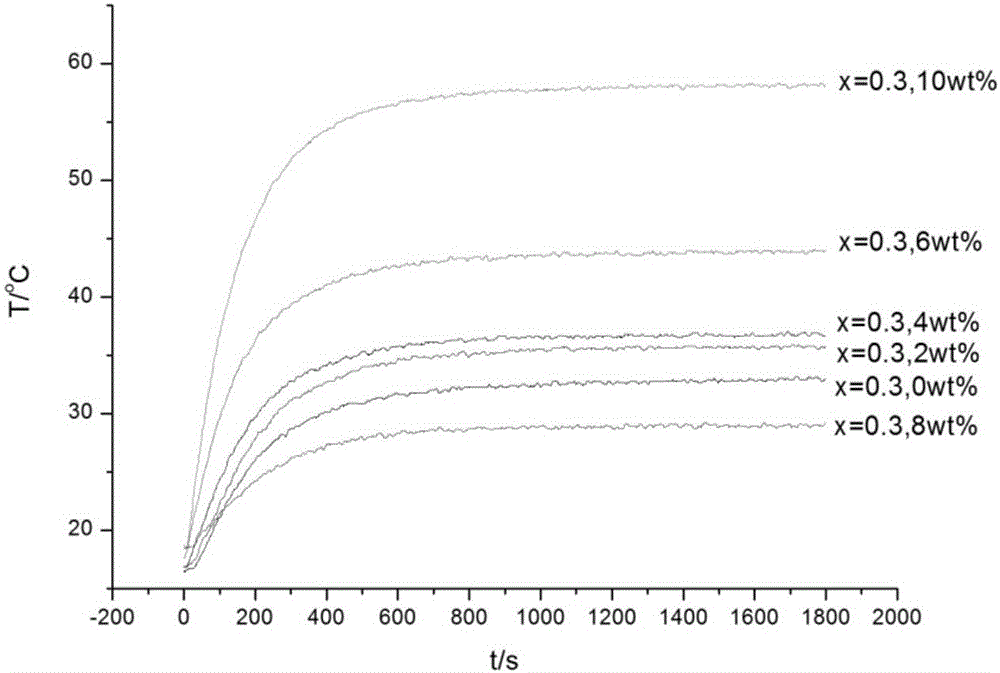

Method for improving thermoelectric properties of cement-based composite material by ionic liquid

Provided is a method for improving thermoelectric properties of a cement-based composite material by an ionic liquid. In the process of preparation of the cement-based composite material, the ionic liquid 1-butyl-3-methyl imidazolium bromide ([Bmim]Br) is added. The ionic liquid 1-butyl-3-methyl imidazolium bromide ([Bmim]Br), a carbon fiber, expanded graphite, sulphoaluminate cement and water areevenly mixed by a stirring process, and the mixture is pressed to form the cement-based composite material. The prepared cement-based composite material has the characteristics of high Seebeck coefficient, good thermoelectric property, low cost, simple production process and the like. In the case of greatly increasing the Seebeck coefficient, due to high ionic migration rate of the used ionic liquid, the electrical conductivity of the cement-based composite material is still up to 0.078 S / cm, and the thermoelectric properties of the cement-based composite material are significantly improved.The steps of pretreating the cement-based composite material at the temperature of 80 DEG C can realize uniform distribution of the ionic liquid in the cement base, and the Seebeck coefficient and thethermoelectric properties of the cement-based composite material are further enhanced.

Owner:西安华清科教产业(集团)有限公司

Graphene oxide/molybdenum disulfide composite thermoelectric material and preparation method thereof

ActiveCN110364615AImprove energy filtering effectConductivity can be maintainedThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsFilter effect

The invention provides a preparation method of a graphene oxide / molybdenum disulfide composite thermoelectric material, which comprises the steps of S1) mixing graphene oxide and molybdenum disulfidenanosheets in water, and performing ultrasonic treatment to obtain a mixed system; S2) coating the mixed system on a base material, drying at a low temperature to obtain the graphene oxide / molybdenumdisulfide composite thermoelectric material; or filtering the mixed system to obtain the graphene oxide / molybdenum disulfide composite thermoelectric material. Compared with the prior art, the molybdenum disulfide nanosheet layer is added into the graphene oxide nanosheet layer, the energy filtering effect in the obtained composite thermoelectric material can be improved, the electric conductivityof the composite material can be continuously maintained, the thermal conductivity can be continuously reduced, the Seebeck coefficient of the composite thermoelectric material is improved, and the ZT value of the composite thermoelectric material is greatly increased. In addition, the graphene oxide / molybdenum disulfide composite thermoelectric material obtained according to the invention has adjustable P-N thermoelectric characteristics.

Owner:THE HONG KONG POLYTECHNIC UNIV

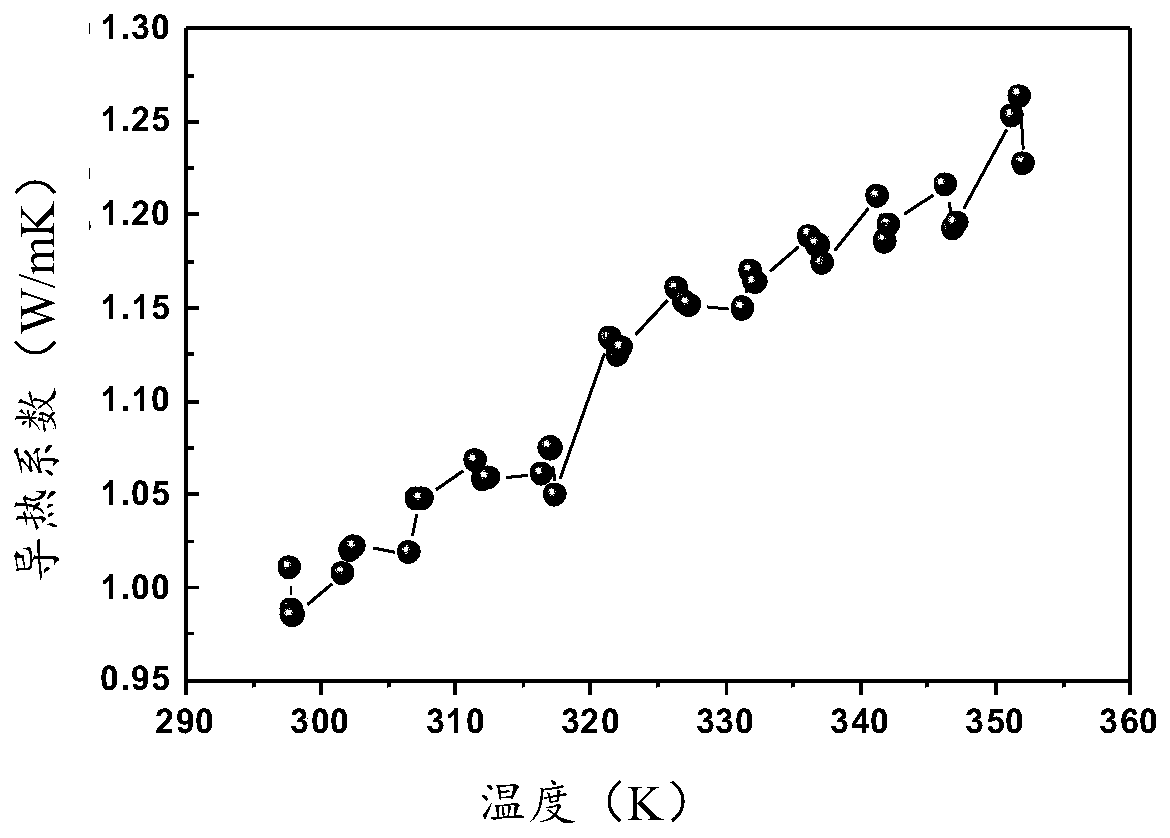

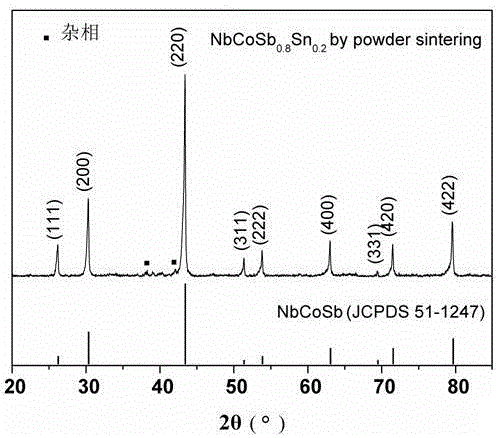

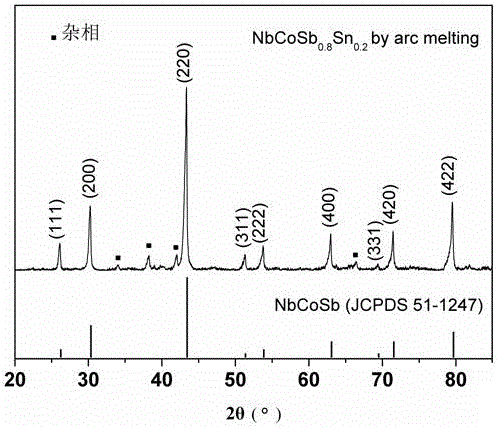

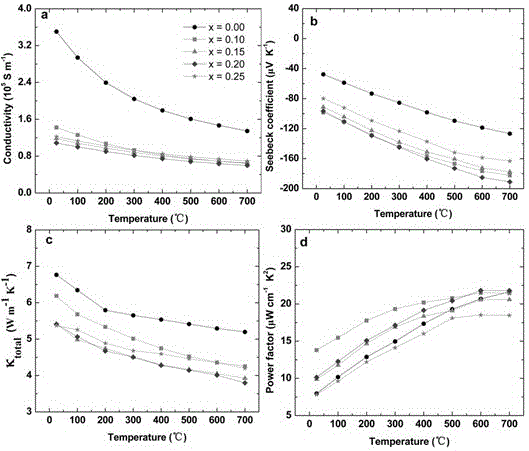

19-valence-electron n-type NbCoSbSn thermoelectric material and preparation method thereof

InactiveCN106756423ALow thermal conductivityImprove Seebeck coefficientValence electronElectron doped

The invention relates to the field of semiconductor thermoelectric materials, in particular to a 19-valence-electron n-type NbCoSbSn thermoelectric material and a preparation method thereof. The chemical formula of the 19-valence-electron n-type NbCoSbSn thermoelectric material is NbCoSb1-xSnx, wherein X is equal to 0.01-0.4. After raw materials are selected according to an amount-of-substance ratio, the 19-valence-electron n-type NbCoSbSn thermoelectric material can be obtained after mixing and cool pressing, vacuum sealing, solid state sintering, solid block pulverizing and quick thermocompression are carried out, and can also be obtained after electric arc fusion, the solid block pulverizing and the quick thermocompression are carried out. A physical unit cell of the 19-valence-electron n-type NbCoSbSn thermoelectric material is internally provided with 19 valence electrons, the prior theoretical conception is broken through, a new material is developed, and the 19-valence-electron n-type NbCoSbSn thermoelectric material has innovative significance. Through Sn doping / alloying, compared with NbCoSb, the prepared 19-valence-electron n-type NbCoSbSn thermoelectric material is low in heat conductivity, high in Seebeck coefficient, high in power factor and good in thermoelectric properties.

Owner:XIHUA UNIV

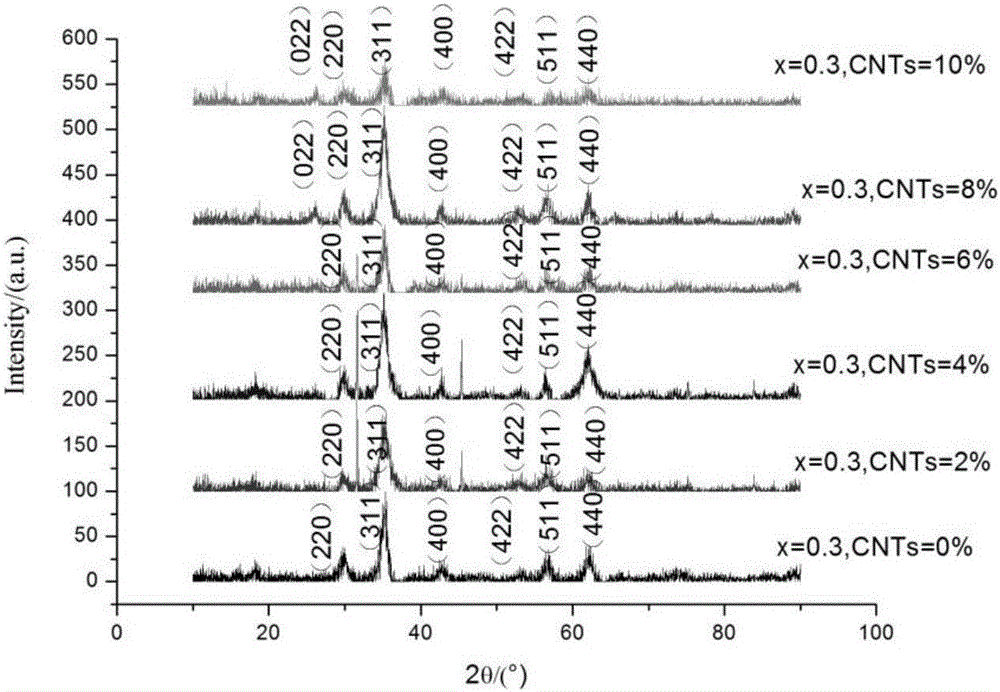

A temperature-controllable oxide thermoelectric material, a preparing method thereof and applications of the oxide thermoelectric material

InactiveCN105859274ALow Curie temperatureImprove conductivityThermoelectric materialsTemperature control

A temperature-controllable oxide thermoelectric material, a preparing method thereof and applications of the oxide thermoelectric material are disclosed. The oxide thermoelectric material is prepared by preparing metal salts containing Mn<2+>, Fe<3+> and Zn<2+> into a solution, adding dropwise the solution into an alkali solution of carbon nanotubes, reacting, performing suction filtration, washing to obtain carbon nanotube-Mn<1-x>Zn<x>Fe2O4 composite powder, and finally sintering, wherein the objective of precise temperature controlling is achieved by controlling the adding amount of the carbon nanotubes, and the x is less than 1. The composite material formed by adding the carbon nanotubes into a manganese-zinc-iron ferrite has increased conductivity, a high Seebeck coefficient and low thermal conductivity. The composite material of the carbon nanotubes and the manganese-zinc-iron ferrite can control the temperature rising situation of the manganese-zinc-iron ferrite under actions of an alternating magnetic field through controlling the adding amount of the carbon nanotubes, thus achieving high thermoelectric performance and achieving a precise temperature controlling objective. The oxide thermoelectric material, the method and the applications have advantages of a simple process, a low cost, simple operation, short preparation time, a small grain size of the prepared material, and the like.

Owner:SHANDONG UNIV

Thermoelectric material

InactiveCN108565331AChanging the electronic density of statesImprove Seebeck coefficientMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsManufacturing technology

The invention discloses a thermoelectric material and a manufacture technology thereof, and particularly relates to a polyimide Bi2Te3 thermoelectric film composite material and a manufacture method thereof. The thermoelectric material is good in size and good in thermoelectric performance.

Owner:佛山市领卓科技有限公司

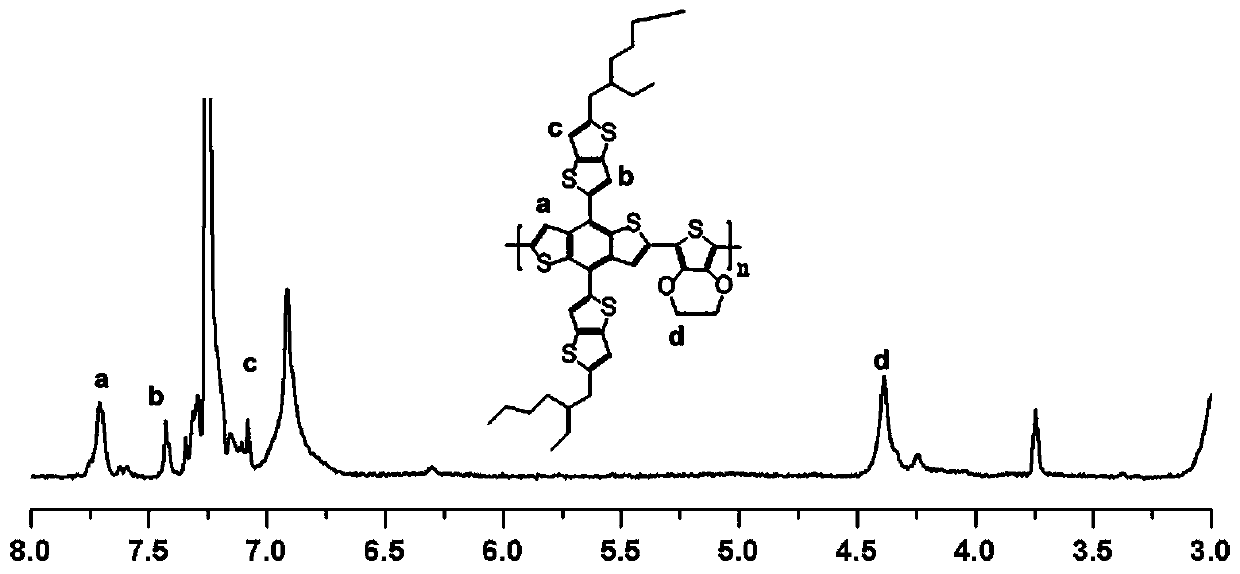

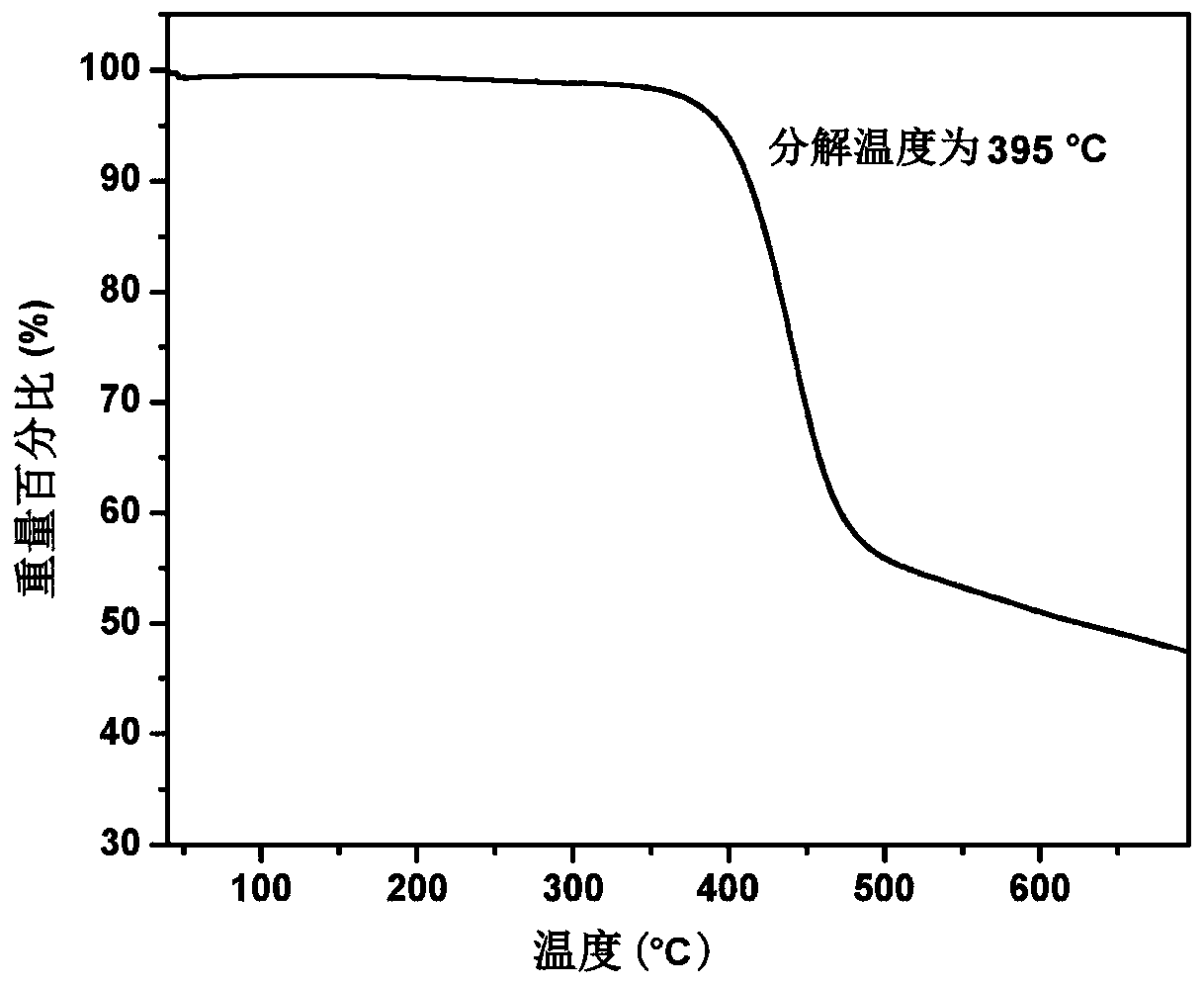

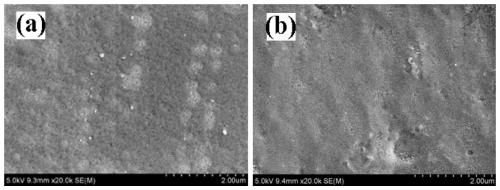

Conjugated polymer based on benzodithiophene units as well as preparation method and application thereof

The invention discloses a conjugated polymer based on benzodithiophene units as well as a preparation method and application thereof. The conjugated polymer based on the benzodithiophene units has a structural formula shown in the specification, wherein n is an integer between 15 and 40. Compared with conventional organic conjugated polymers such as polyaniline, polypyrrole, polythiophene, polycarbazole and the like, the conjugated polymer based on the benzodithiophene units has relatively high carrier mobility due to the large planar pi electron conjugated structure and the strong pi-pi interaction, and further shows relatively high Seebeck coefficient and excellent thermoelectric performance. Meanwhile, the polymer is easily dissolved in common organic solvents such as dichloromethane, trichloromethane, chlorobenzene and the like, has good machinability and thermal stability and can be made into a large-area flexible thermoelectrical component.

Owner:SHENZHEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com