Method for improving thermoelectric properties of cement-based composite material by ionic liquid

A technology of composite materials and ionic liquids, which is applied in the field of preparation of cement-based composite materials, can solve the problems of poor thermoelectric performance and achieve the effects of improved thermoelectric performance, simple production process, and high ion mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

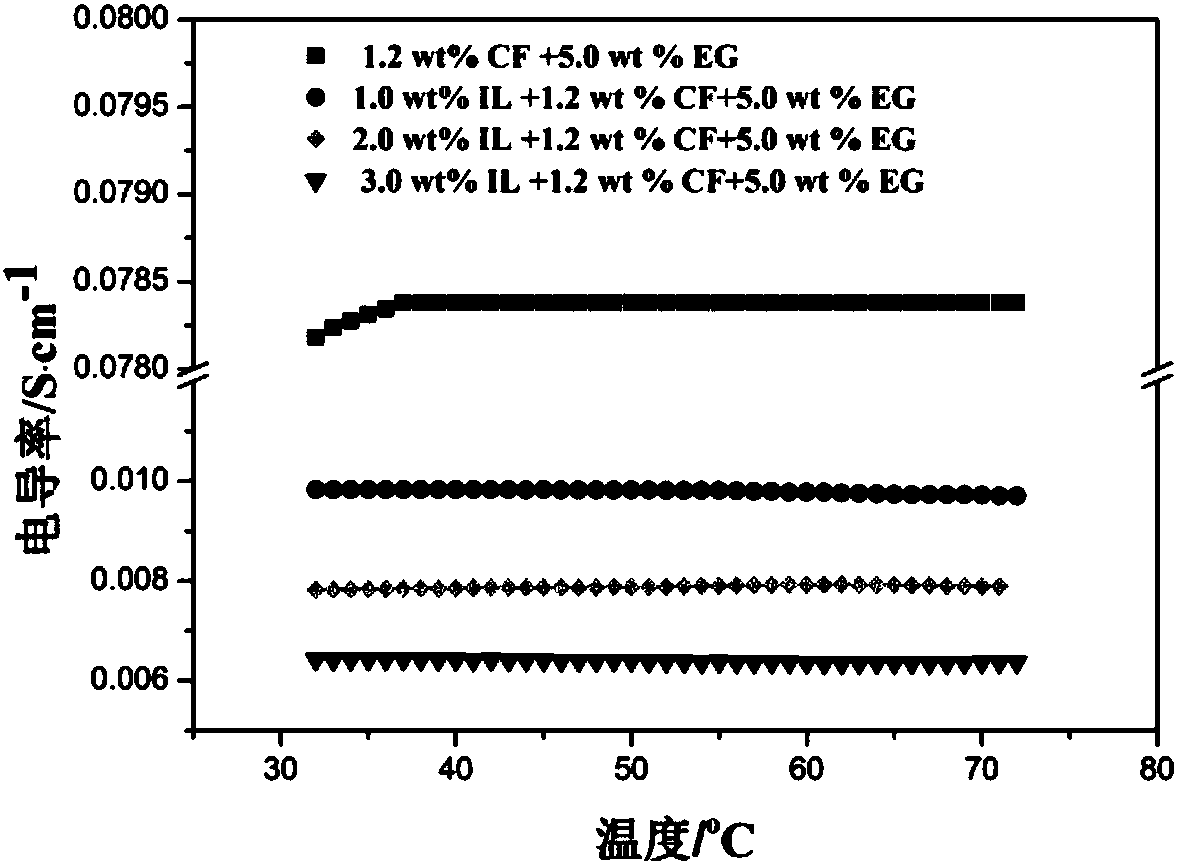

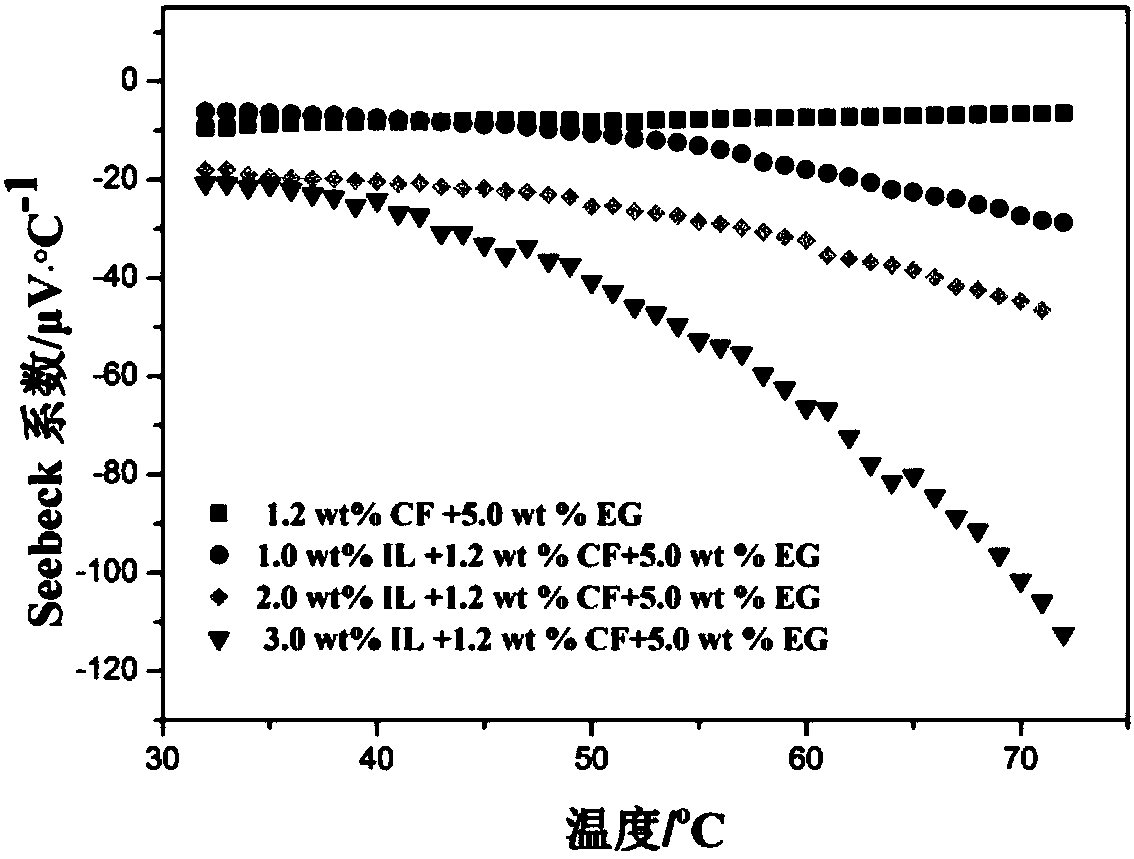

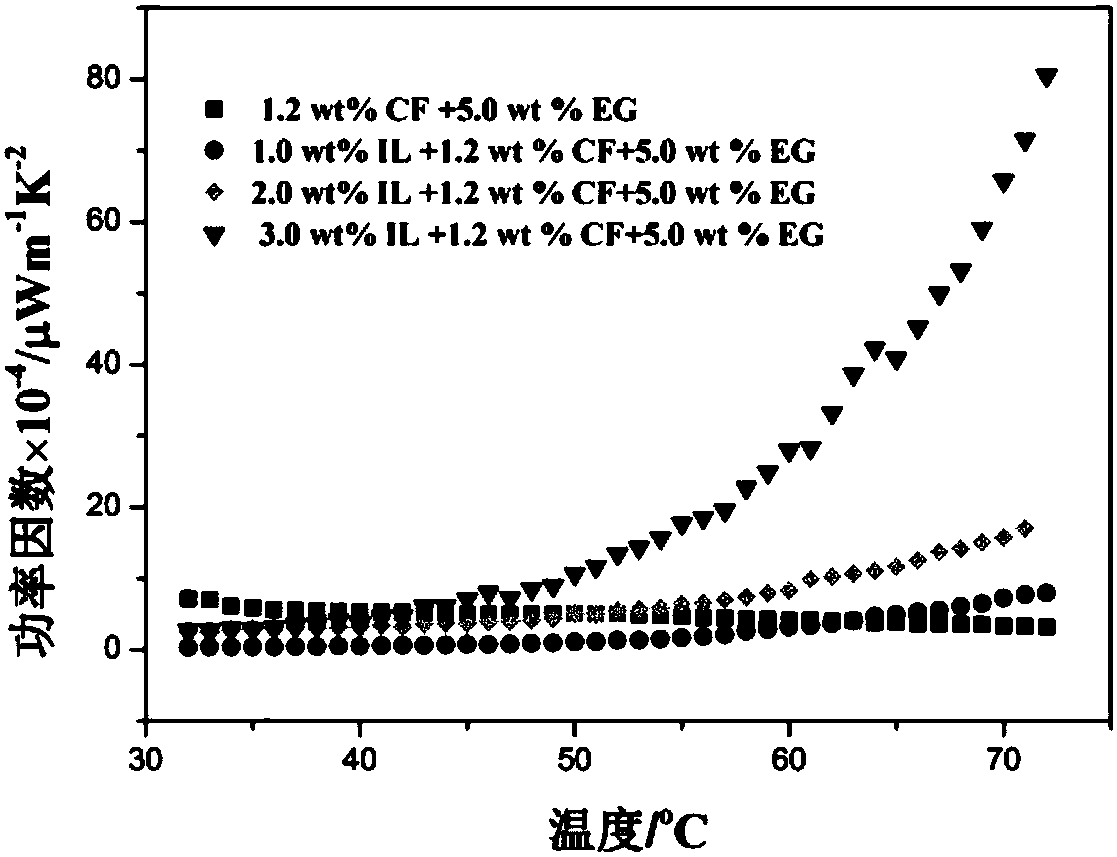

[0029] Example 1: Sulphoaluminate cement, PAN-based chopped carbon fibers, expanded graphite and [Bmim]Br ionic liquid were weighed according to the mass ratio of 100.0:1.2:5.0:1.0 before use.

[0030] First, the chopped carbon fibers are dispersed into a monofilament state using a mortar mixer. Secondly, pour the weighed sulfoaluminate cement, PAN-based chopped carbon fiber in monofilament state, expanded graphite and [Bmim]Br ionic liquid into the mortar mixer and stir for 3 minutes, then pour the stirred mixture into Put it into the roller type sand mixer and continue to stir until the color is uniform. After the stirring is completed, put it in a steel mold, and prepare the cement-based composite material green body through the press molding process, and then make the green body at a humidity of more than 90% and a temperature of 20- Curing at 25°C until the cement is completely hydrated to obtain a cement-based composite material doped with ionic liquids.

[0031] The el...

Embodiment 2

[0032] Example 2: Sulphoaluminate cement, PAN-based chopped carbon fibers, expanded graphite and [Bmim]Br ionic liquid were weighed according to the mass ratio of 100.0:1.2:5.0:2.0 before use.

[0033] First, the chopped carbon fibers are dispersed into a monofilament state using a mortar mixer. Secondly, pour the weighed sulfoaluminate cement, PAN-based chopped carbon fiber in monofilament state, expanded graphite and [Bmim]Br ionic liquid into the mortar mixer and stir for 3 minutes, then pour the stirred mixture into Put it into the roller type sand mixer and continue to stir until the color is uniform. After the stirring is completed, put it in a steel mold, and prepare the cement-based composite material green body through a pressurized molding process, and then make the green body at a humidity of more than 90% and a temperature of 20- Curing at 25°C until the cement is completely hydrated to obtain a cement-based composite material doped with ionic liquids.

[0034] Th...

Embodiment 3

[0035] Example 3: Sulphoaluminate cement, PAN-based chopped carbon fibers, expanded graphite and [Bmim]Br ionic liquid were weighed according to the mass ratio of 100.0:1.2:5.0:3.0 before use.

[0036] First, the chopped carbon fibers are dispersed into a monofilament state using a mortar mixer. Secondly, pour the weighed sulfoaluminate cement, PAN-based chopped carbon fiber in monofilament state, expanded graphite and [Bmim]Br ionic liquid into the mortar mixer and stir for 3 minutes, then pour the stirred mixture into Put it into the roller type sand mixer and continue to stir until the color is uniform. After the stirring is completed, put it in a steel mold, and prepare the cement-based composite material green body through a pressurized molding process, and then make the green body at a humidity of more than 90% and a temperature of 20- Curing at 25°C until the cement is completely hydrated to obtain a cement-based composite material doped with ionic liquids.

[0037]The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seebeck coefficient | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com