19-valence-electron n-type NbCoSbSn thermoelectric material and preparation method thereof

A technology of thermoelectric materials and valence electrons, applied in the field of semiconductor thermoelectric materials, can solve problems such as little research, and achieve the effects of low production cost, good thermoelectric performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of 19 valence electron n-type NbCoSbSn thermoelectric material, its chemical formula is NbCoSb 0.8 sn 0.2 .

[0036] NbCoSb as above 0.8 sn 0.2 The preparation method comprises the following steps:

[0037] ① Arc melting: divided into NbCoSb by composition 0.8 sn 0.2The stoichiometric ratio of each metal raw material (Nb, Co, Sb, Sn) was weighed in a certain amount, and an additional 5% of Sb was added. The raw materials are arc smelted under the protection of circulating argon gas, and ingots are obtained after repeated smelting 5 times;

[0038] ② Solid block milling: the ingot is milled for 7 hours by high-energy ball milling method to pulverize the ingot to obtain nano-scale powder;

[0039] ③Rapid hot pressing: put the nano-powder into the mold and use the rapid hot pressing method to keep pressure and sinter at 1000 ℃ and 77 MPa for 2 minutes to obtain the product.

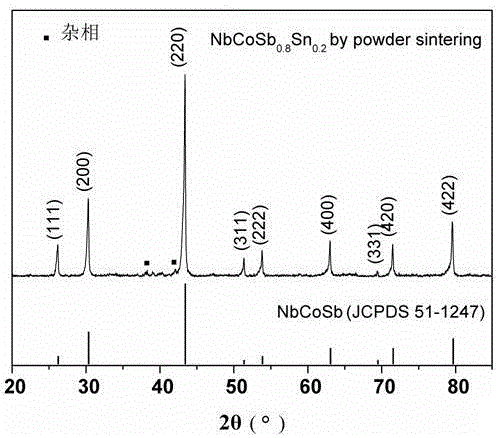

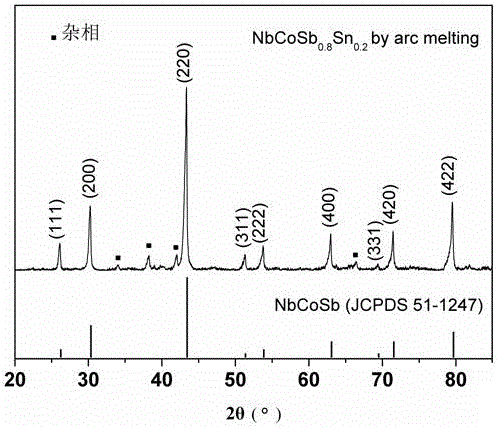

[0040] Adopt PANalytical X'Pert Pro type X-ray polycrystal diffractom...

Embodiment 2

[0041] Embodiment 2: A kind of 19 valence electron n-type NbCoSbSn thermoelectric material, its chemical formula is NbCoSb 0.8 sn 0.2 .

[0042] NbCoSb as above 0.8 sn 0.2 The preparation method comprises the following steps:

[0043] a Mixed cold pressing: first follow the NbCoSb 0.8 sn 0.2 , the proportion of molar ratio weighed a certain amount of Nb powder, Co powder, Sb powder, Sn powder, under the protection of an inert gas, fully mixed on a high-energy ball mill for 25 minutes, and the powder after uniform mixing was put into a cold-pressing mold, at 400 Cold pressing under MPa for 20 min to form a block;

[0044] b Vacuum sealing: put the powder block obtained by cold pressing into a container, vacuumize and seal, and the vacuum degree is lower than 8×10 -6 Pa;

[0045] c Solid-state sintering: heat the sealed container in a heat treatment furnace and raise the temperature to 1100 °C for 24 hours, then take it out and air-cool it, with a heating rate of 200 °C / ...

Embodiment 3

[0049] Embodiment 3: A kind of 19 valence electron n-type NbCoSbSn thermoelectric material, its chemical formula is NbCoSb 0.75 sn 0.25 .

[0050] NbCoSb as above 0.75 sn 0.25 The preparation method comprises the following steps:

[0051] ① Arc melting: divided into NbCoSb by composition 0.75 sn 0.25 The stoichiometric ratio of each metal raw material (Nb, Co, Sb, Sn) was weighed in a certain amount, and an additional 8% of Sb was added. The raw materials are arc smelted under the protection of circulating argon gas, and ingots are obtained after repeated smelting 5 times;

[0052] ② Solid block milling: the ingot is milled for 3 hours by high-energy ball milling method to pulverize the ingot to obtain nano-scale powder;

[0053] ③Rapid hot pressing: put the nano-powder into the mold and sinter at 950 ℃ and 70 MPa for 3 minutes under the pressure of 950 ℃ and 70 MPa to obtain the product.

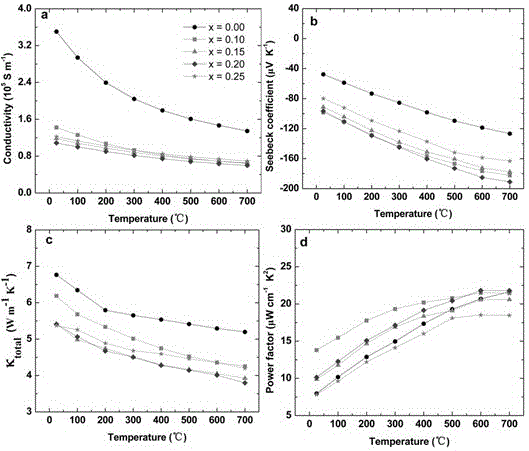

[0054] The thermal conductivity, Seebeck coefficient, and electrical conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com