D-A type conjugated polymer organic thermoelectric thin film material and preparation method thereof

A conjugated polymer and thermoelectric thin film technology is applied in the field of D-A type conjugated polymer organic thermoelectric thin film material and its preparation field, which can solve the problems of high thermal conductivity, high price and difficult processing of inorganic thermoelectric materials, and achieve a good solution The effect of processability, low cost, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Synthesis of polymer PBDDTTBTF-1:

[0053] In a 25ml two-necked flask, sequentially add monomer M1 (100mg, 0.1295mmol), monomer II (137mg, 0.1295mmol), tris(dibenzylideneacetone)dipalladium (6mg, 0.0065mmol), tris(o-toluene) Phosphorus (10mg, 0.0324mmol), 3.5ml of chlorobenzene, under the protection of nitrogen atmosphere, the reaction temperature is controlled at 110°C for 72h, the reaction formula is as follows:

[0054]

[0055] After the reaction is naturally cooled, the reaction solution is added dropwise to methanol to precipitate the polymer, and the solution containing methanol and polymer is centrifuged in a centrifuge at 3000 r / min for 10 minutes, and the supernatant liquid is discarded to obtain polymerization. The crude polymer product is vacuum dried in a vacuum drying oven for 12 hours, and the dried crude polymer product is placed in a Soxhlet extractor, and methanol, acetone, and n-hexane are used as solvents for Soxhlet extraction for 12 hours. , Remove the...

Embodiment 2

[0057] Preparation and doping method of polymer PBDDTTBTF-1 film:

[0058] The obtained polymer PBDDTTBTF-1 was dissolved in chlorobenzene at a concentration of 15mg / ml, and the solution was dripped onto a 15mm*15mm glass slide with a dropper. After the solvent evaporates, the glass attached to the glass slide can be obtained. Polymer film. Prepare a nitromethane solution of anhydrous ferric chloride with a concentration of 0.1 mol / L, put the obtained polymer film into the solution for soaking and doping for 10 minutes, take out the polymer film and rinse with a nitrohexane solution. Organic thermoelectric thin film materials that can be used for thermoelectric testing are available.

Embodiment 3

[0060] Performance characterization and thermoelectric performance test of polymer PBDDTTBTF-1 and polymer PBDDTTBTF-1 thin film materials:

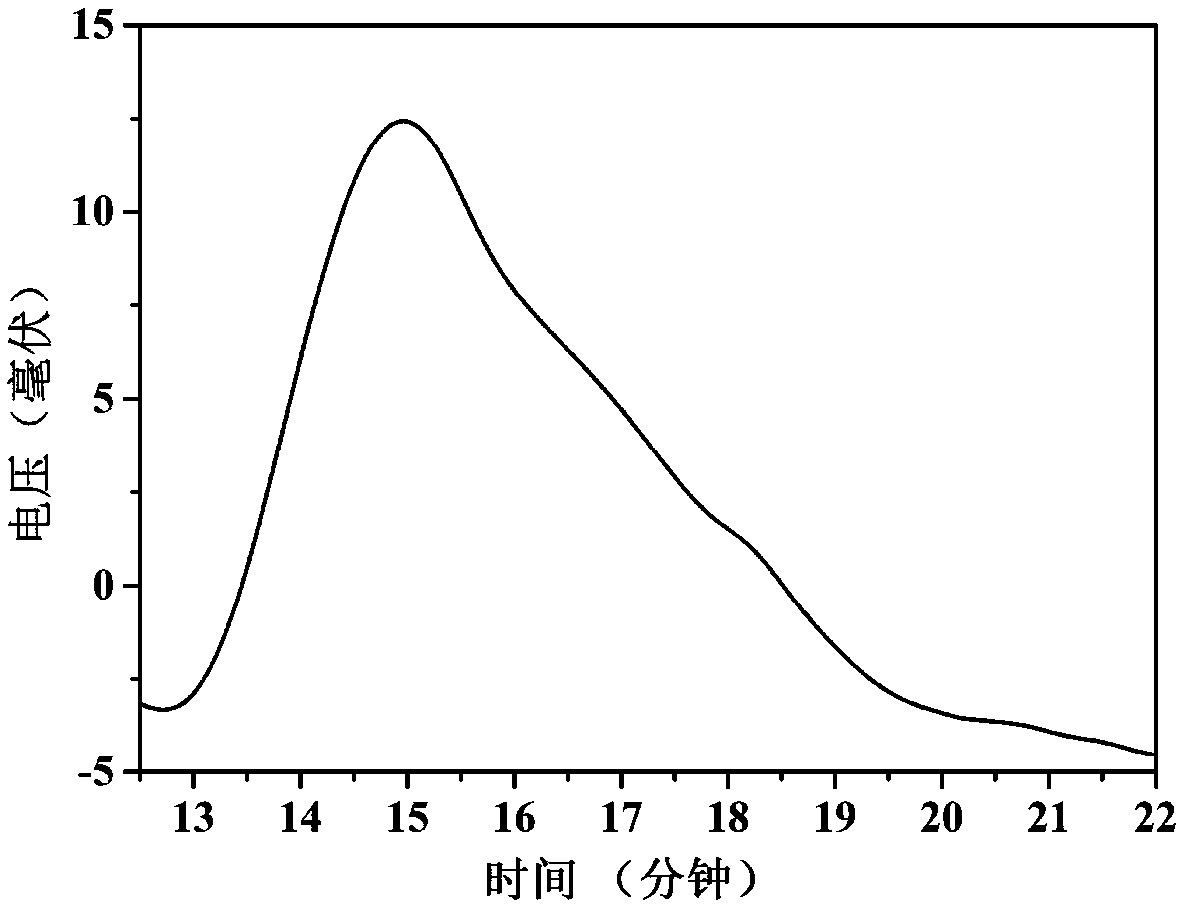

[0061] 1. Test the molecular weight and molecular weight distribution of the polymer PBDDTTBTF-1 by Waters e2695 gel permeation chromatography, and the measured GPC curve is as follows figure 1 As shown, the number average molecular weight of the polymer PBDDTTBTF-1 is 56986, the weight average molecular weight is 109930, and the molecular weight distribution index is 1.93.

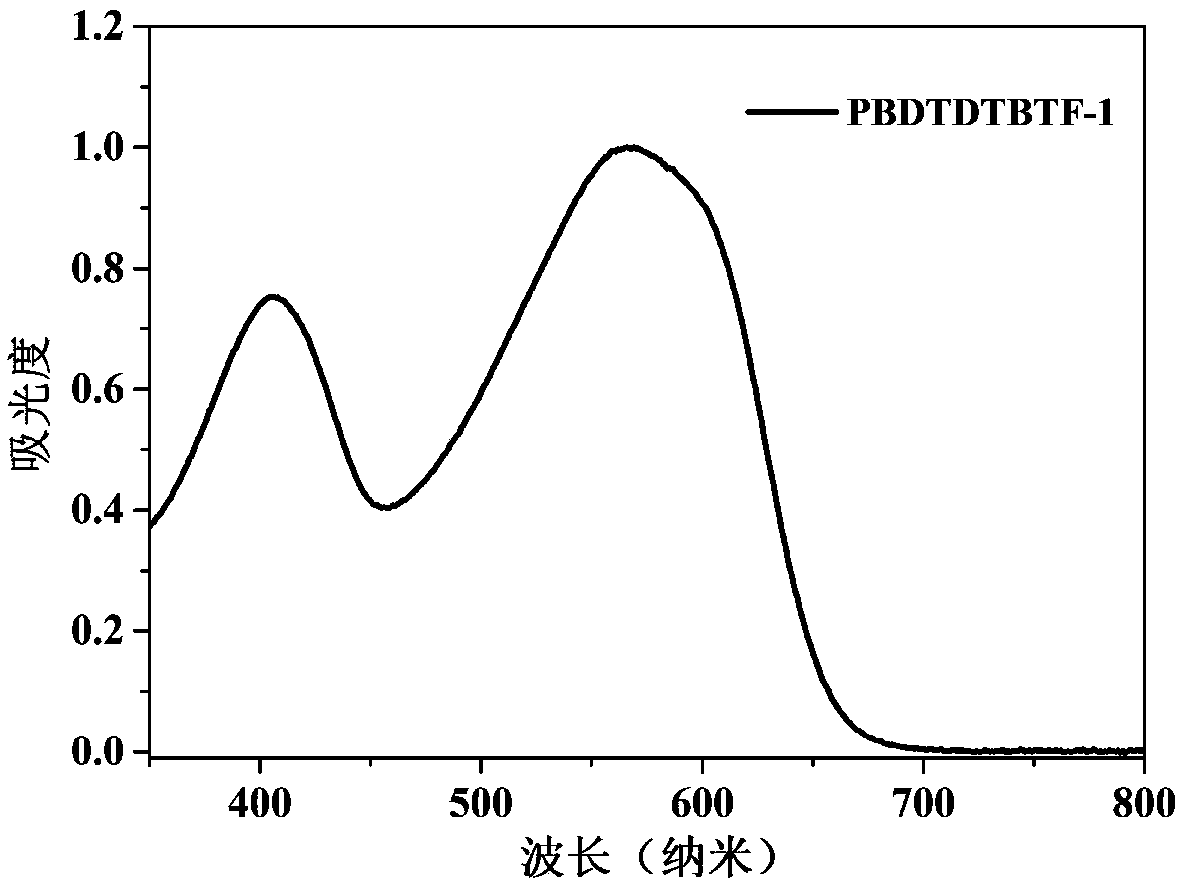

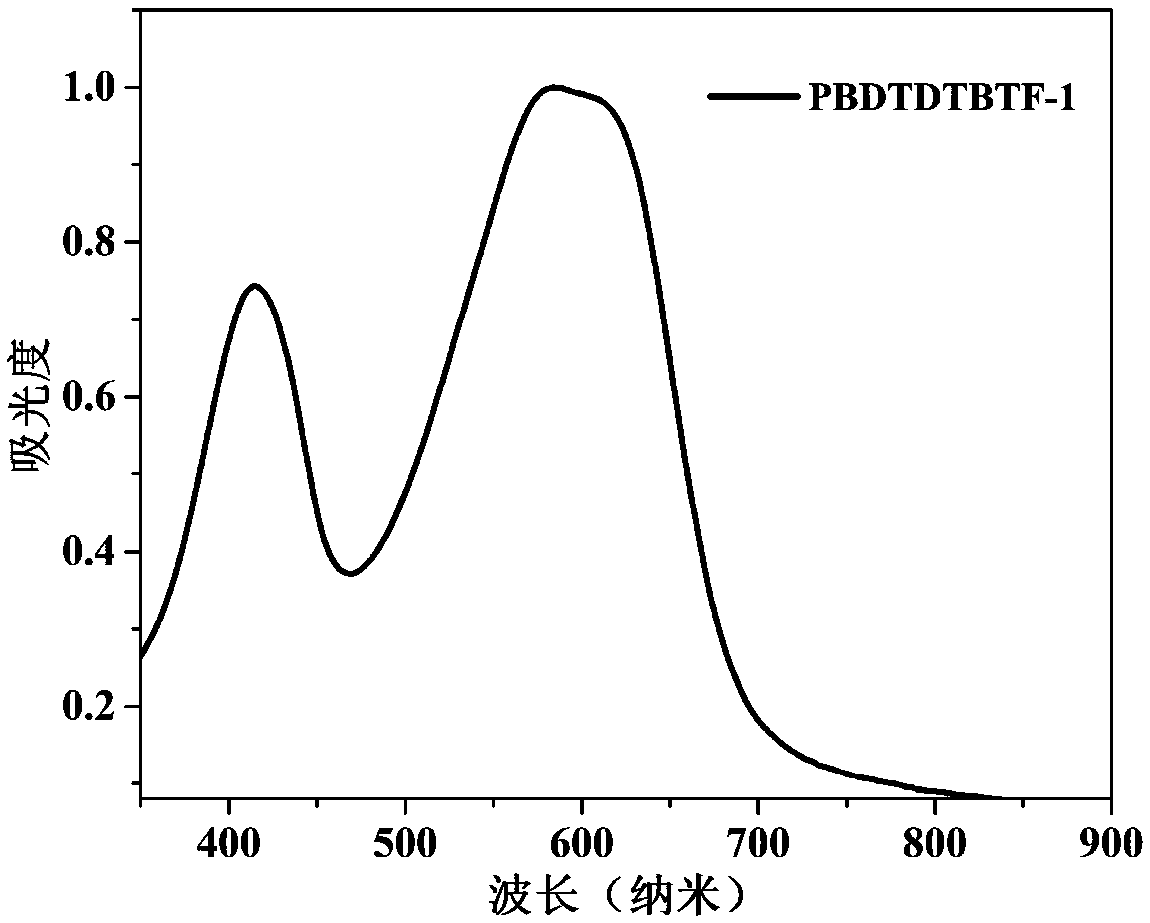

[0062] 2. Measure the polymer PBDDTTBTF-1 and polymer PBDDTTBTF-1 film materials dissolved in chlorobenzene solvent by Thermo Evolution 220 UV-Vis absorption spectrometer: UV-visible absorption spectrum of PBDDTTBTF-1 in chlorobenzene solution Such as figure 2 As shown, the wavelength corresponding to its maximum absorption peak is 566nm; the ultraviolet absorption spectrum of the polymer PBDDTTBTF-1 film material is as follows image 3 As shown, compared with the absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com