Bimetallic-centered organoplatinum complex energy conversion materials with framework structure

A skeleton structure, bimetallic technology, applied in platinum-based organic compounds, platinum-group organic compounds, organic chemistry, etc., can solve the problems of difficult properties of inorganic materials, flexible control of processing and manufacturing difficulties, etc., to increase application value and enhance phosphorescence emission Ability, effect that enhances the ability to leap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

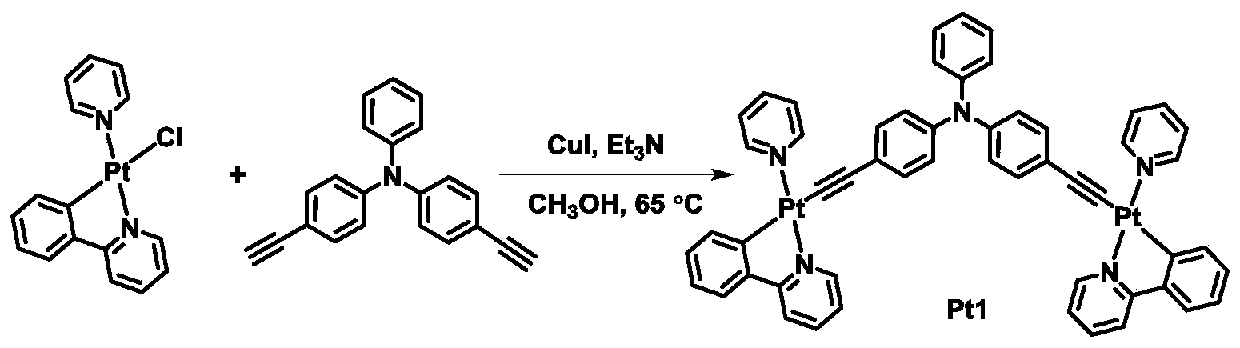

[0040] The skeleton structure bimetallic center organoplatinum metal complex Pt1 of the present embodiment has a chemical formula of C 54 h 39 N 5 Pt 2 , the molecular structure formula is:

[0041]

[0042] Refer to attached figure 1 , the synthesis steps are as follows:

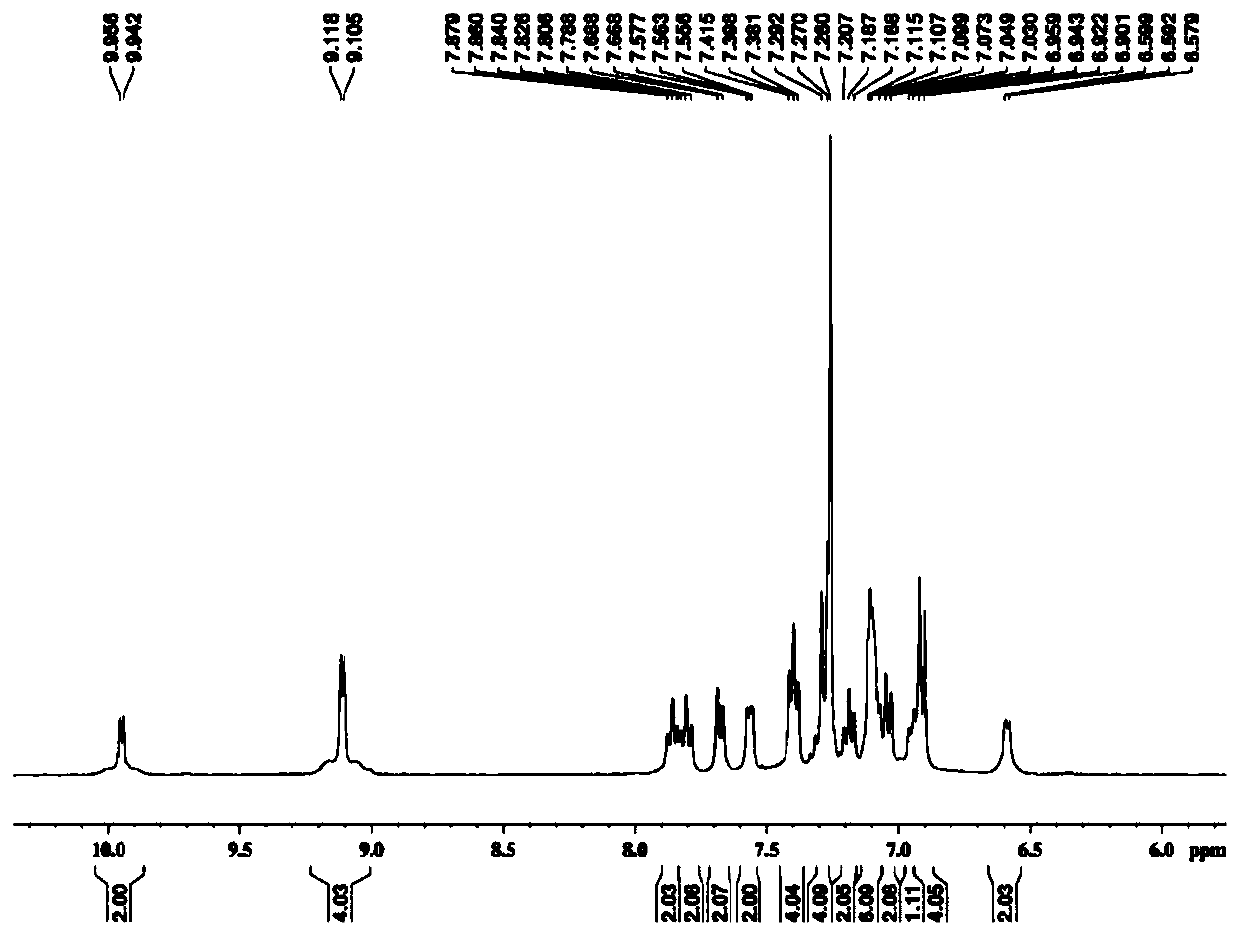

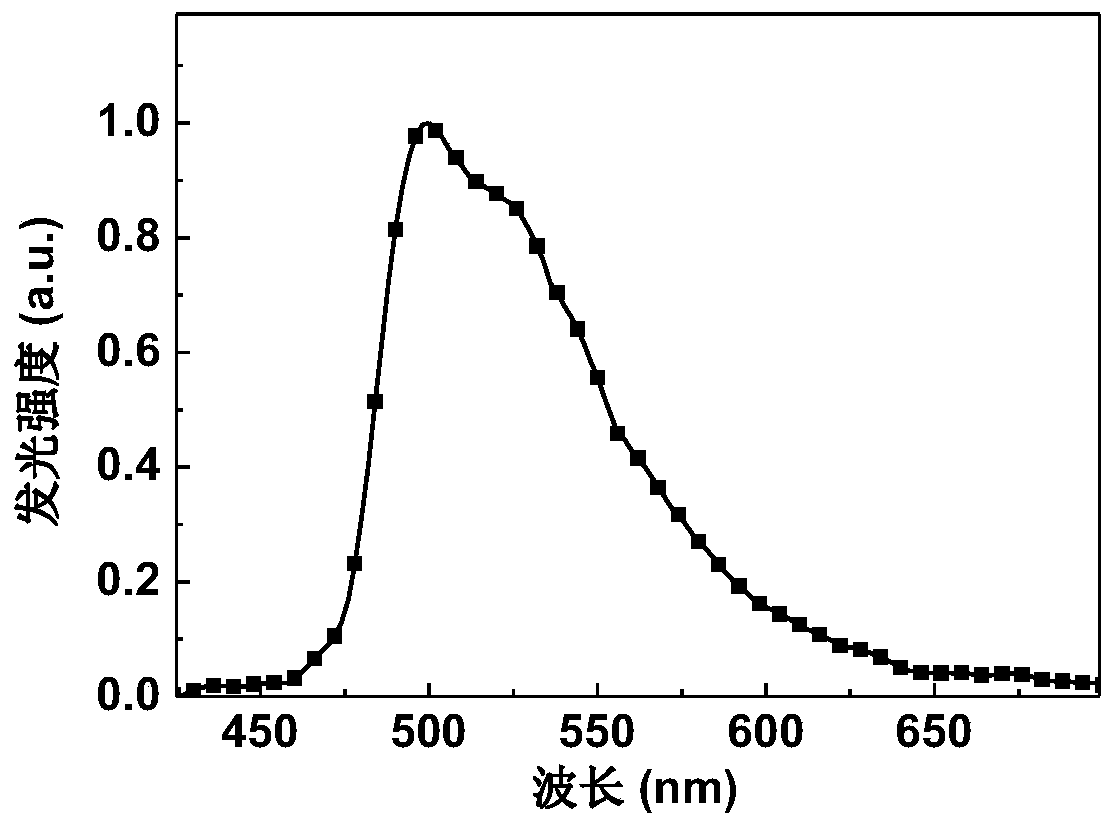

[0043] 0.6mmol precursor With 0.3mmol organic "bridge" structure Put it into a reaction vessel, and add 0.03mmol of catalyst CuI, 30mmol of triethylamine and 15mL of methanol into the reaction vessel under a nitrogen atmosphere. The reaction mixture was heated to 65°C under nitrogen atmosphere and stirred for 12 hours, then cooled to room temperature, resulting in precipitation. The precipitate obtained by filtration was washed three times with deionized water, methanol, and ether, respectively. Then dry it in a vacuum oven and remove the solvent to obtain the bimetallic-centered organic platinum complex Pt1 with a new skeleton structure, with a yield of 73.6%. Its NMR spectrum is as figure 2 ...

Embodiment 2

[0047] The skeleton structure double metal center organoplatinum metal complex Pt2 of the present embodiment, chemical formula is C 54 h 37 N 5 Pt 2 , the molecular structure formula is:

[0048]

[0049] Its synthetic steps are as follows:

[0050] 0.6mmol precursor With 0.3mmol organic "bridge" structure Put it into a reaction vessel, and add 0.03mmol of catalyst CuI, 30mmol of triethylamine and 15mL of methanol into the reaction vessel under a nitrogen atmosphere. The reaction mixture was heated to 65°C under nitrogen atmosphere and stirred for 12 hours, then cooled to room temperature, resulting in precipitation. The precipitate obtained by filtration was washed three times with deionized water, methanol, and ether, respectively. Then dry in a vacuum oven and remove the solvent to obtain a double-metal-centered organic platinum complex Pt2 with a new skeleton structure, with a yield of 82.8%. Mass spectrometry found signal peak (m / z): 1167.2315[M+Na] + .

[...

Embodiment 3

[0053] The skeleton structure bimetallic center organoplatinum metal complex Pt3 of the present embodiment has a chemical formula of C 54 h 39 N 4 OPP 2 , the molecular structure formula is:

[0054]

[0055] Its synthetic steps are as follows:

[0056] 0.6mmol precursor With 0.3mmol organic "bridge" structure Put it into a reaction vessel, and add 0.03mmol of catalyst CuI, 30mmol of triethylamine and 15mL of methanol into the reaction vessel under a nitrogen atmosphere. The reaction mixture was heated to 65°C under nitrogen atmosphere and stirred for 12 hours, then cooled to room temperature, resulting in precipitation. The precipitate obtained by filtration was washed three times with deionized water, methanol, and ether, respectively. Then dry in a vacuum oven and remove the solvent to obtain a double-metal-centered organic platinum complex Pt3 with a new skeleton structure, with a yield of 79.8%. Mass spectrometry found signal peak (m / z): 1202.2648[M+Na] + . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com