Patents

Literature

162 results about "Thermoelectric thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

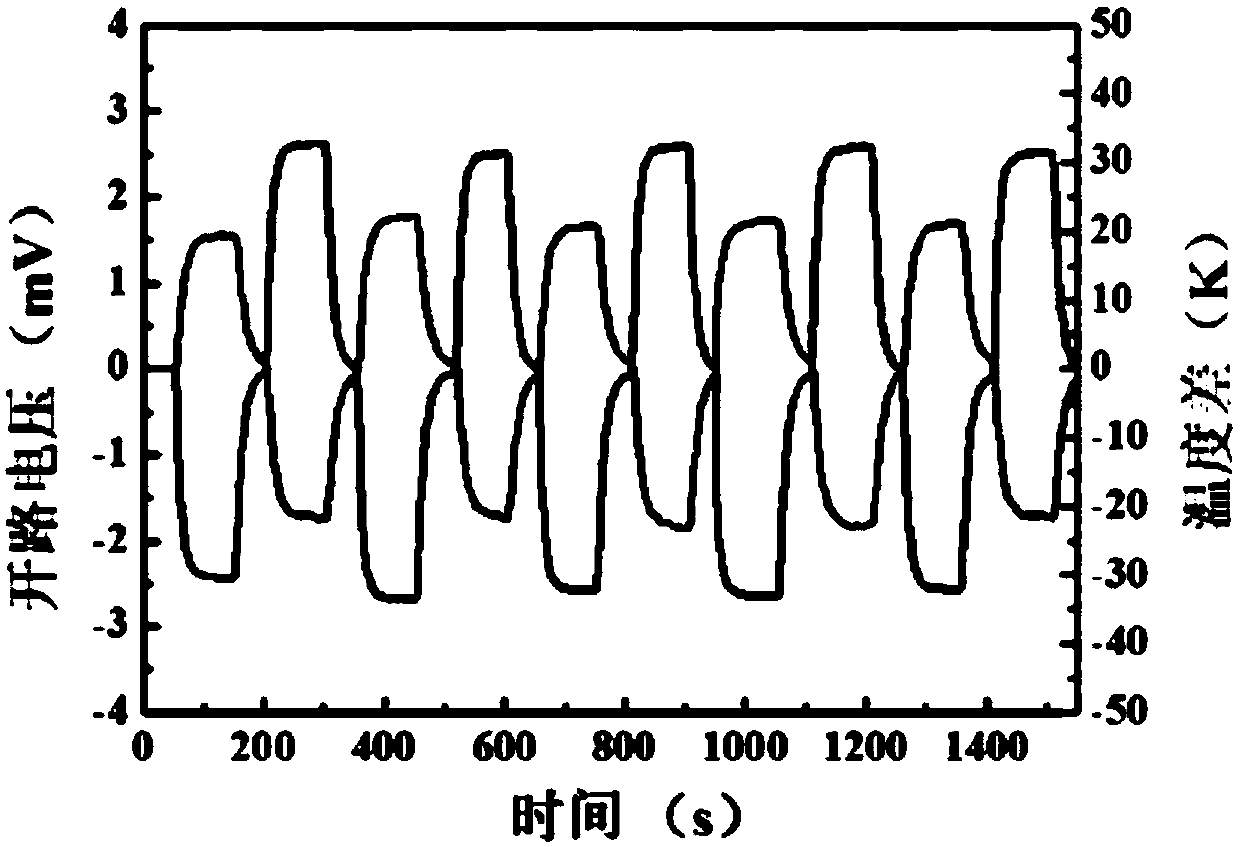

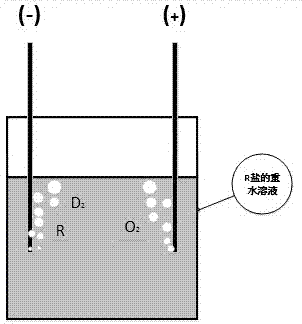

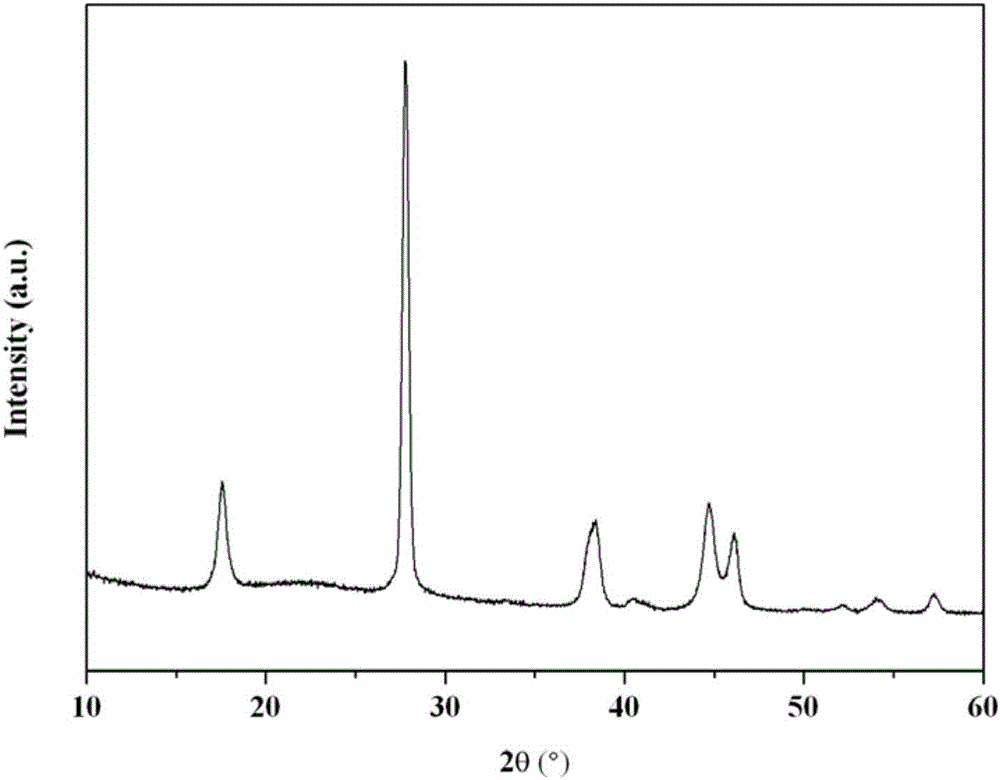

Method for manufacturing graphene/polyaniline thermoelectric thin film

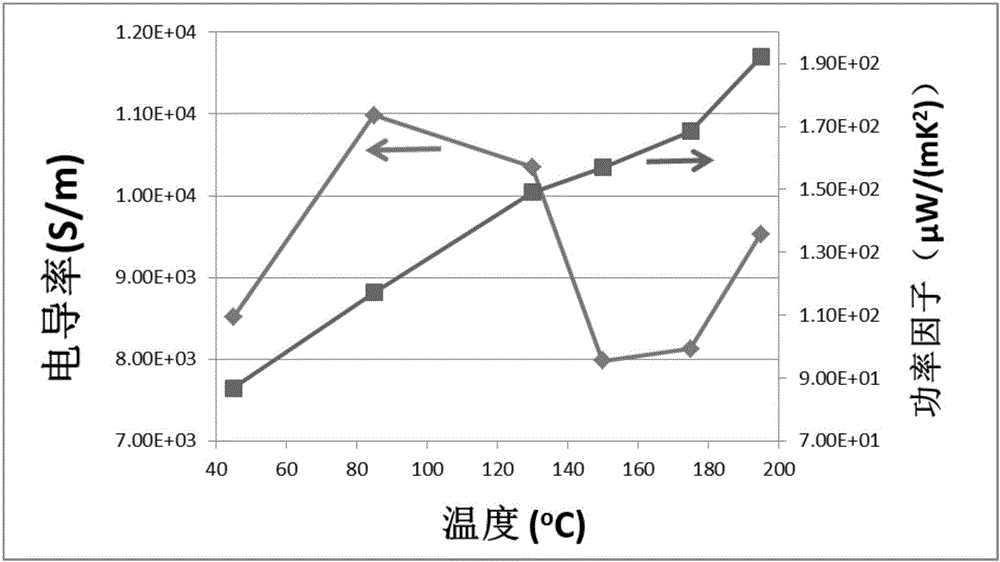

ActiveCN103311428ALow costSimple processElectrolytic coatingsThermoelectric device manufacture/treatmentAnilineFigure of merit

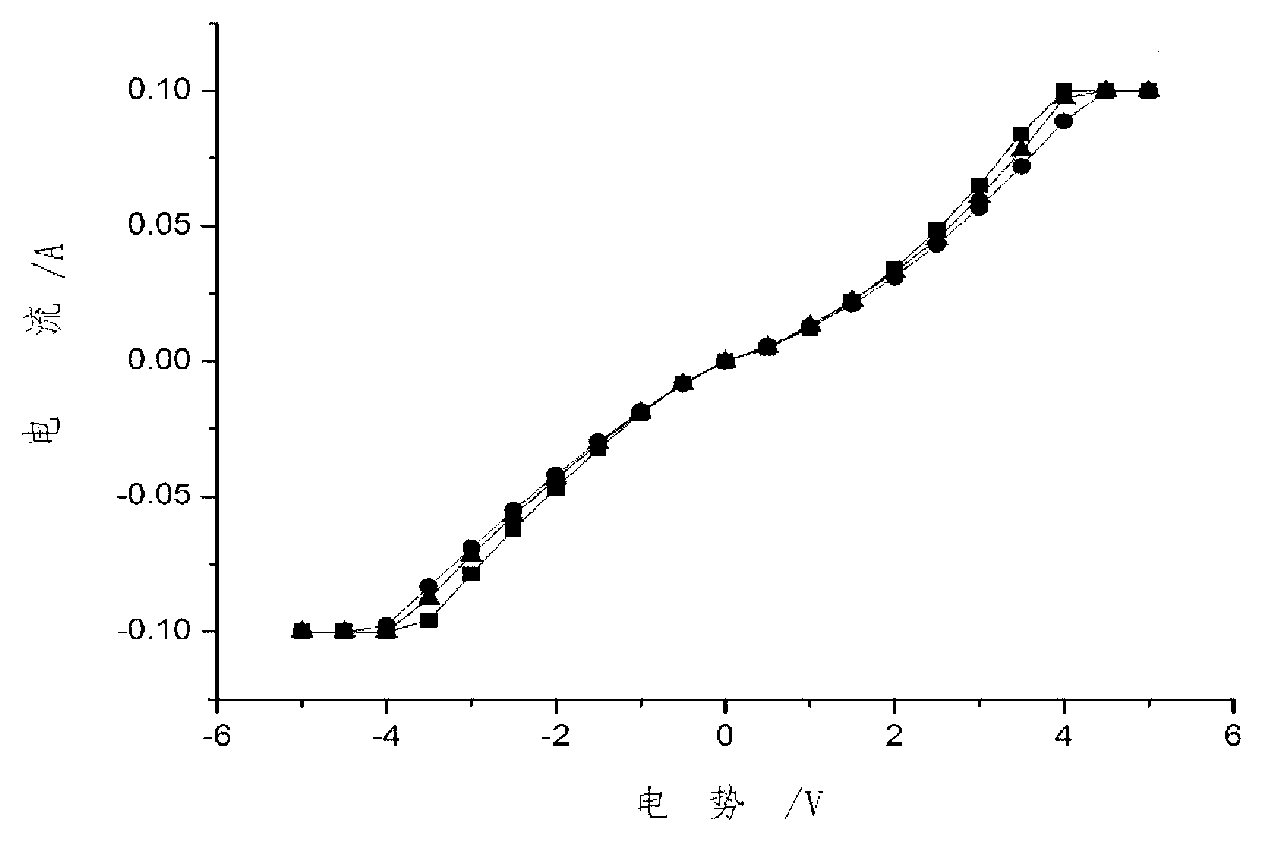

The invention discloses a method for manufacturing a graphene / polyaniline thermoelectric thin film, and relates to a method for manufacturing a thermoelectric thin film. The method for manufacturing the graphene / polyaniline thermoelectric thin film includes firstly, manufacturing graphene oxide powder; secondly, manufacturing graphene oxide / aniline mixed solution; thirdly, manufacturing a graphene / polyaniline composite powder material; fourthly, manufacturing the thermoelectric thin film by means of oriented deposition. The method has the advantages that the technical problem of low thermoelectric conversion efficiency due to a low figure of merit (a ZT value) of an existing organic thermoelectric material is solved, and the method can be applied to industrial temperature differential power generation.

Owner:HARBIN INST OF TECH

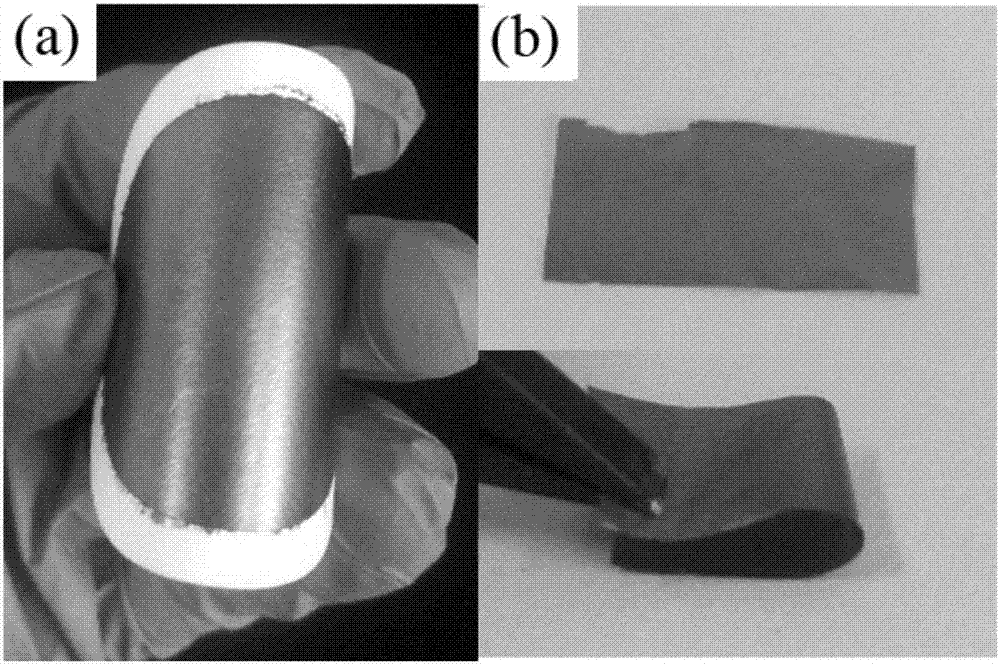

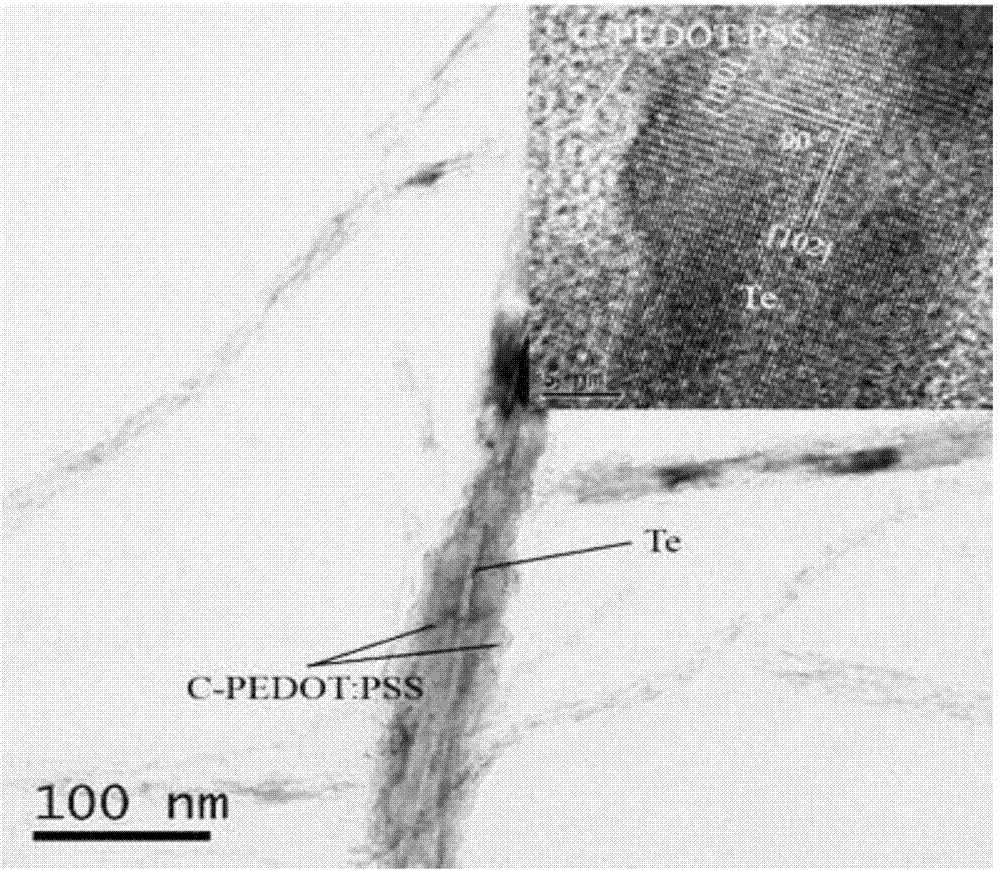

Flexible composite thermoelectric thin film and preparation method therefor

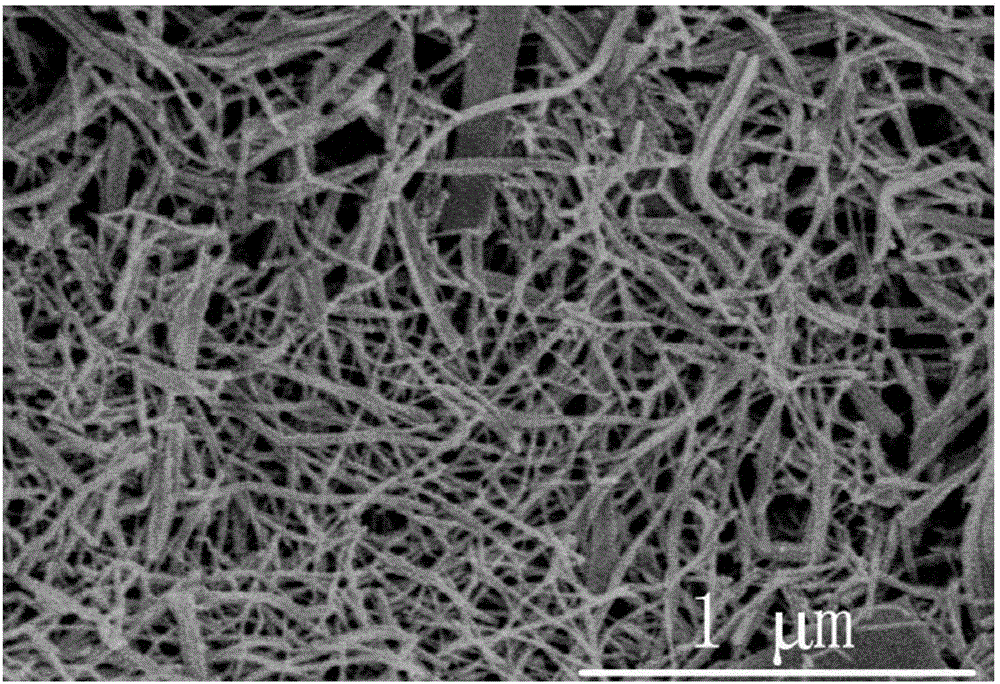

InactiveCN107546317ASimple ingredientsSimple preparation processMaterial nanotechnologyThermoelectric device manufacture/treatmentNanowireTe element

The invention discloses a flexible composite thermoelectric thin film and a preparation method therefor, and belongs to the field of a composite thermoelectric material. The flexible composite thermoelectric thin film is prepared from PEDOT: PSS, tellurium nanowires and glucose; the mass ratio of the tellurium nanowires to glucose is 1-5 to 1; and the mass ratio of the tellurium nanowires to PEDOT: PSS is 0.5-9 to 1. The prepared composite material has high Seebeck coefficient as well as high electrical conductivity after acid treatment, wherein the tellurium nanowires are coated with PEDOT: PSS in the composite material.

Owner:JIANGXI SCI & TECH NORMAL UNIV

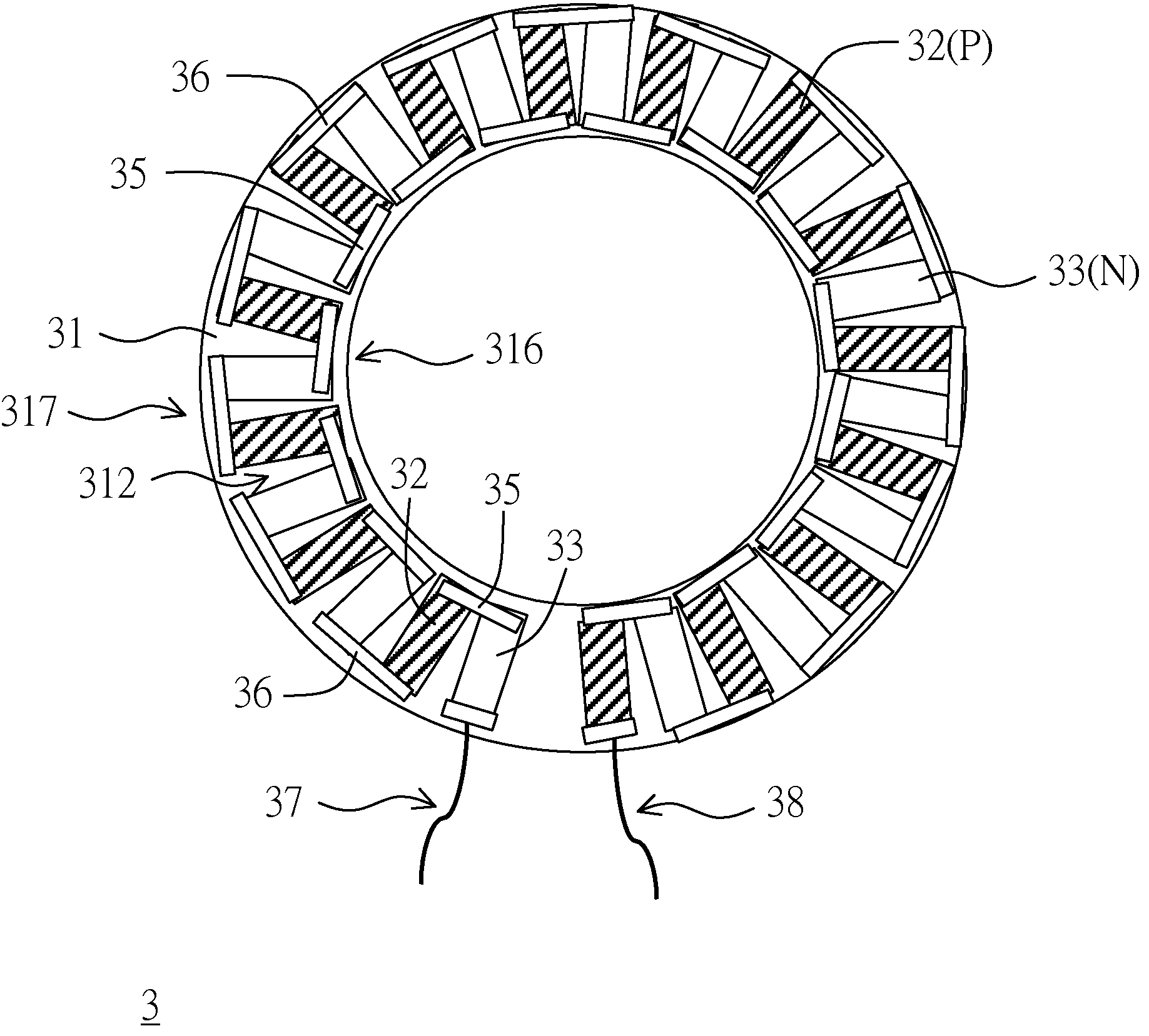

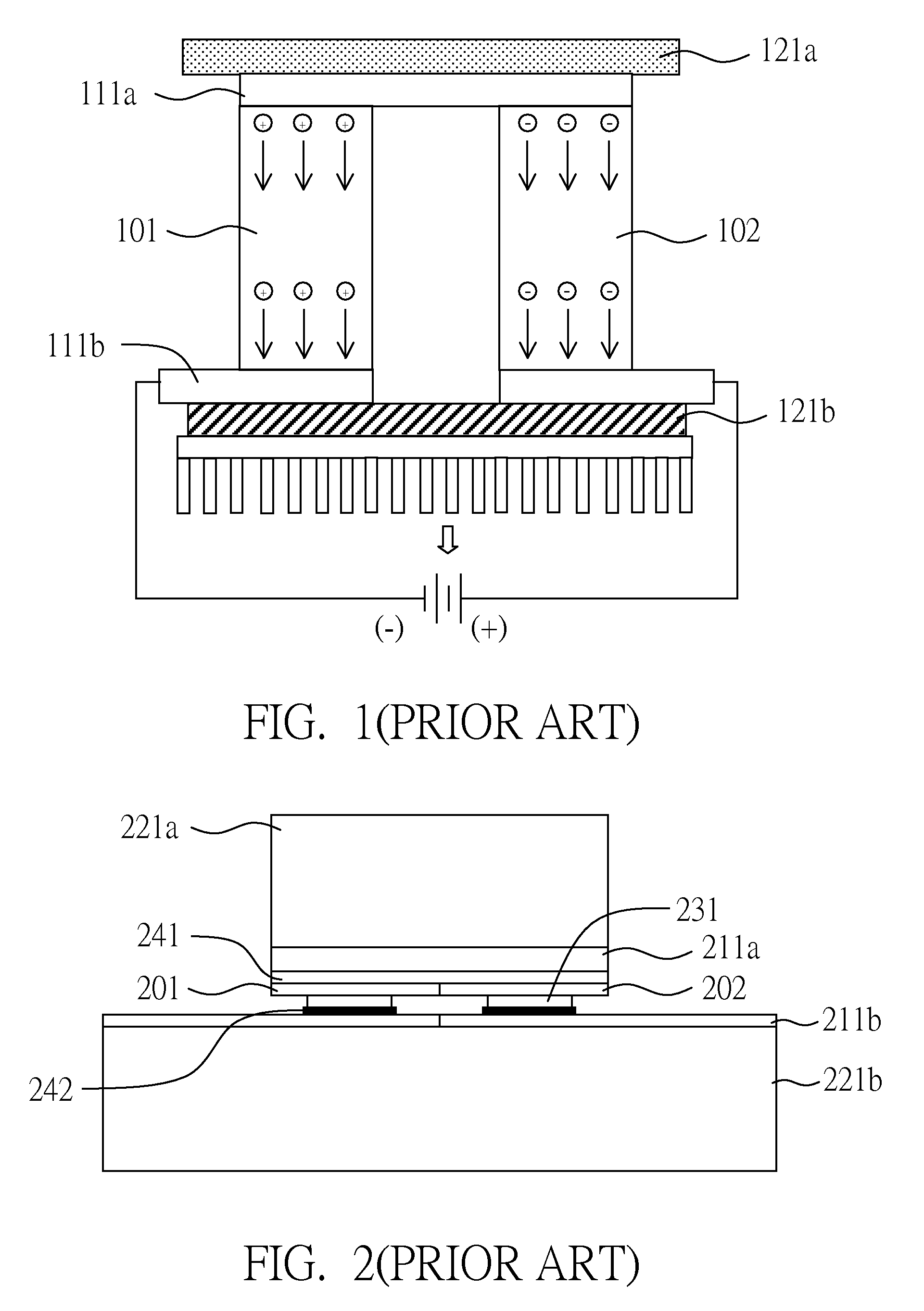

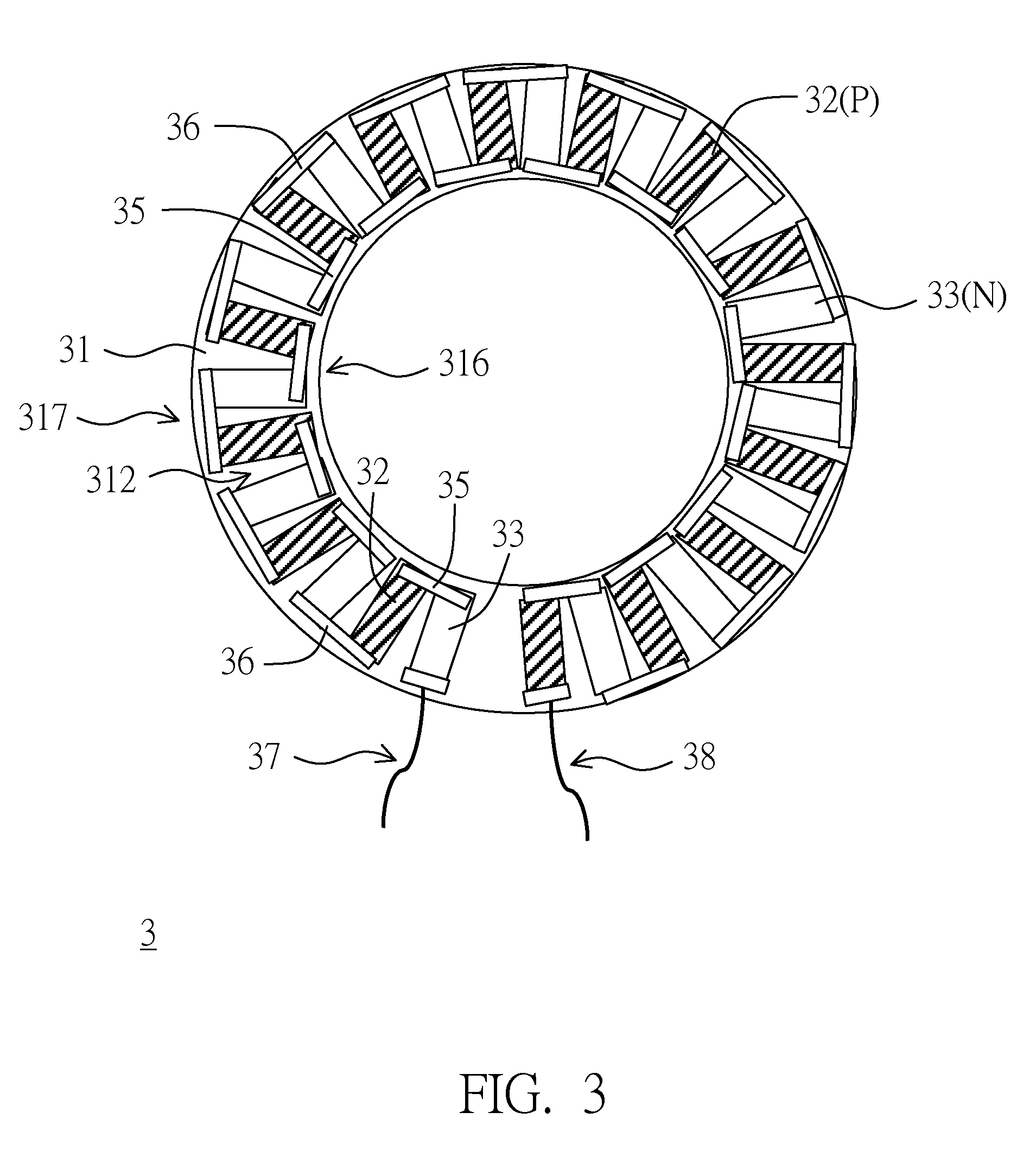

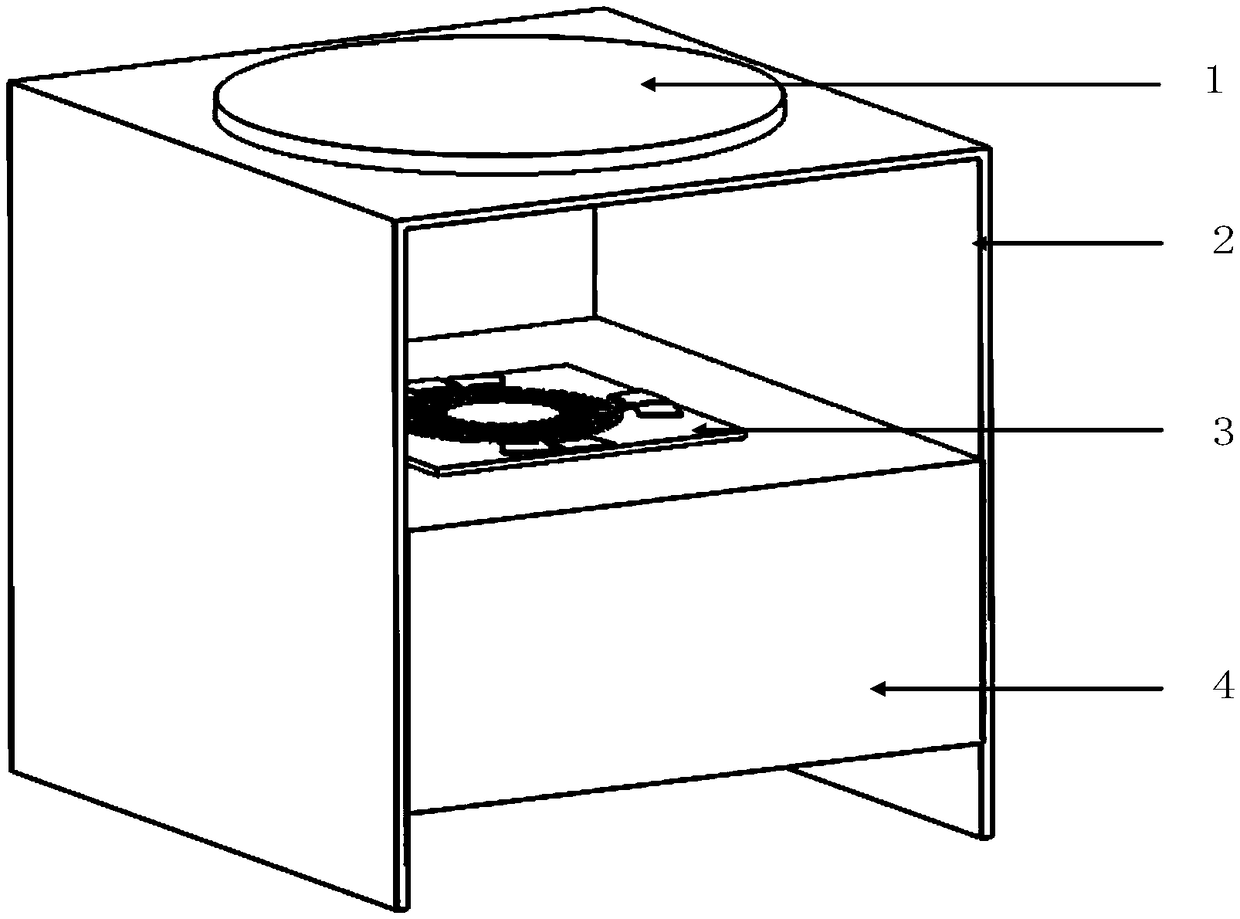

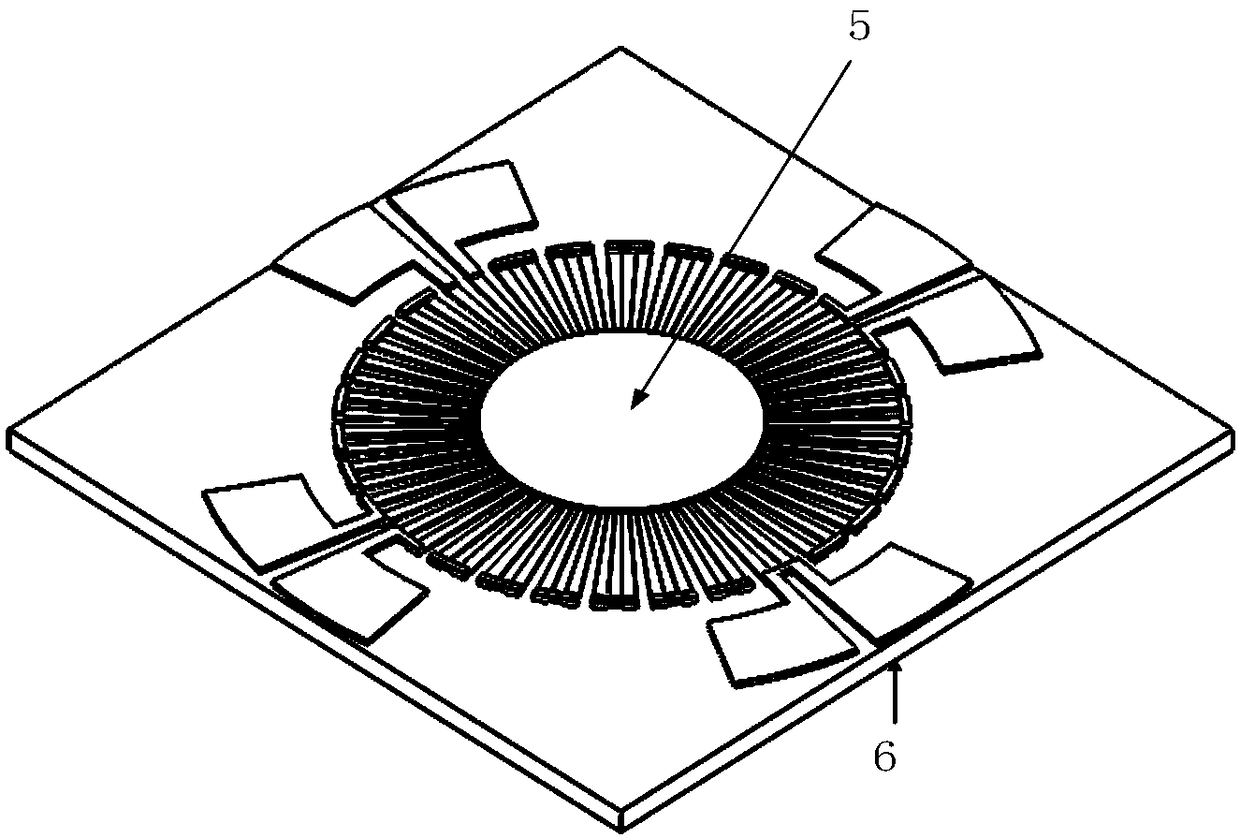

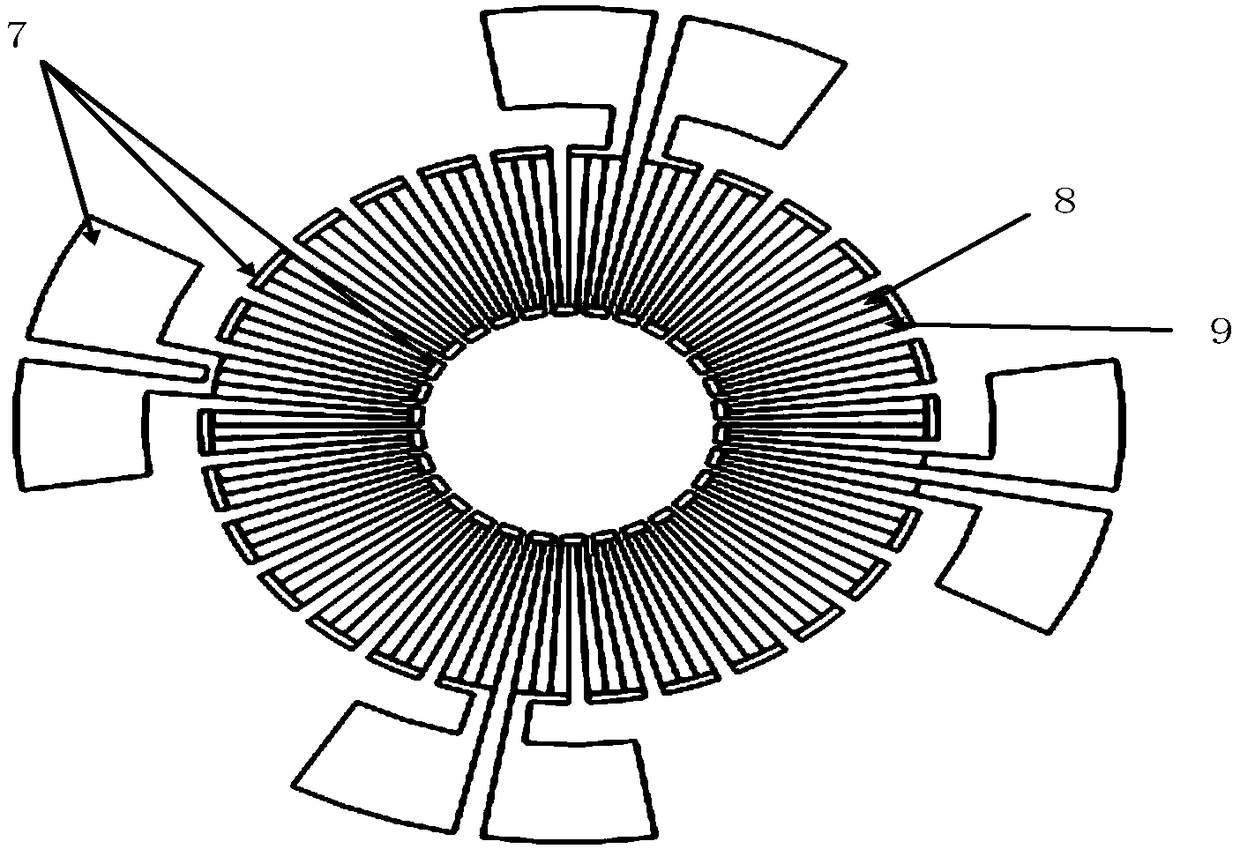

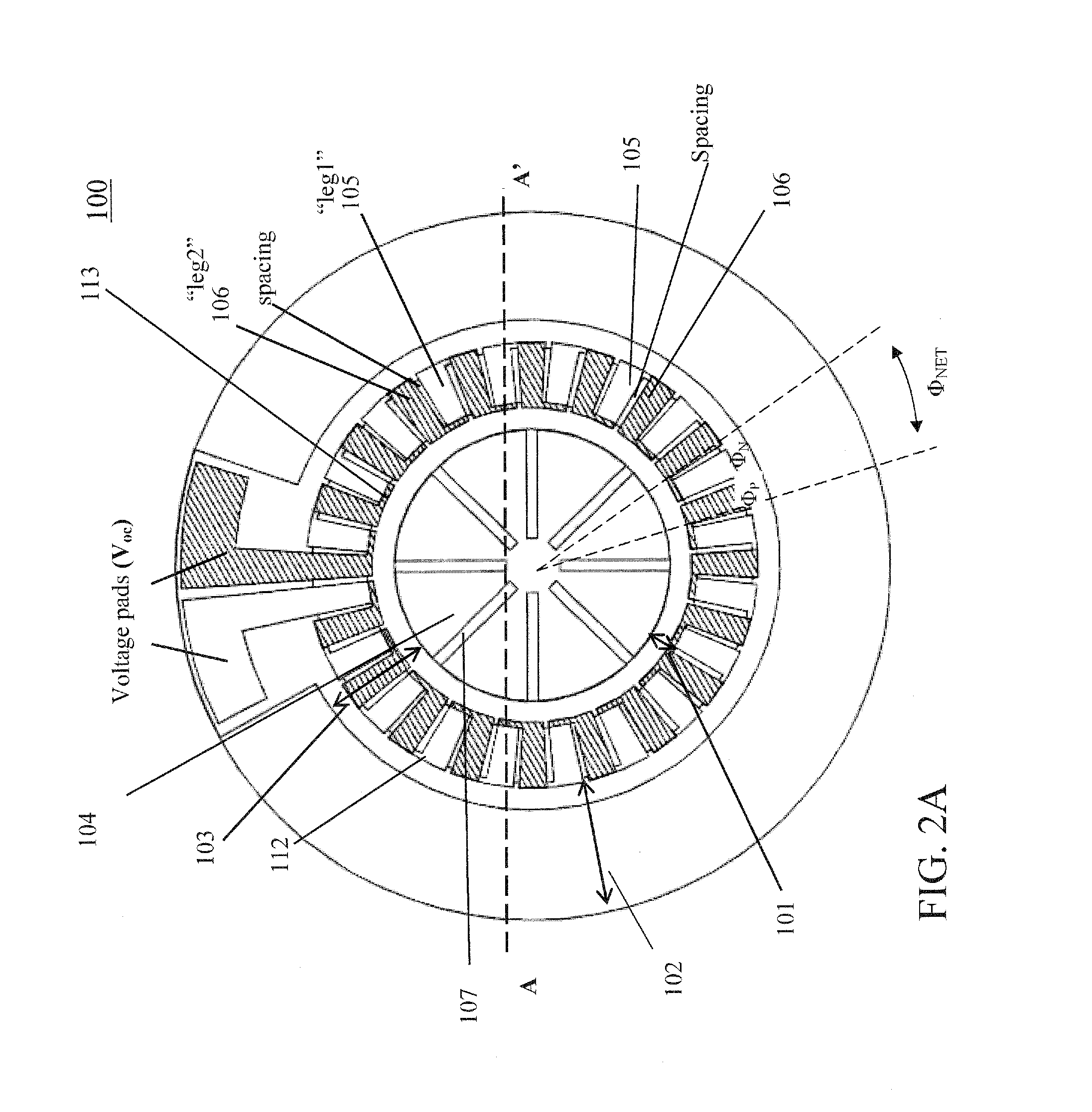

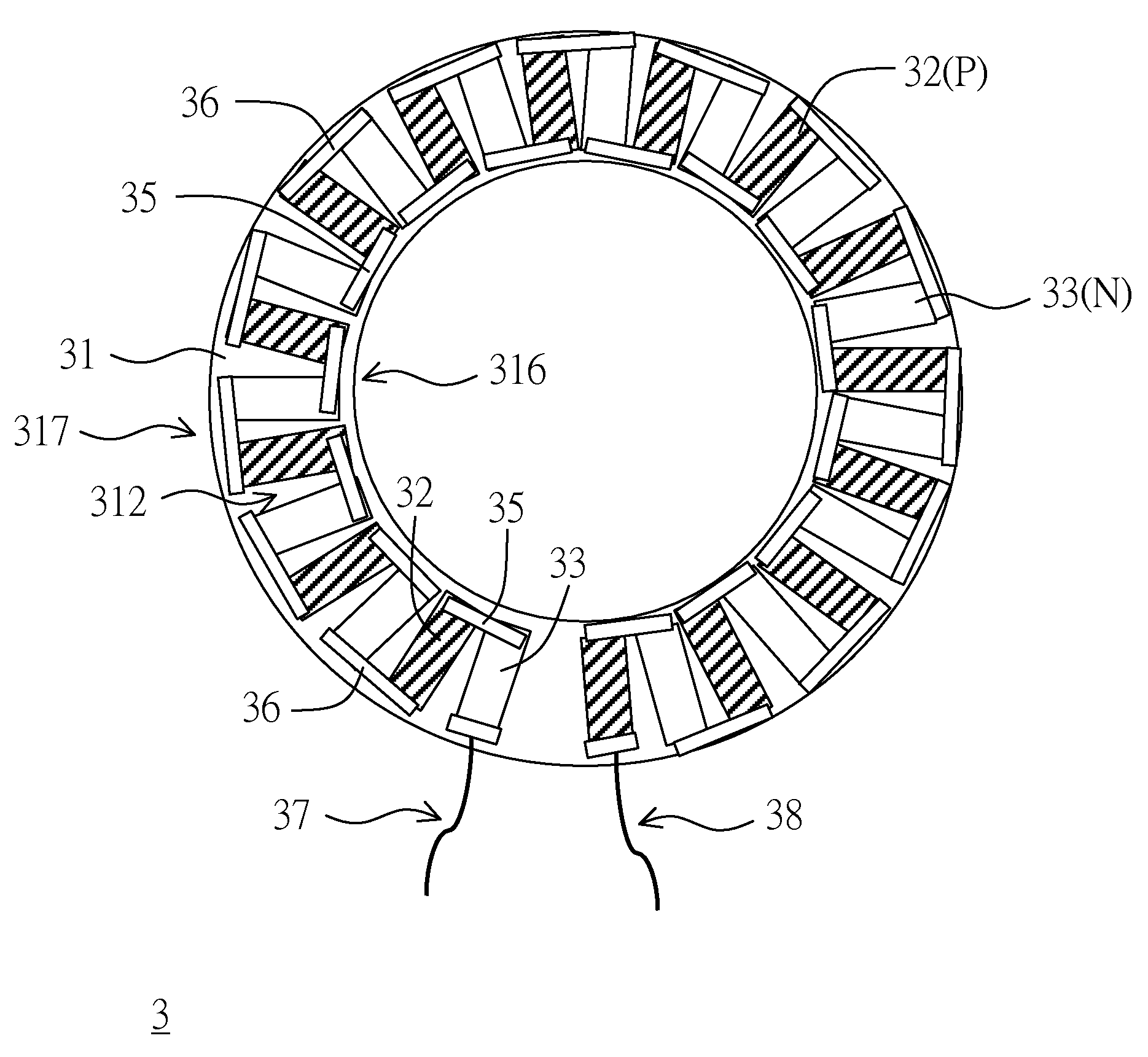

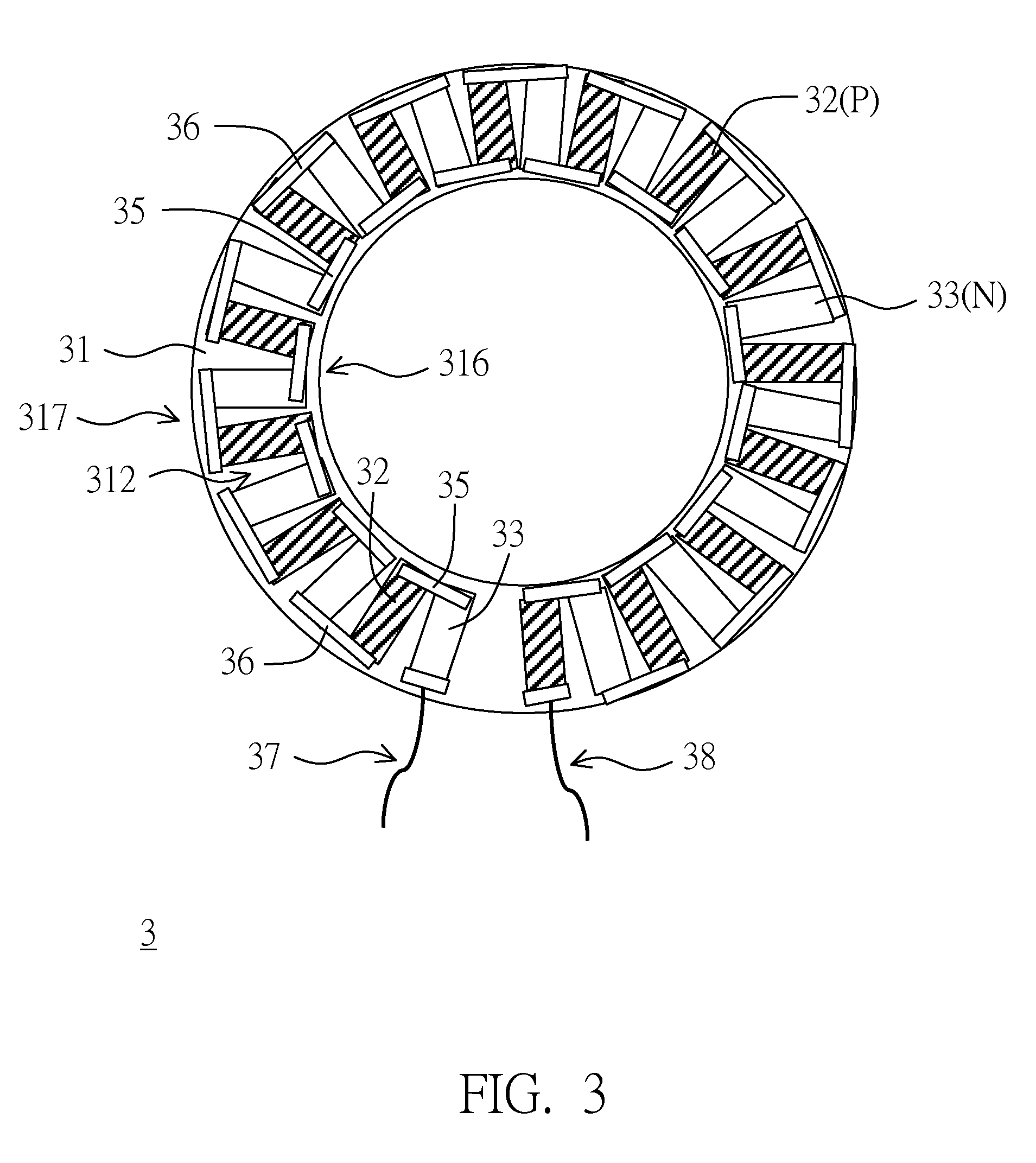

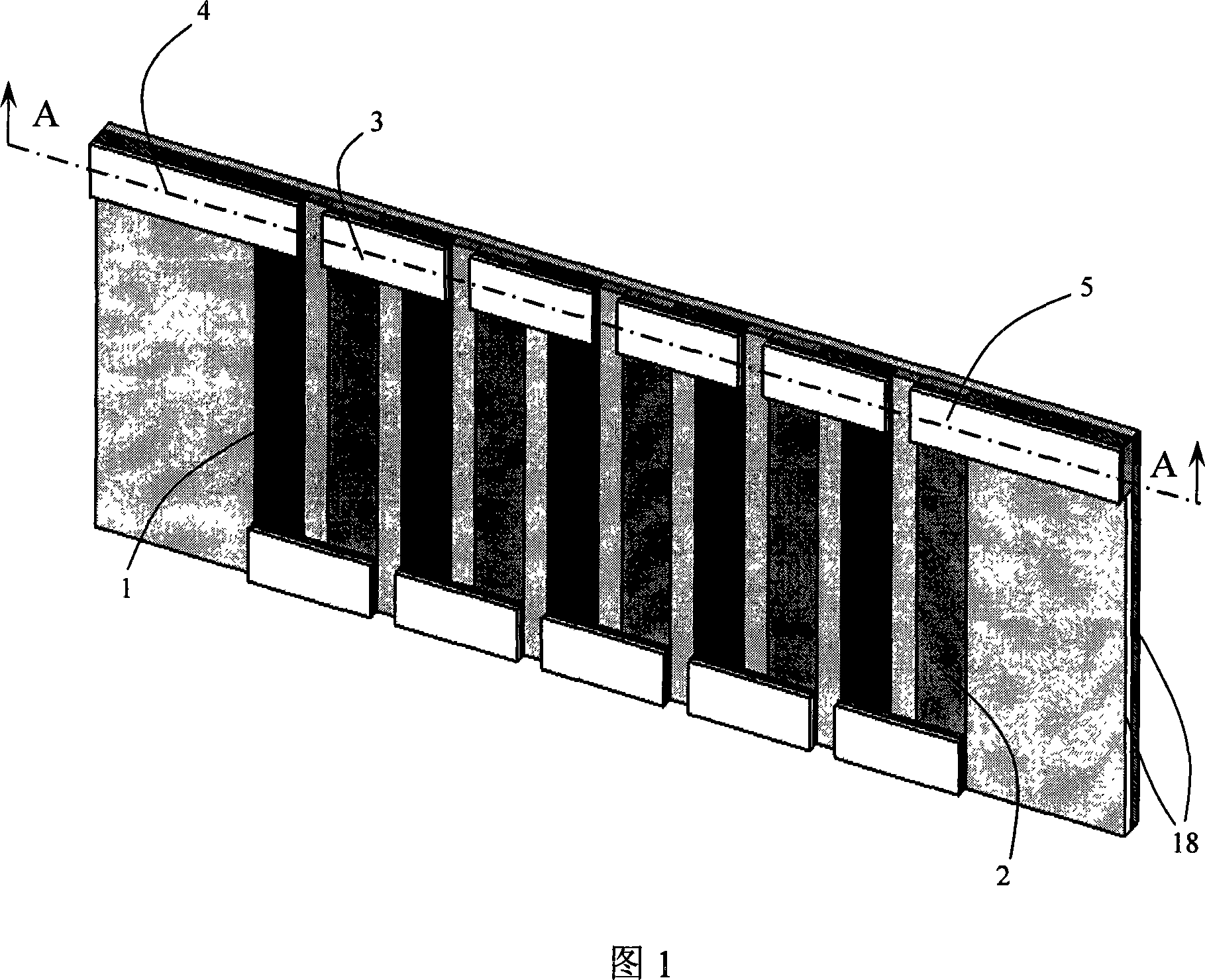

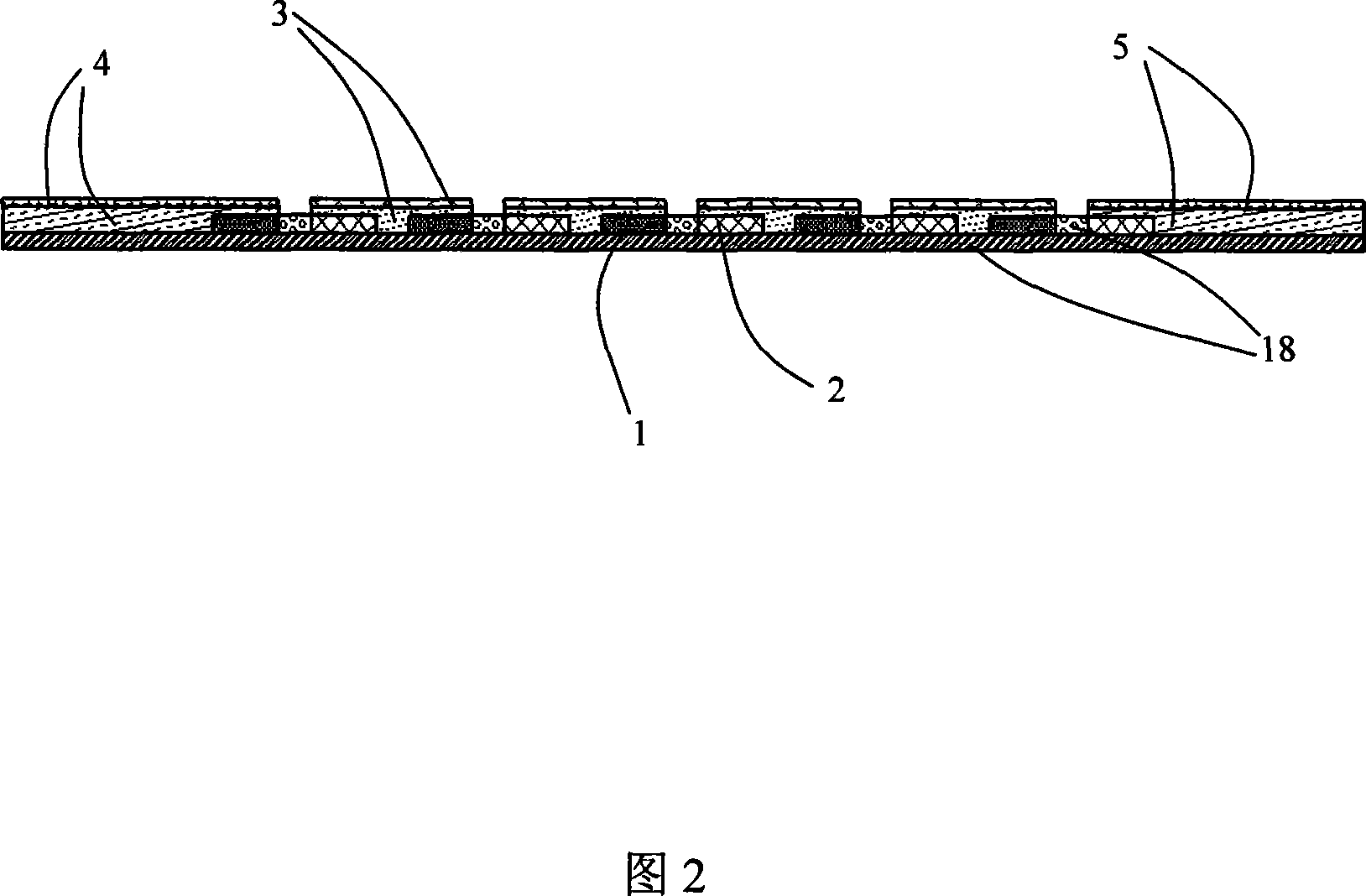

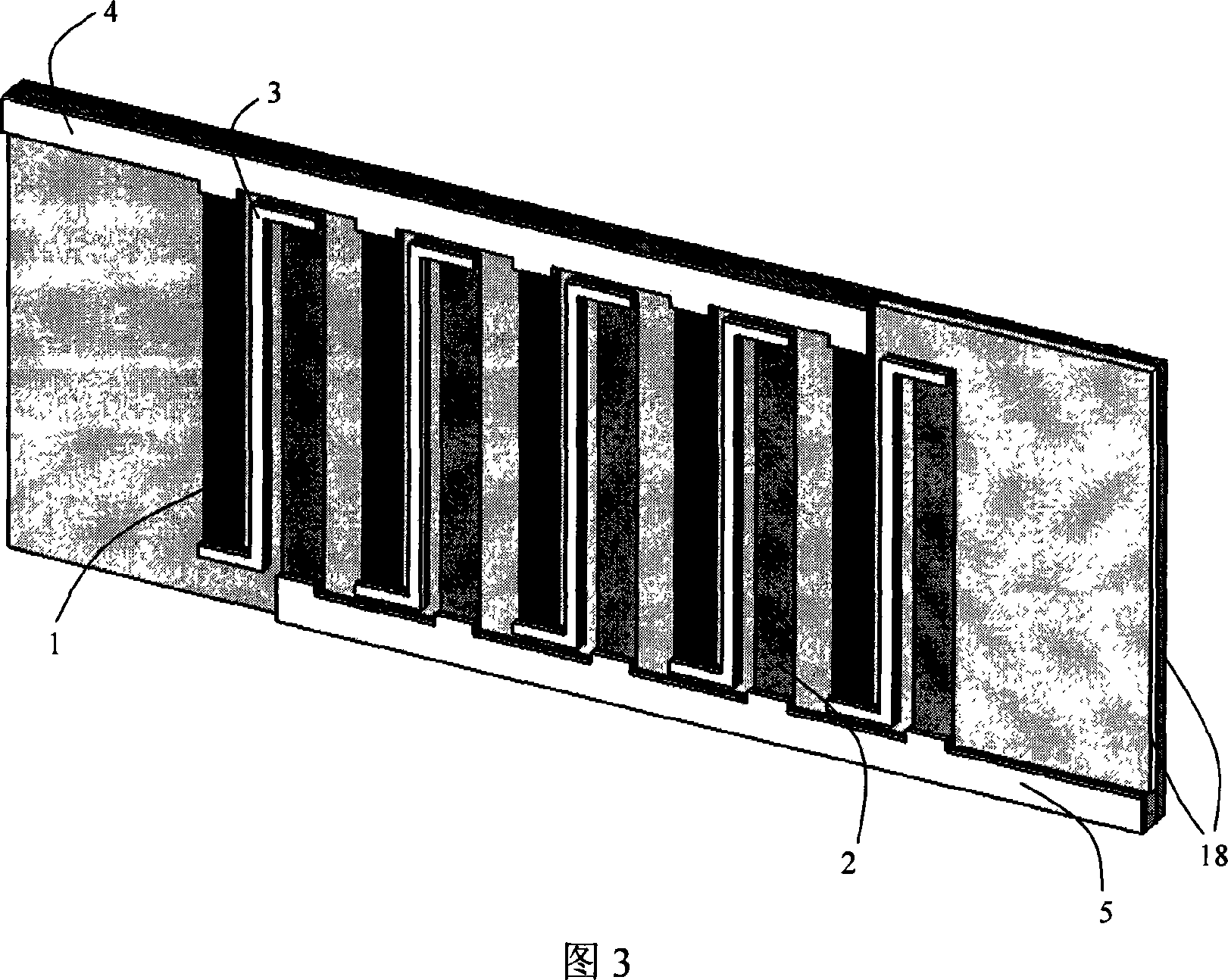

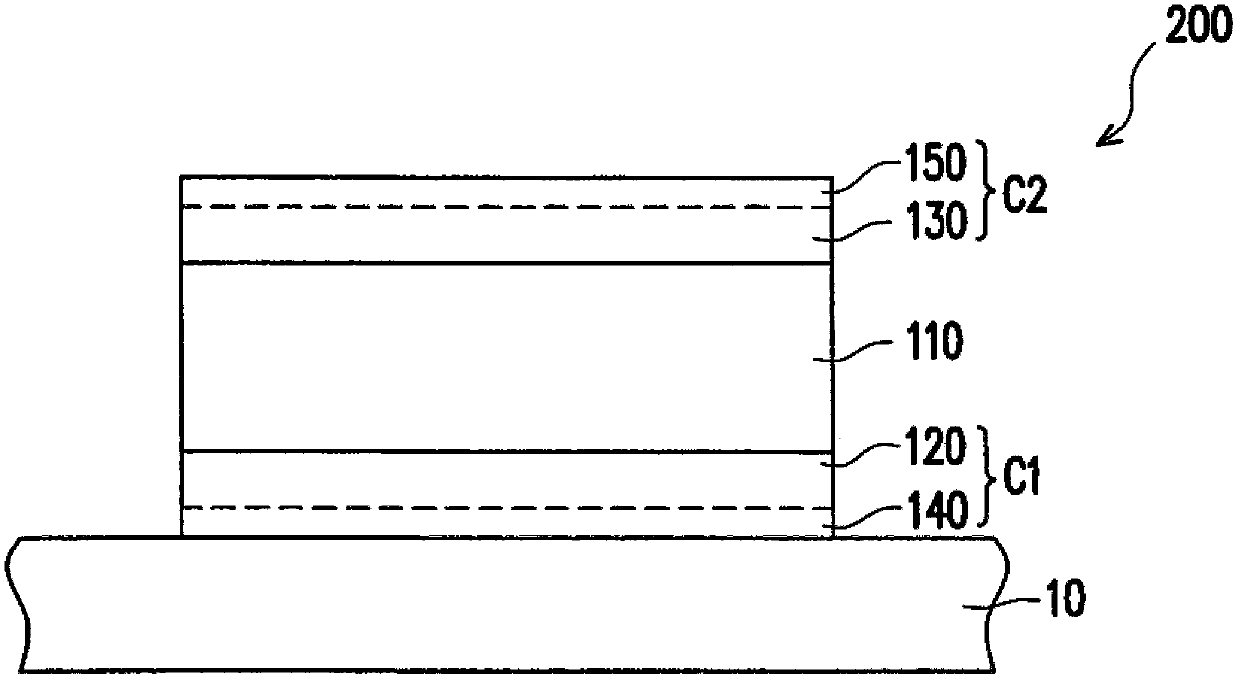

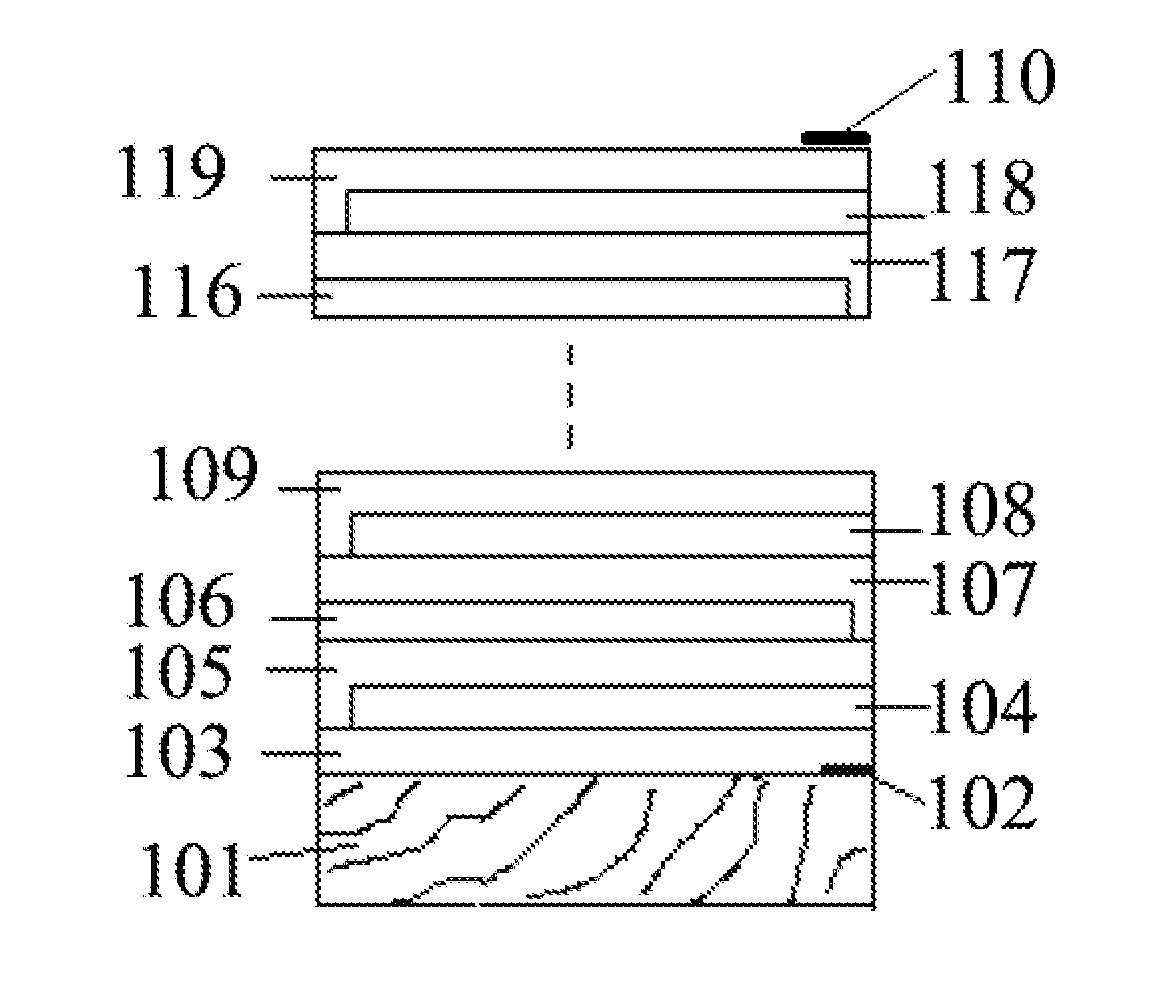

Thermoelectric device with thin film elements, apparatus and stacks having the same

InactiveUS7777126B2High thermoelectric efficiencySufficient distanceThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsTemperature differenceThermoelectric effect

A thermoelectric device at least includes a ring-shaped insulated substrate and plural sets of thermoelectric thin film material pair (TEP) disposed thereon. The ring-shaped insulated substrate has an inner rim, an outer rim and a first surface. The sets of TEP electrically connected to each other are disposed on the first surface of the ring-shaped insulated substrate. Each set of TEP includes a P-type and an N-type thermoelectric thin film elements (TEE) electrically connected to each other. Also, the N-type TEE of each set is electrically connected to the P-type TEE of the adjacent set of TEP. When a current flows through the sets of TEP along a direction parallel to the surfaces of P-type and N-type thermoelectric thin film elements, a temperature difference is generated between the inner rim and the outer rim of the ring-shaped insulated substrate.

Owner:IND TECH RES INST

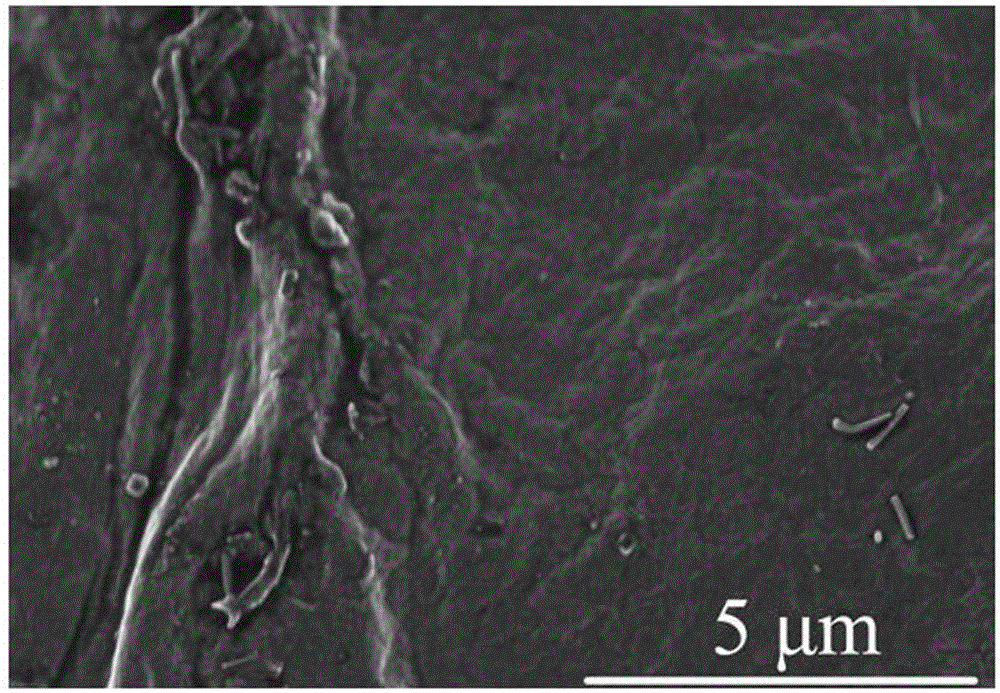

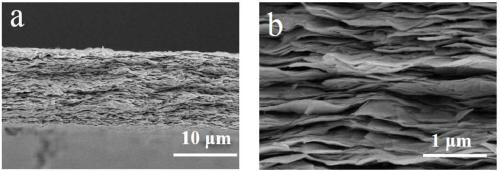

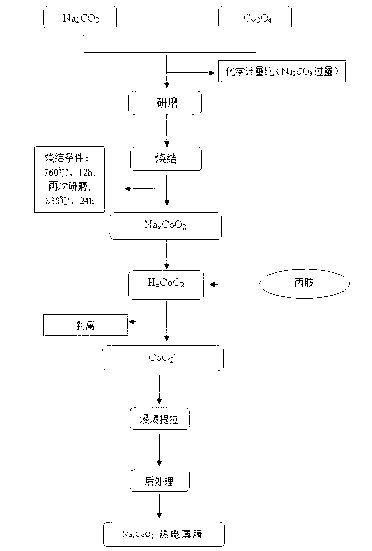

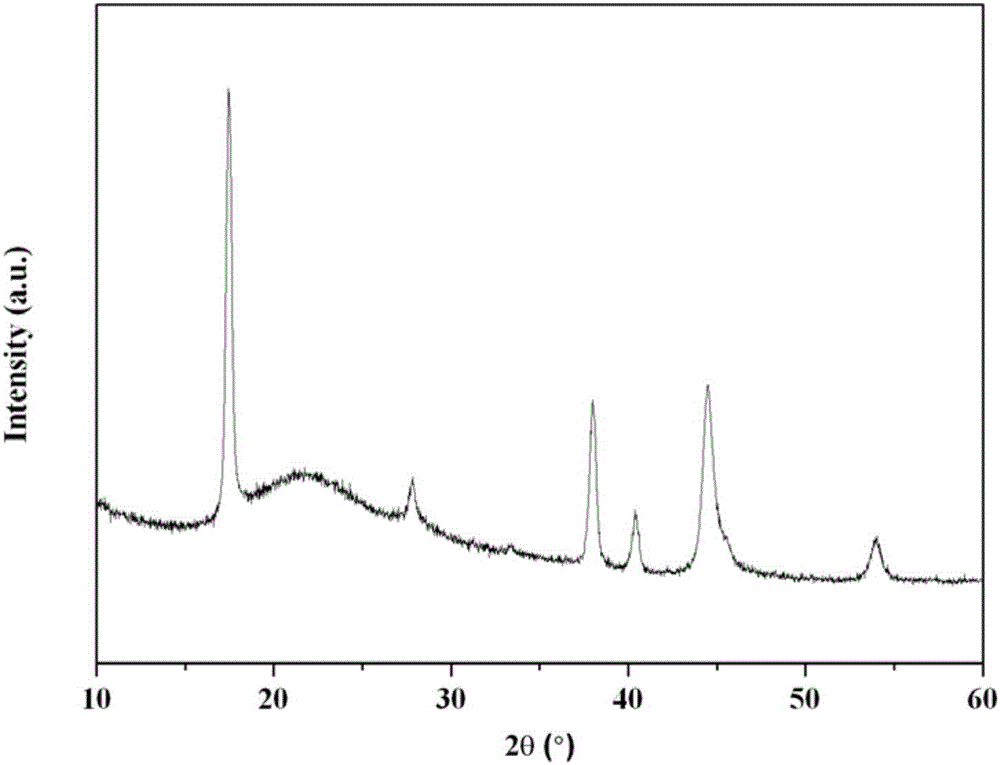

Preparation method for composite thermoelectric film with flexible reduced graphene oxide and tellurium nano wires

InactiveCN105633266AImprove conductivityOptimizing the Seebeck coefficientThermoelectric device manufacture/treatmentComposite filmFiltration

The invention relates to a preparation method for a composite thermoelectric film with flexible reduced graphene oxide (RGO)and tellurium nano wires (Te NWs). The preparation method comprises: reducing preparation is carried out by using oxidized graphene (GO) powder and sodium polystyrene sulfonate (NaPSS) as raw materials according to a hydrothermal method to obtain RGO that can be dispersed in water; reducing preparation is carried out by using sodium tellurite (Na2TeO3) as a raw material and hydrazine hydrate (N2H4.H2O) as a reducing agent according to a hydrothermal method to obtain TeNWs that can be dispersed in watewr; after a certain number of RGO and Na2TeO3 materials are dispersed in water ultrasonically, RGO dispersion liquid and Te NWs dispersion liquid drip on a flexible glass fiber film successively with assistance of vacuum filtration and the glass fiber film is dried in a vacuum environment; annealing is carried out on the glass fiber covered with a composite film at a mixed atmosphere of Ar and H2 under the temperature of 200 DEG C for some time to obtain a composite thermoelectric film with the RGO and Te NWs. The provided preparation method has characteristics of simple and easily controlled process, short reaction time, low energy consumption, high security, good pollution-free performance, and excellent flexible film thermoelectric property and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A preparation method of a multifunctional thermoelectric thin film power generation and light intensity sensor device

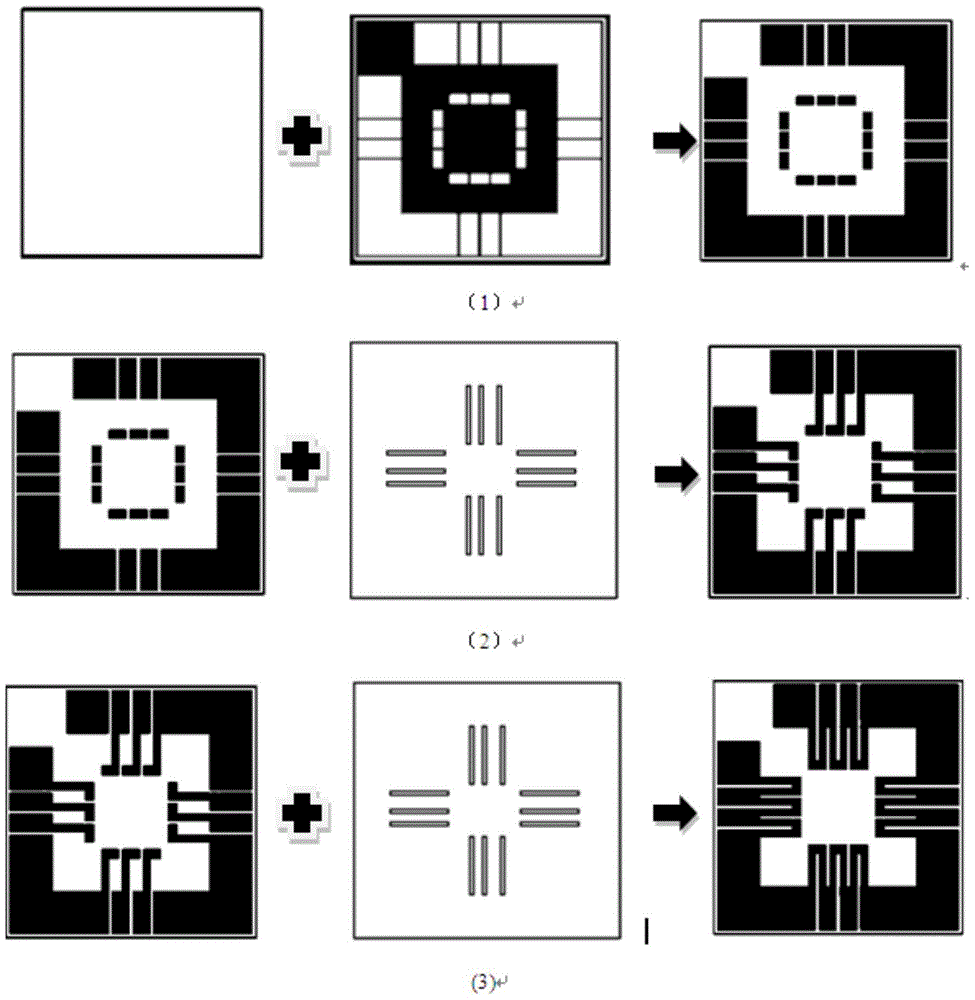

ActiveCN109087989ARealize pattern processingImprove thermoelectric performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentFresnel lensHigh density

The invention discloses a preparation method of a multifunctional thermoelectric thin film power generation and light intensity sensor device, belonging to the technical field of energy collection andsensing of a miniature thin film functional device. The method comprises the steps of: pretreating a substrate; depositing patterned high-density N-type thermoelectric thin films on the pretreated substrate; annealing the N-type thermoelectric film; depositing a patterned high-density P-type thermoelectric thin film and an electrode thin film on the pretreated substrate, wherein the electrode thin film serially connects a thermocouple formed by the pattern of the P-type thermoelectric thin film and the N-type thermoelectric thin film; forming a thermoelectric device by pasting a heat-absorbing film on the hot end of the thermocouple; and assembling the thermoelectric device with the Fresnel lens, the heat dissipation structure and the housing to form the multifunctional thermoelectric thin film power generation and light intensity sensor device. The invention can realize power generation and light intensity sensing, and the thermoelectric thin film device prepared by the method of theinvention has the characteristics of high output voltage, high responsiveness and the like through the light intensity sensing test.

Owner:BEIHANG UNIV

N-type thermoelectric thin film and preparation method and application thereof

ActiveCN109560186ASimple manufacturing methodExcellent ElectricalThermoelectric device manufacture/treatmentGrapheneComposite filmFiltration

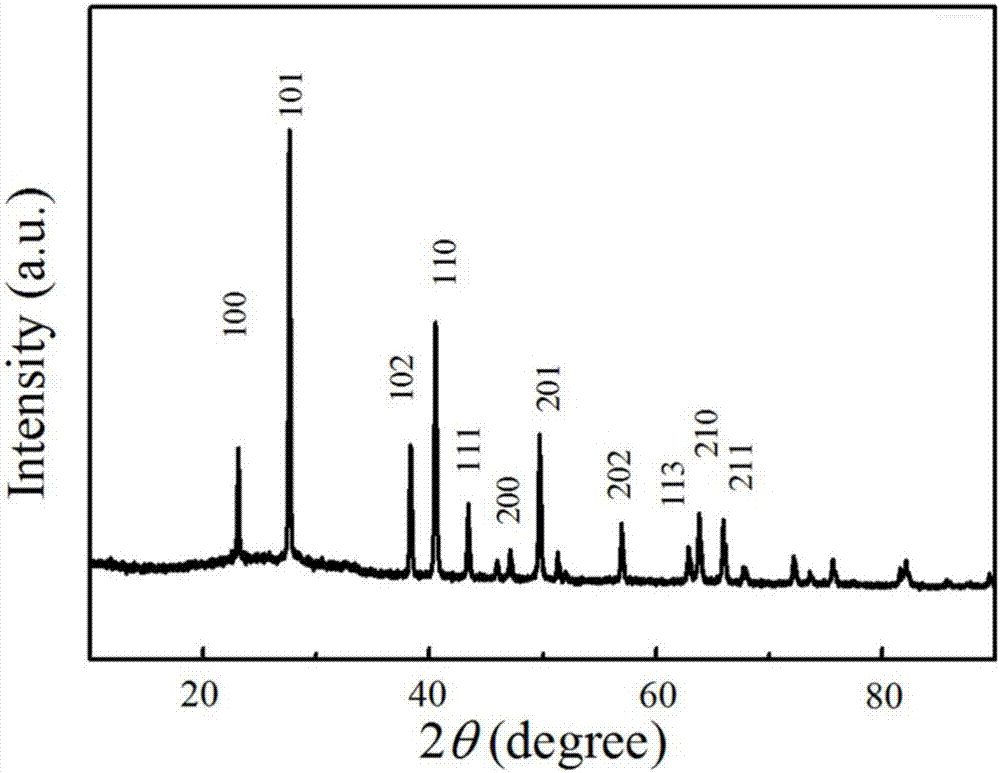

The invention relates to an N-type thermoelectric thin film and a preparation method and application thereof. The thin film takes bismuth telluride as a basal body and graphene as an electric conduction bridge to be connected with bismuth telluride so as to form a three-dimensional network structure. The preparation method comprises the following steps: mixing oxidized graphene-bismuth telluride into dispersion liquid for suction filtration film formation, and then carrying out high temperature reduction in an NH3 gas environment so as to obtain the N-type thermoelectric thin film. The graphene-bismuth telluride composite thin film can be directly used for converting heat energy such as human body waste heat, sunlight heat and mechanical waste heat into electric energy, and has important scientific value and wide application prospect in the wearable field.

Owner:DONGHUA UNIV

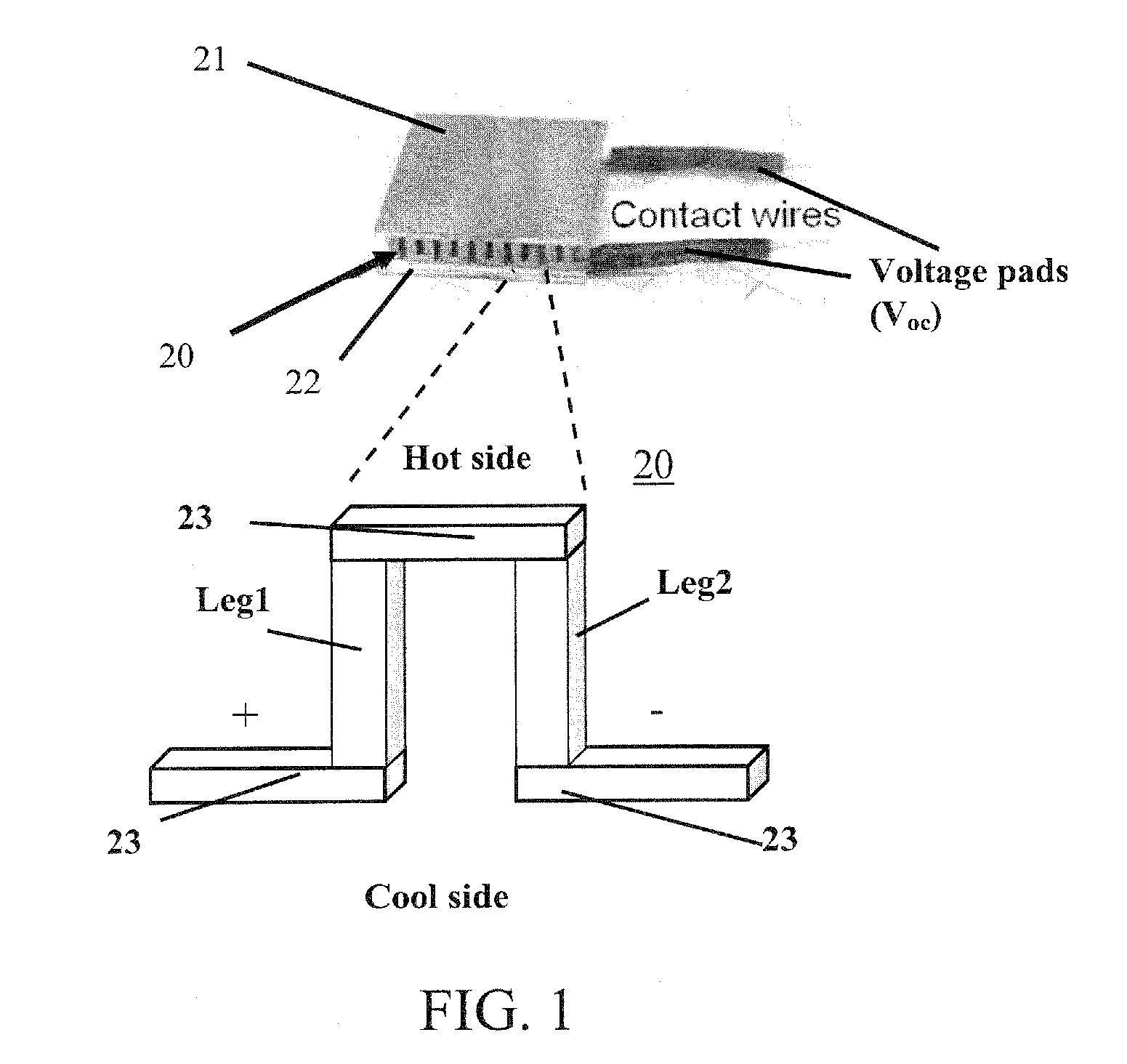

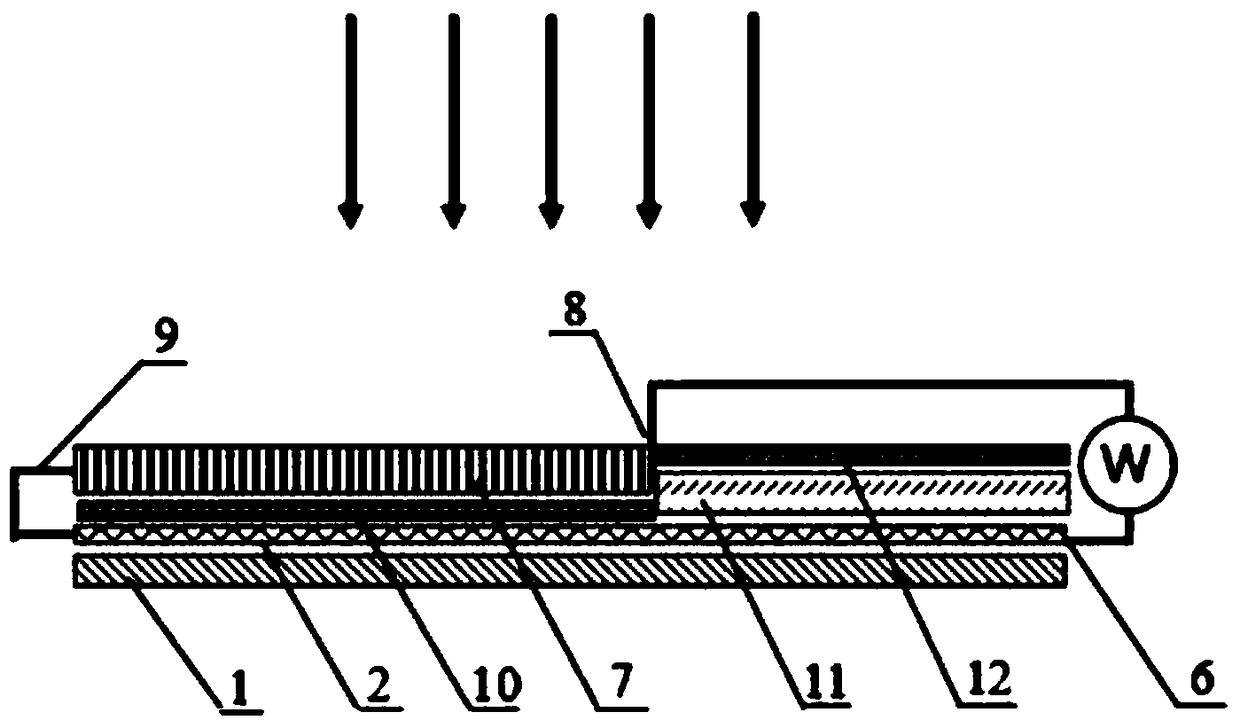

Miniature Thermoelectric Power Generator

ActiveUS20110155202A1More integrableImprove performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermopileEngineering

The subject invention pertains to thermoelectric power generation. According to certain embodiments, a stack of silicon-micromachined chips can be connected to form a cylindrical heat exchanger that enables a large, uniform temperature difference across a radially-oriented thermopile. Each layer in the stack can comprise two thermally-isolated concentric silicon rings connected by a polyimide membrane that supports patterned thermoelectric thin films. The polyimide membrane can be formed by selectively etching away the supporting silicon, resulting in thermally-isolated inner and outer rings. In operation, hot gas can flow through a finned central channel, and an external cross flow can enhance heat transfer to ambient to keep the outer surfaces cool. The resulting temperature gradient across the thermopile generates a voltage potential across the open ends due to the Seebeck effect. When connected to a load, current flows, and electrical power is supplied by the generated voltage potential caused by the temperature gradient.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

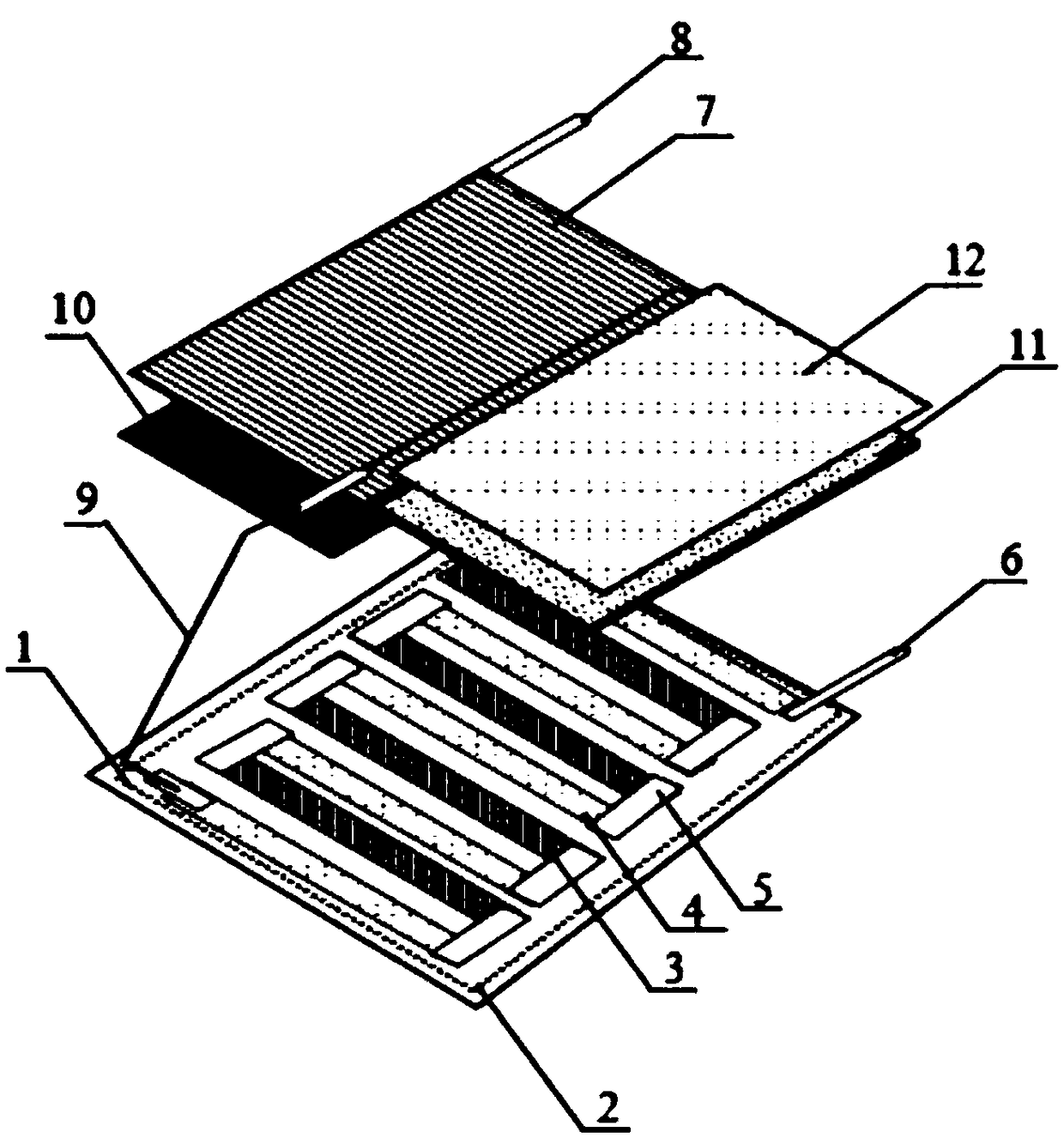

A flexible thin film solar-thermo electricity conversion device

ActiveCN109104138AImprove energy utilizationIncrease the open circuit voltagePV power plantsThermoelectric device detailsThermal energyElectricity

The invention relates to a flexible thin film solar-thermo electricity conversion device, comprising a flexible thin film substrate, a flexible thermoelectric thin film module and a flexible photovoltaic thin film module, wherein the flexible thin film substrate is provided with a flexible thermoelectric thin film module; the light-facing surface of the flexible thermoelectric film module is provided with a flexible heat conduction layer and a flexible heat insulation layer in parallel, and the light-facing surface of the flexible heat conduction layer is provided with the flexible photovoltaic film module; the light-facing surface of the flexible thermal insulation layer is equipped with a flexible reflective layer to reduce the absorption of solar thermal energy, and the temperature difference is manufactured in the flexible thermoelectric thin film module. An output port of one end of the flexible thermoelectric thin film module is connected with one output port of one end of the flexible photovoltaic thin film module to form a photovoltaic thermoelectric universal output port, the other end output port of the flexible thermoelectric thin film module is used as a thermoelectricoutput port, and the other end output port of the flexible photovoltaic thin film module is used as a photovoltaic output port. The invention can effectively improve the comprehensive utilization rateof solar energy.

Owner:DONGHUA UNIV

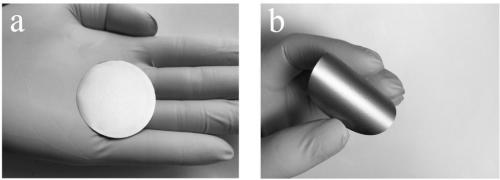

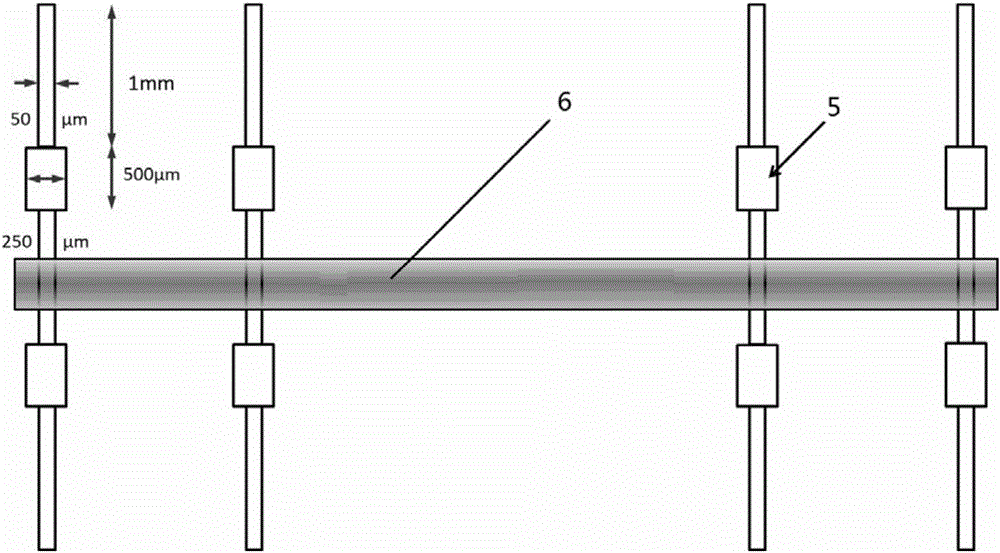

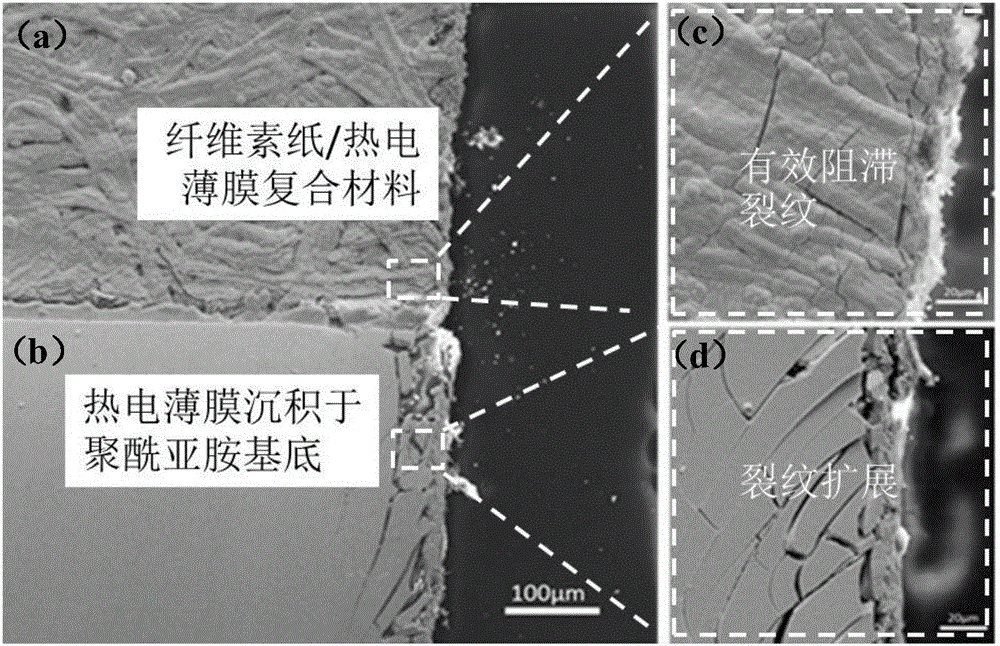

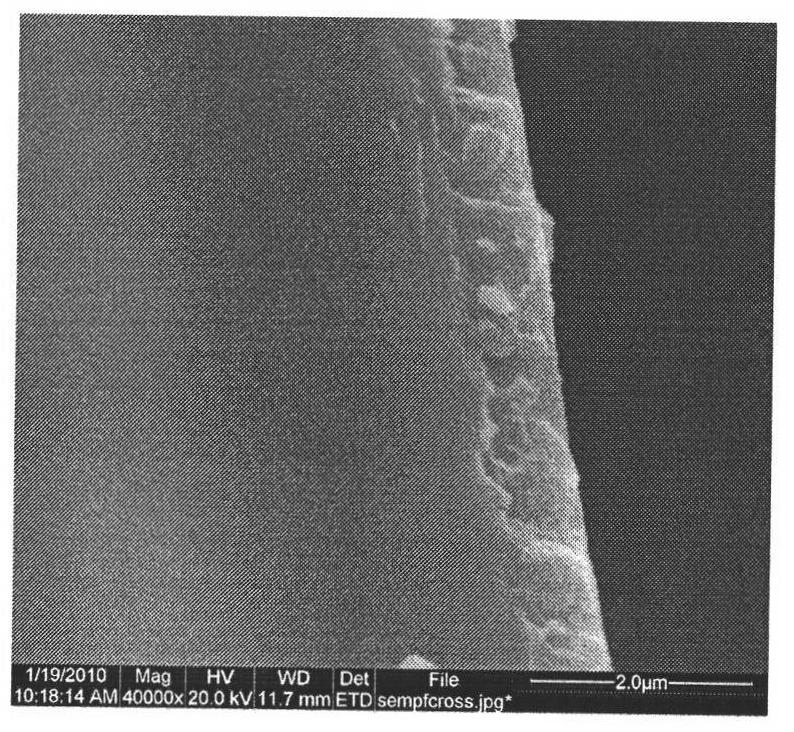

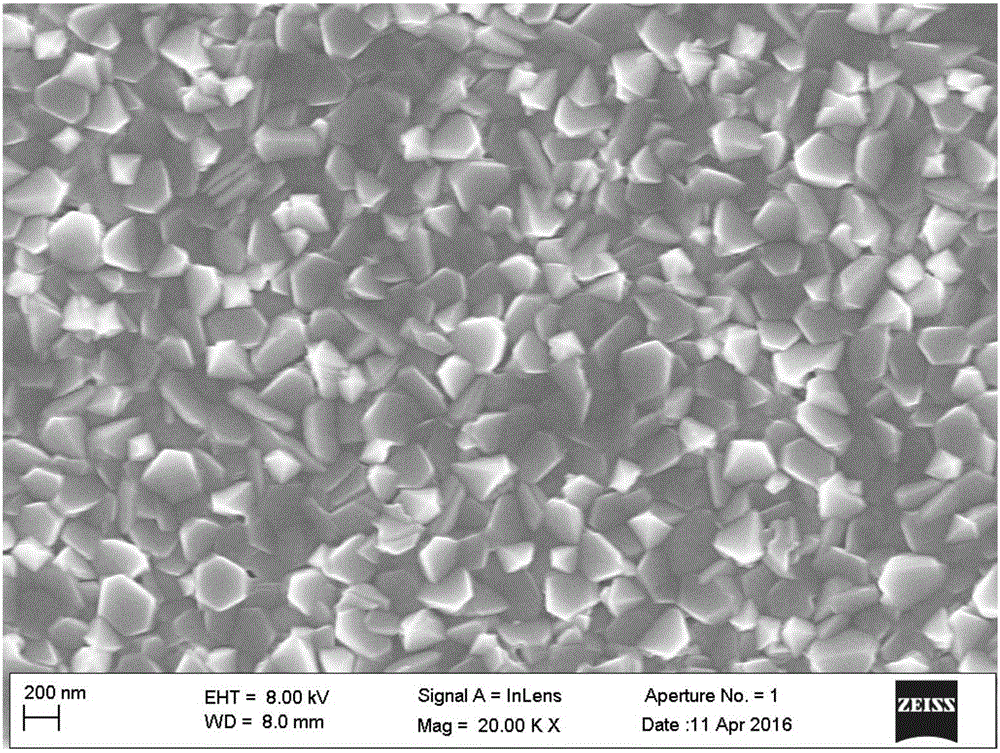

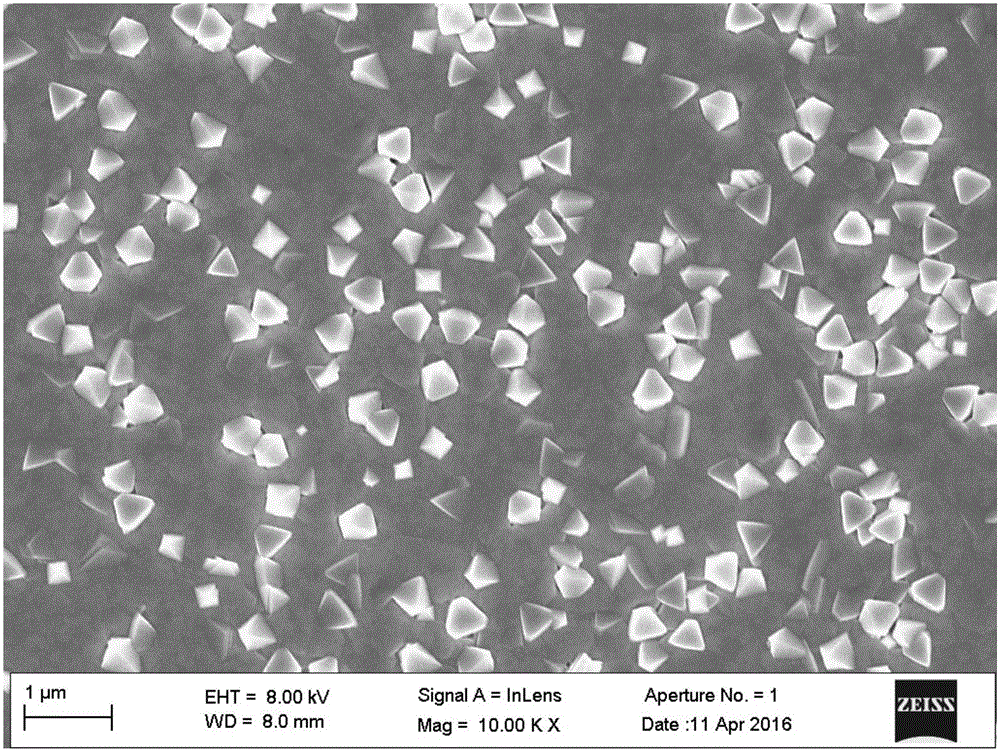

Cellulose paper/Bi2Te3 thermoelectric thin-film composite material and preparation method thereof

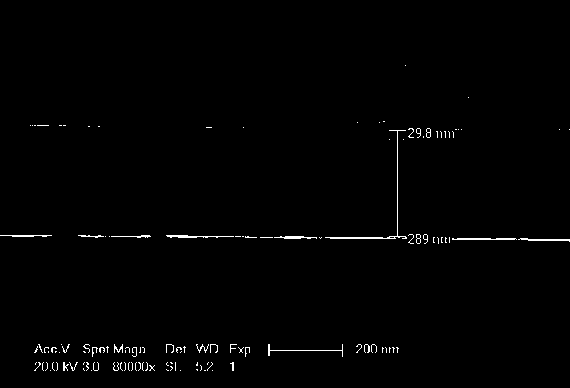

ActiveCN105789425AReduce strainLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsCelluloseTemperature control

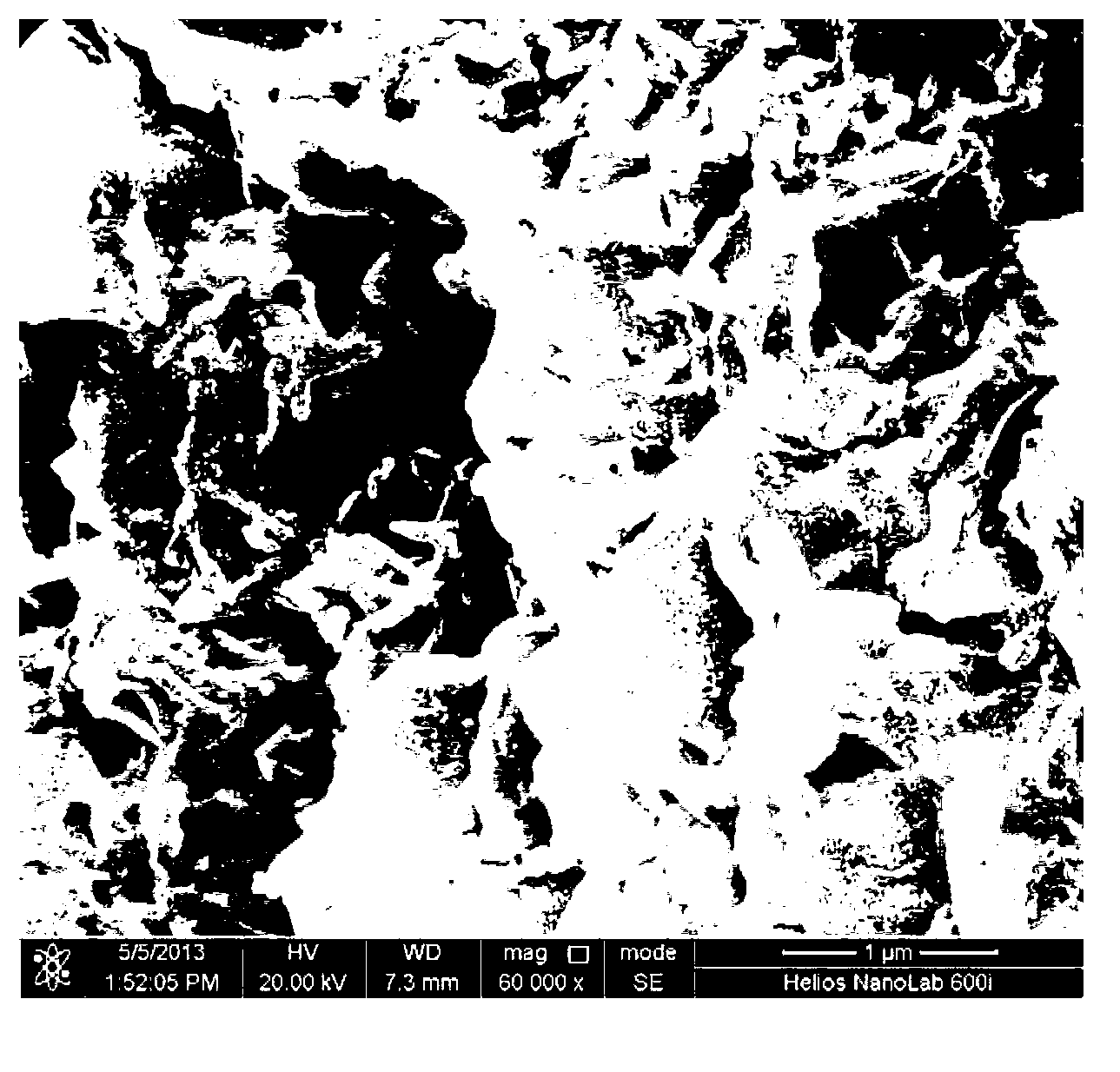

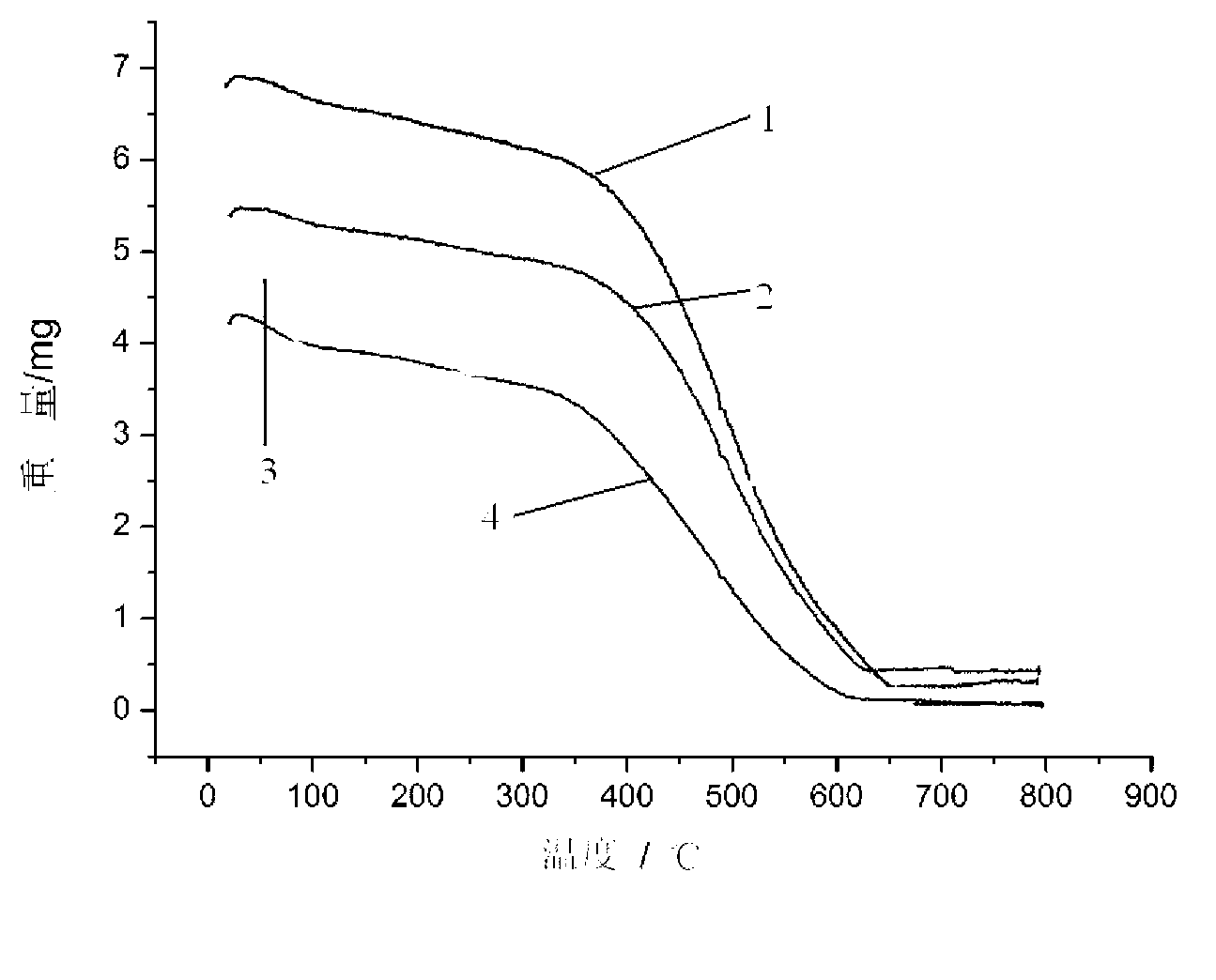

The invention relates to the field of composite materials, in particular to a cellulose paper / Bi2Te3 (bismuth telluride) thermoelectric thin-film composite material and a preparation method thereof. The composite material comprises a cellulose paper substrate and a Bi2Te3 thermoelectric thin-film layer, wherein the Bi2Te3 thermoelectric thin-film layer is evenly deposited on the surface of the cellulose paper substrate; the thickness of cellulose paper is 50-100 microns; and the nominal thickness of the Bi2Te3 thermoelectric thin-film layer is 5-10 microns. The cellulose paper / thermoelectric thin-film composite material is prepared by an unbalanced magnetron deposition technology, has very high thermoelectric energy conversion efficiency, demonstrates good flexibility and is a flexible thermoelectric energy conversion material with an application prospect. The deposited thermoelectric material is high in crystal quality and has a compact structure of nanoscale grains; the thickness and the components are uniform and adjustable; the thermoelectric properties are close to those of a commercial block material; and the composite material can be applied to the field of a flexible energy device, a miniature sensor, a temperature control component and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

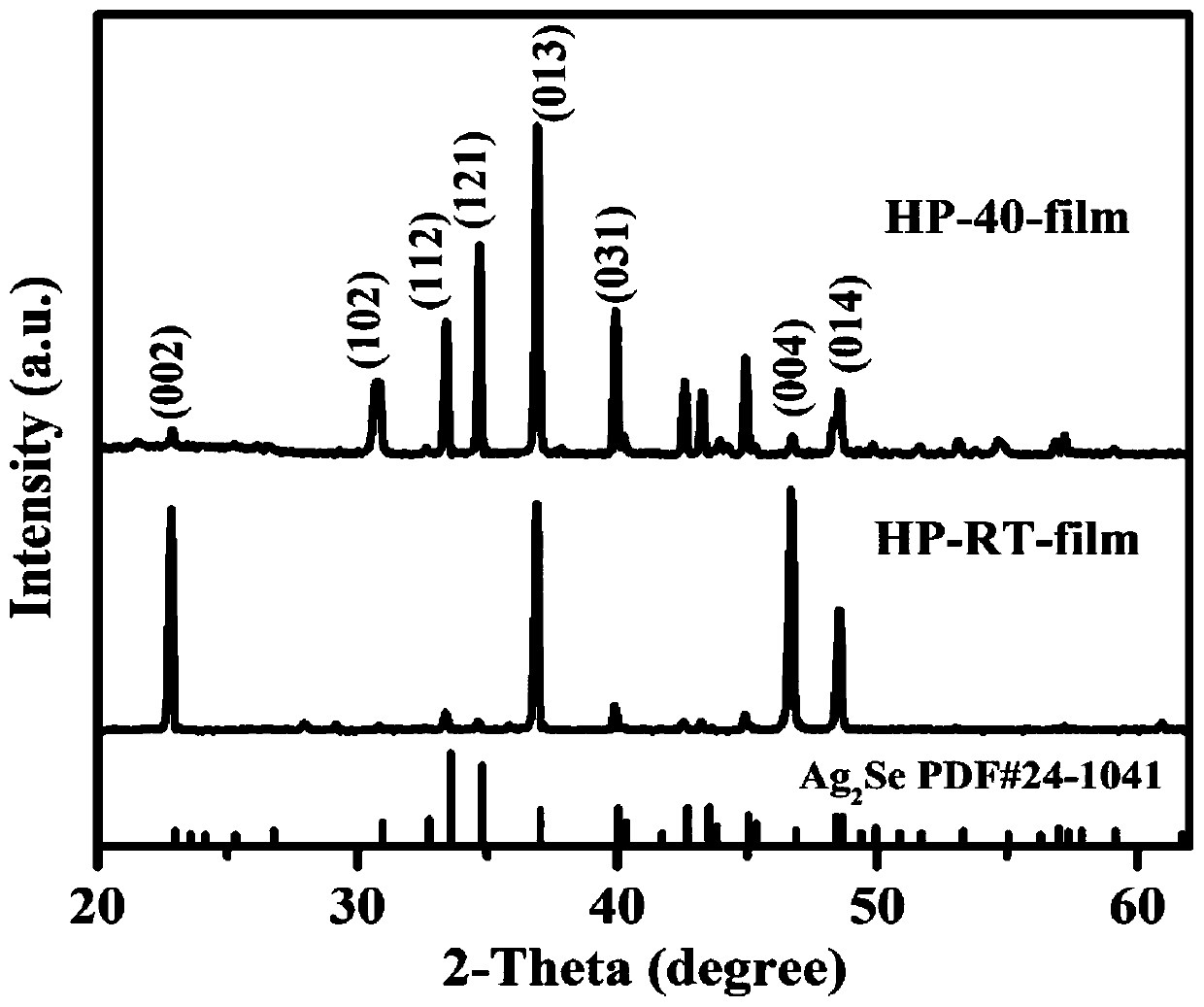

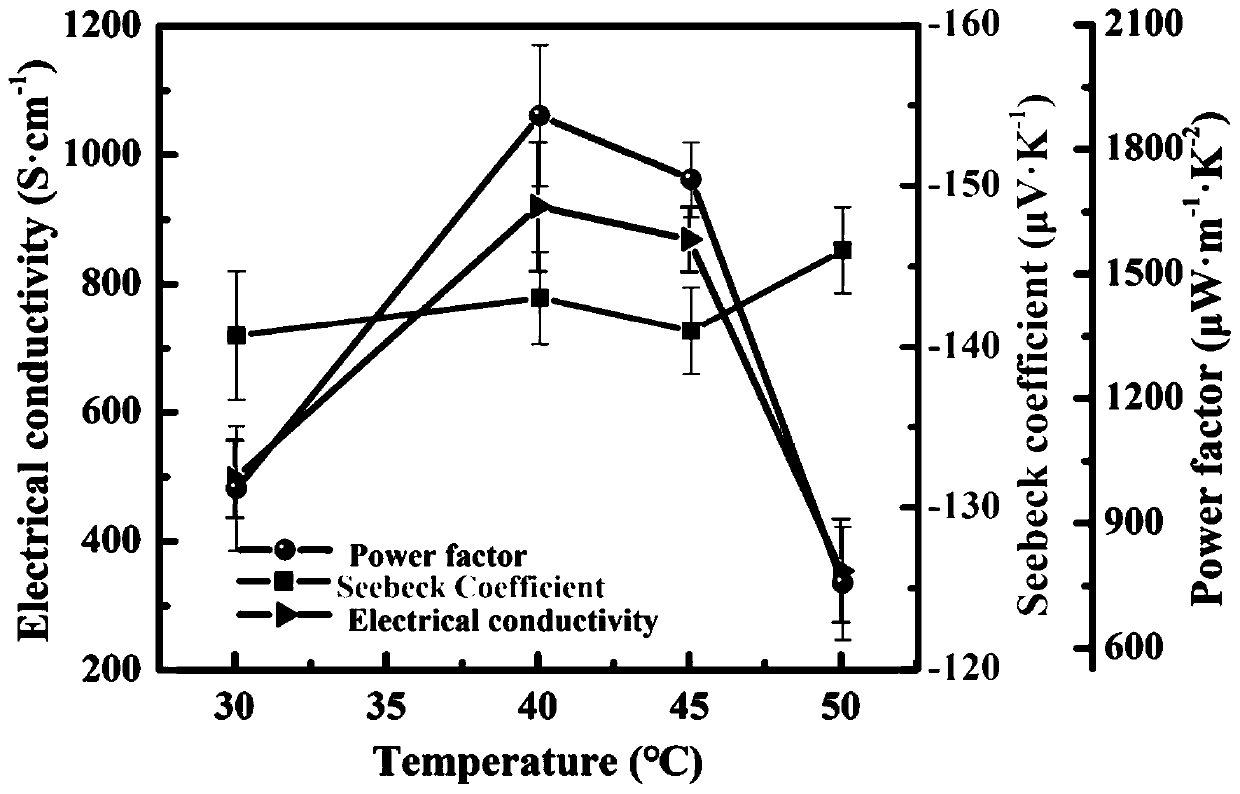

Preparation method for optimizing thermoelectric performance of silver selenide/nylon flexible composite film

ActiveCN110828651ASimple manufacturing processLow costThermoelectric device manufacture/treatmentThermoelectric device detailsNanowireComposite film

The invention relates to a preparation method for optimizing the thermoelectric performance of a silver selenide / nylon flexible composite film, and the method comprises the following steps: (1) takinga selenium nanowire as a template, enabling the selenium nanowire to react with silver nitrate in an ethylene glycol solvent at 40 DEG C, and carrying out separation, thereby obtaining a silver selenide nanostructure; (2) dispersing the silver selenide nanostructure in absolute ethyl alcohol, taking a nylon filter membrane as a substrate, and performing suction filtration and drying to obtain a nylon-silver selenide film; and (3) finally, carrying out hot pressing treatment on the nylon-silver selenide film obtained in the step (2) to obtain a target product. Compared with the prior art, themethod has the advantages that the high-performance flexible thermoelectric thin film can be prepared, and the thin film is used for manufacturing a high-output-performance thermoelectric device to supply power to a wearable electronic device.

Owner:TONGJI UNIV

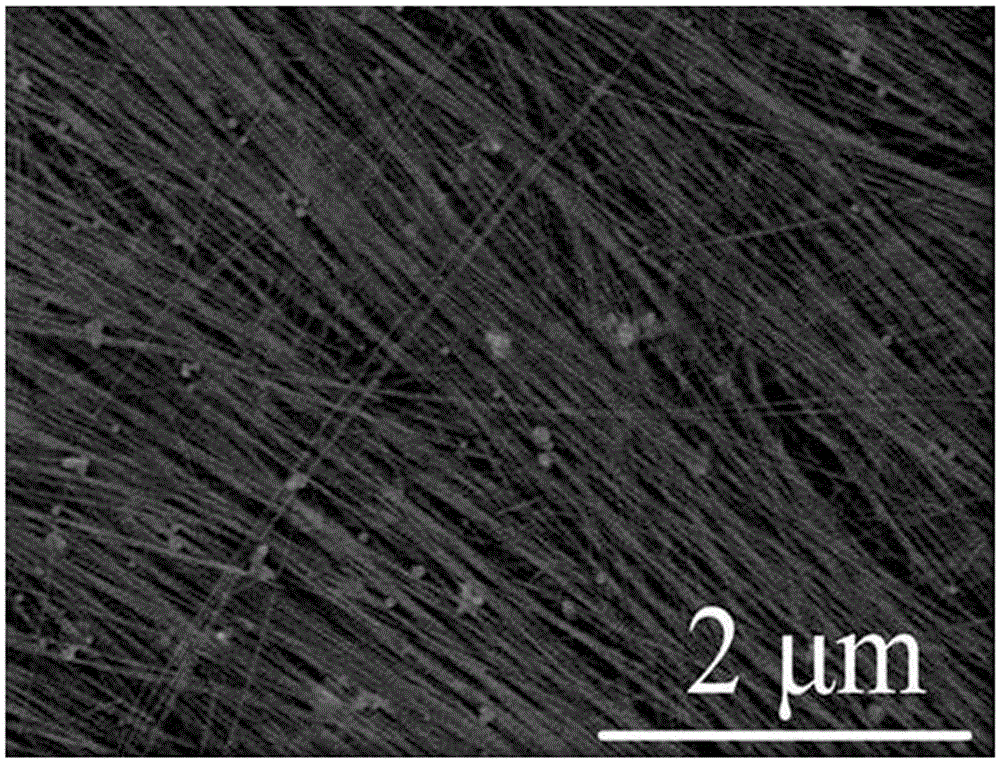

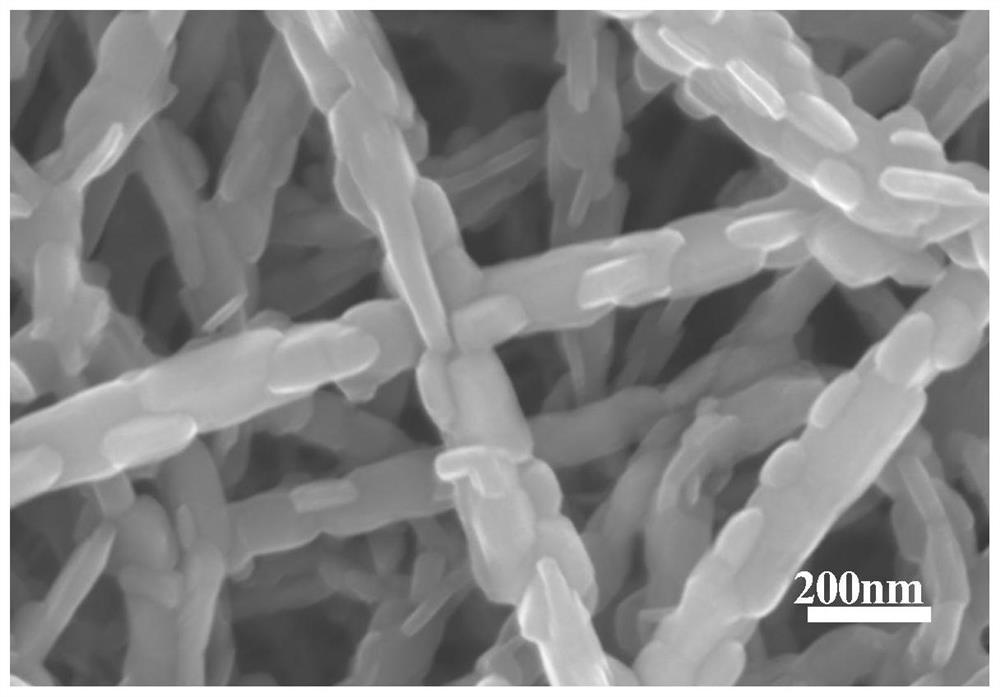

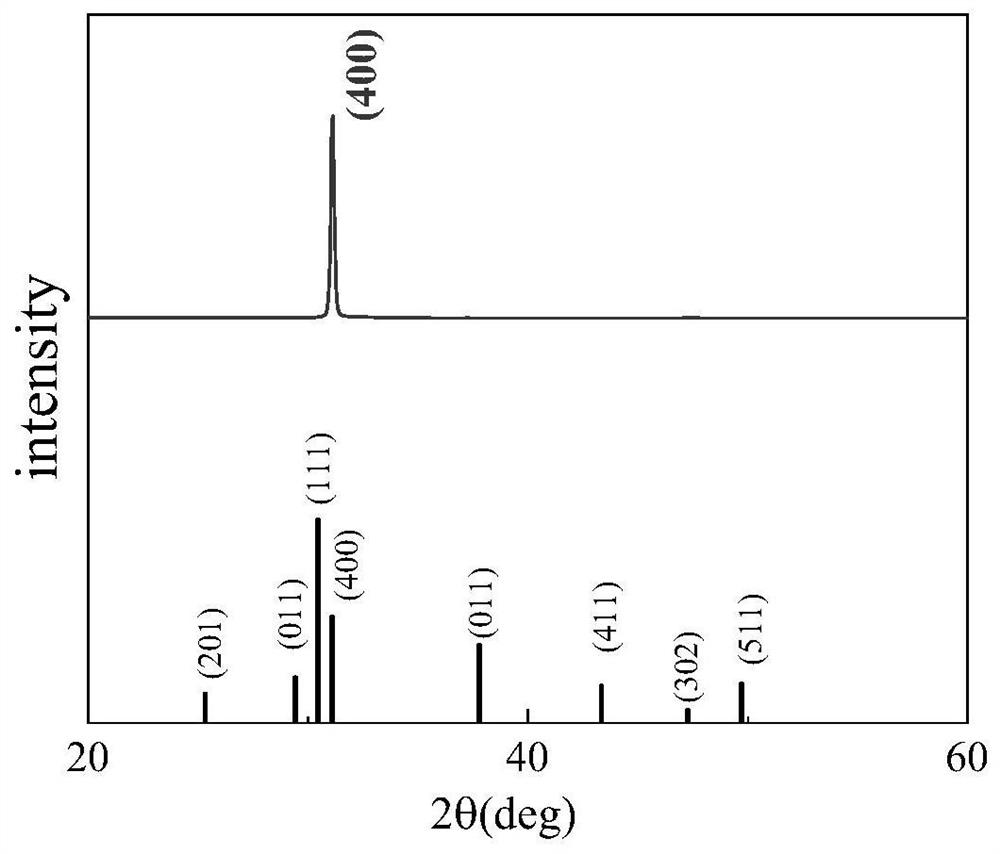

Method for preparing flexible N type silver telluride nanowire thermoelectric thin film

ActiveCN106505142AImprove flexibilityControl thermoelectric propertiesThermoelectric device junction materialsGlass fiberNanowire

The invention discloses a method for preparing a flexible N type silver telluride nanowire thermoelectric thin film. The method includes the following steps: mixing a silver telluride nanowire with polyvinylpyrrolidone, and performing ultrasonic dispersion of the mixture in a solvent to obtain a silver telluride nanowire dispersion liquid; under the condition of vacuum filtration, uniformly dripping the silver telluride nanowire dispersion liquid on a glass fiber filter membrane, and performing vacuum drying at 75 DEG C to obtain a silver telluride nanowire thin film adhered to the glass fiber filter membrane; clamping the silver telluride nanowire thin film between two pieces of copy paper, placing the whole in a tablet press to perform extrusion forming, then using a brush to remove glass fiber filter membrane fragments on the reverse side of the silver telluride nanowire thin film, and placing the silver telluride nanowire thin film in a vacuum oven for annealing to obtain a target product. The method for preparing the flexible N type silver telluride nanowire thermoelectric thin film is simple and controllable, short in preparation cycle, safe and pollution-free, and low in energy consumption, an obtained thin film has excellent thermoelectric performance and good flexibility, flexible thermoelectric thin films of different sizes and shapes can be prepared flexibly according to the sizes and shapes of glass fiber membranes, and thus the method has wide application prospects.

Owner:GUILIN UNIV OF ELECTRONIC TECH

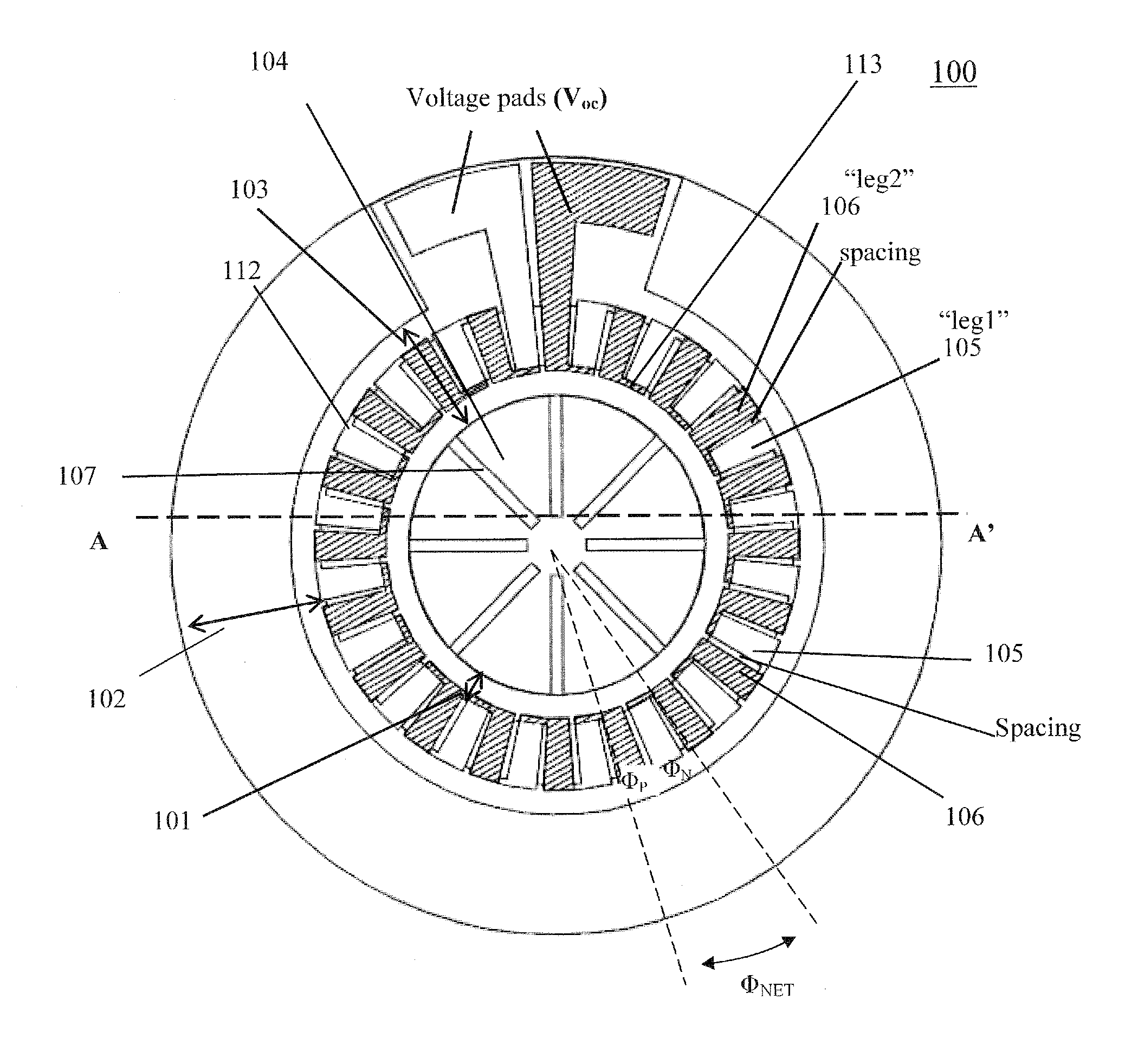

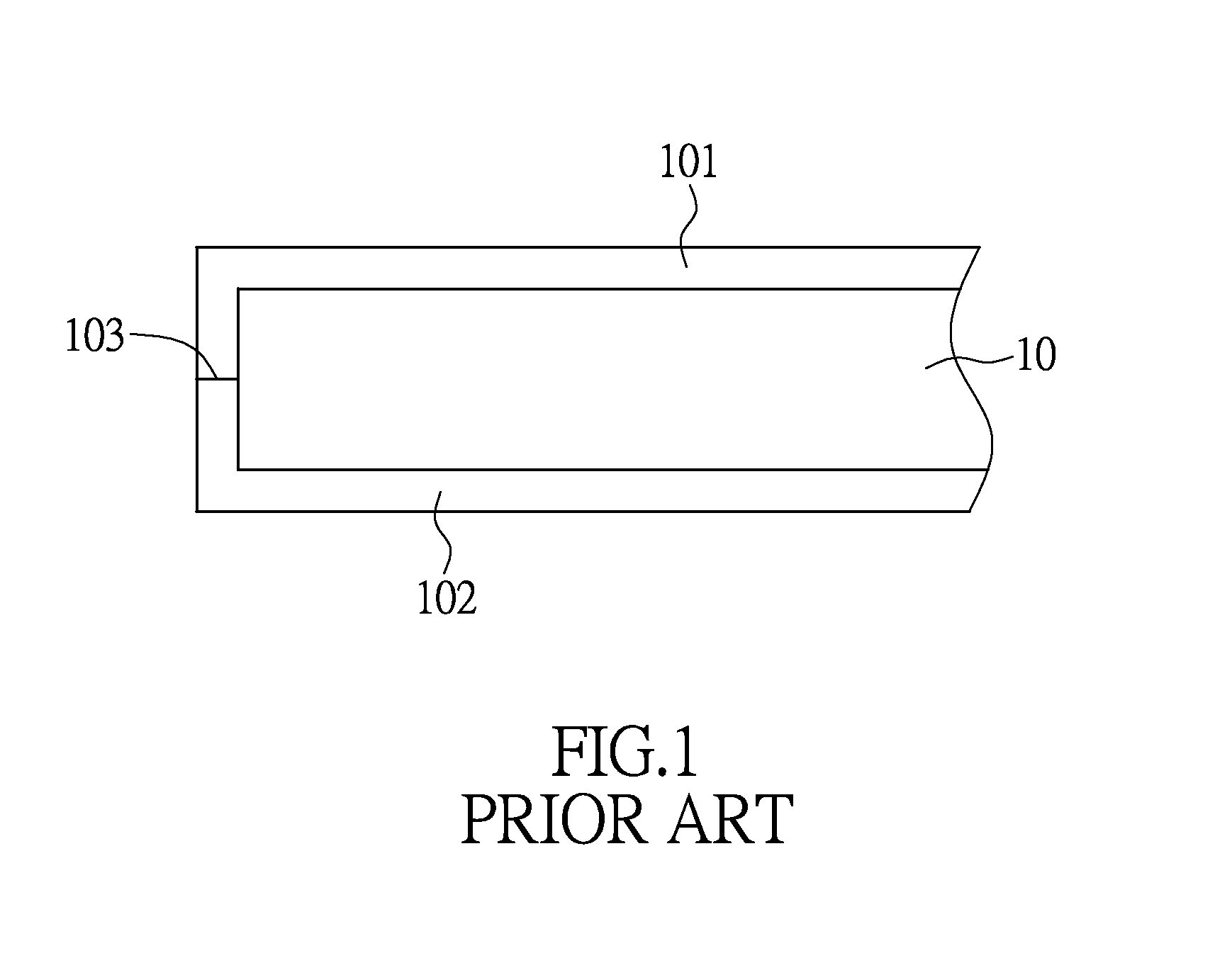

Thermoelectric device with thin film elements, apparatus and stacks having the same

InactiveUS20090165835A1High thermoelectric efficiencySufficient distanceThermoelectric device with peltier/seeback effectTemperature differencePhysics

A thermoelectric device at least includes a ring-shaped insulative substrate and plural sets of thermoelectric thin film material pair (TEP) disposed thereon. The ring-shaped insulative substrate has an inner rim, an outer rim and a first surface. The sets of TEP electrically connected to each other are disposed on the first surface of the ring-shaped insulative substrate. Each set of TEP includes a P-type and an N-type thermoelectric thin film elements (TEE) electrically connected to each other. Also, the N-type TEE of each set is electrically connected to the P-type TEE of the adjacent set of TER When a current flows through the sets of TEP along a direction parallel to the surfaces of P-type and N-type thermoelectric thin film elements, a temperature difference is generated between the inner rim and the outer rim of the ring-shaped insulative substrate.

Owner:IND TECH RES INST

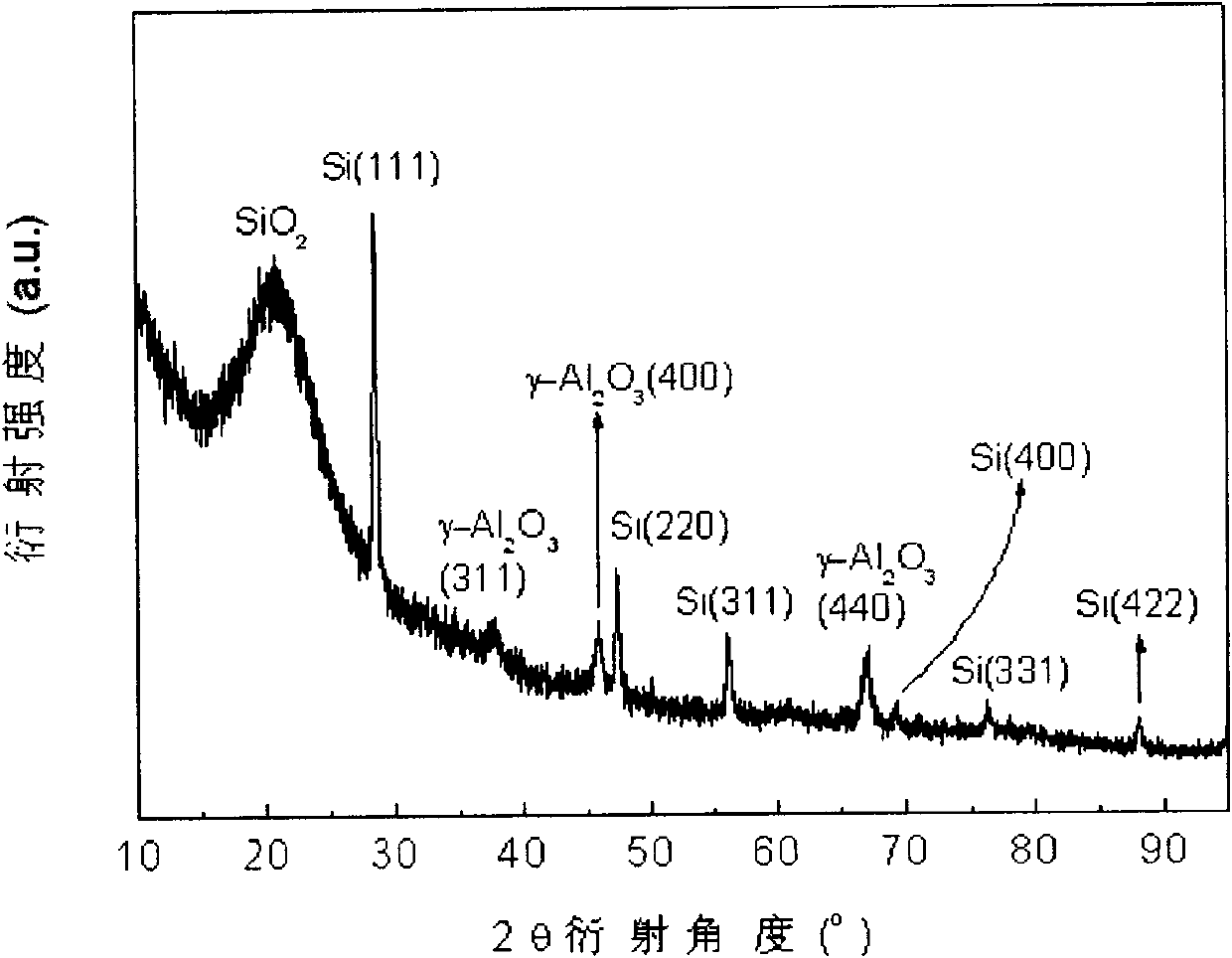

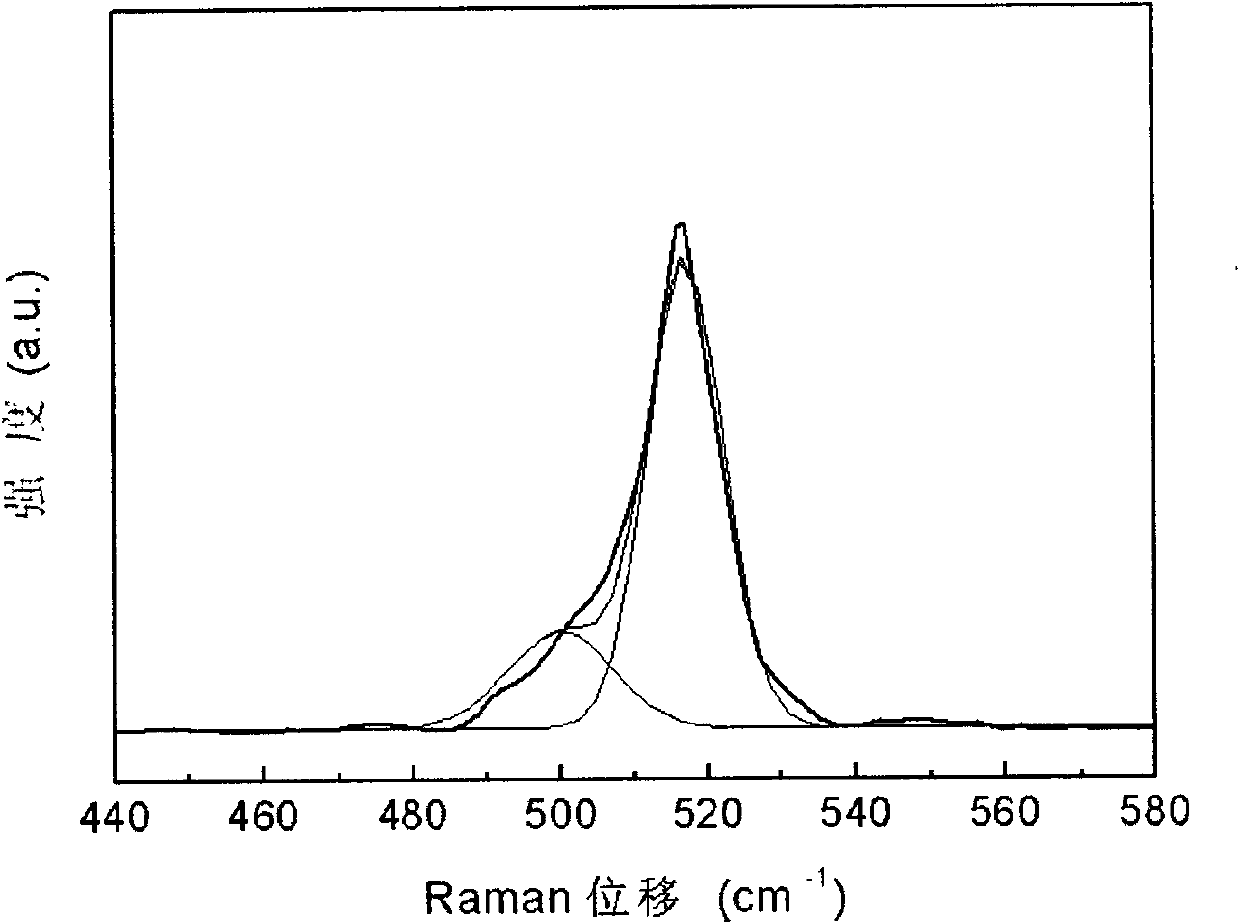

Preparation method of nanocrystalline silicon-aluminum oxide/silicon oxide thermoelectric film material

InactiveCN102002673AEasy to prepareReduce the temperatureVacuum evaporation coatingSputtering coatingMetallic aluminumNanocrystalline silicon

The invention discloses a preparation method of a nanocrystalline silicon-aluminum oxide / silicon oxide thermoelectric film material. The preparation method comprises the following steps: cleaning a quartz glass substrate, performing vacuum evaporation of an aluminum film and annealing. As the metal aluminum with relatively low cost is used as a thermal evaporation material, the resistivity and the Seebeck coefficient of the prepared nanocrystalline silicon-aluminum oxide / silicon oxide thermoelectric film material are as good as or better than those of the traditional thermoelectric film material. Compared with the traditional thermoelectric material and the preparation method thereof, the invention has the advantages of simple preparation method, relatively low temperature and low production cost, ensures no environmental pollution and can be popularized and applied in the production of preparing the nanocrystalline silicon-aluminum oxide / silicon oxide thermoelectric film material.

Owner:SHAANXI NORMAL UNIV

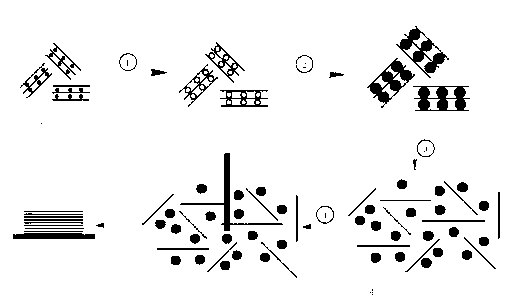

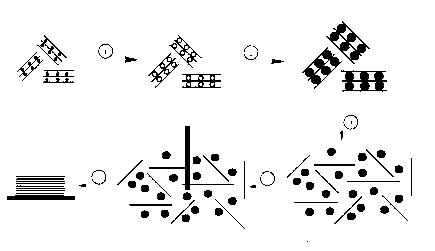

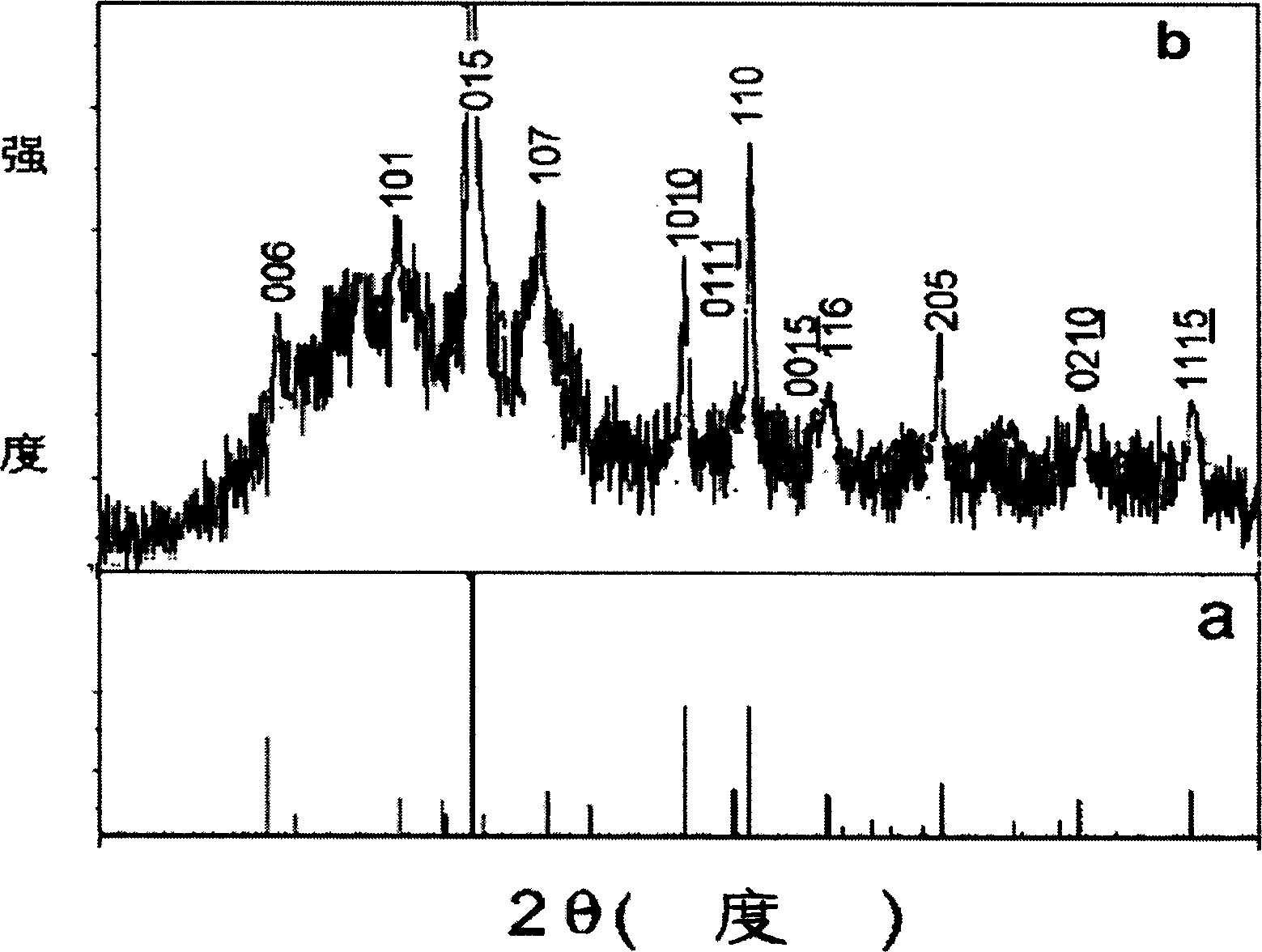

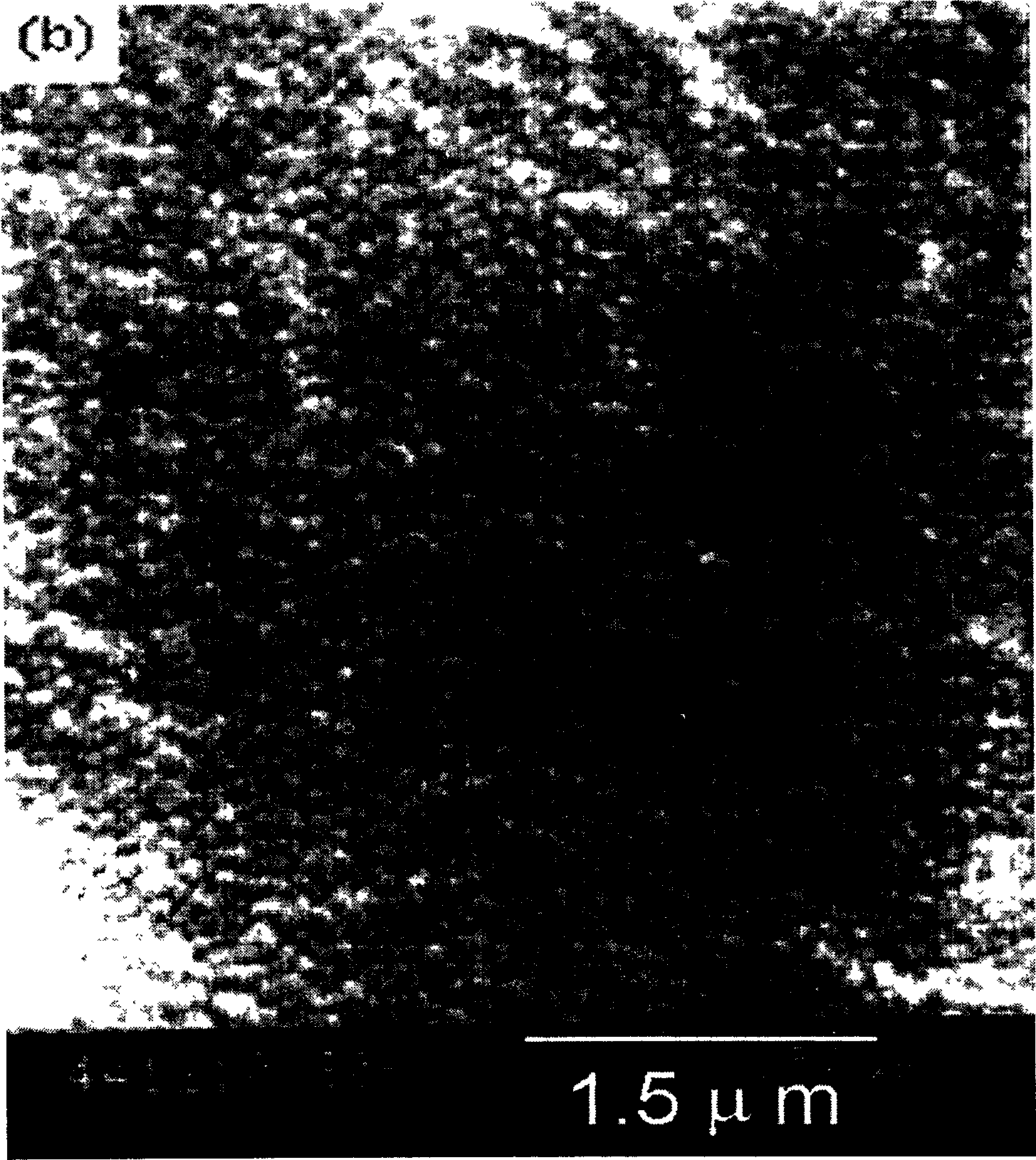

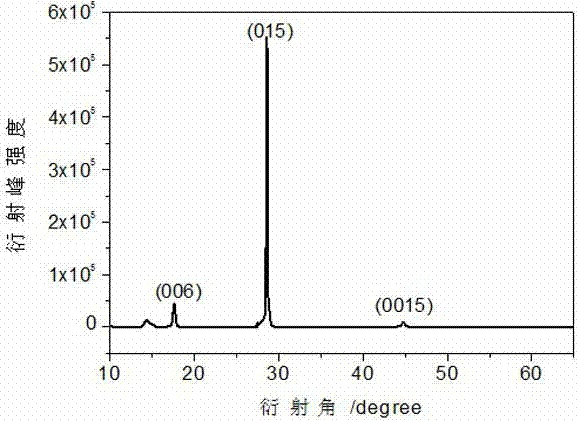

Method for preparing thermoelectric film by using layer by layer self-assembly

ActiveCN102912333AEase of mass productionEasy to operateSolid/suspension decomposition chemical coatingSelf assembleThin membrane

The invention discloses a method for preparing a thermoelectric film by using a layer by layer self-assembly. The method comprises the following steps of: (1) preparing nanometer sheet suspension liquid of a thermoelectric material: preparing a precursor material, then conducting proton exchange to obtain proton exchange products, conducting proton exchange on the proton exchange products to obtain intercalation products, and peeling the intercalation products to obtain peeling products; (2) selecting a substrate; (3) conducting self-assembly to form the thermoelectric film: centrifuging the nanometer sheet suspension liquid, using the substrate to conduct manual lifting, leaching lifting or soaking on centrifuged nanometer sheet suspension liquid, namely forming the thermoelectric film on the substrate. Different elements can be doped in a preparation process, kinds of thermoelectric films obtained by preparation are abundant, and the thermoelectric film is good in orientation and excellent in performance. Compared with other methods for preparing the thermoelectric film, the method is low in cost, simple in operation, capable of achieving mass production, good in controllability, and capable of preparing abundant and various high-performance target thermoelectric films.

Owner:SHANGHAI UNIV

Method for preparing chalkogenide thermoelectric film using liquid-phase chemical method

InactiveCN1677704AAchieve integrationImprove performanceThermoelectric device manufacture/treatmentLiquid/solution decomposition chemical coatingAdditive ingredientChalcoides

Predecessor solution is prepared from material of salts of Bi, Sb, Sn or Ph and mineral of Se and Te. Film of predecessor is made through throwing method. Coreduction method deoxidizes dried film of predecessor and then through heat treatment obtains composite dopes thermoelectric film of sulfur family compound. Second layer of film of sulfur family compound in different ingredients is prepared on film of polycrystal sulfur family compound in the method. Thermoelectric superlattice of sulfur family compound in high thermoelectric performance is fabricated by alternating two kinds of films. Subminiature integrated thermoelectric parts can be realized through thermoelectric films prepared by using chemical process, and technique of printing integrated circuit. The invention promotes development in areas of refrigeration, microelectronic, photoelectronic, laser and superconduct etc.

Owner:SHANDONG UNIV

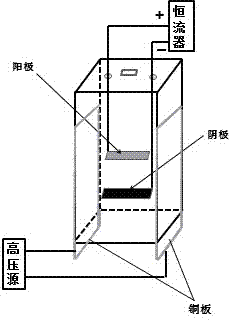

Method for electrochemically preparing thermoelectric film by using seeding layer

InactiveCN102867906ADefinite growth orientationLow growth temperatureThermoelectric device manufacture/treatmentGrown filmElectrochemistry

The invention belongs to the field of electrochemical preparation of a thermoelectric material, and relates to a method for electrochemically preparing a thermoelectric film by using a seeding layer, which comprises the following steps: preparing a seeding layer having a nano-level thickness on a substrate through molecular beam epitaxy, magnetron sputtering and other modes; and electrochemically growing a thermoelectric film material, wherein the thickness of the film can be of the nano level. By using the method, the growth orientation of the epitaxial film can be controlled, and a thermoelectric film having an obviously column structure orientation is prepared, so that the thermoelectric properties of the electrochemically grown film can be improved. Due to the self characteristics of electrochemistry such as low cost and convenient growing process, a material preparation foundation is provided for the assembly of a thermoelectric device in future.

Owner:SHANGHAI UNIV

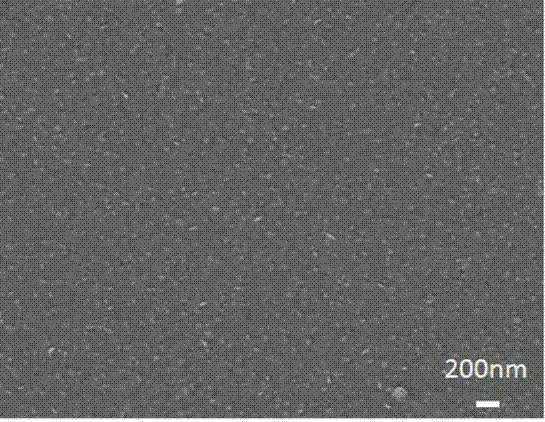

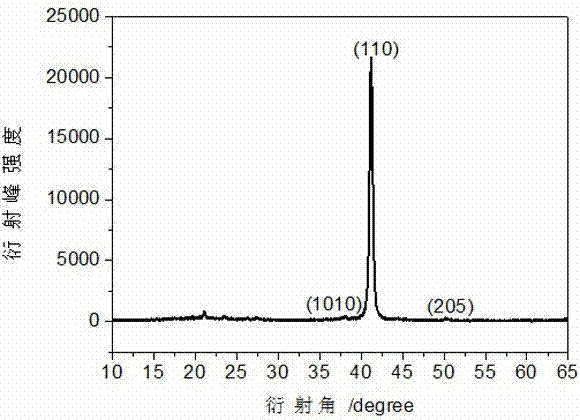

Method for preparing preferred-orientation bismuth telluride thermoelectric thin film

InactiveCN106399937AImprove mobilityImprove thermoelectric performanceThermoelectric device manufacture/treatmentVacuum evaporation coatingVacuum pumpingBismuth telluride

The invention discloses a method for preparing a preferred-orientation bismuth telluride thermoelectric thin film, and method adopts a magnetron sputtering method to prepare the bismuth telluride thermoelectric thin film. The method comprises the following steps of: firstly mounting a bismuth telluride (Bi2Te3) alloy target, and then, putting cleaned magnesium oxide (MgO) single crystal on a substrate; regulating a target-substrate distance to be 100mm-140mm, and vacuum-pumping to 5*10<-4>Pa-7.5*10<-4>Pa; heating a magnesium oxide (MgO) substrate to 350-450 DEG C, introducing argon gas (Ar), and starting sputter coating under working gas pressure being 0.3Pa-0.5Pa; and finally, carrying out annealing treatment on the sputtered film at a temperature being 250-350 DEG C, thereby forming the preferred-orientation bismuth telluride thermoelectric thin film.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

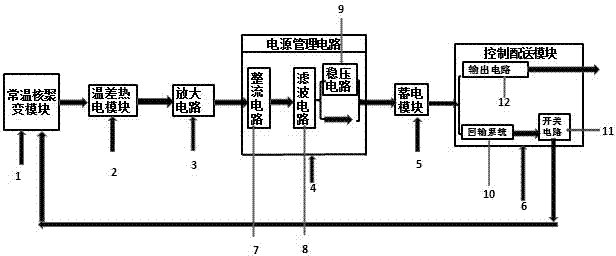

Chip-level self-sustained thermoelectric generation system

InactiveCN104518708AIncrease energy densityUninterrupted heatingGenerators/motorsThermal energyHigh energy

The invention discloses a chip-level self-sustained thermoelectric generation system. The chip-level self-sustained thermoelectric generation system comprises a normal-temperature nuclear fusion module, a temperature difference thermoelectric module, an amplifying circuit module, a power management circuit module, an electricity storage module and a control and distribution module which are connected sequentially. The chip-level self-sustained thermoelectric generation system has the advantages that thermal energy is converted into electric energy by using a temperature difference thermoelectric thin film as an energy conversion medium, so that unnecessary heat dissipation cannot be generated, and energy conversion ratio is increased remarkably; quite high energy gain can be generated by normal-temperature nuclear fusion, in other words, energy generated during normal operation of the system is far more than energy inputted from the outside, so that self-sustained electricity generation can be achieved, and the electric energy is outputted continuously.

Owner:SHANGHAI UNIV

A flexible thermoelectric thin film device

InactiveCN104701449BReliable depositionImprove bindingThermoelectric device manufacture/treatmentThermoelectric device detailsPolyimide substrateThin film electrode

A flexible thermoelectric thin film device, the device includes a polyimide flexible substrate, a copper electrode film, a nickel transition layer and a thermoelectric thin film, the particle size of the thermoelectric thin film is arranged in a gradient, and the thermoelectric thin film includes a P-type thermoelectric Thin film and N-type thermoelectric film, the P-type thermoelectric film and N-type thermoelectric film are connected by a copper electrode film, forming an arrayed arrangement and series p-n thermocouple pairs on a flexible substrate to form an in-plane structure Flexible thermoelectric thin film devices. By adjusting the sputtering parameters and heat treatment process to optimize the microscopic interface structure of thin film materials, the reliable deposition of inorganic thin films on flexible substrates can be achieved, and reliable high-performance flexible thermoelectric thin film devices can be obtained.

Owner:STATE GRID CORP OF CHINA +2

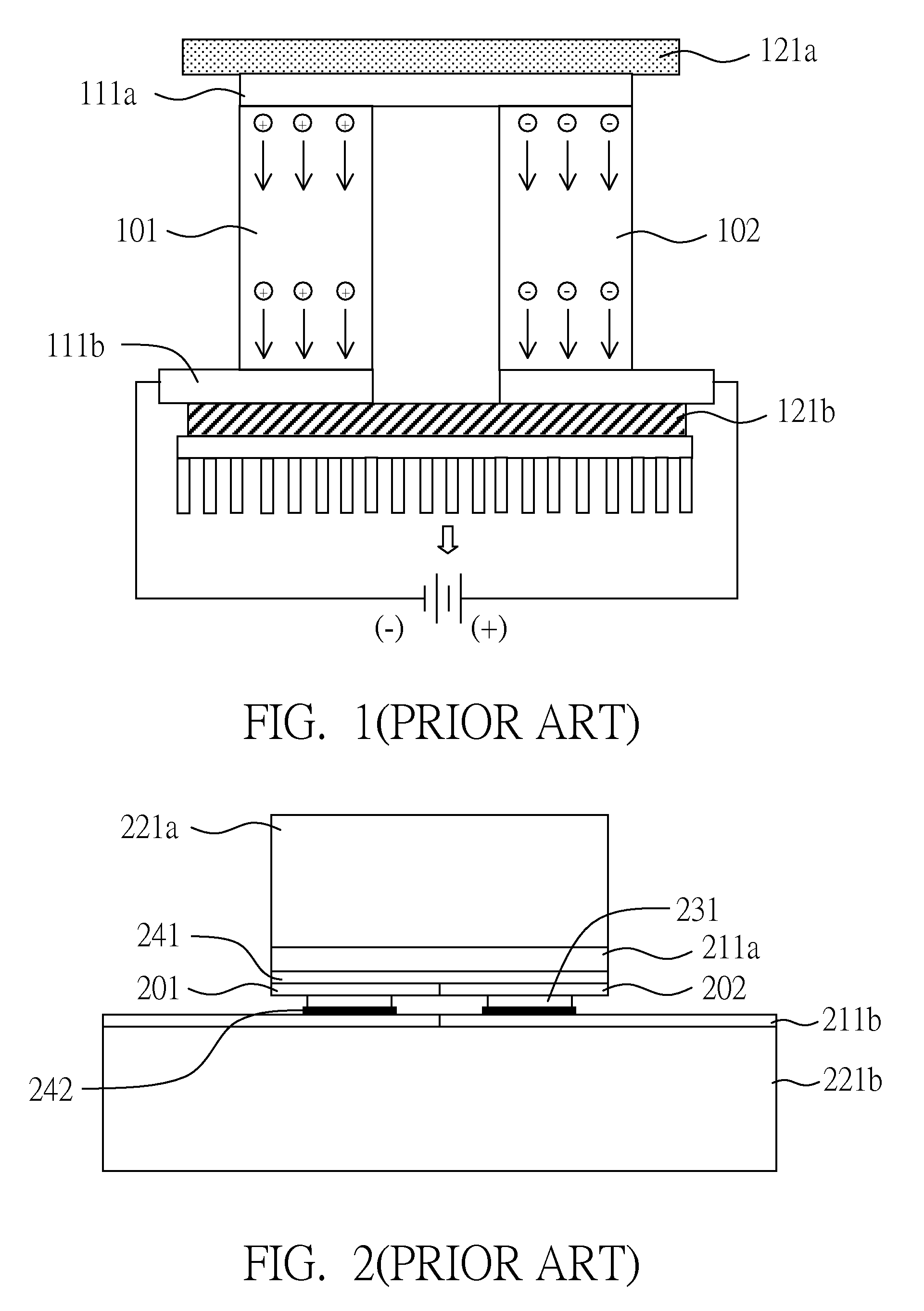

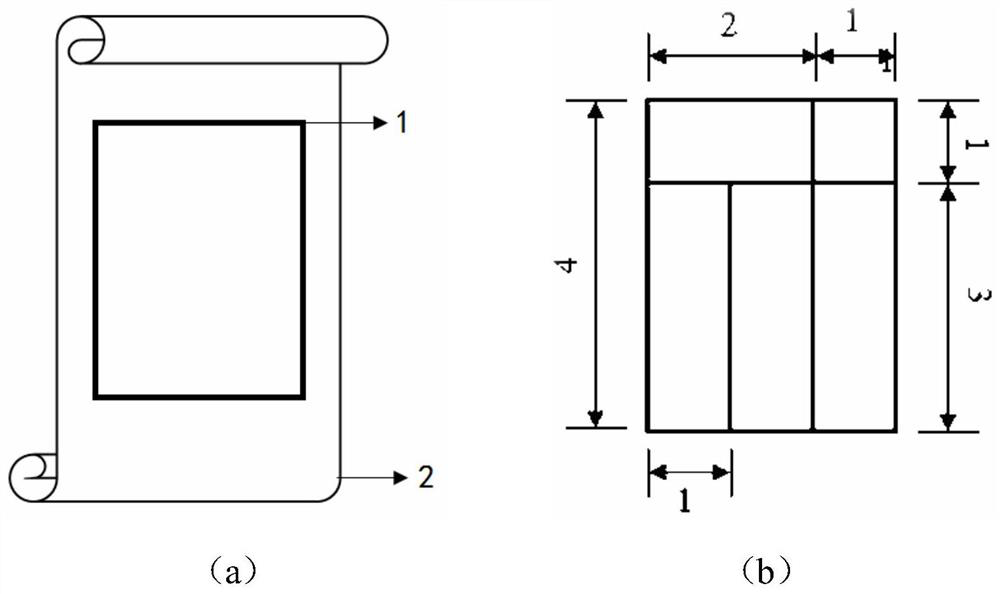

Single-layer temperature difference part and integrated micro-temperature difference electric part made by film temperature different electric material

InactiveCN101079465AIncrease specific energyMulti-integratedThermoelectric device with peltier/seeback effectOptoelectronicsMono layer

The invention relates to a single-layer thermoelectric device manufactured by the thin-film thermoelectric material and an integration micro thermoelectric device. The single-layer thermoelectric device comprises P type thermoelectric thin-film material monomer and N type thermoelectric thin-film material monomer by electric series connection and electric parallel connection, the difference in temperature with the conductive ejector is established along the length direction of the thermoelectric material. The integration micro thermoelectric device which comprises the single-layer thermoelectric device manufactured by the thin-film thermoelectric material by electric series connection and electric parallel connection is an integration thermoelectric device with lamellar structure in the interior. The invention integrates more thermoelectric monomers on the smaller cross-sectional area of heat flow, the thermoelectric battery with the structure is provided with more energy per unit volume, the cryostat with the structure can establish more difference in the temperature, the infrared detector and thermometric indicator with the structure is provided with high measurement accuracy.

Owner:TIANJIN UNIV

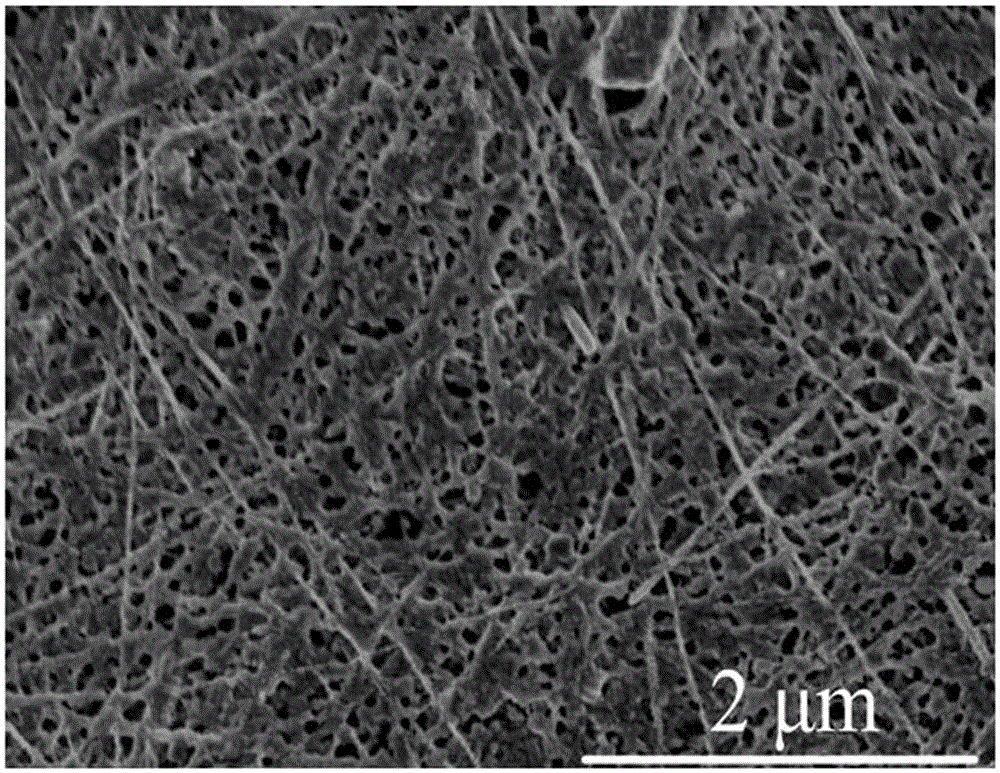

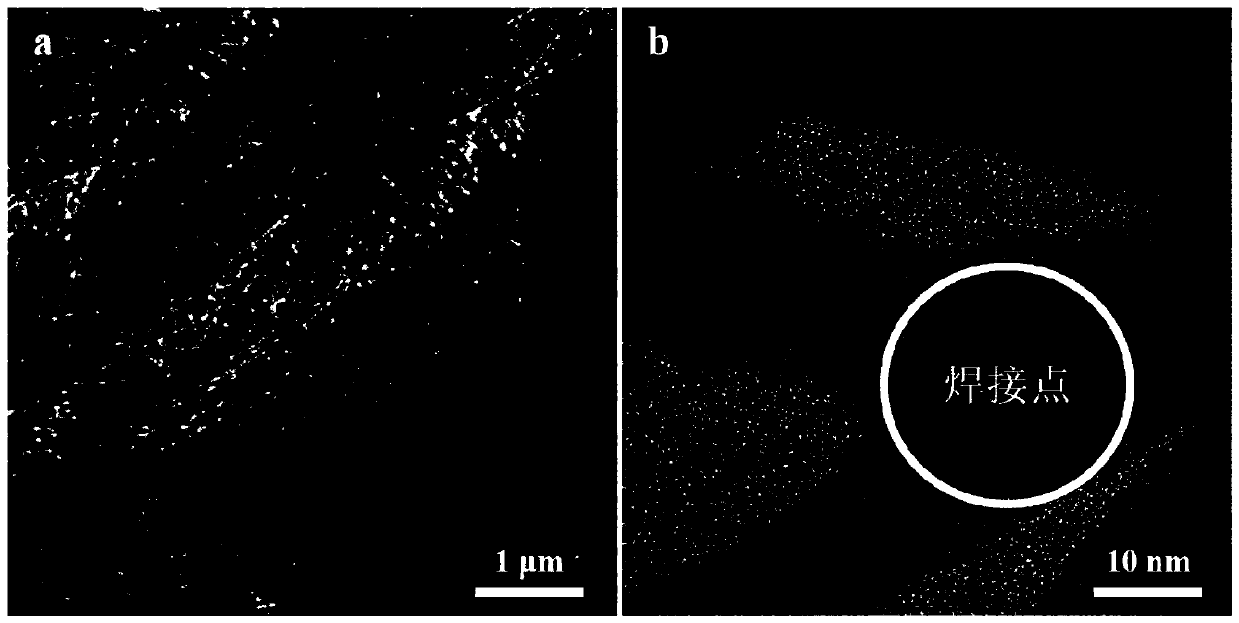

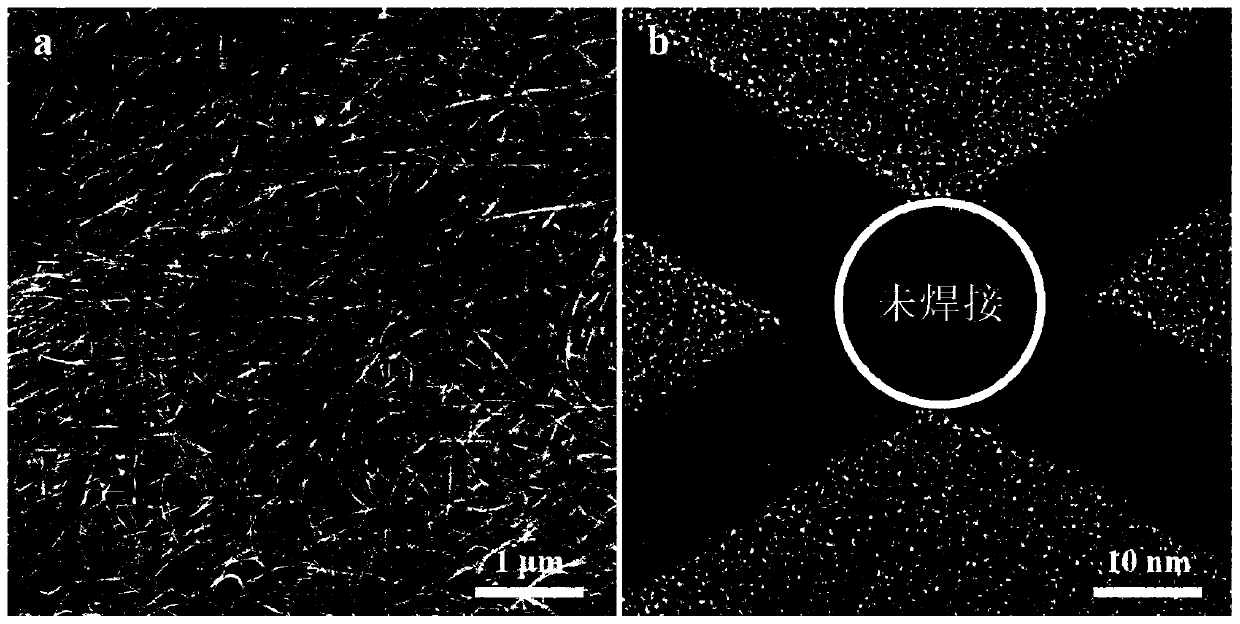

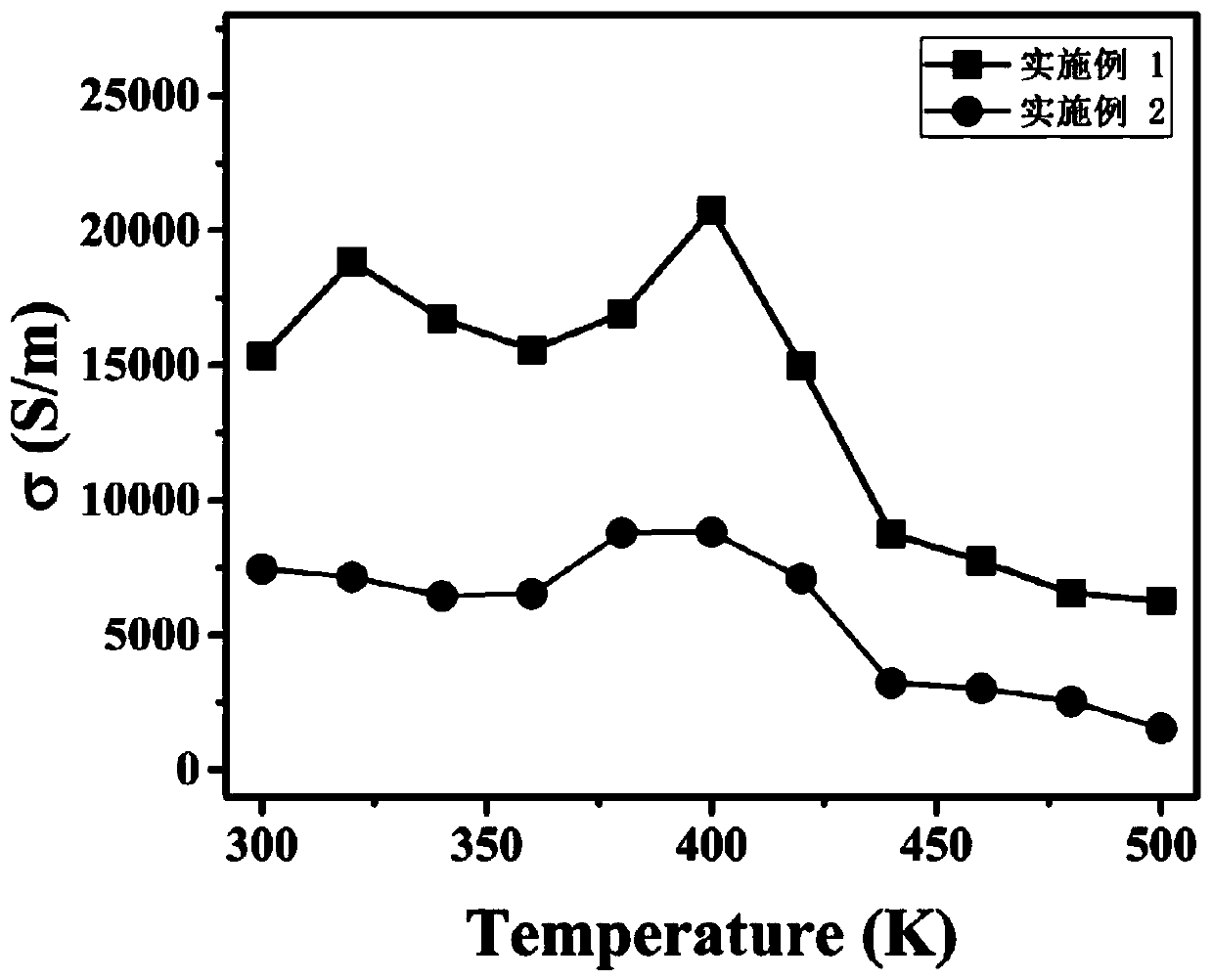

Silver telluride nanowire flexible thermoelectric film welded at room temperature and preparation method thereof

ActiveCN110364616AUniform thicknessImprove conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsNanowirePower factor

The invention relates to a silver telluride nanowire flexible thermoelectric film welded at a room temperature and a preparation method thereof. The preparation method comprises the following steps: (1) tellurium nanowires are dispersed in a first solvent to obtain a tellurium nanowire dispersion; (2) a tellurium nanowire film is prepared by the tellurium nanowire dispersion; (3) silver ion salt is dissolved in a second solvent, and a silver ion salt solution is prepared; and (4) the silver ion salt and the tellurium nanowire film react, the film is cleaned after the reaction, and after drying, the silver telluride nanowire flexible thermoelectric film welded at the room temperature is obtained. The prepared flexible thermoelectric film has high conductivity and power factor.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

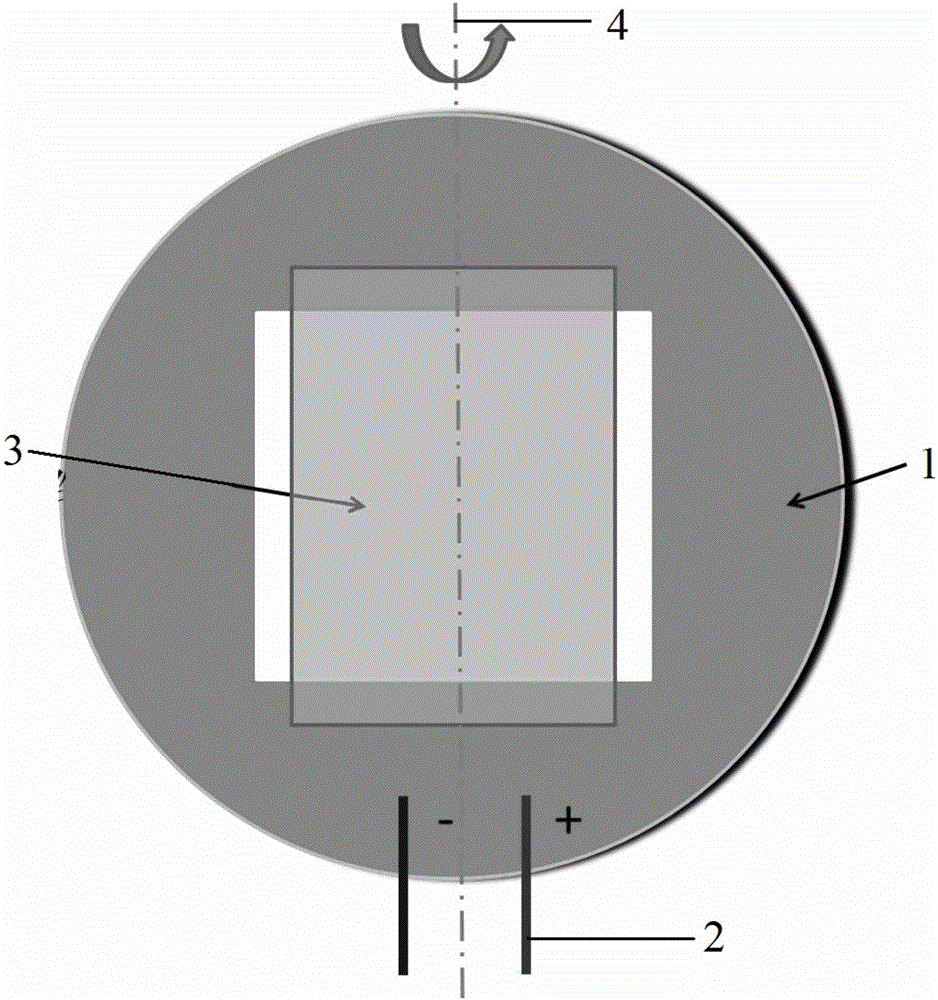

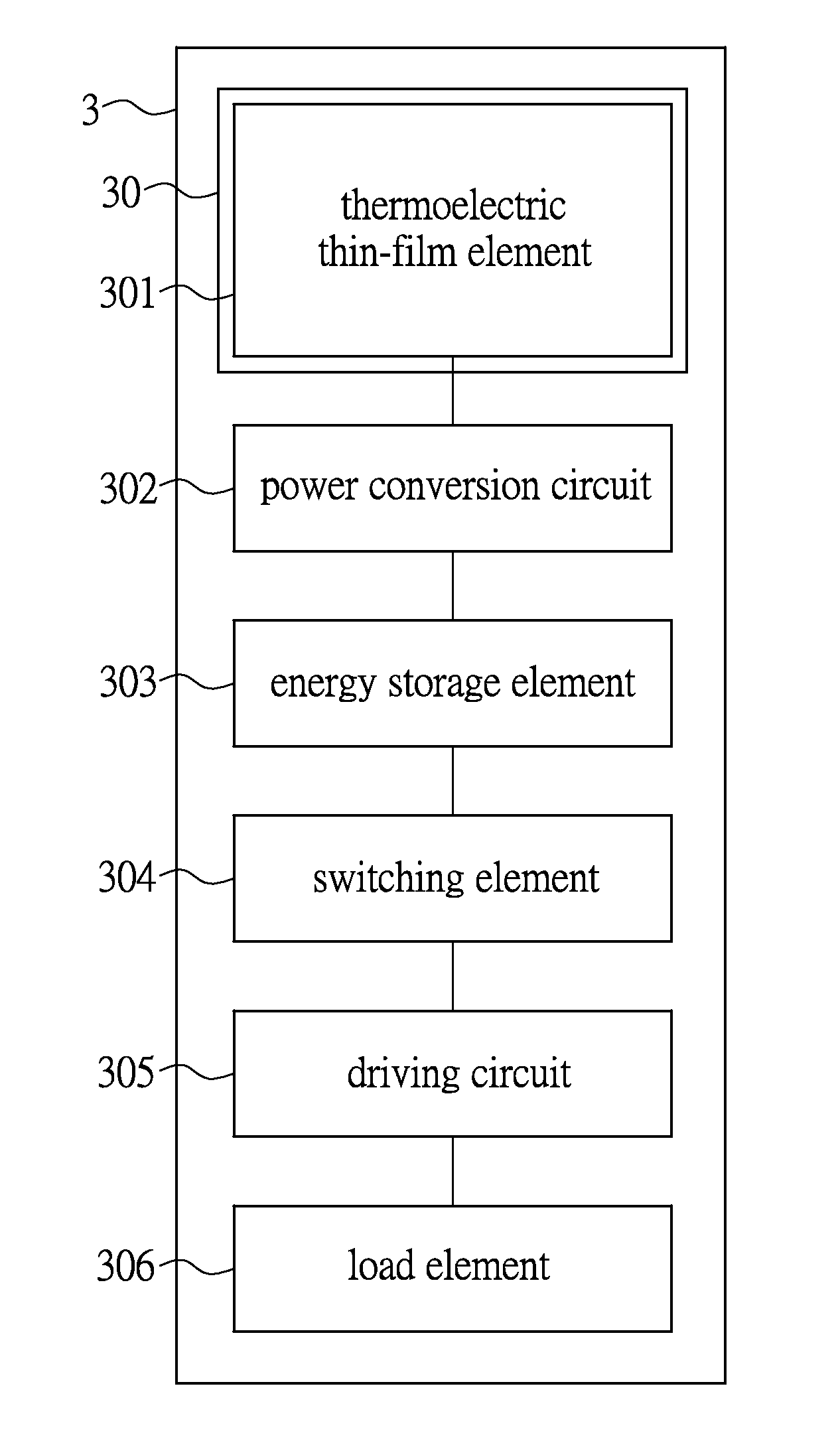

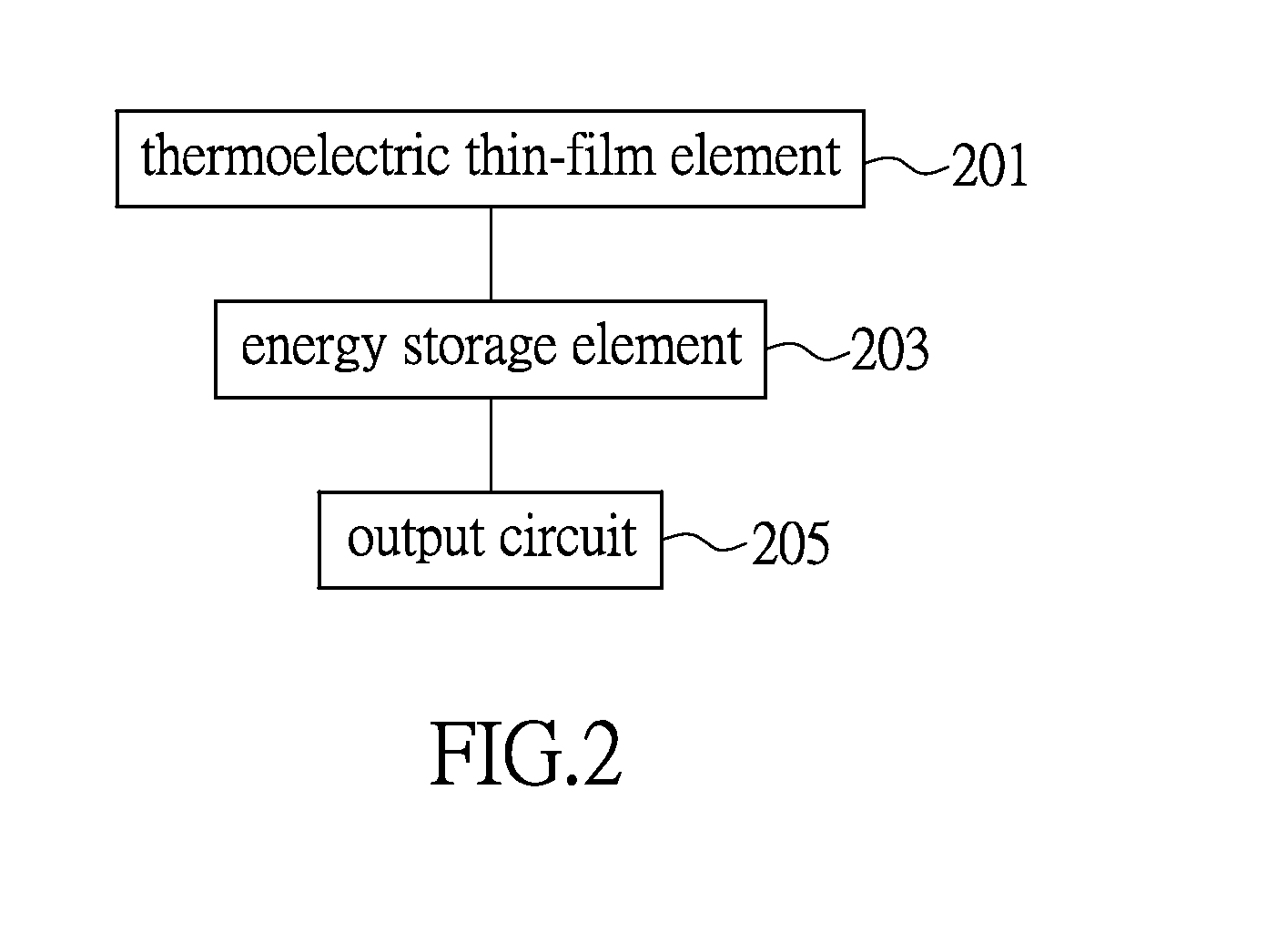

Thermoelectric power generator

InactiveUS20160126442A1Thermoelectric device with peltier/seeback effectSingle network parallel feeding arrangementsEngineeringTemperature difference

Disclosure is related to a thermoelectric power generator. The generator essentially includes a thermoelectric thin-film element which is such as a thin film used to generate voltages according to a temperature difference. The output electric signals are converted to energy stored in an energy storage element. An output circuit is included to output power. In an exemplary embodiment, the thermoelectric power generator has a contact interface for sensing external temperate. The thermoelectric thin-film element is enabled to output voltages when temperature difference is induced. The generator further has a switch, which is used to control if the power is output. The output element is such as a light-emitting element.

Owner:J TOUCH CORPORATION

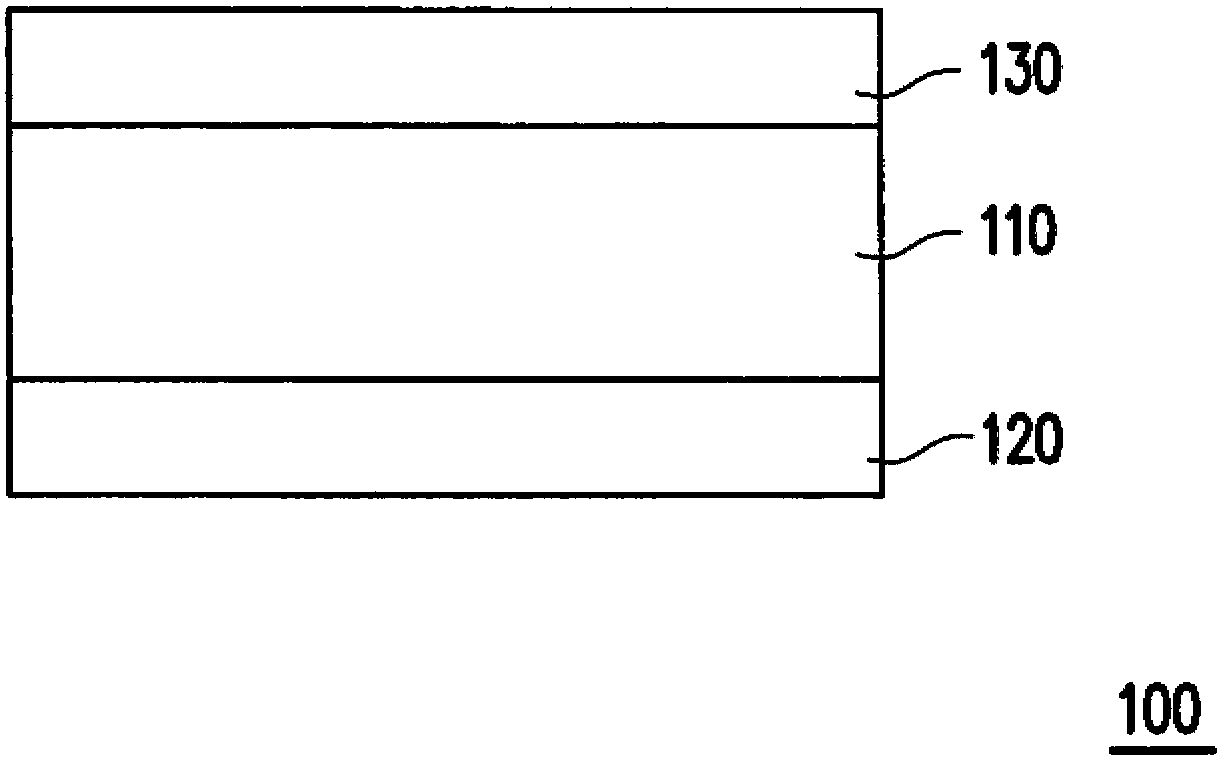

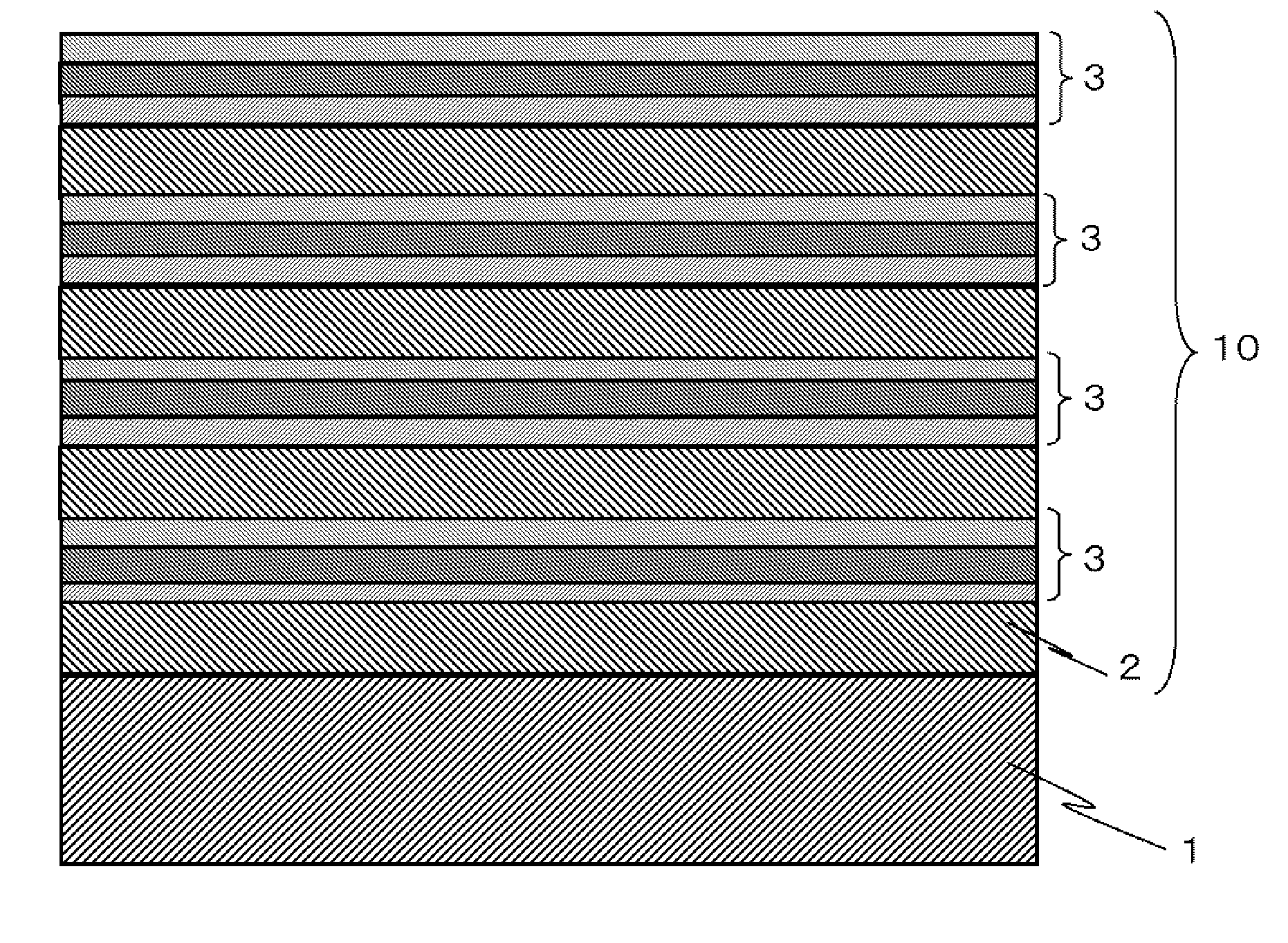

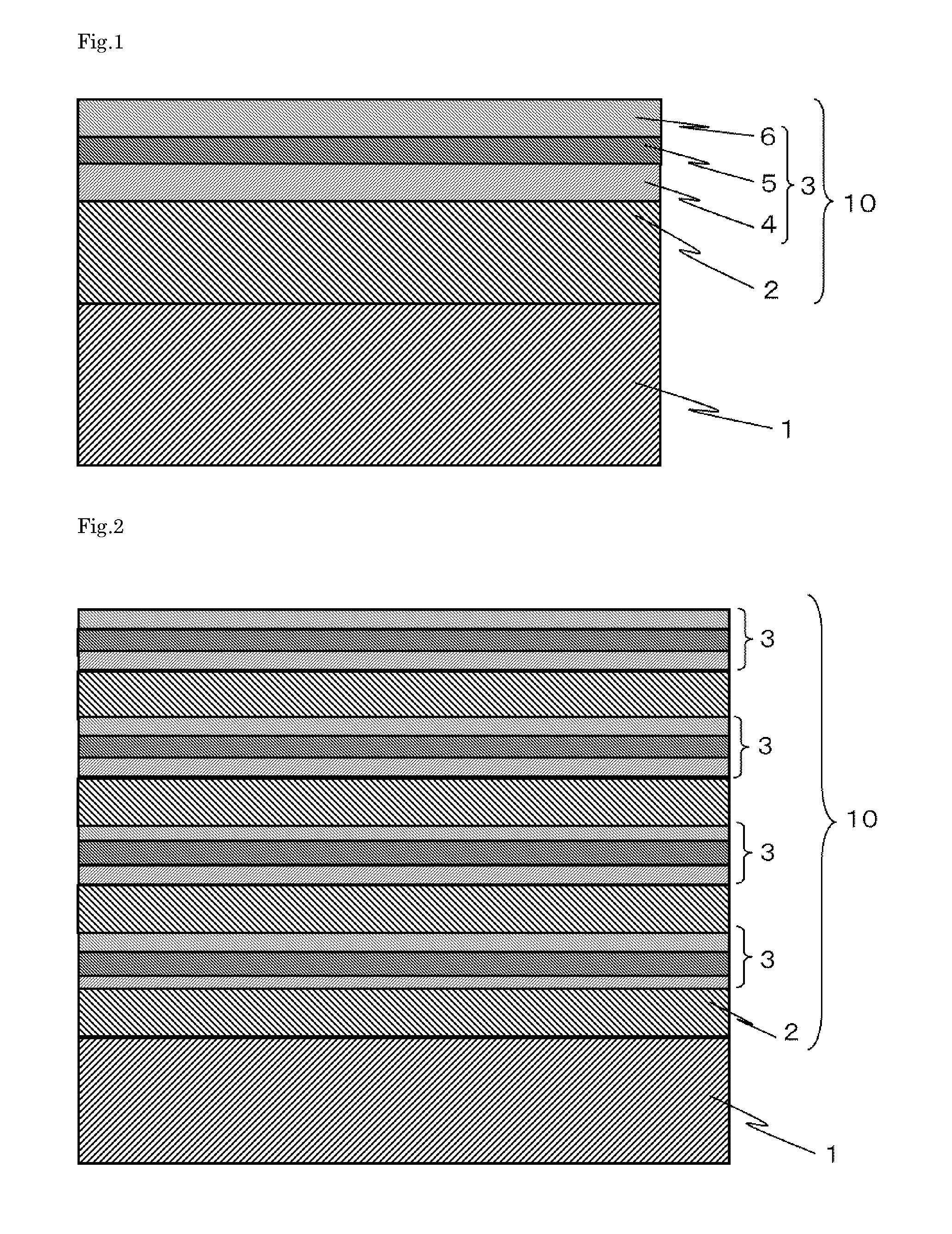

Structure of thermoelectric film

ActiveCN103872236AAdjust the resistance valueImprove thermal conductivityThermoelectric device detailsThermoelectric device junction materialsThin membraneEngineering physics

A structure of a thermoelectric film including a thermoelectric substrate and a pair of first diamond-like carbon (DLC) layers is provided. The first DLC layers are respectively located on two opposite surfaces of the thermoelectric substrate and have electrical conductivity.

Owner:IND TECH RES INST

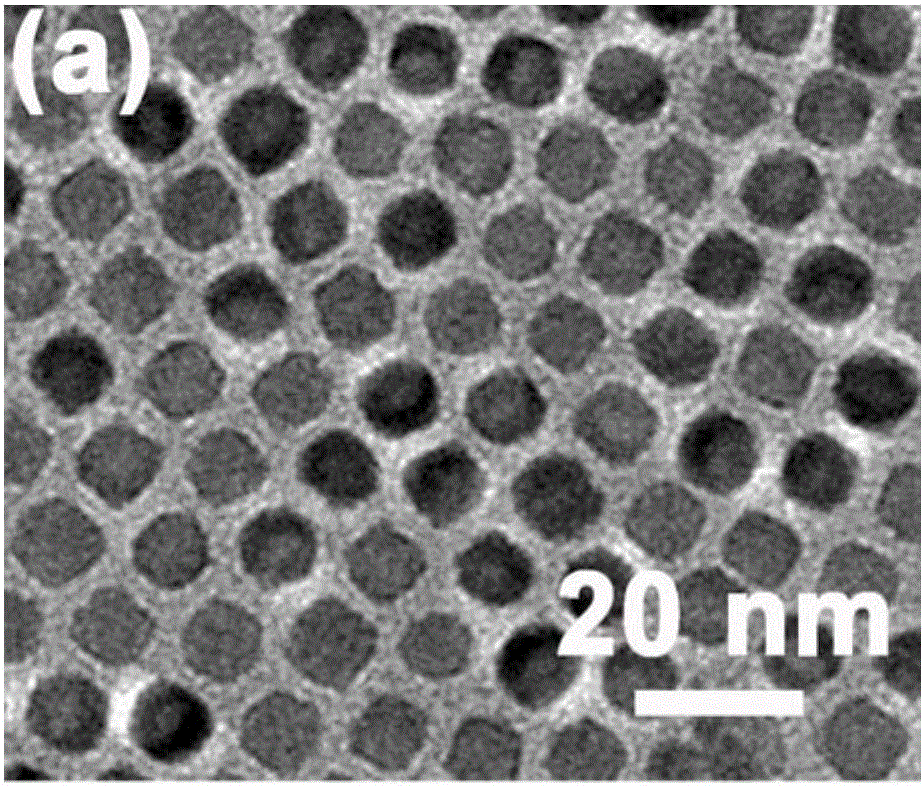

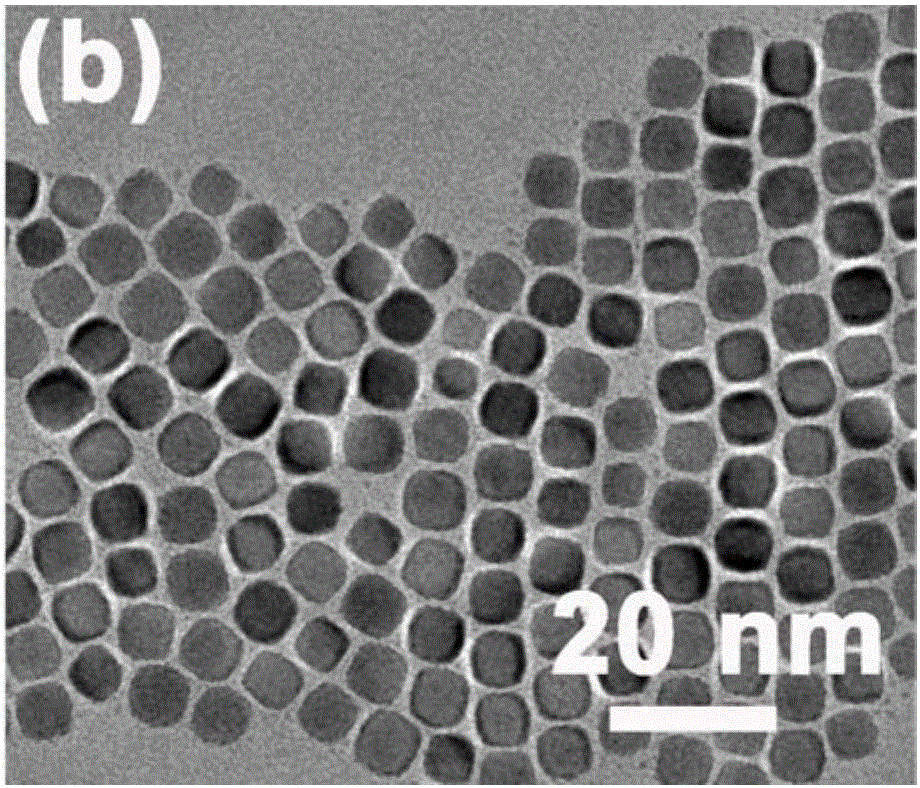

Method for preparing solvated nanocrystalline thermoelectric thin film through interface control method

ActiveCN106328801AImprove thermoelectric performanceLow costMaterial nanotechnologyThermoelectric device manufacture/treatmentSpinsNanocrystalline silicon

The present invention provides a method for preparing a solvated nanocrystalline thermoelectric thin film through an interface control method. The method includes the following the steps that: (1) a solvated nanocrystalline solution is spin-coated on a substrate, so that a nanocrystalline thin film can be prepared; (2) the obtained nanocrystalline thin film is immersed in a short-chain ligand solution, an original organic ligand on the surface of the nanocrystalline thin film is stripped; and (3) annealing treatment is performed on the nanocrystalline thin film of which the original organic ligand is stripped, so that the solvated nanocrystalline thermoelectric thin film can be obtained. The solvated nanocrystalline thermoelectric thin film prepared through the interface control method has excellent thermoelectric performance. The method is compatible with semiconductor device preparation methods in the current microelectronics field and has the advantages of high operability, low cost and wide applicability. With the method adopted, a direction is guided for the large-scale production and preparation of thermoelectric thin film devices in the microelectronics field.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

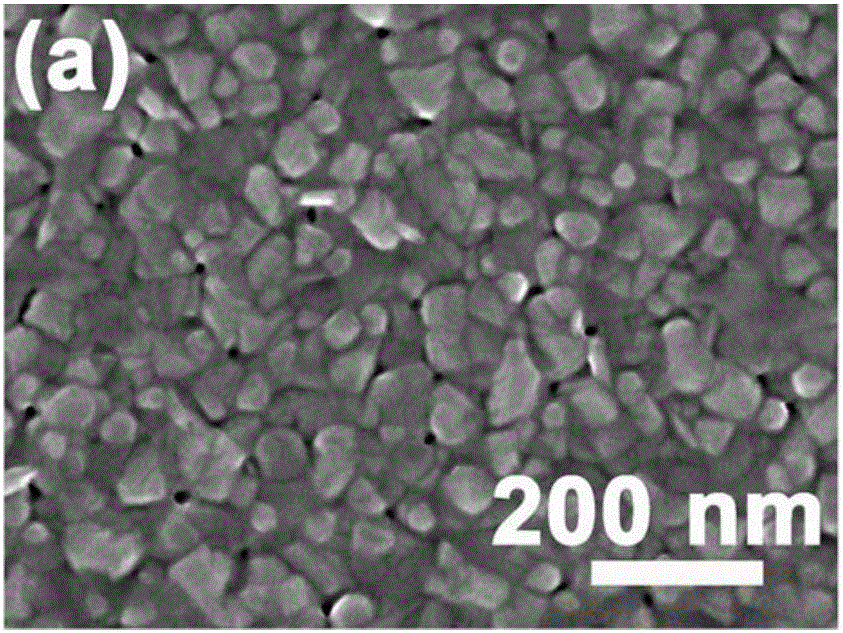

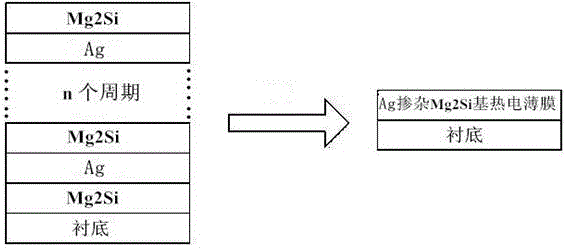

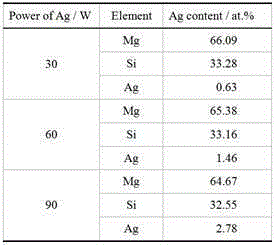

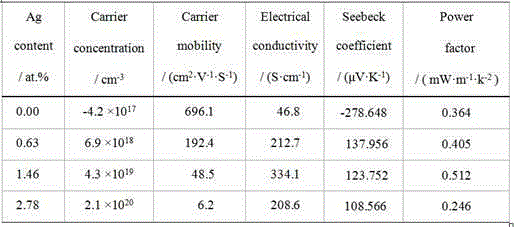

Ag-doped Mg2Si-based thermoelectric thin film and preparing method thereof

InactiveCN105220119AAdjust the amount of dopingGood adhesionVacuum evaporation coatingSputtering coatingThin membraneDeposition process

The invention discloses Ag-doped Mg2Si-based thermoelectric thin film and a preparing method thereof. Double-target cyclic sputtering is carried out on an insulating substrate by a magnetron sputtering deposition process, wherein in one target position, an Mg2Si target is placed, and a radio frequency power supply is used as the power supply; in another target position, an Ag elemental target is placed, and a direct current power supply is used as the power supply; first, an Mg2Si layer is plated, next, an Ag layer is plated, then an Mg2Si layer is plated again, and one period is finished; cyclical sputtering is carried out according to the period for multiple times so as to prepare and obtain thin film with a laminated structure; and finally, the Ag-doped Mg2Si-based thermoelectric thin film is obtained by adopting vacuum annealing. The magnetron sputtering process preparing technology has the advantages of being strong in film layer and substrate binding force, even and dense in film layer, simple in technology, low in cost and the like, and can be used and popularized in the production of preparing the thermoelectric thin film.

Owner:FUZHOU UNIV

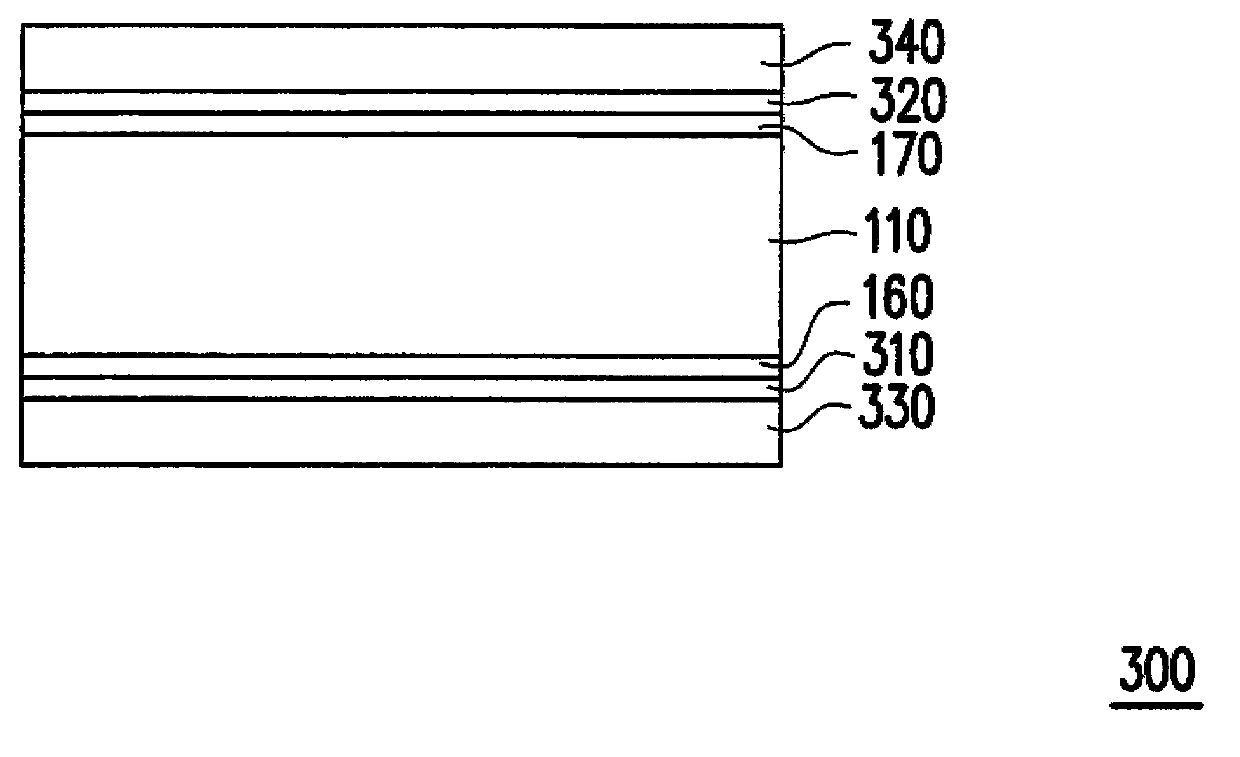

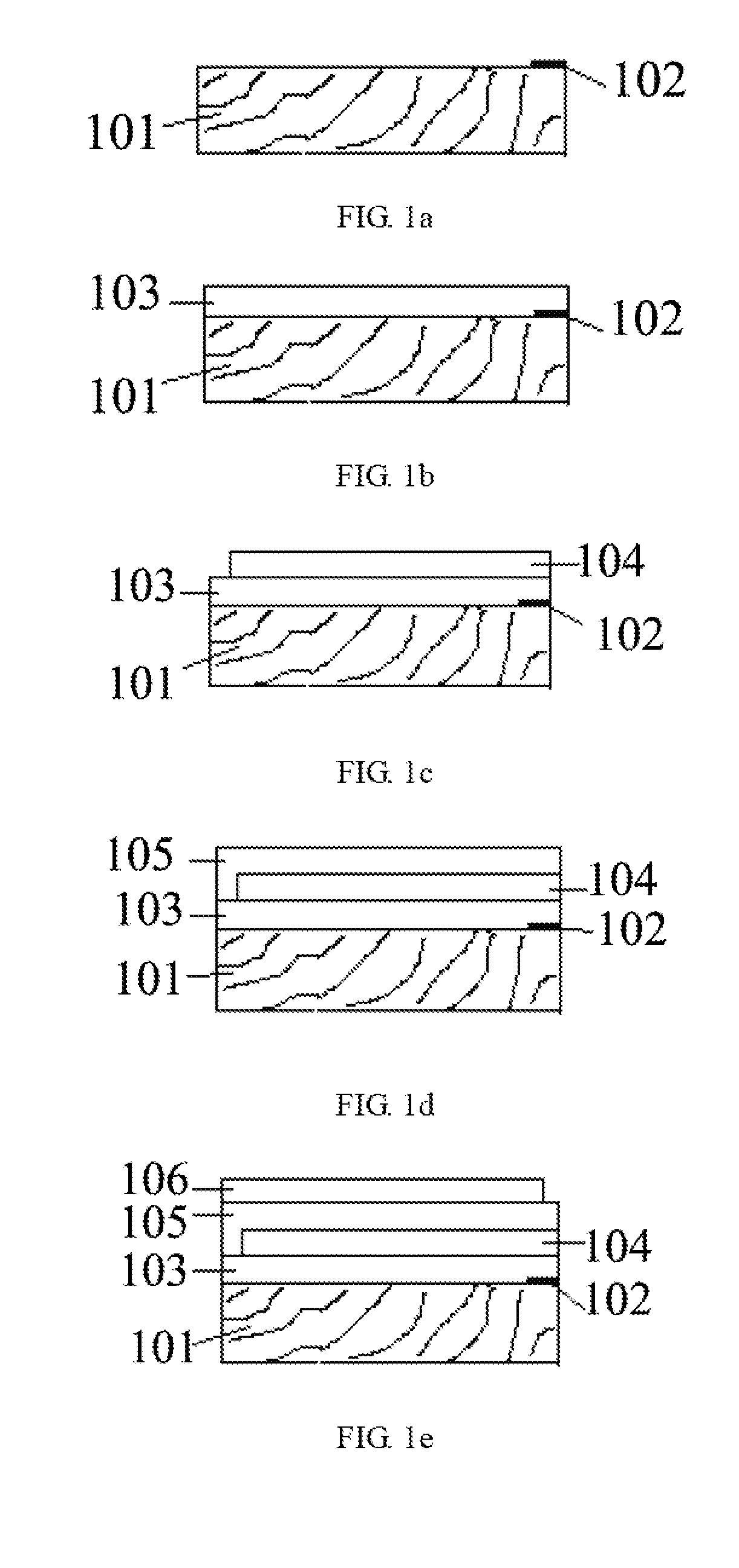

Thin-film thermo-electric generator and fabrication method thereof

ActiveUS20110197942A1Improve performanceSimplify the manufacturing processThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThin membraneMaterials science

For the thin-film thermo-electric generator and fabrication method of this invention, a P-type thermo-electric thin-film layer, an insulating thin-film layer and a N-type thermo-electric thin-film layer is deposited on a substrate to form a three-layer PN junction, multiple three-layer PN junctions in series are available, an insulating thin-film layer is provided between every to serial three-layer PN junctions, and electrodes are extracted from the substrate and the outermost thin-film layer of the last three-layer thin-film PN junctions. The present invention applies the deposition of P-type thermo-electric thin-film layer, an insulating thin-film layer and a N-type thereto-electric thin-film layer to form a three-layer PN junction, thus a thermo-electric generator is formed, during the deposition of the insulating thin-film layer, intentionally sheltering the substrate and one end of the deposited thin-film layer and depositing the P-type or N-type materials on the substrate and one end of the deposited thin-film layer directly, to form a connection of PN junction or a serial connection between two PN junction, the separate connection of the P-type or N-type materials is not required, simplifying the fabrication processes of the thin-film thermo-electric generator, owning to the function of the thin-film thermo-electric materials and serial connection structure of multiple three-layer PN junctions, the performance of the thin-film thermo-electric generator is greatly improved.

Owner:SHENZHEN UNIV

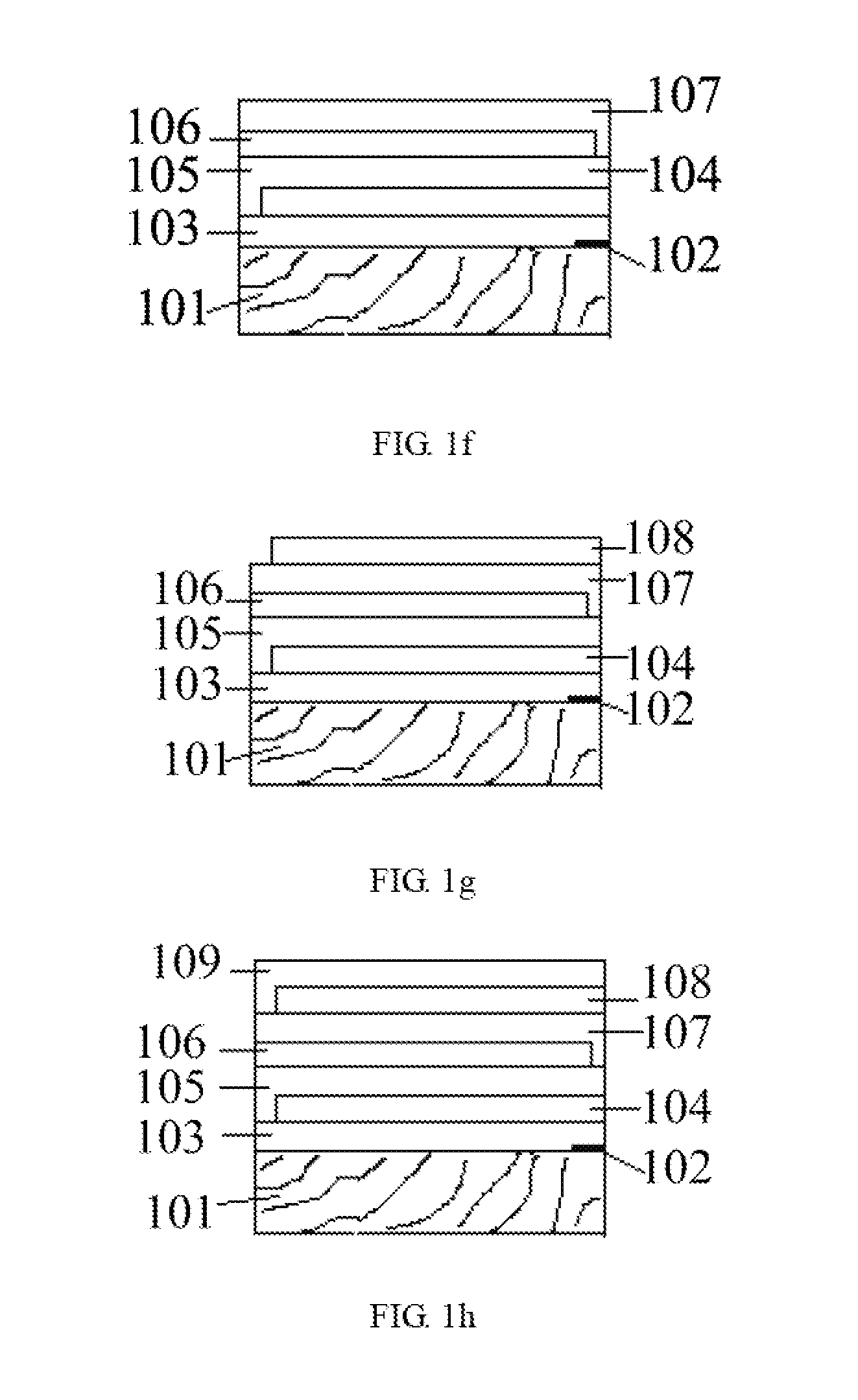

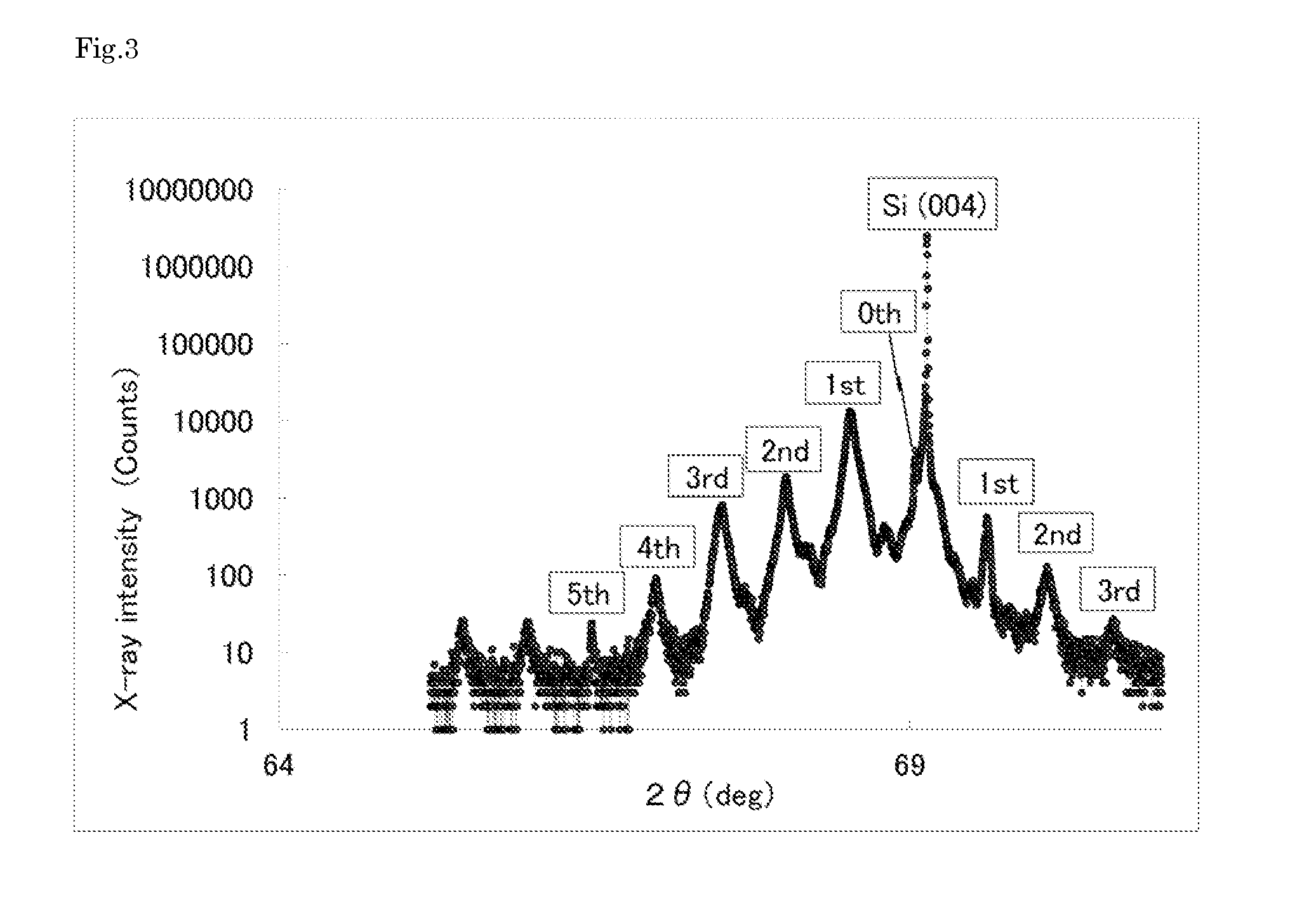

Thermoelectric device

ActiveUS20150255698A1Decrease in Seebeck coefficientImprove conductivityThermoelectric device with peltier/seeback effectPhysical chemistryThin membrane

A thermoelectric device includes a semiconductor stacked thermoelectric thin film including a first high-purity layer composed of SiGe as a main material and a composite carrier supply layer formed on the first high-purity layer. The composite carrier supply layer includes a second high-purity layer and third high-purity layer composed of Si as a main material, and a carrier supply layer held between the second and third high-purity layers and composed of SiGe as a main material. The carrier supply layer is a P-type carrier supply layer to which an additive of a group XIII element is added or a N-type carrier supply layer to which an additive of a group XV element is added.

Owner:TDK CORPARATION

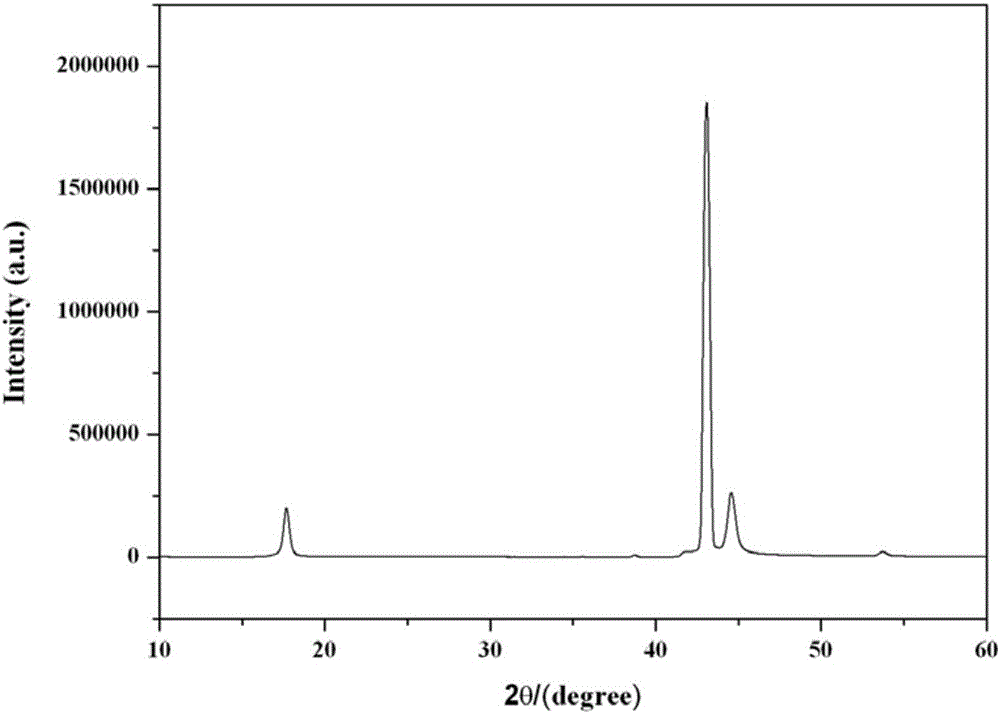

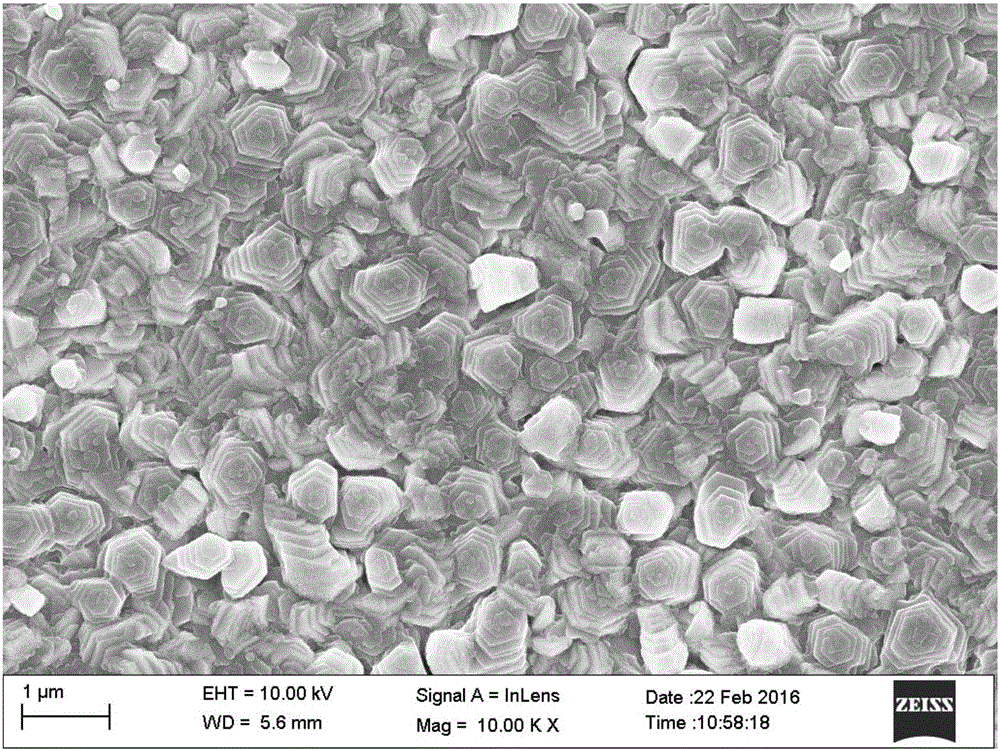

Method for preparing hexagonal spiral morphology bismuth telluride thermoelectric thin film

InactiveCN106498354AImprove performanceAvoid crackingVacuum evaporation coatingSputtering coatingSputteringBismuth telluride

The invention discloses a method for preparing a hexagonal spiral morphology bismuth telluride thermoelectric thin film. The bismuth telluride thermoelectric thin film is prepared through a magnetron sputtering method. The method comprises the steps that firstly, a cavity of magnetron sputtering equipment is cleaned, a bismuth telluride (Bi2Te3) alloy target and a tellurium (Te) simple substance target are installed, and a cleaned quartz glass substrate is fixed to a base; secondly, the distance between the bismuth telluride alloy target and the quartz glass substrate is adjusted to be 100-120 mm, the distance between the tellurium simple substance target and the quartz glass substrate is adjusted to be 130-140 mm, and vacuum is pumped to be 5*10<-4>-7.5*10<-4> Pa; thirdly, the quartz glass substrate is heated to 300-400 DEG C, argon (Ar) is injected, under the condition that the working air pressure is 0.3-0.5 Pa, a direct current source and a radio source are opened, the power of the direct current source is set to be 18 W, the power of the radio source is set to be 18-20 W, and film coating is started through co-sputtering; and finally, a sputtered thin film is subjected to annealing treatment at the temperature of 250-350 DEG C, and the hexagonal spiral morphology bismuth telluride thermoelectric thin film is formed.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

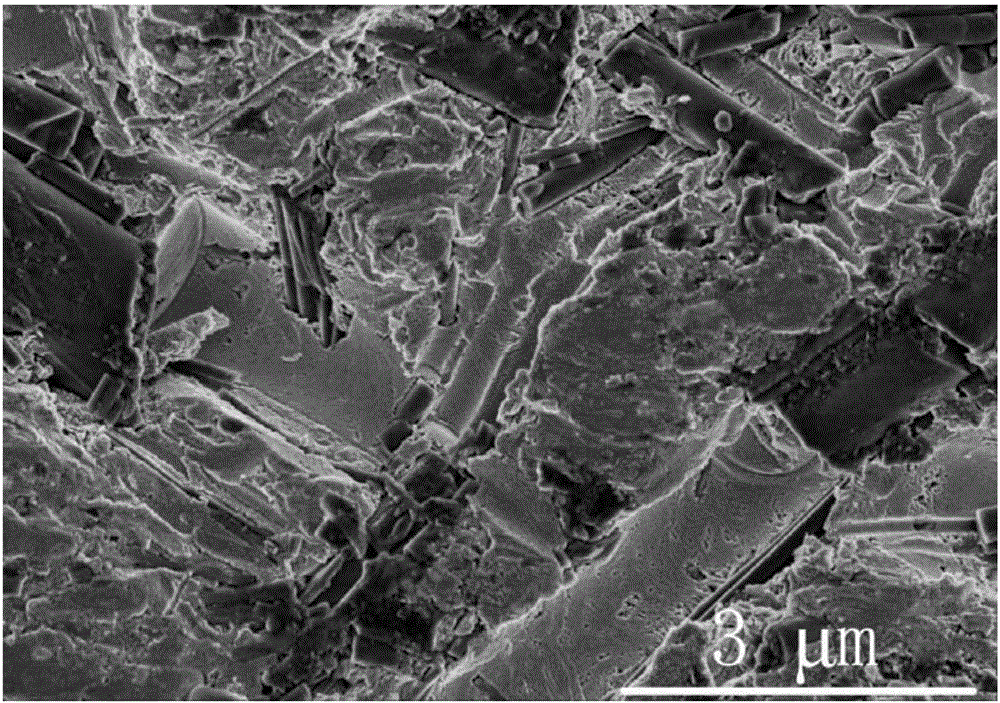

SnSe/CNT high-temperature flexible thermoelectric thin film material and preparation method thereof

ActiveCN112853492AImprove electrical performanceGood flexible deformation performancePolycrystalline material growthFrom condensed vaporsComposite filmCarbon nanotube

The invention relates to the field of functional thin film materials, in particular to a SnSe / CNT high-temperature flexible thermoelectric thin film material and a preparation method thereof. The composite thin film is prepared by utilizing a physical vapor deposition technology, so that a certain crystallographic direction of selenide crystal grains is parallel to the axis direction of a CNT tube bundle, and a flexible composite thin film material with a certain out-of-plane orientation nanoscale porous structure is formed. The material comprises a carbon nanotube film substrate and a SnSe functional film uniformly deposited on the surface of a carbon nanotube bundle, the specific crystallographic direction of SnSe crystal grains is parallel to the groove and axis direction of the CNT bundle, a small-angle orientation tilting grain boundary is formed between adjacent crystal grains, and a three-dimensional composite network with a nano-porous structure is formed. The SnSe / CNT high-temperature flexible thermoelectric material has relatively good thermoelectric performance and flexible performance, fills the gap of a high-temperature flexible thermoelectric film material, and provides a thought for the research of medium-high-temperature flexible thermoelectric materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

P-n type lead telluride/polypyrrole double-layer thermoelectric thin film material and preparation method thereof

ActiveCN109166958AExcellent thermoelectric performanceLow costThermoelectric device manufacture/treatmentThermoelectric device junction materialsGas phasePolypyrrole

The invention provides a p-n-type lead telluride / polypyrrole double-layer thermoelectric film material and a preparation method thereof are disclose. That p-type lead telluride / polypyrrole double-layer thermoelectric film material is prepared by a hydrothermal method and a gas phase method. N-type lead telluride / polypyrrole bilayer thermoelectric thin film, the thickness of the lead telluride layer thin film is 20 nm-300 nm, and the thickness of the polypyrrole film is 20 nm-300nm. The lead telluride / polypyrrole double-layer thermoelectric thin film material prepared by the method has good thermoelectric performance, can be used for portable wireless sensor power supply, refrigeration of integrated circuit chips, refrigeration of light emitting diodes and photodetectors and other fields, has the advantages of simplicity, low cost, convenience and rapidity, and can be produced on a large scale.

Owner:HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com