Patents

Literature

32results about How to "Uninterrupted heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

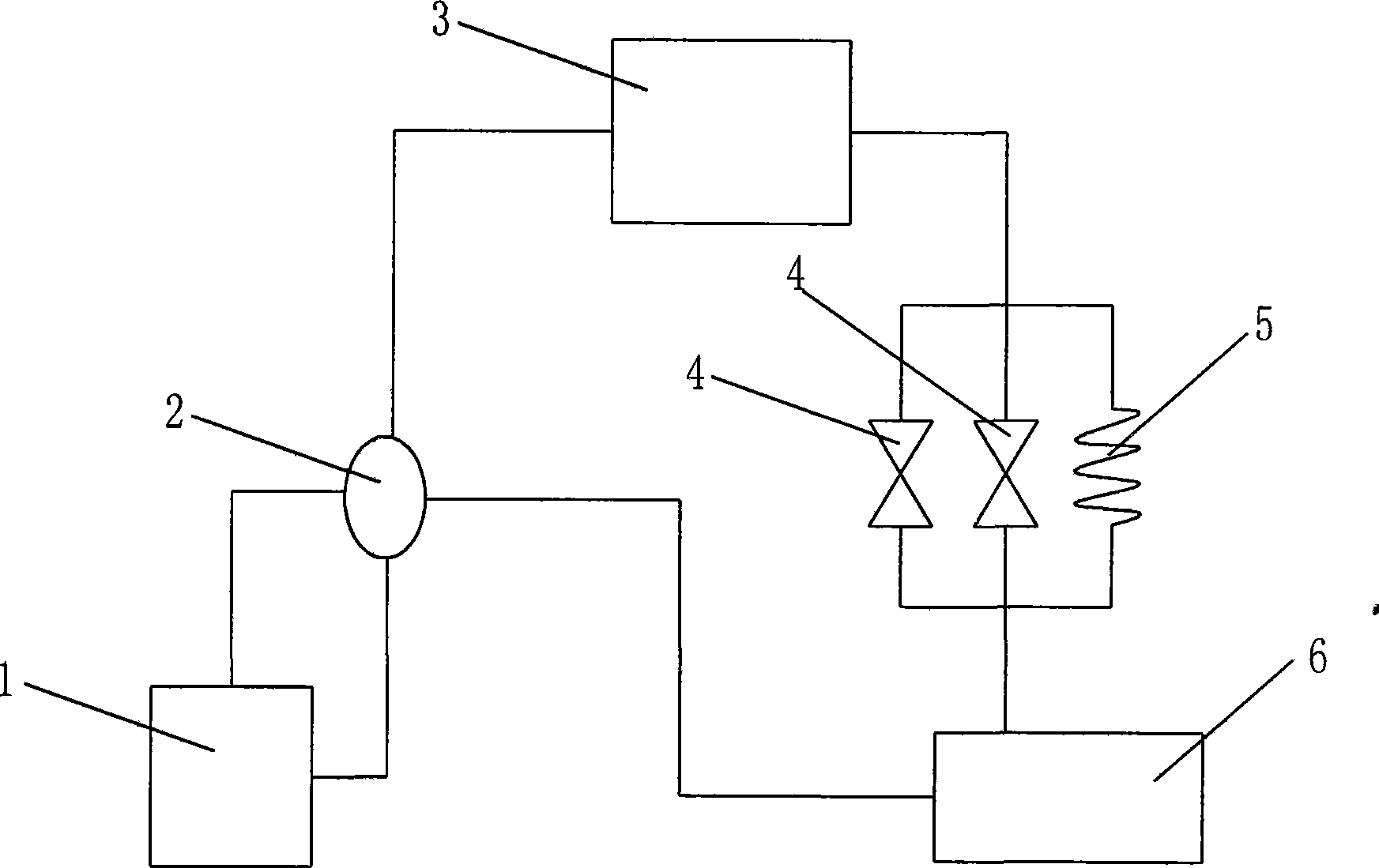

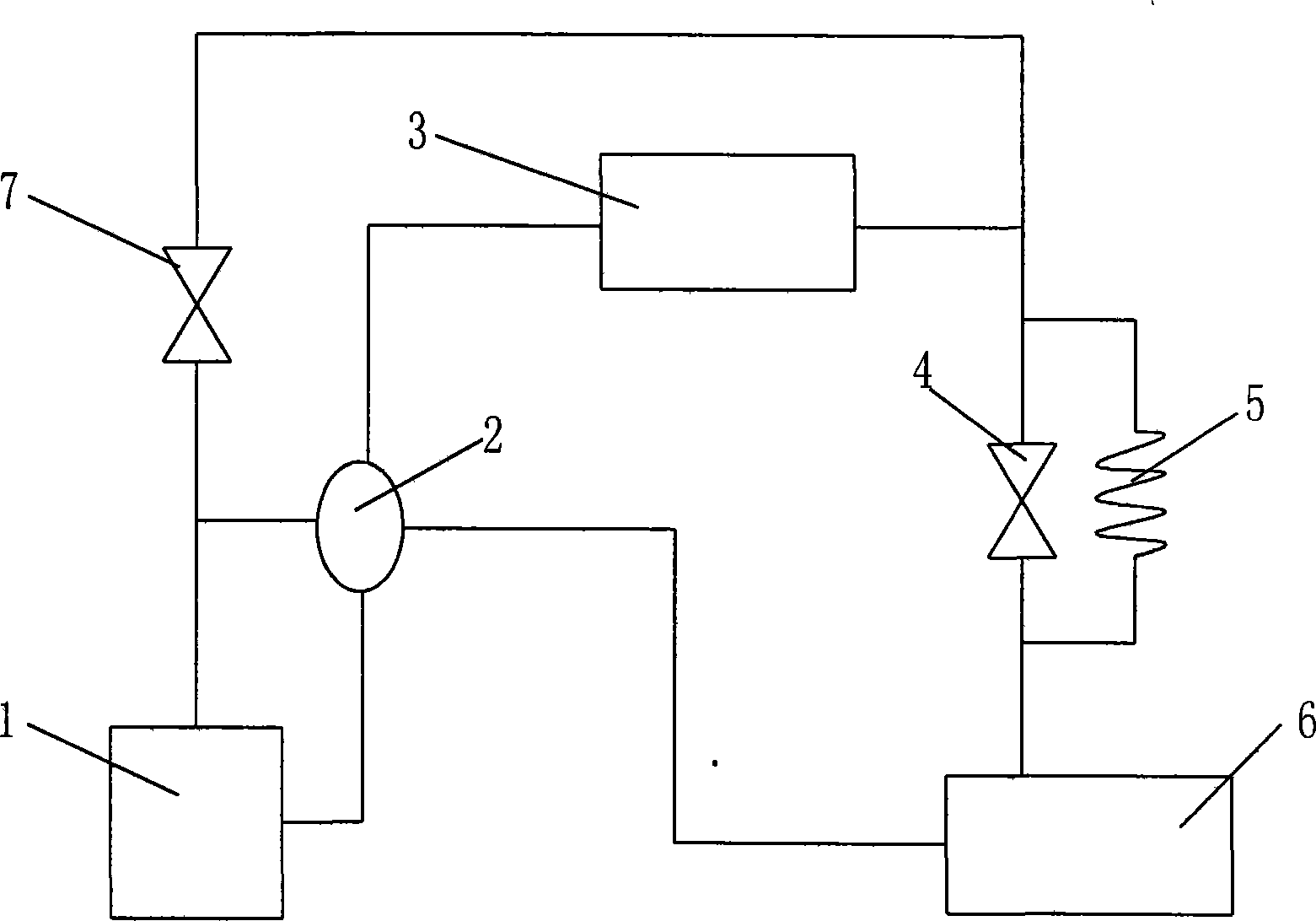

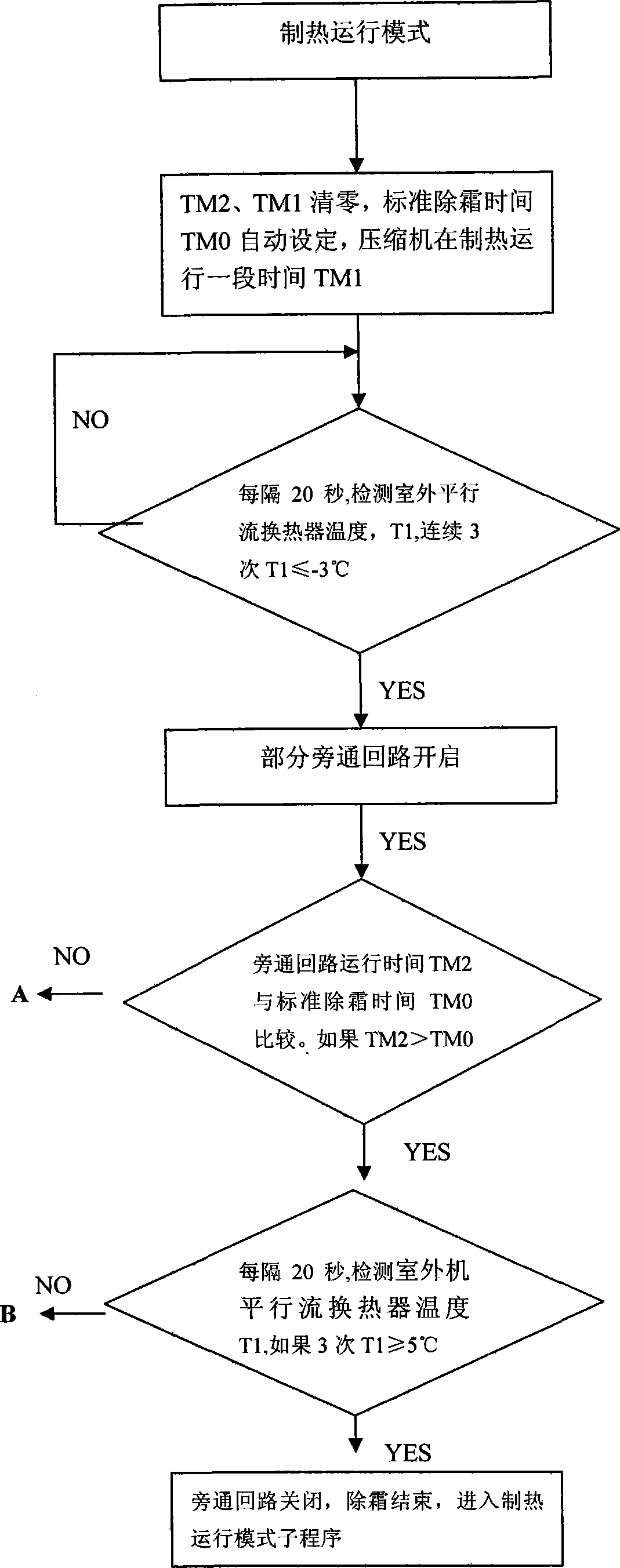

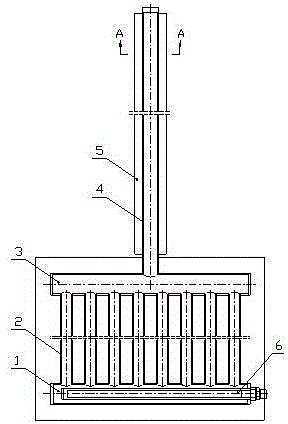

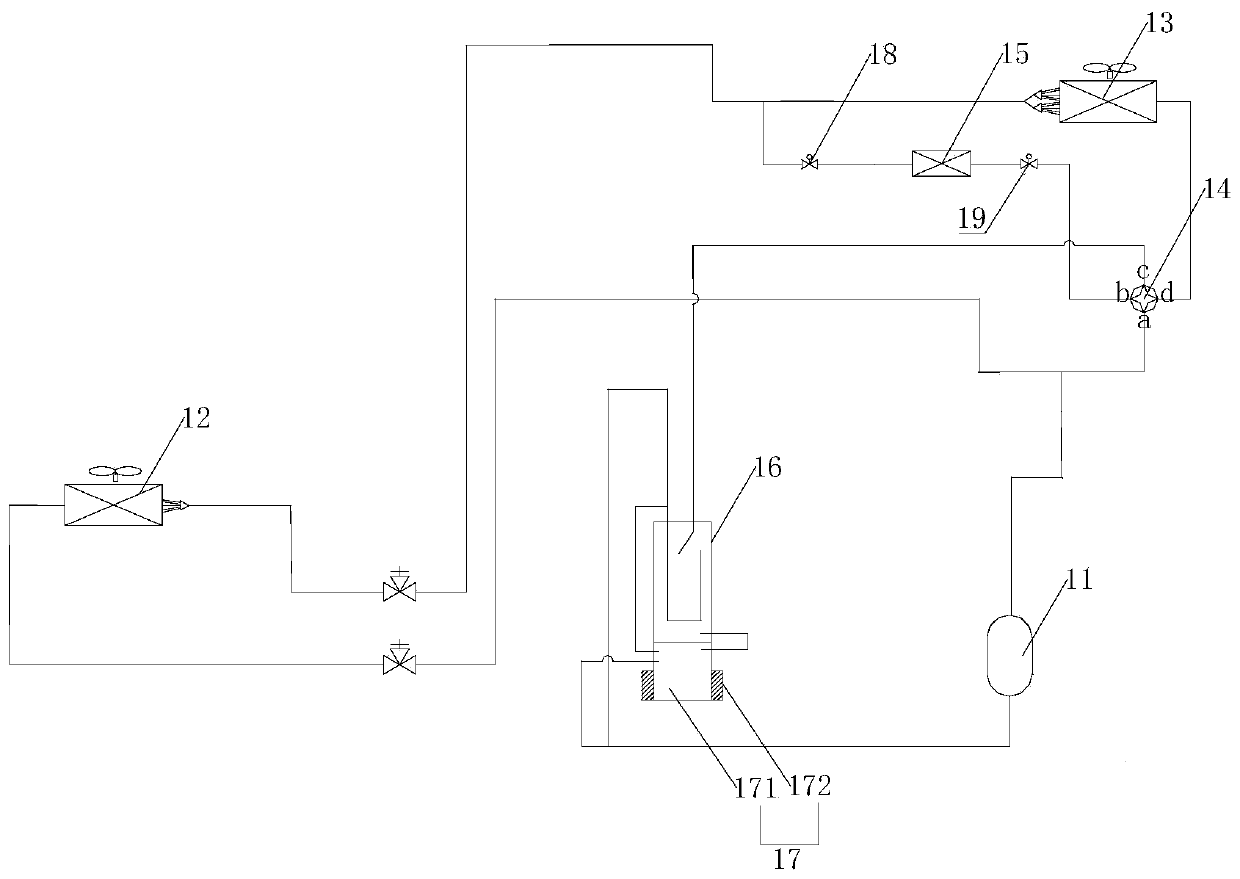

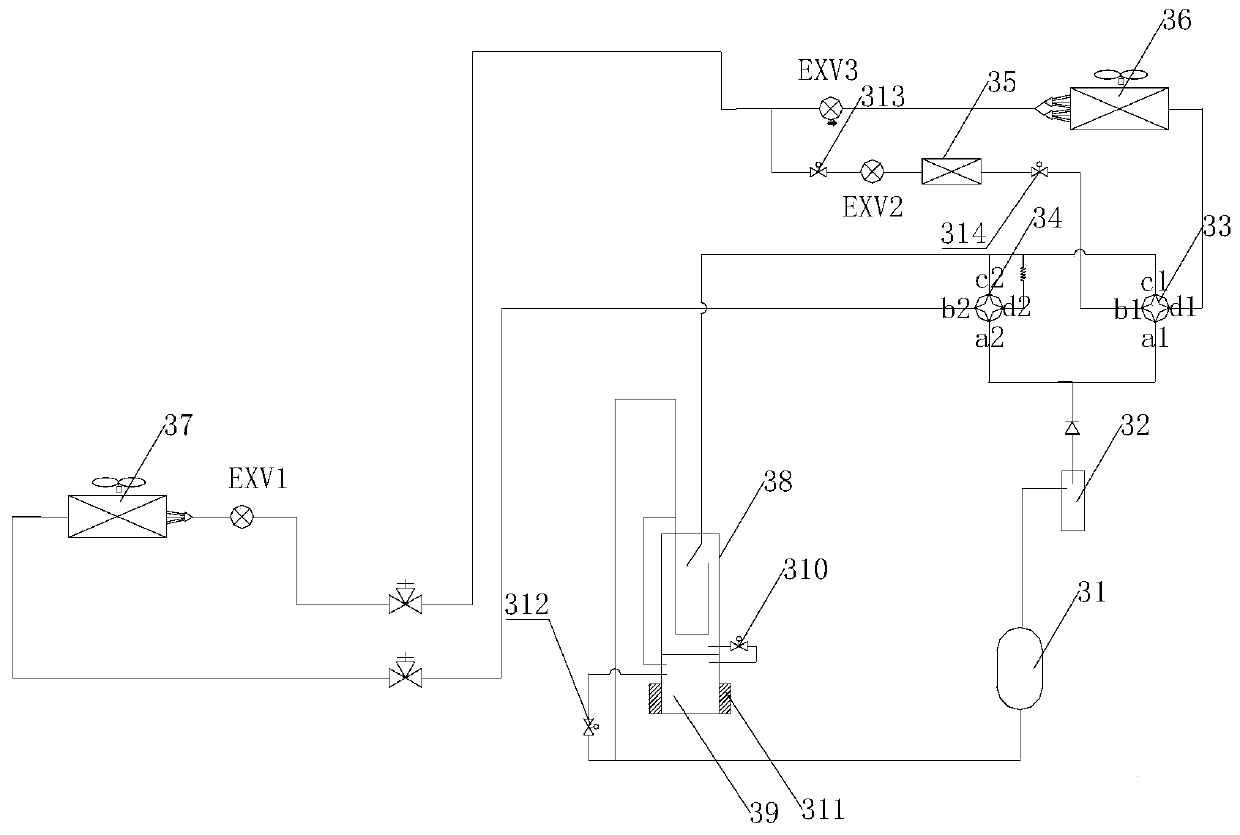

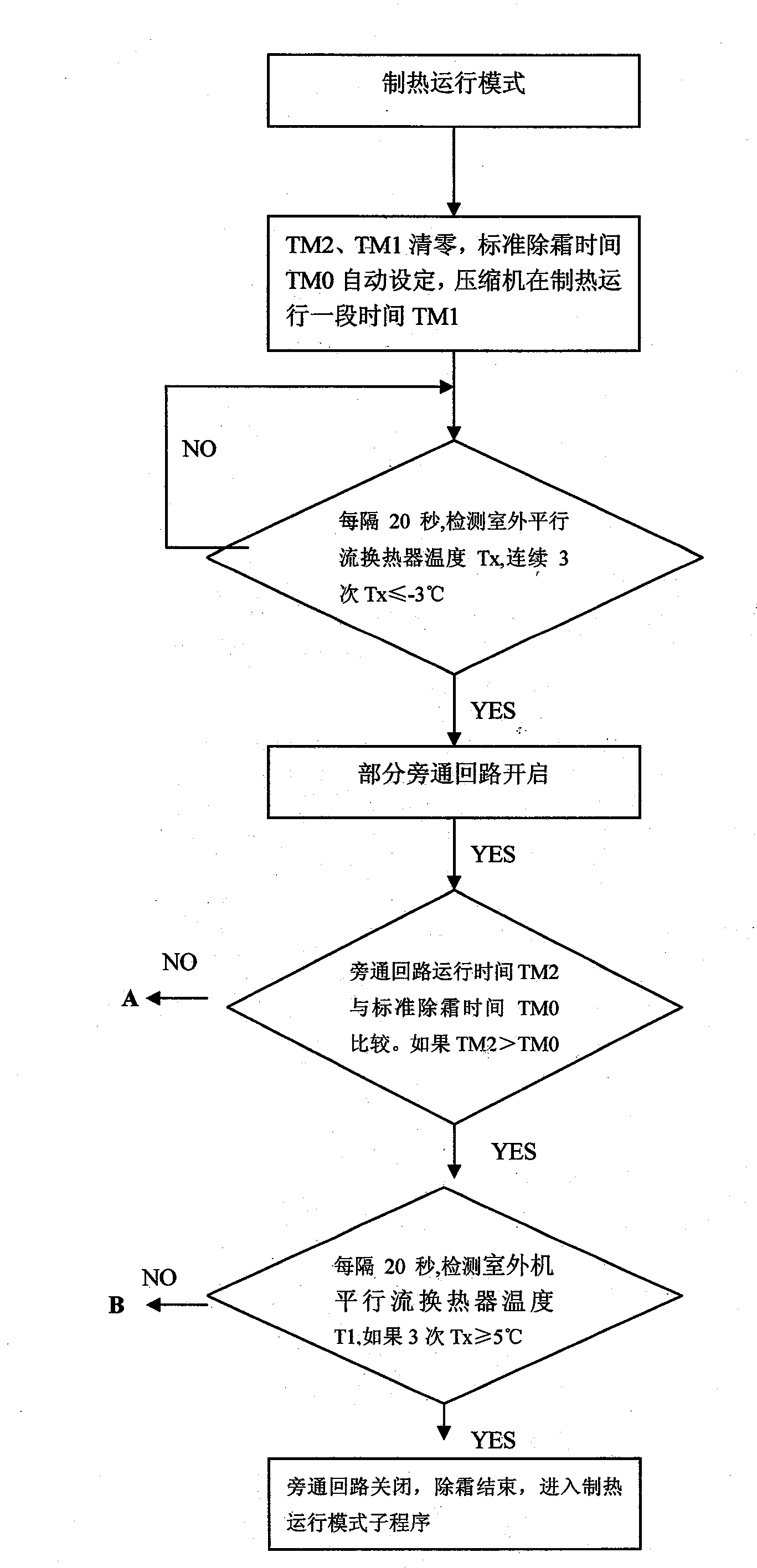

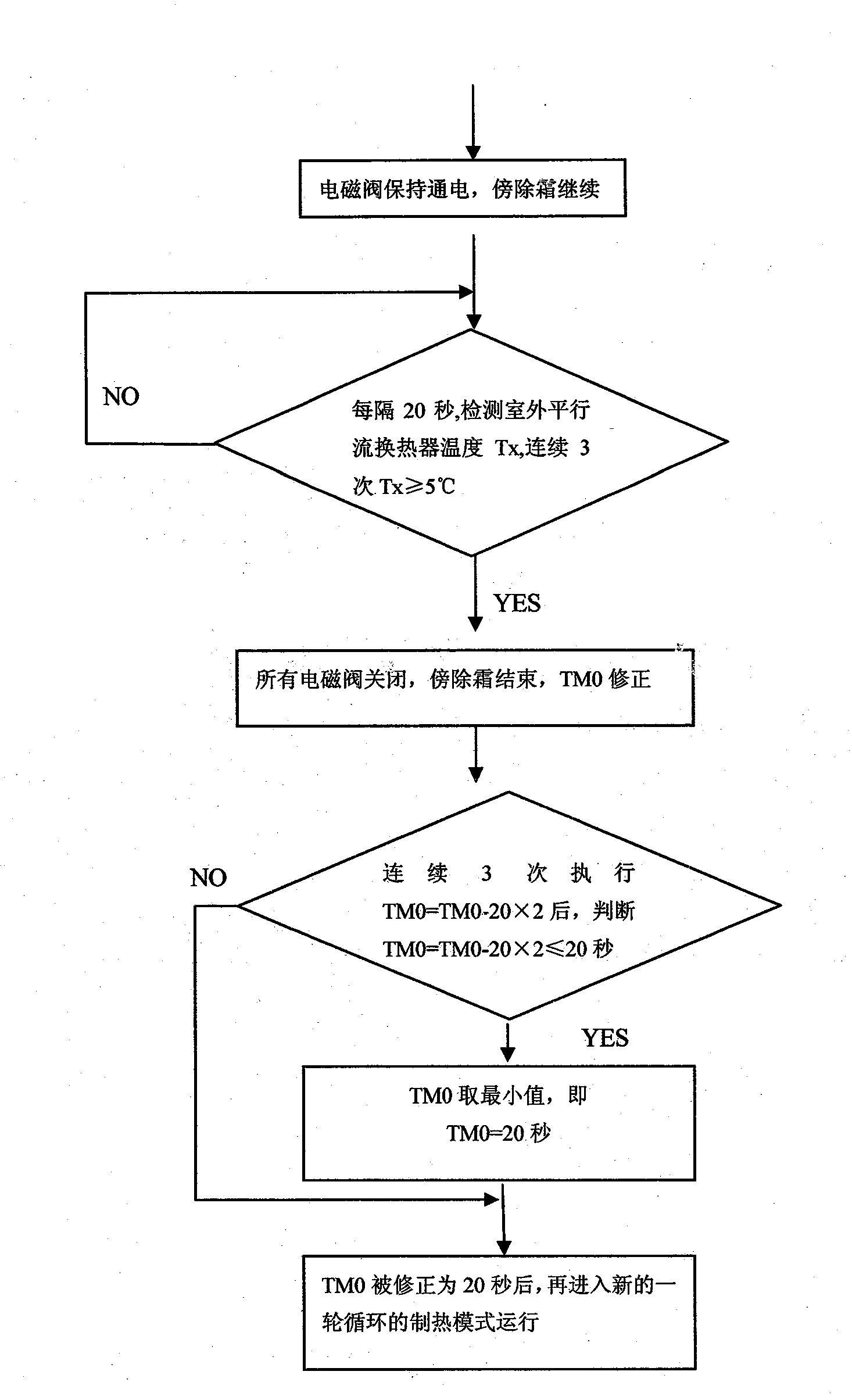

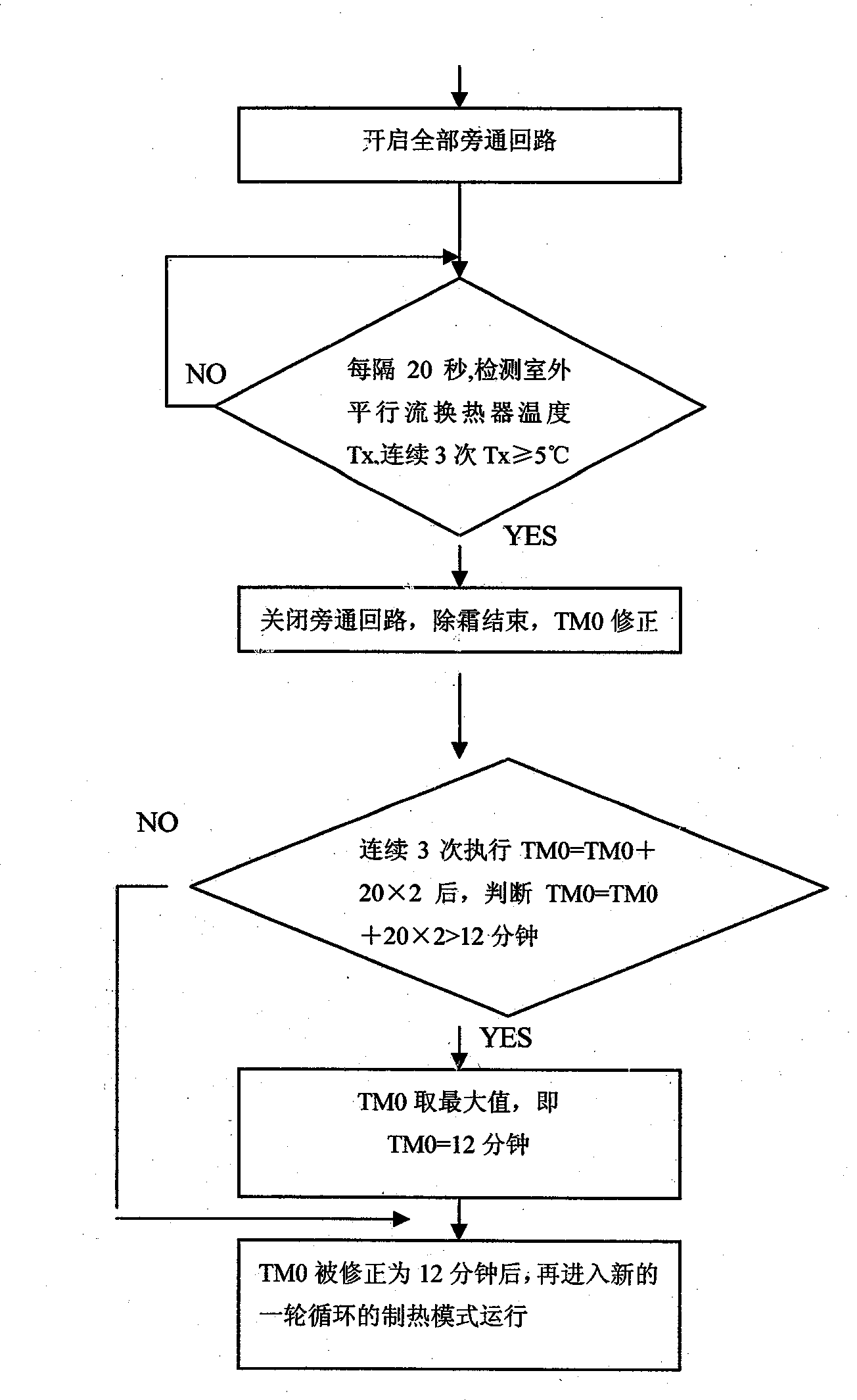

Parallel flow air conditioner and defrosting control method thereof

InactiveCN101387455AImprove comfortUninterrupted heatingHeat pumpsCorrosion preventionEngineeringHeat exchanger

Owner:TCL CORPORATION

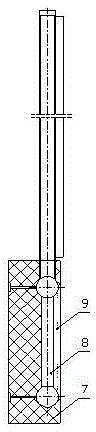

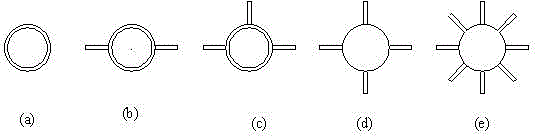

Method for preventing and controlling freeze-expanded damage to water-containing subgrade in cold region and bunched low-temperature heat pipe

InactiveCN104596122AStrong complementarityUninterrupted heatingSolar heating energyRoadwaysEvaporationEngineering

The invention discloses a method for preventing and controlling freeze-expanded damage to water-containing subgrade in a cold region and a bunched low-temperature heat pipe. The method is characterized in that a T-shaped bunched solar low-temperature heat pipe capable of transmitting solar energy or electric energy heat into the subgrade is arranged in the subgrade; when the environmental temperature is lower than 0 DEG C, a working medium on the evaporation segment of the low-temperature heat pipe absorbs solar energy heat and rises to be conducted into the condensation segment of the low-temperature heat pipe; on cloudy days, the working medium on the evaporation segment is heated through electric heating, and is conducted into the condensation segment of the low-temperature heat pipe; heat is transmitted into the water-containing subgrade through the condensation segment in order that the temperature of the water-containing subgrade is greater than the icing temperature; the working medium which releases heat returns back into the evaporation segment under the action of gravity to absorb heat, and the abovementioned work is performed circularly in order that the temperature of the water-containing subgrade is kept higher than the icing temperature, so that the occurrence of freeze-expanded damage to the subgrade is prevented. The method is simple and reliable, the phenomenon of frost heaving of the subgrade can be effectively avoided, and the transportation safety is ensured.

Owner:江苏中圣压力容器装备制造有限公司

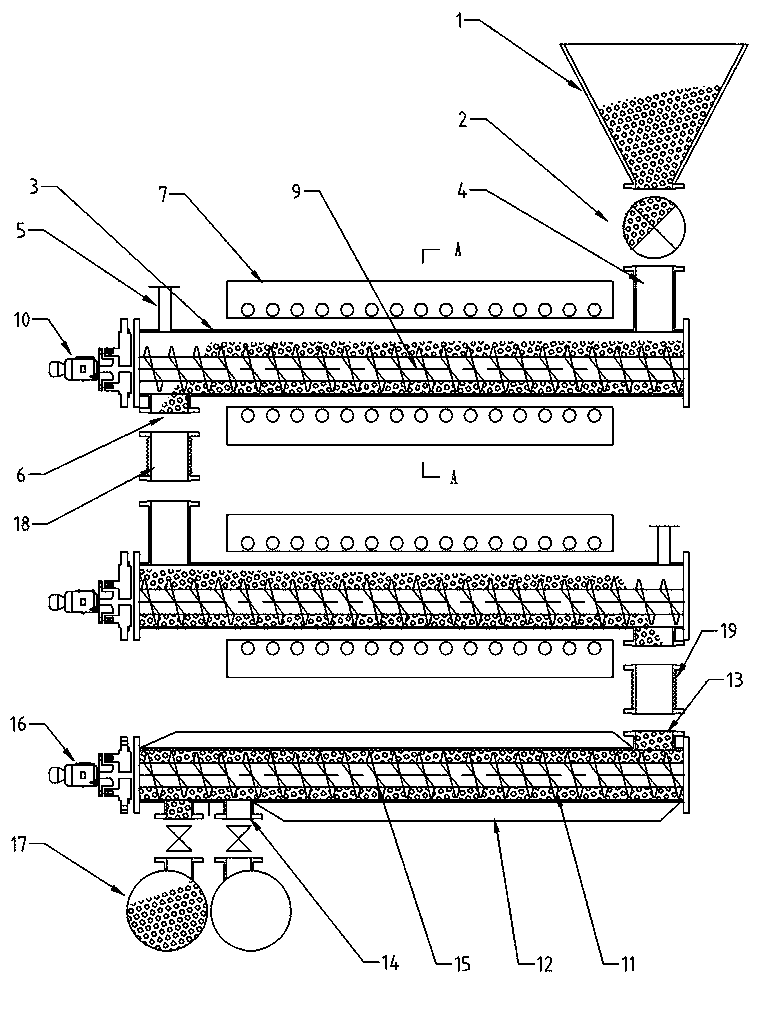

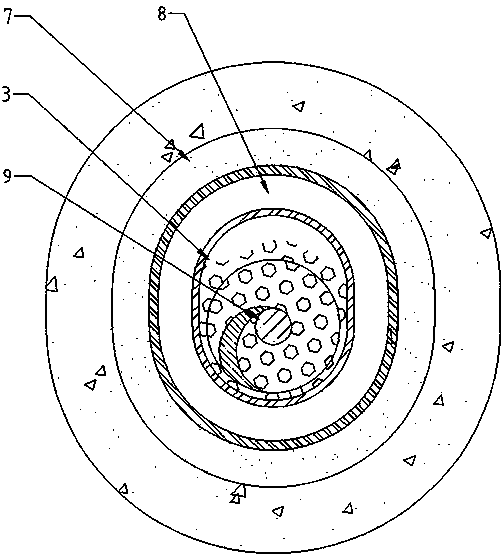

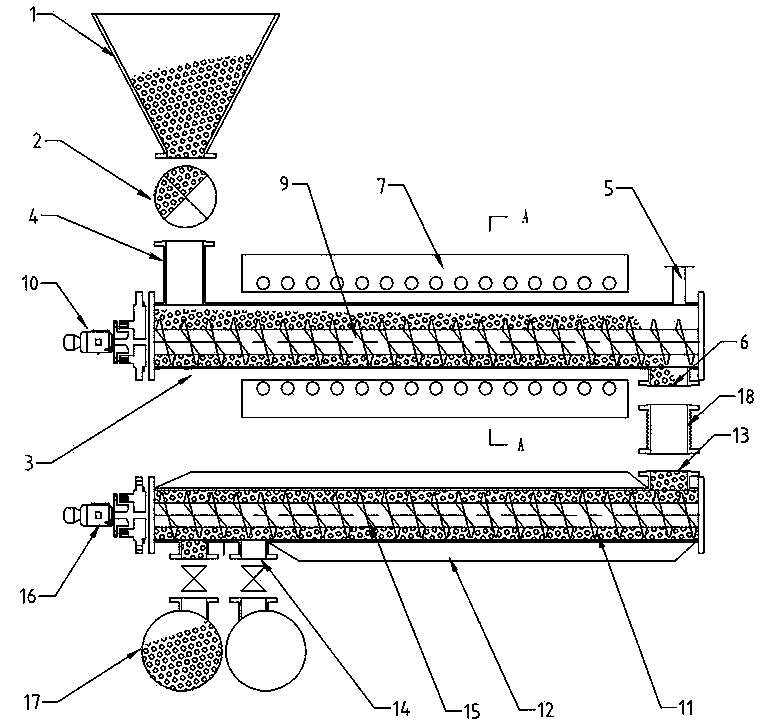

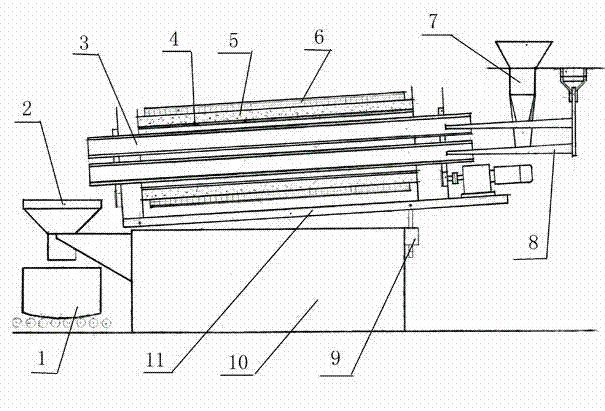

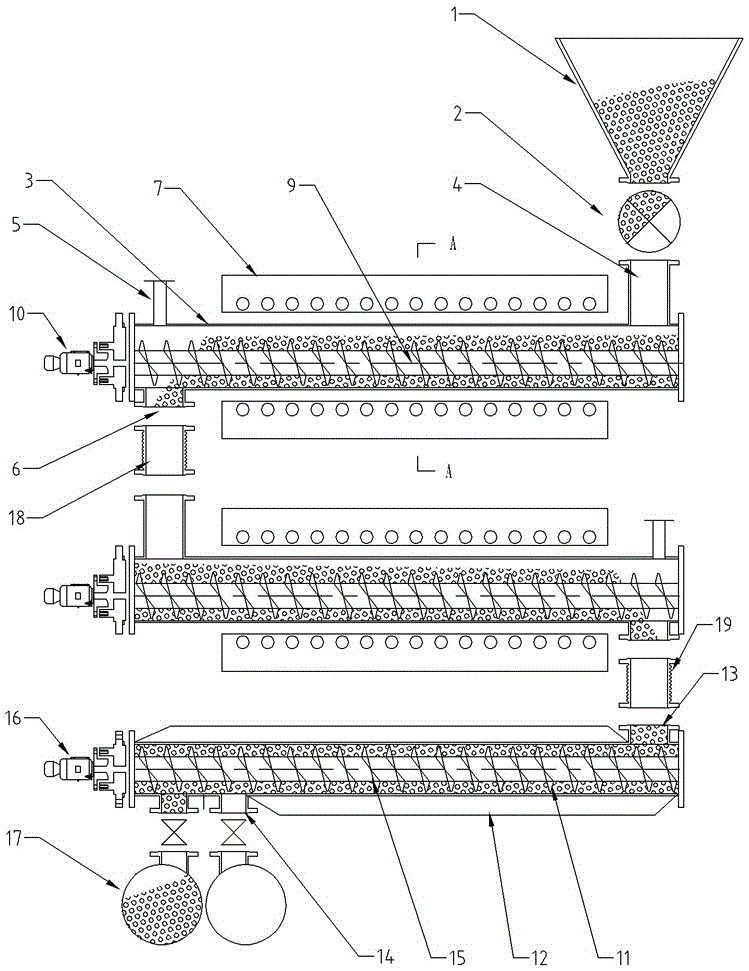

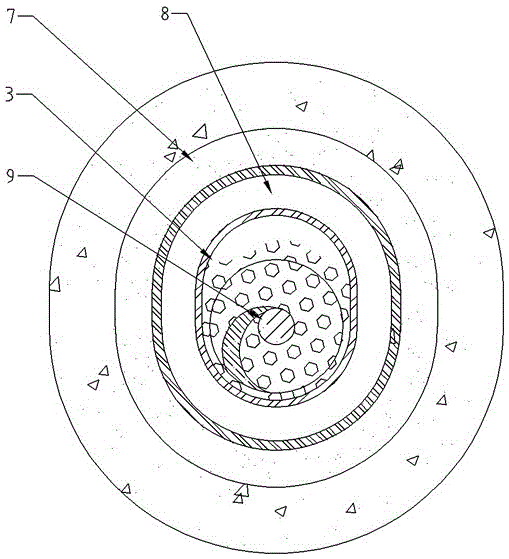

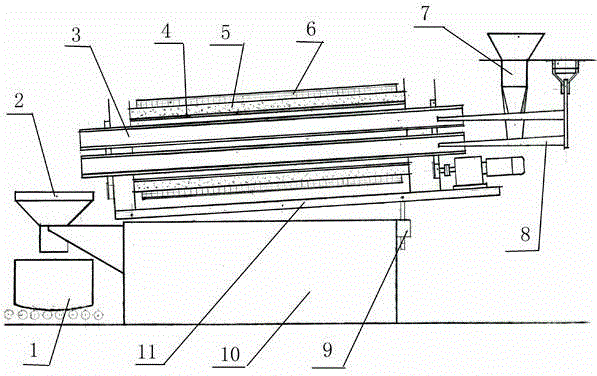

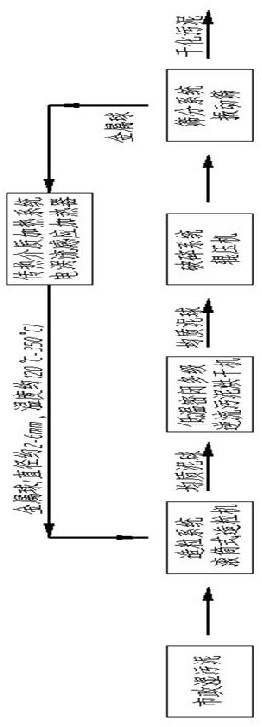

Horizontal-tube carbon intermediate continuous thermal treatment device

ActiveCN104215066ASignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemWater jacket

The invention relates to a horizontal-tube carbon intermediate continuous thermal treatment device. The horizontal-tube carbon intermediate continuous thermal treatment device comprises a feeding system, a heating segment, a cooling segment, a tail gas system and a discharging system which are connected in sequence, wherein the feeding system consists of a conical stock cabin of which the bottom is provided with a hopper hole, and a feeding machine; the feeding system, the heating segment, the cooling segment and the discharging system are connected with a measuring and controlling system through a sensing circuit; long barrels enclosed by sealing covers are arranged at the two ends of a heating segment horizontal tube; the transverse sections of the long barrels have bilaterally-symmetrical straight edges and longitudinally-symmetrical semi-circular-arc edges; a first screw rod is arranged in the lower semi-circular-arc edge of each whole segment of long barrel; the cooling segment is a metal long barrel of which the two ends are enclosed by sealing covers; the outer surface of the metal long barrel is provided with an interlayer water jacket. The horizontal-tube carbon intermediate continuous thermal treatment device is used for treating carbon intermediates, mainly powder or small particles, and has the advantages of low energy consumption, low cost, easiness in operation, and lowering of pollution to the maximum extent.

Owner:CHENZHOU SHANSHAN NEW MATERIAL

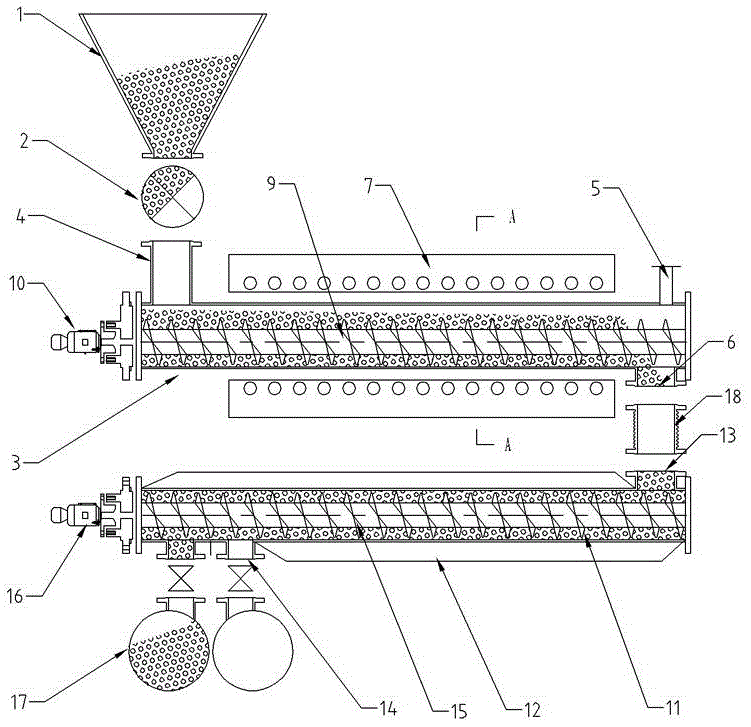

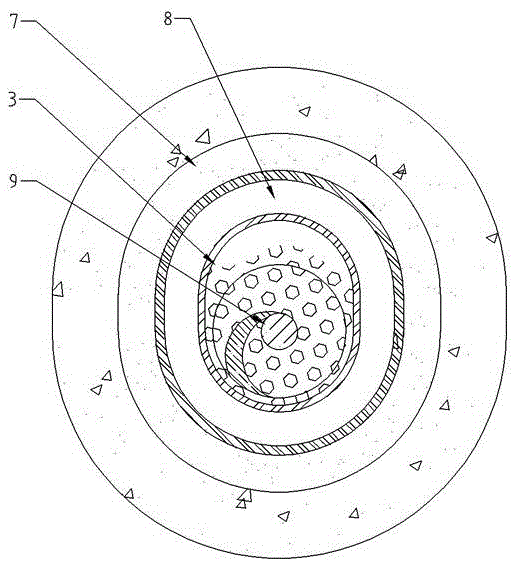

Single-horizontal-pipe type continuous heat treatment device for carbon intermediate

ActiveCN104215065ASignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemWater jacket

The invention relates to a single-horizontal-pipe type continuous heat treatment device for a carbon intermediate. The device comprises a feeding system, a heating section, a cooling section, a tail gas system and a discharging system, which are sequentially connected, wherein the feeding system is formed by a tapered feed bin with a bottom funnel opening, and a feeder; the feeding system, the heating section, the cooling section and the discharging system are connected with a measurement and control system through a sensing circuit; the heating section is a long barrel of which the two ends are sealed by sealing covers, and the cross section of the long barrel is formed by left and right symmetric straight edges and upper and lower symmetric semicircular arc edges; a first screw rod is arranged in the whole lower semicircular arc edge of the whole long barrel; the cooling section is a metal long cylinder of which the two ends are sealed by sealing covers; an interlayer water jacket is arranged on the outer surface of the metal long cylinder. The device is used for treating carbon intermediate materials which mainly comprise powder or small particles, and is low in energy consumption and cost and easy to operate, and pollution is maximally reduced.

Owner:CHENZHOU SHANSHAN NEW MATERIAL

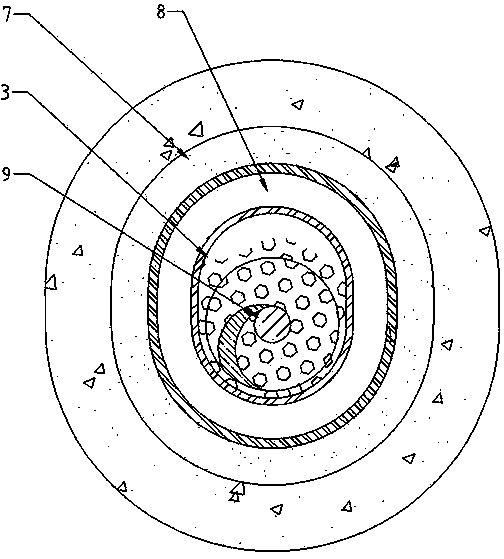

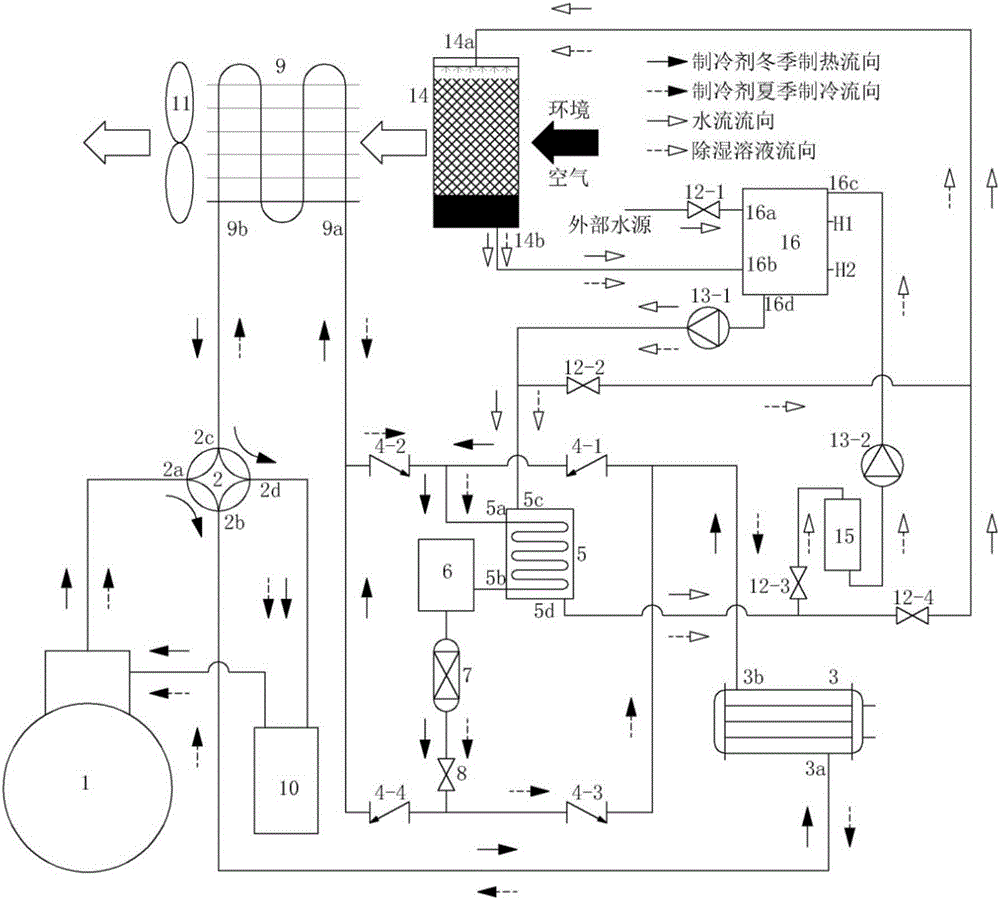

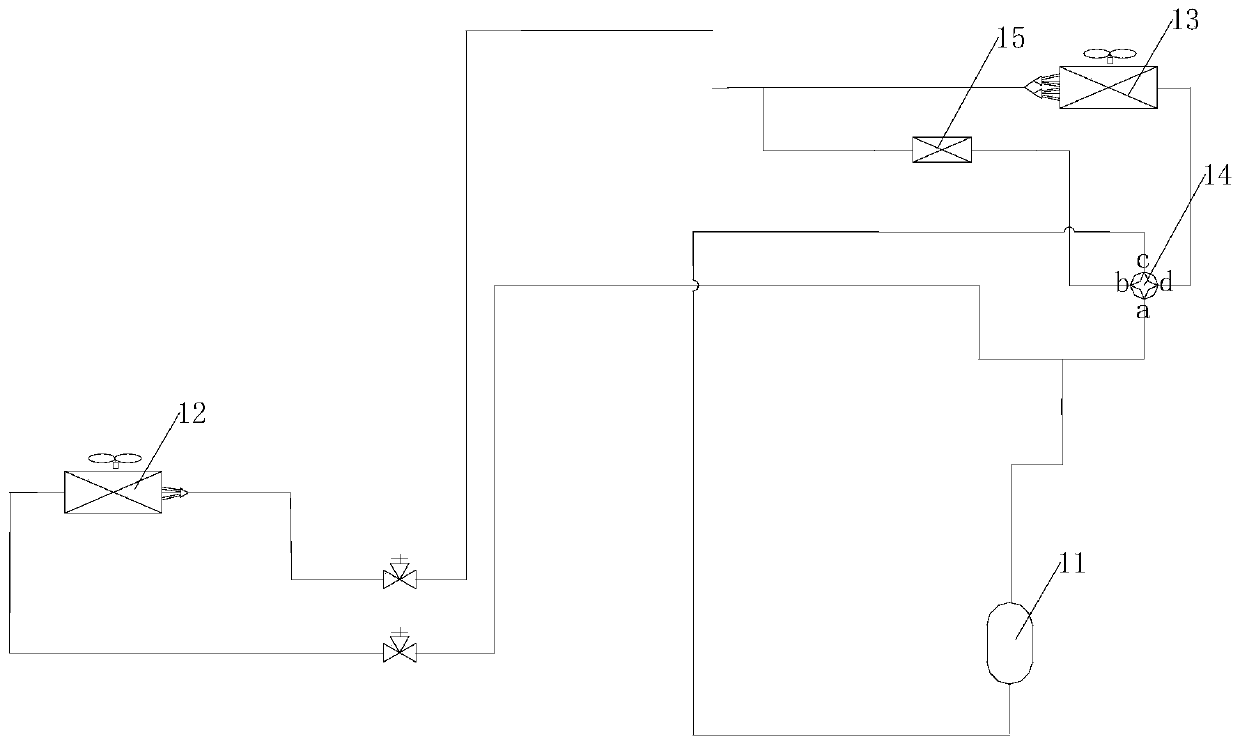

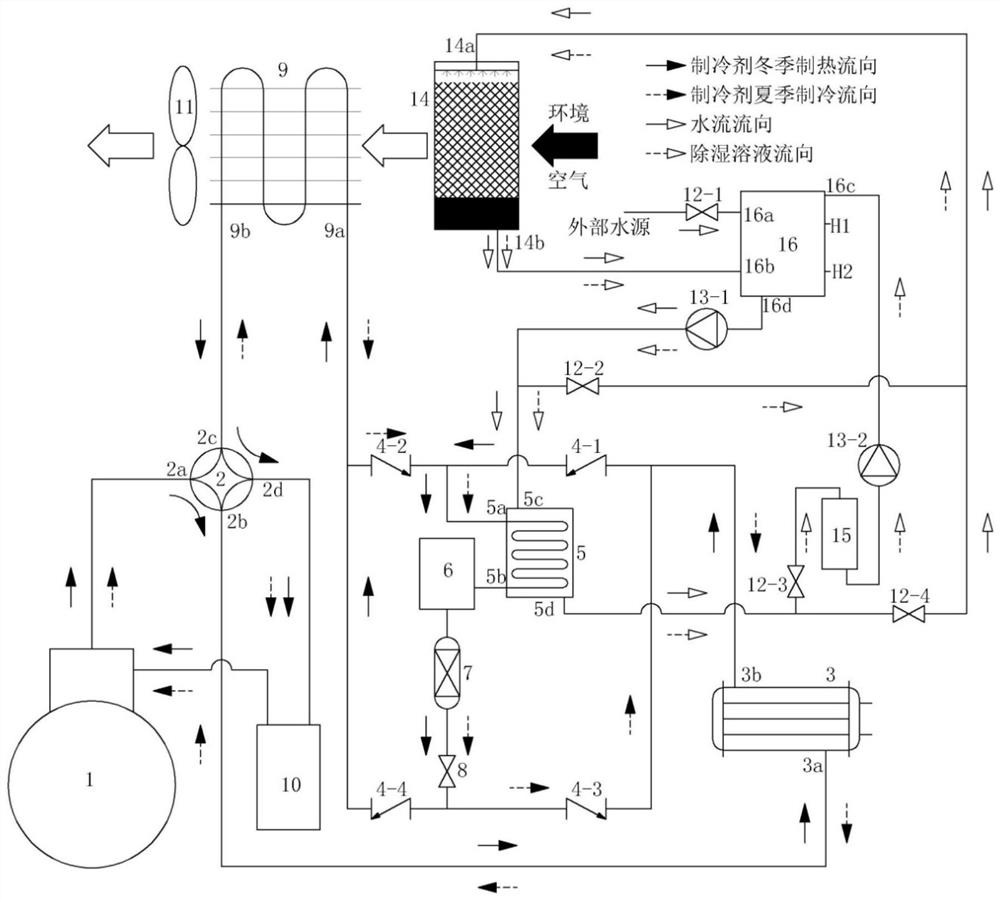

Frostless air source heat pump system based on humidity adjustment and evaporative cooling

ActiveCN106322810AReduce the temperatureImprove cooling efficiencyMechanical apparatusHeat pumpsVapor–liquid separatorFour-way valve

The invention discloses a frostless air source heat pump system based on humidity adjustment and evaporative cooling. The frostless air source heat pump system based on humidity adjustment and evaporative cooling comprises a refrigerant circuit, a water and humidity adjustment solution circuit and an air circuit. The refrigerant circuit comprises a compressor, a four-way valve, a first heat exchanger, a first one-way valve, a second one-way valve, a third one-way valve, a fourth one-way valve, a heat exchanger, a liquid accumulator, a drying and filtering device, an electronic expansion valve, a finned tube exchanger and an air-liquid separator; the water and humidity adjustment solution circuit comprises a humidity adjustment device, a first valve, a second valve, a third valve, a fourth valve, a first solution pump, a second solution pump, a fluid reservoir, a heat exchanger and a regenerating device; and the air circuit comprises the finned tube exchanger , the humidity adjustment device and a fan. When the system provided by the invention runs at a heating mode in winter, the frosting can be avoided, when the system runs at a cooling mode in summer, the condensing temperature can be lower through evaporative cooling, and higher cooling efficiency is achieved, so that dual efficient running of the system in winter and summer is realized.

Owner:SOUTHEAST UNIV

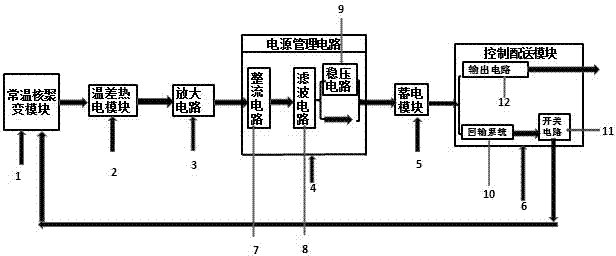

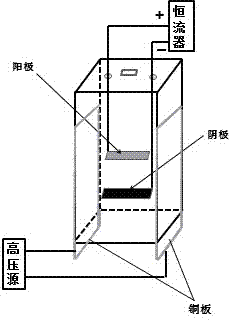

Chip-level self-sustained thermoelectric generation system

InactiveCN104518708AIncrease energy densityUninterrupted heatingGenerators/motorsThermal energyHigh energy

The invention discloses a chip-level self-sustained thermoelectric generation system. The chip-level self-sustained thermoelectric generation system comprises a normal-temperature nuclear fusion module, a temperature difference thermoelectric module, an amplifying circuit module, a power management circuit module, an electricity storage module and a control and distribution module which are connected sequentially. The chip-level self-sustained thermoelectric generation system has the advantages that thermal energy is converted into electric energy by using a temperature difference thermoelectric thin film as an energy conversion medium, so that unnecessary heat dissipation cannot be generated, and energy conversion ratio is increased remarkably; quite high energy gain can be generated by normal-temperature nuclear fusion, in other words, energy generated during normal operation of the system is far more than energy inputted from the outside, so that self-sustained electricity generation can be achieved, and the electric energy is outputted continuously.

Owner:SHANGHAI UNIV

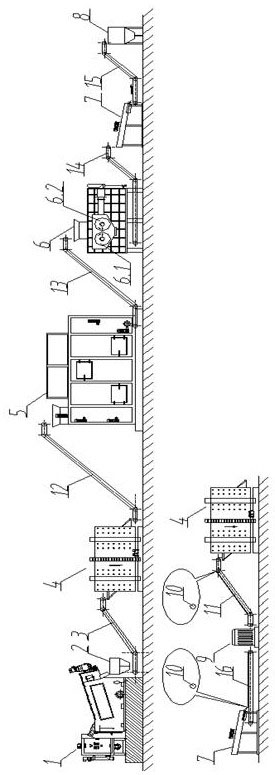

Line-frequency induction type dynamic drying machine with four quartz tubes

ActiveCN102829613ANo pollution in the processReduce lossDrying solid materialsDrying machines with non-progressive movementsThree stageEngineering

The invention discloses a line-frequency induction type dynamic drying machine with four quartz tubes. The line-frequency induction type dynamic drying machine comprises the four quartz glass drying material tubes which are arranged obliquely, wherein an annular heating barrel is arranged at the middles of the quartz glass drying material tubes; a feeder is arranged at upper feeding ends of the quartz glass drying material tubes; a material receiving device is arranged at lower discharging ends of the quartz glass drying material tubes; the feeder is provided with a material bin; a reamer breaking and dispersing mechanism is arranged in the material bin; a vibration material conveying groove is formed at the lower end of the material bin; the material receiving device is provided with a three-stage cascade type suddenly cooling device and a material collecting device; the cascade type suddenly cooling device is provided with a material receiving hopper, a cooling barrel and an air collecting barrel; a group of cooling tubes arranged in a fence shape is arranged at the upper part of the cooling barrel; a quartz glass sleeve is sheathed outside each cooling tube; and jet flow air holes are formed in a hole wall of a suddenly cooling plate along the tangential direction. Induction heating is carried out on a heating cavity by using an excitation coil, so that materials can be heated continuously, and powder can be at a movement state all the time, so that the drying effect is good, and the cooling efficiency is high.

Owner:江苏省晶瑞石英工业开发研究院有限公司

A horizontal tube type carbonaceous intermediate continuous heat treatment device

ActiveCN104215066BSignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemEngineering

Owner:CHENZHOU SHANSHAN NEW MATERIAL

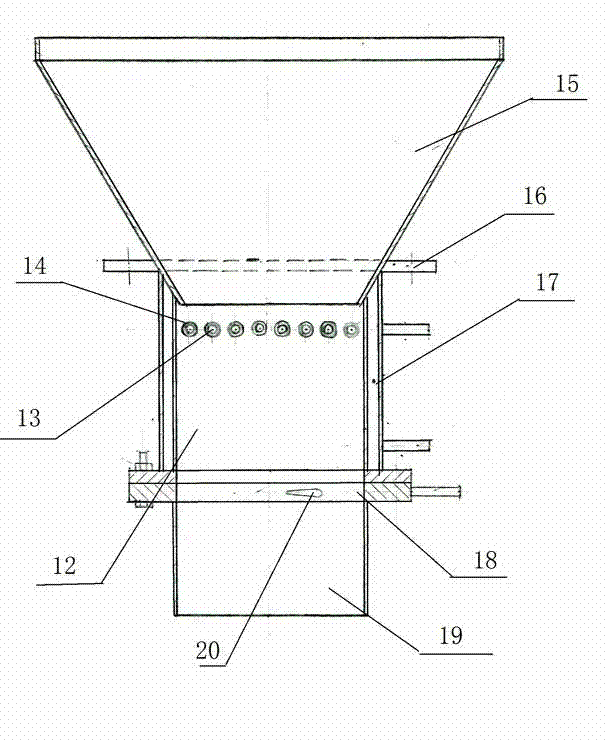

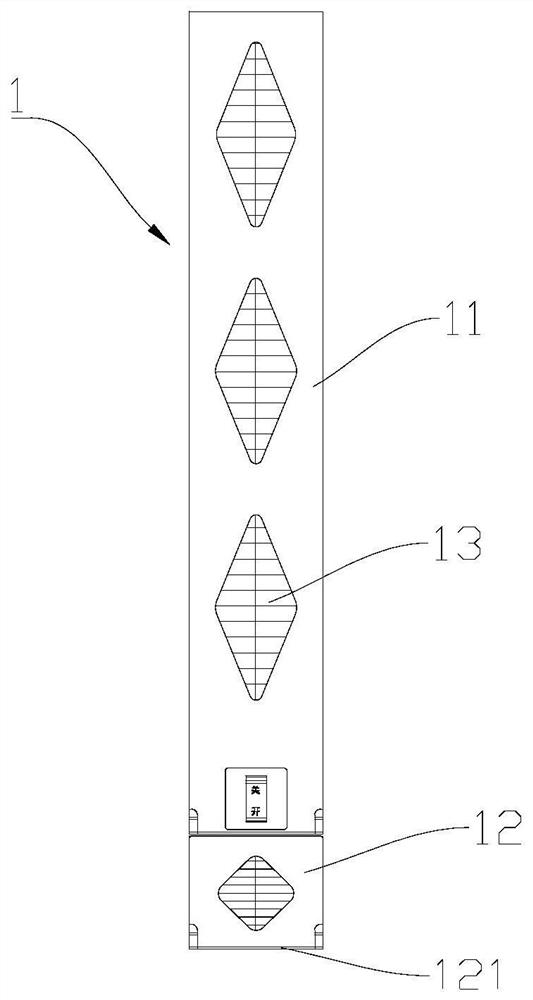

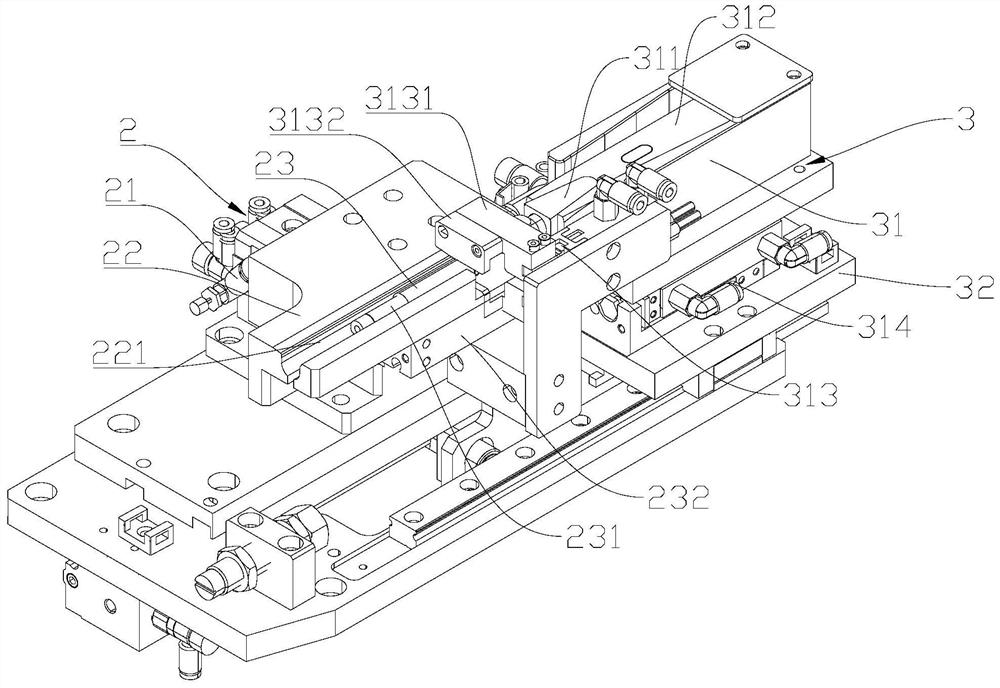

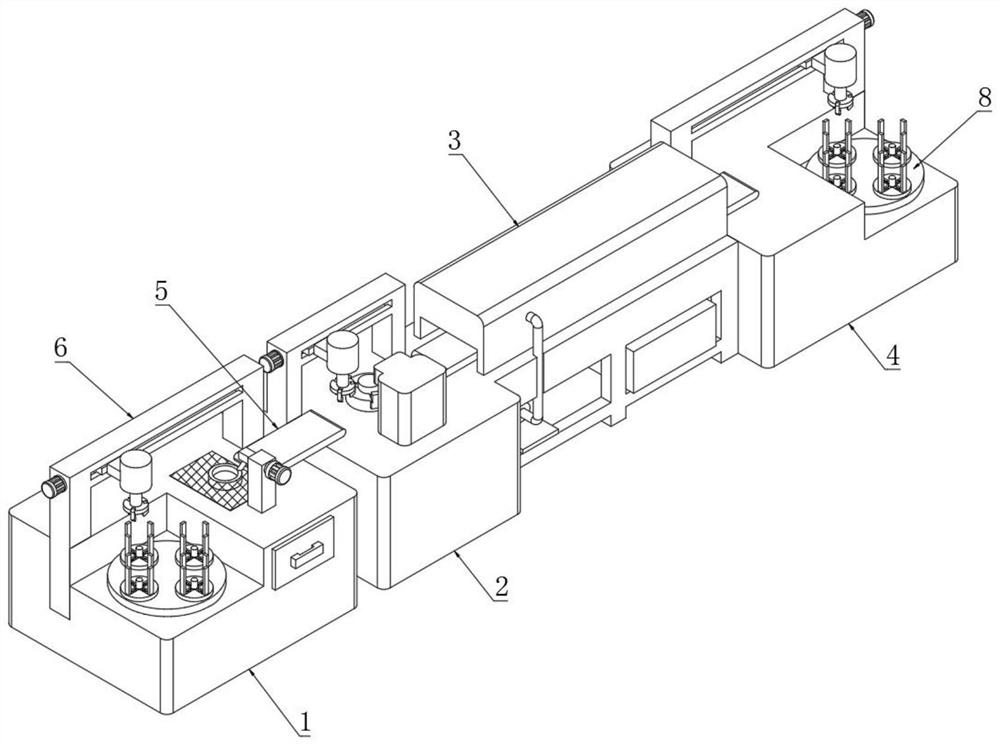

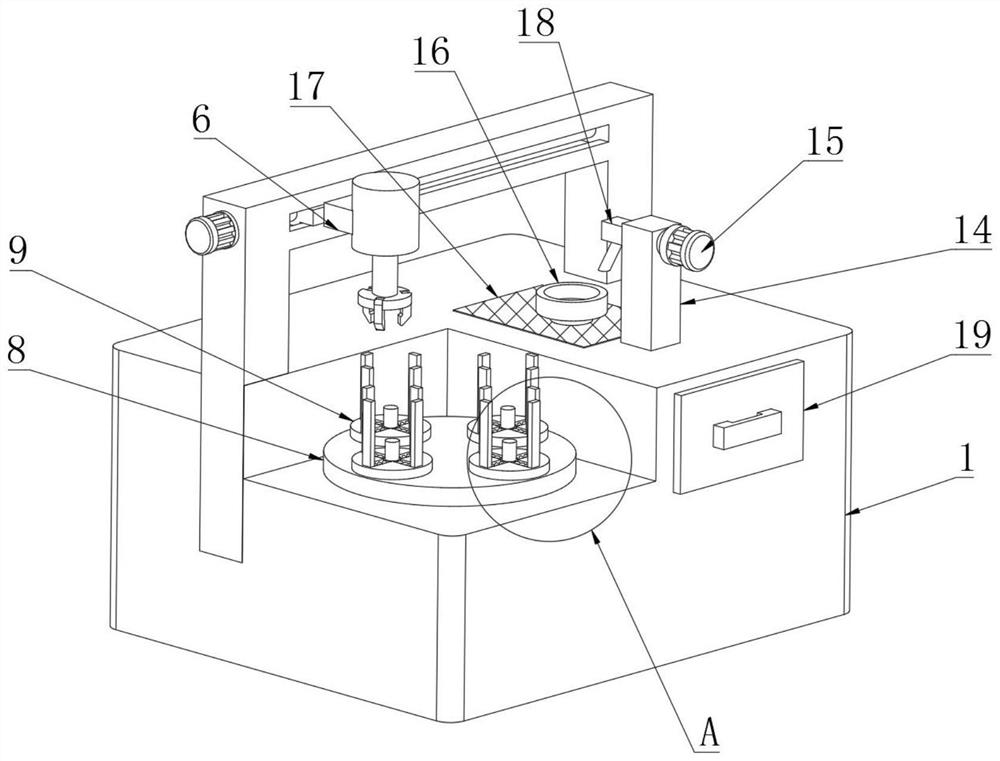

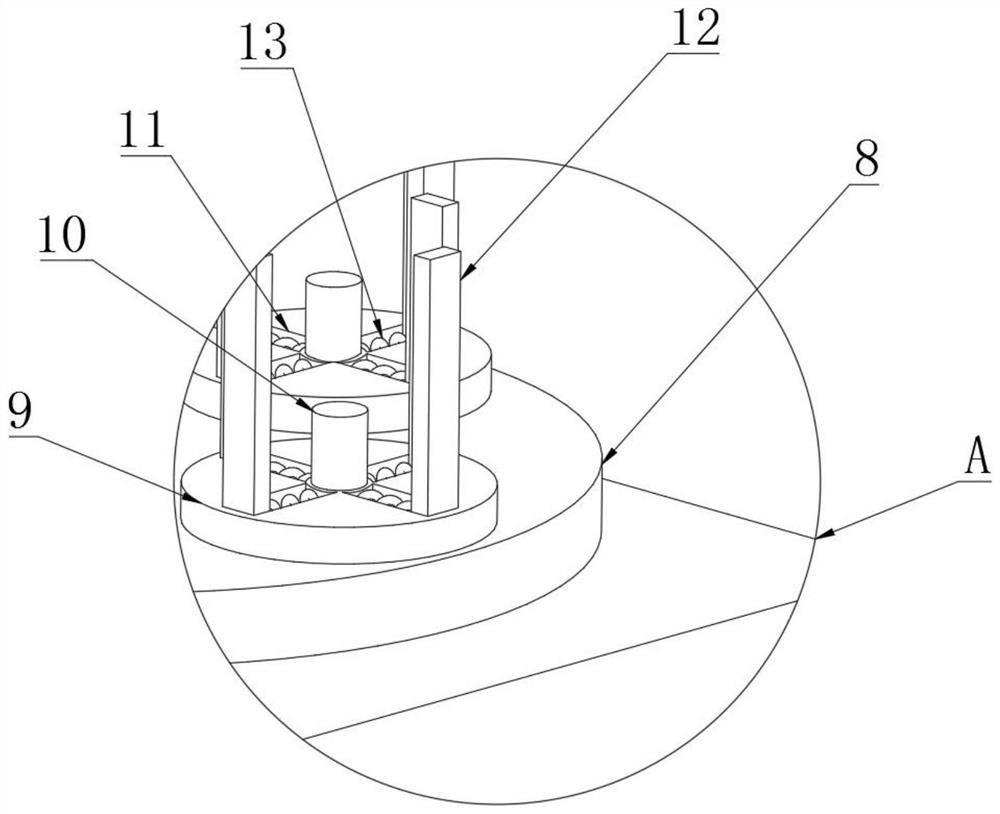

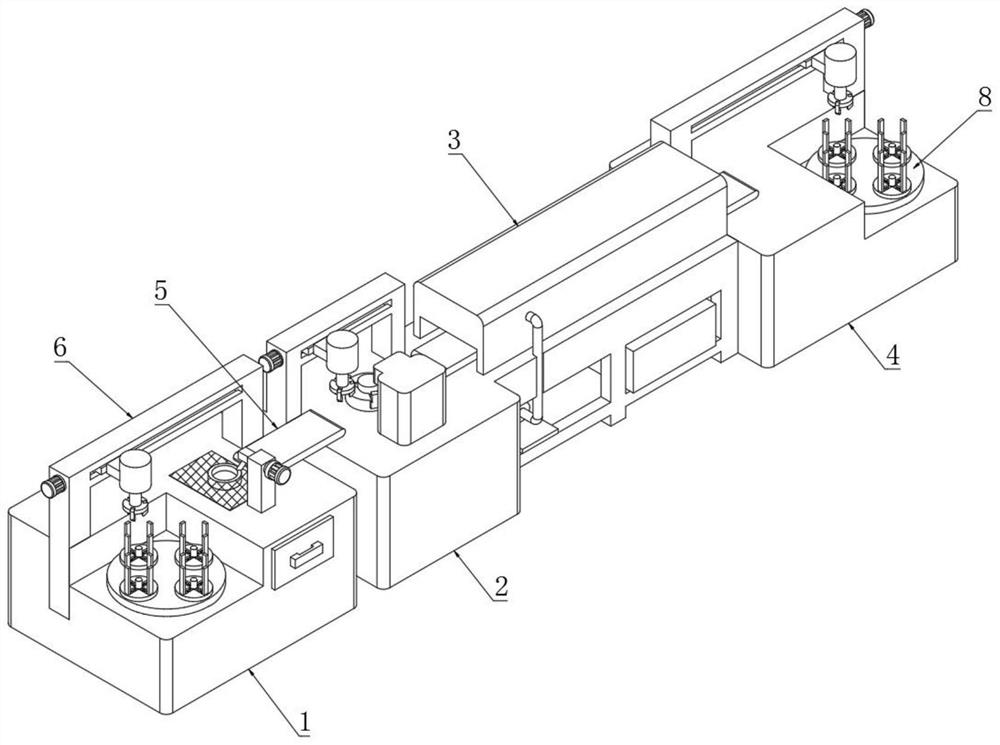

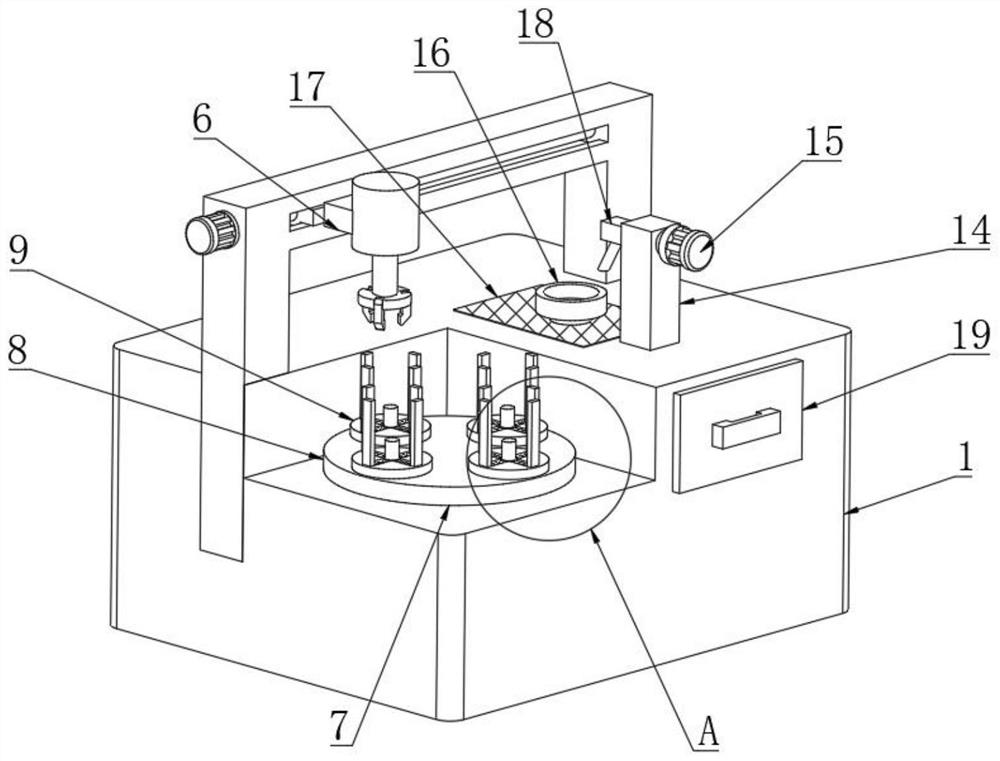

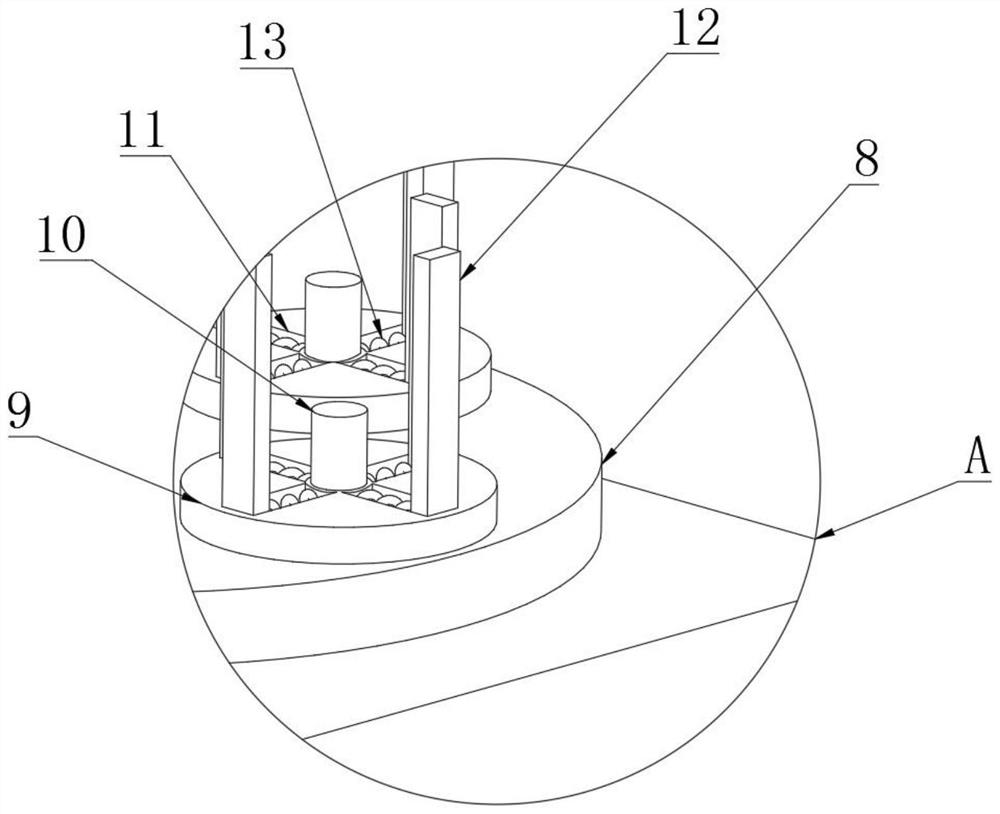

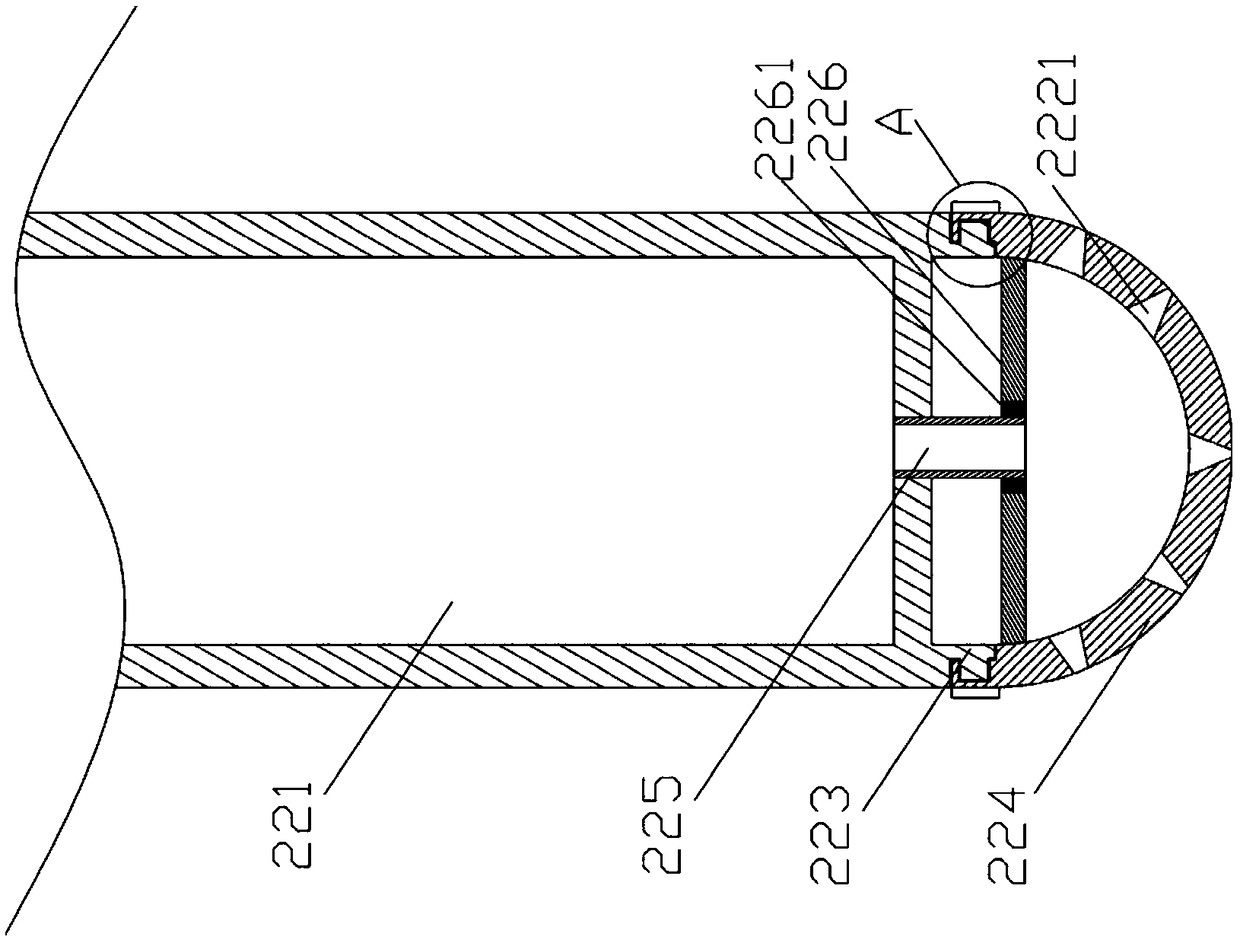

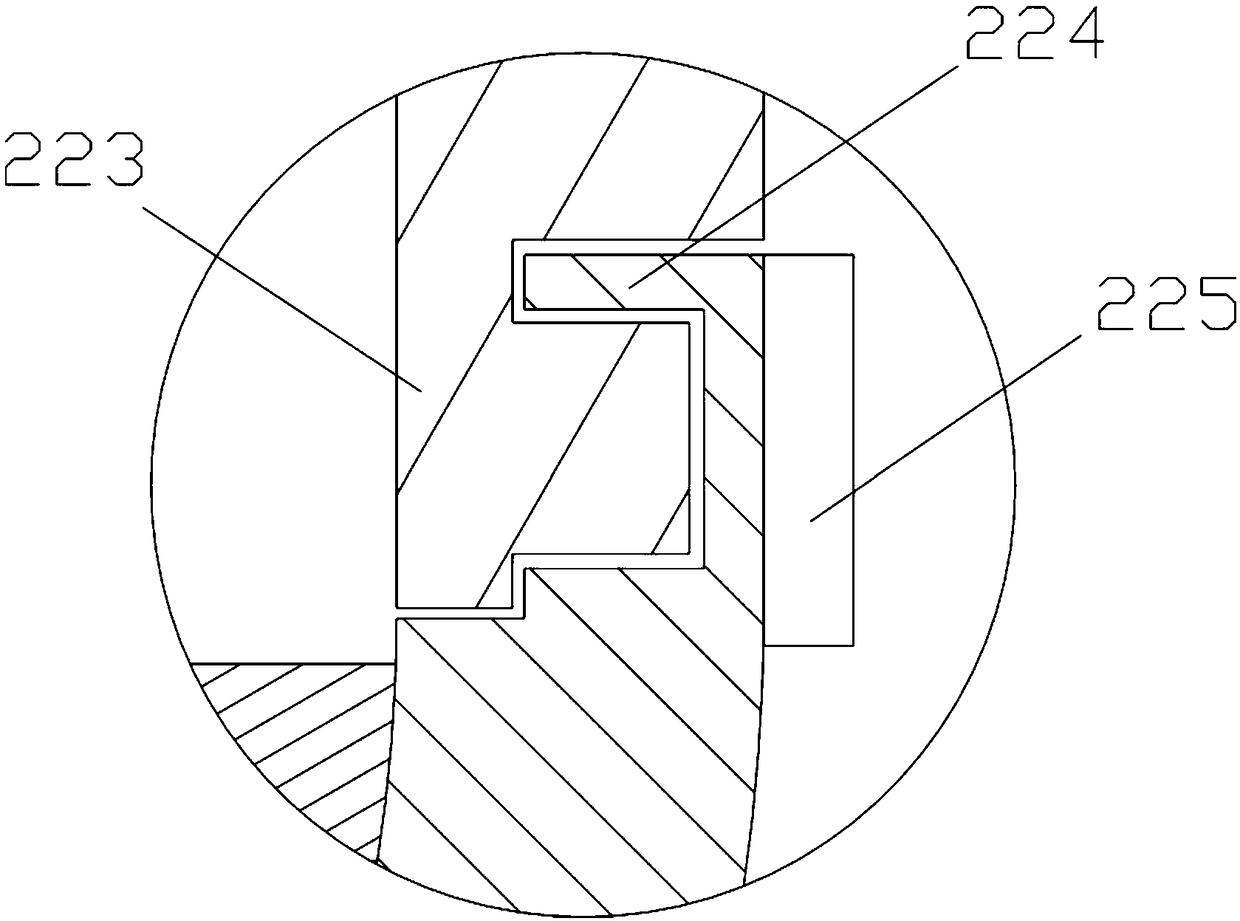

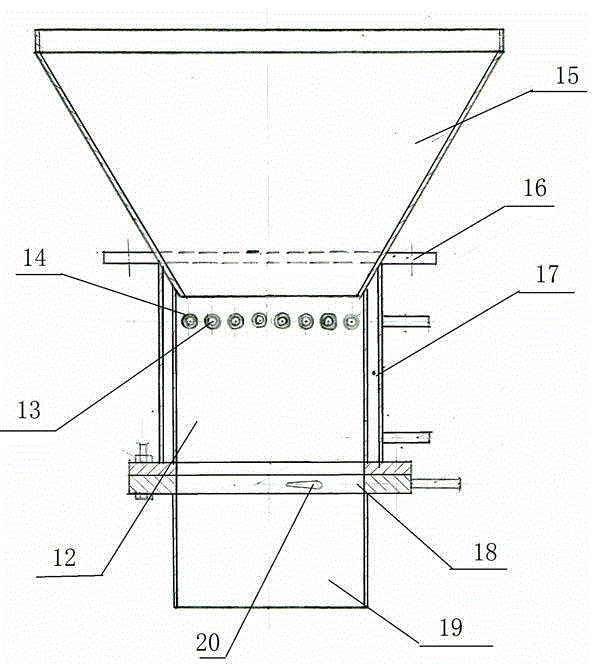

Heating cigarette cartridge automatic filling experimental device and animal exposure smoking machine

ActiveCN112945694AUninterrupted heatingHigh degree of automationPreparing sample for investigationBiological testingAnimal scienceANIMAL EXPOSURE

The invention relates to a heating cigarette cartridge automatic filling experiment device and an animal exposure smoking machine. The heating cigarette cartridge automatic filling experiment device comprises a stock bin, a feeding mechanism, a heating device and a discharging mechanism. The stock bin can contain a plurality of smoke cartridges and is provided with a discharge port; the feeding mechanism comprises a conveying unit and a guide part and a push rod assembly which are arranged on the conveying unit, the guide part is provided with a feeding port facing the discharging port, and the push rod assembly is arranged in the guide direction of the guide part; the heating device comprises a heating piece and a moving piece; the discharging mechanism comprises a cigarette cartridge clamping piece, and the cigarette cartridge clamping piece clamps the cigarette cartridges and separates the cigarette cartridges from the heating piece. Uninterrupted feeding, heating and discharging can be achieved, the automation degree is high, the working efficiency is high, only the stock bin needs to be replaced manually, and the labor cost is saved.

Owner:QINGDAO ETSONG TECH CO LTD +1

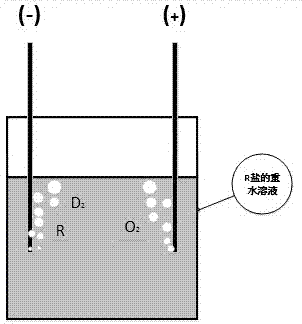

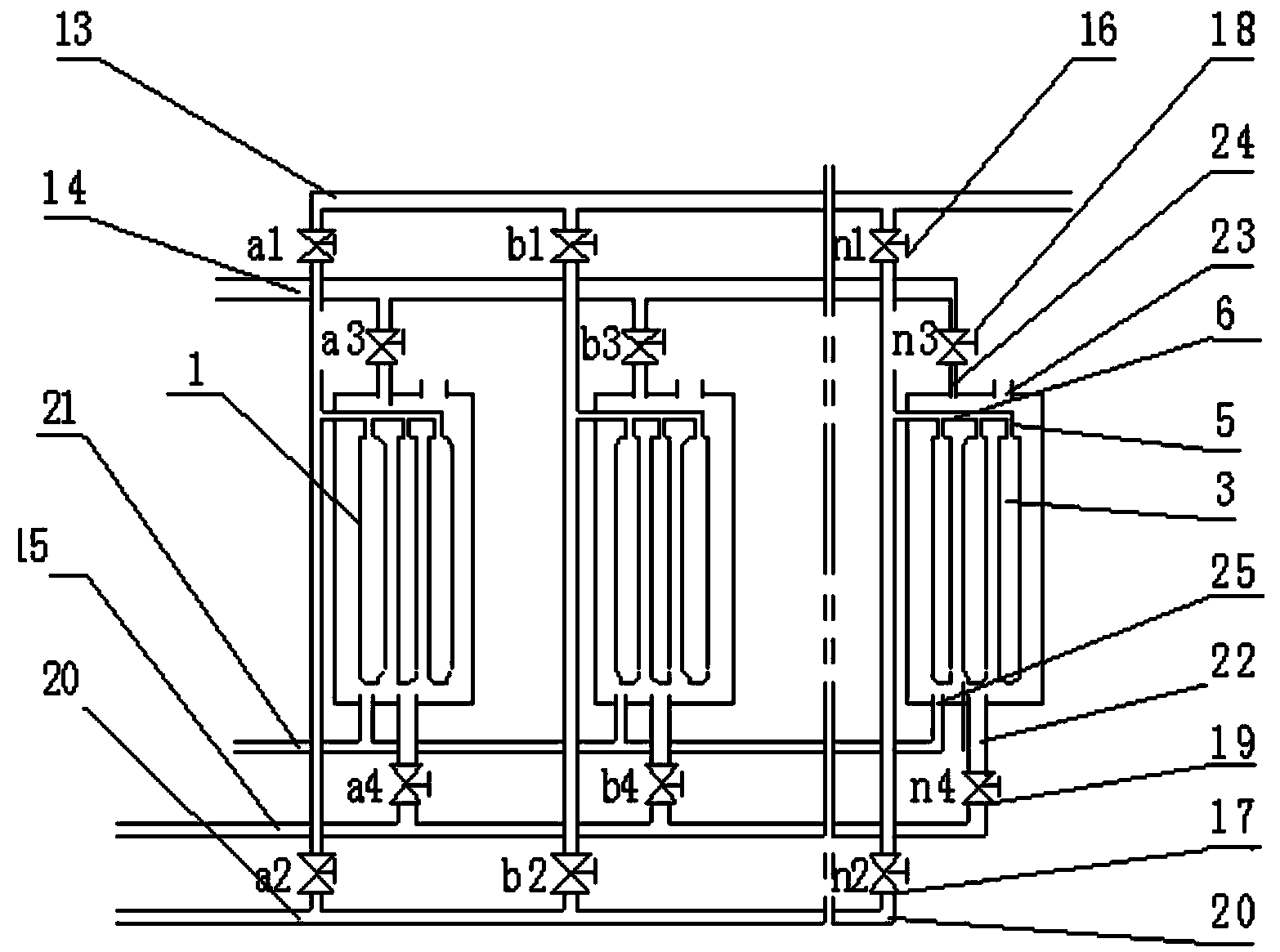

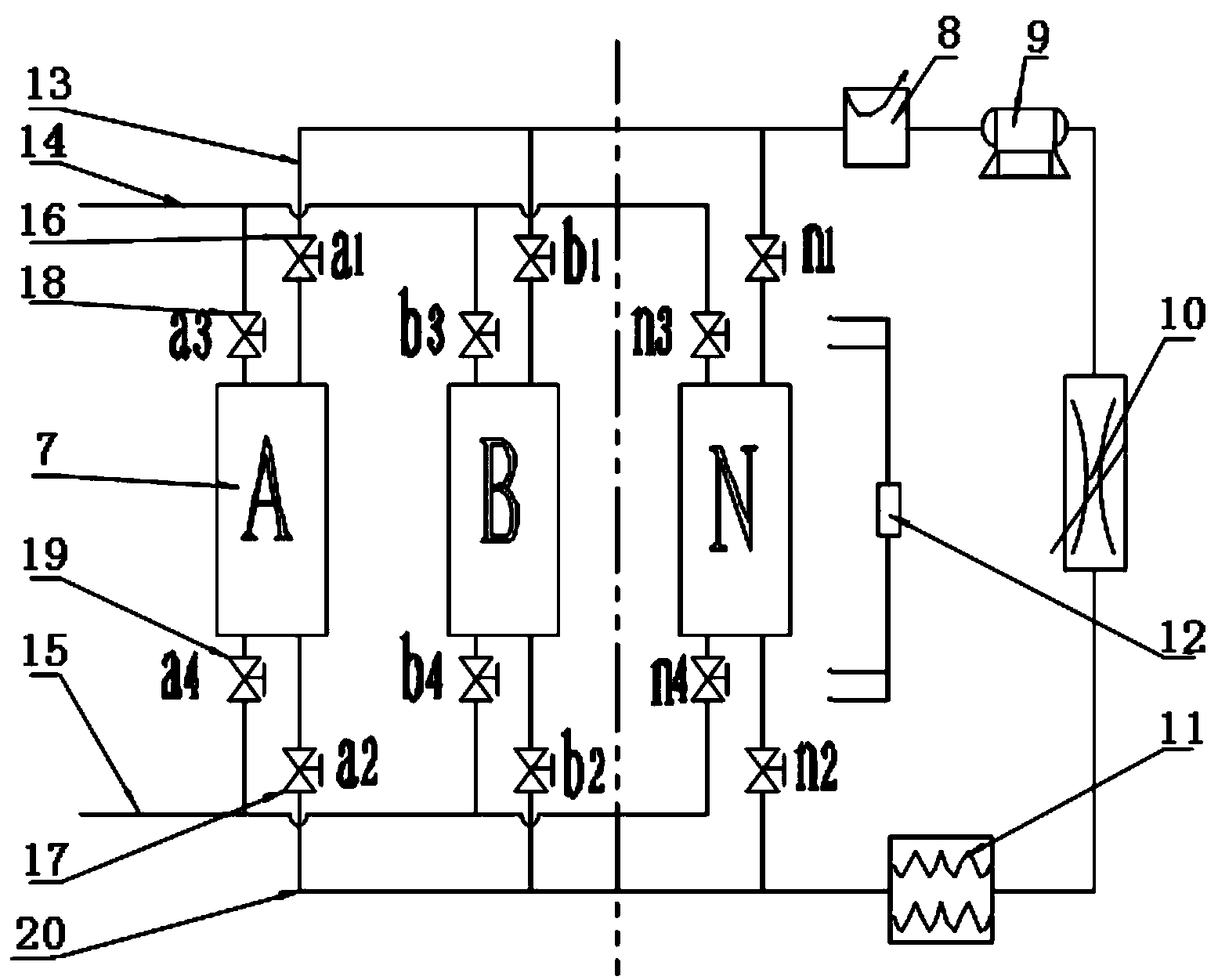

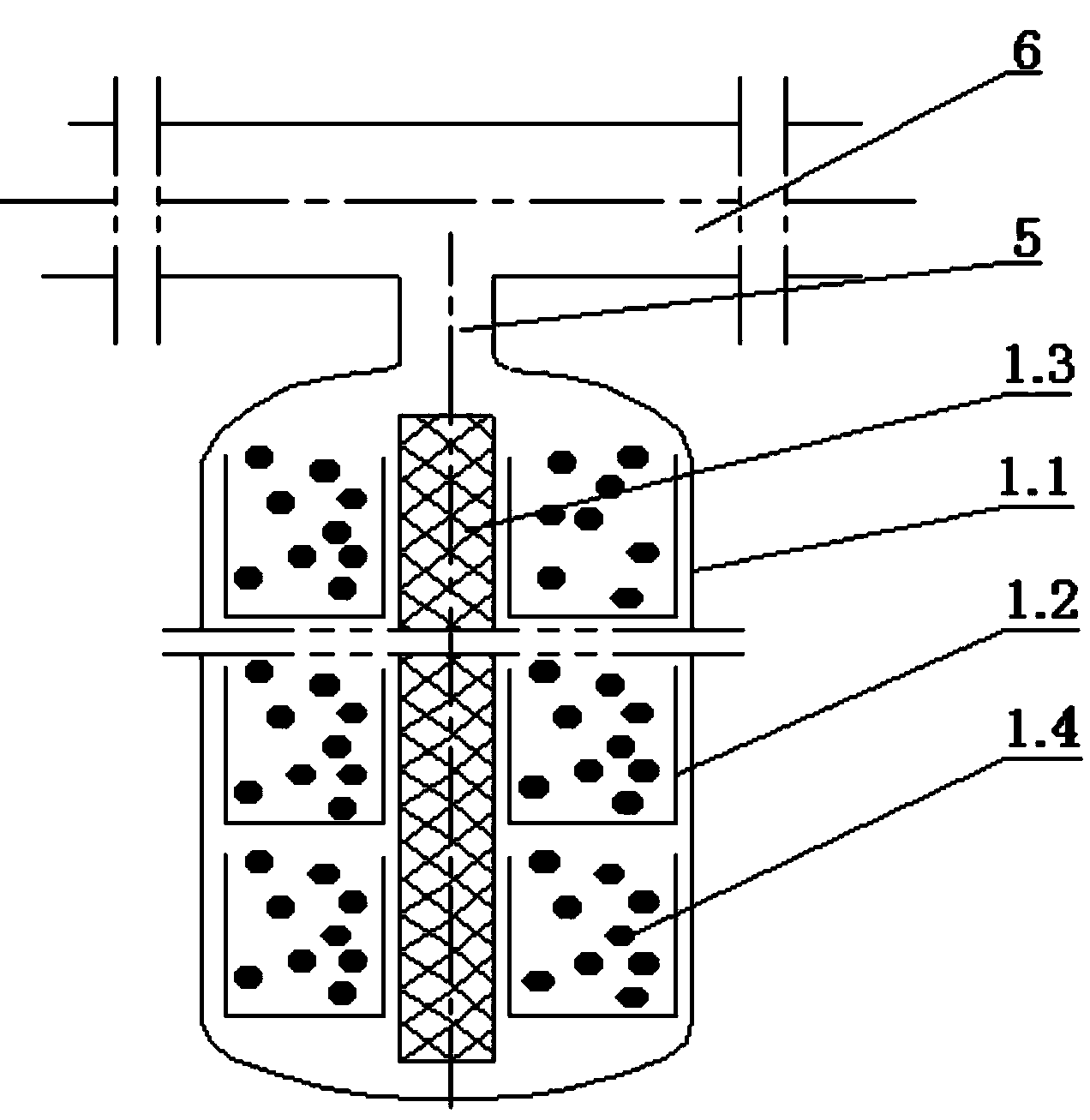

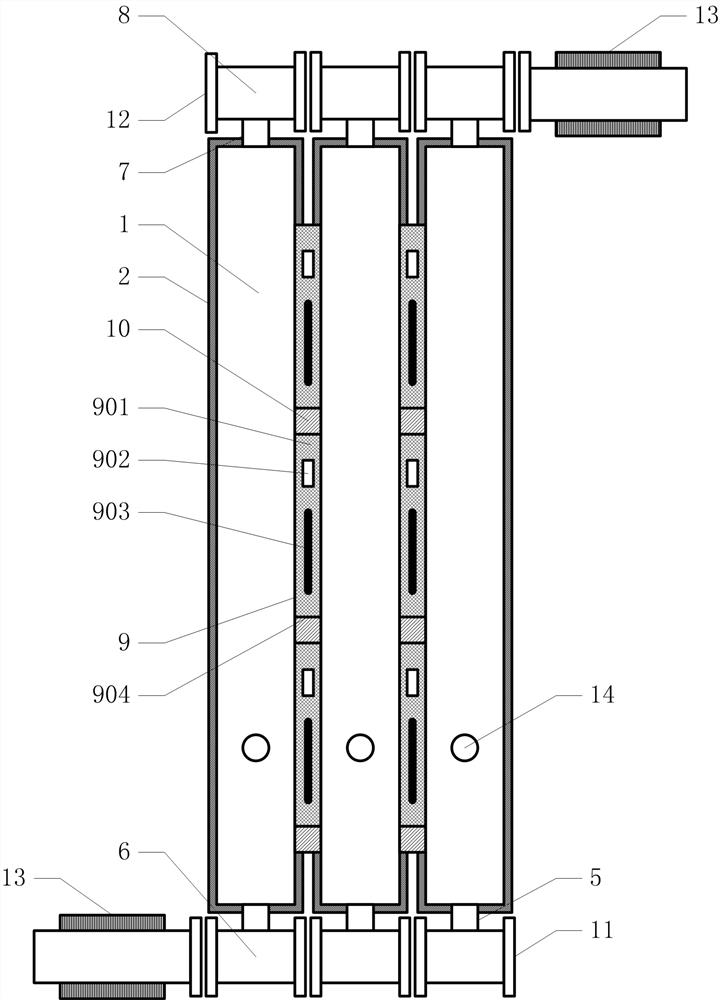

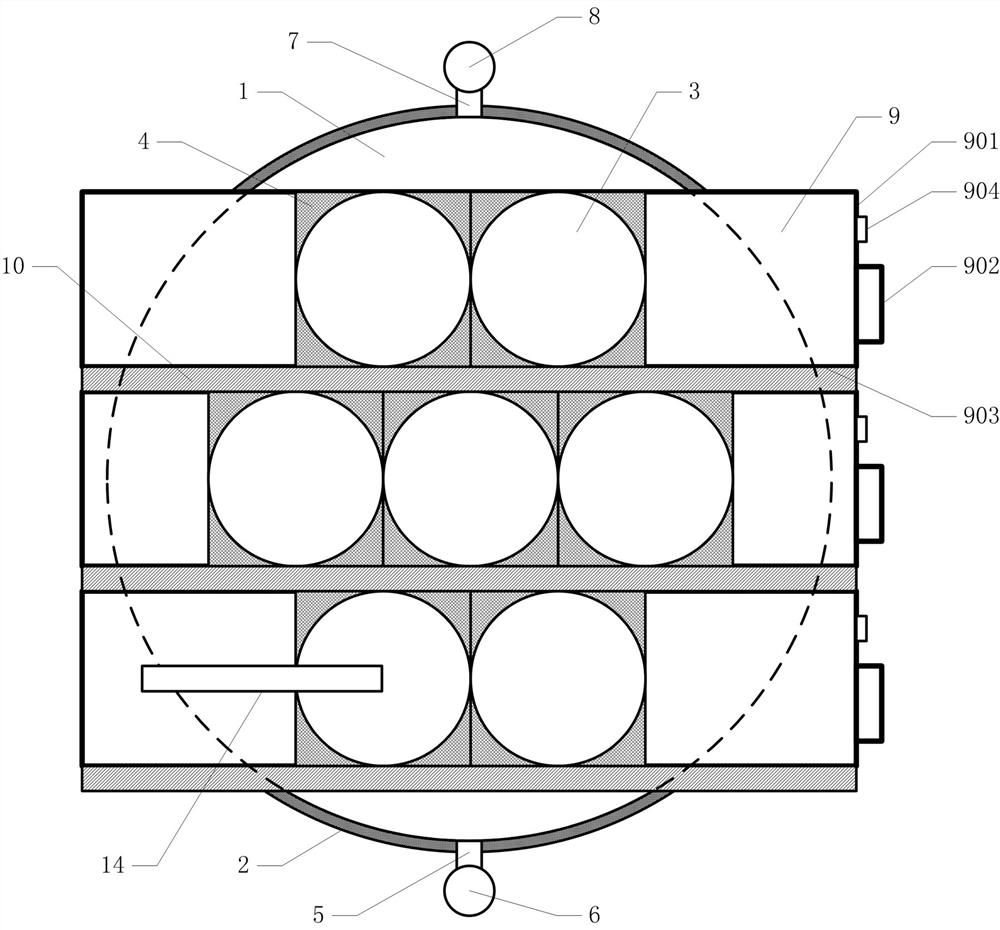

Chemical adsorption type heat refrigeration system employing alkaline-earth metal halide

ActiveCN104048440AImprove cooling effectAdd depthEnergy efficient heating/coolingClimate change adaptationAlkaline earth metalDesorption

The invention discloses a chemical adsorption type heat refrigeration system employing an alkaline-earth metal halide. The chemical adsorption type heat refrigeration system comprises N adsorption bed components, wherein each adsorption bed component comprises an adsorption bed unit tube component, an ammonia gas adsorption pipeline and an ammonia gas desorption pipeline, a heat source inlet pipeline, a cooling water inlet pipeline and a cooling water return pipeline; each adsorption bed unit tube component comprises M adsorption unit tubes, each adsorption unit tube comprises an adsorption outer tube, a plurality of trays arranged in the adsorption outer tube and a filter screen arranged between two adjacent rows of trays, an adsorbent is arranged in each tray, and the top ends of the adsorption outer tubes are connected to a gas manifold; a condenser, a liquid ammonia tank, a throttle valve and an evaporator are connected between each ammonia gas adsorption pipeline and each ammonia gas desorption pipeline in sequence. According to the chemical adsorption type heat refrigeration system, through cooperative application of chemical adsorption beds for adsorption and desorption, the uninterrupted heating or cooling is realized, and the refrigerating capacity and the refrigeration depth are improved under the same heat source condition.

Owner:武汉箕星制冷有限公司

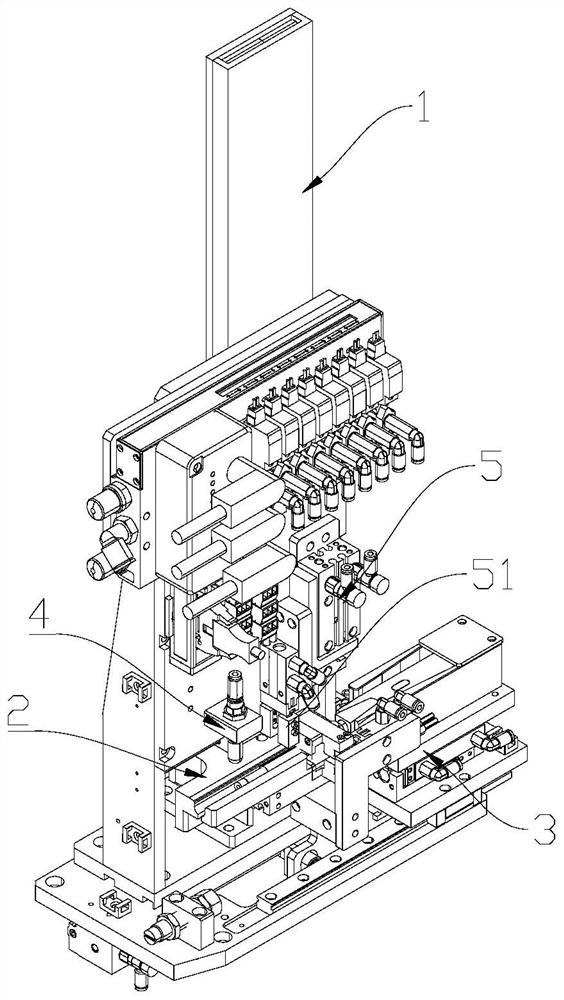

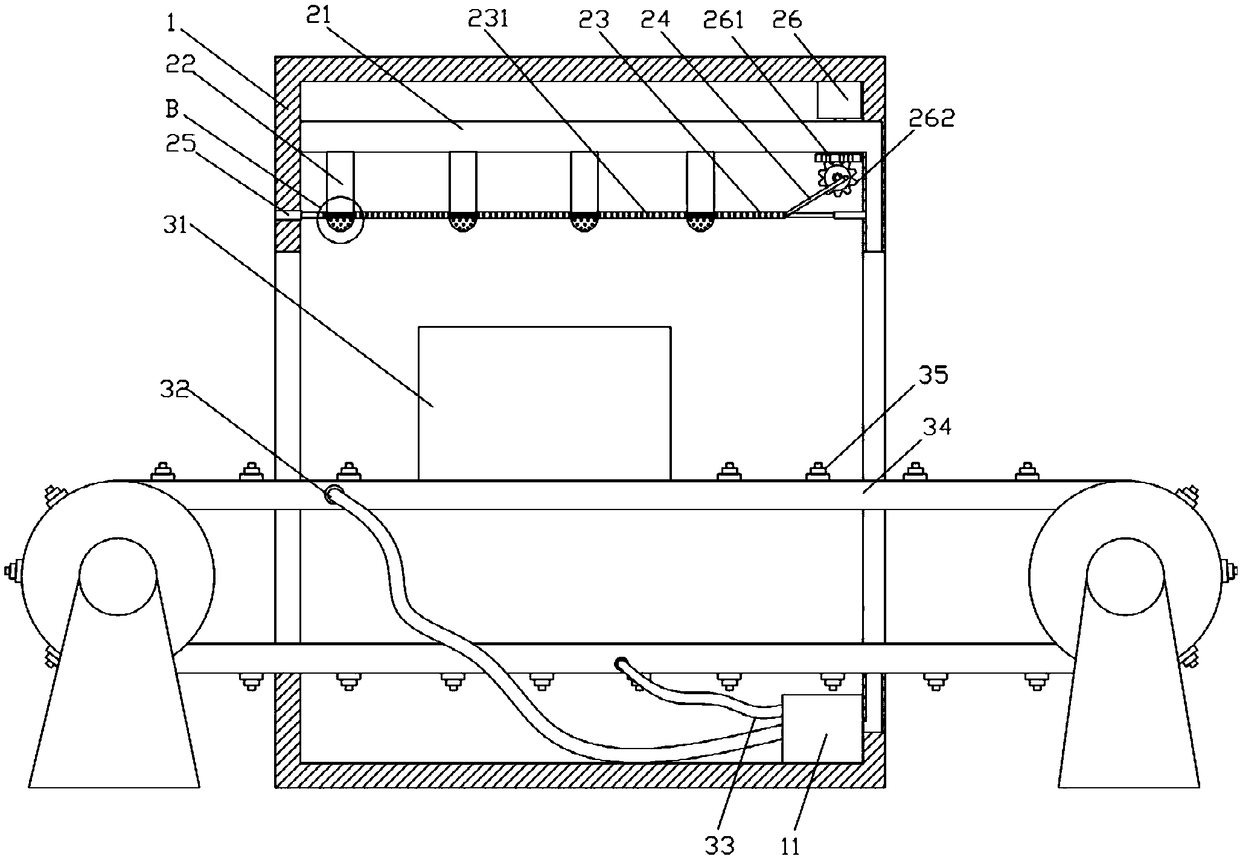

Equipment for spraying PTFE on framework oil seal lip and spraying method of spraying PTFE on framework oil seal lip

ActiveCN111715455AScientific and reasonable structureEasy to usePretreated surfacesCleaning using gasesEngineeringMechanical engineering

The invention discloses equipment for spraying PTFE on a framework oil seal lip and a spraying method of spraying the PTFE on the framework oil seal lip. The equipment comprises a feeding table, wherein a spraying table is fixedly connected to one end of the feeding table, a drying channel is fixedly connected to the other end of the spraying table, a discharging table is fixedly connected to theother end of the drying channel, and conveyors are fixedly connected to positions of adjacent sides of top end of the feeding table and the top end of the spraying table. The equipment is scientific and reasonable in structure and safe and convenient to use, station rotary discs, placement bases, fixing rods, clamping grooves, limiting rods and tension springs are arranged, and products are conveniently stacked in order through the station rotary discs on the feeding table and the discharging table, so that movable clamps conveniently grab the products, the product feeding and discharging speed is increased, the working efficiency is improved, and meanwhile, the limiting rods are pulled through the tension springs to drive the limiting rods to retract along the clamping grooves, and then the station rotary discs conveniently place the products with different specifications.

Owner:陕西奉航科技有限责任公司

A kind of equipment and method for spraying PTFE on lip of skeleton oil seal

ActiveCN111715455BScientific and reasonable structureEasy to usePretreated surfacesCleaning using gasesMechanical engineeringIndustrial engineering

The invention discloses a device for spraying PTFE on the lip of a skeleton oil seal and a spraying method thereof. It includes a feeding table, one end of the feeding table is fixedly connected with a spraying table, and the other end of the spraying table is fixedly connected with a drying channel. The other end of the drying channel is fixedly connected with a blanking table, and the top of the feeding table and the adjacent side of the top of the spraying table are fixedly connected with a conveyor. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. Position turntable, placement seat, fixed rod, card slot, limit rod and tension spring, through the station turntable on the loading table and unloading table, it is convenient to stack the products neatly, so as to facilitate the mobile fixture to grab the products and improve the The speed of product loading and unloading is improved, and the efficiency of work is increased. At the same time, the limit rod is pulled by the tension spring, which drives the limit rod to shrink along the card slot, thereby facilitating the placement of products of different specifications on the station turntable.

Owner:陕西奉航科技有限责任公司

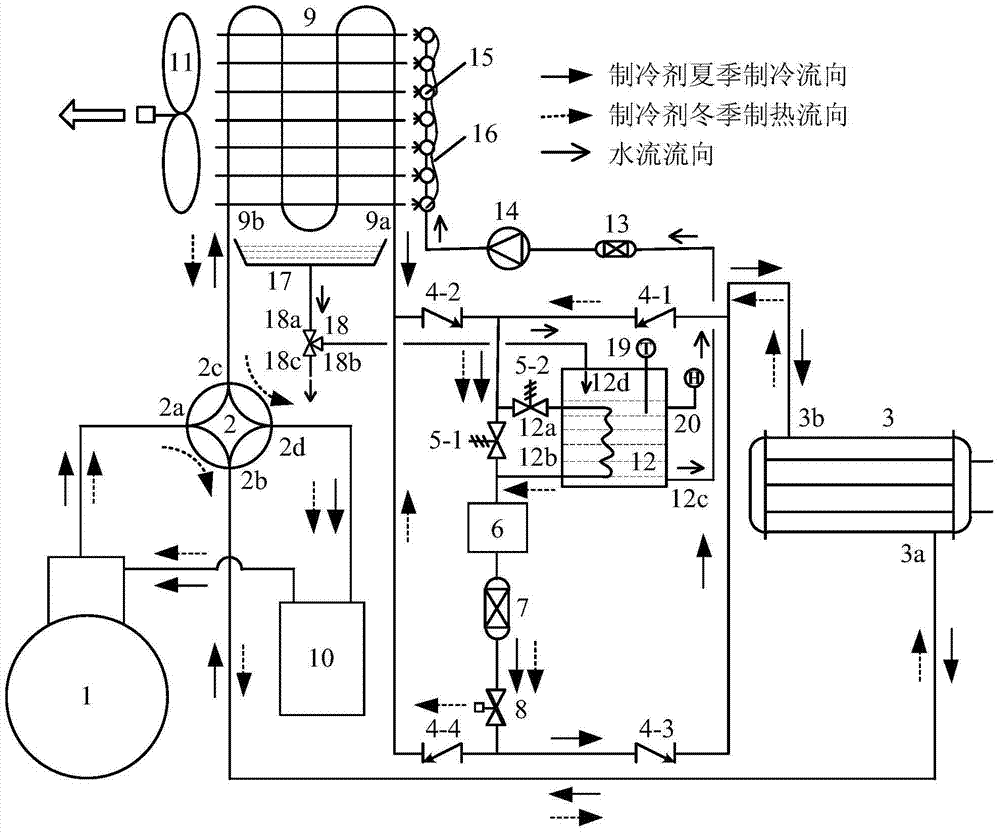

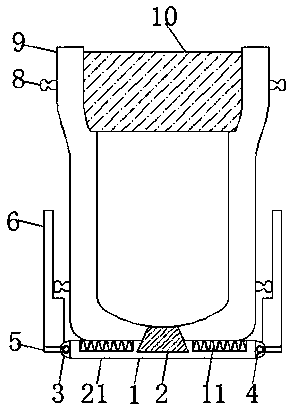

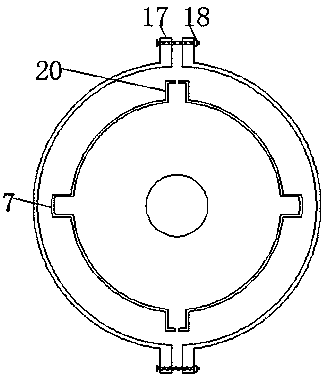

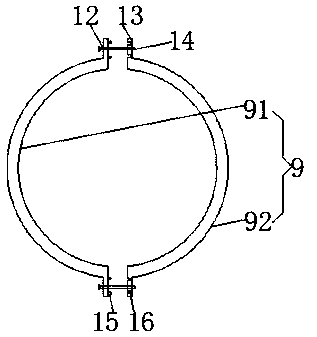

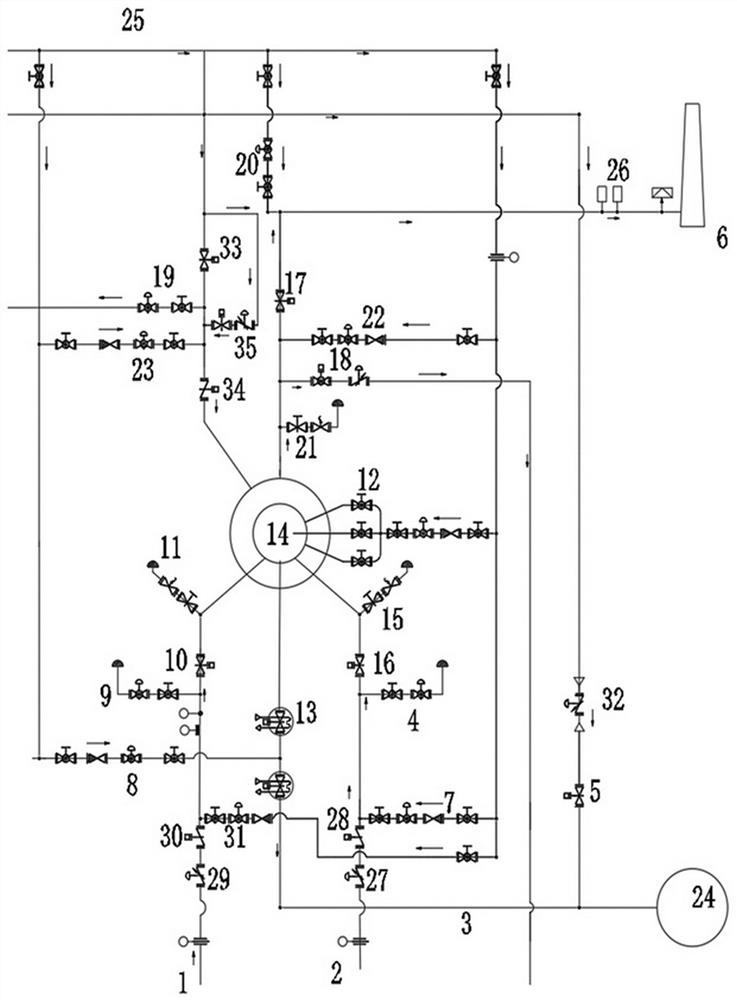

Air source heat pump spray defrosting device based on superhydrophobic finned tube heat exchanger

ActiveCN105299987BLess water retention in defrostingShort defrosting timeCorrosion preventionRefrigeration componentsFour-way valveSolenoid valve

An air source heat pump spray defrosting device based on a super-hydrophobic finned tube heat exchanger, comprising a refrigerant loop, a hot water loop, and an air loop. The refrigerant loop comprises a compressor (1), a four-way valve (2), a first heat exchanger (3), a first check valve (4-1), a second check valve (4-2), a third check valve (4-3), a fourth check valve (4-4), a first solenoid valve (5-1), a second solenoid valve (5-2), a liquid reservoir (6), a desiccant filter (7), an electronic expansion valve (8), a finned tube heat exchanger (9), a gas-liquid separator (10), and a heating-type water storage tank (12). The hot water loop comprises the heating-type water storage tank (12), a filter (13), a water pump (14), a nozzle (15), an electric heating tape (16), a water collection pan (17), a three-way valve (18), a temperature sensor (19), and a liquid level sensor (20), wherein a three-way valve first input end (18a), a three-way valve first output end (18b), and a three-way valve second output end (18c) are provided on the three-way valve (18). The air loop comprises the finned tube heat exchanger (9) and a fan (11). Said device spends less time and consume less heat for defrosting, so that continuous heat supply during the defrosting can be realized, and the heat supply time and the heat supply efficiency of the heat pump system are improved.

Owner:SOUTHEAST UNIV

Laboratory test tube automatic washing device

InactiveCN108941114AImprove the heating effectEnsure adequate heatingHollow article cleaningDrying gas arrangementsHeat lossesEngineering

The invention discloses a laboratory test tube automatic washing device. The laboratory test tube automatic washing device comprises a box; a flushing mechanism is arranged in the box; the flushing mechanism comprises a water spraying device for flushing the outer walls of test tubes, and a flushing device for flushing the inner walls of the test tubes; the flushing device comprises a tube placingbox; a drying mechanism is arranged on one side of the box; the drying mechanism comprises a heating chamber, and a conveying belt for conveying the tube placing box; and the conveying belt is inserted in the heating chamber. Through arrangement of the drying mechanism, the cleaned test tubes can be dried, so that water on the test tubes can be quickly removed, the test tubes can be directly used, and the water removing efficiency of the test tubes is improved; through cooperative arrangement of the heating chamber and the conveying belt, the test tubes can be heated in the heating chamber while being conveyed on the conveying belt, so that the needed conveying time after heating is saved; and meanwhile, the heat loss of the heating chamber can be reduced, so that the drying effect of thetest tubes is better.

Owner:徐春英

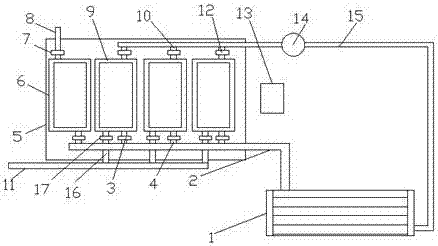

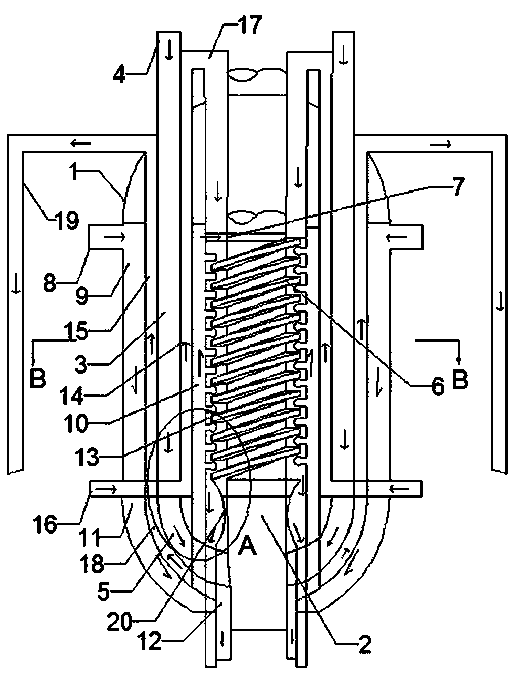

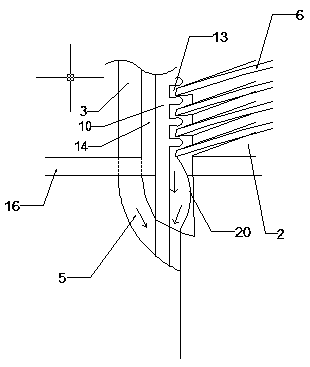

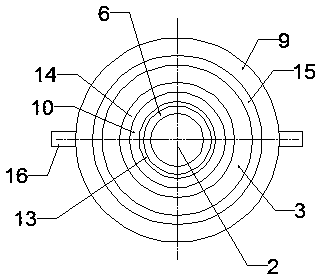

Pressure-type high-power double-sided electromagnetic heater

The invention provides a pressure-type large-power bilateral electromagnetic heater and belongs to the technical field of electric heating. The pressure-type large-power bilateral electromagnetic heater comprises heating water tanks, an electromagnetic coil, a drawer-type assembly, a magnetizing coil, a frequency variable ultrasonic energy converter and the like. Each heating water tank is a flatcylinder, and liquid can be heated or steam is produced under pressure. The electromagnetic coil is arranged between the two adjacent heating water tanks, bilateral heat generation is achieved while water electric separation is conducted, the electromagnetic heat generation area and the electromagnetic coil utilization rate are effectively increased, and electromagnetic radiation is reduced. Through the combined structure of the heating water tanks and the drawer-type assembly, production and mounting are quite facilitated, and hotline overhaul and maintenance can be achieved. Through scale prevention of the magnetizing coil and the scale removing effect of the frequency variable ultrasonic energy converter, the service life of the system is effectively prolonged, the efficiency of the system is effectively improved, additionally the drawer-type bilateral electromagnetic heat-generating system further has the advantages that the production cost is low, the technique is simple, capacityincreasing is convenient, the size is small, the operation cost is low, the energy saving effect is remarkable, and safety and reliability are achieved, and can be widely applied to various electricheating occasions, and the energy saving and environment protection effects are effectively improved.

Owner:山东世普润能源科技有限公司

3.2 t steel ingot mold capable of preventing secondary shrinkage cavity

InactiveCN109954847APlace stableSolve the problem of inconvenient fixed placementMaterials scienceIngot

The invention discloses a 3.2 t steel ingot mold capable of preventing secondary shrinkage cavity. The 3.2 t steel ingot mold comprises a base, wherein a sealing block is arranged in the middle of thetop of the base in a penetrating manner, the bottom of the sealing block penetrates through the base and extends to an inner cavity of the base, ear plates are both fixedly connected to the front side and the back side of the two sides of the base, the front surfaces of the ear plates are connected with clamping strips in a penetrating mode, the outer sides of the clamping strips are connected with a bottom plate in a sleeve mode, and one side, away from the base, of the top of the bottom plate is fixedly connected with a side plate, one side, close to the base, of the side plate is providedwith a sliding groove, a heating groove is formed in the top of the base, and heating wires are arranged at equal intervals in an inner cavity of the heating groove. According to the mold, through thecooperation of the ear plates, the bottom plate, the side plate, the sliding groove, lifting ears and clamping grooves for using, the problem that a traditional steel ingot production mold is inconvenient to fix and place is solved; and through cooperation of a sealing block, a heat preservation cap, the heating wires, a heating groove and through holes for using, the problem that the secondary shrinkage cavity is easily caused by the traditional steel ingot production is solved.

Owner:镇江宝瑞通机械有限公司

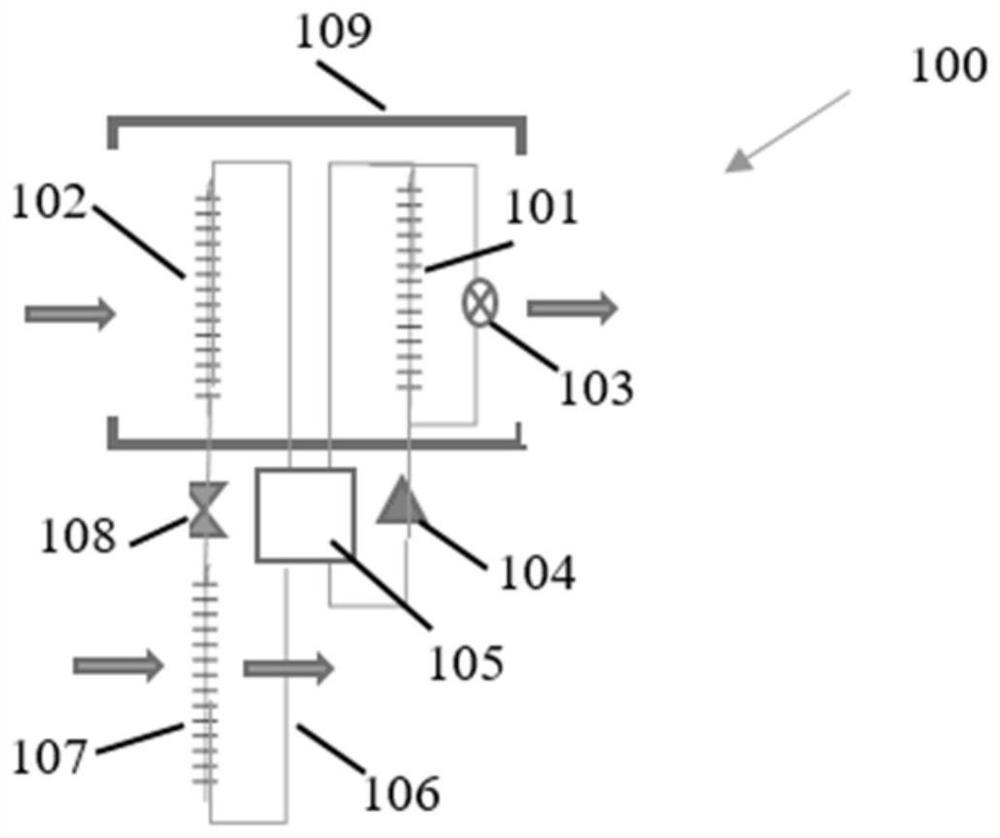

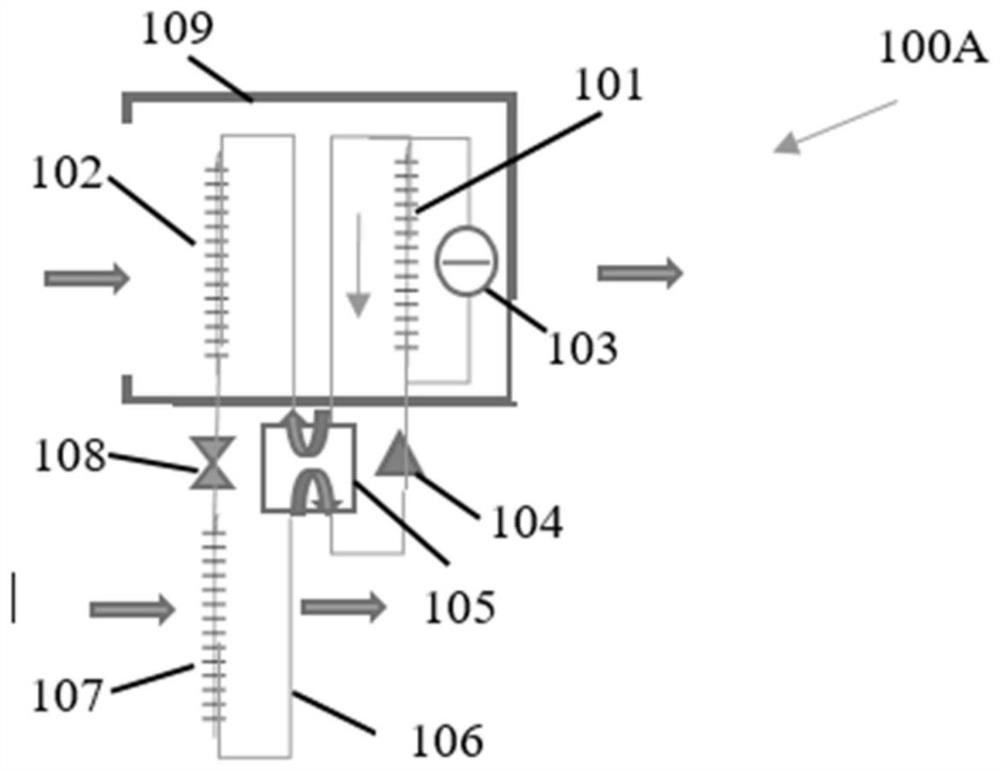

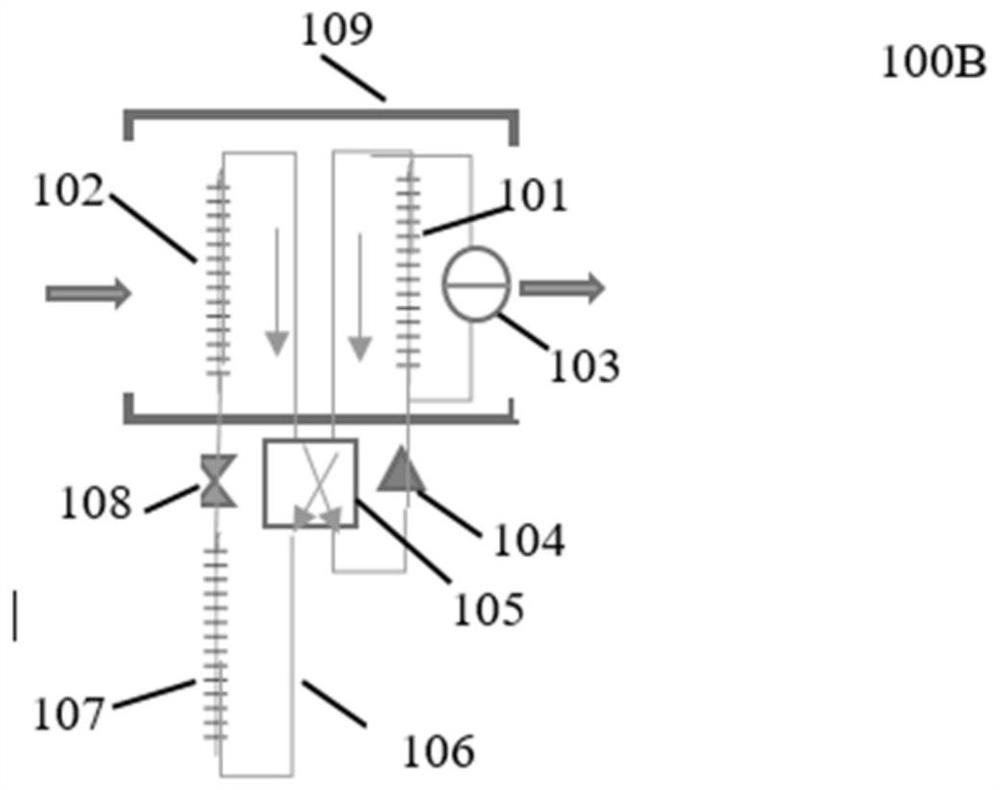

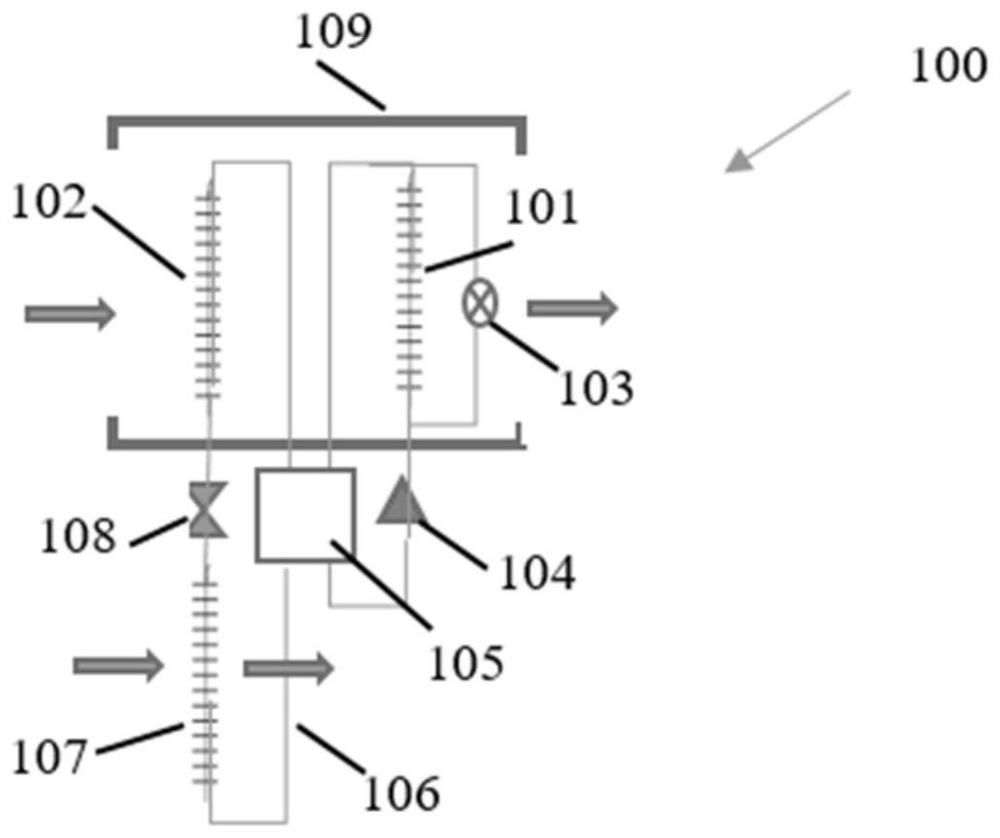

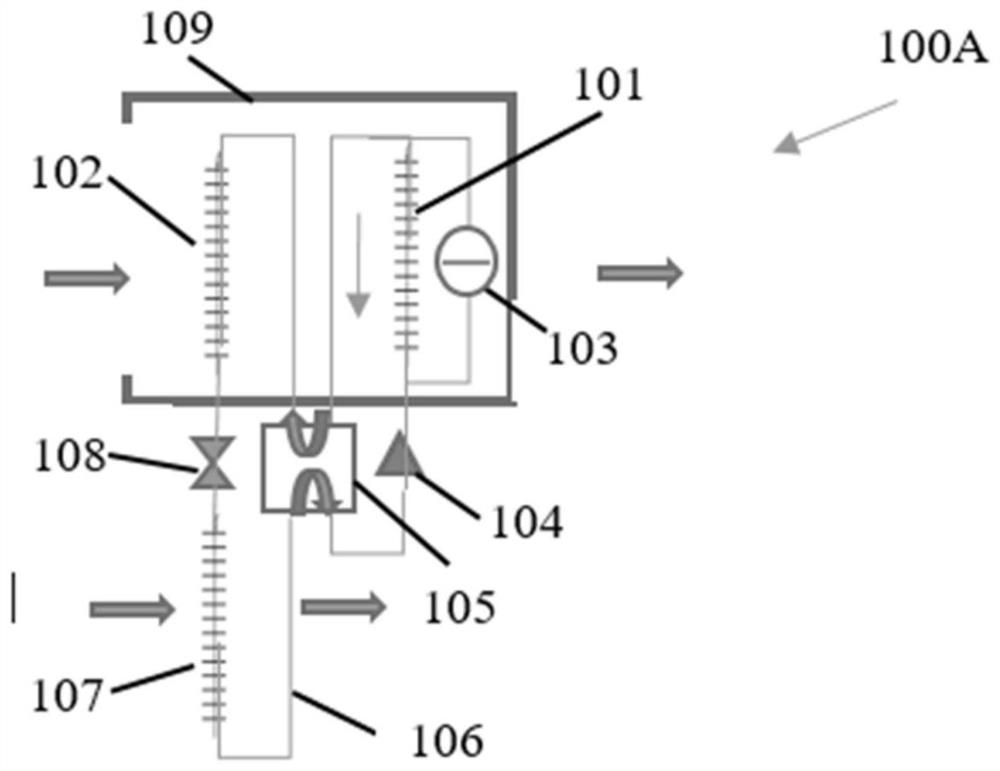

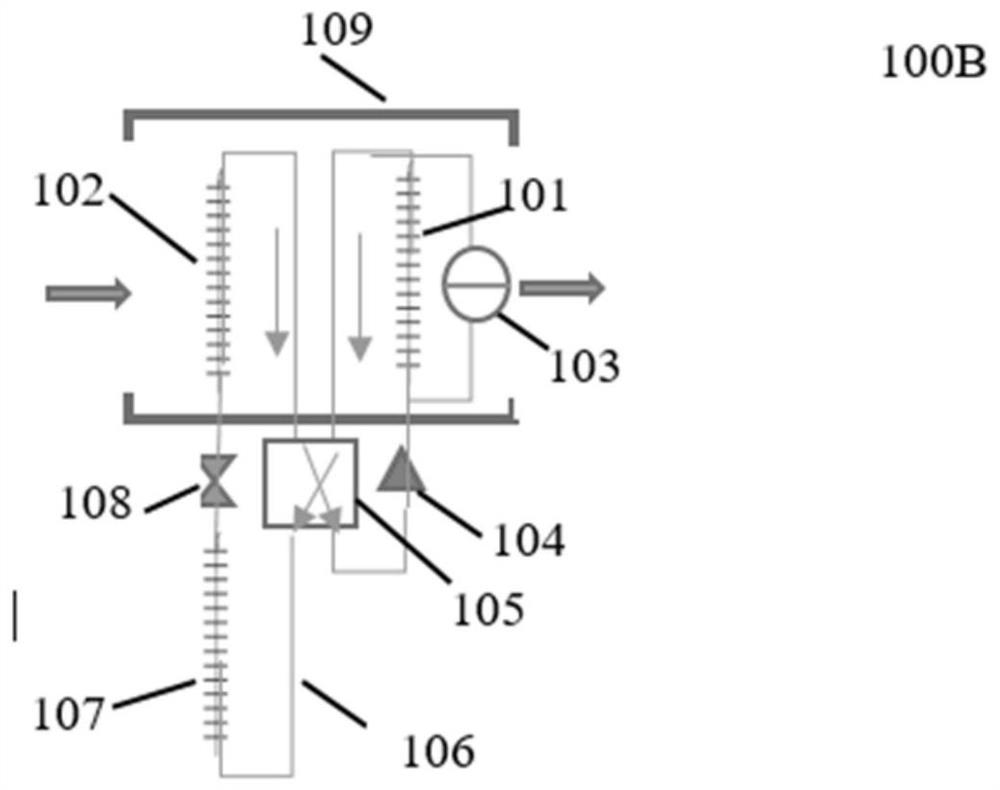

Uninterrupted heating air conditioning system, control method thereof and air conditioning equipment

PendingCN111102774AImprove comfortUninterrupted heatingCompressorMechanical apparatusFour-way valveProcess engineering

The invention discloses an uninterrupted heating air conditioning system, a control method thereof and air conditioning equipment. The air conditioning system comprises a four-way valve and a heat accumulating module. The four-way valve is used for gaining electricity for the air conditioning system which needs to enter a normal heating mode, wherein the first end of the four-way valve and the second end of the four-way valve are connected and the fourth end of the four-way valve and the third end of the four-way valve are connected. The four-way valve is used for losing electricity for the air conditioning system which needs to enter a defrosting heating mode, wherein the first end of the four-way valve and the fourth end of the four-way valve are connected and the second end of the four-way valve and the third end of the four-way valve are connected. The heat accumulating module is used for connection in a direction from the second end of the heat accumulating module to the second end of a heat exchanger of an outdoor unit when the air conditioning system needs to enter the normal heating model to store heat and is used for connection in a direction from the second end of a heatexchanger of an indoor unit to the second end of the heat accumulating module when the air conditioning system needs to enter the defrosting heating mode so as to achieve heating circulation in the defrosting heating mode. According to the invention, uninterrupted heating when the heat exchanger of the outdoor unit defrosts can be achieved, so that the comfort of the air conditioning system is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Parallel flow air conditioner and defrosting control method thereof

InactiveCN101387455BImprove comfortUninterrupted heatingHeat pumpsCorrosion preventionEngineeringHeat exchanger

Owner:TCL CORPORATION

A gas treatment method and system based on a three-device refrigerant compression cycle

ActiveCN113218098BImprove energy efficiencyImprove heating energy efficiencyMechanical apparatusCorrosion preventionHeating effectRefrigeration

The invention provides a gas treatment method and system based on three-device refrigerant circulation, the system includes a first gas heat exchanger, a second gas heat exchanger, an outdoor air heat exchanger, a compressor, a throttling mechanism, and a four-way valve Wait. Gas treatment includes heating, cooling and dehumidification. During heating, the gas passes through the first gas heat exchanger and the second gas heat exchanger to be heated by the refrigerant to achieve heating. The refrigerant circulation during heating includes the first heating cycle and the second heating cycle. Two heating cycles, four-way valve switching can realize evaporator defrosting while heating. During refrigeration, the gas passes through the first gas heat exchanger and the second gas heat exchanger in turn to be cooled by the refrigerant to realize refrigeration. During dehumidification, the gas is first cooled and dehumidified by the first gas heat exchanger, and then heated by the second gas heat exchanger to reduce the relative humidity. The invention can improve the energy efficiency of the system, ensure the heating effect and provide uninterrupted heat supply, etc., and can be used in various air-conditioning heat pump dehumidification systems, including commercial, civil and industrial occasions.

Owner:湖南雅立科技开发有限公司

Frost-free air source heat pump system based on humidity control and evaporative cooling

ActiveCN106322810BReduce the temperatureImprove cooling efficiencyMechanical apparatusHeat pumpsCondensation temperatureRefrigeration

The invention discloses a frost-free air source heat pump system based on humidity control and evaporative cooling, which includes a refrigerant circuit, a water and humidity control solution circuit and an air circuit. The refrigerant circuit includes a compressor, a four-way valve, a first heat exchanger, a first one-way valve, a second one-way valve, a third one-way valve, a fourth one-way valve, a heat exchanger, a liquid receiver, a drying Filter, electronic expansion valve, finned tube heat exchanger, gas-liquid separator; water and humidity control solution circuit includes humidifier, first valve, second valve, third valve, fourth valve, first solution pump , a second solution pump, a fluid storage, a heat exchanger and a regeneration device; the air circuit includes a finned tube heat exchanger, a humidifier and a fan. The system of the present invention can avoid frosting during heating operation in winter, and lower condensation temperature and higher cooling efficiency through evaporative cooling during cooling operation in summer, thereby realizing efficient operation of the system in both winter and summer.

Owner:SOUTHEAST UNIV

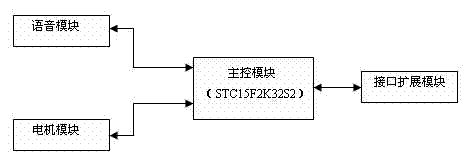

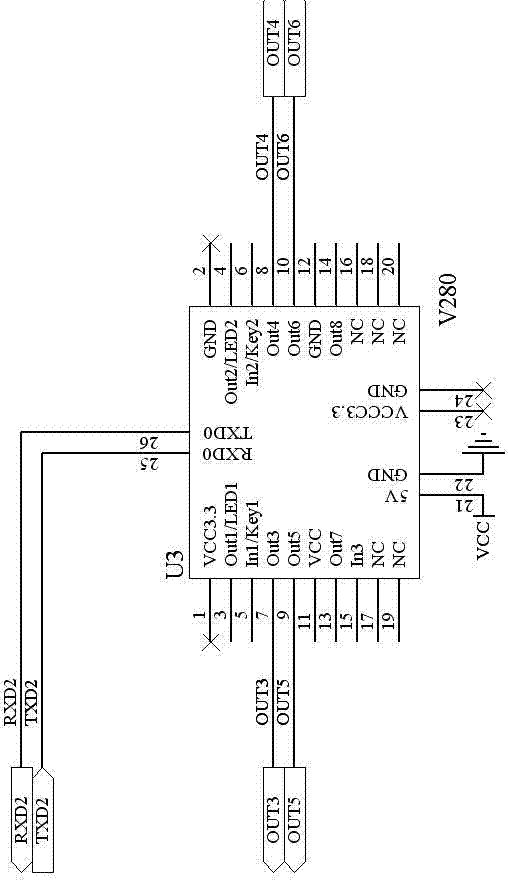

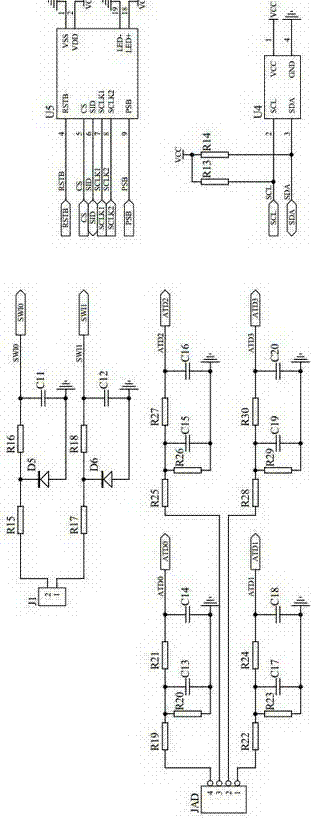

Voice intelligent straw direct combustion controller

InactiveCN103336468BAchieve combustion efficiency controlLower heating costsProgramme controlComputer controlGreenhouseElectronic control system

The invention relates to a voice intelligent straw direct-fired controller and belongs to the technical field of automation. The invention aims to provide the voice intelligent straw direct-fired controller which adopts an electronic control system to control high-efficiency combustion of simply cut straws automatically by environment temperature or voice and realize continuous heat supply. The voice intelligent straw direct-fired controller consists of a main control module, a voice module, a motor module and an interface extension module. Aiming at the defects in the existing straw gasification, pelleting and the like, the invention provides the straw direct-fired controller which is low in cost and simple to operate, adopts simply cut straws as raw materials and can be controlled by voice. According to the voice intelligent straw direct-fired controller, an operator can liberate double hands, the combustion efficiency of the straws can be effectively controlled, and energy conservation and emission reduction are realized. Under the control of a control module, high-efficiency combustion of the simply cut straws is controlled automatically by environment temperature or controlled by voice, continuous heat supply is realized, and the voice intelligent straw direct-fired controller is low in cost and simple to operate. The voice intelligent straw direct-fired controller can greatly reduce the heating cost of vast rural families and breeding plants, in particular winter vegetable greenhouses.

Owner:CHANGCHUN UNIV OF TECH

Line-frequency induction type dynamic drying machine with four quartz tubes

ActiveCN102829613BNo pollution in the processReduce lossDrying machines with non-progressive movementsDrying solid materialsThree stageEngineering

The invention discloses a line-frequency induction type dynamic drying machine with four quartz tubes. The line-frequency induction type dynamic drying machine comprises the four quartz glass drying material tubes which are arranged obliquely, wherein an annular heating barrel is arranged at the middles of the quartz glass drying material tubes; a feeder is arranged at upper feeding ends of the quartz glass drying material tubes; a material receiving device is arranged at lower discharging ends of the quartz glass drying material tubes; the feeder is provided with a material bin; a reamer breaking and dispersing mechanism is arranged in the material bin; a vibration material conveying groove is formed at the lower end of the material bin; the material receiving device is provided with a three-stage cascade type suddenly cooling device and a material collecting device; the cascade type suddenly cooling device is provided with a material receiving hopper, a cooling barrel and an air collecting barrel; a group of cooling tubes arranged in a fence shape is arranged at the upper part of the cooling barrel; a quartz glass sleeve is sheathed outside each cooling tube; and jet flow air holes are formed in a hole wall of a suddenly cooling plate along the tangential direction. Induction heating is carried out on a heating cavity by using an excitation coil, so that materials can be heated continuously, and powder can be at a movement state all the time, so that the drying effect is good, and the cooling efficiency is high.

Owner:江苏省晶瑞石英工业开发研究院有限公司

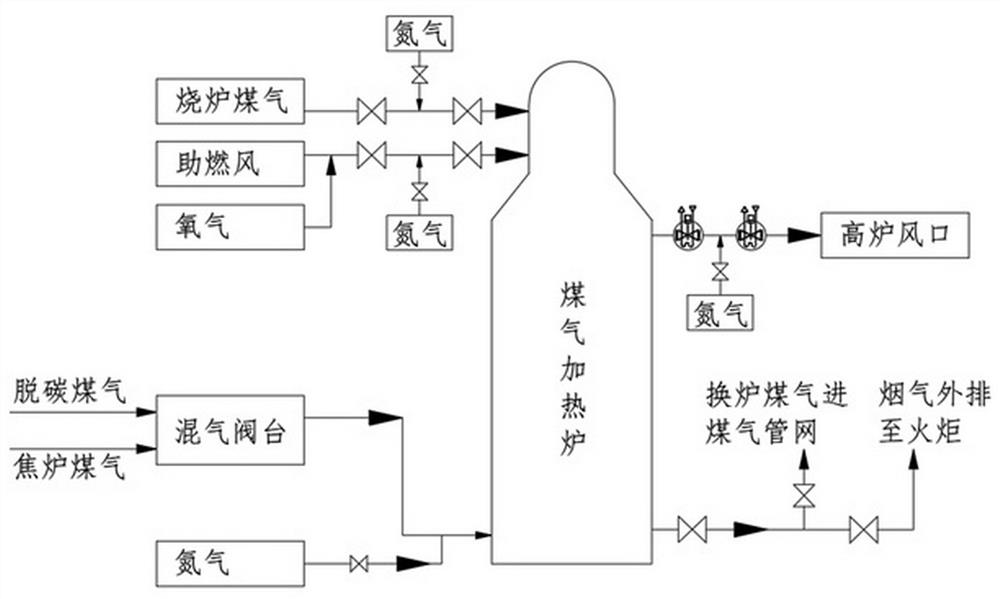

Coal gas heating method for iron-making blast furnace

PendingCN114480756AOvercoming flammable and explosive characteristicsUninterrupted heatingAir heatersBlast furnace detailsEnvironmental geologyHeating furnace

The invention discloses a coal gas heating method for an iron-making blast furnace, which comprises the following steps of: introducing furnace burning coal gas and combustion-supporting air into a coal gas heating furnace to burn and heat lattice bricks, closing the furnace, stopping feeding the furnace burning coal gas and the combustion-supporting air, purging the space in an inerting furnace, and feeding normal-temperature metallurgical pressurized coal gas to an inlet of the coal gas heating furnace, the coal gas is heated through heat transfer of checker bricks of the coal gas heating furnace, is sent out from an outlet of the coal gas heating furnace, is mixed with part of cold coal gas in a gas mixing chamber according to a certain proportion before entering the blast furnace and then is injected into the blast furnace, and when the temperature of the mixed coal gas does not meet user requirements, other coal gas heating furnaces which burn the furnace are replaced to send the coal gas; and the replaced gas heating furnace is stuffy, residual gas in the furnace is discharged to a low-pressure gas main pipe, the space in the inerting furnace is purged, then the residual gas discharging direction is switched to a flue main pipe, the gas heating furnace is subjected to next-round furnace burning, and circulation is conducted in sequence.

Owner:XINJIANG BAYI IRON & STEEL

Gas treatment method and system based on three-device refrigerant compression cycle

ActiveCN113218098AImprove energy efficiencyImprove heating energy efficiencyMechanical apparatusCorrosion preventionEngineeringProcess engineering

The invention provides a gas treatment method and system based on a three-device refrigerant cycle. The system comprises a first gas heat exchanger, a second gas heat exchanger, an outdoor air heat exchanger, a compressor, a throttling mechanism, a four-way valve and the like. Gas treatment comprises heating, refrigerating and dehumidifying, during heating, gas sequentially passes through the first gas heat exchanger and the second gas heat exchanger to be heated with a refrigerant to achieve heating, refrigerant cycle during heating comprises a first heating cycle and a second heating cycle, and defrosting of an evaporator can be achieved while heating is conducted through switching of a four-way valve. During refrigeration, gas sequentially passes through the first gas heat exchanger and the second gas heat exchanger and is cooled with a refrigerant to realize refrigeration. During dehumidification, gas is firstly refrigerated and dehumidified with the first gas heat exchanger, and then is heated by the second gas heat exchanger to reduce relative humidity. According to the method and the system, the energy efficiency of the system can be improved, the heating effect is guaranteed, the system supplies heat uninterruptedly, and the system can be used for various air conditioner heat pump dehumidification systems including various occasions such as commercial occasions, civil occasions and industrial occasions.

Owner:湖南雅立科技开发有限公司

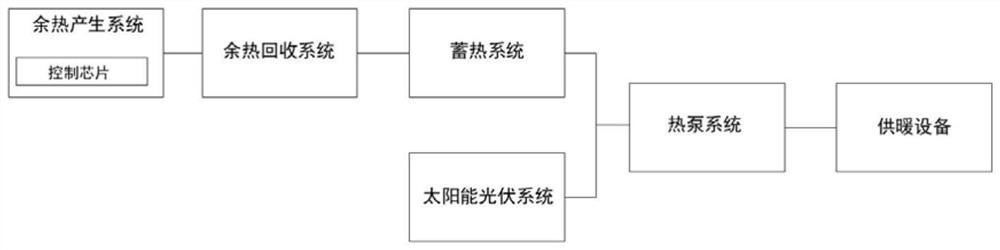

Double-source heating system

InactiveCN114034078AUninterrupted heatingBatteries circuit arrangementsLighting and heating apparatusThermal energyProcess engineering

The invention discloses a double-source heating system, and relates to the technical field of heating. The double-source heating system comprises a waste heat generation system, a waste heat recovery system, a heat pump system and a solar photovoltaic system; waste heat generated by the waste heat generation system is recovered by the waste heat recovery system and converted into waste heat electric energy to be stored or reused, and the heat pump system supplies heat to the heating equipment through the solar photovoltaic system or heat of the waste heat electric energy; and heat generated by the waste heat generation system is generated when a control chip for controlling the whole heating system works. According to the invention, heat generated by working of the control chip for controlling the whole heating system is recovered by the waste heat recovery system and converted into waste heat electric energy to be stored or reutilized; the waste heat electric energy and the heat energy converted by the solar photovoltaic system are used for providing a heat source for heating equipment in all weather and environments, additional energy does not need to be arranged for providing the heat source for the heating equipment, and the heating cost is reduced.

Owner:江西锋铄新能源科技有限公司

Zoning circulation heating phase change heat storage solar water heating system

PendingCN107166773AIncrease profitIncrease temperatureSolar heat devicesSolar thermal energy generationSolar water heating systemSolar water

The invention discloses a zoning circulation heating phase change heat storage solar water heating system. The zoning circulation heating phase change heat storage solar water heating system comprises a phase change heat storage solar water heater and a heat preservation box. A cold water box and a plurality of heat storage boxes are arranged in the heat preservation box. A water supply pipe extending into the heat preservation box is arranged at the water outlet end of the phase change heat storage solar water heater. A first water pipe connected with the water supply pipe is arranged on the top of each heat storage box and provided with a first electromagnetic valve. A second water pipe connected with a water inlet pipe is arranged at the bottom of each of the cold water box and the heat storage boxes. Each second water pipe is provided with a second electromagnetic valve. By means of the above manner and the zoning circulation heating phase change heat storage solar water heating system, through control over independent opening and closing of the first electromagnetic valves and the second electromagnetic valves, the phase change heat storage solar water heater is used for heating stored water in single heat storage boxes, heating of other heat storage boxes is not influenced during using, and constant circulation heating is achieved.

Owner:PIONEER ENERGY JIANGSU

Heat exchange and heat storage device for biogas power generation high-temperature exhaust air

ActiveCN110173750ALong durationLittle change in temperatureLighting and heating apparatusCentral heating componentsWater storageEngineering

The invention relates to a heat exchange and heat storage device suitable for biogas power generation high-temperature exhaust air. The device comprises a heat exchange tank, a water storage part arranged in the heat exchange tank, and a heat source conveying part and a heat storage part arranged in the water storage part in a sleeved mode; the heat source conveying part comprises a heat source discharge pipe arranged on the axial center line of the heat exchange tank, and a heat source layer arranged out of the heat source discharge pipe; the heat source layer is provided with an input pipe;the heat source discharge pipe and the heat source layer communicate by a first channel; the water storage part comprises a spiral pipe coiled out of the heat source discharge pipe, and a water storage layer; the water storage layer and the spiral pipe communicate through a second channel; the spiral pipe is provided with a drainage pipe; the water storage layer is provided with a water inlet pipe; the heat storage part comprises a heat storage layer annularly arranged out of the spiral pipe; and the heat storage layer is filled with a heat storage medium. The device can realize multistage heat exchange of the heat exchange device, and can reasonably control the smoke temperature to prevent the device corrosion caused by quicker reduction of the smoke temperature.

Owner:HENAN AGRICULTURAL UNIVERSITY

Rapid sludge granulation and drying treatment system and method based on medium loading

PendingCN112408748AImprove stabilityReduce heat lossSludge treatment by de-watering/drying/thickeningMetallurgySludge dewatering

The invention provides a rapid sludge granulation and drying treatment system and method based on medium loading, and belongs to the technical field of sludge treatment. The system comprises a sludgedewatering device, a heat transfer medium heating device, a granulator, a sludge dryer, a rolling crushing device and a screening device which are connected in sequence. A plurality of metal balls areheated in the heat transfer medium heating device and sent into a granulator, and sludge is dewatered and sent into the granulator; the metal balls are mixed with wet sludge to form homogenized sludge balls with the ball centers being the metal balls and the outer surfaces being wrapped with the wet sludge, then the homogenized sludge balls enter the sludge drying machine to remove moisture in the sludge, the sludge is ground through grinding, the metal balls and the sludge are separated, and after screening is conducted through the screening machine, the metal balls are repeatedly heated andrecycled, and the dried sludge is conveyed to a dry material bin. The system has the advantages that heat is provided by the metal balls in the sludge balls so that sludge is internally and externally heated, the energy consumption of sludge drying is greatly reduced, the moisture content of the sludge is further reduced, and the sludge drying efficiency is improved.

Owner:天津市融泰水务有限公司

A single-horizontal tubular carbonaceous intermediate continuous heat treatment device

ActiveCN104215065BSignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemWater jacket

The invention relates to a single-horizontal tubular carbonaceous intermediate continuous heat treatment device, which includes a feeding system, a heating section, a cooling section, an exhaust system and a discharging system connected in sequence; the feeding system is a cone with a funnel opening at the bottom The silo and the feeder; the feeding system, the heating section, the cooling section and the discharge system are all connected through the sensor circuit and the measurement and control system; the two ends of the horizontal tube of the heating section have a long cylinder closed with a cover. The cross-section of the cylindrical cylinder is a symmetrical straight side left and right, and a semicircular arc side symmetrical up and down; a first screw rod is placed in the lower semicircular side of the entire elongated cylinder, and the above cooling section is a two A metal long cylinder with a cover at the end; a sandwich water jacket on the outside of the metal long cylinder; the invention is aimed at the treatment of carbonaceous intermediate materials mainly composed of powder or small particles, and has low energy consumption, low cost and simple operation , Minimize pollution.

Owner:CHENZHOU SHANSHAN NEW MATERIAL

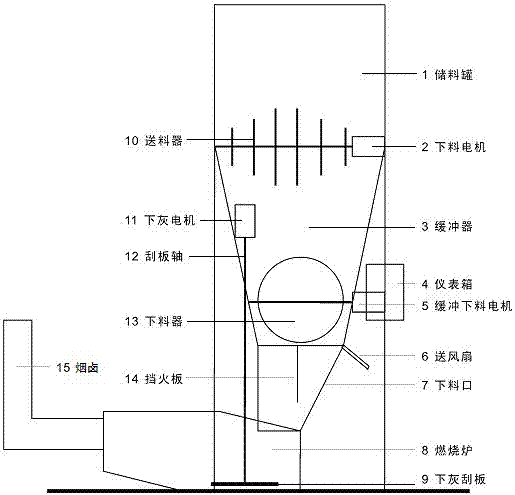

Straw direct combustion heating device

InactiveCN104566342BEfficient combustionAchieve uninterrupted heatingSolid fuel combustionCombustion apparatusBuffer tankGreenhouse

The invention discloses a straw direct combustion heating device, which comprises a storage tank, a feeding motor, a buffer tank, an instrument box, a feeding motor, a blowing fan, a feeding port, a fuel furnace, an ash lowering scraper, a feeder, a lower Ash motor, scraper shaft, feeder, fire baffle, chimney. An automatic feeder is set between the storage tank and the buffer tank, an automatic feeder is set between the buffer tank and the discharge port, an automatic ash discharge scraper is provided in the combustion furnace, and an automatic fan and a fire baffle are provided at the discharge port. Put the simply cut straw into the storage tank and the buffer tank; then select the firepower from the control panel of the controller or manually set the parameters; then ignite the straw in the combustion furnace, start the straw burning controller, and the controller will Firepower parameters, automatic feeding, ash and air supply, make the straw in the furnace burn with high efficiency and achieve the purpose of uninterrupted heating. The invention is convenient and simple to use, and will greatly reduce the heating costs of rural families and greenhouses in winter.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com