Laboratory test tube automatic washing device

A washing device, laboratory technology, applied in the direction of drying gas layout, cleaning hollow objects, dryers, etc., can solve the problems of low efficiency, time-consuming, wasting time, etc., and achieve the goal of improving efficiency, increasing storage, and reducing heat. drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

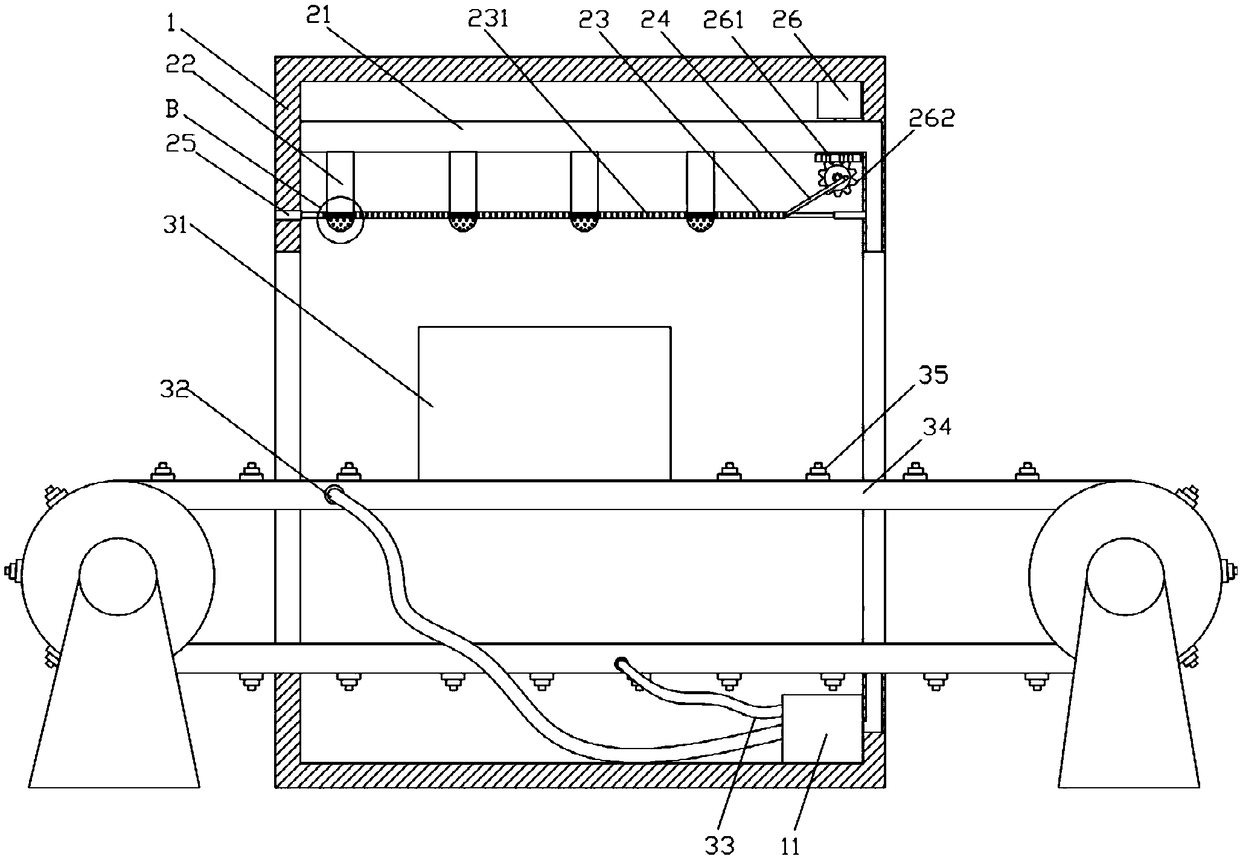

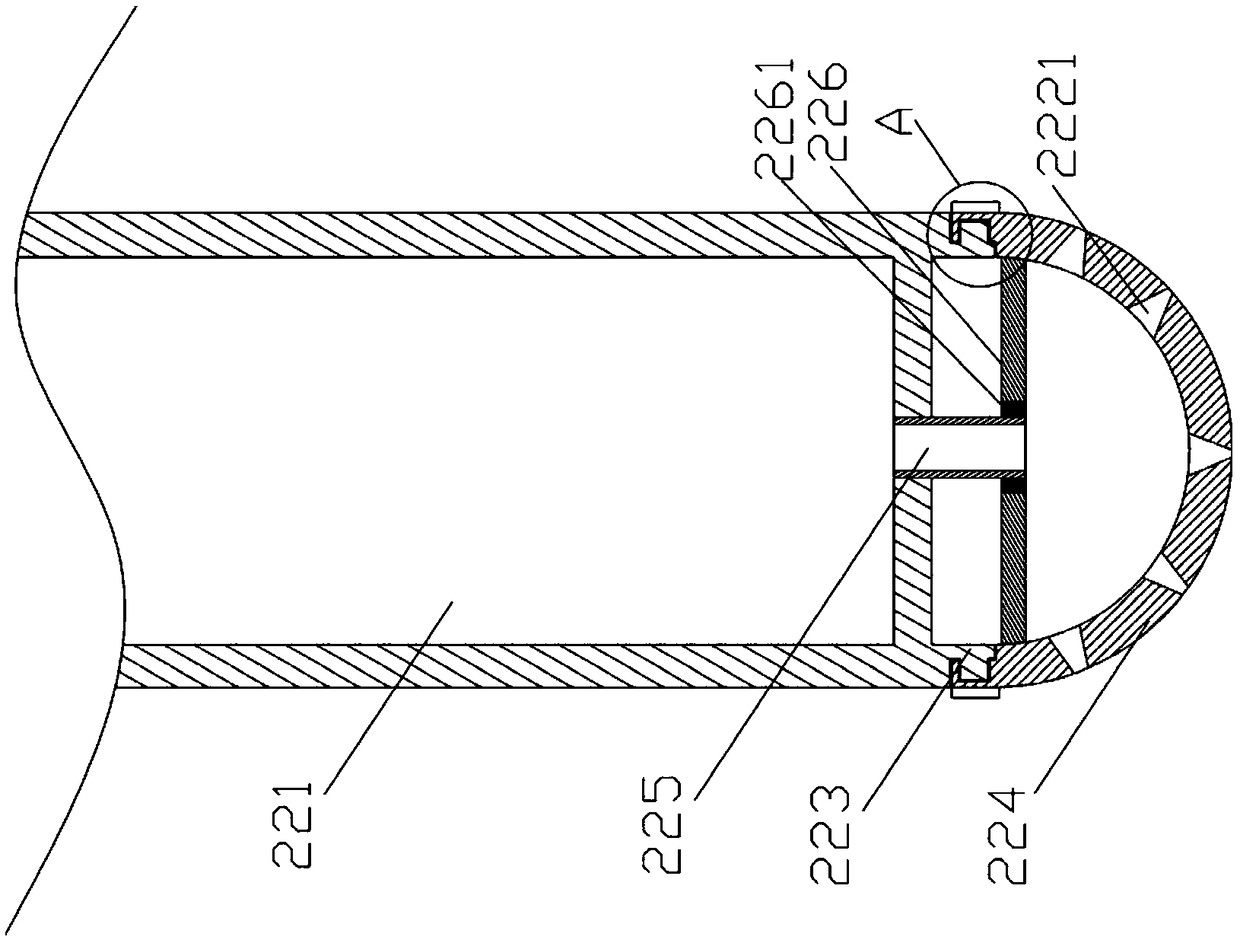

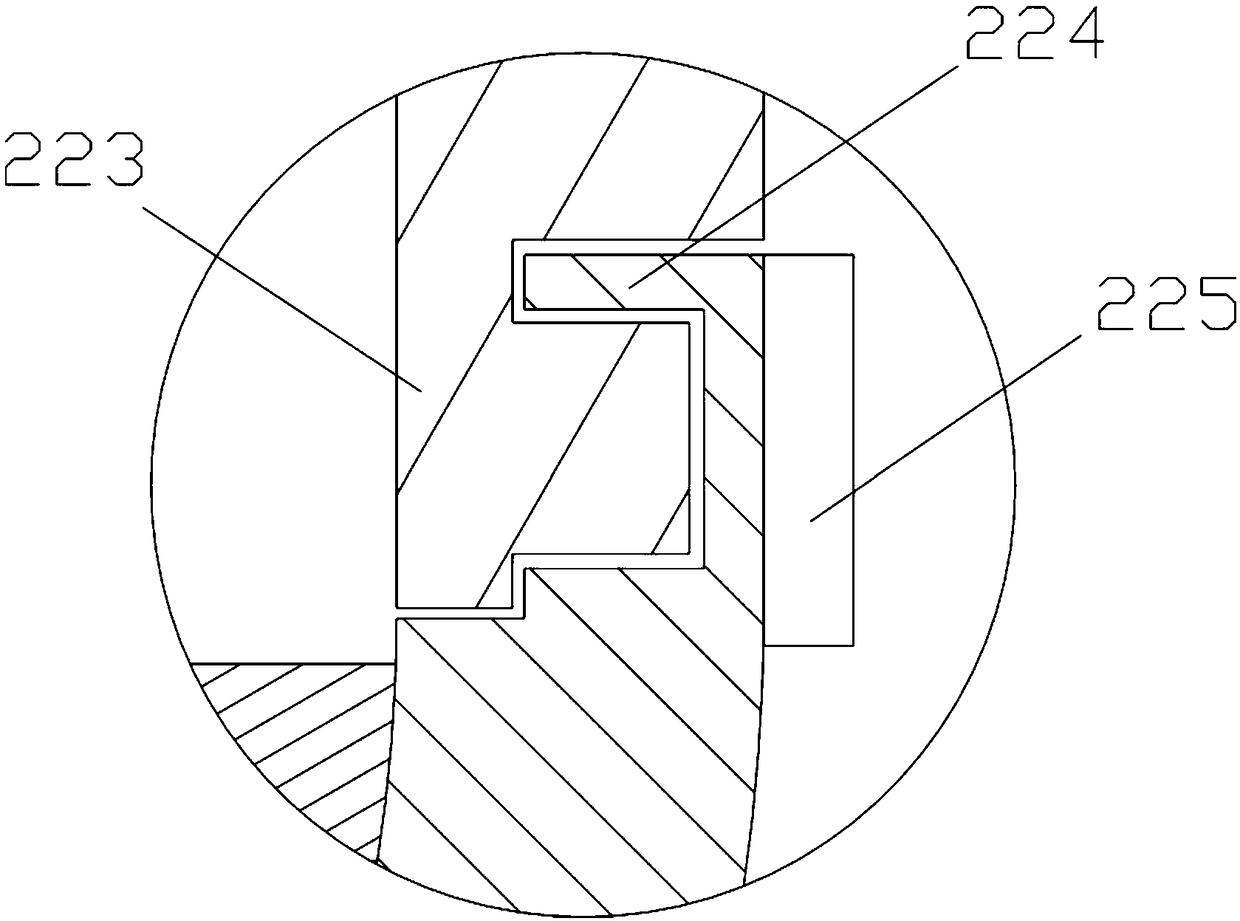

[0032] Such as Figure 1-9As shown, a laboratory test tube automatic washing device includes a box body 1, and the two sides of the box body 1 are provided with openings for the conveyor belt 34 to pass through, and the box body 1 is provided with a flushing mechanism, and the flushing mechanism includes A water spray device for rinsing the outer wall of the test tube, a rinsing device for rinsing the inner wall of the test tube and a water tank 11 for providing a water source. Below the device, through the setting of the above-mentioned flushing mechanism, the flushing mechanism can rinse the test tubes cleaned by the cleaning agent, so as to remove the cleaning agent on the washed test tubes, and through the cooperation of the water spray device and the flushing device, The inner wall and outer wall of the test tube can be cleaned at the same time, which improves the efficiency of test tube cleaning, and realizes the automation of test tube cleaning at the same time. The tes...

Embodiment 2

[0042] Such as Figure 10-12 As shown, the difference between this embodiment and Embodiment 1 is that a drying mechanism is provided on one side of the box body 1, and the drying mechanism includes a heating chamber 4 and a conveyor belt 41 for transporting the tube placement box 31. The conveyor belt 41 is installed in the heating chamber 4, and the conveyor belt 41 is arranged under the drying mechanism. Through the setting of the above drying mechanism, the test tube after cleaning can be dried, so that the test tube can quickly remove moisture, thereby The test tube can be used directly, which improves the efficiency of removing water from the test tube, and the combination of the heating chamber 4 and the conveyor belt 41 enables the test tube to be heated in the heating chamber 4 while being transported on the conveyor belt 41, which saves After heating, it needs to transport the time, while the heating chamber 4 can reduce the loss of heat, so that the effect of test t...

Embodiment 3

[0046] Such as Figure 13-16 As shown, the difference between this embodiment and Embodiment 1 is that: the water inlet telescopic hose 33 and the water outlet telescopic hose 32 are detachably connected to the conveyor belt 34 through a locking snap ring 5 respectively, and the above-mentioned locking clip The cooperation between the ring 5 and the conveyor belt 34 makes the water inlet telescopic hose 33 and the water outlet telescopic hose 32 detachably connected, so that when the conveyor belt 34 is damaged, the water inlet telescopic hose 33 and the water outlet telescopic hose 32 Disassemble, thereby can bleed off the water flow in the conveyor belt 34, so that the conveyor belt 34 is replaced, so that the conveyor belt 34 can be disassembled and replaced so that the conveyor belt 34 can continue to work, while making the dismounting of the conveyor belt 34 more convenient; The water outlet of the water outlet flexible hose 32 and the water inlet of the water inlet flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com