Patents

Literature

252results about How to "Promote warm-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

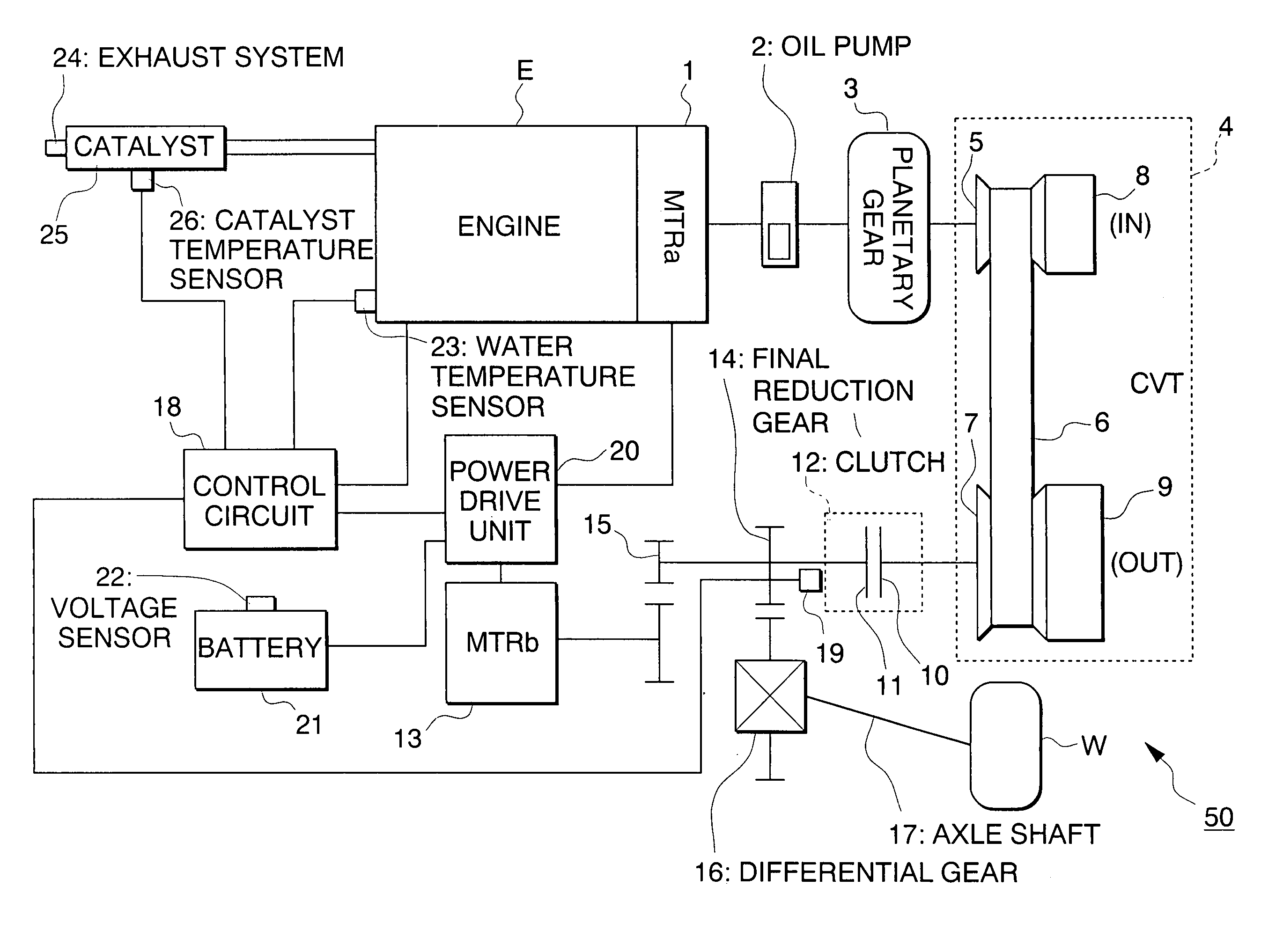

Catalyst warming control-apparatus

InactiveUS7007464B1Shorten the timeEasy loadingInternal combustion piston enginesExhaust apparatusInternal combustion engineControl circuit

The catalyst warming control apparatus of the present invention is provided for a hybrid vehicle having an internal combustion engine, a generator for generating electric power from the output from the internal combustion engine, a power storage unit for storing electric power generated by the generator, and an electric motor driven by the electric power stored in the power storage unit, the hybrid vehicle being driven by at least one of the outputs from the internal combustion engine and the motor. The catalyst warming control apparatus includes a temperature detector for detecting the temperature of a catalyst or a value relating to the same; a first comparison circuit for comparing the detected result from the temperature detector with a preset reference value; and a control circuit for allowing the generator to generate electric power and to store the power in the power storage unit when the internal combustion engine is driven, and when the detected result by the temperature detector is equal to or below the reference value according to the output from the comparison circuit.

Owner:HONDA MOTOR CO LTD

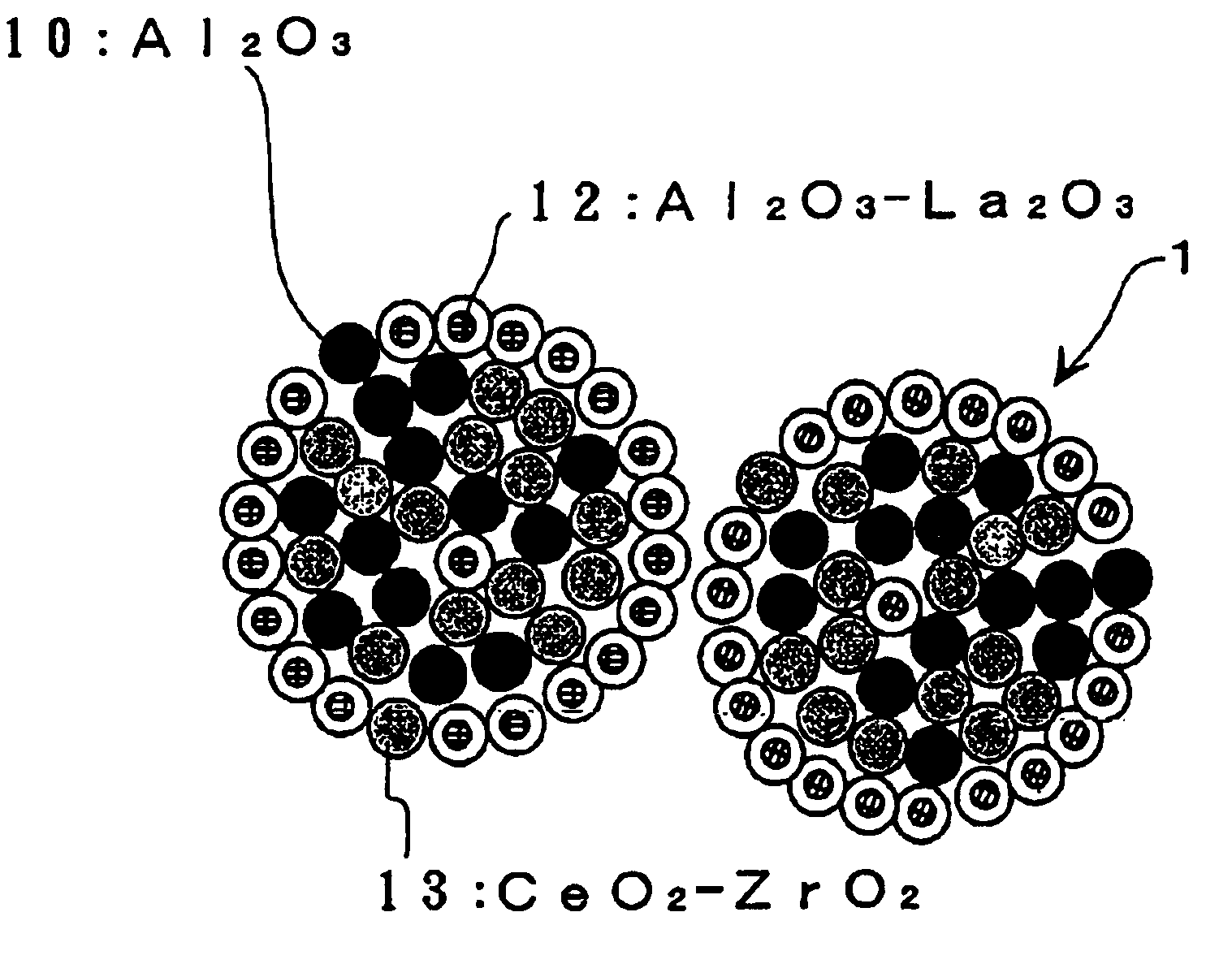

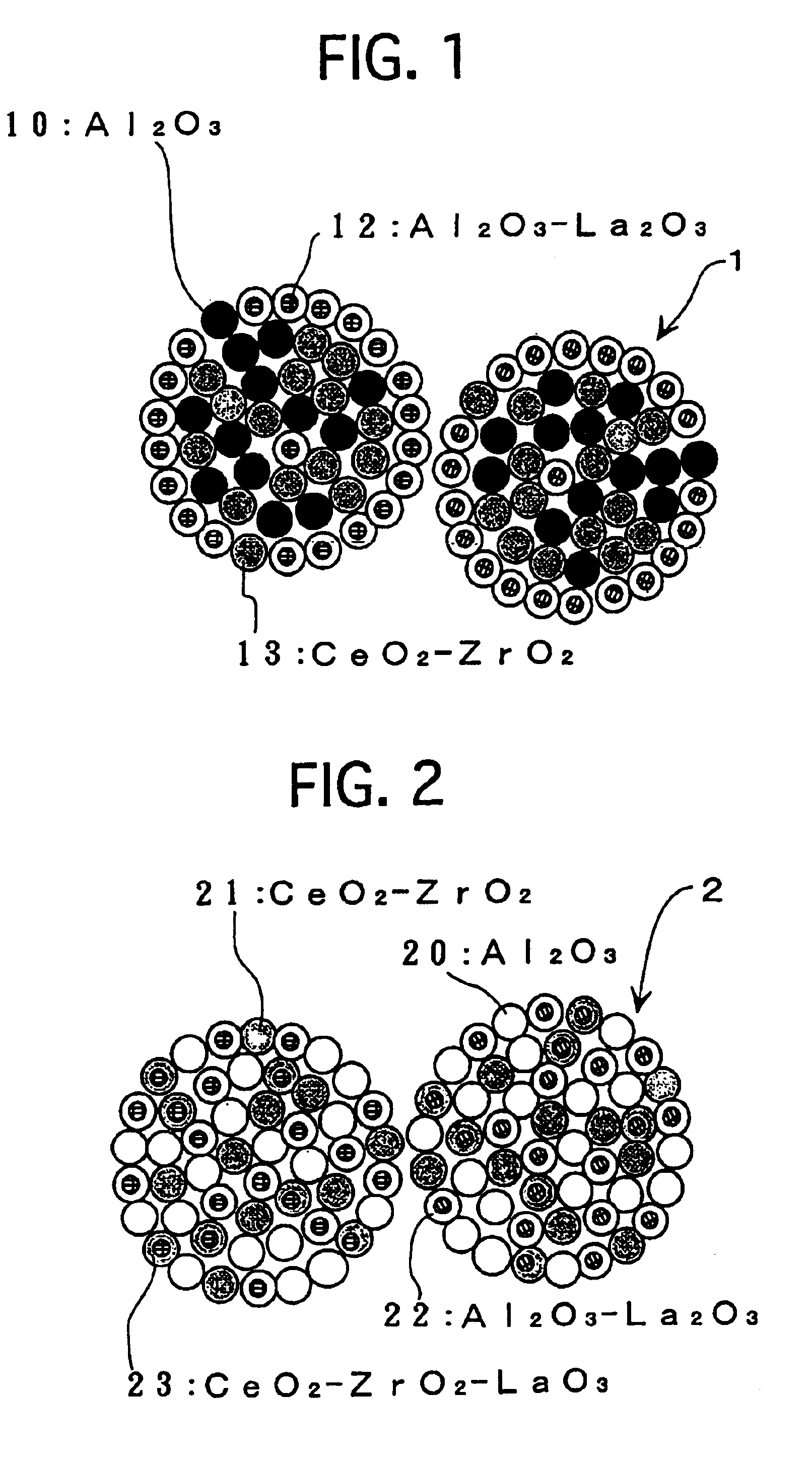

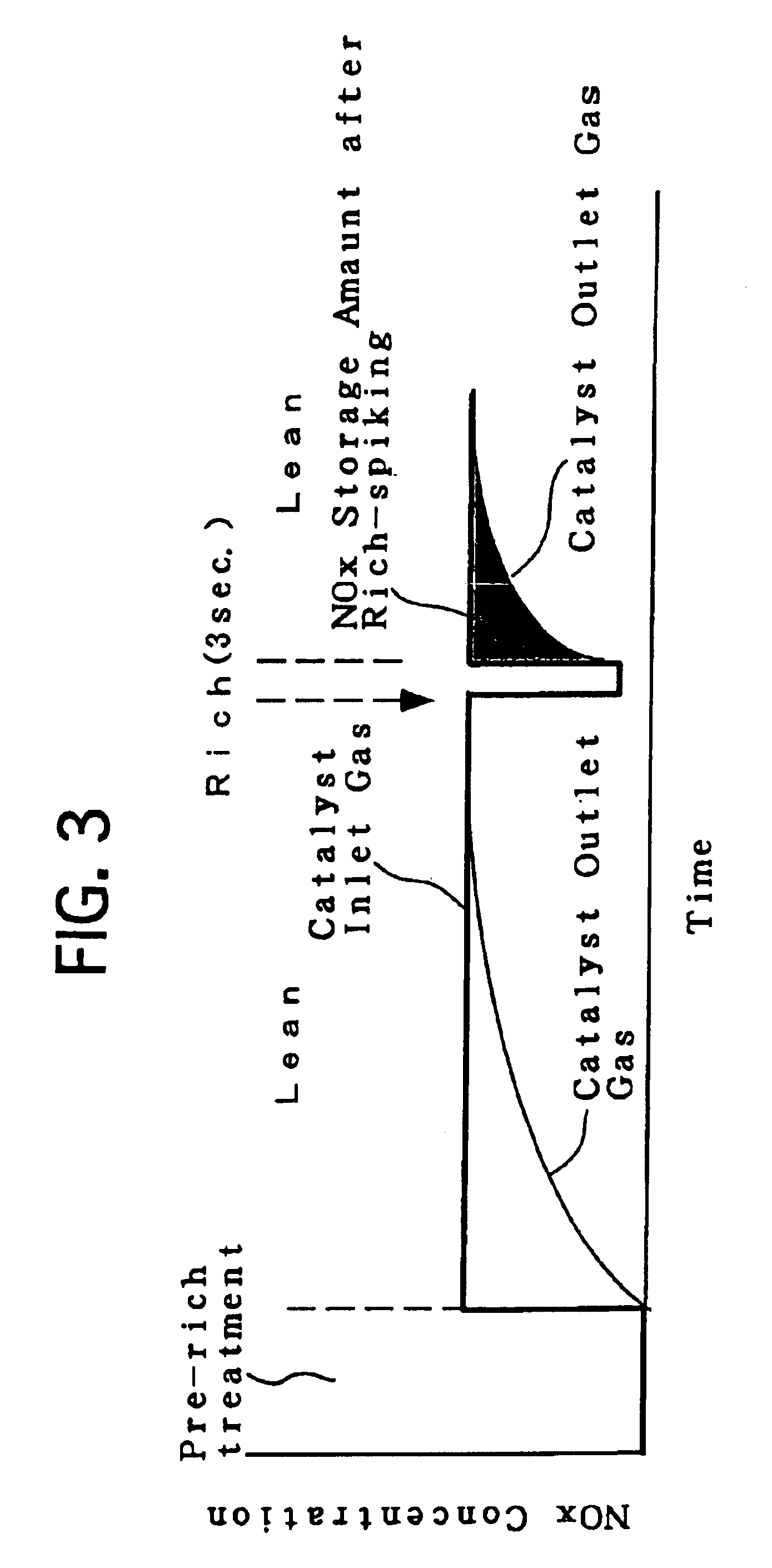

Composite oxide, process for producing the same, catalyst for purifying exhaust gas, and process for producing the same

InactiveUS6852665B2Improve performanceImprove ignition performanceCatalyst carriersMolecular sieve catalystsSulfurComposite oxide

A composite oxide includes agglomerated particles which have an average particle diameter of 20 μm or less, which are composed of a plurality of metallic element oxides being in form of fine particles having an average diameter of 50 nm or less, and which have a surface and an inner portion whose metallic element distributions differ with each other. The characteristics of the respective metallic elements are exhibited maximally. Hence, it is extremely useful as a support for an exhaust gas purifying catalyst. The catalyst exhibits the activities which degrade less even after it is subjected to a sever durability, is good in terms of the heat and sulfur-poisoning resistance, and can efficiently purify the harmful components in exhaust gases. Moreover, it is possible to produce such a composite oxide and catalyst easily and stably by production processes disclosed herein.

Owner:TOYOTA CENT RES & DEV LAB INC

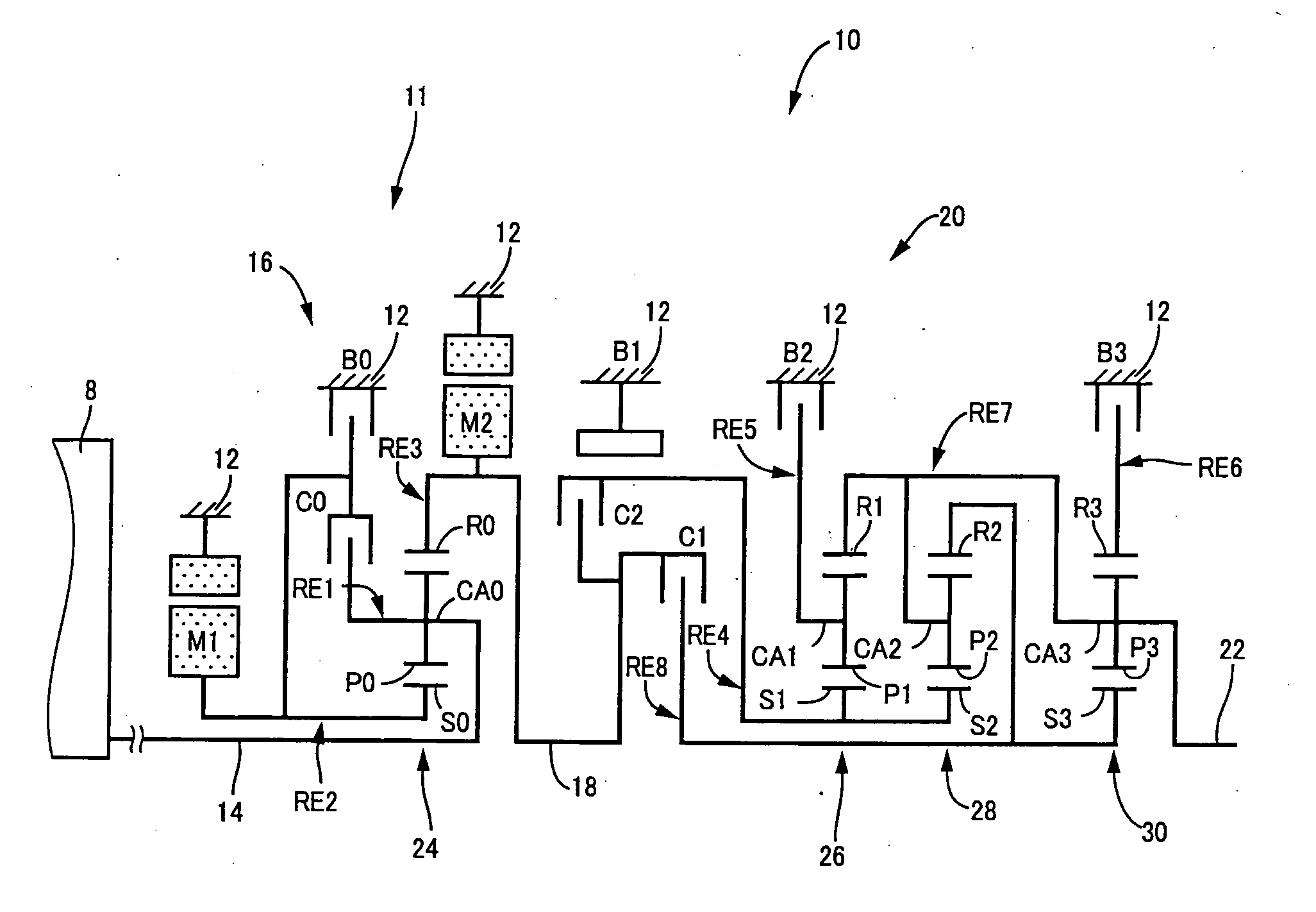

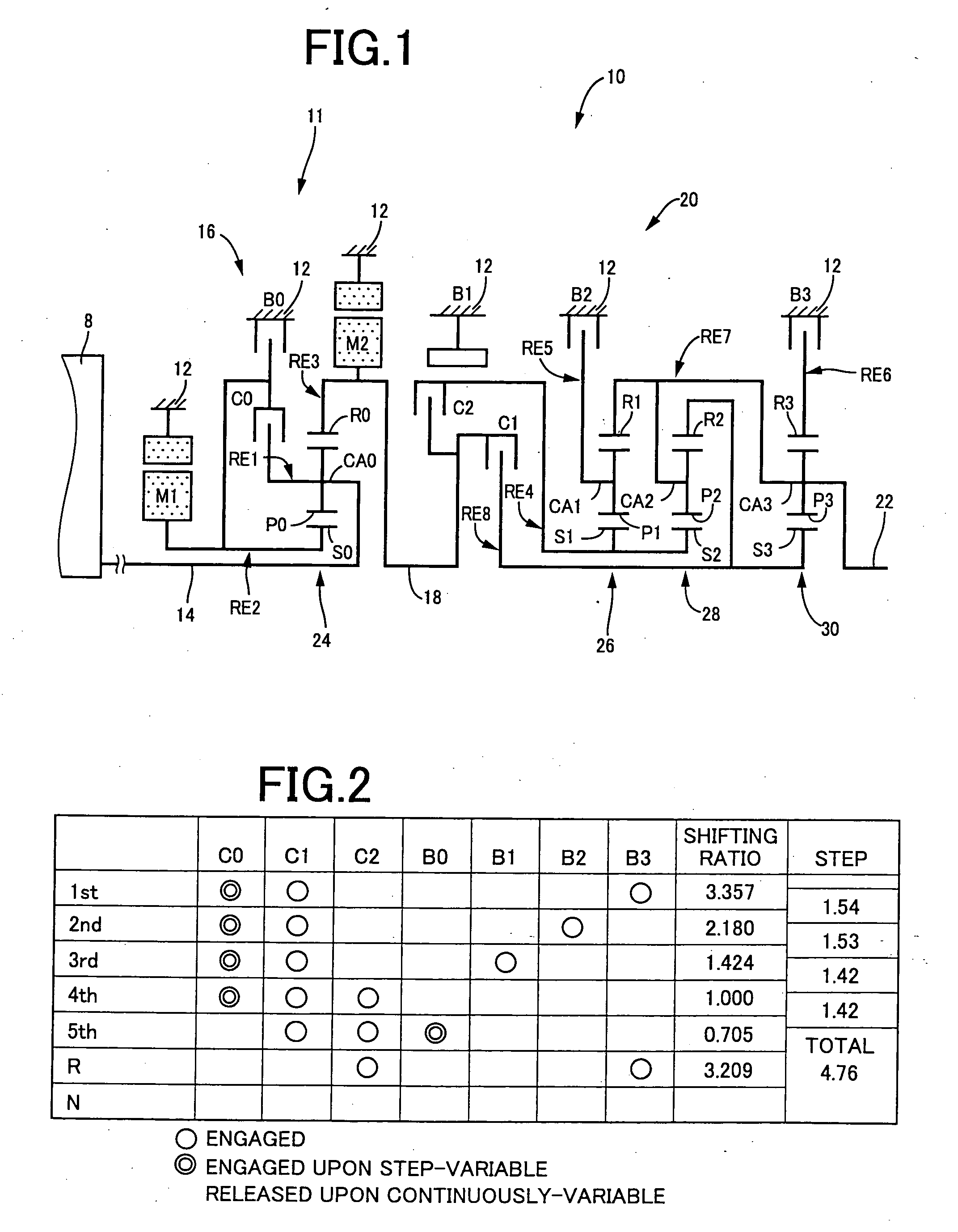

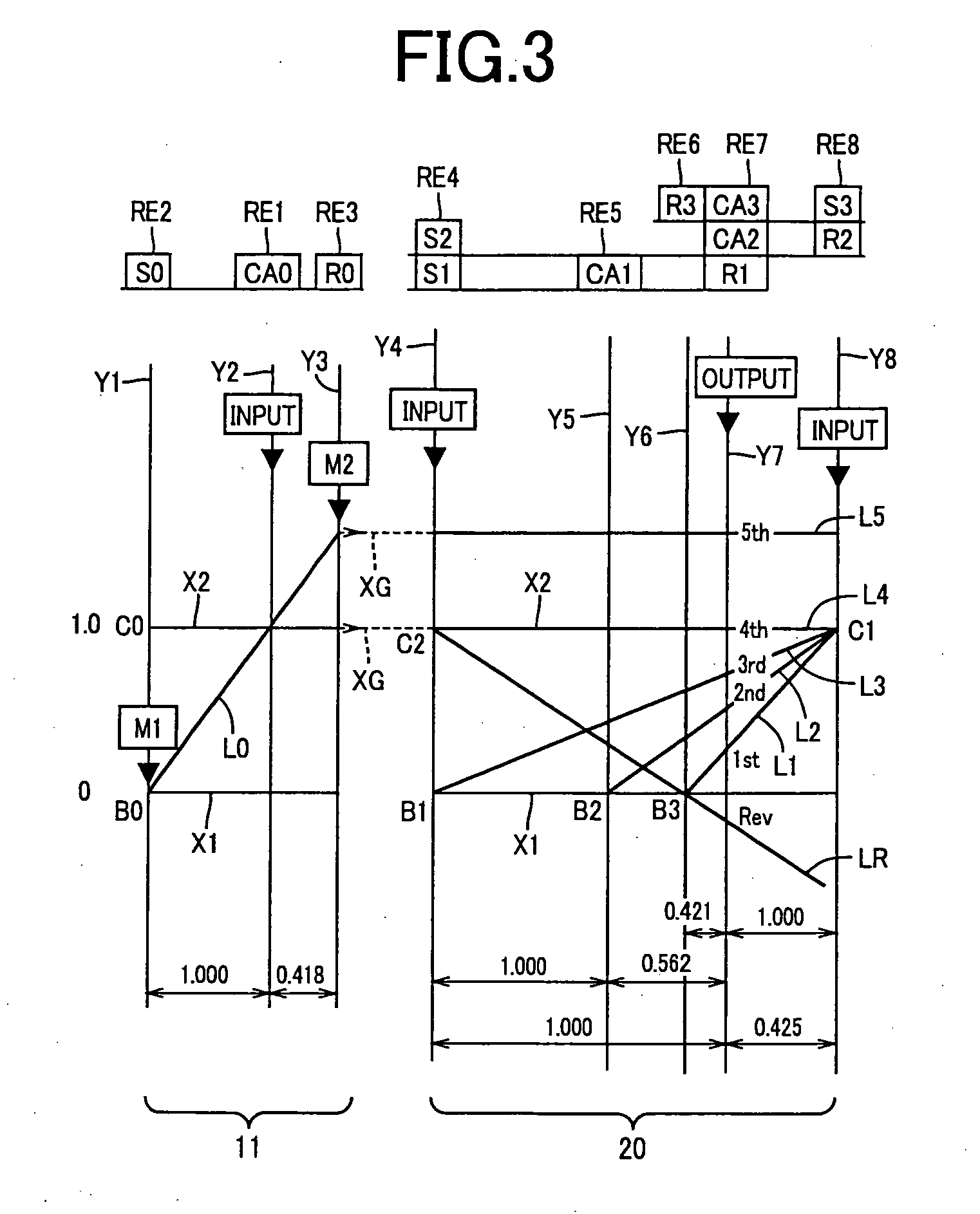

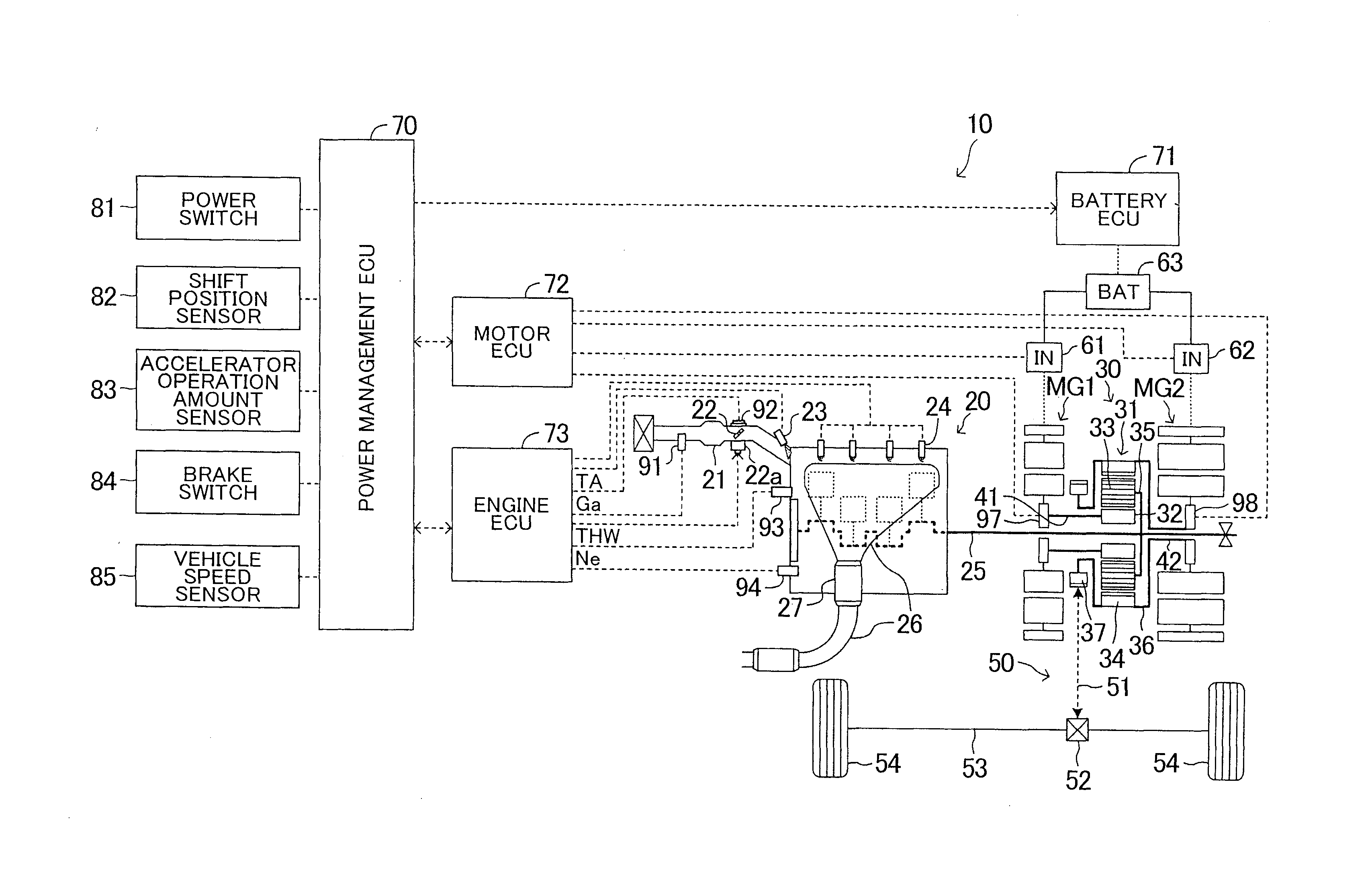

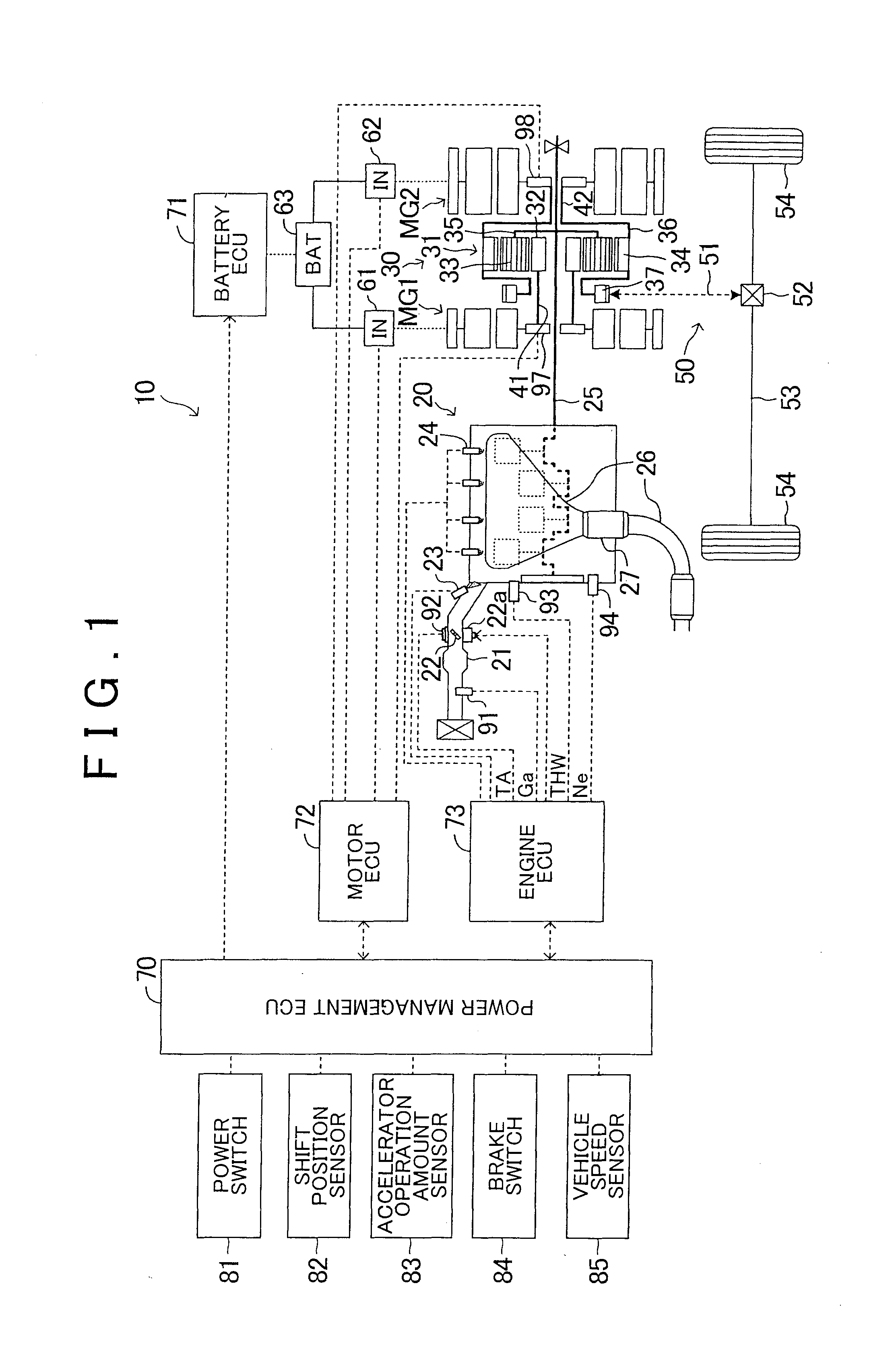

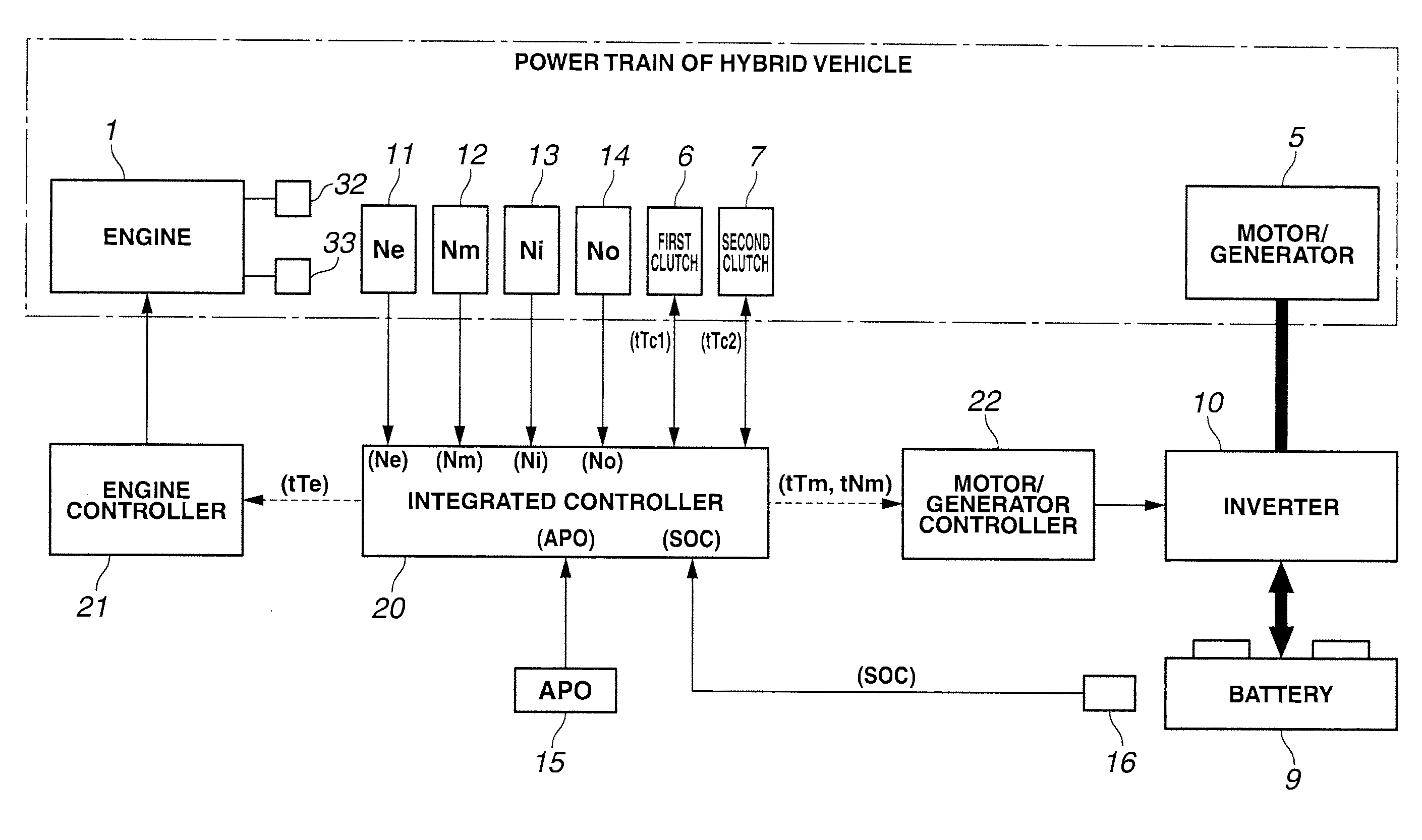

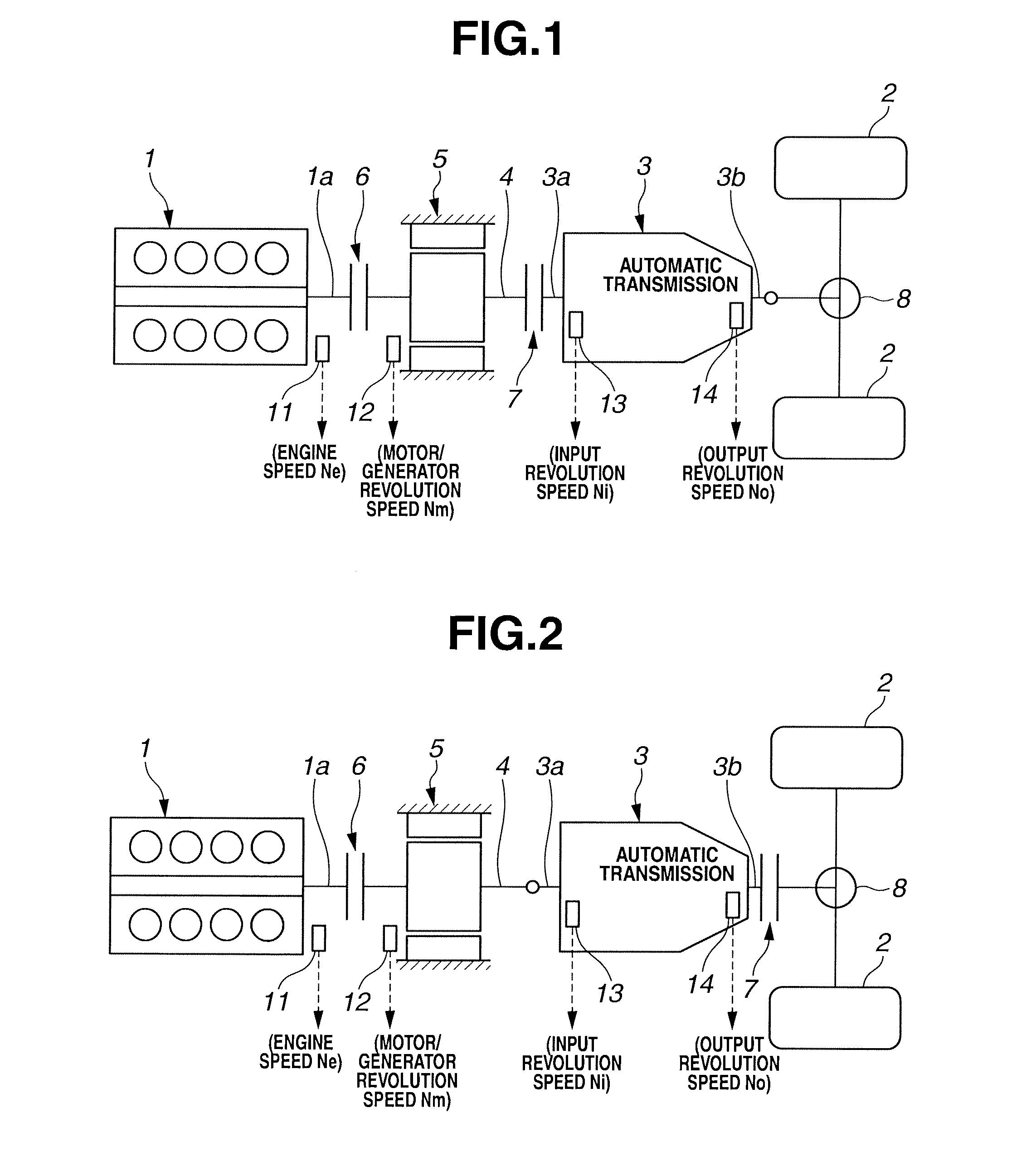

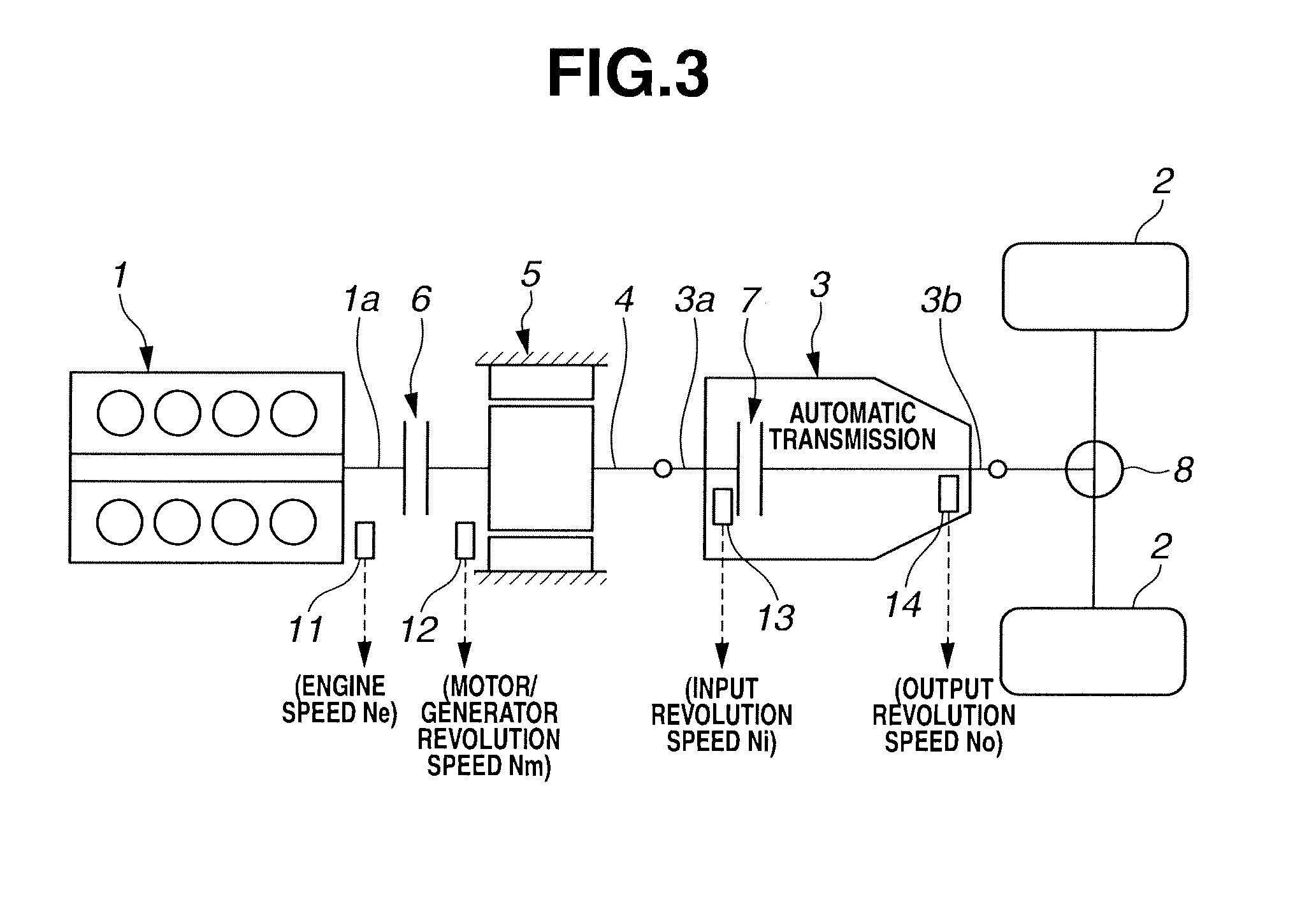

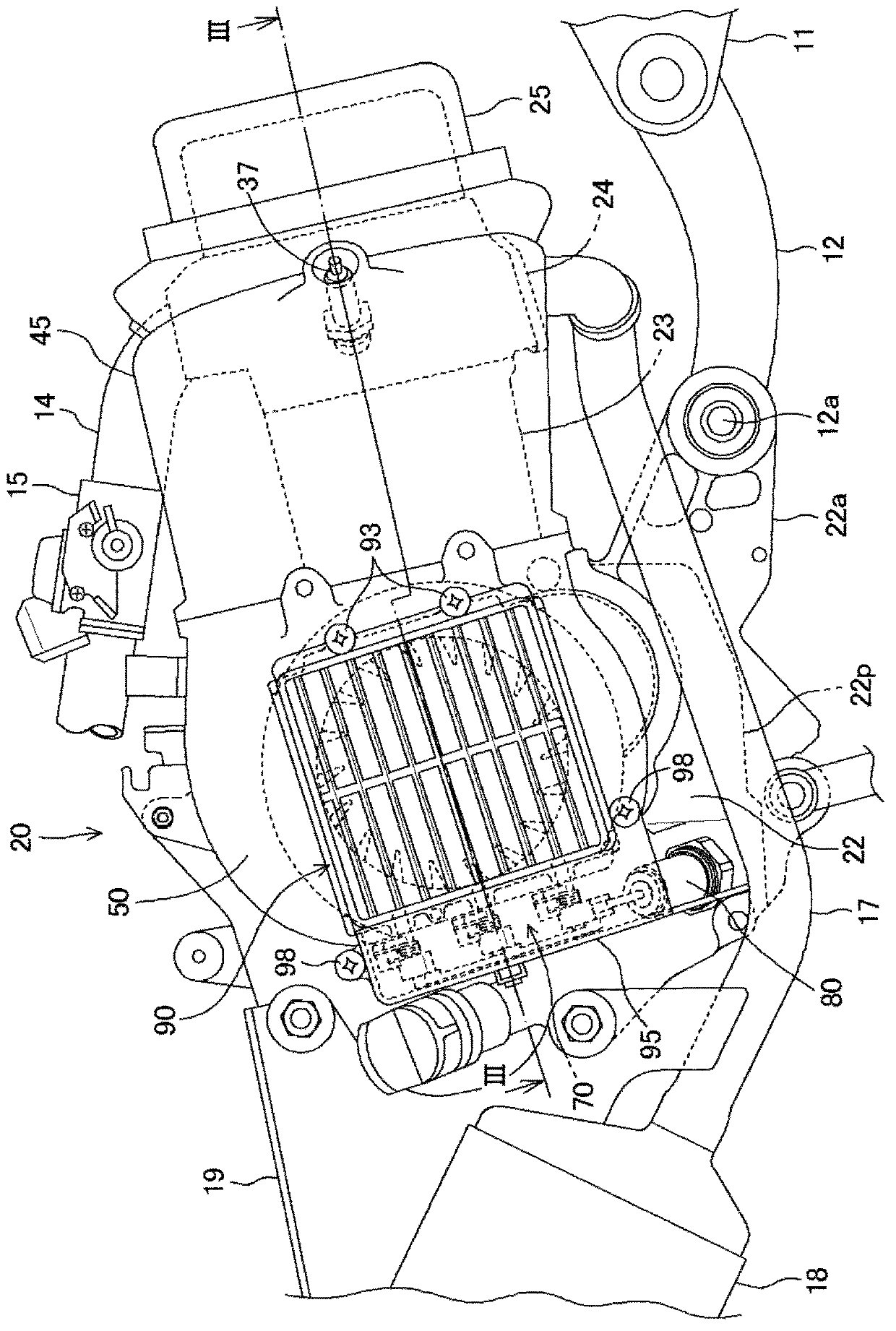

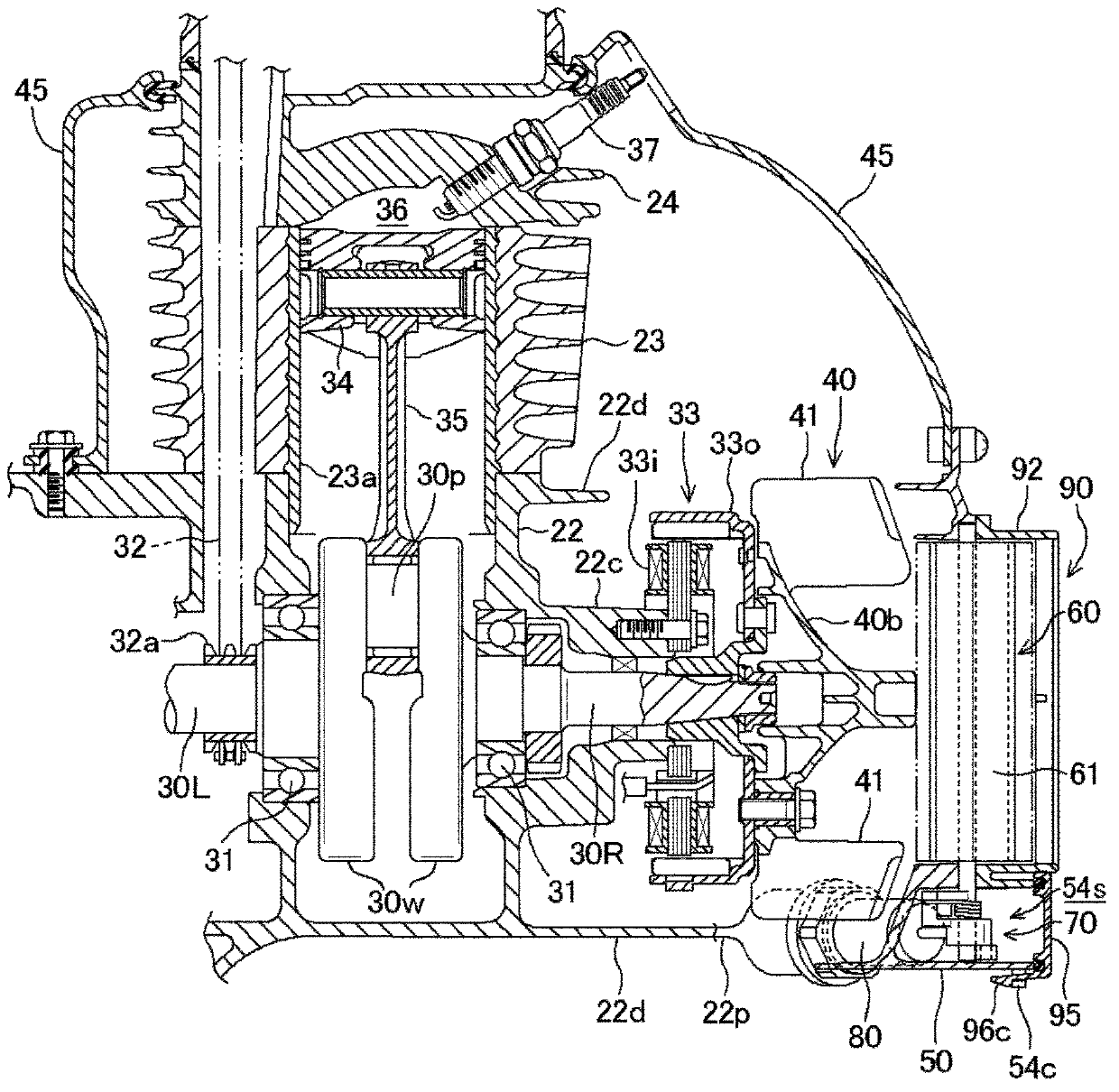

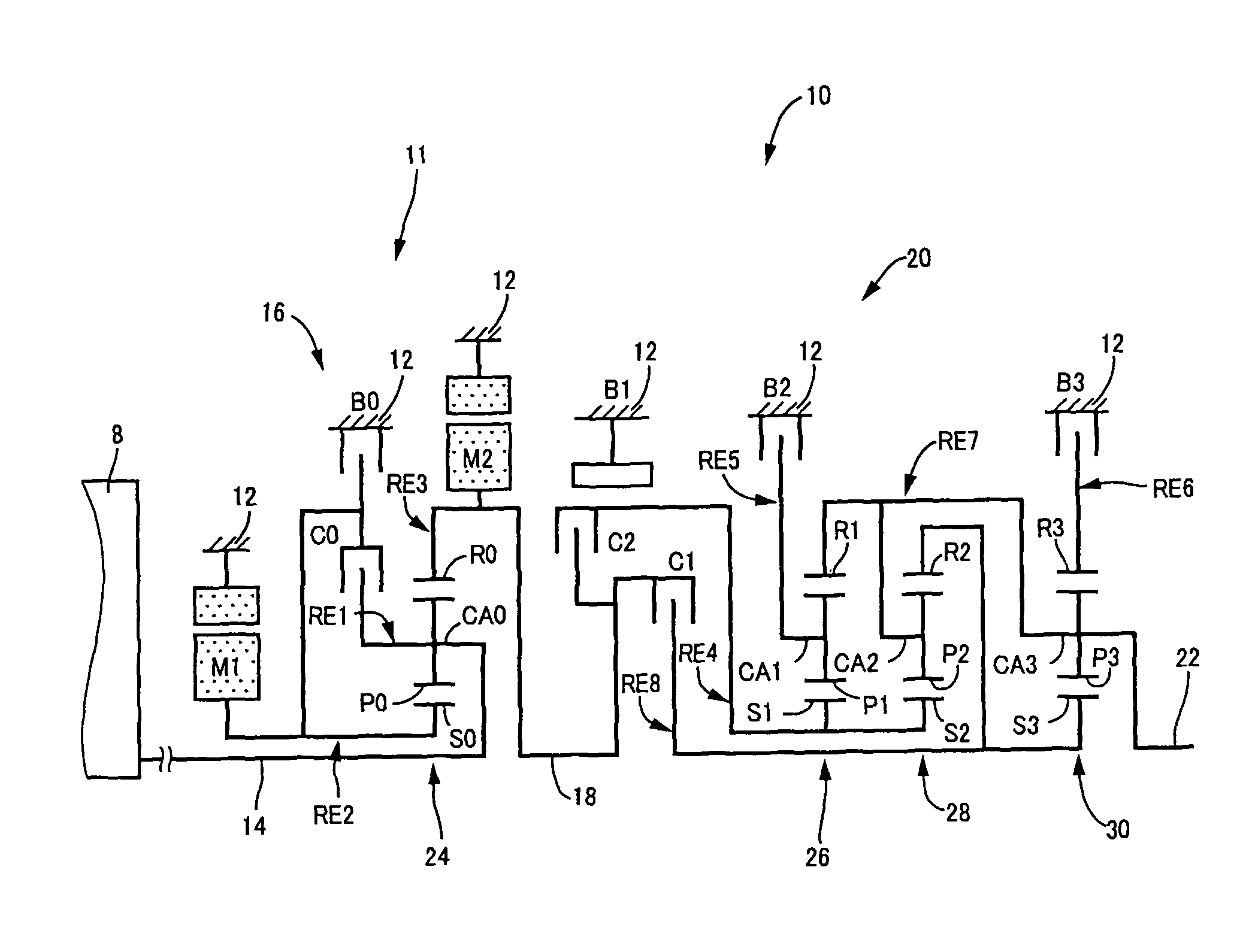

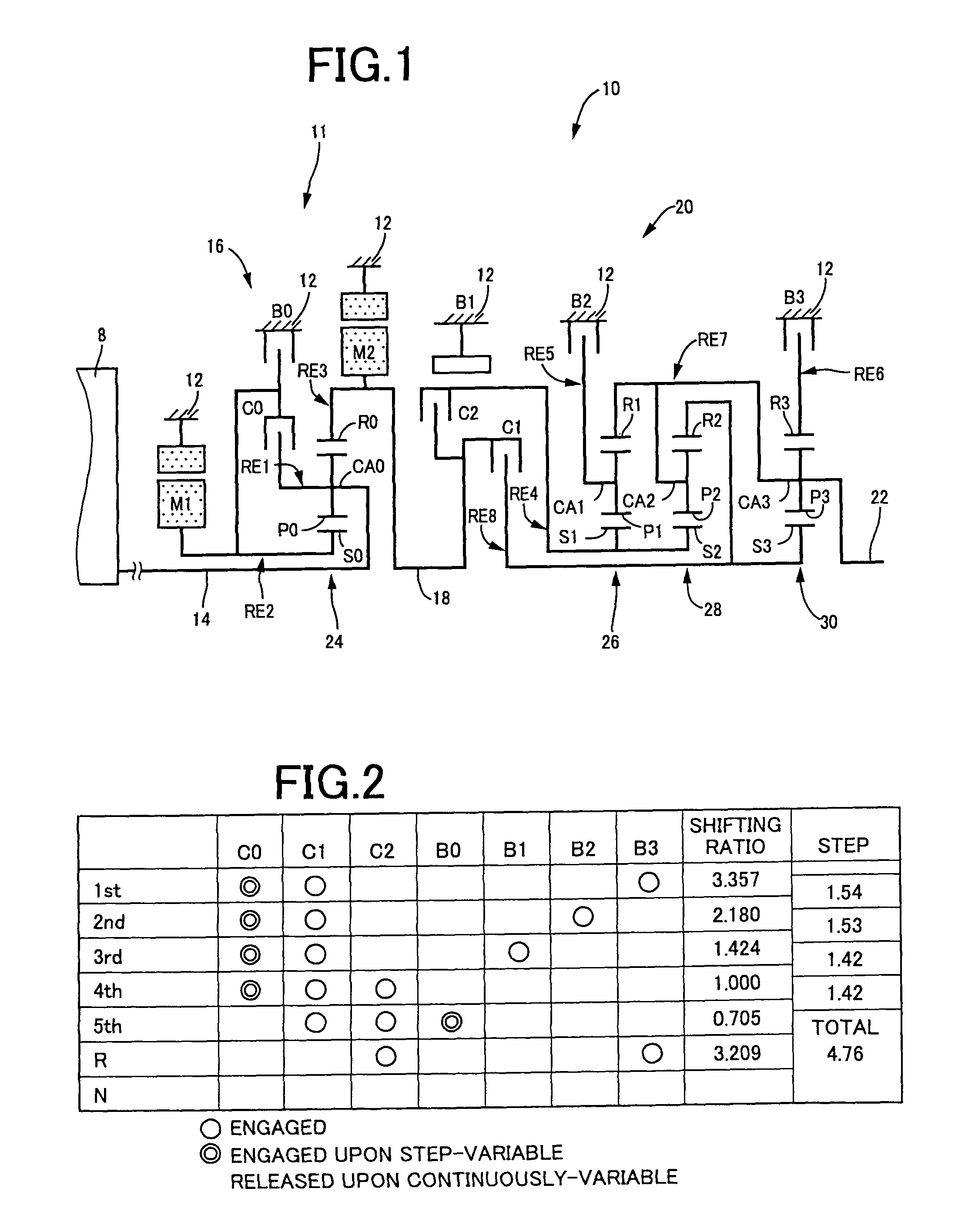

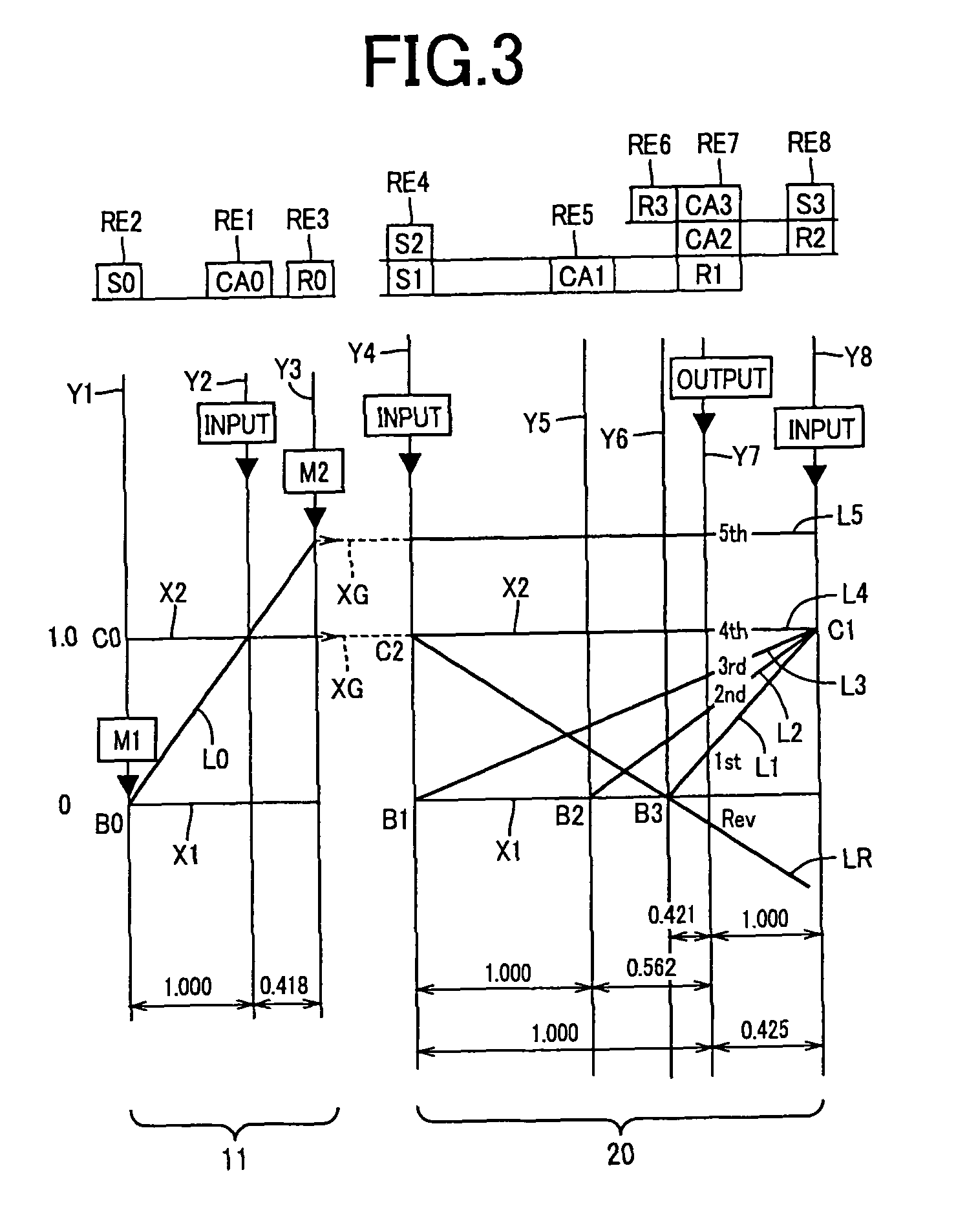

Control device for hybrid vehicle power transmitting apparatus

ActiveUS20090023548A1Facilitate warm upPromote warm-upHybrid vehiclesGearingDifferential equationHybrid vehicle

This invention relates to a control device for a hybrid vehicle power transmitting apparatus. A heat generation control is executed to increase a heat generation amount of an electric motor M1 when a differential portion 11 is placed in a non-differential state and a temperature of a shifting mechanism 10 is less than a given transmitting apparatus temperature determining value TEMP11. This allows the first electric motor M1 to develop a heat with which the temperature of a shifting mechanism 10 is promptly raised, thereby promptly completing a warm-up of the shifting mechanism 10 to achieve improved fuel consumption.

Owner:TOYOTA JIDOSHA KK

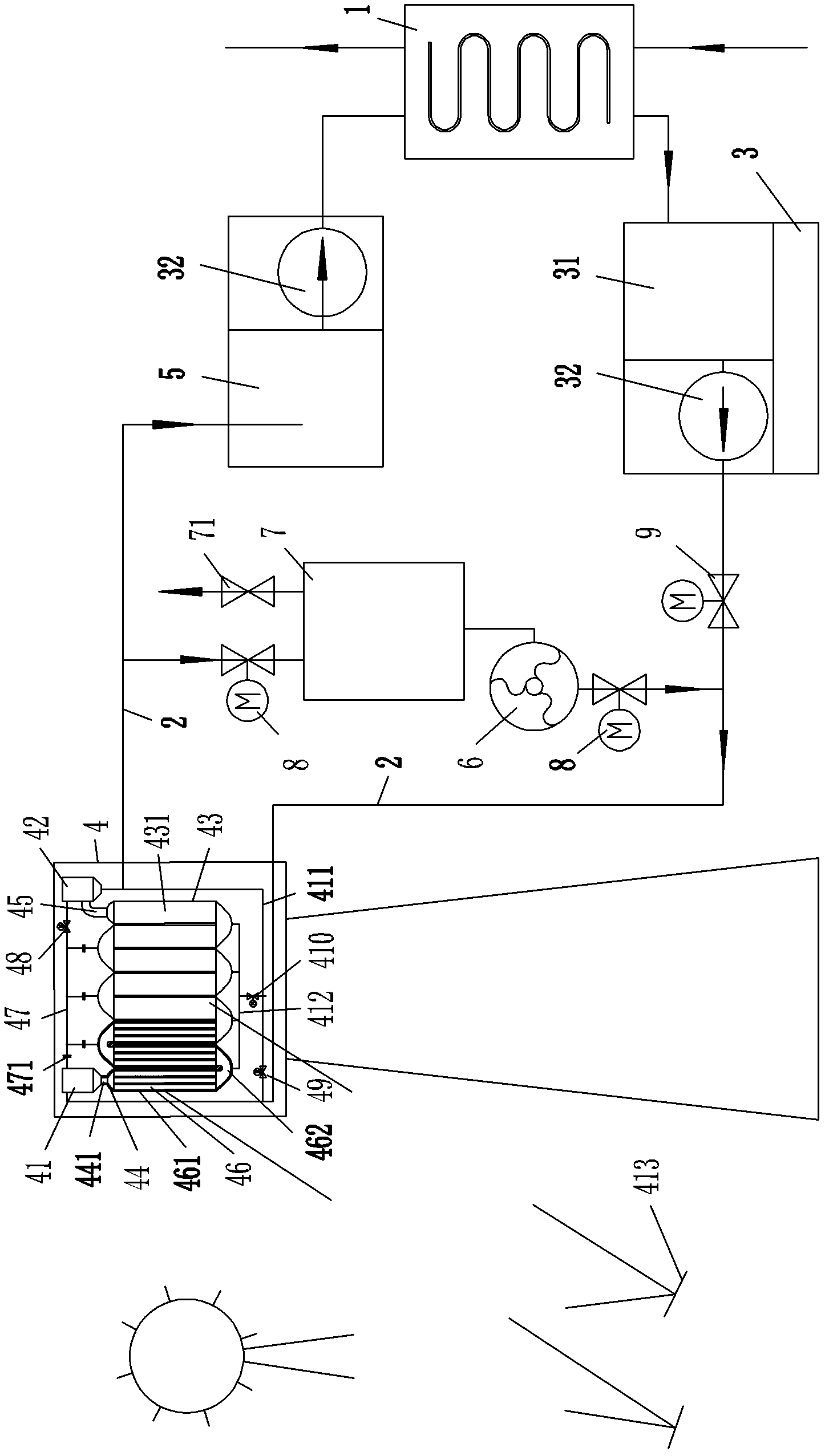

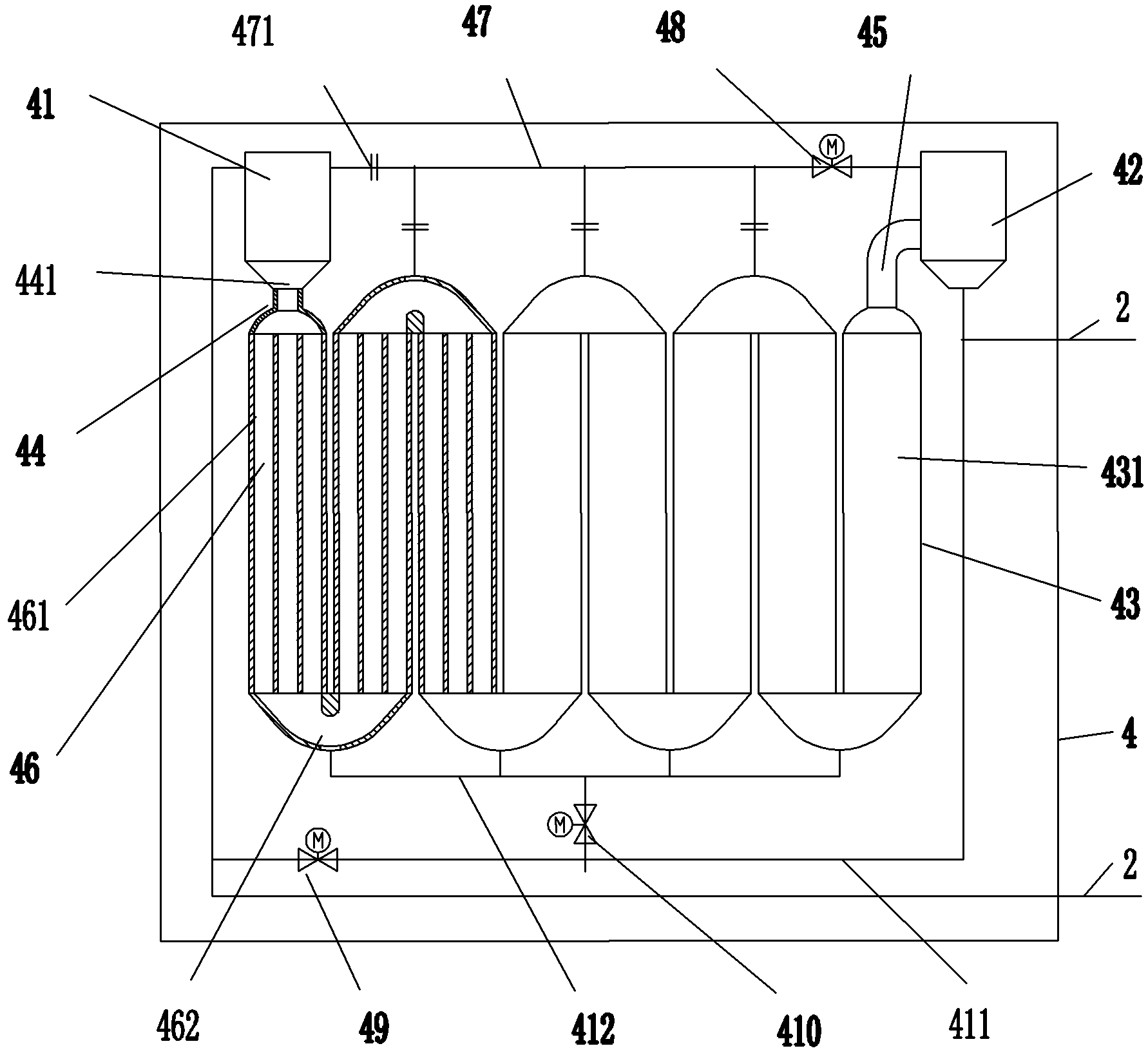

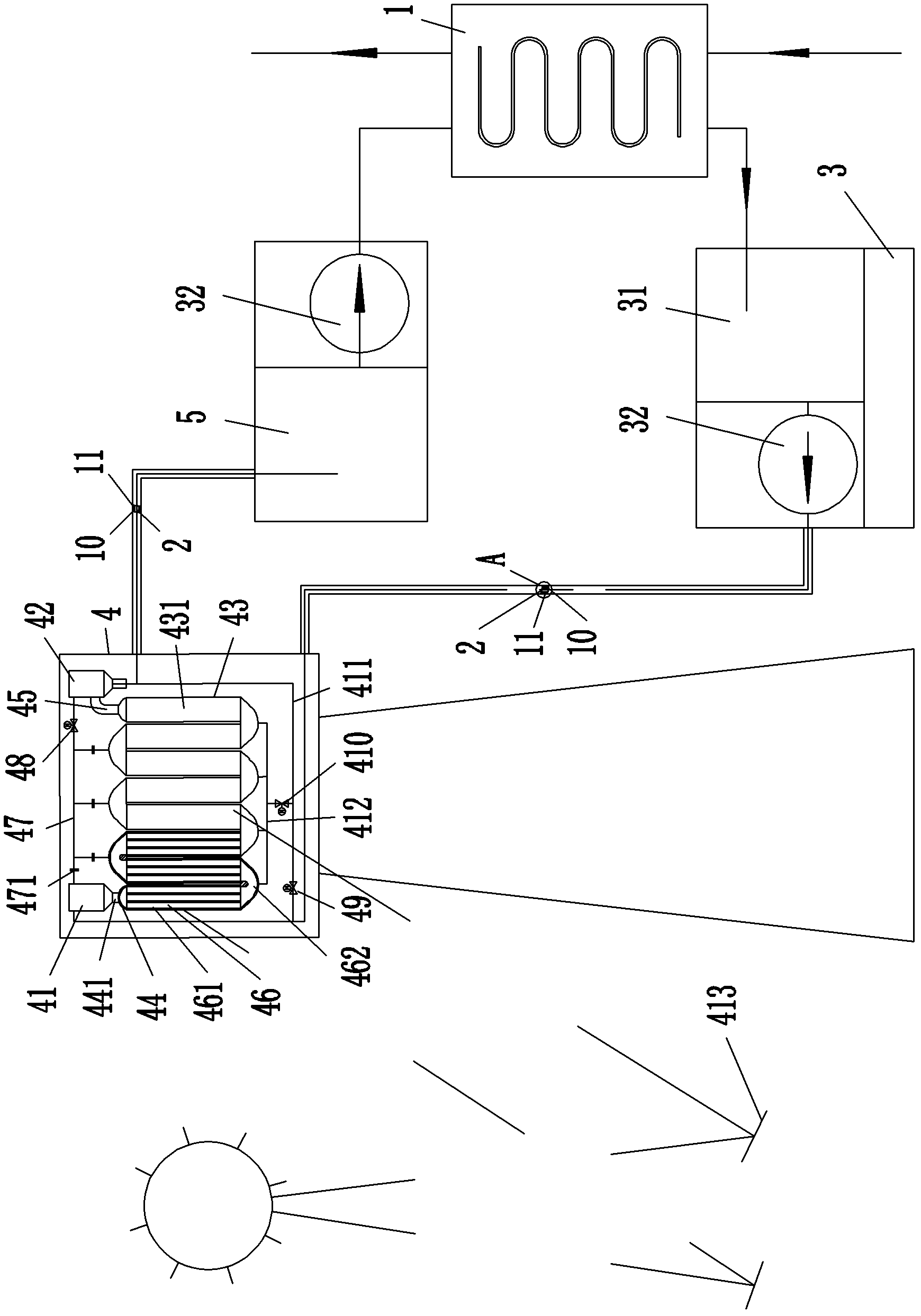

Solar-heating assisted salt melting system

ActiveCN102563867AReduce consumptionReduce flow rateSolar heat devicesStorage heatersMolten saltHot Temperature

The invention belongs to the field of the salt melting equipment and aims to provide a solar-heating assisted salt melting system which consumes less fuel and less affects the environment. The solar-heating assisted salt melting system comprises a salt melting furnace and a heating device, wherein the salt melting furnace is provided with a low-temperature salt storage tank with a salt melting pump; the solar-heating assisted salt melting system further comprises a solar heat absorbing device, two heating pipes and a high-temperature salt storage tank with a salt melting pump; the outlet of the salt melting pump of the low-temperature salt storage tank is communicated with the inlet of the solar heat absorbing device through a first heating pipe; the outlet of the solar heat absorbing device is communicated with the high-temperature salt storage tank through a second heating pipe; the outlet and the inlet of the heating device are communicated with the inlet of the low-temperature salt storage tank and the outlet of the salt melting pump of the high-temperature salt storage tank respectively; and the solar-heating assisted salt melting system is provided with a preheating device used for preheating the heating pipes. The solar-heating assisted salt melting system consumes less fuel and less affects the environment.

Owner:HANGZHOU BOILER GRP CO LTD

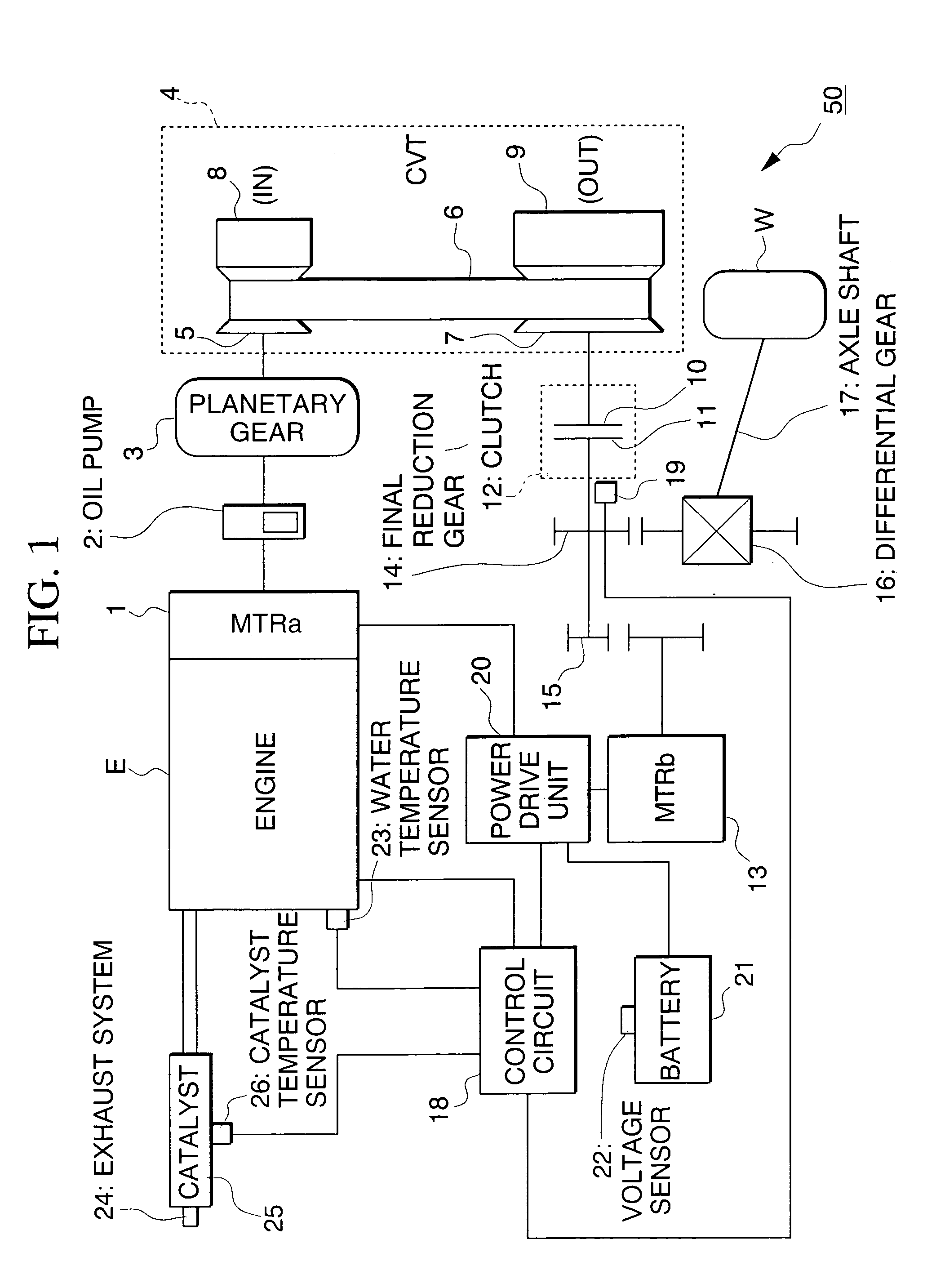

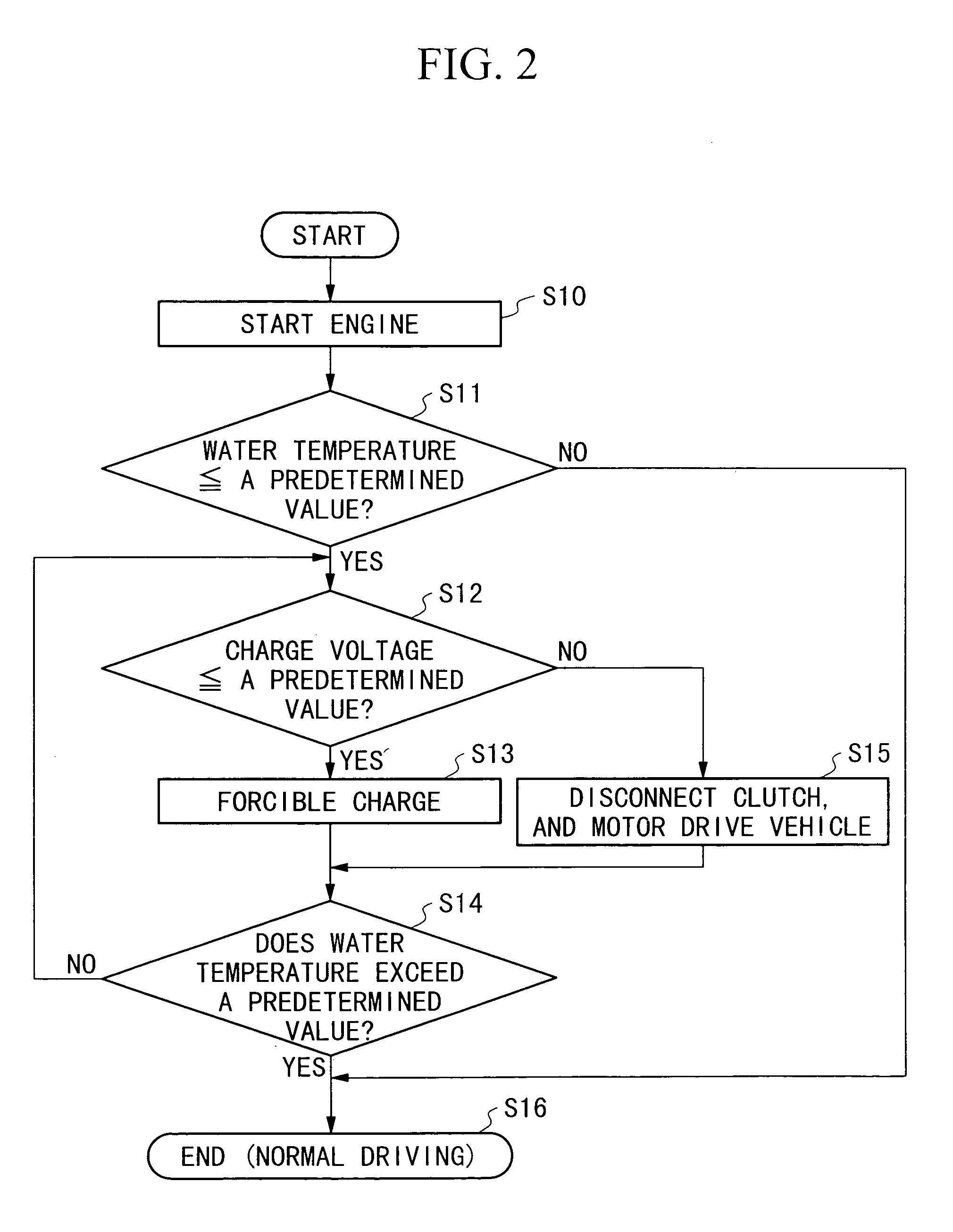

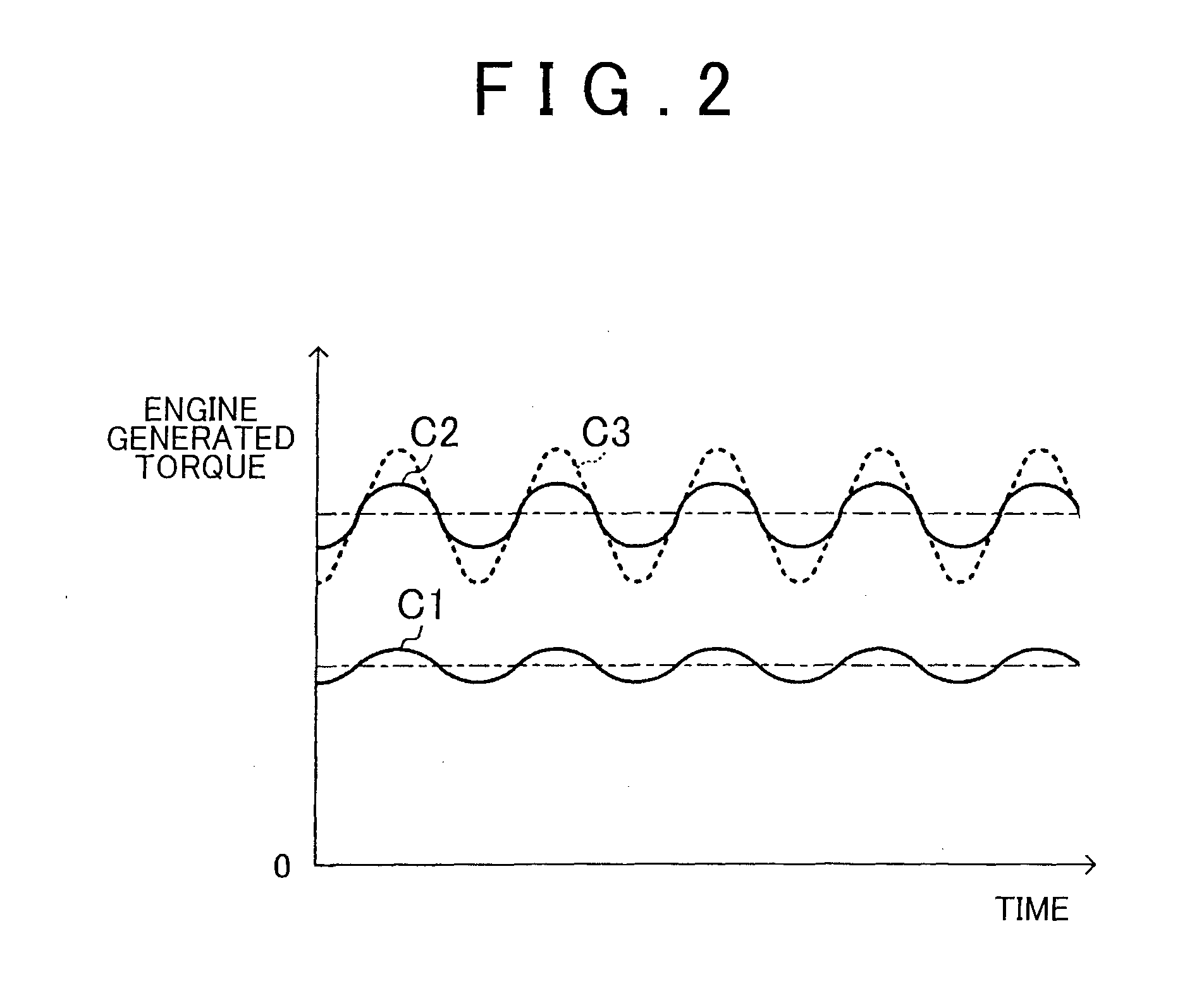

Hybrid vehicle and control method for hybrid vehicle

ActiveUS20140297088A1Lower latencyEasy loadingHybrid vehiclesInternal combustion piston enginesDrive shaftCoolant temperature

A hybrid vehicle including an engine having a catalyst in an exhaust passage, first and second motor generators, a battery and a power transmission mechanism coupling a drive shaft, the engine and the motor generators by a gear mechanism such that torque is transmittable, and its control method, are provided. When a coolant temperature is a threshold or below, catalyst warm-up operation for starting the engine and retarding an ignition timing by a retardation amount is executed. When a battery level is a threshold or below, forced charging operation for starting the engine and charging the battery by driving the first motor generator is executed. During the forced charging operation, an engine load is changed on the basis of the battery level. When the catalyst warm-up operation is executed during the forced charging operation, the retardation amount for facilitating warm-up of the catalyst is reduced as the engine load increases.

Owner:TOYOTA JIDOSHA KK +1

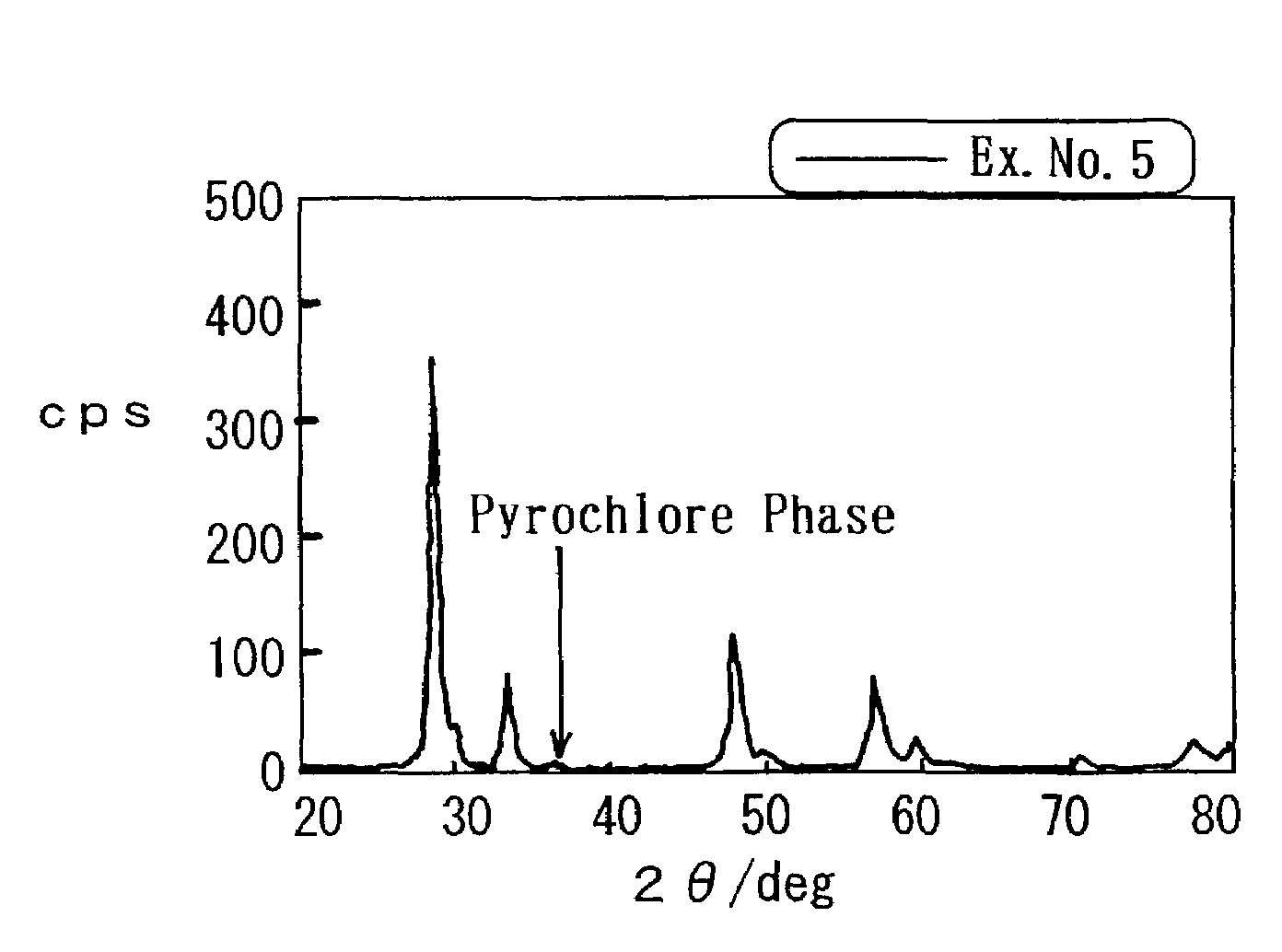

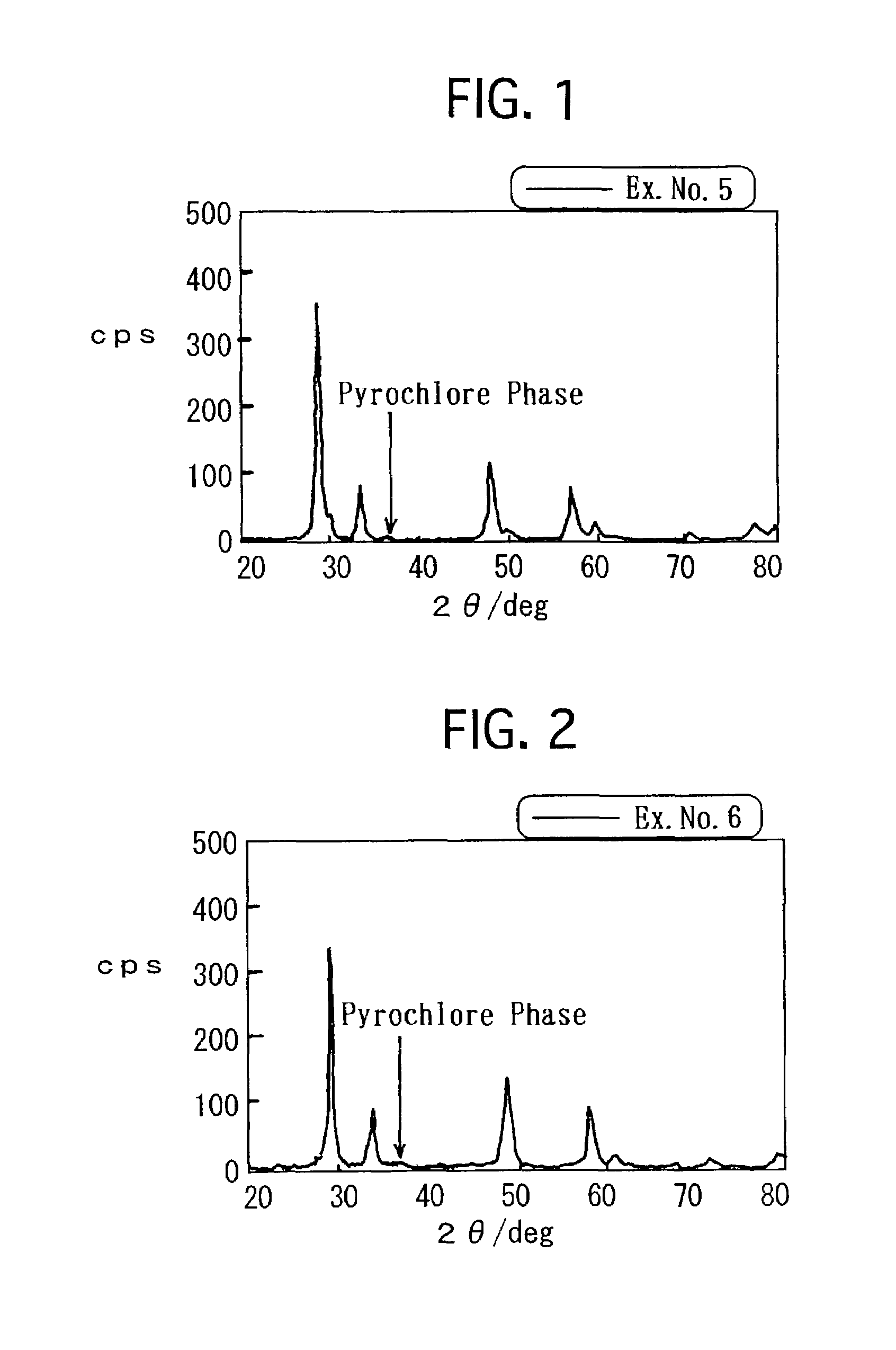

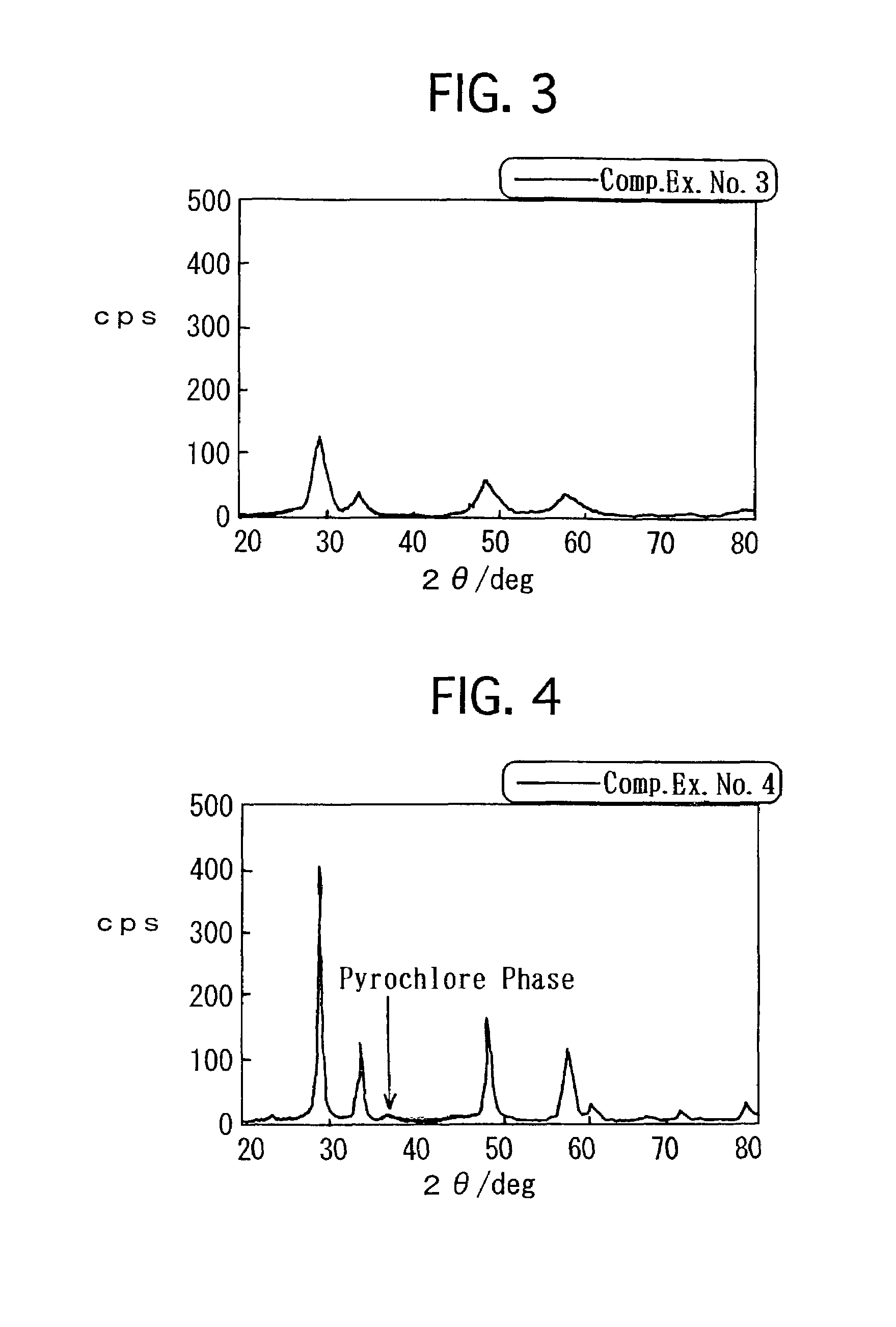

Composite oxide, process for producing the same, and exhaust gas reducing co-catalyst

ActiveUS7247597B2Decrease in activityLack of durabilityDispersed particle separationCatalyst activation/preparationExhaust gasComposite oxide

A composite oxide includes CeO2, ZrO2 and a metallic oxide being free from reacting with CeO2 and ZrO2 at 700° C. or more, preferably at 900° C. or more and further preferably at 1,000° C. or more. The composite oxide has a regulatory oriented phase, such as a pyrochlore phase, etc., in which at least a part of Ce cations and Zr cations are oriented regularly. The composite oxide makes a catalytic support. The CeO2—ZrO2 composite oxide and the reaction-free metallic oxide make barriers each other which suppress the granular growth when the composite oxide is subjected to high-temperature heat in a reducing heat treatment to form the regulatory oriented phase. The regulatory oriented phase improves the oxygen storage-and-release capability of the catalytic support. Thus, it is possible to simultaneously attain a large a specific surface area and a high oxygen storage-and-release capability.

Owner:TOYOTA CENT RES & DEV LAB INC

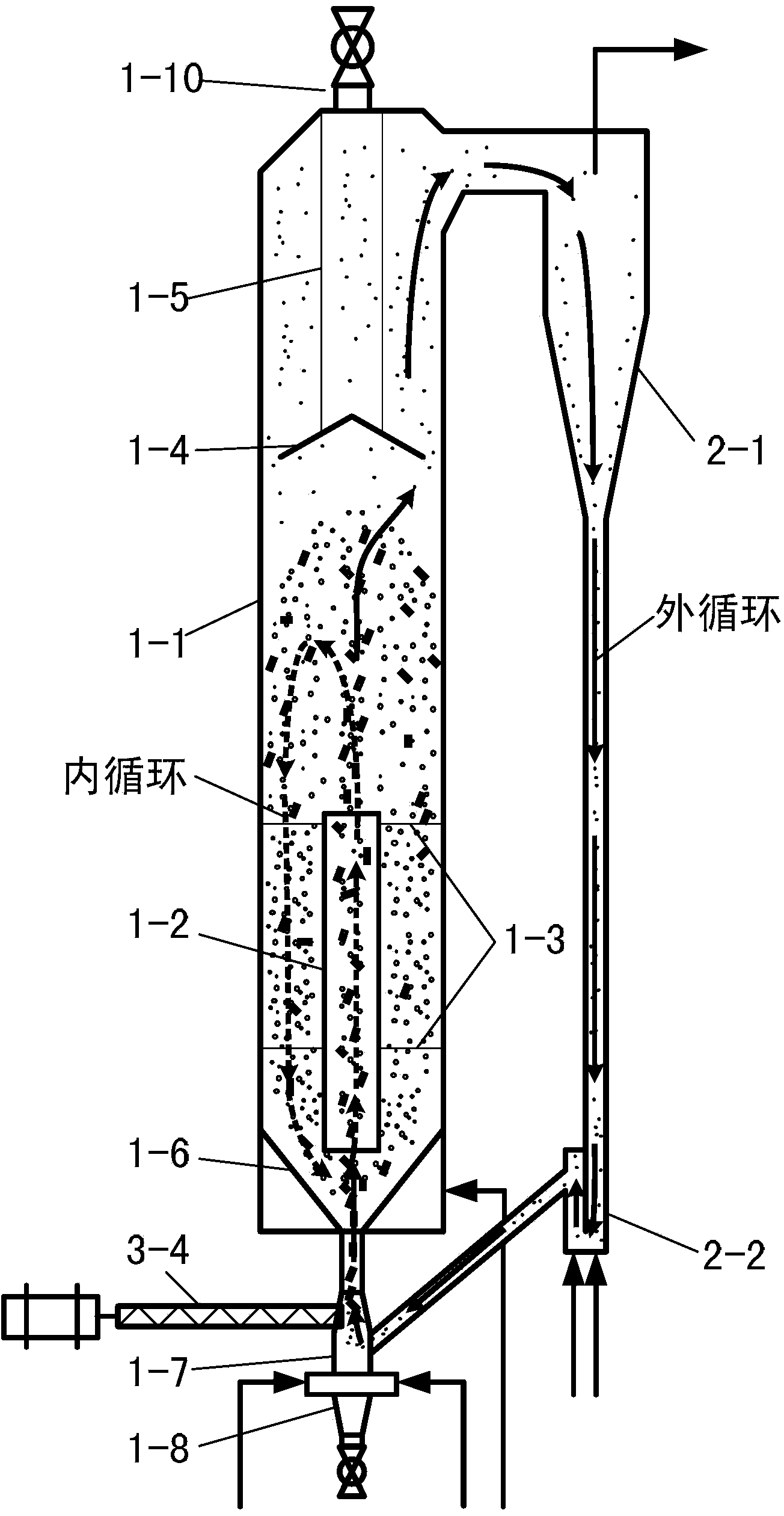

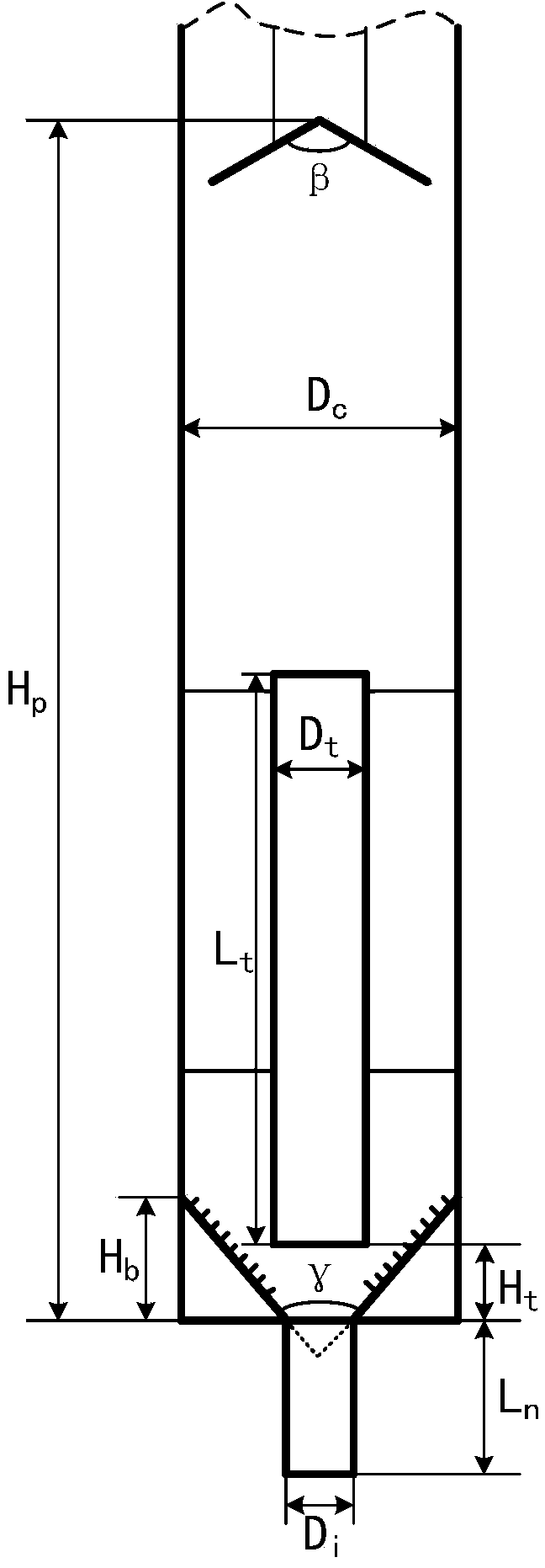

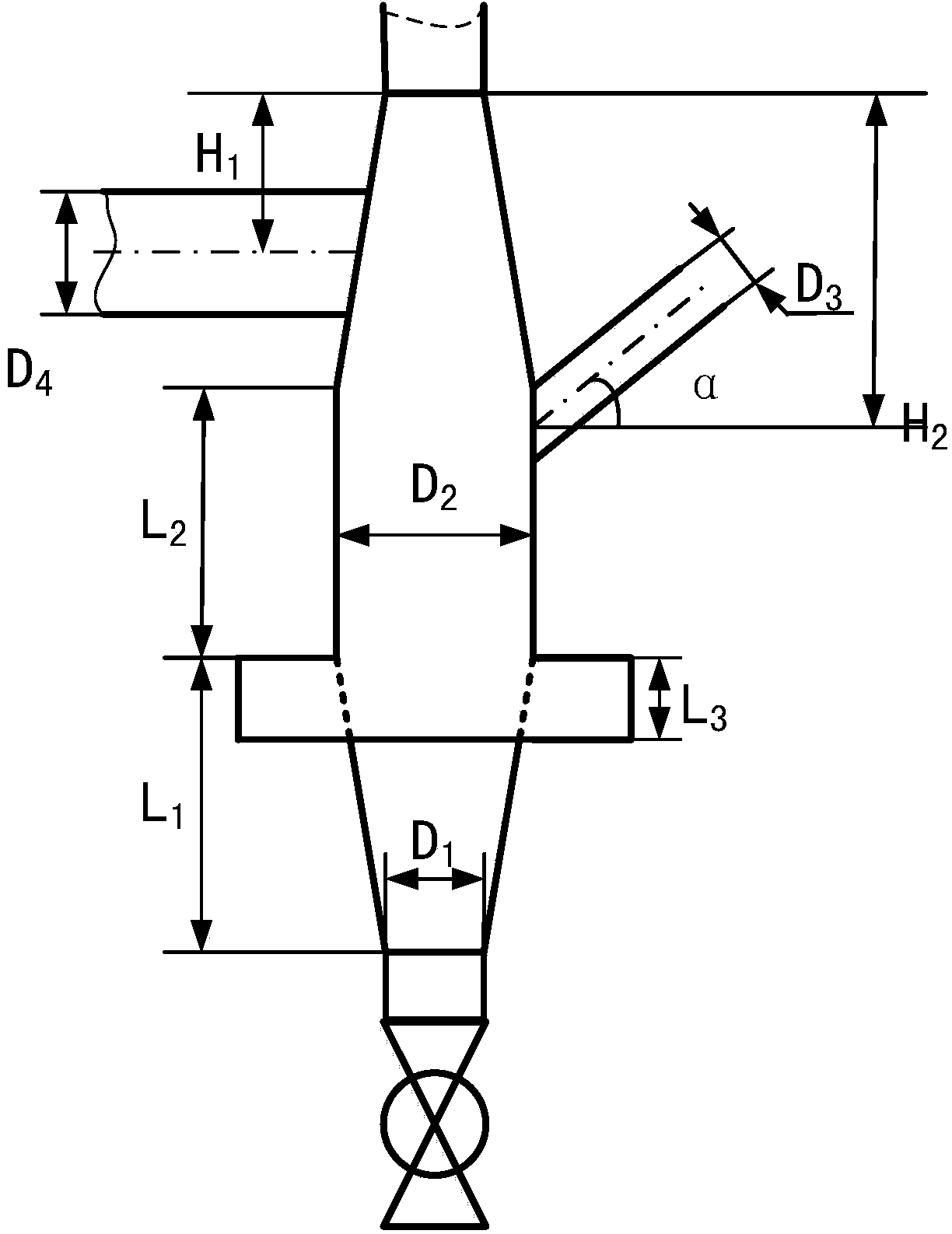

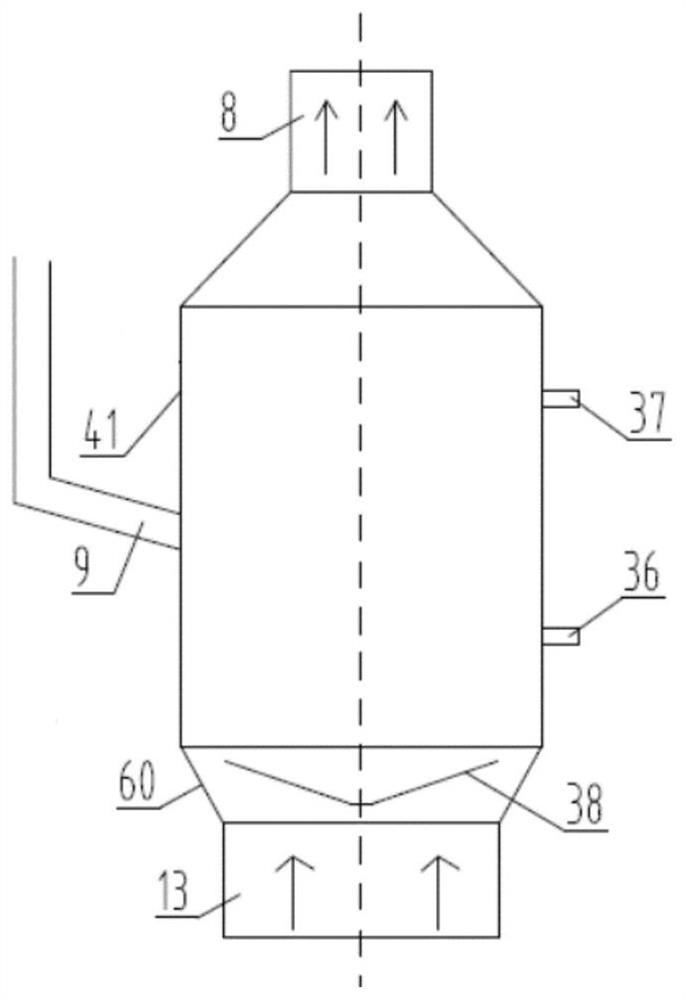

Biomass quick cracking device based on internal-external circulation spouted fluidized bed

ActiveCN103756712AShort stayGuaranteed dwell timeBiofuelsLiquid hydrocarbon mixture productionFluidized bedRetention time

The invention discloses a biomass quick cracking device based on an internal-external circulation spouted fluidized bed. The biomass particles are added through a bottom feeding chamber and conveyed into a pyrolysis reactor by spouted wind and generate a violet pyrolysis reaction through a guide pipe and a spouting area; the unreacted relatively large biomass particles form internal circulation along with a circulation medium through an annular space area; a catalyst and the unreacted tiny biomass particles are separated from the reaction area along with the pyrolysis gas and then return back into the bottom feeding chamber through a cyclone separator and a return feeder to form external circulation, and generate a pyrolysis reaction again. The device can perfectly meet the requirements of short gas phase retention time and sufficient solid phase reaction of the biomass pyrolysis technology, and the structure is simple and easy to enlarge; meanwhile, the external circulation of the catalyst particles and the early premixing and preheating thereof with the biomass particles in the bottom feeding chamber facilitate the direct efficient contact and sufficient mixing of the catalyst particles and the biomass particles, the utilization efficiency of the catalyst can be effectively improved, and the dosage of the catalyst is reduced.

Owner:SOUTHEAST UNIV

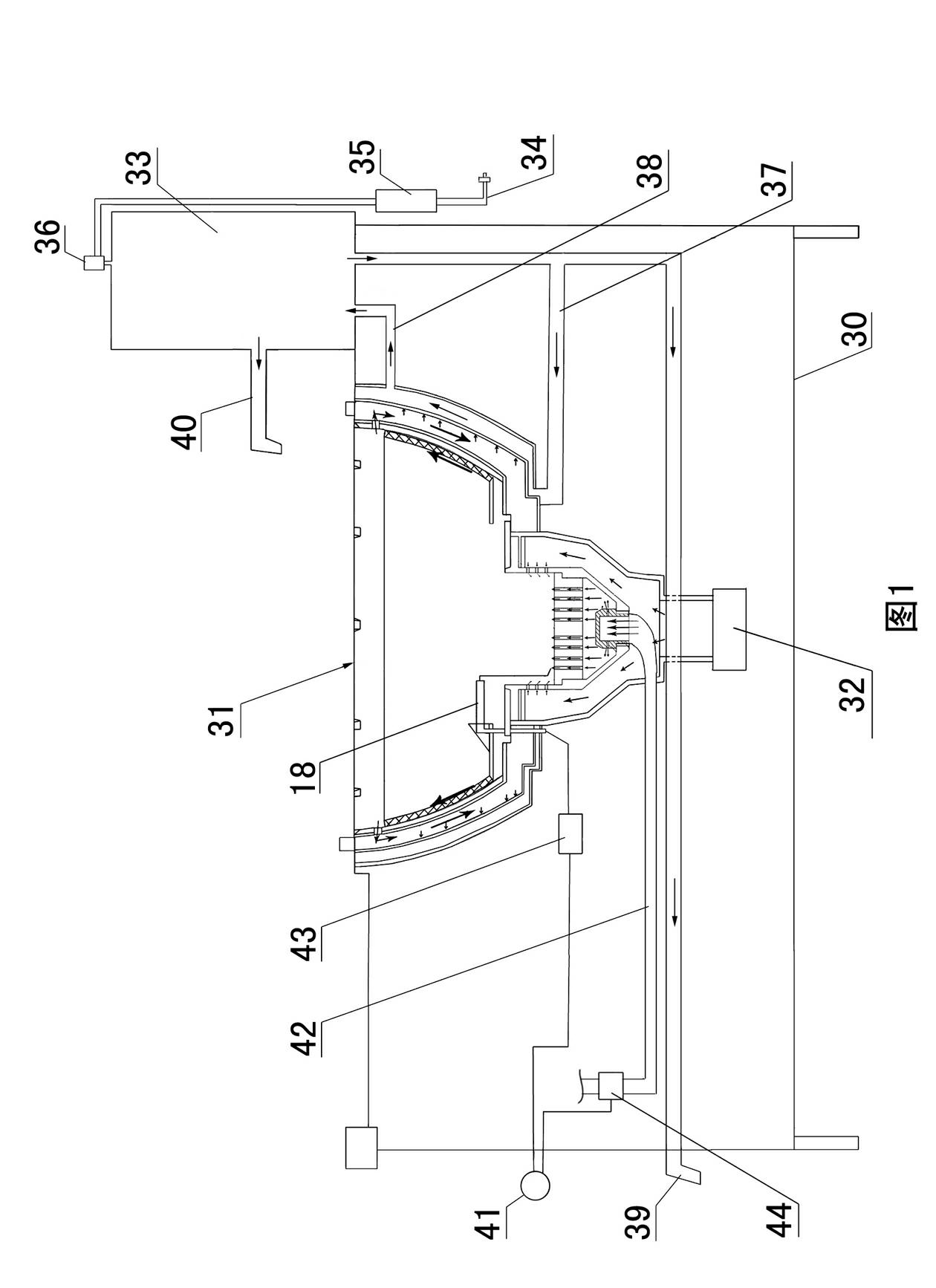

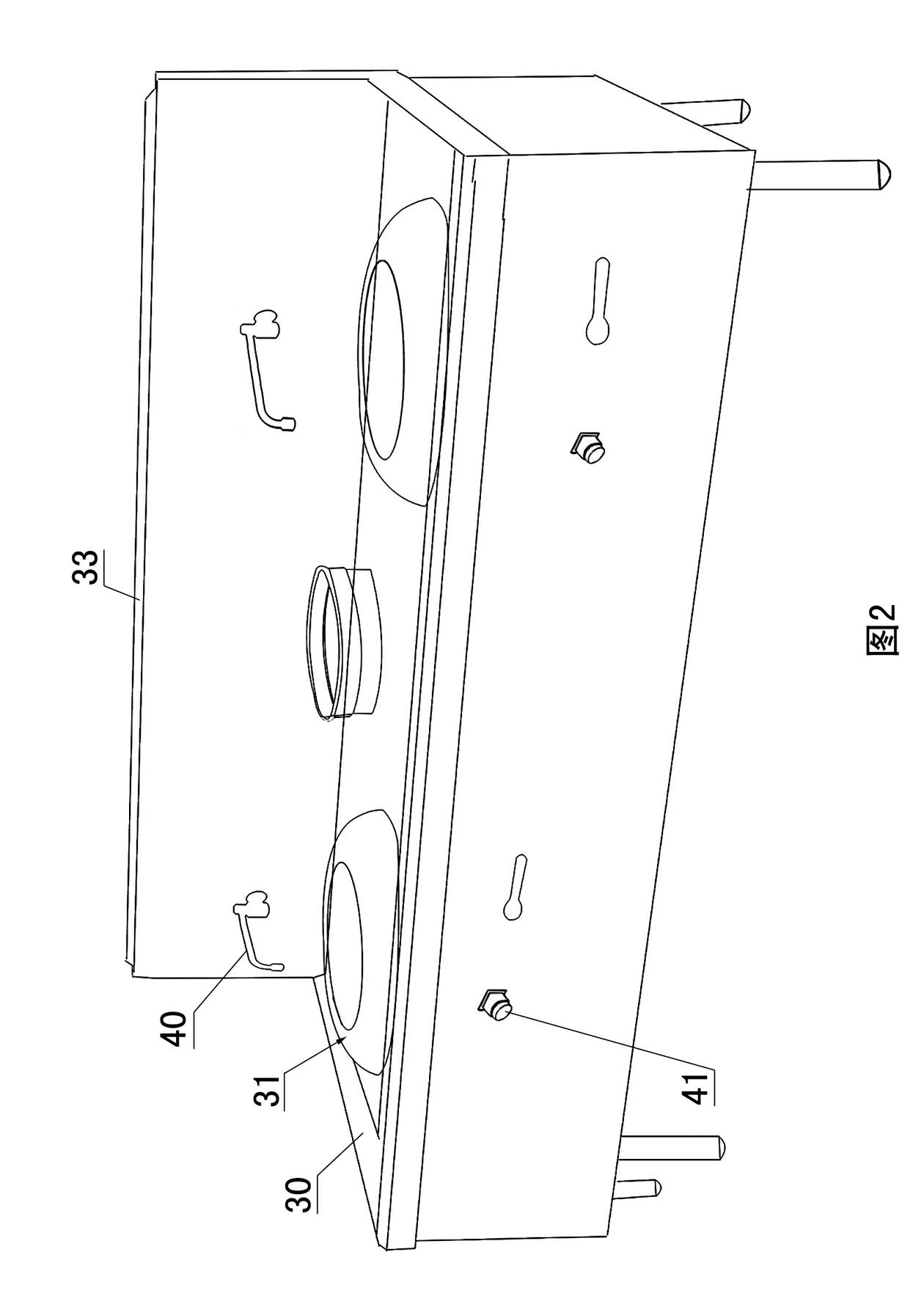

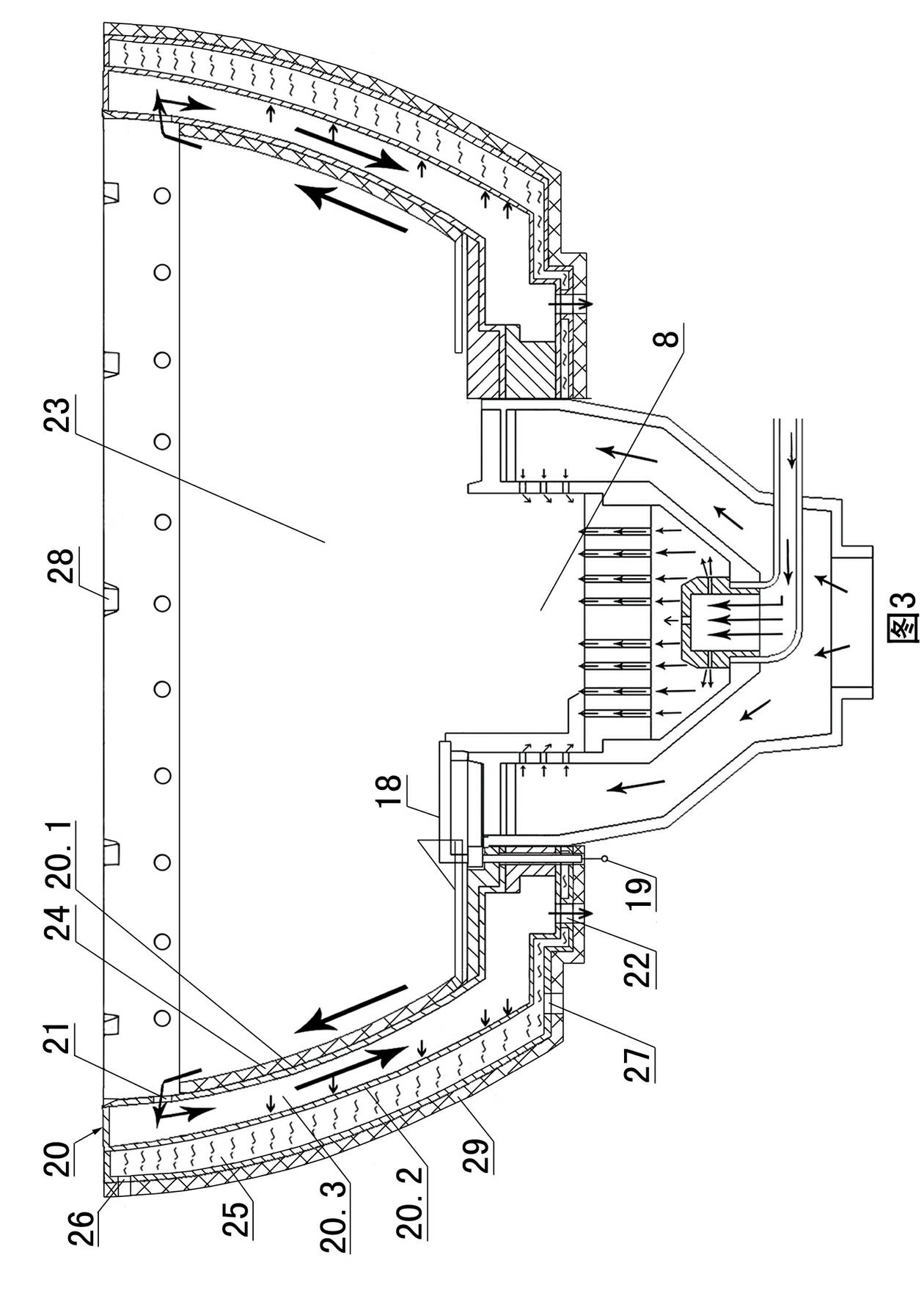

Collected heat type high efficient and energy-saving burning Chinese food frying-oven

InactiveCN102221228ATemperature does not dropSpeed will not decreaseWater heating stoves/rangesCooking fumes removalThermal energyCombustor

The invention relates to a collected heat type energy-saving burning Chinese food frying-oven which comprises a cooking stove and a burner assembly, a fan, a storage water tank, an electronic ignition device arranged on the cooking stove, wherein, the burner assembly comprises a burner and a hearth, the storage water tank is connected with a swing hot-water cock, the hearth comprises a side wall of the hearth and a waste heat collected jacket, the side wall of the hearth is of a hollow structure and comprises an inner side wall, an outer side wall and an air cavity clipped the inner side wall and the outer side wall, wherein, the upper part of the inner side wall is provided with a waste gas air hole which is communicated with the air cavity, the lower part of the outer side wall is provided with a waste gas air inlet which is communicated with the air cavity, the waste heat collected jacket is attached to the outer side surface tightly and is connected with the storage water tank to form a cycling water way through a water inlet and a return water pipe. The frying-oven has the advantages of energy-saving effect and high economic benefit, providing hot water to the kitchen, meanwhile, the frying-oven effective reduces the influence of the Chinese style frying-furnace on kitchen environment, and the capability of collecting the heat energy from hearth is greatly improved.

Owner:宫润涛

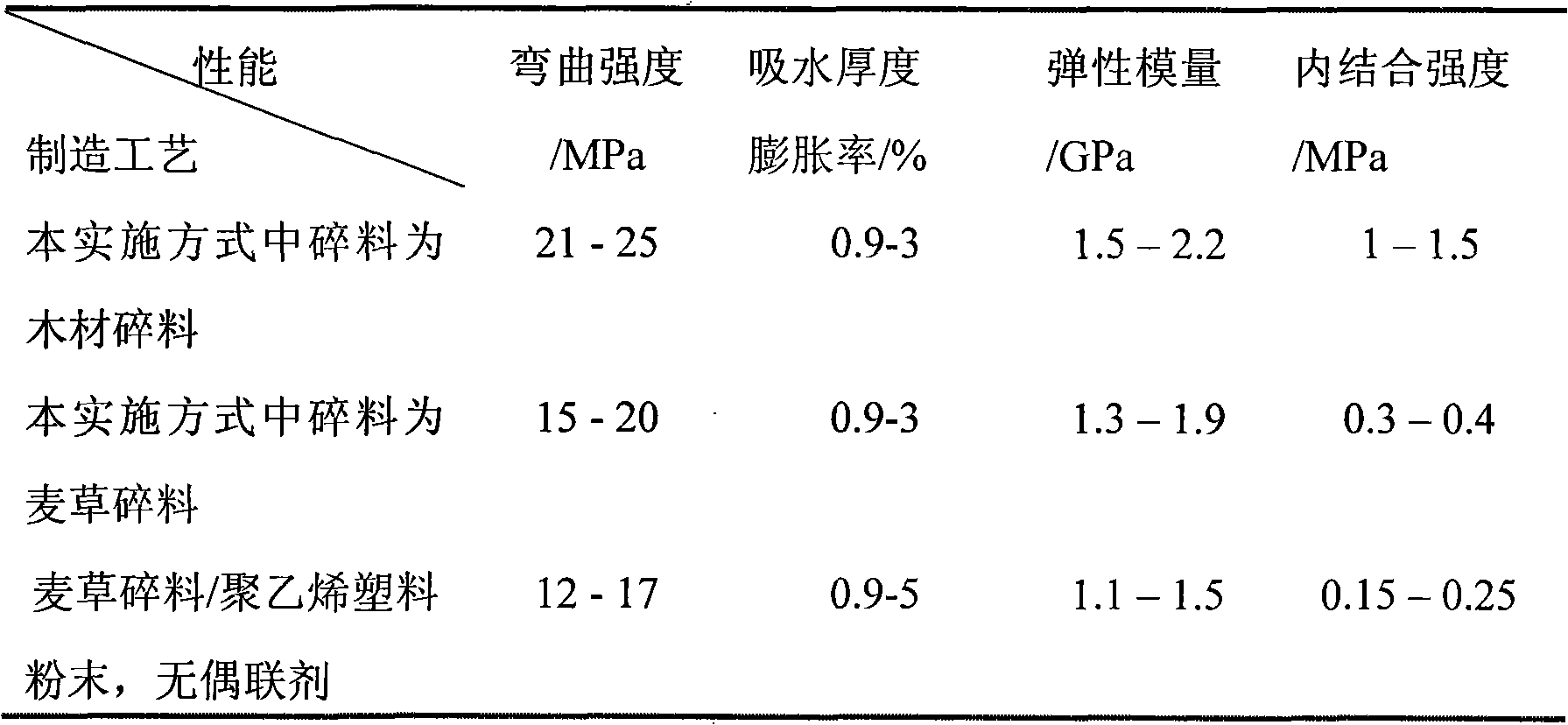

Heat pressing production method of polyethylene fiber-plant fibre compound material

InactiveCN101323130AShorten heating timeEasy to melt and transfer heatFlat articlesDomestic articlesFlexural strengthPlastic compounding

A heat pressing method for polyethylene plant fiber composite material relates to a method for manufacturing plant fiber material. The invention solves the problems that only fibril can be applied, plant format is narrower, straw is liable to thermolysis and charring and the mechanical properties of plant manufactured by pre-heat pressing are poor in the production of WPC in the manner of extraction. The method of the invention has the steps that: PE plastic fiber is mixed with crushed plant aggregates to obtain mixture that is paved into a plate base; the plate base is pre heated under a pressure of 1 to 3 MPa and at a temperature of 170 to 190 CEG D; the plate base is kept under a pressure of 4 to 6 MPa for 8 to 15mins; and at last, the plate base is cooled to 70 to 80 CEG D under a pressure of 3 to 6 MPa; and after pressure relief, the plank is obtained. The flexural strength of the plank manufactured in the method of the invention is 20 MPa. The invention adopts the polyethylene in fiber configuration and the crushed aggregates of the plant and the fiber is evenly mixed and has high productivity. In addition, the crushed aggregates of the plant and the fiber can be prevented from being deteriorated and darkened due to high temperature.

Owner:NORTHEAST FORESTRY UNIVERSITY

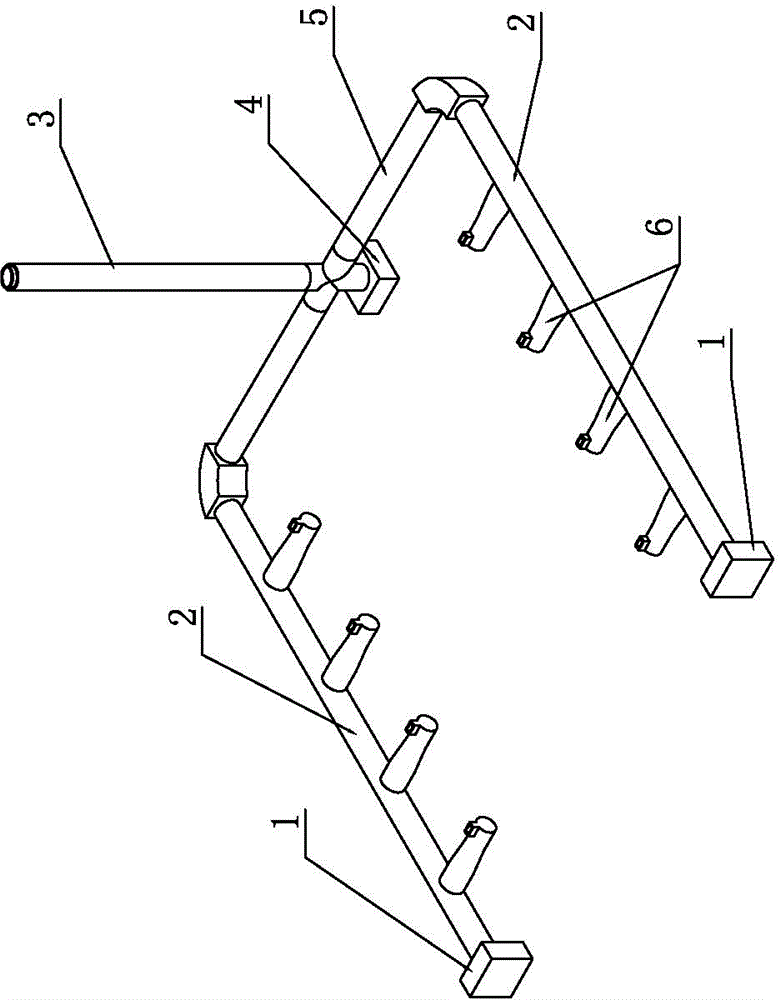

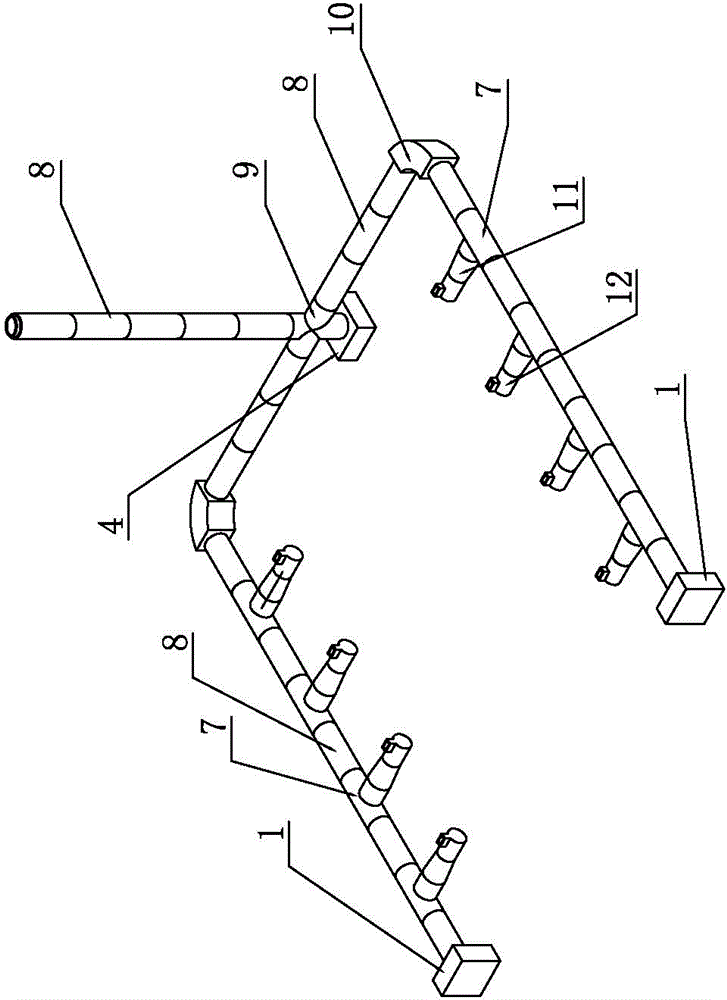

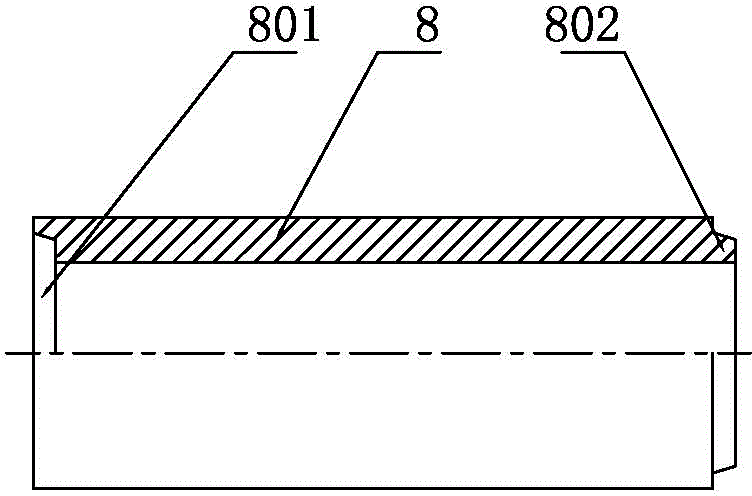

Ceramic casting system

ActiveCN103978158APurified hot metalEasy to manufactureFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a ceramic casting system in the technical field of casting. A sprue, a cross gate and an ingate of the ceramic casting system are obtained by connection of several equal-diameter straight pipes, a fourway pipe, elbow pipes, variable-diameter straight pipes, t-branch pipes and flat mouth pipes made of a ceramic material. The sprue and the inlet section of the cross gate are obtained by connection of the equal-diameter straight pipes. The upward opening of the fourway pipe is connected to a lower end of the sprue. Two side openings of the fourway pipe are connected to one end of the inlet section of the cross gate. The elbow pipes are connected between the inlet section and an outlet section of the cross gate. The outlet section of the cross gate is obtained by connection of the equal-diameter straight pipes and the t-branch pipes. The equal-diameter straight pipes are connected to straight-through openings of the t-branch pipes. The ingate is obtained by connection of the variable-diameter straight pipes and the flat mouth pipes. Large-diameter ends of the variable-diameter straight pipes are connected to side openings of the t-branch pipes and each one of small-diameter ends of the variable-diameter straight pipes is connected to an end of the corresponding flat mouth pipe. Sides of the flat mouth pipes are provided with rectangular outlets communicated with a casting cavity. The ceramic casting system solves the problem of sand washing of the existing casting system in large-scale part casting, improves casting quality and is suitable for large-scale part casting.

Owner:KOCEL EQUIP

Engine-cooling system

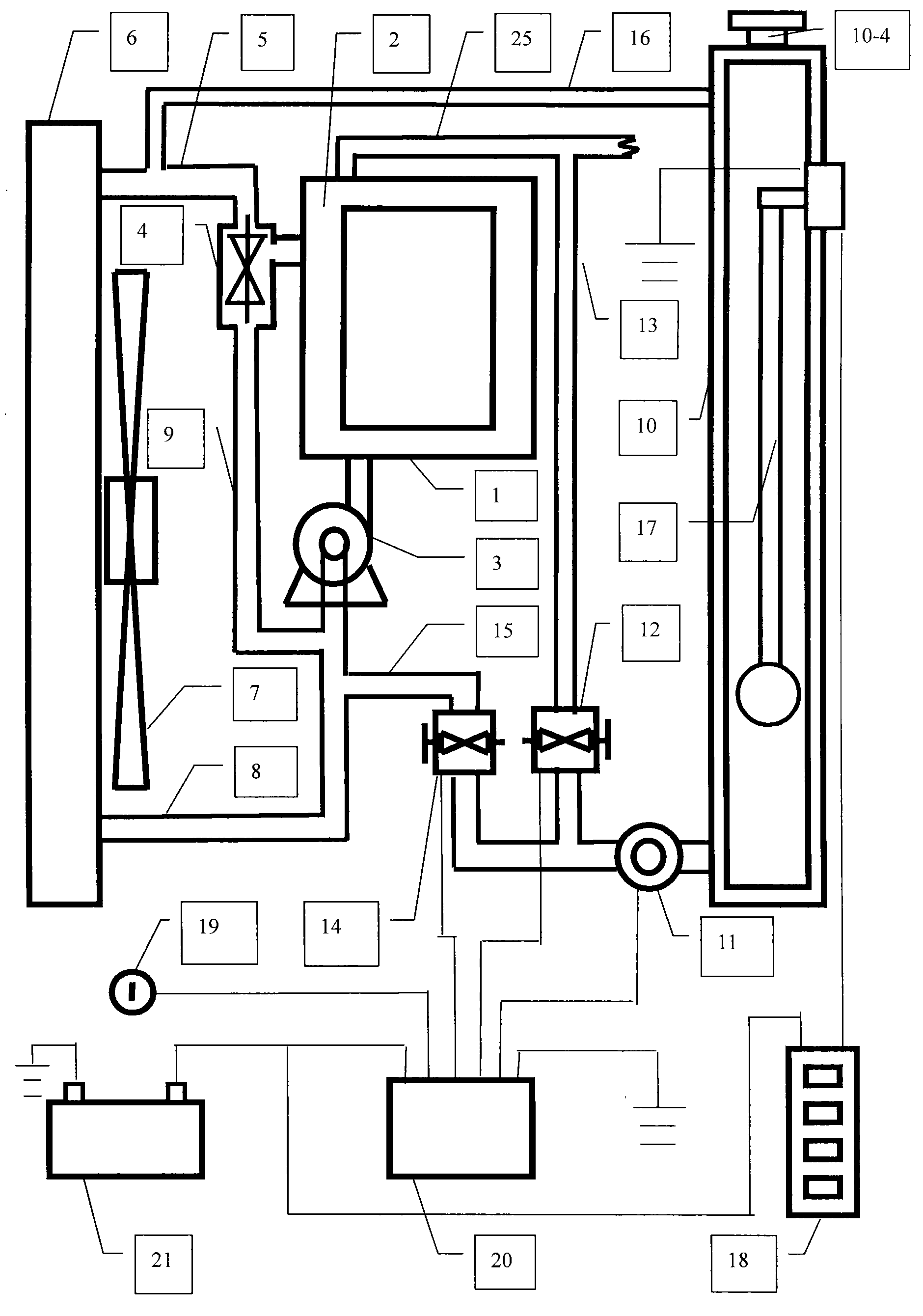

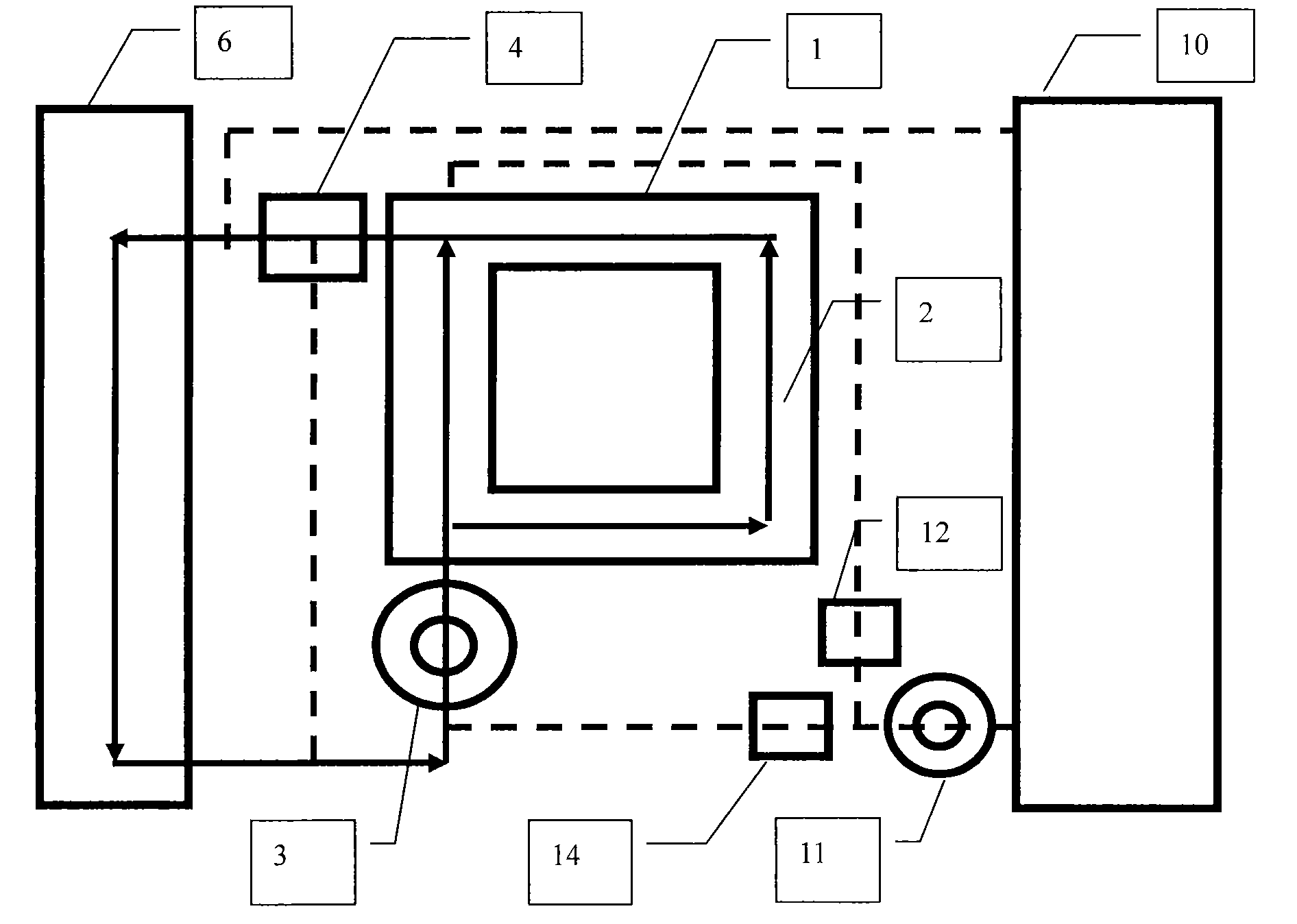

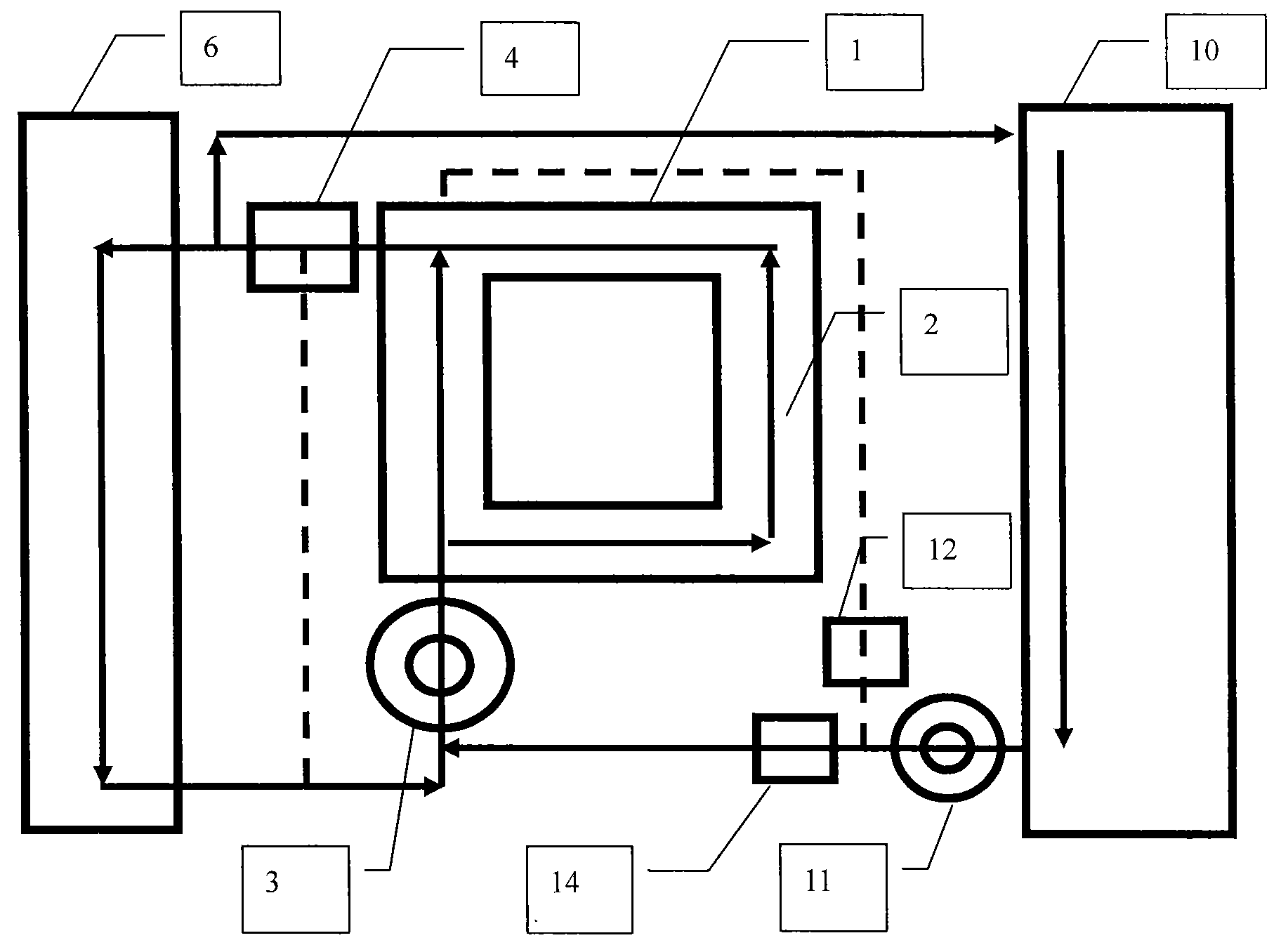

InactiveCN101598061APromote warm-upAvoid wastingCoolant flow controlMachines/enginesStopped workExternal energy

The invention relates to an engine-cooling system comprising a radiation branch and a heat preservation branch. The heat preservation branch comprises a heat preservation water tank, a bidirectional electric water pump, a pumping electromagnetic valve, an affusion electromagnetic valve, a pumping pipe, an affusion pipe, a backwater aeration pipe, a water quantity display, a water quantity displaysensor, a central controller, and the like, can preserve the heat of cooling liquid preserved in the heat preservation water tank when water in an engine reaches a normal temperature and full draws the high-temperature cooling liquid in the engine to the heat preservation water tank for preserving heat when the engine stops working so that the high-temperature cooling liquid in the heat preservation water tank preheats the engine when the engine is started up next time. The cooling system enables the cold-startup engine in an ideal temperature without external energy, effectively solves the problems of startup difficulties caused by the lower temperature of the engine, severe emission pollution, fuel waste, severe part abrasion, and the like and avoids causing energy waste during using the external energy for preheating.

Owner:刘传鹏

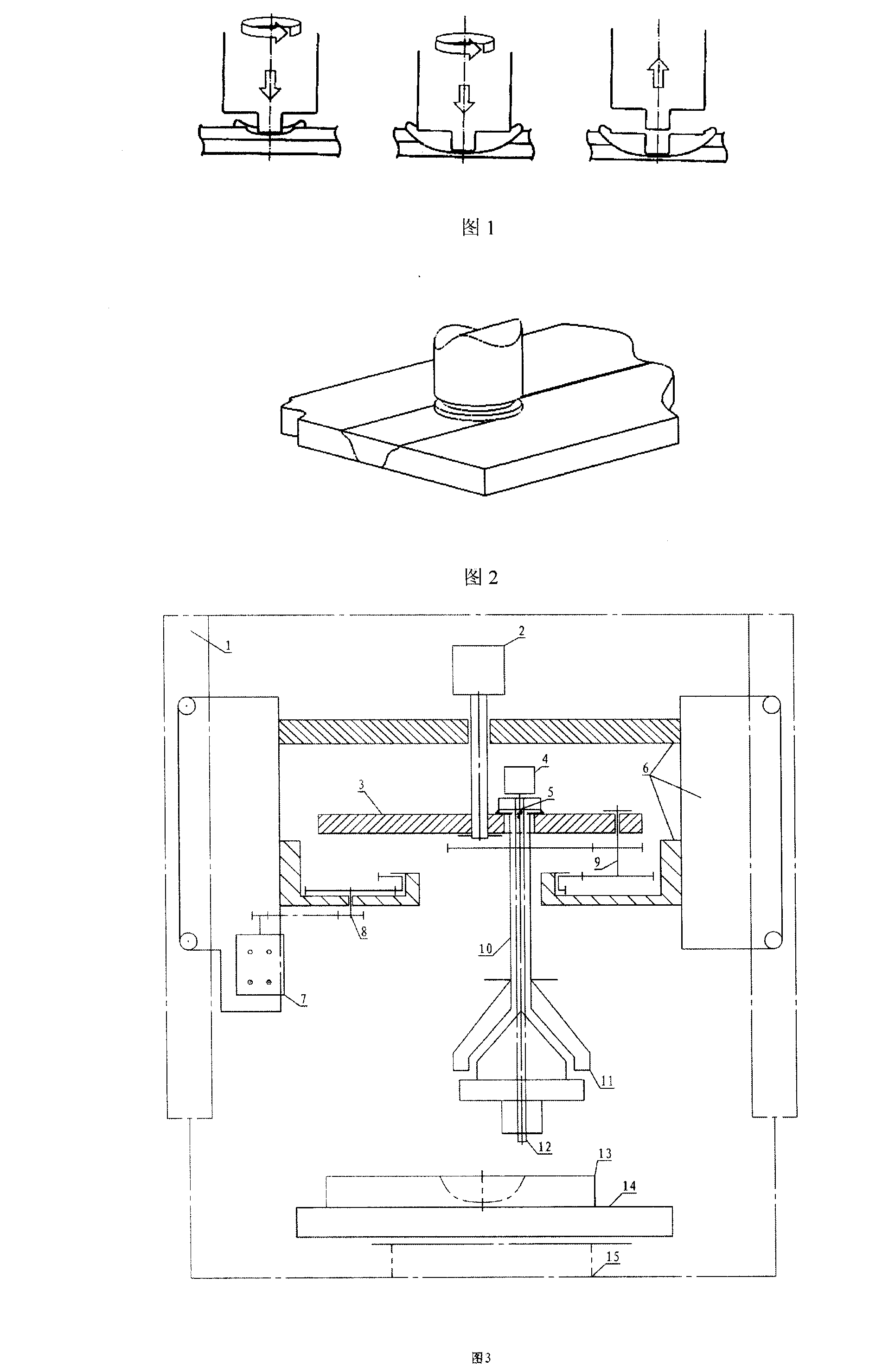

Double helix circumduction stirring friction free key hole spot welding method and device

InactiveCN101200021AImprove welding qualityIncreased shear strengthNon-electric welding apparatusLow speedGear system

Disclosed is a spot welding method without spoon hole and a device for double spiral circumduction stirring friction. A fixed mount of the device is arranged on a vertical elevating guide rail of the machine tool; a high speed driving motor, a low speed driving motor, a main driving transmission mechanism and a planetary gear system are all arranged on the fixed mount; the high speed driving motor is connected with the main driving transmission mechanism which is connected with the planetary gear system; the low speed driving servo motor arranged on the fixed mount is connected with the central axis of the eccentric wheel which is equipped with a stirring shaft; the stirring shaft is connected with the flexing servo motor through a flexing mechanism; a clamp head is arranged below the stirring shaft whose bottom end is equipped with a stirring friction tool head; the centre of the stirring friction tool head is equipped with a flexible friction stirring pin; the planetary gear system shaft is connected with an eccentric wheel; using the device to carry out spot welding can has a relative large welding zone; the welding quality is good, the surface of the welding spot has no defect of spoon hole; the shear strength and the tensile strength of the welding spot is high.

Owner:谢里阳

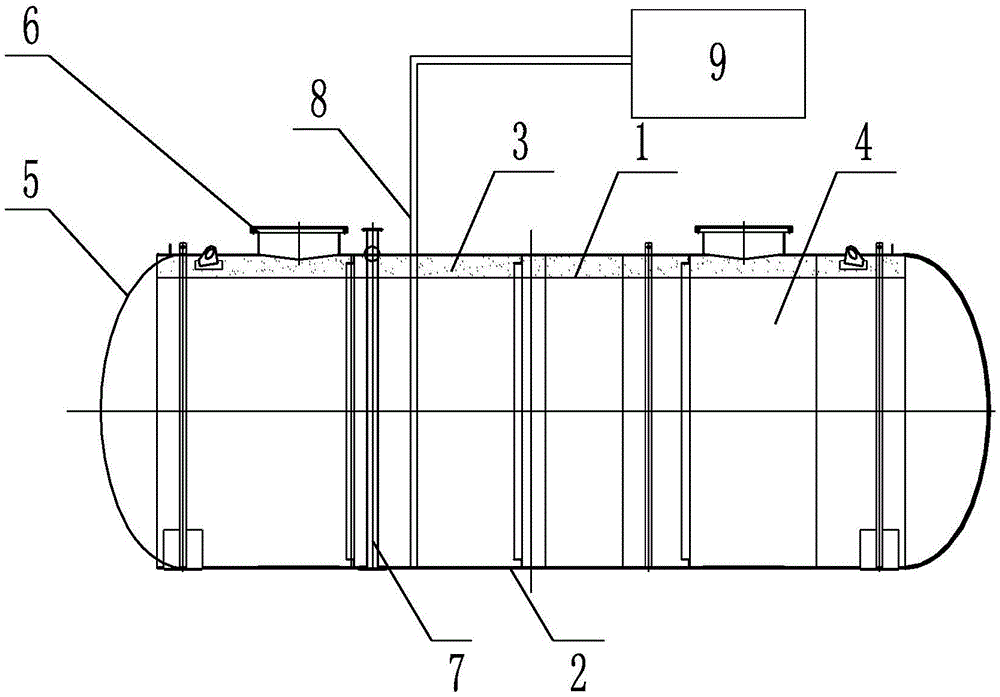

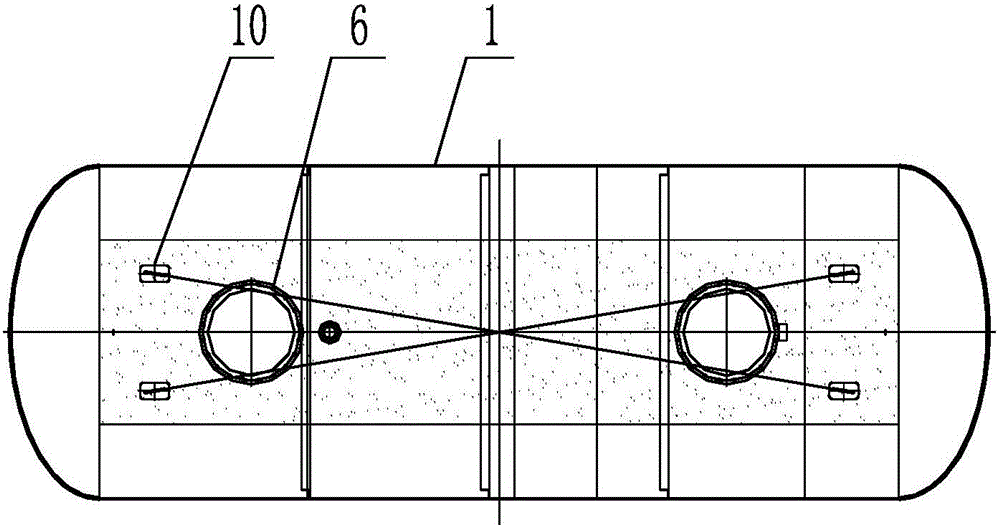

Underground double-layered oil tank and preparation method thereof

InactiveCN106628698ALess investmentLow investment costMeasurement of fluid loss/gain rateLarge containersControl roomRemote communication

The invention relates to an underground double-layered oil tank and a preparation method thereof and provides the underground double-layered oil tank and the preparation method thereof. The underground double-layered oil tank comprises an inner-layer steel tank and a housing, wherein a vacuum interlayer is formed between the inner-layer steel tank and the housing; a detection device for detecting the liquid leakage of the inner-layer steel tank and the housing is arranged in the vacuum interlayer; and the detection device is in remote-communication connection with a control room. The underground double-layered oil tank and the preparation method thereof have the advantages of simple structure, convenience in preparation, low production and maintenance cost, high automation degree, safe and reliable operation, short preparation period and the like, and is conductive to environmental protection.

Owner:CNPC BOHAI EQUIP MFG

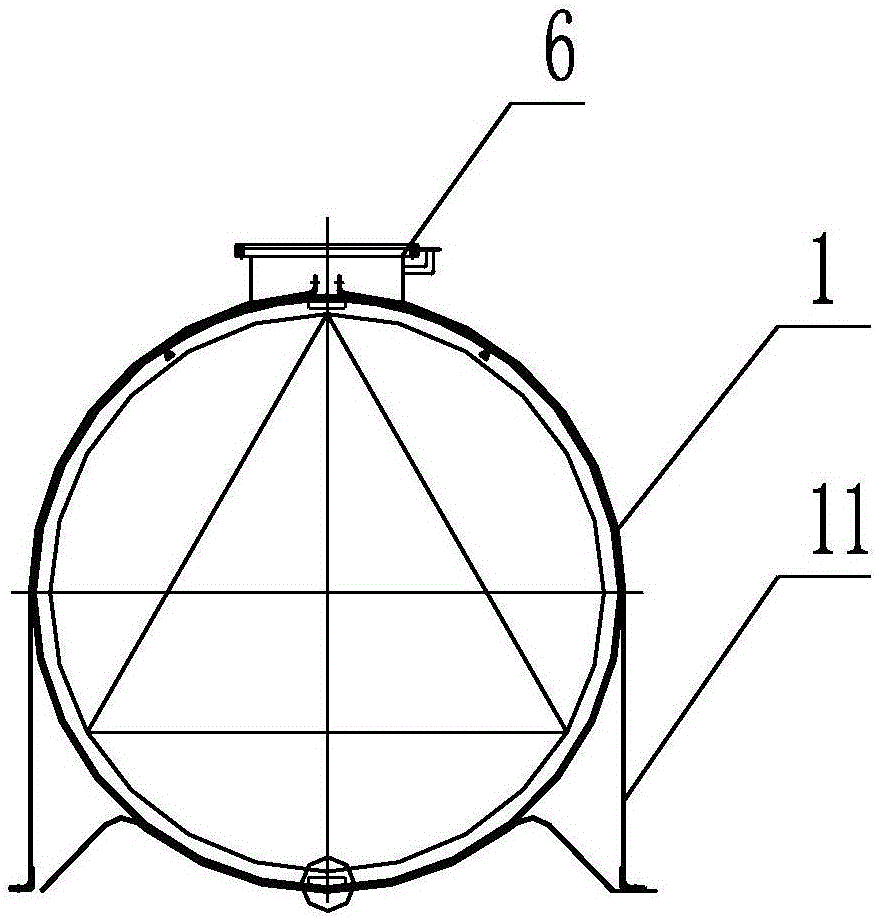

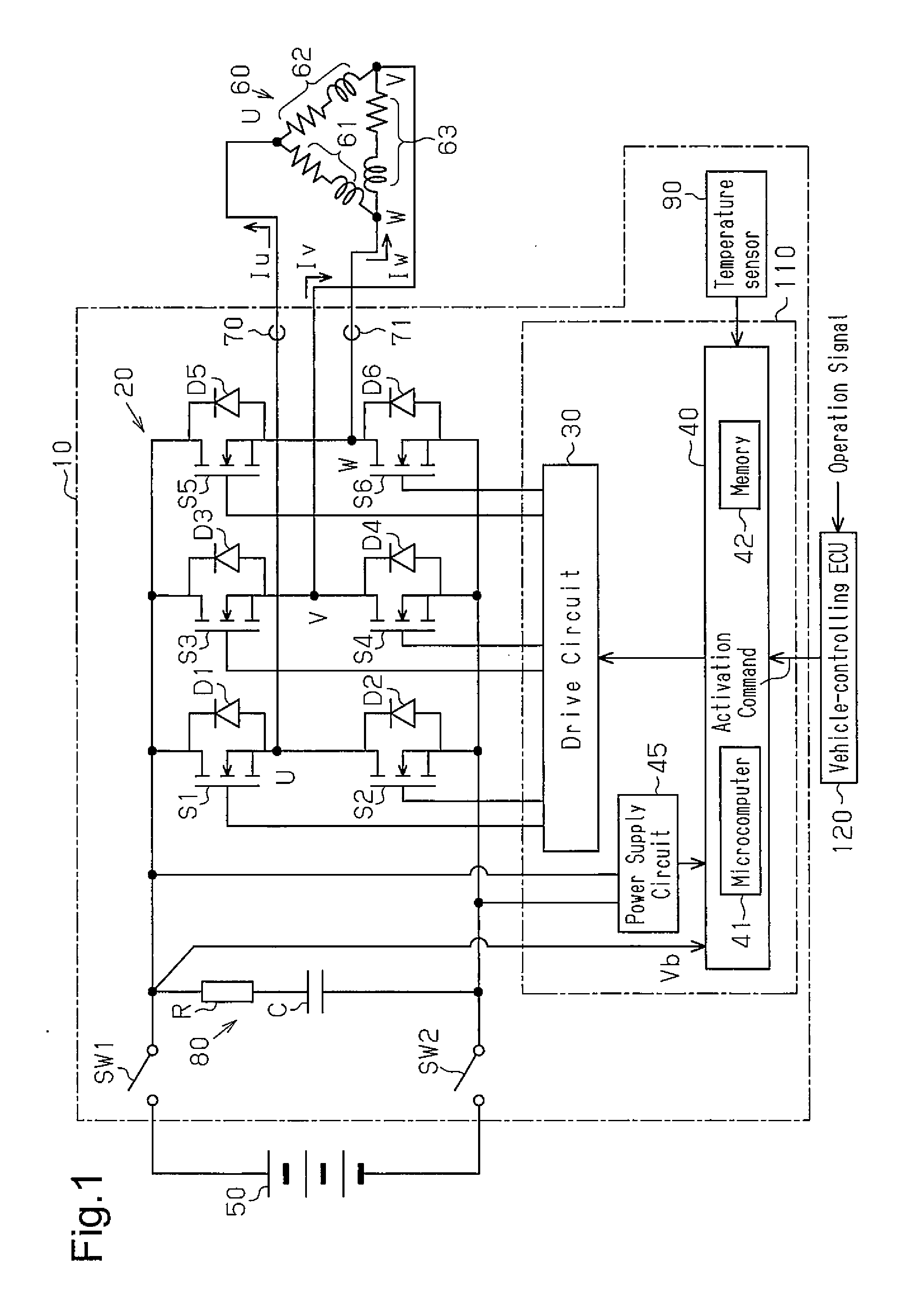

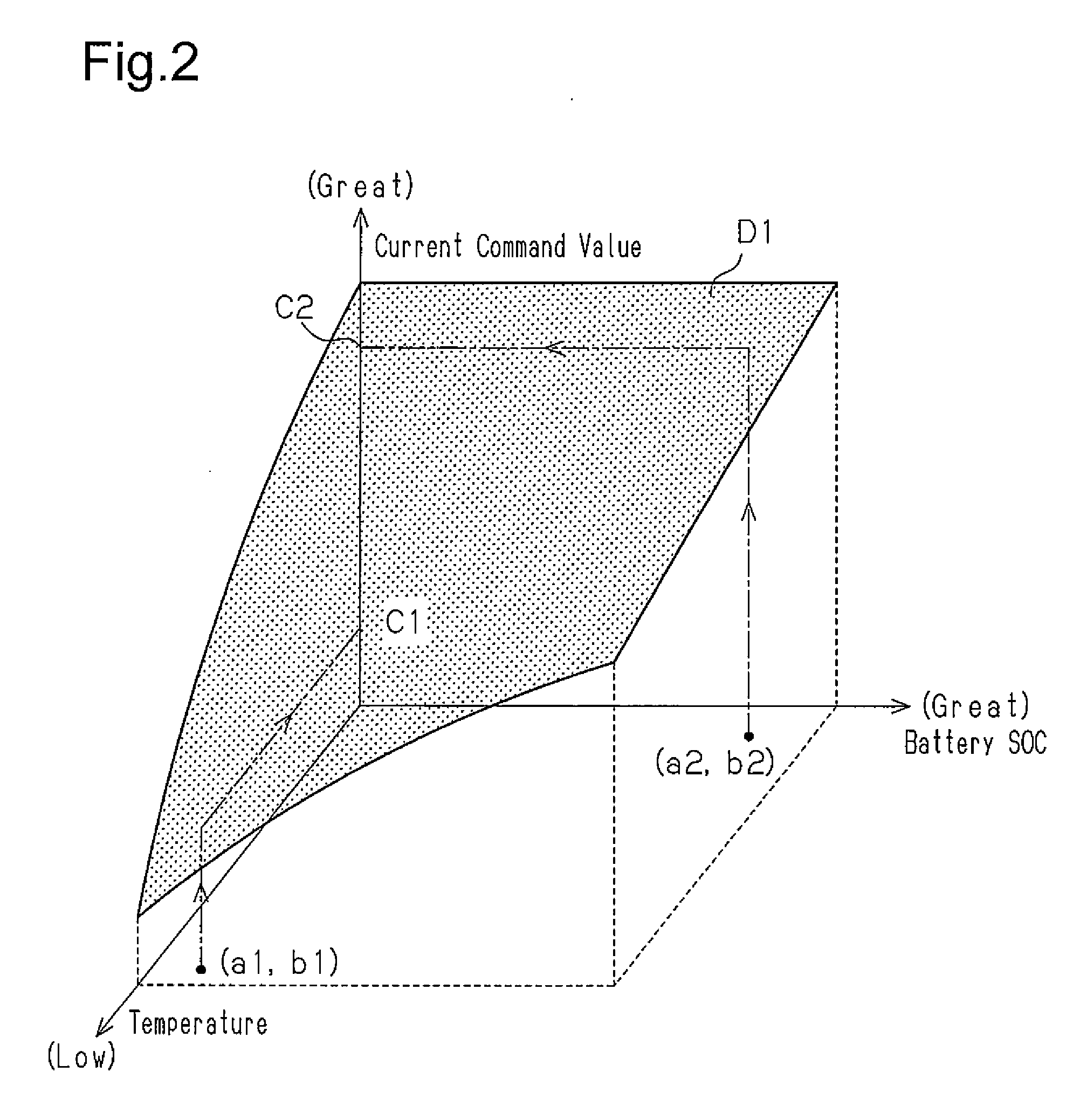

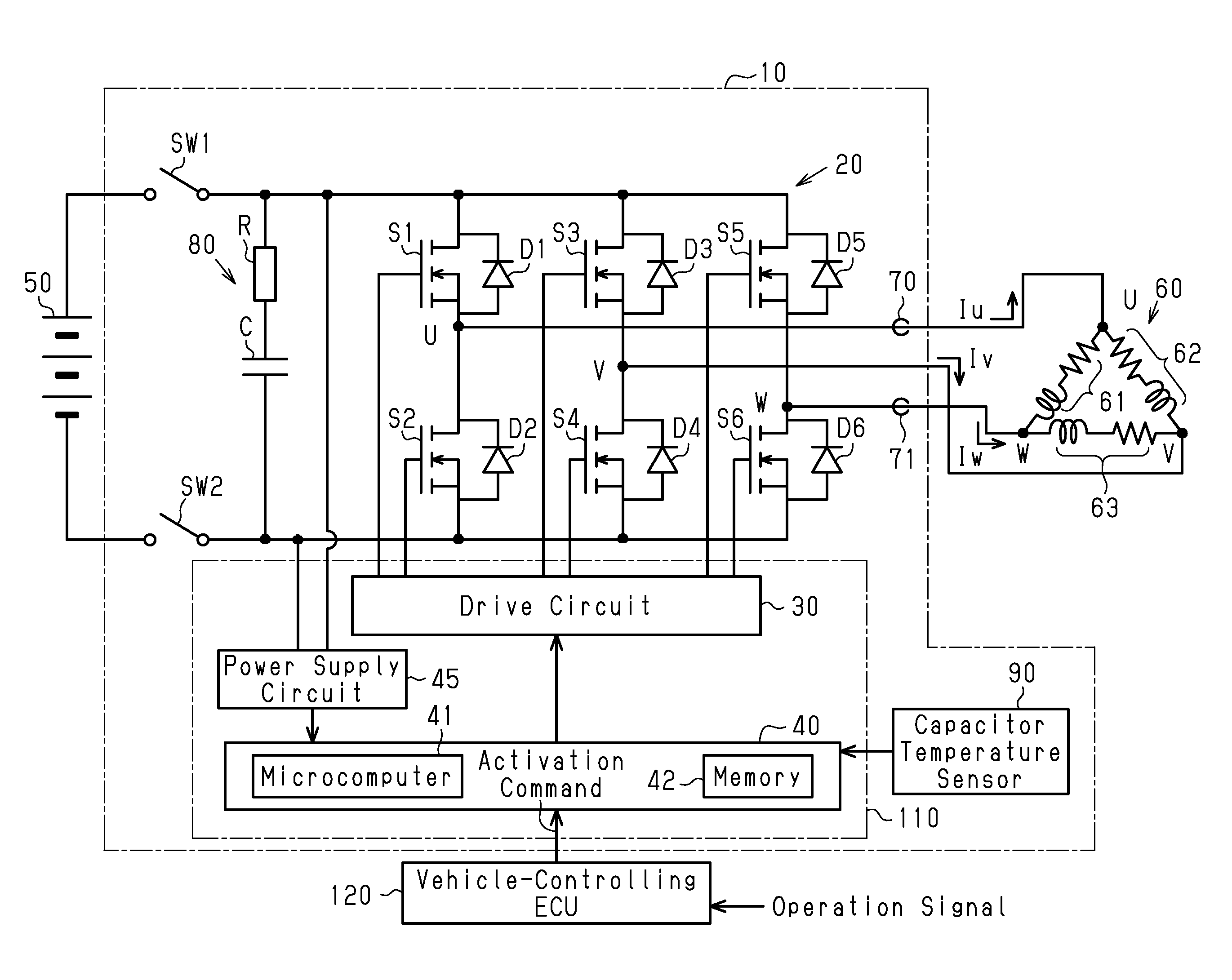

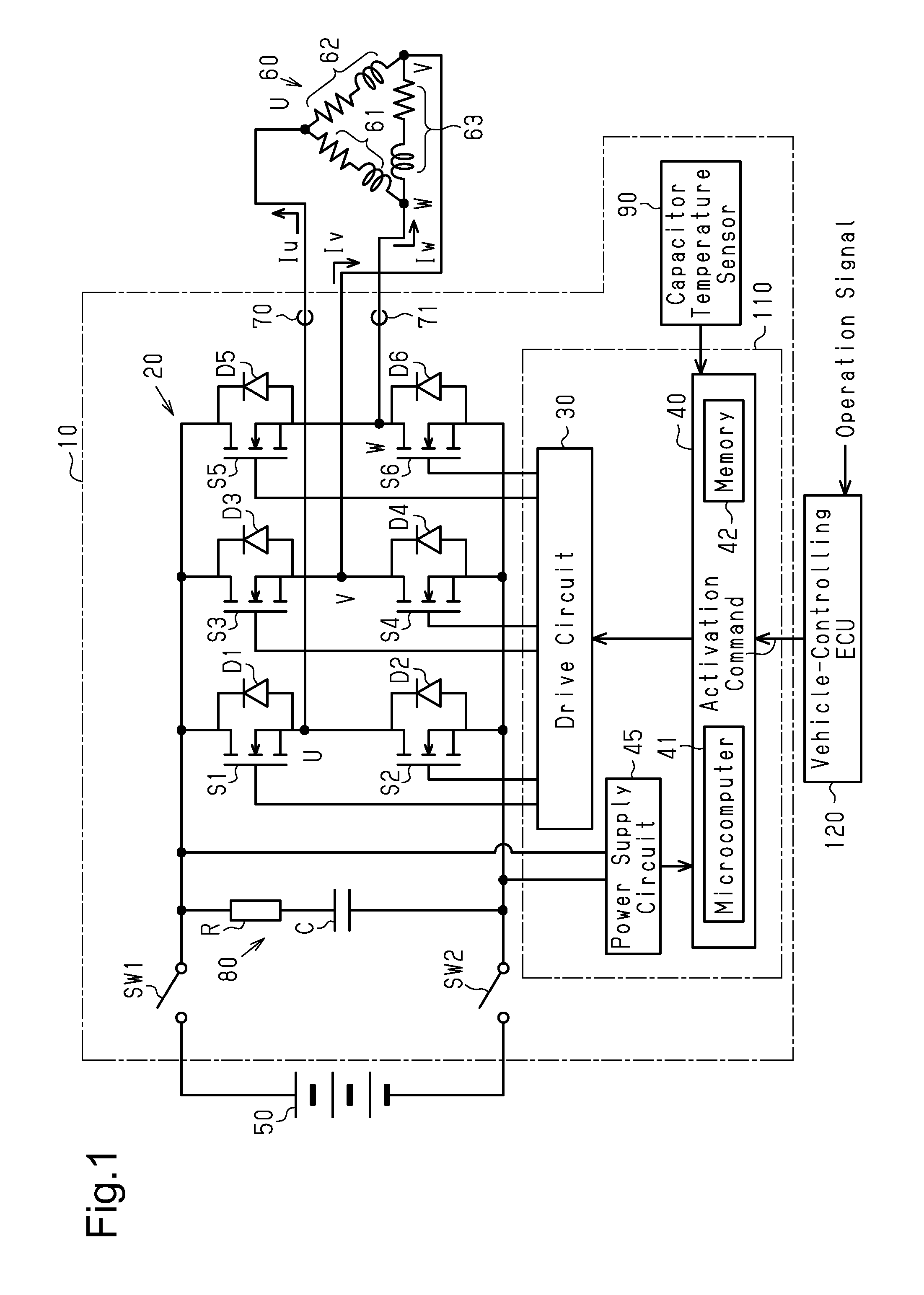

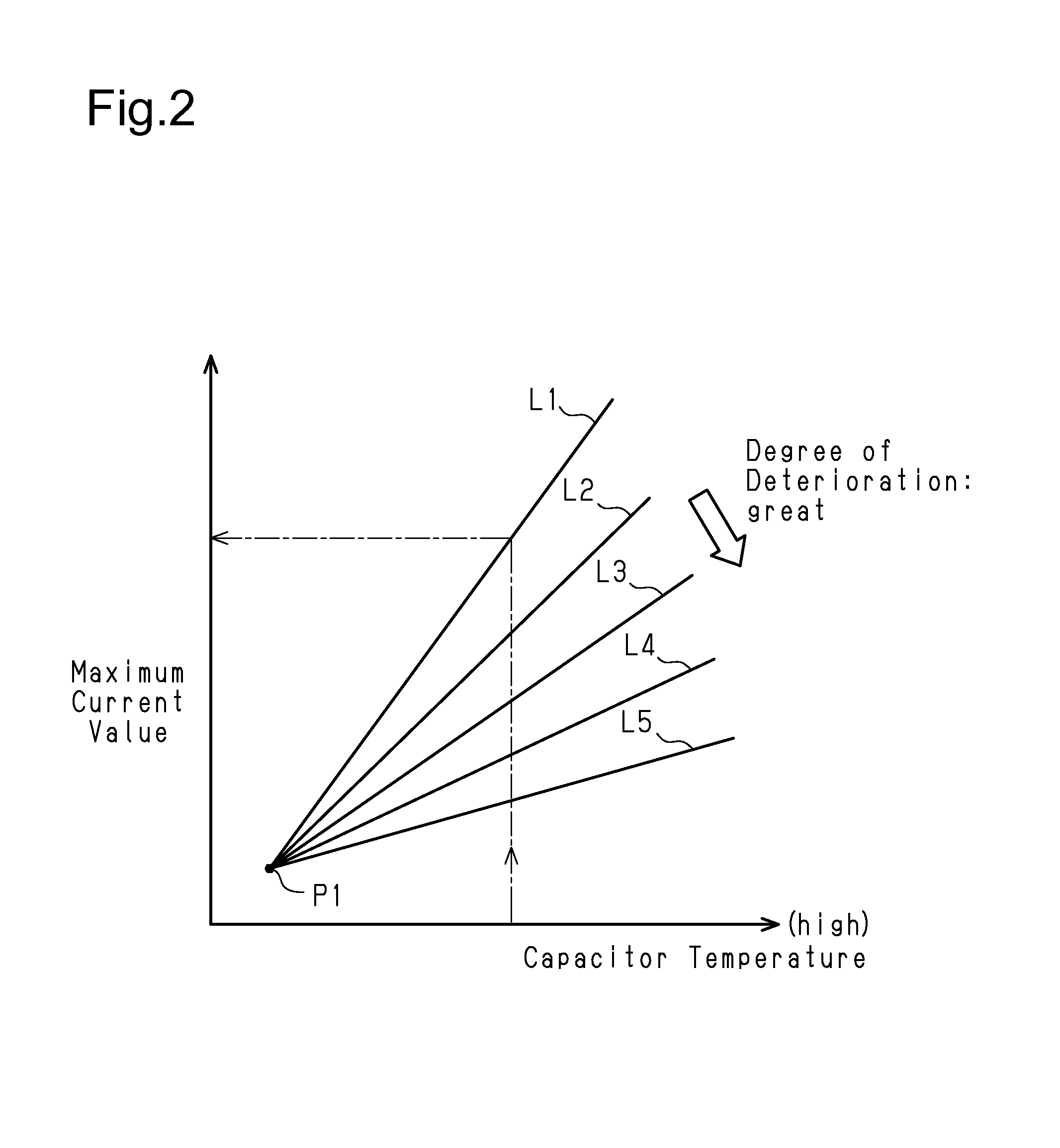

Inverter device

InactiveUS20150295514A1Voltage drop amount is undesirablyIncreasing resistance of batteryAC motor controlConversion with intermediate conversion to dcPower inverterBattery charge

An inverter device includes an inverter circuit, which has switching elements in a bridge connection, a capacitor, which is connected in parallel to the input side of the inverter circuit, a temperature detector, which detects the temperature of the capacitor, a battery charge information acquisition section, which acquires charge information related to a battery connected to the input side of the inverter circuit, and a warm-up controller. When the temperature of the capacitor detected by the temperature detector is lower than a prescribed temperature, the warm-up controller determines a warm-up current based on the battery charge information acquired by the battery charge information acquisition section and the temperature of the capacitor detected by the temperature detector, and controls the switching elements of the inverter circuit to supply the warm-up current to the coil of an electric motor connected to the output side of the inverter circuit.

Owner:TOYOTA IND CORP

Idling control device for vehicle

ActiveUS20130204478A1Exhaust rise temperature effect becomes higherReduce controlElectrical controlInternal combustion piston enginesBattery state of chargeBattery charge

An idling revolution speed control which maintains an engine speed at a predetermined target idling revolution speed during the idling drive includes an engine idling mode which performs the idling revolution speed control through an engine and a motor idling mode which performs the idling revolution speed control through a motor. The two modes are switched in accordance with a battery charged state. During the to idling drive in an engine cold state, an ignition timing of the engine in the motor idling mode is retarded and the retardation quantities R3, R4 are expanded to be larger than the retardation quantities R1, R2 in the engine idling mode. Thus, a rise in an exhaust temperature of the engine is promoted.

Owner:NISSAN MOTOR CO LTD

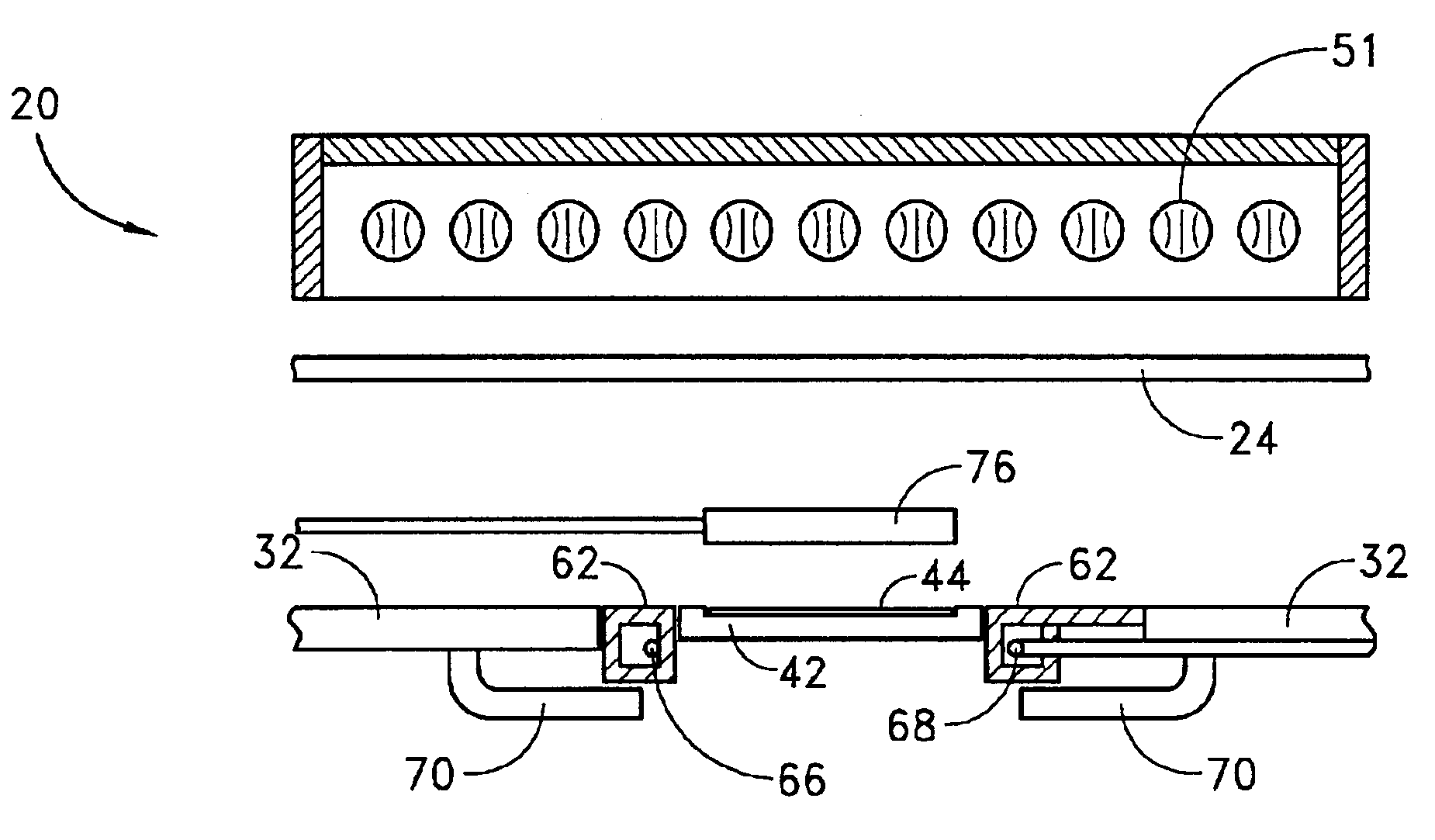

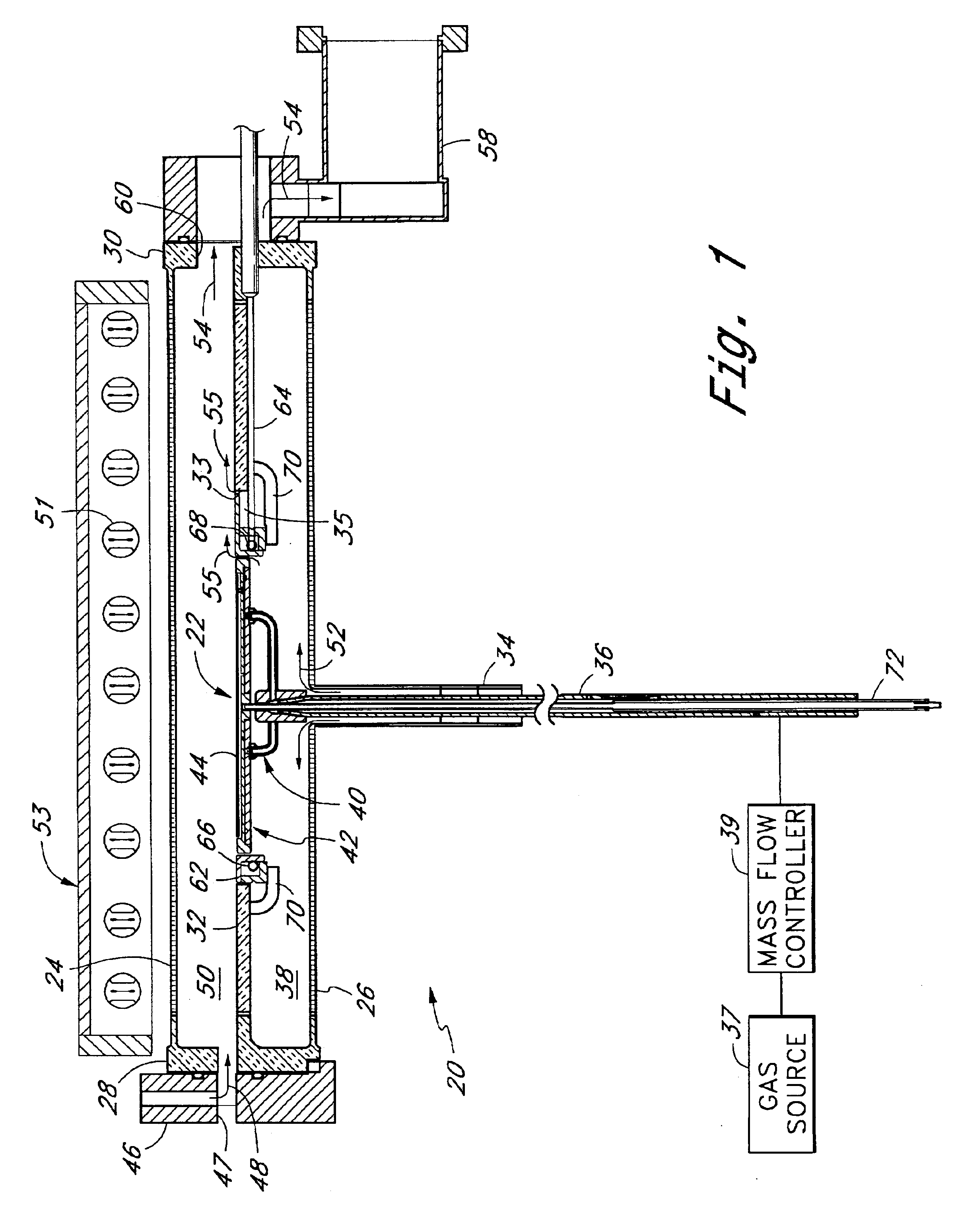

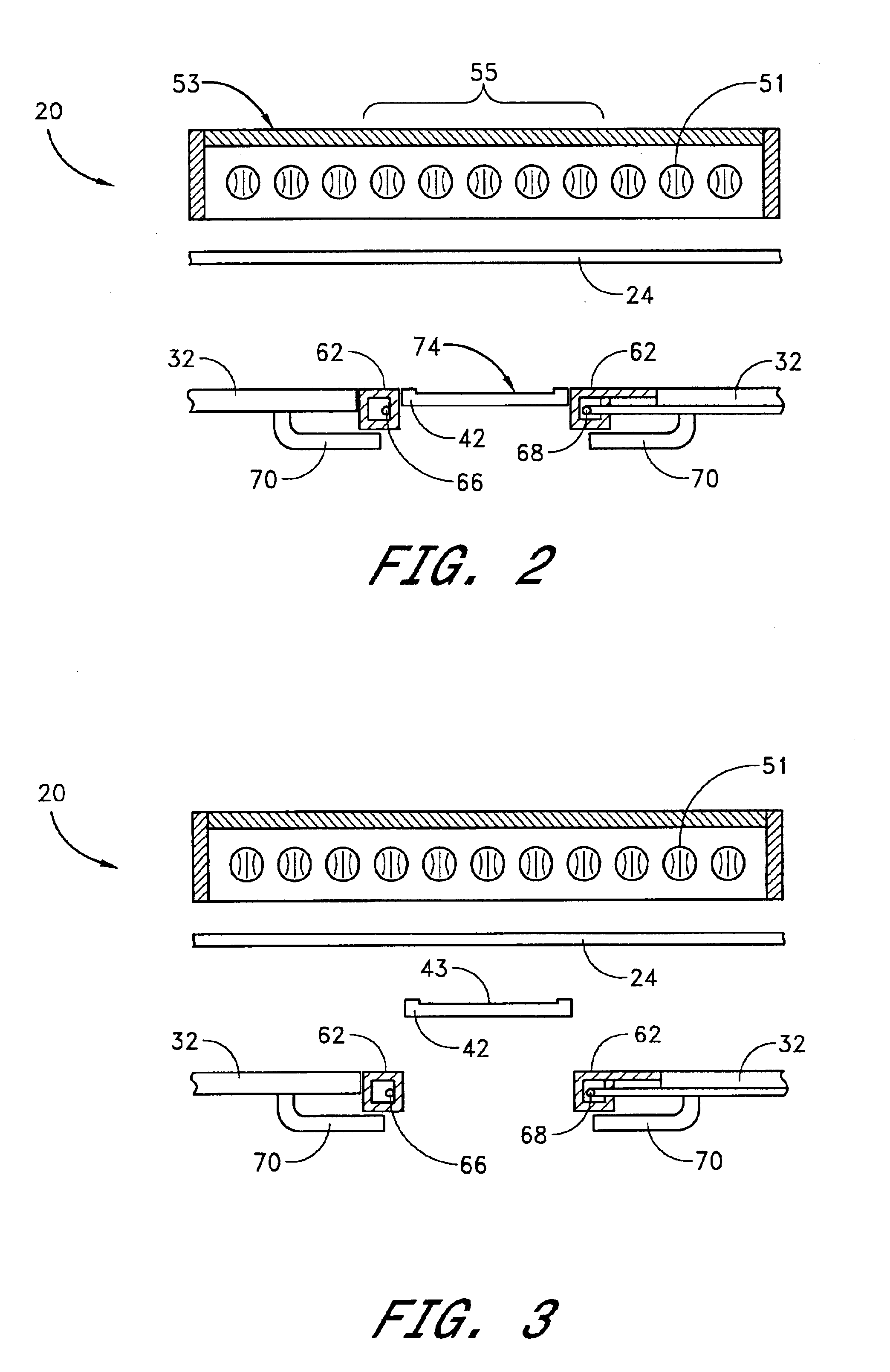

Method of loading a wafer onto a wafer holder to reduce thermal shock

InactiveUS6861321B2Reduce the possibilityGreat gradientSemiconductor/solid-state device manufacturingCharge manipulationEngineeringThermal shock

One or more of three different measures are taken to preheat a wafer before it is loaded into direct contact with a wafer holder, in order to provide optimal throughput while reducing the risk of thermal shock to the wafer. The first measure is to move the wafer holder to a raised position prior to inserting the wafer into the reaction chamber and holding the wafer above the wafer holder. The second measure is to provide an increased flow rate of a heat-conductive gas (such as Hs purge gas) through the chamber prior to inserting the wafer therein. The third measure is to provide a power bias to radiative heat elements (e.g., heat lamps) above the reaction chamber.

Owner:ASM IP HLDG BV

Method and system for heating of robots in cold environments

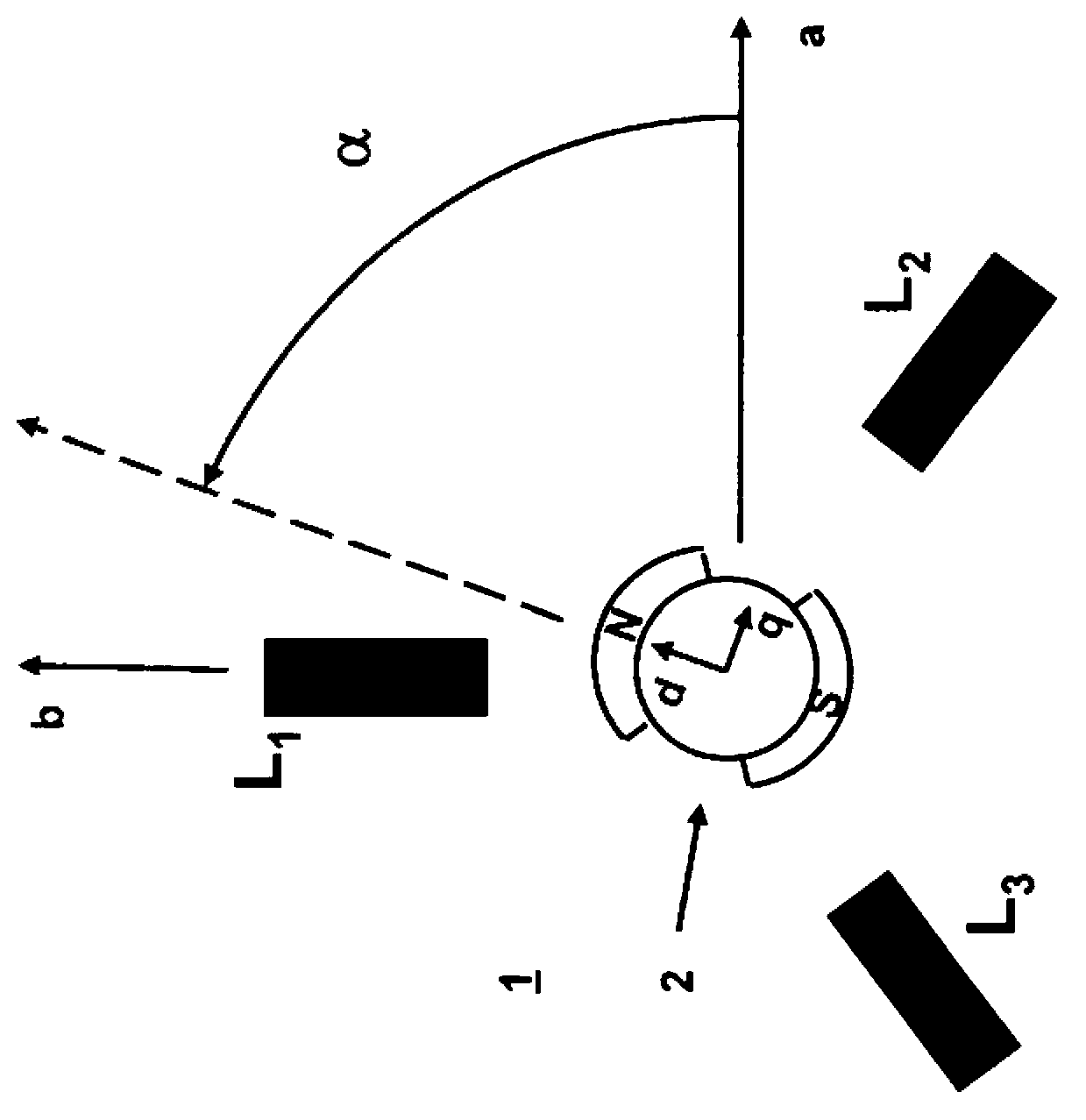

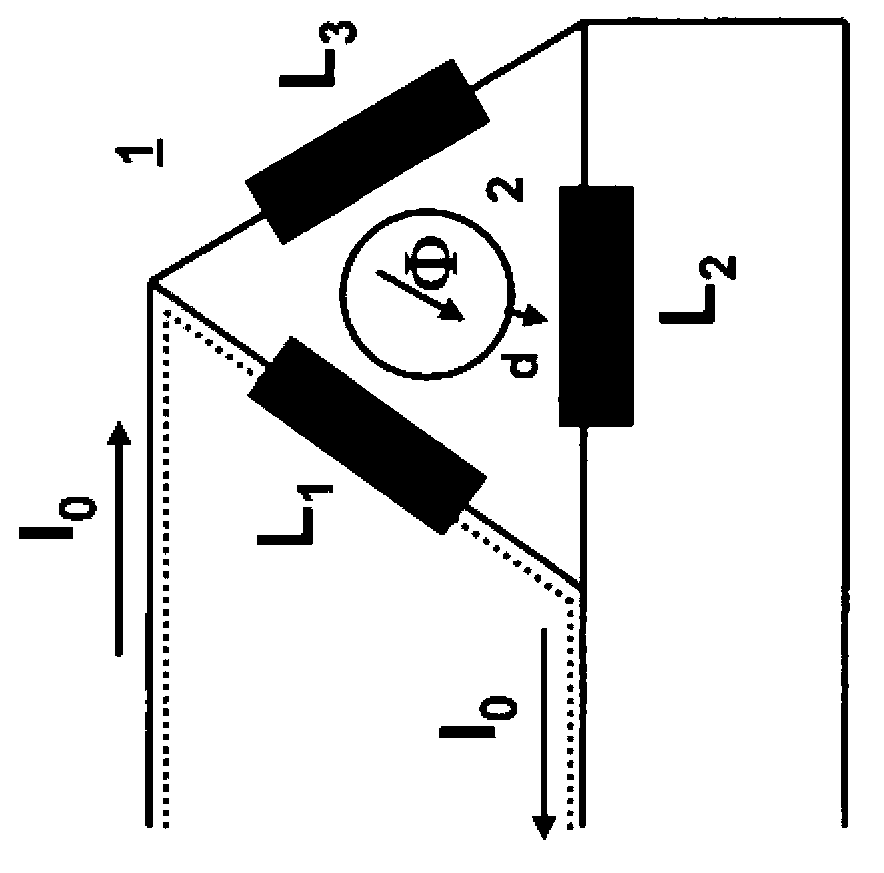

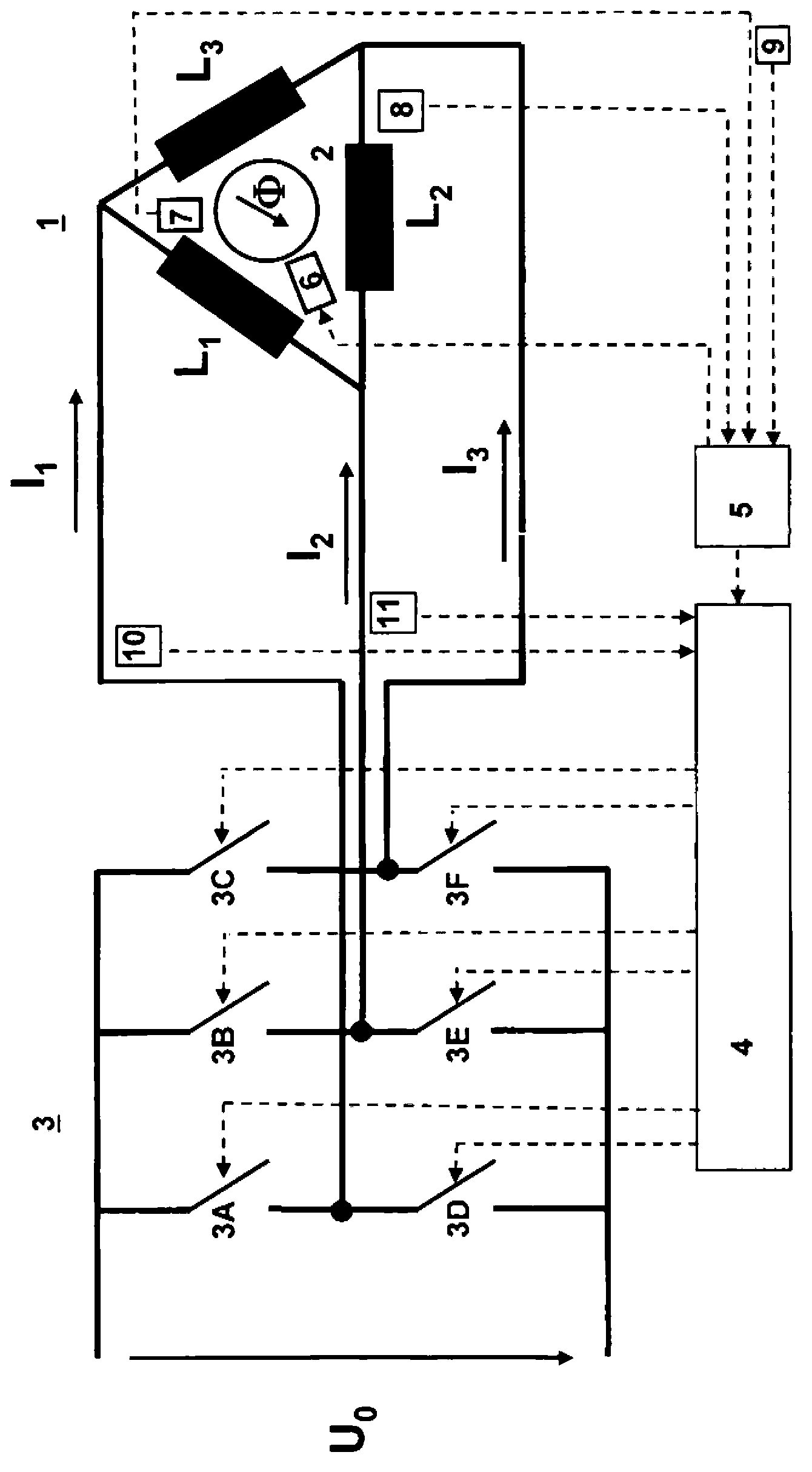

ActiveCN102741021APromote warm-upHeating fastProgramme-controlled manipulatorElectric motor controlSynchronous motorStator coil

The invention proposes a method for heating of robots in cold environments, whereby the robot possesses permanent magnet brushless or three-phase synchronous motors (1) with three motor phases comprising three stator coils (L1, L2, L3) connected to an inverter (3) controllable by a control-unit (4) and with a rotor with permanent magnet excitation (2). A current is applied to at least one phase respectively stator coil (L1, L2, L3) of the motor (1) if the motor stands still creating a directed magnetic flux (phi) which interacts with the permanent magnets of the rotor in such a way that the resulting torque will be close to zero. Further the invention proposes a system for heating of robots in cold environments whereby the inverters (3) and motors (1) in standstill are used to heat up the critical drive train components, where by at least one supervisory-control-unit (5) monitors the motor temperature in order to avoid overheating.

Owner:ABB (SCHWEIZ) AG

Pile-up welding method of turbine low pressure heater pipe plate and shell, water chamber junction

ActiveCN100999034AIncrease productivityImprove product qualityArc welding apparatusFurnace typesCarbon steelAlloy steel

The present invention relates to a surfacing method of turbine low-pressure heater tube-plate and shell body and water chamber connection position, belonging to a welding method of turbine low-pressure heater tube-plate and connection component. Said surfacing method is characterized by adopting the following steps: adopting 20MnMo or 16MnR alloy steel forged piece whose thickness is 90-240 mm as turbine low-pressure heater tube-plate; making two ring recessed grooves on said forged piece, the depth of every ring recessed groove is 20-30 mm; preheating and layer-by-layer surfacing carbon steel in two ring recessed grooves, the bead interlayer temperature is 100-150 deg.C, after the surfacing operation is completed, covering with ashestos cloth, cooling to normal temperature, making postweld heat treatment, tempering temperature is 600-630 deg.C and tempering for 10-25 h.

Owner:HARBIN TURBINE

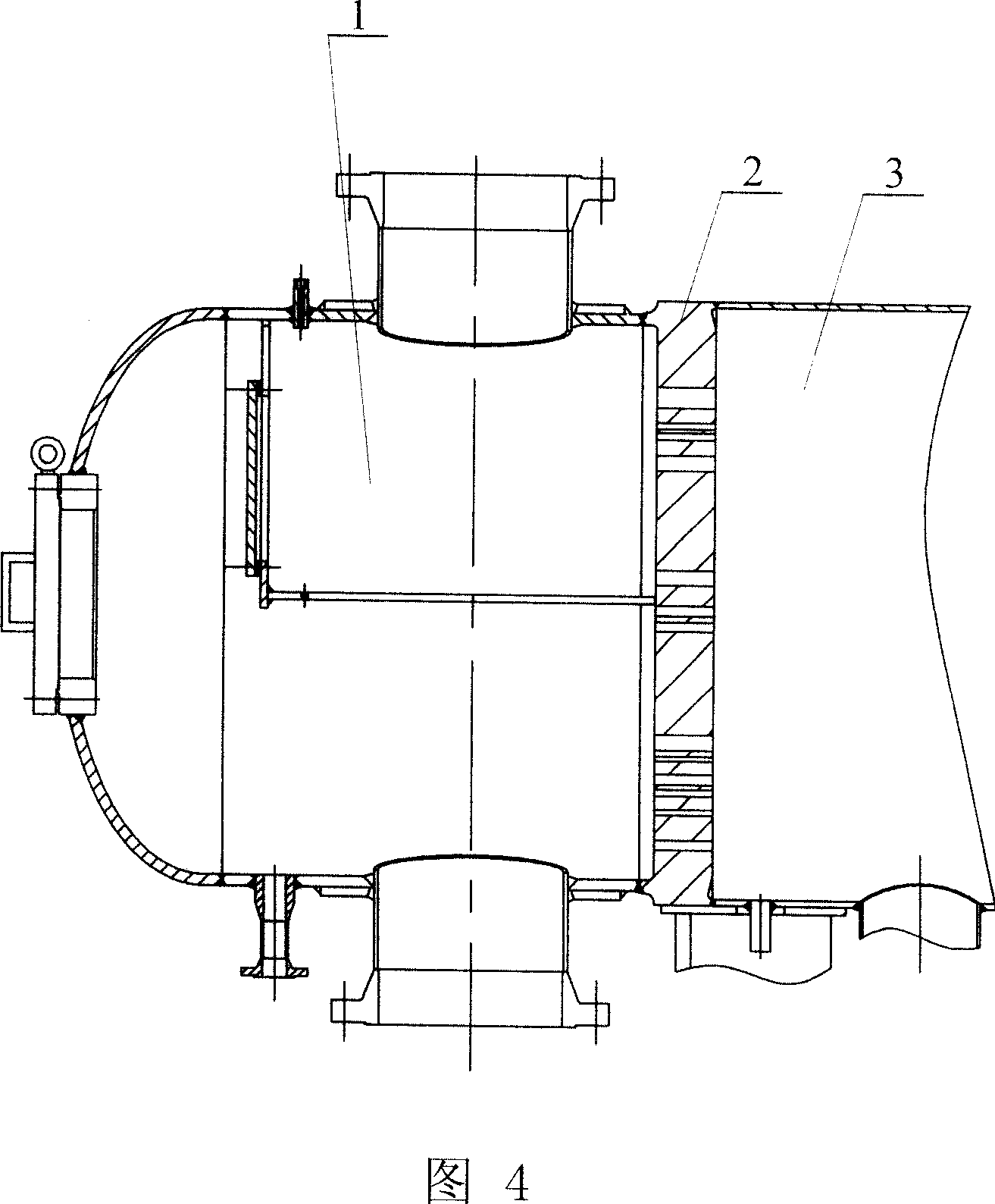

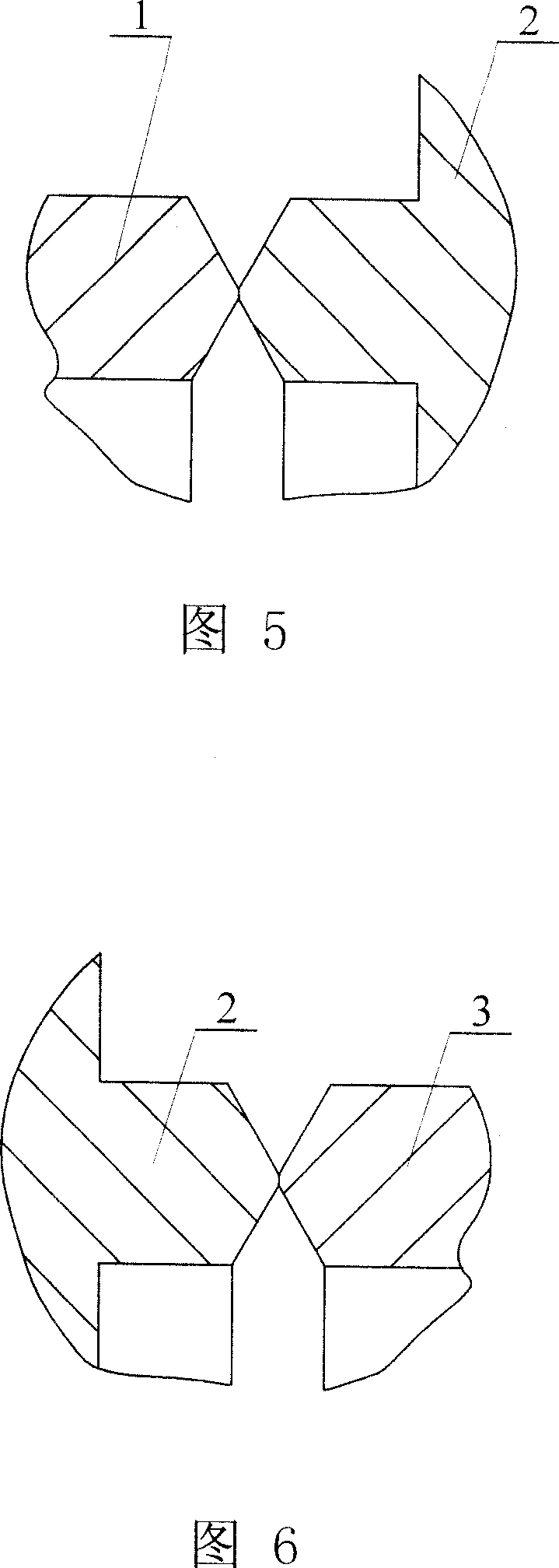

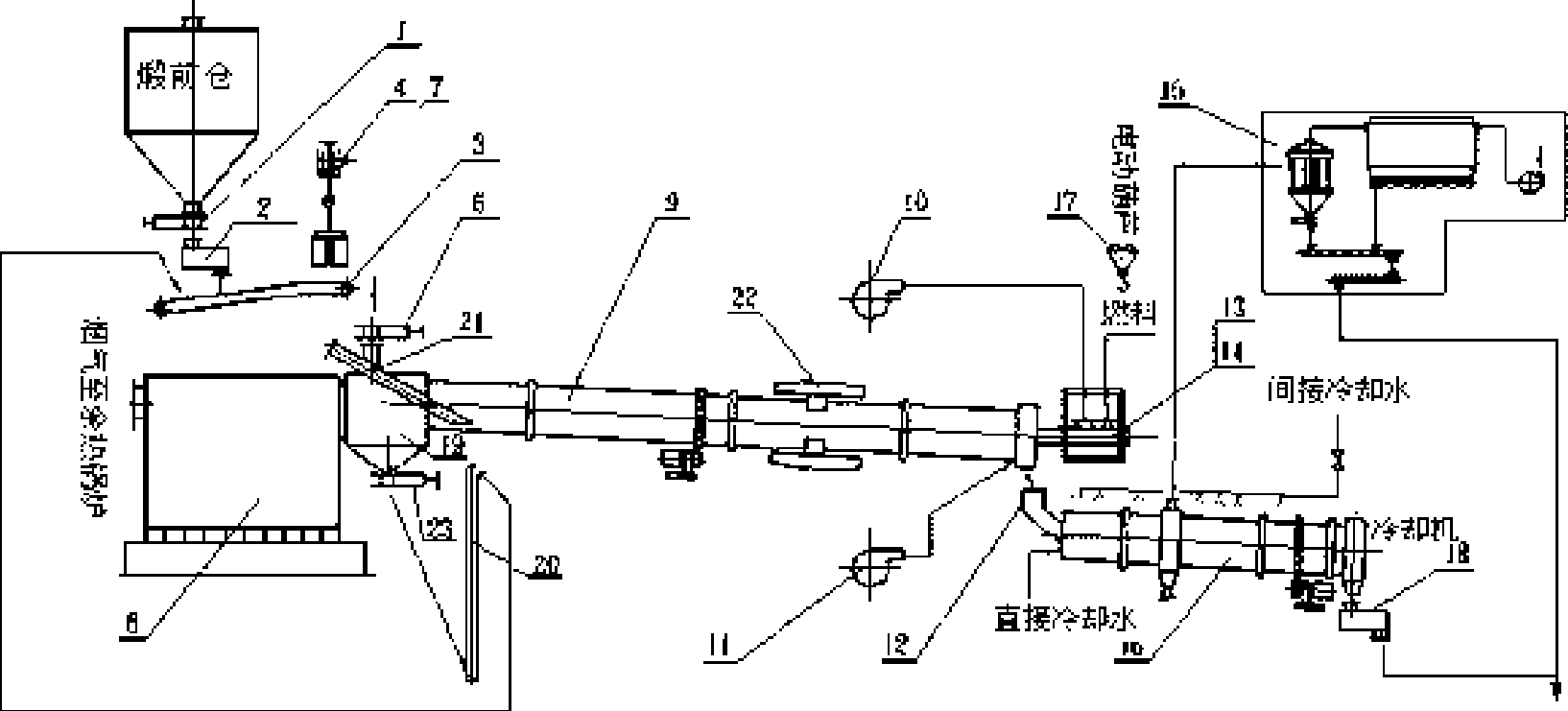

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

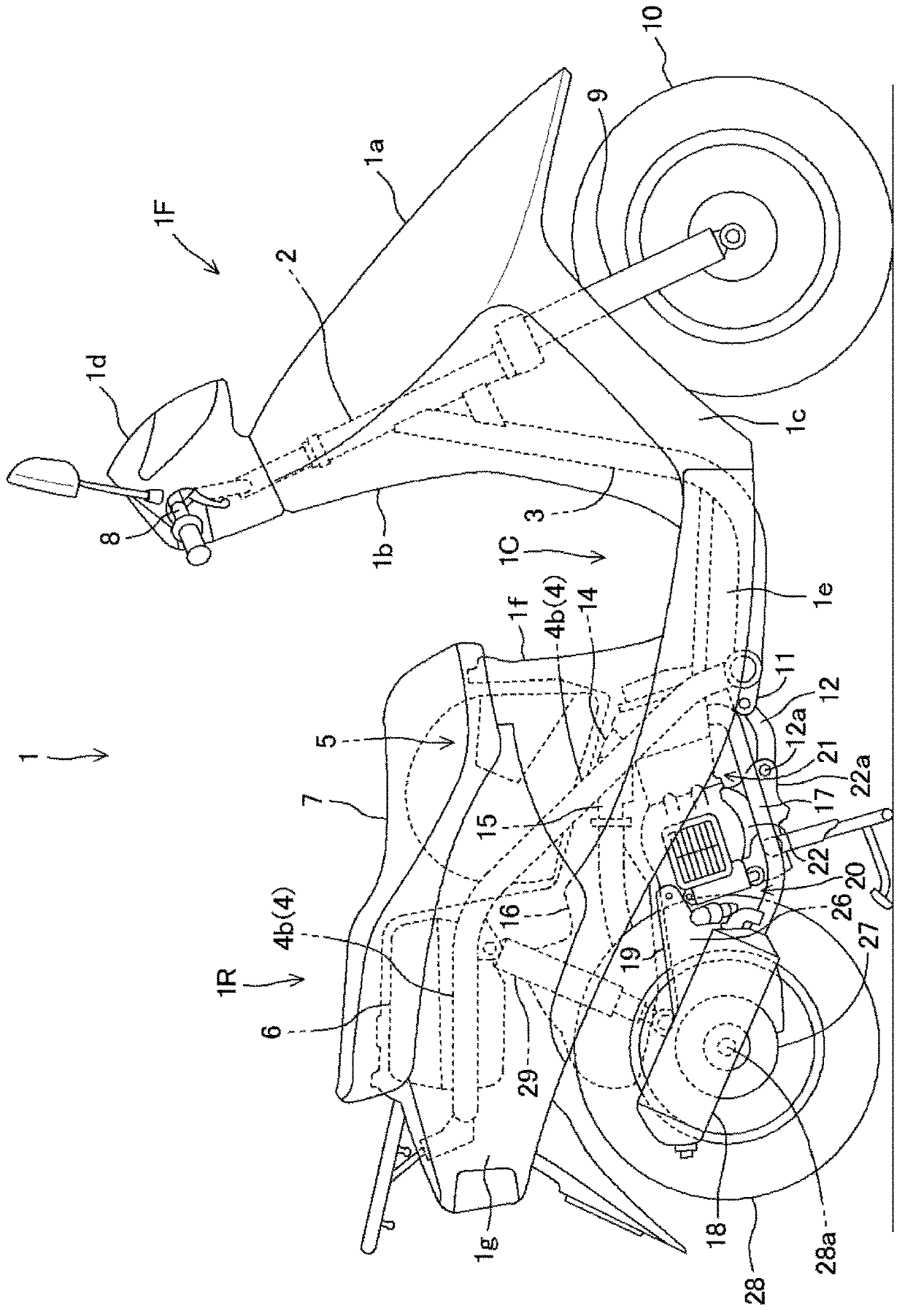

Cooling device for internal combustion engine

ActiveCN102996219APromote warm-upClose fullyCoolant flow controlMachines/enginesBlade plateExternal combustion engine

The present invention provides a cooling device for an internal combustion engine, capable of blocking gaps formed at a peripheral part of a blade plate to fully block a cooling air inlet when a movable blind window closes the cooling air inlet of a fan housing, so as to facilitate a heating machine during cold start. In the cooling device for the internal combustion engine having the movable blind window (60) capable of opening or closing the cooling air inlet (53) of the fan housing (50), housing side step parts (56u, 56l, 57u, 57l) are formed along an opening rim of the cooling air inlet (53) of the fan housing (50), blind window side step parts (61id, 61od) opposite to the housing side step parts (56u, 56l, 57u, 57l) are formed at the peripheral part of the blade plate (61) of the movable blind window (60), the blind window side step parts (61id, 61od) and the housing side step parts (56u, 56l, 57u, 57l) are abutted and superposed when the cooling air inlet (53) is closed through rotation of the blade plate (61).

Owner:HONDA MOTOR CO LTD

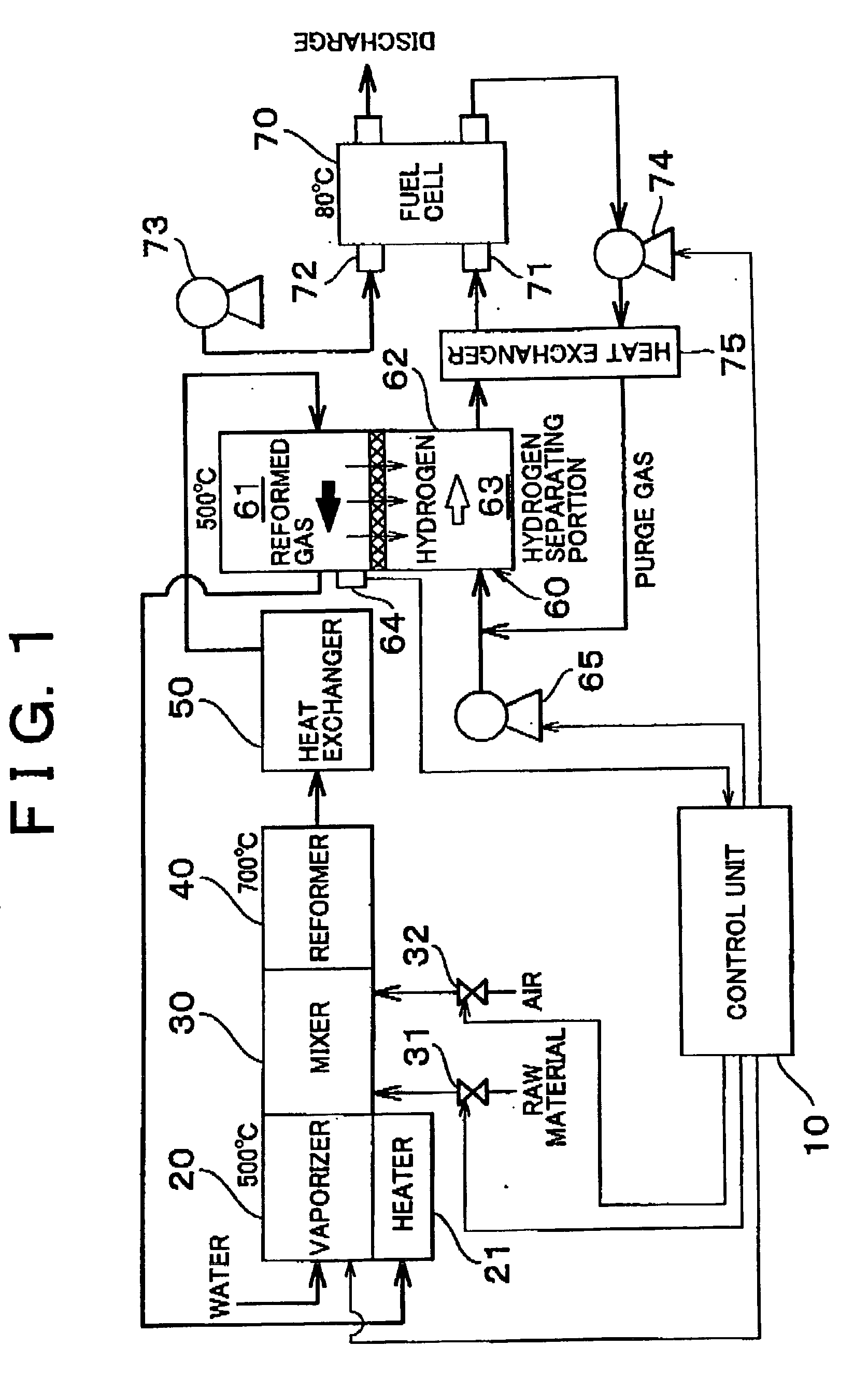

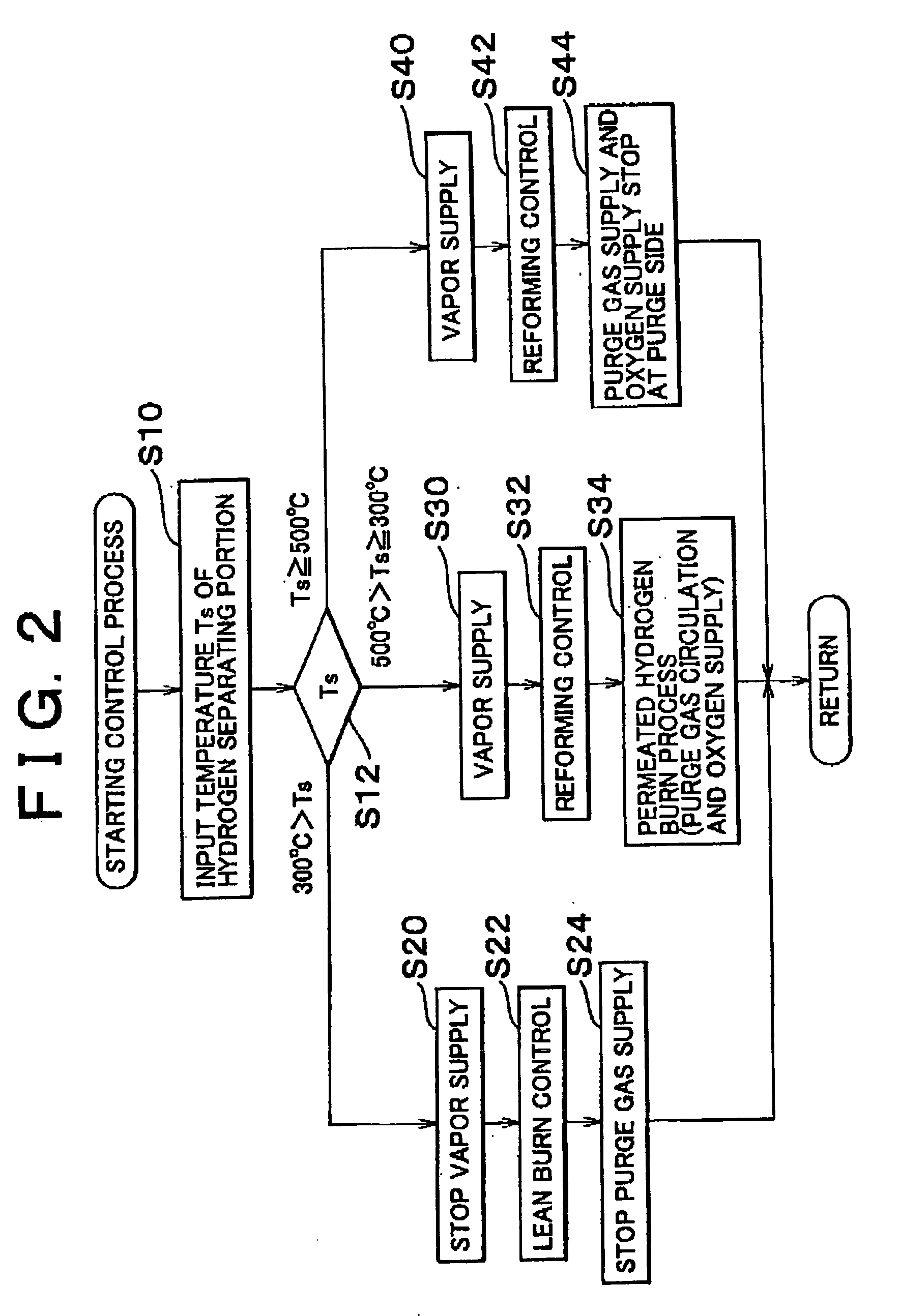

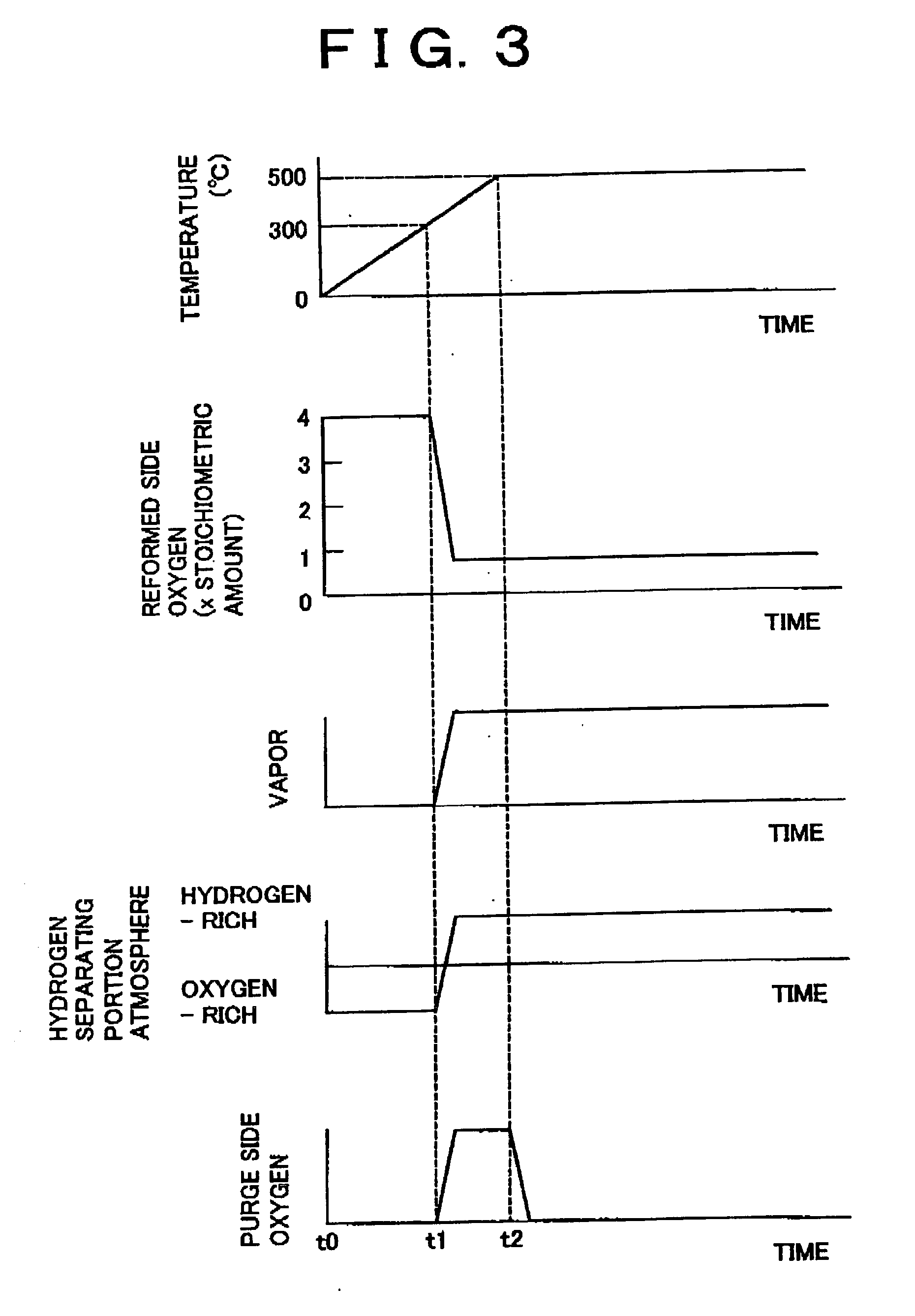

Hydrogen generating device having hydrogen separator membrane and control method therefor

InactiveUS20030056440A1Avoiding hydrogen embrittlement of hydrogenSuppression temperatureProcess control/regulationLayered productsChemistryWarming up

When the hydrogen separating membrane is in a low temperature condition, a lean bus operation is carried out in a reformer in order to conduct warm-up while suppressing generation of hydrogen. At the timing t1 where the temperature of the hydrogen separator membrane has reached a temperature at which hydrogen embrittlement does not occur, reforming is initiated. In such a condition, oxygen is supplied to hydrogen which is permeated through the hydrogen separator membrane for burning the hydrogen, so as to further facilitate the warm-up. At the timing t2 where the temperature has reached an operation temperature, the supply of oxygen in a purge side is stopped so as to stop the burning of hydrogen, and an operation mode is shifted to a normal operation.

Owner:TOYOTA JIDOSHA KK

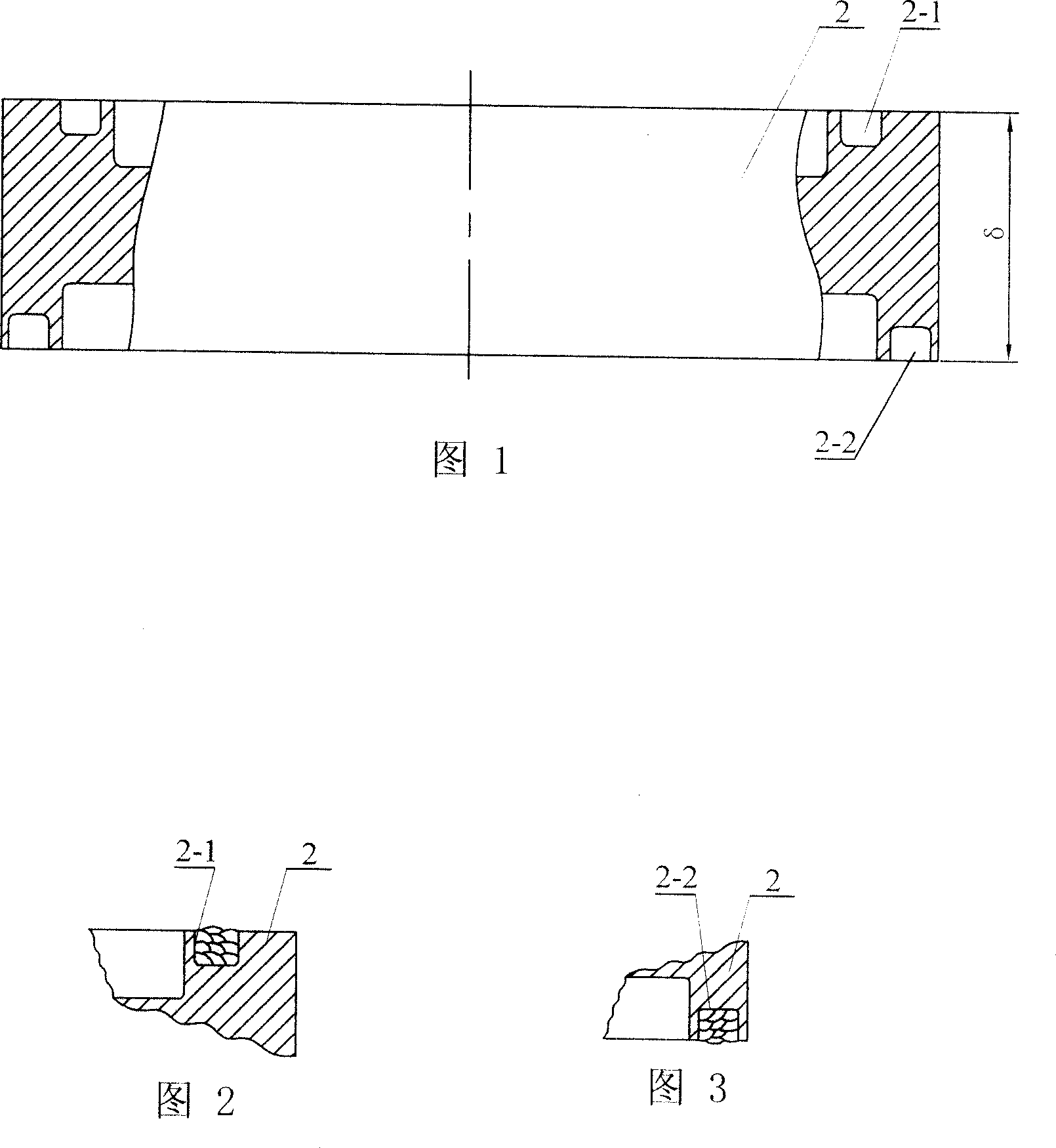

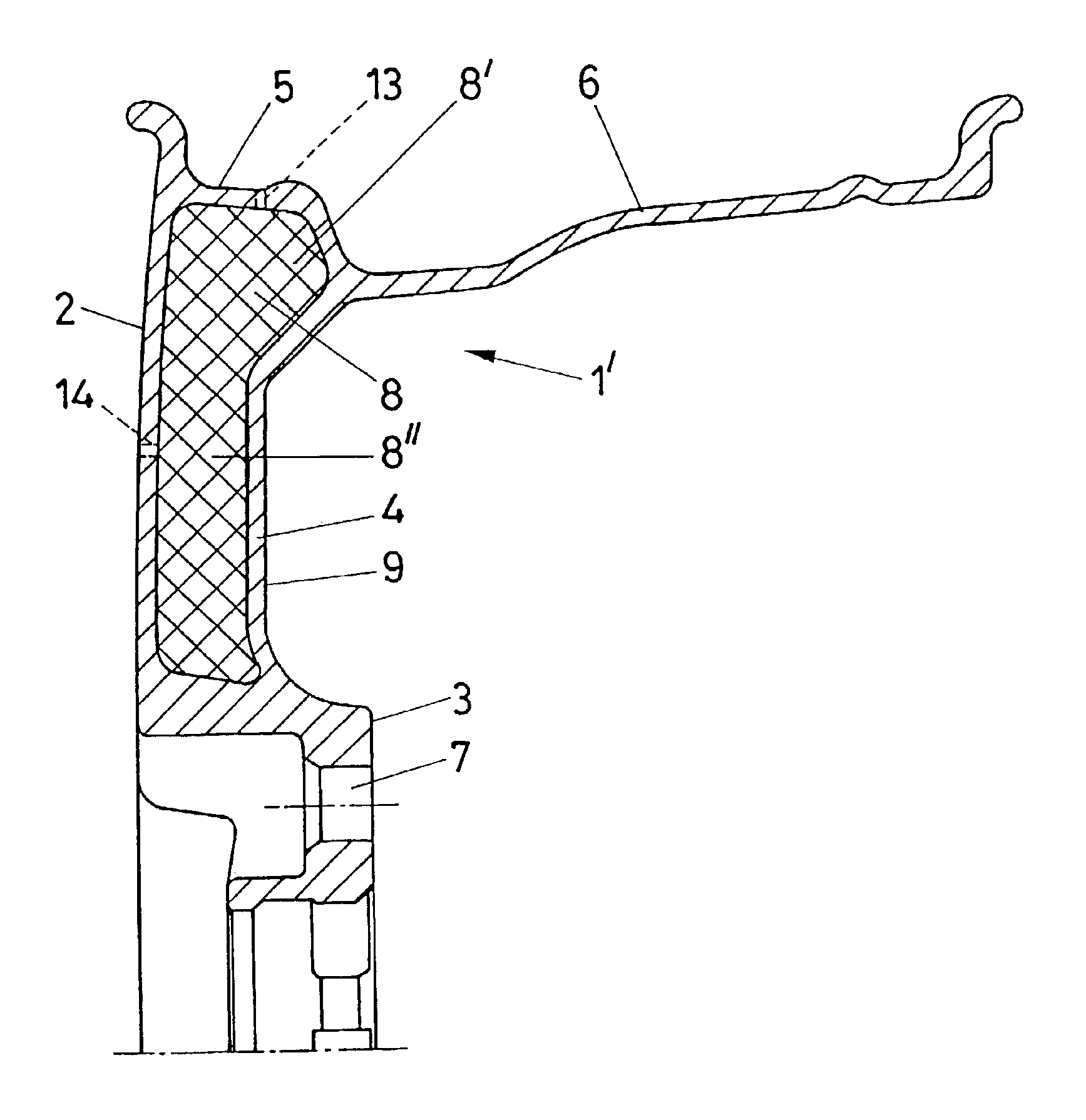

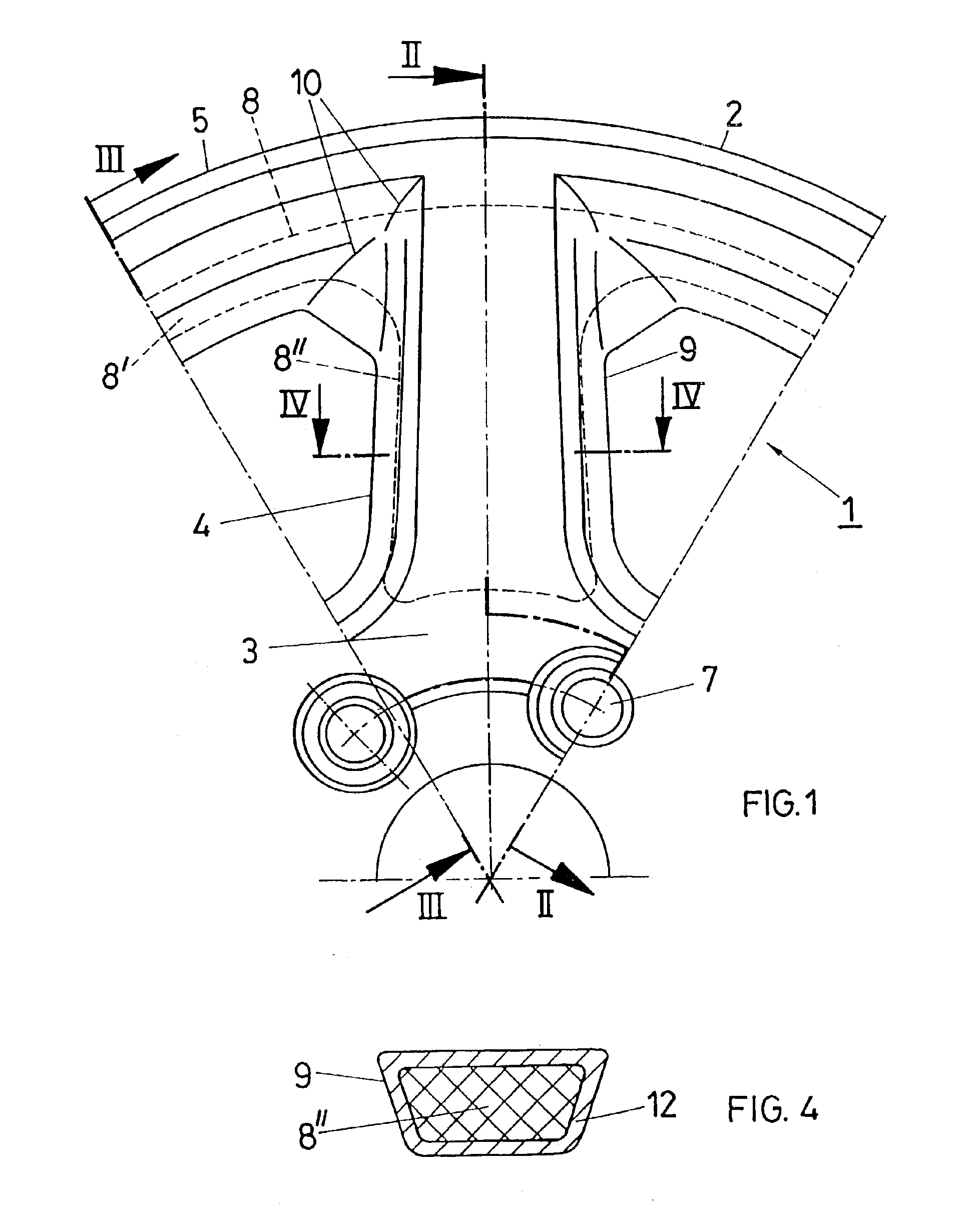

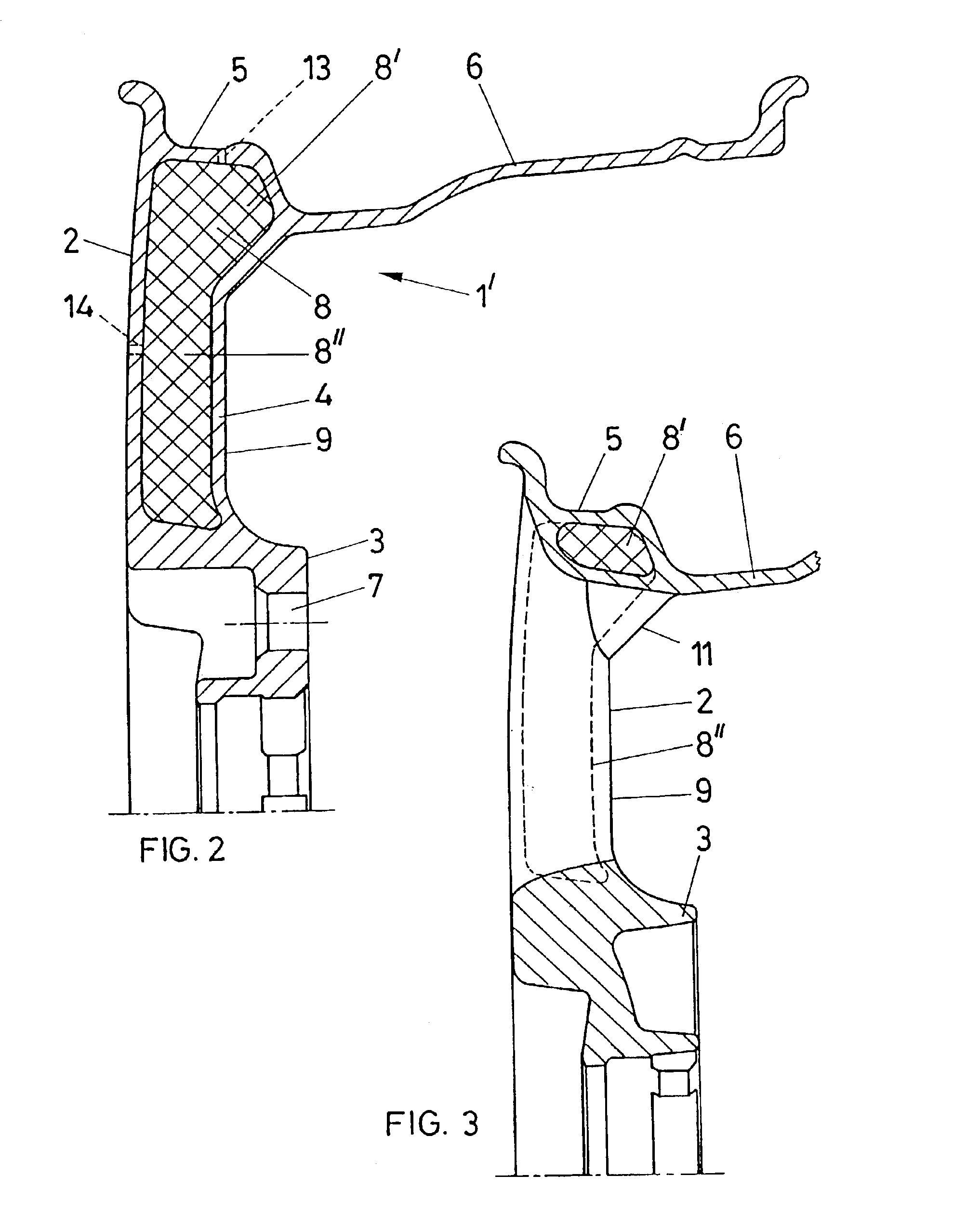

Cast wheel rim

A cast wheel rim including a light-metal body which at least partially encompasses at least one shaped part forming a cast-in core and having a mean specific weight smaller than that of the light metal used for the body, wherein the shaped part is comprised of a pressed body made of a porous silicate material.

Owner:AUSTRIA ALU GUSS

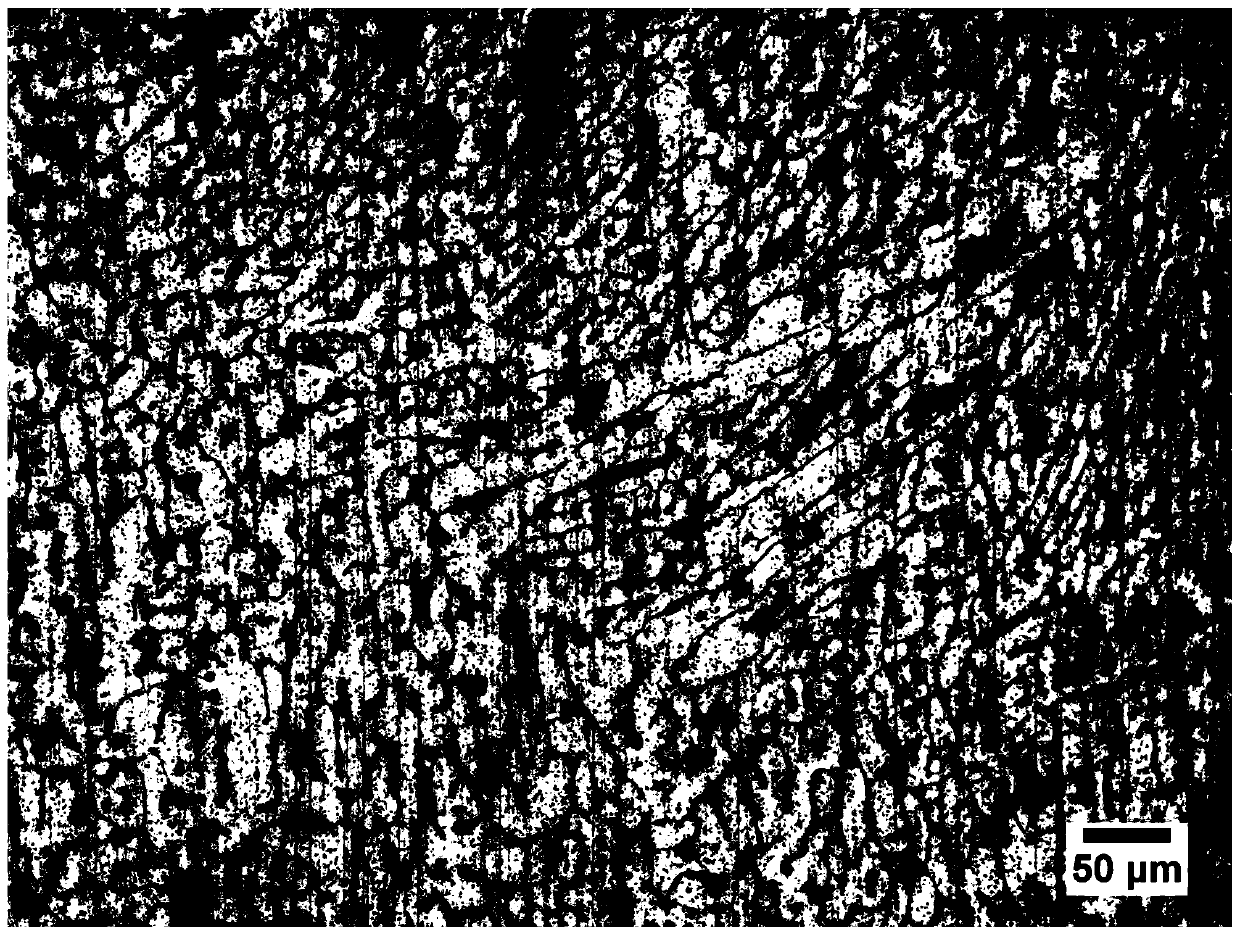

Structure grain refining method for arc additive manufacturing by adopting aluminum-silicon alloy

ActiveCN110076418AEasy to changeElimination of coarse columnar crystalsAdditive manufacturing apparatusArc welding apparatusSilicon alloyEquiaxed crystals

The invention relates to the technical field of alloy optimization, and particularly discloses a structure grain refining method for arc additive manufacturing by adopting aluminum-silicon alloy. Themethod comprises the following steps that Al-5Ti-1B intermediate alloy is prefabricated into thin sheets, cleaned and dried; the thin sheets are placed between the adjacent aluminum-silicon alloy layers, and aluminum-silicon alloy arc additive manufacturing is carried out by adopting an arc additive manufacturing method, wherein the mass of the thin sheets placed in each layer is 1-5% of the massof the aluminum-silicon alloy in the corresponding layer.. According to the structure grain refinement method for arc additive manufacturing by adopting the aluminum-silicon alloy, coarse columnar crystals can be converted into fine equiaxed crystals, and the effects of crystal form conversion and grain refinement are achieved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

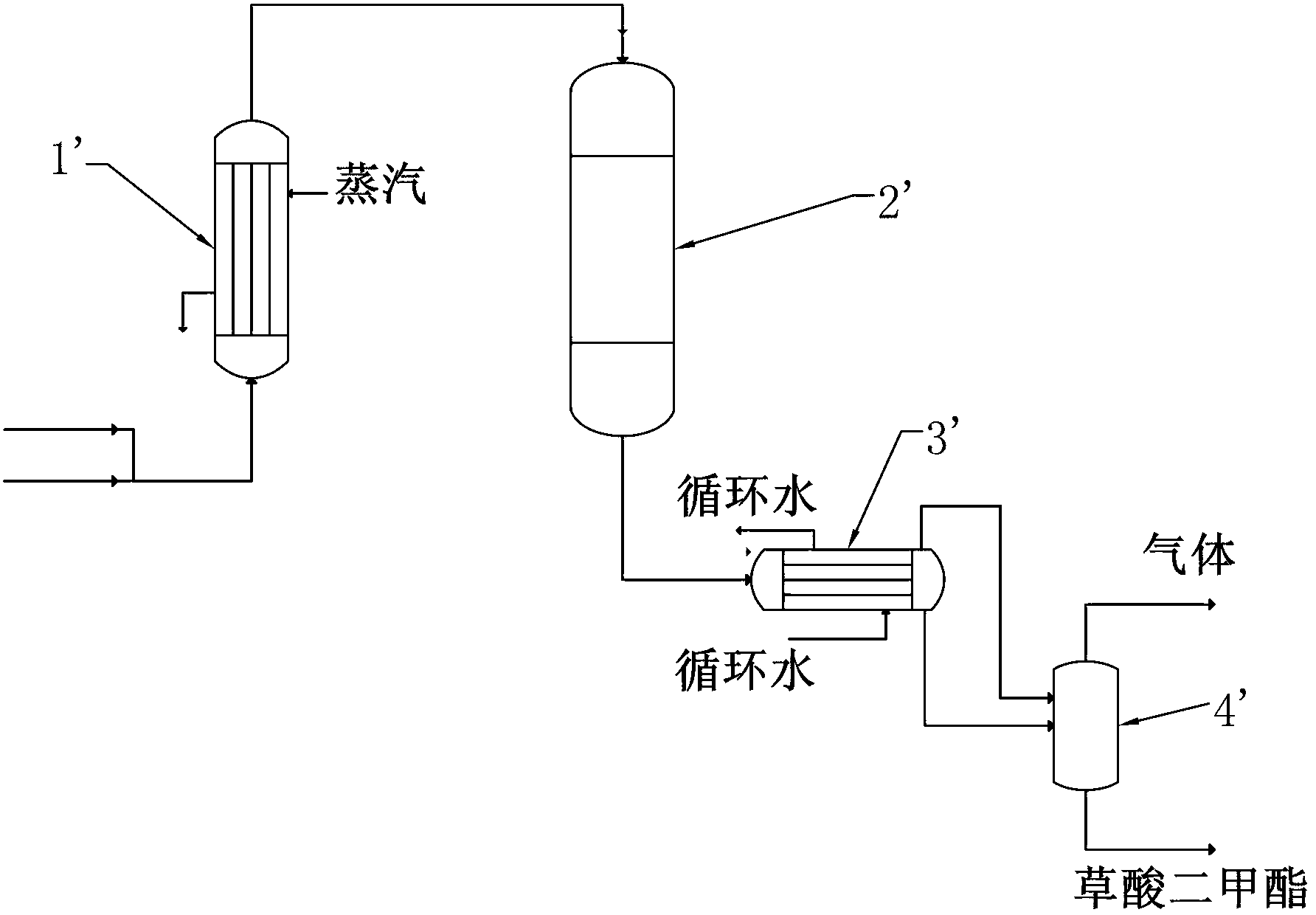

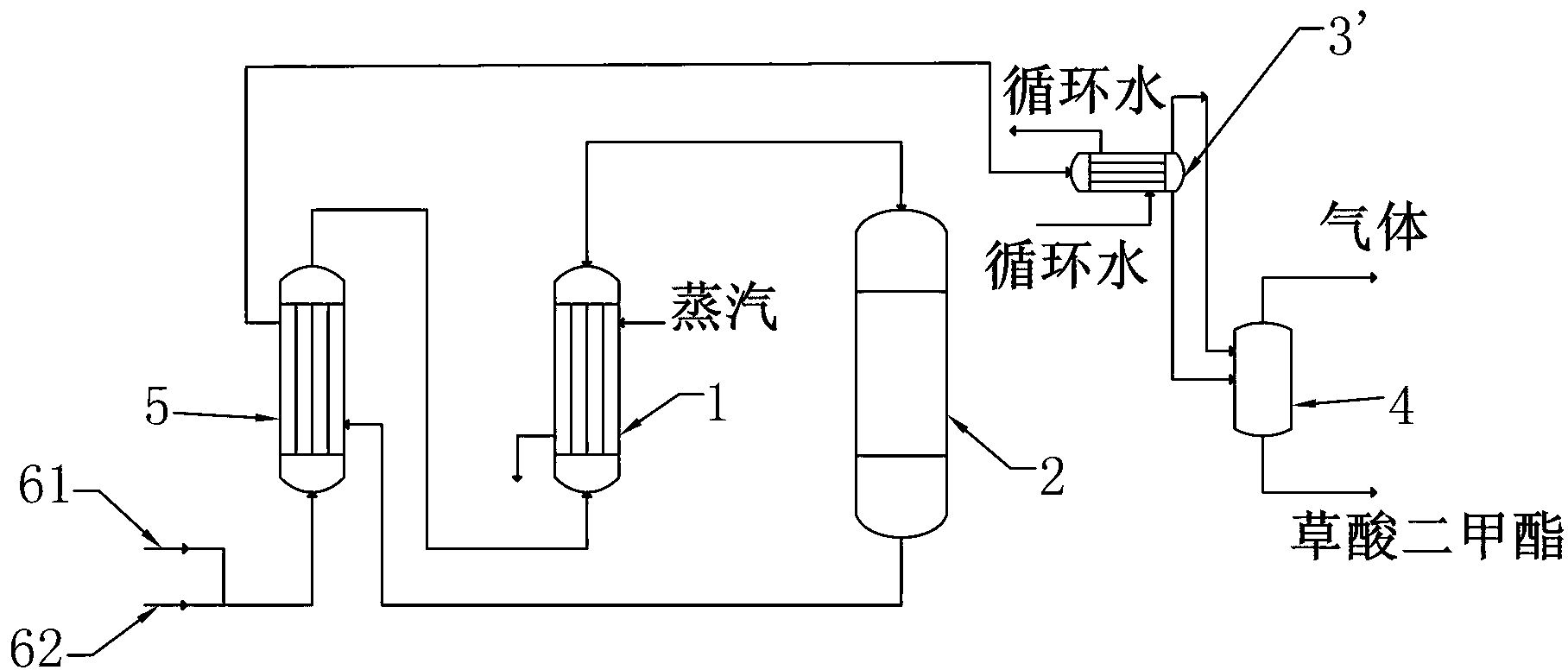

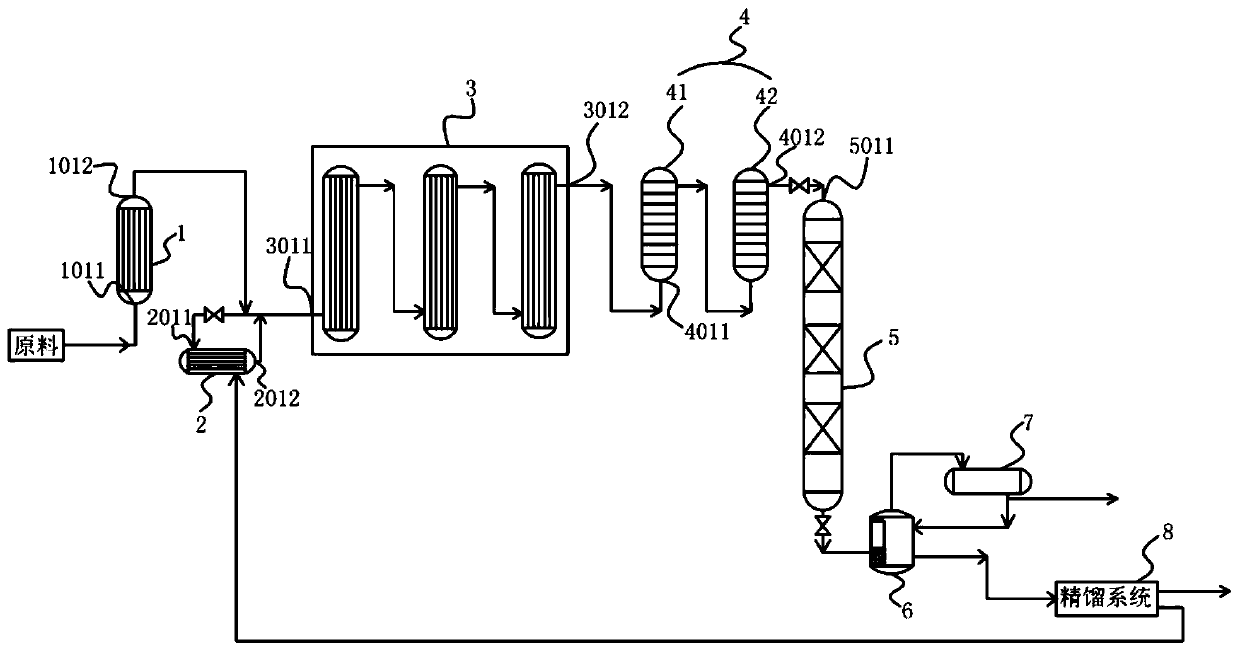

Dimethyl oxalate production device

ActiveCN102850216AReduce dosagePromote warm-upPreparation by carbon monoxide or formate reactionVapor–liquid separatorProcess engineering

The invention discloses a dimethyl oxalate production device and relates to a chemical product production device. The device comprises a heater (1), a carbonylation reactor (2), a condenser (3), a gas-liquid separator (4) and a preheater (5), wherein an inlet of materials to be heated of the preheater (5) is communicated with a methyl nitrite conveying pipeline (61) and a CO conveying pipeline (62), an outlet of the materials to be heated of the preheater (5) is connected with an inlet of the materials to be heated of the heater (1), an outlet of the materials to be heated of the heater (1) is connected with a reaction mass inlet of the carbonylation reactor (2), a reaction mass outlet of the carbonylation reactor (2) is connected with a heating medium inlet of the preheater (5), a heating medium outlet of the preheater (5) is connected with a condensation material inlet of the condenser (3), and a condensation material gas outlet and a condensation material liquid outlet of the condenser (3) are respectively connected with an inlet of the gas-liquid separator (4). The dimethyl oxalate production device has the advantages of being simple in structure, energy-saving and consumption-reducing.

Owner:PUJING CHEM IND SHA

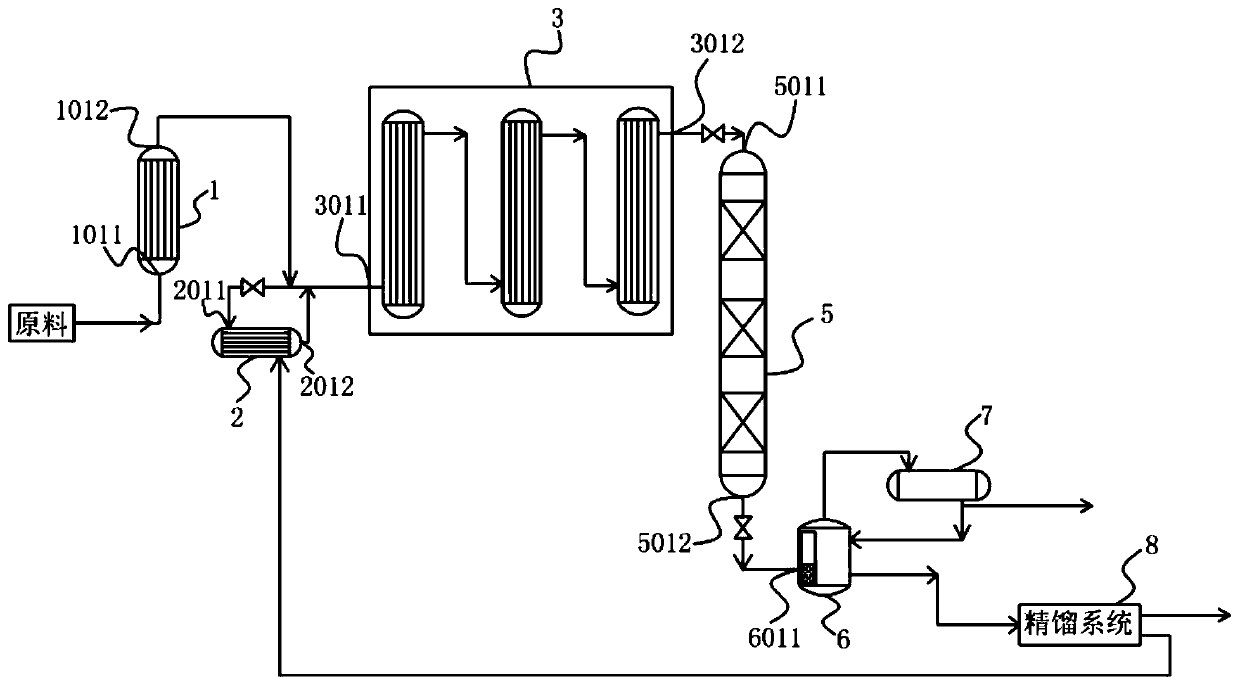

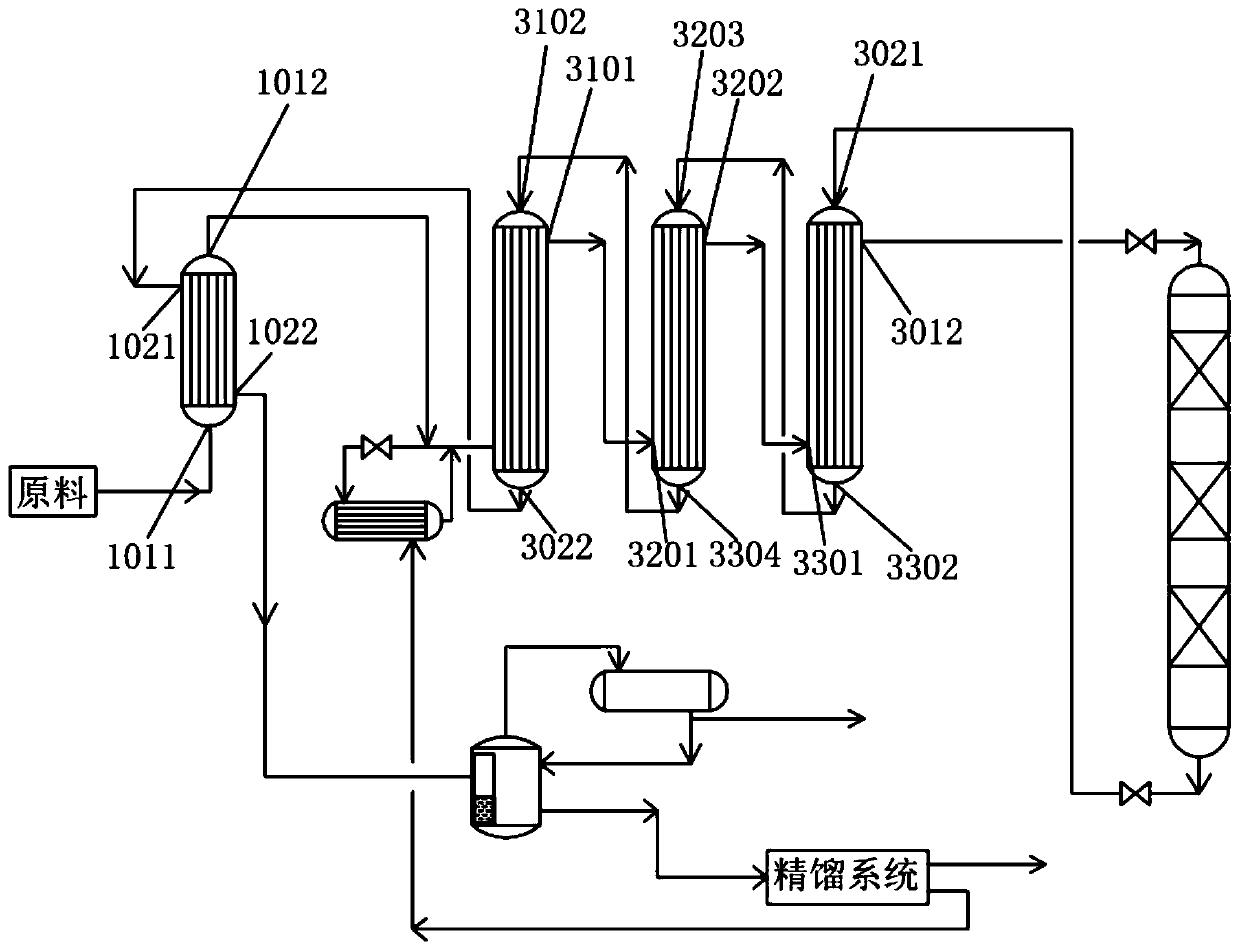

Temperature regulating system in methylamine synthesis

PendingCN110918022AEasy to recycleReduce lossesChemical/physical/physico-chemical processesThermodynamicsIntermediate heat exchanger

The invention provides a temperature regulating system in methylamine synthesis, wherein the temperature regulating system comprises a low-temperature heat exchanger; a first low-temperature outlet ofthe low-temperature heat exchanger communicates with a first medium-temperature inlet of an intermediate heat exchanger, and a first medium-temperature inlet of the intermediate heat exchanger communicates with a first high-temperature inlet of a high-temperature heat exchanger; a first high-temperature outlet of the high-temperature heat exchanger communicates with an inlet of the top of a methylamine synthesis tower, an outlet of the bottom of the methylamine synthesis tower communicates with an inlet of a crude product gas-liquid separation tank, the top end of the crude product gas-liquidseparation tank communicates with a condensation tank, and the bottom end communicates with a rectification system; an outlet of the rectification system communicates with a second medium-temperatureinlet of the intermediate heat exchanger. According to the system, the temperature of a material in the reaction process is recovered for heating a raw material at the inlet of a methylamine reactiontower, so that the raw material can reach the required initial temperature, and no extra energy and cost are consumed; in addition, the system can control the temperature in the reaction tower in time, the phenomenon that the temperature rises drastically is prevented, and the safety problem is effectively avoided.

Owner:安阳九天精细化工有限责任公司

Inverter device

InactiveUS20150295490A1Voltage drop amount is undesirablyIncrease internal resistanceSpeed controllerAC motor controlPower inverterEngineering

An inverter device includes an inverter circuit, which has switching elements in a bridge connection, a capacitor, which is connected in parallel to the input side of the inverter circuit, a control device, which controls the inverter circuit, a temperature detector, which detects the temperature of the capacitor, a degree-of-deterioration determiner, which determines the degree of deterioration of the capacitor, and a warm-up controller. When the temperature of the capacitor detected by the temperature detector is lower than a prescribed temperature, the warm-up controller controls the switching elements of the inverter circuit to supply a direct current set based on the degree of deterioration and the temperature of the capacitor to the coil of an electric motor connected to the output side of the inverter circuit.

Owner:TOYOTA IND CORP

Control device for hybrid vehicle power transmitting apparatus

ActiveUS8088034B2Promote warm-upHybrid vehiclesElectric propulsion mountingHybrid electrical vehicleHybrid vehicle

Owner:TOYOTA JIDOSHA KK

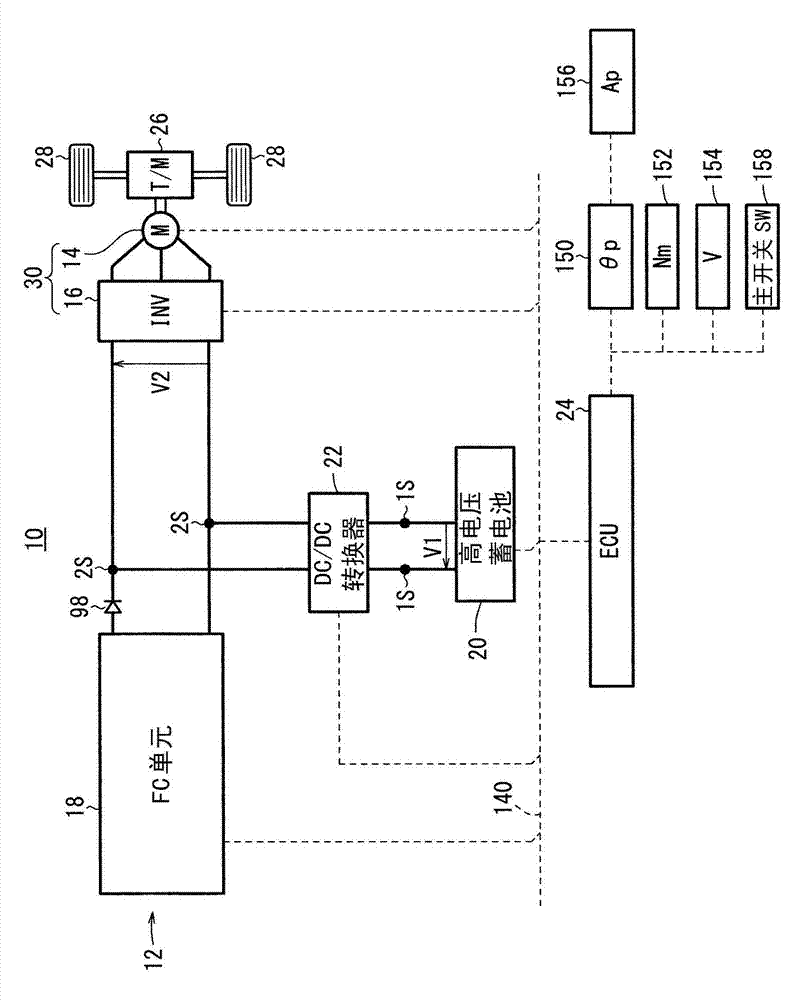

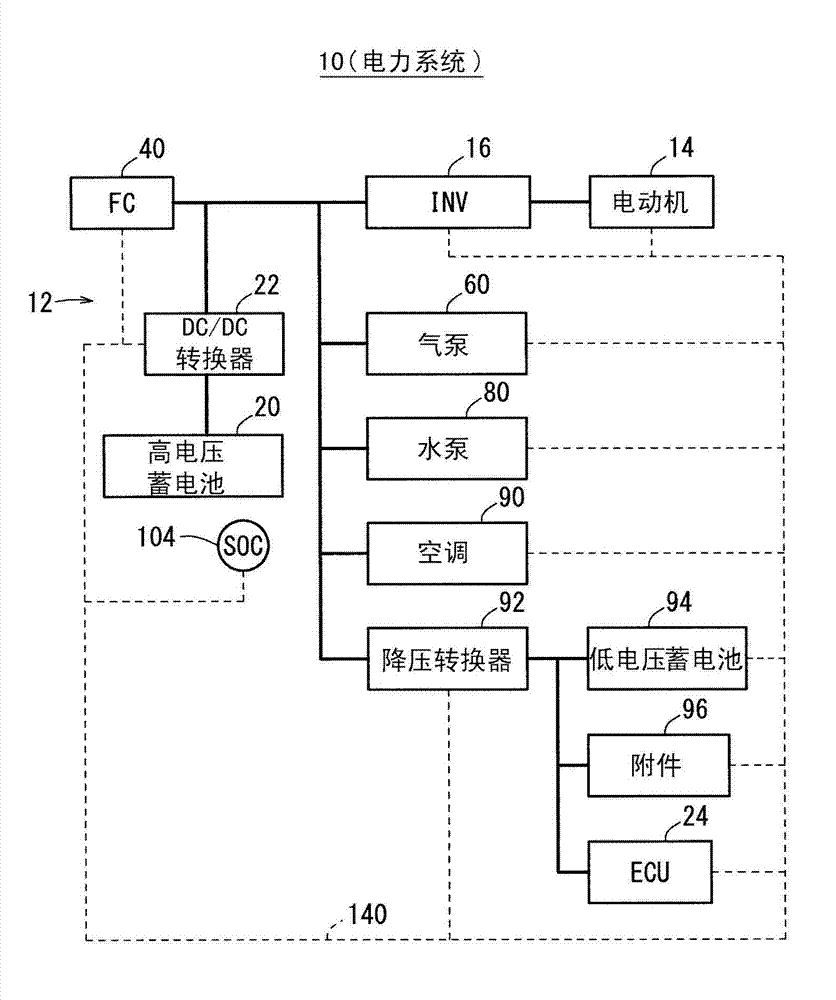

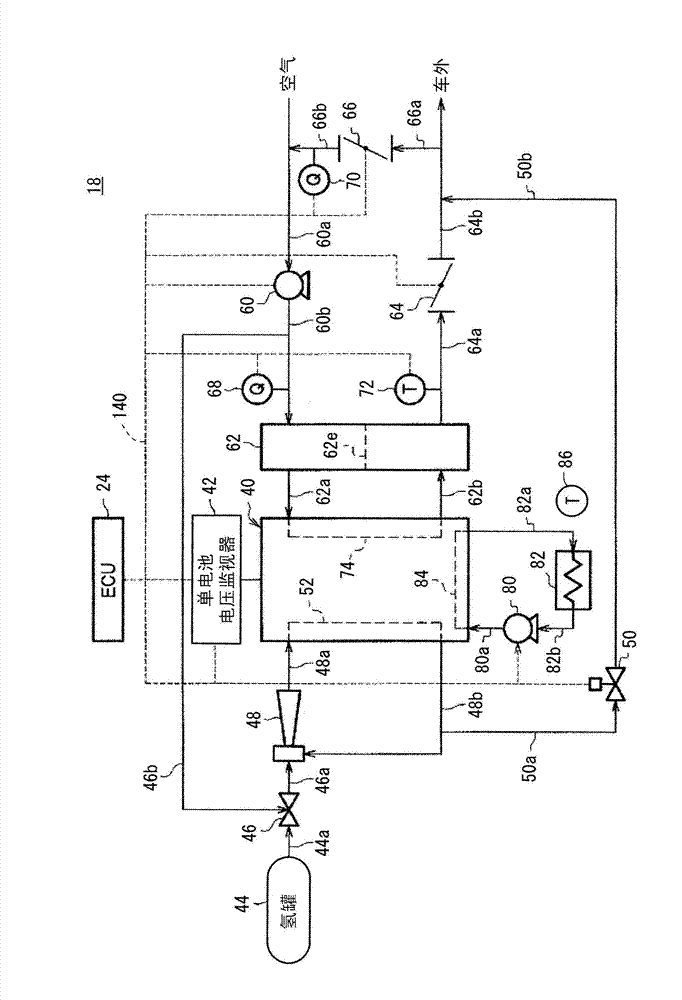

Fuel cell system

ActiveCN102780016AInhibit deteriorationSuppress surplus powerBatteries circuit arrangementsFuel cell auxillariesFuel cellsEngineering

Provided is a fuel cell system. In a case where a gas supply controller (24) of the FC (Fuel Cell) system (12) determines that the temperature of an FC (40) is a predetermined temperature or less, the gas supply controller fixes the FC voltage to a voltage value within a voltage region where degradation is relatively small, the voltage value being below a voltage range where an oxidation-reduction proceeds. Further, the amount of a gas supplied to the FC (40) is changed in accordance with electric power required by a load (30).

Owner:HONDA MOTOR CO LTD

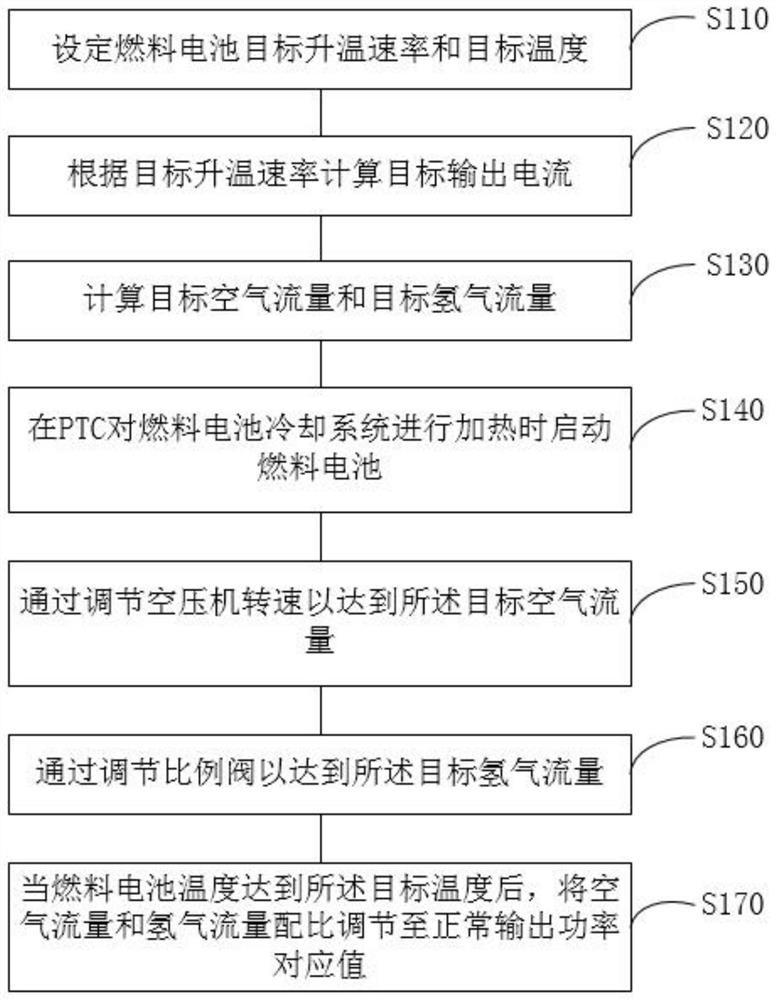

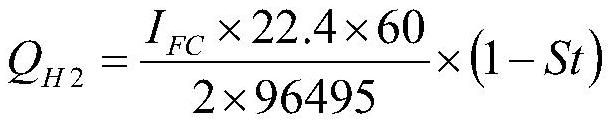

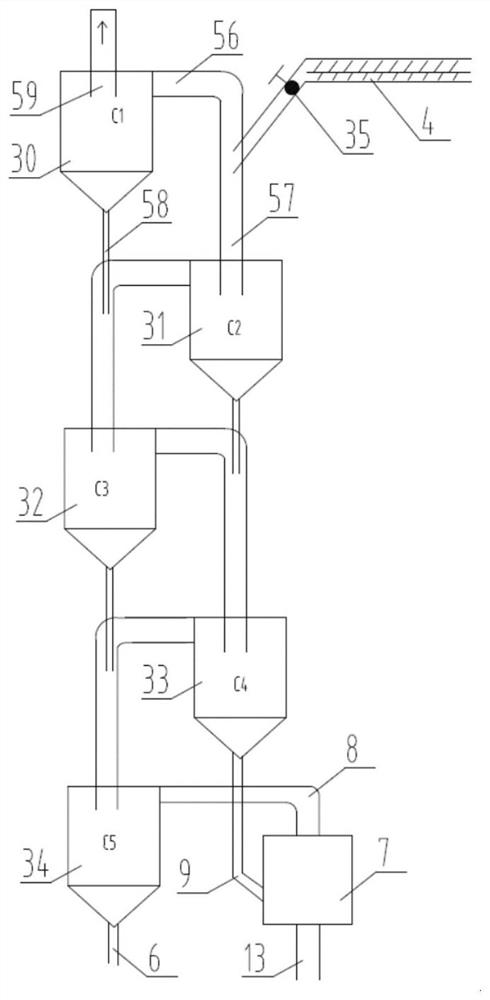

Low-temperature cold start method and system for hydrogen fuel cell

ActiveCN111613811APull down the external output efficiencyPromote warm-upFuel cell heat exchangeMotive system fuel cellsHydrogen fuel cellEngineering

The invention discloses a low-temperature cold start method and system for a hydrogen fuel cell. The method comprises the following steps of setting a target heating rate and a target temperature of the fuel cell; calculating a target output current according to the target heating rate; calculating a target air flow and a target hydrogen flow; starting the fuel cell when a PTC heats a fuel cell cooling system; achieving the target air flow by adjusting the rotating speed of an air compressor; achieving the target hydrogen flow by adjusting a proportional valve; and after the temperature of thefuel cell reaches the target temperature, adjusting the ratio of the air flow to the hydrogen flow to a normal output power corresponding value. According to the low-temperature cold starting methodand system for the hydrogen fuel cell, the concentration difference overpotentials of the hydrogen side and the oxygen side of the fuel cell are used for lowering the external output efficiency of thefuel cell, the chemical energy as much as possible is converted into the heat energy to be used for heating a fuel cell stack body, so that the fuel cell is rapidly warmed up.

Owner:KUSN FUERSAI ENERGY

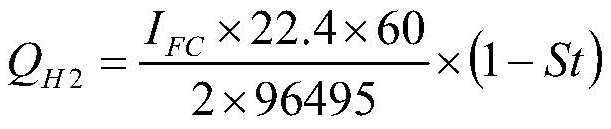

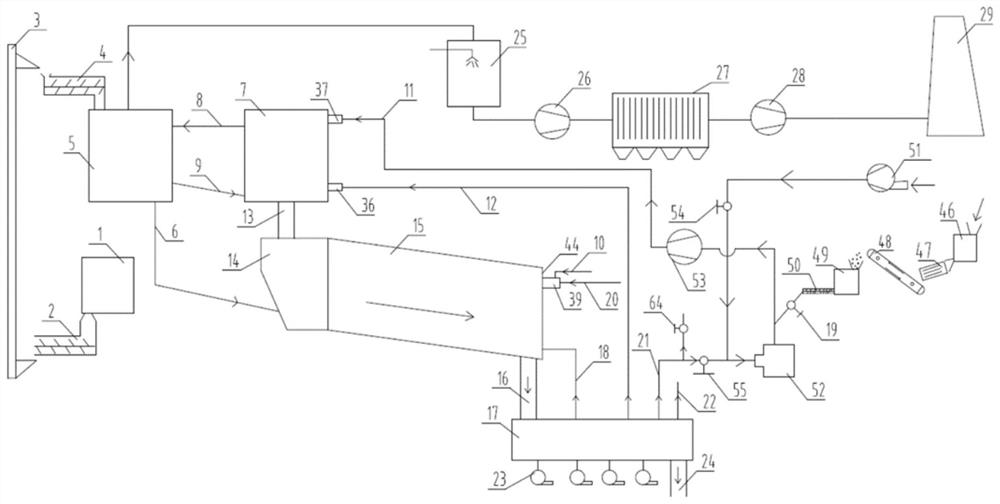

System for treating waste fan blades in decomposing furnace and working method of system

The invention discloses a system for treating waste fan blades in a decomposing furnace and a working method of the system, and belongs to the technical field of resource recovery. The system comprises a blade crushing system, a raw material feeding system, a flue gas treatment system, a suspension preheater, a decomposing furnace, a rotary kiln, a clinker cooling device and a fan coal mill. Crushed waste fan blade particles are merged into a pneumatic conveying pipeline at the downstream of the fan coal mill and are conveyed into the decomposing furnace together for pyrolysis and combustion, heat released by combustion of organic composite materials of the waste blade particles and heat released by combustion of pulverized coal provide energy for dehydration and decomposition of raw materials together, and the potential heat value of fan blades is effectively utilized. Glass fibers in the blade particles, combusted pulverized coal and ash residues formed by combustion of the pulverized coal are mixed into the raw material together, enter a downstream suspension preheater, are finally separated and are returned to the rotary kiln to participate in clinker firing. Harmless and resourceful treatment of the waste fan blades is achieved, and good environmental protection benefits and economic benefits are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com