Underground double-layered oil tank and preparation method thereof

A double-layer oil tank and oil tank technology, which is applied to tank trucks, containers, underwater structures, etc., can solve the problems of oil pollution and short service life of oil tanks, and achieve environmental protection, investment cost reduction, and high environmental protection. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

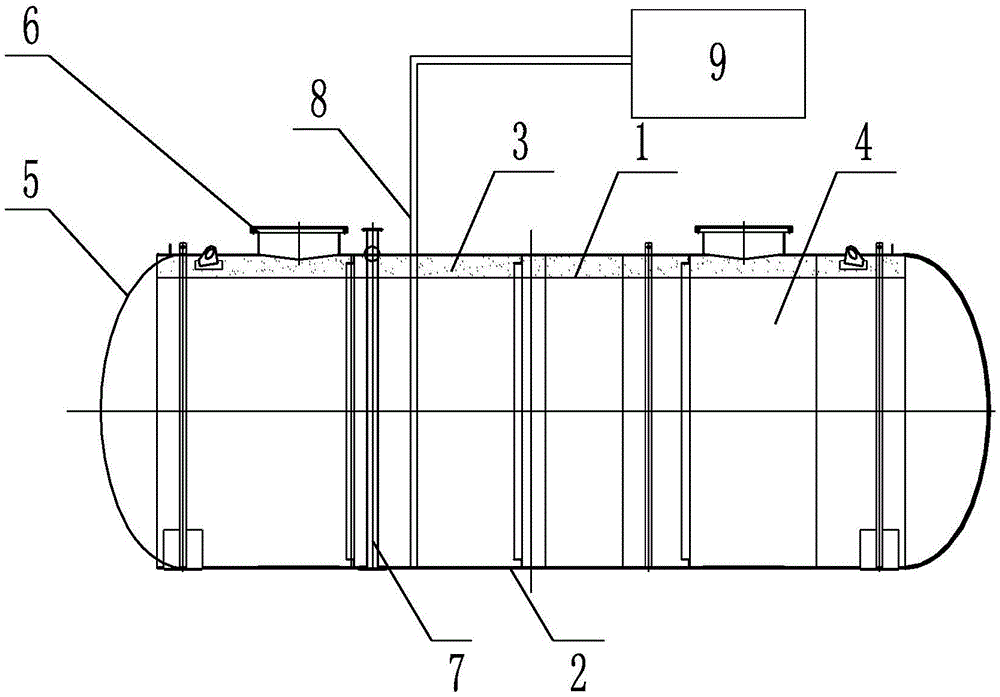

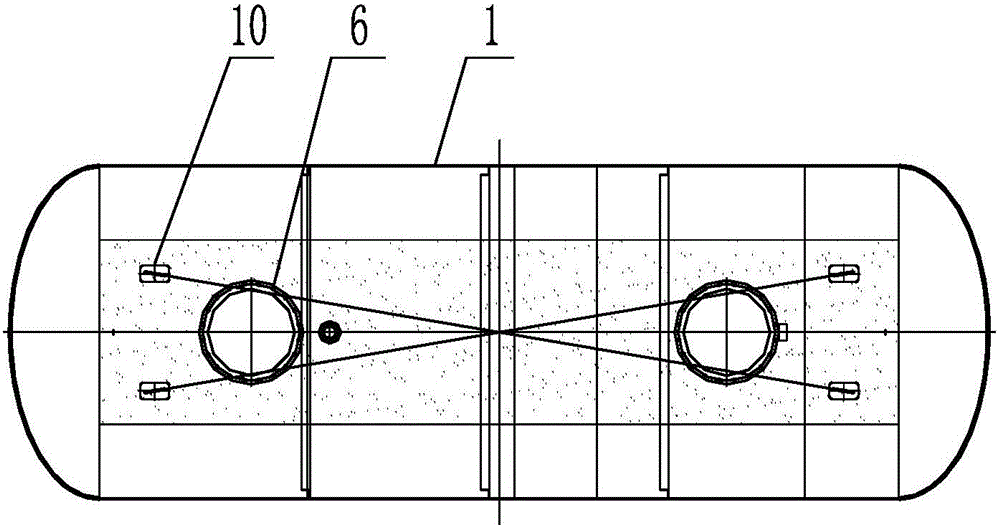

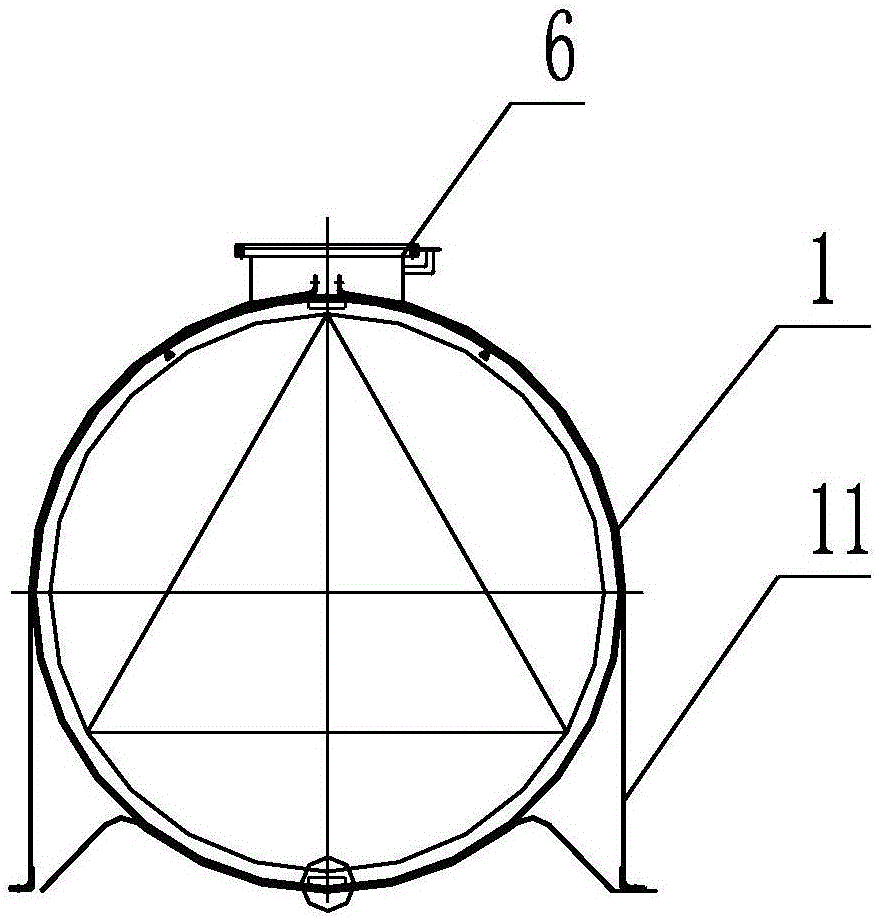

[0028] Attached below Figure 1-3 The buried double-layer oil tank of the present invention and its preparation method are described in detail.

[0029]A buried double-layer oil tank, the buried double-layer oil tank includes an inner steel tank 1 and an outer shell 2; wherein, a vacuum interlayer 3 is formed between the inner steel tank and the outer shell; There is a detection device for detecting liquid leakage between the inner steel tank and the outer shell. The detection device is connected to the control room by remote communication. Manhole 6 and detection well 7 at the top of the cylinder; the detection device includes a detection tube 8 and a probe arranged in the vacuum interlayer, and the detection tube is arranged in the vacuum interlayer of the outer wall of the bottom of the cylinder for guiding the leakage liquid; the probe is set Real-time detection of leaked liquid is performed at the bottom of the detection tube, and is connected with the control room 9 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com