Patents

Literature

479 results about "Electrolytic corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolytic corrosion is a process of accelerated corrosion. In this process, a metallic surface is continuously corroded by other metal it is in contact with, due to an electrolyte and the flow of an electrical current between the two metals, caused from an external source of electromotive force (EMF).

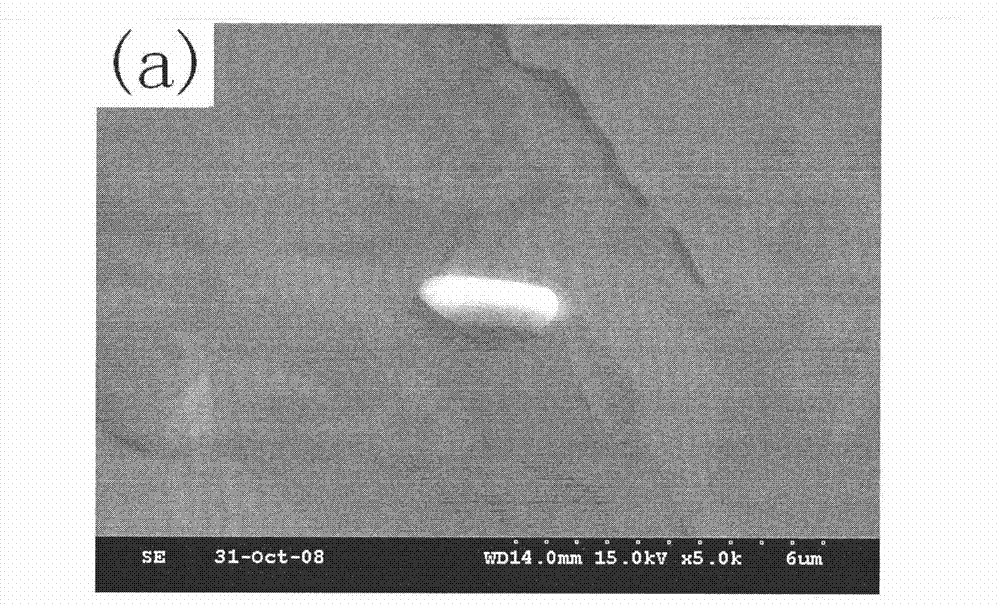

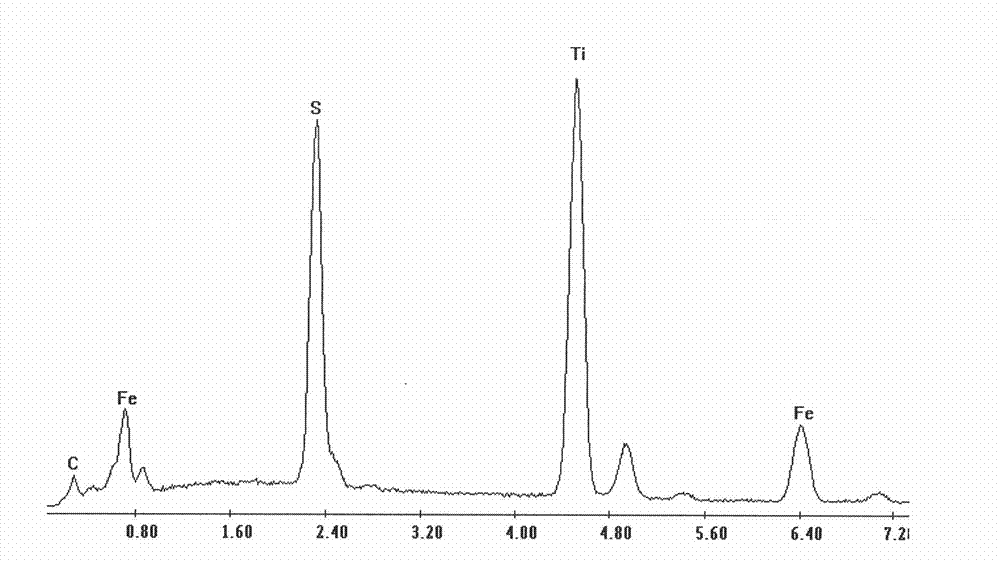

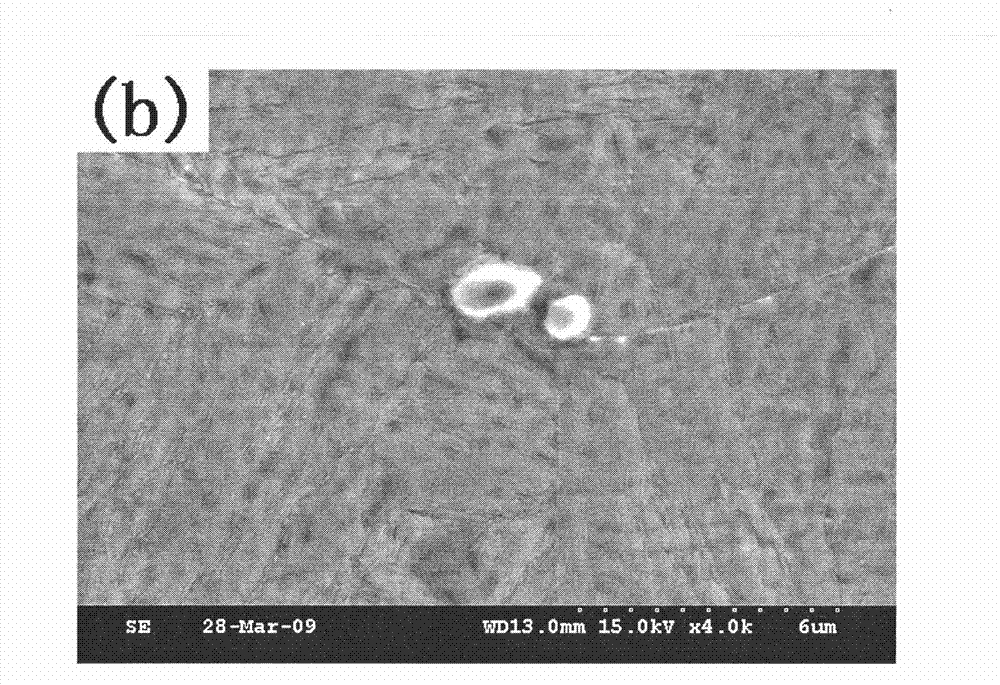

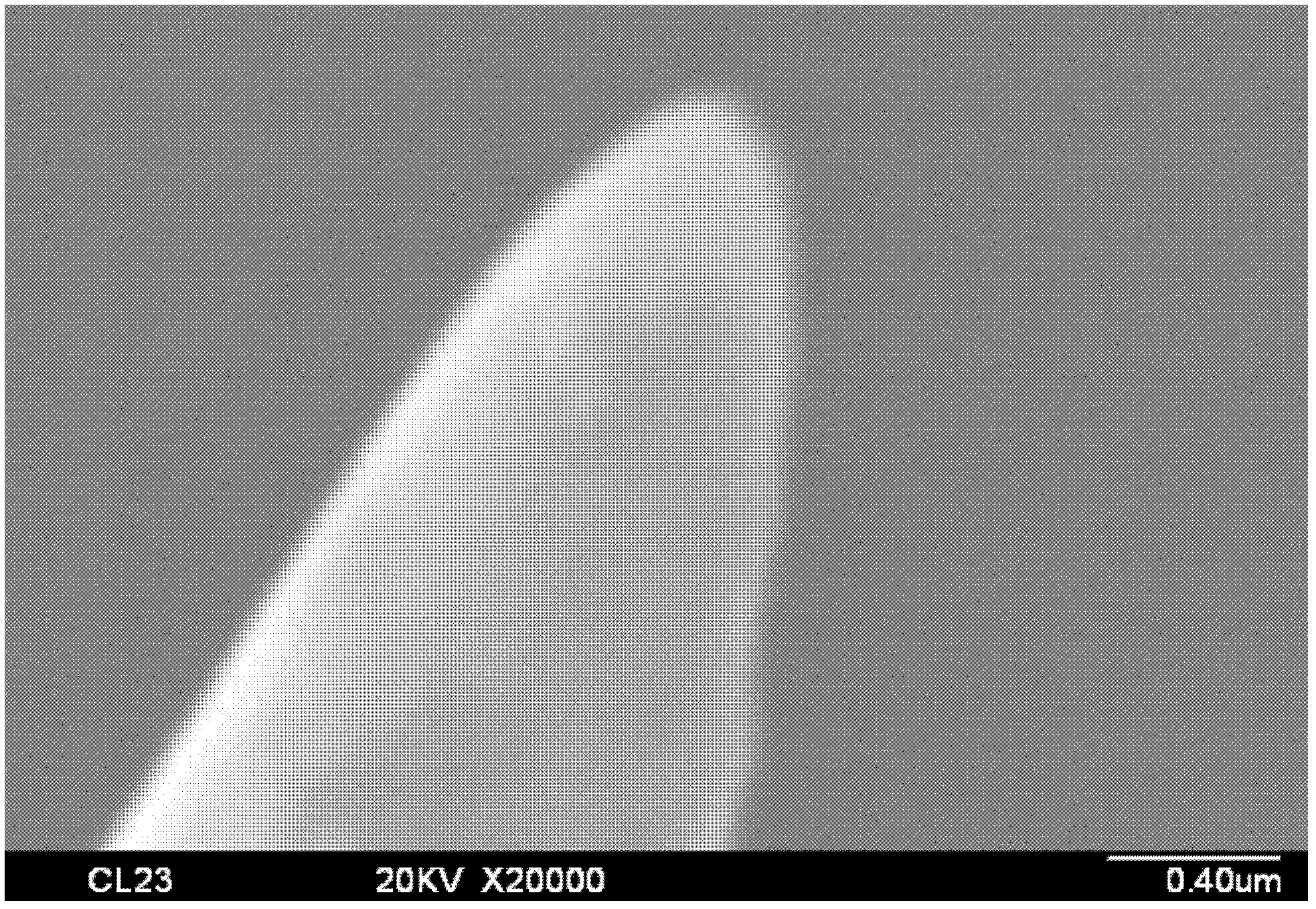

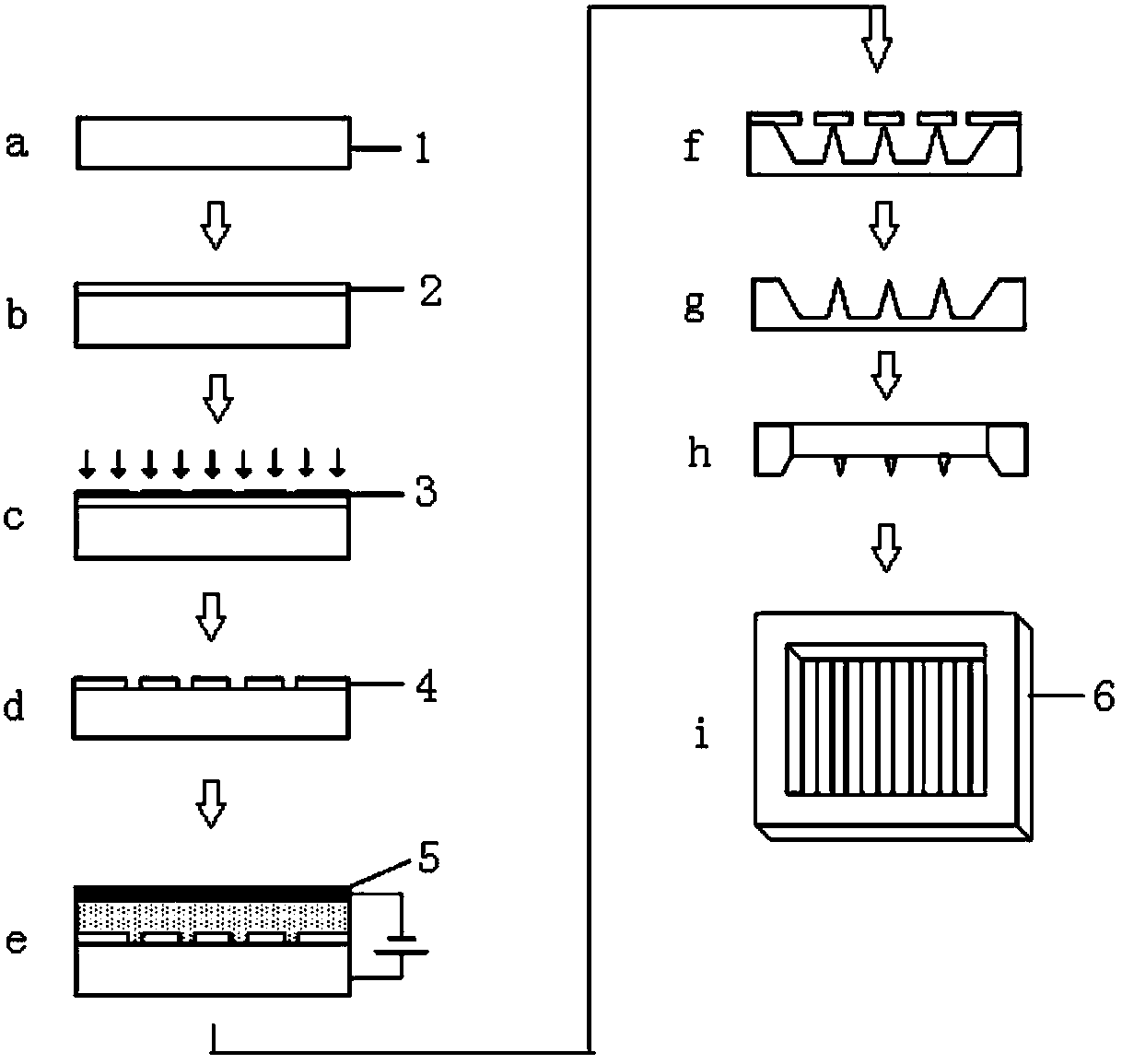

Method for observing in-situ morphologies of nonmetallic inclusions in steel

InactiveCN102879412ATrue form completeThe real shape is fully presentedPreparing sample for investigationMaterial analysis by measuring secondary emissionSpectroscopyGlycerol

The invention relates to a method for observing the in-situ morphologies of the nonmetallic inclusions in steel. The method is characterized by comprising the following steps: a metallographic specimen is prepared and a surface to be observed is polished to be a plane; the superficial electrolytic corrosion is performed on an electrochemical polishing apparatus, an electrolyte is as follows: 5% (v / v) HCl (hydrogen chloride)+5%(v / v) glycerol+1% (v / v) citric acid methanol solution, and the setup parameters of the electrochemical polishing apparatus are as follows: the current density is 0.02A to 0.10A / cm<2>, the electrolytic temperature is from below 15 DEG C to below 5 DEG C, and the electrolytic time is 20 to 40s; a rubber rod is utilized for slightly wiping off the corrosive products on an electrochemical polishing surface of a test sample after the electrochemical polishing, the surface of the test sample is dried by a blow drier, and the nonmetallic inclusions are highlighted on an electrolytic etched surface of the test sample, so that the true morphologies of the nonmetallic inclusions with the different dimensions are completely displayed; and the morphologies of the nonmetallic inclusions are observed by a scanning electron microscope and an energy disperse spectroscopy. The method for observing in-situ morphologies of nonmetallic inclusions in steel provided by the invention has the advantages that the sample is prepared simply, the period is short, the analysis speed is fast, and the constituents and the varieties of the nonmetallic inclusions can be determined accurately by observing the three-dimensional morphologies and dimensions of the nonmetallic inclusions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

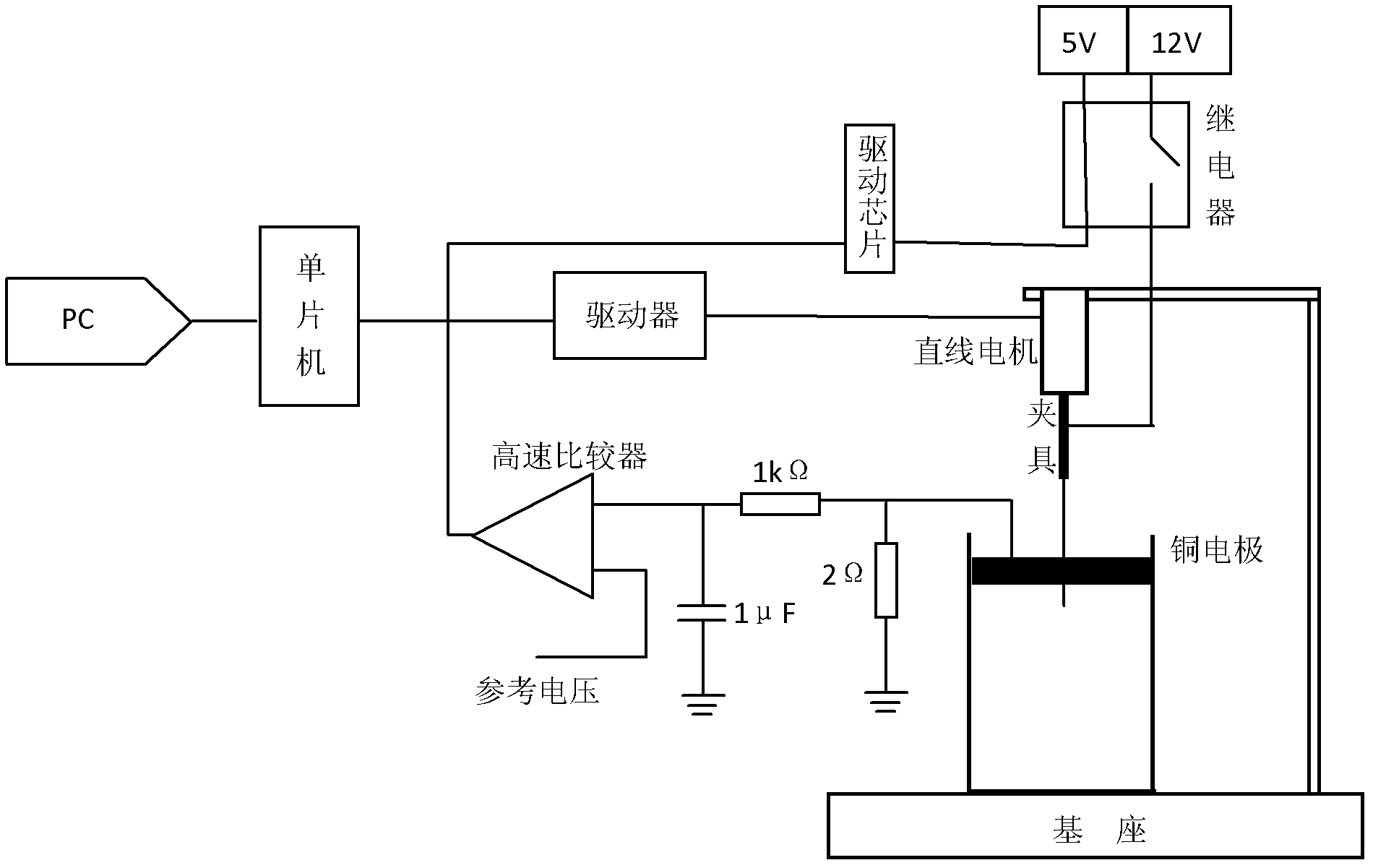

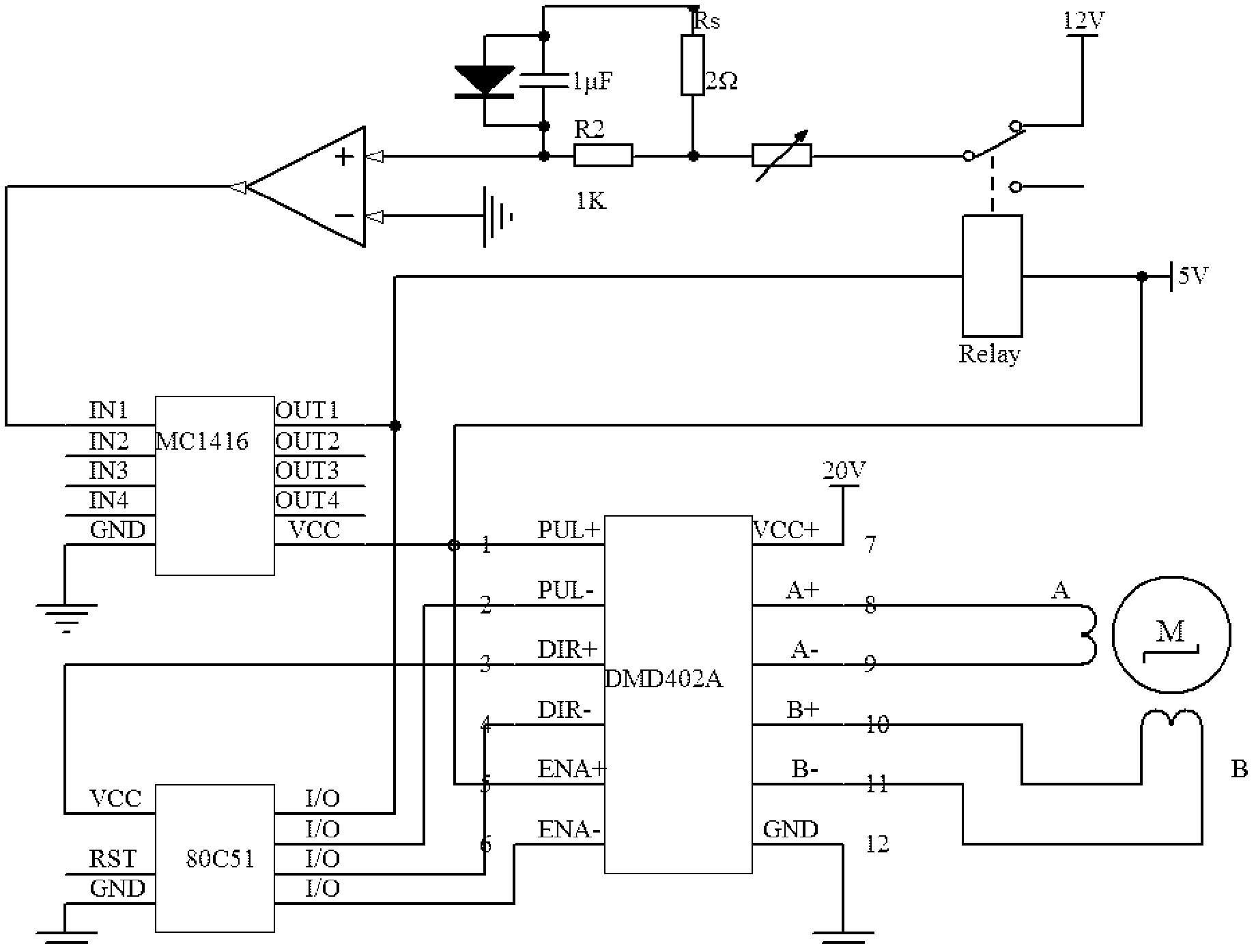

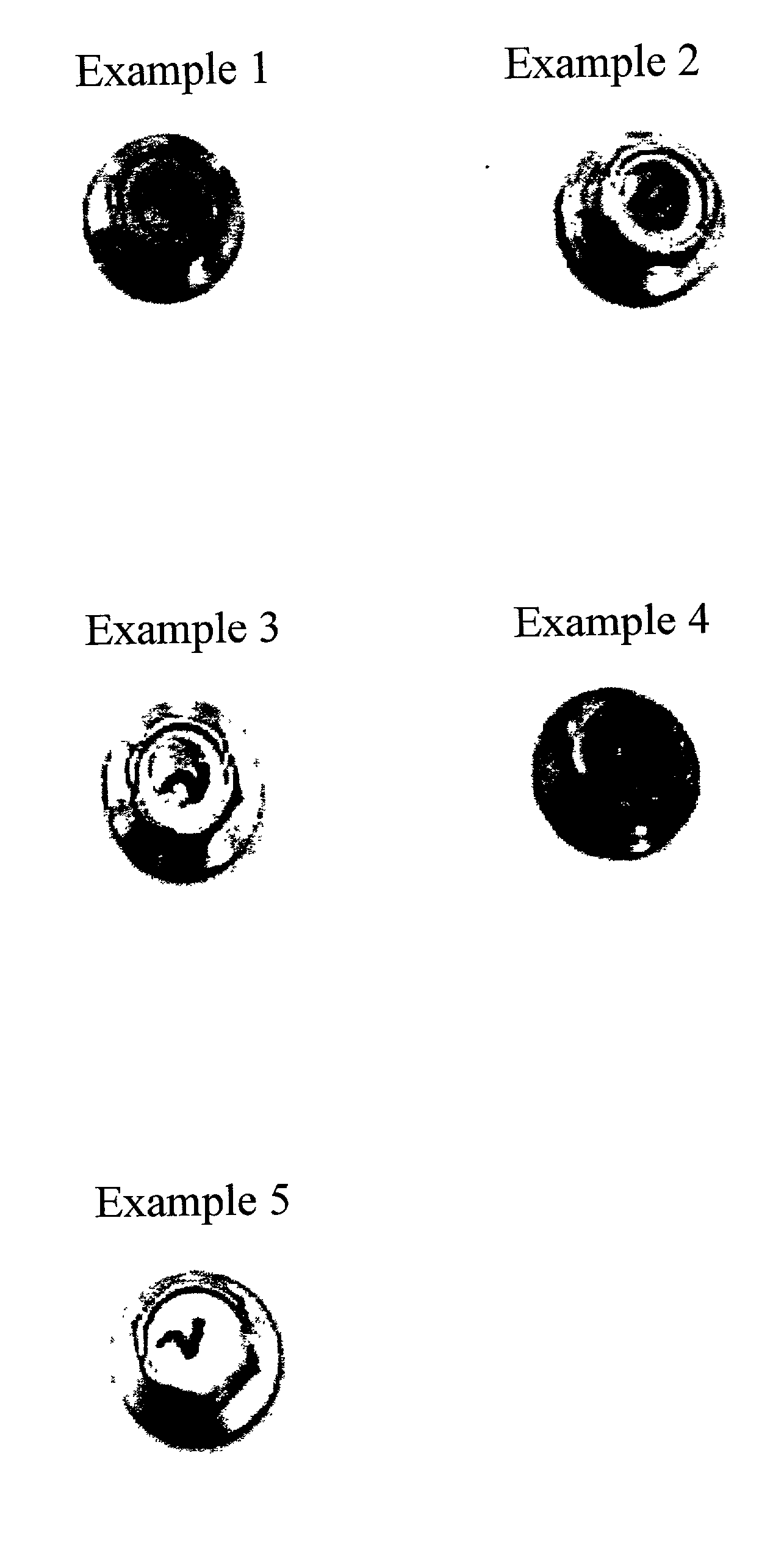

High-efficiency automatic tungsten needle manufacturing device and method

ActiveCN102586854AImprove corrosion efficiencyReduce corrosion costsElectrolysis componentsNanotechnologyElectrochemical responseElectrolysis

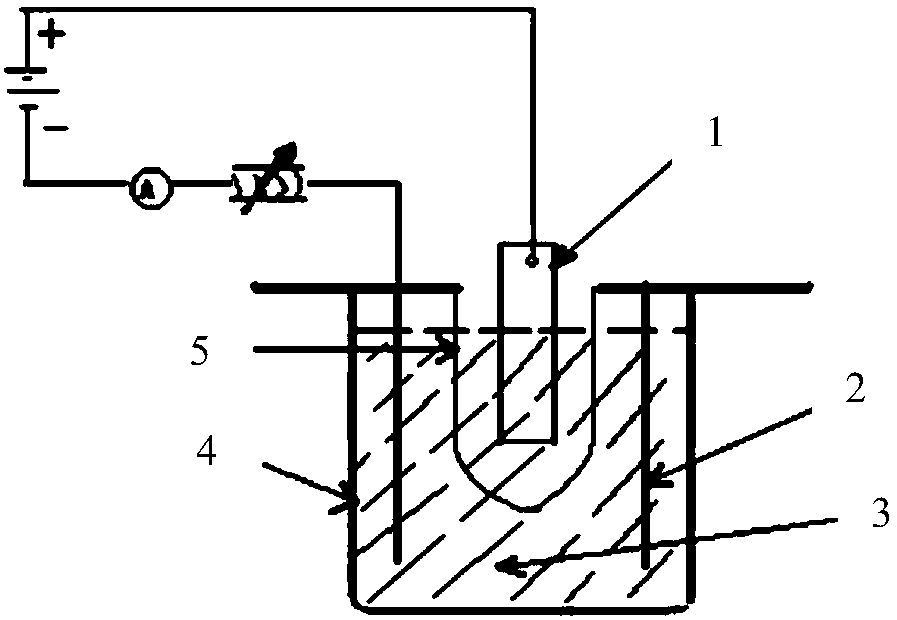

The invention discloses an automation high-efficiency direct-current-controlled dynamic manufacturing device and method of tungsten needles. In the device, an electrochemical reaction principle is adopted, a tungsten wire is driven by a linear motor to move up and down in NaOH corrosion liquid in a reciprocating manner so that a reaction is carried out between an anode tungsten wire and a cathode annular copper electrode, and the change of current in a circuit is monitored by utilizing a sampling resistor, a low-pass filter circuit, a voltage follower and a high-speed comparer; when the tungsten wire is corroded to be broken in an electrolyte solution, the sudden change of the current in the circuit causes an output signal of the comparer to change, a voltage applying circuit is switched off and a whole electrolytic corrosion process is finished; and furthermore, the conical degree and the tip radius of the tungsten needle can be adjusted by utilizing the change of motion speed of the linear motor. The device and the method, disclosed by the invention, have the characteristics of high automation degree of tungsten needle preparation, good repeatability and high efficiency.

Owner:咸阳瞪羚谷新材料科技有限公司

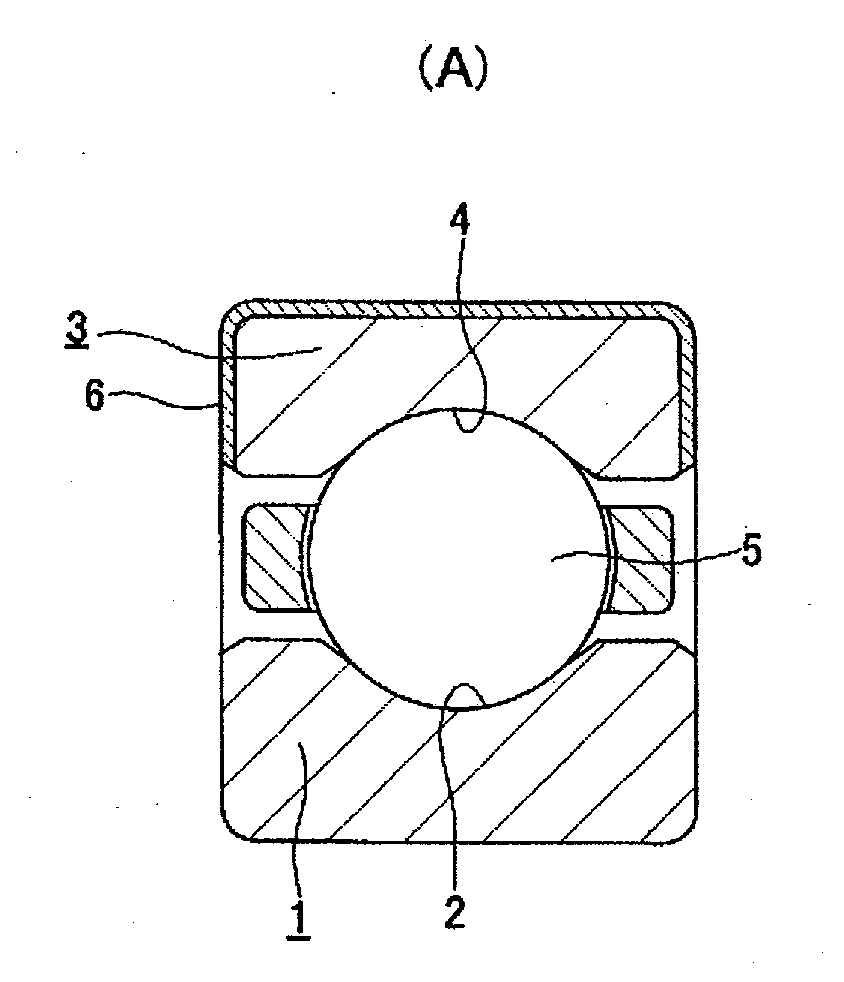

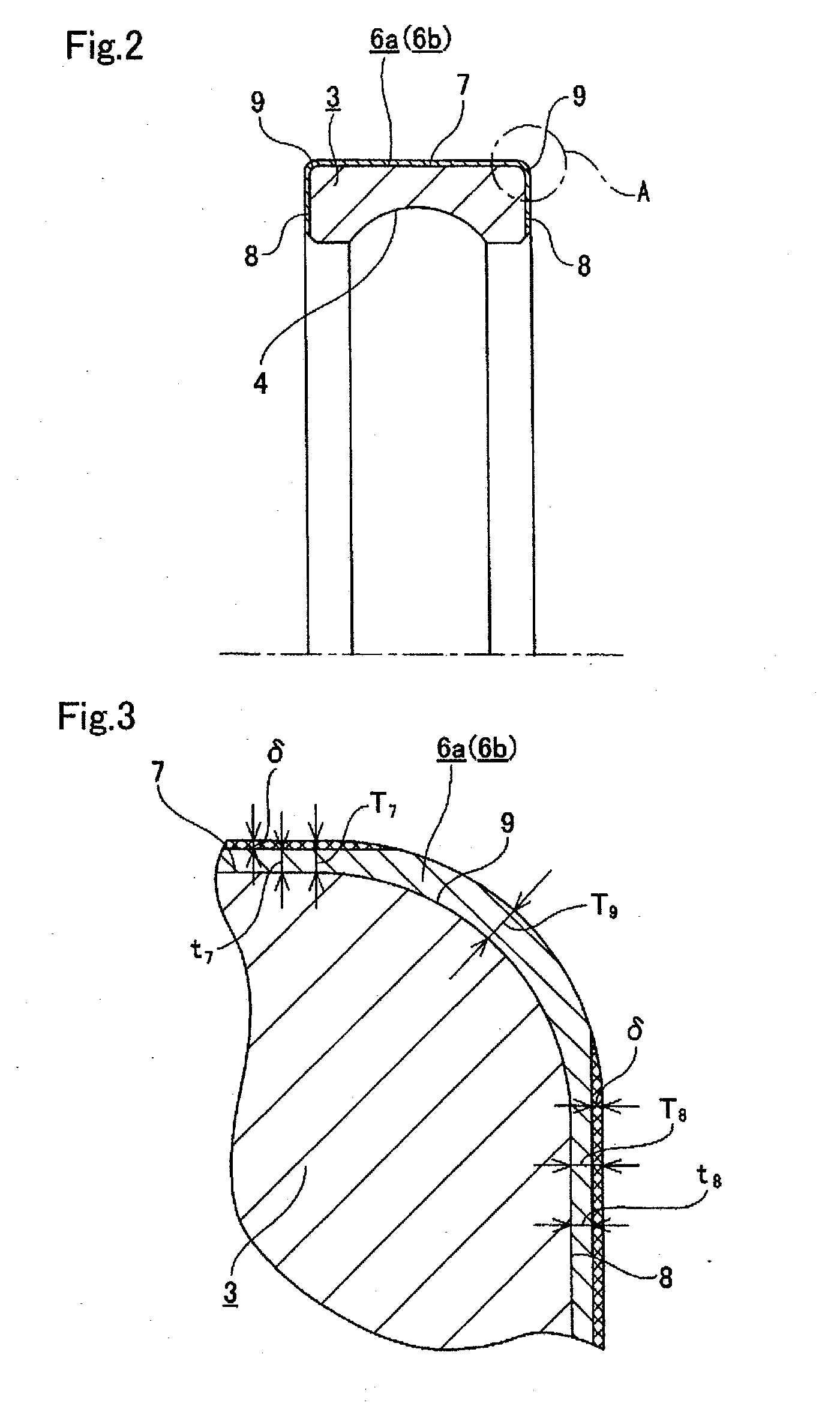

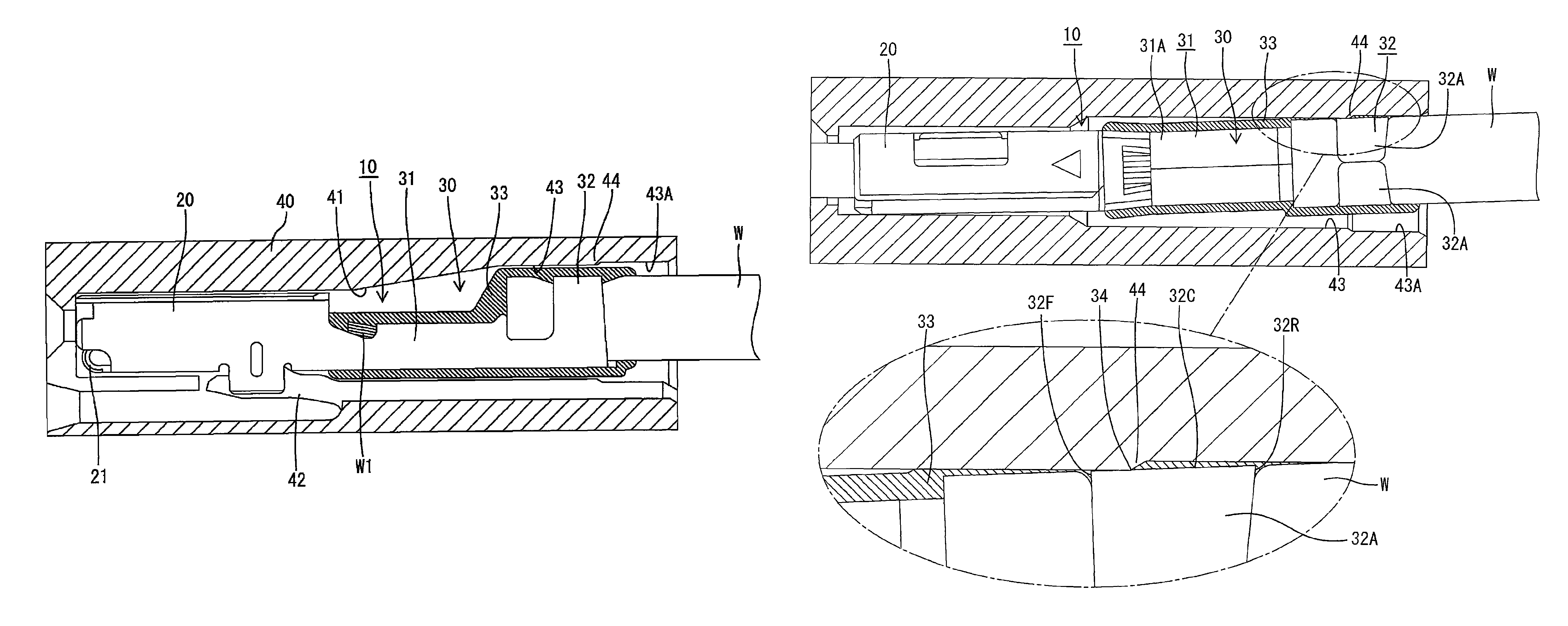

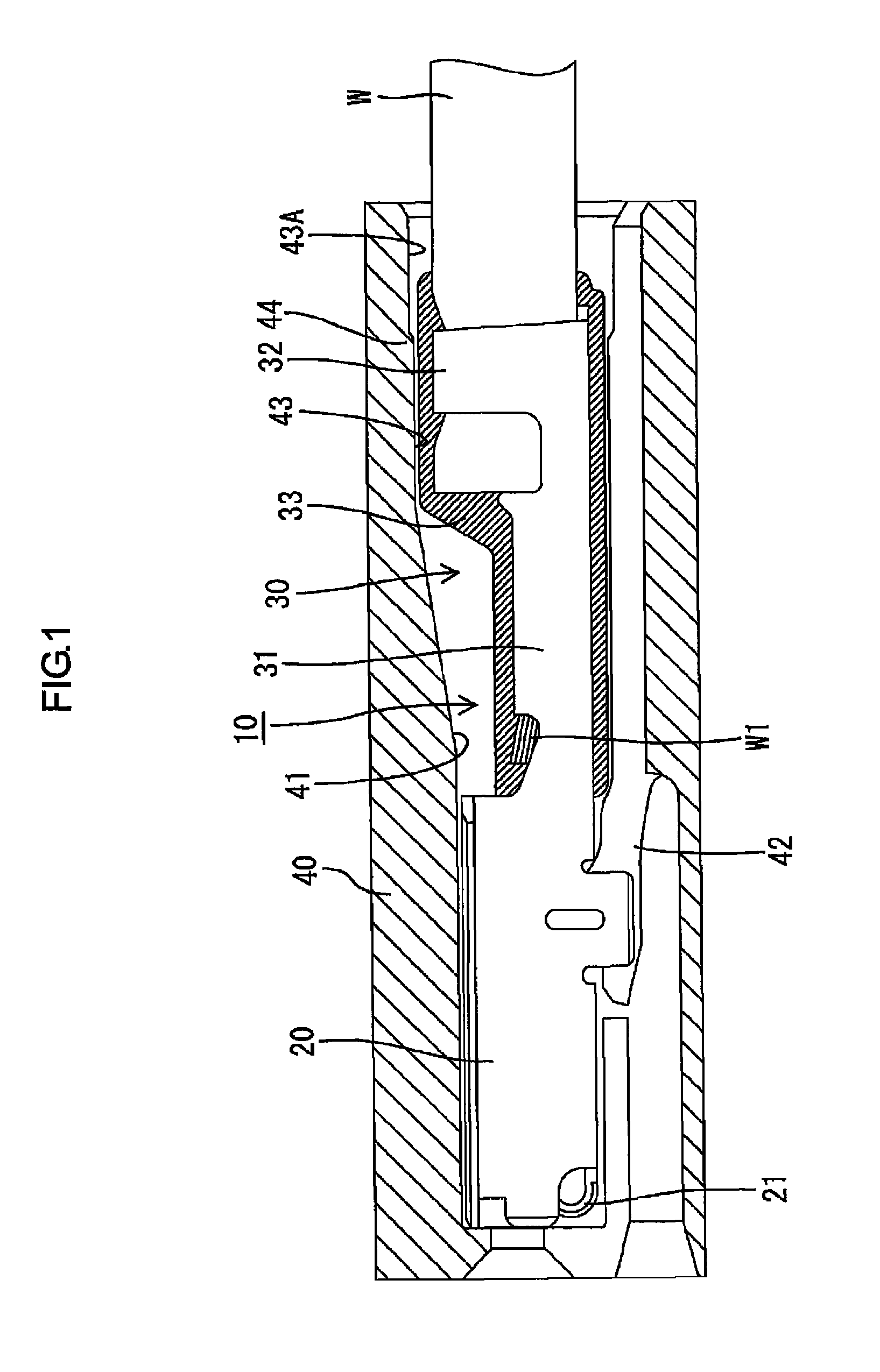

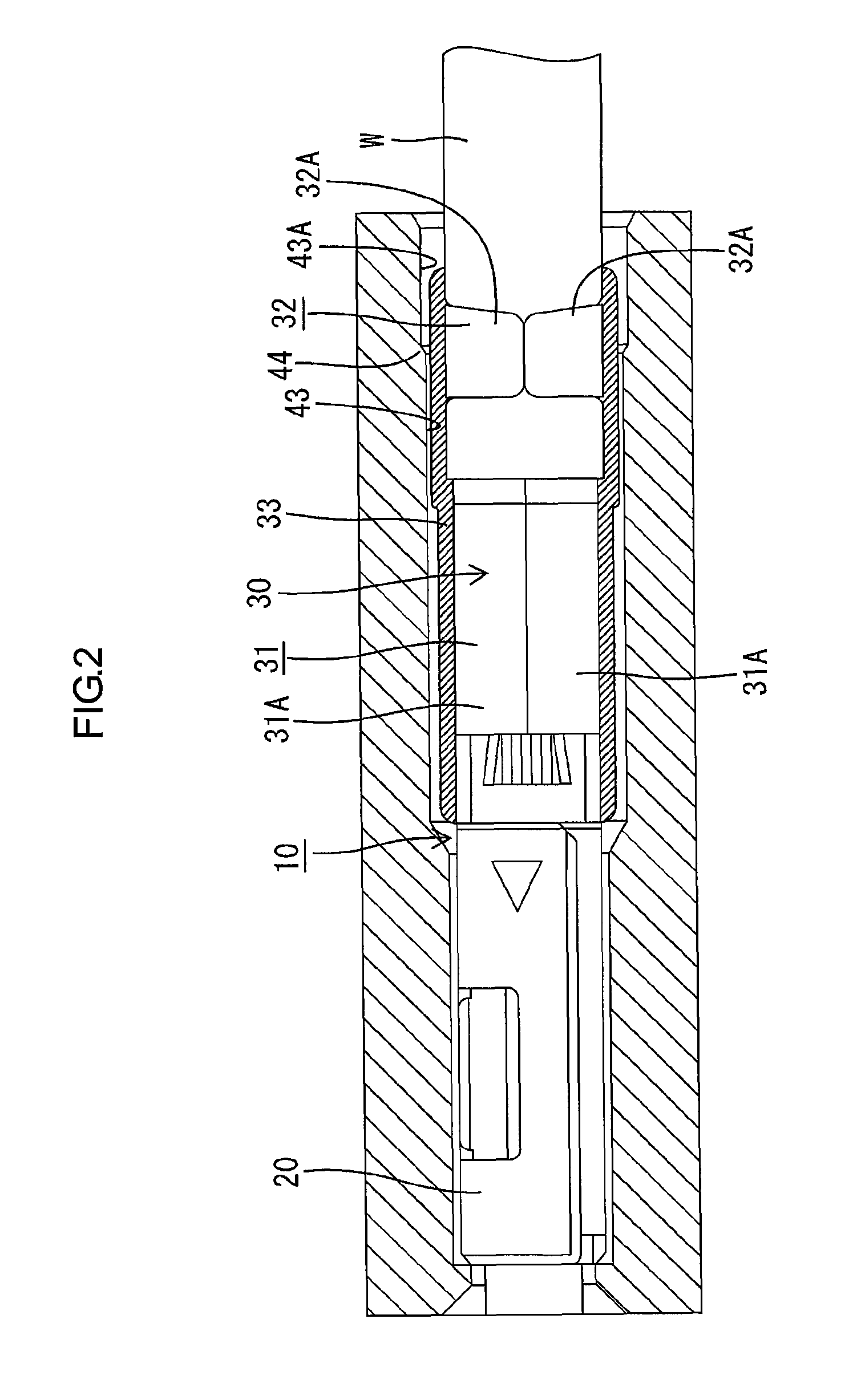

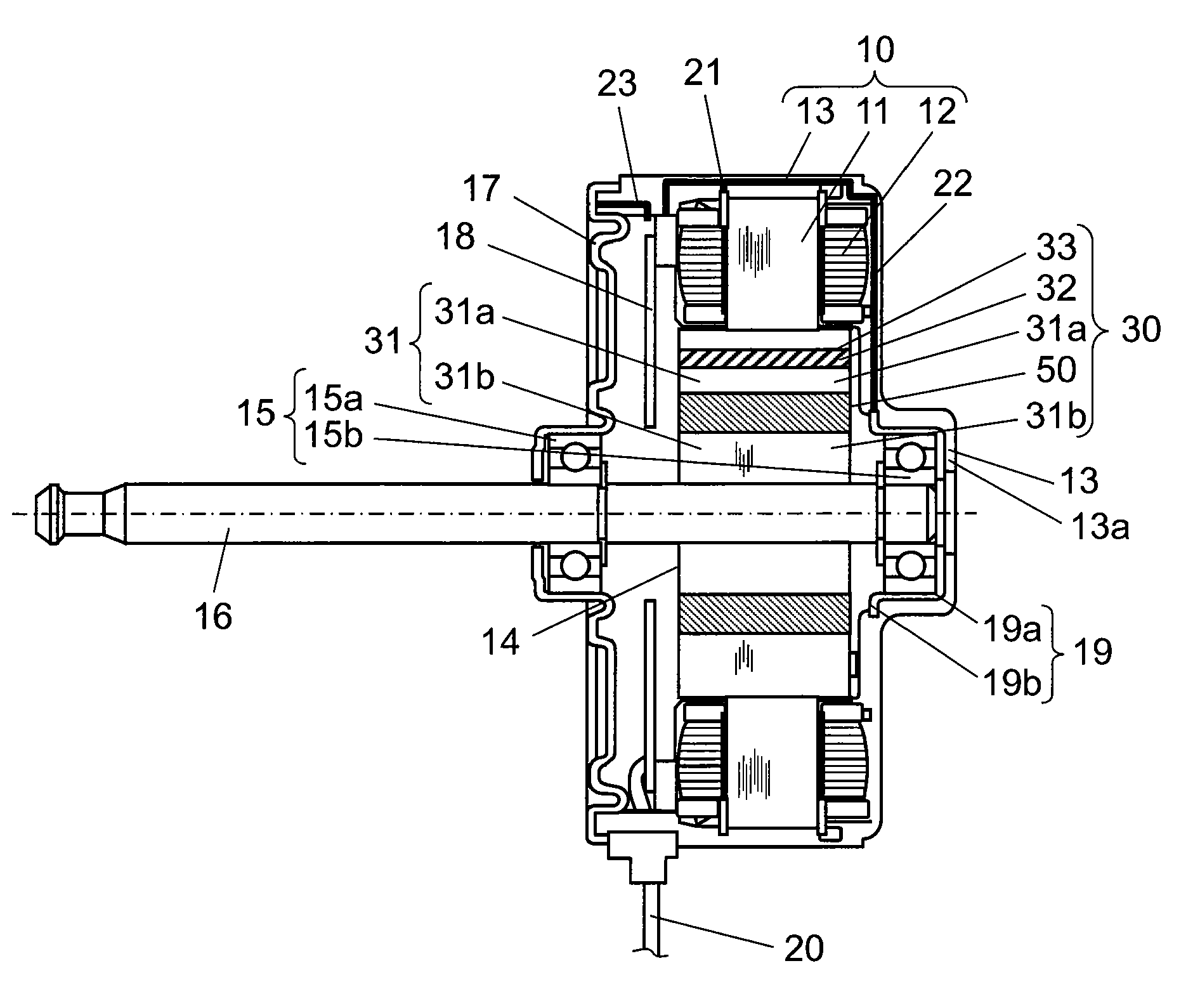

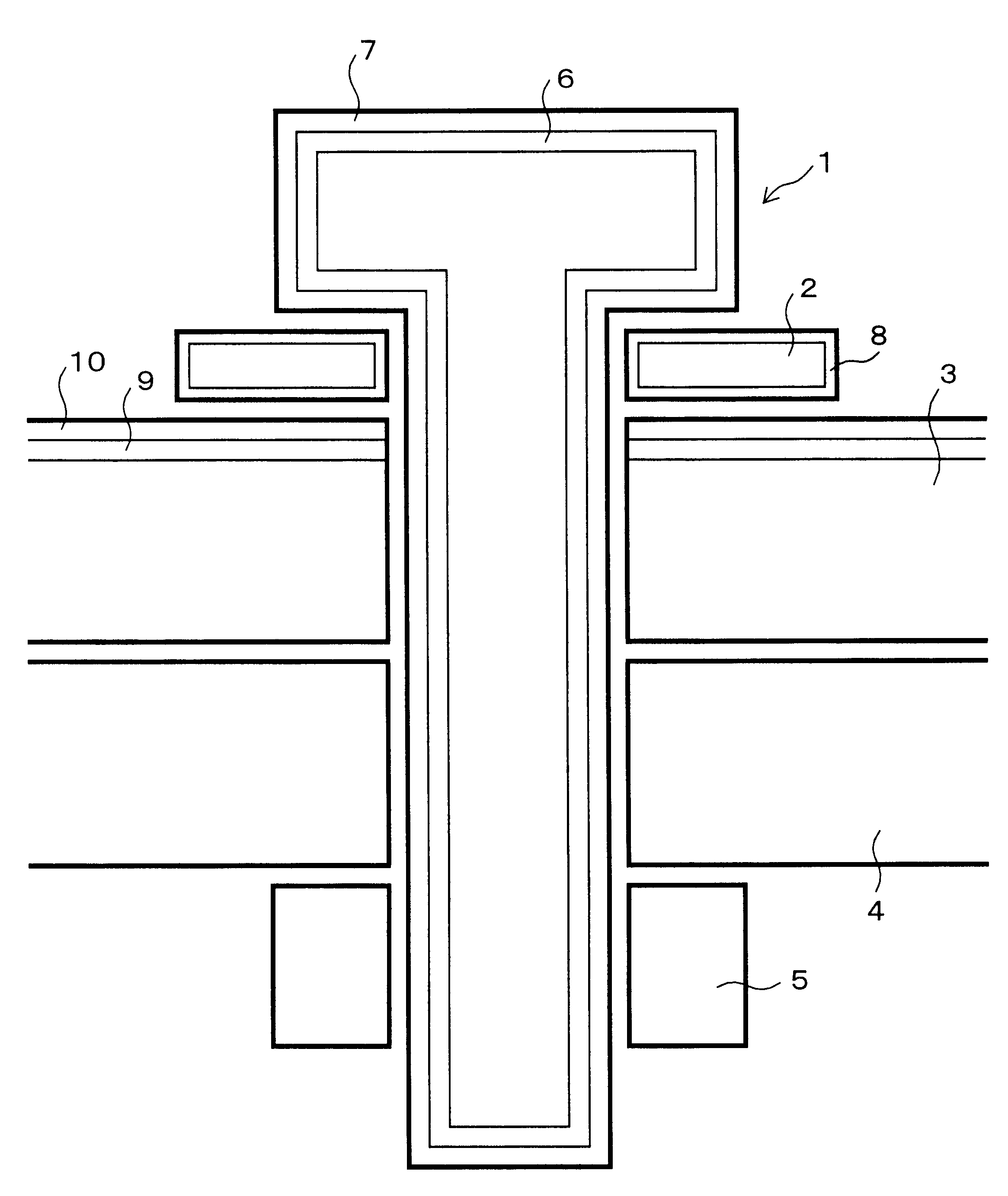

Electrolytic Erosion Preventing Insulated Rolling Bearing, Manufacturing Method Thereof, and Bearing Device

ActiveUS20090304318A1Increased durabilityHigh of insulation performanceBearing assemblyShaftsElectrolysisCeramic coating

In order to ensure high levels of insulation performance, and low cost, and have an excellent external appearance, as a ceramic constituting an insulating coating 6 being a ceramic coating layer, one with alumina as its main component, and in which the content of titanium oxide is limited to 0.01 to 0.2 percent by weight is used. Moreover, a particle size of ceramic forming the coating layer is 10 to 50 μm, and average particle size is 15 to 25 μm. By limiting the content of titanium oxide, the insulating coating 6 can be made thin, and by limiting the particle size the film thickness accuracy can be improved, thus simplifying finishing. Moreover, by mixing of titanium oxide, deterioration of the external appearance after sealing can be prevented. As a result, the above problem is solved.

Owner:NSK LTD

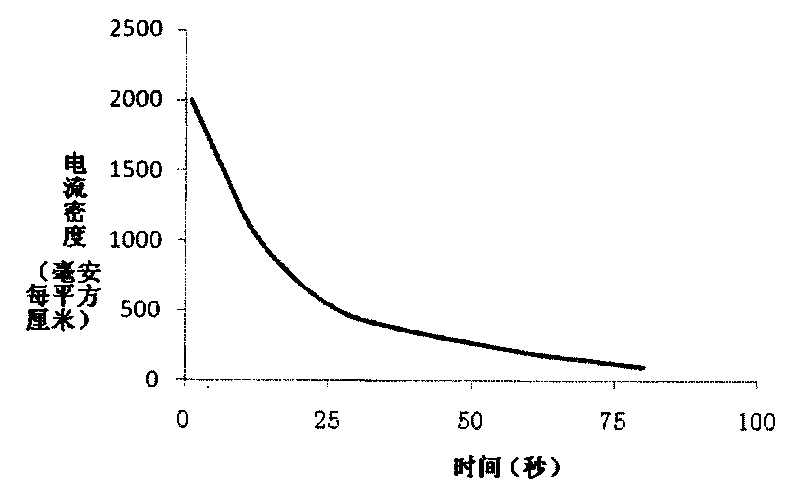

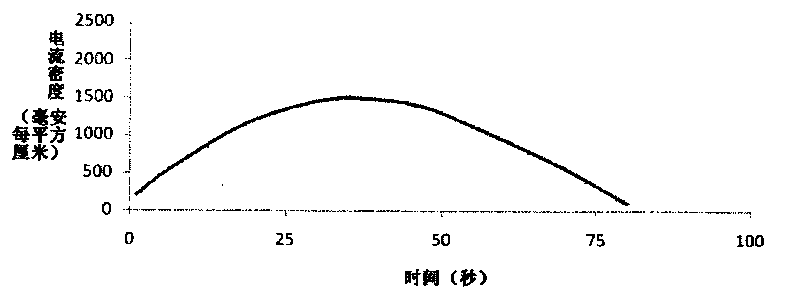

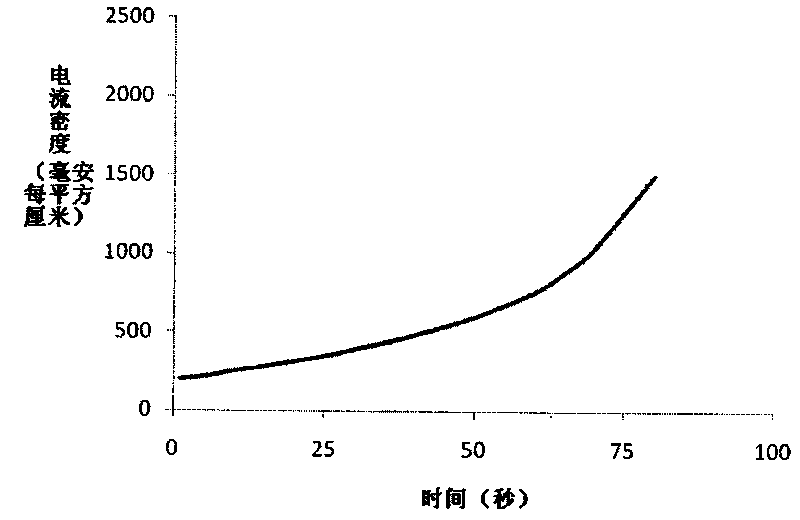

Method for etching holes by corroding aluminum foil

InactiveCN101752095AHigh densityUniform densityElectrolytic capacitorsConstant current densityMaterials science

The invention discloses a method for etching holes by eroding an aluminum foil, which comprises the steps of pretreatment, first level corrosion, second level corrosion, post treatment and drying. The first level corrosion comprises the following steps of: putting the aluminum foil after the pretreatment into mixed solution of hydrochloric acid and sulfuric acid, wherein the mixed solution contains 0.5 to 1.0 N / L of aluminum, the temperature of the mixed solution is between 65 and 90 DEG C and the total acidity of the mixed solution is 5.0 to 8.0 N / L; and applying 45 to 80 seconds of direct current of which the current density changes along with the time to perform electrolytic corrosion for etching the holes in mainly three modes that: one, the current density changes from high to low along with the time; two, the current density changes from low to high and then to low again; and three, the current density changes form low to high. The hole etching mode that the current density changes from high to low along with the time improves the specific volume by 7 to 12 percent compared with the existing hole etching method with constant current density under the premise of not reducing the mechanical strength of the aluminum foil.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

Laser melting rehabilitation method for titanium alloy thin-wall case

InactiveCN1966201AHigh hardnessQuality improvementLaser beam welding apparatusHeat inorganic powder coatingHydrogenThermal deformation

The invention relates to a method for using laser fusion to repair titanium alloy frame, wherein the inventive method comprises that: smoothing the abrasive area of element surface; cleaning out the solder electrolytic corrosion layer and solder vacuum anneal hydrogen removing treatment; at 750-800Deg. C, for 40-60min, 0.2-0.4MPa, using argon gas to cool down to 80Deg. C, discharging from furnace; laser fusion, while fusion frequency f=5-6Hz, time t=4-5m, under argon gas whose flux Q-4.5-5.5L / min, the fusion solder fills the abrasive part higher than 0.2-0.4mm, to cove 40-75%; abrading to needed size and roughness. The invention has simple operation and high rigidity, without thermal deformation.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

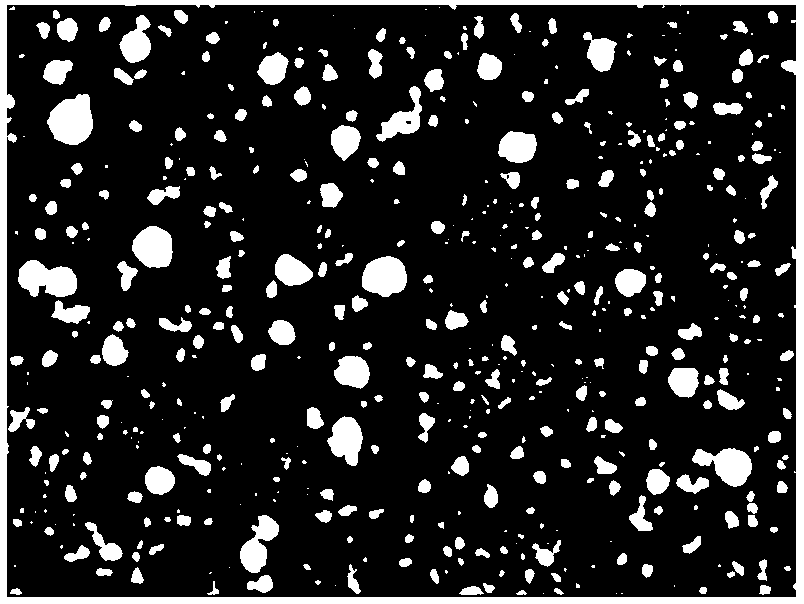

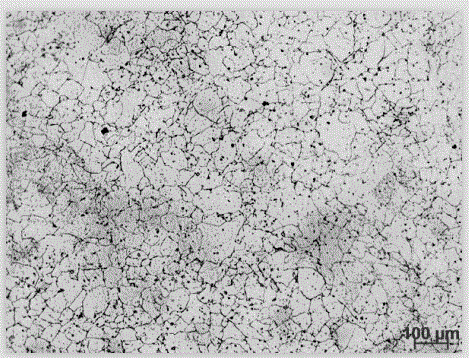

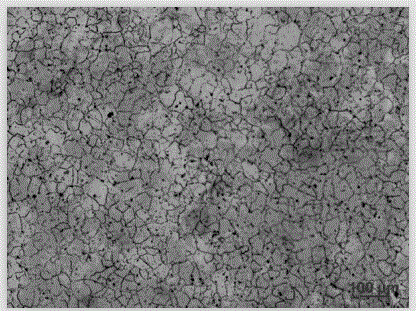

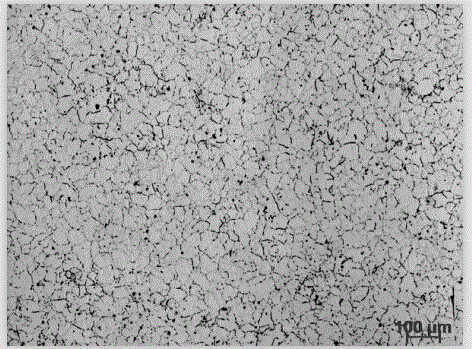

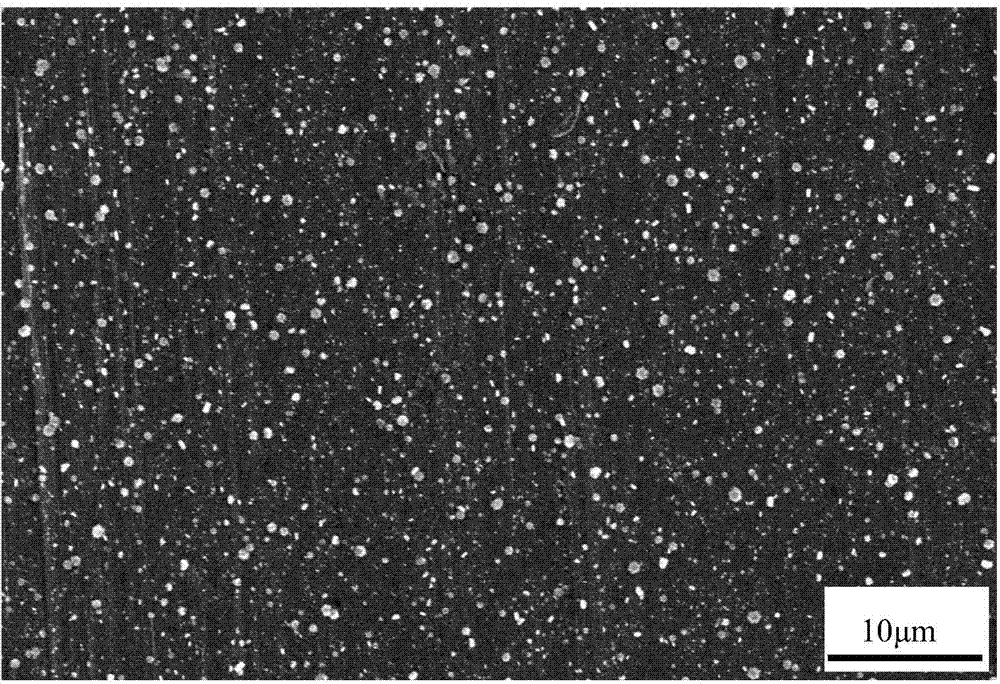

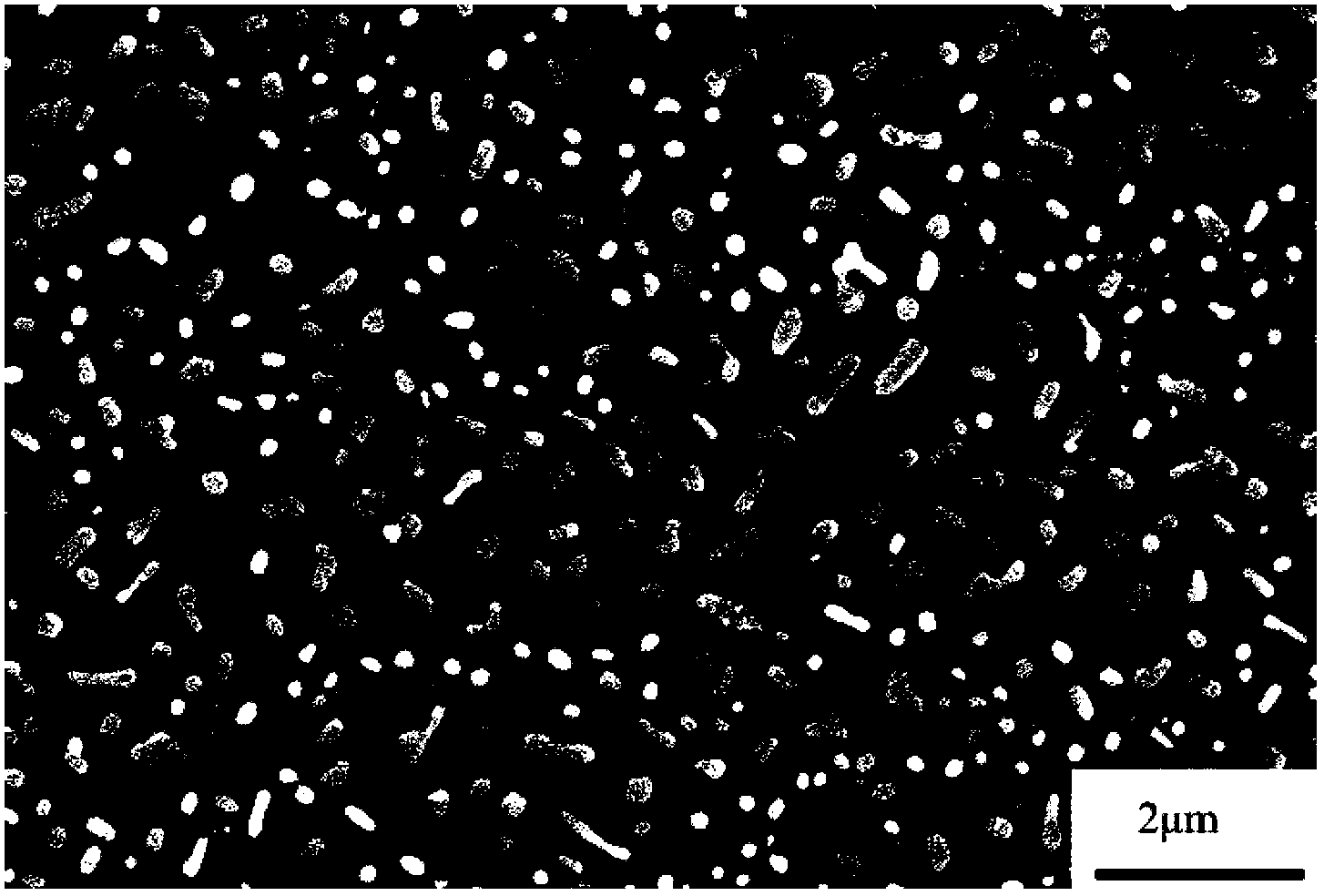

Full-view-field quantitative statistical distribution representation method of precipitated phase particles in metal material

ActiveCN108226159ARealize analysisEliminate statistical incompletenessImage enhancementImage analysisMathematical modelMetallic materials

The invention belongs to the technical field of the quantitative statistical distribution analysis of characteristic chromatograms of microstructures and precipitated phases in metal materials, and relates to a full-view-field quantitative statistical distribution representation method of precipitated phase particles in a metal material. The method comprises the following steps of electrolytic corrosion of a metallic material sample, automatic collection of a characteristic chromatogram of a metallurgical structure, automatic splicing and fusion of the characteristic chromatograms of full-view-field metallurgical structures, automatic identification and segmentation of the precipitated phase particles and quantitative distribution representation of the large-range full-view-field precipitated phase particles. According to the full-view-field quantitative statistical distribution representation method, through establishing a mathematic model, the automatic splicing and fusion of the characteristic chromatograms of the full-view-field large-area metallurgical structures in a characteristic region and the automatic segmentation and identification of the precipitated phase particles are realized; the quantitative statistical distribution representation information of the full-view-field morphology, quantity, size, distribution and the like of plentiful precipitated phases in a larger range is quickly obtained, and the method has the features of being accurate and high-efficiency and large in quantitative distribution representation information quantity, and has much more statistical representativeness compared with conventional single-view-field quantitative image analysis.

Owner:CENT IRON & STEEL RES INST

Method for erosion of high pressure high specific volume anode foil

InactiveCN101206956ASolving Corrosion ProblemsHigh mechanical strengthElectrolytic capacitorsPhosphoric acidPolyethylene glycol

The invention relates to a corrosion method of anode foil with high pressure and high specific volume. Firstly, preliminary treatment is performed to aluminum foil; secondly, primary direct current electrolytic corrosion is performed in the mixed liquor with the concentration of 0.5 to 5 wt percent of sulphuric acid and 1 to 10 wt percent of sulphuric acid; thirdly, secondary direct current electrolytic corrosion is performed in the mixed liquor with the concentration of 5 to 15 wt percent of sulphuric acid, 0.01 to 0.1 wt percent of phosphoric acid and 0.01 to 0.1 wt percent of polyethylene glycol (The molecular weight is 10000); thirdly, the tertiary direct current electrolytic corrosion is performed in the mixed liquor with the concentration of 5 to 15 wt percent of chlorhydric acid, 0.01 to 0.1 wt percent of phosphoric acid and 0.01 to 0.1 wt percent of polyethylene glycol; finally, the immersion is performed in the water solution with the concentration of 0.5 to 5 wt percent of nitric acid. The adoption of the corrosion method of the invention not only solves the corrosion problem of the high voltage anode foil, but also improve the surface expand rate of the aluminum foil, the specific volume of the aluminum foil is greatly improved, and the high voltage anode foil has better mechanical strength on the premise of obtaining high specific volume.

Owner:横店集团东磁有限公司

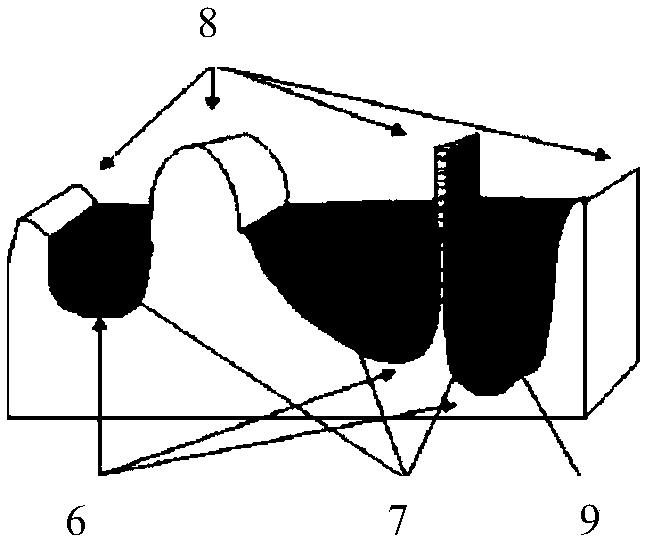

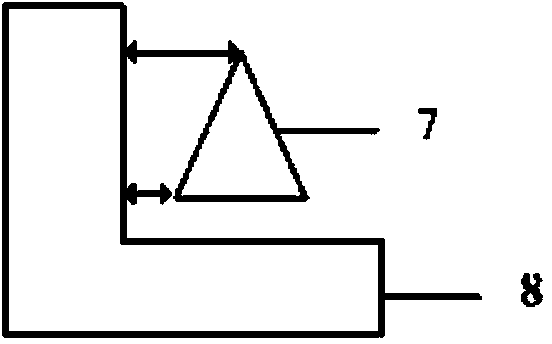

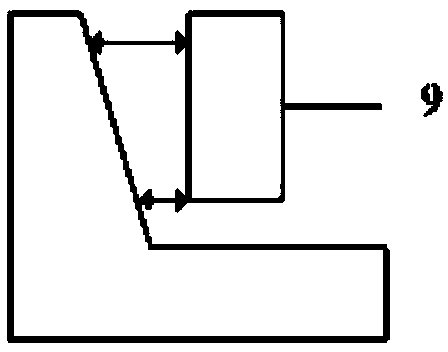

Wire electrode array structure preparation method for micro-electrochemical machining

ActiveCN103706899AEfficient preparationReduce the impactMachining electrodesElectrical-based machining electrodesElectrolysisElectrode array

The invention discloses a wire electrode array structure preparation method for micro-electrochemical machining. The wire electrode array structure preparation method includes the steps of 1), pretreating a metal base; 2), manufacturing a graphical masking film; 3), subjecting the masking film to profound electrolytic corrosion, namely taking the metal base with the graphical surface as a positive electrode for electrolytic machining to obtain a tool negative electrode in a wire electrode template machined and manufactured in the profound electrolytic corrosion, and determining electrolytic corrosion time according to photoresist pattern width and electrolysis current density till to obtain a metal gate line array pattern with the point top; 4), removing back materials, namely removing the back materials corresponding to the manufactured metal gate lines to obtain a wire electrode array integrated with a frame. By means of the method, the metal microstructure array with cross sections different in shapes like square, rectangle and rhombus can be manufactured, so that the metal microstructure array with large depth-to-width ratio, high density and high machining quality can be efficiently realized.

Owner:江苏蔚之领域智能科技有限公司

Anti-tracking polyethylene sheathing material

The invention relates to an anti-tracking polyethylene sheathing material which comprises a mixture of high-density polyethylene resin and low-density polyethylene resin, and an anti-tracking agent is filled in the blended and modified polyethylene resin. The anti-tracking polyethylene sheathing material has a favorable anti-tracking property and can eliminate the electrolytic corrosion phenomenon on the surface of an optical cable in a highfield and operate for a long time in a severe environment outdoors without faults.

Owner:成都亨通光通信有限公司

Preparation method of V-based alloy metallographic sample

InactiveCN103884566AContribute to researchImprove the finishPreparing sample for investigationMegasonic cleaningAlloy

The invention provides a preparation method of a V-based alloy metallographic sample, and belongs to the fields of heterogeneous alloy metallographic phase preparation. The method includes: subjecting a block V-based alloy sample to coarse grinding pretreatment, grinding with water step by step, preparing an electrolytic polishing solution, subjecting the sample to electrolytic polishing, subjecting the polished sample to cleaning under ultrasonic wave, wiping with alcohol, blowing the sample to dry the sample, preparing an electrolytic corrosion solution, subjecting the sample to electrolytic corrosion, washing the sample, wiping the sample with alcohol, blowing the sample to dry the sample, and performing metallographic observation. By adjusting experiment parameters and controlling the preparation steps of the V-based alloy metallographic sample, different metallographic phase shapes of the V-based alloy can be obtained, thus meeting observation requirements of different metallographic phases, reflecting comprehensive V-based alloy microstructure and providing experiment support for research of the V-based alloy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Formation technique of medium/high-voltage anode aluminum foil for enhancing aluminum electrolytic capacitance

ActiveCN103243369AIncrease capacityShort boost timeSurface reaction electrolytic coatingCapacitanceElectrolysis

The invention relates to the technical field of medium / high-voltage formation of anode foils, particularly a six-stage formation technique for enhancing capacity of an anode foil for an aluminum electrolytic capacitor and lowering the boosting time Tr and Tr60 by medium / high voltage. The technique is characterized by comprising the following steps: treating an aluminum foil subjected to electrolytic corrosion treatment in 50-100 DEG C pure water, and forming with phytic acid and citrate solution in the primary, secondary and tertiary stages; forming in phytic acid, boric acid and citrate solution in the quaternary, quinary and senary stages; and depolarizing by heat treatment and phosphate treatment. The boosting time Tr is at least lowered by 23%, the boosting time Tr60 is at least lowered by 66%, and the specific capacity effect of the aluminum foil is enhanced by 10-20%.

Owner:YIDU DONGYANGGUANG FORMED FOIL

Six-level forming method of medium and high voltage aluminum electrolytic capacitor anode foil

InactiveCN103187181AIncrease capacityMeet the volumeMetal surface removal provisionCapacitor electrodesElectrolysisMetallurgy

The invention discloses a six-level forming method of a medium and high voltage aluminum electrolytic capacitor anode foil. The six-level forming method comprises the main steps of carrying out high-temperature water treatment on an aluminum foil after electrolytic corrosion treatment after the aluminum foil passes through an aluminum feeder roller, carrying out first-level, second-level and third-level forming, and sequentially carrying out four-level, five-level and six-level forming after liquid feeding, wherein only one forming groove is used in the previous five levels of forming process, five forming grooves are used in the six-th level of forming process, and the three forming grooves in the middle are connected in series. The anode foil prepared by the method is high in capacity and high in bending strength. Compared with the film formed in the prior art, the film formed by using the six-level forming method has the advantages that quality is greatly improved; and the demands of the existing electrolytic capacitor on small size, high capacity and long service life are completely met.

Owner:YINGJING XUGUANG ELECTRONICS

Formation foil for aluminium electrolytic capacitor and production process of formation foil

ActiveCN106653373ALoss of dielectric propertiesSmall pressure resistance thicknessElectrolytic capacitor manufactureFiberElectrolysis

The invention relates to a formation foil for an aluminium electrolytic capacitor and a production process of the formation foil. The production process comprises the following steps of 1) performing pretreatment on an electrolytic corrosion foil; 2) performing liquid spraying and four-stage formation on an aluminium foil by a formation solution; 3) cleaning; 3) performing sheet burning; 5) performing five-stage formation and six-stage formation on the four-stage formed foil to obtain six-stage formed foil; 6) performing after treatment; and 7) cleaning the six-stage formed foil after the foil is subjected to after treatment, and putting into a drying oven to be dried. According to the formation process of the formation foil for the aluminium electrolytic capacitor disclosed by the invention, a technology of spraying by formation groove liquid is added, so that impurities in corrosion holes can be effectively removed and surface fiber-shaped aluminium oxide crystals can be dissolved, and growth of outer layer hydrate is controlled; and a compact oxide film is generated through six-stage formation, so that specific capacity and anti-bending strength of the formation foil are further improved.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Anti-corrosion structure for wire connecting portion

InactiveUS8927863B2Avoid wire connectionsElectrolytic corrosion can be preventedConnections effected by permanent deformationCable junctionsMechanical engineeringMetal

A terminal assembly includes a wire including a core made of metal and covered with a coating, a terminal including a wire connecting portion connected to an end portion of the wire, a sealing resin sealing the wire connecting portion, and a housing including a through hole with a front opening and a rear opening. The terminal is made of a different kind of metal from the core of the wire. The housing accommodates the terminal in the through hole. The wire connecting portion includes an exposed portion not covered with the sealing resin and unexposed portions covered with the sealing resin. The exposed portion is positioned between the unexposed portions in a front and rear direction, thereby protecting the wire connecting portion from electrolytic corrosion. The exposed portion is obtained after the sealing resin is worn by being rubbed against an inner wall of the through hole.

Owner:SUMITOMO WIRING SYST LTD

Electrolytic corrosion agent capable of displaying nickel-based corrosion-resistant alloy metallographic structure and corrosion method thereof

InactiveCN104451851AStable in natureSlow down the rate of electrolytic corrosionPreparing sample for investigationCorrosion resistant alloyElectrolysis

The invention discloses an electrolytic corrosion agent capable of displaying a nickel-based corrosion-resistant alloy metallographic structure and a corrosion method thereof and belongs to the technical field of metallographic electrolysis corrosion. The electrolytic corrosion agent comprises 40-60g of oxalic acid, 120-180g of glycerol and 400-500ml of deionized water. The corrosion method comprises the following steps: (1) preparing an electrolytic corrosion agent; (2) grinding a to-be-corroded nickel-based corrosion-resistant alloy by waterproof abrasive paper, then polishing the alloy by using a diamond polishing agent; (3) pouring the electrolytic corrosion agent prepared by the step (1) into an electrolytic corrosion instrument to carry out electrolytic corrosion; and (4) taking a sample out of the corrosion agent, washing the sample by using absolute ethyl alcohol and then airing. The electrolytic corrosion agent is simple in formula, free of toxicity and free of pungent smell; the damage to health of experimenters can be greatly reduced; the electrolytic corrosion agent is hard to volatilize, can be stored for a long time and can be reused, is good in corrosion effect and is capable of clearly displaying the nickel-based corrosion-resistant alloy metallographic structure.

Owner:HEBEI IRON AND STEEL

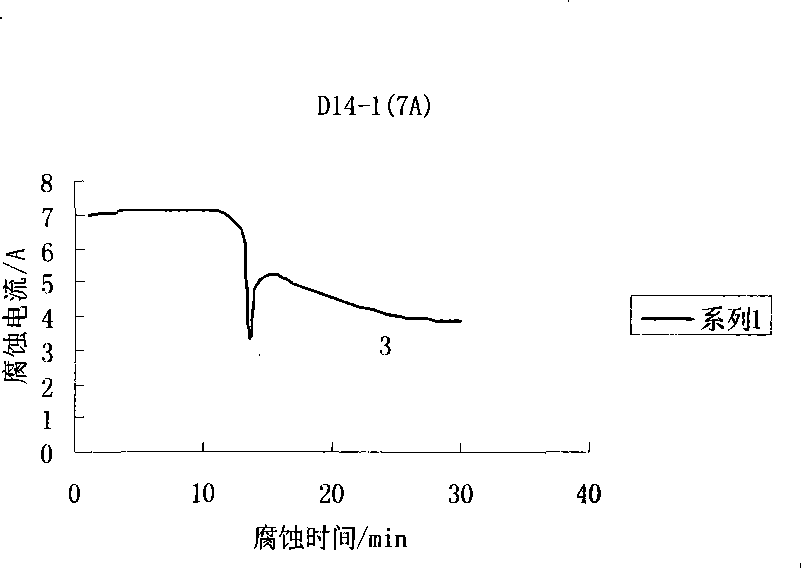

Method for detecting residual stress of steel by X-ray

InactiveCN101451965AVisually observe the internal stressEasy to measureMaterial analysis using radiation diffractionX-rayAqueous solution

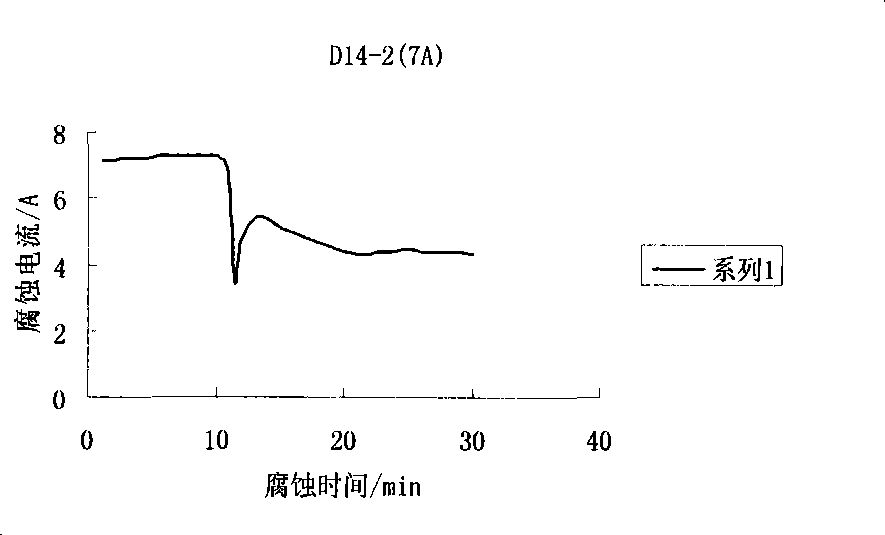

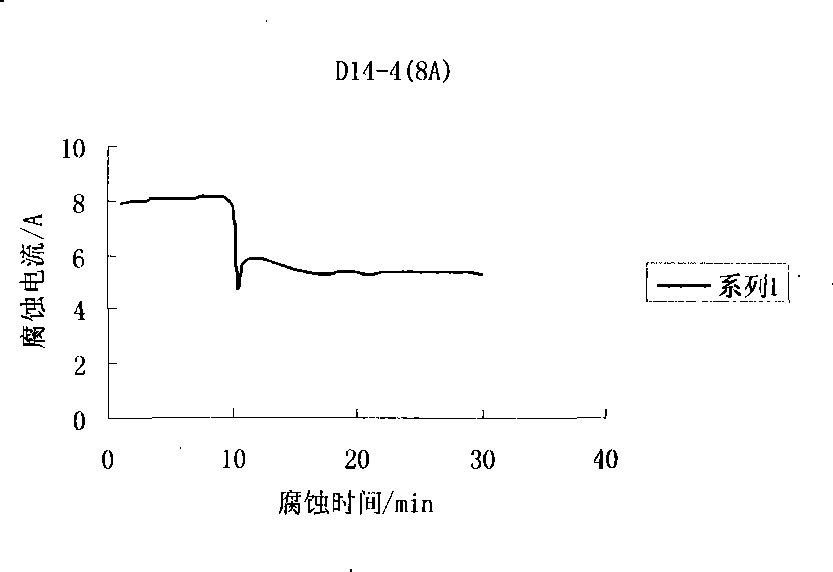

The invention relates to a method of mensurating steel residual stress using X rays, comprising: (1) taking a galvanized sheet, polishing smooth surface layers; taking saturated NaCl aqueous solution as electrolyte, using measured components as anode corrosion ends, using galvanized sheet iron as a cathode, eroding by DC constant pressure, corrosion current being 7-8 A; (2) after corrosion cleavage, mensurating residual stress on vertical direction of welding using X rays, then correcting residual stress measurement value after cleavage using single side cleavage measurement stress value correction method, namely obtaining steel residual stress. According to the inventive method to measurate the steel residual stress, novel additional stress is not increased by electrolytic corrosion cleavage, also measurement result along heavy gauge workpieces is obtained, measurement result is simple, device cost is low.

Owner:CHONGQING UNIV

Thermosetting resin composition, and prepreg, metal-clad laminated board and printed wiring board using the same

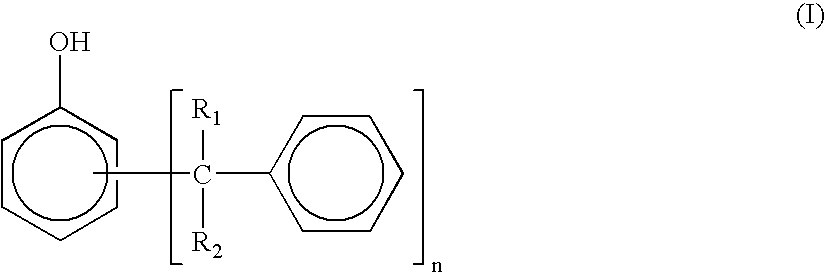

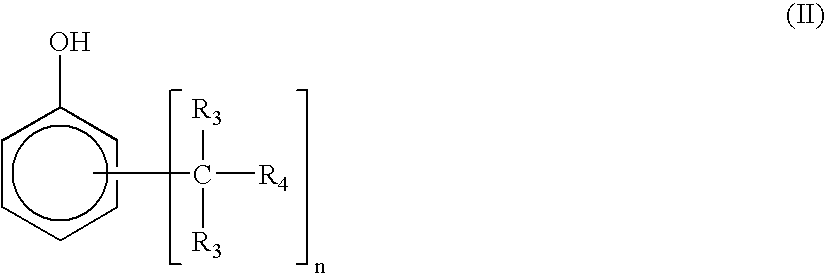

InactiveUS20060099391A1Improve featuresPrinted circuitsThin material handlingEquivalence ratioCopper foil

The present invention provides a thermosetting resin composition superior with respect to all characteristics of dielectric characteristics, heat resistance, moisture resistance, electrolytic corrosion resistance, adhesiveness with a copper foil, chemical resistance and flame retardancy using a halogen-free flame retardant, its use, and for example, a prepreg, laminated board and printed wiring board. The present invention relates to: (1) a resin thermosetting resin composition comprising: (A) a phenol-modified cyanate ester oligomer obtained by reacting a cyanate compound (a) containing two or more cyanato groups in a single molecule, and (b) a phenol compound represented by the formula (I) and / or formula (II), such that a blending equivalence ratio of hydroxyl group (b) / cyanato group (a) is within a range of 0.01 to 0.3, and the monomer conversation rate of cyanate compound (a) containing two or more cyanato groups in a single molecule is 20 to 70%, (B) an epoxy resin containing two or more epoxy groups in a single molecule, and (C) at least one member selected from a metal salt of a di-substituted phosphinic acid and a phosphazene compound as a flame retardant; (2) a thermosetting resin composition comprising: components (A), (B), (C), (D) a silicone polymer containing at least one member of siloxane unit selected from a tri-functional siloxane unit represented by the formula: RSiO3 / 2 (wherein, R represents an organic group, and the R groups in the silicone polymer may be mutually the same or different) and a tetra-functional siloxane unit represented by the formula: SiO4 / 2, having a degree of polymerization of 7,000 or less, and having one or more functional groups on its terminals that react with hydroxyl groups, and (E) an organic filler; and, a prepreg obtained by using the same, and a metal-clad laminated board and printed wiring board obtained by using the same.

Owner:HITACHI CHEM CO LTD

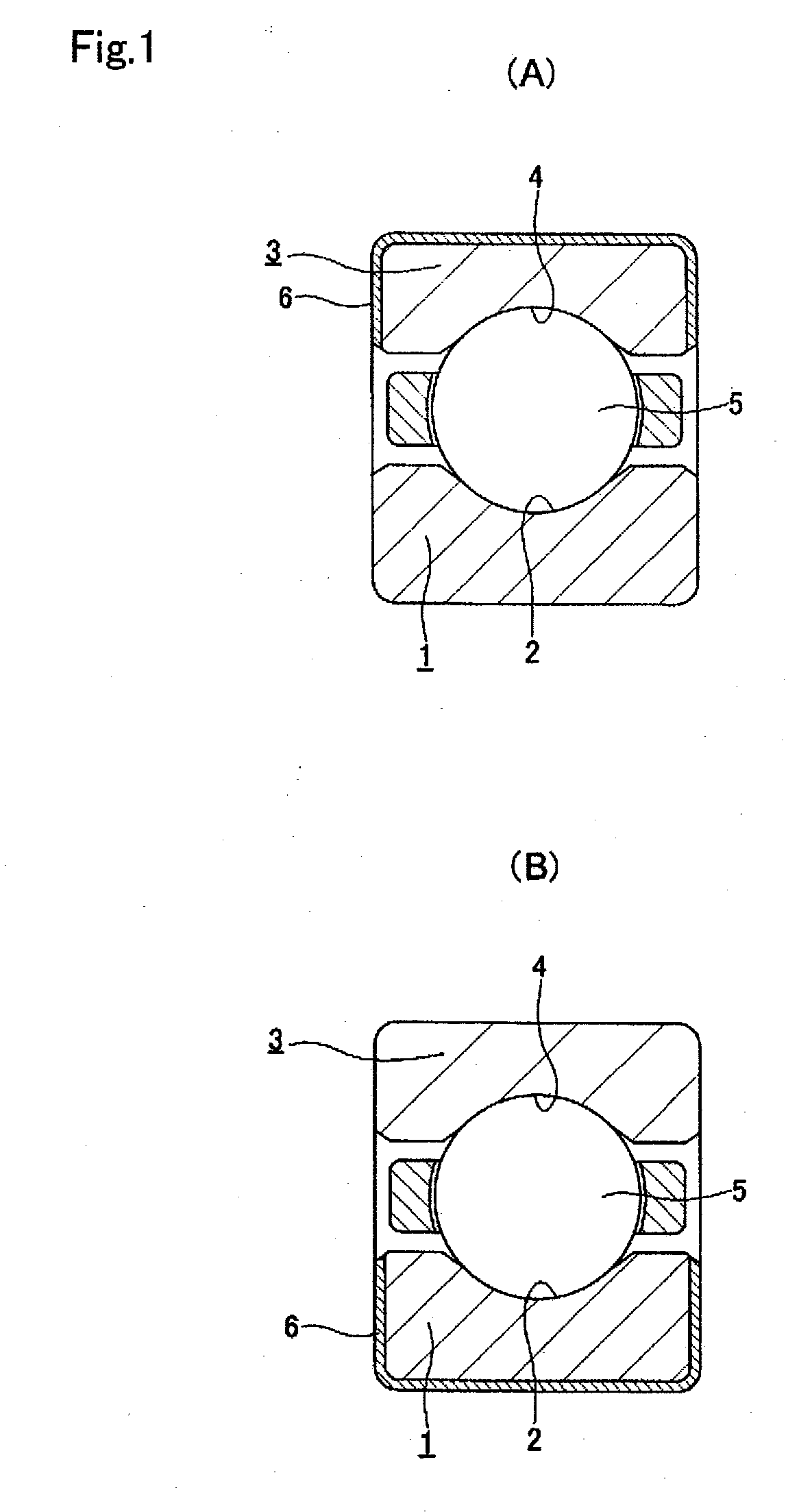

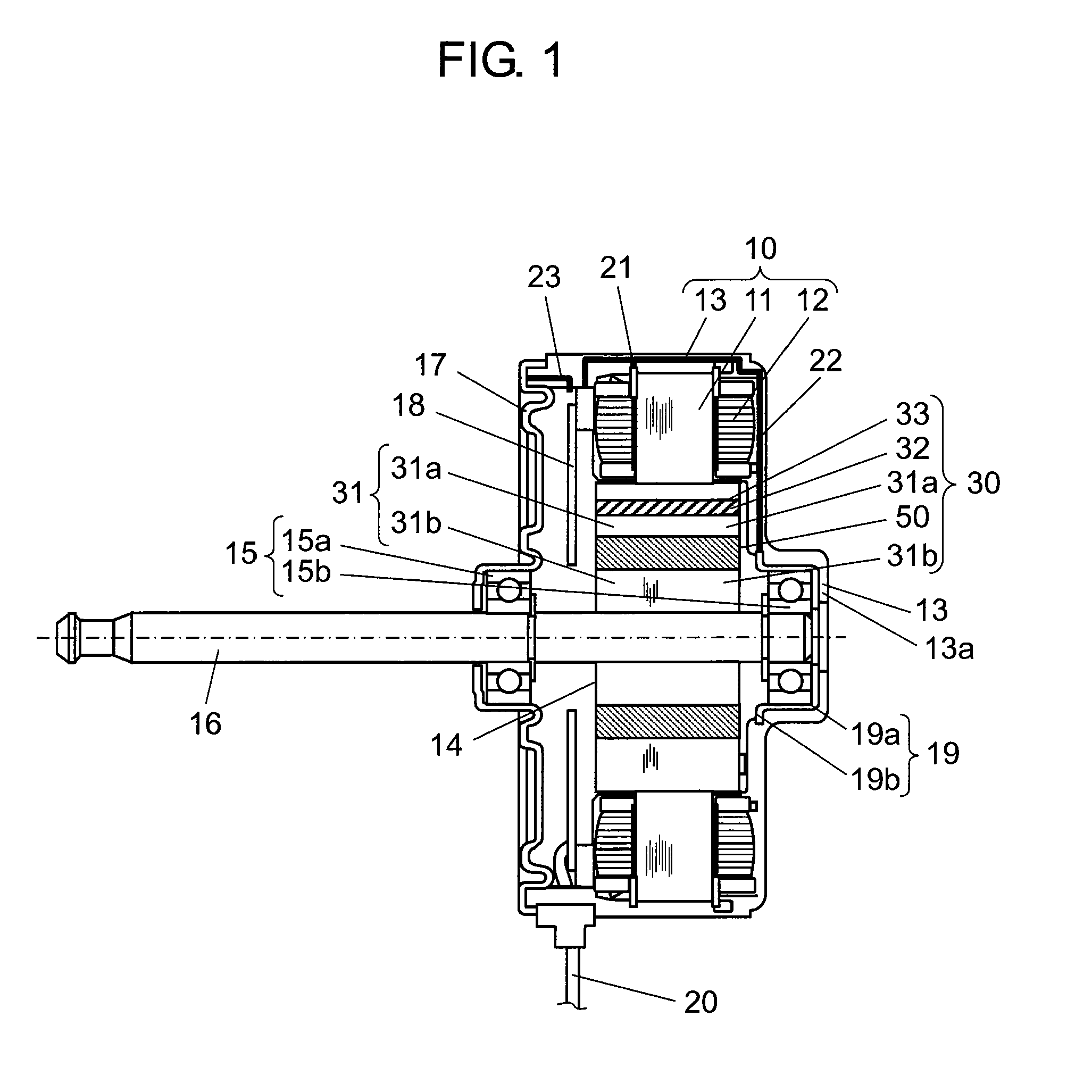

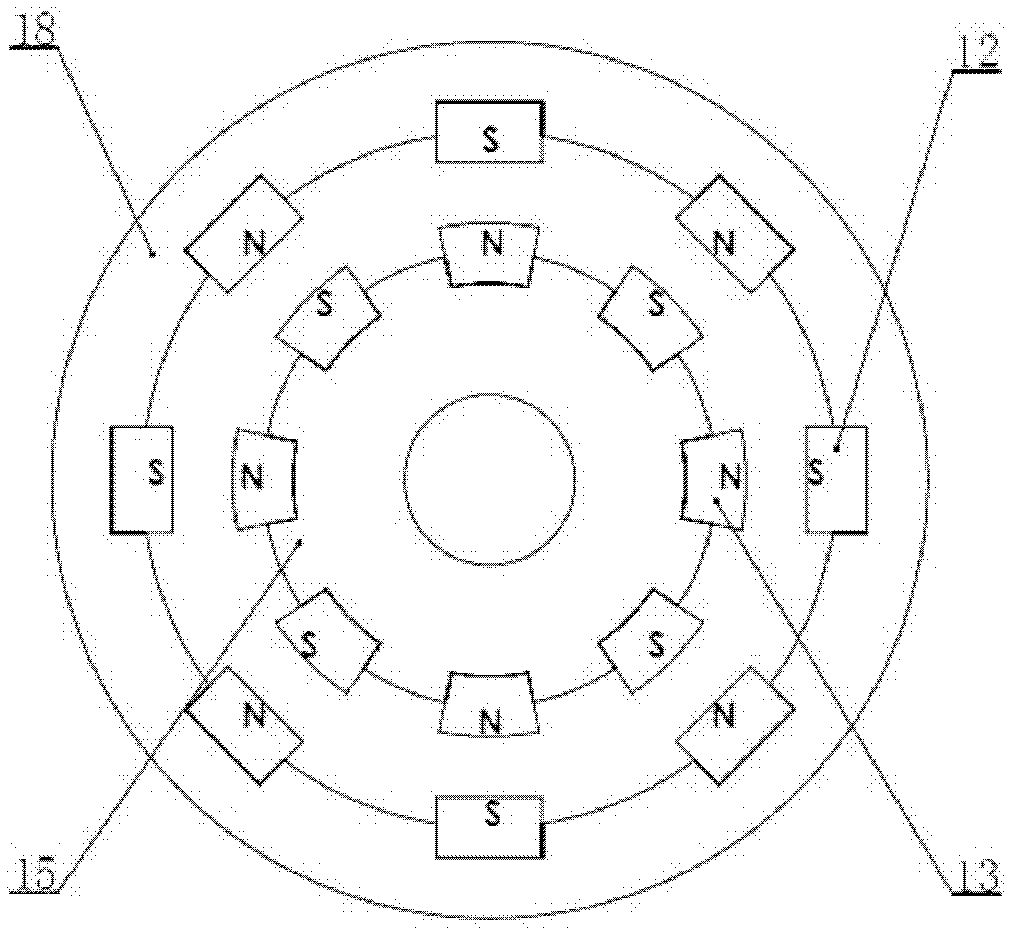

Electric motor and electric device provided therewith

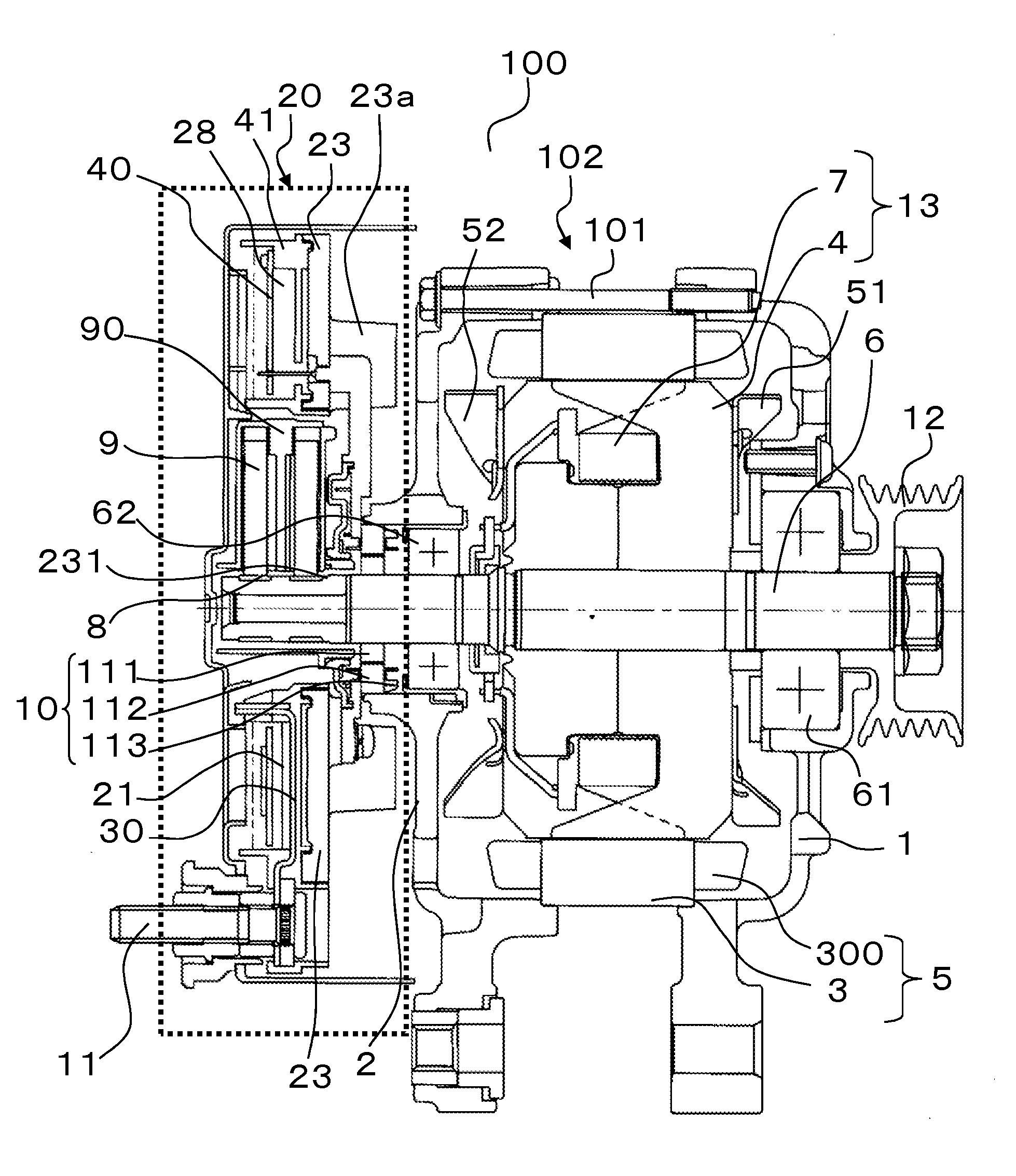

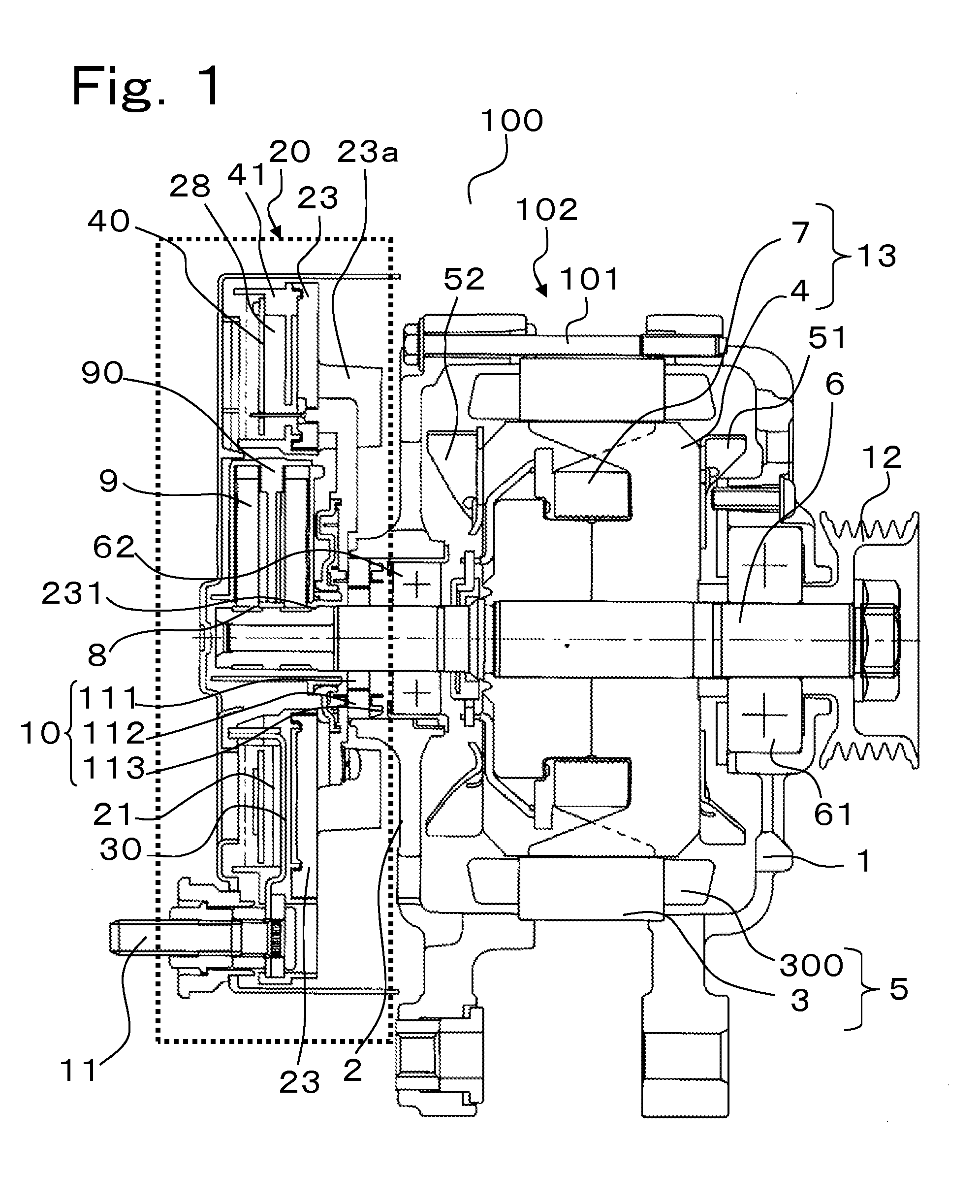

ActiveUS20120112588A1High retention strengthInhibitionAssociation with grounding devicesMagnetic circuitDielectric layerMagnet

Provided is an electric motor driven by an inverter of PWM method, and devised to retard electrolytic corrosion in a bearing. A rotating body of a rotor comprises an outer iron core configuring an outer peripheral portion of the rotating body, an inner iron core configuring an inner peripheral portion connected to a shaft, a dielectric layer disposed between the outer iron core and the inner iron core, a plurality of insertion holes penetrating the outer iron core in the axial direction, and permanent magnets inserted individually in the plurality of insertion holes. It thus becomes possible to increase impedance of the rotor side (inner ring side of bearing) to approximate it to impedance of the stator side (outer ring side of the bearing) to thereby bring high frequency potentials balanced between the inner ring side and the outer ring side of the bearing, so as to provide the electric motor that retards electrolytic corrosion liable to occur in the bearing, and an electric device equipped with the same.

Owner:PANASONIC CORP

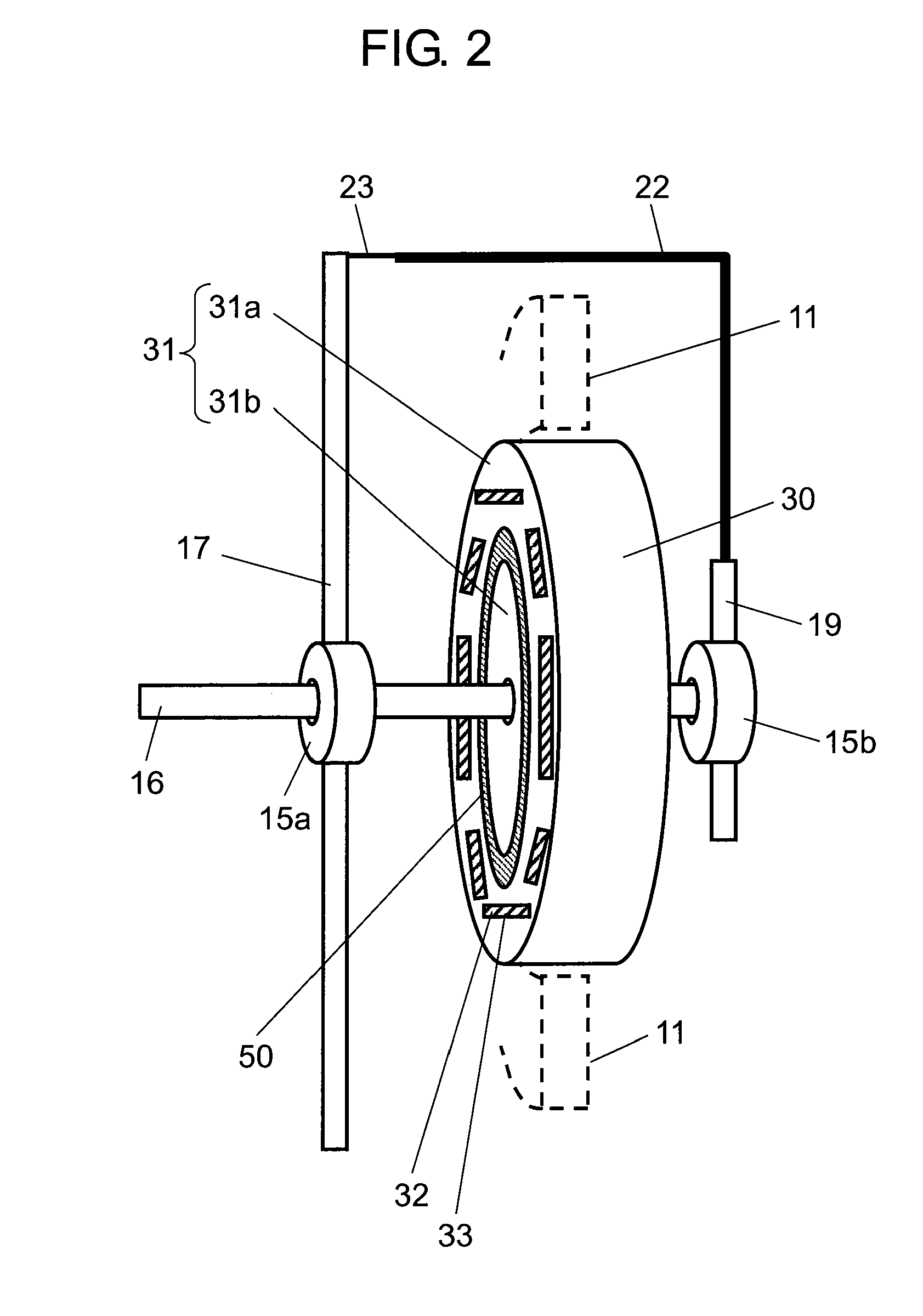

Method for preparing reflection reduction film with surface embedded type porous silicon structure of silicon base solar battery

InactiveCN101673785AAfter-treatment detailsFinal product manufactureVolumetric Mass DensitySolar battery

The invention relates to a method for preparing a reflection reduction film with a surface embedded type porous silicon structure of a silicon base solar battery, which belongs to the technical fieldof electrochemical corrosion. The method is characterized in that a metal aluminum film anode electrode is prepared at the back face of a silicon wafer by a traditional silk screen printing method firstly, and Al and silicon have favorable ohmic contact; in addition, a platinum wafer or a platinum wire is used as a cathode electrode; afterwards, the front face of the silicon wafer is put into corrosive liquid with HF:H2O of 1:10 (volume ratio) and soaked for 1 minute; the temperature of the corrosive liquid is 26 DEG C; then, the front face of the silicon wafer is put into a container under anultrasonic condition of the ultrasonic frequency of 40-60Hz, and electrochemical corrosion processing is carried out in mixed liquid with HF:H2O:C2H5OH of 2:1:1 (volume ratio) of electrolyte; the temperature of the electrolyte is 40 DEG C; the surface density of electrolytic corrosion current is 5-10mA / cm<2>; the electrolytic corrosion time is 40-60s; and finally, the reflection reduction layer film with the surface embedded type porous silicon structure is formed at the front face of the silicon wafer, and the reflectivity of the reflection reduction layer film is 1.42% averagely.

Owner:SHANGHAI UNIV

Bolt structure for use with a magnesium alloy member for tightening magnesium alloy members with each other or with a heterogenenous material

InactiveUS6979161B2Avoid it happening againImprove corrosion resistanceLiquid surface applicatorsWashersZincMaterials science

The present invention provides for a bolt structure for use with a magnesium alloy member that can insulate between magnesium alloy members and steel or other bolts without lowering the bolt shaft power, and prevent occurrence of electrolytic corrosion with an electrolyte such as water. A cationic electrodeposition coating is also provided for the bolts structure, said coating having a film thickness of 15 μm or more is provided at least on the surface of the magnesium alloy member contacting with a bolt head, a powder coating having a film thickness of 40 to 150 μm is provided on the surface of the cationic electrodeposition coating, zinc-nickel plating and then cosmer treatment are carried out on the bolt, and an alumite-treated aluminum washer is interposed between the bolt head and the magnesium alloy member.

Owner:HONDA MOTOR CO LTD

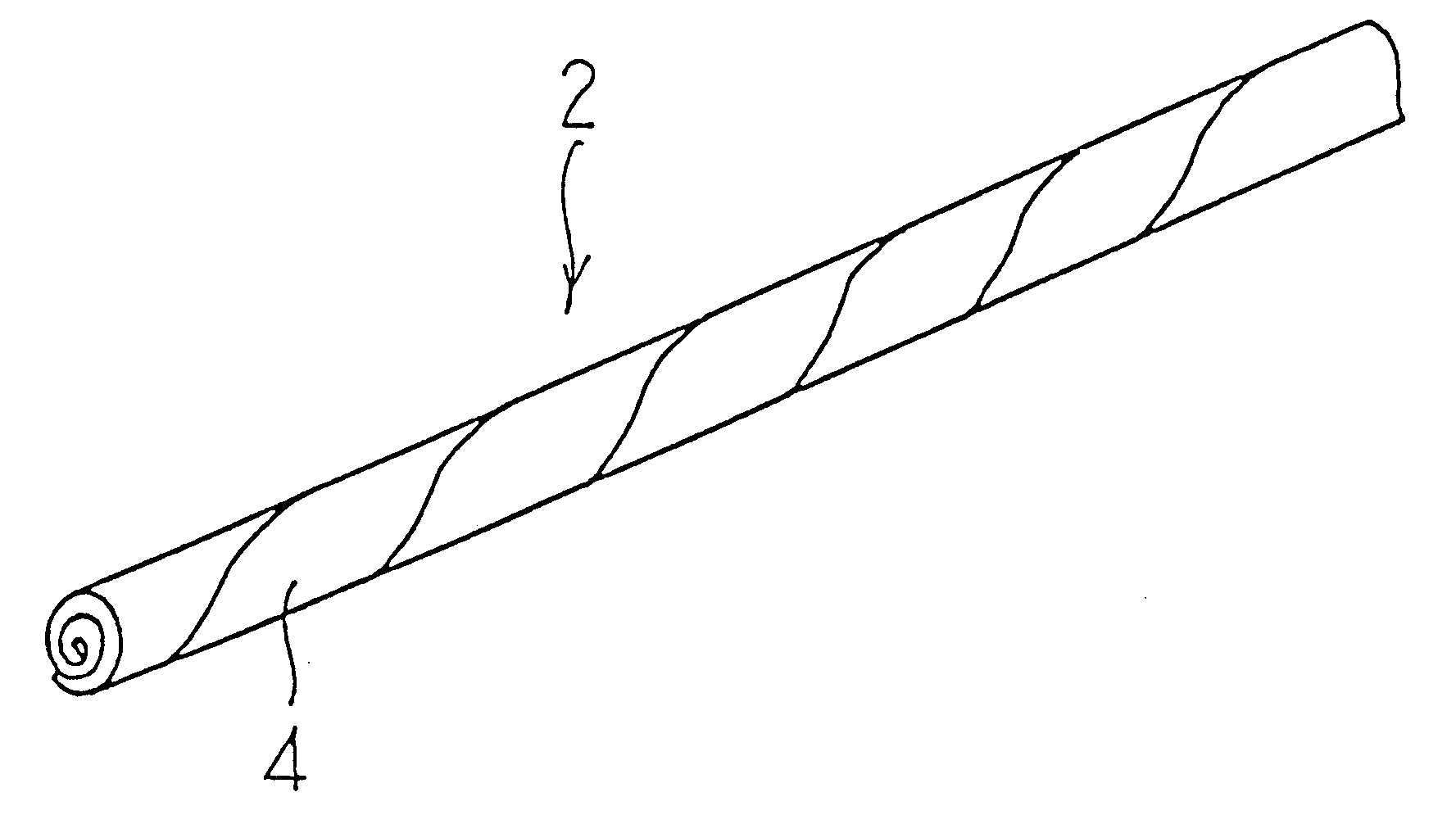

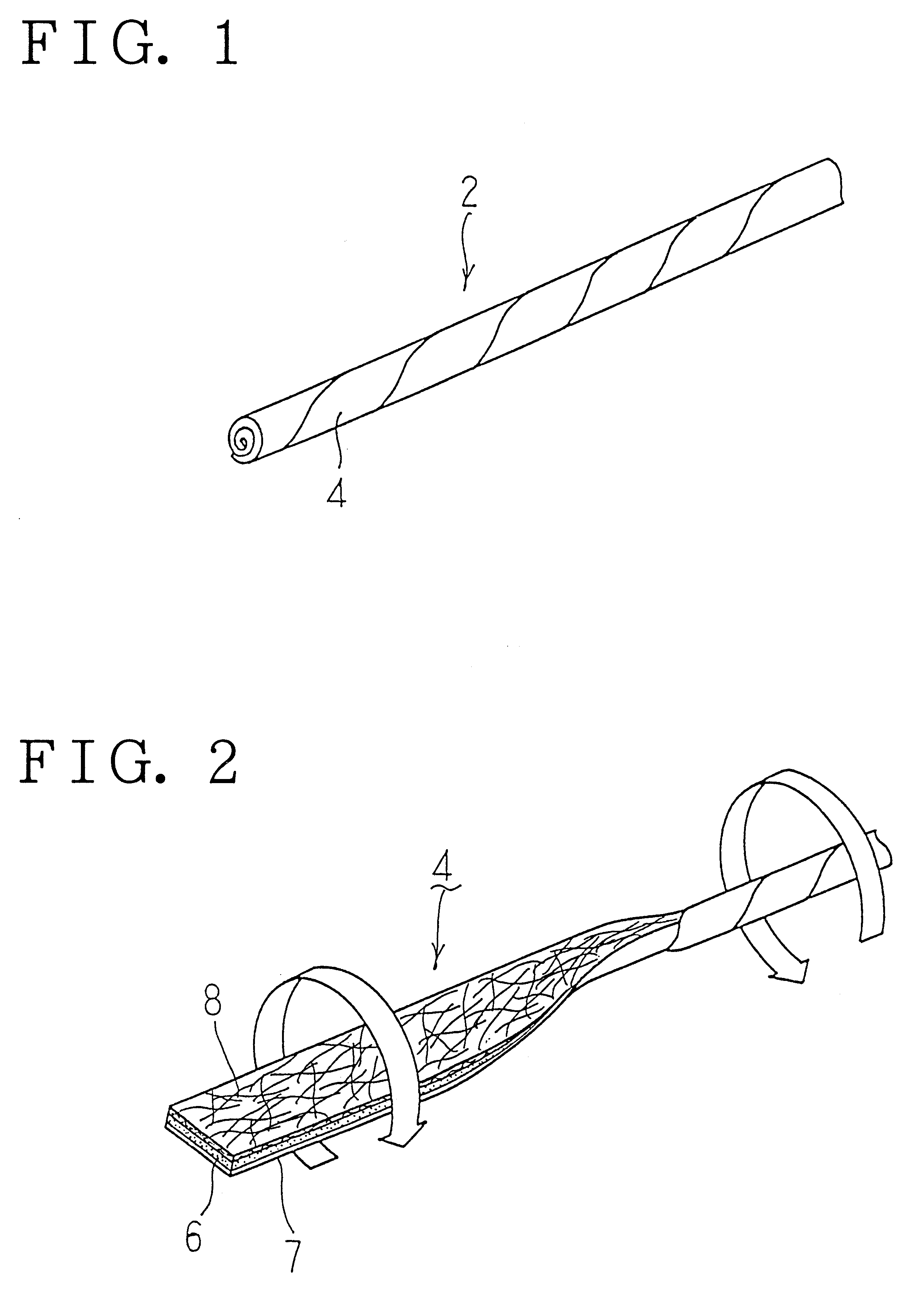

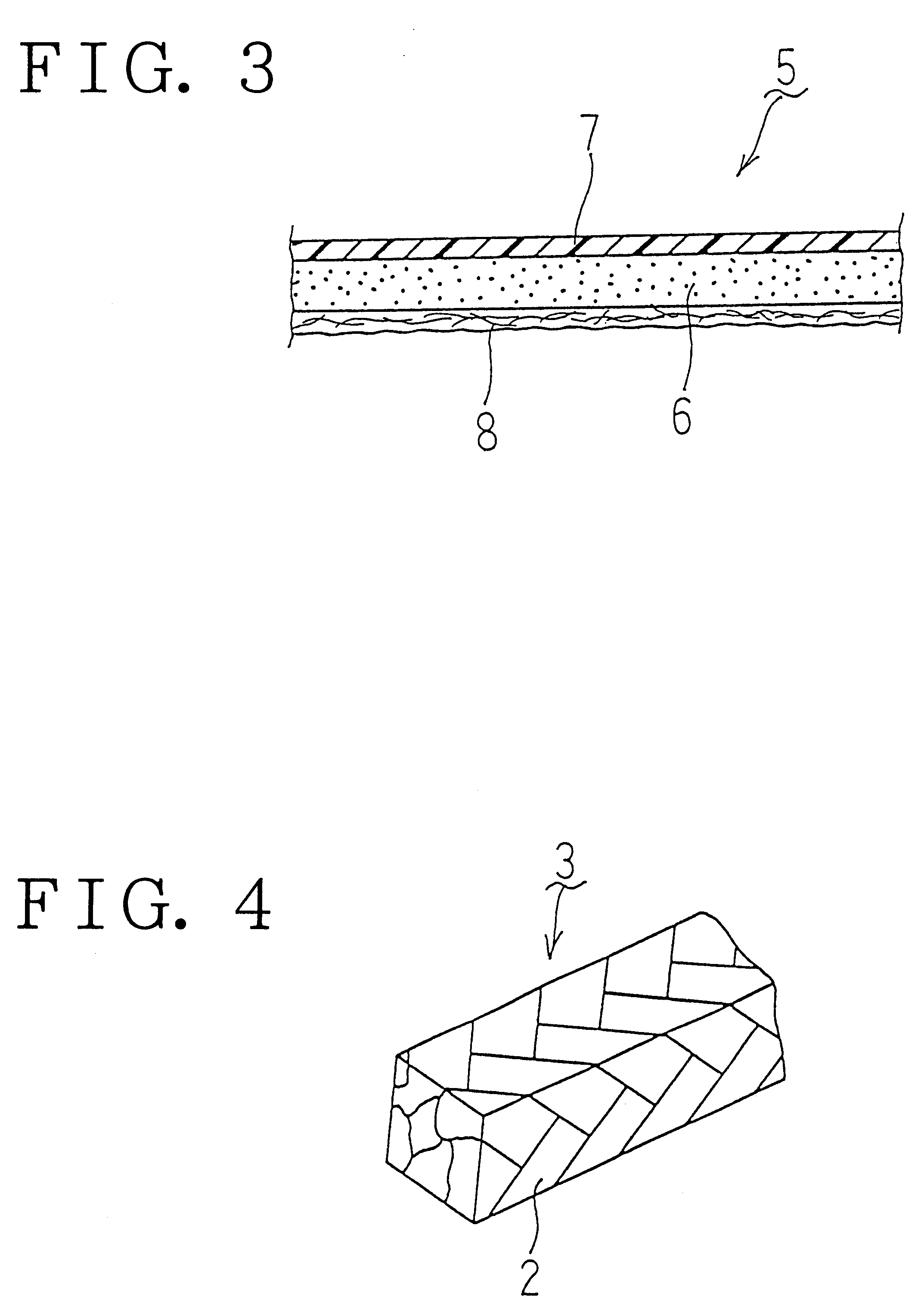

Materials used in gland packing made from expansive graphite, gland packing made from expansive graphite made from the materials, and a producing method of gland packing made from expansive graphite

The present invention relates to the materials used in a gland packing made from expansive graphite, the gland packing made from expansive graphite using the materials and a producing method of the gland packing made from expansive graphite, with producing facility in addition to sealing ability, heat resistance, chemical resistance and such properties and with causing no electrolytic corrosion to shaft and apparatus casing, and braiding thread which constructs these is braiding thread wherein a strip laminated sheet comprising an expansive graphite sheet laminated with a film made from polytetrafluoroethylene on one side thereof and is set with polyvinylalcohol layer on the other side thereof, is twist processed so that the film made from polytetrafluoroethylene positions on the outside.

Owner:TSUKAMOTO KATSURO

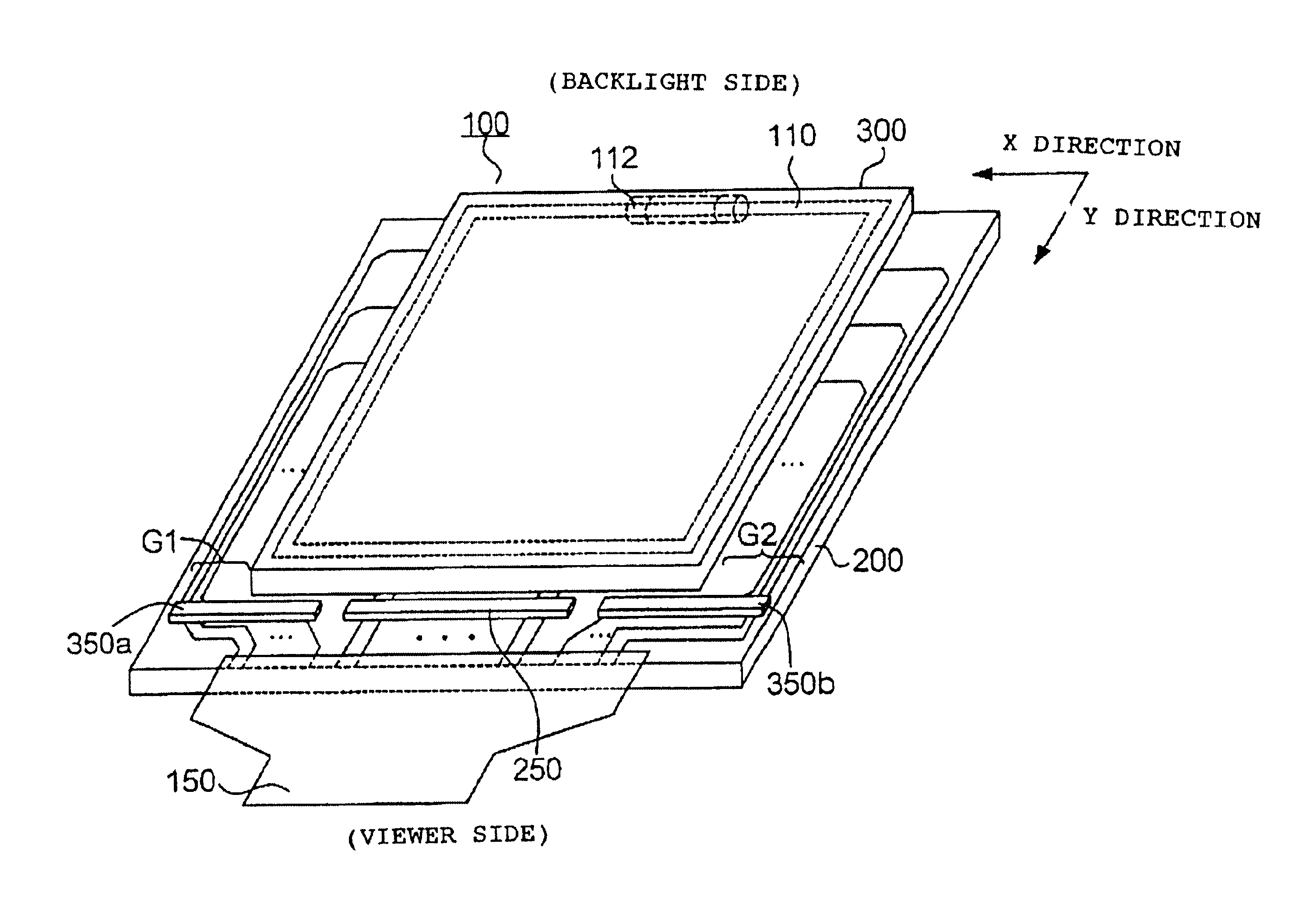

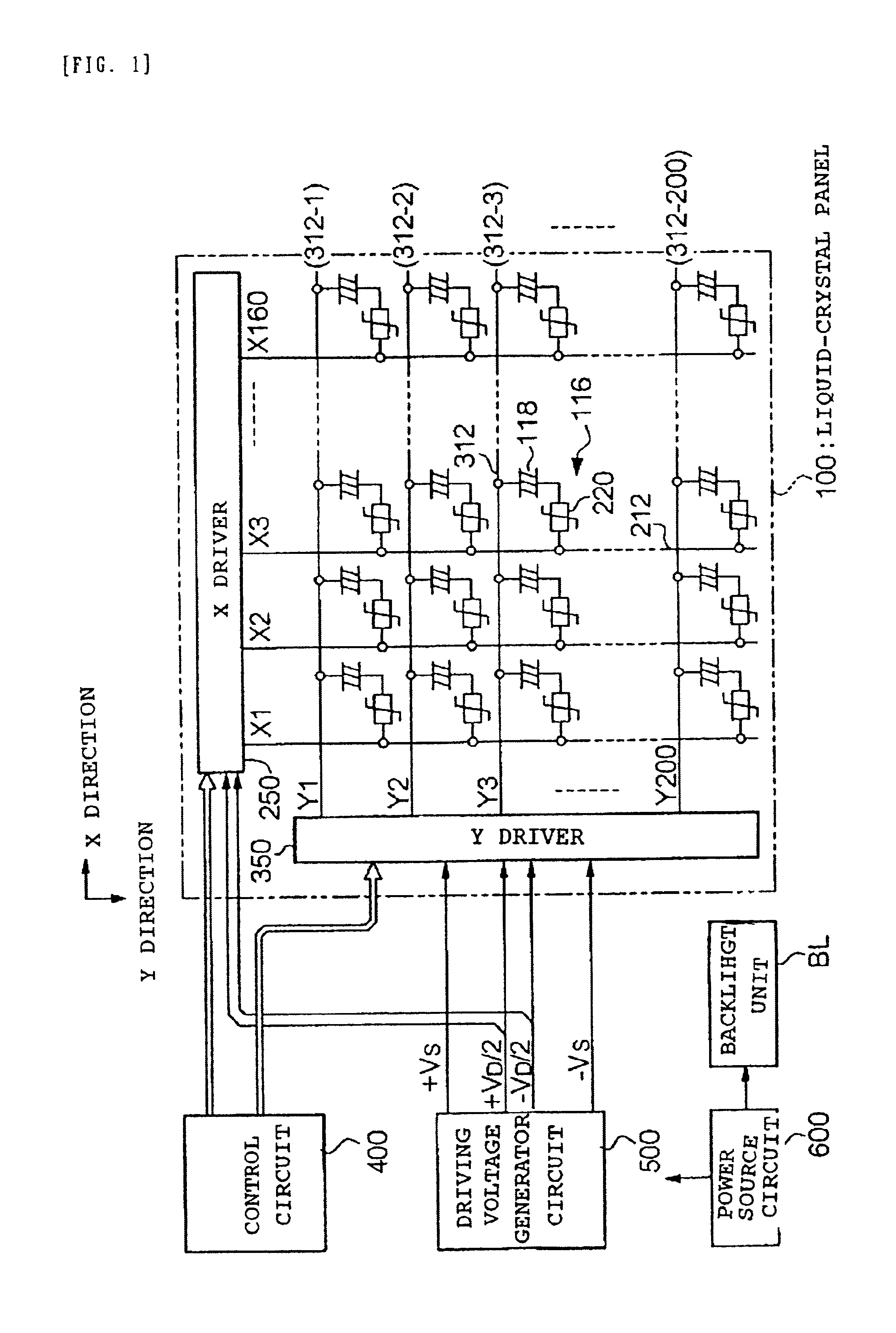

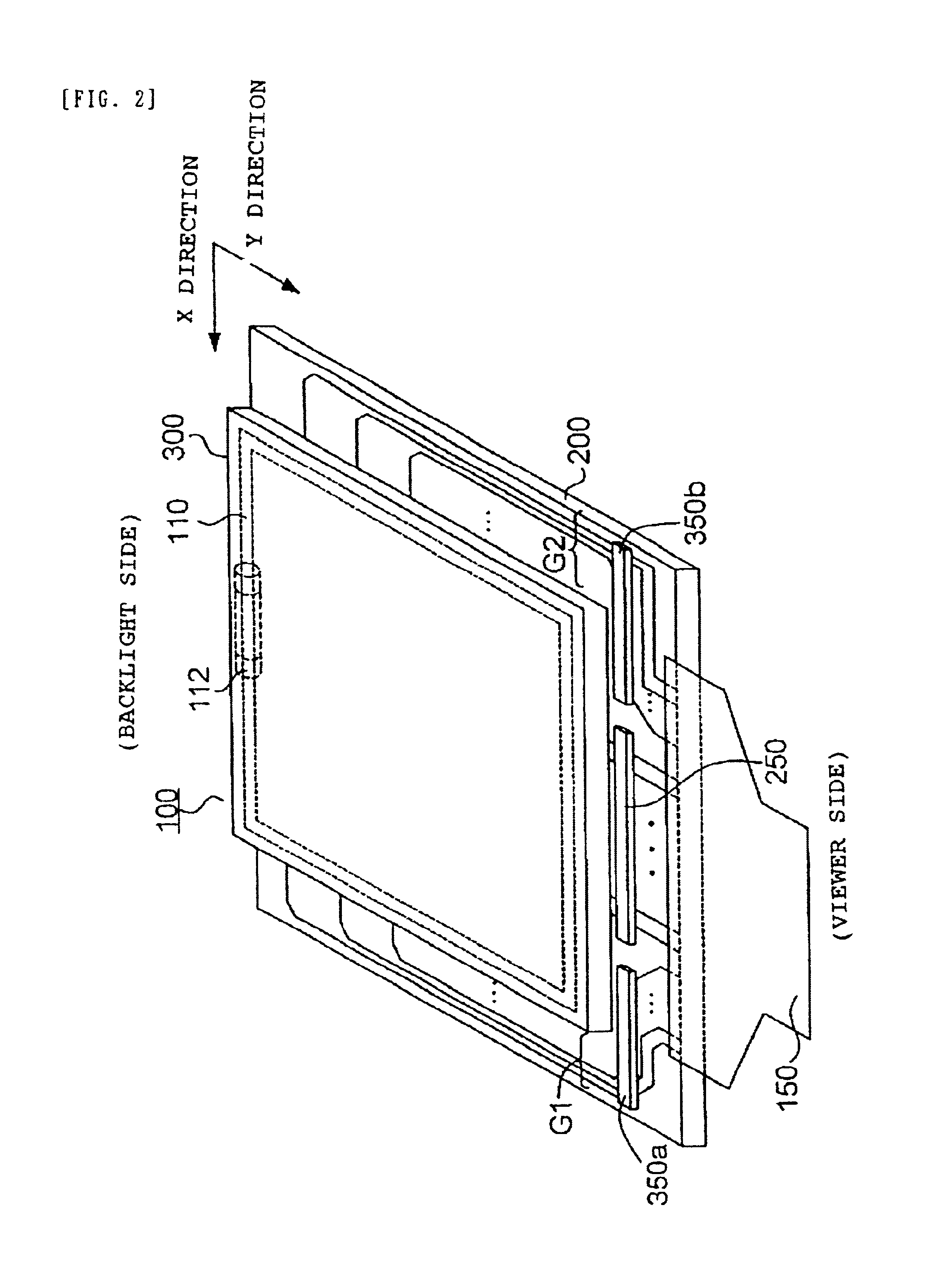

Electrooptical panel, method for driving the same, and electronic equipment

InactiveUS6853361B2Reliable maintenanceNarrow spaceStatic indicating devicesNon-linear opticsHigh densityElectrical polarity

This present invention provides a liquid-crystal panel that presents a high-density wiring while maintaining reliability of the wiring. Odd-numbered scanning lines are connected to a first wiring group while even-numbered scanning lines are connected to a second wiring group. Each of the scanning lines is supplied with a scanning signal the polarity of which is inverted every horizontal scanning period. Among wirings forming the first wiring group and the second wiring group, a line-to-line voltage between any adjacent wirings becomes zero volt for a majority of the time. Accordingly, degradation of the wirings due to electrolytic corrosion is controlled even if the spacing between the wirings is narrowed.

Owner:SEIKO EPSON CORP

Method for electrolytic-depositing dispersed zinc crystal nucleuses on surface of medium-high voltage electronic aluminum foil

The invention relates to a method for electrolytic-depositing dispersed zinc crystal nucleuses on the surface of a medium-high voltage electronic aluminum foil. The method comprises the following steps: after performing homogenizing annealing, forming a medium-high voltage high-purity aluminum foil, wherein a [100] structure occupancy of the medium-high voltage high-purity aluminum foil is more than 95 percent, elements of Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga, Ge, In, Sn and Pb electrode potentials of which are higher than that of aluminum are not enriched on the surface of the medium-high voltage high-purity aluminum foil; pretreating to remove an oxidation film on the surface, and simultaneously forming a new water-containing film; and then depositing dispersed zinc crystal nucleuses on the surface of the aluminum foil in an electrolyte by adopting quick electrochemical deposition. The medium-high voltage electronic aluminum foil deposited with the dispersed zinc crystal nucleuses on the surface is adopted, pit etching of the aluminum foil can be effectively guided by the zinc crystal nucleuses during electrolytic corrosion, the uniformity of the distribution of tunnel holes is improved, and the self-corrosion thinning of the aluminum foil is reduced, thus the specific capacitance and bending resistance performance of the aluminum foil can be remarkably improved.

Owner:新疆广投桂东电子科技有限公司

Bolt tightening structure of magnesium alloy member

InactiveUS20020127083A1Avoid it happening againImprove corrosion resistanceLiquid surface applicatorsWashersZincPowder coating

The present invention provides a bolt tightening structure of a magnesium alloy member capable of insulating between magnesium alloy members and steel or other bolts without lowering the bolt shaft power, and preventing occurrence of electrolytic corrosion if contacting with electrolyte such as water. This is a bolt tightening structure of a magnesium alloy member for tightening magnesium alloy members with each other or a magnesium alloy member and a heterogeneous material by means of a bolt. Cationic electrodeposition coating having a film thickness of 15 .mu.m or more is provided at least on the surface of the magnesium alloy member contacting with a bolt head, a powder coating having a film thickness of 40 to 150 .mu.m is provided on surface of the cationic electrodeposition coating, zinc-nickel plating and then cosmer treatment are carried out on the bolts, and an alumite-treated aluminum washer is interposed between the bolt head and the magnesium alloy member.

Owner:HONDA MOTOR CO LTD

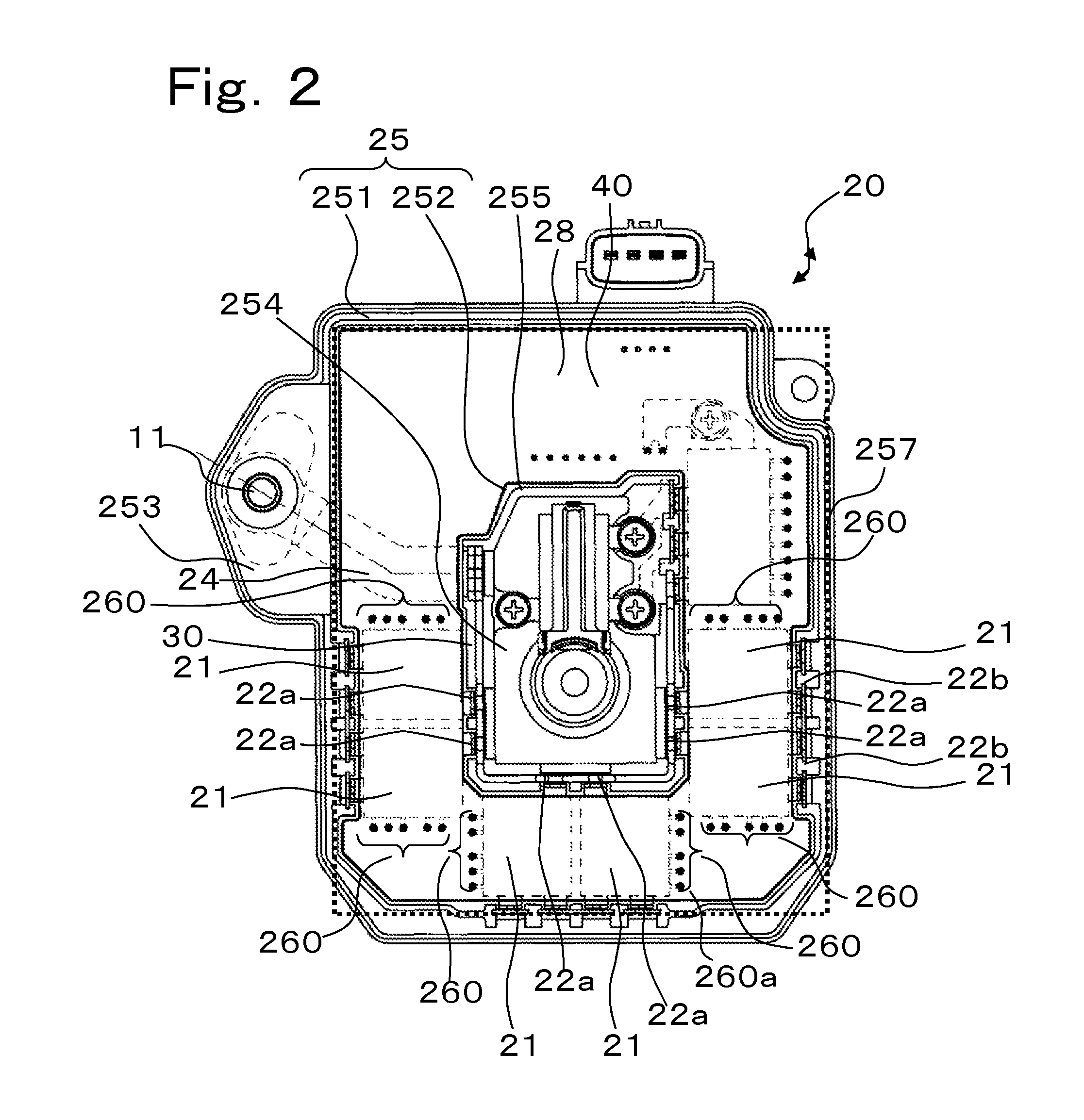

Controller-integrated rotary electric machine

ActiveUS20150229172A1Improve corrosion resistanceSupports/enclosures/casingsAssociation for rectificationElectricityElectric machine

Owner:MITSUBISHI ELECTRIC CORP

Medium-high voltage electronic aluminum foil diffused tin nucleus electro-deposition method

The invention relates to a medium-high voltage electronic aluminum foil diffused tin nucleus electro-deposition method. The method comprises the steps that: a high-purity medium-high voltage aluminum foil with no potential correction element enriched on the surface is pretreated in high-purity water, or an alkali solution, or a phosphoric acid solution, or nitric acid, such that surface oxide film is removed, and a new water-containing film is formed on the surface of the aluminum foil; or high-purity medium-high voltage aluminum foil with no potential correction element enriched on the surface is subjected to an electrochemical polishing treatment, such that an original oxide film on the surface of the aluminum foil is removed, and a new water-containing film is simultaneously formed on the surface of the aluminum foil; or an aluminum foil is pretreated in an alkali solution, or a phosphoric acid solution, or nitric acid, such that an alloy layer with enriched potential correction element on the surface of the medium-high voltage aluminum foil is removed, and a new water-containing film is formed on the surface of the aluminum foil; a rapid tin electro-deposition technology is adopted, such that diffused tin nuclei are deposited on the surface of the aluminum foil. With the medium-high voltage electronic aluminum foil with the diffused tin nucleus electro-deposited on the surface, in electrolytic corrosion, tunnel hole formation uniformity can be improved, and aluminum self-corrosion thinning can be reduced, such that aluminum foil specific capacitance and bending resistance performance can be substantially improved.

Owner:新疆广投桂东电子科技有限公司

Epoxidized phenol-hydroxybenzaldehyde condensate, bisphenol-formaldehyde condensate and masked imidazole

InactiveUS6329474B1Increase crosslink densityImprove responseEngine sealsPlastic/resin/waxes insulatorsHigh resistanceHeat resistance

An epoxy resin composition for printed wiring boards which comprises as the essential components (a) an epoxy resin obtained by epoxidizing a condensation product of a phenol with hydroxybenzaldehyde, (b) a condensation product of bisphenol A with formaldehyde, (c) a flame retardant, and (d) a curing accelerator, and a laminate for printed wiring boards which has a low hygroscopicity, a high heat resistance, good high-temperature characteristics, a high resistance against electrolytic corrosion, a high resistance against color change due to heating, and a high Tg.

Owner:HITACHI CHEM CO LTD

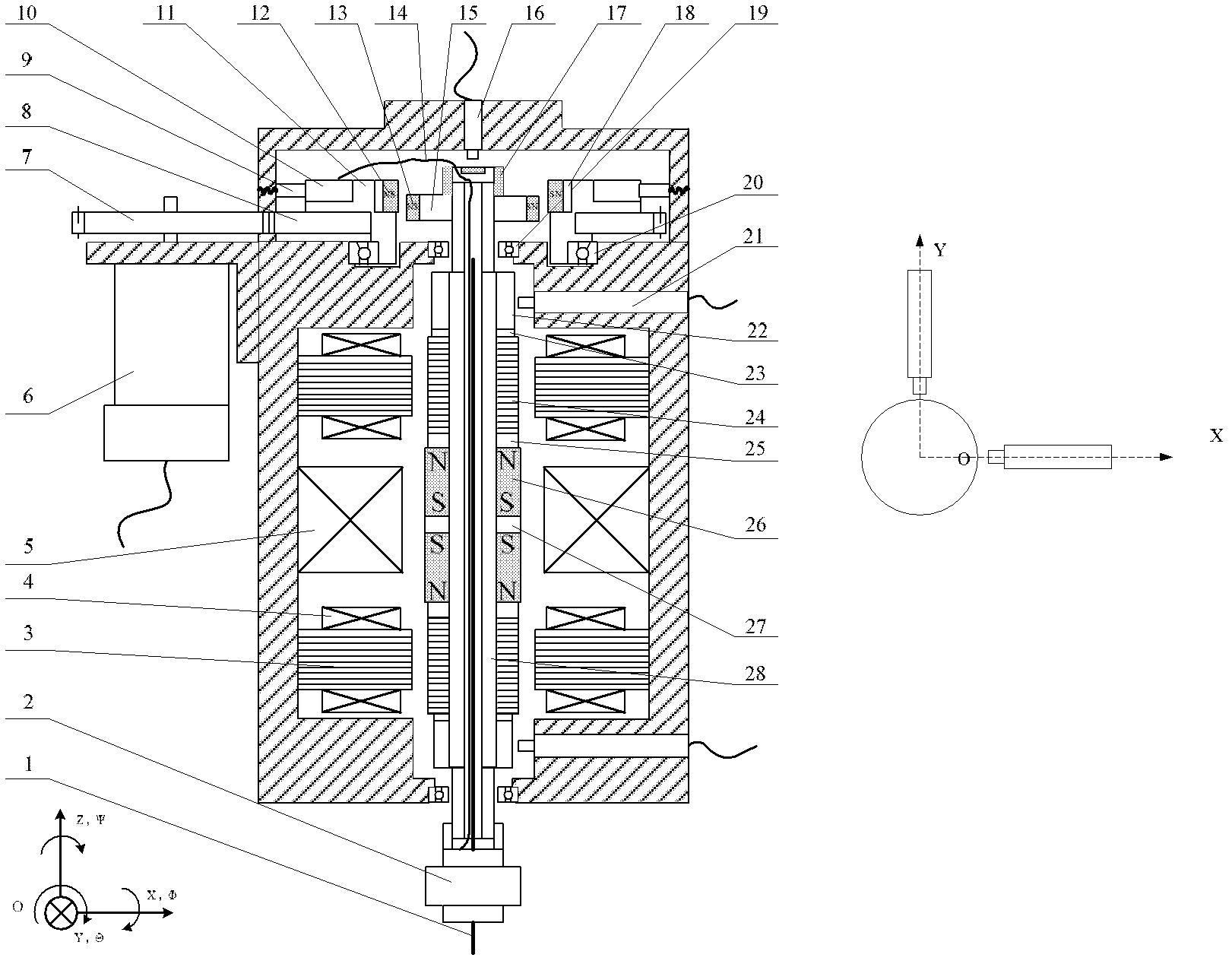

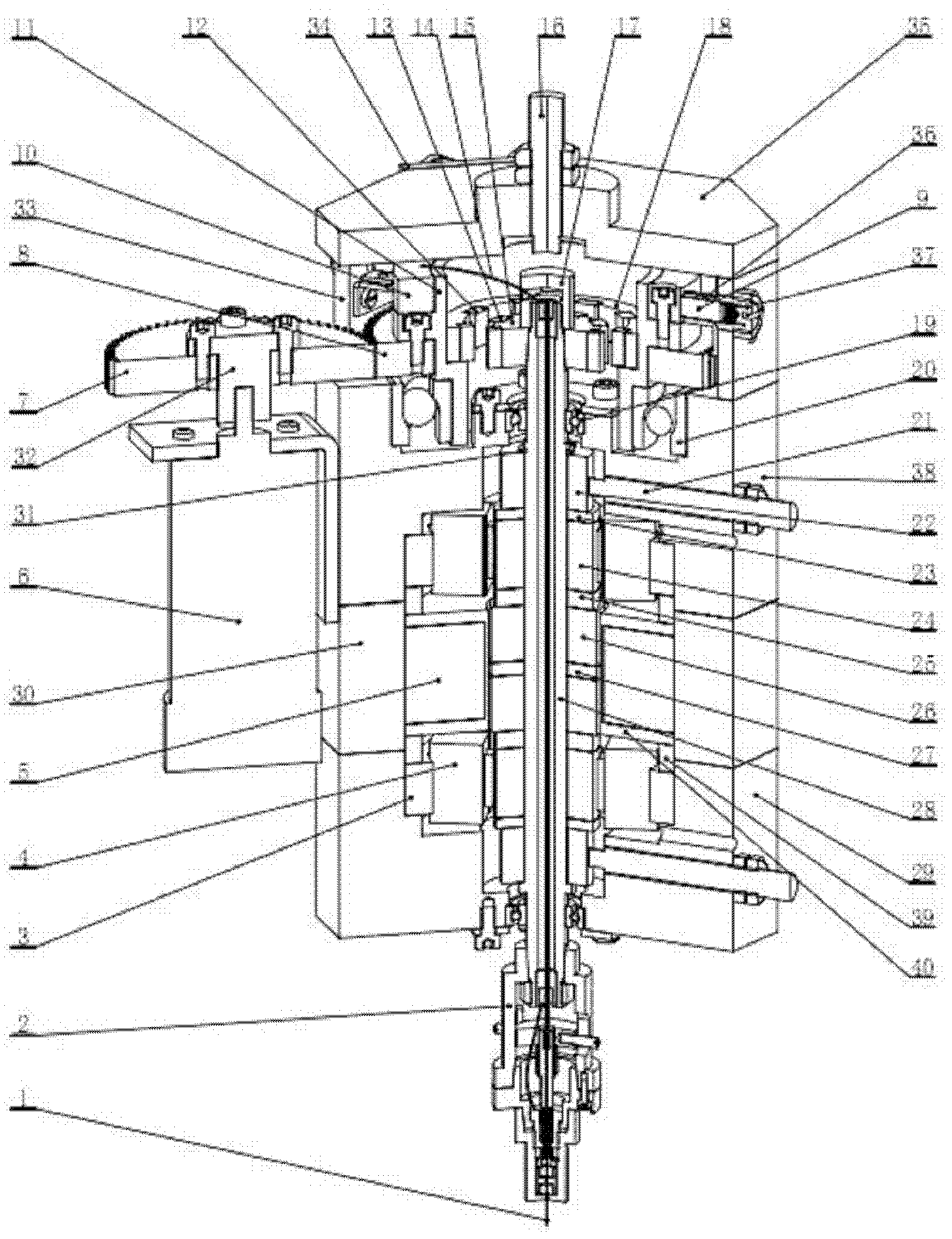

Spindle device for processing micro-hole electric spark based on magnetic levitation servo drive

ActiveCN102601473AIncrease servo tracking speedEasy to adjustMagnetic holding devicesElectrical-based auxillary apparatusBall bearingCoupling

The invention relates to a spindle device for processing a micro-hole electric spark based on a magnetic levitation servo drive. A magnetic coupling inner rotor is fixedly connected with an upper part of a hollow mandrel; a rotor end cover is arranged on the hollow mandrel at an upper part of the magnetic coupling inner rotor; a flexible lead enters in a cavity of the hollow mandrel through the rotor end cover; an inner rotor permanent magnet is arranged on the magnetic coupling inner rotor; a radical eddy current displacement sensor is fixed inside an upper shell; a lower end of an insulatedturntable is arranged on the upper shell at an inner side of an angular contact ball bearing; a magnetic coupling outer rotor is fixed on an upper part of the insulated turntable; and an outer rotor permanent magnet is fixed on the magnetic coupling outer rotor. According to the invention, the spindle device provided by the invention is helpful for discharging an electrolytic corrosion product intime and improving discharge condition of a discharge gap; and is helpful for improving the quality and efficiency of electric spark micro-hole processing. The spindle device can realize processing of micro-straight holes, taper holes and stepped holes of hole diameters phi ranging from 100mum to 300mum according to different processing requirements.

Owner:HARBIN INST OF TECH

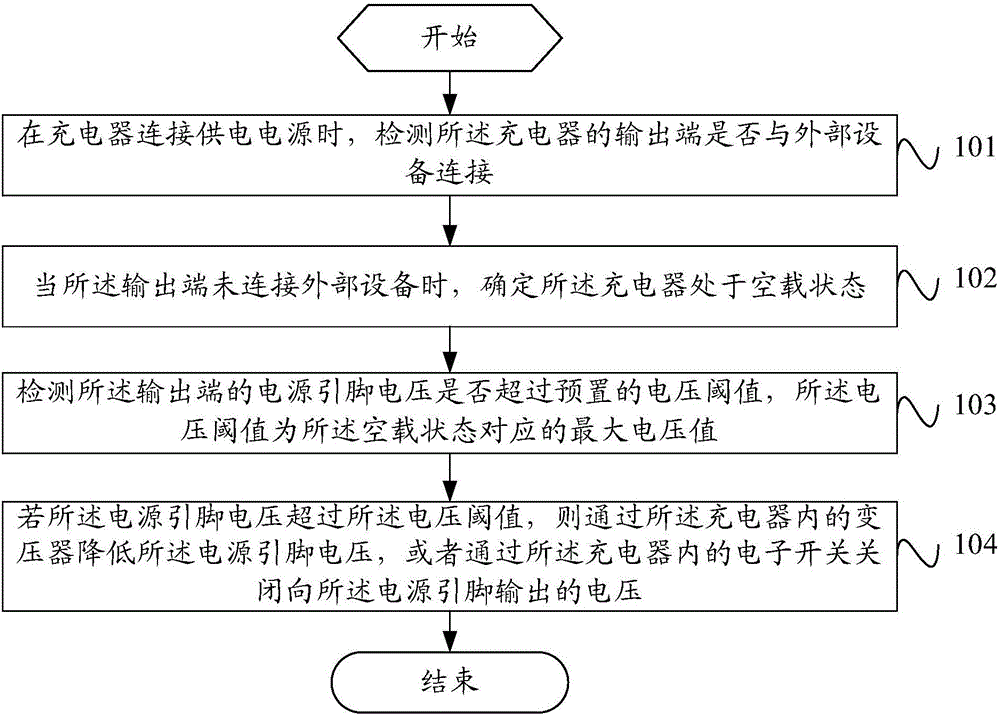

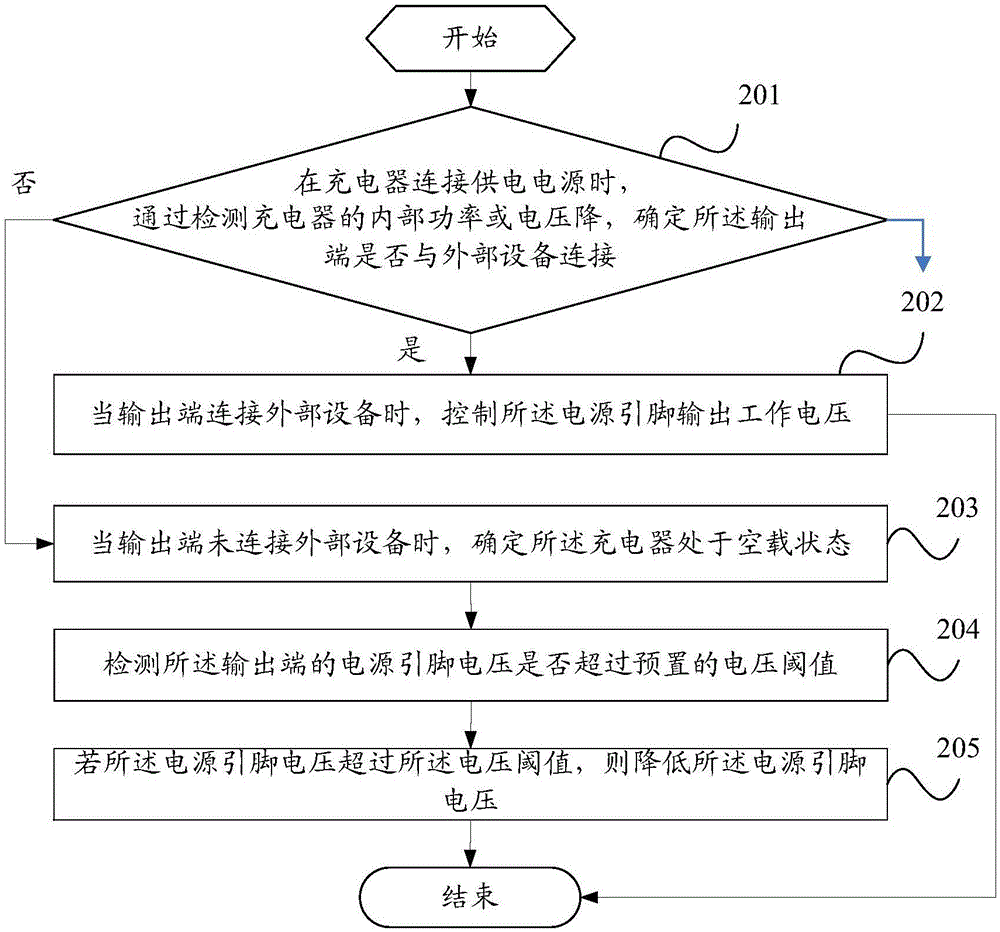

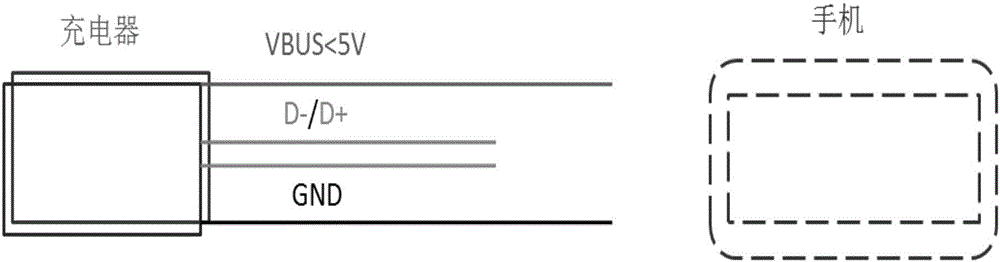

Voltage output method for charger and charger

ActiveCN106374581AReduces electrolytic corrosionBatteries circuit arrangementsElectric powerLow voltageEngineering

Embodiments of the invention provide a voltage output method for a charger and the charger, and relate to the technical field of communications. The method comprises the steps of detecting whether the output end of the charger is connected with an external device or not when the charger is connected with a power supply; when the output end is not connected with the external device, determining that the charger is in a no-load state; detecting whether a power pin voltage of the output end exceeds a preset voltage threshold or not, wherein the voltage threshold is a maximum voltage value corresponding to the no-load state; and if the power pin voltage exceeds the voltage threshold, reducing the power pin voltage or turning off a voltage output to a power pin. According to the method and the charger provided by the embodiments of the invention, the output end of the charger in the no-load state is provided with a low voltage or is not electrified, so that the purpose of reducing an electrolytic corrosion situation of the charger in the no-load state is achieved.

Owner:VIVO MOBILE COMM CO LTD

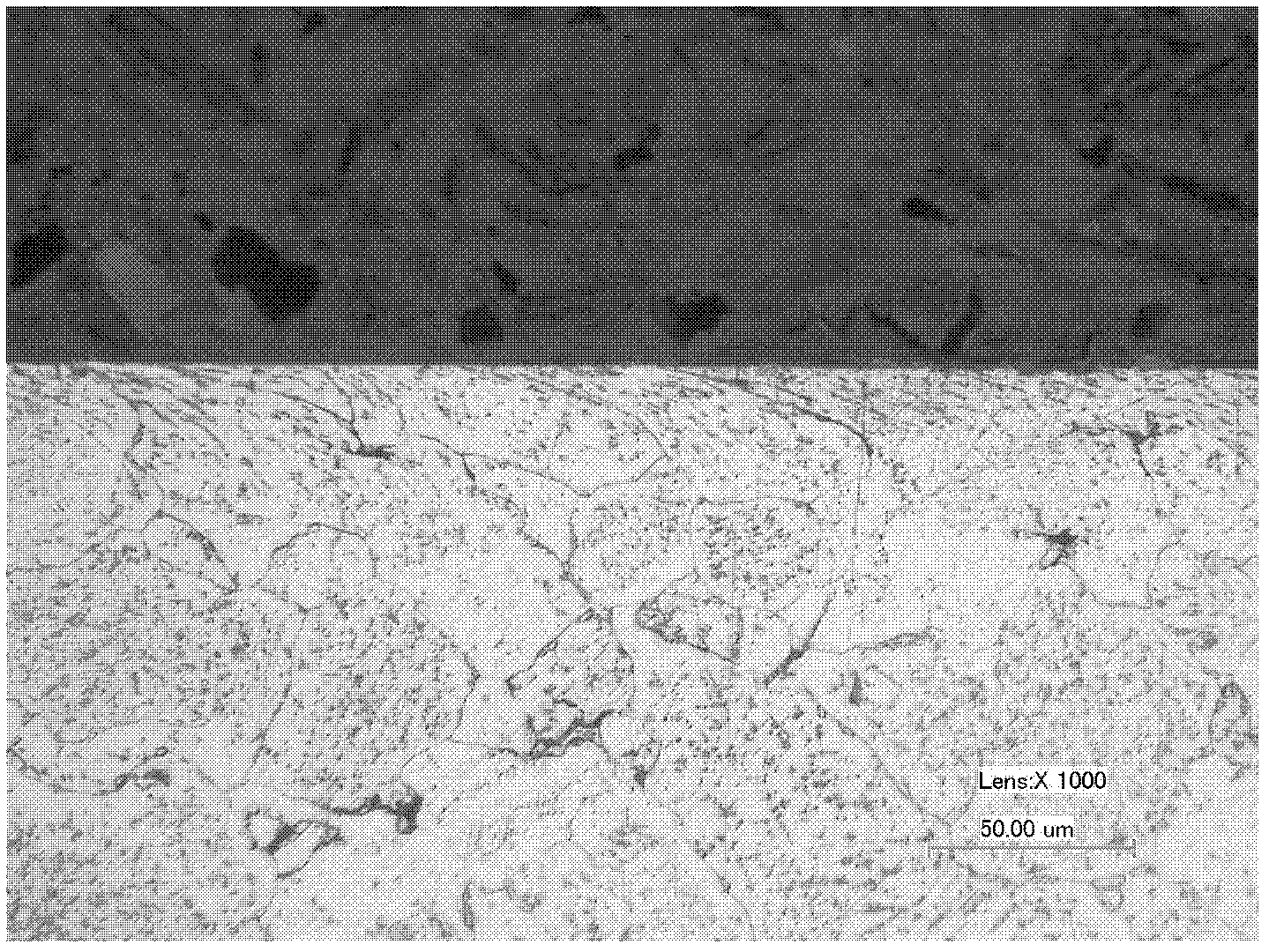

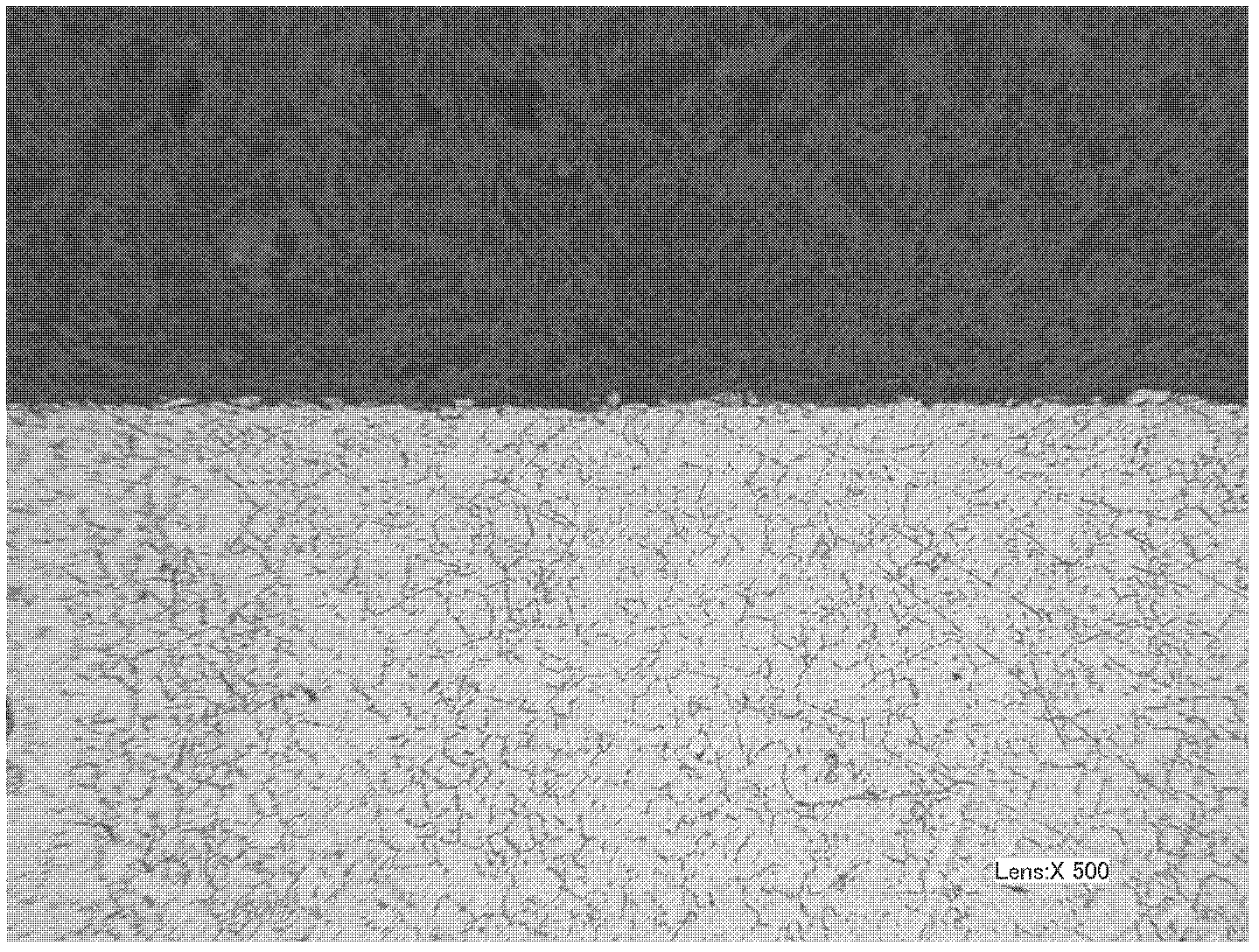

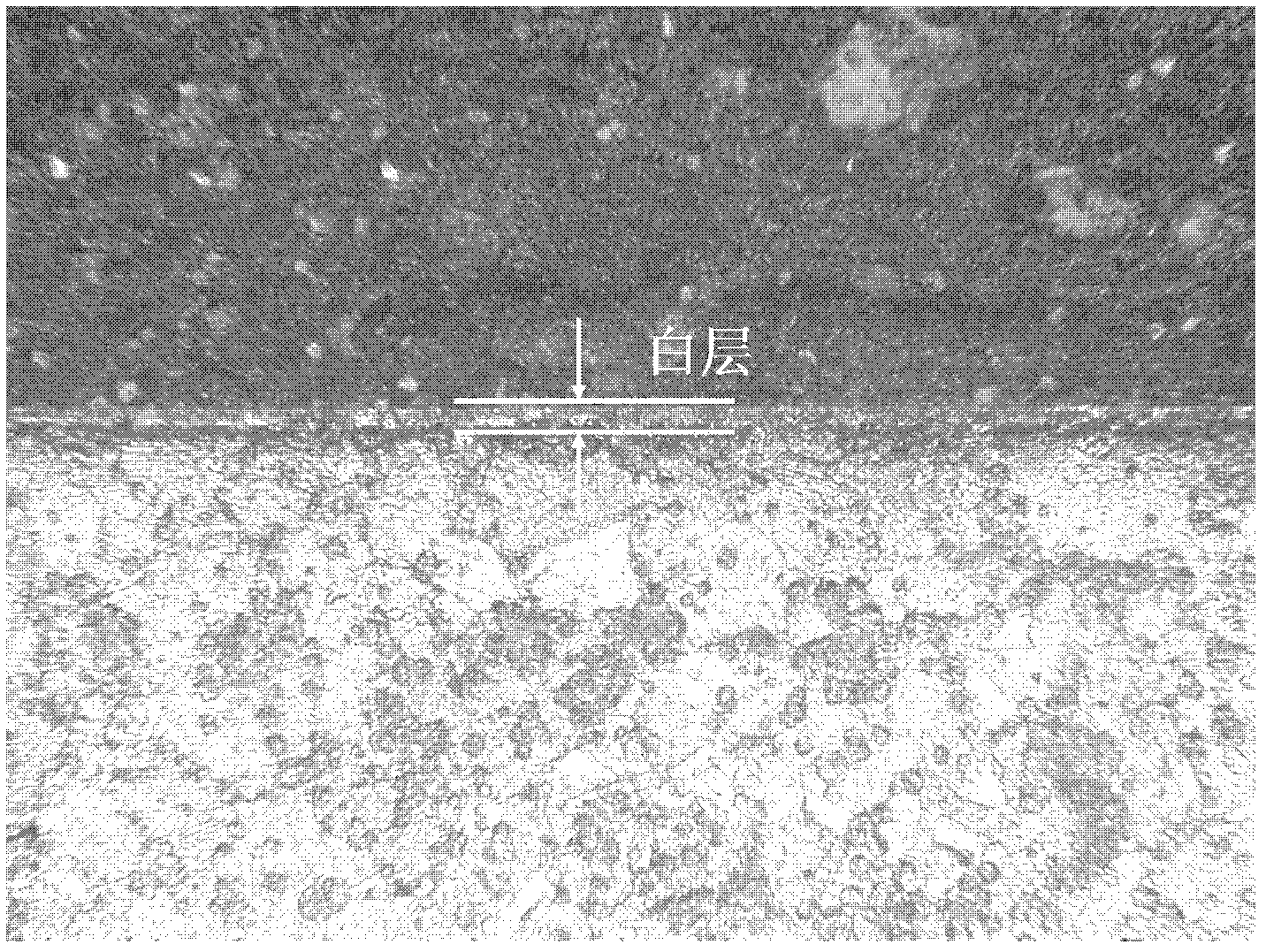

Corrosive for showing white layer of processed surface of nickel-base superalloy as well as preparation method and applications thereof

InactiveCN102494933ASimple recipeLow costPreparing sample for investigationElectrolysisCopper sulfate

The invention provides a corrosive for showing a white layer of the processed surface of nickel-base superalloy as well as a preparation method thereof. The corrosive comprises 70-75ml of hydrochloric acid, 8-10ml of nitric acid, 10-15ml of hydrofluoric acid, 3-5ml of sulfuric acid and 10-20g of copper sulfate. The preparation method is as follows: putting the hydrochloric acid into a glass container, then adding the nitric acid, the hydrofluoric acid, the sulfuric acid and the copper sulfate in sequence, and finally stirring the mixture uniformly. The corrosive is added into an electrolytic corrosion instrument, the anode of the electrolytic corrosion instrument is conducted with a corroded nickel-base superalloy workpiece with the processed surface, the cathode, the workpiece and the anode are dipped into the corrosive, and the electrolytic corrosion parameters are as follows: the voltage is 1.5V-2V, the current is 0.45A-0.5A, and the corrosion time is 30-40seconds. According to theinvention, the textures of the white layer on the processed surface of the nickel-base superalloy can be shown clearly, the boundary line between the textures of the white layer and the texture of a base body of the processed surface can be distinguished easily, and the observation and the measurement of the white layer on the processed surface of the nickel-base superalloy can be well facilitated.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com