Medium-high voltage electronic aluminum foil diffused tin nucleus electro-deposition method

An electronic aluminum foil, medium and high voltage technology, used in electrolytic capacitors, circuits, capacitors, etc., to improve the utilization rate and mechanical properties, reduce the occurrence of parallel holes, and improve the specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

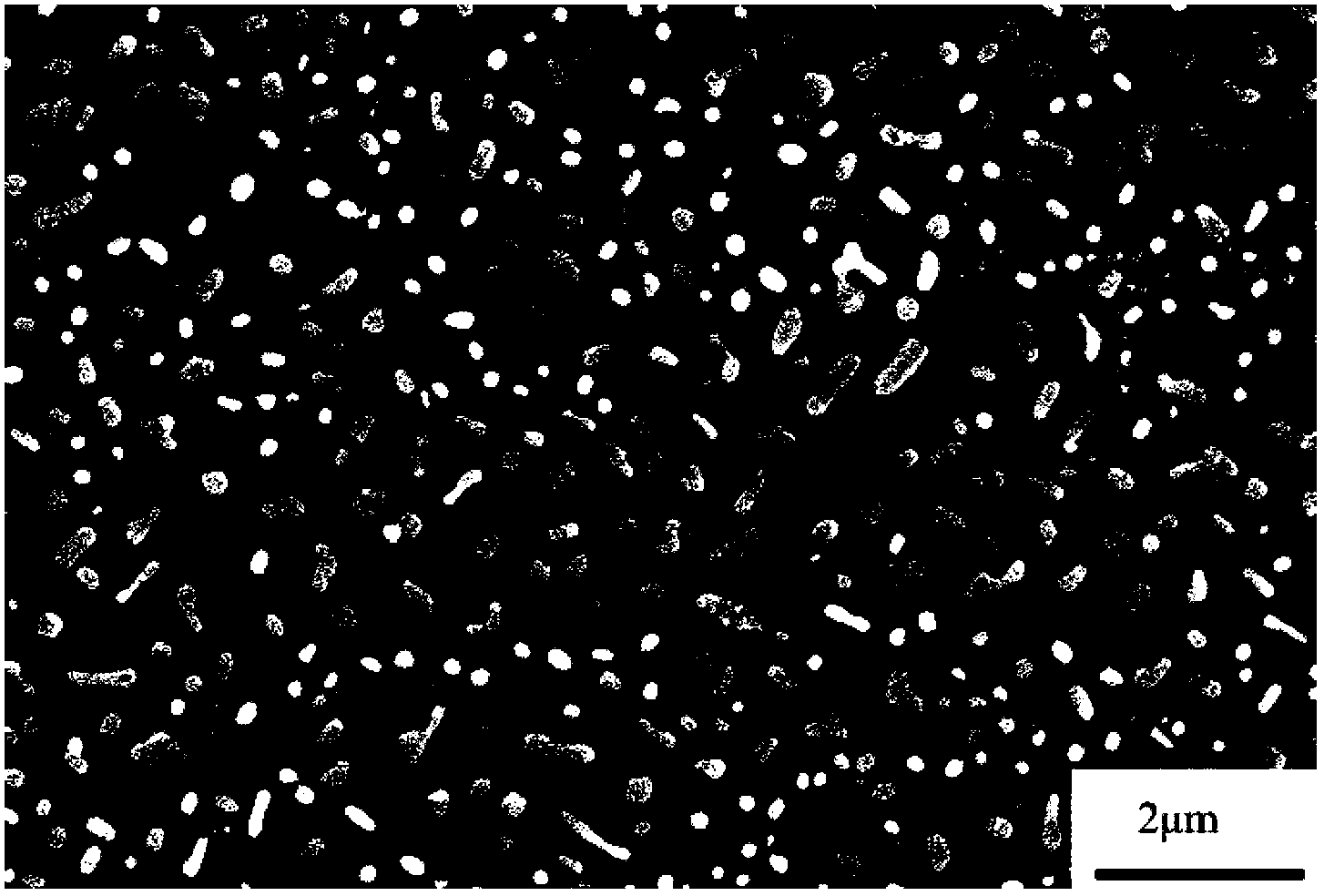

Image

Examples

Embodiment 1

[0024] The lead-free aluminum foil with a purity of 99.99%, a thickness of 110 μm, and a cubic texture occupancy rate of more than 95% is boiled in boiling water at 100°C for 30 seconds, and a new water-containing film is formed on the surface of the aluminum foil. The above-mentioned aluminum foil is placed in a tin plating solution for electroplating. The composition of the plating solution is: 1wt% sodium stannate trihydrate + 0.1wt% acetic acid; graphite is used as an anode, and a new water-containing film is formed on the above-mentioned boiled surface. The medium and high voltage aluminum foil is used as the cathode, and the aluminum foil is charged into the electrolyte, where the temperature of the electroplating solution is 60°C, and the current density of the electrodeposition is 40mA / cm 2 , The electrodeposition time is 15 seconds.

[0025] The above-mentioned aluminum foil that has been electrodeposited on the surface to obtain dispersed tin nuclei is subjected to p...

Embodiment 2

[0027] Put lead-free aluminum foil with a purity of 99.99%, a thickness of 110 μm, and a cubic texture occupancy of more than 95% in an alkaline solution with a temperature of 60°C and a concentration of 2wt% for 15 seconds to form a new water-containing film on the surface of the aluminum foil back. The above-mentioned aluminum foil is placed in a tin plating solution for electroplating. The composition of the plating solution is: 1wt% sodium stannate trihydrate + 0.1wt% acetic acid; graphite is used as an anode, and a new water-containing film is formed on the above-mentioned boiled surface. The medium and high voltage aluminum foil is used as the cathode, and the aluminum foil is charged into the electrolyte, where the temperature of the electroplating solution is 60°C, and the current density of the electrodeposition is 40mA / cm 2 , The electrodeposition time is 15 seconds. The above-mentioned aluminum foil that has been electrodeposited on the surface to obtain dispersed ...

Embodiment 3

[0029] Put a lead-free aluminum foil with a purity of 99.99%, a thickness of 110 μm, and a cubic texture occupancy of more than 95% in a polishing solution for electrochemical polishing. The composition of the polishing solution is: volume concentration: 60% phosphoric acid + 40% Sulfuric acid + 1% glycerol mixed solution; the polishing current density is 60mA / cm when polishing 2 , the polishing time is 30 seconds, and a new water-containing film is formed on the surface of the aluminum foil. The above-mentioned aluminum foil is placed in a tin plating solution for electroplating. The composition of the plating solution is: 1wt% sodium stannate trihydrate + 0.1wt% acetic acid; graphite is used as an anode, and a new water-containing film is formed on the above-mentioned boiled surface. The medium and high voltage aluminum foil is used as the cathode, and the aluminum foil is charged into the electrolyte, where the temperature of the electroplating solution is 60°C, and the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com