Method for etching holes by corroding aluminum foil

A technology for corroding aluminum foil and aluminum foil, which is applied in the direction of electrical components, electrolytic capacitors, capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

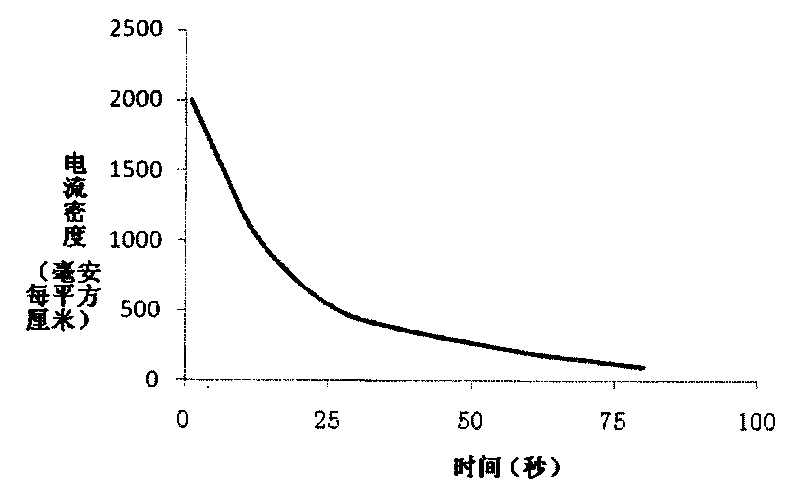

[0023] Put the pre-treated aluminum foil into the primary corrosion solution, press figure 1 Ways to apply current density from high to low, from 2000mA / cm 2 Change to 100mA / cm 2 Corroded by direct current for 45 seconds, cleaned with pure water, put into secondary corrosion solution for energized corrosion and reaming, then cleaned with pure water and then post-processed, after post-processing, take it out, clean it with pure water and dry it .

Embodiment 2

[0025] Put the pre-treated aluminum foil into the primary corrosion solution, press figure 1 Ways to apply current density from high to low, from 1500mA / cm 2 Change to 50mA / cm 2 Corrode with direct current for 65 seconds, clean it with pure water, put it into the secondary corrosion solution for energized corrosion reaming, clean it with pure water and carry out post-treatment, after post-treatment, take it out, clean it with pure water and dry it .

Embodiment 3

[0027] Put the pre-treated aluminum foil into the primary corrosion solution, press figure 1 Ways to apply current density from high to low, from 1500mA / cm 2 Change to 200mA / cm 2 Corroded by direct current for 80 seconds, cleaned with pure water, put into the secondary corrosion solution for energized corrosion and reaming, then cleaned with pure water, and then post-processed, after post-processing, take it out, clean it with pure water and dry it .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com