Patents

Literature

460results about How to "Increase specific volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur electrode, and preparation and application thereof

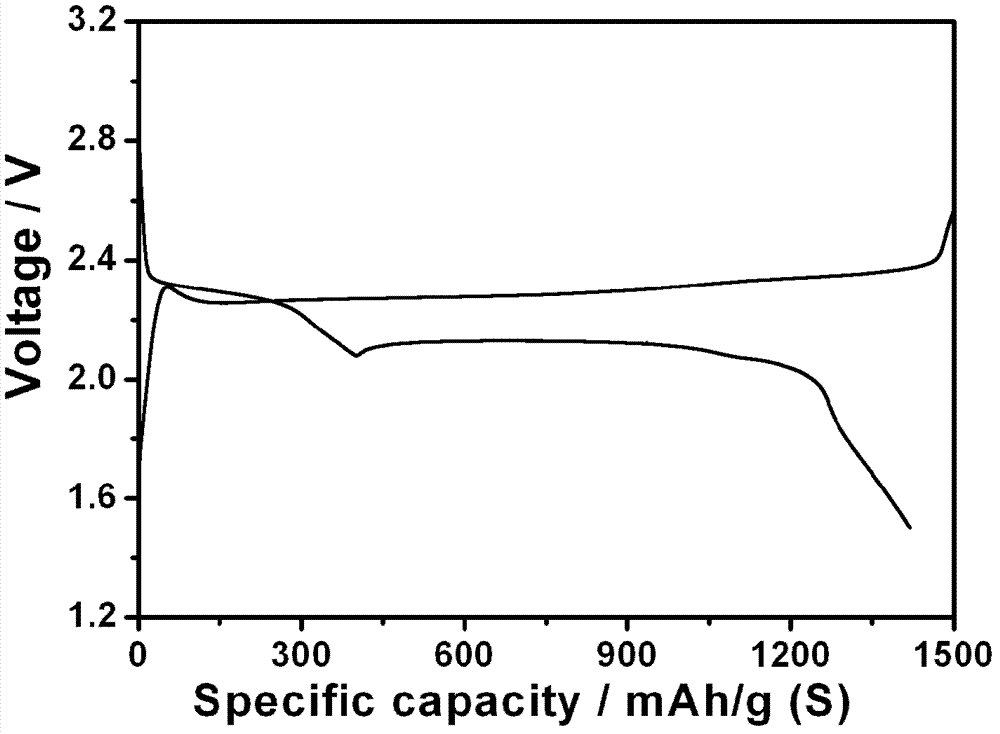

ActiveCN102903887AImprove cycle stabilityIncrease profitNon-aqueous electrolyte accumulator electrodesCarbon compositesPorous carbon

A sulfur electrode, and preparation and application thereof. The sulfur electrode comprises a sulfur / carbon composite, a conductive agent and a binder, wherein the sulfur is an electrode active material. The content of sulfur / carbon composite in the electrode is 10-95%; a mass ratio of sulfur to porous carbon material in the sulfur / carbon composite is 1:0.05-19; the porous carbon material in the sulfur / carbon composite has conductivity greater than or equal to 0.1S / cm, specific surface area greater than or equal to 500 m<2> / g, and pore volume greater than or equal to 0.3cm<3> / g; and the pore structure comprises microporous and mesoporous. The porous carbon material is treated by an acid modification method, in which a mass fraction of acid is 1-50%. The sulfur electrode prepared by the method provided by the invention has advantages of high specific energy, excellent cycle stability, cheap and easily available electrode material, and simple and practical preparation method, and can be applied to a secondary battery.

Owner:中科派思储能技术有限公司

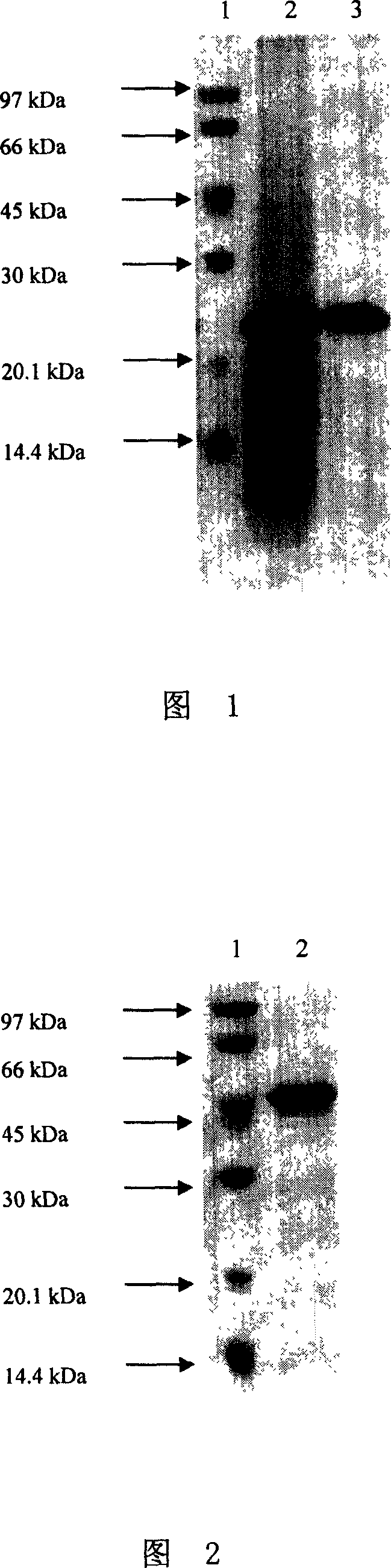

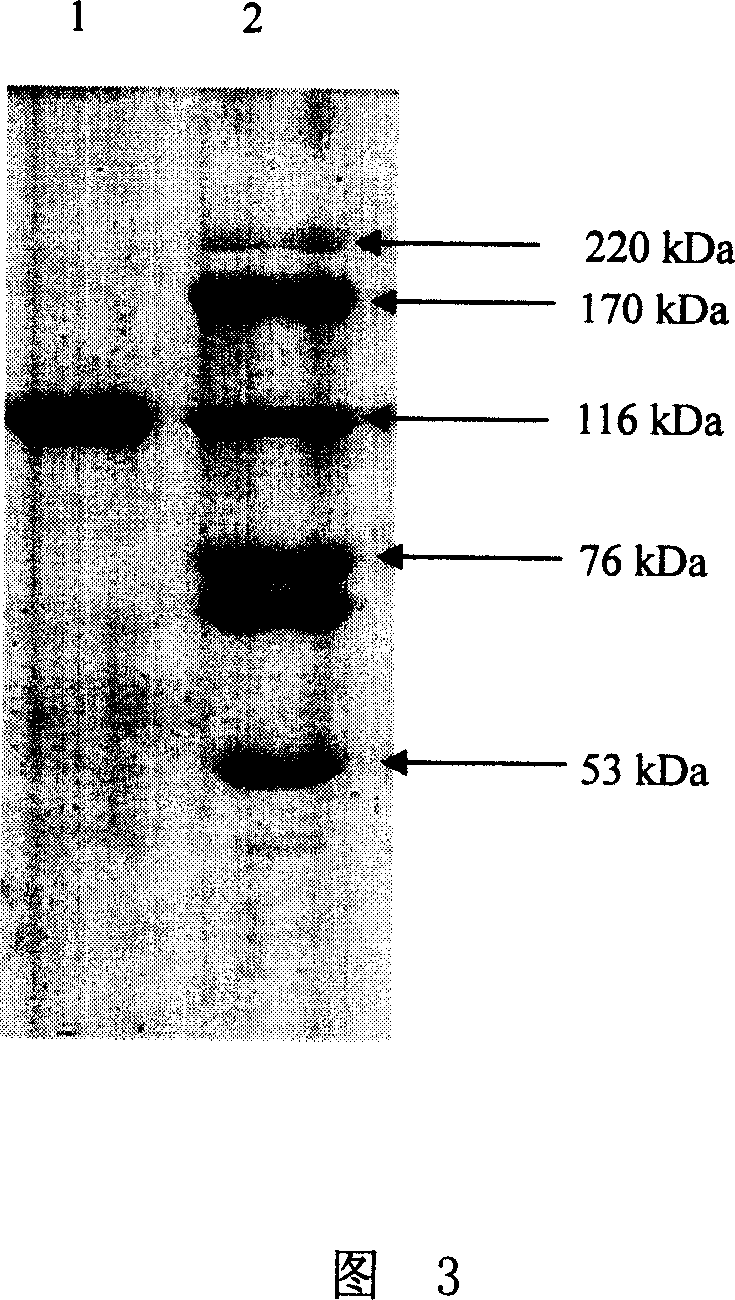

Method of preparing heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase

The invention discloses a making method of heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase, which comprises the following steps: adopting agricultural waste as carbon source; fermenting Paecilomyces thermophila J18 at 40-60 deg.c to obtain the ferment liquid with heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase; purifying; obtaining electrophoretic grade product.

Owner:CHINA AGRI UNIV

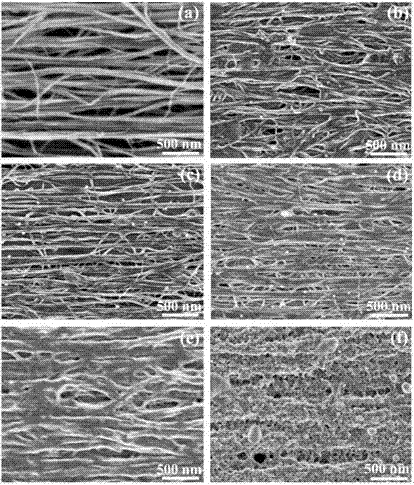

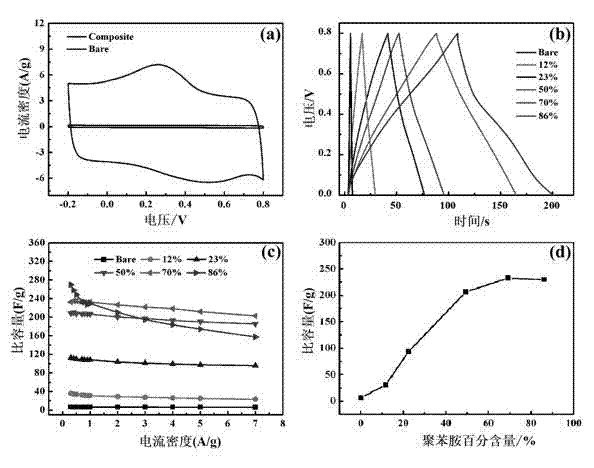

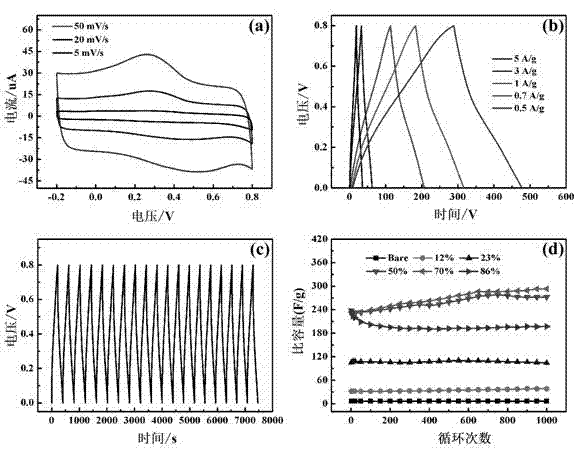

Super capacitor taking polyaniline/aligned carbon nanotube compound film as electrode and manufacturing method thereof

ActiveCN102810406AIncrease specific volumeImprove cycle stabilityElectrolytic capacitorsHybrid capacitor electrodesElectrolytic agentCarbon nanotube

The invention belongs to the technical field of super capacitors, in particular to a super capacitor taking a polyaniline / aligned carbon nanotube compound film as an electrode and a manufacturing method thereof. The method comprises the following steps of: adsorbing a polymer monomer onto the surface of a carbon tube by adopting an electrochemical polymerization method; and performing constant-potential electro-deposition of three electrodes in an aniline-sulfuric acid electrolyte to obtain the polyaniline / aligned carbon nanotube compound film. The super capacitor constructed by using the compound film as an electrode has high specific capacity and stable circulating performance; and meanwhile, the super capacitor has high flexibility and high transparency. The invention designs a method for manufacturing a flexible, transparent and efficient super capacitor.

Owner:宁国市龙晟柔性储能材料科技有限公司

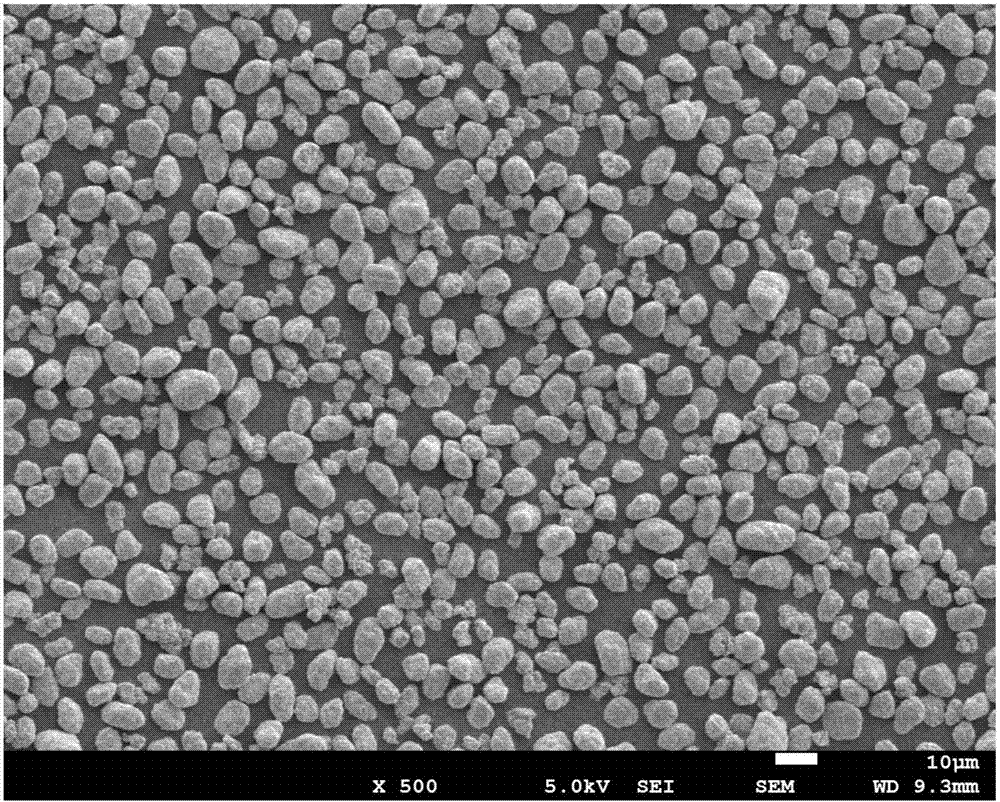

Core-shell structured lithium nickel manganese cobalt precursor, fabrication method thereof and application thereof in lithium ion battery

ActiveCN107968198AHigh nickel content insideIncrease contentCell electrodesSecondary cellsDischarge efficiencyManganese

The invention relates to a core-shell structured lithium nickel manganese cobalt precursor, a fabrication method thereof and application thereof in a lithium ion battery. The precursor is nickel manganese cobalt carbonate and sequentially comprises an inner core and more than one shell layer from inside to outside, and mole concentration of the corresponding Ni is gradually reduced from the innercore to the shell layers sequentially arranged outside. The invention also provides a surface coated lithium nickel manganese cobalt composite material prepared by employing the precursor and the lithium ion battery employing the composite material as a positive electrode material. By the precursor, the problems that the synthesis process of a ternary nickel manganese cobalt positive electrode material is not mature and is complicated, the precursor research is neglected and the improvement of the performance of the ternary nickel manganese cobalt material is limited are solved. In the batteryprepared from a nickel-rich gradient-concentration ternary nickel manganese cobalt positive electrode material, the initial discharge specific capacity under 0.1C rate is larger 194mAh / g, the initialcharge-discharge efficiency is larger than 92%, and the capacity retention rate after circulation for 300 times under 1C rate is larger than 80%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

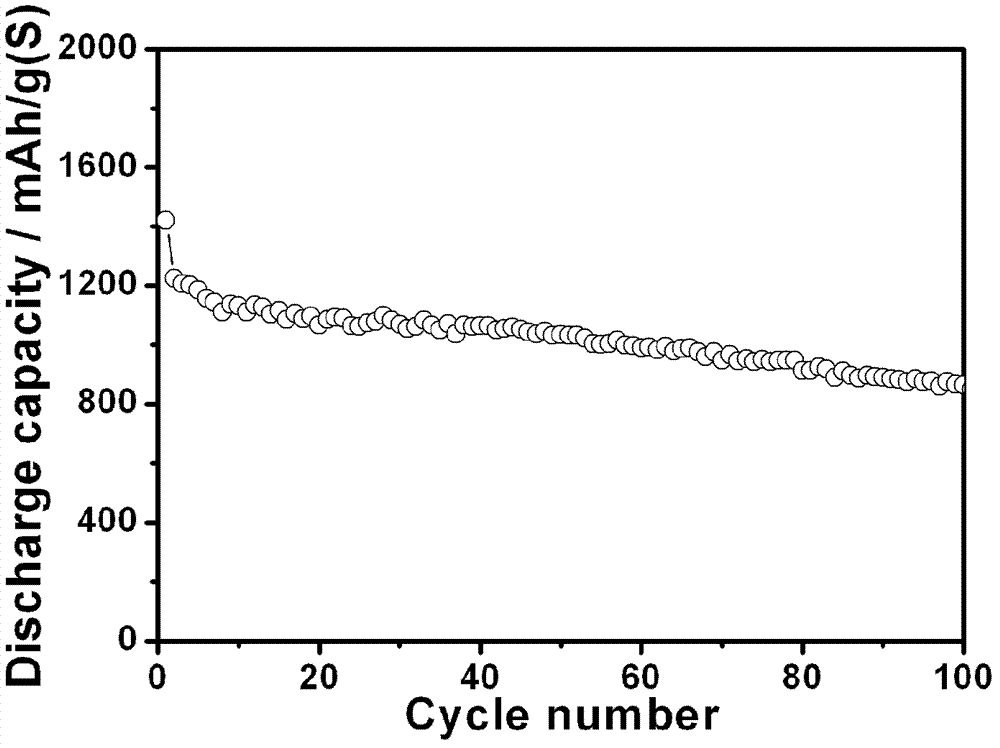

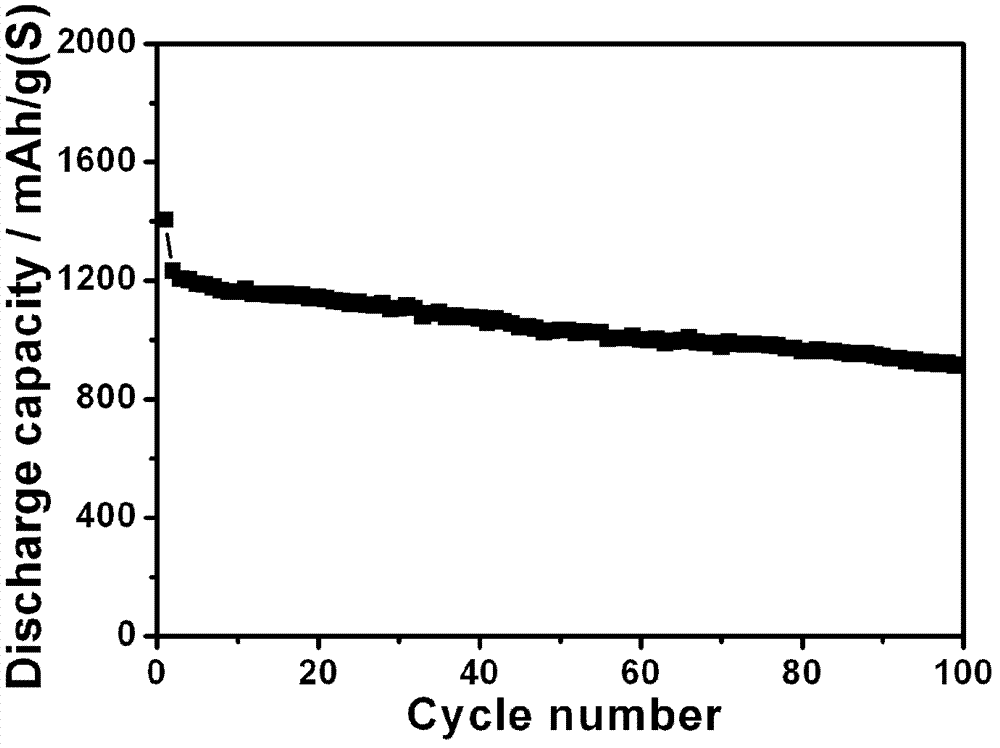

Sulphidepolymer coated sulfur / carbon composite material and preparation method thereof

InactiveCN104241612AIncrease specific volumeImprove cycle stabilityCell electrodesLi-accumulatorsCarbon compositesHigh rate

A sulfide polymer coated sulfur / carbon composite material and a preparation method thereof. The composite material includes composite containing carbon with high surface area and sulfur and a sulfide polymer cladding layer. The preparation method is as below: conducting ball-milling on sulfur and carbon with high surface area in a ball mill and conducting heat treatment on the product under protective atmosphere; dispersing the product in a solution containing polymer monomers and adding a initiator to initiate polymerization; filtering, washing and drying; and conducting heat treatment on the product under protective atmosphere, so as to obtain the sulfide polymer coated sulfur / carbon composite material. The composite material provided by the invention as an anode material for lithium sulfur battery has the following advantages: high surface area carbon material can improve the electronic conductivity of sulfur, and inhibit polysulfide erosion; the sulfide polymer coating layer not only inhibits the loss of polysulfide but also provides part of the capacity. Lithium sulfur battery composed of the composite material has the advantages of high specific capacity, long service life, high rate capability, simple preparation and low cost, and has good application prospect.

Owner:中科派思储能技术有限公司

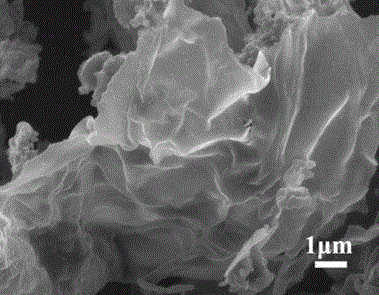

Preparation method of supercapacitor carbon material

ActiveCN104157470AReduce manufacturing costIncrease specific volumeHybrid capacitor electrodesHybrid/EDL manufactureBiomassCyclic stability

The invention provides a preparation method of a supercapacitor carbon material. In the method, cheap and easily available biomass such as pericarp, vegetables and the like is taken as raw materials, and the supercapacitor carbon material is obtained through steps including thiourea hydro-thermal processing, impurity removing processing, freeze drying processing, calcining processing, alkali / microwave activation processing and the like. The material has the characteristics of a layered structure and a large specific surface area. Since a thiourea hydro-thermal step is carried out in a preparation process, S and N in thiourea molecules are introduced, the specific volume of the material is effectively improved, and an electrode prepared by use of the material has the advantages of large specific volume and good circulating stability. According to the invention, wastes such as watermelon peel, shaddock peel and the like and cheap vegetables such as sweet potatoes, radishes and the like are taken as the raw materials, such that the production cost is decreased, and the preparation method also accords with the strategy of sustainable development for environmental protection and has an important popularization value.

Owner:JIANGSU SUPERBIO LIFE SCI CO LTD

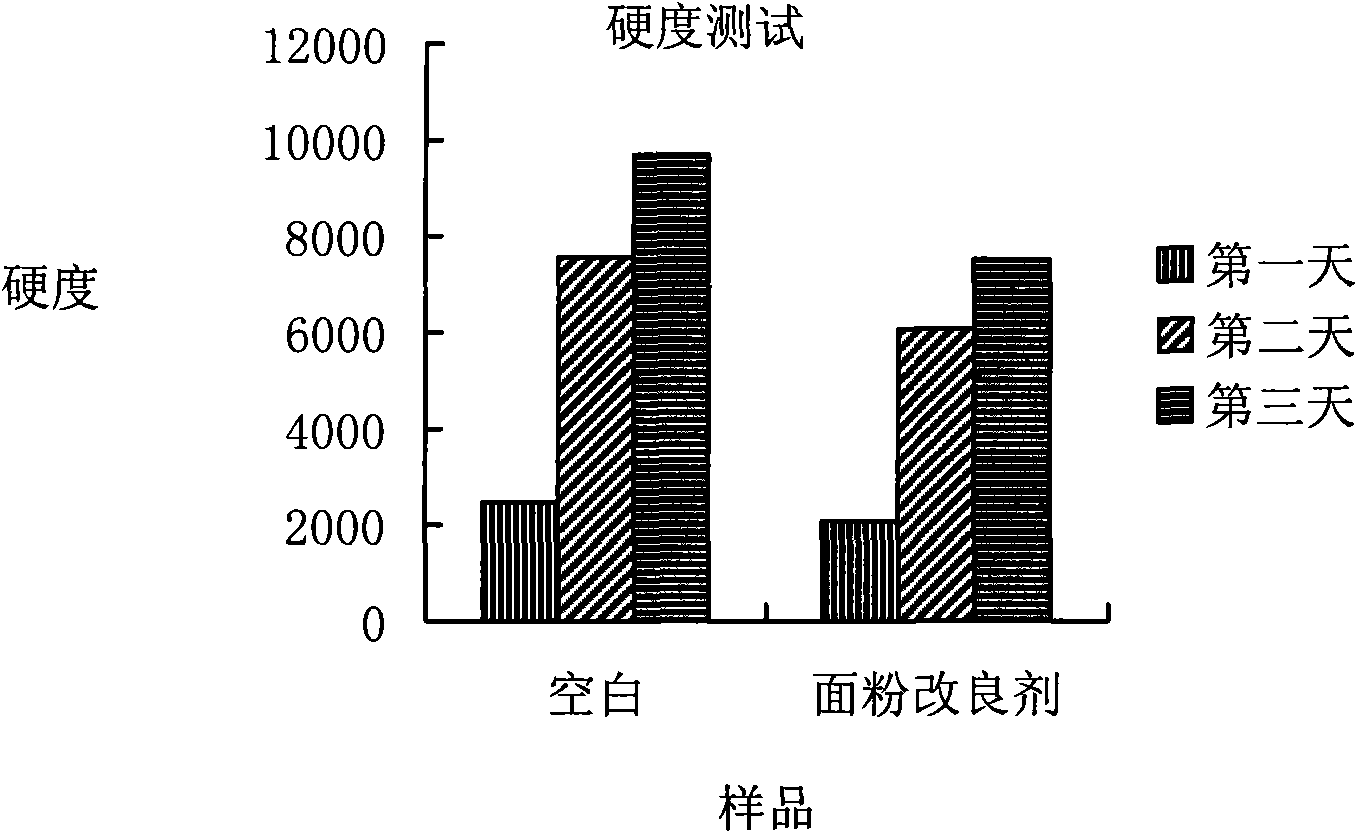

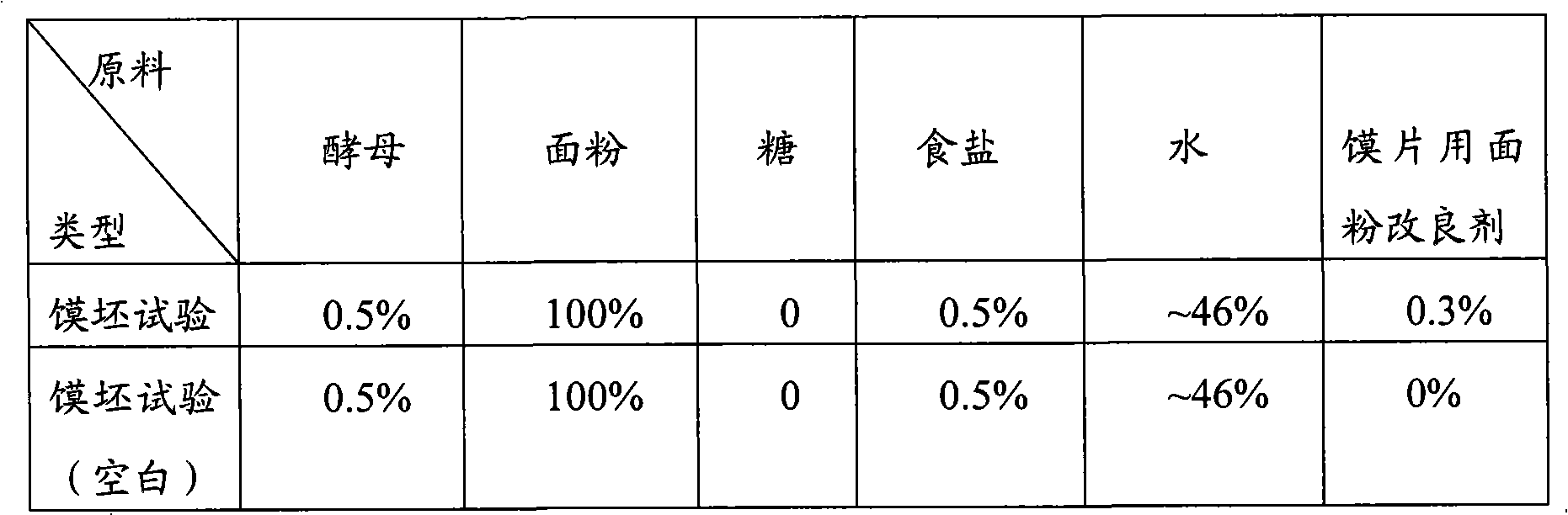

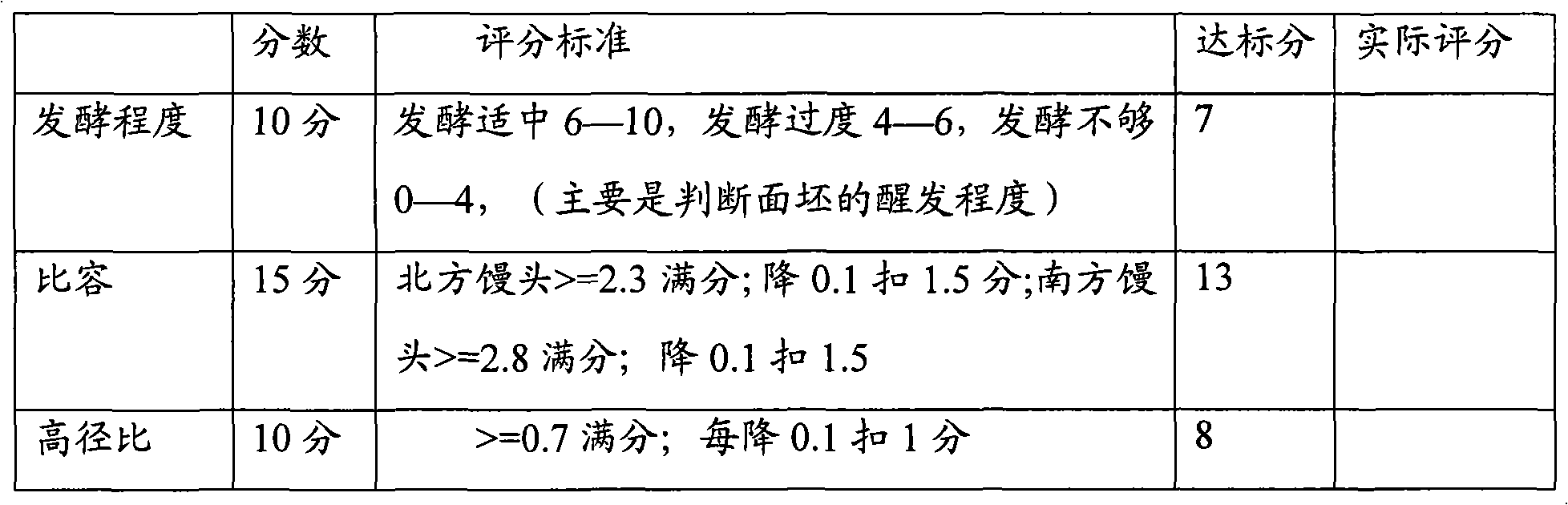

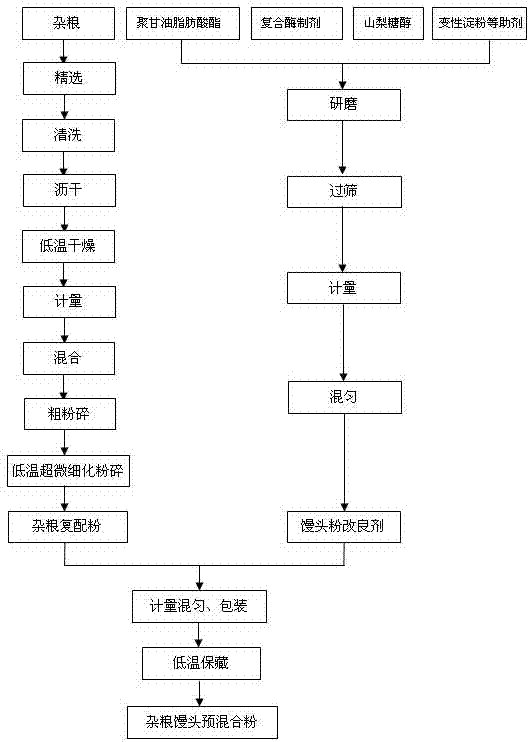

Steamed bread slice making flour modifier and use thereof

InactiveCN101664048AIncrease specific volumeImprove organizational structurePre-baking dough treatmentFood productsSteamed bread

The invention relates to a flour modifier and use thereof, in particular to a steamed bread slice making flour modifier and use thereof. The flour modifier comprises an enzyme preparation, an oxidant,an emulsifier, a swelling agent, a phosphate and starch, can be used for making wheaten food product such as steamed bread and steamed bread slices, improve the structure of steamed bread slices, make the hole in the steamed bread slices more uniform, provide the steamed bread slices with good appearance and improve the crisp degree and yield of the steamed bread slices.

Owner:ANGELYEAST CO LTD

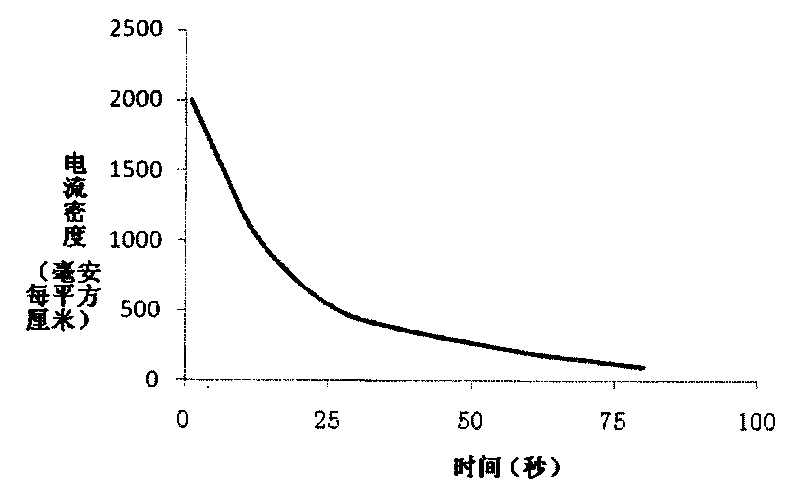

Method for etching holes by corroding aluminum foil

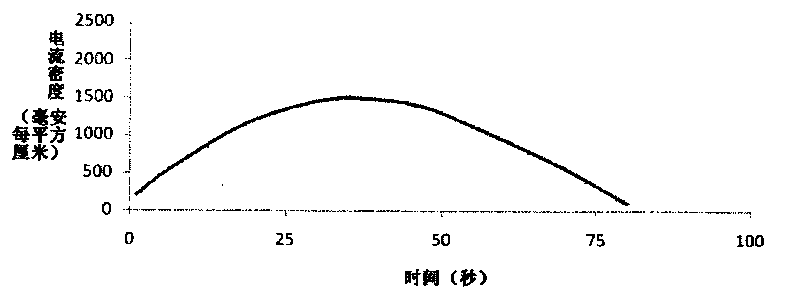

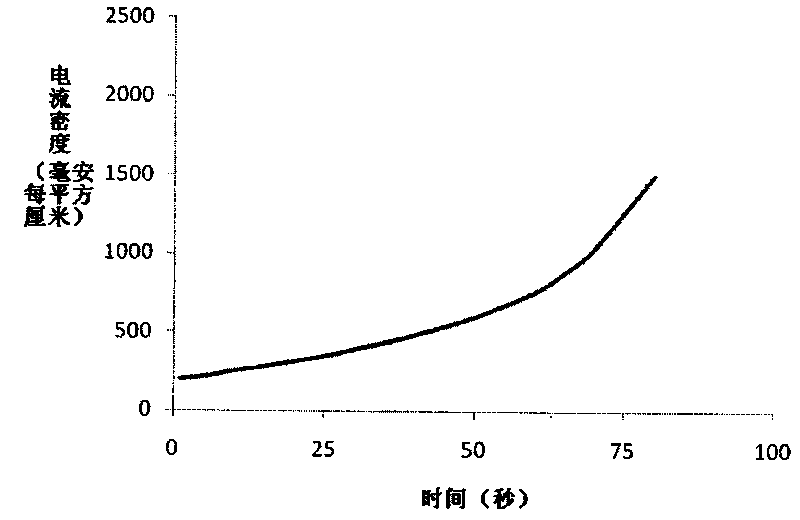

InactiveCN101752095AHigh densityUniform densityElectrolytic capacitorsConstant current densityMaterials science

The invention discloses a method for etching holes by eroding an aluminum foil, which comprises the steps of pretreatment, first level corrosion, second level corrosion, post treatment and drying. The first level corrosion comprises the following steps of: putting the aluminum foil after the pretreatment into mixed solution of hydrochloric acid and sulfuric acid, wherein the mixed solution contains 0.5 to 1.0 N / L of aluminum, the temperature of the mixed solution is between 65 and 90 DEG C and the total acidity of the mixed solution is 5.0 to 8.0 N / L; and applying 45 to 80 seconds of direct current of which the current density changes along with the time to perform electrolytic corrosion for etching the holes in mainly three modes that: one, the current density changes from high to low along with the time; two, the current density changes from low to high and then to low again; and three, the current density changes form low to high. The hole etching mode that the current density changes from high to low along with the time improves the specific volume by 7 to 12 percent compared with the existing hole etching method with constant current density under the premise of not reducing the mechanical strength of the aluminum foil.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

Capacitor electrode member, its manufacturing method and capacitor with same

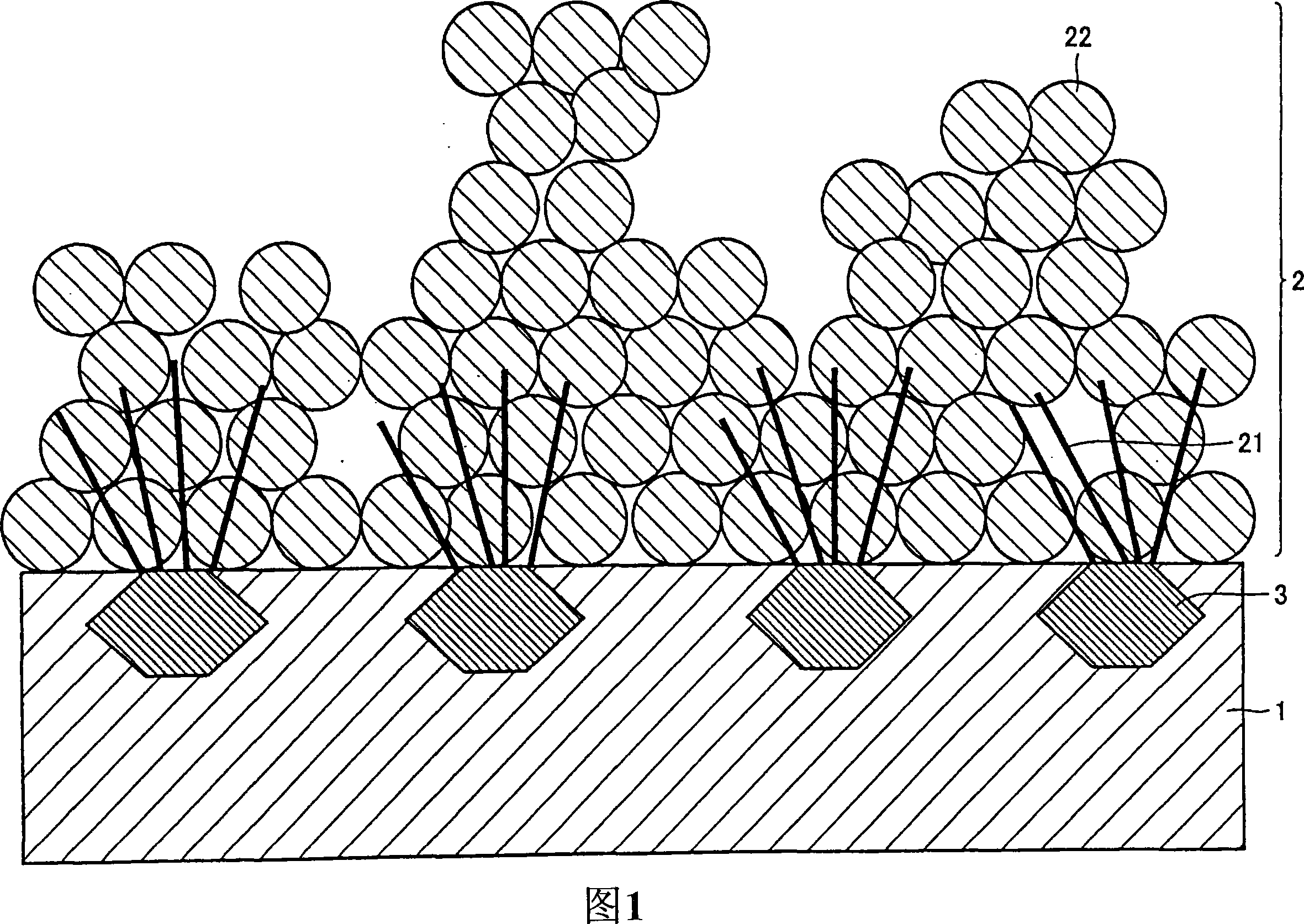

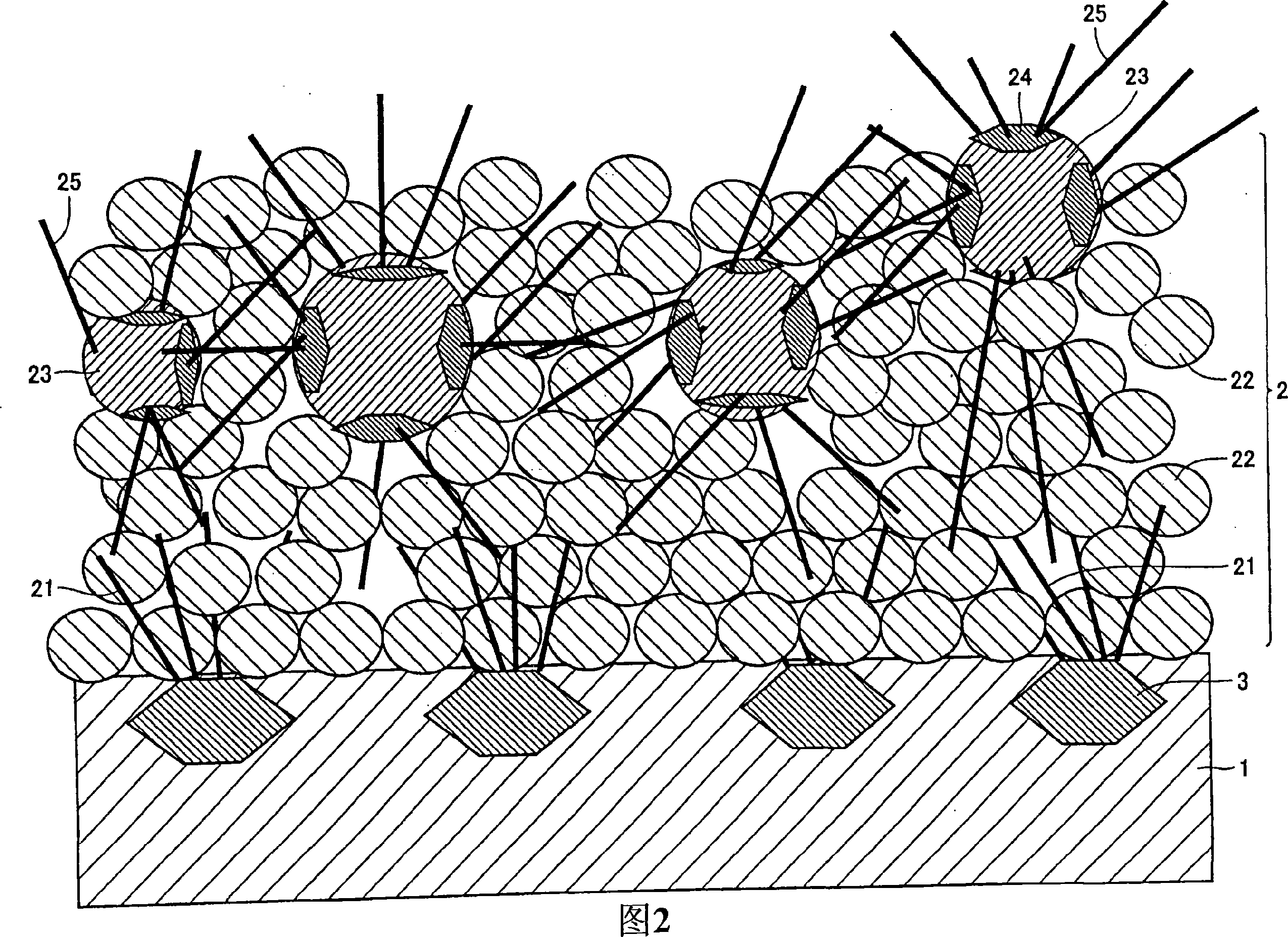

ActiveCN101027736AExcellent adhesionLarge capacityHybrid capacitor electrodesDouble layer capacitorsCarbideCarbon particle

The invention provides a capacitor electrode member in which layers constituting the electrode member are highly adhesive. The capacitor electrode member comprises aluminum material (1), a carbon-containing layer (2) formed on the surface of the aluminum material (1), and further an interposition layer (3) containing an aluminum element and a carbon element, the interposition layer being formed between the aluminum material (1) and the carbon-containing layer (2). The interposition layer (3) constitutes a first surface portion which is formed on at least a part of the region of the surface of the aluminum material (1) and contains a carbide of aluminum. The carbon-containing layer (2) constitutes a second surface portion (21) formed so as to extend outward from the first surface portion (3). The carbon-containing layer (2) further contains carbon particles (22) and the second surface portion (21) is formed between the first surface portion (3) and the carbon particles (22) and contains a carbide of aluminum.

Owner:TOYO ALUMINIUM KK

Method for preparing nickel-manganese-based cobalt-covering lithium ion anode material

ActiveCN101378126AImprove cycle performanceIncrease capacityCell electrodesSecondary cellsManganesePhysical chemistry

The invention relates to a preparation method of the anode material of a nickel-manganese-based cobalt-coated lithium ion battery, which is the preparation method of the anode material LiNi<0.5-x>Co<2x>Mn<0.5-x>O2(x is more than 0.03 and less than or equal to 0.4) of a nickel-manganese-based lithium ion battery with the structure of Alpha-NaFeO2; a cocrystallization method is used for preparing an Ni0.5Mn0.5(OH)2 precursor, then a mode of gradient coating is adopted to carry out the processing of cobalt coating to the precursor so as to obtain a y(Ni0.5Mn0.5(OH)2) question mark (1-y)(Co(OH)2) precursor (y is equal to or more than 0.2 and equal to or less than 0.8); the coated precursor is pre-treated, then is added with lithium and sintered for 8 to 24 hours at the temperature of 750 to 1000 DEG C so as to obtain the nickel-manganese-based lithium ion battery LiNi<0.5-x>Co<2x>Mn<0.5-x>O2. The preparation method has the advantages of high specific volume, stable cycle performance, low cost and convenient operation and is easy for industrial production.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Sulfur-free ring stabilizing agent propellant powder

The invention discloses sulfur-free ring stabilizing agent propellant powder which consists of the following components in parts by weight: 70 parts of an oxidant, 34 parts of a burnable agent, 6 parts of an adhesive, 2 parts of a stabilizing agent, 2 parts of an anti-aging agent, 1 part of a catalyst and 2 parts of an antismoke agent which are uniformly mixed according to a general method, wherein the oxidant is a mixture consisting of potassium perchlorate, amine perchlorate and barium nitrate; the burnable agent is a mixture consisting of potassium hydrogen terephthalate, potassium acid phthalate, nitrocellulose, purified terephthalic acid and hemp stem carbon powder; the stabilizing agent adopts calcium stearate; the anti-aging agent adopts calcium phthalate; the catalyst adopts copper oxide; the antismoke agent adopts aluminum hydroxide; the adhesive is selected from one or a mixture of multiple of phenolic resin, strong adhesive powder, glutinous rice flour and polyvinyl alcohol according to any ratio. The sulfur-free ring stabilizing agent propellant powder is high in power capability and excellent in safety performance indexes and has excellent storage stability, and the environment-friendly performance is greatly improved.

Owner:HUNAN FEIYU NEW MATERIAL CO LTD

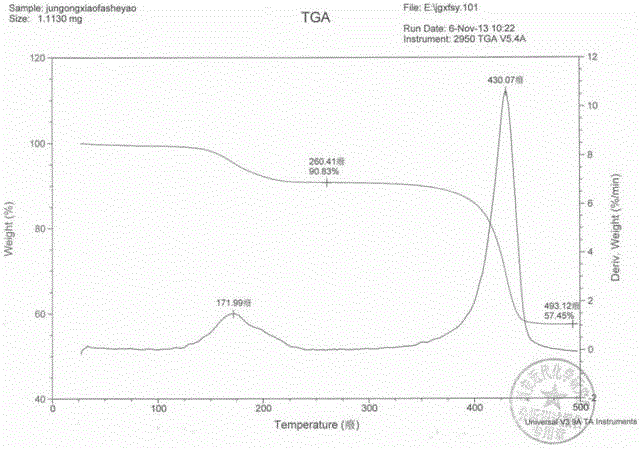

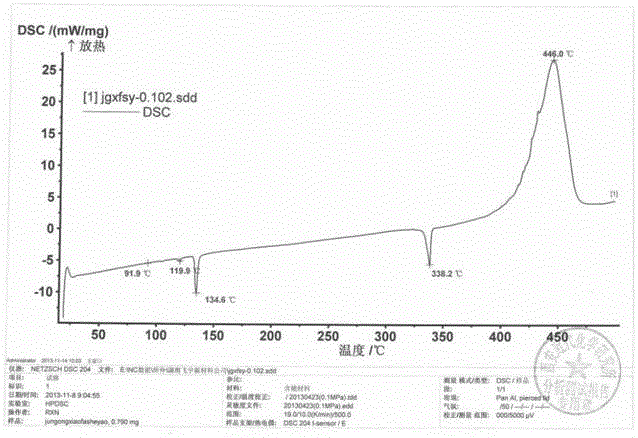

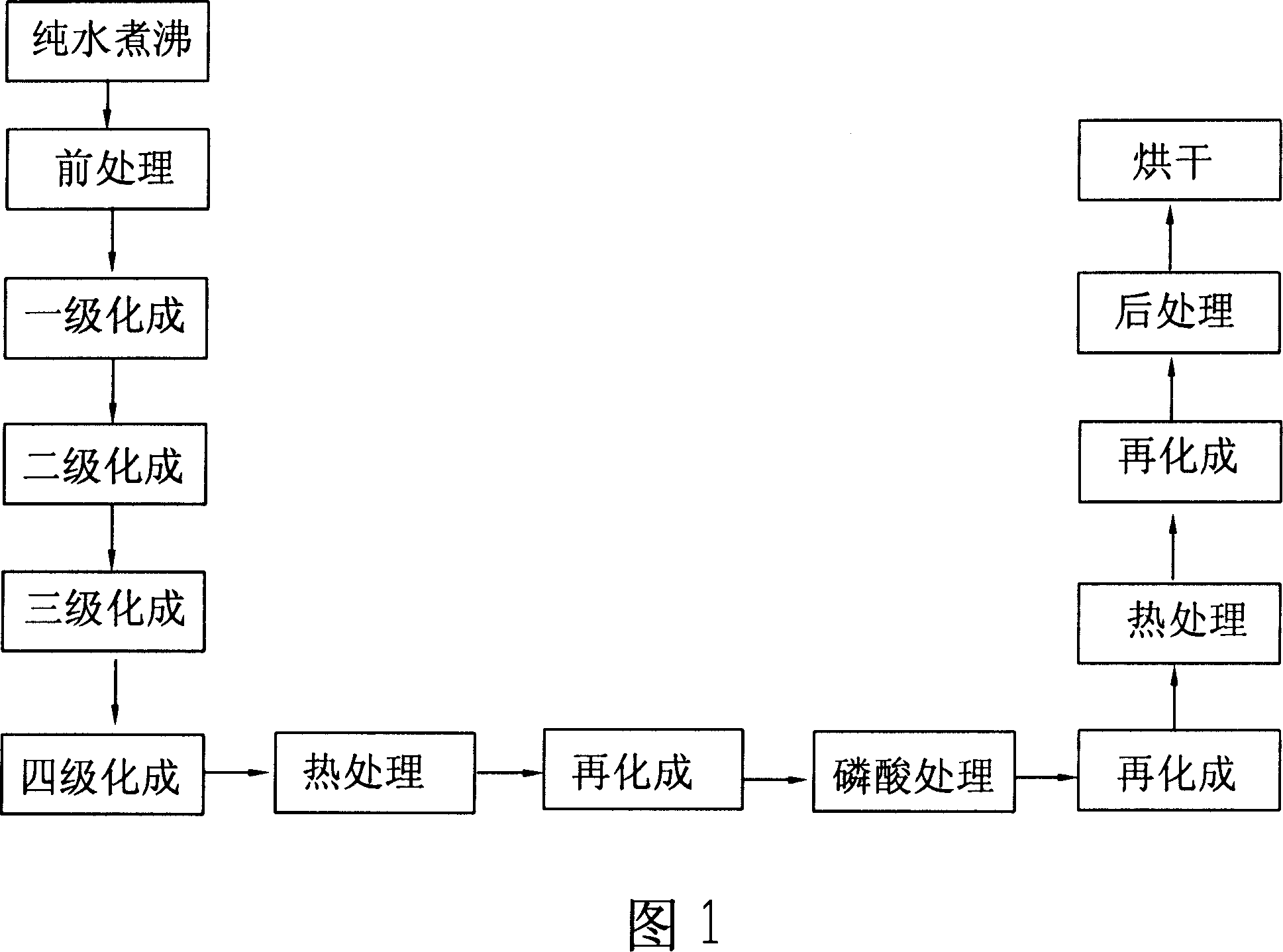

Method for manufacturing positive electrode aluminum foil of electrolytic capacitor

InactiveCN101110298AIncrease specific volumeBend wellAnodisationElectrolytic capacitorsSpecific volumeOrganic acid

The invention belongs to a method for producing high voltage anode aluminum foil in electrolytic capacitor, which relates to a reduction technology about the method for producing high voltage anode aluminum foil in electrolytic capacitor. The invention mainly comprises a number of procedures comprising pure water boiling, pre-processing, four-stage reduction, heat treatment, phosphoric acid treatment, depolarization treatment and after-treatment. After the treatment of pure water boiling, the aluminum foil will be treatment with a plurality of unsaturated organic acids, then undergone first-state reduction in phosphoric acid and salt, then undergone the second-stage, third-stage and fourth-stage reduction and depolarization in boric acid, boric acid ammonium (or natrium) or minim organic acid solution. Therefore, the produced anode aluminum foil has the advantages of high specific volume and excellent bending performance.

Owner:DONGGUAN HEC CONDENSER CO LTD

Ultrahigh voltage anode foil corrosion method for aluminum electrolytic capacitor

InactiveCN102983008AReduce leakage currentShort boost timeElectrolytic capacitorsUltra high voltageDrain current

Disclosed is an ultrahigh voltage anode foil corrosion method for an aluminum electrolytic capacitor. The method comprises steps of conducting pretreatment, conducting first direct current electrochemical corrosion, conducting first middle treatment, conducting second direct current electrochemical corrosion, conducting second middle treatment, conducting third direct current electrochemical corrosion, and conducting post treatment. By the aid of the method, produced anode foil can meet ultrahigh voltage requirements of 800 V to 1000 V, and produced products have the advantages of being low in drain current, quick in boost time and good in mechanical performance.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

Niobium oxide electrolytic capacitor cathode and producing method thereof

InactiveCN1549286AStable performanceAnode performance is stableElectrolytic capacitorsCapacitor manufactureMicrometerConstant voltage

The present invention relates to an electrode of electrolytic capacitor, in particular, it is an positive electrode of the electrolytic capacitor which is prepared by using columbium monoxide or doped columbium monoxide and its making method. It is characterized by that using columbium monoxide or doped columbium monoxide whose average grain size is 0.1 micrometer-20 micrometers as raw materials, and making it undergo the processes of pressing to make blank, vacuum sintering and energizing positive electrode block so as to obtain the invented columbium monoxide electrolytic capacitor positive electrode. Its energizing liquor is 0.01%-0.1% H3PO4, energizing voltage Vf is 10V-80V, energizing temp. is 10-90 deg.C, energizing current density is 10 mA.g(-1)-120 mA.g(-1), and time for constant voltage is greater than or equal to 0.5h. Said obtained positive electrode of electrolytic capacitor is stable in performance, high in specific capacity and small in leakage current.

Owner:CENT SOUTH UNIV

Anode material of lithium ion cell and preparation method thereof

ActiveCN101436666AImprove distributionEvenly distributedElectrode manufacturing processesCobalt compoundsLithium carbonatePhysical chemistry

The invention discloses a method for preparing lithium cobaltate positive pole material for a lithium ion cell and the obtained lithium cobaltate positive pole material. The method comprises the following steps: adopting a multiple-step synthesizing process; in a first synthesis, adopting excessive lithium so as to obtain larger lithium cobaltate particles at lower temperature; and before a second synthesis, adhering mixed powder of cobalt carbonate and lithium carbonate with small particle size and larger specific surface area to the one-step synthesized lithium cobaltate large particles through a mechanical granulation mode. The method can effectively improve the particle size and the tap density of the lithium cobaltate positive pole material so as to improve the compacted density and the volume specific capacity of the positive pole material.

Owner:广东风华新能源股份有限公司

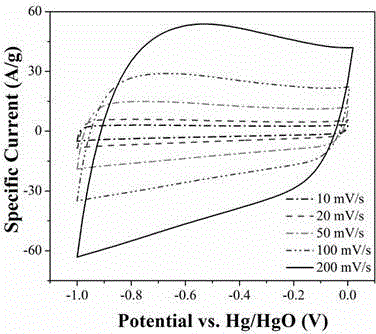

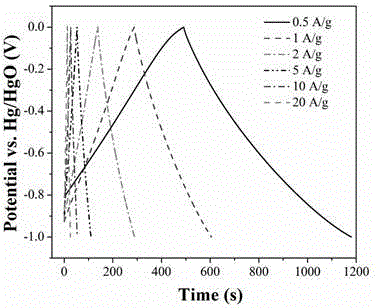

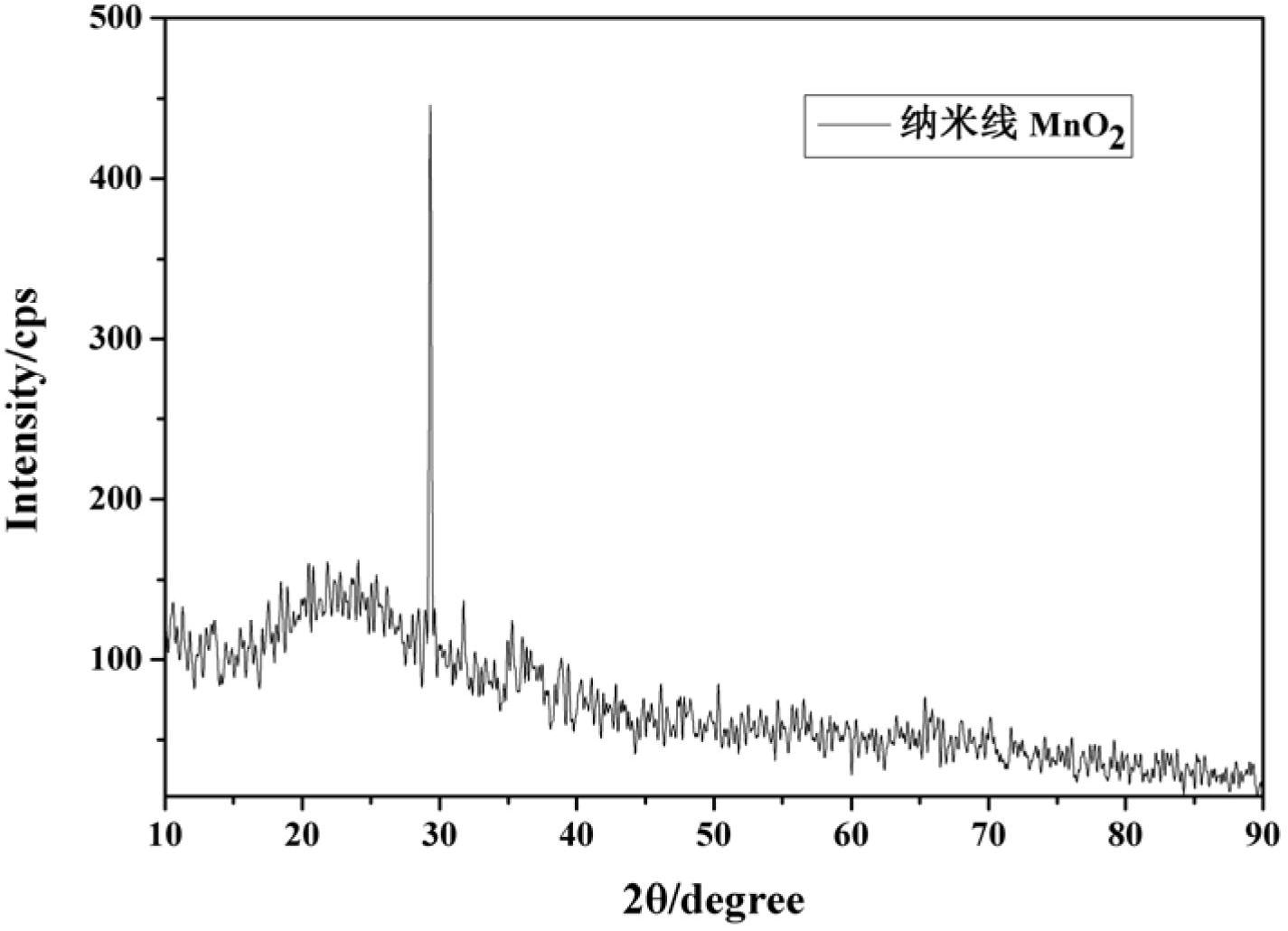

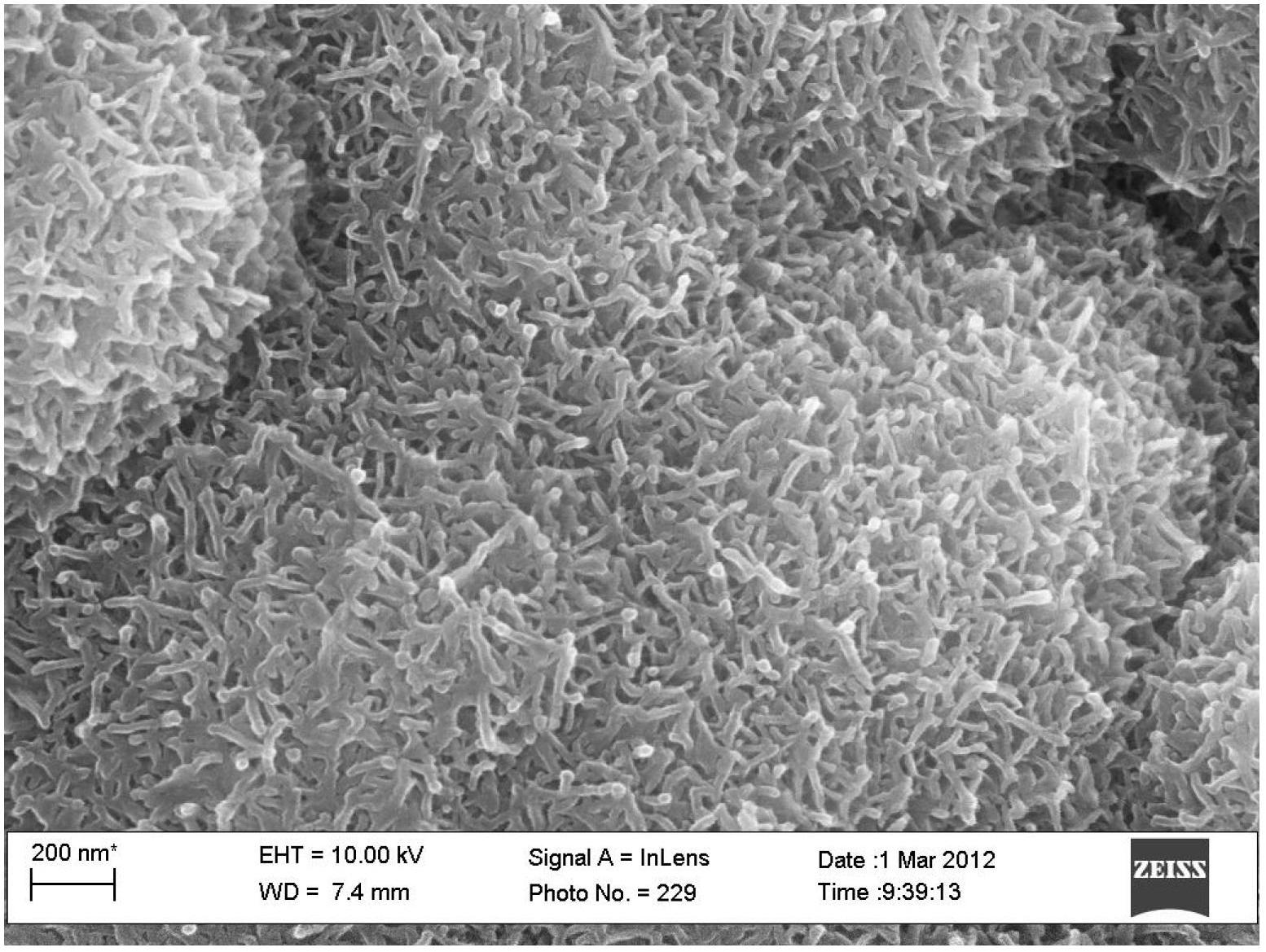

Preparation method of nano-manganese dioxide electrode

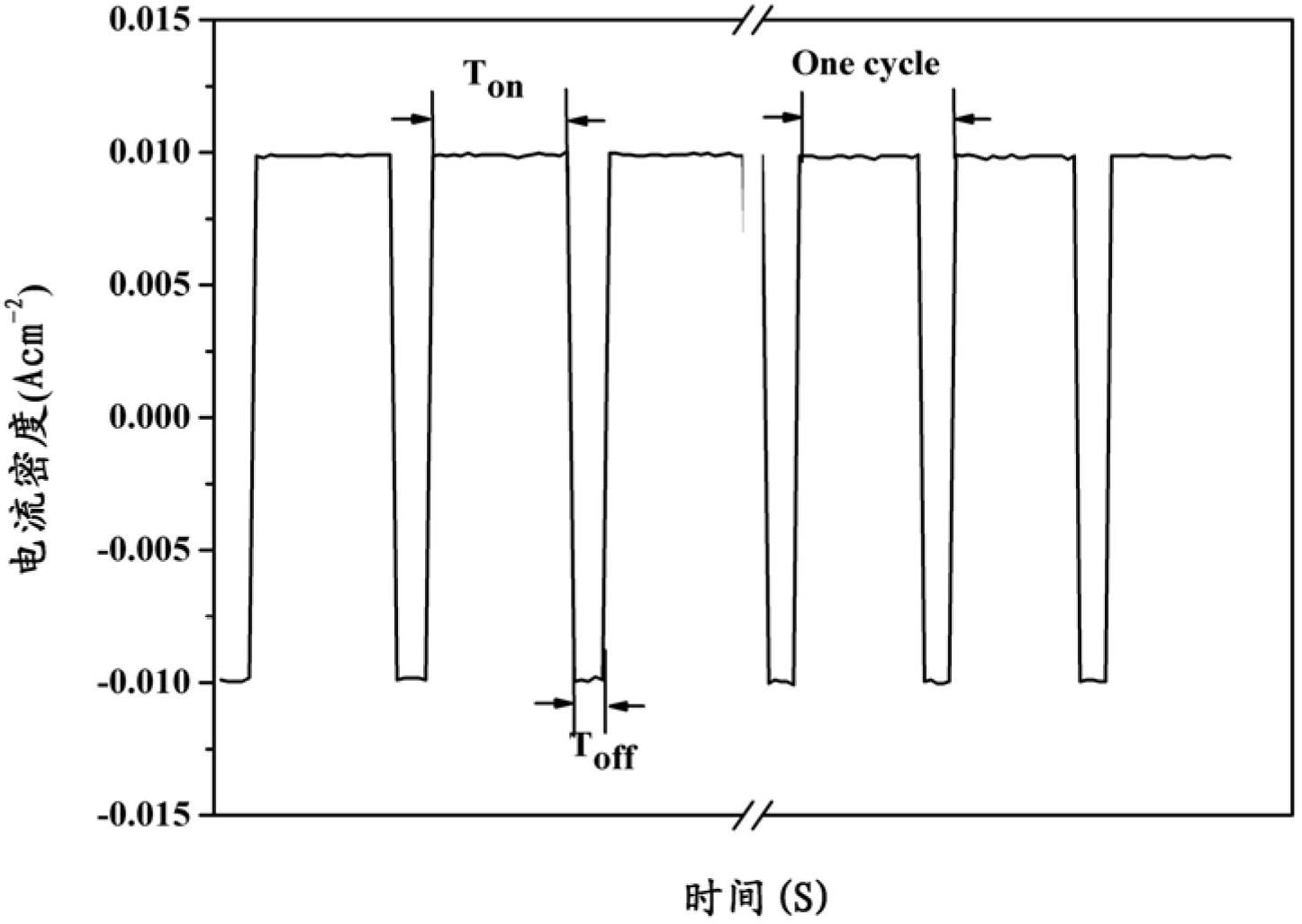

InactiveCN102664107AImproved ability to store ionsImprove abilitiesElectrolytic capacitorsHybrid/EDL manufactureNanowireManganese

The invention provides a preparation method of a nano-manganese dioxide electrode, and belongs to the field of preparation of electrode materials. The preparation method comprises the following specific steps of: (1) pretreating the surface of foam nickel by use of acetone and 5% hydrochloric acid; (2) taking soluble salt of manganese as main salt, and NaNO3 as an addition agent, preparing an electric deposition liquid at room temperature, and adjusting the pH value to 6.5-7.0 by ammonia water dropwise; (3) taking foam nickel as a base body, and a graphite plate as a counter electrode, so that the manganese dioxide electrode can be prepared by the constant current pulse deposition of a two-electrode system; and (4) drying at 80 DEG C to obtain the nano-wire manganese dioxide electrode. The CV (coefficient of variation) curve has an obvious oxidation / reduction peak when the obtained nano-wire manganese dioxide is taken as an electrode of a super capacitor; and the nano-manganese dioxide electrode is larger in superficial area, so that the use ratio of a manganese dioxide active substance can be improved, therefore, the nano-manganese dioxide electrode is higher in specific volume and good in super capacitor characteristic.

Owner:UNIV OF SCI & TECH BEIJING

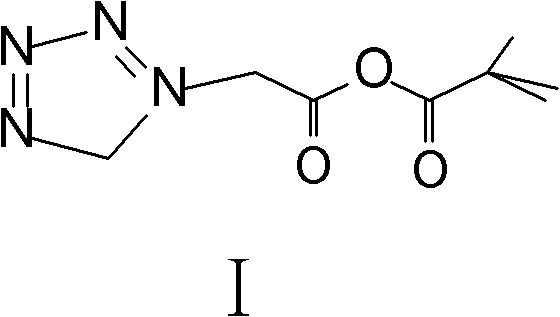

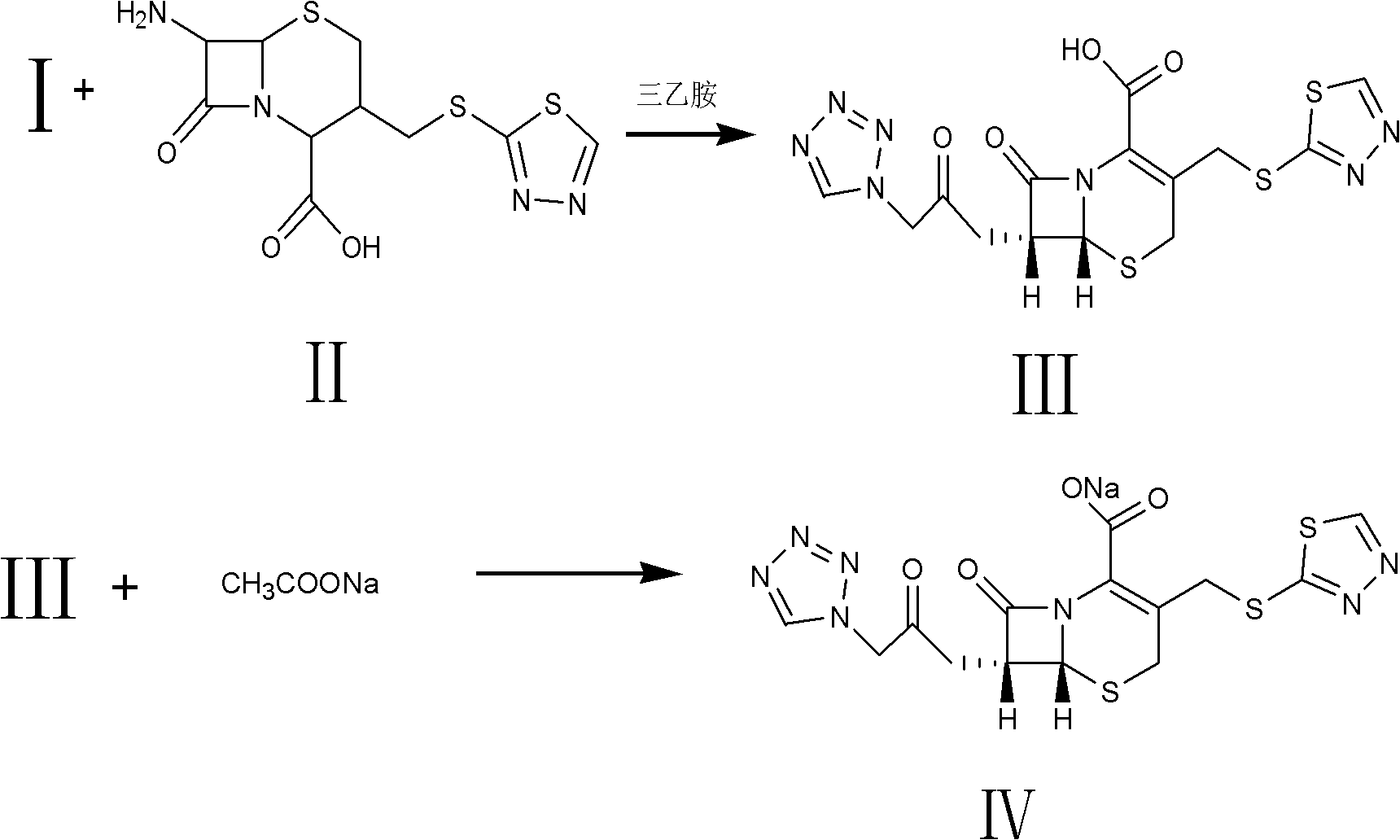

Method for preparing ceftezole sodium compound

ActiveCN102617606AReduce pollutionHigh yieldAntibacterial agentsOrganic chemistryCeftezole SodiumMethyl carbonate

The invention relates to a method for preparing an antibacterial compound, in particular to a method for preparing a ceftezole sodium compound. The method comprises the following steps of: 1, synthesizing TZT II, and reacting 2-mercapto-1,3,4 thiadiazole and 7-aminocephalosporanic acid (ACA) to obtain TZT, wherein dimethyl carbonate is used as a reaction solvent; a boron trifluoride-dimethyl carbonate complex is used as a catalyst; after reaction, the agent used by adjusting pH of reaction liquid is sodium carbonate; the weight ratio of boron trifluoride to 7-ACA is 0.7 to 1.3; and 2, synthesizing anhydride I, namely reacting 1H-tetrazole-1-acetic acid and pivaloyl chloride to obtain anhydride; 3, synthesizing ceftezole III, namely reacting TZT II and anhydride I to obtain ceftezole; and 4, synthesizing ceftezole sodium IV, namely reacting ceftezole and sodium salt to obtain ceftezole sodium IV, wherein salt is sodium hydroxide.

Owner:哈药集团股份有限公司 +1

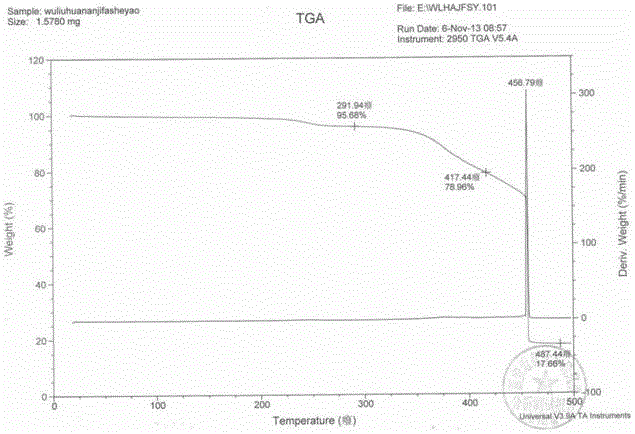

Formation method for anode foil of intermediate-voltage aluminum electrolytic capacitor

InactiveCN102709059AIncrease specific volumeGood hydration resistanceElectrolytic capacitorsPhosphateThree stage

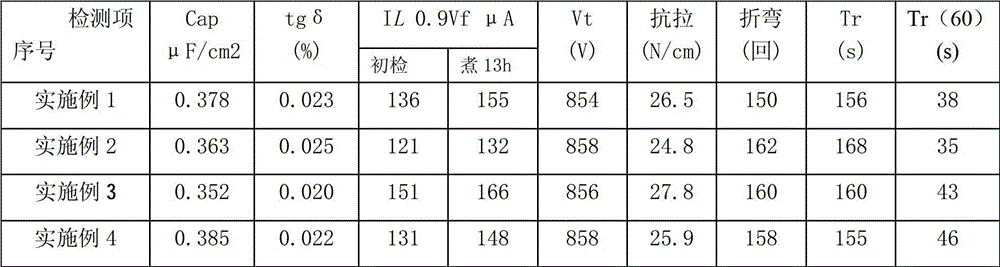

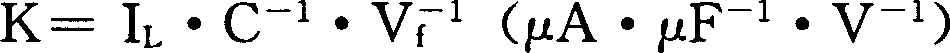

The invention discloses a formation method for an anode foil of an intermediate-voltage aluminum electrolytic capacitor, and belongs to the technical field of manufacture of anode foils of aluminum electrolytic capacitors. According to the formation method for the anode foil of the intermediate-voltage aluminum electrolytic capacitor, ammonium adipate is adopted as four-stage formation electrolyte. The technical scheme is that: the method comprises the following steps of: performing three-stage formation by adopting a solution of ammonium adipate as electrolyte, performing the formation of a fourth stage by using a boric acid and ammonium dihydrogen phosphate, performing high-temperature treatment, performing treatment by using a phosphate solution, and performing drying to obtain the anode foil of the intermediate-voltage aluminum electrolytic capacitor. The ammonium adipate is adopted as the formation electrolyte, so that the obtained anode foil of the capacitor is high in specific capacity and high in hydration resistance, boosting time is shortened, and a Tr60 value is decreased.

Owner:YONGJI SUHAI ALUMINUM

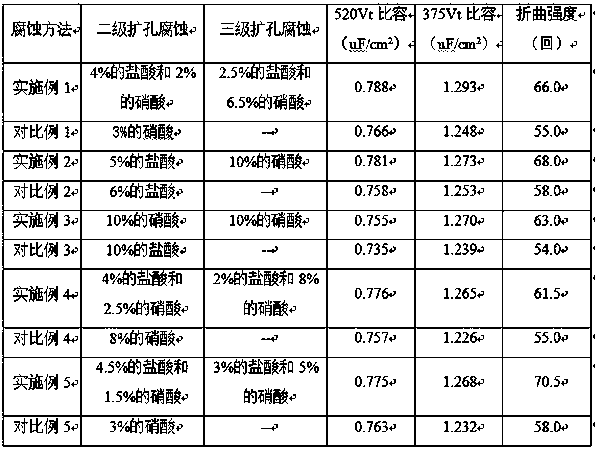

Acid-mixed reaming corrosion method for high-voltage anode foil in aluminum electrolysis

ActiveCN108538600AGood effectIncrease specific volumeElectrolytic capacitorsSpecific volumePre treatment

The invention relates to the technical field of anode foil corrosion for aluminum electrolytic capacitors, in particular to an acid-mixed reaming corrosion method for high-voltage anode foil in aluminum electrolysis. The method comprises six steps of pre-treatment, first-stage pitting corrosion, second-stage reaming corrosion, third-stage reaming corrosion, post-treatment and formation treatment,and is characterized in that the aluminum foil after the first-stage pitting corrosion is subjected to second-stage and third-stage acid-mixed reaming corrosion, respective characteristics of hydrochloric acid and nitric acid are fully utilized for common reaming, so that defects of single acid reaming corrosion can be overcome; 520 Vt specific volume of the aluminum foil is 0.750-0.799 uF / cm<2>,which is increased by 1.57%-3.03% than the specific volume of the aluminum foil in single acid reaming corrosion; 375 Vt specific volume is 1.265-1.293 uF / cm<2>, which is increased by 1.59%-3.60% thanthe specific volume of the aluminum foil in single acid reaming corrosion.

Owner:新疆广投桂东电子科技有限公司

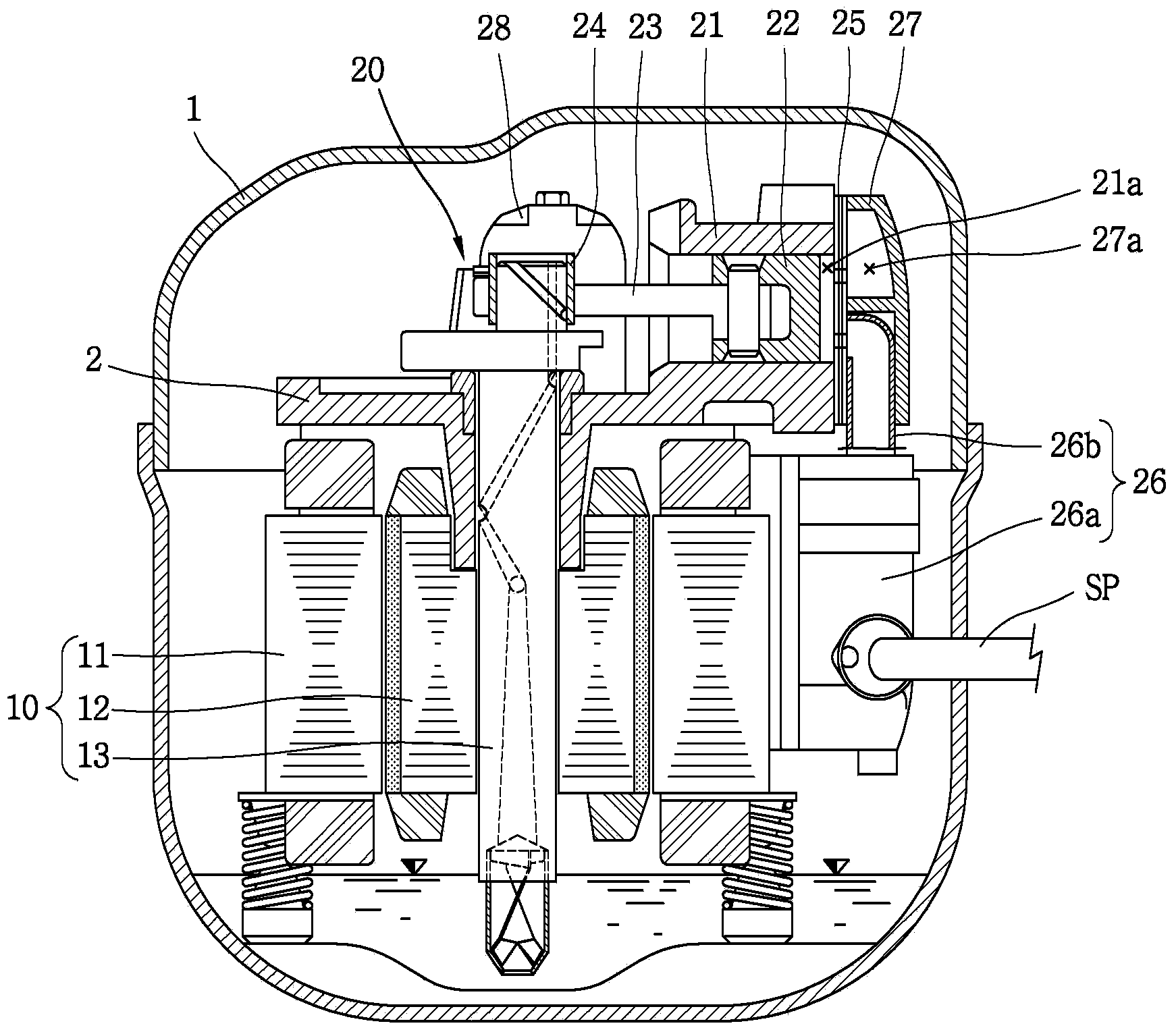

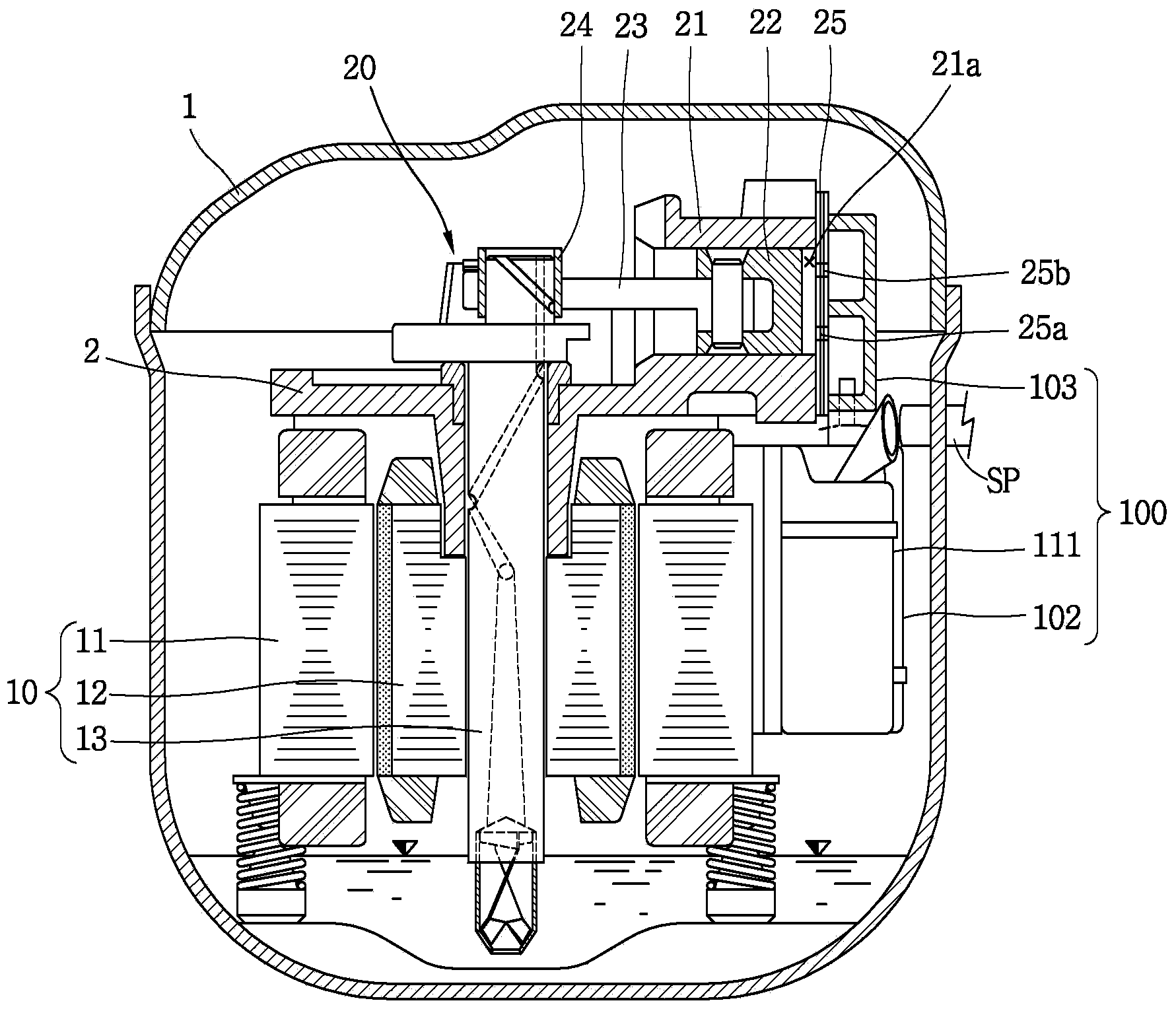

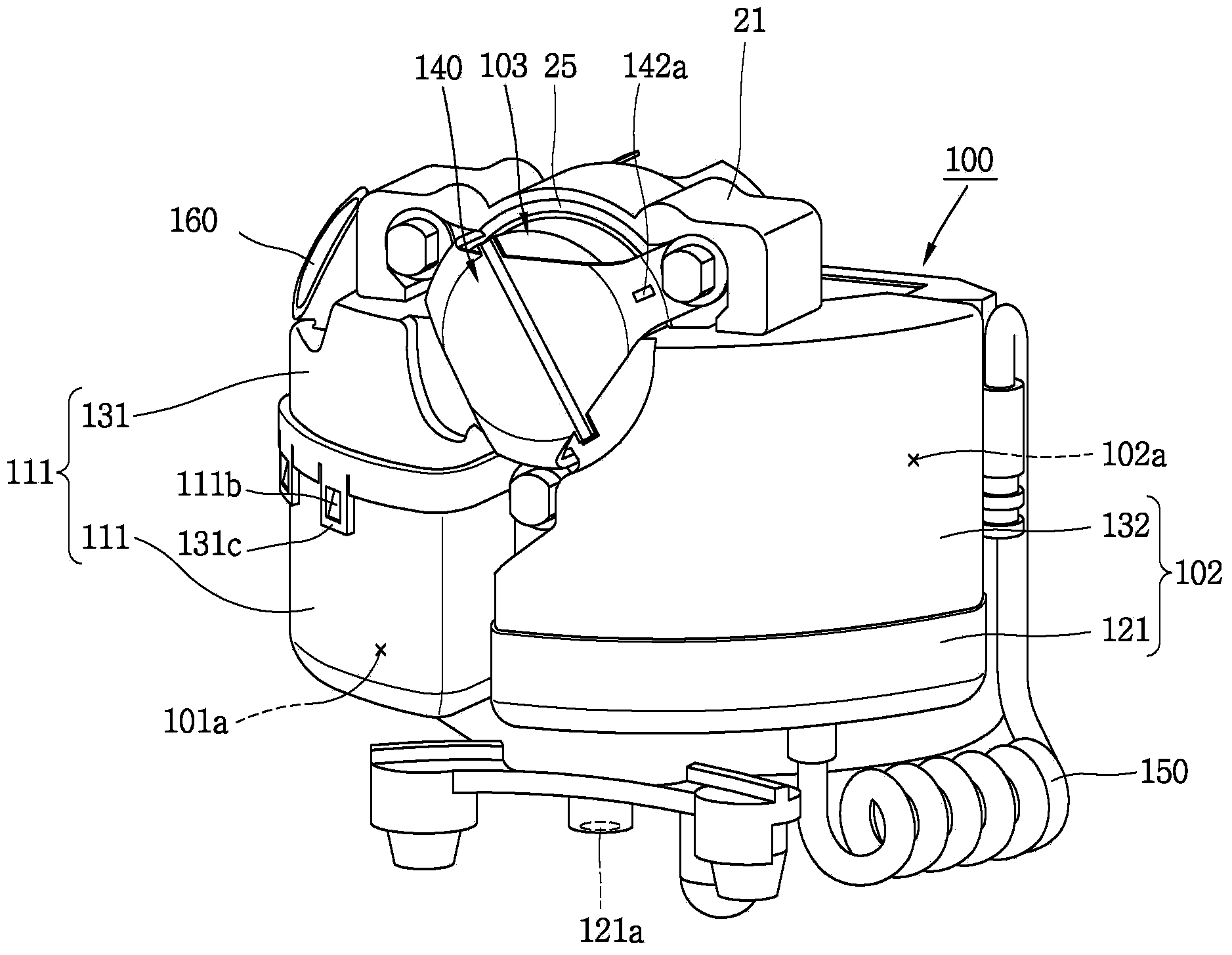

Muffler for compressor and compressor having the same

ActiveCN104121163AImprove performanceReduce the numberPositive displacement pump componentsPositive-displacement liquid enginesNoise removalPlastic materials

In a muffler for a compressor and a compressor having the same according to the present disclosure, an integral formation of a suction noise unit and a discharge noise unit may reduce the number of components for configuring a suction side muffler and a discharge side muffler so as to reduce a leakage of a refrigerant generated at an assembled portion of the muffler and also reduce a suction passage and a discharge passage in length. Also, the division between the suction noise unit and the discharge noise unit may prevent a discharged refrigerant from heating a sucked refrigerant, which may result in a reduction of a suction loss. The formation of the suction noise unit and the discharge noise unit using a plastic material may result in a reduction of fabricating costs. In addition, the structures of the suction side noise space and the discharge side noise space may be simplified and noise removal effect can be increased using the suction chamber and the discharge chamber. This may result in a reduction of an entire size of the muffler and improvement of the noise effect.

Owner:LG ELECTRONICS INC

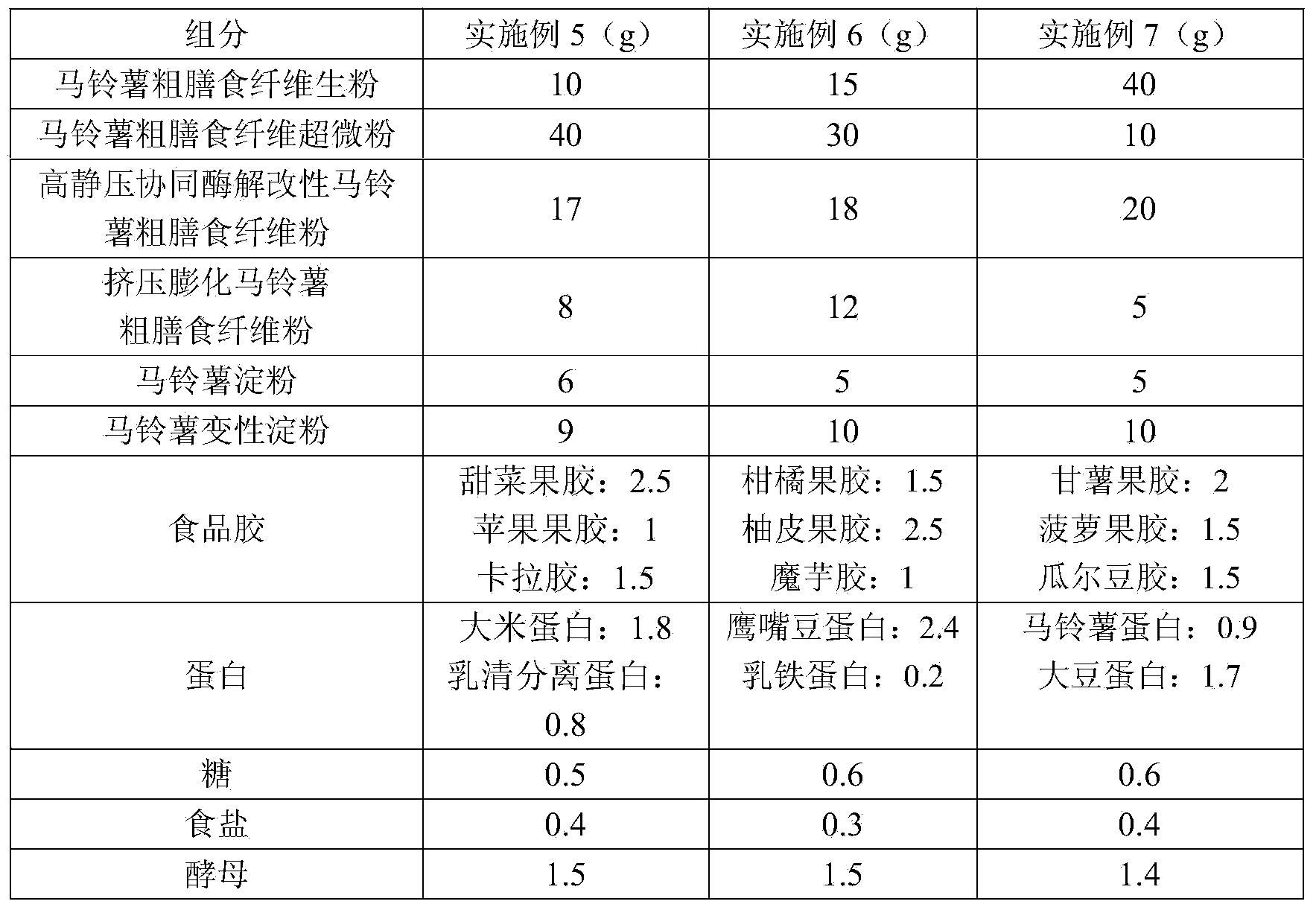

Potato dietary fiber bread and making method of potato dietary fiber bread

ActiveCN104365733AOvercoming the low proportion of ingredientsOvercoming low nutritional valueDough treatmentModified nutritive productsPotato starchAntioxidant

The invention relates to the field of foods, in particular to potato dietary fiber bread and a making method of the potato dietary fiber bread. The potato dietary fiber bread comprises, by mass, 10 parts to 40 parts of potato coarse dietary fiber starch, 10 parts to 40 parts of potato coarse dietary fiber submicron powder, 10 parts to 20 parts of high-hydrostatic-pressure synergetic enzymatic hydrolysis modified potato coarse dietary fiber powder, 4 parts to 12 parts of extrusion potato coarse dietary fiber powder, 5 parts to 12 parts of potato starch, 5 parts to 13 parts of potato modified starch, 2 parts to 6 parts of food gum, 1 part to 3 parts of egg white, 0.5 part to 3 parts of sugar, 0 part to 1 part of salt and 1 part to 3 parts of yeast. The potato dietary fiber bread does not contain gluten, the contents of protein, mineral substances, dietary fibers, vitamins and antioxidants are obviously higher than the contents of protein, mineral substances, dietary fibers, vitamins and antioxidants in existing wheat bread, and the potato dietary fiber bread is suitable for being eaten by the crowd allergic to wheat or celiac disease patients.

Owner:北京中农探味科技有限公司

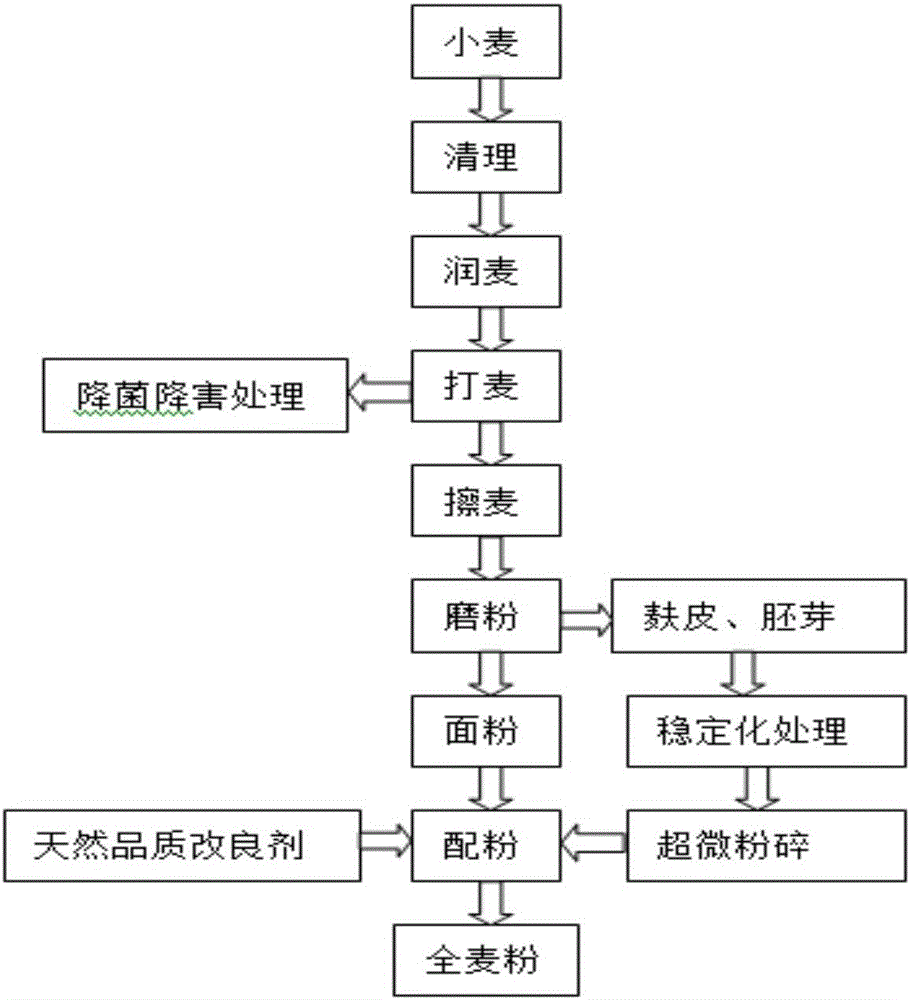

Preparation method of special wholewheat staple food flour with long shelf life

The invention relates to a preparation method of special wholewheat staple food flour with the long shelf life. The method comprises the following steps that a wheat raw material is subjected to impurity removal through the processes such as cleaning, wheat wetting, wheat threshing and wheat rubbing and then threshed, ground and sieved, germs and bran are separated out, and a smashed endosperm material is obtained; the separated germs and bran are treated through microwave humidifying and extrusion expanding and then smashed at the temperature of below 40 DEG C, germ flour and bran flour are obtained and then mixed with endosperms in different proportions, and then the flour special for different kinds of wholewheat staple food is obtained. The preparation method has the following advantages that harmful substances such as eggs and microorganisms can be effectively killed, lipase, protease, amylase and the like can be completely inactivated simultaneously, the product quality is guaranteed, and the shelf life of the product is prolonged; the technological process is shortened, the operation time is short, the nutrient ingredients in wheat grains are protected, and therefore the nutritional value of the product is increased; 3, the wheat aroma of the product is increased, the mouthfeel and the color uniformity are improved, and the specific volume is increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Prepn of carbon naotube-polyaniline composite material for super capacitor

InactiveCN1887965AImprove performanceIncrease specific volumeElectrolytic capacitorsCapacitanceSupercapacitor

In the preparation process of carbon nanotube-polyaniline composite material for super capacitor, polyaniline is deposited onto the surface of carbon nanotube. During charging and discharging, polyaniline produces electrochemical doping-dedoping effect to generate false capacitance and to increase the specific capacitance of carbon nanotube. By means of the selection of the deposited material and the control of the deposition process, the present invention prepares carbon nanotube-polyaniline composite material with excellent performance and greatly raised specific capacitance.

Owner:JIANGXI UNIVERSITY OF FINANCE AND ECONOMICS

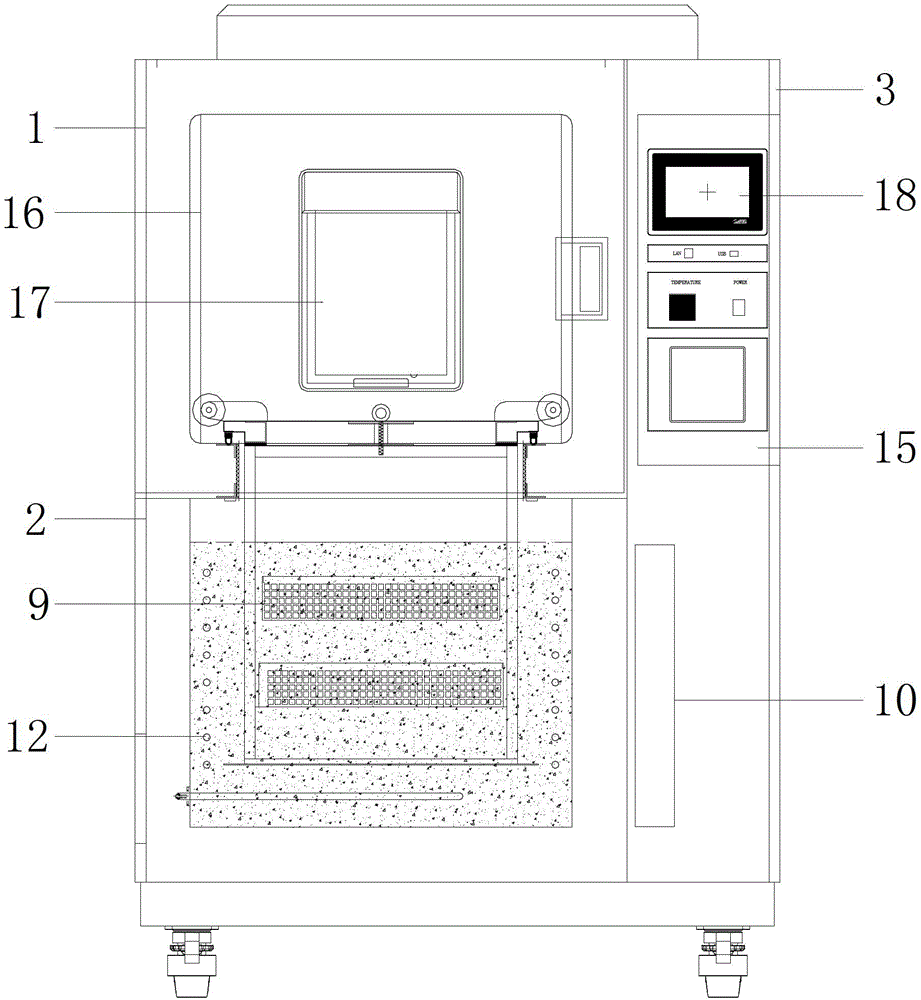

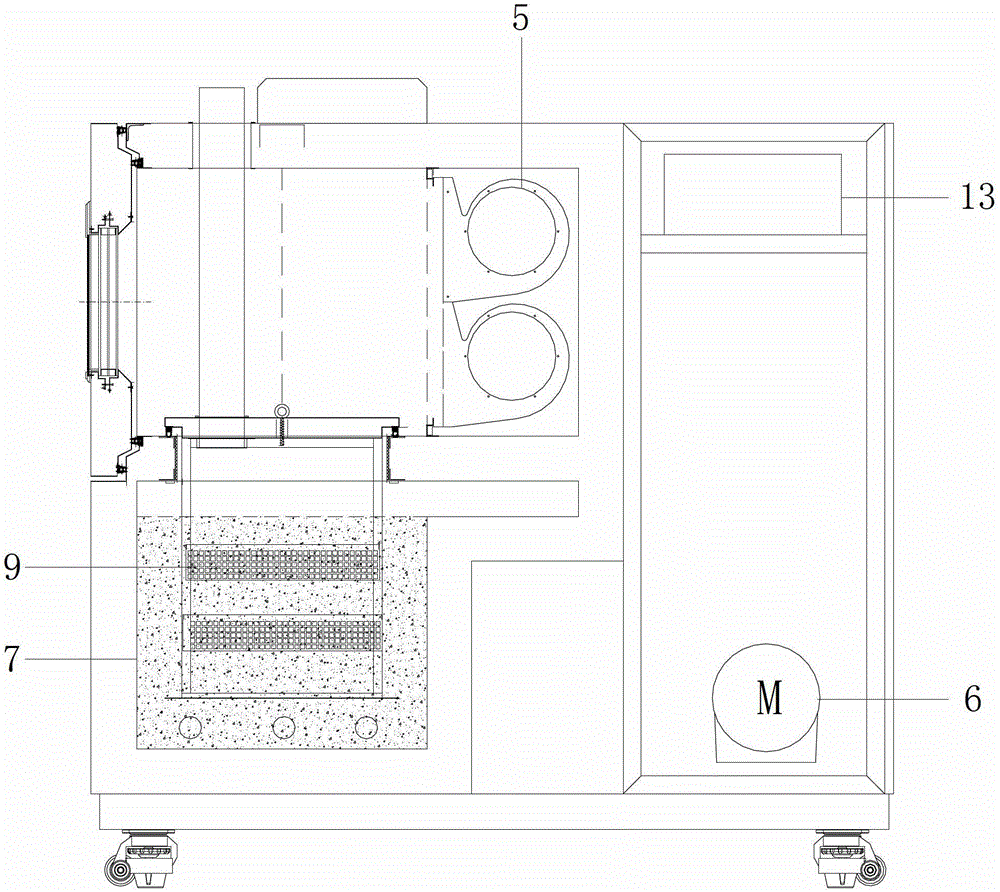

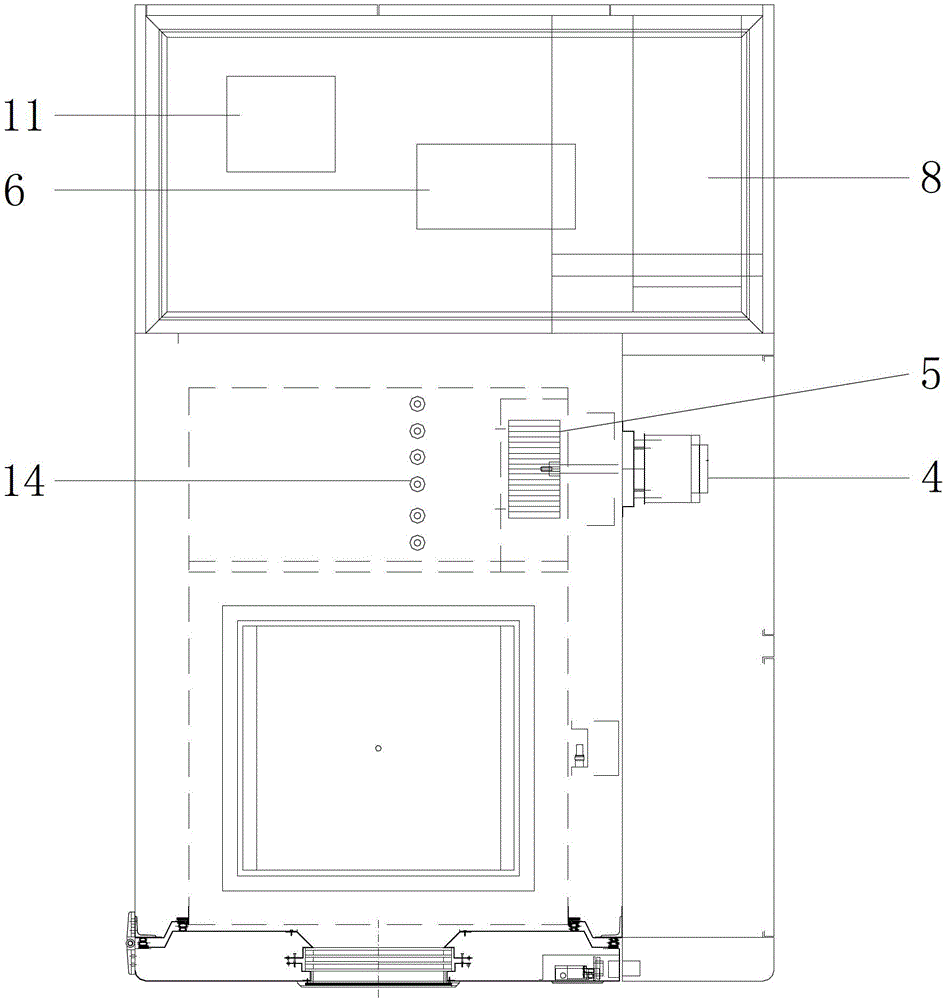

High-low temperature impact test box

InactiveCN103335909AIncrease specific volumeMeet the test requirementsStrength propertiesSpecific volumeEngineering

The invention relates to the technical field of sample temperature impact test instruments, in particular to a high-low temperature impact test box which comprises a high temperature box body, a low temperature box body, an electrical cabinet, an electrical system, a refrigeration system and a heating system, wherein the heating system is arranged inside the high temperature box body, the refrigeration system is arranged inside the low temperature box body, and both the heating system and the refrigeration system are in wired connection with the electrical system. The high-low temperature impact test box is characterized in that a high temperature slot air-conditioning system is arranged inside the high temperature box body, a low-temperature slot circulating system is arranged inside the low-temperature box body, both the high temperature slot air-conditioning system and the low-temperature slot circulating system are in wired connection with the electrical system, and basket transmission systems capable of moving up and down are arranged inside the high temperature box body and the low-temperature box body respectively. According to the invention, since the upper and lower boxes adopt different media, the high-temperature box adopts air, and the low-temperature box adopts water, the specific volume of water is very large, and during impacting, a test piece is enabled to reach a low temperature instantaneously. Therefore, the testing is enabled to be rigorous and the testing requirements of special material can be met.

Owner:SHANGHAI LINPIN INSTR

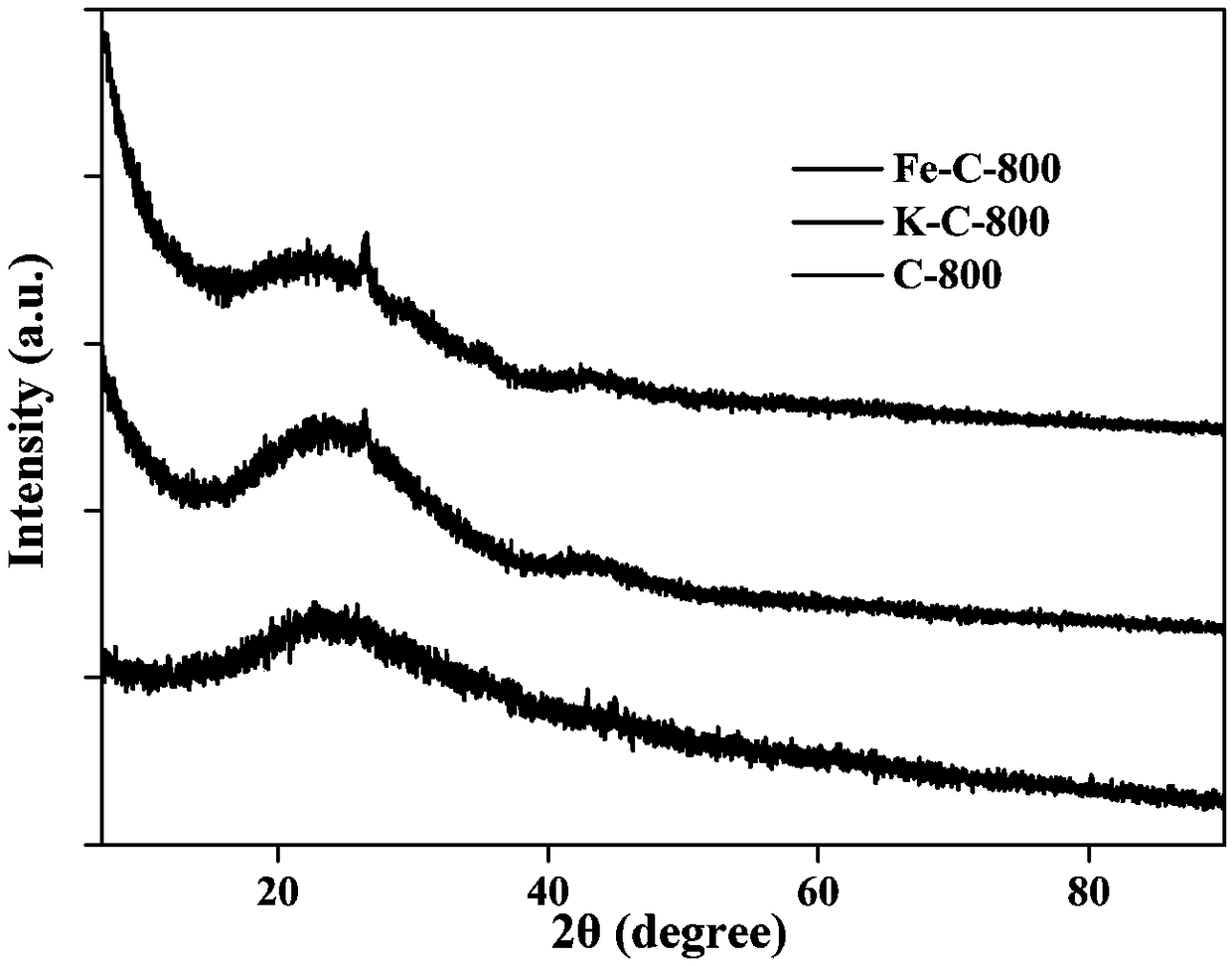

Method for preparing bean dregs-based nitrogen-boron co-doped porous carbon material

ActiveCN109336106AIncrease contentMany typesCarbon compoundsHybrid capacitor electrodesActivation methodPorous carbon

The invention provides a method for preparing a bean dregs-based nitrogen-boron co-doped porous carbon material. The method is a one-step impregnation carbonization activation method, and comprises the following steps: (1) pretreating bean dregs: boiling, fermenting, then adding a catalyst into the fermented bean dregs for catalysis, washing and then freeze-drying; (2) adding deionized water intothe pretreated bean dregs, adding an activator and a boron source, stirring and mixing, transferring into a culture dish, and putting into a drying oven for drying; (3) heat-treating the bean dregs treated in the step (2), soaking in an HCl solution after cooling, washing, and finally drying by microwave to obtain treated bean dregs; and (4) adding a binder and a pore forming agent into the treated bean dregs in the step (3), and mixing to form a bean dregs-based porous carbon material. According to the invention, the one-step impregnation carbonization activation method is adopted; and compared with the prior art, the one-step impregnation carbonization activation method has the advantages of simple method, low energy consumption and the like.

Owner:宿州学院

Manufacturing method of ultralow-voltage anodized aluminum foil

The invention relates to a manufacturing method of an ultralow-voltage anodized aluminum foil. The manufacturing method comprises the following steps: treating a corroded aluminum foil in soaking treatment liquid, and cleaning with deionized water, so as to obtain the pretreated aluminum foil; soaking the pretreated aluminum foil in an ammonium adipate water solution at 50-90 DEG C, and carrying out continuous anodization until an anode oxide film aluminum foil is formed; thermally treating the anode oxide film aluminum foil at 300-600 DEG C for 2-5 minutes, so as to obtain thermally treated aluminum foil; treating the thermally treated aluminum foil in a 0.01%-5% phosphorous compound water solution at 30-80 DEG C for 1-20 minutes, and then carrying out electrochemical treatment at the voltage of 4V-13V and the current density lower than or equal to 20mA / cm<2>, so as to obtain the ultralow-voltage anodized aluminum foil. Compared with an untreated anode aluminum foil, the specific volume of the ultralow-voltage anodized aluminum foil manufactured by virtue of the manufacturing method can be increased by 10%-20%.

Owner:XI AN JIAOTONG UNIV

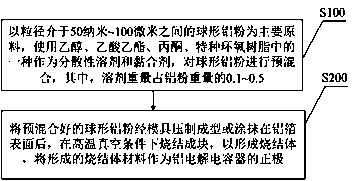

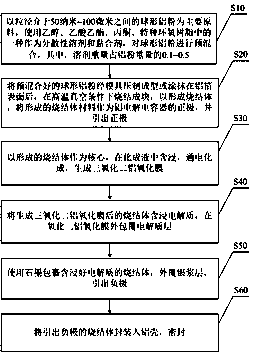

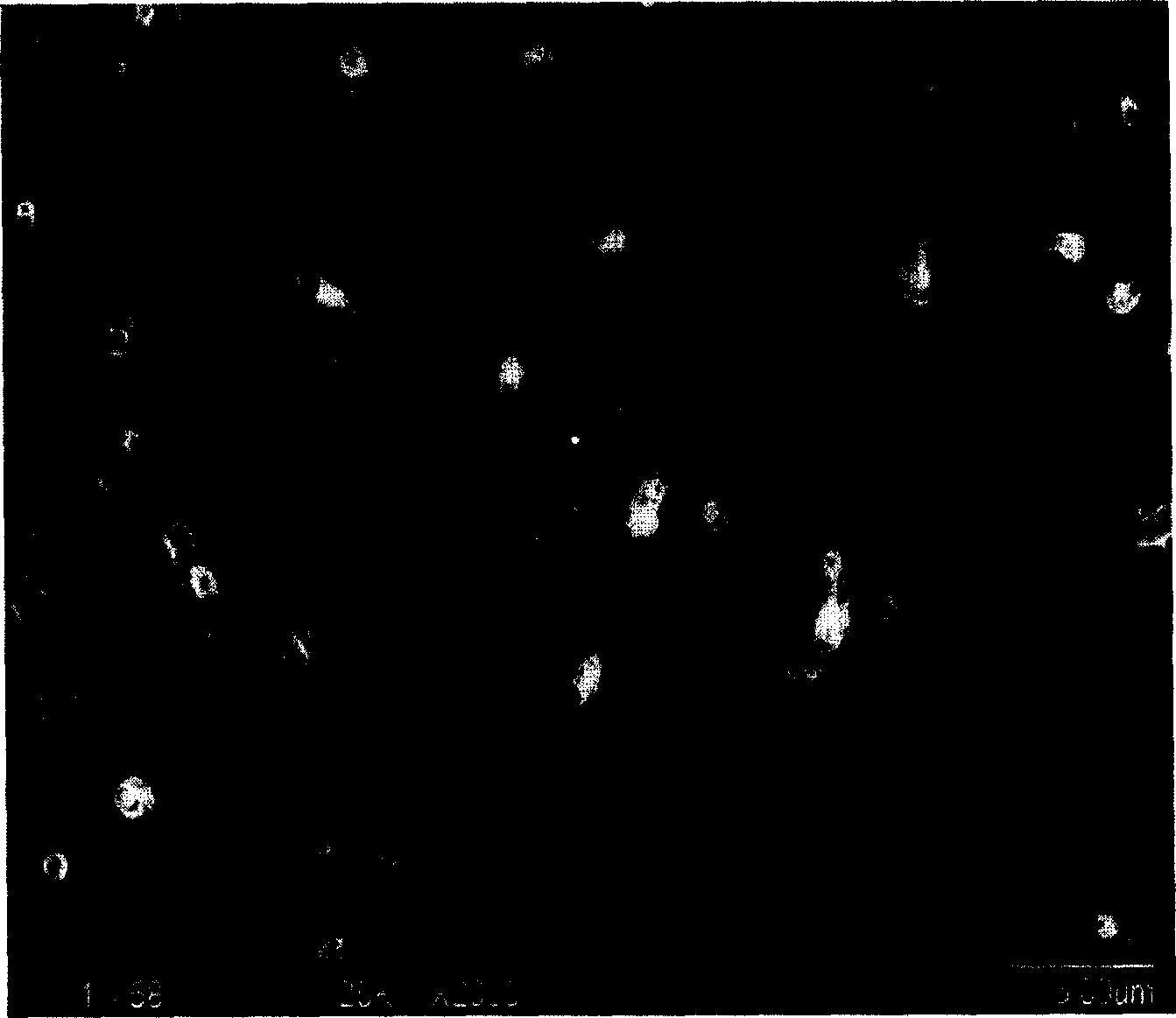

Novel powered aluminum positive electrode material and fabrication method of aluminum electrolytic capacitor

InactiveCN108172403ALarge specific surface areaReduce energy consumption and pollutionElectrolytic capacitor manufactureSolventMicrometer

The invention discloses a novel powdered aluminum positive electrode material and a fabrication method of an aluminum electrolytic capacitor. The preparation method comprises the steps of mixing spherical aluminum powder in advance by taking the spherical aluminum powder with a grain size being between 50 nanometers and 100 micrometers as a main raw material and taking one of ethyl alcohol, ethylacetate, acetone and special epoxy resin as a dispersion solvent and a binding agent, wherein the weight of the solvent accounts for 0.1-0.5 of the weight of the aluminum powder; pressing and formingthe pre-mixed spherical aluminum powder by a die or coating the spherical aluminum powder on a surface of an aluminum foil, sintering under a high-temperature vacuum condition to form a sintering body, and taking the formed sintering body material as a positive electrode of the aluminum electrolytic capacitor. The novel powdered aluminum positive electrode material and the fabrication method of the aluminum electrolytic capacitor, provided by the invention, have the advantages of small pollution, low energy consumption and low fabrication cost, and the fabricated aluminum electrolytic capacitor has high specific capacitance.

Owner:HUNAN AIHUA GRP

Method for preparing composite conductive high molecular electrode material in use for super capacitor

InactiveCN1760226AIncrease specific volumeHigh specific capacityElectrolytic capacitorsCapacitancePolypyrrole

An electrically conductive composite high-molecular electrode material used for super capacitor is prepared through using pyrrole monomer to form polypyrrole on working electrode. It features the synergestic effect between polypyrrole and the polymer of phenylamine, vinyldioxy thiophene and p-phenylene, resulting in high specific capacitance (200 F / g) and wide potential window (0-1.2 V for aqueous solution and 0-3 V for organic solvent).

Owner:XI AN JIAOTONG UNIV

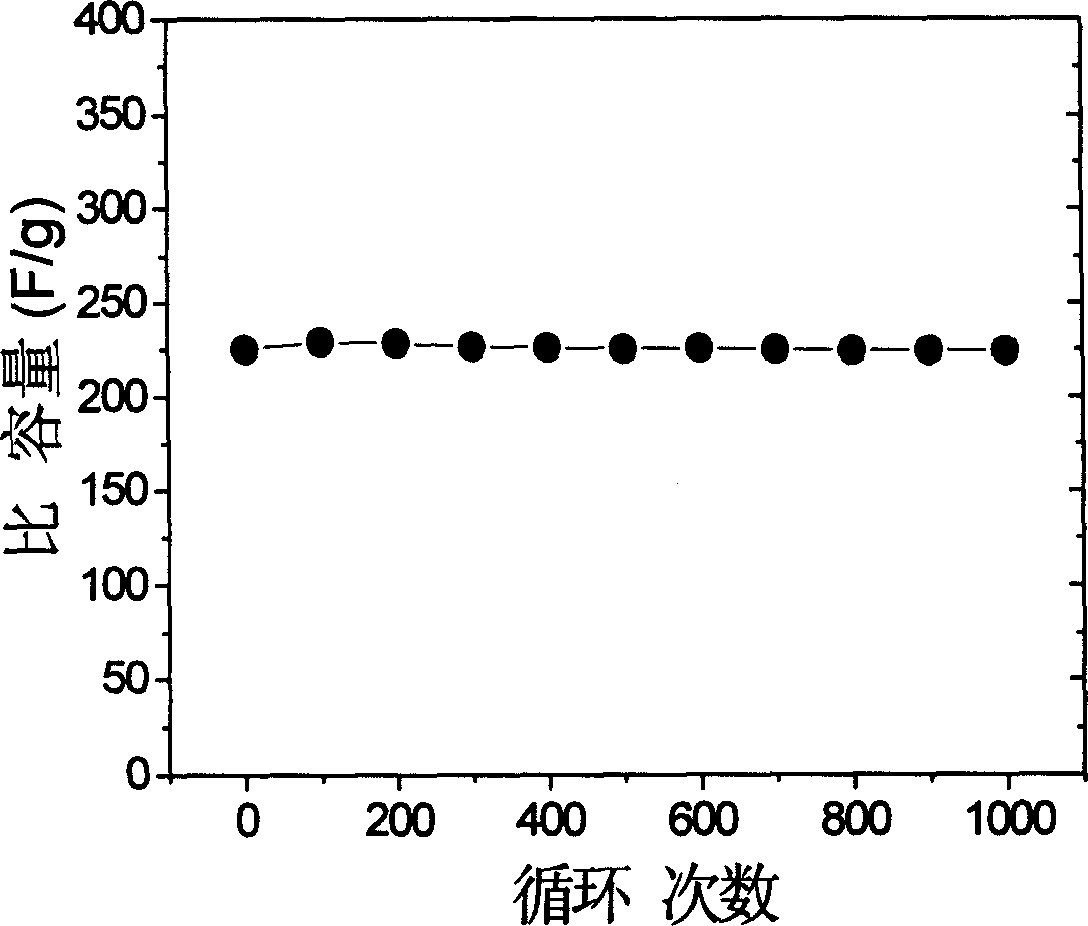

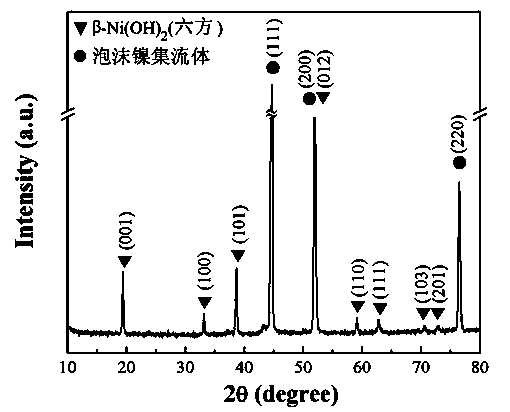

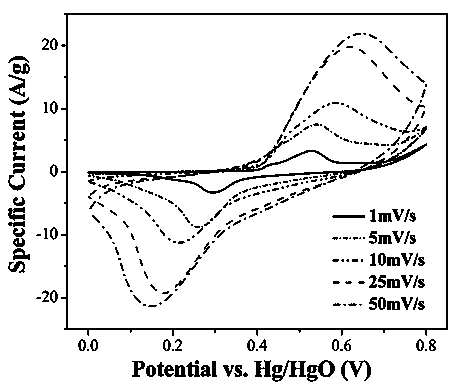

Self-collecting supercapacitor electrode material and preparing method thereof

ActiveCN103762090AReduce productionIncrease specific volumeHybrid capacitor electrodesNanotechnologyMaterials scienceHydrogen peroxide

The invention provides a self-collecting supercapacitor electrode material and a preparing method thereof. The electrode material is composed of a foamed nickel current collector and a b-nickel hydroxide hexagonal nanosheet grown on the surface of the foamed nickel current collector in an in-situ mode. According to the preparing method of the electrode material, the conductive current collector foamed nickel is immersed into a hydrogen peroxide solution for low-temperature hydrothermal oxidation, and then the b-nickel hydroxide hexagonal nanosheet is directly grown on the conductive current collector in the in-situ mode. The electrode material has the advantages of being large in specific volume and good in circulating stability. Due to the fact that the active material nickel hydroxide is directly grown on the foamed nickel current collector, the electrode material can be used directly without extra current collectors, or conductive additives or binding agents, complicated electrode preparing processes are omitted, and self-collecting is achieved. The electrode material preparing method only relates to the cheap hydrogen peroxide solution, other chemical reagents are not needed, and then zero pollution and low cost are guaranteed. The preparing processes only relate to hydrothermal oxidation and vacuum drying, operation is easy and convenient, reproducibility is good, and bulk preparation and industrialized production are facilitated.

Owner:CHONGQING UNIV

Premixed powder for preparing whole coarse cereal steamed bun

The invention relates to premixed powder for preparing whole coarse cereal steamed bun. The premixed powder for preparing the whole coarse cereal steamed bun is prepared by mixing and processing the following materials in parts by weight: 20-40 parts of corn flour, 5-10 parts of small red bean flour, 5-10 parts of black bean flour, 5-10 parts of kidney bean flour, 5-10 parts of mung bean flour, 5-10 parts of soybean flour, 5-10 parts of black rice flour, 5-10 parts of small yellow rice flour, 5-10 parts of broomcorn flour, 5-10 parts of coix seed flour, 5-10 parts of buckwheat, 1-5 parts of sesame flour, 0.1-0.5 part of polyglycerol fatty acid ester, 0.001-0.015 part of a complex enzyme preparation, 0.1-1 part of sorbitol, 0.5-1 part of active dry yeast, 0.1-0.5 part of baking powder, 0.001-0.003 part of tricalcium phosphate and 0.5-2 parts of cross-linked pre-gelatinized carboxymethyl starch. According to the premixed powder disclosed by the invention, about 12 kinds of different types of varicolored coarse cereal flour (having five colors) of which the function and the nutrient are optimized and complementary to one another are scientifically and reasonably selected to completely replace wheal flour so as to comprehensively balance nutrient demands of human bodies, is good in taste of prepared steamed bun, and greatly simplifies the steamed bun production procedures.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com