Patents

Literature

89results about How to "Reduce electrode polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nano-network conductive polymer coated lithium iron phosphate anode material

ActiveCN102185140AImprove cycle performanceFunction increaseCell electrodesIn situ polymerizationConductive polymer

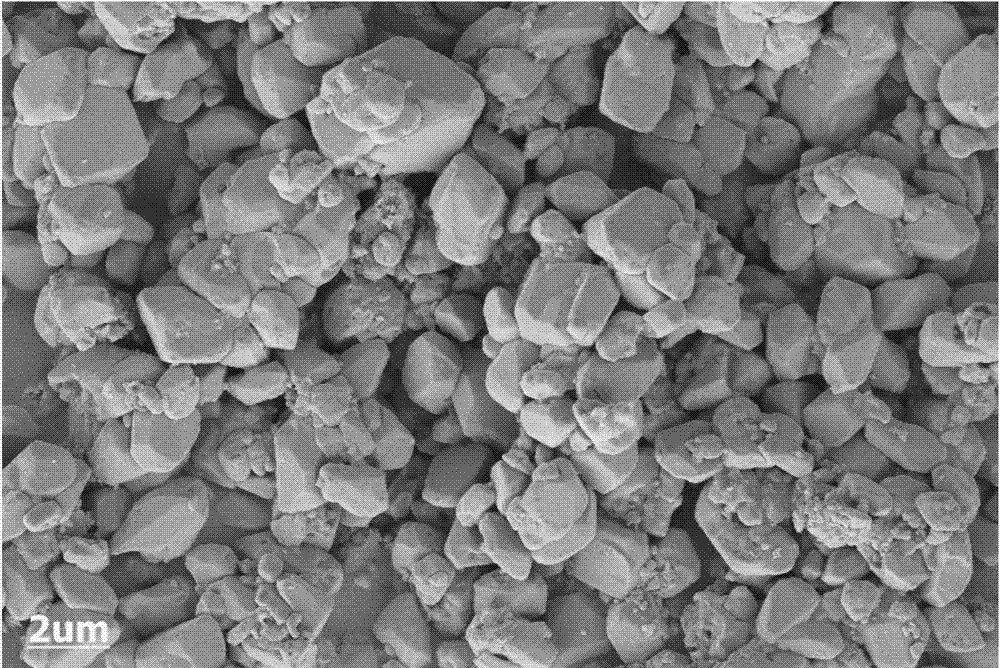

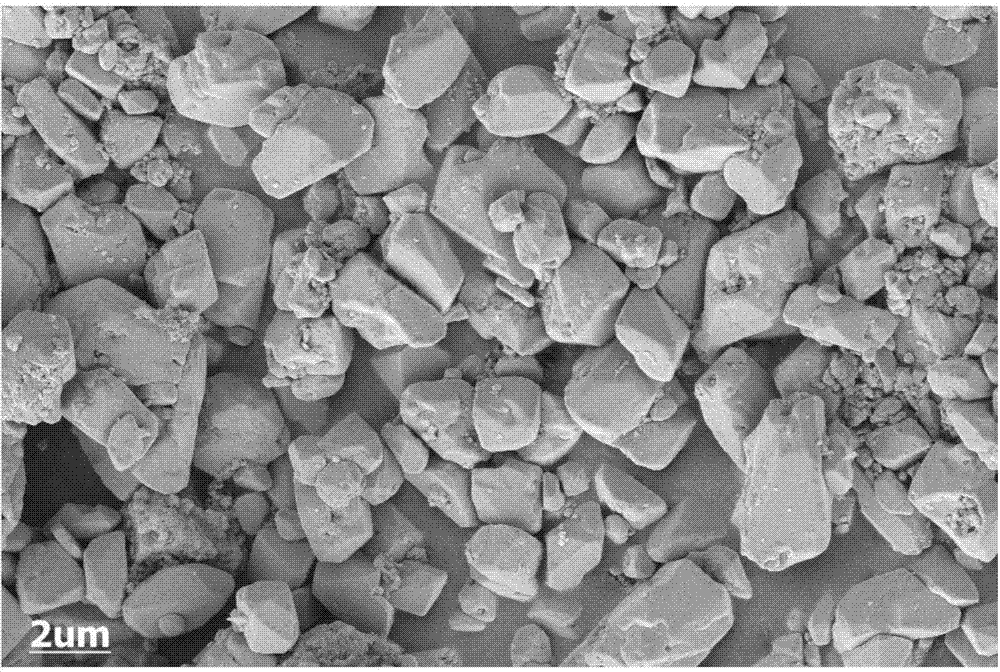

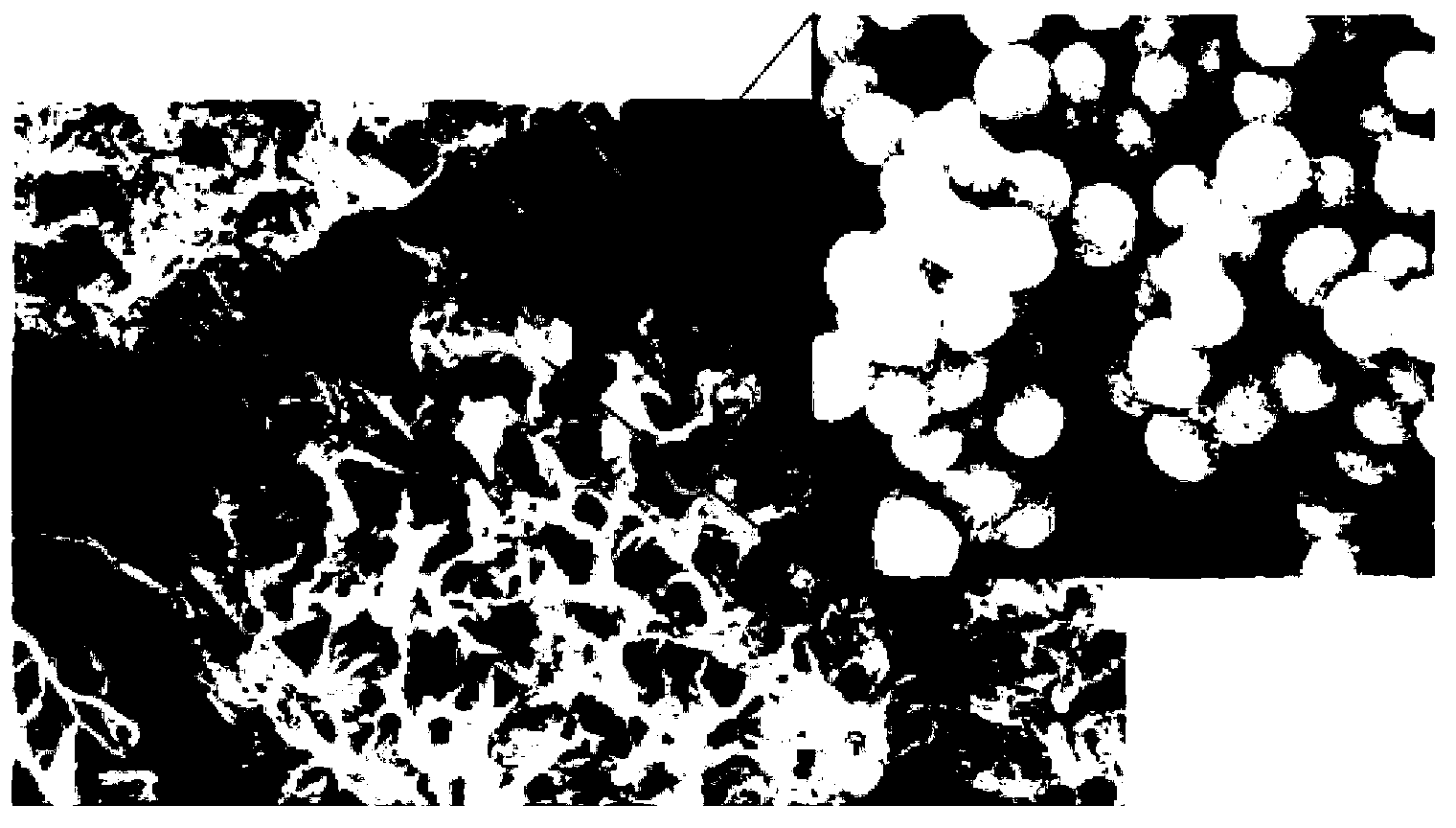

The invention discloses a preparation method of a nano-network conductive polymer coated lithium iron phosphate anode material. The preparation method is characterized in that: a surfactant is used as a template; and a conductive polymer monomer is subjected to in-situ polymerization on a lithium iron phosphate surface in a low-temperature acid solution medium and a nano-network structure is grown; and thus, the nano-network conductive polymer coated lithium iron phosphate anode material is formed. The special shape of the nano-network conductive polymer is favorable for a current carrier to be conducted among polymer aggregate particles; and the nano-network conductive polymer has high current carrier mobility ratio, and can effectively connect surfaces among lithium iron phosphate particles when coated on the lithium iron phosphate surface to form an effective conductive network, so the lithium iron phosphate conductivity is significantly improved, and the contact resistance and electrode polarization among the particles are reduced to ensure that the electrochemical performance of an electrode material is greatly improved. The preparation method has a simple process and readily-available raw materials, and is suitable for carrying out industrial large-scale production.

Owner:ZHONGKE LITHIUM BATTERY NEW ENERGY CO LTD

Electrolyte for lithium manganese battery

The invention discloses an electrolyte for a lithium manganese battery, which comprises a non-aqueous organic solvent, lithium salt, a film forming additive, an anti-overcharge additive and a stabilizing additive, and also comprises the following components by weight percent: 0.1-5% of unsaturated sultone as a high temperature additive and 0.01-1% of fluorocarbon surfactant. Based on the reasonable deign of each component, the electrolyte is added with the novel high-temperature additive and the fluorocarbon surfactant, so that the lithium manganese battery using the electrolyte has excellent cycle life and high temperature properties.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

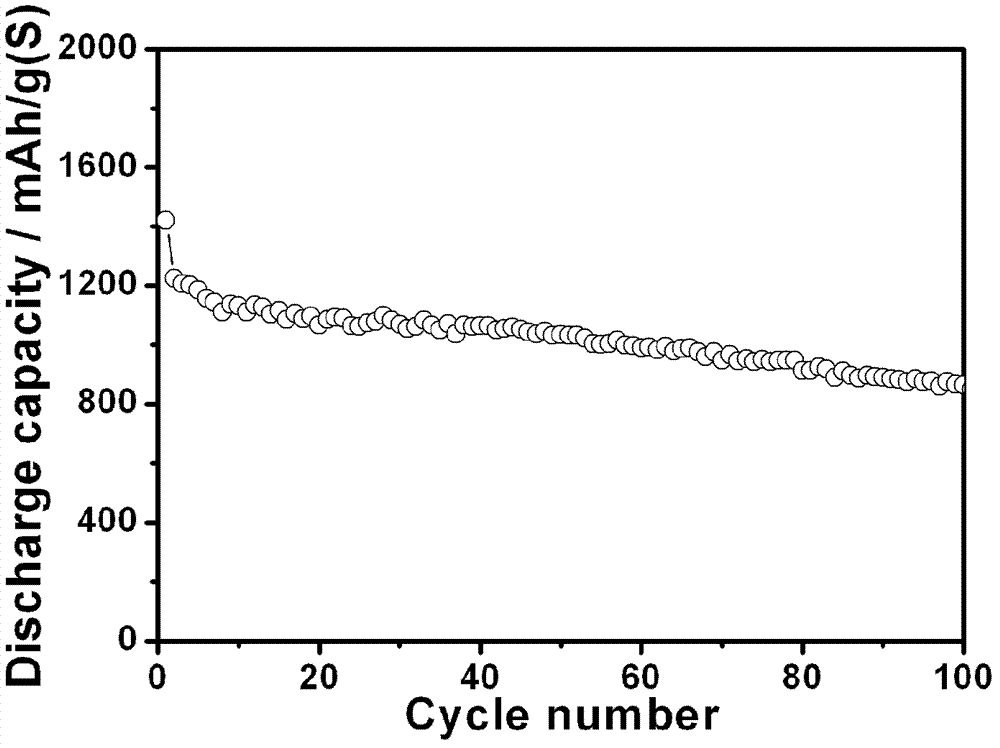

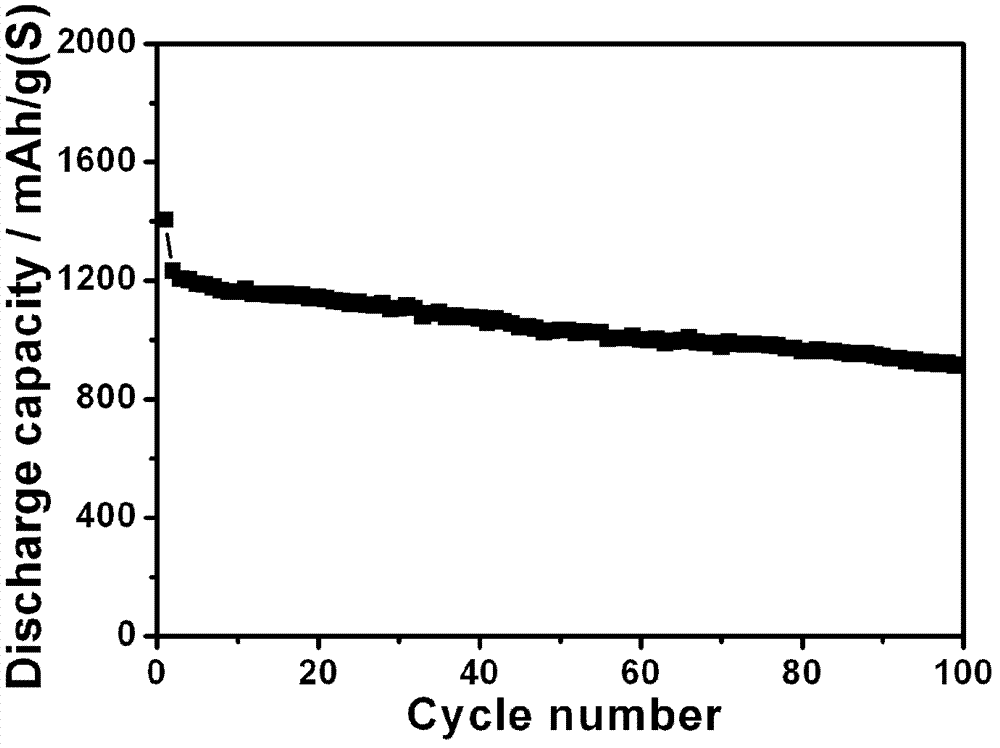

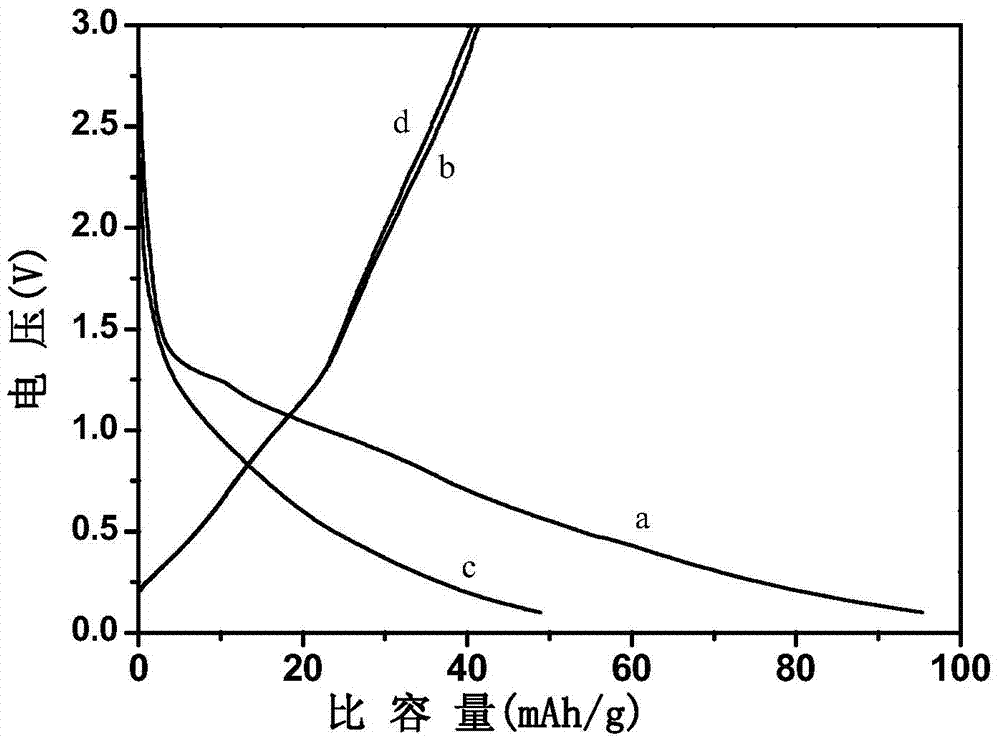

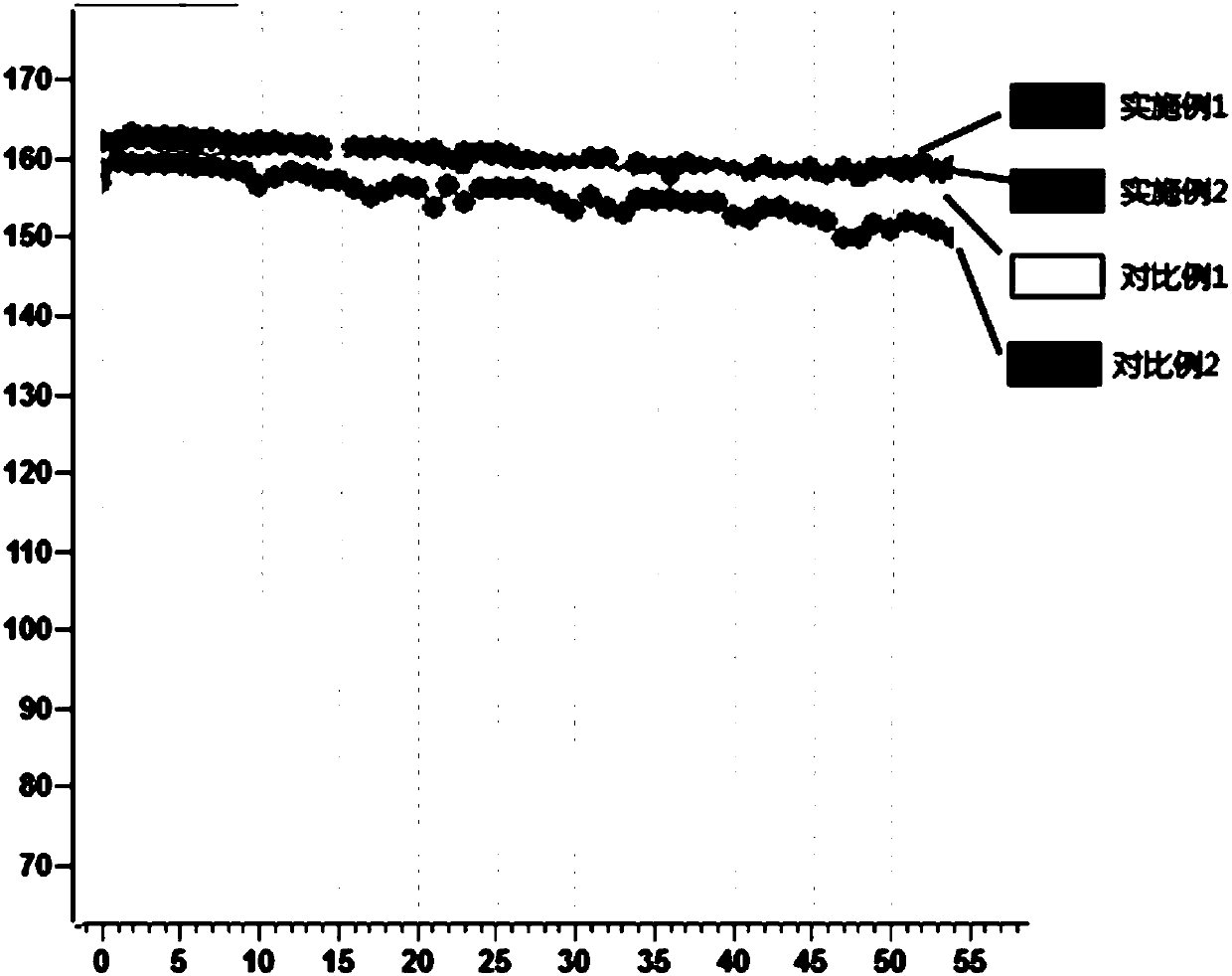

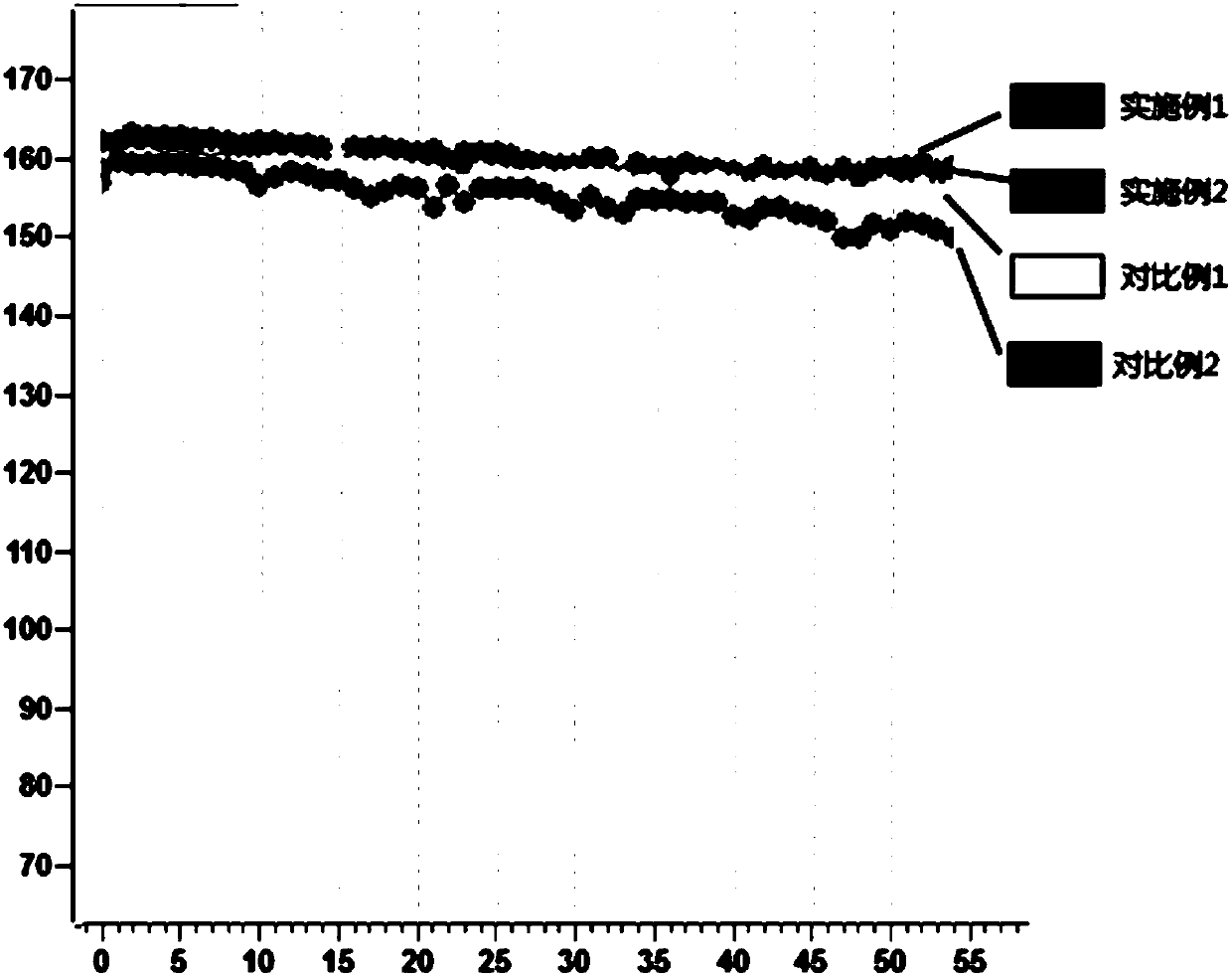

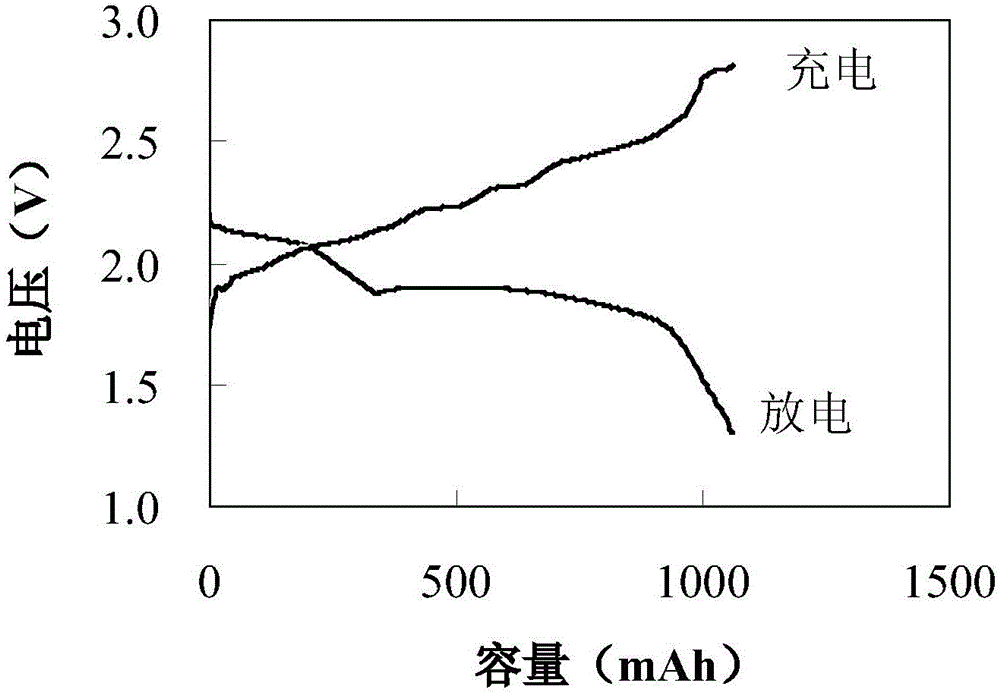

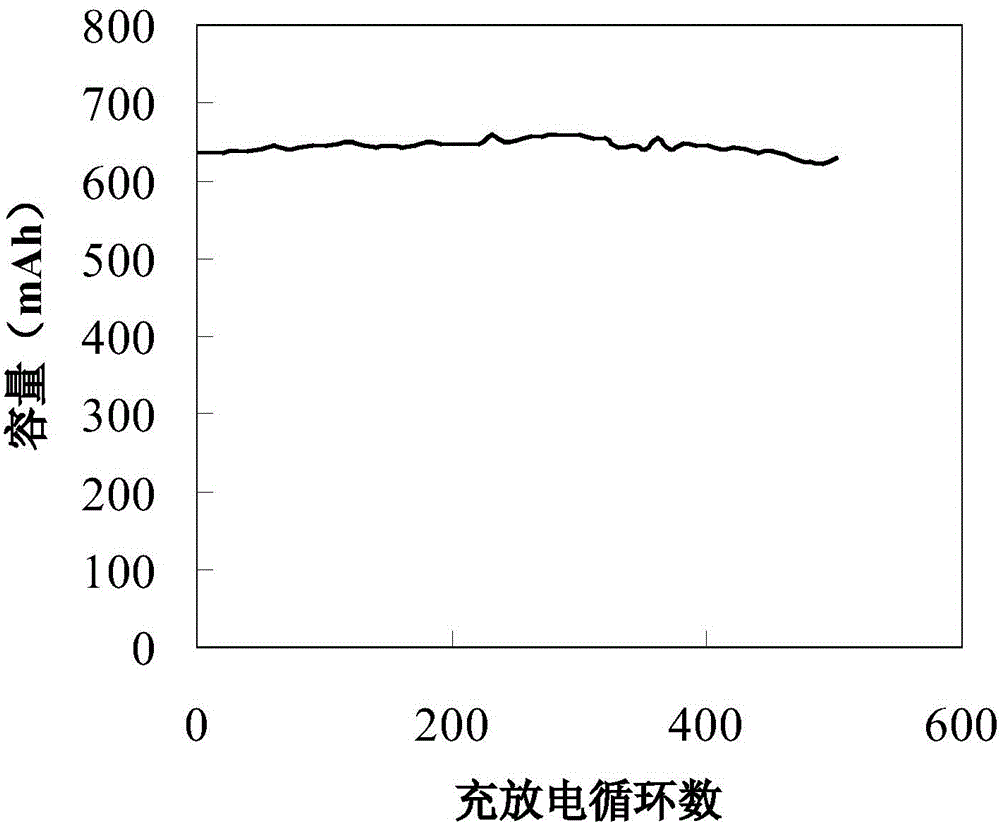

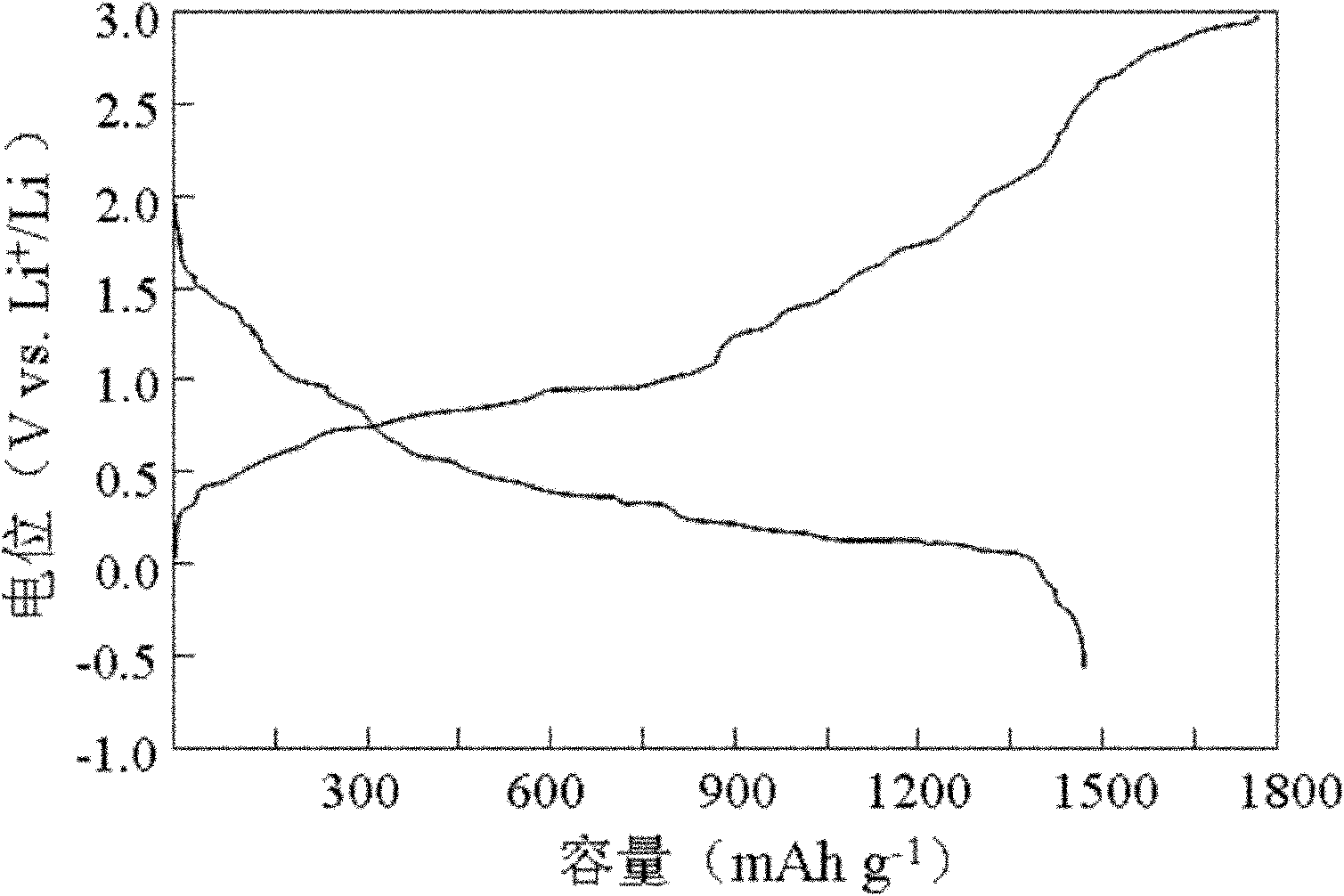

Sulfur electrode, and preparation and application thereof

ActiveCN102903887AImprove cycle stabilityIncrease profitNon-aqueous electrolyte accumulator electrodesCarbon compositesPorous carbon

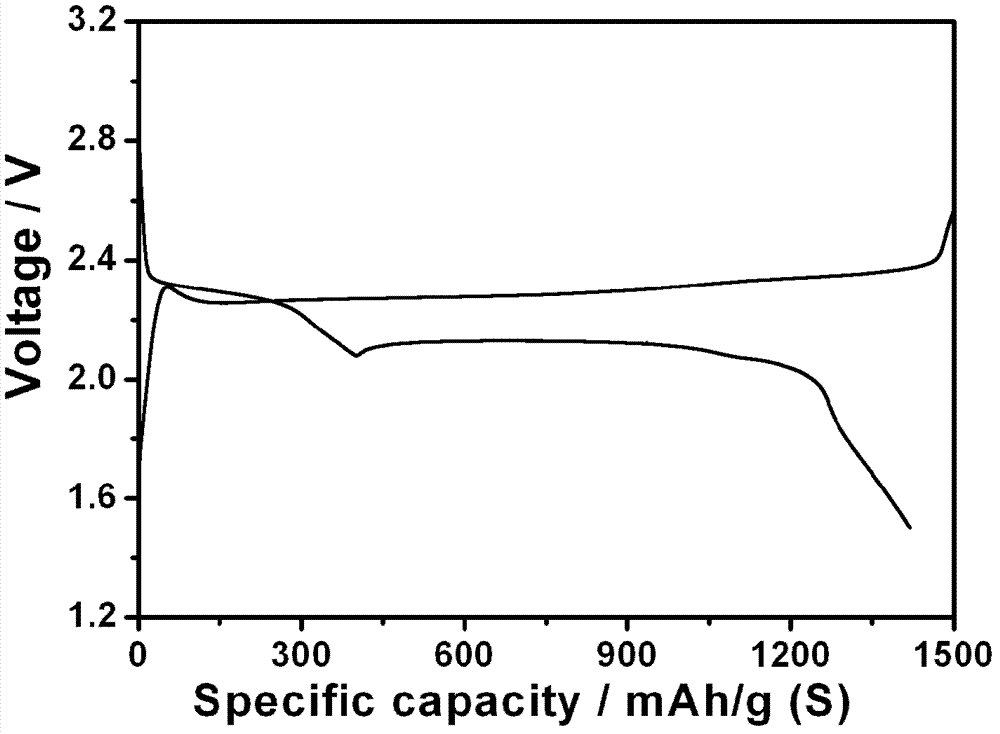

A sulfur electrode, and preparation and application thereof. The sulfur electrode comprises a sulfur / carbon composite, a conductive agent and a binder, wherein the sulfur is an electrode active material. The content of sulfur / carbon composite in the electrode is 10-95%; a mass ratio of sulfur to porous carbon material in the sulfur / carbon composite is 1:0.05-19; the porous carbon material in the sulfur / carbon composite has conductivity greater than or equal to 0.1S / cm, specific surface area greater than or equal to 500 m<2> / g, and pore volume greater than or equal to 0.3cm<3> / g; and the pore structure comprises microporous and mesoporous. The porous carbon material is treated by an acid modification method, in which a mass fraction of acid is 1-50%. The sulfur electrode prepared by the method provided by the invention has advantages of high specific energy, excellent cycle stability, cheap and easily available electrode material, and simple and practical preparation method, and can be applied to a secondary battery.

Owner:中科派思储能技术有限公司

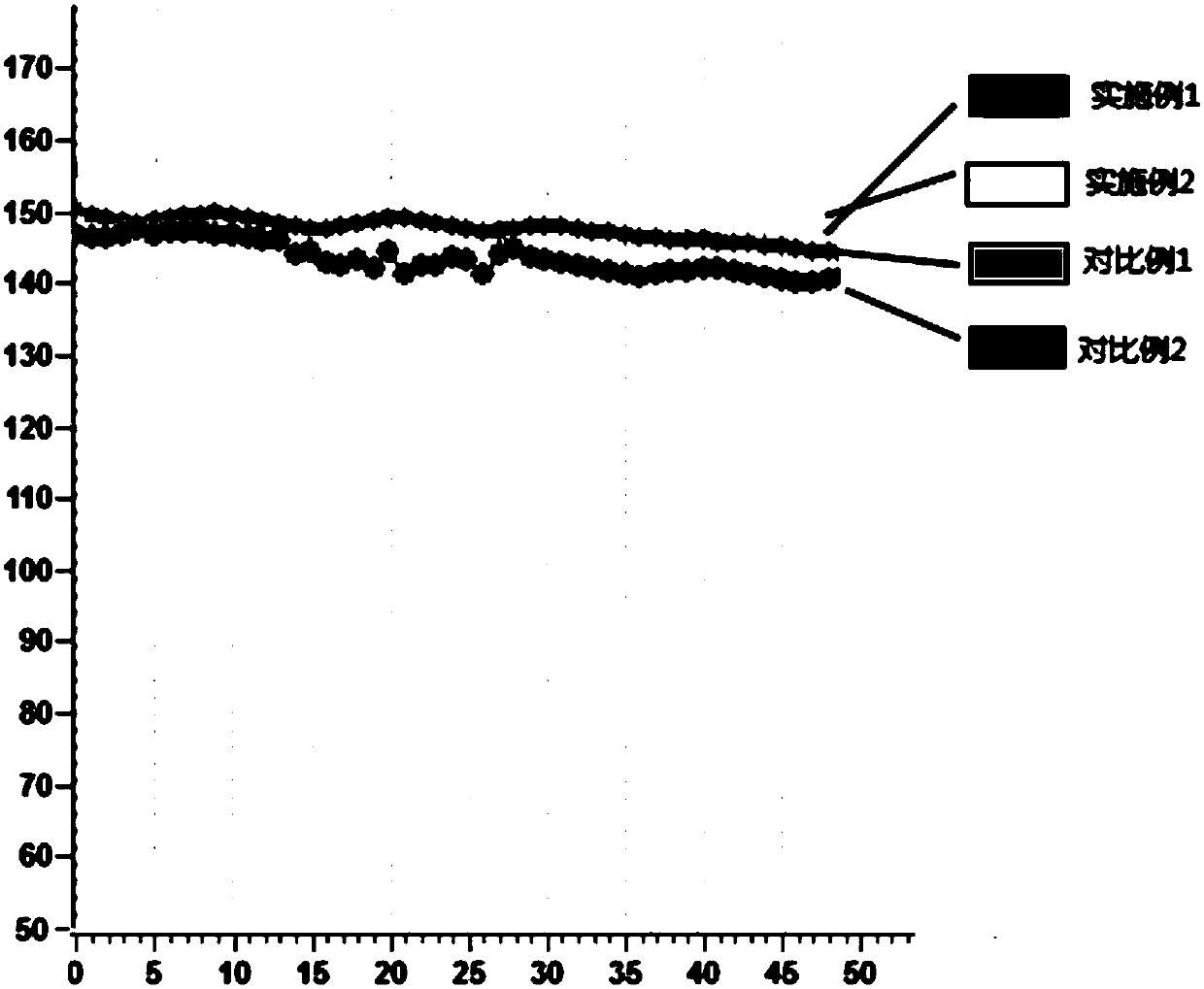

High-nickel ternary cathode material coated with fast ion conductor and preparation method thereof

InactiveCN110690435AClose contactSolving lithium-ion transport problemsCell electrodesSecondary cellsElectrical conductorInternal resistance

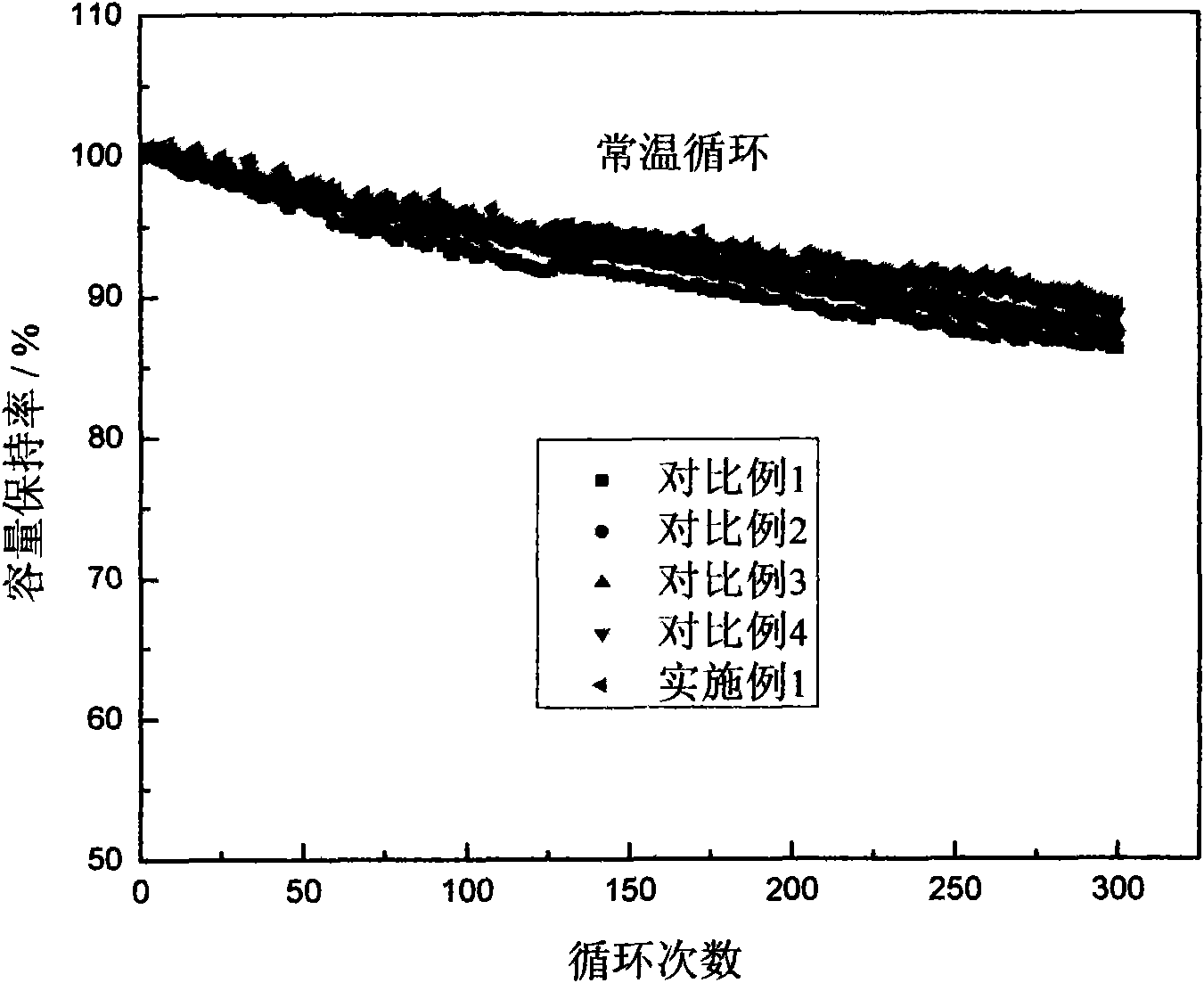

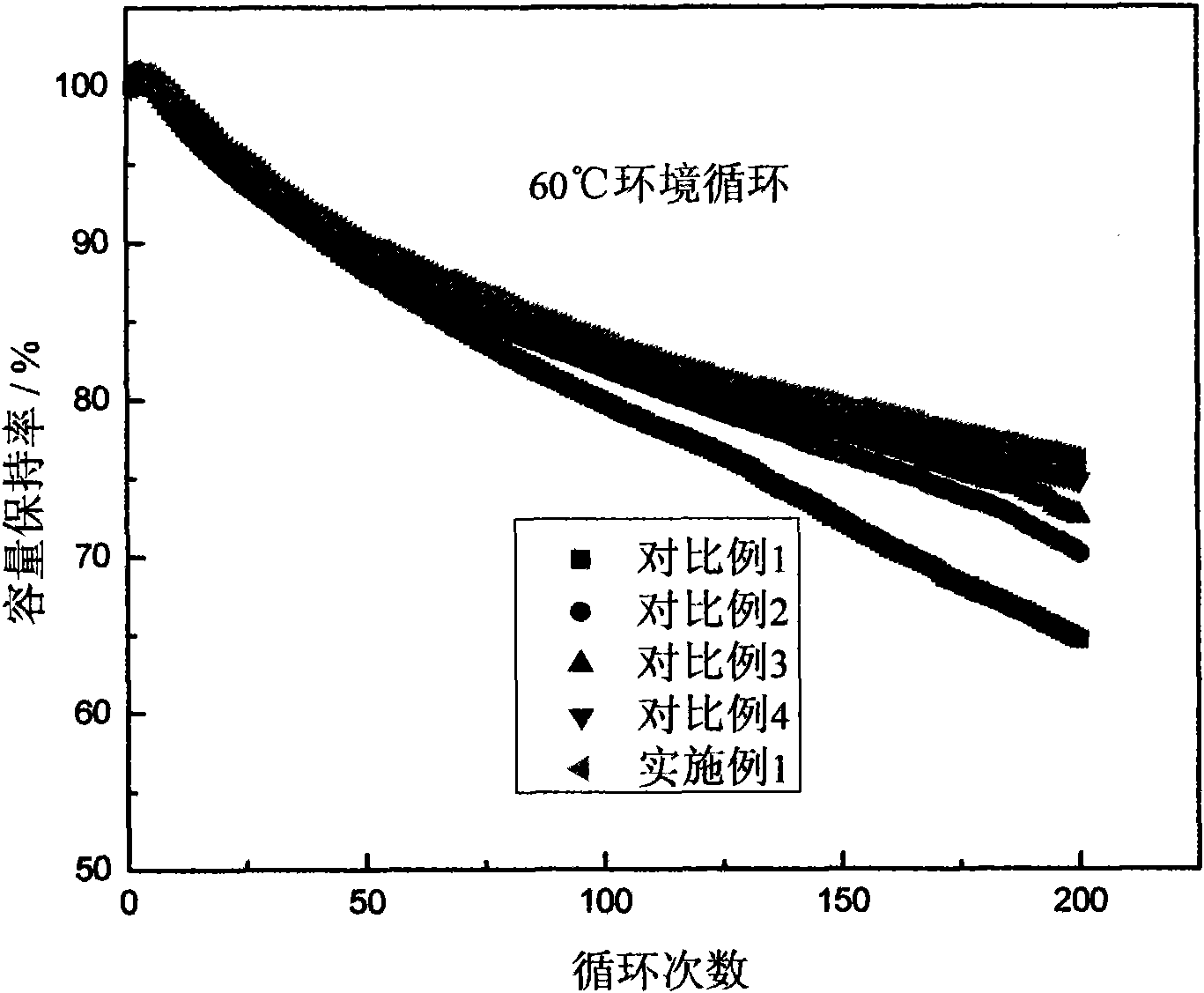

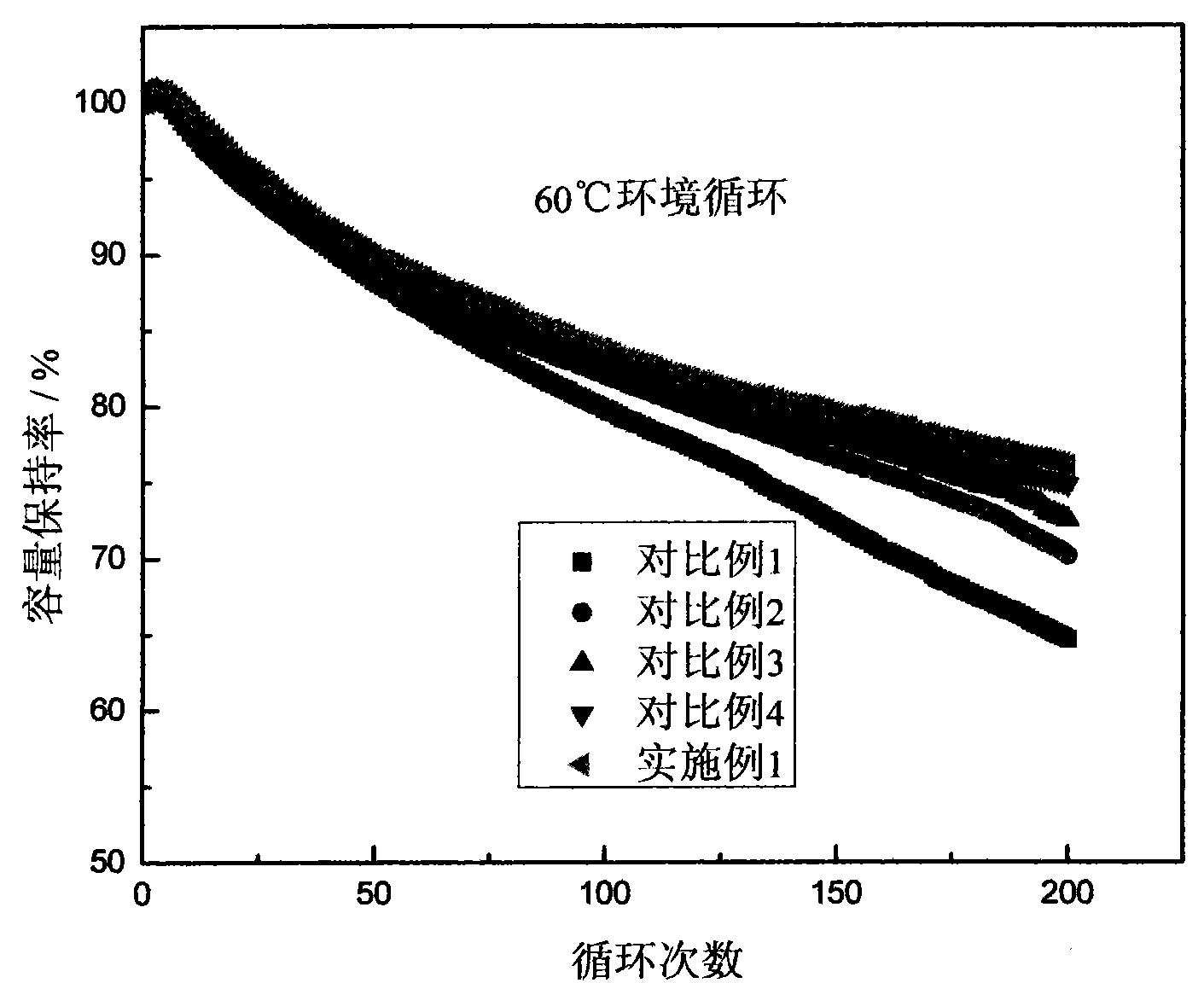

The invention provides a high-nickel ternary cathode material coated with a fast ion conductor and a preparation method thereof. The high-nickel ternary cathode material is spherical or spheroidic secondary particles composed of primary particles, the diameter of the high-nickel ternary cathode material is 1-30 [mu]m, and the chemical formula of the high-nickel ternary cathode material is LiNi0.8Co0.1Mn0.1O2. The preparation method comprises the following steps of: weighing raw materials for synthesizing the fast ion conductor in proportion, and uniformly dispersing the raw materials in a solvent to obtain a mixed solution; adding the high-nickel ternary precursor into the mixed solution, and then performing stirring, drying and grinding to obtain high-nickel ternary precursor powder coated with the fast ion conductor; and uniformly mixing the obtained precursor powder with a lithium salt, and performing sintering to obtain the high-nickel ternary cathode material coated with the fastion conductor. The fast ion conductor material is used as a coating substance of the ternary cathode material and can provide a fast transmission channel for lithium ion transmission, so that the purpose of reducing the internal resistance of the battery is achieved; and after coating, the cycling stability of the battery is improved under the condition that the specific discharge capacity of thebattery is not reduced.

Owner:CENT SOUTH UNIV +1

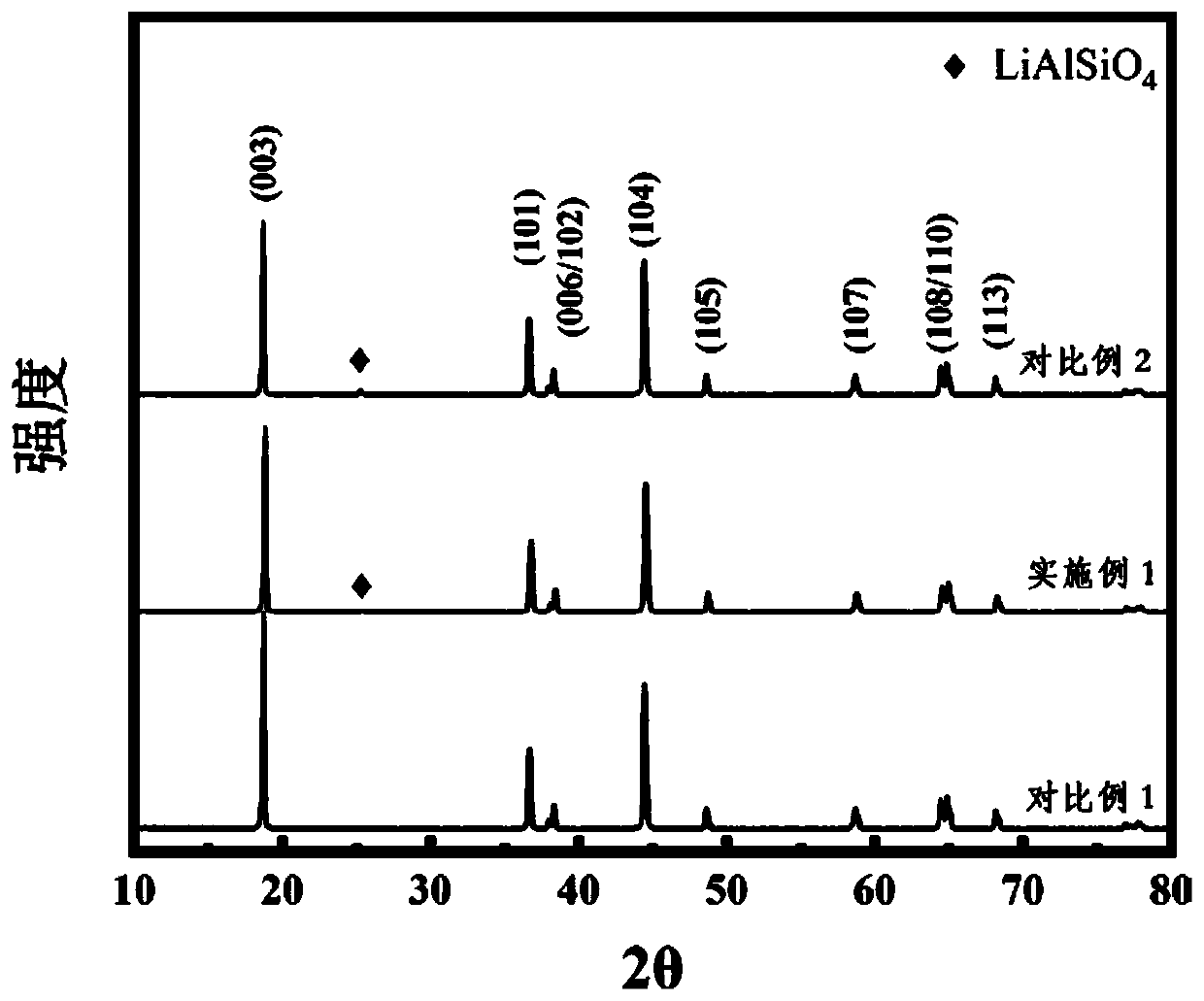

High-temperature solid-phase preparation method of negative electrode material lithium orthosilicate of lithium ion battery

InactiveCN103943827ASimple processPromote crystallizationCell electrodesSecondary cellsElectrical batteryTube furnace

The invention discloses a high-temperature solid-phase preparation method of a negative electrode material lithium orthosilicate of a lithium ion battery. The preparation method comprises the steps of uniformly mixing a silicon source and a lithium source according to a mole ratio of lithium to silicon being 4:1, and carrying out ball milling to obtain a precursor; heating the uniformly mixed precursor at the temperature of 200-400 DEG C for 2-12 hours under an air atmosphere, an inert gas atmosphere or a reducing gas atmosphere, and after naturally cooling, grinding to obtain a powder material; carrying out ball-milling on the powder material again for 6-24 hours, arranging the powder material in a tube furnace, sintering at the temperature of 450-1000 DEG C for 4-24 hours under the air atmosphere, the inert gas atmosphere or the reducing gas atmosphere, and naturally cooling to obtain the negative electrode material lithium orthosilicate. The invention further relates to a carbon-coated negative electrode material lithium orthosilicate obtained by adding a carbon material in a preparation process. The high-temperature solid-phase preparation method is simple in process and easy to operate. The negative electrode material lithium orthosilicate synthesized by adopting the preparation method is low in lithium-embedding potential (0.1-1 V) and excellent in cycle performance.

Owner:SOUTH CHINA UNIV OF TECH

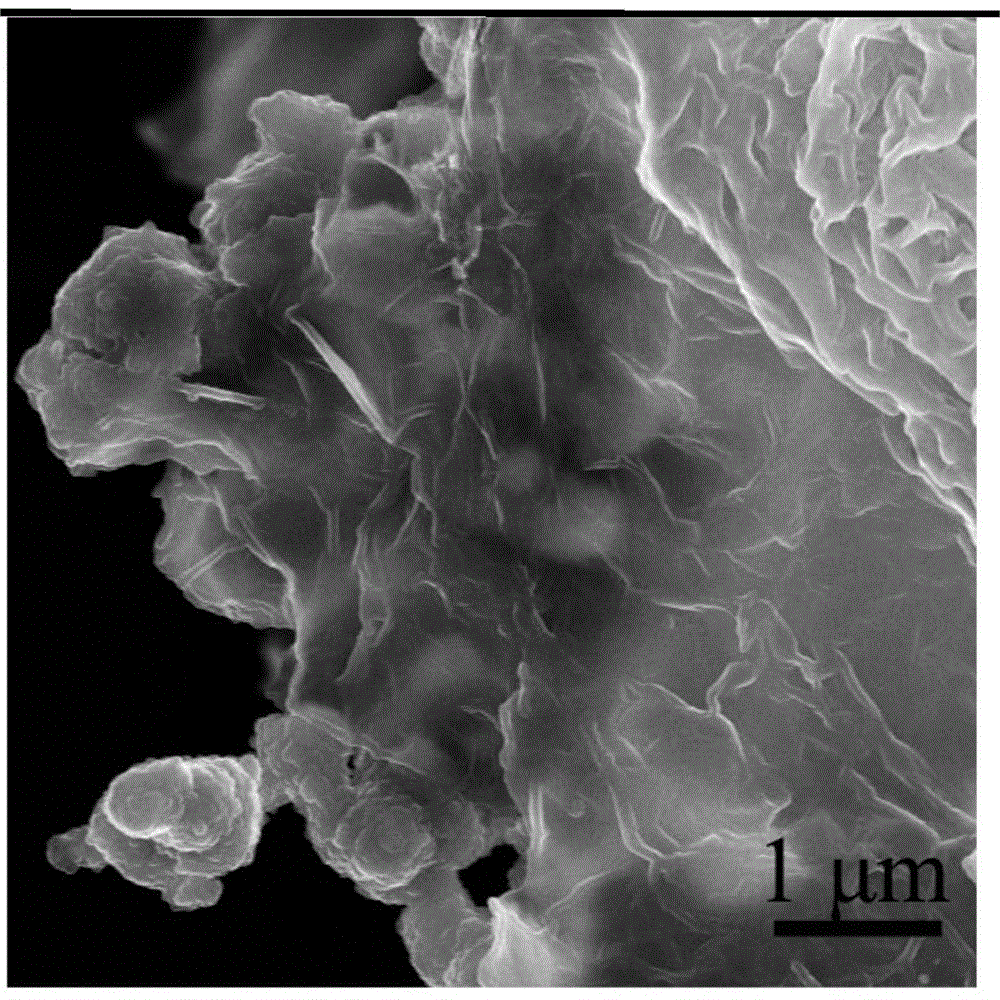

Nano-NiS/graphene composite anode material and preparation method thereof

ActiveCN104134783ABuffer volume expansionImprove cycle stabilityCell electrodesSecondary cellsActive agentDissolution

The invention provides a preparation method of a NiS / graphene composite anode material. The method includes: firstly preparing NiS nanoparticles by a solvothermal method, performing surface modification on the NiS particles by a surfactant, then compounding the modified NiS particles with graphene oxide under electrostatic attraction; and reducing graphene oxide by hydrazine hydrate so as to finally form graphene packaged nano-NiS / graphene composite anode material. The dispersion and packaging effects of graphene on NiS can effectively buffer NiS's volume expansion generated during charging and discharging, and inhibit dissolution of the product in an electrolyte solution in an electrode reaction process, thus improving the cyclic stability of the composite material. At the same time, graphene provides a good conductive network, which is conducive to rapid transmission of electrons, thereby reducing electrode polarization and greatly improving the rate performance of the composite material. The NiS / graphene composite material prepared by the method provided by the invention has excellent electrochemical performance, and the preparation process is simple, the conditions are mild, so that the method is suitable for large-scale industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

Composite conductive agent, preparation method thereof and application of composite conductive agent in positive electrode slurry

The invention discloses a composite conductive agent, a preparation method thereof and the application of the composite conductive agent in a positive electrode slurry. The composite conductive agentis a composite conductive slurry, a solvent in the composite conductive slurry is an organic solvent, conductive particles include acetylene black, conductive graphite, nano carbon fibers, carbon nanotubes and graphene, the mass ratio of the acetylene black to conductive graphite is 1: (0.2 to 5), and the mass ratio of the nano carbon fibers to the carbon nanotubes to the graphene is 1: (0.2 to 5): (0.2 to 5). The composite conductive agent of the invention has a good point-to-surface omnidirectional conductive network, a larger contact point is formed by conductive particles in the compositeconductive agent and an active material, the electrical conductivity of an electrode sheet can be improved, the electrode sheet polarization and the battery internal resistance are reduced, and the battery performance is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Preparation method of lithium sulfur battery membrane electrode

InactiveCN104157909AImprove performanceEliminates the possibility of a reactionFinal product manufactureElectrolyte accumulators manufactureLithium–sulfur batteryInternal resistance

The invention relates to the technical field of a lithium sulfur battery, and aims at providing a preparation method of a lithium sulfur battery membrane electrode. The preparation method of the lithium sulfur battery membrane comprises the following steps: preparing a carbon material with nano ferrous sulfide being dispersed on the surface of a carbon carrier, and then preparing a positive electrode material by utilizing the carbon material; respectively preparing a positive electrode and a negative electrode as well as a lithium ion exchange membrane, and finally pressing the positive electrode, the negative electrode and the lithium ion exchange membrane into the lithium sulfur battery membrane electrode. The prepared lithium sulfur battery membrane electrode is good in conductivity, low in internal resistance, good in electrode reaction reversibility, good in chemical stability and thermal stability, low in price, easy to prepare, pollution-free, simple in battery manufacturing process, favorable for mass production and capable of effectively reducing the production cost.

Owner:ZHEJIANG UNIV

Preparation method of lithium iron phosphate anode material co-coated by conducting polymer/nanometer metal particles

ActiveCN102983329ACapable of deintercalating lithiumEasy accessCell electrodesWater bathsConductive polymer

The invention discloses a preparation method of a lithium iron phosphate anode material co-coated by conducting polymer / nanometer metal particles. The preparation method comprises the following steps of: (1) sufficiently diffusing a polymer monomer and lithium iron phosphate powder in an acid solution, so as to obtain a mixed solution A, wherein the polymer monomer is one or a combination of more than one of aniline, pyrrole, thiophene and 3,4-ethylenedioxythiophene; (2) adding a metallic compound in the mixed solution, and sufficiently diffusing to obtain a mixed solution B, wherein the metallic compound is one of silver nitrate, nickel nitrate, nickel sulfate, copper nitrate, copper sulfate, chloroauric acid and chloroplatinic acid; and (3) adding an oxidant in the mixed solution B, carrying out ultrasonic water bath on the obtained reaction mixtures at a temperature of 0-30 DEG C for 1-4 hours; standing for 1-2 hours at the room temperature, filtering, washing and drying so as to obtain the lithium iron phosphate anode material co-coated by the conducting polymer / nanometer metal particles by. The material provided by the invention has the advantages of high material capacity and good rate capability.

Owner:嘉善县国创新能源研究院

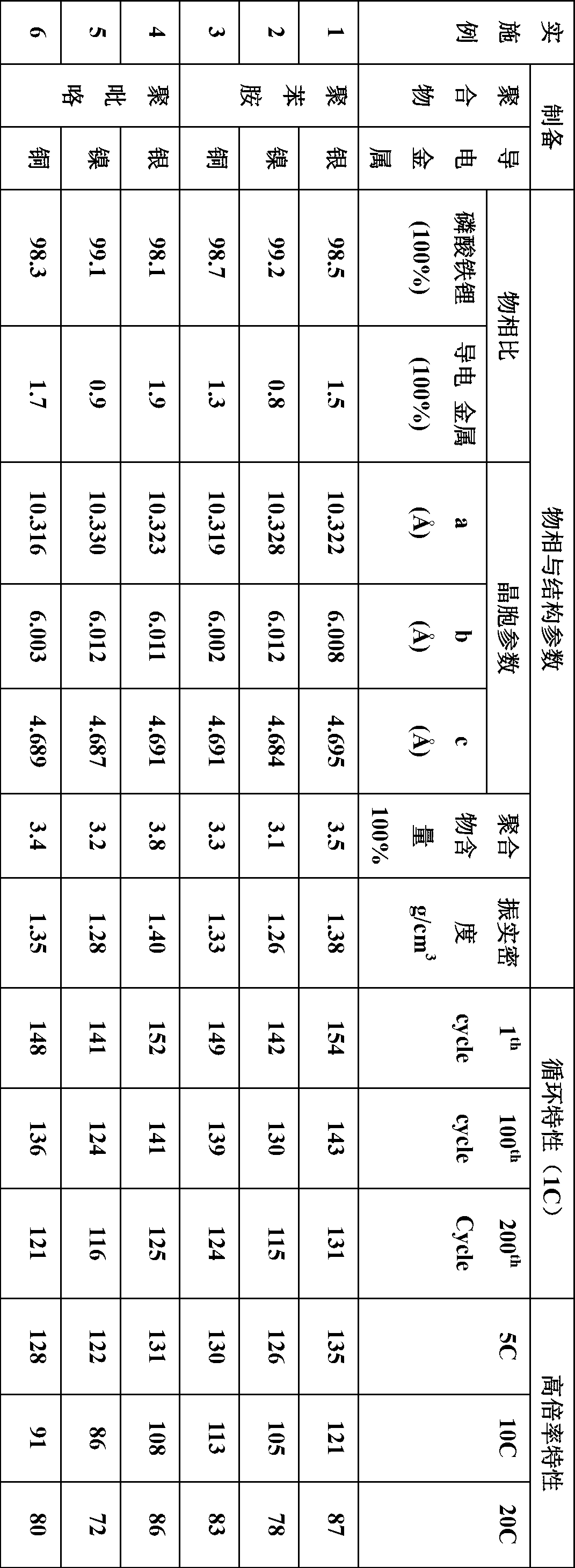

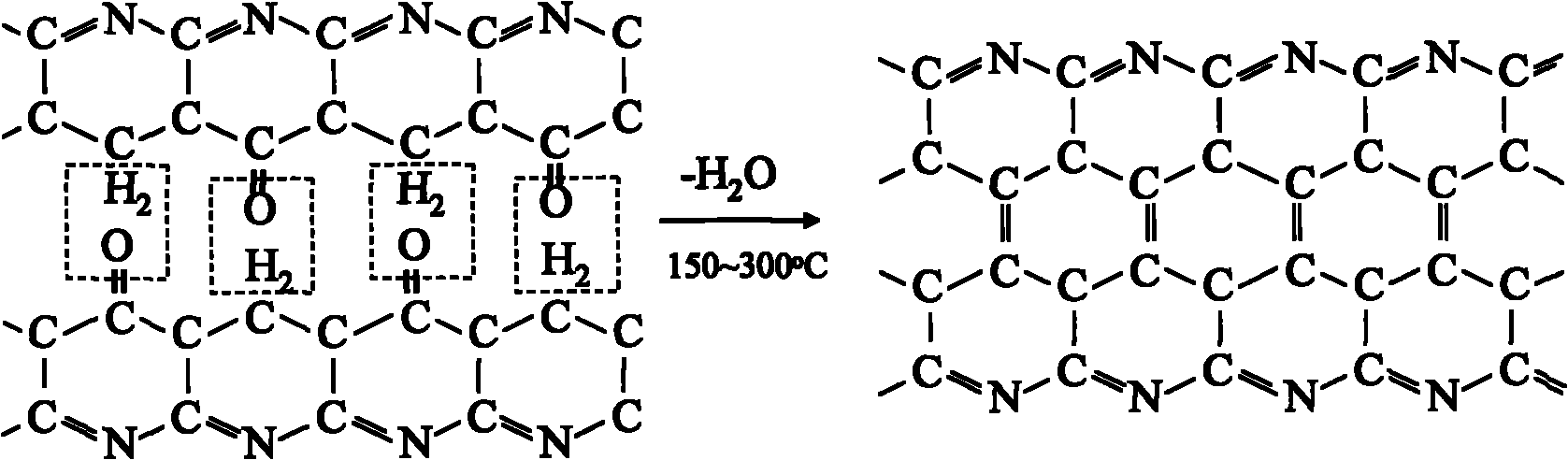

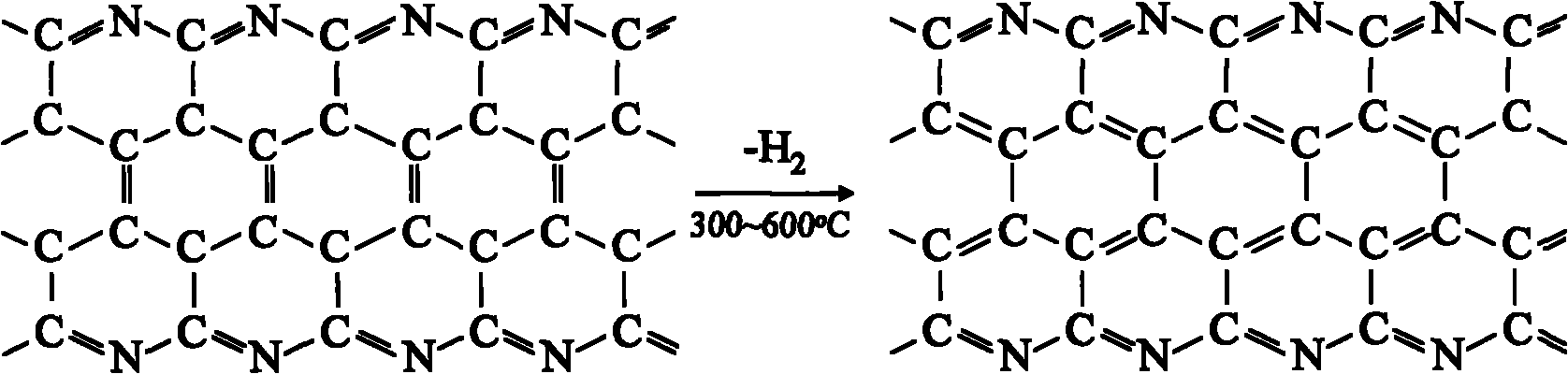

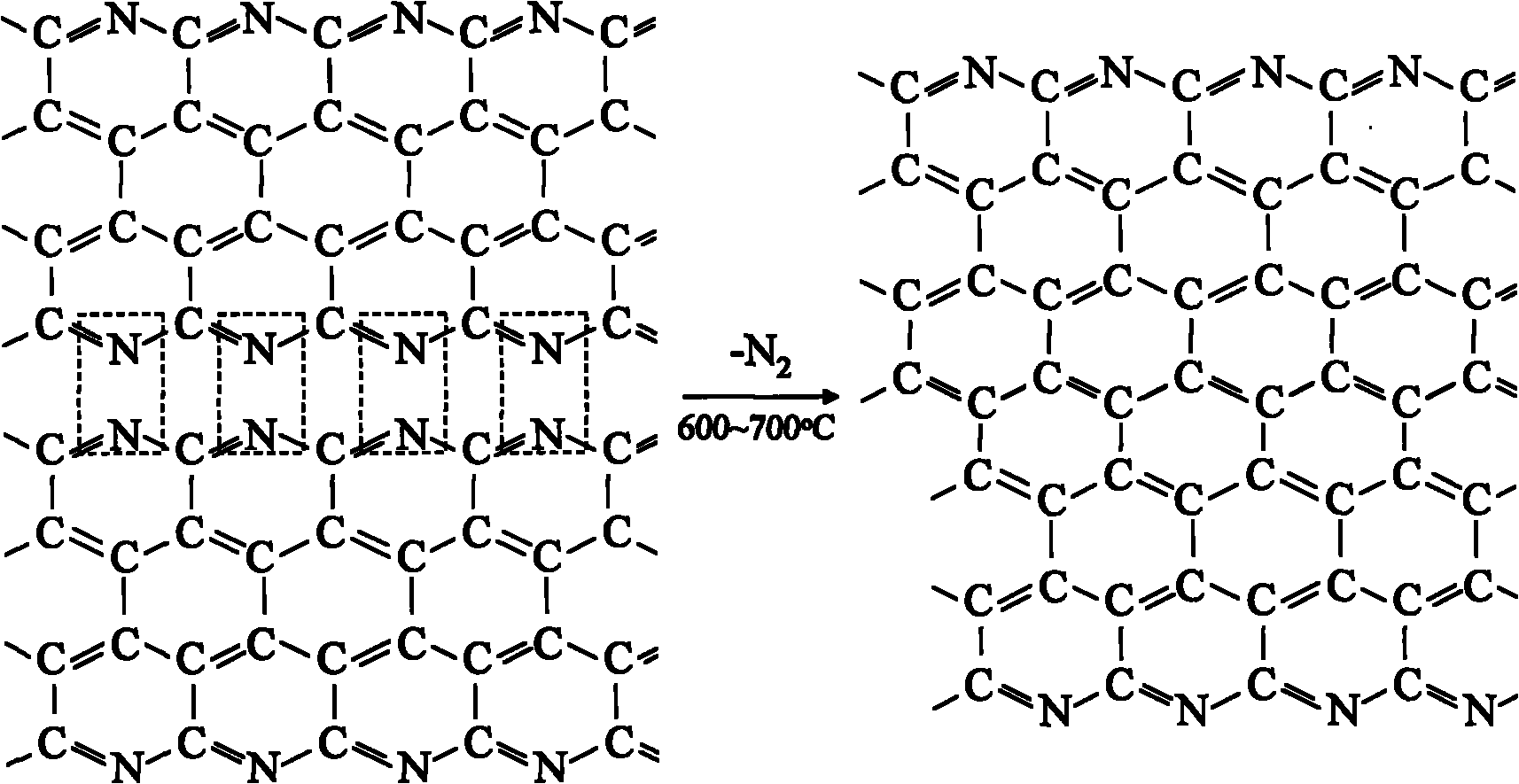

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204AImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmReaction temperature

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

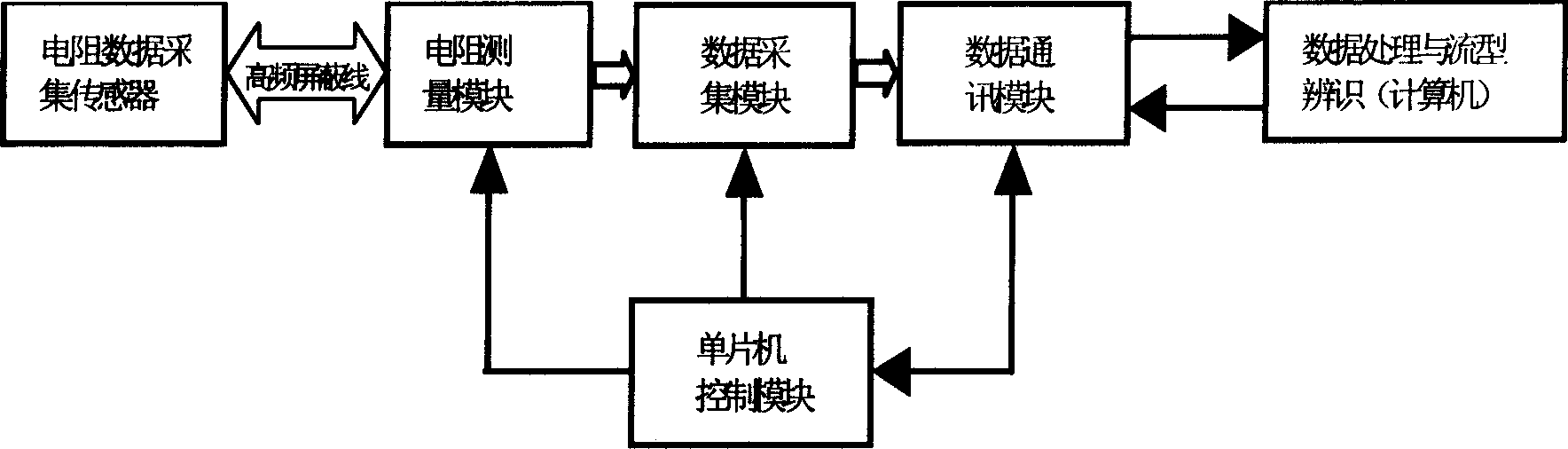

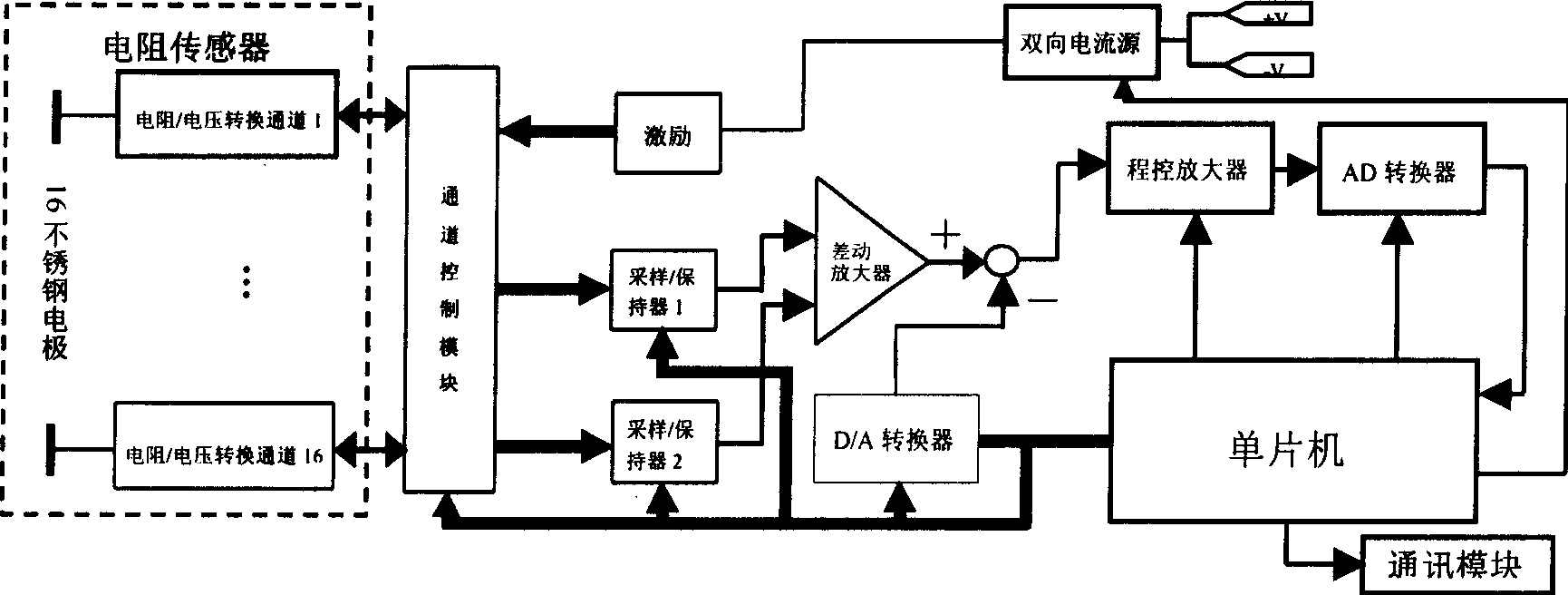

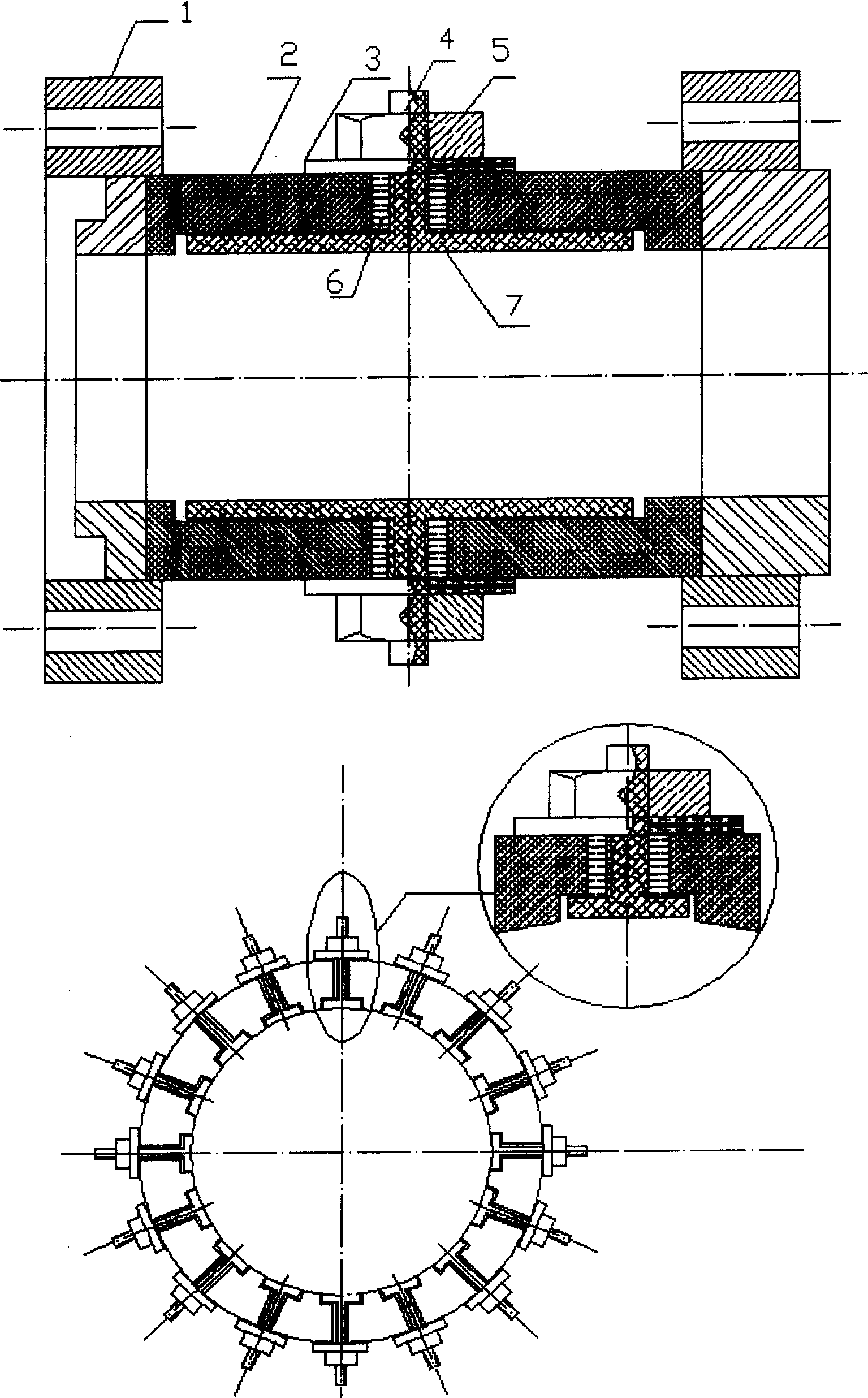

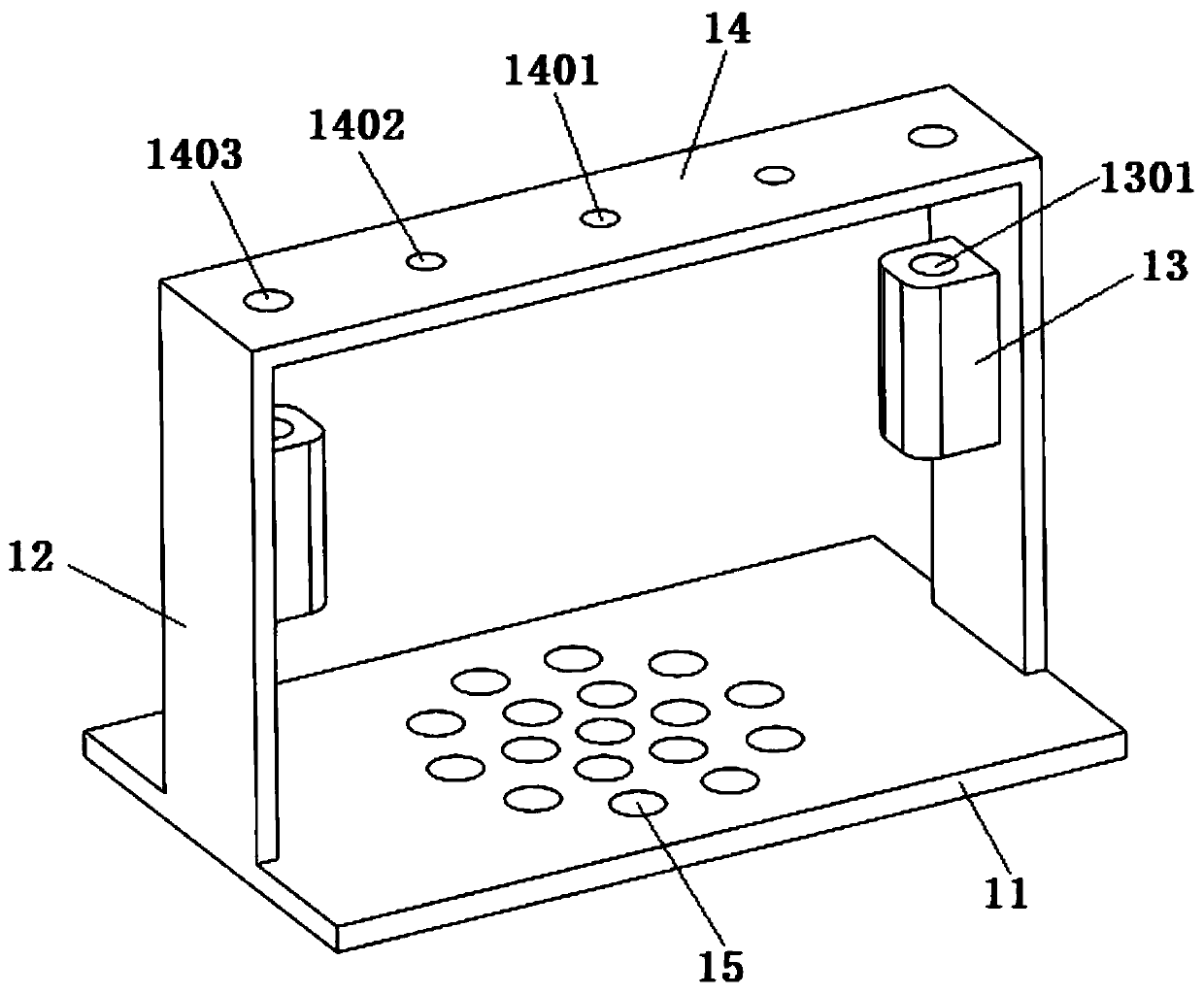

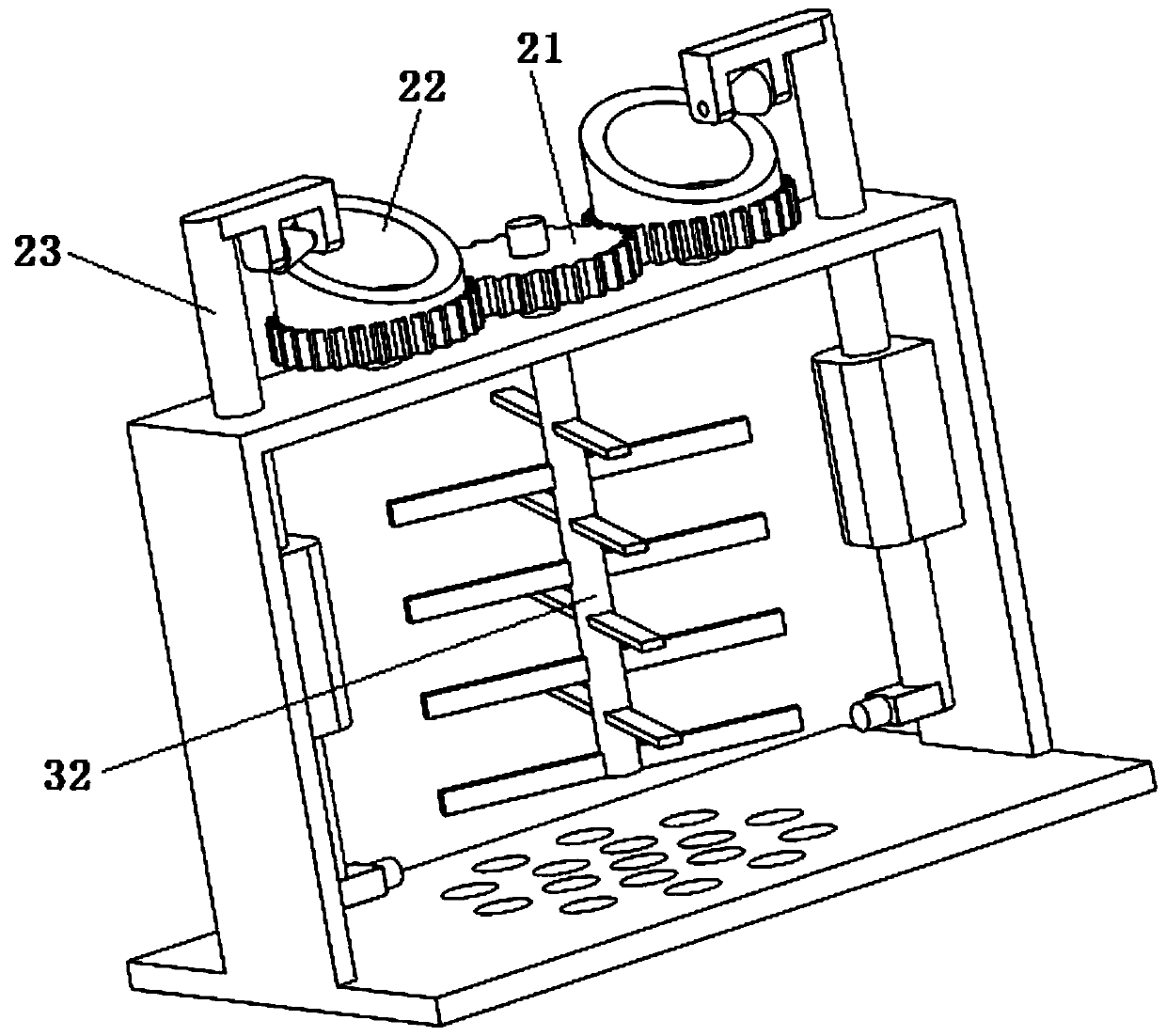

Resistance tomography data acquisition system based on bipolar pulse current drive

InactiveCN1544959AWeaken the intractable electrical polarization problemReduce electrode polarizationResistance/reactance/impedenceDiagnostic recording/measuringMicrocontrollerData acquisition

The invention discloses a bipolar pulse current excited resistance chromographic imaging data collecting system, and its character: in sequence, it has resistance data collecting sensor, resistance measuring module, data collecting module, data communication module and MCU control module, where the MCU control module is connected with the resistance measuring module, data collecting module, data communication module, the electrodes of the resistance data collecting sensor are connected with the input end of the resistance measuring module by high frequency screening wires. The invention implements the integration of resistance measuring circuit with data collecting system, micro-computerization of data collecting system and modularization of communication system.

Owner:ZHEJIANG UNIV

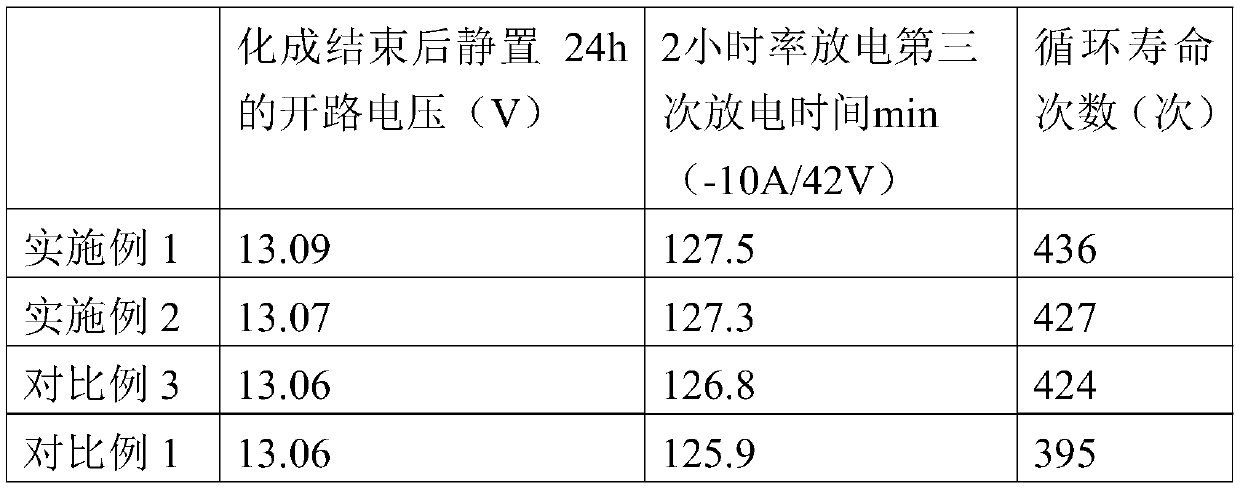

Power lead storage battery

ActiveCN109755564ALower internal resistanceHigh porosityLead-acid accumulatorsLead-acid accumulator electrodesPorosityHeat conducting

The invention discloses a power lead storage battery. The power lead storage battery comprises a positive plate and a negative plate, wherein the positive plate comprises a positive grid and positivelead plaster, and the negative plate comprises a negative grid and negative lead plaster. The power lead storage battery disclosed by the invention has the advantages that carbon nanotubes are used toreplace activated carbon and acetylene black adopted in the traditional art, so that the current density and the electrode polarization during discharging are effectively reduced, a smaller internalresistance of the battery is achieved, the lead plaster porosity is increased, and the lead plaster utilization efficiency and the charge acceptance are improved; and titanium nitride, which has a high melting point, high intensity, high hardness, high acid and alkali corrosion resistances, high wear resistance, high pyrochemical stability and excellent electricity-conducting and heat-conducting performances, is added to prevent the forming of a passivation layer between each grid and the corresponding lead plaster, so that early capacity fading of the storage battery can be avoided, and the overall service life of the storage battery can be prolonged.

Owner:TIANNENG BATTERY GROUP

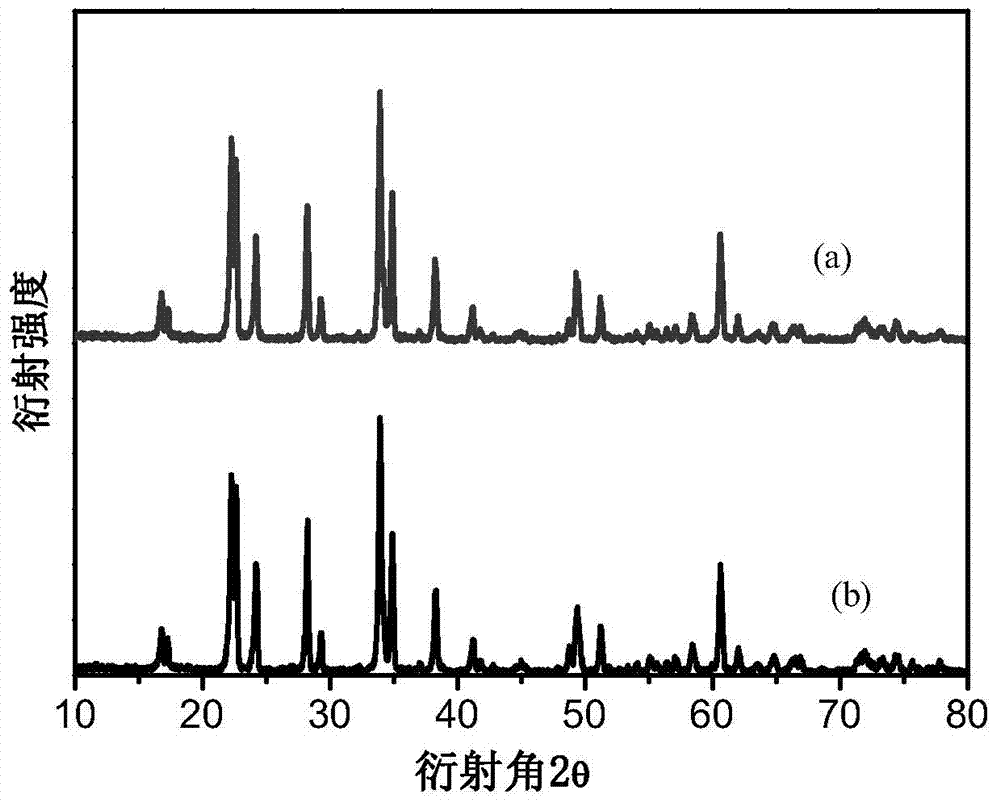

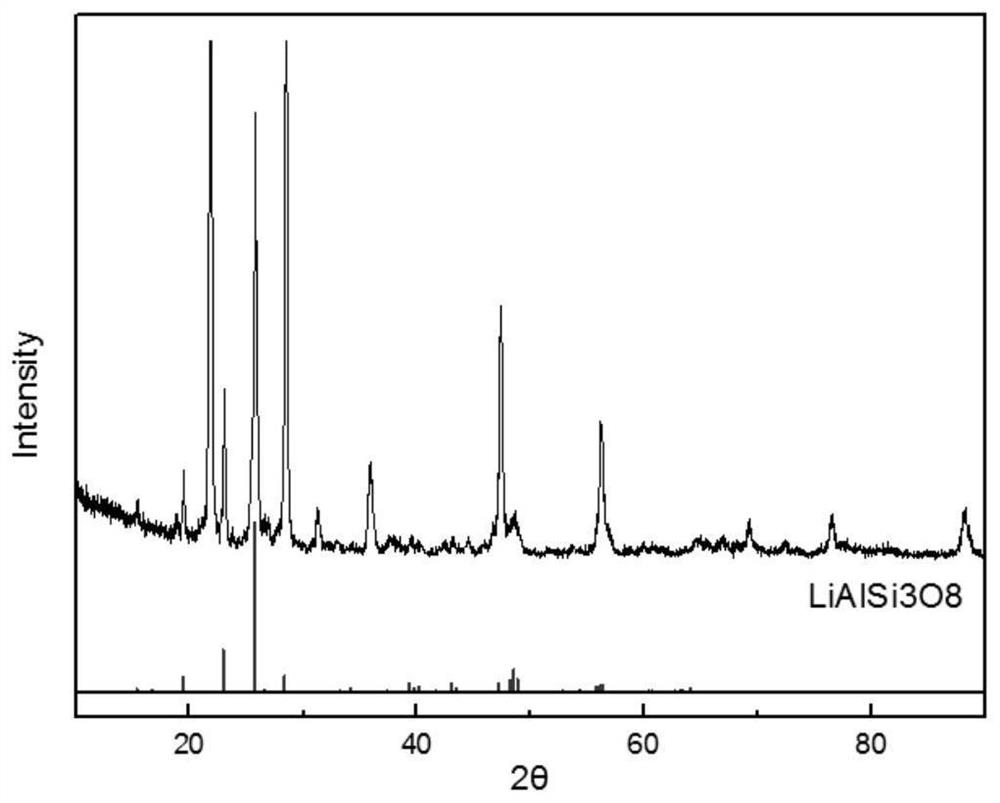

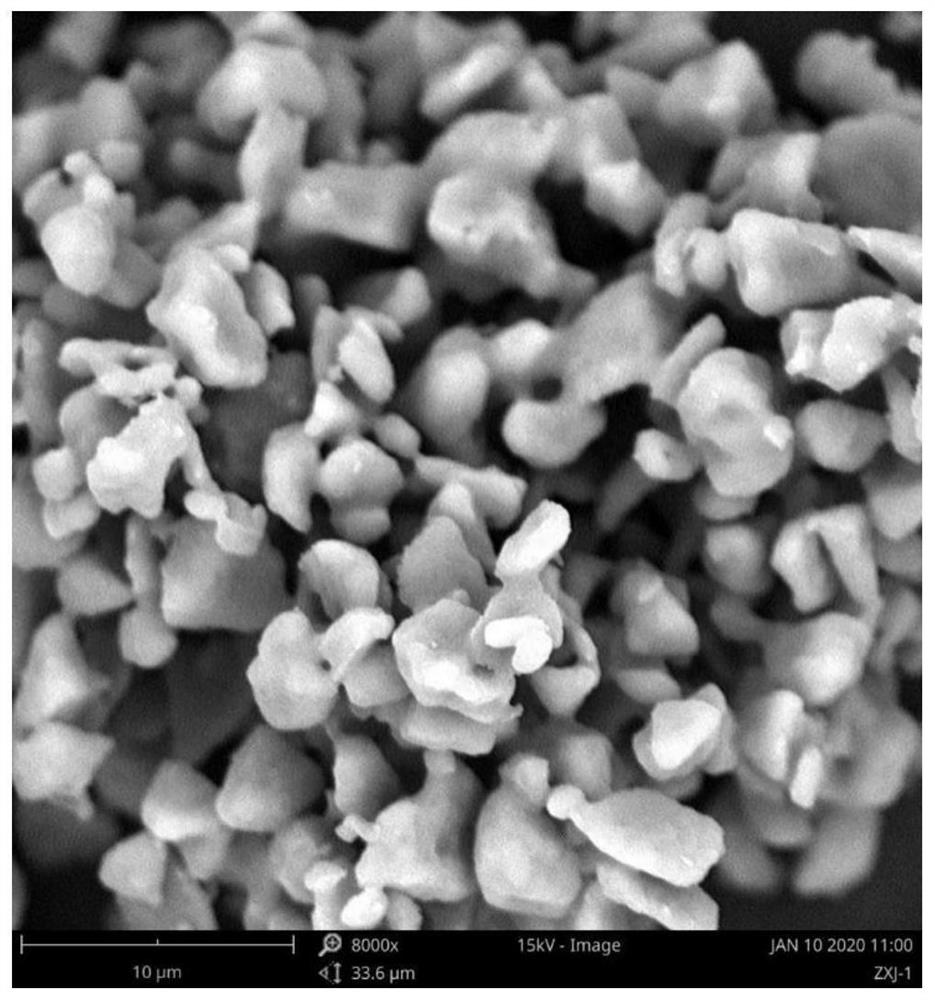

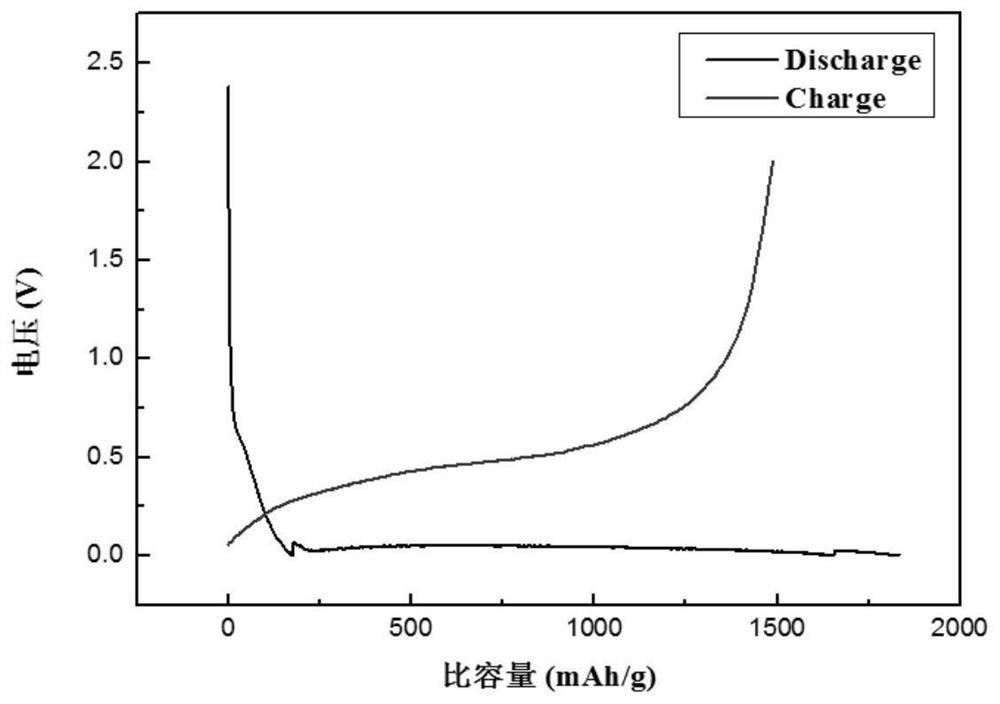

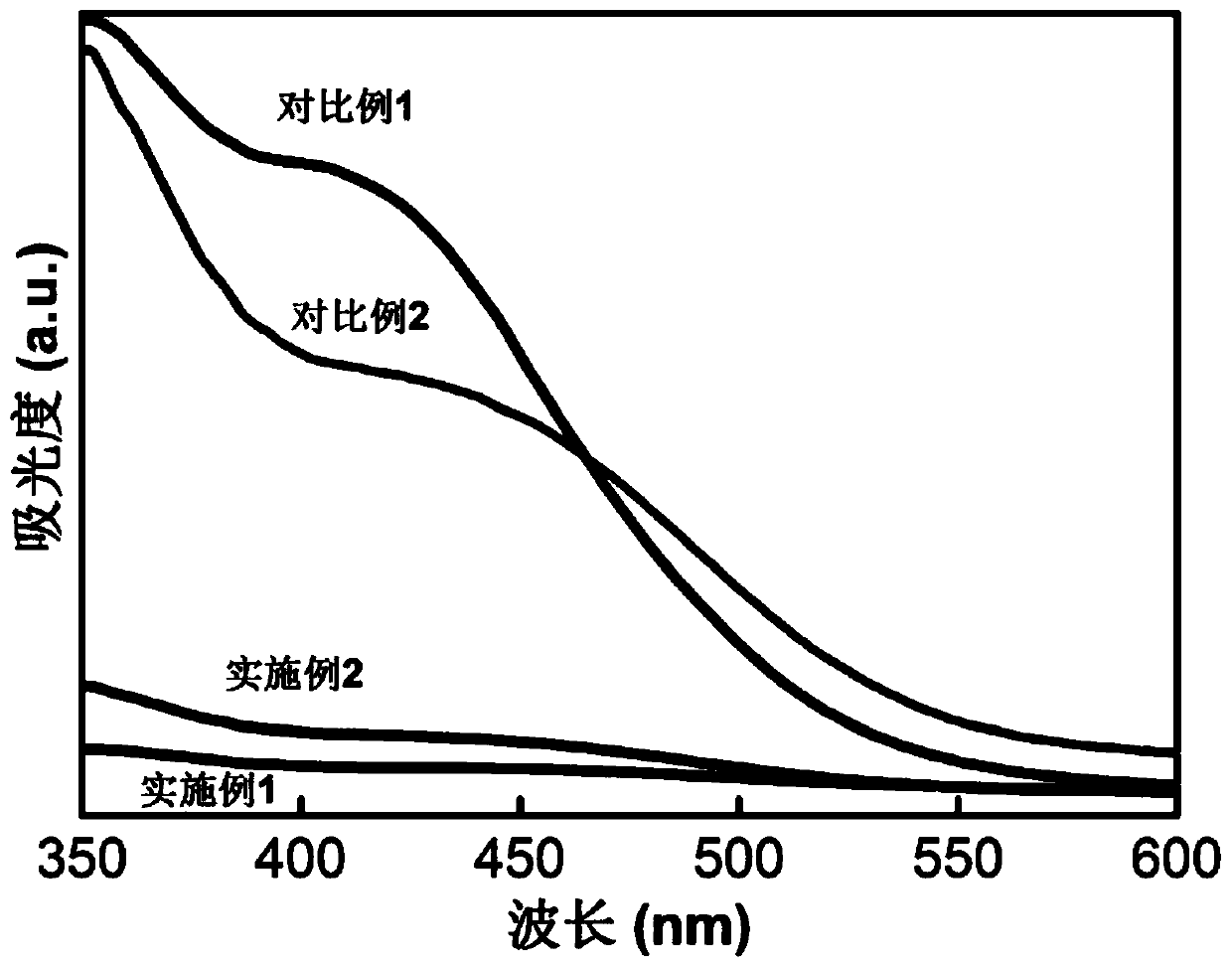

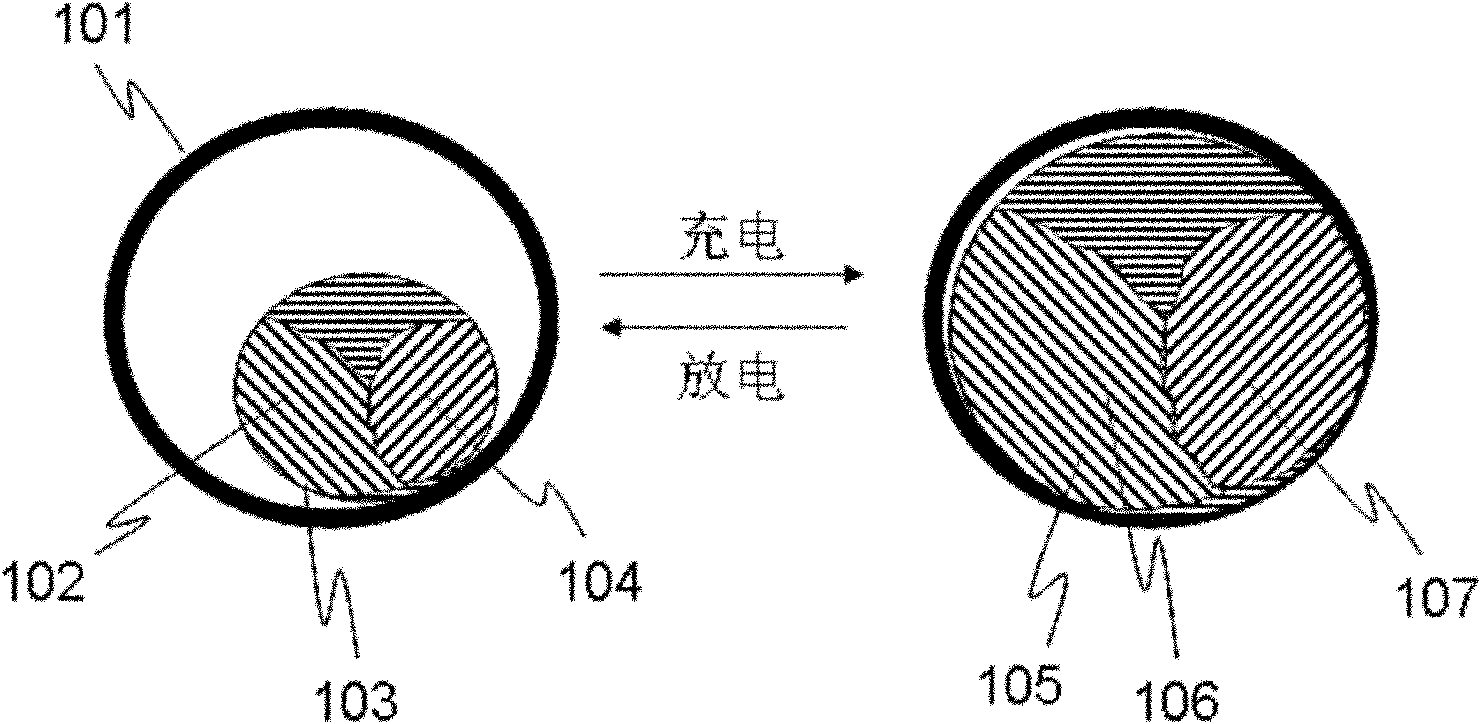

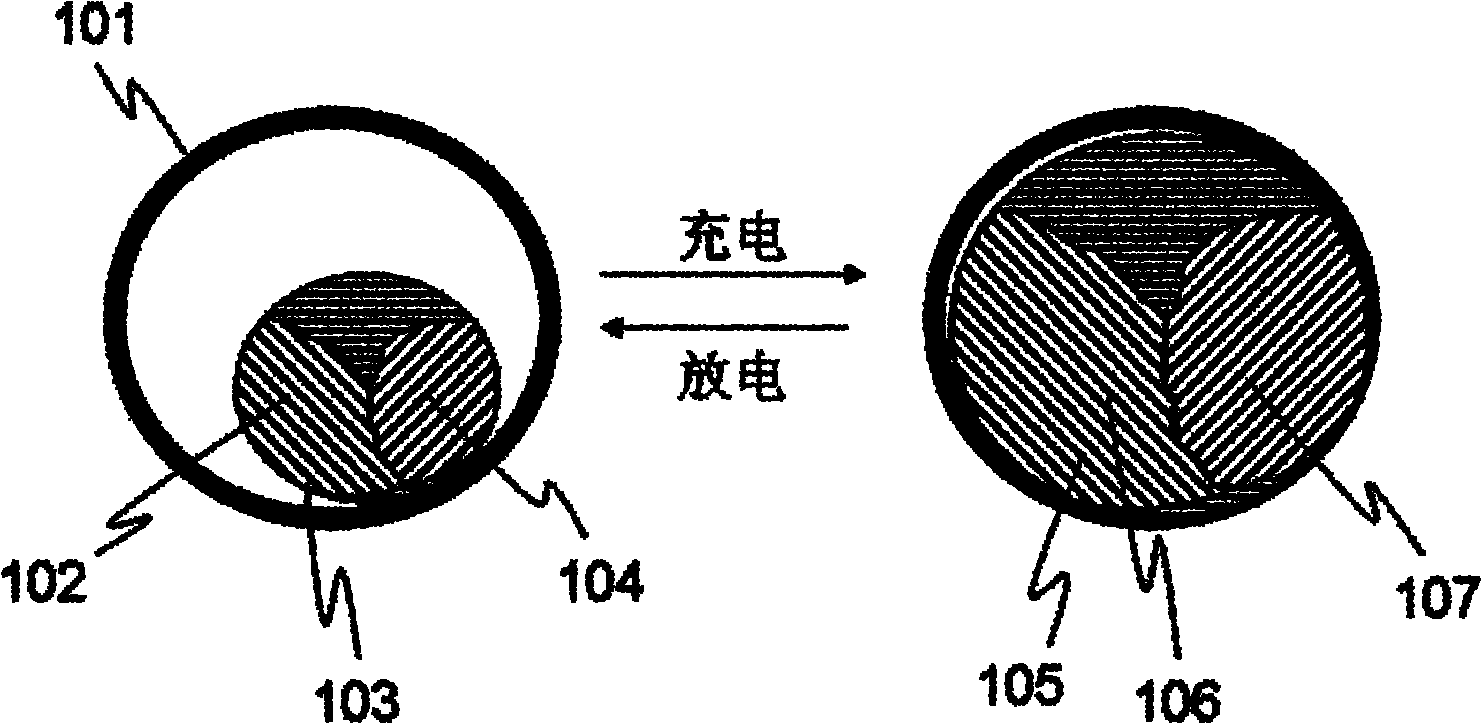

Silicon-based composite material and preparation method thereof

InactiveCN111653759ARelieve swellingPower optimizationNegative electrodesSecondary cells servicing/maintenanceCarbon coatingCarbon layer

The invention provides a silicon-based composite material and a preparation method thereof. The silicon-based composite material provided by the invention comprises a silicon-based matrix, a fast ionconductor layer coating the surface of the silicon-based matrix, and a carbon layer coating the surface of the fast ion conductor layer. A fast ion conductor of the fast ion conductor layer is LiAlSixOy, x is greater than or equal to 1, and y is greater than or equal to 1. According to the invention, the specific fast ion conductor layer LiAlSixOy and the carbon coating sequentially coat the surface of the silicon-based matrix, so that problems of relatively high charge transmission impedance and relatively low power output of the silicon-based negative electrode material are effectively improved, and the rate capability is improved; and meanwhile, the specific double coating layers are matched, so that the expansion of the silicon-based material is effectively relieved, and the cycle performance is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Water-based soy protein-based supramolecular sulfur positive electrode binder and preparation method and application thereof

ActiveCN111430716AImprove lithium ion conductivityStrong lithium polysulfide adsorptionLi-accumulatorsNon-aqueous electrolyte accumulator electrodesPhosphorylationLithium sulfur

The invention discloses a water-based soy protein-based supramolecular sulfur positive electrode binder and a preparation method and application thereof. The binder is prepared from phosphorylated soybean protein, a lithium ion transmission promoter and a physical cross-linking agent through a physical blending method. The binder has a three-dimensional network cross-linked structure and the characteristics of the raw materials so that the binder has excellent mechanical properties, high ionic conductivity, strong lithium polysulfide adsorption capacity and certain biodegradability. When the binder is applied to the lithium-sulfur battery, the cycle life, the rate capability and the specific capacity of the battery can be effectively improved. A physical blending preparation method is used, a phosphorylated soybean protein aqueous solution, a lithium ion accelerant aqueous solution and a physical cross-linking agent aqueous solution are directly mixed to obtain the binder which is cross-linked by intermolecular hydrogen bonds and has a three-dimensional network structure, the process conditions are simple, efficient and convenient, and no pollution is caused to the environment whenwater is used as a solvent.

Owner:SOUTH CHINA UNIV OF TECH

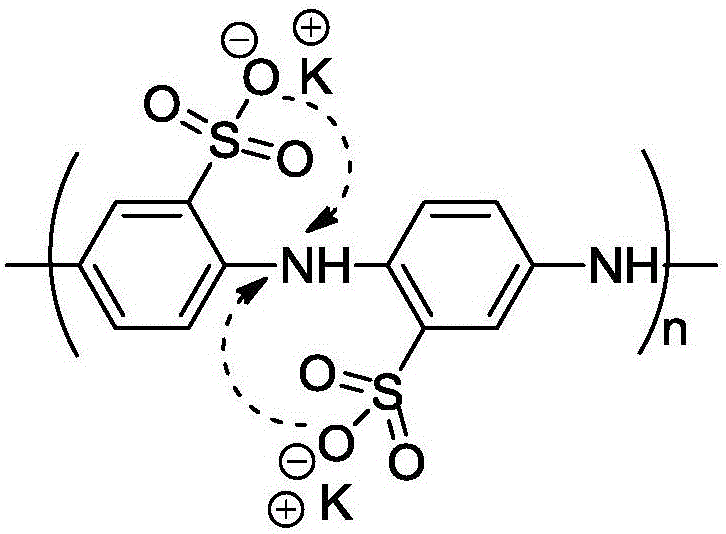

Battery cathode diachylon formulation high in utilization rate of active substance and preparation method of battery cathode diachylon formulation

The invention relates to a battery cathode diachylon formulation high in utilization rate of active substance and a preparation method of the battery cathode diachylon formulation and belongs to the technical field of lead-acid storage batteries. The the battery cathode diachylon formulation comprises dilute sulfuric acid of 1.38g / ml in density, deionized water, lignin Vanisperse AT, polyaniline potassium sulfonate PAN-K, nano hollow barium sulfate, acetylene black, emulsion carbon naotube Sus-CNT and lead powder. On the basis of a conventional cathode diachylon formulation, water-soluble PAN-K is adopted to completely replace conventional polyester staple fiber, nano hollow barium sulfate is adopted to completely replace conventional precipitated barium sulfate, and the emulsion carbon nanotube Sus-CNT is adopted to partly replace deionized water for paste mixing. On the premise that circulating life of a cathode produced by the formulation is not shortened, active substance utilization rate and charging receiving capability of the cathode are remarkably improved, and the battery cathode diachylon formulation is about to have great application and popularization prospect in the field of lowering weight of active substance of the cathode and lowering manufacturing cost of the lead-acid storage batteries.

Owner:CAMEL GRP HUAZHONG BATTERY

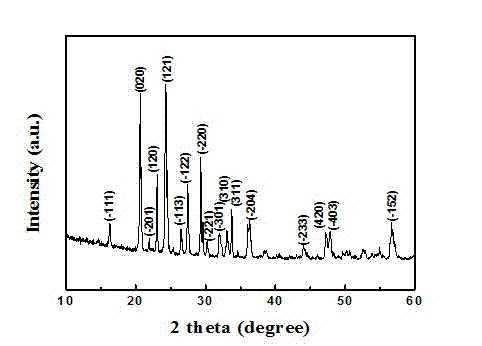

Method for preparing binary doped cathode material lithium vanadium phosphate of lithium ion battery

InactiveCN103094570ALower transfer resistanceReduce demandCell electrodesPolyethylene glycolSodium-ion battery

The invention discloses a method for preparing a binary doped cathode material lithium vanadium phosphate of a lithium ion battery. The method comprises the following steps of: mixing aqueous hydrogen peroxide solution and vanadium pentoxide to react to obtain vanadium pentoxide hydrogel; synthesizing a precursor of the cathode material Li3-xNaxV2(PO4-yFy)3 of the lithium ion battery by one step by using the vanadium pentoxide hydrogel, diammonium hydrogen phosphate, lithium hydroxide monohydrate, sodium salt, fluorine-containing salt and polyethylene glycol as raw materials; and roasting the precursor under the protection of inert gas to facilitate V<5+> to be completely reduced into V<3+> and generate the product Li3-xNaxV2(PO4-yFy)3. The method is simple and convenient, and has the characteristics of easy control and low cost; the synthesis process is simplified, sodium-doped Li3V2(PO4)3 has a larger lithium ion transportation channel, and the body conductivity of Li3V2(PO4)3 can be increased; and besides, by adding a little amount of fluorine, the polarization of the electrode can be reduced, the charge transfer resistance can be reduced, the diffusion rate of Li<+> can be increased, and the charging and discharging performance and the rate capability of the sample are improved finally.

Owner:JIANGXI YOULI NEW MATERIALS

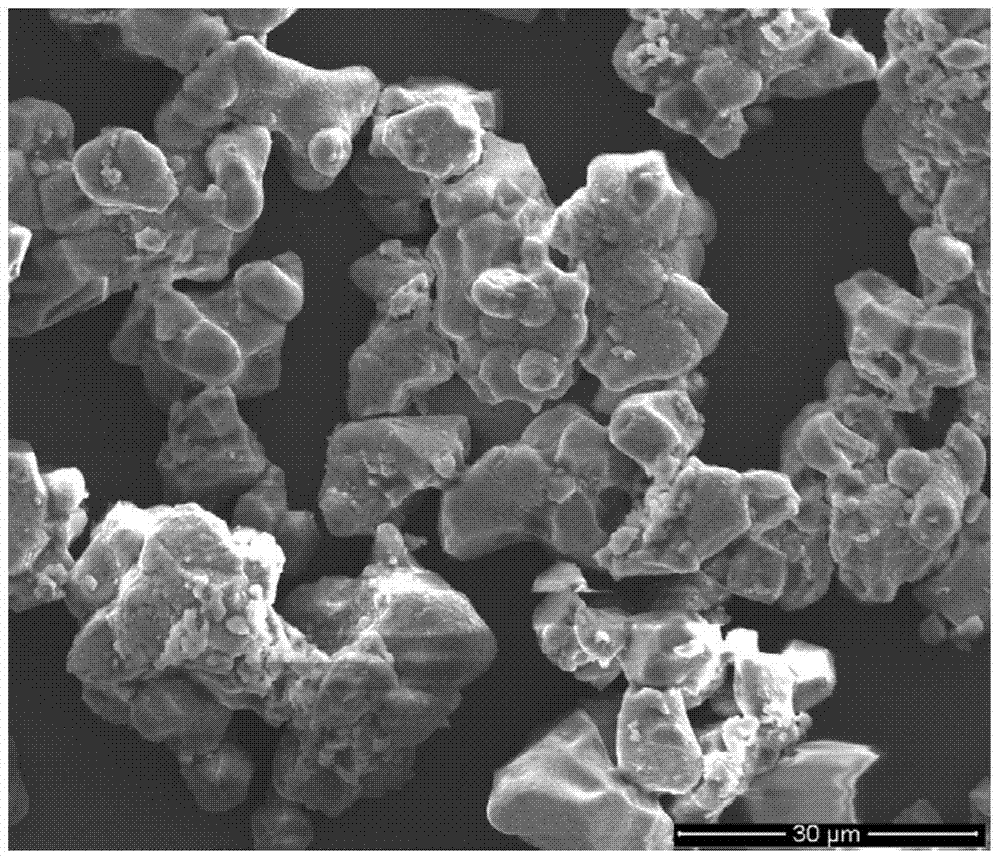

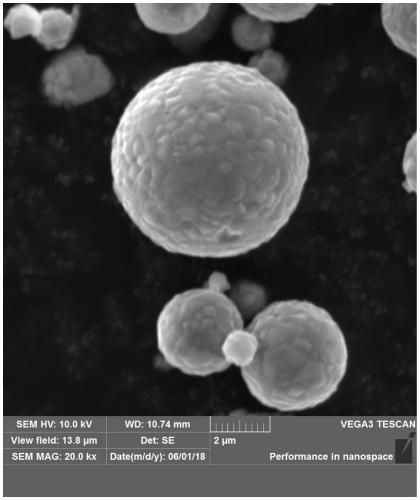

Method for preparing lithium titanate by spray drying-solid phase method

PendingCN110092413AHigh tap densityIncrease the degree of diffusionAlkali titanatesCell electrodesMicro nanoLithium

The invention discloses a method for preparing lithium titanate by a spray drying-solid phase method, the method comprises the following steps: (1) weighing a titanium source, adding ammonia water, preparing metatitanic acid under a first reaction condition, adding concentrated nitric acid, and ultrasonically preparing a titanium oxynitrate clear solution; (2) weighing a lithium source, adding a dispersant and deionized water, and stirring to obtain a first solution; (3) mixing the titanium oxynitrate clear solution with the first solution, and then drying with a spray drier to obtain precursor powder; and (4) roasting and cooling the precursor powder to prepare the lithium titanate. According to the method, the lithium titanate is prepared by a method spray drying and solid phase combinedmethod, and the prepared lithium titanate is uniform and non-heterogenous micro-nano spherical lithium titanate particles, and the lithium titanate particles have high diffusion degree, good chemicaluniformity, atomic-level uniform distribution and high tap density. The lithium titanate can slow down the polarization of a electrode and increase the contact area between an electrode material andan electrolyte.

Owner:CHINA TOBACCO YUNNAN IND

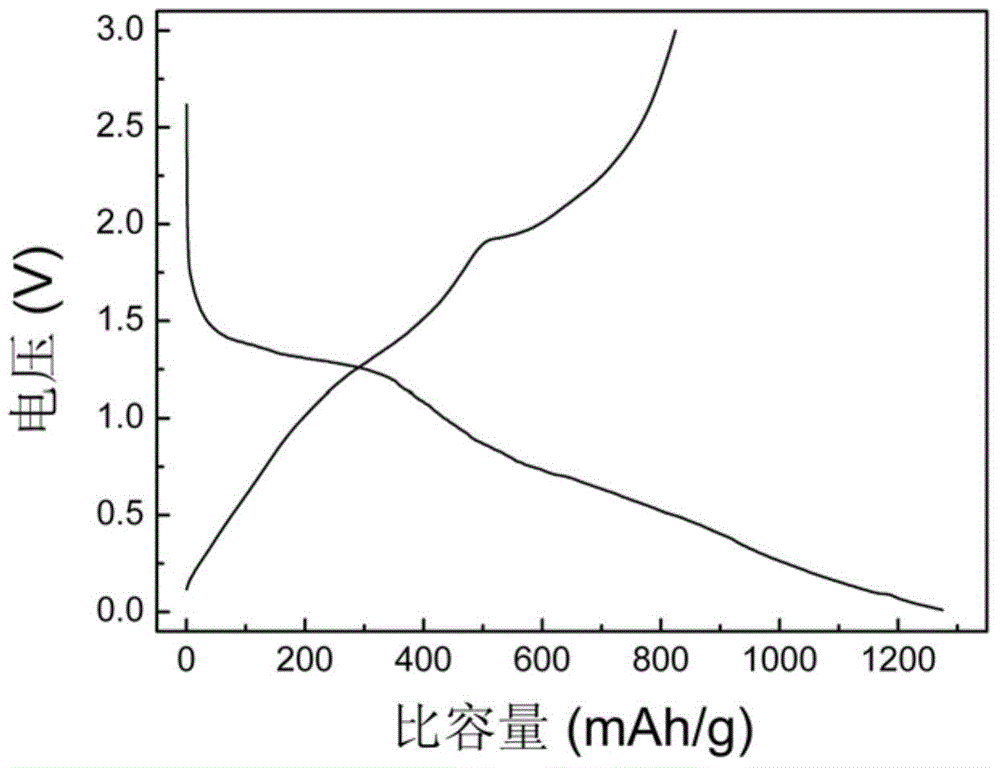

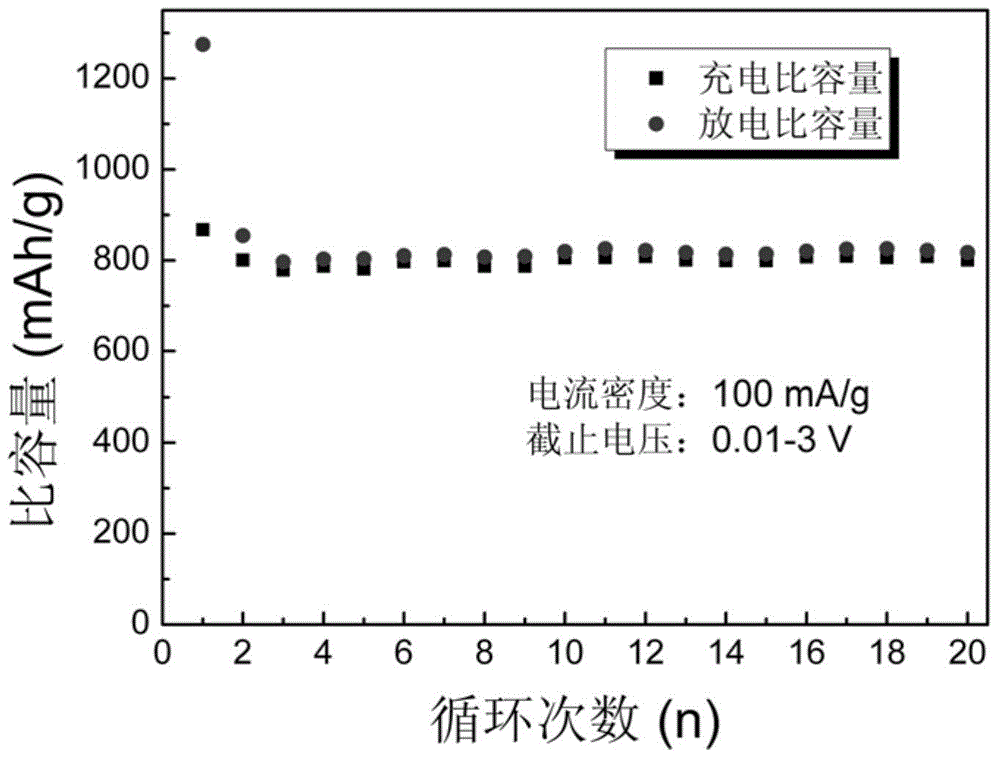

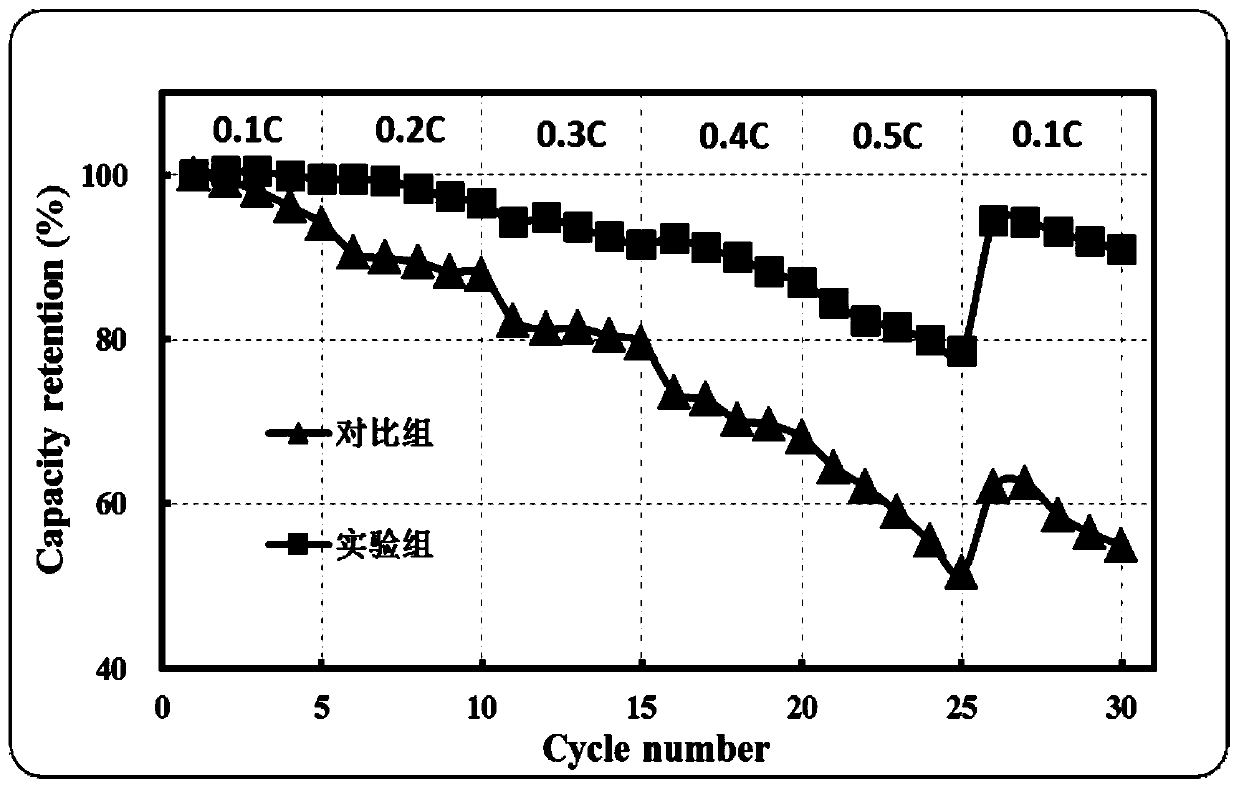

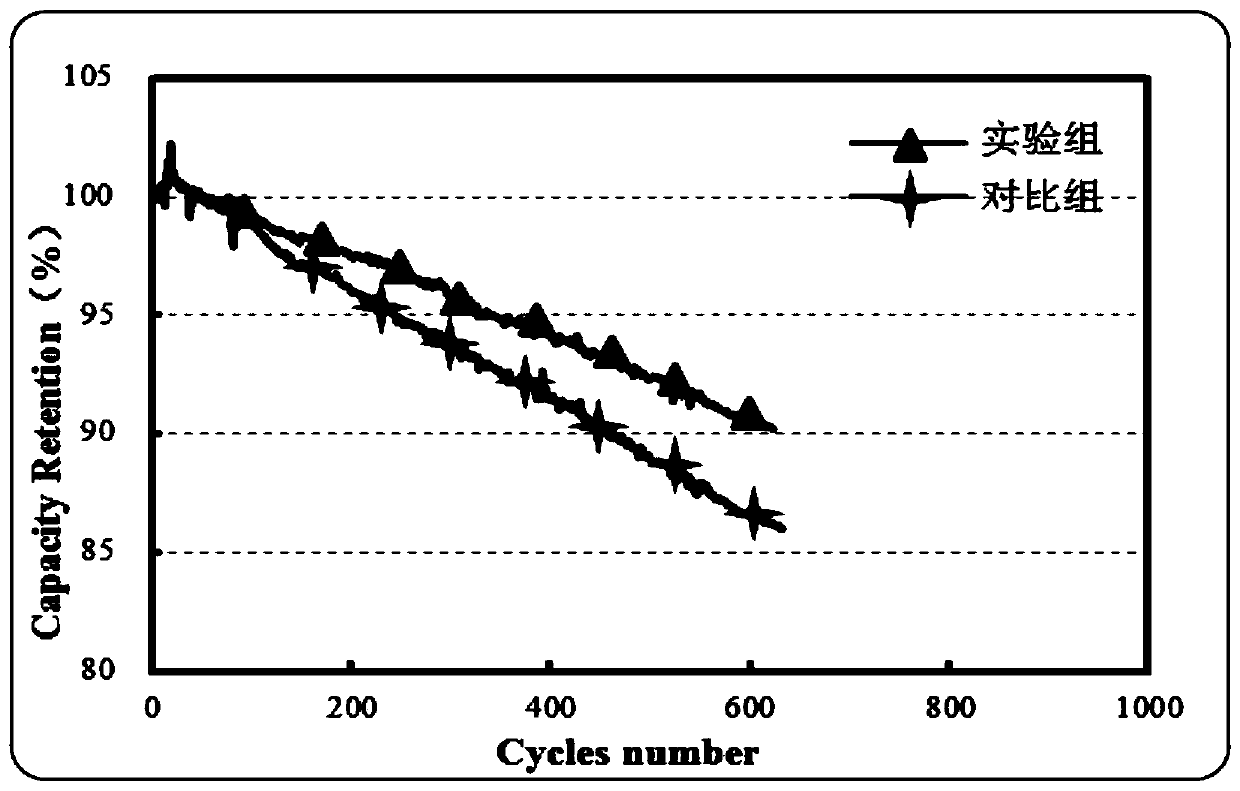

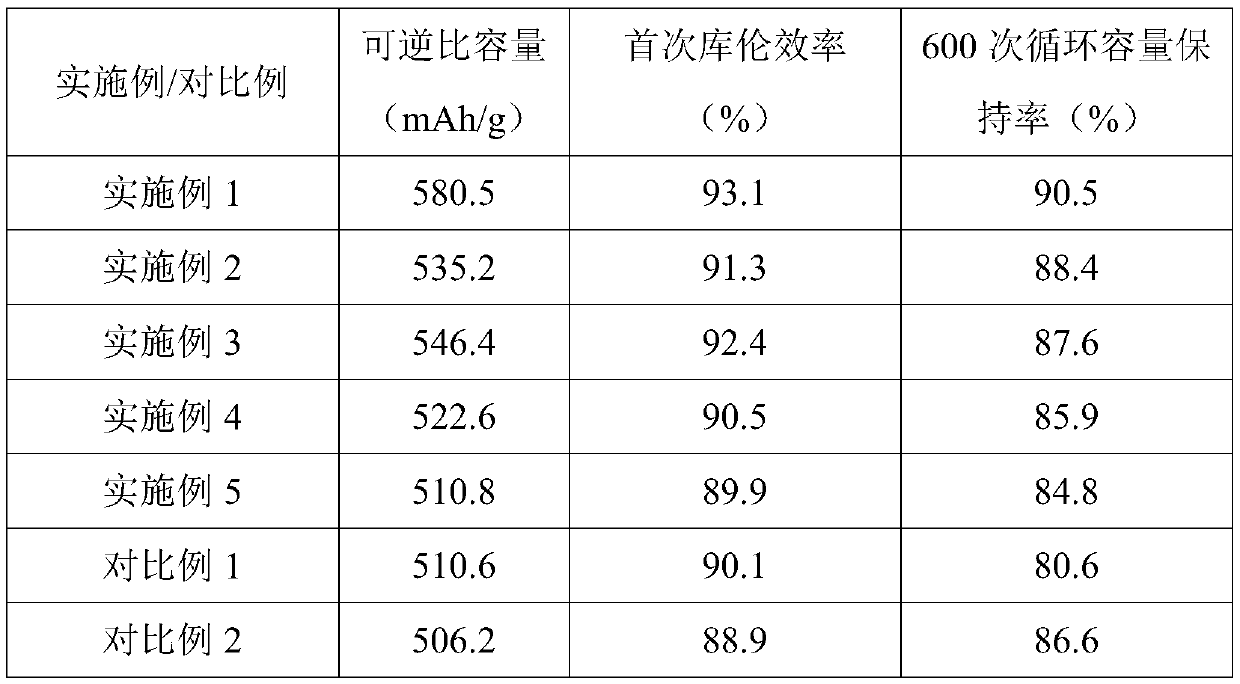

Zinc oxide/nickel composite micron rod electrode material and preparation method thereof

ActiveCN109301221ASpeed up the responseImprove electrochemical activityMaterial nanotechnologyCell electrodesEthylenediamineZinc nitrate

The invention discloses a zinc oxide / nickel composite micron rod electrode material and a preparation method thereof. The method includes, preparing a precursor by taking a mixed solution of zinc nitrate, nickel nitrate and ethylenediamine as a raw material through a homogeneous precipitation method; and then calcining the precursor in a hydrogen argon mixed reduction atmosphere to prepare the zinc oxide / nickel composite micron rod material. The material has the advantages of high initial coulomb efficiency, high reversible capacity, good cycle stability and the like when the material is usedas a lithium ion battery cathode material.

Owner:TAIZHOU UNIV

Method for preparing conductive carbon film-coated calcium or calcium-tin alloy serving as anode material of lithium battery

InactiveCN102082263AIncrease speed capacityUniform thicknessCell electrodesLi-accumulatorsCarbon filmPolyethylene glycol

The invention relates to a method for preparing an anode material of a lithium battery and aims to provide a method for preparing a conductive carbon film-coated calcium or calcium-tin alloy serving as the anode material of the lithium battery. The method comprises the following steps of: melting high-purity calcium metal or calcium metal and tin metal, spraying into polyethylene glycol liquid byusing high purity argon, and cooling fog drops in the polyethylene glycol liquid to obtain spherical powder; carbonizing polyethylene glycol to obtain a carbon coated calcium material; filtering out the carbon coated calcium material; calcining again in vacuum or high purity nitrogen atmosphere at the temperature of below 700 DEG C; further carbonizing to remove residual polyethylene glycol on the carbon coated calcium material; and cooling to obtain the conductive carbon film-coated calcium serving as the anode material for preparing the lithium battery. A conductive carbon film is formed onthe surfaces of the calcium or calcium-tin alloy particles and is favorable for the stability of an electrode structure. A gas spraying method for preparing the carbon coated material is favorable for scale production and cost reduction.

Owner:ZHEJIANG UNIV

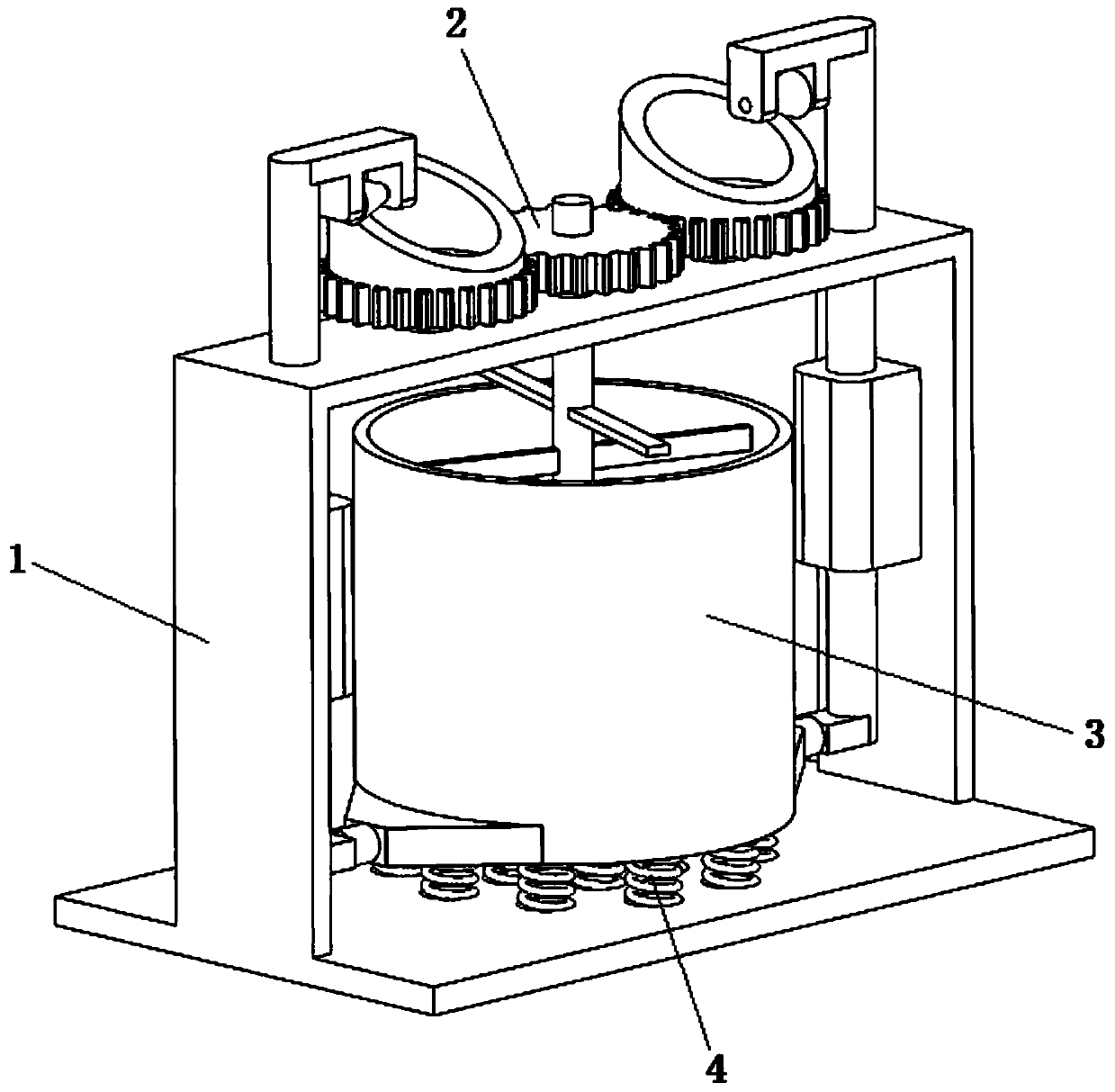

Efficient production technology of lithium battery negative electrode slurry

ActiveCN109841792AEvenly dispersedImprove conductivityShaking/oscillating/vibrating mixersElectrode manufacturing processesCarboxymethyl cellulosePolymer science

The invention discloses an efficient production technology of lithium battery negative electrode slurry, which includes the following steps: S1, weighing and taking graphite, modified carbon nanotubes, sodium carboxymethyl cellulose and styrene-butadiene rubber according to the mass ratio of 95:3:1:1; S2, adding ultra-pure water into a homogeneous material barrel, and adding sodium carboxymethyl cellulose at a mass concentration of 1% into the ultra-pure water and carrying out homogenization for 9-10h; S3, continuing to add graphite and modified carbon nanotubes into the homogeneous material barrel; and S4, adding styrene-butadiene rubber into the homogeneous material barrel. According to the invention, sodium carboxymethyl cellulose is added to the negative electrode slurry to aid the dispersion of graphite particles, modified carbon nanotubes are used as a conductive agent of the negative electrode slurry, and a specific homogenizing treatment device is used to homogenize the raw materials step by step. Therefore, the slurry obtained has good homogeneity and stability, the processing efficiency is high, the processing process is easy to control and manage, and the production efficiency is greatly improved.

Owner:上海玖银电子科技有限公司

Lead-carbon composite material, and preparation method and application thereof

ActiveCN103943859AFix production issuesGood capacitance characteristicsHybrid capacitor electrodesCell electrodesCarbon compositesCarbonization

The invention discloses a lead-carbon composite material, and a preparation method and an application thereof. The preparation method comprises the following steps: processing an organic carbon source to prepare a solution, adding lead powder, grinding, uniformly mixing, and drying to obtain mixed powder; and adding concentrated sulfuric acid to the mixed powder under stirring, allowing the obtained solution to stand for carbonization for a period of time, washing, and drying to prepare the lead-carbon composite material, wherein the mass fractions of carbon and lead in the lead-carbon composite material are 0.1-25% and 75-99.9% respectively. The invention also discloses the lead-carbon composite material prepared through the preparation method, and the application of the composite material. The method has the advantages of simplicity, low cost and low energy consumption, and lead carbon batteries made by using the composite material have substantially longer heavy current charge and discharge life and higher mass specific power than present lead acid storage batteries.

Owner:TIANNENG BATTERY GROUP +1

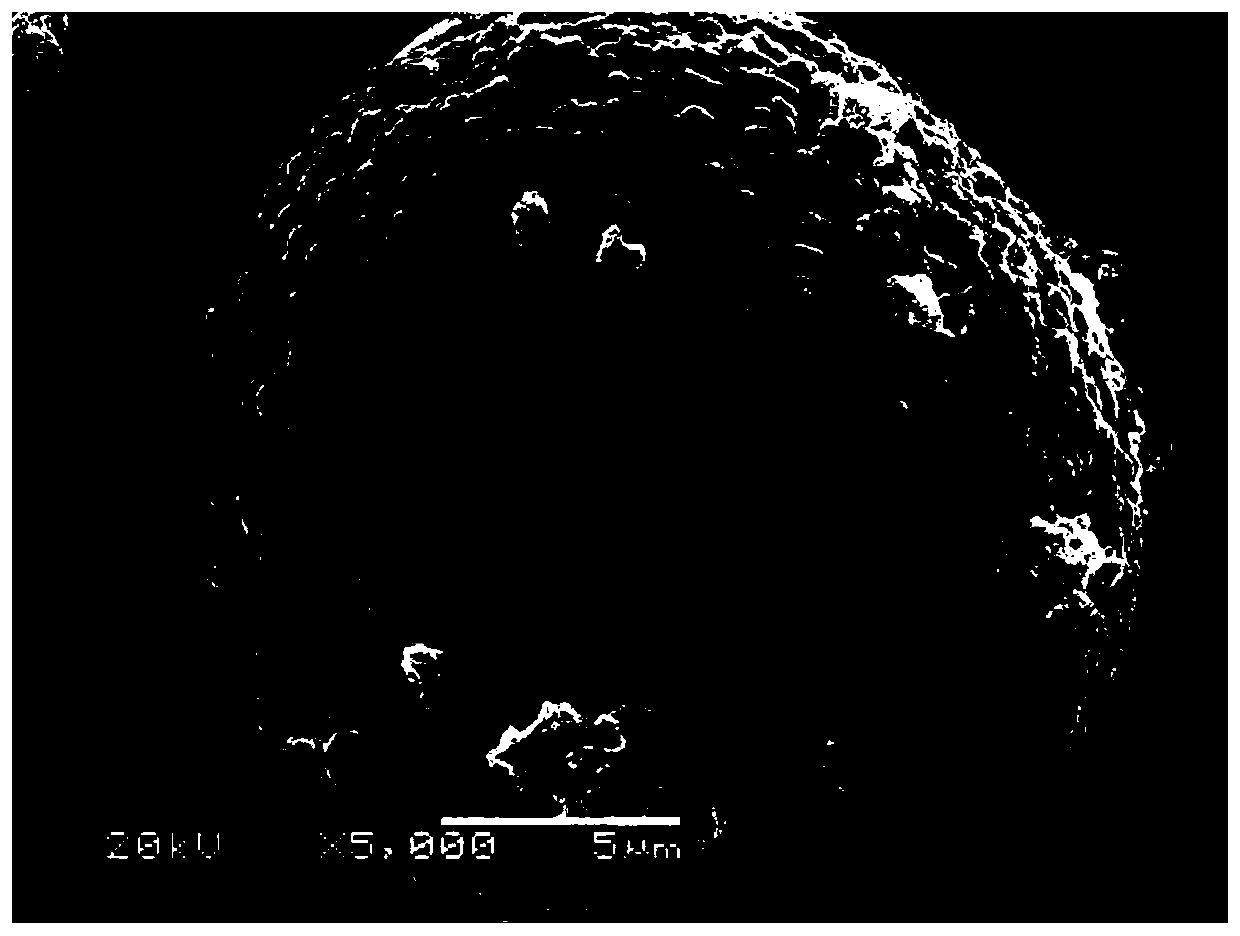

Preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material

InactiveCN103311512AIncrease speed capacityImprove reliabilityCell electrodesSecondary cellsModified carbonHeat stability

The invention relates to the technology of batteries, and aims at providing a preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material. The method comprises the following steps: reacting carbon source material, deionized water and spherical aluminum powder at the temperature of 250 DEG C, and performing centrifugal separation to obtain a brown or black solid powder sample; washing, performing centrifugal separation, drying, and then carbonizing at a constant temperature in nitrogen; performing acid treatment or alkaline treatment after cooling; washing and performing vacuum drying after filtering so as to obtain hollow carbon spheres; reacting the hollow carbon spheres, indole and transition metals at the temperature of 100-300 DEG C, performing vacuum drying after filtering and washing so as to obtain hollow carbon spheres modified by indole and transition metals; grinding and mixing with elemental sulfur, placing in a reactor, vacuumizing and heating to complete sulfur storage process through reactions, and cooling to room temperature. Organic electrolytes are safe in the application of battery; the anode material has good electrode reaction reversibility and good chemical stability and heat stability, and is low in cost, easy to prepare and free from pollution.

Owner:ZHEJIANG UNIV

Preparation method of nano-network conductive polymer coated lithium iron phosphate anode material

ActiveCN102185140BImprove cycle performanceFunction increaseCell electrodesIn situ polymerizationConductive polymer

Owner:ZHONGKE LITHIUM BATTERY NEW ENERGY CO LTD

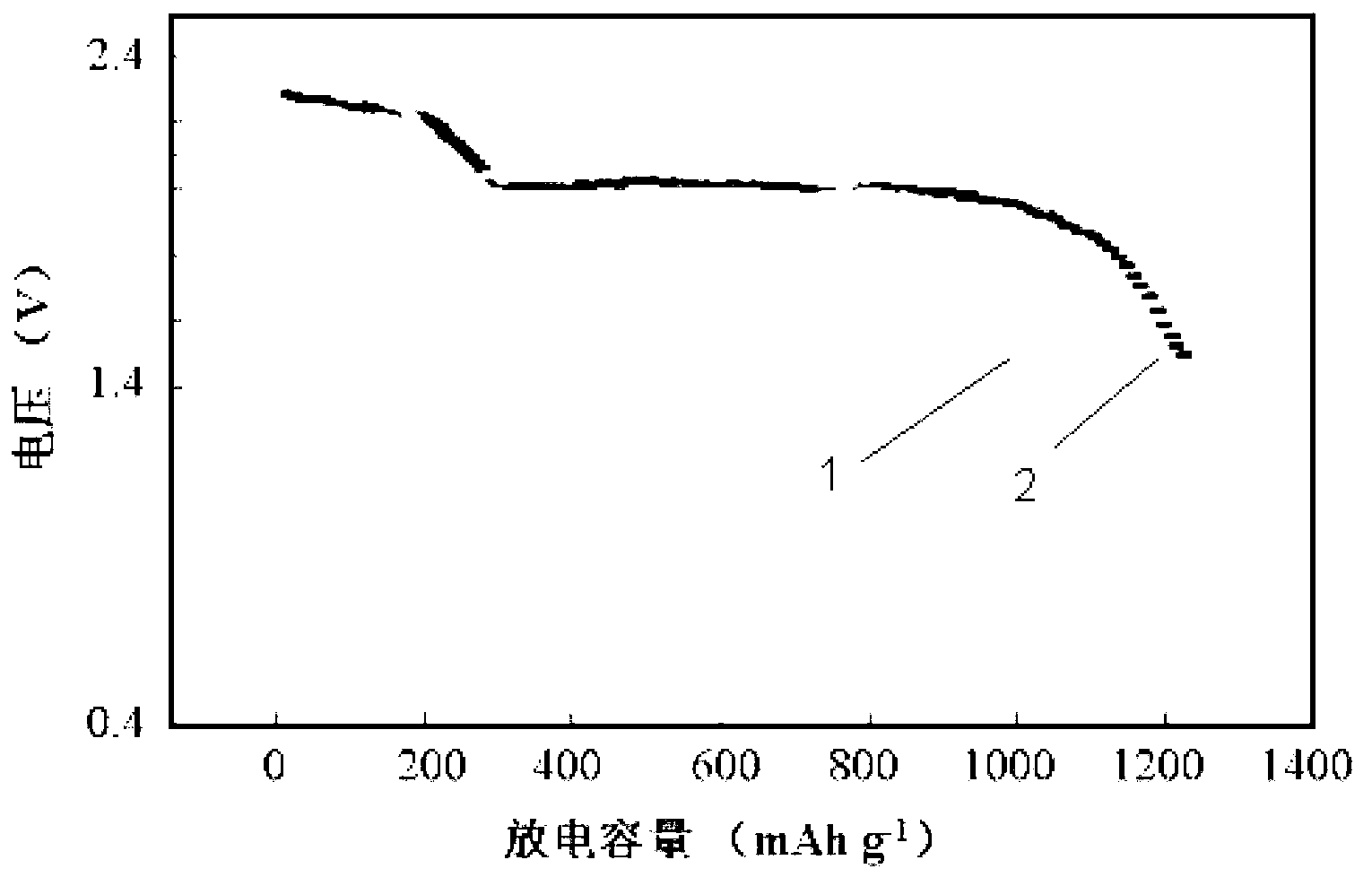

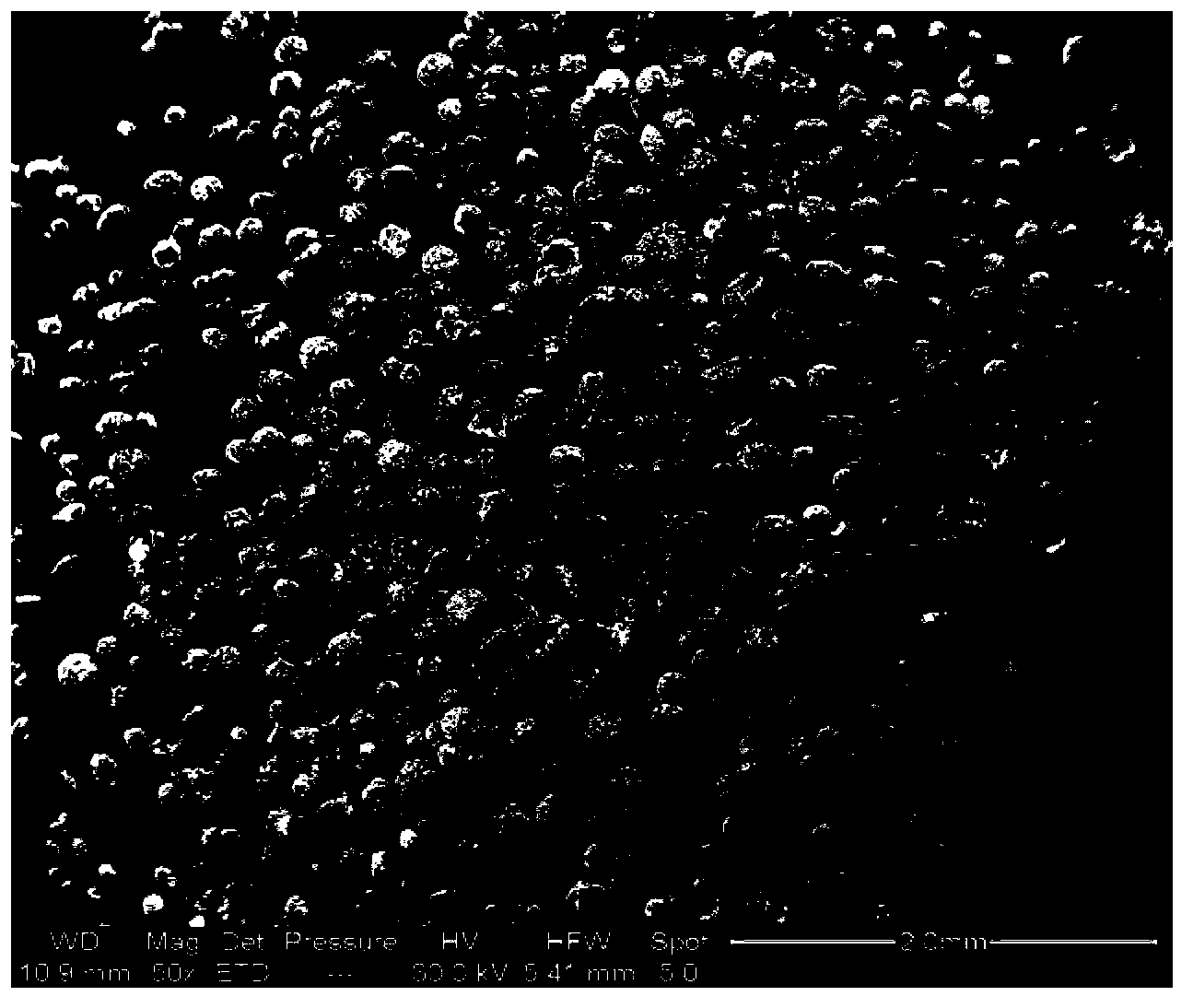

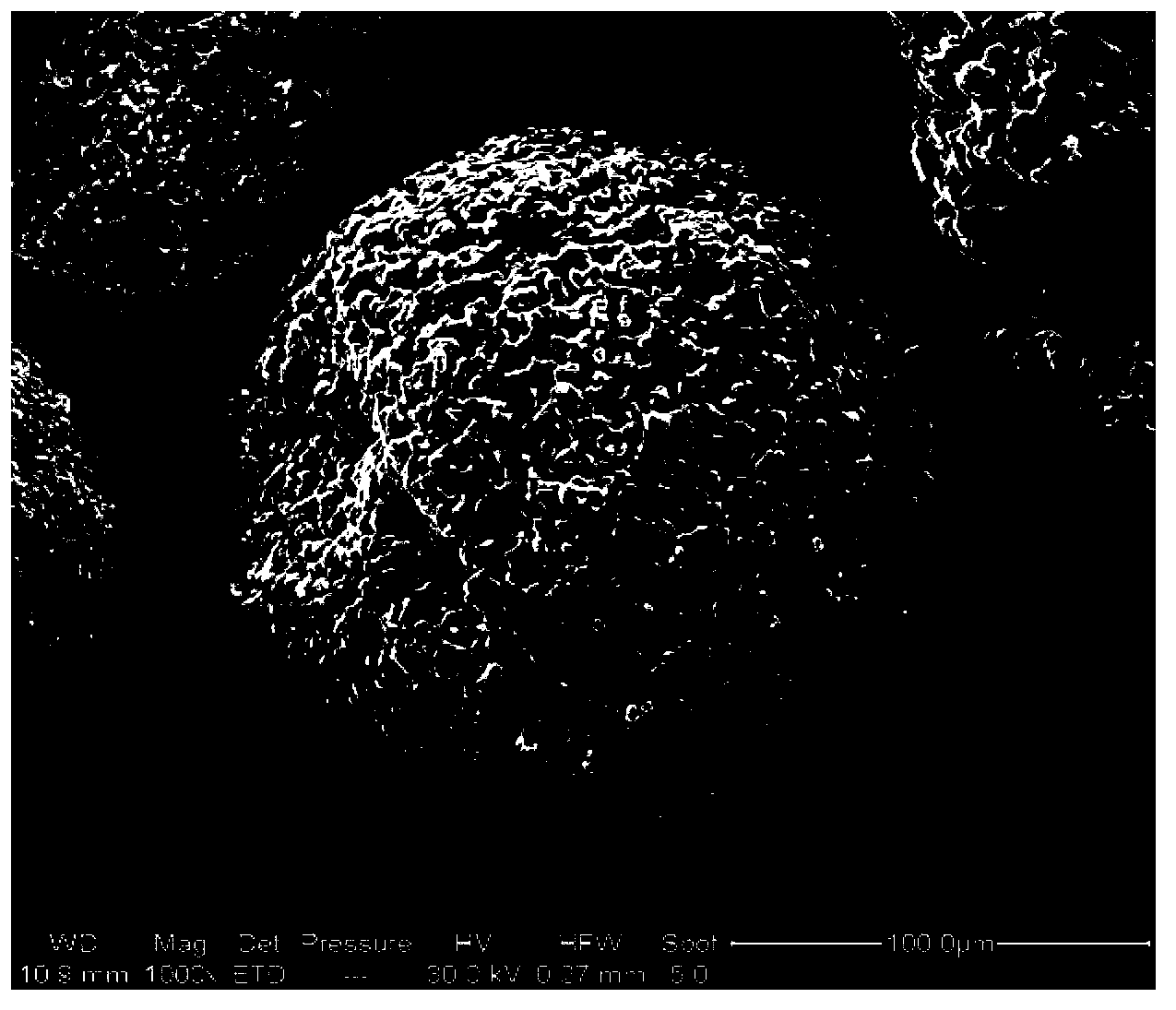

High-activity hollow-out silver powder and preparation method thereof

InactiveCN104096832AThe overall thickness is thinIncrease the effective reaction areaPorosityPower flow

The invention relates to high-activity hollow-out silver powder and a preparation method thereof and belongs to the field of preparation for high-activity silver powder. The silver powder particles are of hollow-out sphere-like shapes; the diameters of the particles are 35-150 micrometers; the specific area of the particles is not smaller than 25 square meters / gram. The silver powder disclosed by the invention is hollow-out sphere-like powder; in addition, a large quantity of nano holes exist in each particle; the inside of each particle is of a three-dimensional mesh structure; the holes are mutually communicated; by using a prepared silver oxide anode, the effective reaction area of the electrode can be effectively increased, the electric current density is reduced, further the polarization of the electrode is reduced and output performances (current and voltage) of a battery are improved; the voltage of the battery and the utilization rate of active substances are improved; in addition, under the condition that the porosity is ensured, compared with the traditional silver powder, the high-activity silver powder has the advantages that the thickness of the pressed silver oxide electrode is thinner under the condition of equal quantity, further the mass transfer efficiency is improved and the utilization rate of anode active substances is improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method for silicon-carbon negative electrode material doped with nickel-silver alloy particles

InactiveCN110797517AImprove first-time efficiencyImprove cycle performanceMaterial nanotechnologySecondary cellsNano siliconGraphite

The invention relates to the field of lithium batteries, and discloses a method of preparing a silicon-carbon negative electrode material by doping nickel-silver alloy particles, which comprises the following steps of: (1) carrying out ball milling on raw material micron-sized silicon powder to prepare nanoscale silicon powder, (2) mutual mixing of the nanoscale silicon powder and the nickel-silver alloy particles and adopting a solid-phase mixing method, (3) forming an amorphous carbon coating layer on the surfaces of the nano silicon powder and the nickel-silver alloy by adopting liquid-phase coating, (4) carrying out high-temperature sintering on the coating material in an inert gas protection furnace, (5) preparing a silicon-carbon material with proper granularity by adopting a mechanical ball milling method, and (6) mixing the silicon-carbon material and commercial graphite to prepare the silicon-carbon negative electrode material. According to the preparation method, the first coulombic efficiency and the cycle performance of the material are obviously improved, the process is simple, efficient and environmentally friendly, and large-scale production of the silicon-carbon negative electrode material is facilitated.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

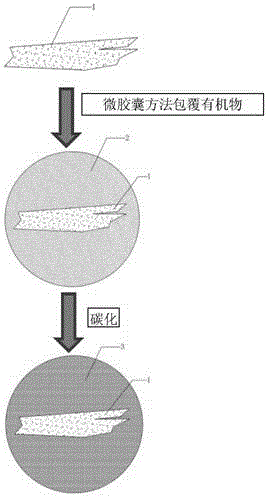

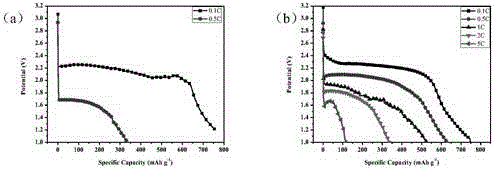

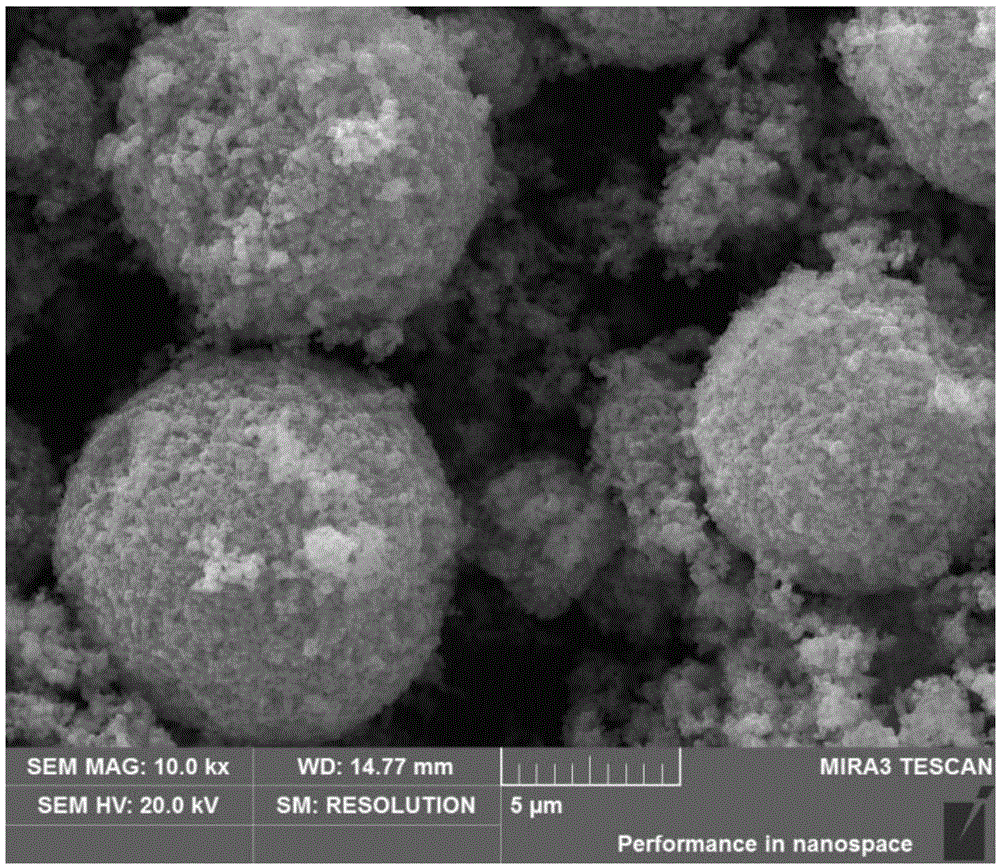

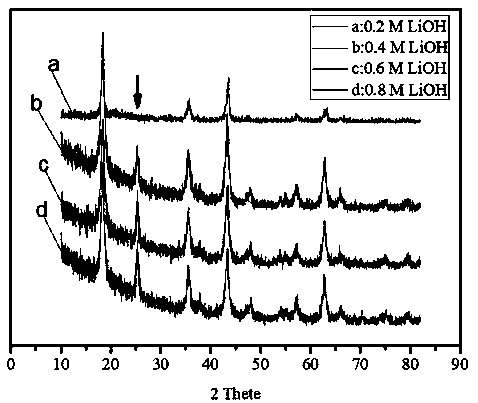

Microencapsulated carbon-coated carbon fluoride cathode material and preparation method thereof

InactiveCN105161681AImprove conductivityNot easy to reuniteCell electrodesPrimary cellsCarbonizationOrganic matter

The invention discloses a microencapsulated carbon-coated carbon fluoride cathode material and a preparation method thereof. The cathode material is formed by coating the surfaces of carbon fluoride particles with a layer of carbon. The preparation method comprises the following steps: firstly coating the surfaces of carbon fluoride particles with a layer of an organic matter to prepare carbon fluoride microcapsule particles by microencapsulation technologies such as an interfacial polymerization method and a complex coacervation method; and then preparing the carbon-coated carbon fluoride cathode material by a high-temperature carbonization or concentrated sulfuric acid carbonization technology. The carbon-coated carbon fluoride cathode material prepared by the method is uniform in particles and good in conductivity; particle agglomeration can be avoided; the battery discharge voltage can be improved; and the rate discharge property is improved.

Owner:XIANGTAN UNIV

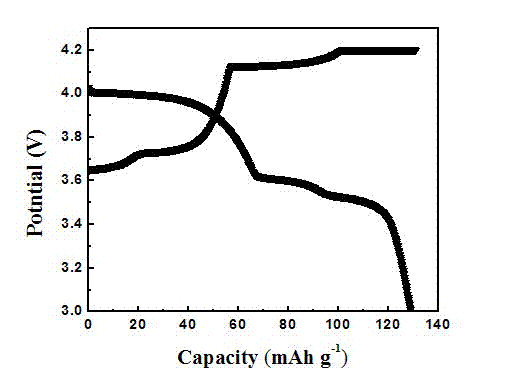

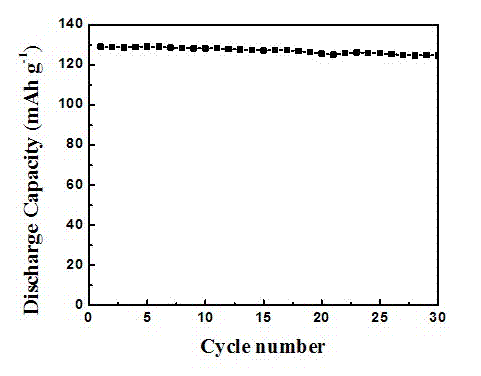

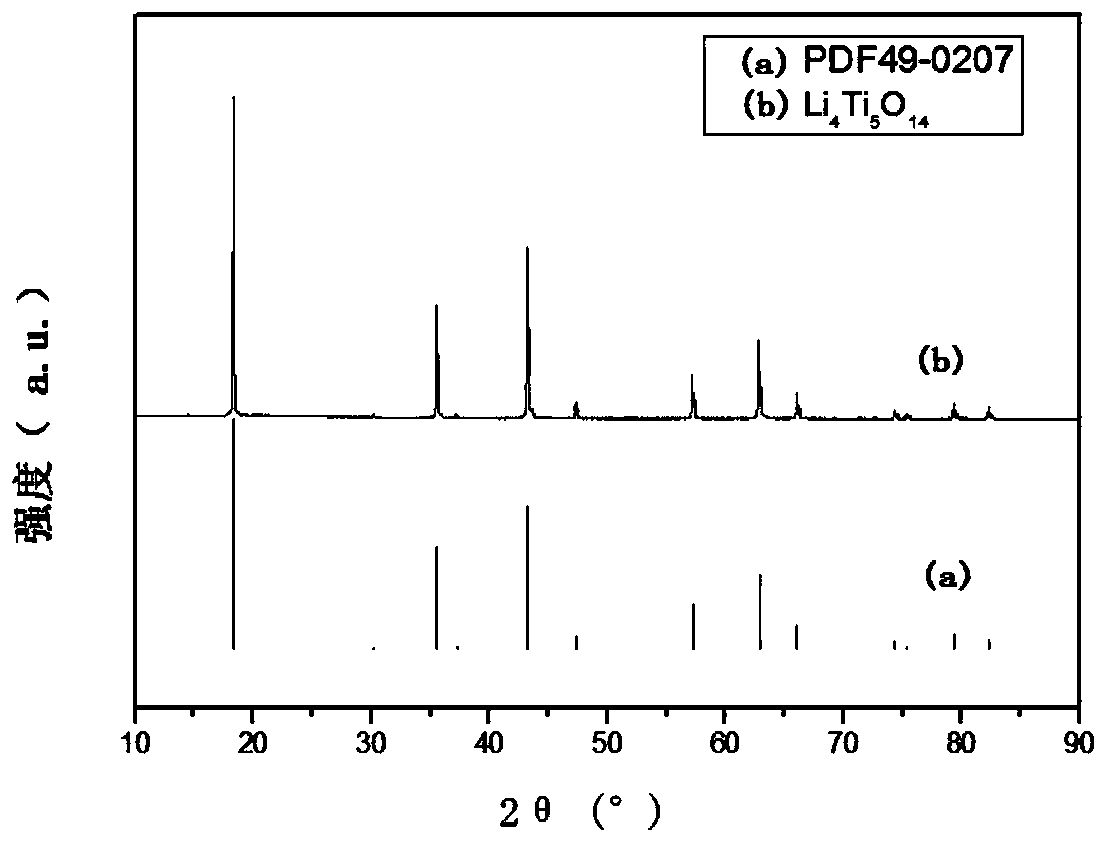

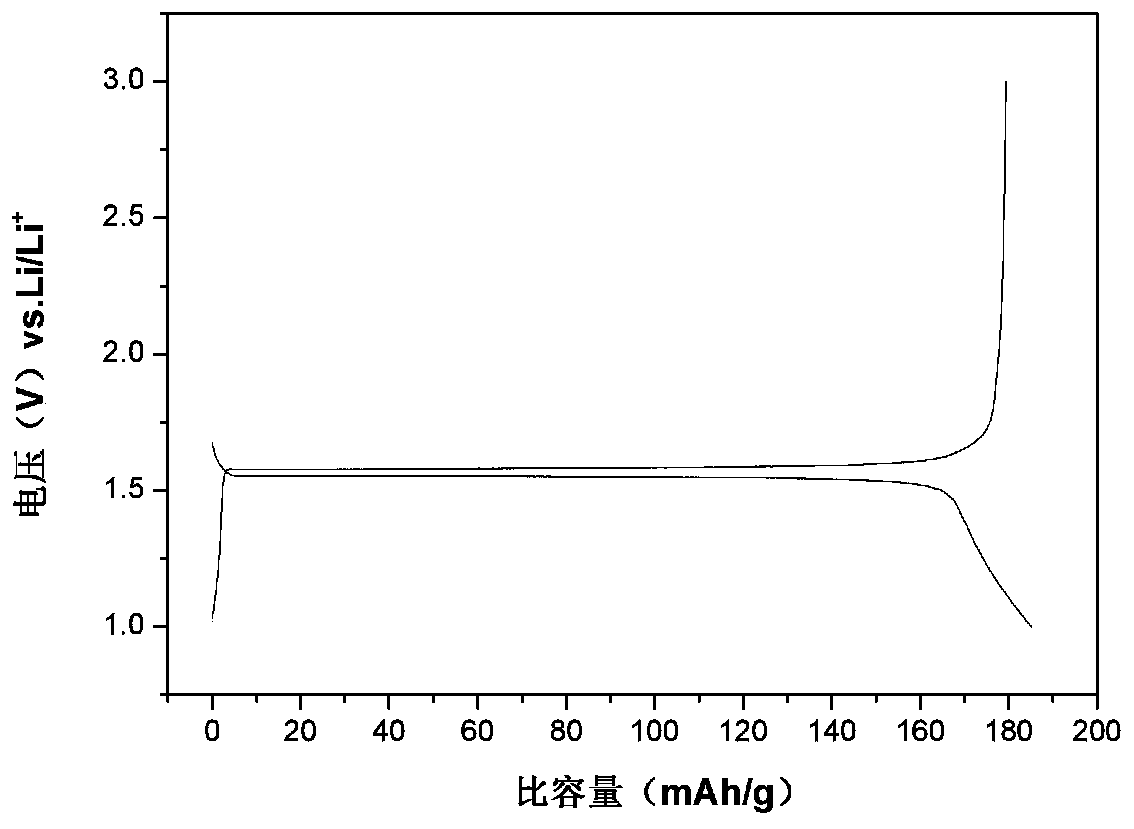

Lithium-ion battery Li4Ti5O12 and TiO2 complex phase electrode material and preparation method thereof

InactiveCN108666557AQuick migrationReduce electrode polarizationMaterial nanotechnologyCell electrodesEngineeringLithium-ion battery

The invention discloses a lithium-ion battery Li4Ti5O12 and TiO2 complex phase electrode material which comprises tetrabutyl titanate, NaOH and HCl. According to the lithium-ion battery Li4Ti5O12 andTiO2 complex phase electrode material prepared in the invention, the Li4Ti5O12 can achieve a buffering effect during high current discharge, and the TiO2 achieves a buffering effect during high current discharge, so that polarization of electrodes is reduced, and the capacity is improved. Different from a single-phase material and a general mixed electrode material for simply physically mixing twoactive materials, the lithium-ion battery Li4Ti5O12 and TiO2 complex phase electrode material disclosed by the invention has the advantages that due to an in-situ reaction method, Li4Ti5O12 grains and TiO2 grains in the prepared complex phase material are tightly connected by virtue of semi-coherent or non-coherent boundaries, so that lithium ions can rapidly migrate between the two materials inthe charge and discharge process, and the synergistic effect is well achieved.

Owner:陕西动力越源科技有限公司

Preparation method of ZnO/C nano composite microsphere material with capsule structure

InactiveCN111261866AImprove cycle stabilitySolve the problem of pulverization failureNegative electrodesSecondary cellsAir atmosphereMicrosphere

The invention discloses a preparation method and application of a ZnO / C nano composite microsphere material with a capsule structure. The method comprises the steps of heating a mixed aqueous solutionof zinc chloride, resorcinol, formaldehyde and hydrochloric acid in a water bath to react to generate gel, fully drying the gel, calcining in an air atmosphere, and carbonizing in an argon atmosphereto obtain a product. When the ZnO / C nano composite microsphere material with the capsule structure is used as a negative electrode material of a lithium ion battery, the capsule microsphere structurecan effectively inhibit pulverization failure of a ZnO active material, reduce the generation of a solid electrolyte interface (SEI) film and improve the electrode reaction kinetic performance, thereby improving the cycling stability, Coulombic efficiency and high-rate capacity of the material.

Owner:TAIZHOU UNIV

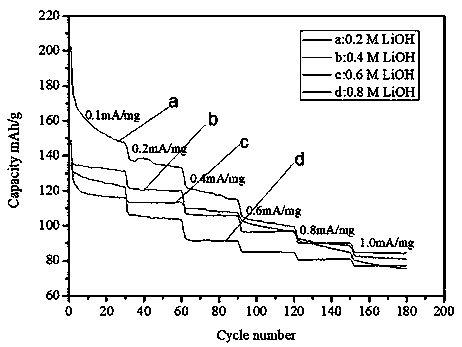

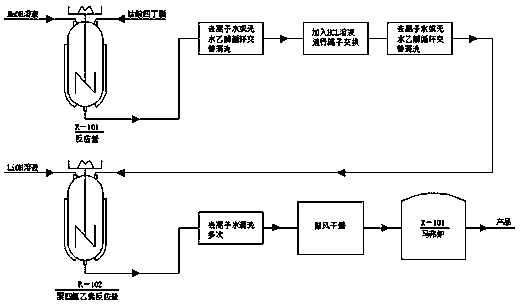

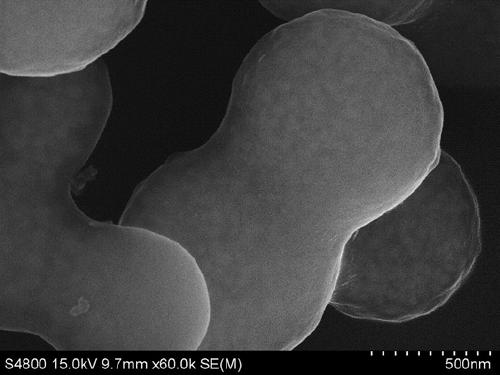

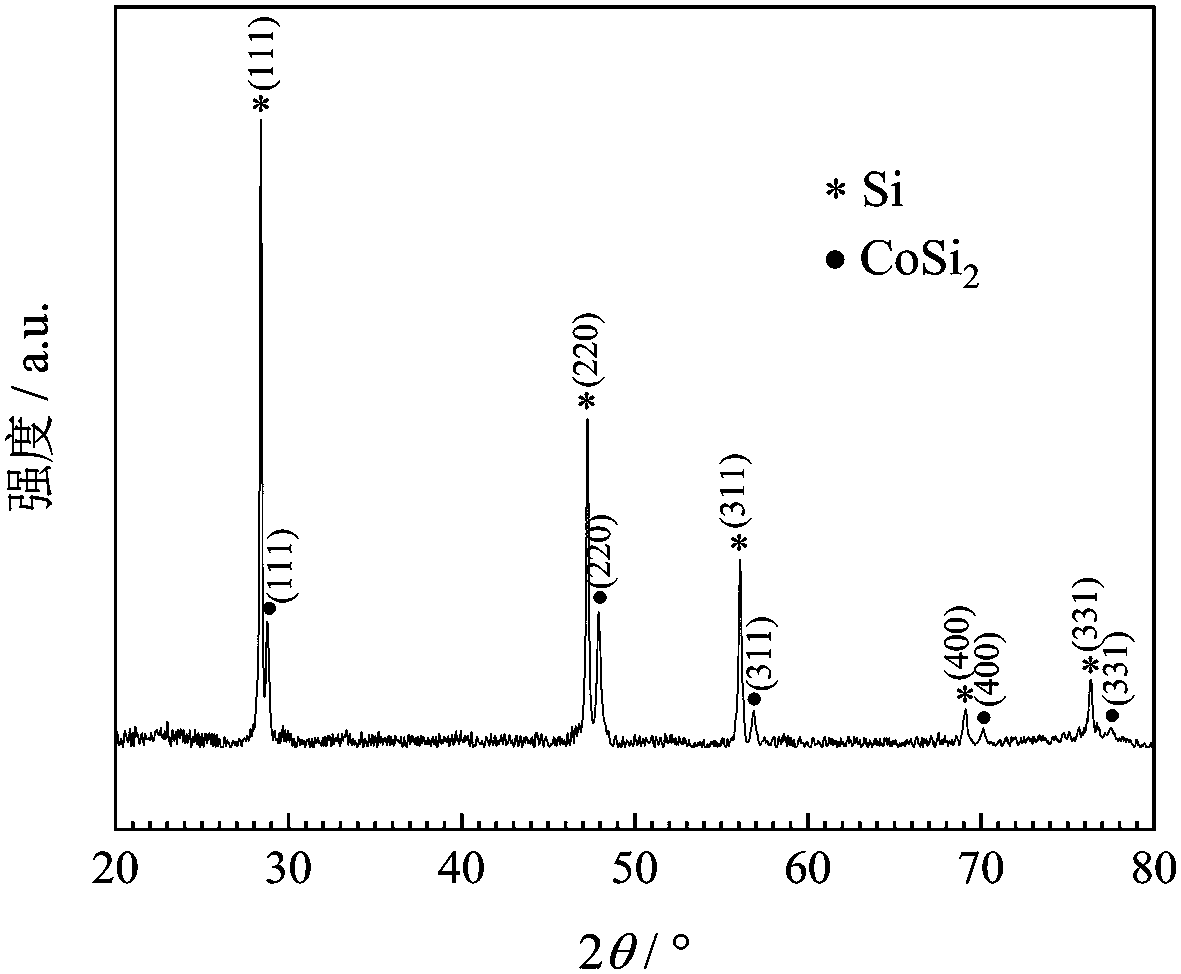

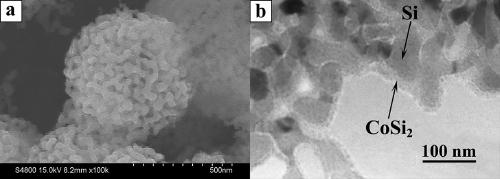

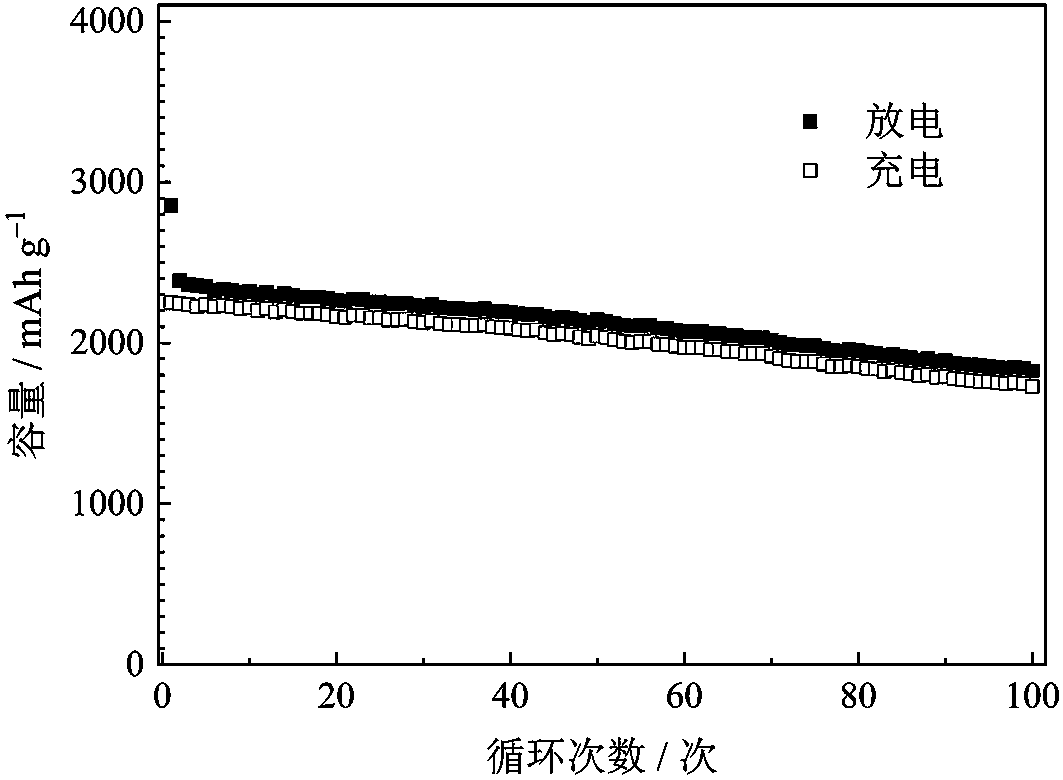

Mesoporous silicon/cobalt disilicide composite microsphere material as well as preparation method and application thereof

ActiveCN109987607ASolve reunionShorten the transmission distanceMaterial nanotechnologyCell electrodesHigh rateMicrosphere

The invention discloses a mesoporous silicon / cobalt disilicide composite microsphere material as well as a preparation method and application thereof. The method comprises the following steps: sequentially adding ammonia water and an ethyl orthosilicate ethanol solution into a cobalt nitrate ethanol solution under stirring to prepare a precursor, performing reduction on the obtained precursor by adopting a magnesiothermic process, and finally washing the reduced product by using hydrochloric acid. When the mesoporous silicon / cobalt disilicide composite microspheres provided by the invention are used for preparing a negative electrode material of a lithium ion battery, the cobalt disilicide component and the mesoporous structure of the composite microspheres facilitate suppressing materialpowdering and improving electrode reaction kinetics, so that the actual capacity, cycle performance and high rate performance of the material are effectively improved.

Owner:TAIZHOU UNIV

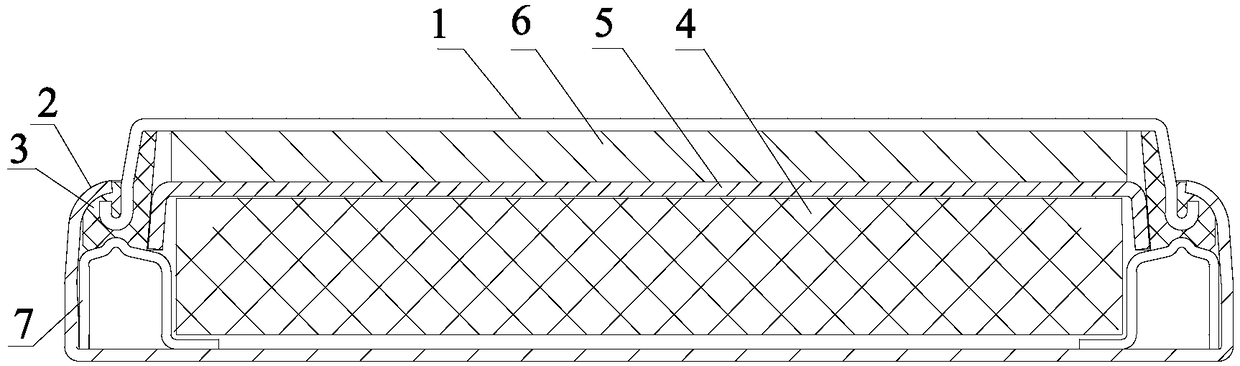

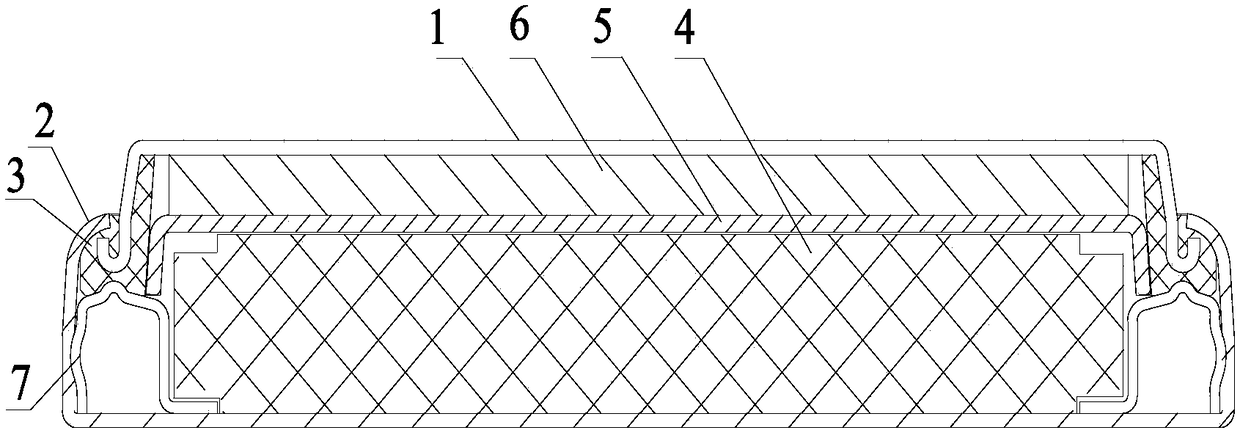

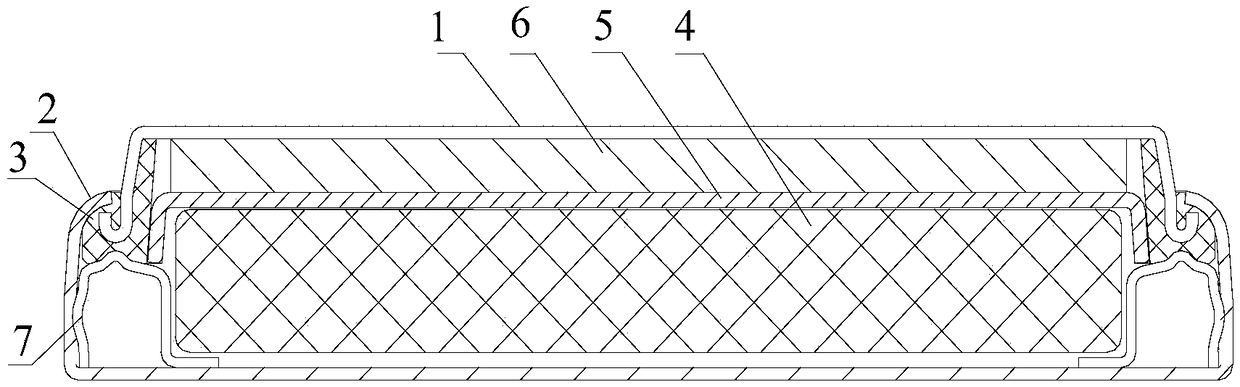

Button cell with base

PendingCN108550718ASave spaceReduce electrode polarizationCell sealing materialsOperating temperature rangeEngineering

The invention discloses a button cell with a base. The button cell with the base comprises a negative electrode cover, a positive electrode shell, a sealing ring, a positive electrode, a diaphragm, anegative electrode and electrolyte; the sealing ring is in sealed connection with the negative electrode cover and the positive electrode shell; furthermore, the negative electrode cover and the positive electrode shell form a sealing cavity; the positive electrode, the diaphragm, the negative electrode and the electrolyte are arranged in the sealing cavity; the button cell further comprises an energy gathering ring arranged in the positive electrode shell; the energy gathering ring comprises an outer annular wall, an inner annular wall and a top wall used for connecting the outer annular wallto the inner annular wall; the outer annular wall, the inner annular wall and the top wall form an annular cavity; the top wall and the sealing ring are in abutting joint; a first through hole, through which electrolyte and / or gas go / goes in and out, is arranged on the annular cavity; and the positive electrode part is positioned in the inner ring of the energy gathering ring. According to the button cell with the base, because the energy gathering ring with the annular cavity is arranged, the capacity and the discharging power of the cell are improved; the working temperature range is expanded; the global stability, the storage property, the consistency and the leakproof property of the cell are improved; and the service life of the cell is prolonged.

Owner:YICHANG LIJIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com