Microencapsulated carbon-coated carbon fluoride cathode material and preparation method thereof

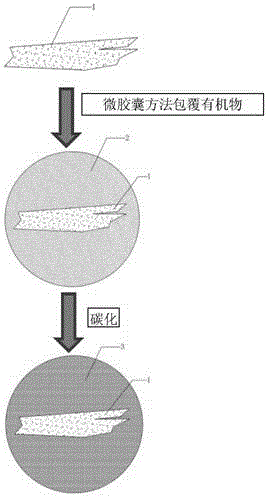

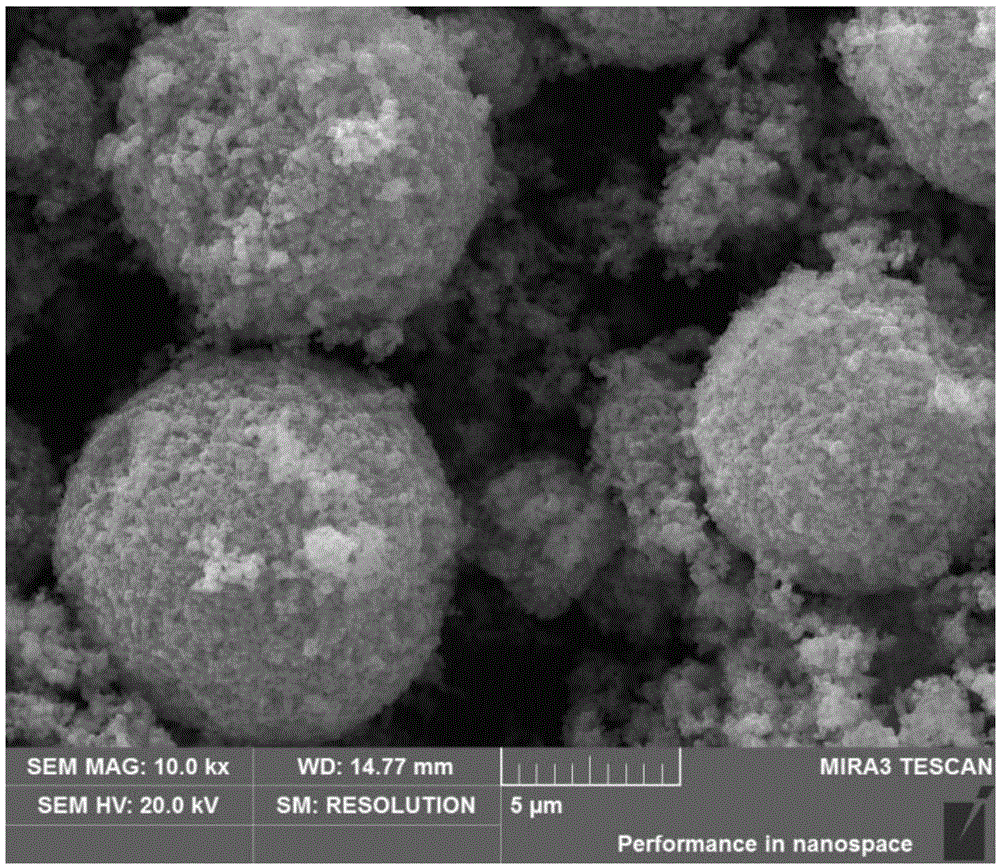

A technology of carbon fluoride coating and microencapsulation, which is applied in the direction of battery electrodes, primary batteries, electrochemical generators, etc., can solve the problems of reduced specific surface area, easy aggregation of particles, and influence on the power density of electrode materials and the utilization rate of active materials. , to achieve the effect of large specific surface area, not easy to agglomerate, and conducive to electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

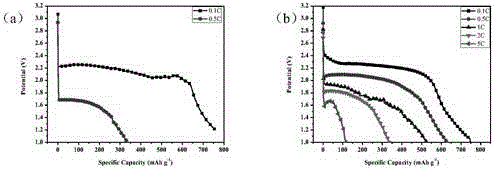

Embodiment 1

[0027] Take fluorinated graphite with a fluorine-to-carbon ratio of 1.0, with a particle size of 5-10μm, and use interfacial polymerization to coat it with microencapsulated carbon. The specific process is:

[0028] First use the interfacial polymerization method to coat a layer of polyurea on the surface of the fluorocarbon. The specific process is as follows:

[0029] (1) Mixed

[0030] Add 0.1 g of surfactant alkylphenol polyoxyethylene ether (OP-10) into 100 mL of distilled water, and stir evenly with a glass rod. Add 2g of fluorinated graphite and stir until the mixture is uniform.

[0031] (2) Emulsification

[0032] Weigh 2 g of isophorone diisocyanate (IPDI) into the solution of step (1), stir with a high-speed stirrer under 2000 rpm stirring conditions for 15 minutes to form an oil / water mixed phase emulsion.

[0033] (3) Aggregation

[0034] Place the solution of step (2) in a constant temperature water bath at 40° C., with a stirring speed of 500 rpm, add 0.05 g of dibutyl tin...

Embodiment 2

[0044] Take fluorinated graphite with a fluorocarbon ratio of 1.0, and the particle size is 5-10μm.

[0045] Firstly, a layer of gum arabic-gelatin is coated on the surface of carbon fluoride by complex coacervation method. The specific process is:

[0046] (1) Configuration solution

[0047] Add 1g of gelatin and 1g of gum arabic into 100mL of distilled water, add 0.1g of OP-10 surfactant and 0.1g of polyvinyl alcohol (PVA) as surfactants, stir evenly, stir evenly and adjust the pH to 8.0; then add 4g of fluorocarbon Add to the solution and stir until well mixed.

[0048] (2) Emulsification

[0049] The solution prepared in step (1) is placed in a constant temperature water bath at 50° C. and stirred at 600 rpm for 15 minutes to form a microemulsion.

[0050] (3) Crosslinking and curing

[0051] The solution of step (2) was gradually adjusted to pH 4.7 with 5% mass fraction of acetic acid solution within 30 minutes, and reacted for 1 hour; then the temperature was reduced to 5°C, and 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com