Patents

Literature

709results about How to "Increase the reaction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

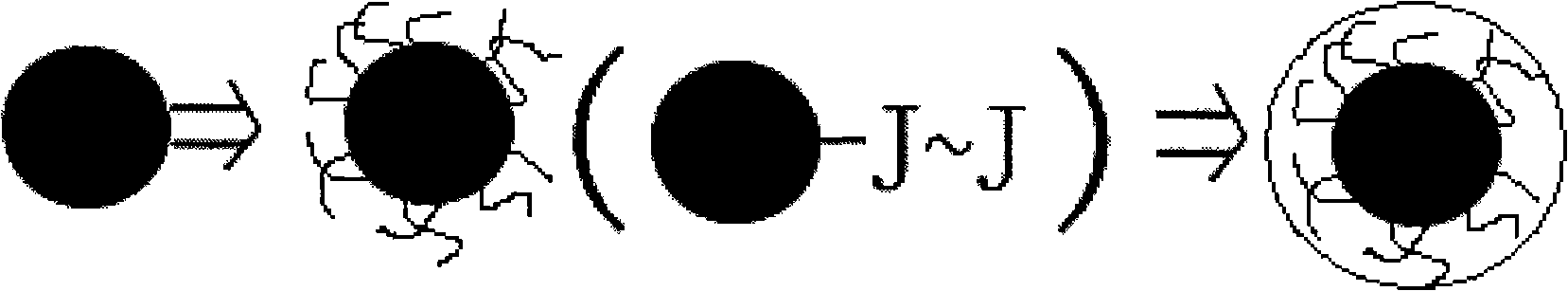

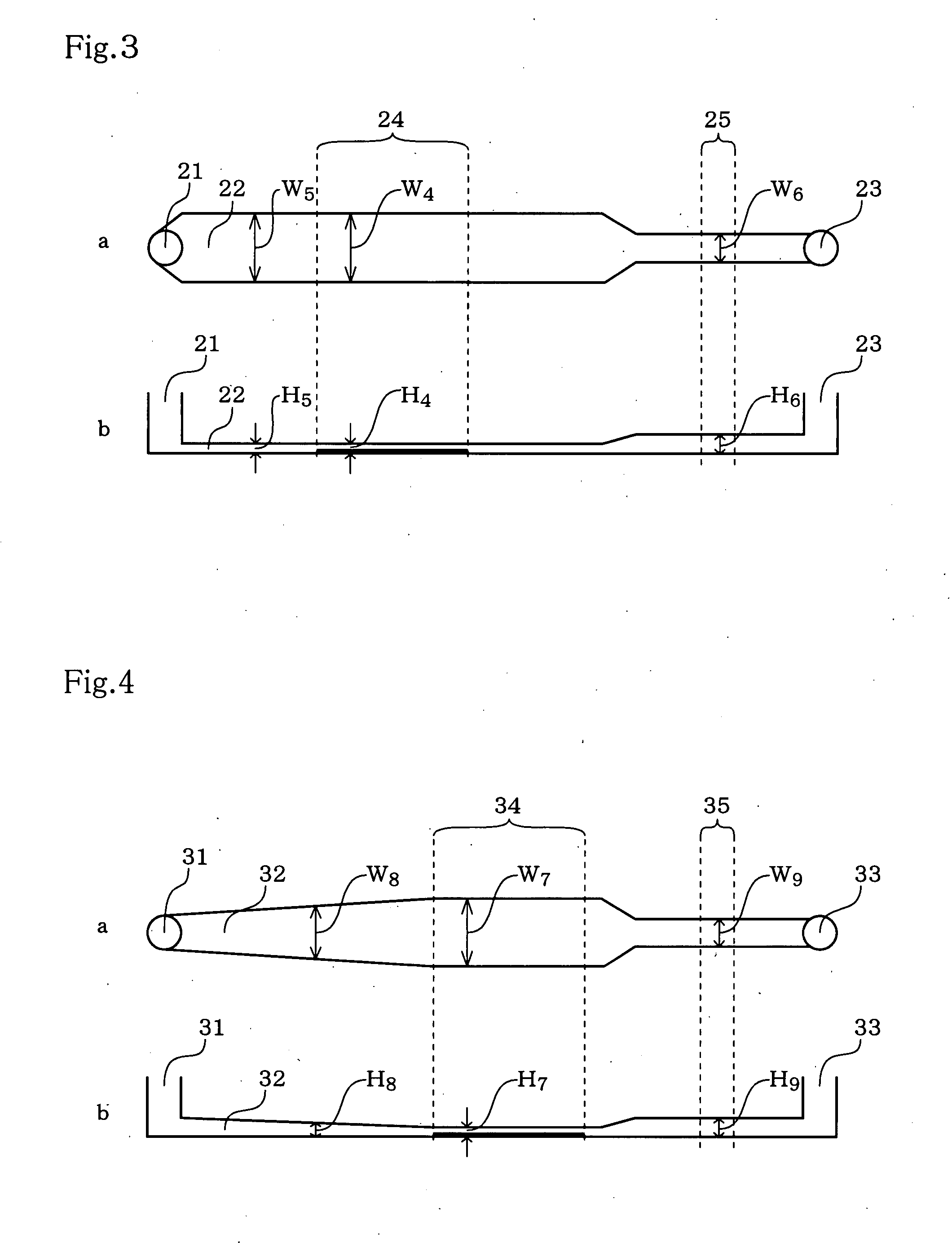

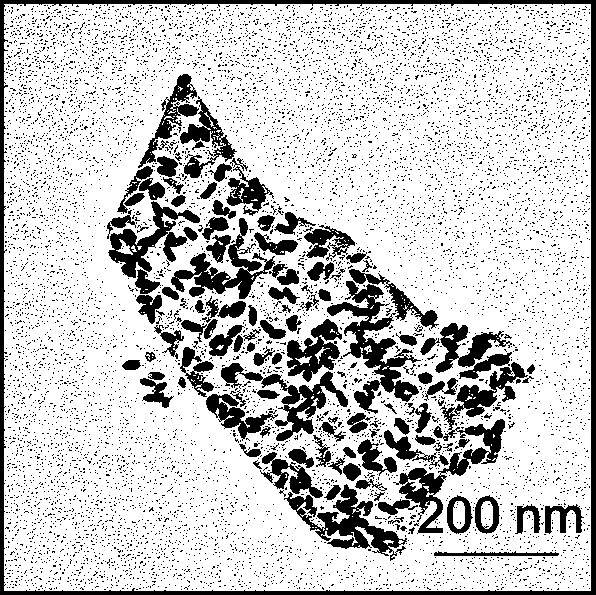

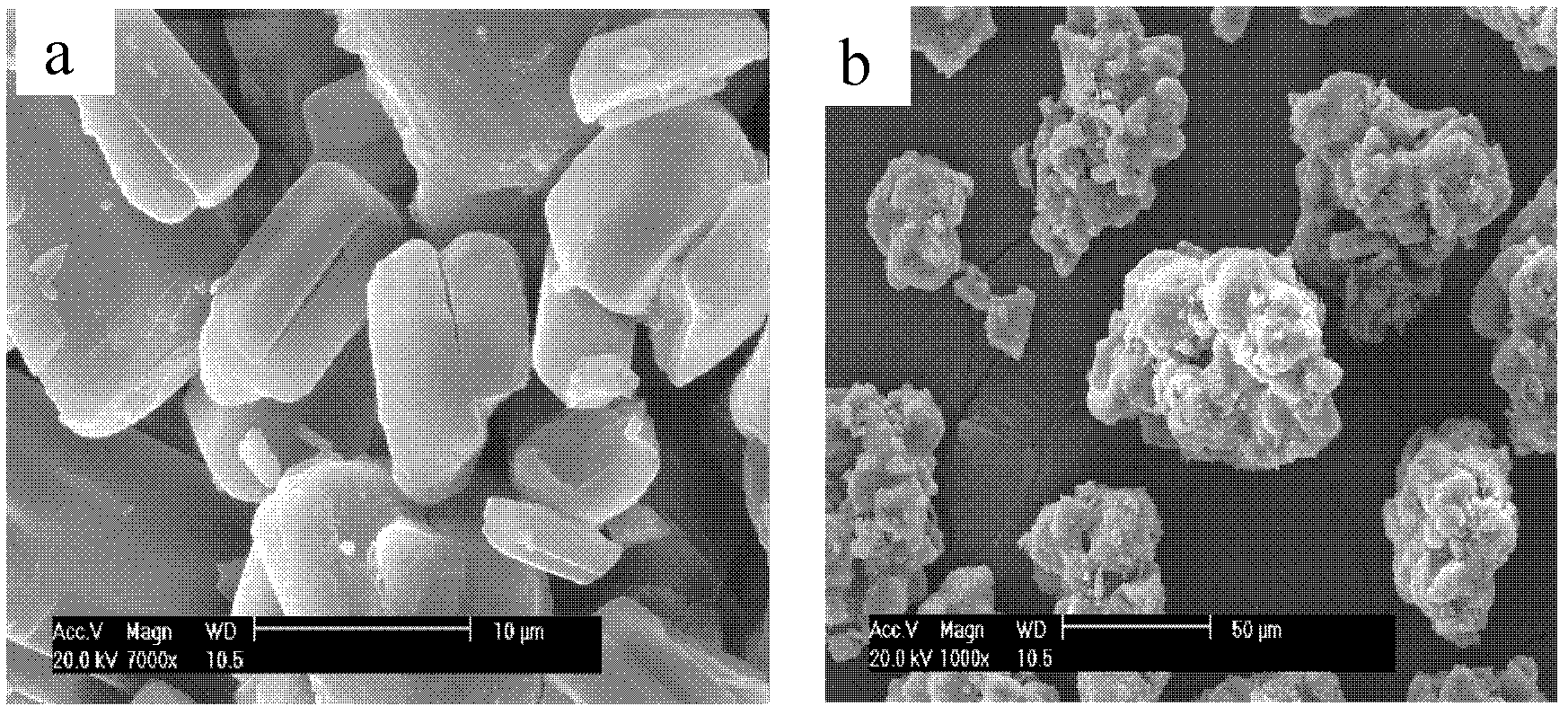

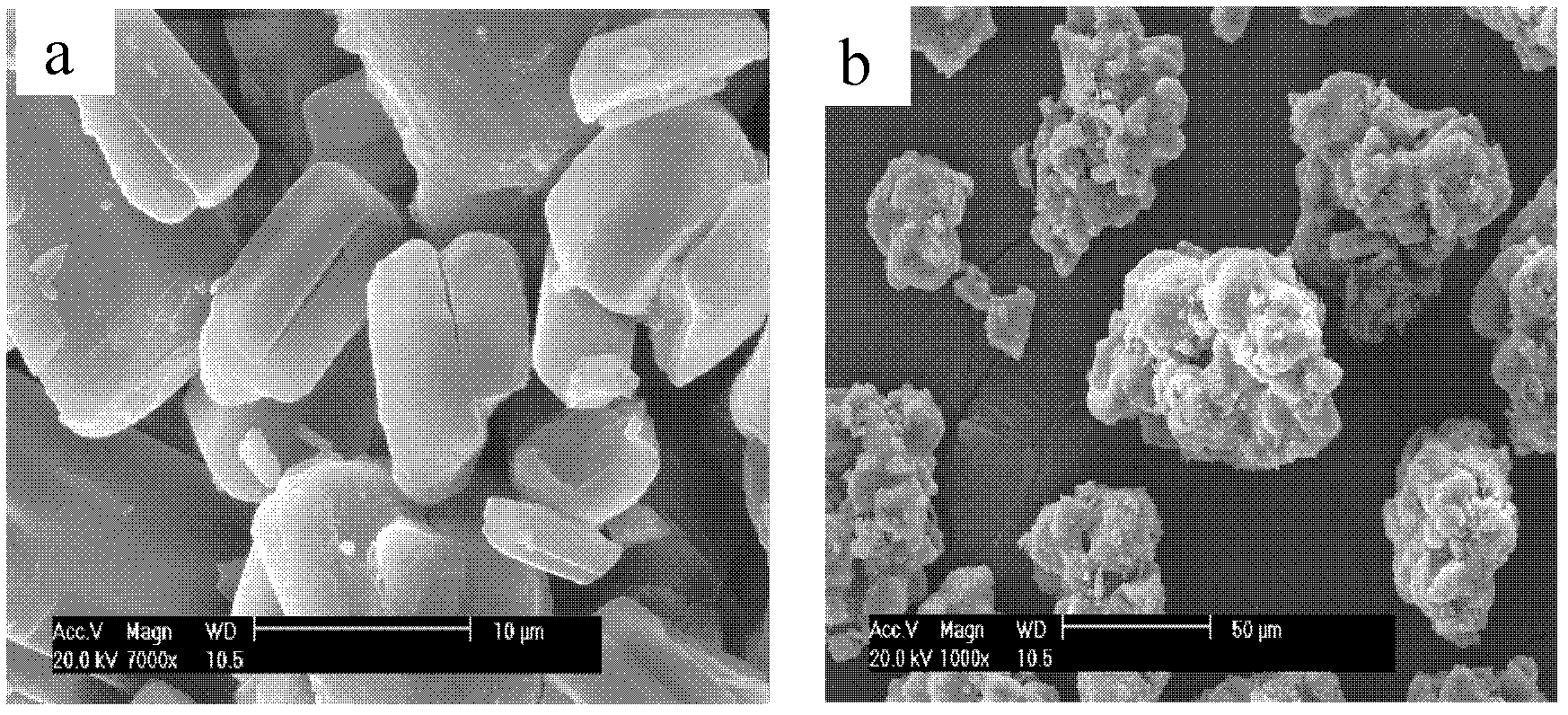

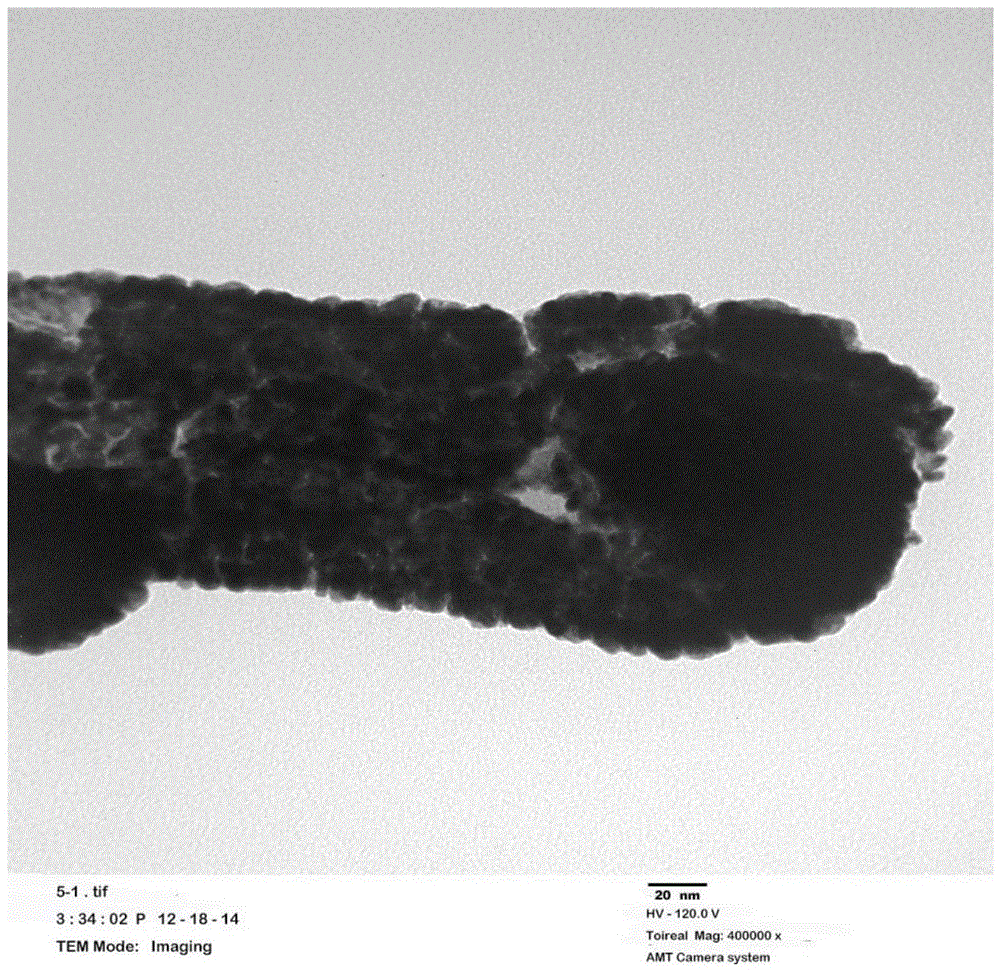

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

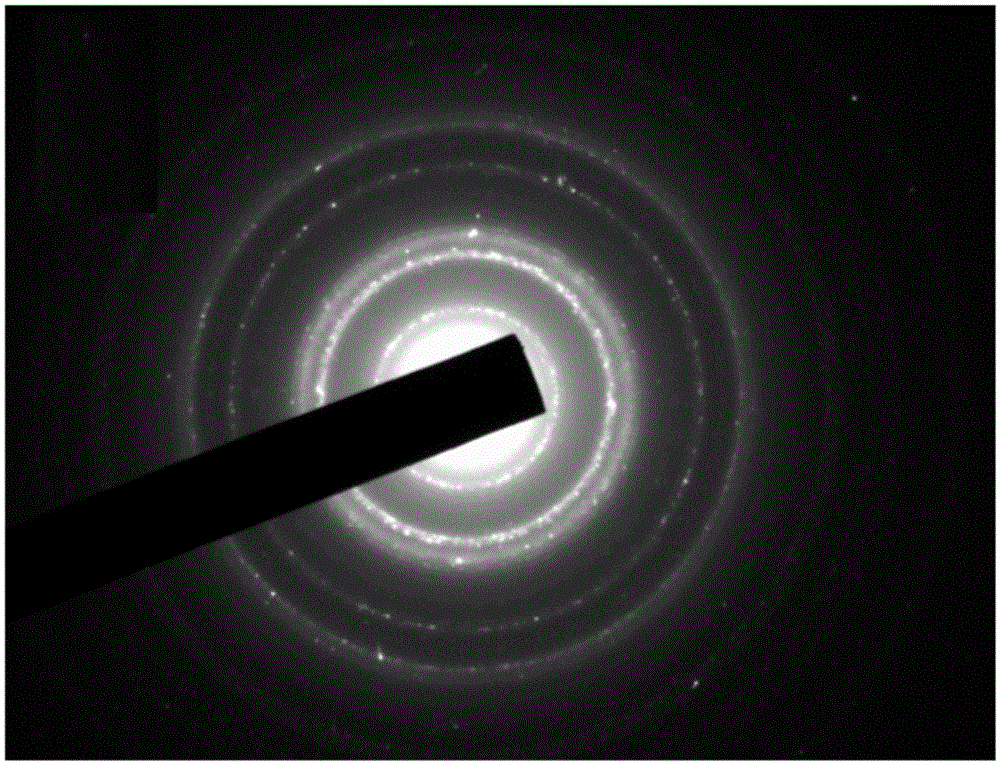

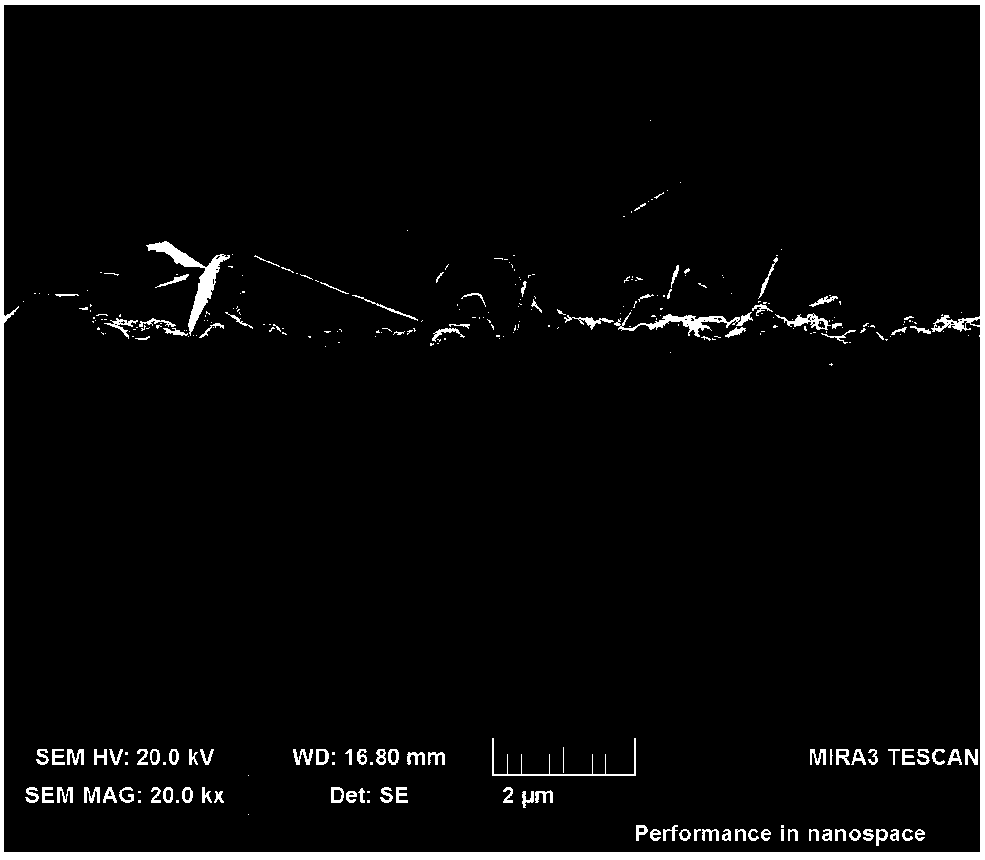

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

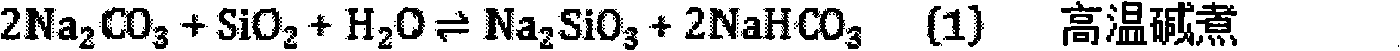

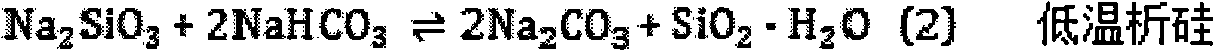

Method for producing porous nano silica and active carbon by utilizing rice hull ash

InactiveCN101920966AIncrease the reaction areaImprove reaction speedSilicaSolid waste disposalActive carbonChemistry

The invention discloses a method for producing porous nano silica and active carbon by utilizing rice hull ash, which comprises the following steps of: at lower temperature and normal pressure, performing secondary alkali dissolution on subcarbonate, and filtering to obtain alkali-dissolved filter liquor and filter residue; adding a certain amount of dispersing agent into the filter liquor, reducing temperature for ageing, filtering, washing, and removing the dispersing agent to obtain the porous nano silica; and adding an activating agent into the alkali-dissolved filter residue, activating, washing and drying to obtain the high specific surface area active carbon. The alkali and the active carbon can be recycled, and only a small amount of alkali and active carbon is lost. The method has the advantages of not seriously corroding equipment due to no high-temperature and high-pressure alkali boiling, sufficient raw materials, low price, no environmental pollution, and higher quality of the obtained active carbon and silica.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

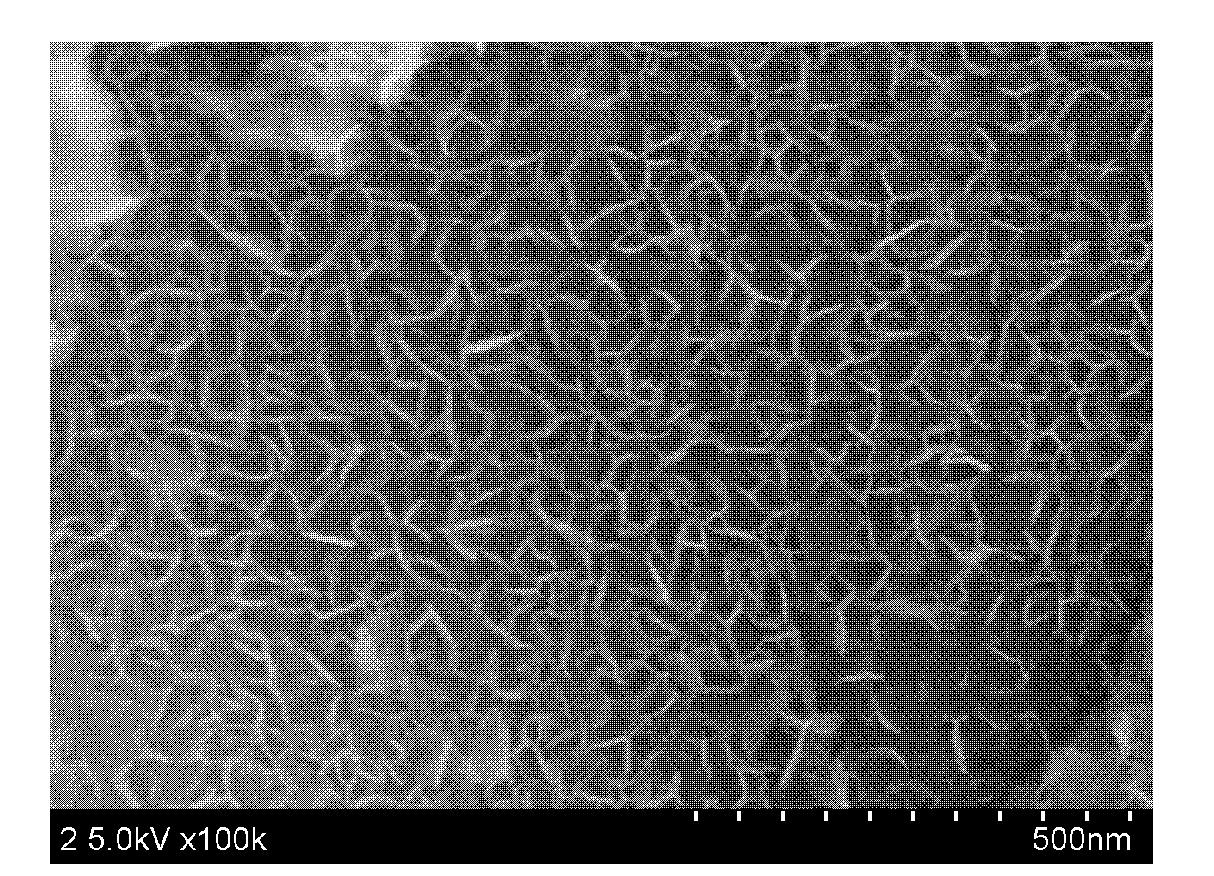

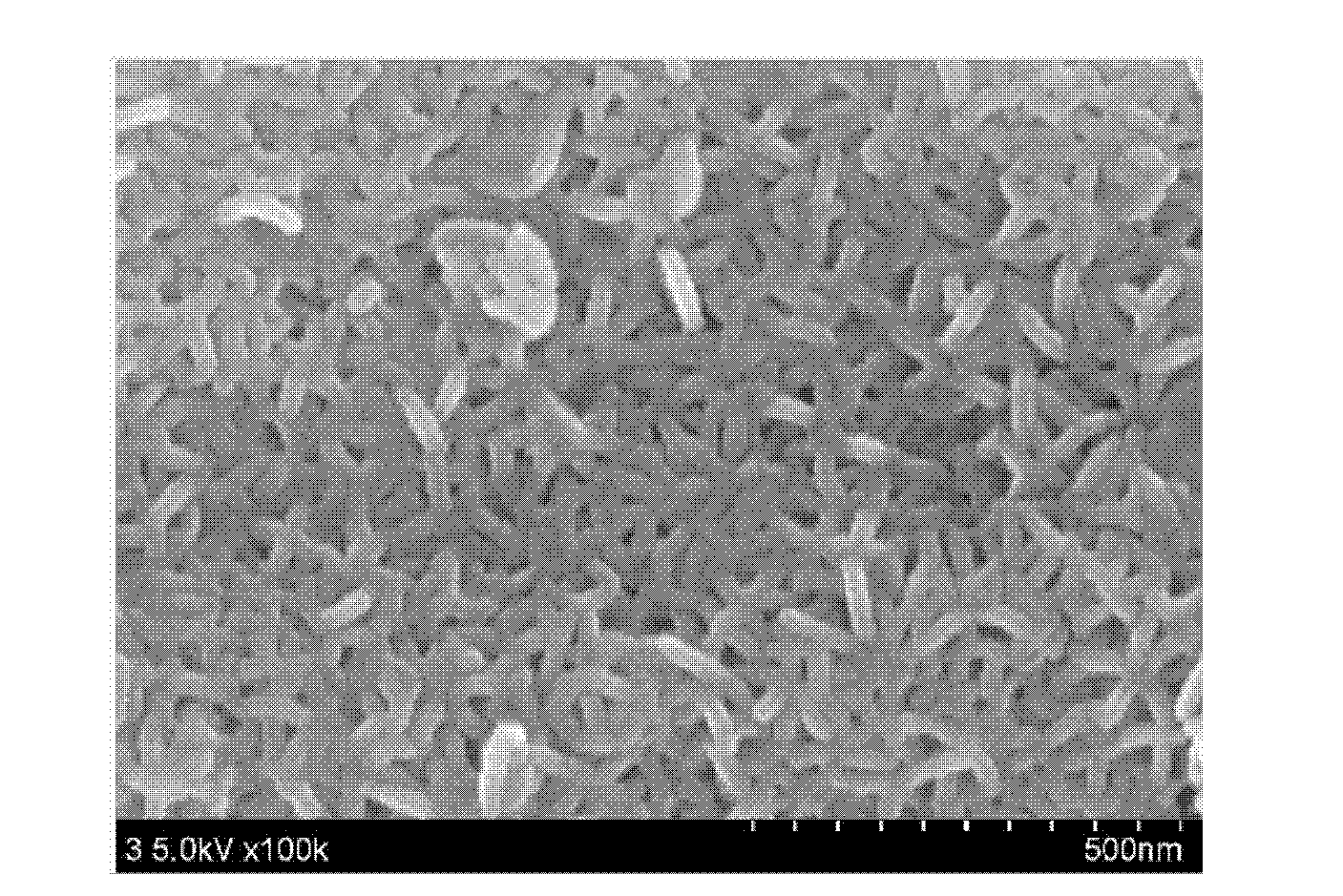

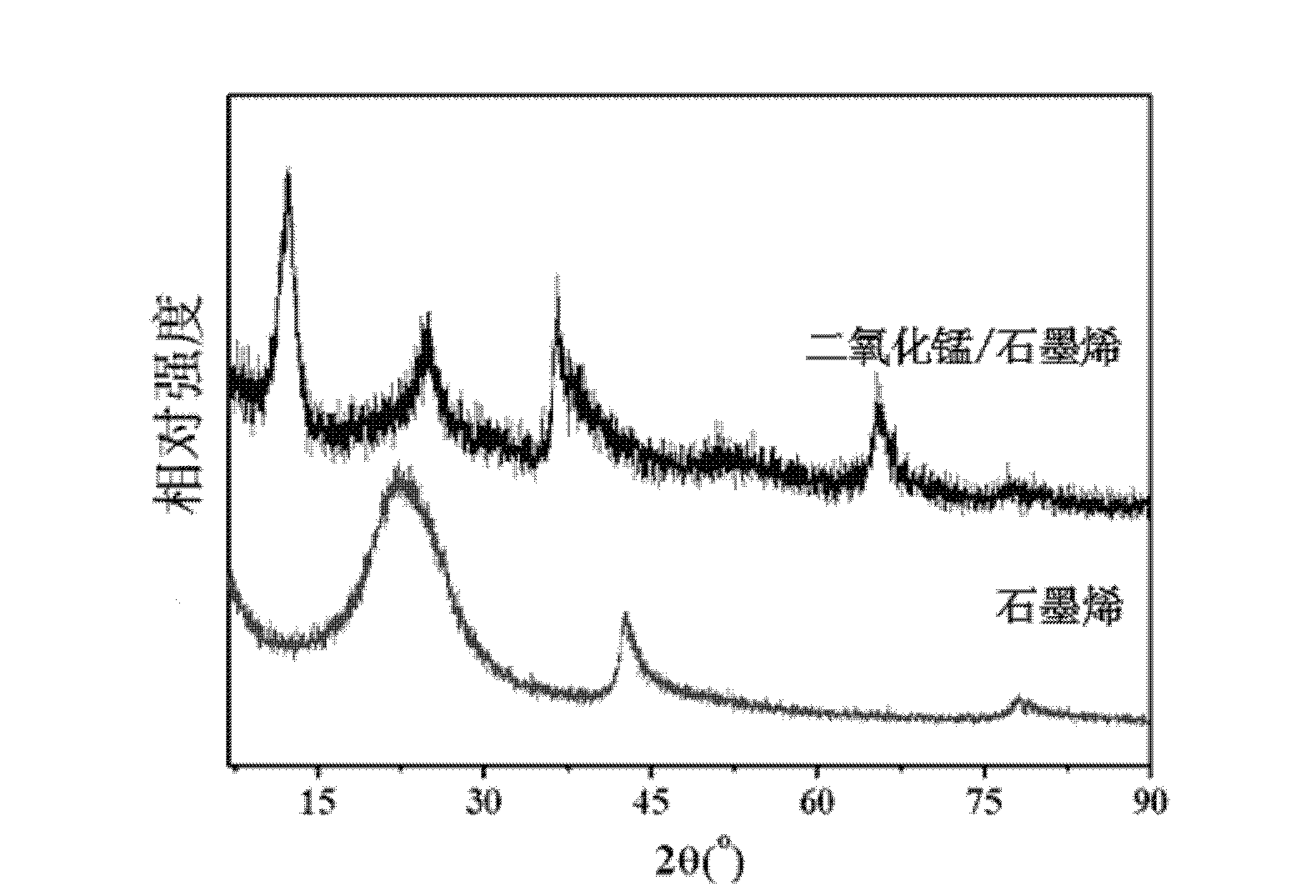

A kind of preparation method of graphene and manganese dioxide nanocomposite material

InactiveCN102275903AReduce typesLow costMaterial nanotechnologyManganese oxides/hydroxidesHydrazine compoundManganese

The invention relates to a preparation method of a graphene and manganese dioxide nanocomposite material, comprising: (1) stirring and mixing graphite, potassium nitrate and concentrated sulfur evenly, adding potassium permanganate, and reacting at 30-40° C. for 20-40 minutes , add deionized water at room temperature, add hydrogen peroxide after reacting for 15 to 30 minutes to obtain graphite oxide; (2) disperse the above graphite oxide in water, add hydrazine hydrate, and react at 95°C for 1 to 24 hours to obtain graphene (3) ultrasonically disperse the graphene in a saturated potassium permanganate solution, add acid, and react at 60-80° C. for 1-5 hours to obtain graphene and manganese dioxide nanocomposite material. The invention has the advantages of simple reaction, easy control, convenient operation and simple process; the obtained composite material has broad application prospects and can be used for catalysts, biosensing materials, electrode materials of lithium ion batteries and supercapacitor electrode materials, and the like.

Owner:DONGHUA UNIV

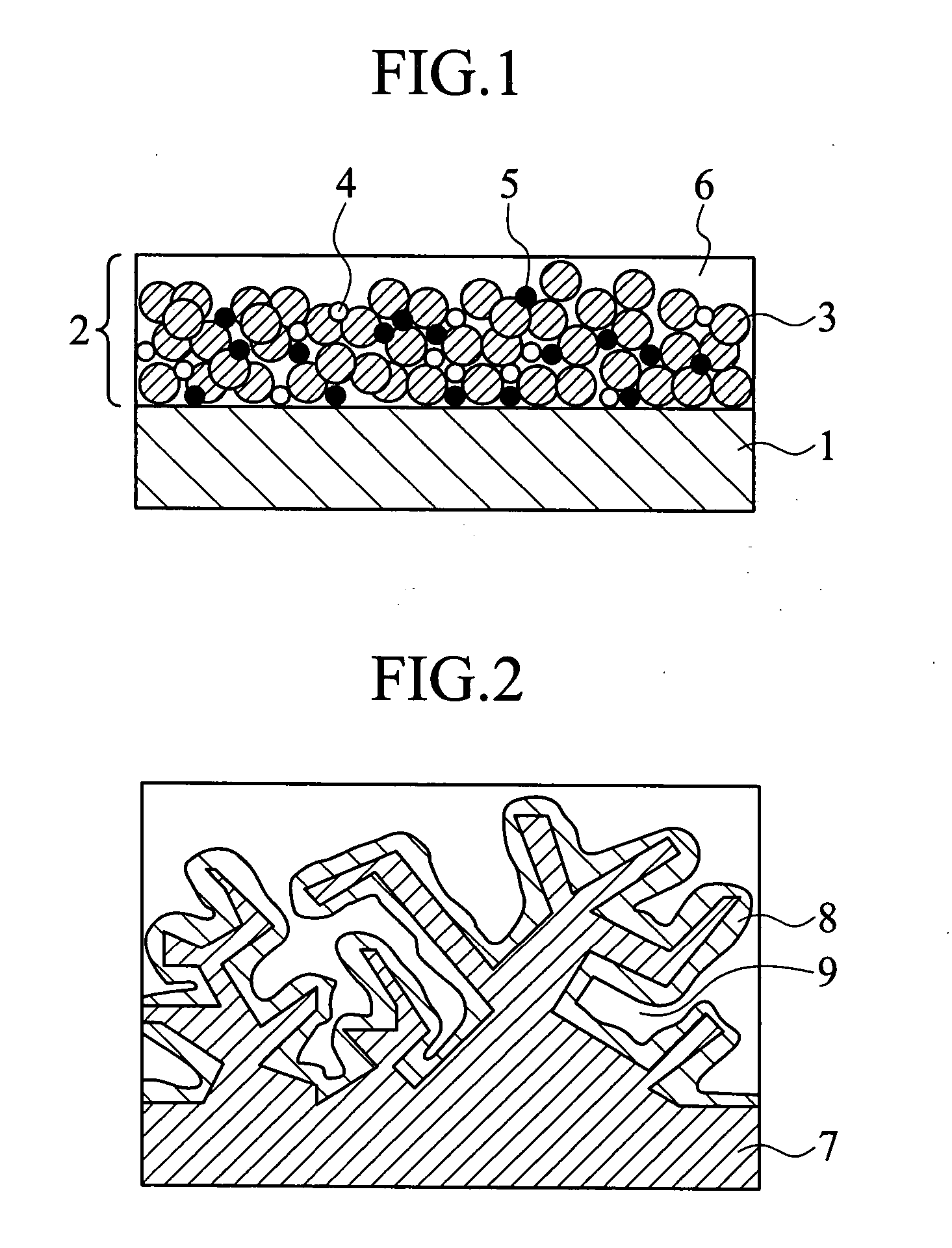

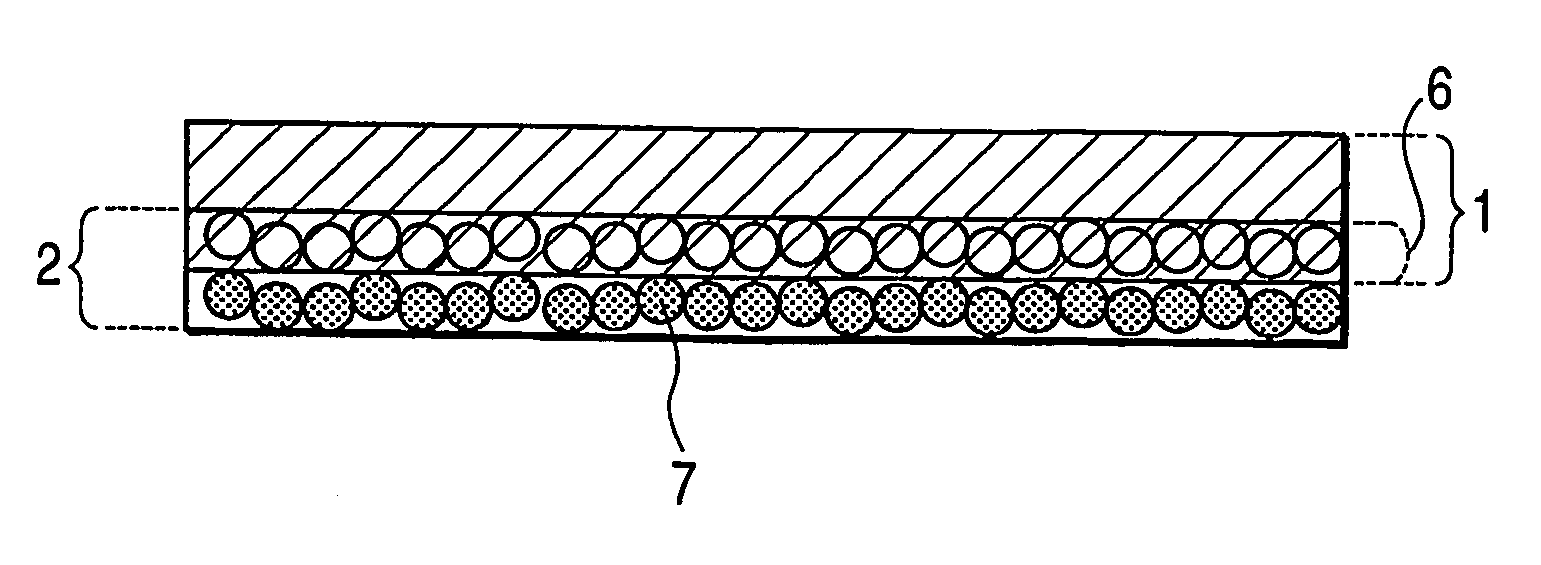

Non-aqueous electrolyte secondary battery

InactiveUS20050048371A1Easy to chargeIncrease the reaction areaElectrochemical processing of electrodesElectrode thermal treatmentConductive materialsCharge and discharge

A non-aqueous electrolyte secondary battery of the present invention has an electrode and an electrolyte layer. The electrode includes a collector having a lot of fine pores on its surface, and a membrane layer made of an electrode active material provided along the surface shape of the fine pores of the collector. By this structure, the battery can manifest an excellent performance even in charging and discharging at high speed without using a binder and conductive material.

Owner:NISSAN MOTOR CO LTD

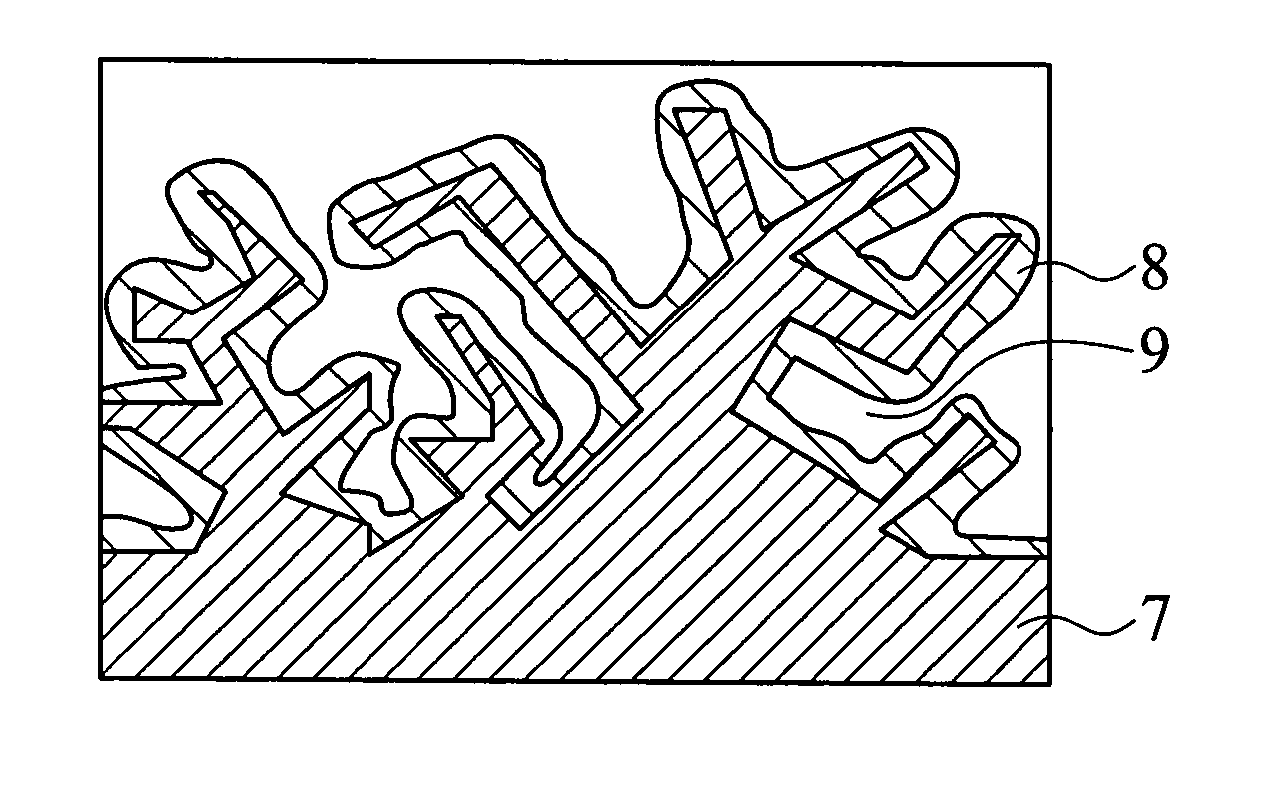

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

InactiveCN103474633AInhibition of dissolution and diffusion lossIncrease profitMaterial nanotechnologyElectrode manufacturing processesPolycyclic aromatic hydrocarbonLithium–sulfur battery

The invention relates to a carbon-sulfur-shell matter composite material having a network dual-core shell structure and a preparation method thereof. The carbon-sulfur-shell matter composite material has a carbon-sulfur-shell three layer structure, a central core (inner core) is nano carbon particles, sulfur elemental or a polysulfide containing-Sm-structure (m>2) is directly deposited on the nano carbon particles, or functional groups are introduced onto the nano carbon particles by use of polycyclic aromatic hydrocarbon like reaction capacity of the carbon material and through an irreversible chemical reaction, polymeric chains are introduced in, a crosslinked network structure is formed through stretching, bending and crosslinking of the polymeric chains on the surface of the nano carbon particles, the sulfur elemental or the polysulfide containing the-Sm-structure (m>2) is composited onto the crosslinked network structure to form a nano sulfur layer having a network structure, then a mono-core shell nano composite material having a network structure is obtained and is used as a second layer (outer core) of the carbon-sulfur-polymer composite material having the network dual-core shell structure, an outermost layer is a shell matter layer, electronic and / or ionic conductivity of the material are / is improved, dissolving loss of discharge products can be further inhibited, and structural stability of the material is improved. The material is suitable for positive poles of lithium sulfur batteries, and has a prominent effect on improvement of cycle stability of the lithium sulfur batteries.

Owner:NO 63971 TROOPS PLA

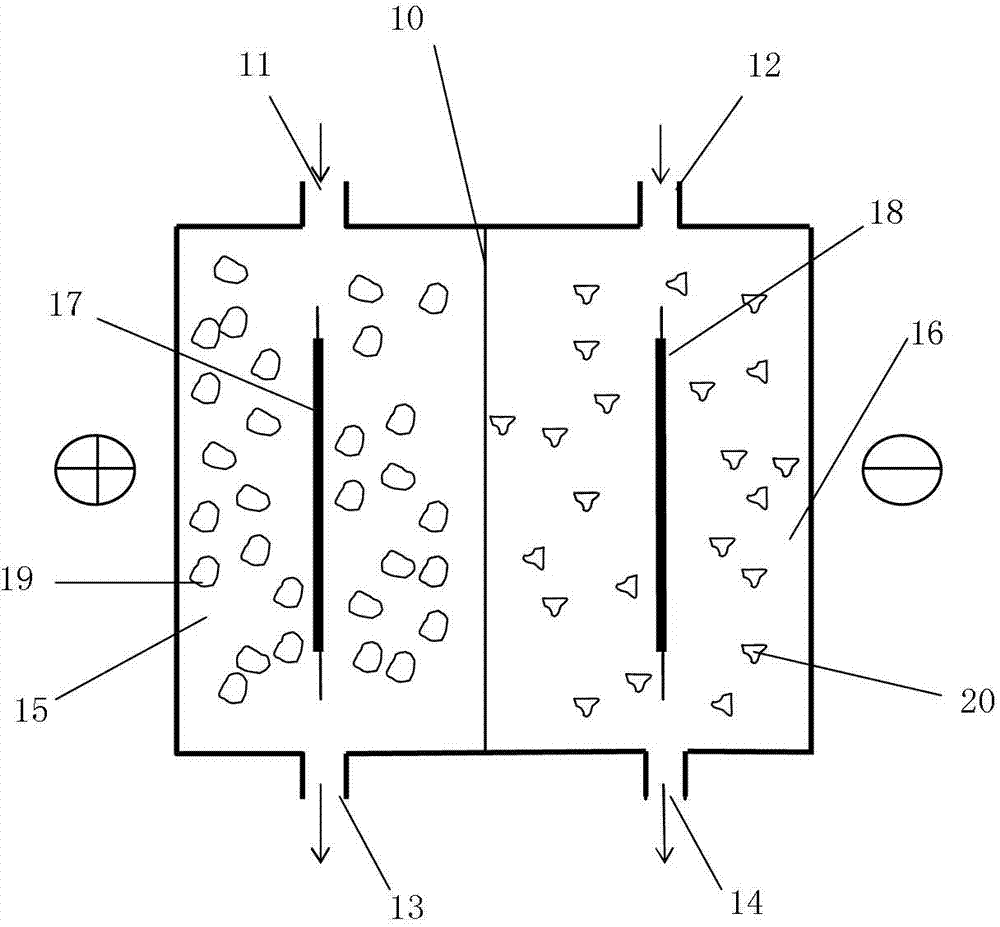

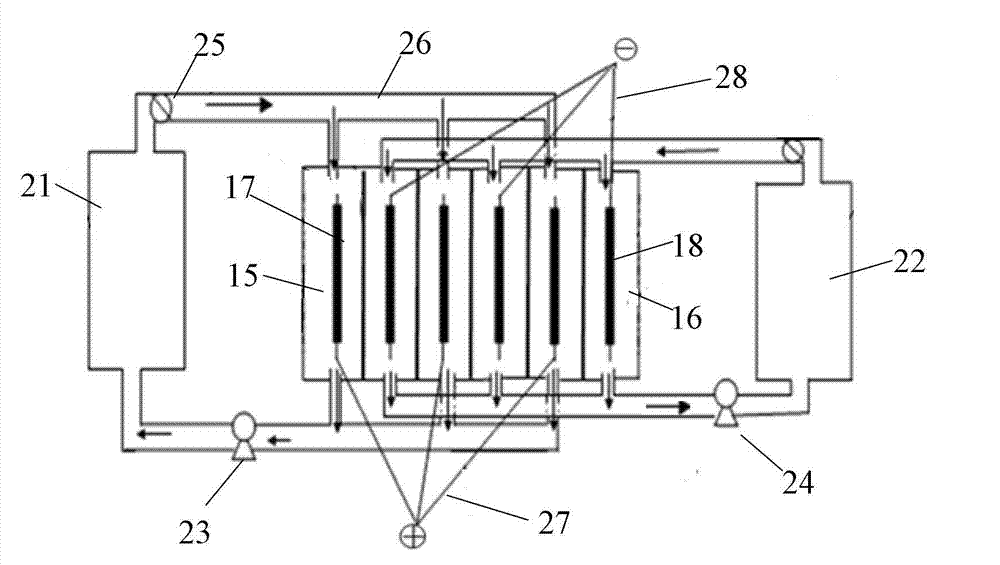

Semi-solid flow cell

ActiveCN103247816AIncrease working current densityGood rate characteristicsFinal product manufactureRegenerative fuel cellsElectrochemical responseElectrical battery

Owner:南京竞予能源有限公司

Neutral oil removal rust remover and preparation method thereof

The invention discloses a neutral oil removal rust remover, which is mainly prepared from deionized water and the following components by mass fraction: 4-8% of physical dispersing agent, 8-10% of chemical chelating agent, 4-6% of oil-removing emulsifier and 1-4% of corrosion inhibitor. The preparation method disclosed by the invention comprises the following steps: firstly, preparing the components according to the proportioning requirements; weighting the ingredients in the chemical chelating agent to put into a container; adding the deionized water to evenly agitate, so as to obtain a solution A; adding the physical dispersing agent and the corrosion inhibitor to the solution A; agitating to obtain a solution B; additionally, adding the prepared components of the oil-removing emulsifier to the container; adding the deionized water to dissolve; adding a functional additive to obtain a solution C; and evenly mixing the solution B with the solution C under the agitation condition to obtain the neutral oil removal rust remover. By adopting the product disclosed by the invention, the oil and rust removal work can be quickly and efficiently finished, and the neutral oil removal rust remover is free of damage to a substrate.

Owner:HUNAN UNIV

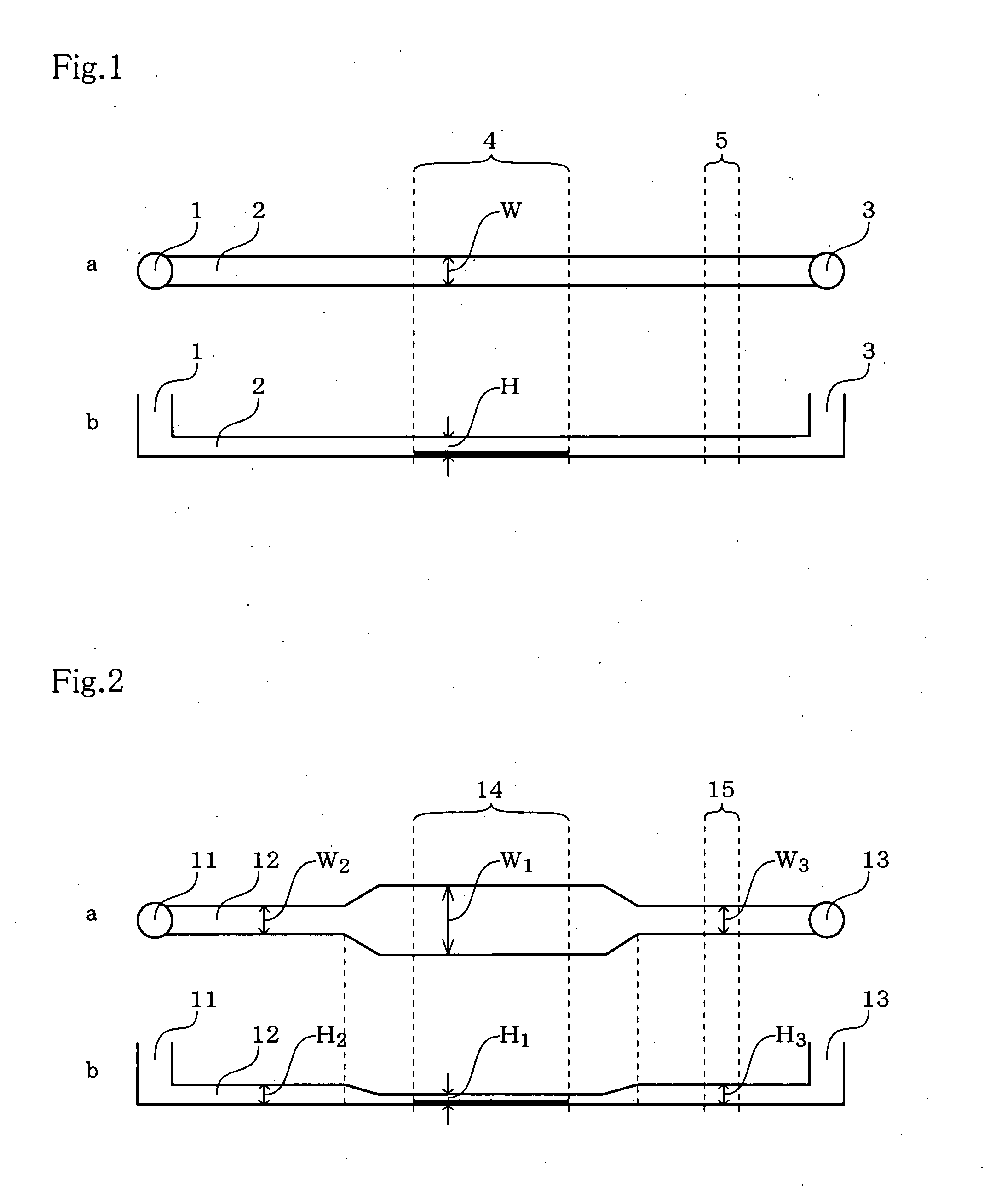

Microchip

InactiveUS20110038758A1High detection stability and reproducibilityGreat specific interface areaComponent separationFixed microstructural devicesEngineeringDiagnostic system

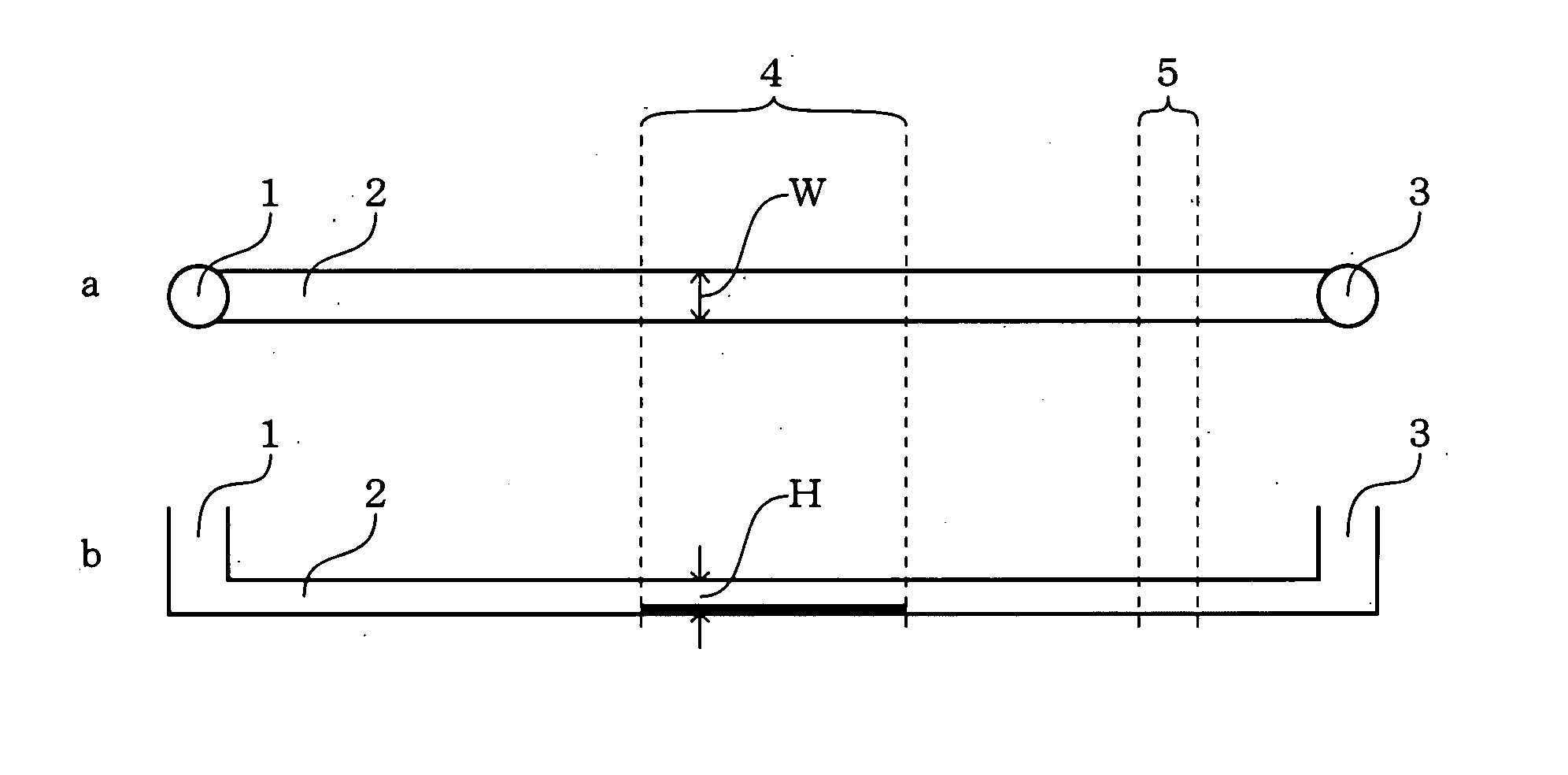

A microchip, which is used in a diagnostic system using a microfluid system, has a flow path capable of greatly improving the reaction efficiency and realizing a stable measurement with high reproducibility. The microchip has two substrates with at least a flow path 12 formed at the interface between the two substrates, the flow path 12 having a reaction area 14 and a detection area 15 downstream of the reaction area 14, and the flow path 12 at the detection area 15 having a depth which is deeper than the flow path 12 in the reaction area 14.

Owner:NISSUI PHARMA

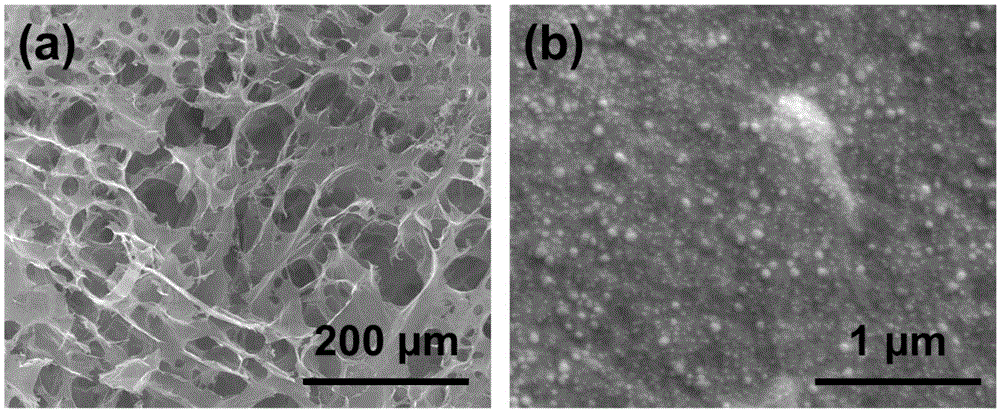

Reduction-oxidation graphene/nanometer metallic silver aerogel with three-dimensional structure and preparation method

ActiveCN105251484AIncreased reactive areaGood catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsCvd grapheneGraphite oxide

The invention relates to a reduction-oxidation graphene / nanometer metallic silver aerogel with a three-dimensional structure and a preparation method thereof. The aerogel has a three-dimensional porous structure which is formed by a reduction-oxidation graphene slice layer and a polycrystal nanometer metallic sliver uniformly loaded on the reduction-oxidation graphene slice layer. The aerogel is prepared according to the preparation method which comprises the following steps: (1) uniformly mixing a soluble silver salt aqueous solution with a graphene oxide aqueous solution, thereby acquiring a pecursor solution; (2) transferring the pecursor solution into a reducing agent solution, reacting at room temperature, thereby acquiring a three-dimensional graphene / metallic silver nanometer grain hydrogel; and (3) taking out and cleaning the three-dimensional graphene / metallic silver nanometer grain hydrogel, drying, and then acquiring a target product. Compared with the prior art, the reduction-oxidation graphene / nanometer metallic silver aerogel has the advantages that the preparation method is simple, the whole reaction process is performed at a room temperature, no excessive extra energy consumption is required, and the like.

Owner:SHANGHAI JIAO TONG UNIV

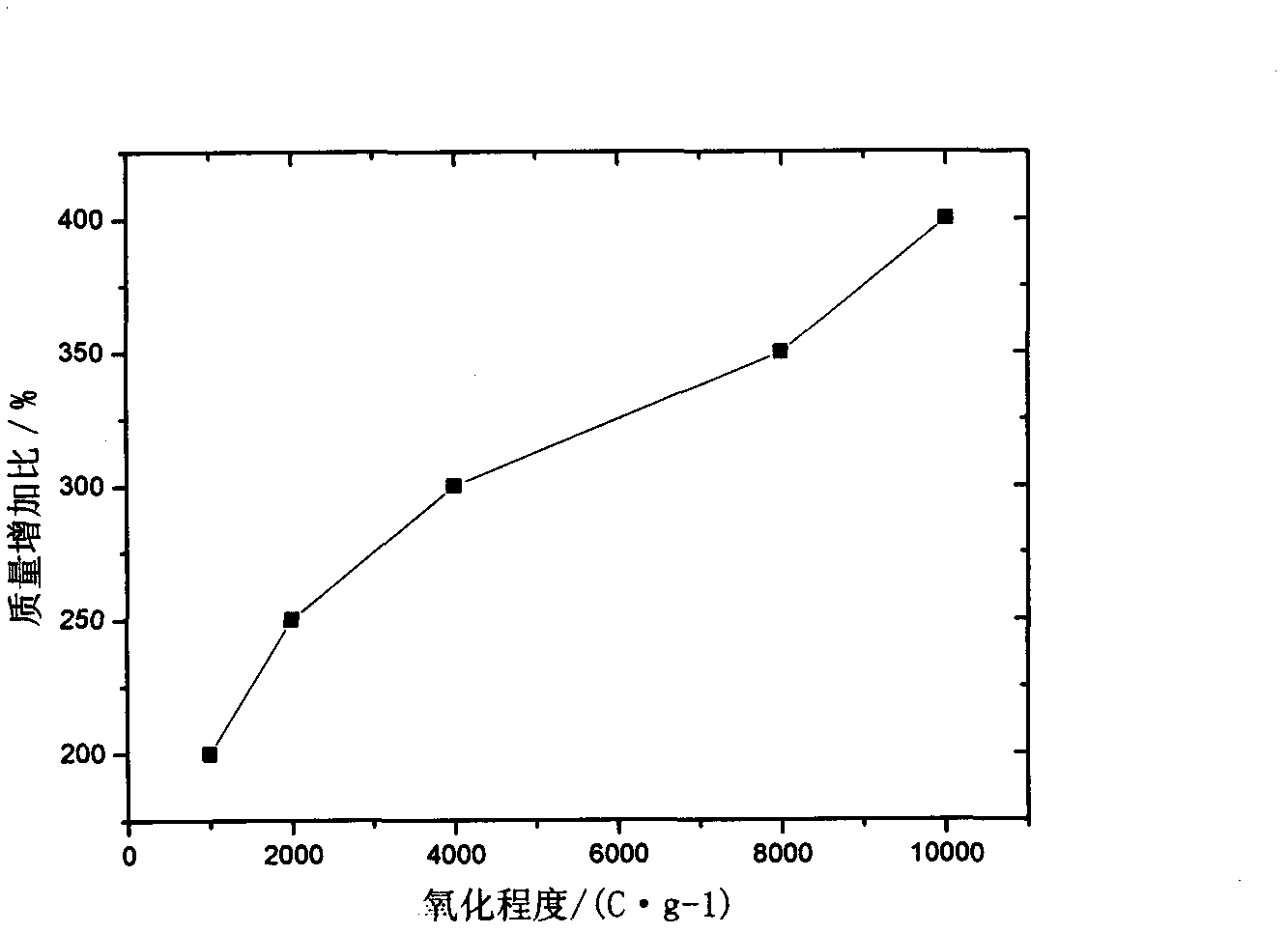

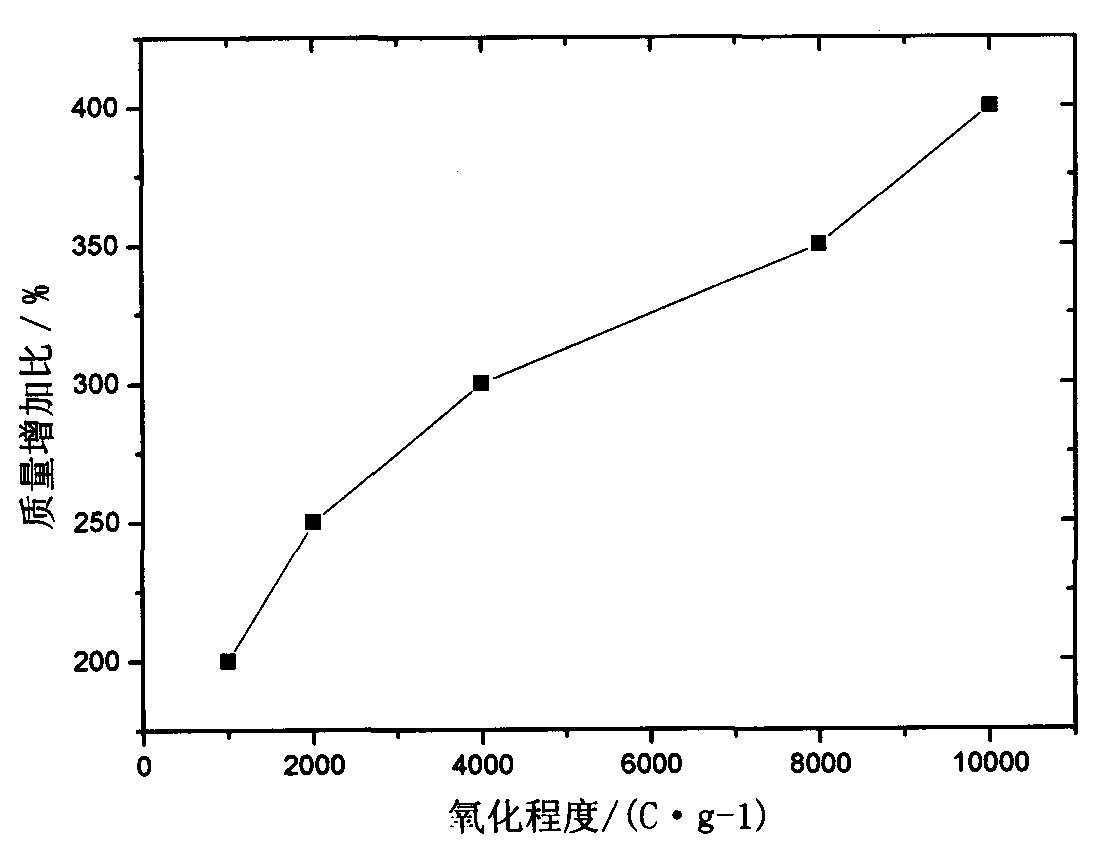

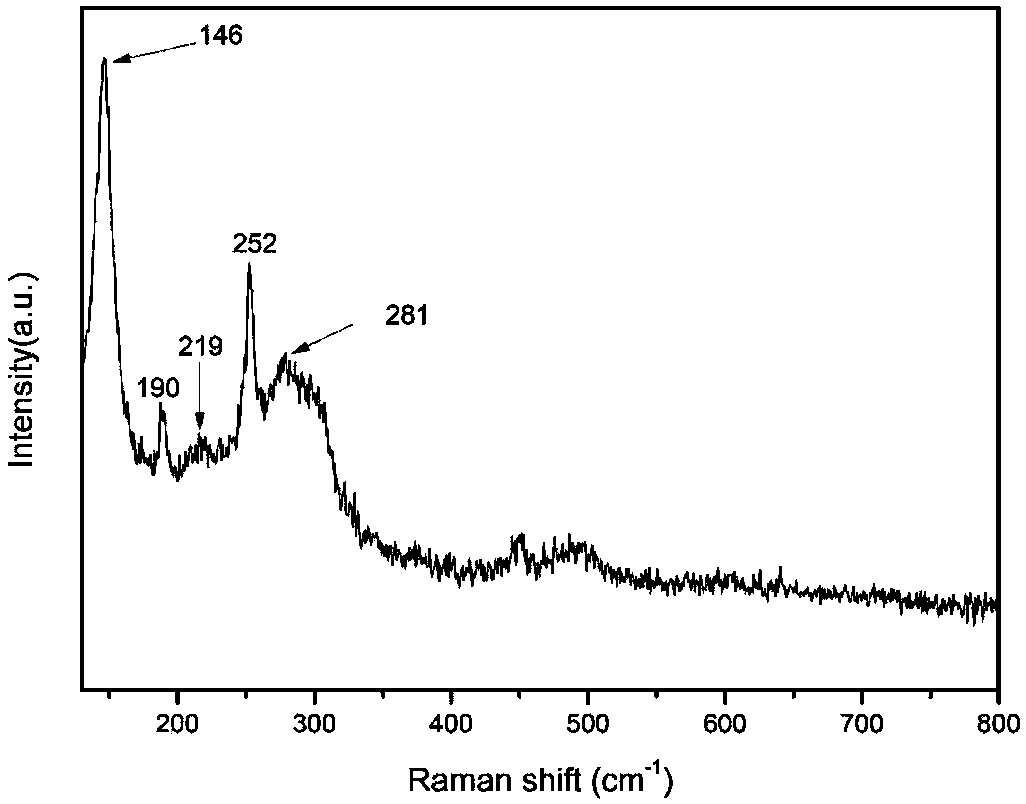

Modified method of graphite felt used for full-vanadium fluid flow battery electrode

ActiveCN102136579AControl the rate of oxidation reactionIncrease the reaction areaCell electrodesFenton reagentDistilled water

The invention relates to a modified method of a graphite felt used for a full-vanadium fluid flow battery electrode. Firstly a graphite felt is processed by an air oxidation method, and then the graphite felt processed by the air oxidation method is modified by utilizing hydrogen peroxide or an Fenton reagent. The modified method comprises the following steps: a. air oxidation processing: placingthe washed graphite felt into a heating device for heating; oxidizing in the hot air environment; naturally cooling to room temperature in the heating device after oxidation; and washing the cooled graphite felt; b. hydrogen peroxide or Fenton reagent modified processing: placing the washed graphite felt into the hydrogen peroxide or the Fenton reagent to be modified to obtain the modified graphite felt; and c. processing residues on the surface of the graphite felt: washing the graphite felt after being processed by a hydrogen peroxide solution or the Fenton reagent by utilizing distilled water; and removing the hydrogen peroxide or the Fenton reagent residual on the surface of the graphite felt. The modified method provided by the invention has the advantages of being simple and feasible in operation and low in cost and environment-friendly.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

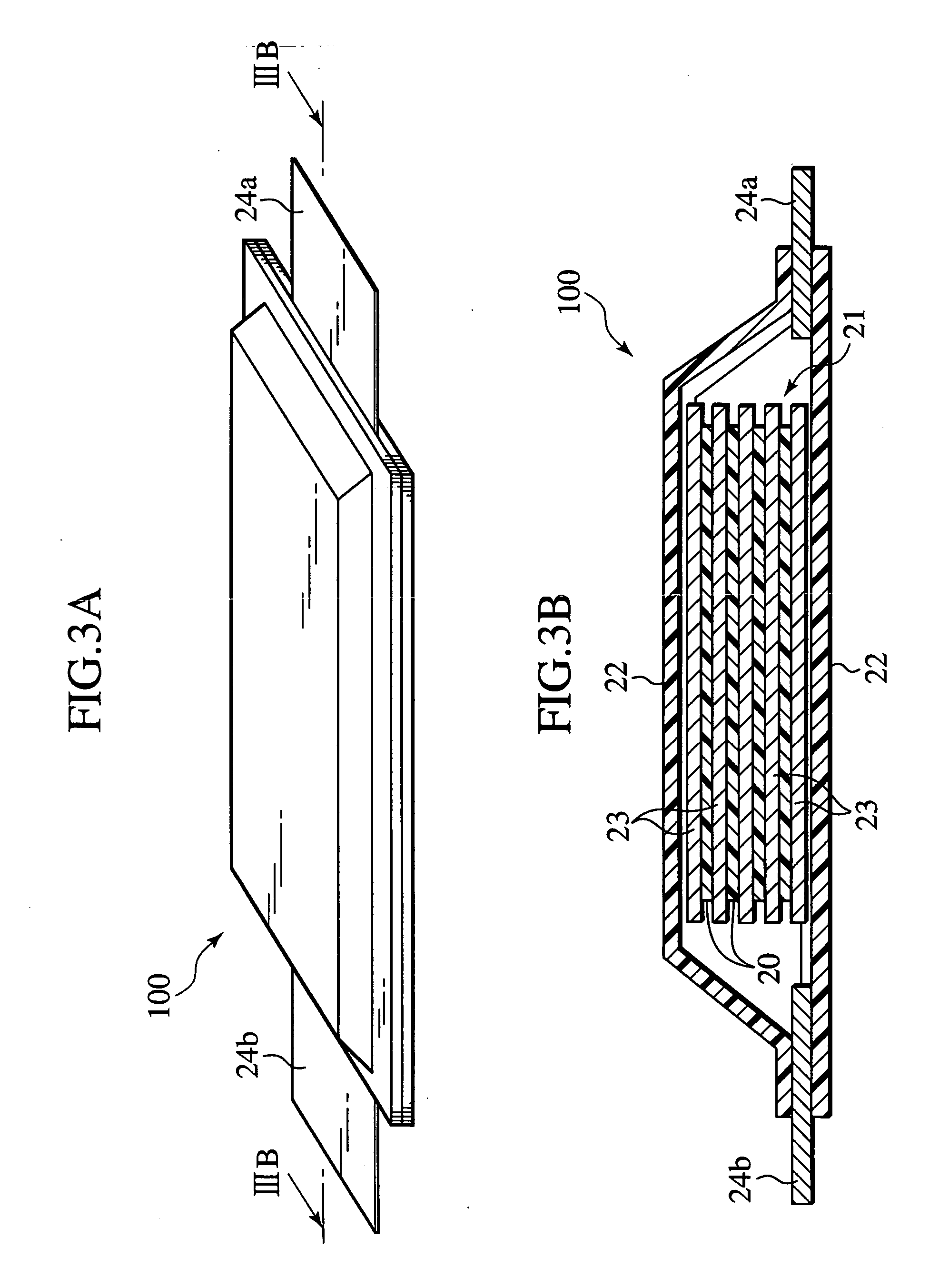

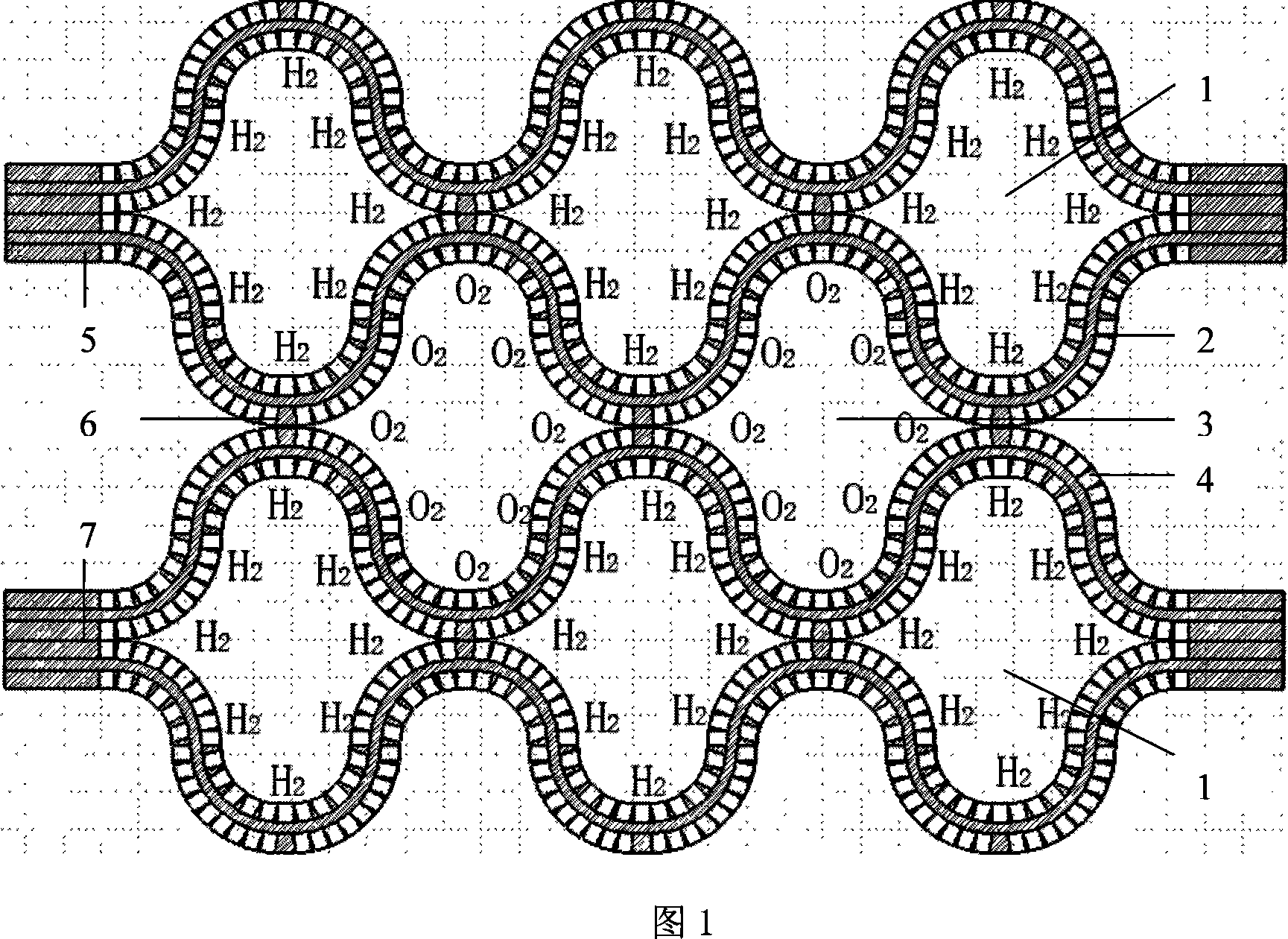

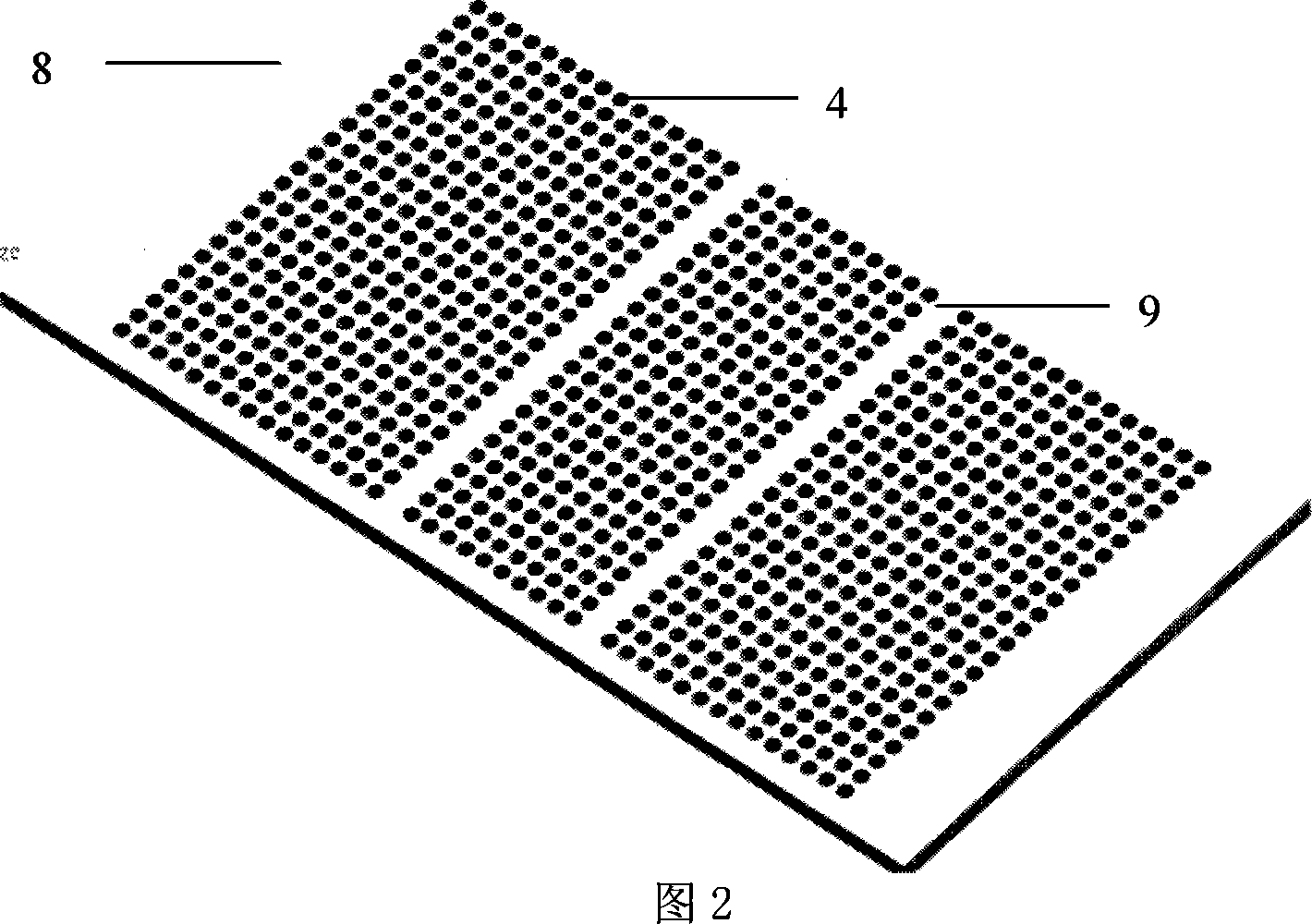

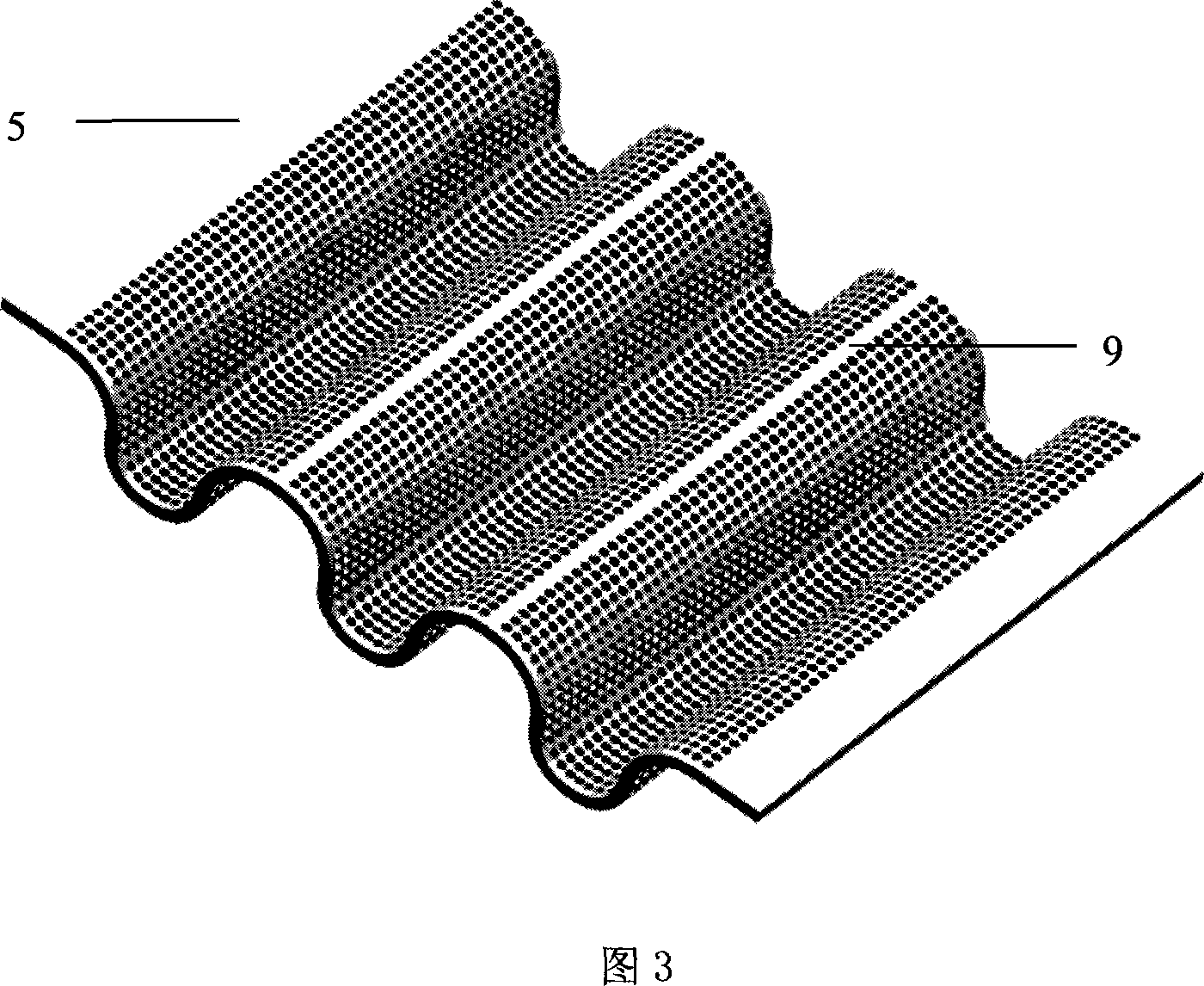

Making method of proton exchange film fuel cell electric piling

ActiveCN101079494AIncrease contact areaDoes not affect chemical and physical propertiesFuel cells groupingFinal product manufactureConductive polymerEngineering

The invention discloses a making method of proton exchange film fuel battery pile in the fuel battery technical domain, which comprises the following steps: (1) pressing plane MEA into wave shape under heating condition; (2) adopting micro-fine pushing technique to punch the hyperthin plane metal plate; punching the plate with hole into wave shape to mate wave-shaped MEA; obtaining monopole board; (3) adopting laser welding technique to weld a couple of monopole board into double-pole board; (4) plating a layer of conductive polyaniline on the metal surface through circulating volt-ampere method. The invention improves the reacting efficiency and energy density, which lightens the weight and resists corrosion.

Owner:上海氢晨新能源科技有限公司

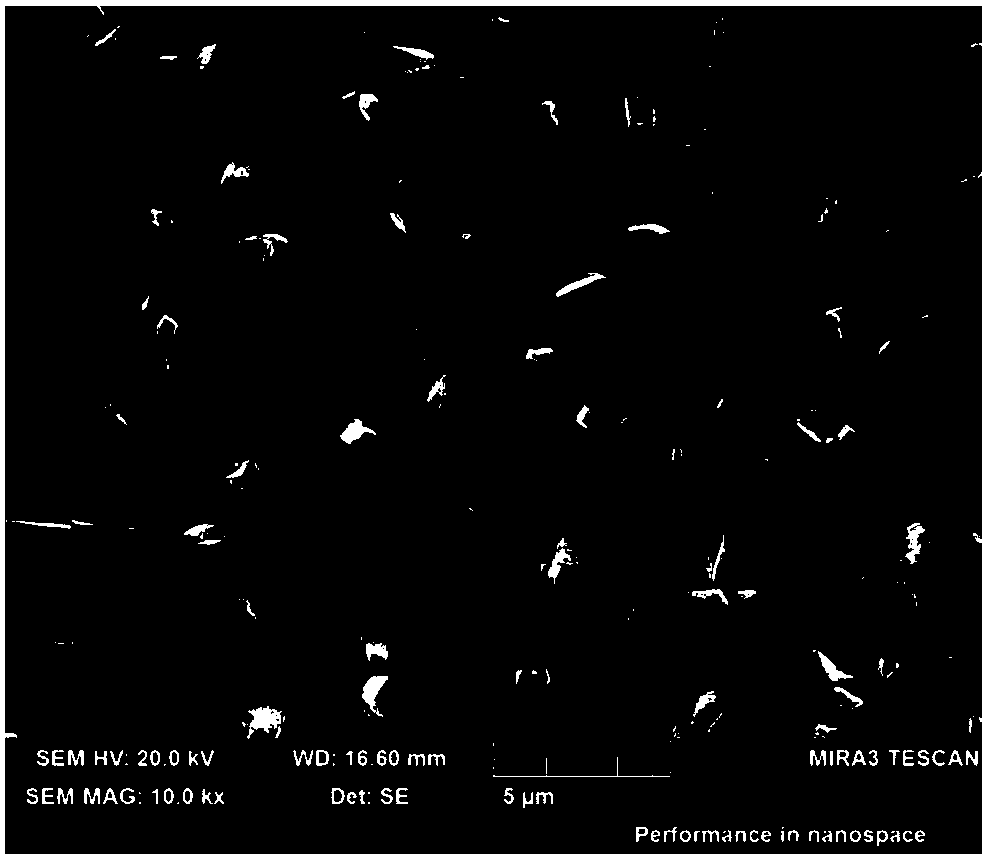

Preparation method of thermally-reduced graphene oxide/nano carbon fiber composite electrode for full-vanadium flow battery

InactiveCN104332640ALarge specific surface areaIncrease the reaction areaCell electrodesFiberCarbon fibers

The invention relates to the field of battery manufacturing and energy source storage and particularly provides a preparation method of a thermally-reduced graphene oxide / nano carbon fiber composite electrode for a full-vanadium flow battery. The preparation method comprises the following steps: firstly, preparing a spinning solution for an experiment; secondly, uniformly mixing graphite oxide powder and the spinning solution; stripping the graphite oxide powder into graphene oxide by using an ultrasonic manner; preparing a nano fiber membrane by adopting an electrostatic spinning method; and then pre-oxidizing the nano fiber membrane in the air and carbonizing in an inert atmosphere pipe type furnace to obtain the needed thermally-reduced graphene oxide / nano carbon fiber composite electrode. According to the full-vanadium flow battery composite electrode prepared by the method, the diameter of carbon fibers is a nano scale; and the carbon fibers are compounded with thermally-reduced graphene oxide and the roughness of the fibers is greatly increased, so that the specific surface area of the electrode is two orders of magnitudes higher than that of a traditionally-used electrode material. Meanwhile, the high-activity thermally-reduced graphene oxide is adopted so that the electrochemical activity of the electrode is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Nano metal oxide/MXene heterostructure composite material and preparation method thereof

InactiveCN108630920AImprove conductivityImprove cycle performanceMaterial nanotechnologyHybrid capacitor electrodesNanowireLithium-ion battery

The invention provides a nano metal oxide / MXene heterostructure composite material and a preparation method thereof. According to the nano metal oxide / MXene heterostructure composite material, nano metal oxide is adsorbed on the surface of lamella MXene through van der waals force and evenly dispersed on a lamella base material to form the composite material of an integrated structure; metal oxideparticles with the size as 5 to 100nm occupies 10 to 90% of the total mass of the composite material; the nano metal oxide is one or several of TiO2, SnO2, Fe3O4, RuO2 and MnO2; the nano metal oxideis in a shape of one or several of a nanorod shape, a nanowire shape and a quantum dot shape. According to the nano metal oxide / MXene heterostructure composite material disclosed by the invention, thenano metal oxide is evenly dispersed on the MXene lamella, morphology is regular, a proportion is adjustable, and material conductivity is remarkably improved; the preparation method has the advantages of simpleness, lower cost and large-scale preparation; when being applied to lithium ion batteries or super capacitor composite materials, the nano metal oxide / MXene heterostructure composite material has excellent cycling performance and rate capability.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for combination electrode for all-vanadium redox flow battery

InactiveCN104241661AImprove electrochemical activityImprove energy efficiencySucessive textile treatmentsCell electrodesCarbon fibersCharge discharge

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method of a bismuth-base catalyst / carbon nanofiber combination electrode for an all-vanadium redox flow battery. Firstly, spinning solution required for an experiment is prepared and then bismuth salt and the spinning solution are uniformly mixed. According to an electrostatic spinning method, a required nanofiber film is prepared and then the nanofiber film is pre-oxidized in the air and is carbonized in an inert atmosphere tube furnace so as to obtain the required bismuth-base electrocatalyst / carbon nanofiber combination electrode. After the obtained electrode material is cleaned and dried, testing of related electrochemical performance representation and charge-discharge properties can be carried out on the electrode material. The carbon fiber diameter, which is prepared according to the preparation method, is in the nano class; compared with a specific surface area of a conventionally used electrode material, the specific surface area of the bismuth-base catalyst / carbon nanofiber combination electrode is greatly increased. Moreover, the carbon nanofibers are compounded with a high-activity bismuth-base electrocatalyst, and thus, electrochemical activity of the electrode can be greatly improved, so that energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

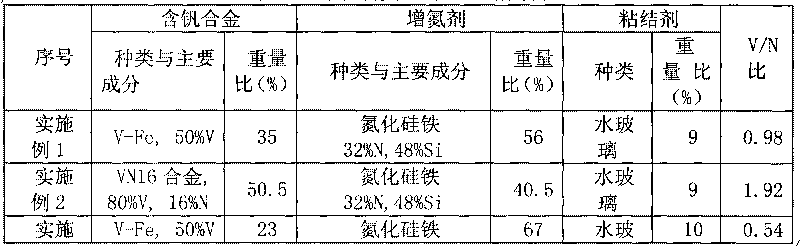

Vanadium-nitrogen additive for smelting microalloyed steel and method for preparing same

The invention discloses a vanadium-nitrogen additive for smelting microalloyed steel and a method for preparing same. The vanadium-nitrogen additive and the method are characterized in that the vanadium-nitrogen additive is uniformly mixed by vanadium-contained alloy powder, nitrogen increasing agent powder, and adhesive, wherein the mass ratio of the adhesive is 5-12%, the total mass ratio of the vanadium-contained alloy powder and the nitrogen increasing agent powder is 88-95%, and the ratio of V / N is controlled within 0.1-4. The method for preparing the vanadium-nitrogen additive used for smelting microalloyed steel comprises the following steps: mixing the vanadium-contained alloy powder and the nitrogen increasing agent powder by the weight percentage, mechanically and uniformly blending the mixed powders, subsequently adding 5-12% of the adhesive and uniformly mixing the powders again, finally mechanically forming blocks of spherule shapes or other shapes, and preparing the vanadium-nitrogen additive by drying the blocks. The ratio of V / N of molten steel can be controlled within 3.0-5.0 by the vanadium-nitrogen additive, the enhancement effect of the vanadium can be sufficiently played by utilizing the cheap nitrogen element, and the amount of the vanadium is reduced obviously.

Owner:MAANSHAN IRON & STEEL CO LTD

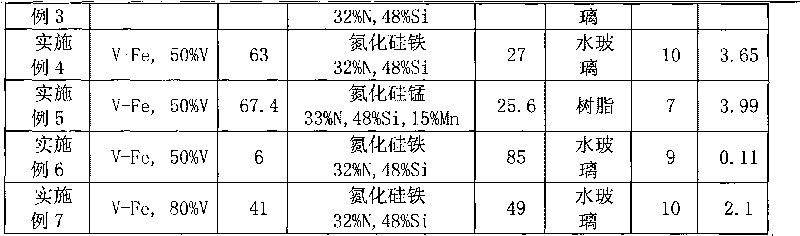

Homogeneous phase immunoassay POCT detection technique and system using same

InactiveCN105758835AOvercoming the problem of high CVSolve highBiological testingFluorescence/phosphorescenceChemistryAssay technique

The invention provides a homogeneous phase immunoassay POCT detection technique and a system using same. The homogeneous phase immunoassay POCT detection technique has the characteristics of high sensitivity, high precision and wide range of chemiluminescence immune assay technique and rapidness, portability and the like of a POCT detection technique; in addition, as pure liquid phase detection, the homogeneous phase immunoassay POCT detection technique overcomes the problem that CV is relatively high due to an NC membrane, so that the detection precision is high, generally the CV can be controlled to be within 5%, and the level of precision of the POCT detection technique can reach or even exceed that of the chemiluminescence immune assay technique. In the system using the homogeneous phase immunoassay POCT detection technique, a reagent card and a POCT analyzer are separately designed, a sample to be tested is acquired by using the reagent card, and the system is convenient to carry over.

Owner:成都爱兴生物科技有限公司

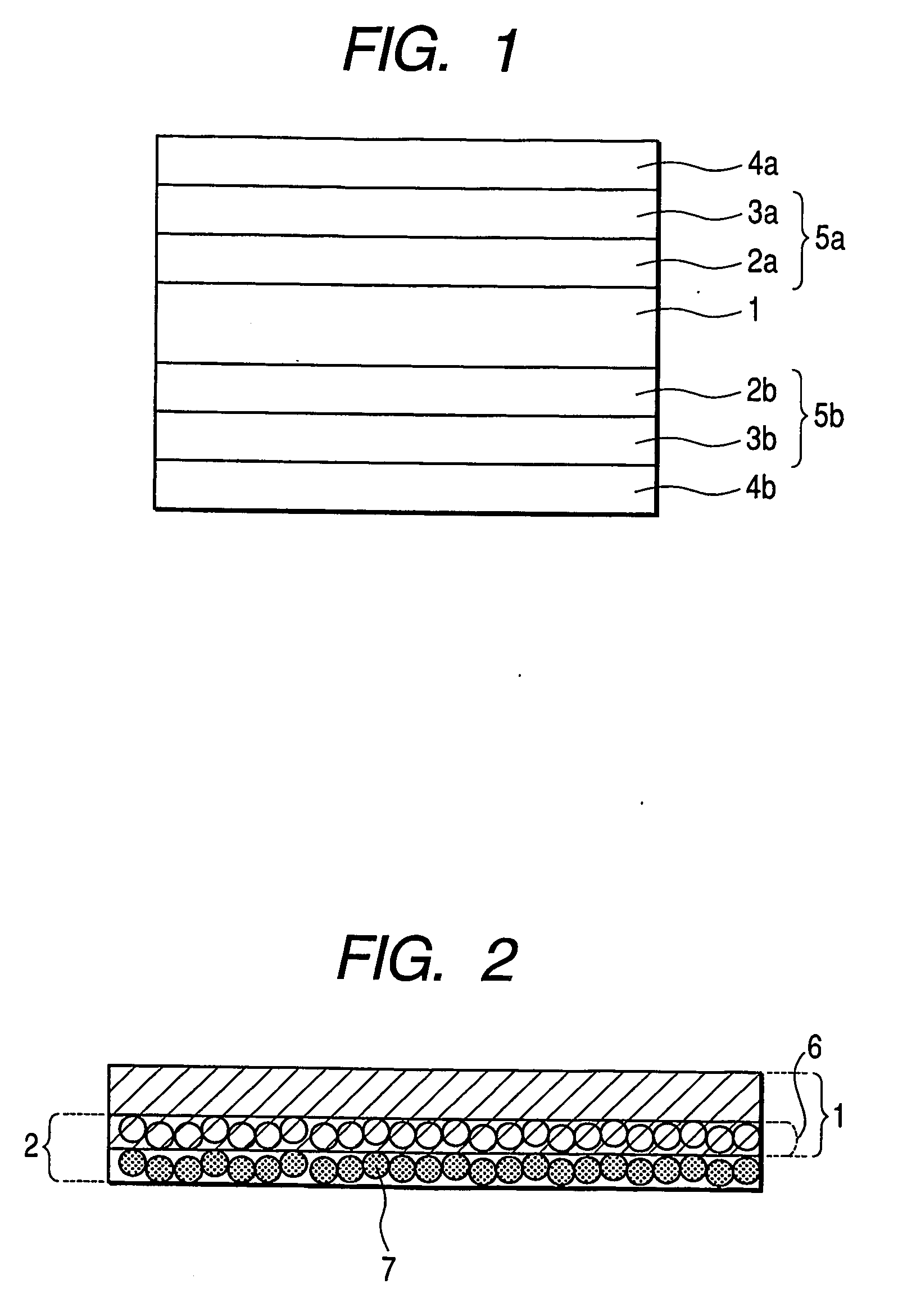

Membrane electrode assembly, production method for the same, and proton-exchange membrane fuel cell

InactiveUS20060154127A1Lower internal resistanceIncrease the reaction areaFinal product manufactureActive material electrodesPolymer electrolytesInternal resistance

The membrane electrode assembly of the present invention for the proton-exchange membrane fuel cell includes a polymer electrolyte membrane and an electrode catalyst layer, wherein at least a part of the polymer electrolyte membrane infiltrates into the electrode catalyst layer, and wherein the polymer electrolyte membrane is formed by polymerizing a composition containing at least a compound having proton conductivity and a compound having activity to an active energy ray, or a composition containing at least a compound having proton conductivity and activity to the active energy ray. The object of the present invention is to provide a membrane electrolyte assembly for realizing a high-output proton-exchange membrane fuel cell by improving a bonding state between the polymer electrolyte membrane and the electrode catalyst layer to reduce an internal resistance, and by providing a three-dimensional three-phase interface to increase reaction areas.

Owner:CANON KK

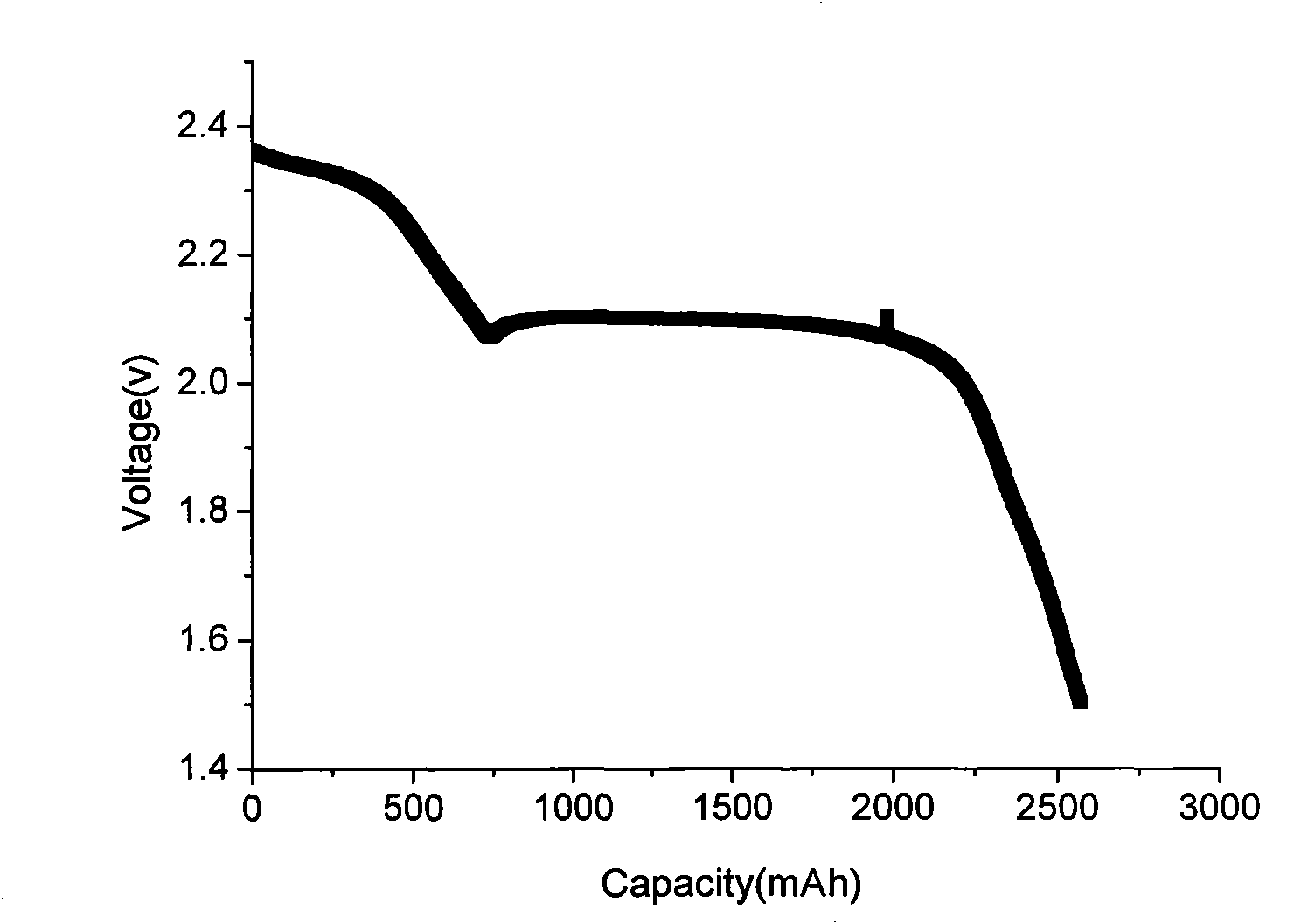

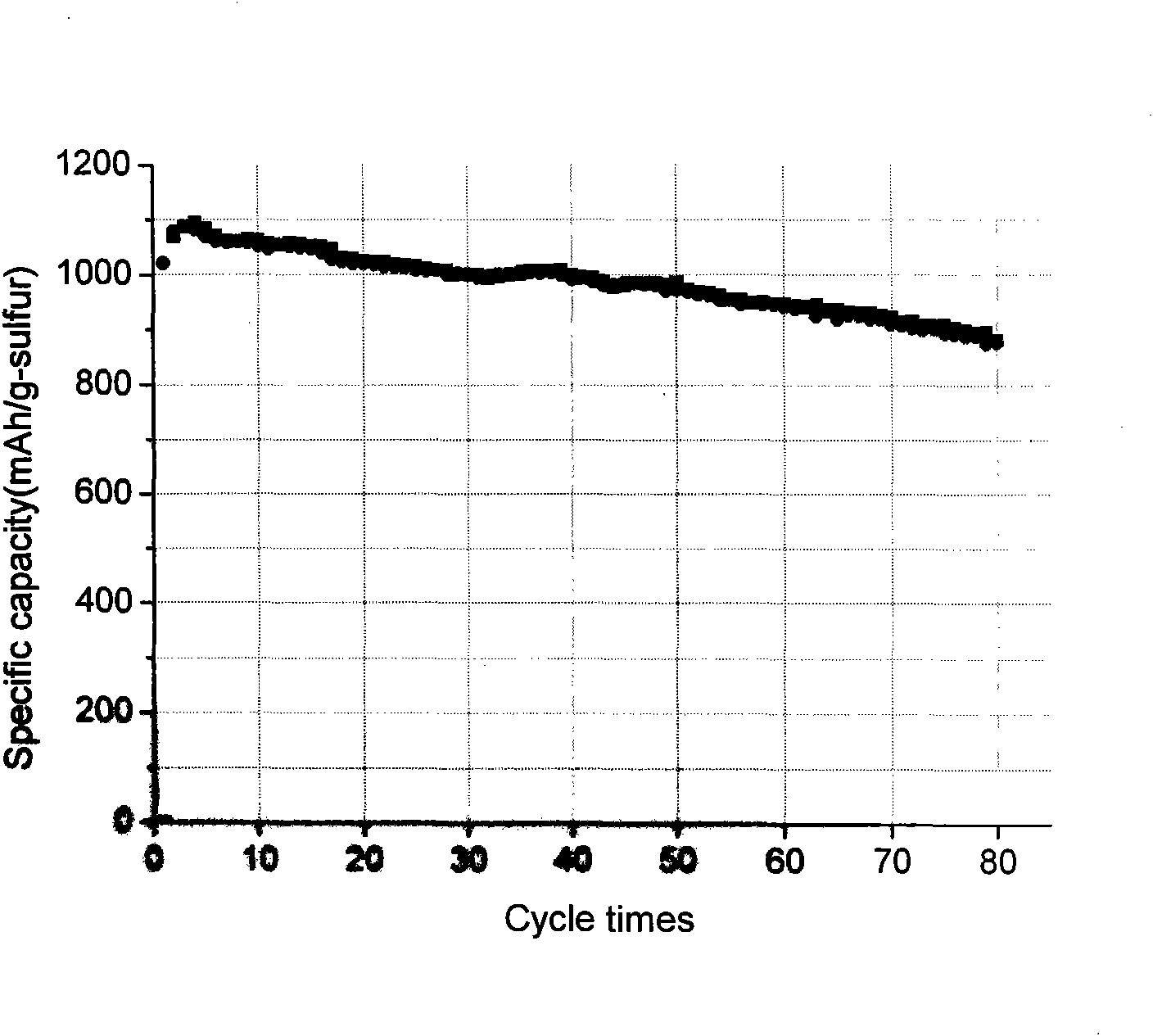

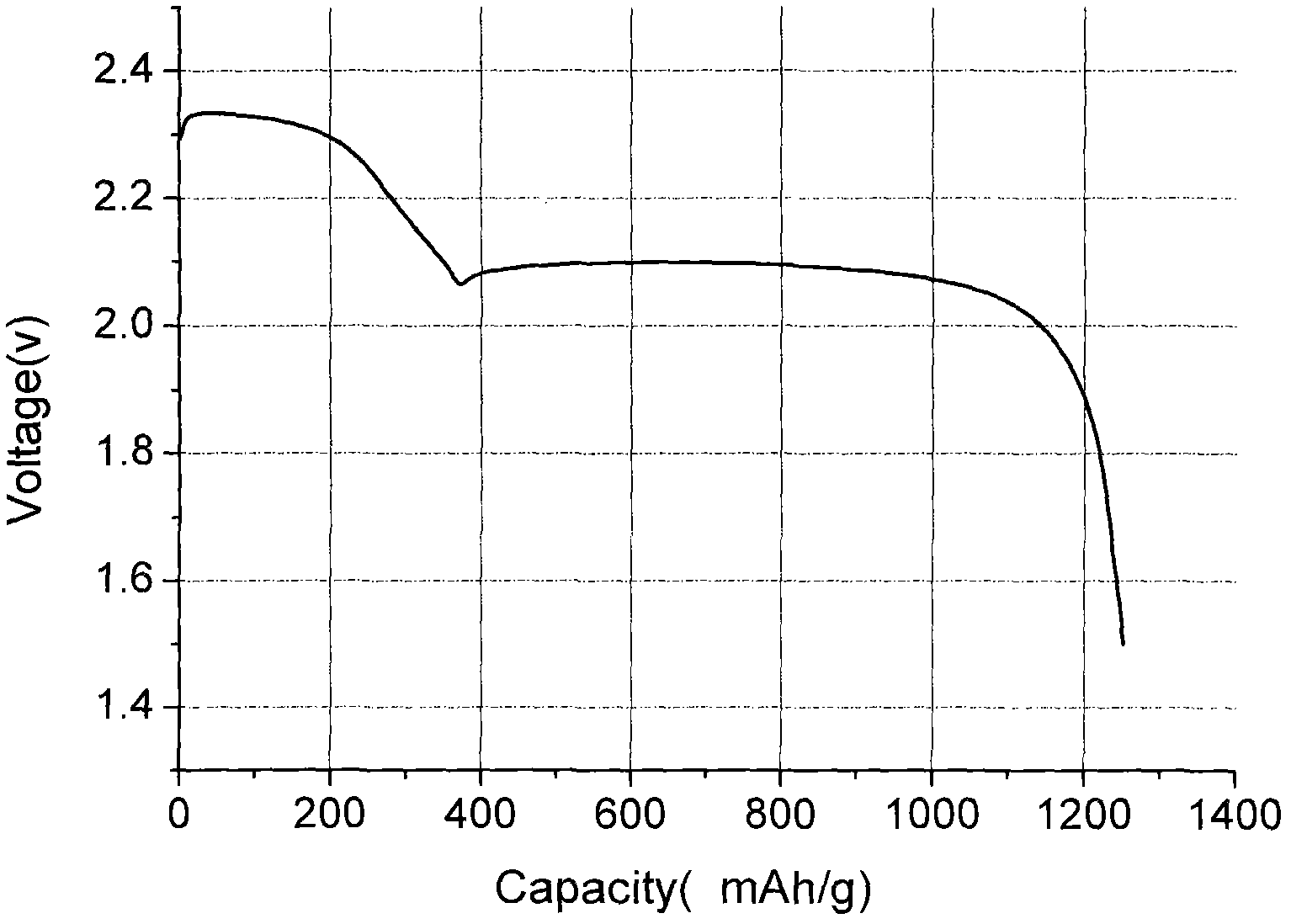

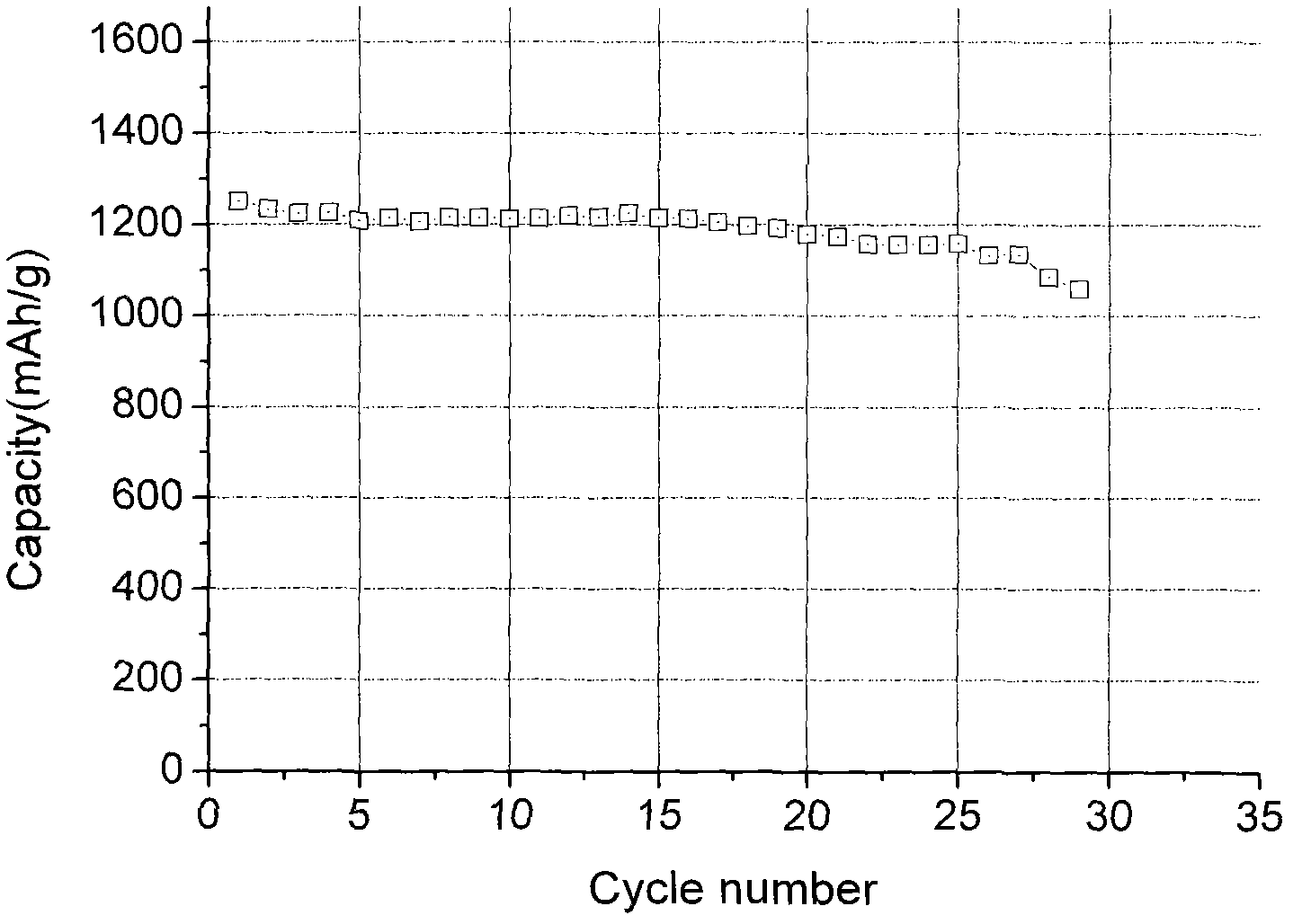

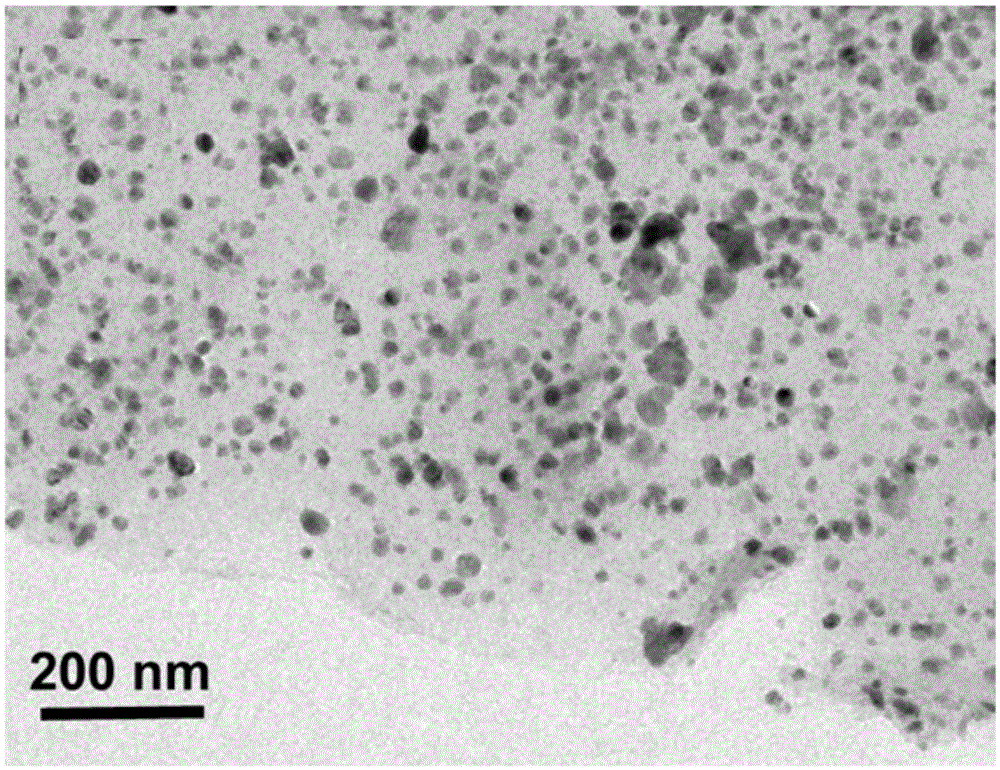

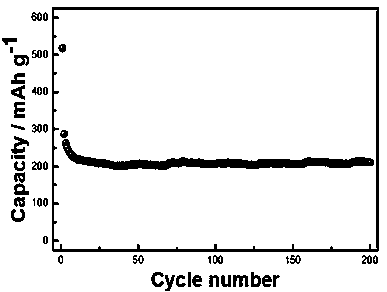

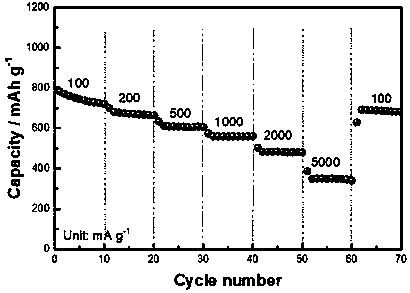

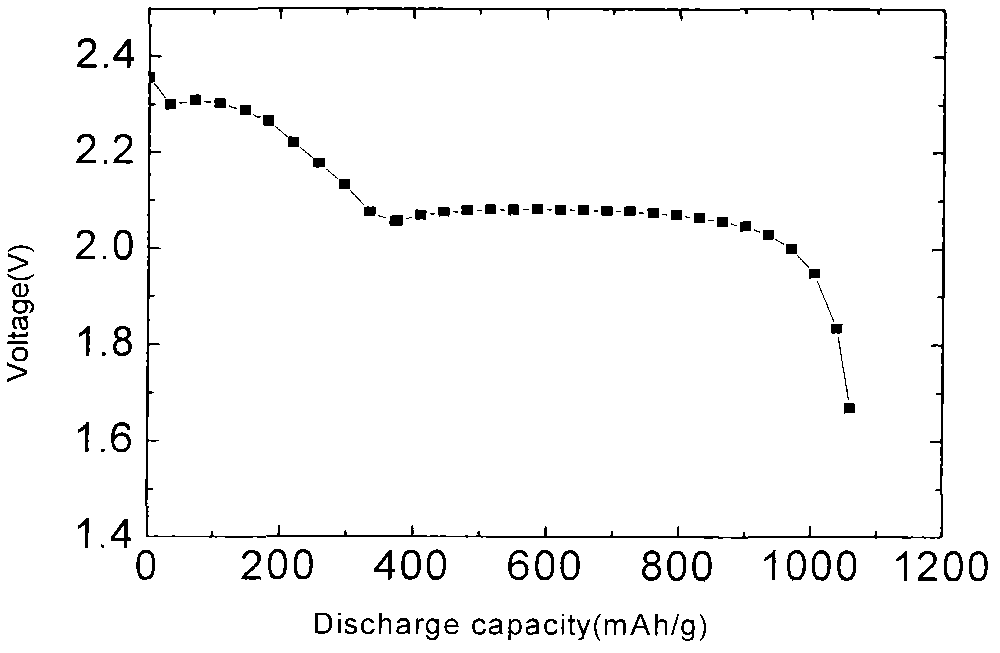

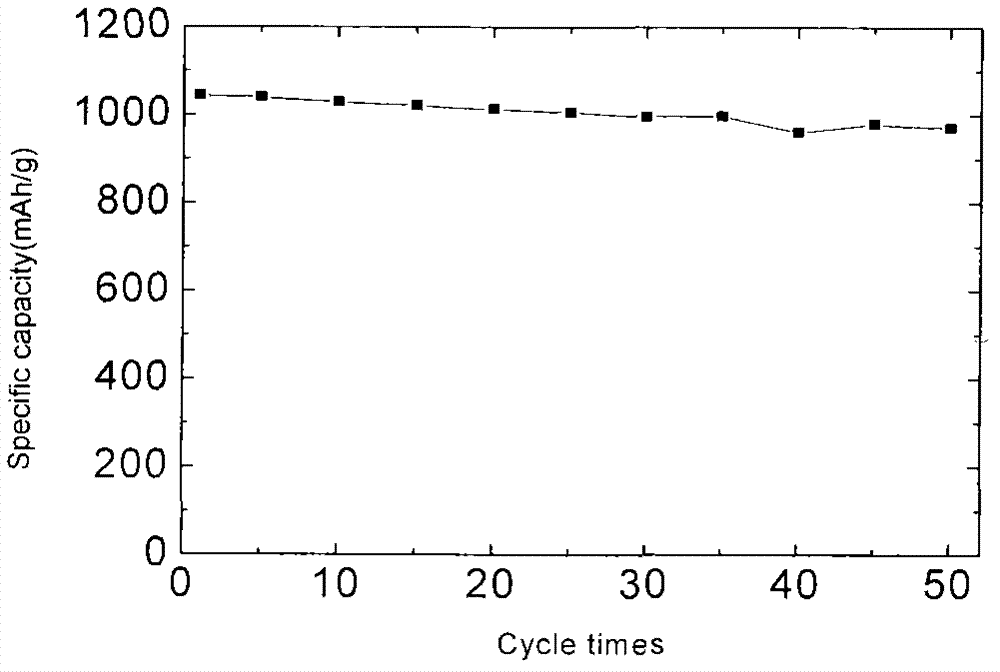

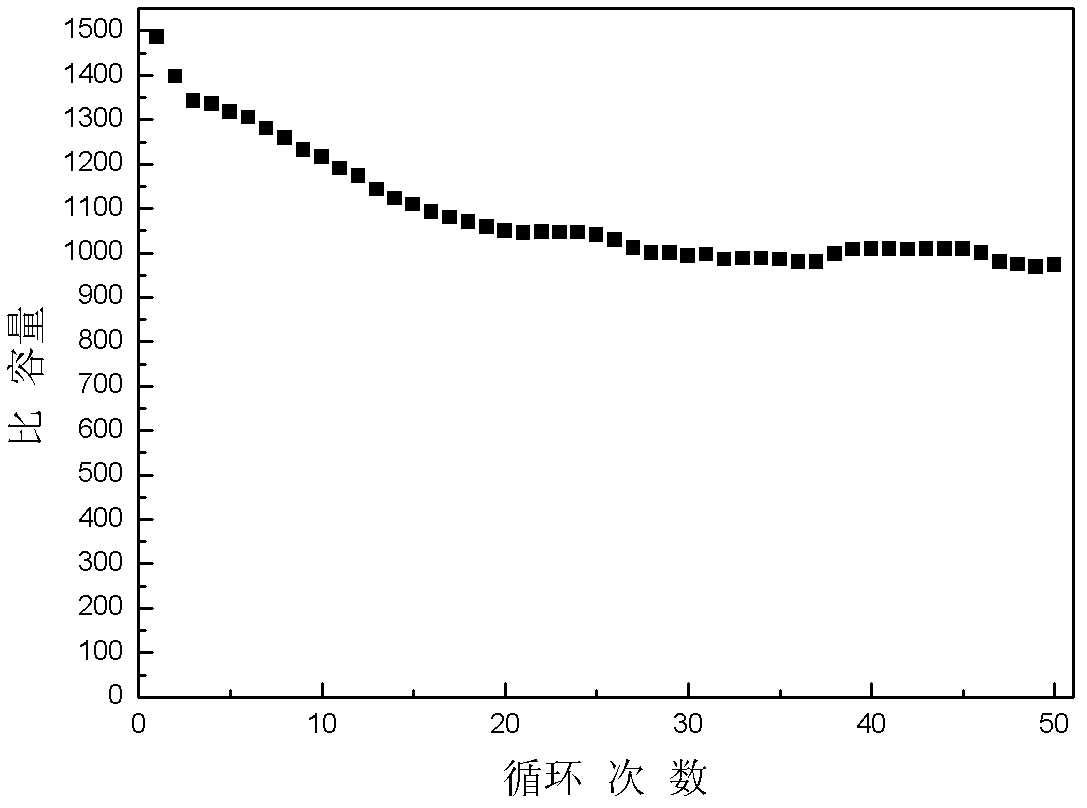

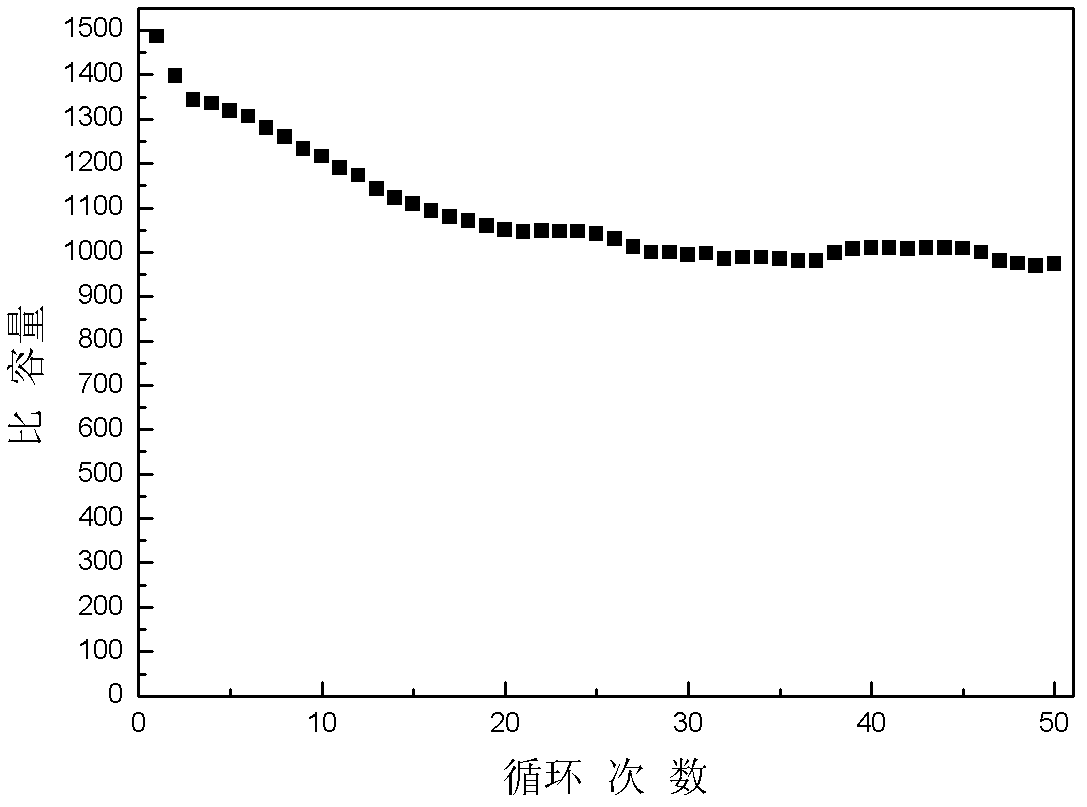

Carbon/sulfur composite positive material having long cycle life, and preparation method thereof

InactiveCN103247799ARich cross-linked network structureSimple structureCell electrodesCarbon fibersSulfur

A grafted carbon nanofiber / sulfur composite material having a high specific capacity and a long cycle life and applied in a lithium sulfur battery is obtained through carrying out melt compounding of grafted carbon nanofibers having an outstanding conductive performance and a network structure and elemental sulfur at a reaction temperature of 110-380DEG C for 2-60h, and the mass content of sulfur in the composite material is 40-85%. The initial discharge specific capacity of the composite positive electrode material is 1186mAh / g, and the discharge specific capacity of the composite positive electrode material after 50-time cycle still maintains 948mAh / g, so the composite positive electrode material has a good cycle stability.

Owner:NO 63971 TROOPS PLA

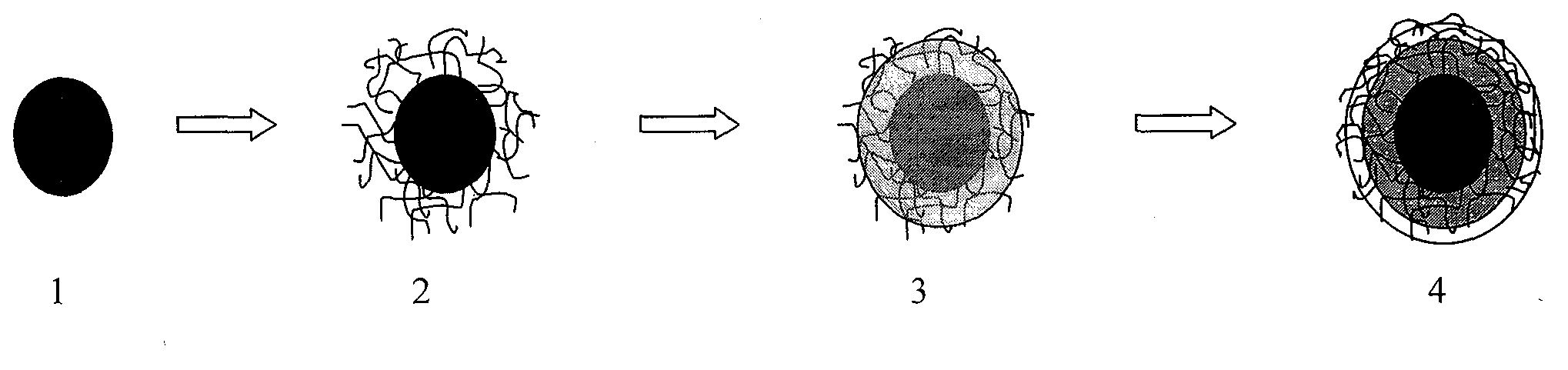

Expansible fire retardant having double-layer core-shell structure, and preparation method and application thereof

InactiveCN102408897AGood compatibilityNot easy to loseMicroballoon preparationMicrocapsule preparationAmmonium polyphosphatePrepolymer

The invention discloses an expansible fire retardant having a double-layer core-shell structure, and a preparation method and application thereof. In the fire retardant, ammonium polyphosphate is used as a capsule core, and the capsule material sequentially comprises an epoxy resin layer and a melamine-formaldehyde resin layer from inside to outside. The preparation method comprises the following steps: mixing melamine and a 37% (mass percent) formaldehyde water solution, and dissolving in water to obtain a reaction system; regulating the pH value to 8-9, stirring while heating up to 60-95 DEG C, and reacting while keeping the temperature to obtain a melamine-formaldehyde prepolymer water solution; suspending ammonium polyphosphate powder particles in dispersant, adding epoxy resin and curing agent, and reacting while stirring; adding the melamine-formaldehyde prepolymer water solution and hardening agent, and reacting while stirring; and carrying out vacuum filtration, washing, and drying to obtain the expansible fire retardant having a double-layer core-shell structure. Since the fire retardant has the double-layer core-shell structure, the capsule material can not be extruded and broken easily in the processing procedure of the composite material, thereby avoiding the loss of the capsule core; and the fire retardant has better compatibility, fire retardance and water resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

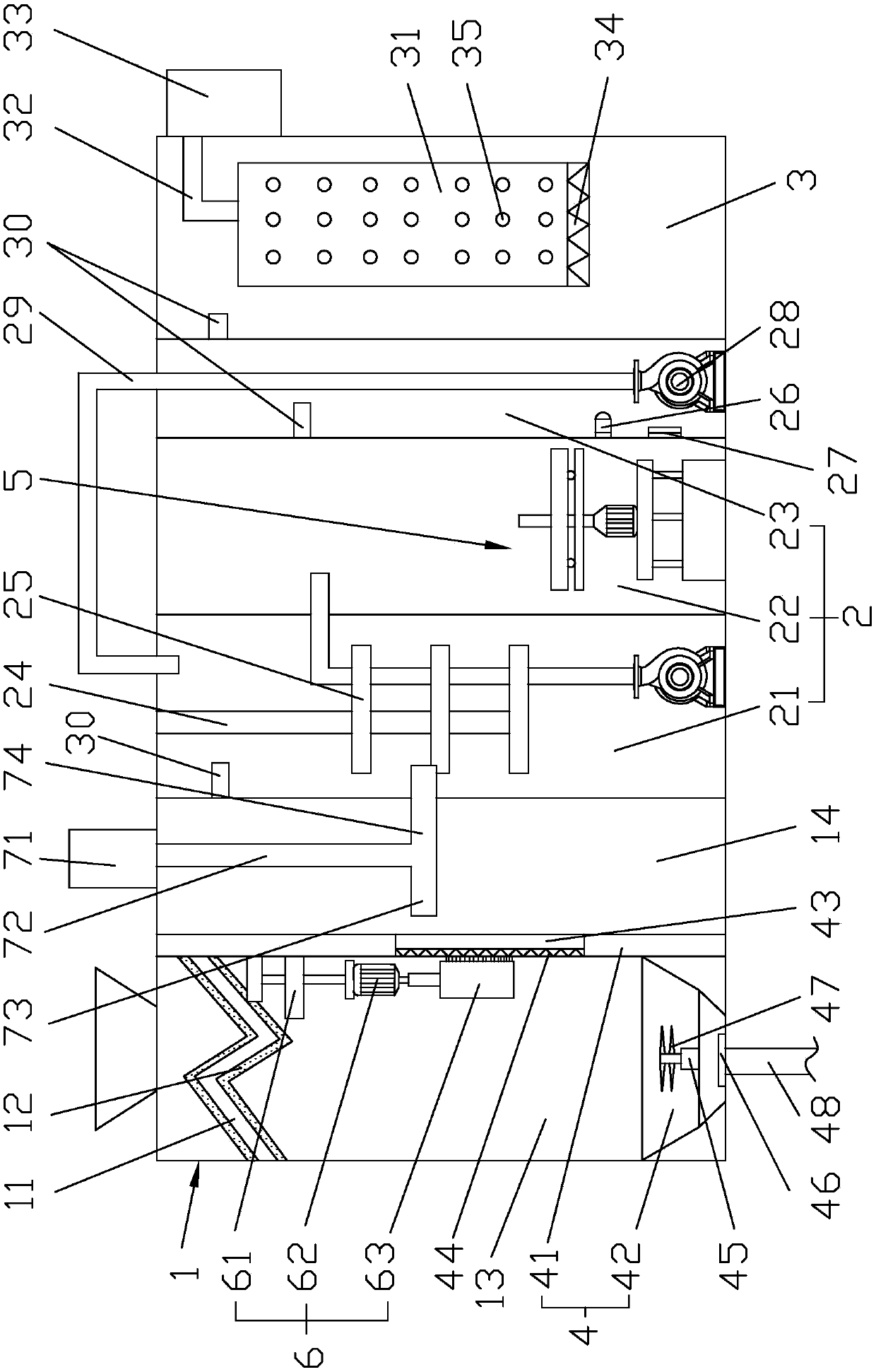

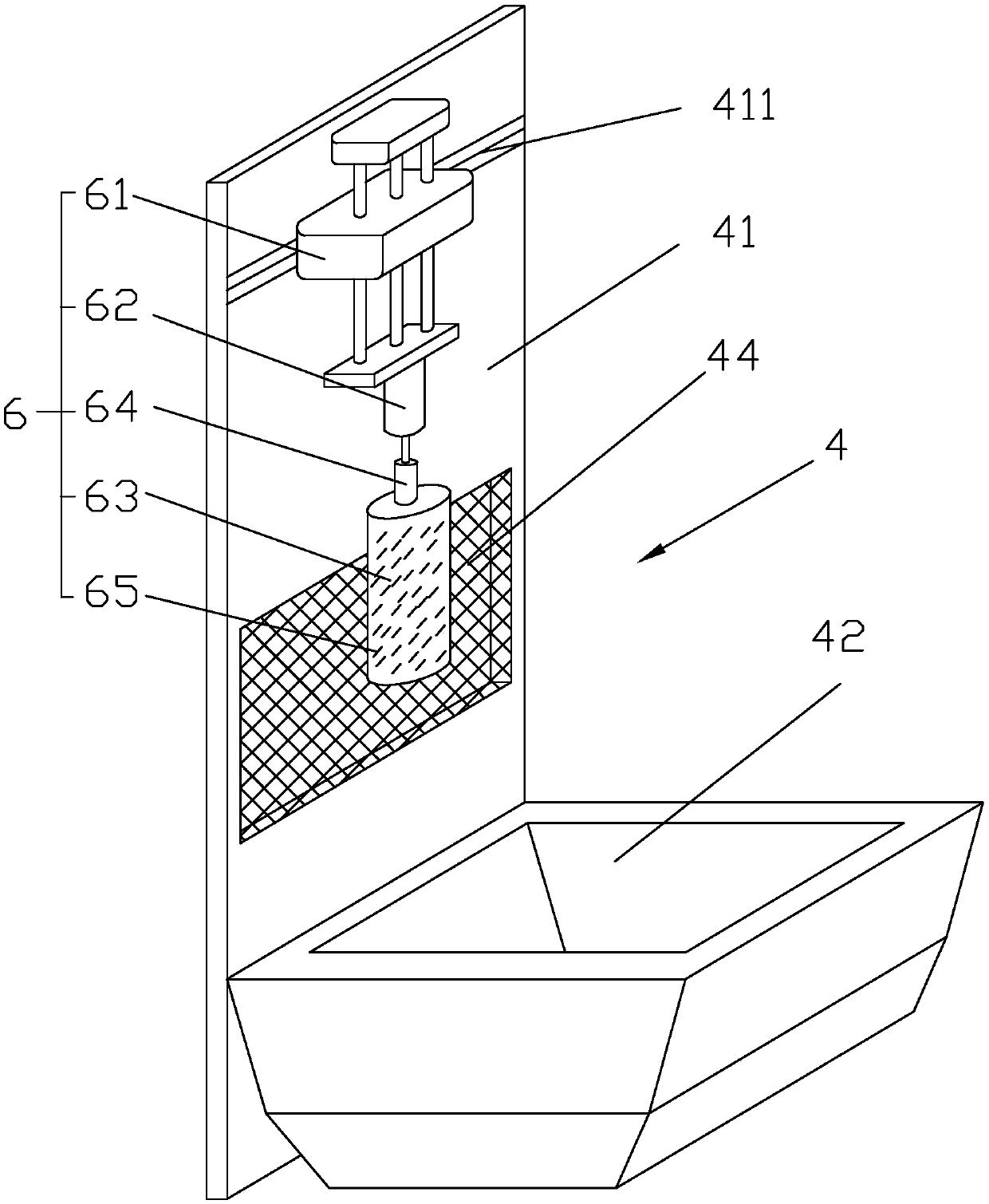

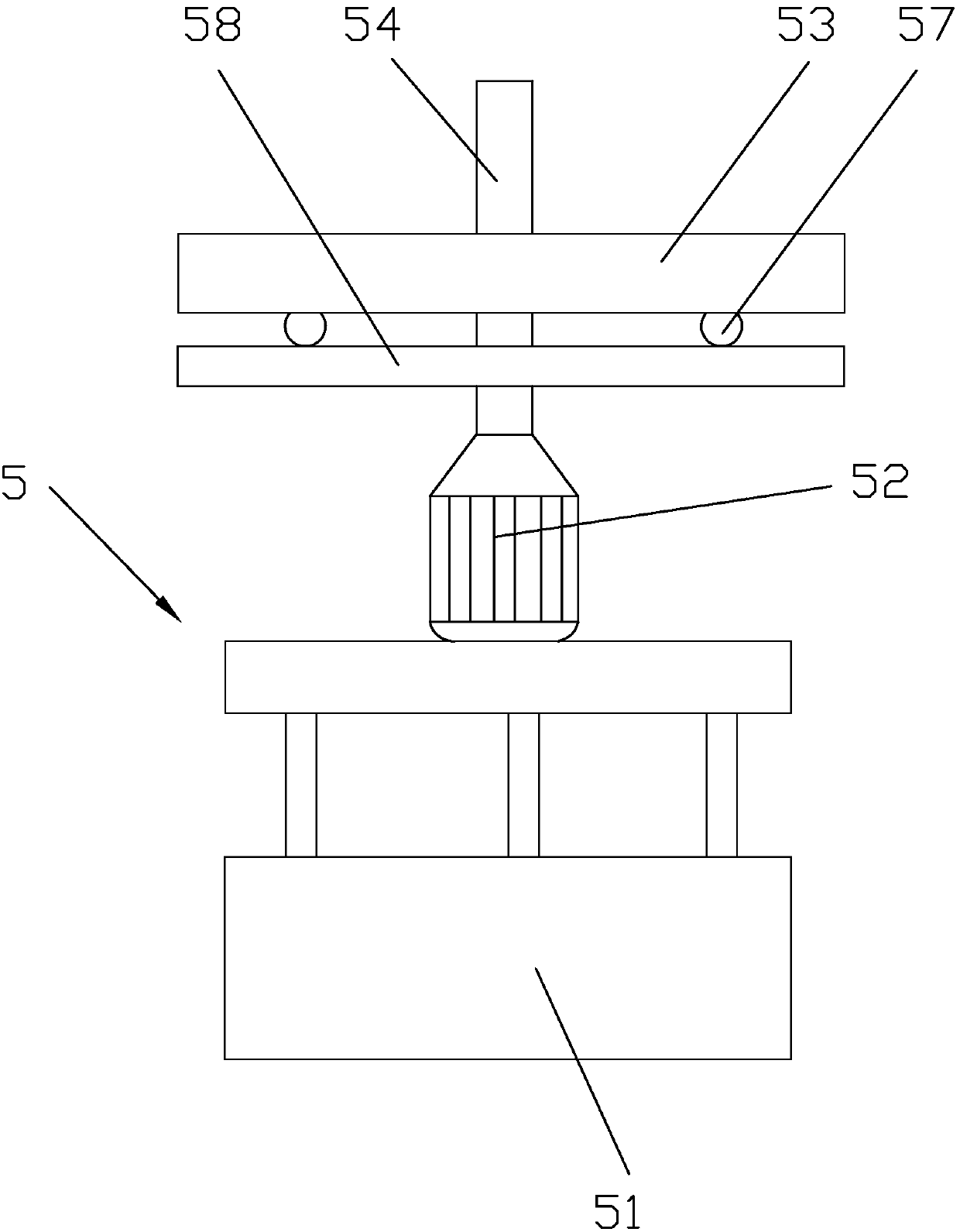

Aeration type sewage treatment device and method

InactiveCN106698823AStrong storageAvoid cloggingTreatment using aerobic processesSpecific water treatment objectivesHazardous substanceSewage

The invention mainly discloses an aeration type sewage treatment device and method. The technical scheme is as follows: the device comprises a primary sedimentation tank, a biodegradation tank and a disinfection tank, wherein a filtering device is arranged in the primary sedimentation tank and comprises a filtering plate and a collection box; the biodegradation tank comprises a facultative tank, an aerobic tank and a clarifying tank in mutual connection; a biological packing frame is arranged in the facultative tank; an aeration device is arranged in the aerobic tank and comprises a lifting cylinder, a spiral aerator and a rotating disk; the spiral aerator is mounted on the upper side of the lifting cylinder; a rotating shaft of the spiral aerator penetrates the rotating disk; and aerobic microbial packing is arranged on the rotating disk. Particle impurities of sewage are removed by the primary sedimentation tank, and then the sewage enters the biodegradation tank for reacting and finally is subjected to disinfection treatment. In the invention, through multi-stage treatment of the sewage, harmful substances in the sewage are separated and degraded better, the blocking phenomenon does not happen frequently, the treatment efficiency is high while the effect is good, and the treated sewage reaches the national discharge standard.

Owner:ZHEJIANG BUSINESS TECH INST

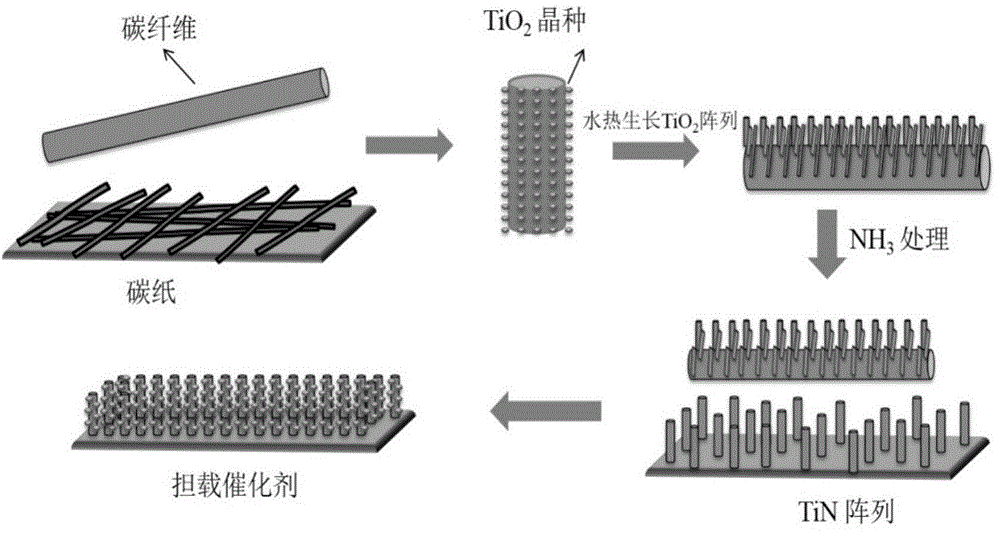

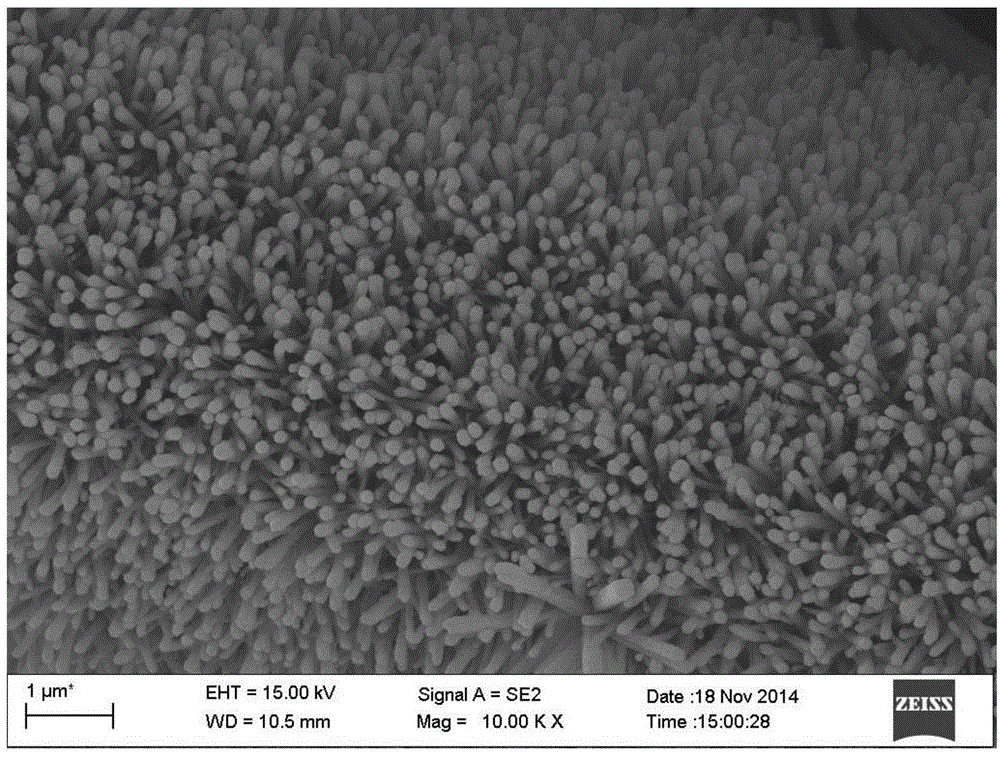

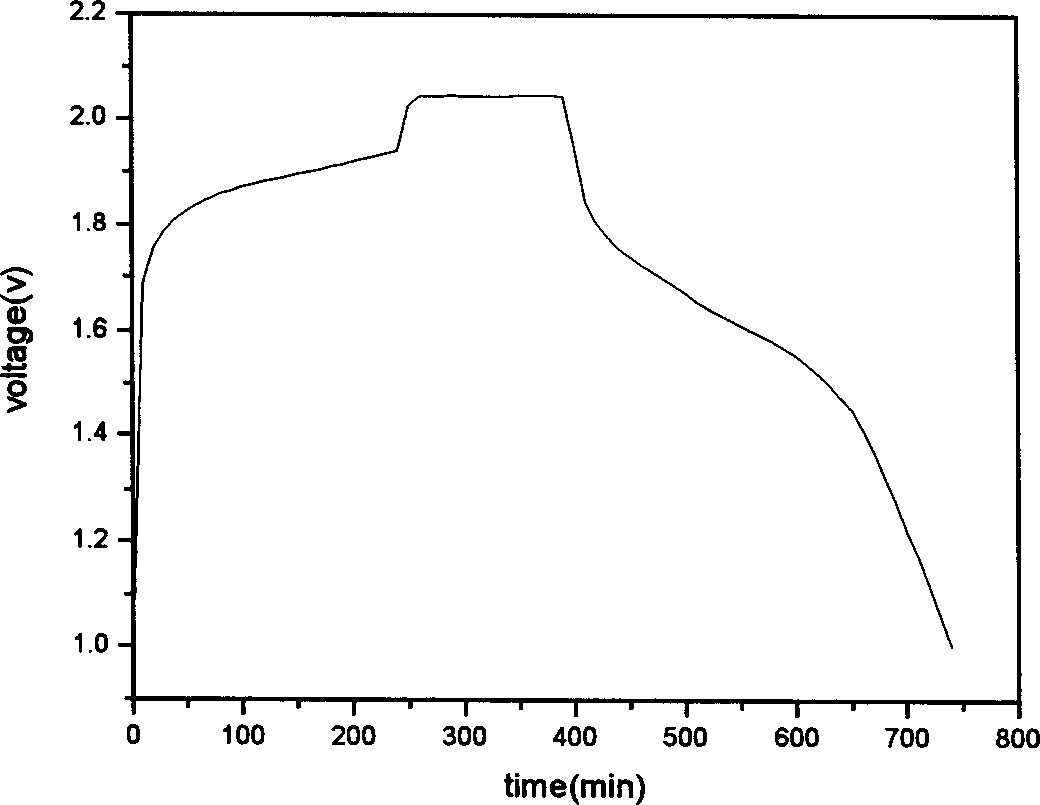

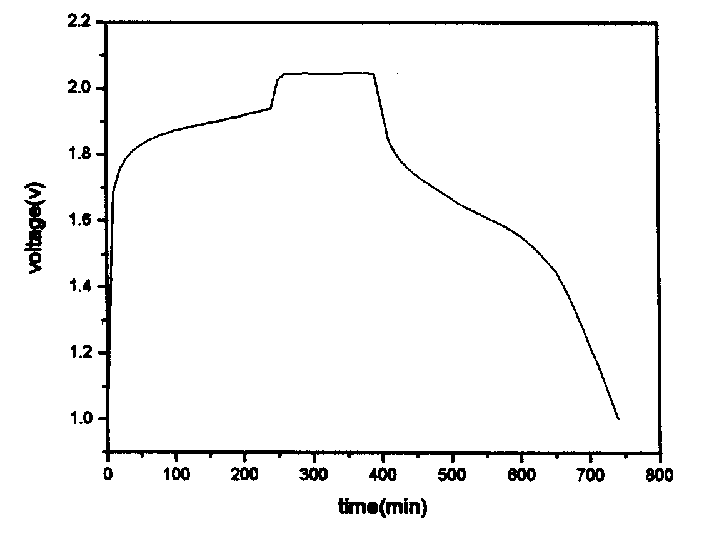

Preparation method for ordered ultra-thin catalyst layer, catalyst layer and application

ActiveCN106159285AIncrease the reaction areaIncrease profitCell electrodesElectrical conductorProton

The invention relates to a preparation method for an ordered ultra-thin electrode of a proton exchange membrane fuel cell. The preparation method comprises the steps of preparing an ordered electrode structure and establishing an ultra-thin catalyst layer; a process of impregnating and annealing is carried out on a carbon paper to obtain TiO<2> seed crystals; then a TiO<2> nanorod is grown through a hydrothermal method; a TiN ordered array is prepared through NH<3> etching; and the array is loaded with a catalyst to establish the ordered ultra-thin catalyst layer without containing a proton conductor (such as Nafion). The established ordered ultra-thin catalyst layer can be used for the proton exchange membrane fuel cell, other fuel cells and electrochemical devices.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-borne nano ultra-thin steel structure fire retardant coating and preparation method thereof

The invention discloses a water-borne nano ultra-thin steel structure fire retardant coating, which comprises a carbon source, an acid source, an air source and auxiliaries, and consists of the following components by weight percentage: 20-40% of acrylic ester emulsion, 10-30% of ammonium polyphosphate (APP), 5-15% of pentaerythritol, 1-10% of melamine, 1-10% of nanometer material, 0.001-5% of auxiliaries, and 10-30% of water. The invention also discloses a preparation method of the fire retardant coating. The prepared fire retardant coating has the characteristics of stable performance and good fire resistant performance, the thickness of the prepared fire retardant coating is no more than 2mm, and the fire reissuance duration of the prepared fire retardant coating is up to 120 minutes.

Owner:浙江川科防保材料发展有限公司

Production technology for producing nutrient seasoning powder by enzymatic method with comprehensive utilization of avian skeleton

The invention relates to the technical field of condiment production with biological enzyme method, especially relating to a production technology for producing nutrient seasoning powder by enzymatic method with comprehensive utilization of avian skeleton. The production technology includes the following steps: (a) preparing raw materials; (b) performing cooking process; (c) performing a first step of enzymolysis reaction; (d) performing a second step of enzymolysis reaction; (e) performing Maillard reaction; (f) performing homogenizing treatment; and (g) performing powder spraying treatment: subjecting the mixture after homogenizing treatment to powder spraying treatment in a spray tower, sieving to remove the residues with a sieve mesh, and uniformly stirring to obtain the nutrient seasoning powder. The invention uses new biological enzyme to perform enzymolysis and extraction to the nutrients in the avian skeleton completely, so that the prepared condiment has rich nutrition, rich aroma, good quality, pure natural taste, and high product yield.

Owner:广东味霸味业科技有限公司

Zinc-nickel secondary cell and preparation method thereof

InactiveCN1434534ASimple processQuality controllableFinal product manufactureAlkaline accumulators manufactureCapacitanceElectrolytic agent

This invention relates to a preparation method for ZnNi secondary cell and the cell prepared by the said method which is to isolate the positive and negative plates by diaphragm paper to be put into cell shell after being laminated and winded and fill in electrolyte, the positive plate contacts with the shell of positive collector, the negative is connected with the negative cap in weld via conductive terminal, finally go on with sealing, packing and storage, with the advantags of high voltage, large discharge capacitance, long circulation life, small internal resistance, excellent large current discharging performance.

Owner:SOUTH CHINA UNIV OF TECH

Nano-silver antibacterial agent and preparation method thereof

InactiveCN103999873AIncrease viscosityImprove antibacterial propertiesBiocideDisinfectantsEmulsionAntibacterial agent

The invention provides a nano-silver antibacterial agent which includes nano-silver antibacterial stock solutions. Nano-silver is included in the nano-silver antibacterial stock solutions, and the content of the nano-silver is 0.00025 mol / kg to 0.02 mol / kg. The invention further provides a preparation method of the nano-silver antibacterial agent. The nano-silver antibacterial agent can be foam emulsion and sprays in a flow state, can be used as washing-free sprays, and is convenient for people to use when cleaning with water is inconvenient in travel.

Owner:杜一挺

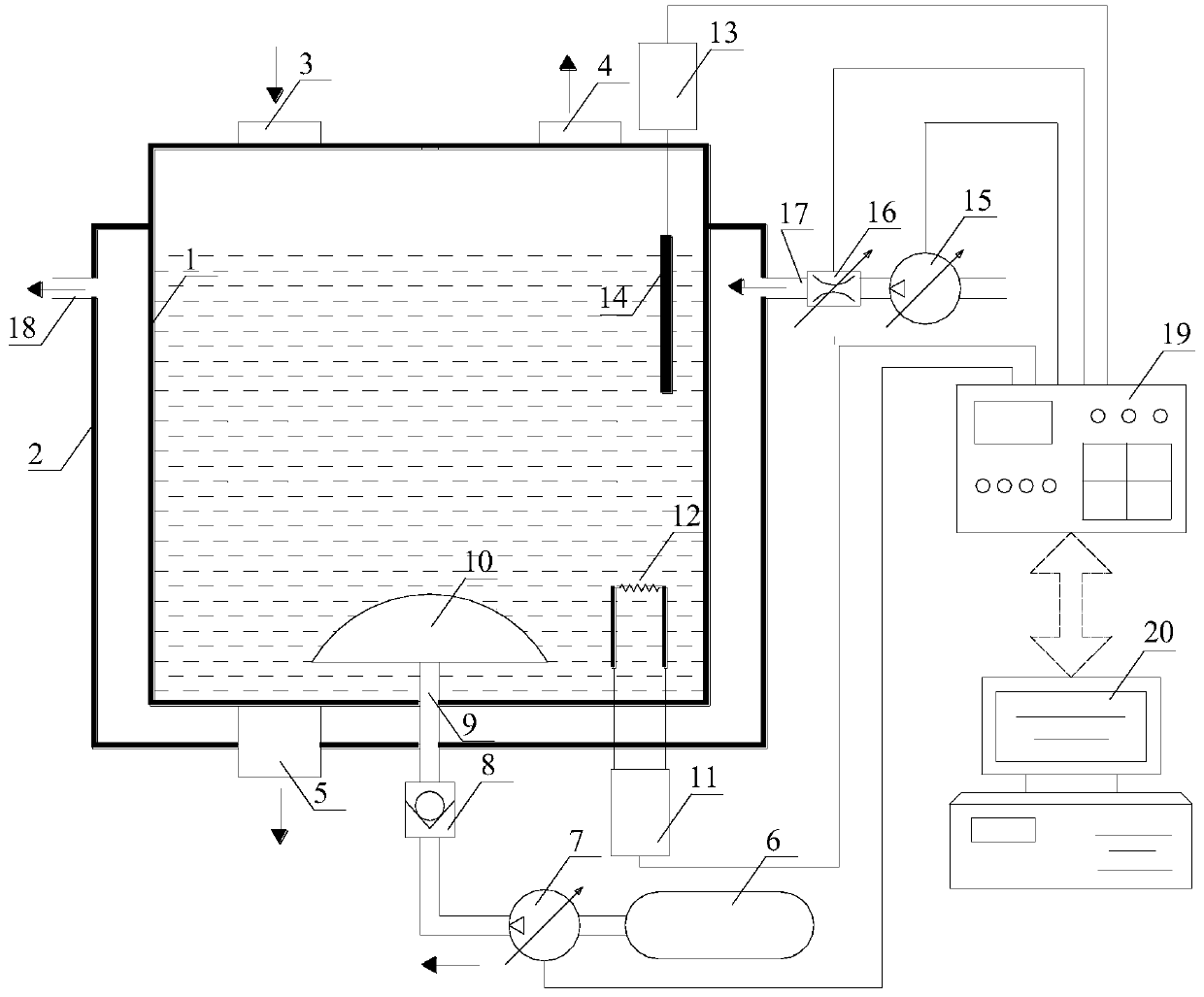

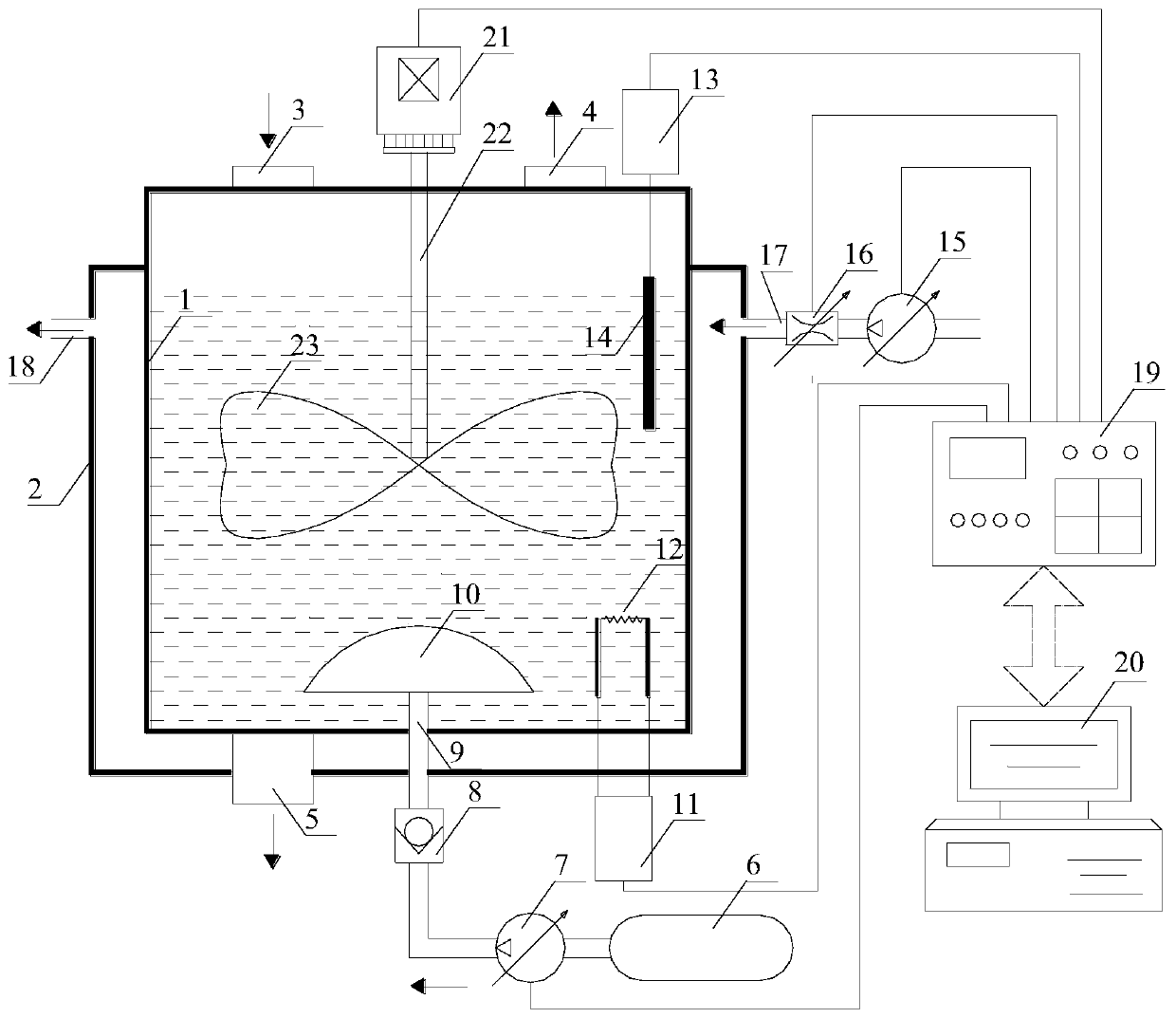

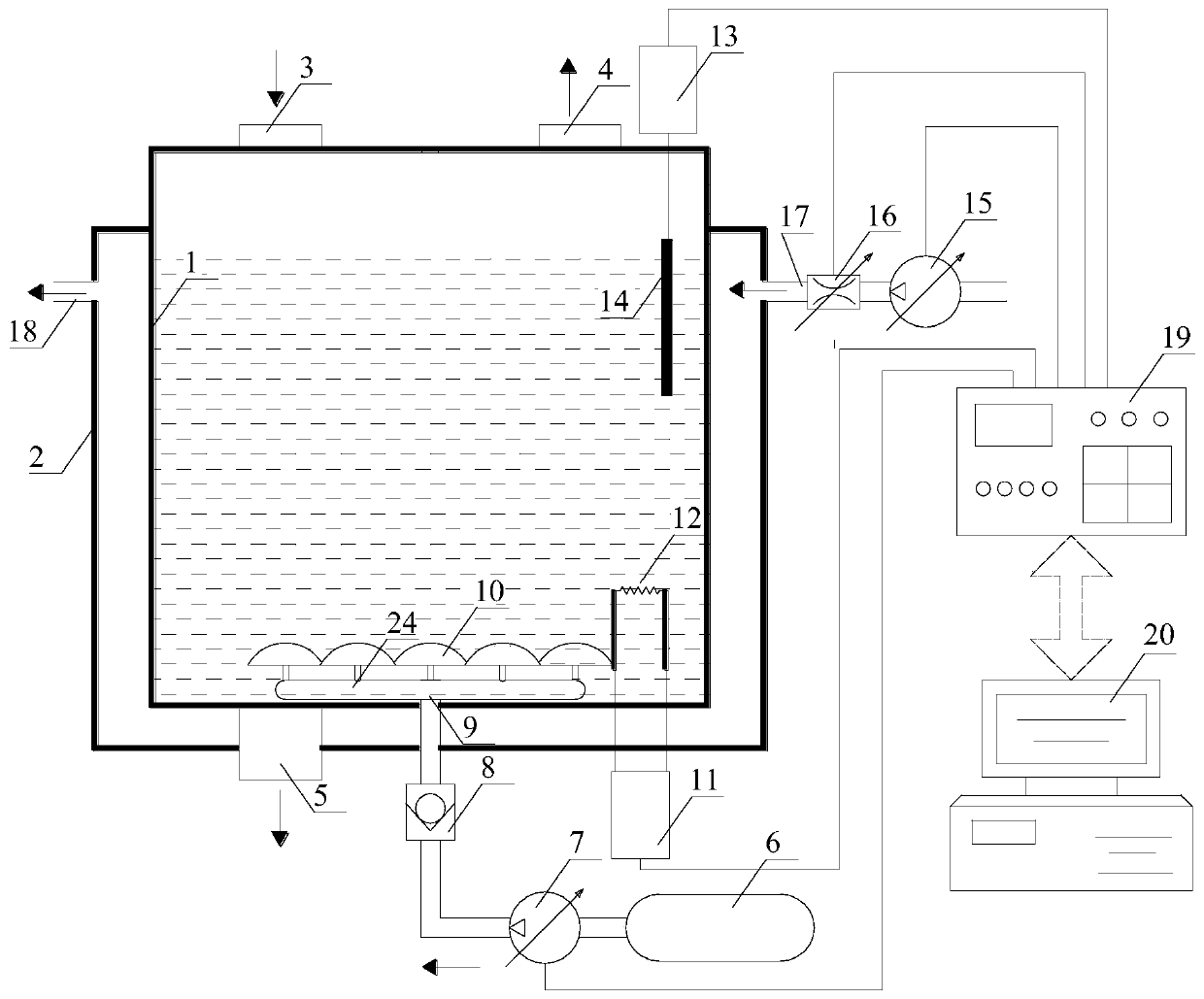

Gas liquid reaction kettle adopting spherical crown-shaped micropore corundum gas supply apparatus

PendingCN110404485ALarge air supplyStrong agitationLiquid-gas reaction as foam/aerosol/bubblesChemical/physical/physico-chemical stationary reactorsGas liquid reactionAging resistance

The invention relates to a gas liquid reaction kettle adopting a spherical crown-shaped micropore corundum gas supply apparatus. The gas liquid reaction kettle comprises a reaction kettle body and a gas supply device, the reaction kettle body comprises a main kettle body, the gas supply device comprises the gas supply apparatus, the gas supply apparatus is arranged in the main kettle body, and thetop surface of the gas supply apparatus is a spherical surface; the gas supply apparatus is in a spherical crown shape and is of an integrated structure, and upper and lower surfaces of the gas supply apparatus release gas simultaneously; the gas liquid reaction kettle has the advantages of a large gas supply amount, high stirring intensity, low resistance, high efficiency, low consumption, reliable operation, no blockage, ageing resistance, corrosion resistance, long service life and the like; in addition, the superficial area of contact between gas and liquid is greatly increased through alarge number of fine bubbles, the reaction speed is increased, and the reaction efficiency is improved; in addition, during gas supply, a high self-stirring effect of a large number of small bubbles is achieved, a stirring device of a conventional gas liquid reaction kettle does not need to be arranged, the structure can be simplified, the cost is reduced, and if the stirring device is arranged, the speed and efficiency of a gas liquid reaction can be further improved.

Owner:TONGLING UNIV

Heterojunction thin film composed of same metals and oxygen family elements as well as preparation and application thereof

ActiveCN108479806ALow costAdjustable thicknessPhysical/chemical process catalystsCell electrodesHeterojunctionSulfur

The invention relates to a preparation method of a heterojunction thin film composed of same metals and oxygen family elements. The preparation method comprises the following steps: mixing metal salt,acid and water to obtain a metal precursor solution; depositing the metal precursor solution on the surface of a base under the conditions that the pH is 2-11, and the temperature is 30-90 DEG C to form metal oxide; performing heat treatment on the metal oxide and at least one of sulfur source and selenium source for 2-120 minutes at a temperature of 100-600 DEG C and an air pressure of minus 0.05-1 MPa to obtain the heterojunction thin film; the heterojunction thin film is a metal oxide-sulfide heterojunction thin film, a metal oxides-selenide heterojunction thin film or a metal oxide-sulfide-selenide heterojunction thin film. The invention further discloses the heterojunction thin film prepared by the preparation method provided by the invention and application thereof. The preparationmethod has the advantages of being simple in equipment, low in cost, easy for large-area continuous production and the like; the prepared thin film is controllable in thickness component, dense and uniform in appearance and good in crystallization and optoelectronic properties.

Owner:CENT SOUTH UNIV

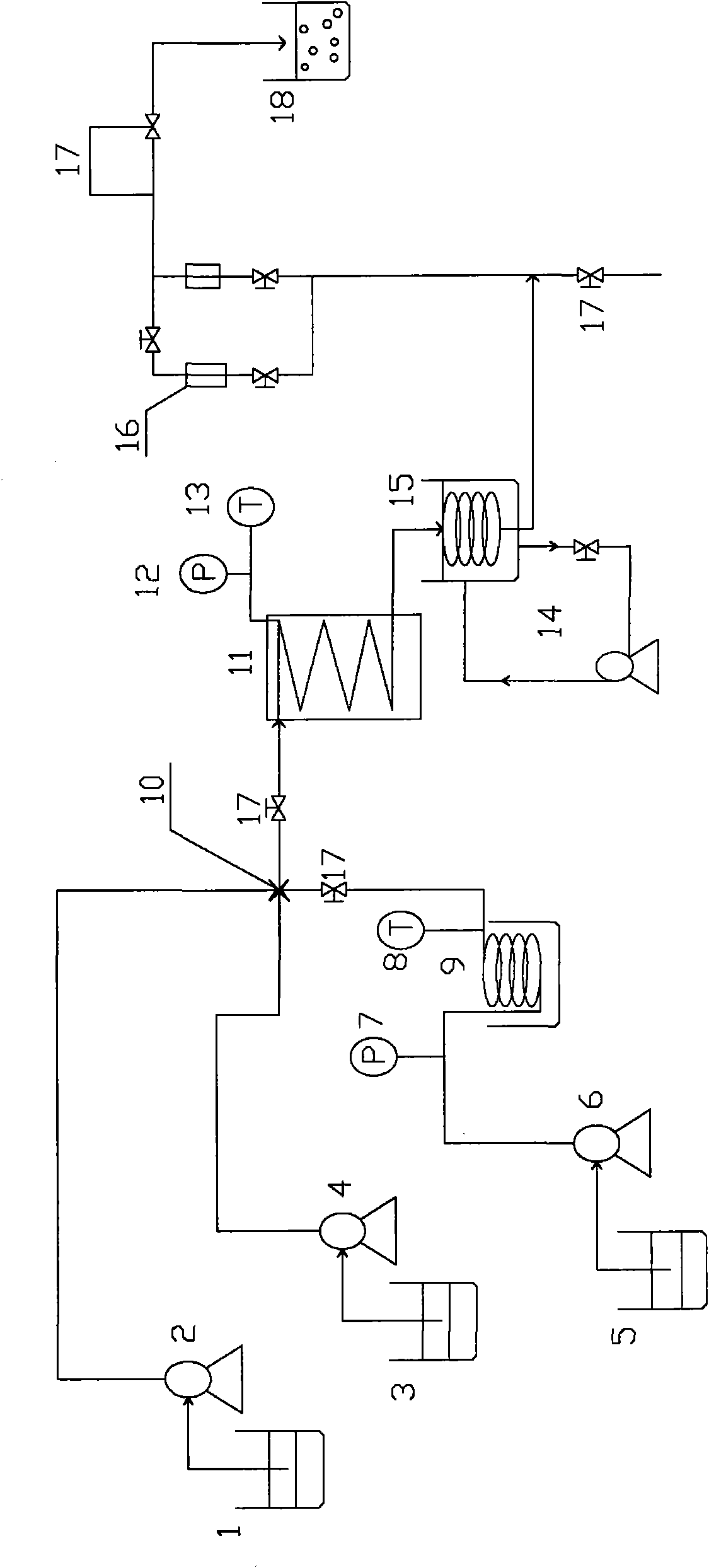

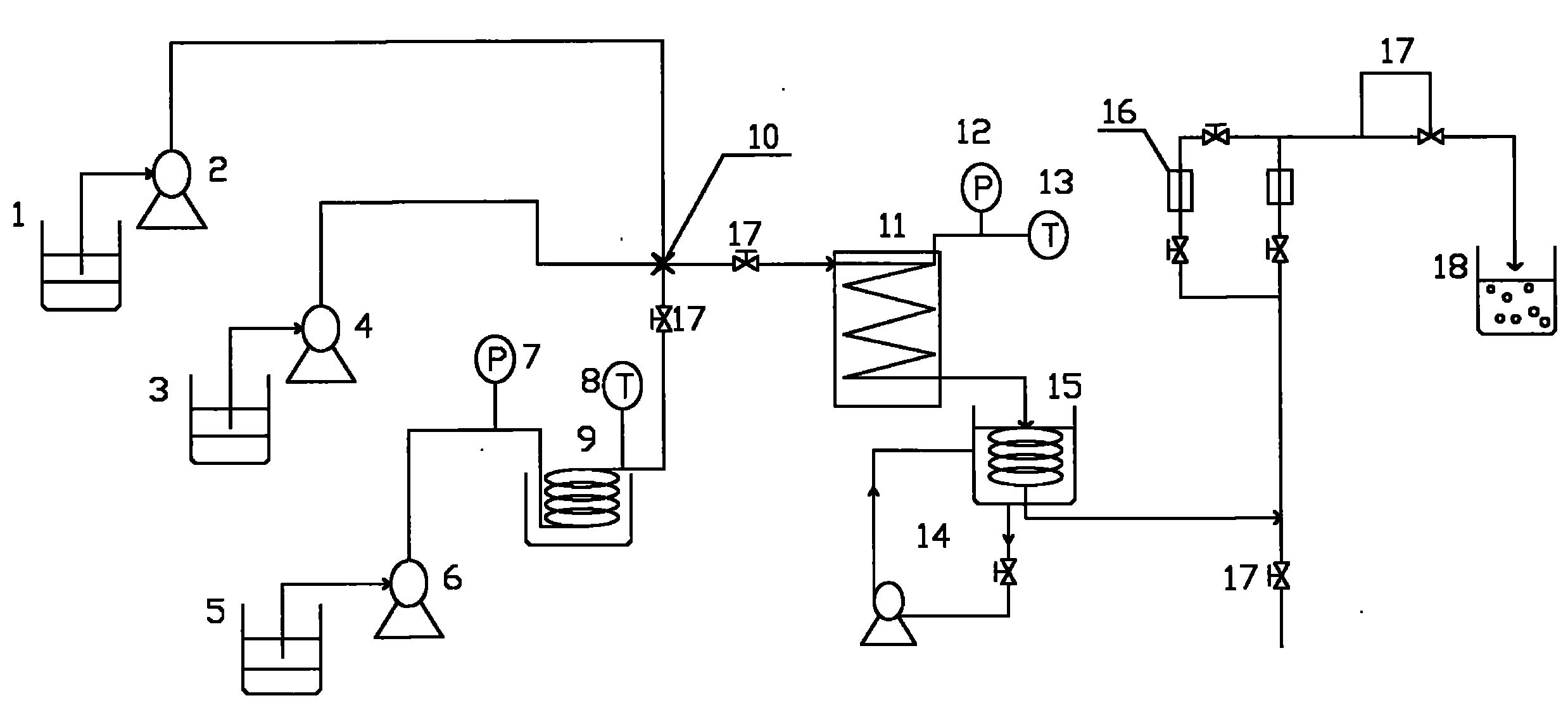

Process for preparing power type lithium-ion battery anode material by using supercritical/subcritcal water thermal process

InactiveCN101807698AIncrease the reaction areaIncrease production per unit timeCell electrodesPhosphorus compoundsElectrical batteryPhosphoric acid

The invention relates to a process for preparing a power type lithium-ion battery anode material by using a supercritical / subcritcal water thermal process. The process comprises the following steps of: (1) continuously injecting two fluids of a raw material lithium source and a mixed liquid consisting of an iron source / manganese source and a phosphoric acid source into a mixer for mixing; (2) preheating a third fluid formed by deionized water, and adding the third fluid into the mixer to be mixed with the two fluids in the step (1); (3) leading the mixed liquid of the three fluids discharging from the mixer in the step (2) to enter a high temperature and high pressure reaction kettle for carrying out hydrothermal crystallization reaction; (4) cooling a product liquid obtained from the hydrothermal crystallization reaction through a heat exchanger, filtering by a filter to remove large-grain particles and impurities, and leading the filtrate into a solid-liquid separator; (5) continuously collecting particles precipitated in the solid-liquid separator, and drying to obtain dry powder of the battery anode material. The process can be carried out continuously and is beneficial to improving the operation efficiency and reducing the energy consumption.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

A kind of sulfur-graphene composite cathode material and preparation method thereof

The invention relates to the field of electrochemistry and new energy materials and in particular relates to a sulphur-graphene composite cathode material and a manufacturing method thereof. The material provided by the invention comprises 80-98wt% of element sulfur and 2-20wt% of grapheme. The manufacturing method comprises the following steps: mixing 80-98wt% of element sulfur with 2-20wt% of graphene, and adding dispersing agents and carrying out ball milling as well as carrying out vacuum drying for 1-2 hours at the temperature of 80-100 DEG C; placing into a vacuum sealing device or sealing device filled with inert gases, putting the sealing device into a tubular heater, heating to 150-160 DEG C and performing heat preservation for 10-24 hours; and then cooling to room temperature so as to obtain the sulphur-graphene composite cathode material. According to the invention, the composite material manufactured by using the graphene has the advantages of low price, light weight and good electric conductivity; and simultaneously, the raw materials are rich, the process is simple, the operation is easy and the mass production can be realized easily.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing lubricating coating with strong stability on surface of medical polyurethane material

InactiveCN101612421AImprove the lubrication effectImprove stabilitySurgeryCatheterGas phaseGraft reaction

The invention discloses a method for preparing a lubricating coating with strong stability on the surface of a medical polyurethane material, comprising the following steps of: step 1, pretreating the medical polyurethane material so as to obtain positions with proper surface roughness and reaction activity; step 2, putting the polyurethane polymer material pretreated in the step 1 into a gas phase system of reaction solution or solute for grafting reaction; and step 3, cleaning and drying the reaction products from the step 2. The method can be widely used for preparing medical polymer materials and high-lubricity coating materials on the surface of medical instruments.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com