A kind of sulfur-graphene composite cathode material and preparation method thereof

A composite cathode material, graphene composite technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low sulfur ion conductivity and electronic conductivity, decreased battery cycle charge and discharge performance, and poor sulfur electrochemical performance. , to achieve the effect of good conductivity, abundant raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] 1) Preparation of composite electrode sheet: The sulfur-graphene composite material, the conductive agent acetylene black and the binder polyvinylidene fluoride (PVDF) were mixed in N-methyl-2-pyrrolidone ( Stir evenly in NMP) solvent, then coat it on an aluminum foil, dry it in vacuum at 60°C for 24 hours, and punch it into a 0.785cm 2 pole piece.

[0025] 2) Battery assembly: the composite electrode sheet prepared by the above method is used as the positive electrode, the metal lithium sheet is used as the negative electrode, and 1M LiClO 4 / PC is an organic electrolyte, which is assembled into a button cell in a glove box filled with argon.

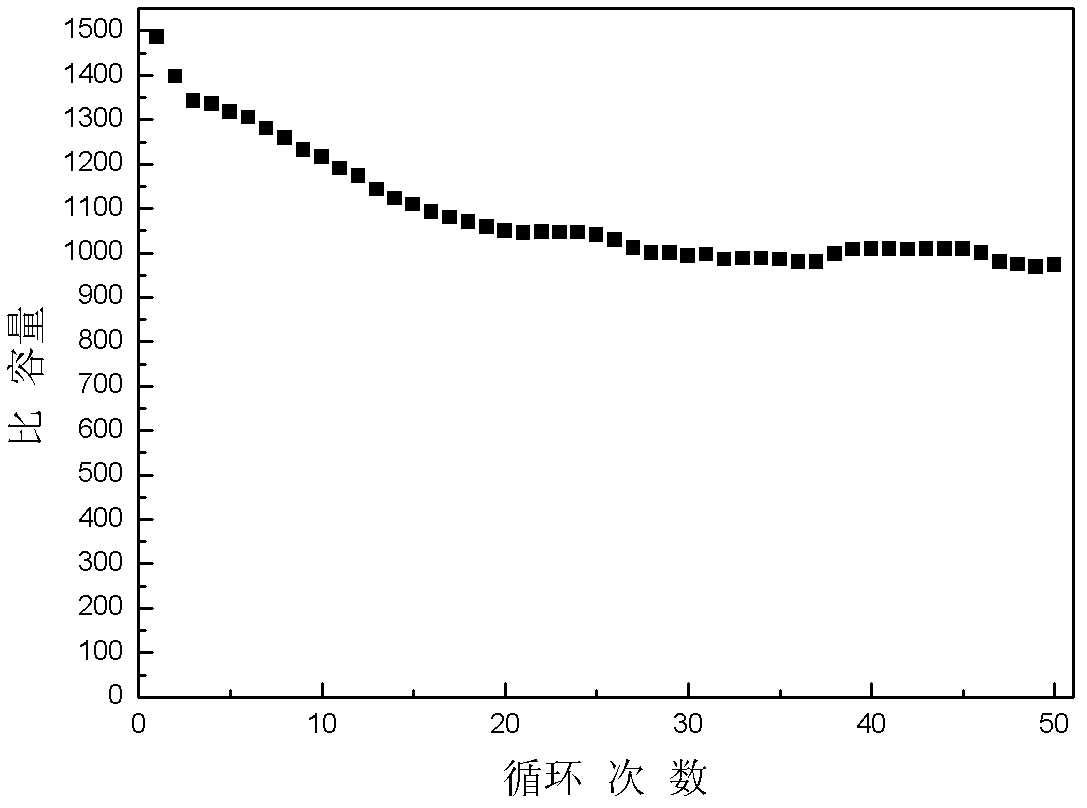

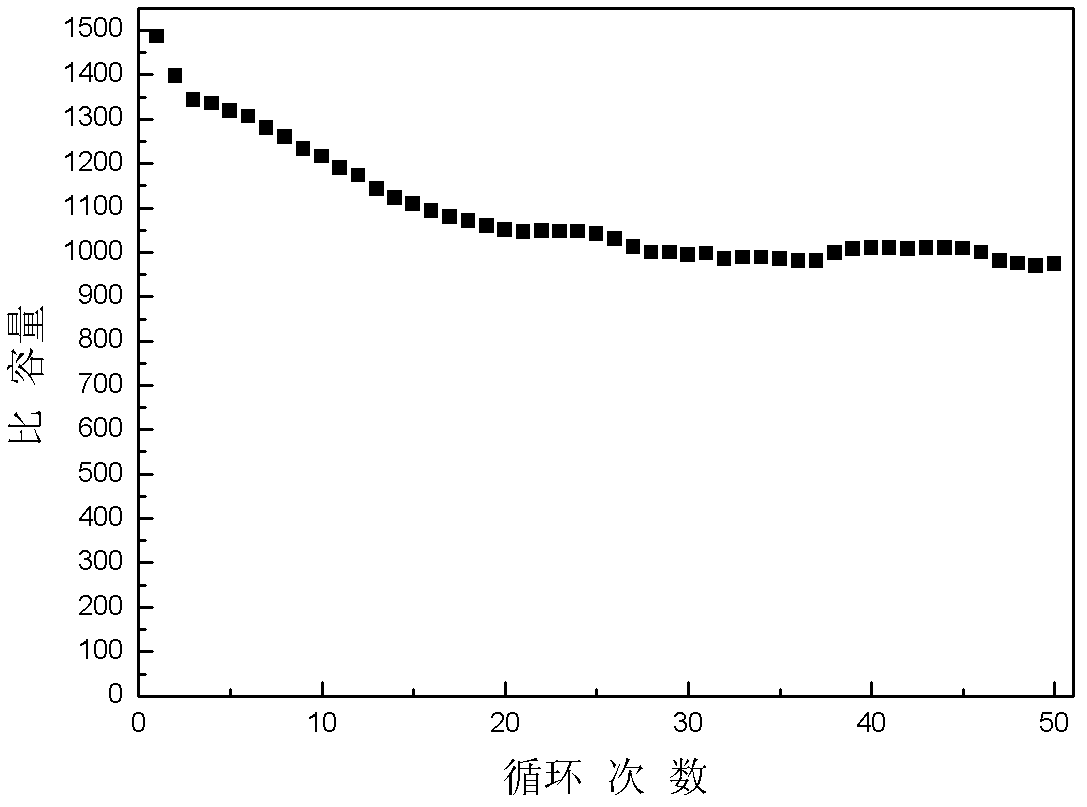

[0026] 3) Battery test: The electrochemical performance test of the button battery assembled by the above method was carried out under the conditions of a current density of 100mA / g and a charging and discharging voltage of 1.5-4.2V.

Embodiment 1

[0029] Add 80wt% elemental sulfur and 20wt% graphene into the ball mill jar, then add 10ml of absolute ethanol and mill at a speed of 200r / min for 0.5h in a high-energy ball mill to mix the raw materials evenly, and then vacuum dry at 80°C for 1h. Put the dried material into a nitrogen-protected quartz sealed tube, then put the quartz sealed tube into a tubular heating furnace and heat it to 150 °C at a heating rate of 5 °C / min and keep it for 10 h, then cool naturally to room temperature to obtain sulfur- Graphene composite cathode material. The sulfur-graphene composite positive electrode material assembled battery obtained in this example has an initial discharge specific capacity of 1080 mAh / g at a charge and discharge current density of 100 mA / g, and the discharge specific capacity remains at 723 mAh / g after 50 cycles.

Embodiment 2

[0031] Add 98wt% elemental sulfur and 2wt% graphene into the ball mill jar, then add 5ml of absolute ethanol and mill at a speed of 500r / min in a high-energy ball mill for 1h to mix the raw materials evenly, and then vacuum dry at 80°C for 2h. Put the dried material into a quartz boat, then put it into a nitrogen-protected quartz sealed tube, and then put the quartz sealed tube into a tubular heating furnace to heat to 160 °C at a heating rate of 3 °C / min and keep it warm 24h, naturally cooled to room temperature to obtain sulfur-graphene composite cathode material. The battery assembled with the sulfur-graphene composite cathode material obtained in this example has an initial discharge specific capacity of 1212 mAh / g at a charge and discharge current density of 100 mA / g, and the discharge specific capacity remains at 752 mAh / g after 50 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com