Patents

Literature

35results about How to "Strong agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

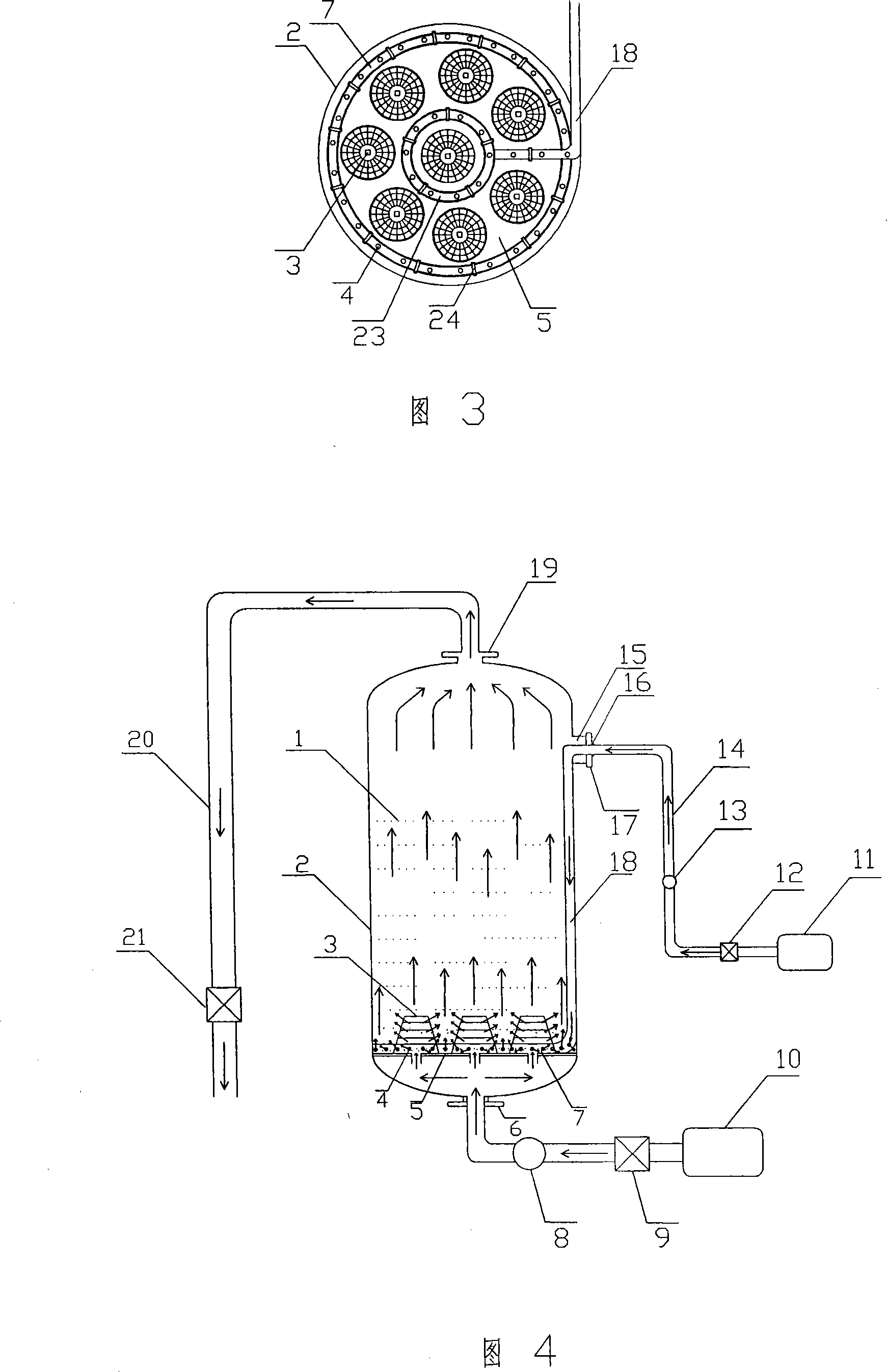

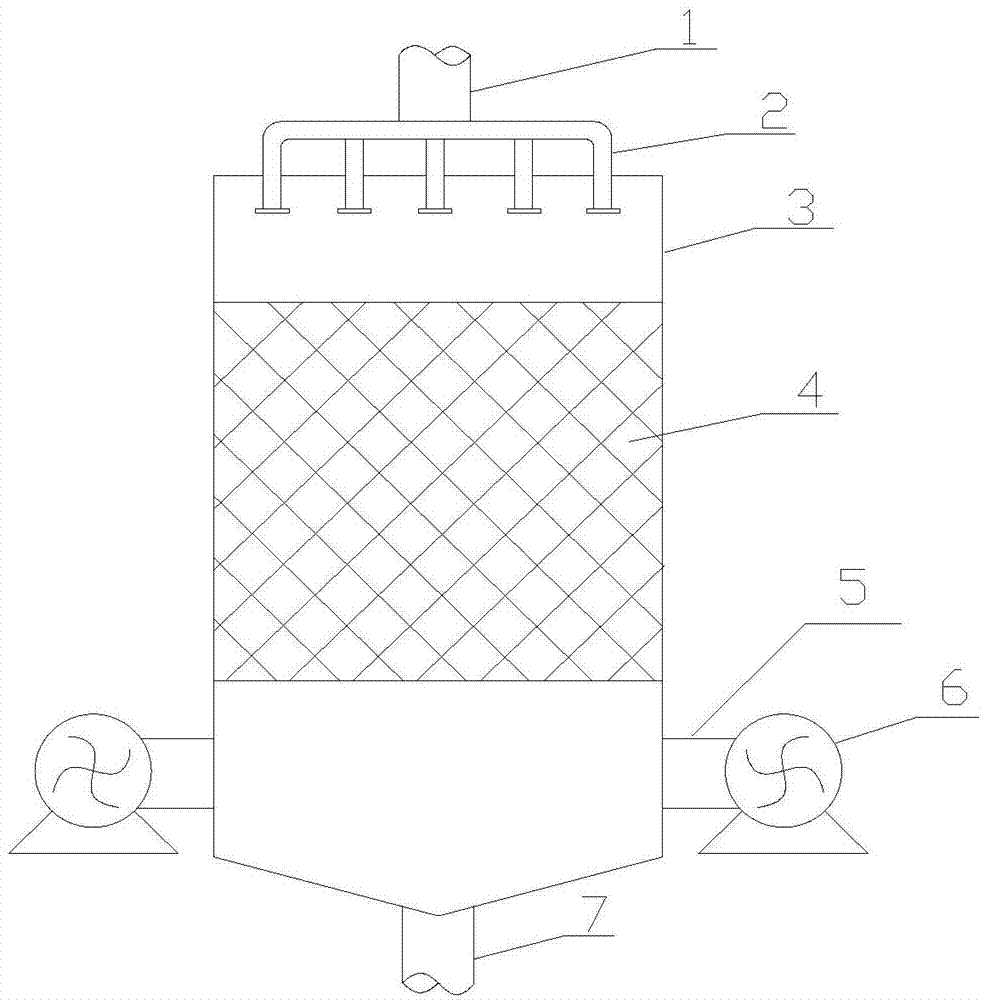

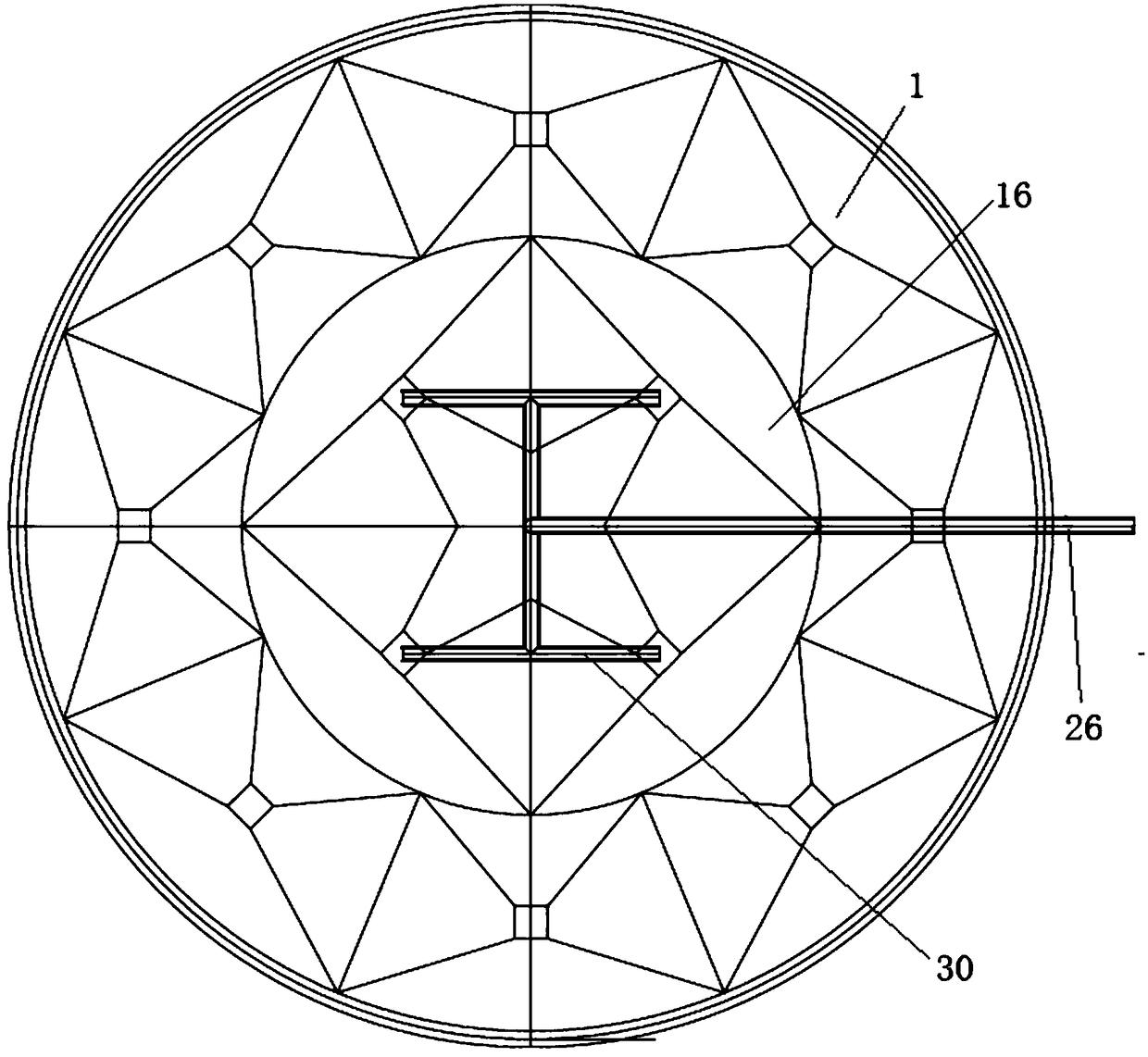

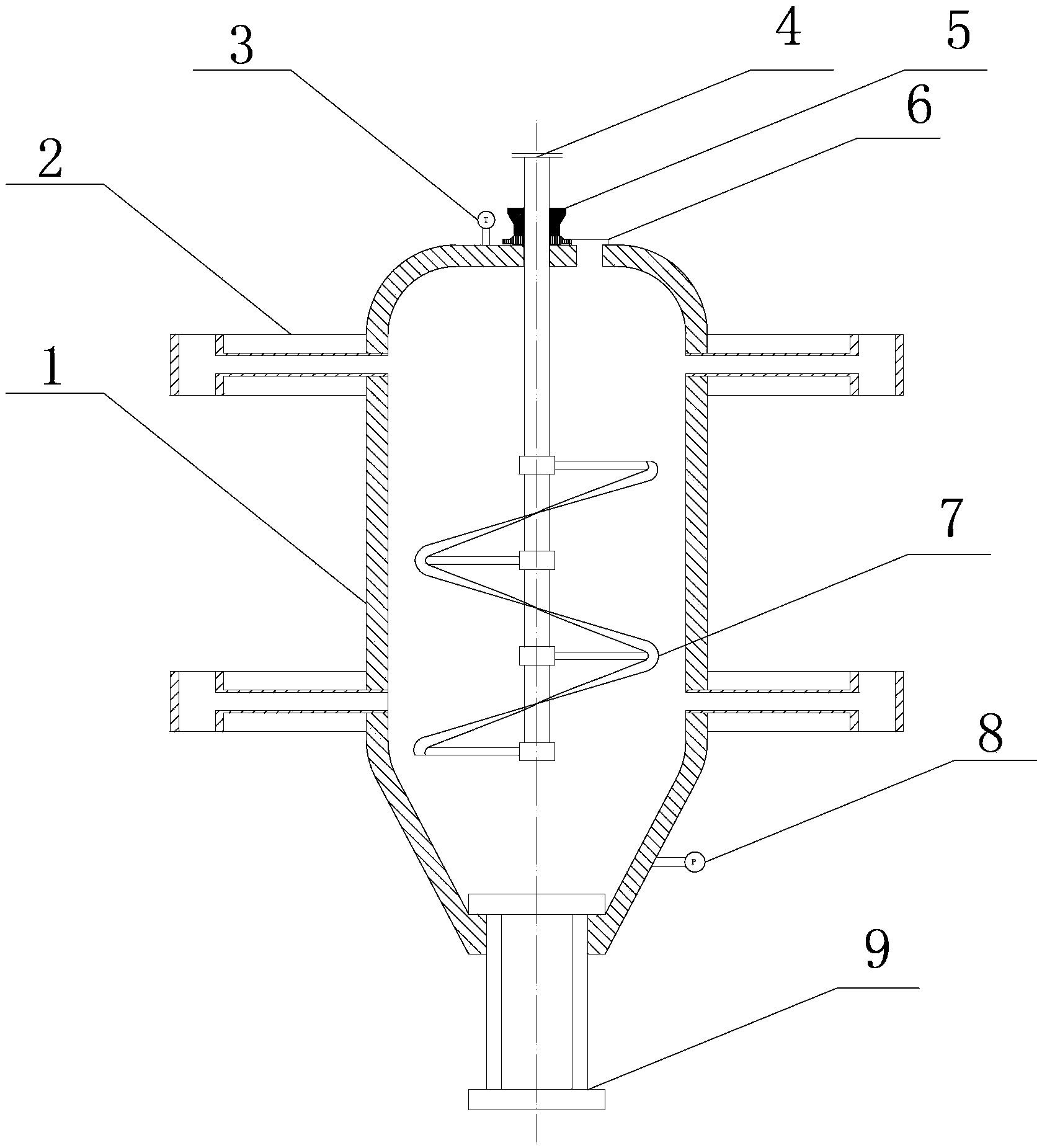

Gas liquid reaction kettle adopting spherical crown-shaped micropore corundum gas supply apparatus

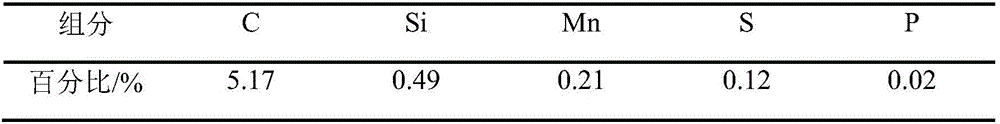

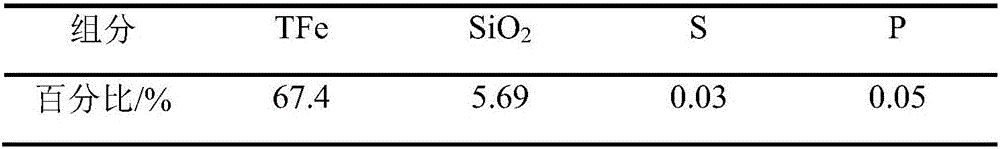

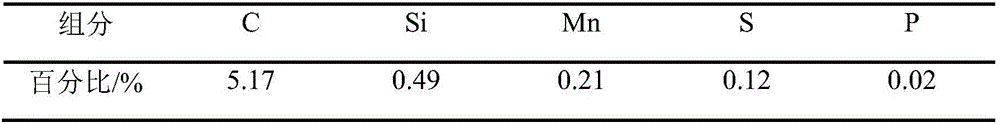

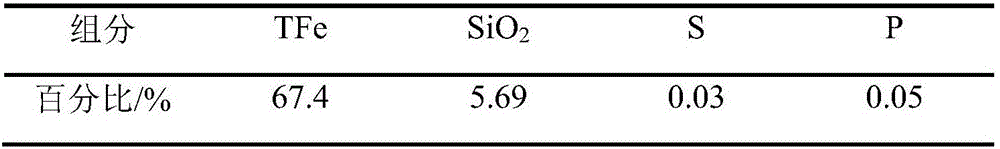

PendingCN110404485ALarge air supplyStrong agitationLiquid-gas reaction as foam/aerosol/bubblesChemical/physical/physico-chemical stationary reactorsGas liquid reactionAging resistance

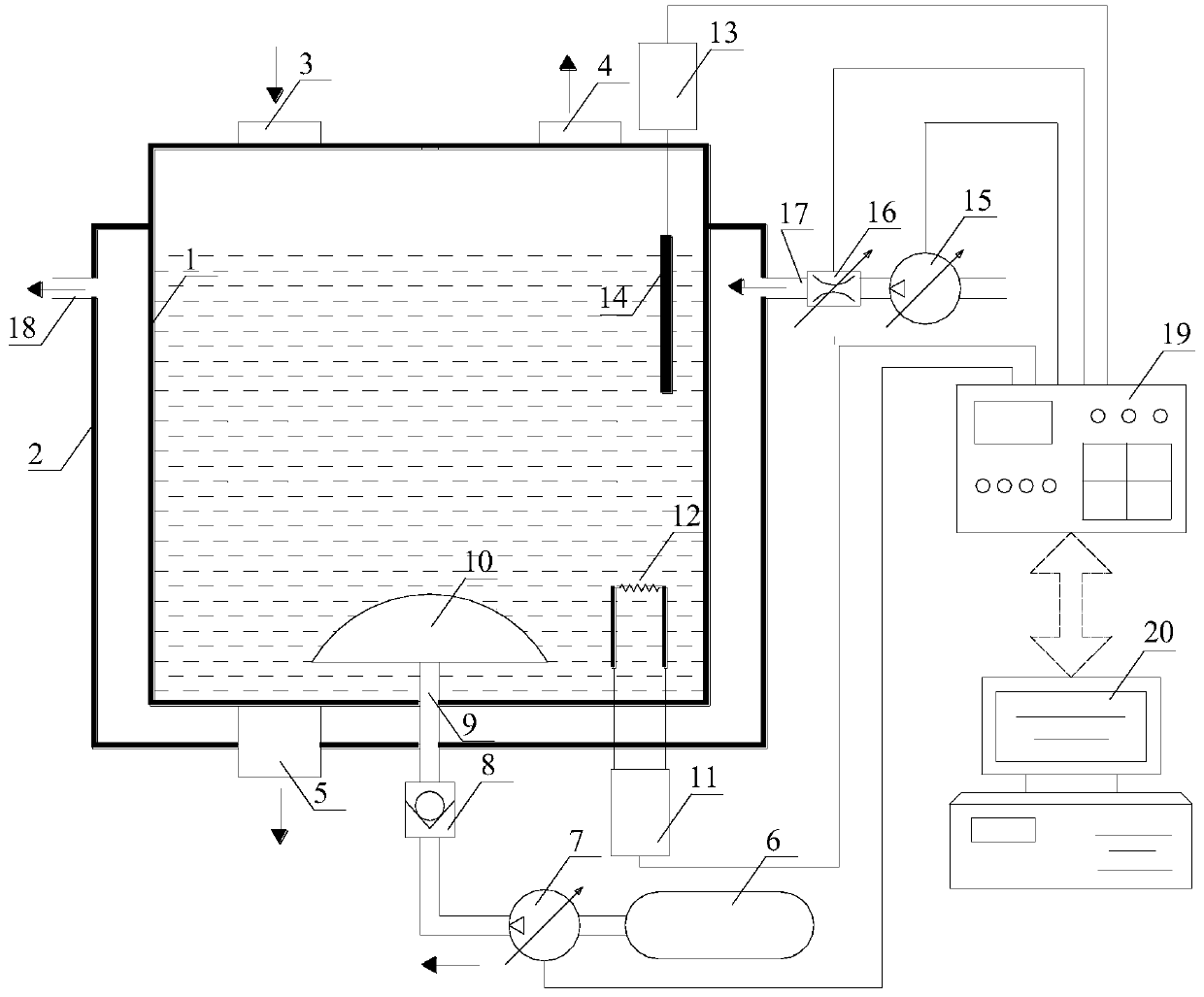

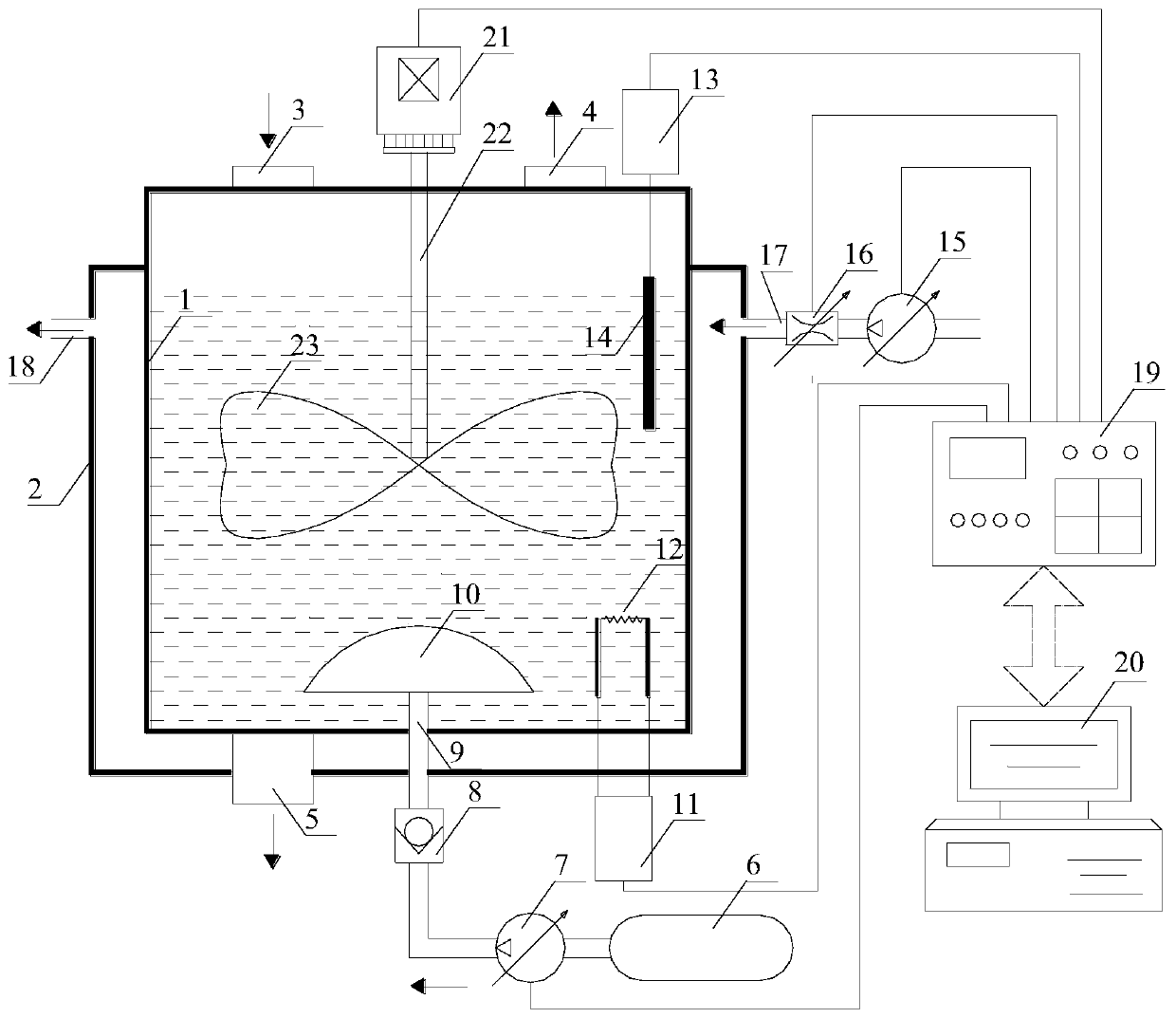

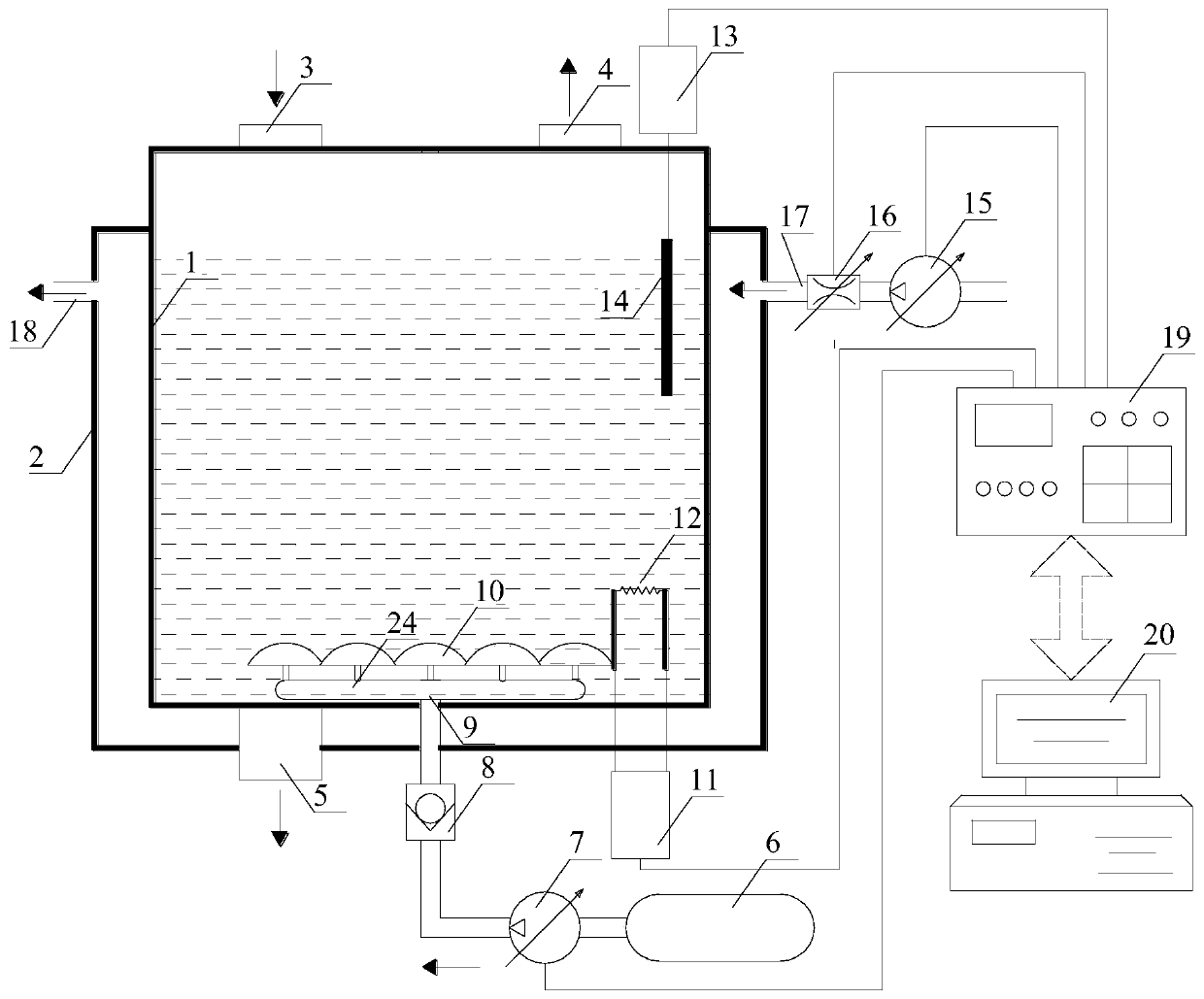

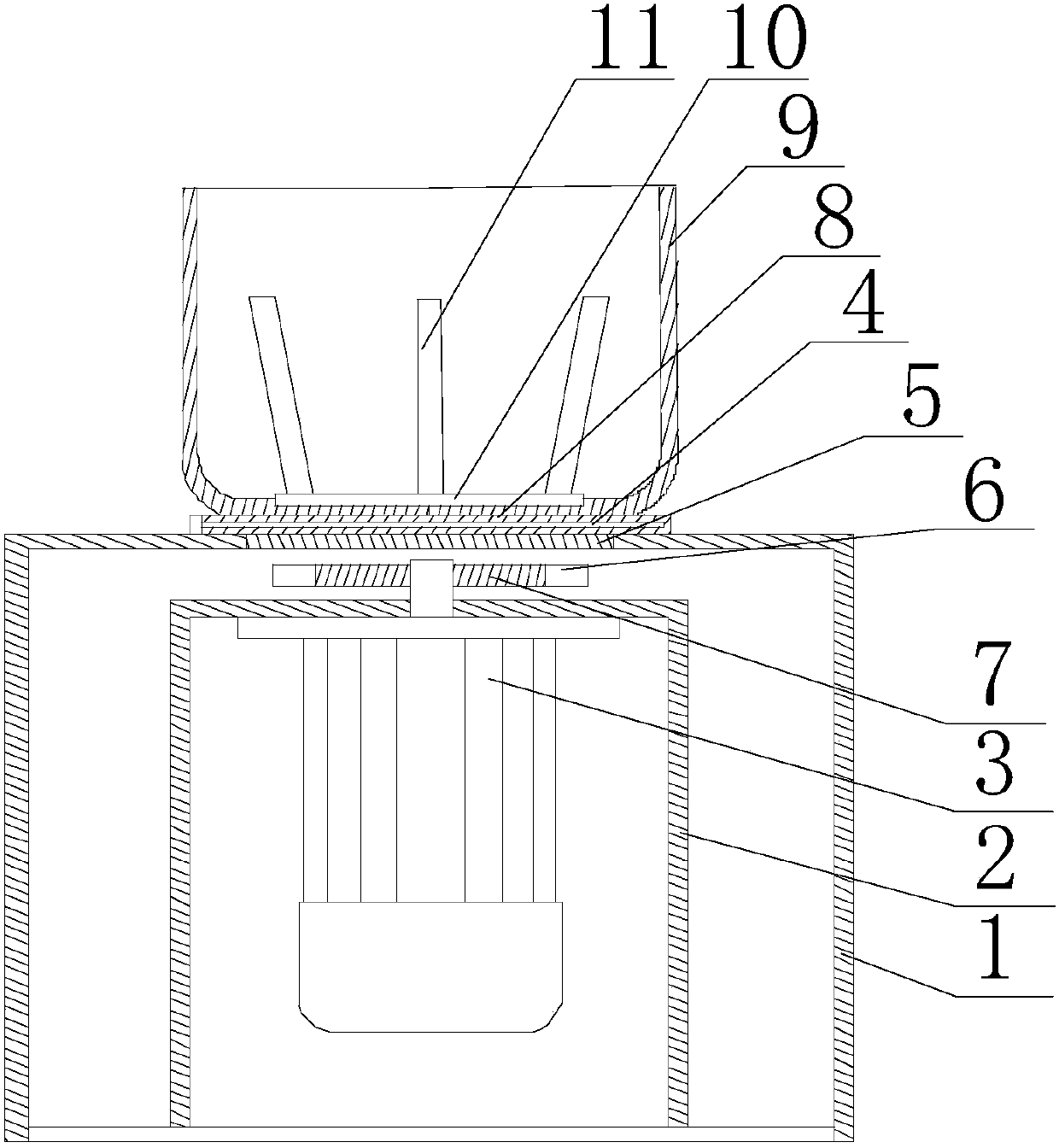

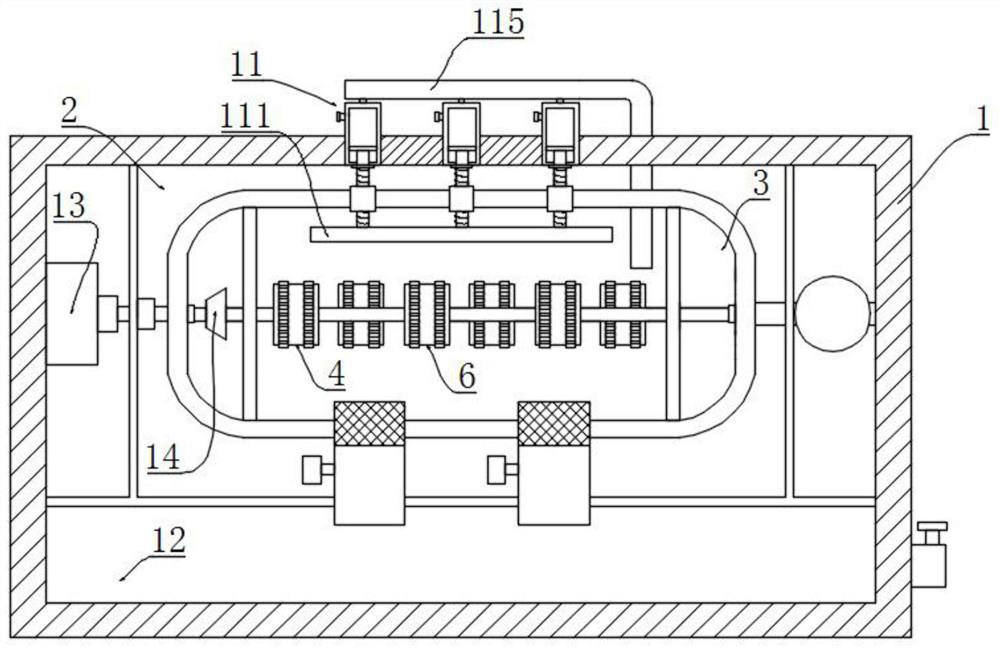

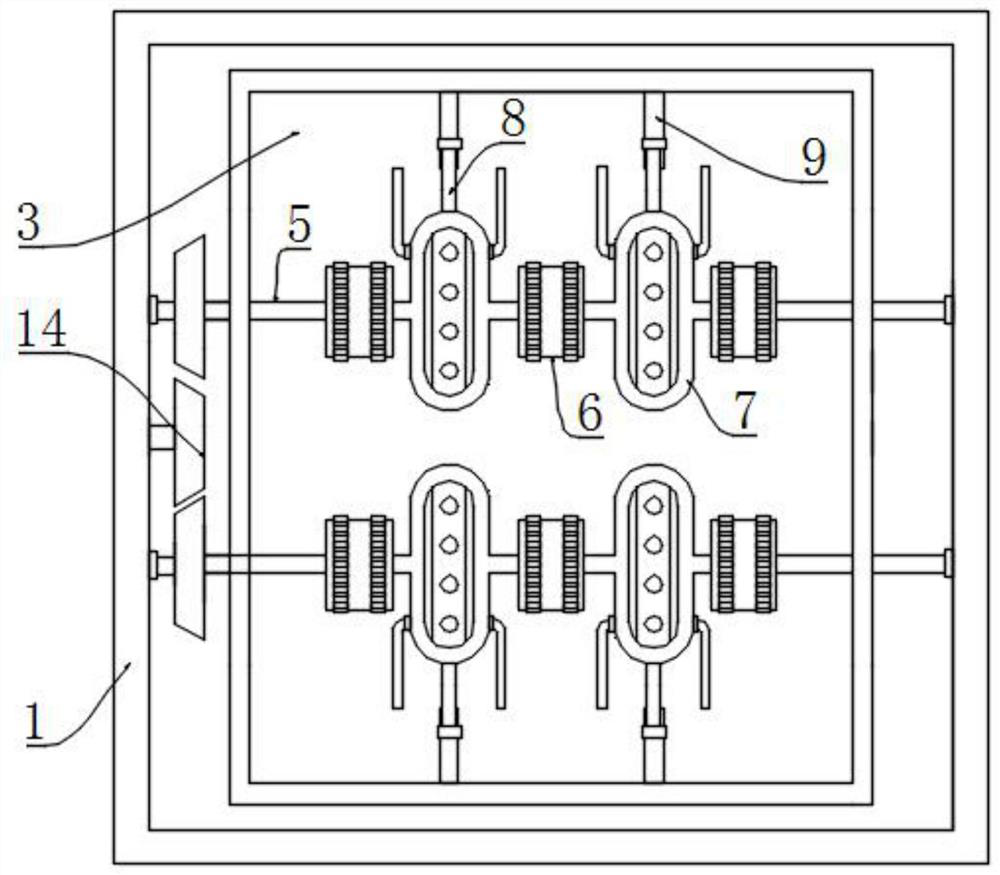

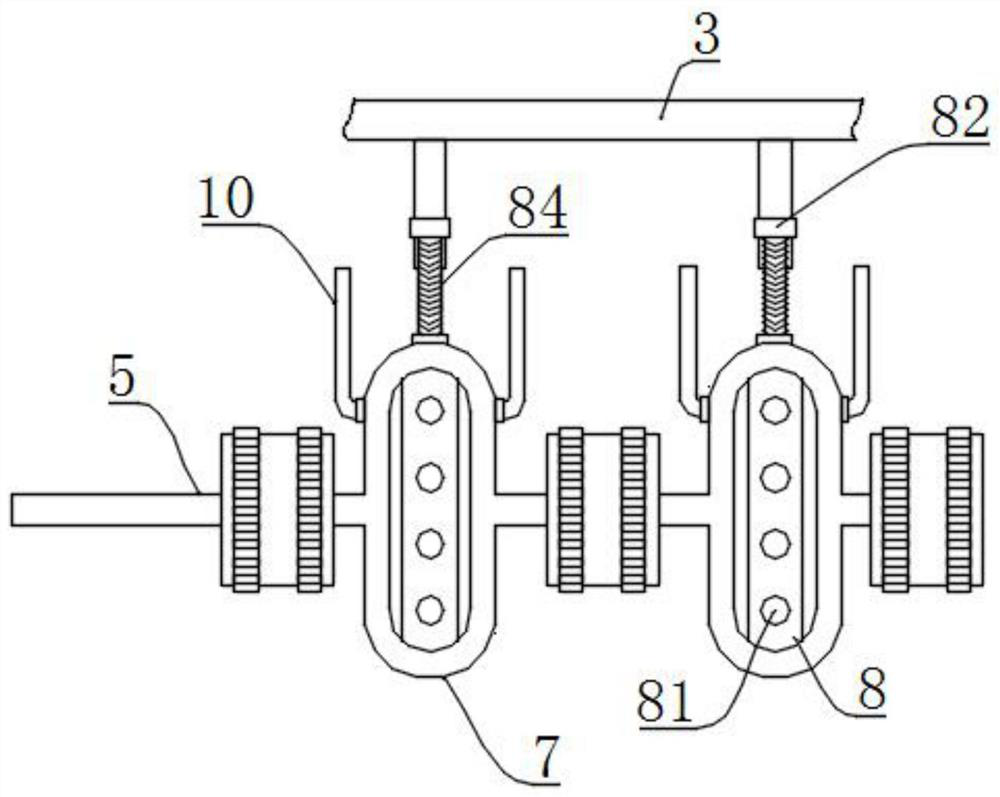

The invention relates to a gas liquid reaction kettle adopting a spherical crown-shaped micropore corundum gas supply apparatus. The gas liquid reaction kettle comprises a reaction kettle body and a gas supply device, the reaction kettle body comprises a main kettle body, the gas supply device comprises the gas supply apparatus, the gas supply apparatus is arranged in the main kettle body, and thetop surface of the gas supply apparatus is a spherical surface; the gas supply apparatus is in a spherical crown shape and is of an integrated structure, and upper and lower surfaces of the gas supply apparatus release gas simultaneously; the gas liquid reaction kettle has the advantages of a large gas supply amount, high stirring intensity, low resistance, high efficiency, low consumption, reliable operation, no blockage, ageing resistance, corrosion resistance, long service life and the like; in addition, the superficial area of contact between gas and liquid is greatly increased through alarge number of fine bubbles, the reaction speed is increased, and the reaction efficiency is improved; in addition, during gas supply, a high self-stirring effect of a large number of small bubbles is achieved, a stirring device of a conventional gas liquid reaction kettle does not need to be arranged, the structure can be simplified, the cost is reduced, and if the stirring device is arranged, the speed and efficiency of a gas liquid reaction can be further improved.

Owner:TONGLING UNIV

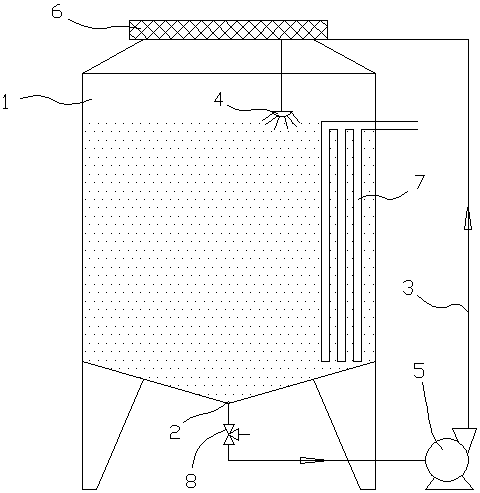

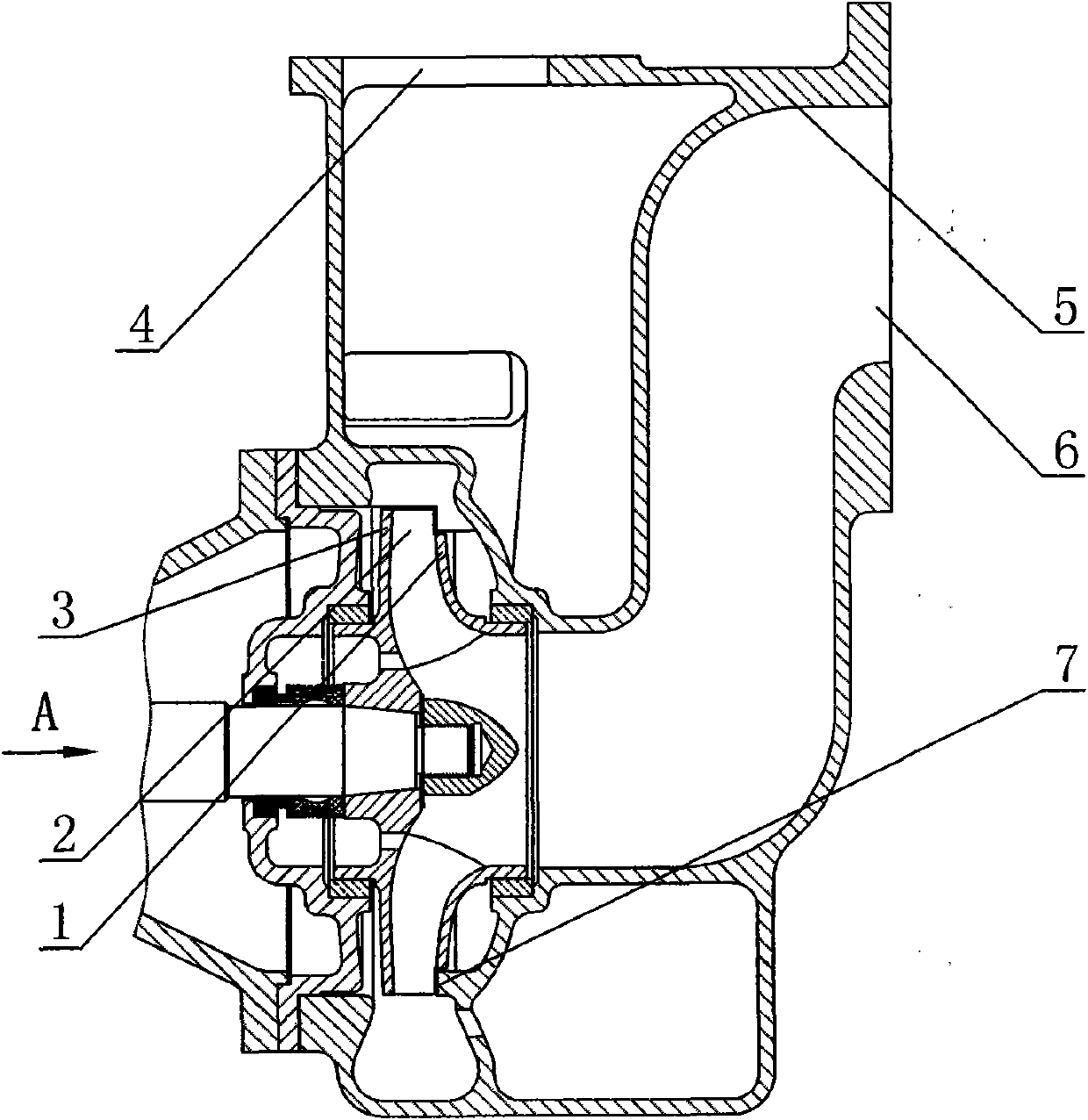

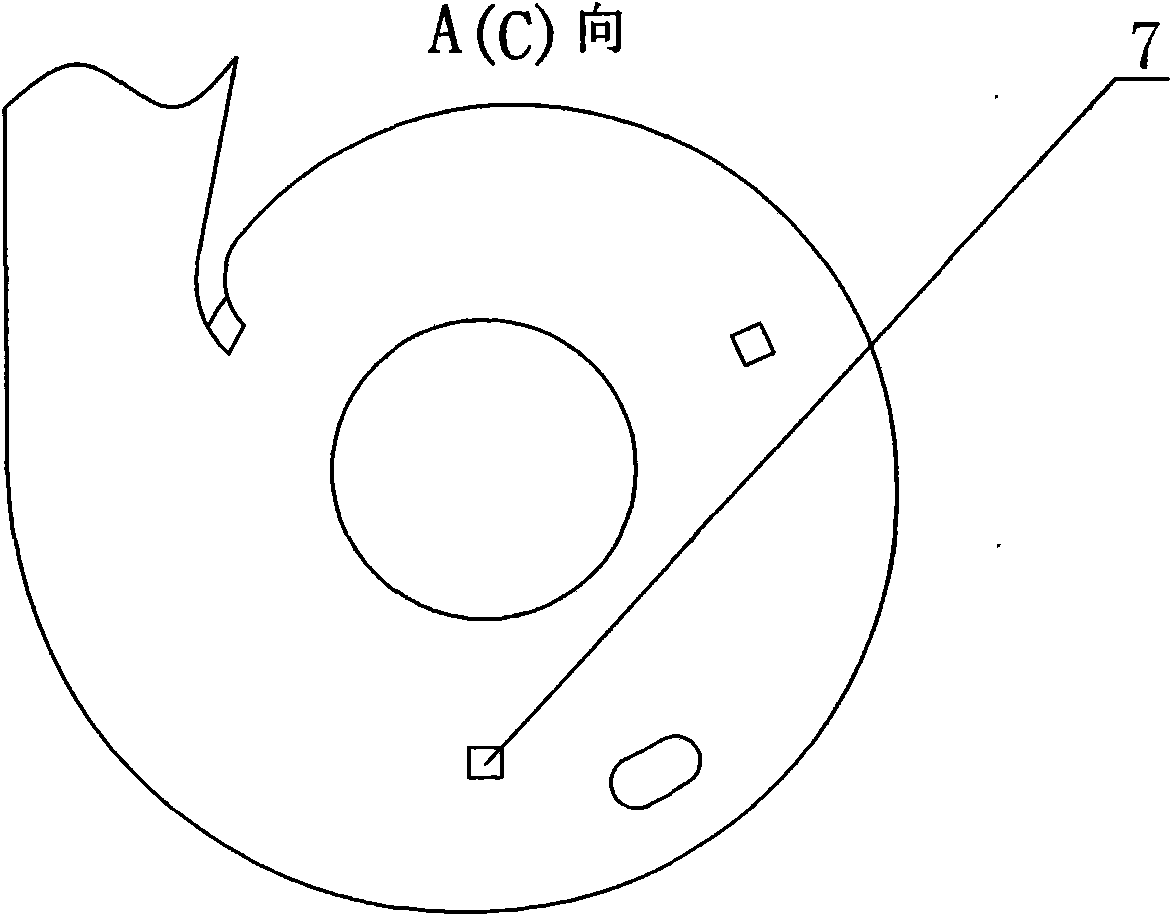

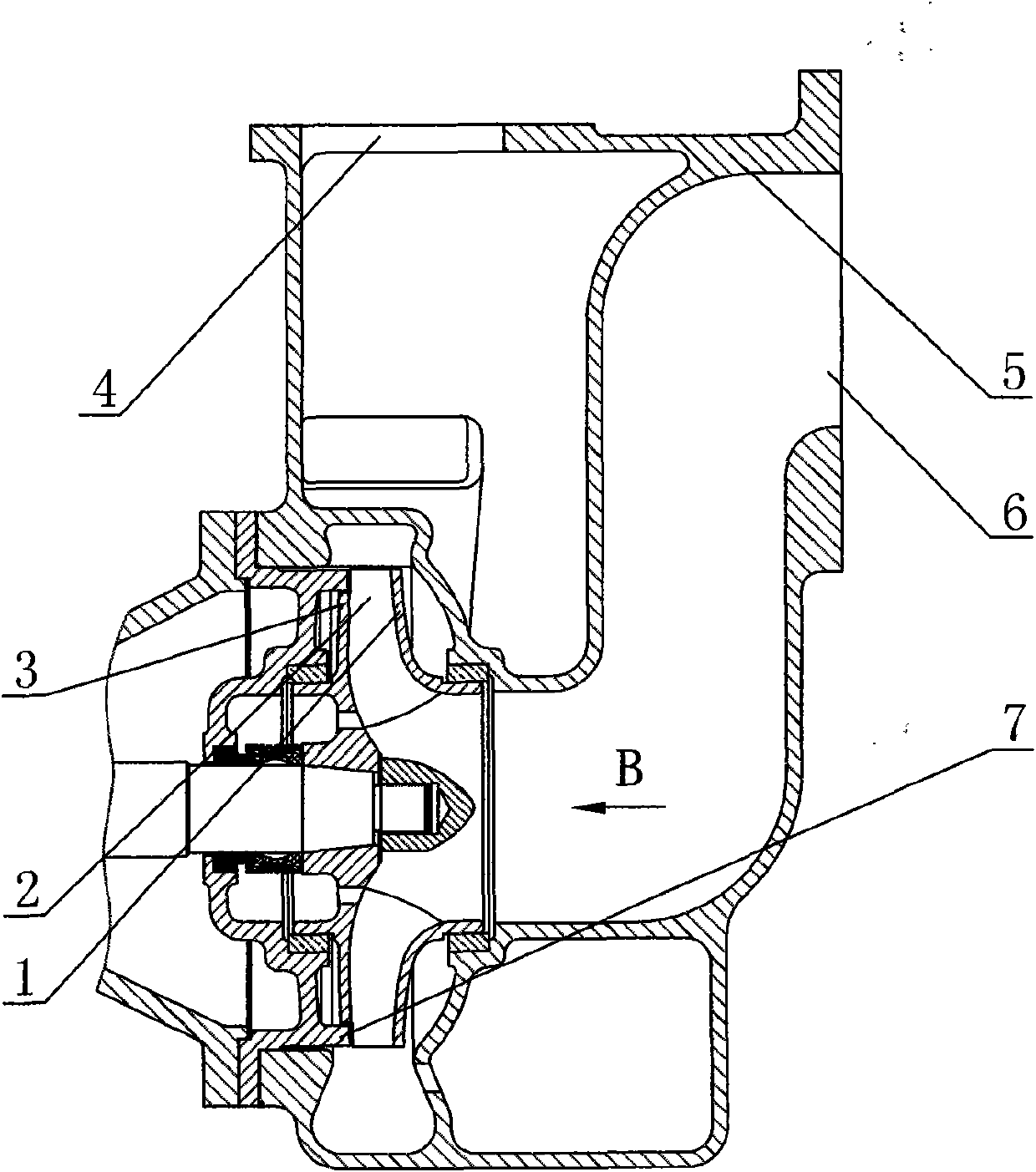

Air entrainment flusher of micro-irrigation sandrock filter

InactiveCN101219294AStrong agitationEffective flushingLoose filtering material filtersGravity filtersWater useAir entrainment

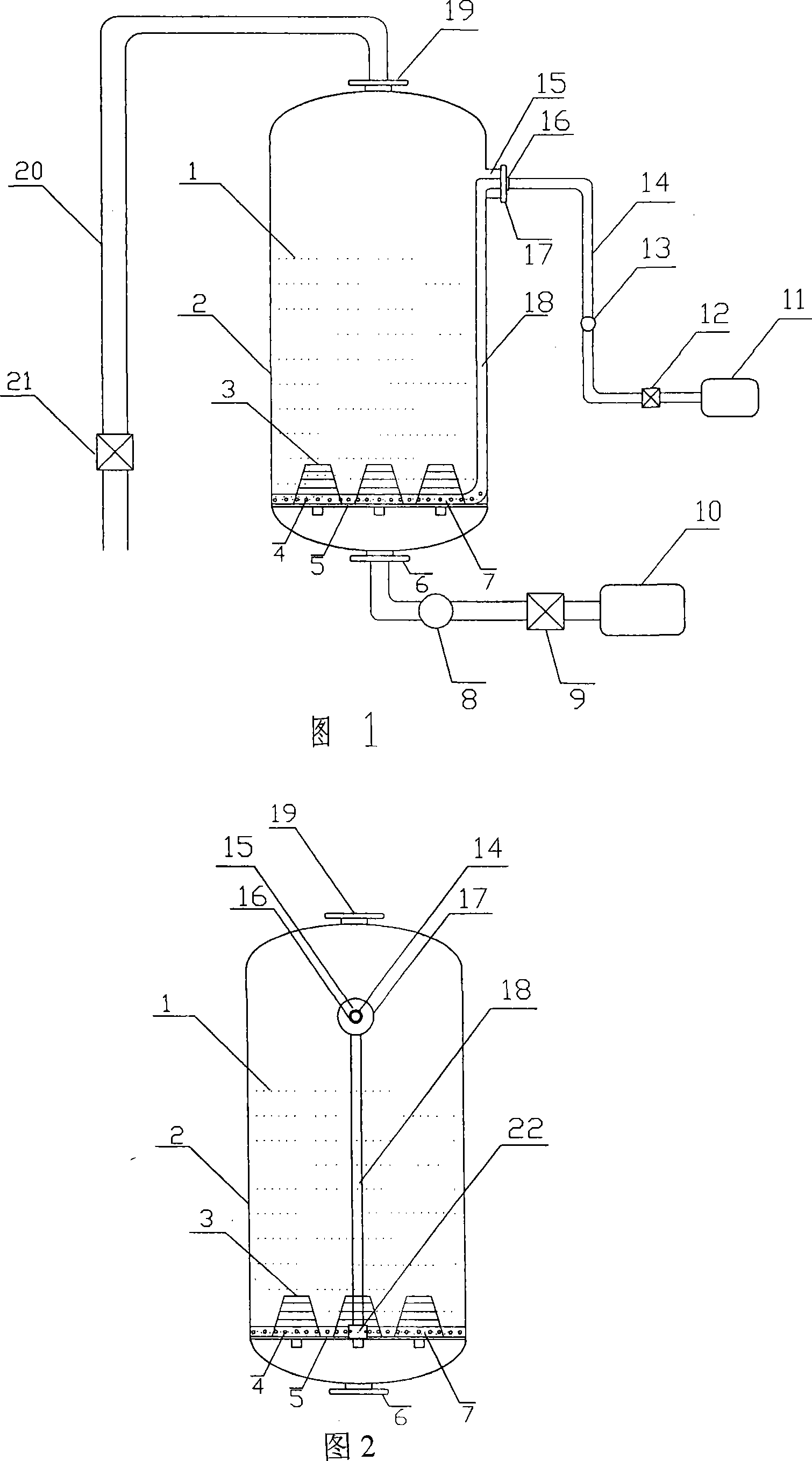

The invention discloses an air-entrapping flusher of a micro-irrigation sandstone filter, comprising a filtering tank and a sandstone filter material filled in the filtering tank. A clapboard of a header tank is arranged below the sandstone filter material at the bottom of the filtering tank. A filter cap is arranged on the clapboard of the header tank and two air washing rings are arranged in the periphery and the middle of the filter cap. Air holes are evenly distributed at the up direction of the air washing rings in an interlaced way. The two air washing rings are connected with an air inlet pipe that runs through upwards along the inner wall of a tank body from a sand feeding port in a seal way and is communicated with an air compressor. The invention utilizes the combined action of water and air to cause a whole filter material layer in the tank body to produce the strong stirring, which can effectively wash impurities adhering to the sandstone cleanly with the action of impact of air and water flow and friction force caused by the collision of sandstones. With convenient operation and good backwashing effect, the invention saves the cleaning water used for washing.

Owner:XINXIANG YUTONG VALVE

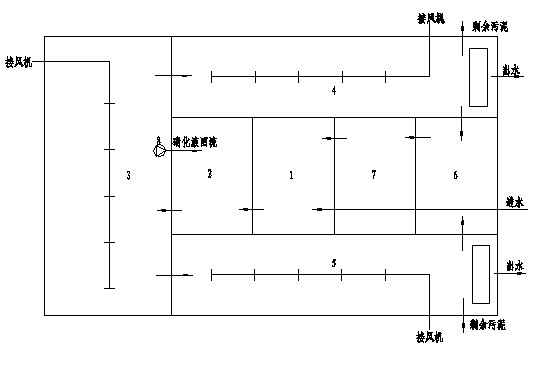

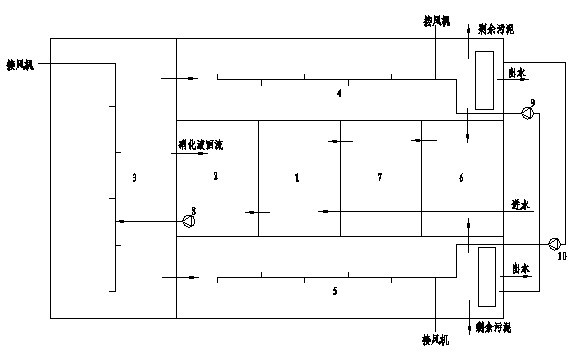

Modified sequencing batch reactor (MSBR) process for sewage treatment

InactiveCN102432101ASave spaceExtended service lifeTreatment with aerobic and anaerobic processesSequencing batch reactorReflux

The invention relates to improvement on the traditional modified sequencing batch reactor (MSBR) process. The process is characterized in that: jet aeration working solution of an aerobic tank is from an anoxic tank, the liquid level of the aerobic tank is raised to exceed the liquid level of the anoxic tank through the jet aeration working solution supplied by the anoxic tank, and mixed liquid of the aerobic tank overflows and automatically flows through a liquid level difference and is refluxed to the anoxic tank according to design reflux quantity; aeration devices in two alternate sequencing batch areas perform jet aeration, so that reflux from the aerobic tank to the anoxic tank is unpowered overflow reflux, reflux energy consumption is reduced, aeration oxygen transfer efficiency can be improved by 20 to 30 percent, the energy consumption of the aerobic tank and the anoxic tank in the section can be reduced by 10 to 20 percent, the liquid levels of the aerobic tank and a subsequent treatment unit tank can be raised by 50 to 80cm compared with the original liquid levels, automatic flow treatment is reduced, tank depth engineering construction cost is reduced, the civil engineering investment of a treatment tank can be saved by 10 to 20 percent, and the energy consumption of a lifting pump can be reduced; and jet aerators are arranged in the two alternate sequencing batch areas, and the jet aeration working solution is provided by the other tank, so that an aeration oxygen transfer rate and denitrification efficiency are improved, stirring equipment is eliminated, an aeration system is difficult to damage, and the service life is prolonged.

Owner:PENYAO ENVIRONMENTAL PROTECTION +3

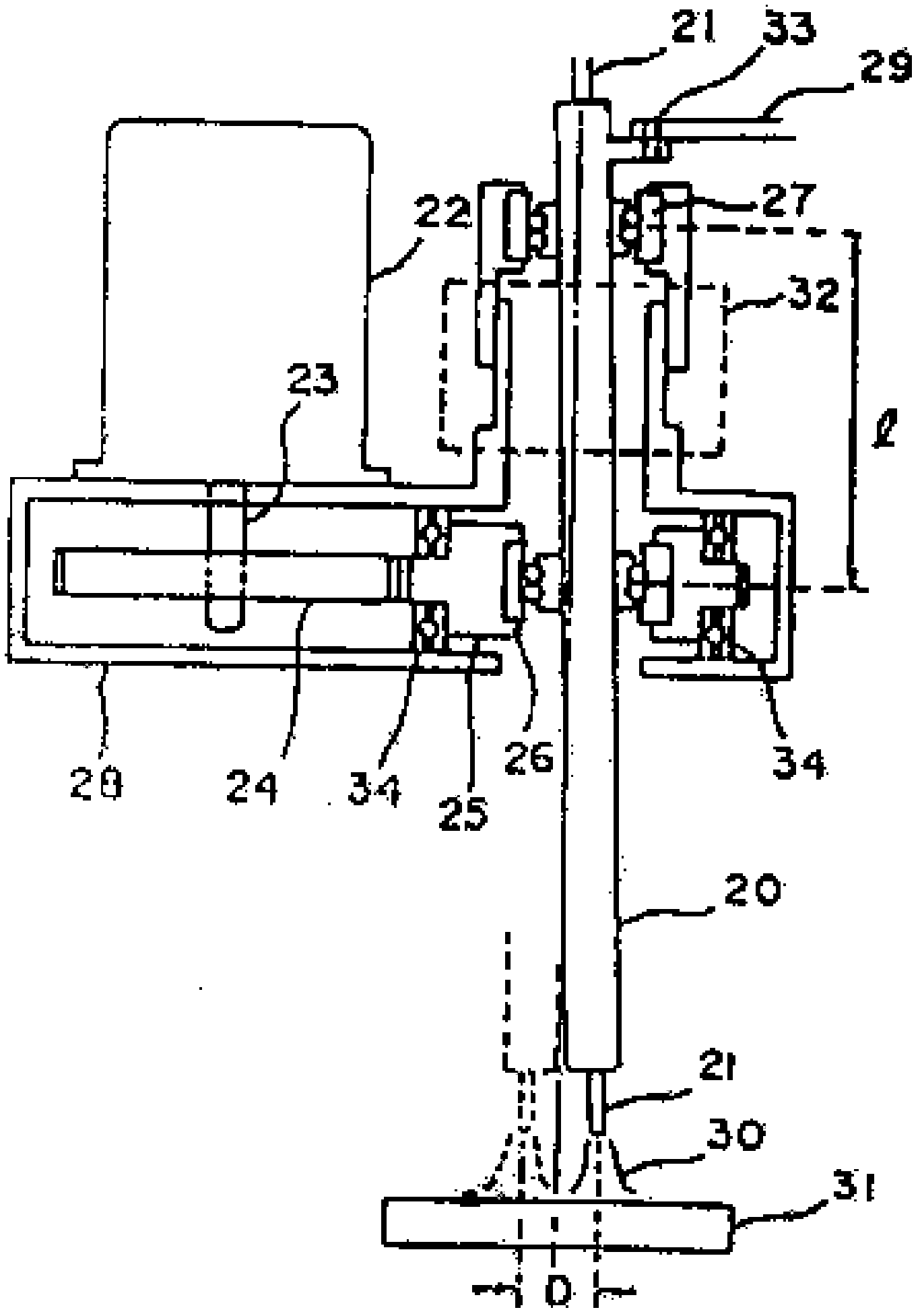

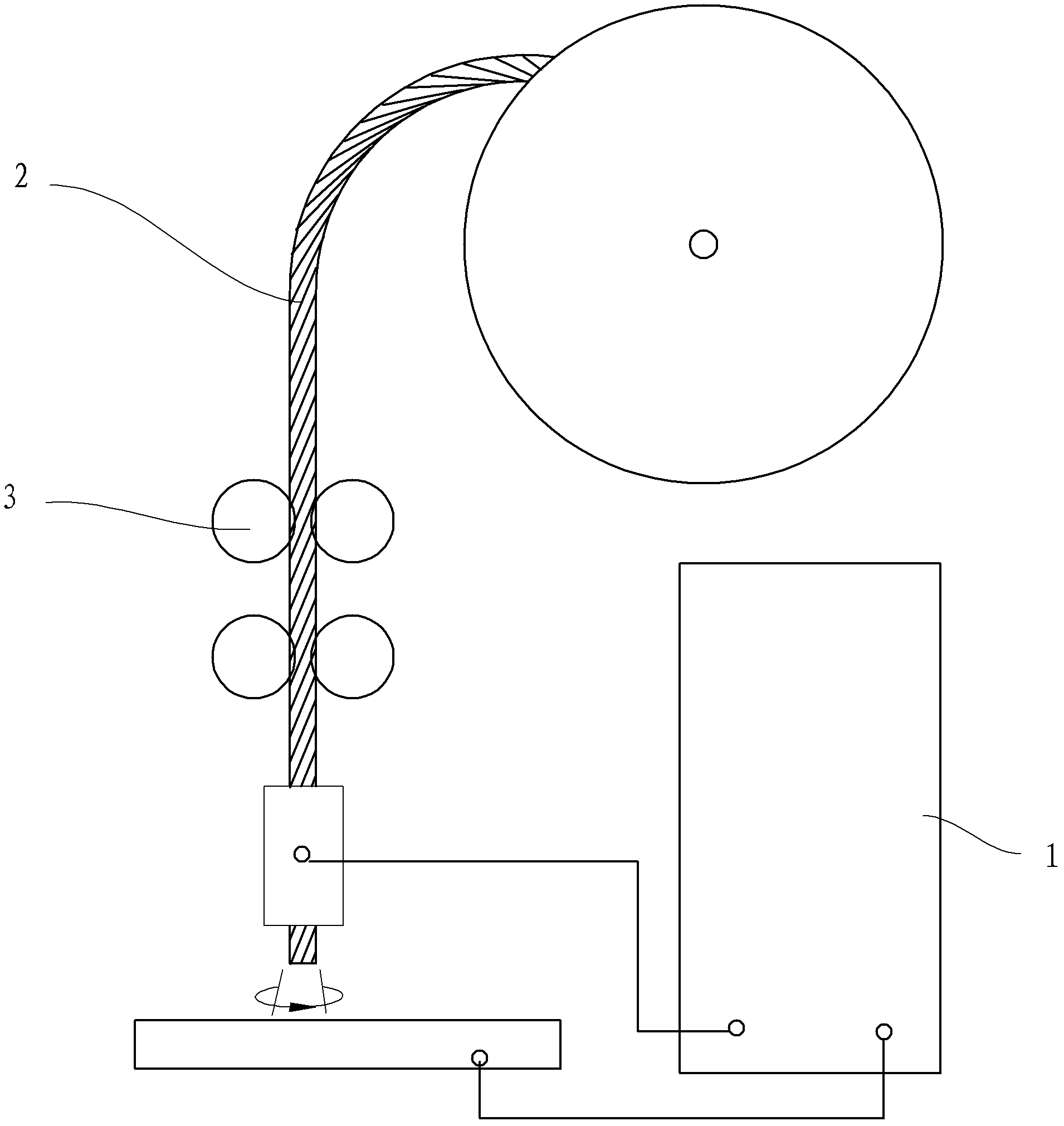

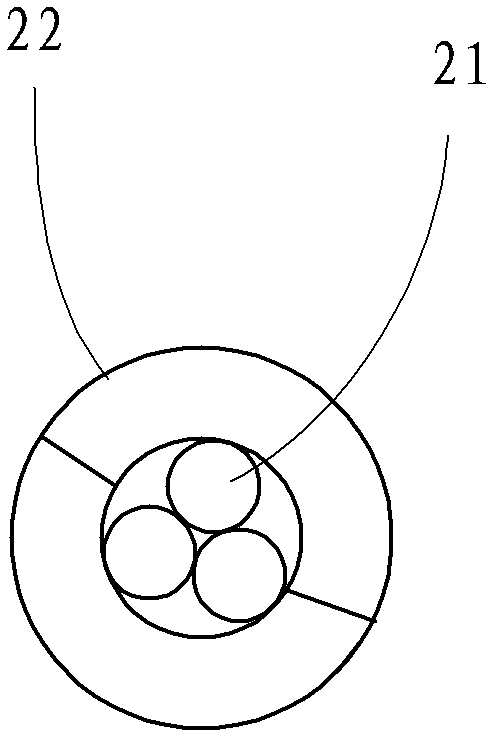

Multi-wire rotating arc welding

InactiveCN102615391AWidely used valueImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsMetal alloyMolten bath

The invention relates to an arc welding, in particular to a multi-wire rotating arc welding, which is a rotating arc welding utilizing welding wires wound in a certain helical angle, automatically formed in the welding process and having stirring effects on a molten bath. The multi-wire rotating arc welding not only improves welding melting efficiency but also enables welding line metal alloy to be even in component, and grain refinement is achieved.

Owner:时振

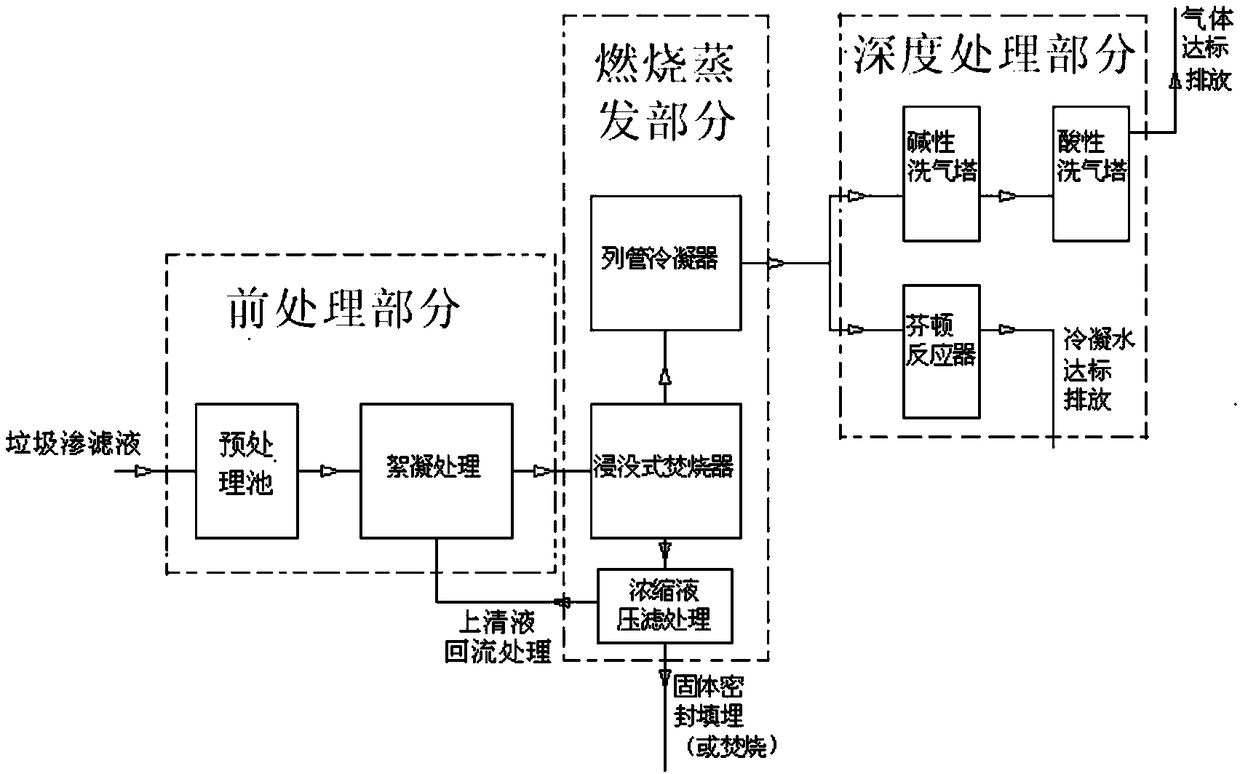

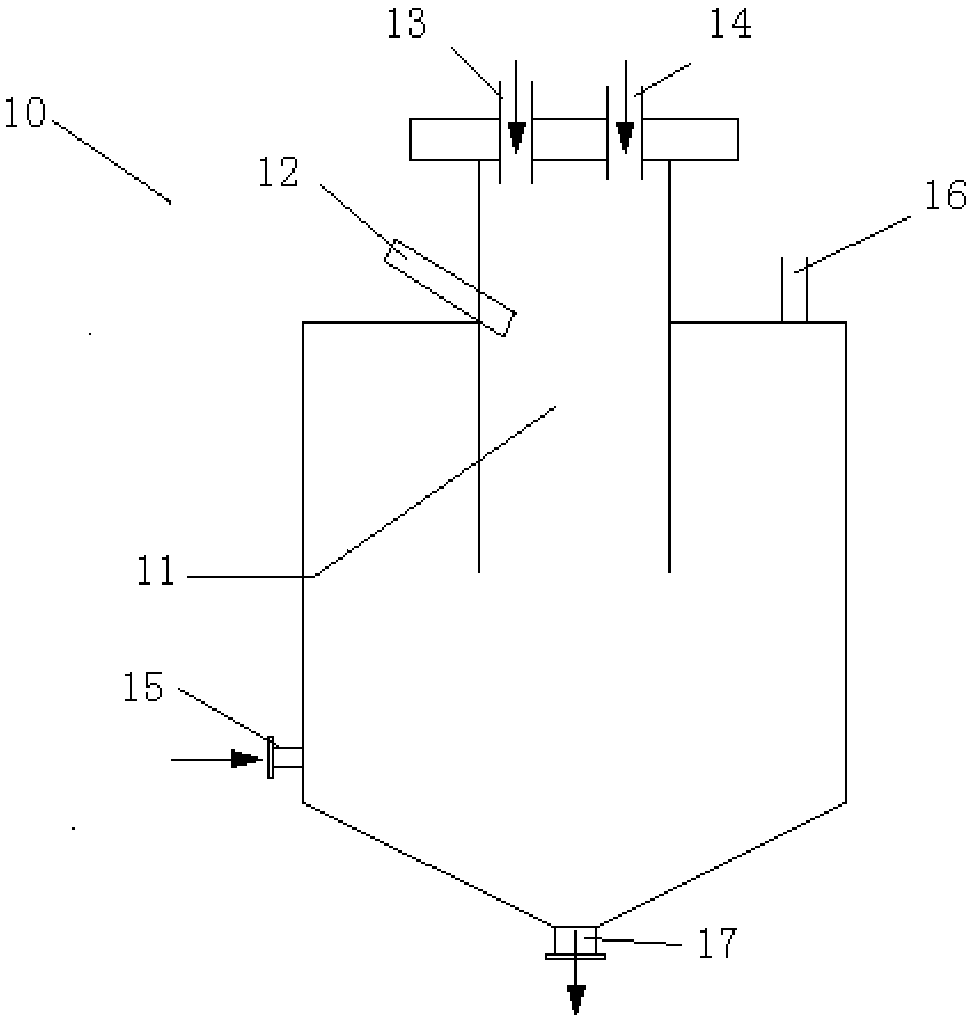

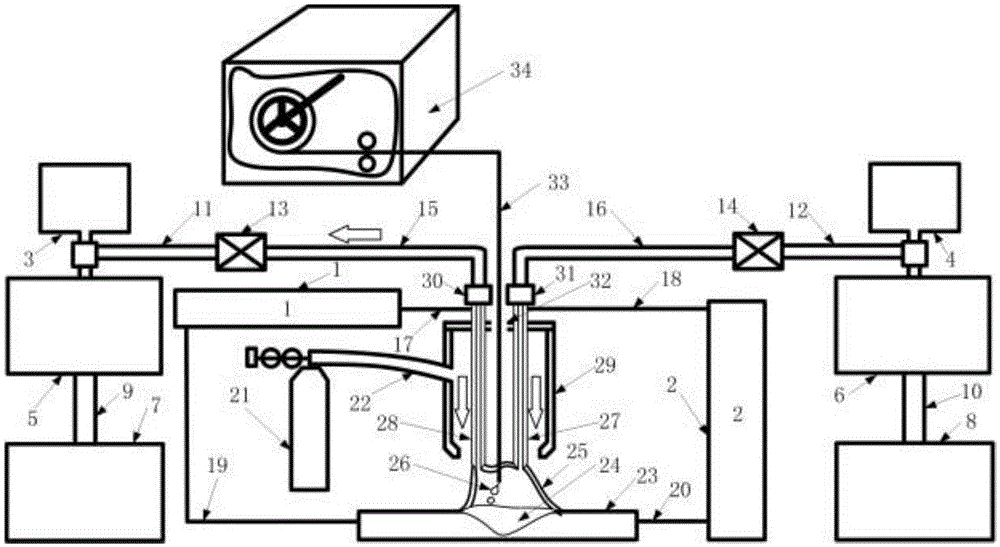

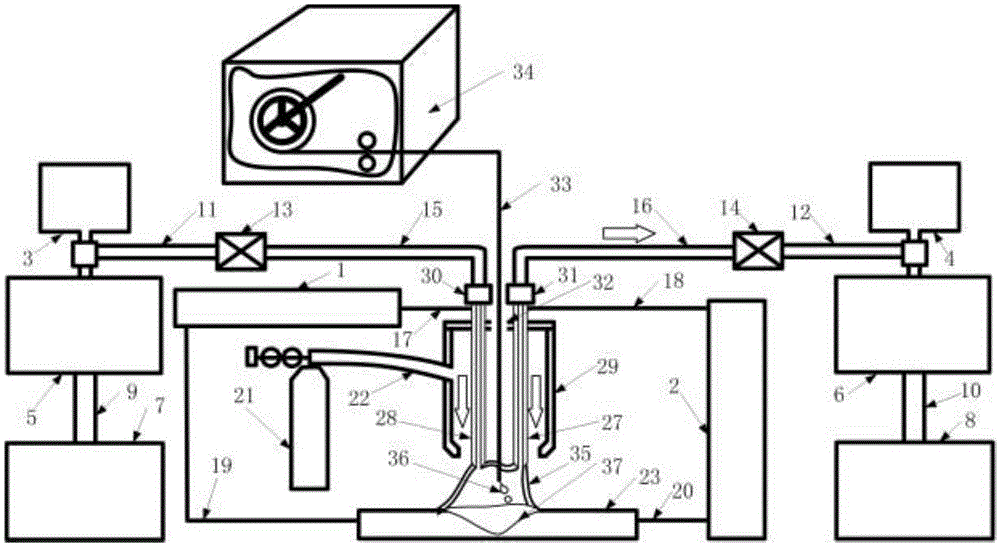

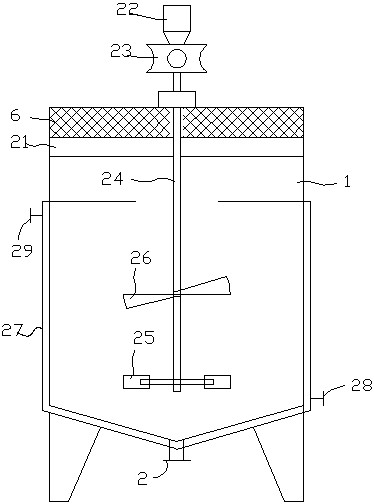

Immersed combustion treatment system for refuse leachate

InactiveCN108609787ALow costIncrease heat transfer areaWater treatment compoundsDispersed particle separationFlocculationCombustion chamber

The invention discloses an immersed combustion treatment system for refuse leachate, which includes: a pretreatment part, which includes a pretreatment tank and a flocculation reaction apparatus communicated therewith; a combustion and evaporation part, which includes an immersed incinerator, a tubular condenser, and a concentrate press filter device, wherein the immersed incinerator is provided with a combustion chamber comprising a fuel gas inlet, a combustion-supporting gas inlet, and an igniter, a steam outlet is disposed on the upper end of the immersed incinerator and the bottom of the immersed incinerator is conical in shape and is provided with a concentrate discharge outlet, after treatment in the flocculation reaction apparatus, a fluid flows into the immersed incinerator, then the tubular condenser is connected to the immersed incinerator through the steam outlet and the concentrate press filter device is connected to the immersed incinerator through the concentrate discharge outlet; a deep processing part, which includes an alkaline gas washing tower, an acidic gas washing tower, and a Fenton reactor, wherein the alkaline gas washing tower is connected to the gas outletof the tubular condenser, the acidic gas washing tower is connected to the alkaline gas washing tower, and the Fenton reactor is connected to a condensate discharge outlet on the tubular condenser.

Owner:BEIJING GREEN USE ENVIRONMENTAL PROTECTION SCI & TECH

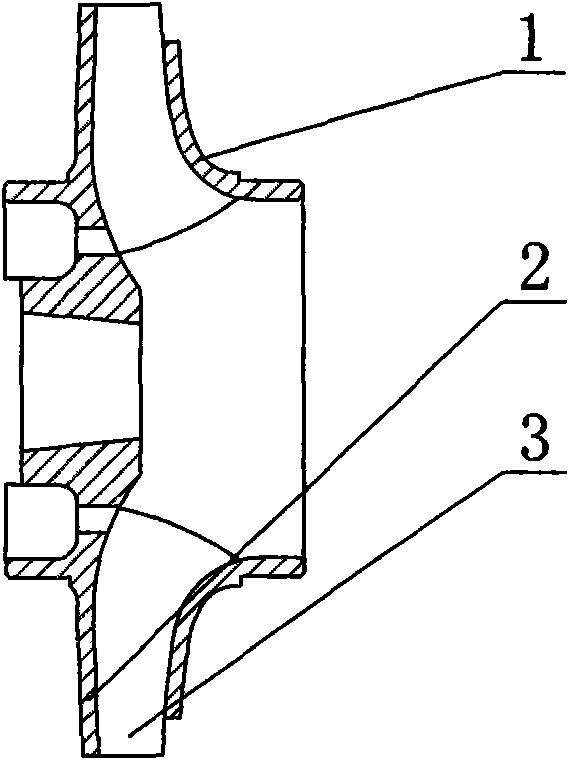

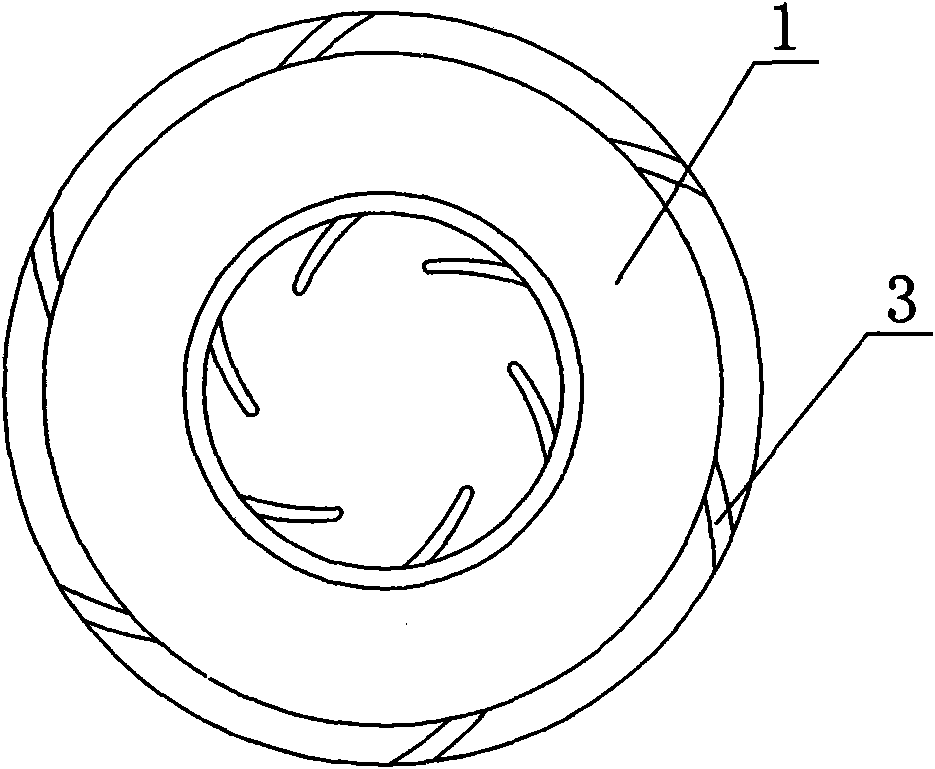

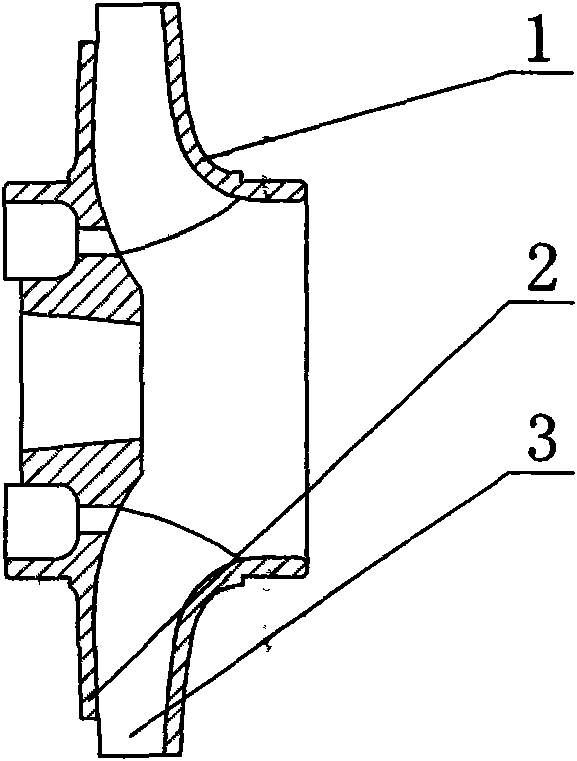

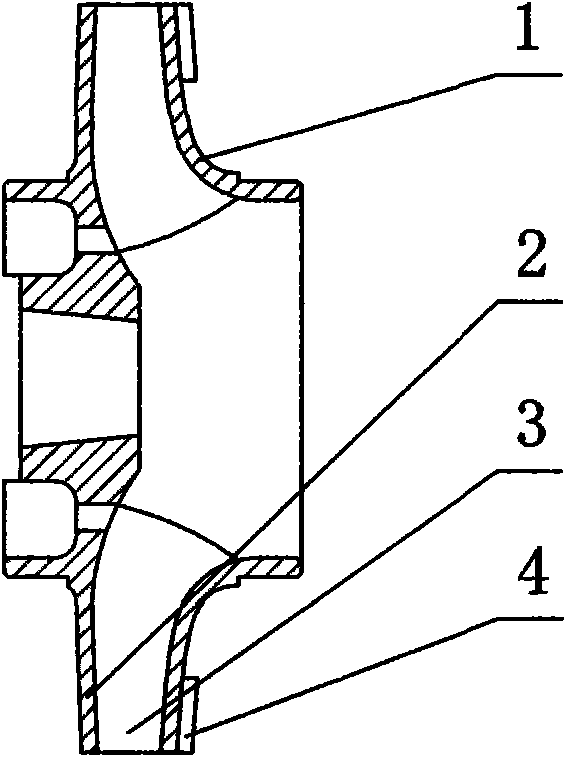

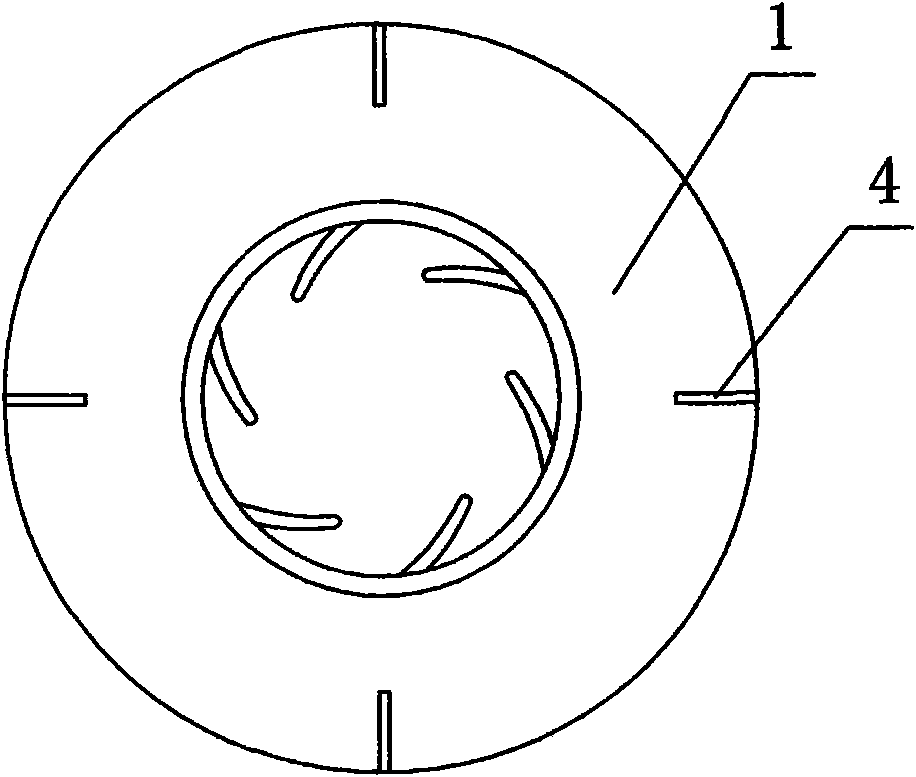

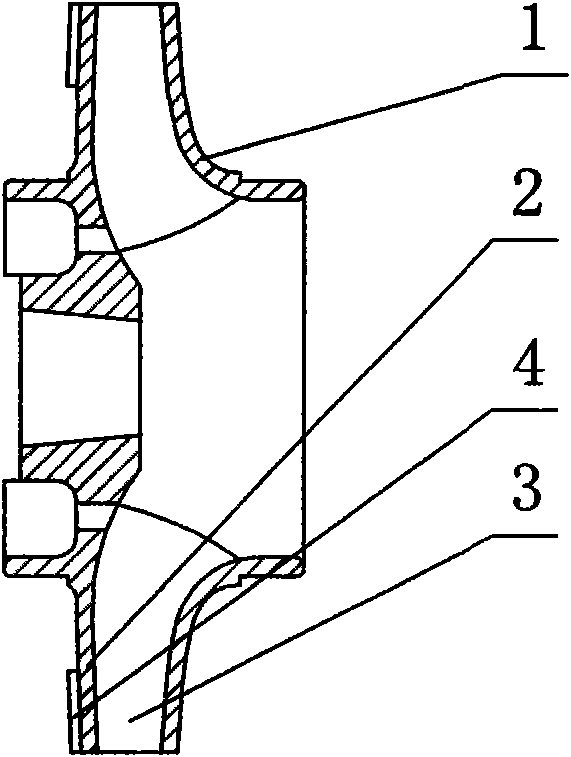

Impeller of externally mixed type self-priming pump

InactiveCN102022374AIncrease contact areaStrong agitationPump componentsPriming pumpAgricultural engineeringFront cover

The invention discloses an impeller of an externally mixed type self-priming pump, relating to pumps. A front cover plate and a rear cover plate are arranged on the impeller, blades are arranged between the front cover plate and the rear cover plate, and annularly cut belts are arranged on the external diameters of the cover plates. As the annularly cut belts are arranged on the external diameters of the cover plates, the blades at the parts of the annularly cut belts are not covered by the cover plates, the blades are exposed, and the contact area of the blades with liquid is large. When the pump starts to work, gas and liquid are well mixed by strong agitation force in the pump, gas discharge time is short, and water is quickly pumped. The impeller is suitable for externally mixed type self-priming pumps.

Owner:山东壮发泵业股份有限公司

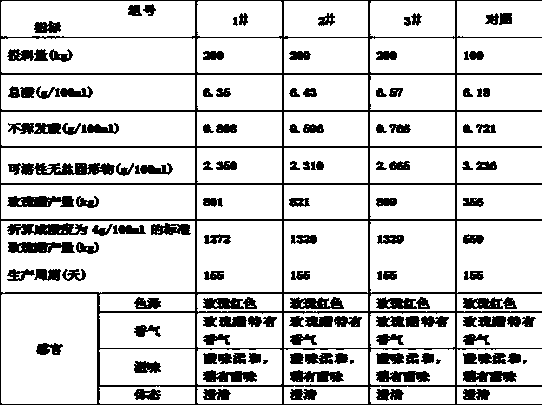

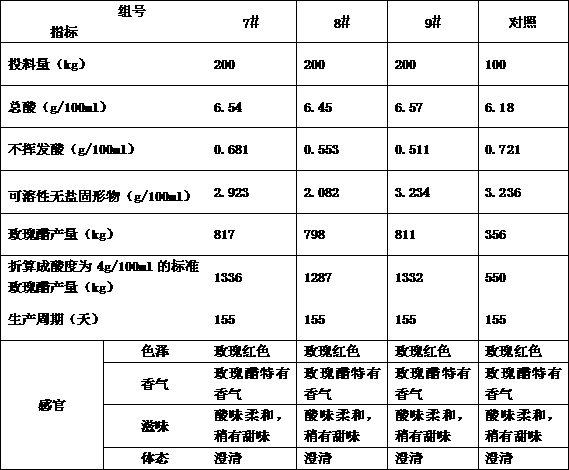

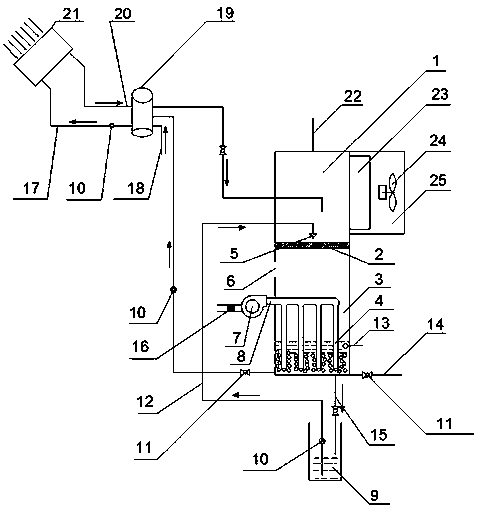

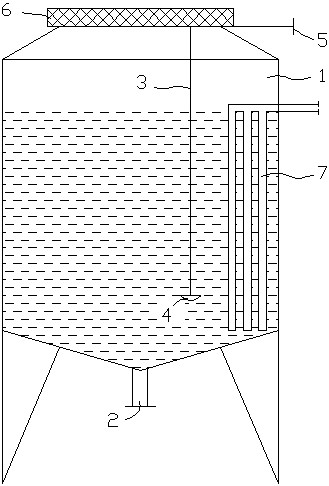

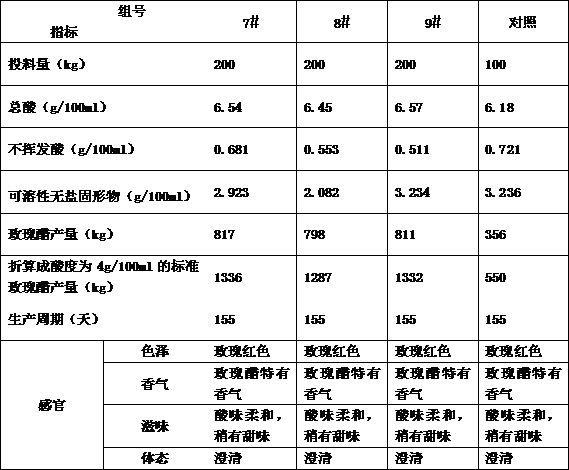

Method for producing rose vinegar by pump reflux method

ActiveCN107904133AReduce labor intensityHigh degree of mechanizationVinegar preparationRefluxBiochemical engineering

The invention discloses a method for producing rose vinegar by a pump reflux method. The method comprises the following steps: rinsing rice; steaming rice; cooling cooked rice; putting the cooked ricein a tank and erecting a nest; floating; adding water; fermenting; aging; squeezing; and sterilizing. The tank is cylindrical, the upper end of the tank is open while the lower end of the tank is provided with a cone-shaped or arc-shaped bottom; a mash discharge hole is formed in the lowest part of the cone-shaped or arc-shaped bottom of the tank; the mash discharge hole is connected to a refluxspray hole in the upper end hole of the tank through a pipeline; a liquid pump is arranged on the pipeline; and a grass cover is arranged on the upper end hole. The fermenting step comprises the following steps: (1) medium frequency large reflux fermentation control in early stage; (2) high frequency medium reflux fermentation control in middle stage; and (3) low frequency small reflux fermentation control in later stage. According to the method for producing rose vinegar by the pump reflux method disclosed by the invention, the production scale of the rose vinegar can be expanded, the yield of the rose vinegar is increased, the quality of the rose vinegar is stabilized and improved, and the labor intensity is alleviated.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Label impurity separator for plastic bottle sheets

InactiveCN107650297AEfficient separationEasy to separatePlastic recyclingMechanical material recoveryImpurityAirflow

The invention discloses a label impurity separator for plastic bottle sheets. A feeding opening is formed in the upper side wall of one end of a stirring box. A bottle sheet discharging opening is formed in the upper side wall of the other end of the stirring box. An airflow outlet is formed in the upper side wall of the stirring box between the feeding opening and the bottle sheet discharging opening. An airflow inlet is formed in the bottom wall of the stirring box below the airflow outlet. A feeding hopper is arranged in the feeding opening of the upper side of the stirring box. Screw blades stir the plastic bottle sheets in the stirring box under the driving action of a motor and push the plastic bottle sheets from the feeding opening to the bottle sheet discharging opening. A wind inlet impurity removing net is arranged in the airflow inlet of the bottom wall of the stirring box. A bottom cover opening of an absorbing cover communicates with the airflow outlet of the upper side wall of the stirring box. A wind inlet of a suction fan communicates with a top cover opening of the absorbing cover. A first wind closing device is arranged in the feeding opening of the stirring box.A second wind closing device is arranged in the bottle sheet discharging opening of the stirring box. The label impurity separator for the plastic bottle sheets separate labels and impurities more efficiently and thoroughly.

Owner:临武县华湘再生资源回收有限公司

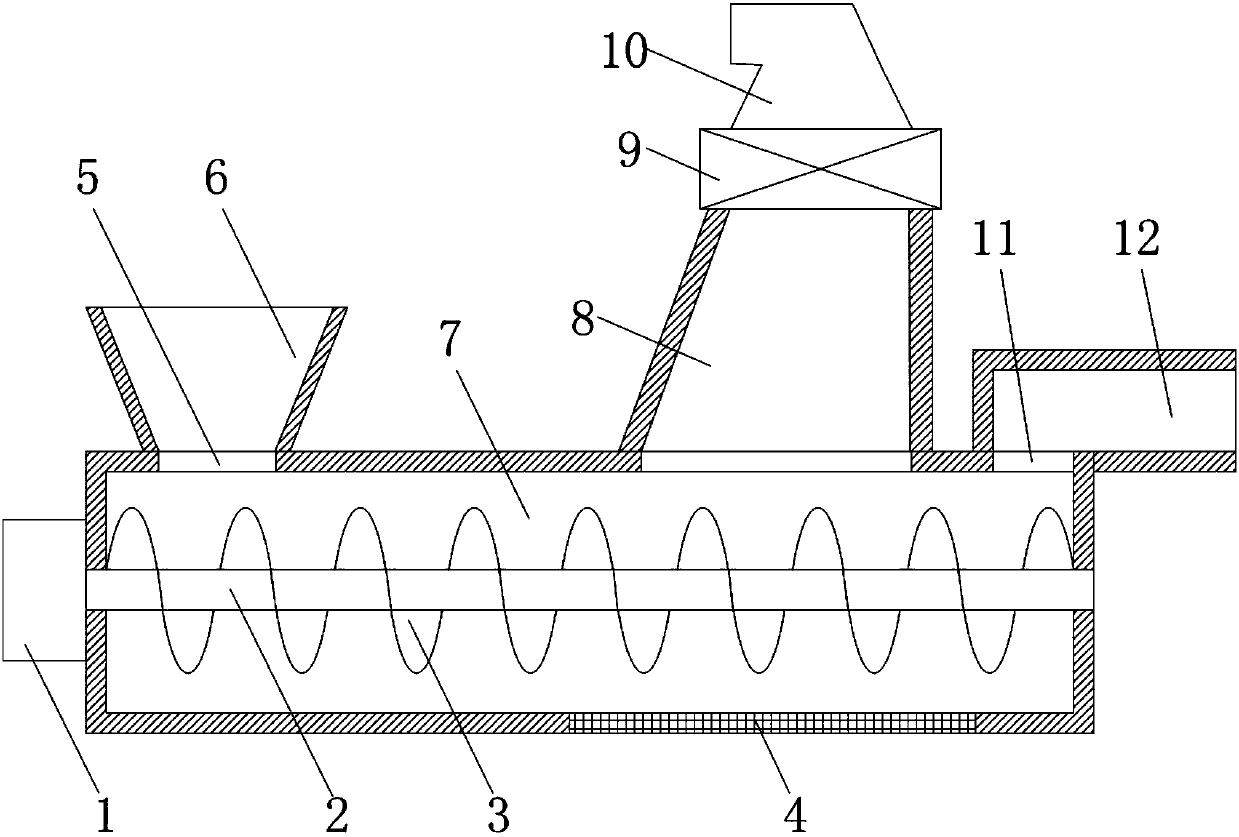

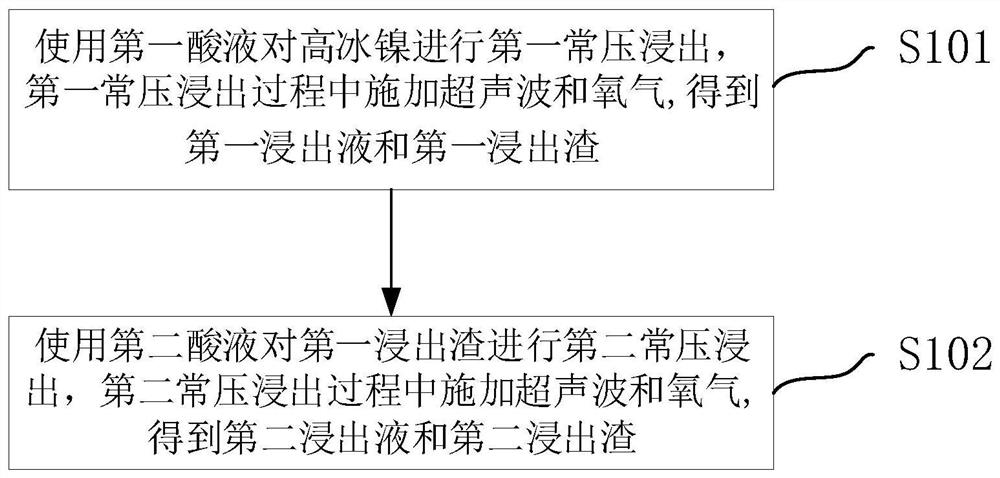

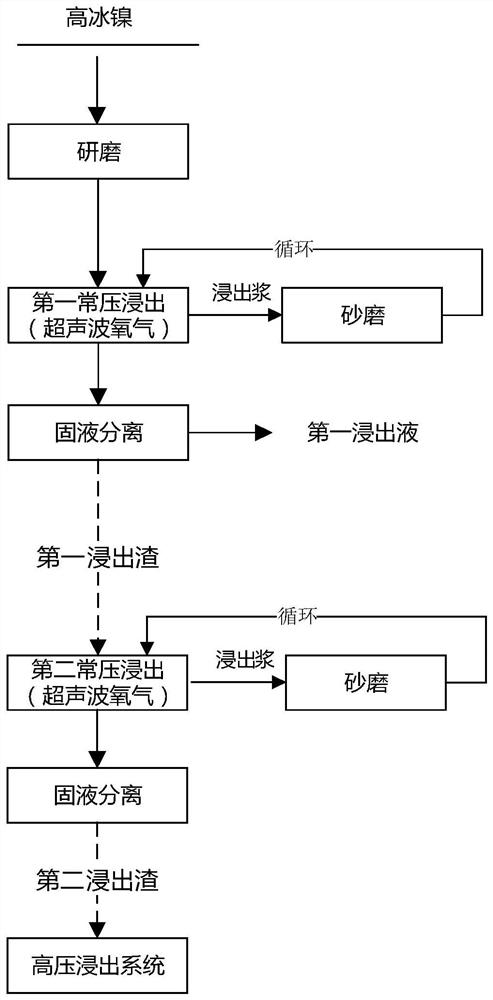

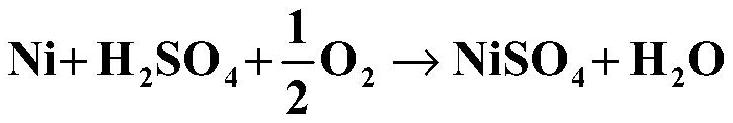

Normal-pressure leaching method for high-grade nickel matte and nickel sulfate

ActiveCN113584314AReduce leaching costsReduced Diffusion ResistanceNickel sulfatesProcess efficiency improvementHydrogen peroxideSulfur hydride

The invention provides a normal-pressure leaching method for high-grade nickel matte and nickel sulfate.The method comprises first normal-pressure leaching and second normal-pressure leaching, ultrasonic waves and oxygen are applied in the first normal-pressure leaching process and the second normal-pressure leaching process, on one hand, no hydrogen peroxide is consumed, the leaching cost is low, and the risks of transportation, storage and process management and control are avoided; on the other hand, the stability of the raw materials in the leaching process is destroyed, the raw materials are prevented from being wrapped by leaching liquid, the activity is prevented from being reduced, the Ni leaching rate in the normal-pressure leaching process is increased, the material throughput of a high-pressure leaching system is greatly reduced, the volume design quantity of an autoclave is small, and production control is safer; and finally, oxygen is promoted to be in efficient contact with the raw materials and hydrogen sulfide generated in the leaching process, hydrogen sulfide can be rapidly converted into sulfuric acid, the treatment risk of hydrogen sulfide gas is effectively reduced, and the leaching process is safer.

Owner:HUNAN CNGR NEW ENERGY TECH CO LTD

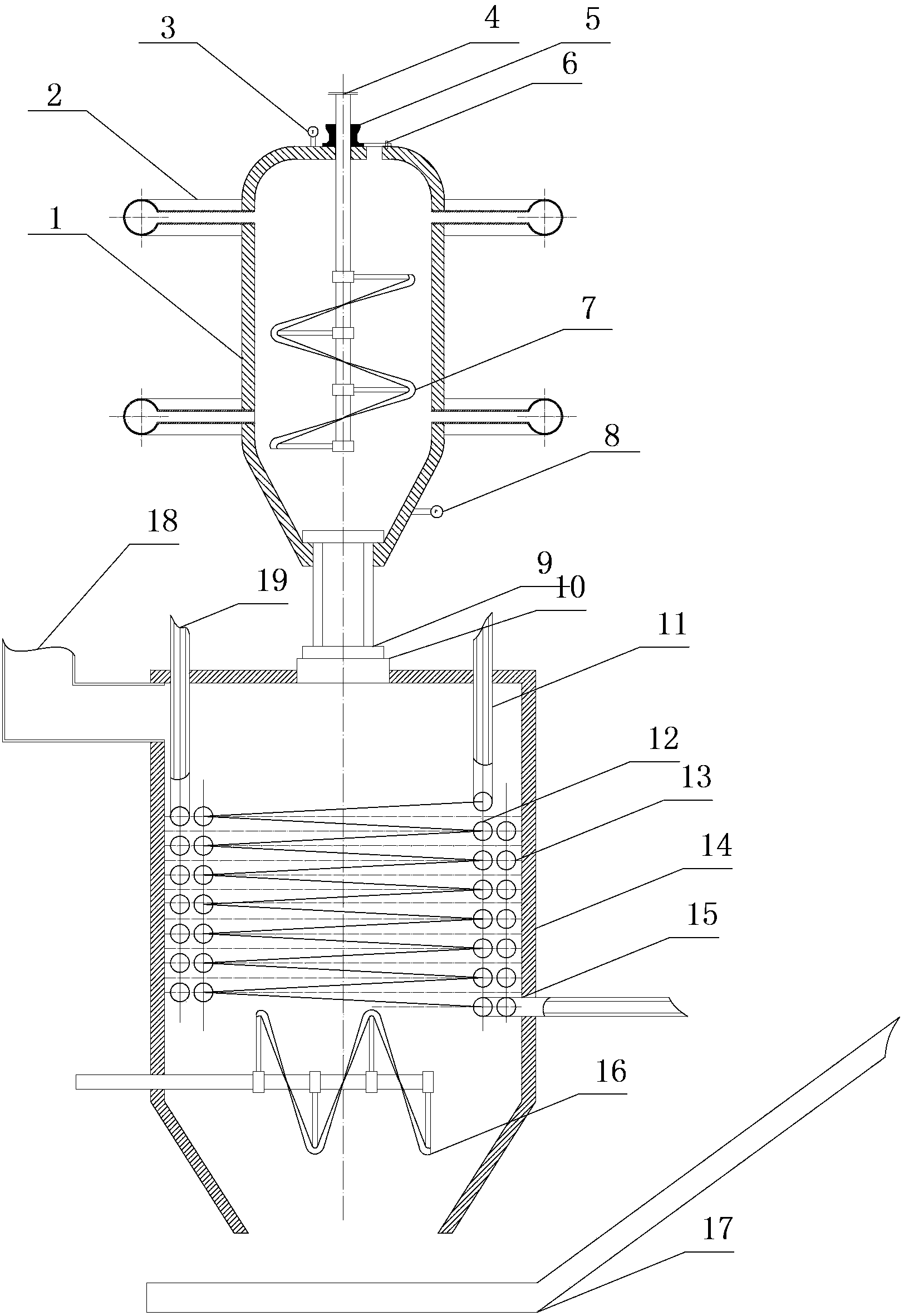

Multichannel combined aeration tower

InactiveCN104211199AHigh oxygen mass transfer efficiencyImprove dissolved oxygen efficiencyWater aerationSustainable biological treatmentHigh energyEngineering

The invention discloses a multichannel combined aeration tower which is particularly applicable to an underground water iron and manganese removal process and solves the problems of low oxygen dissolving efficiency, low effluent DO (dissolved oxygen) concentration, large occupied area and high energy consumption of an existing aeration device. The multichannel combined aeration tower comprises a water inlet pipe, a water distribution device, a tower body, a packing group, air pipes, blast aeration devices and a water outlet pipe, a water outlet of the water distribution device is formed in the top of the tower body, a water inlet of the water distribution device is connected with the water inlet pipe, the packing group is arranged inside the tower body, the blast aeration devices are symmetrically arranged on the lower portion of the tower body and connected onto the outer wall of the tower body through the air pipes, the water outlet pipe is arranged at the bottom center of the tower body, and the bottom of the tower body is inclined downwards from the periphery to the center. The multichannel combined aeration tower is used for secondary aeration in a secondary filtering oxidation process with iron and manganese coexistence.

Owner:HARBIN INST OF TECH

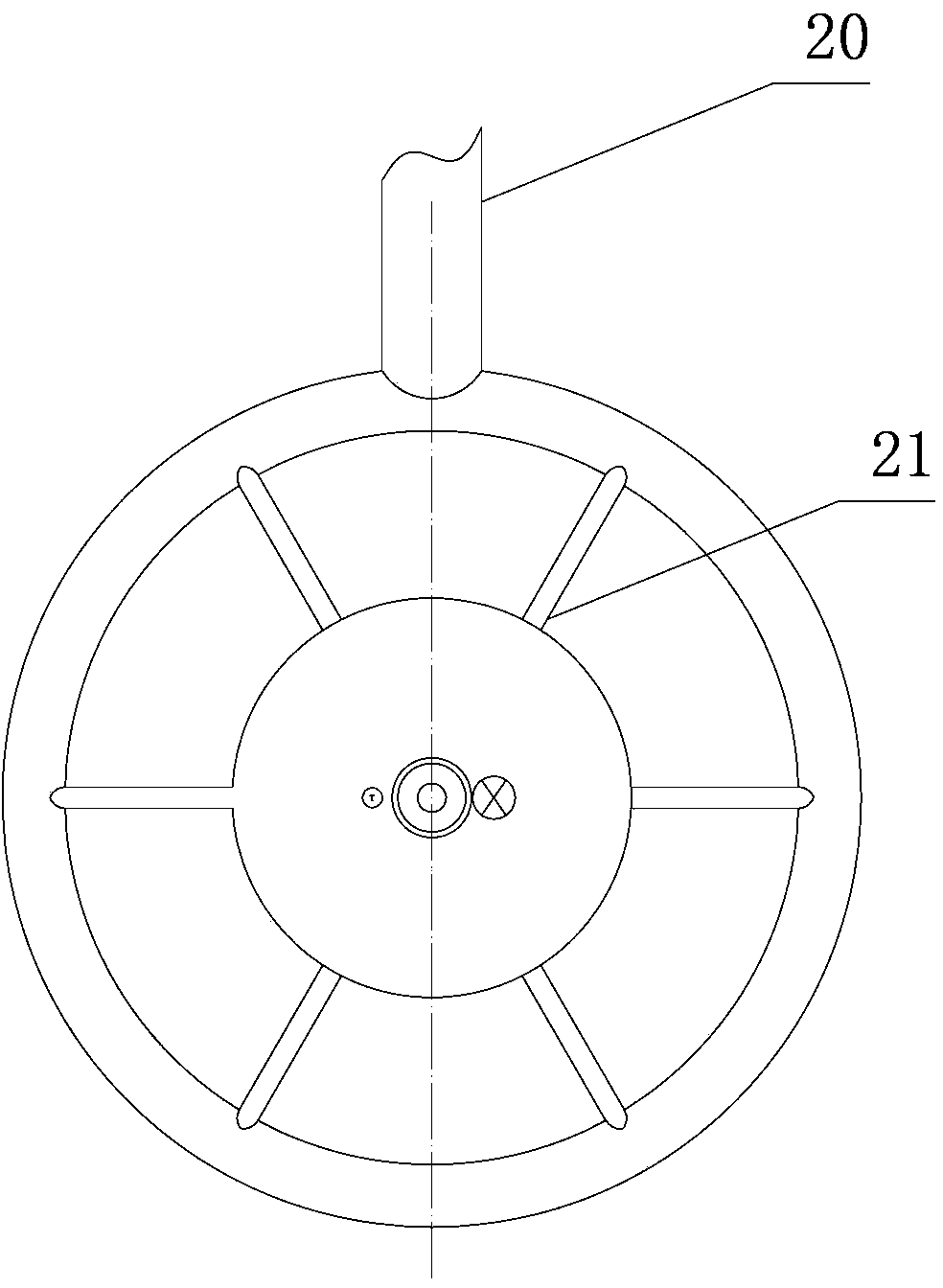

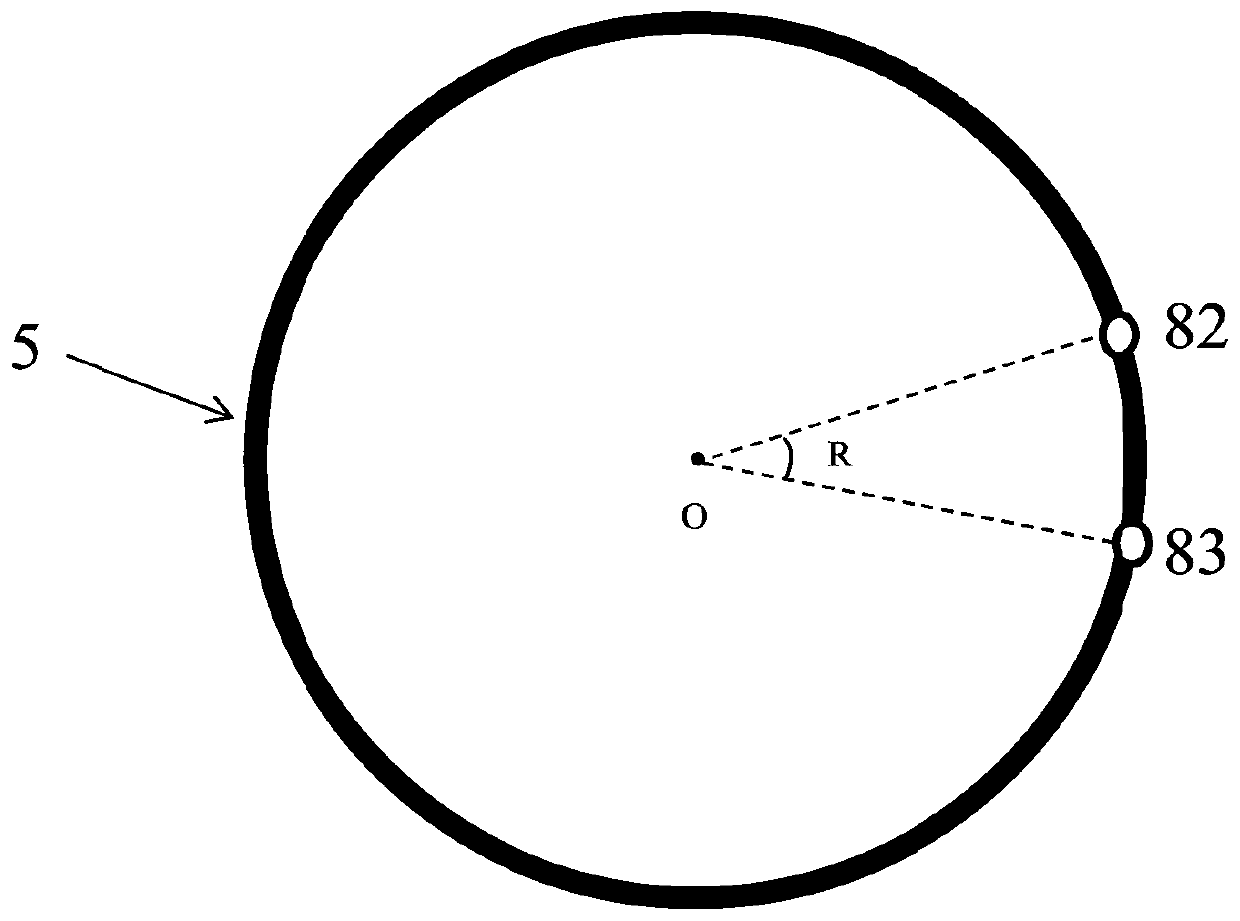

Automatic tank bottom blowdown system

ActiveCN105501717ARealize automatic dischargeEasy to recyclePackage recyclingLarge containersMaterial resourcesPollution

The invention discloses an automatic tank bottom blowdown system. The system comprises a tank inside dirt suction device and a tank outside blowdown device which are connected with each other through a blowdown pipe, wherein the tank inside dirt suction device drives a turntable by a drive mechanism, a plurality of dirt suction pipes are distributed on the turntable, and the turntable and the dirt suction pipes rotate with a hollow stand column as a center of circle. By virtue of strong negative-pressure attraction generated by a dirt suction pump of the tank outside blowdown device, dirt is sucked into the dirt suction pipes, then transported into a column sleeve type collection cavity to be gathered, and finally discharged from the tank outside blowdown device through the blowdown pipe, thereby automatically discharging dirt at the bottom of a tank, avoiding inconvenience of manual cleaning in a traditional way, shortening shutdown time, improving production efficiency, lowering production cost greatly, saving manpower and material resources as well as financial resources, and avoiding potential safety hazard caused by manual cleaning. The automatic tank bottom blowdown system is safe and reliable, is reasonable in structure, convenient to operate and high in automation degree, facilitates recycling and retreatment of dirt, and avoids environment pollution likely to be caused by manual cleaning.

Owner:惠金波

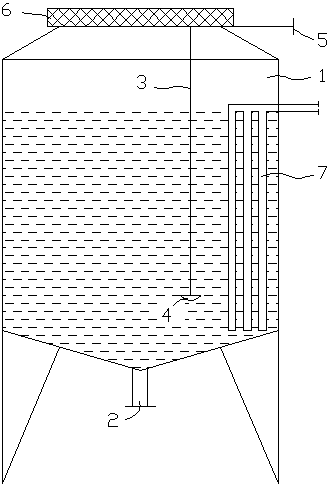

Method for producing rose vinegar by adopting pneumatic stirring way

ActiveCN107937236AStable qualityHigh product yieldVinegar preparationIntermediate stageMedium frequency

The invention discloses a method for producing rose vinegar by adopting a pneumatic stirring way. The method comprises the steps of carrying out immersion cleaning on rice, steaming the cleaned rice,cooling the cooked rice, building a nest, flooding, adding water, fermenting, aging, squeezing and sterilizing; a tank is in a cylinder shape, an opening is formed in the upper end of the tank, and the diameter-height ratio D / H of the cylinder part of the tank is equal to 1 to (0.8-1); one end of a compressed air pipeline is connected with an air inlet, and the other end of the compressed air pipeline is connected with an air nozzle arranged at the lower part of mash in the tank; a grass cover is arranged at the opening formed in the upper end of the tank; step of fermenting comprises the following process: (1) medium-frequency and large-pneumatic stirring intensity fermentation control in the early stage; (2) high-frequency and medium-pneumatic stirring intensity fermentation control in the middle stage; (3) low-frequency and small-pneumatic stirring intensity fermentation control in the late stage. The method for producing the rose vinegar by adopting the pneumatic stirring way can enlarge the production scale, increase the yield, improve and stabilize the quality of the rose vinegar and lighten the labor intensity.

Owner:绍兴至味食品有限公司

Rural bubbling method evaporation cold-hot exchange household air conditioning system

PendingCN110006122AReduce power consumptionLarge temperature differenceSolar heating energyLighting and heating apparatusWater storage tankSolar water

The invention provides a rural bubbling method evaporation cold-hot exchange household air conditioning system. The system comprises an air conditioner outdoor unit and an air box mounted on the air conditioner outdoor unit, the lower portion of the air box communicates with a water storage tank, and a plurality of bubbling pipes are arranged in the water storage tank. The bubbling pipes are connected with an external fan. A porous netty water distributor is arranged between the air box and the water storage tank. A spray nozzle communicating with an underground water well through a pipeline is arranged above the water distributor, the air box communicates with a return water pipe of a solar water heater, and the bottom of the water storage tank communicates with a water inlet pipe of thesolar water heater. According to the rural bubbling method evaporation cold-hot exchange household air conditioning system, when an air conditioner is used for refrigerating and heating, underground water and hot water in the solar water heater are utilized for performing cold-hot exchange with outdoor air, cold-hot exchanging is performed between the air subjected to exchanging and a condenser &an evaporator in the air conditioner outdoor unit, a larger temperature difference can be provided, electric energy consumption of the air conditioner outdoor unit is effectively reduced, the design is reasonable, mounting is easy, existing conditions in rural families can be fully utilized, and a remarkable energy-saving purpose is achieved.

Owner:HENAN UNIV OF URBAN CONSTR

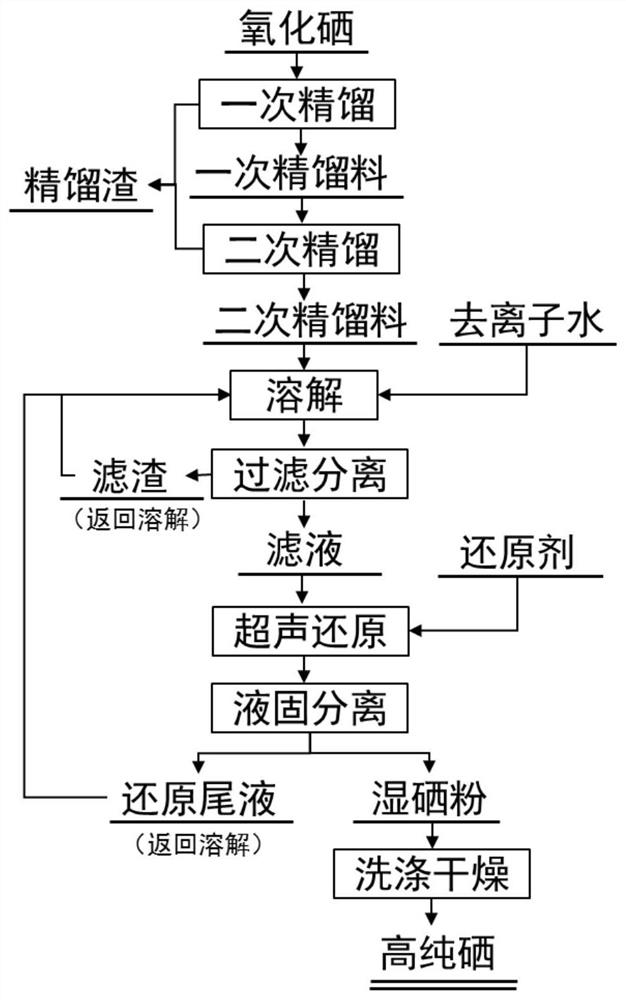

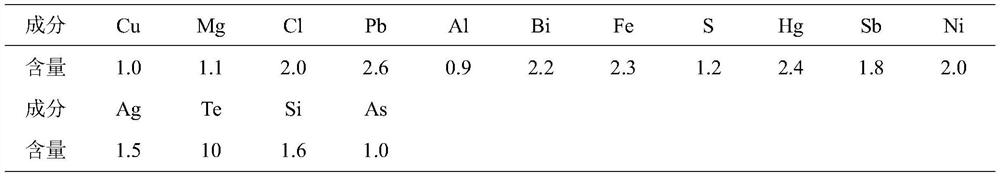

Method for producing high-purity selenium through ultrasonic enhanced reduction

ActiveCN112897475AStrong agitationEnhanced diffusion processElemental selenium/telluriumDistillationSelenium Oxide

The invention relates to a method for producing high-purity selenium through ultrasonic enhanced reduction, and belongs to the technical field of materials. The method comprises the following steps: carrying out cascade inert distillation on selenium oxide to obtain high-purity selenium oxide, dissolving the high-purity selenium oxide in dilute sulfuric acid to obtain a seleninic acid solution, carrying out ultrasonic enhanced reduction reaction on the seleninic acid solution, carrying out solid-liquid separation, and washing and drying the solid to obtain high-purity selenium. According to the method, local stirring is enhanced by utilizing reducibility. H generated by ultrasound and a high-temperature and high-pressure environment, a larger reduction potential is achieved, seleninic acid is reduced to generate high-purity selenium, the production cost of the high-purity selenium is low, the purity of the obtained selenium is high, and operation conditions are friendly.

Owner:KUNMING UNIV OF SCI & TECH

Method for smelting and reducing iron ores through converter steelmaking system

ActiveCN105803147ASolve the problem of furnace lining lifeImprove efficiencyManufacturing convertersSteelmakingIronstone

The invention discloses a method for smelting and reducing iron ores through a converter steelmaking system and belongs to the technical field of iron and steel metallurgy. After the converter slag splashing converter protection process, molten iron is mixed into a converter firstly, then the iron ores and a slag forming agent are added in batches, wherein the adopted slag forming agent comprises limestone, dolomite and lime; and oxygen-enriched air and pulverized coal are simultaneously top-blown through an oxygen lance, the thickness of foaming slag is controlled by adjusting the charging speed, and the iron ores are smelted and reduced. The method is based on the modern mature technology of oxygen converters, the iron ores are smelted and reduced in the converter process, and the problems of too fast lining erosion and high energy consumption cost existing in iron ore direct smelting and reducing at present can be solved.

Owner:TIANJIN TIANGANG UNITED SPECIAL STEEL CO LTD

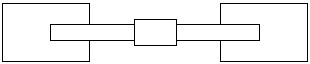

External mixing self-priming pump impeller

InactiveCN102022373AWell mixedShort discharge timePump componentsPriming pumpGas-discharge lampEngineering

The invention relates to an external mixing self-priming pump impeller, and relates to pumps. A front cover plate and a rear cover plate are arranged on the impeller; blades are arranged between the front cover plate and the rear cover plate; and gas-liquid mixing sheets are distributed on the outer sides of the cover plates uniformly. The gas-liquid mixing sheets are distributed on the outer sides of the cover plates uniformly, so during the initial operation of a pump, a pump body has strong stirring, good gas-liquid mixing, short time of gas discharge and high efficiency; and the impeller is suitable for an external mixing self-priming pump.

Owner:山东壮发泵业股份有限公司

Method of swinging electric arc welding with double hollow cathodes

ActiveCN105537723AIncrease welding heat inputFast welding speedArc welding apparatusElectric arcWelding power supply

The invention relates to a method of swinging electric arc welding with double hollow cathodes and belongs to the field of welding methods. The two identical hollow tubular cathodes are arranged and connected with two welding power supplies and two air extractors correspondingly. By means of the air extractors, a negative pressure state is formed in a cavity and an electric arc central area of one tubular cathode, and under the action of atmospheric pressure, a constrained electric arc is formed while the other electric arc is in the free state; the situation is kept for a certain period of time, the constrained electric arc is recovered into the free state while the other electric arc turns into the constrained state, and the situation is repeated, so that the two electric arcs are always in the form that one is in the free state while the other one is in the constrained state. A welding wire is fed in from the space between the two cathodes, and molten drops swing in a reciprocating mode under the condition that the free state and the constrained state occur alternately. The method increases the welding speed, increases the current bearing capacity, reduces welding deformation, generates a vibrating stirring effect on a molten pool, prevents thick and big grains from occurring, and improves the quality of weld joints. The heat input of the electric arcs to workpieces is reduced, and the range of a heat affected zone is narrowed.

Owner:BEIJING UNIV OF TECH

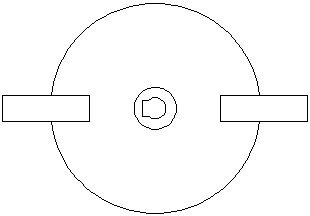

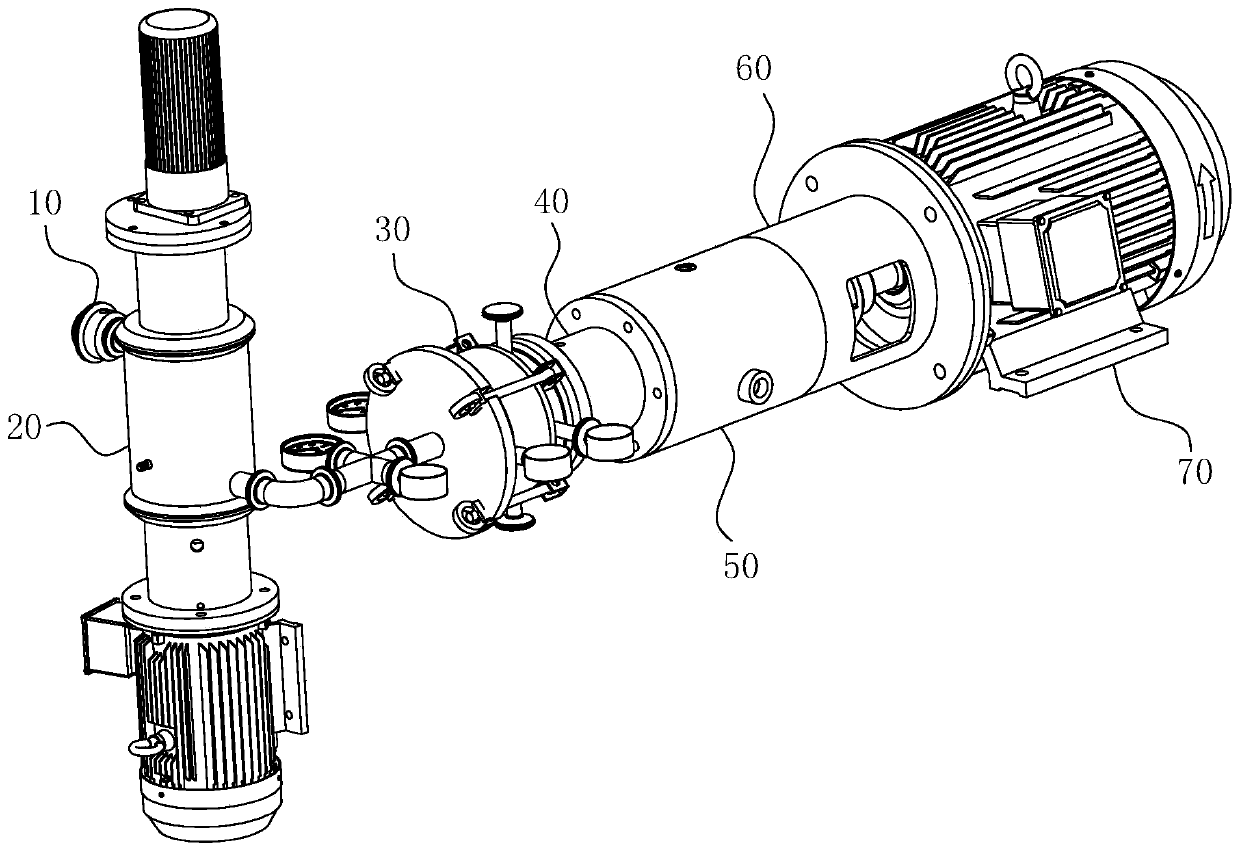

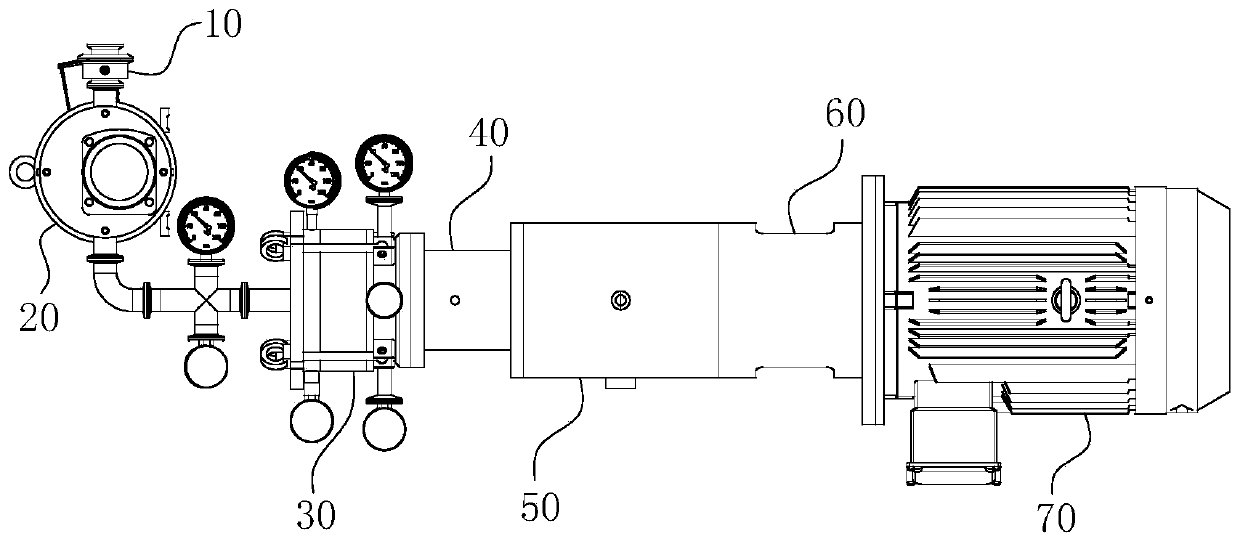

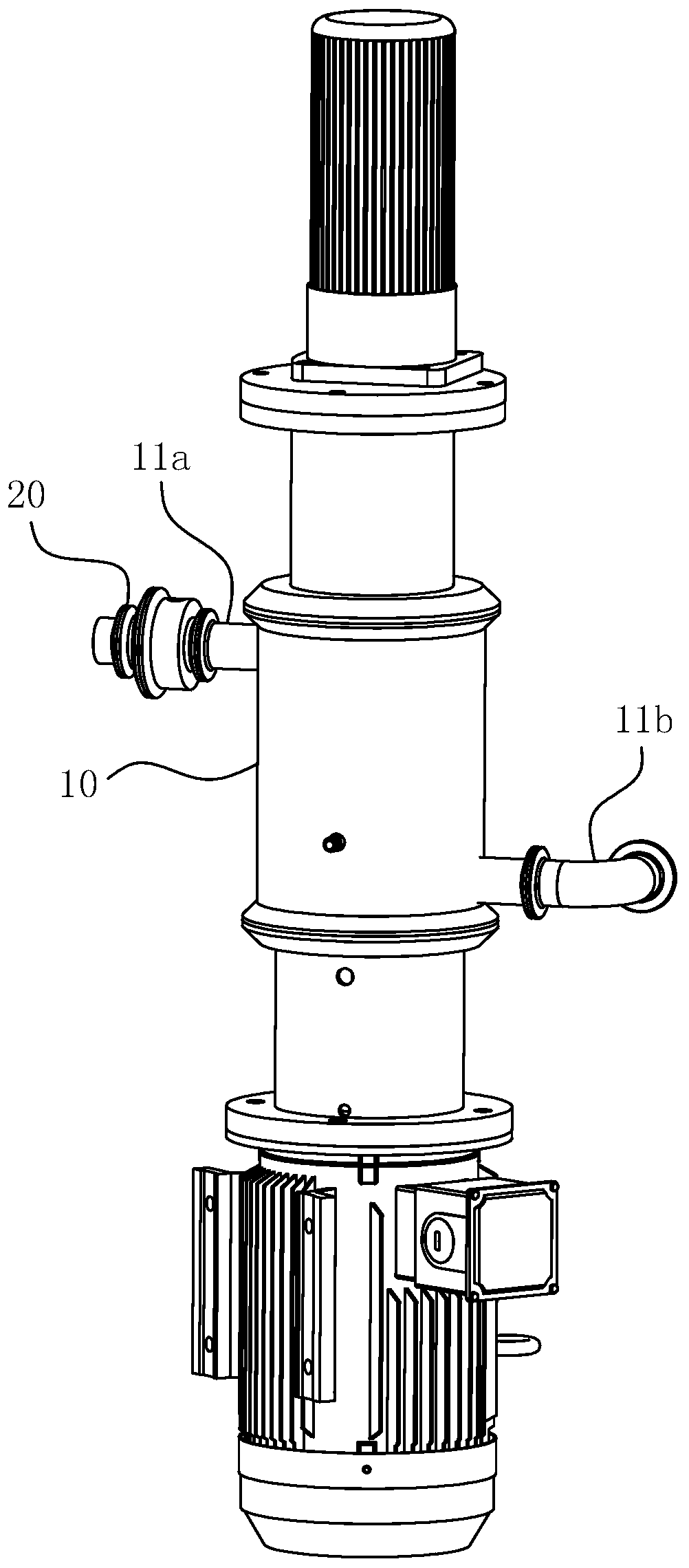

External-mix self-priming pump

InactiveCN102022343AIncrease contact areaStrong agitationPump componentsPriming pumpFront coverSelf priming

The invention discloses an external-mix self-priming pump and relates to pumps. A liquid inlet is formed on one side of a pump body; a liquid outlet is formed on the upper part of the pump body; an impeller is arranged inside the pump body; a front cover plate and a rear cover plate are arranged on the impeller; blades are arranged between the front cover plate and the rear cover plate; an annular cutting belt is arranged on external diameters of the cover plates; and lug bosses corresponding to the annular cutting belt are uniformly distributed inside the pump body. Because the annular cutting belt is arranged on the external diameters of the cover plates, the blades at the annular cutting belt are not covered by the cover plates and are exposed, the contact area of the blades and the liquid is large; when the pump starts to work, the agitation in the pump body is strong, the gas and the liquid is well mixed, the gas exhaust time is short and the water supply speed is high; and the lug bosses corresponding to the annular cutting belt are uniformly distributed inside the pump body, and when the pump works, the lug bosses are matched with the exposed blades; therefore, the gas-liquid mixtures are effectively scraped out, gas-liquid separation is accelerated, the water supply time is shortened, and the invention is applied to the external-mix self-priming pump.

Owner:山东壮发泵业股份有限公司

Reducing agent for slag cleaning furnace top-blown immersion blowing reduction

ActiveCN103409575BImprove reduction efficiencyTurn waste into treasureElectric furnaceMelting tankSlag

The invention relates to a reducing agent for slag cleaning furnace top-blown immersion blowing reduction, and belongs to the technical field of fire method metallurgy. The reducing agent for slag cleaning furnace top-blown immersion blowing reduction is filtered dehydrated waste oil or an oil gas mixture formed from filtered dehydrated waste oil and high pressure nitrogen in a volume ratio of (1-1.25): (200-600). First, the reducing agent of filtered dehydrated waste oil or oil gas mixture formed from filtered dehydrated waste oil and high pressure nitrogen into a pipeline controlled by a self adjusting valve; then a reduction oil gun connected with the pipeline, inserted from the top of the slag cleaning furnace and immersed in a molten pool slag layer is used for top-blown, so that magnetic iron oxide in the electroslag is subjected to a reduction reaction. The invention realizes high-efficiency, low-cost and resource utilization of the waste oil, increases reduction efficiency of the reducing agent and reduces production cost of slag depletion.

Owner:KUNMING UNIV OF SCI & TECH

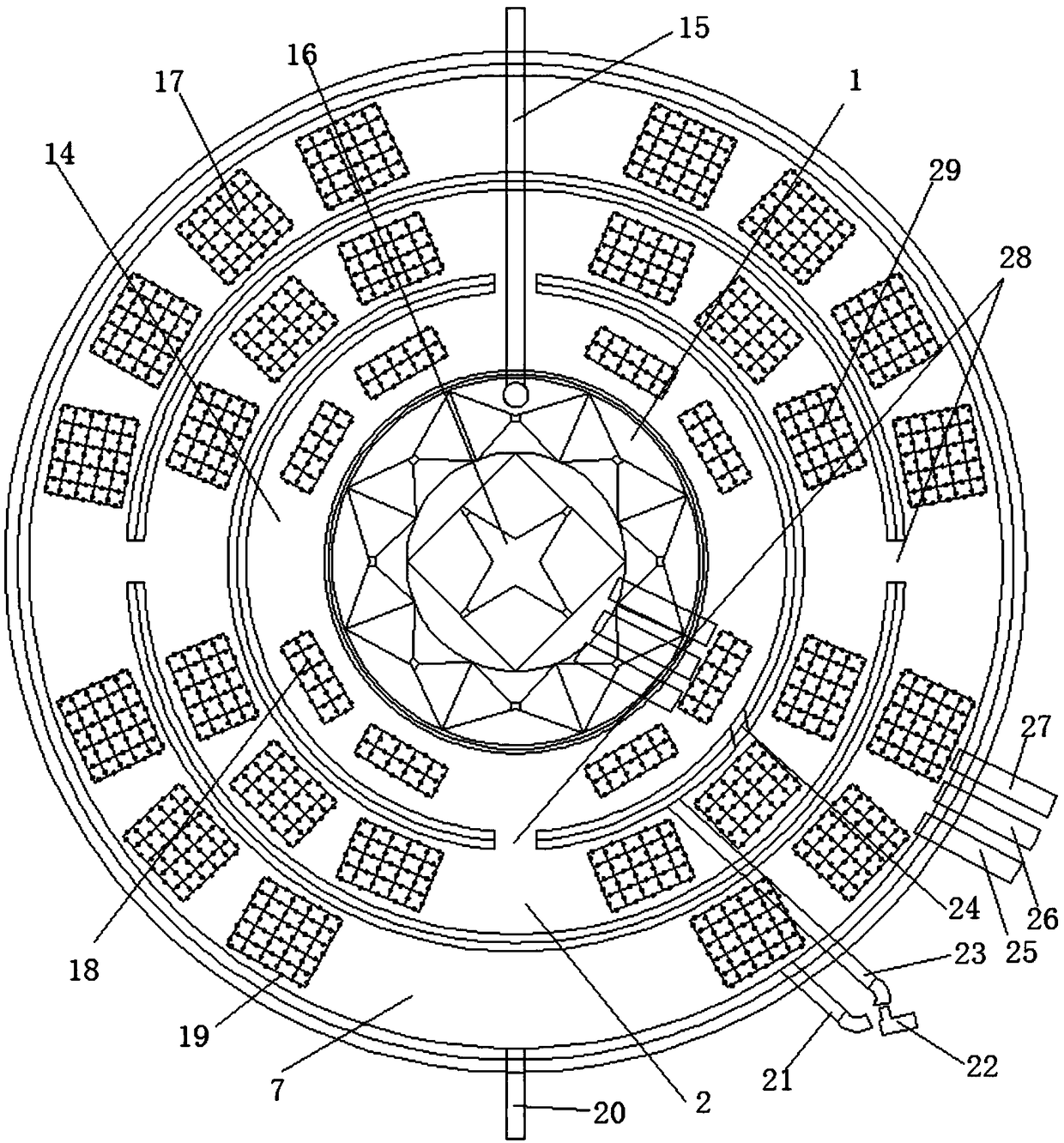

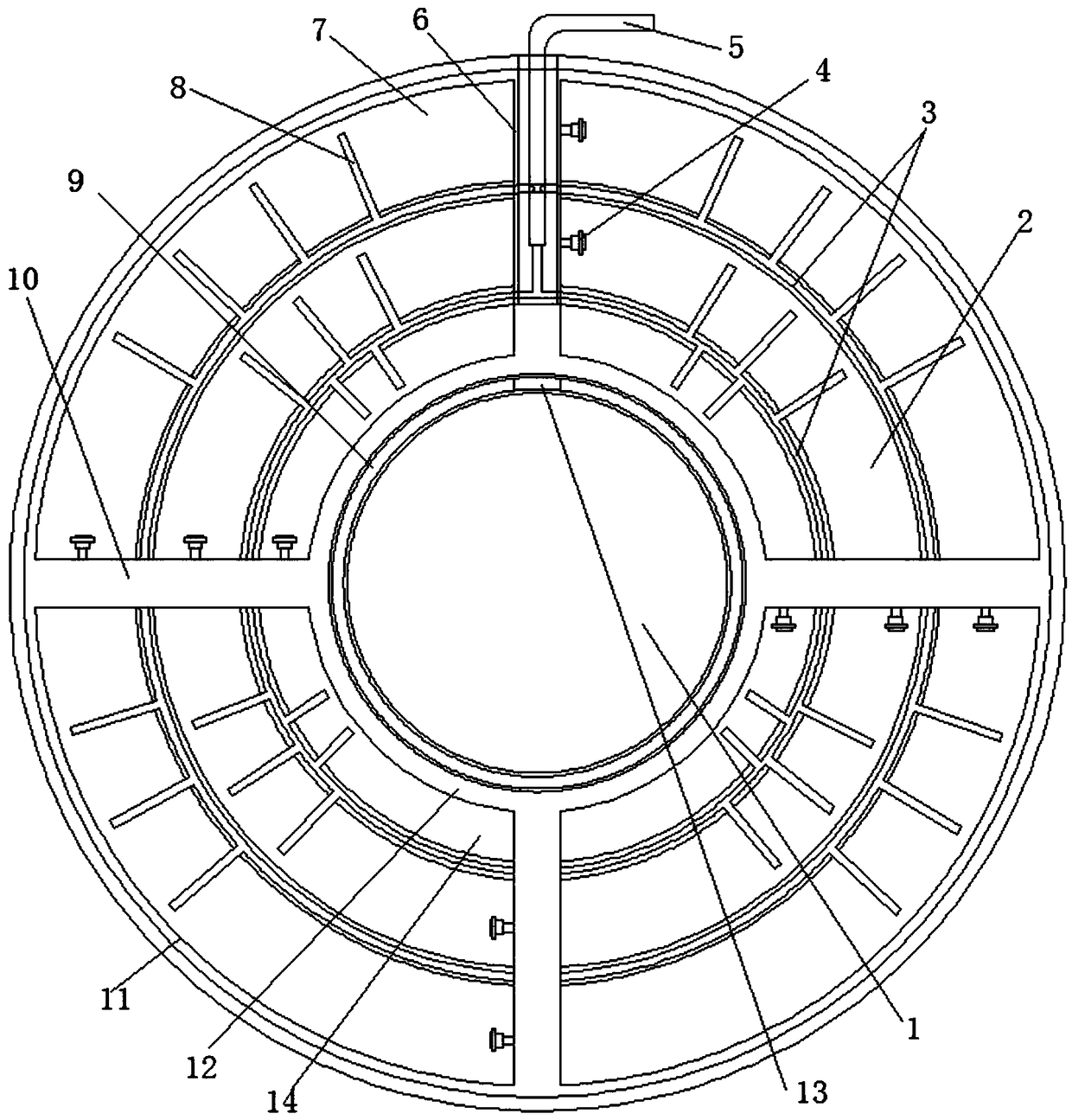

Novel integrated oxidation ditch for sewage treatment

InactiveCN109231457AEasy to handleNo short flow phenomenonTreatment with aerobic and anaerobic processesWater dischargeReturn function

The invention discloses a novel integrated oxidation ditch for sewage treatment. The novel integrated oxidation ditch comprises a round secondary sedimentation tank, wherein a round inner ditch is arranged at the periphery of the secondary sedimentation tank; a round outer ditch is arranged at the periphery of the inner ditch; a round middle ditch is arranged between the inner ditch and the outerditch; a ring-shaped water collecting groove is arranged between the secondary sedimentation tank and the inner ditch; a sludge-discharging arrangement structure is arranged in the secondary sedimentation tank; the inner ditch, the middle ditch and the outer ditch are internally and respectively provided with an aeration mechanism; the side walls of the middle ditch and the inner ditch are provided with air pipeline components; a water discharging hopper is arranged between the secondary sedimentation tank and the water collecting groove; sidewalk plate components are arranged above the secondary sedimentation tank, the inner ditch, the middle ditch and the outer ditch; a sludge discharging hopper is arranged in the secondary sedimentation tank. The novel integrated oxidation ditch disclosed by the invention has the beneficial effects that the oxygen-deficit function, anaerobic function, aerobic function, sedimentation function and sludge returning function are integrated, the sewage treating effect is good, the operation is stable, the investment is less, the process flow is simple and the management is convenient.

Owner:ANHUI MEIZIRAN ENVIRONMENTAL TECH

Food waste hydrolysis and spray explosion system

InactiveCN102674909BConvey evenlyFast deliverySolid waste disposalTransportation and packagingHigh pressureHydrolysis

Owner:四川川润环保能源科技有限公司 +1

Heating stirrer for low viscous reagents

InactiveCN107774187AShorten mixing timeImprove stirring efficiencyTransportation and packagingMixer accessoriesEngineering

The invention discloses a heating stirrer for low viscous reagents. The heating stirrer comprises a supporting seat and a mounting seat. A motor is arranged in the mounting seat, an opening is arranged at the upper end surface of the mounting seat, and a rotating plate is arranged on an extension segment of the output end of the motor. A plurality of magnetic strips are arranged on the upper end surface of the rotating plate, a through hole is arranged in the upper end surface of the supporting base, a heat conducting plate is arranged on the upper end of the through hole, and a non-magnetic heat insulation board is arranged on the lower end of the through hole. A plurality of heating pipes are arranged in the heat conducting plate which is arranged on the through hole, a base is arrangedon the inner wall of the bottom of a cup body, magnetic blocks corresponding to the magnetic strips are installed on the base, and a plurality of stirring blades are fixed on the upper surface of thebase. By accessing a power supply at an electric socket, the heating pipes start to generate heat, and the heat is transferred to the cup body by utilizing the high thermal conductivity of the heat conducting plate, and since the non-magnetic heat insulation plate is disposed at the lower end of the through hole, the heat generated by the heating pipes is prevented from being transferred downwardsto the mounting seat and further to prevent normal operation of the motor from being disturbed.

Owner:成都瞬科仪器仪表有限公司

Method for producing rose vinegar by pneumatic stirring method

ActiveCN107937236BHigh degree of mechanizationFully contactedVinegar preparationProcess engineeringFermentation

The invention discloses a method for producing rose vinegar by a pneumatic stirring method, which comprises the steps of soaking rice, steaming rice, cooling cooked rice, building nests, blooming, adding water, fermenting, aging, pressing, and sterilizing steps. The tank is in the shape of a cylinder. The upper end of the tank is open, the diameter-to-height ratio of the cylindrical part of the tank is D:H=1:(0.8~1), one end of the compressed air pipeline is connected to the air inlet, and the other end is connected to the air nozzle installed at the lower part of the mash in the tank connected, the upper port is provided with a grass cover, and the fermentation steps include: (1) medium frequency and large pneumatic stirring intensity fermentation control in the early stage; (2) mid-term high frequency and medium pneumatic stirring intensity fermentation control; (3) Fermentation control with low frequency and small pneumatic agitation intensity in the later stage. The method for producing the rose vinegar by the pneumatic stirring method of the present invention can expand the production scale, increase the yield, improve and stabilize the quality of the rose vinegar, and reduce the labor intensity.

Owner:绍兴至味食品有限公司

A method for smelting and reducing iron ore using a converter steelmaking system

ActiveCN105803147BImprove efficiencyImprove operational stabilityManufacturing convertersHigh energyMature technology

The invention discloses a method for smelting and reducing iron ores through a converter steelmaking system and belongs to the technical field of iron and steel metallurgy. After the converter slag splashing converter protection process, molten iron is mixed into a converter firstly, then the iron ores and a slag forming agent are added in batches, wherein the adopted slag forming agent comprises limestone, dolomite and lime; and oxygen-enriched air and pulverized coal are simultaneously top-blown through an oxygen lance, the thickness of foaming slag is controlled by adjusting the charging speed, and the iron ores are smelted and reduced. The method is based on the modern mature technology of oxygen converters, the iron ores are smelted and reduced in the converter process, and the problems of too fast lining erosion and high energy consumption cost existing in iron ore direct smelting and reducing at present can be solved.

Owner:TIANJIN TIANGANG UNITED SPECIAL STEEL CO LTD

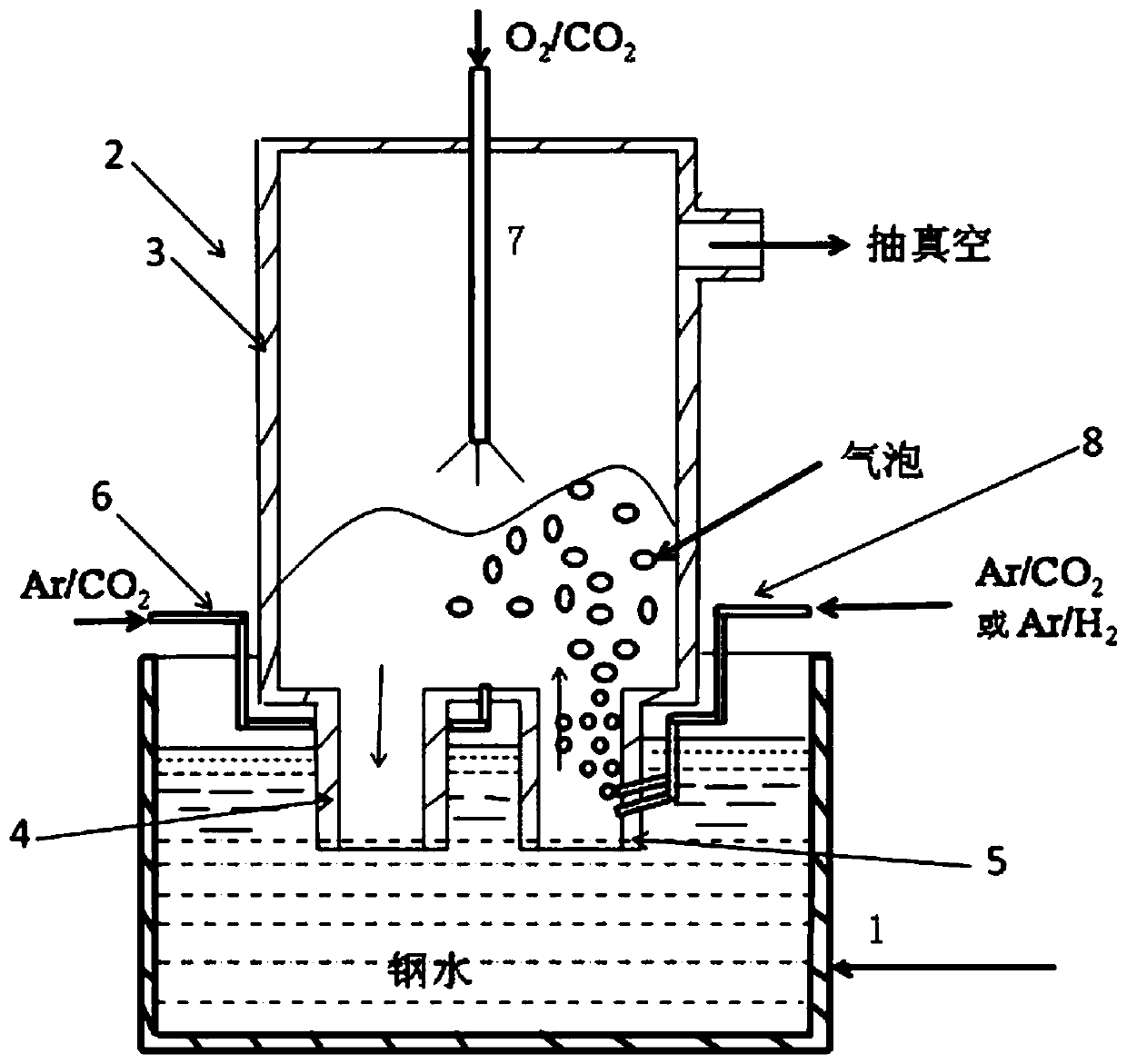

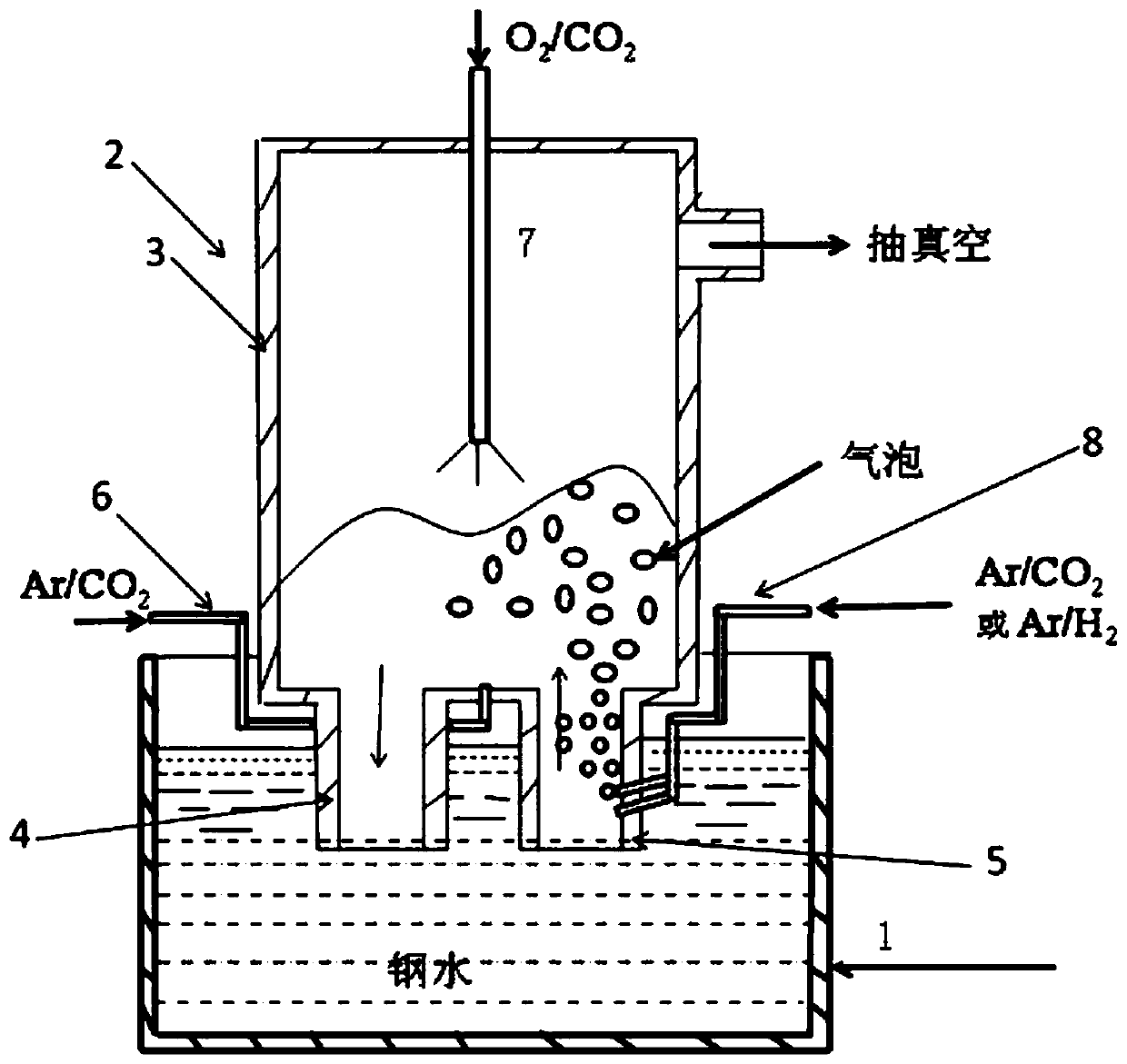

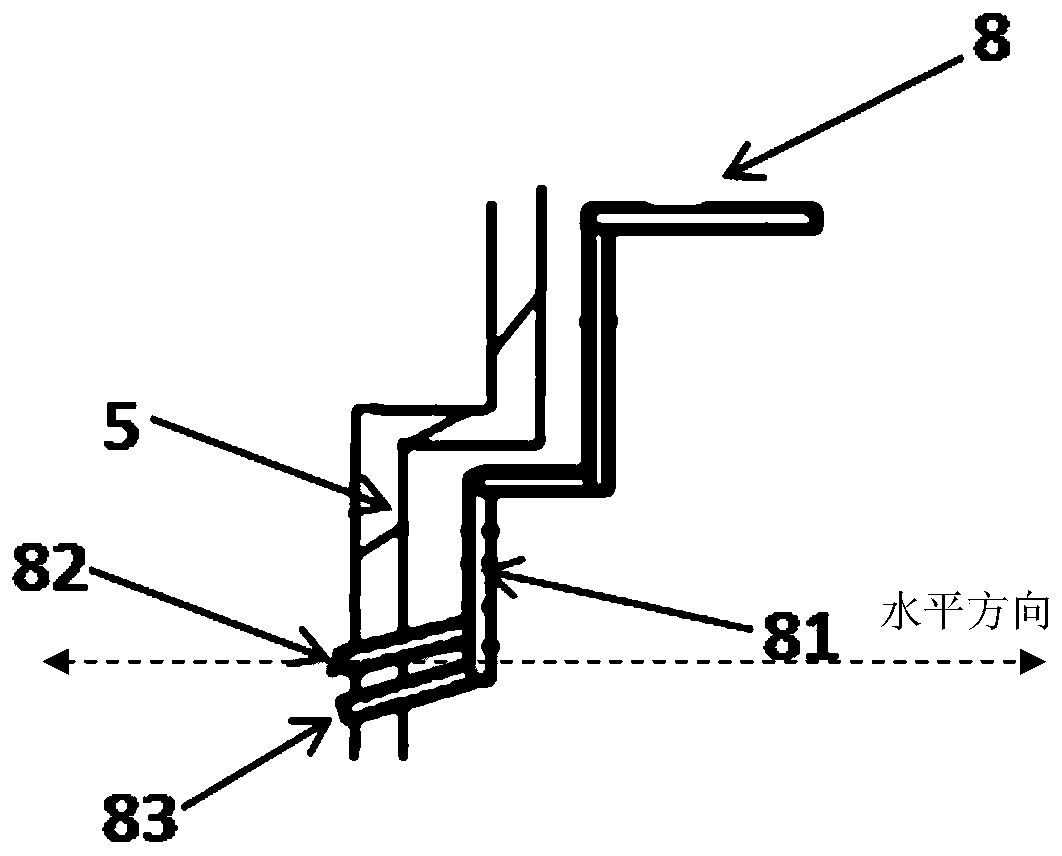

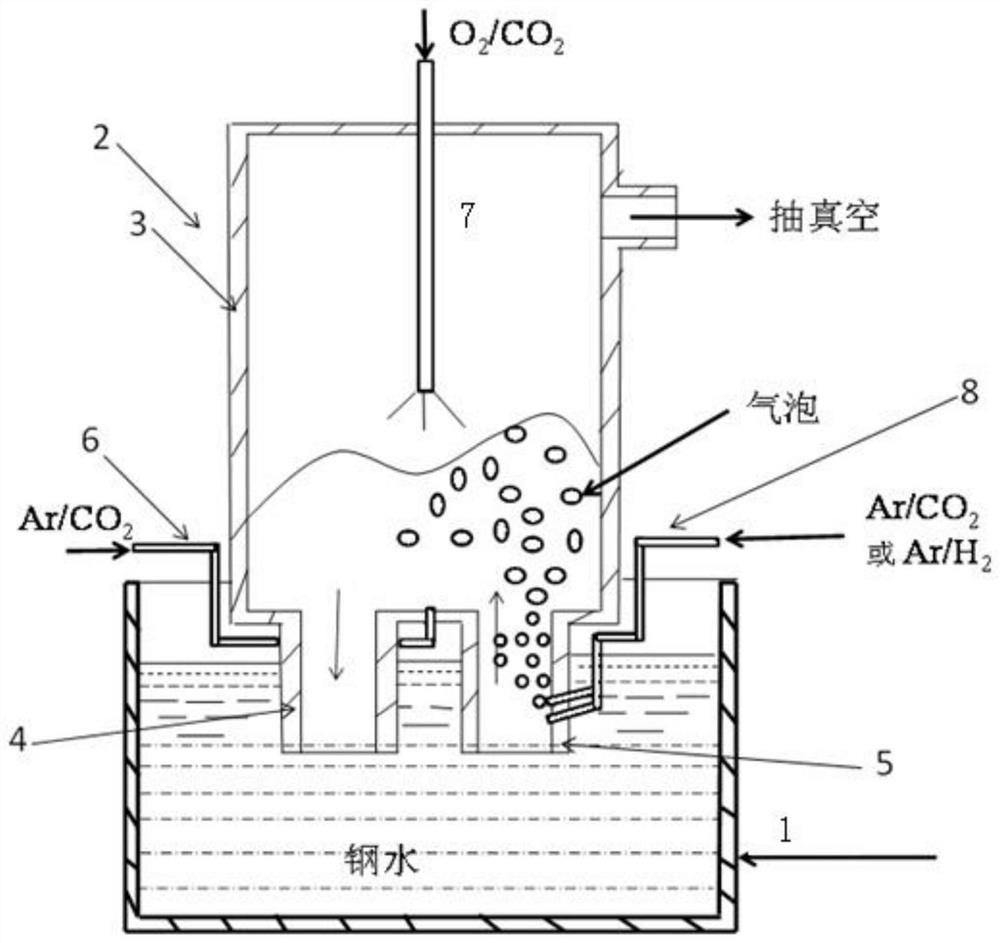

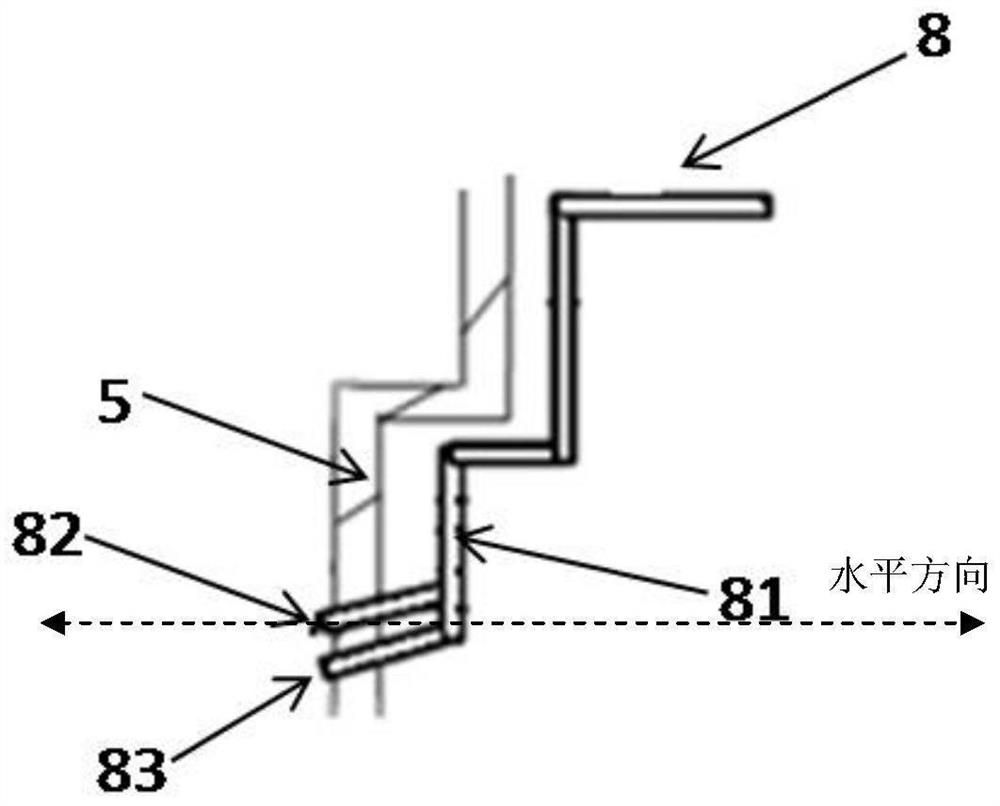

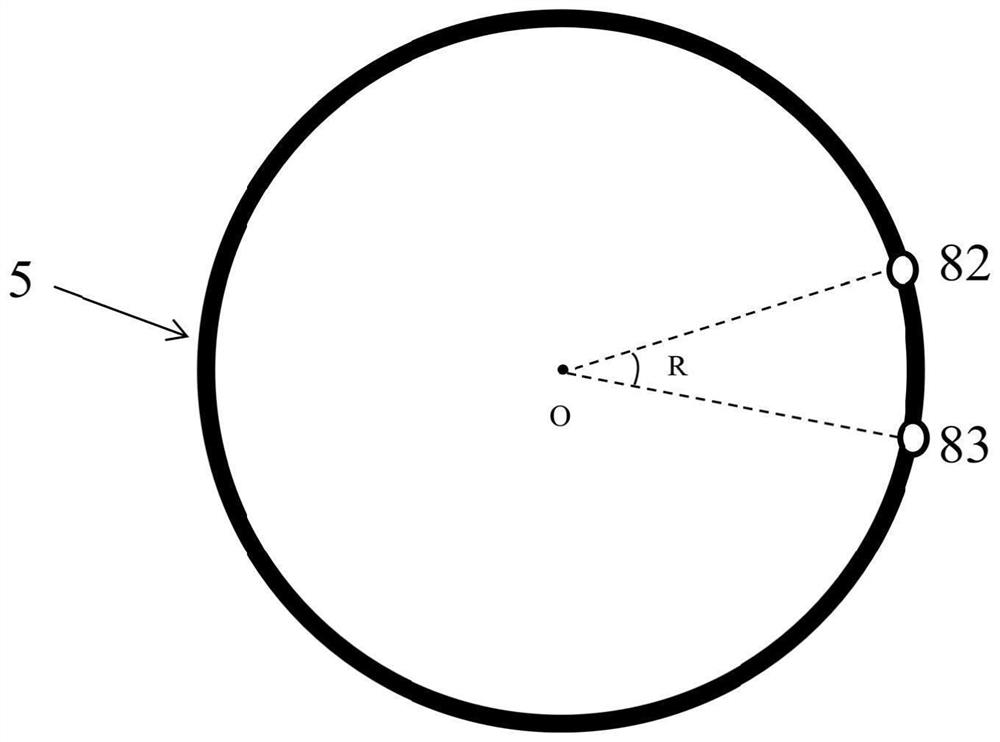

Rapid decarbonization method for performing segmented bottom blowing by adopting multiple gases

The invention discloses a rapid decarbonization method for performing segmented bottom blowing by adopting multiple gases. The rapid decarbonization method comprises the following steps that (a1), when the pressure inside a vacuum degassing tank is less than 17 kPa, an argon blowing tube supplies a first gas; (a2), while the argon blowing tube supplies the first gas, an oxygen gun sprays and blowsO2 gas, and a bottom blowing tube sprays and blows CO2 gas; and (a3), when the pressure inside the vacuum degassing tank is less than 300 Pa, the argon blowing tube stops supplying the first gas andbegins supplying a second gas, and meanwhile, the bottom blowing tube stops spraying and blowing the CO2 gas and begins spraying and blowing Ar gas. By means of the rapid decarbonization method for performing the segmented bottom blowing by adopting the multiple gases, low-cost, rapid and good-effect decarbonization can be realized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

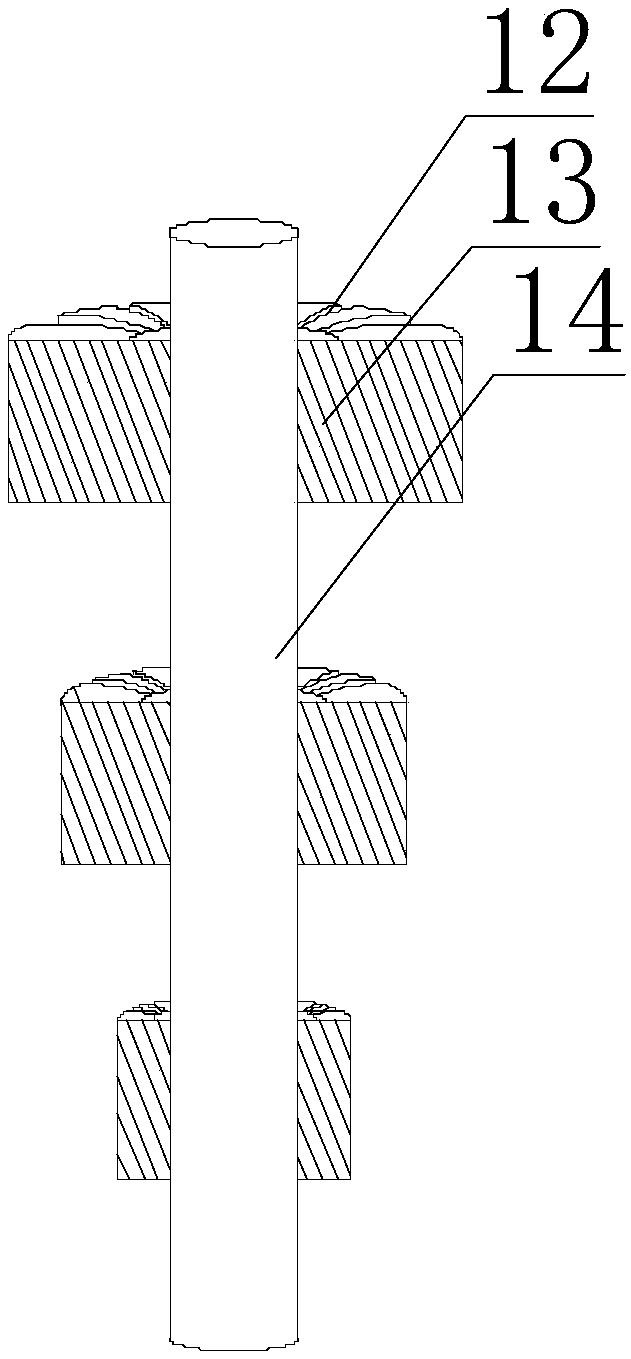

A kind of method that mechanical stirring method produces rose vinegar

ActiveCN107916209BImprove fermentation qualityFacilitates enzymatic actionVinegar preparationEngineeringProcess engineering

The invention discloses a method for producing rosy vinegar through mechanical stirring. The method comprises the following steps: immersing and cleaning rice, steaming the rice, cooling cooked rice,building a nest, flooding, adding water, fermenting, ageing, squeezing and sterilizing; a pot is cylindrical, the upper end of the pot is open, a stainless steel supporting plate used for fixing a stirring device is arranged at the top of the open upper end, a grass cover covers on the upper surface of the stainless steel supporting plate, diameter-height ratio of a cylinder part of the pot is 1:(0.8-1), the stirring device comprises a straight turbine paddle and a propeller type paddle; and the fermenting steps comprises: (1) previous medium-frequency high-stirring-intensity fermentation control; (2) medium-term high-frequency medium-stirring-intensity fermentation control; and (3) later low-frequency low-stirring-intensity fermentation control. The method for producing the rosy vinegar through mechanical stirring has the advantages that labor intensity can be reduced, production efficiency can be increased, production scale is expanded, quality of rosy vinegar is stabilized and improved, and effective solution is provided for automatic control on a rosy vinegar fermentation process and big pot production.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Turntable type dynamic sewage fermentation tank

ActiveCN110683633BPromote fermentationFierce collisionTreatment using aerobic processesSustainable biological treatmentElectric machineryDrive motor

The invention discloses a turntable type dynamic sewage fermentation tank, which comprises a main body of the fermentation tank. A fermentation room is arranged in the main body of the fermentation tank. The fermentation room is provided with a driving motor and a dynamic fermentation bin. The end of the output shaft is connected to the bevel gear set that rotates in different directions, and is driven by the bevel gear set and the bending rotating part; the first crescent plate on the side wall and the upper air intake mechanism are also installed in the dynamic fermentation chamber; the bending and rotating The part includes a waist-shaped rotating ring integrally formed with it, and a first piston device and a second crescent plate are arranged on the waist-shaped rotating ring, and the first piston device and the first crescent plate are rollingly connected, and the second crescent plate and the air intake mechanism slide Connection; the single drive motor of the present invention continuously increases the dissolved oxygen content in the dynamic fermentation chamber, and is always in the state of automatic oxygen supply, thus making the biological fermentation process in the dynamic fermentation chamber more efficient.

Owner:DEZHOU MICROP BIO TECH CO LTD

High-viscosity material fine emulsifying belt pre-mixing system

PendingCN109939577ASolve the problem that it is difficult to uniformly mix trace amounts of additivesRealize online uniform mixing functionMixing methodsMixer accessoriesHybrid systemCavity wall

The invention belongs to the technical field of material pre-mixing and emulsifying, and particularly relates to a high-viscosity material fine emulsifying belt pre-mixing system. The system comprisespre-mixing equipment and emulsification equipment, wherein the pre-mixing equipment comprises a pre-mixing assembly and a synchronous feeding assembly; the synchronous feeding assembly comprises a mixing pipe, wherein a sealed cavity type hollow interlayer is formed in the pipe wall of the mixing pipe, and feeding holes communicated with the hollow interlayer and the mixing pipe are formed between the hollow interlayer and the outer wall of the mixing pipe; the hollow interlayer is of an annular shape coaxial with the axis of the mixing pipe, and equipartition holes communicated with the hollow interlayer and the mixing pipe are formed between the hollow interlayer and the pipe cavity wall of the mixing pipe; the equipartition holes surround the axis of the mixing pipe and distributed inthe pipe cavity wall of the mixing pipe in sequence; the emulsification equipment comprises an emulsification box, a mechanical sealing box, a bearing box, a connecting frame and a power motor. The high-viscosity material fine emulsifying belt pre-mixing system can effectively ensure the mixing quality of the product while ensuring the efficiency of premixing and subsequent emulsification, therebymaximally ensuring the actual production benefits of a manufacturer.

Owner:安徽博尚化工设备有限公司

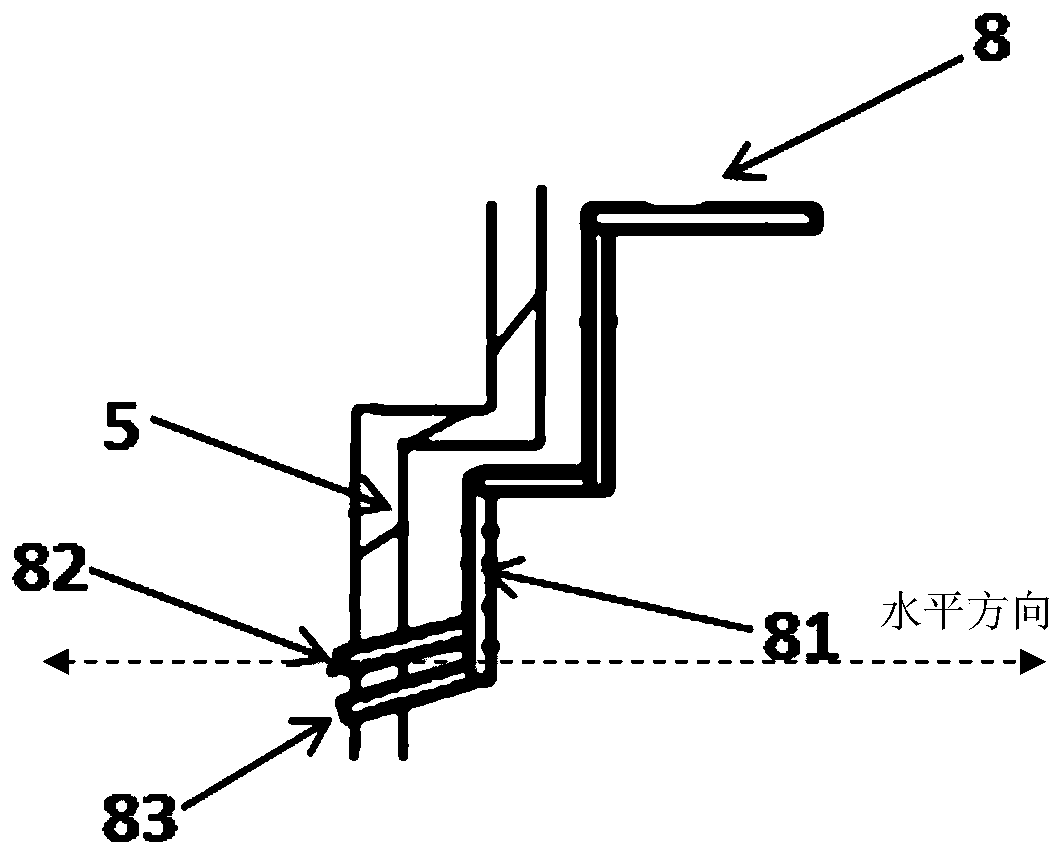

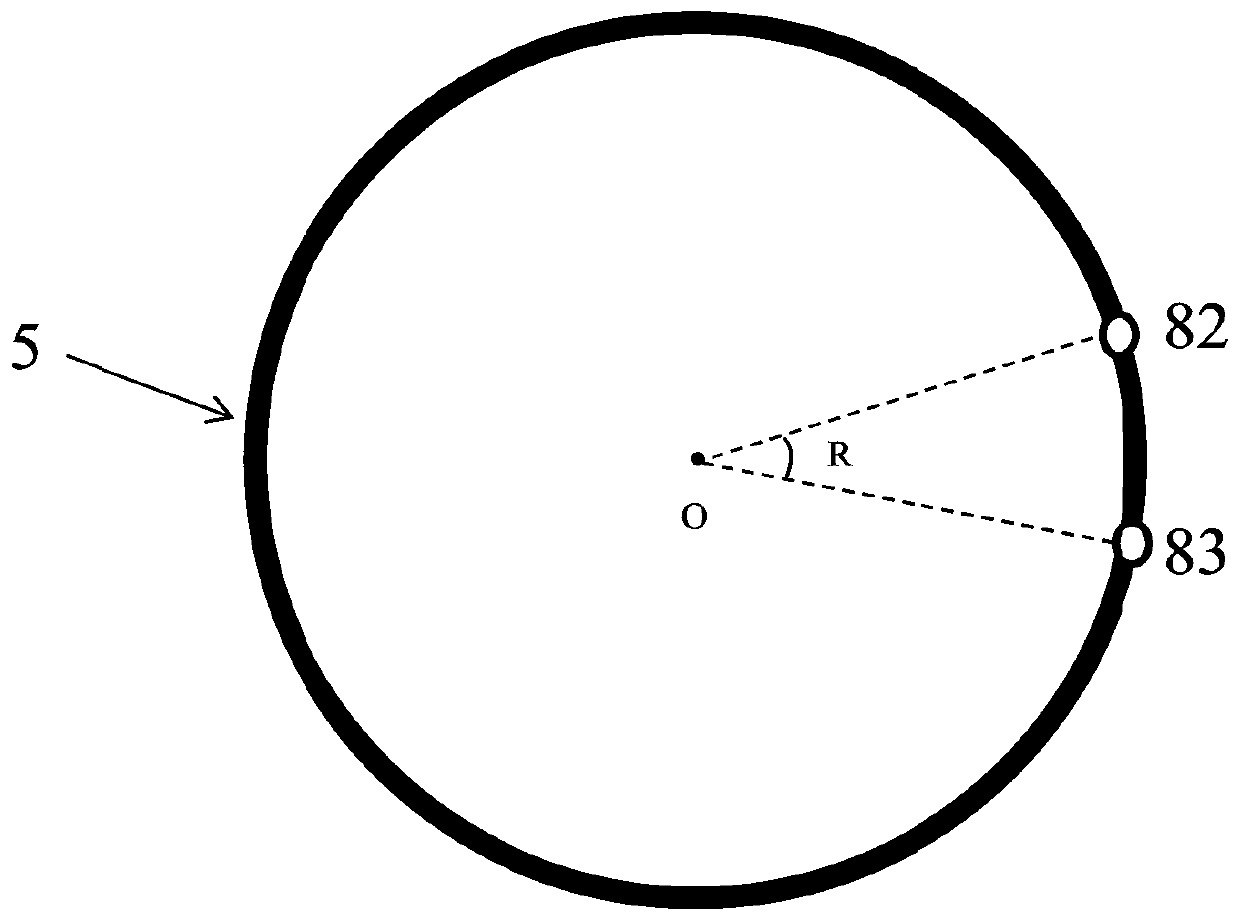

RH vacuum treatment device

The invention discloses an RH vacuum treatment device. The device comprises a steel ladle, a vacuum degassing tank, a bottom blowing pipe, an oxygen gun and an argon blowing pipe; the vacuum degassingtank comprises a tank body, a descending pipe and an ascending pipe, wherein the descending pipe and the ascending pipe communicate with the tank body; the bottom blowing pipe communicates with the bottom of the vacuum degassing tank; the oxygen gun is arranged at the top of the vacuum degassing tank; and the argon blowing pipe is arranged at the ascending pipe and communicates with the ascendingpipe, and the argon blowing pipe comprises a main pipe and a first branch pipe and a second branch pipe, wherein the first branch pipe and the second branch pipe form two paths at the tail end of themain pipe, and the first branch pipe and the second branch pipe communicate with the ascending pipe. According to the device, low-cost, fast and good-effect decarbonizing can be realized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of rh vacuum treatment equipment

The invention discloses a RH vacuum processing equipment, which comprises a ladle, a vacuum degassing tank including a tank body, a downcomer and an upcomer communicating with the tank body, a bottom blowing tube communicating with the bottom of the vacuum degassing tank, a device Oxygen lance and argon blowing pipe at the top of the vacuum degassing tank; the argon blowing pipe is arranged on the riser and communicated with the riser, and the argon blowing pipe includes a main pipe and a first branch pipe and a second branch pipe which are divided into two paths at the end of the main pipe; The first branch pipe and the second branch pipe communicate with the riser pipe. The device can realize low-cost, fast and effective decarburization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com