Modified sequencing batch reactor (MSBR) process for sewage treatment

A sewage treatment and process technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of increased aeration power consumption, increased operating energy consumption, and decreased oxygen transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

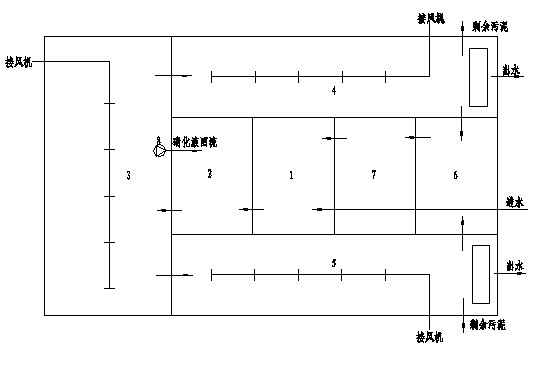

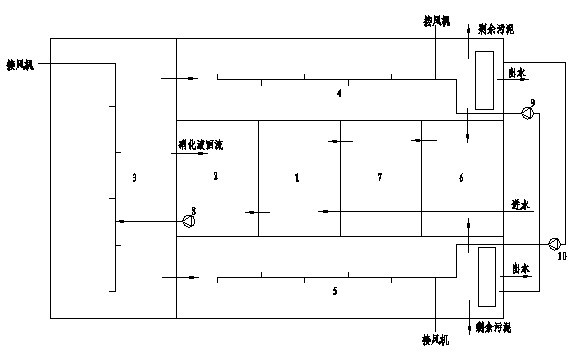

[0021] Example: see figure 2 According to the typical MSBR single-cell multi-compartment design, the pools are arranged, including the horizontal aerobic pool 3, the sequential batch pools 4 and 5 opposite to each other at both ends, and the anoxic pool adjacent to each other between the sequential batch pools. 2. Anaerobic pool 1, sludge pool 7 and mud-water separation pool 6, wherein the anoxic pool is set next to the aerobic pool. The aerobic tank 3 and the two sequence batch tanks 4 and 5 are equipped with jet aerators, and the jet pump 8 of the jet aerator in the aerobic tank is installed in the anoxic tank, so that the aerated jet working fluid is provided by the anoxic tank. The jet aeration jet pumps 9 and 10 of the two sequencing batch pools are arranged outside their respective pools, and are connected by pipelines to extract the mixed liquid from one pool as the aeration jet working fluid in the other pool. The treatment process is the same as that mentioned in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com