Patents

Literature

295 results about "Oxygen transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen transfer is controlled by the partial pressure of oxygen in the atmosphere (0.21 atm) and the corresponding equilibrium concentration in water (approximately 10 mg/L). According to Henry’s Law, the equilibrium concentration of oxygen in water is proportional to the partial pressure of oxygen in the atmosphere.

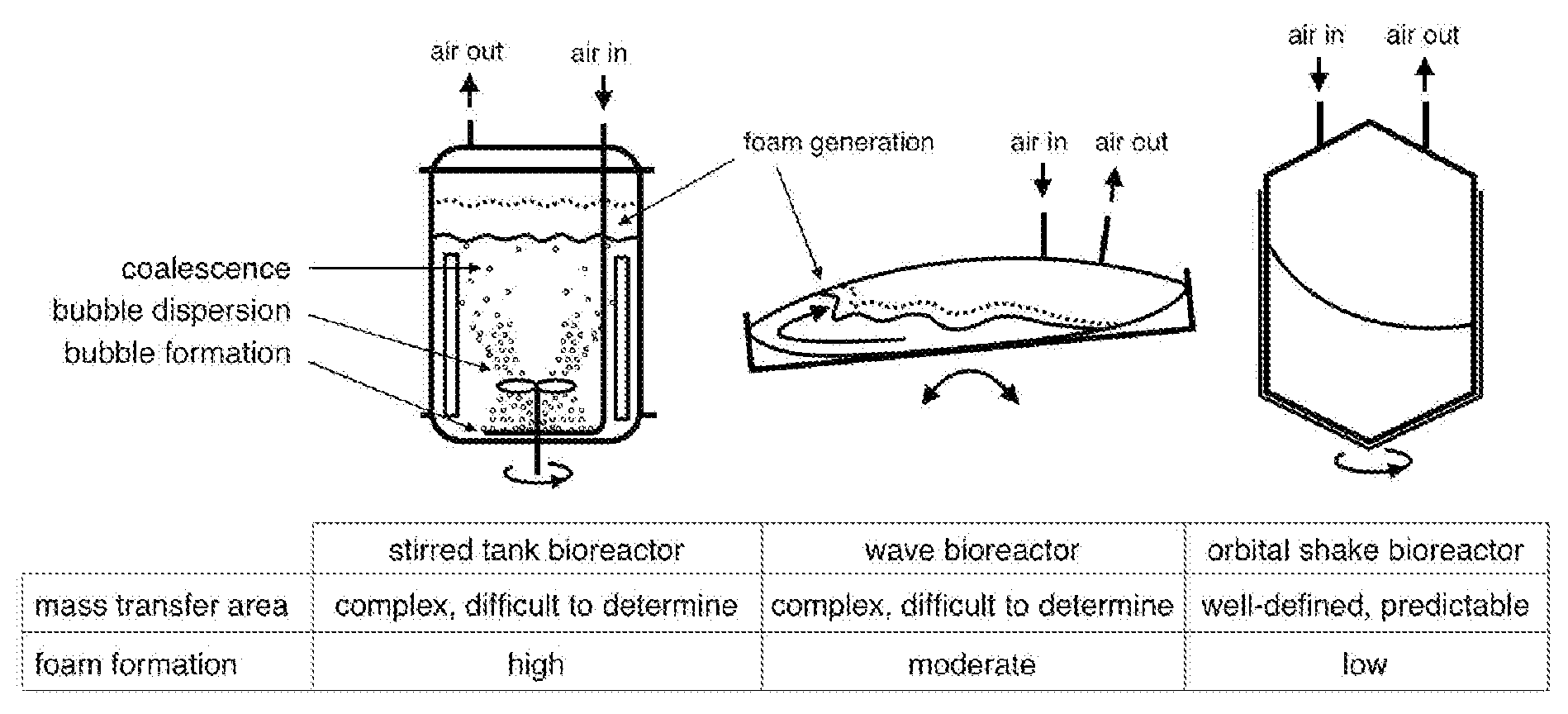

Cell cultivation and production of recombinant proteins by means of an orbital shake bioreactor system with disposable bags at the 1,500 liter scale

InactiveUS20090233334A1High degreeEasy to handleMicroorganismsBiochemistry apparatusCulture cellBiology

The present invention provides a novel method for culturing cells as well as a novel method for producing a recombinant protein by culturing cells at large scale (up to 1,500 L nominal volume and 750 L working volume), whereby an inflated bag provides a sterile, disposable cultivation chamber. The inflated bag is partially filled with liquid cultivation media and cells, and placed into a containment vessel. The containment vessel is positioned onto an orbitally shaken platform. The orbital shaking moves the containment vessel and thus the bag and induces thereby motion to the liquid contained therein (“shake mixing”). This motion (caused by orbital shaking) induces a dynamic force field that ensures cell suspension, bulk mixing, and oxygen transfer from the liquid surface to the respiring cells without damaging shear or foam generation.

Owner:EXCELLGENE SA

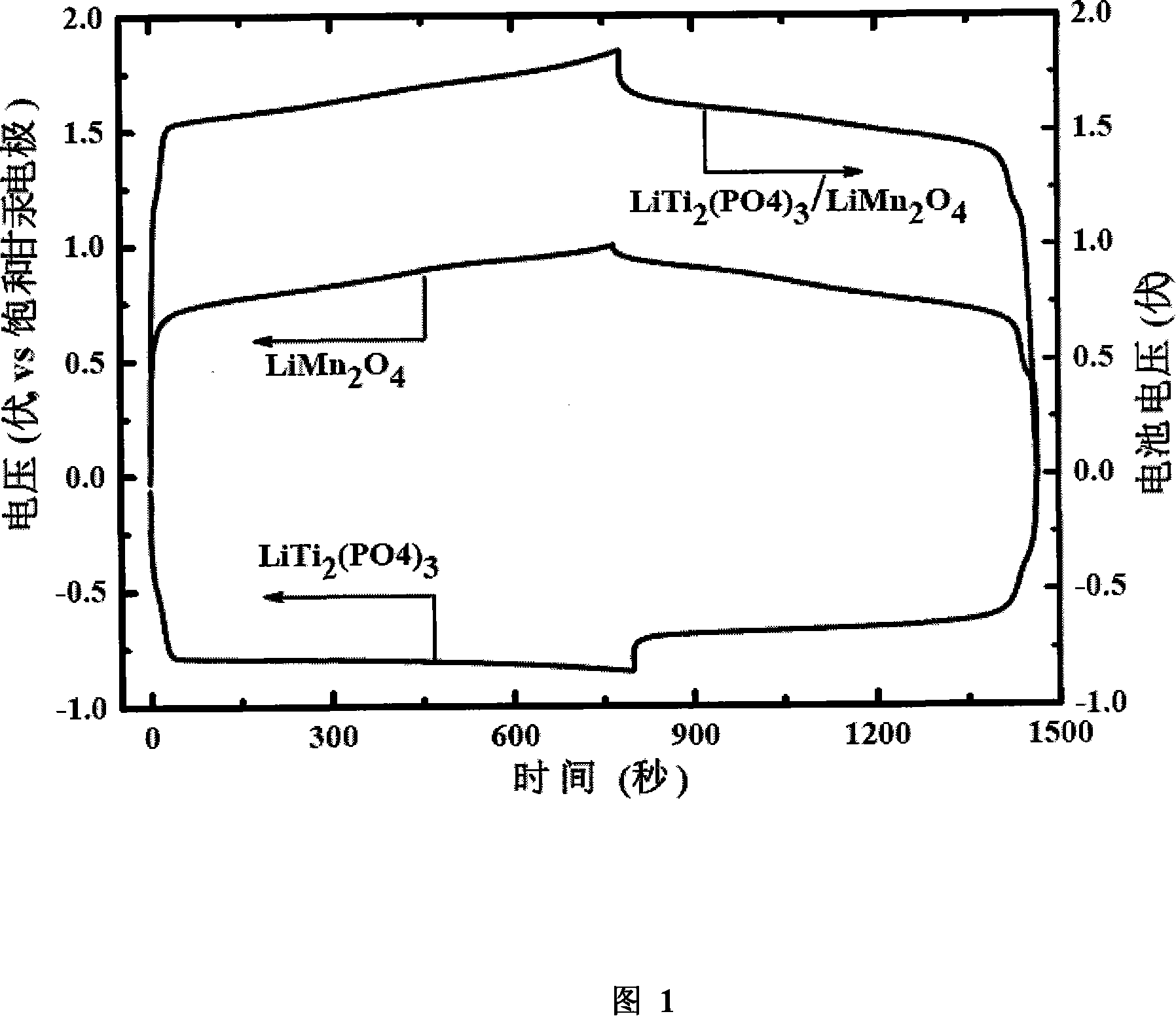

Hydrographical rechargeable lithium or sodium ion battery

InactiveCN101154745ALow costGuaranteed cycle performanceAlkaline accumulatorsCell electrodesPower batteryIon transfer

The invention belongs to electrochemical technical field, in particular to a novel high performance water system lithium ion battery. The invention adopts an ion embedding in-out mechanism used by an organic system lithium ion battery in an energy storage element which uses a water solution as an electrolyte. The embedding-in reaction ion mainly includes lithium ion composite and sodium ion composite. In the invention, the positive pole adopts a material containing the positive ion embedding-in composite while the negative pole adopts a shell structure material of LiTi2(PO4)3; the electrolyte adopts a water system electrolyte of the positive ion. The electric charging and discharging process only relates to the ion transfer between the two electrodes, and the invention can still has the characteristic of a rocking-chair type organic system lithium ion battery; the invention is of long cycling service life, big power, safety, low cost and no pollution, and is particularly suitable to be used as an ideal power battery of electric vehicle.

Owner:FUDAN UNIV

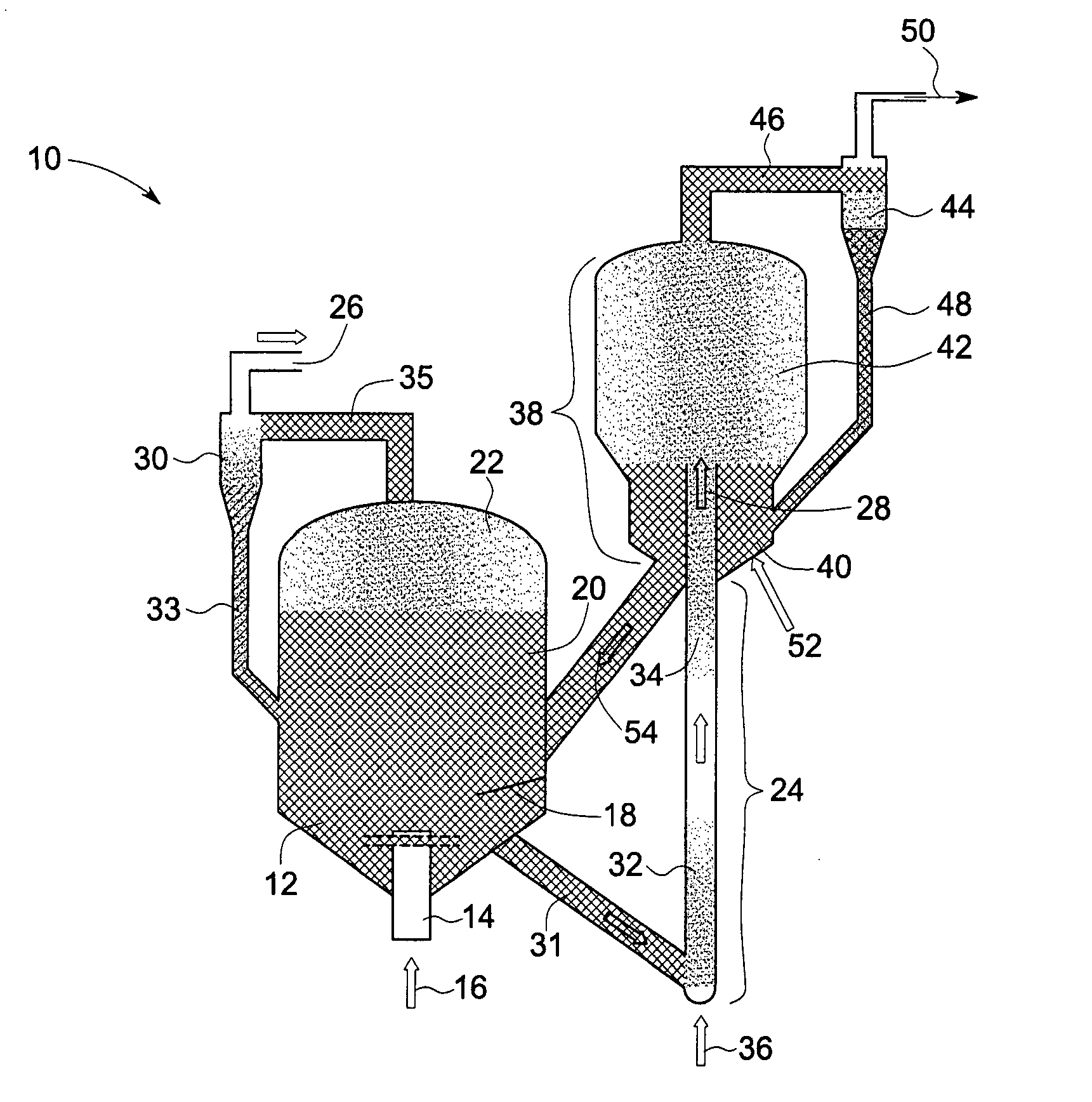

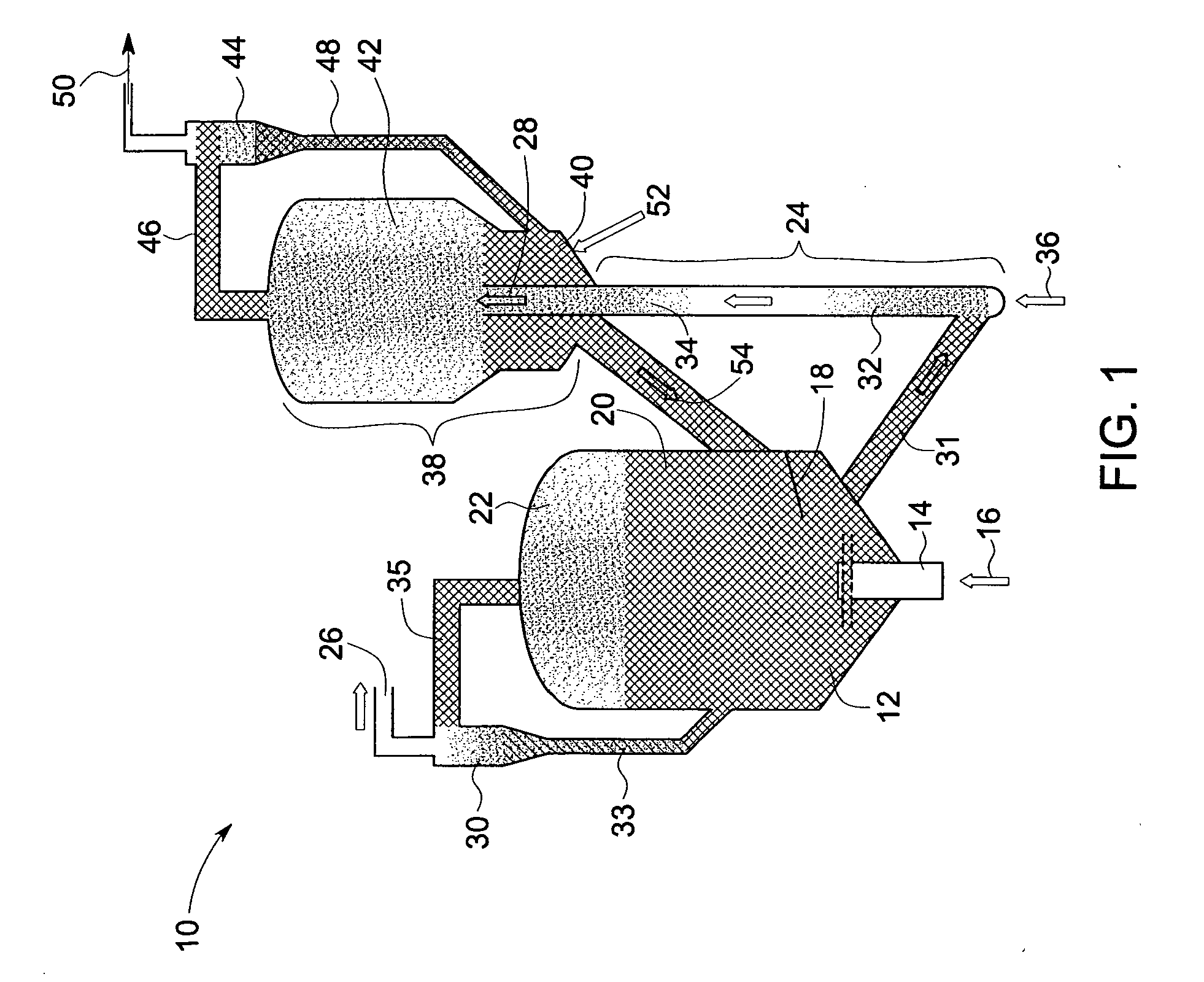

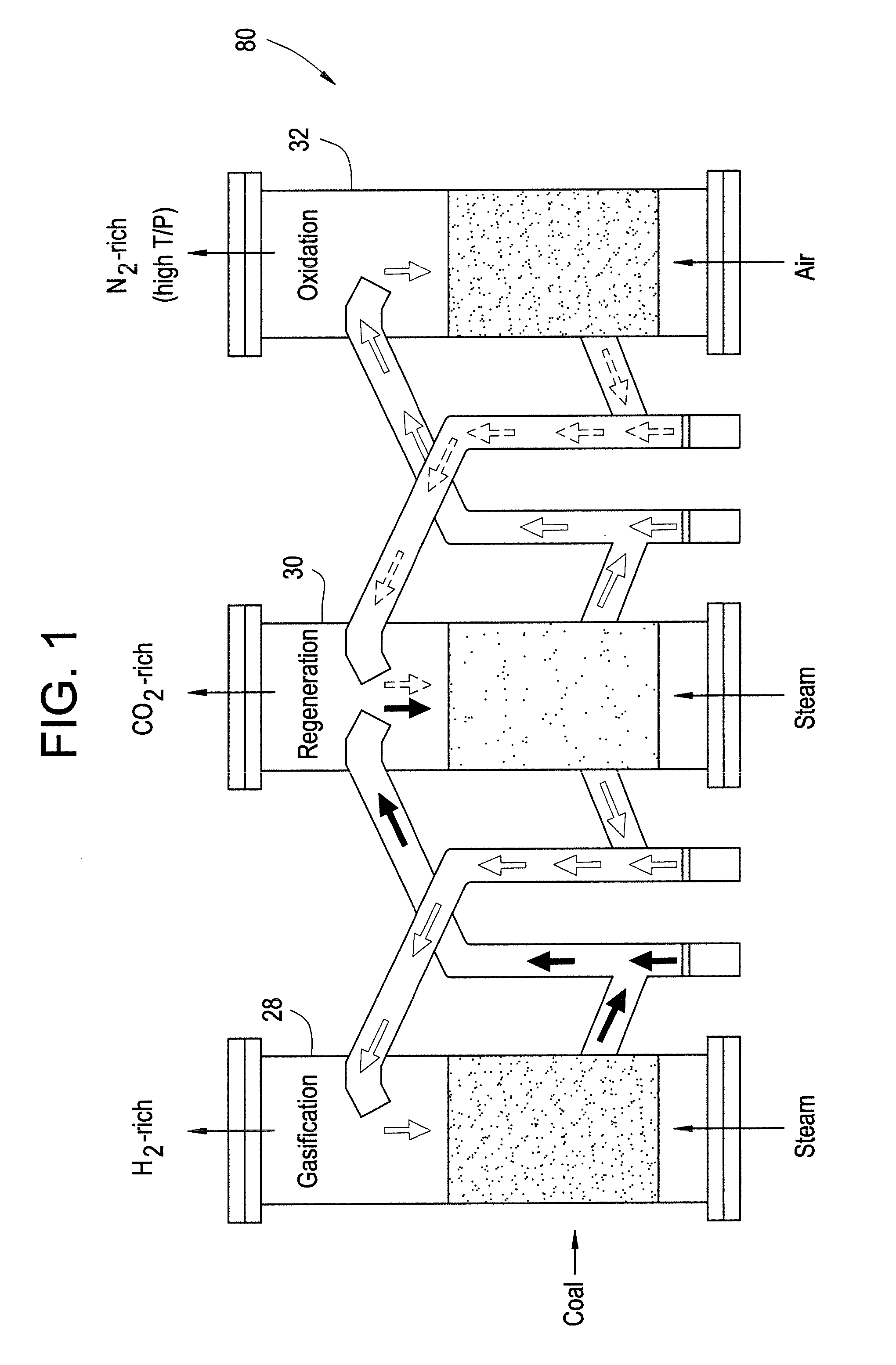

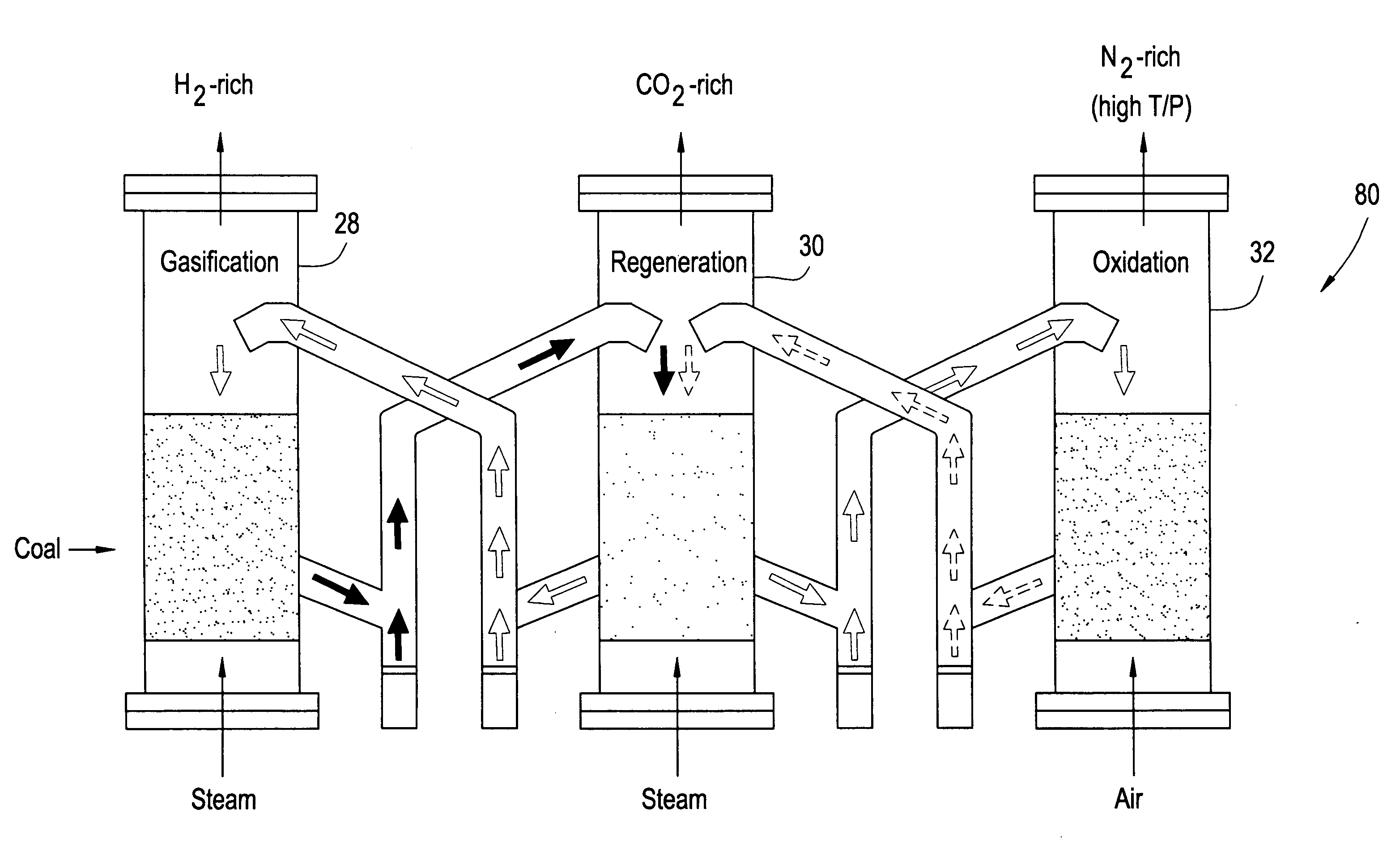

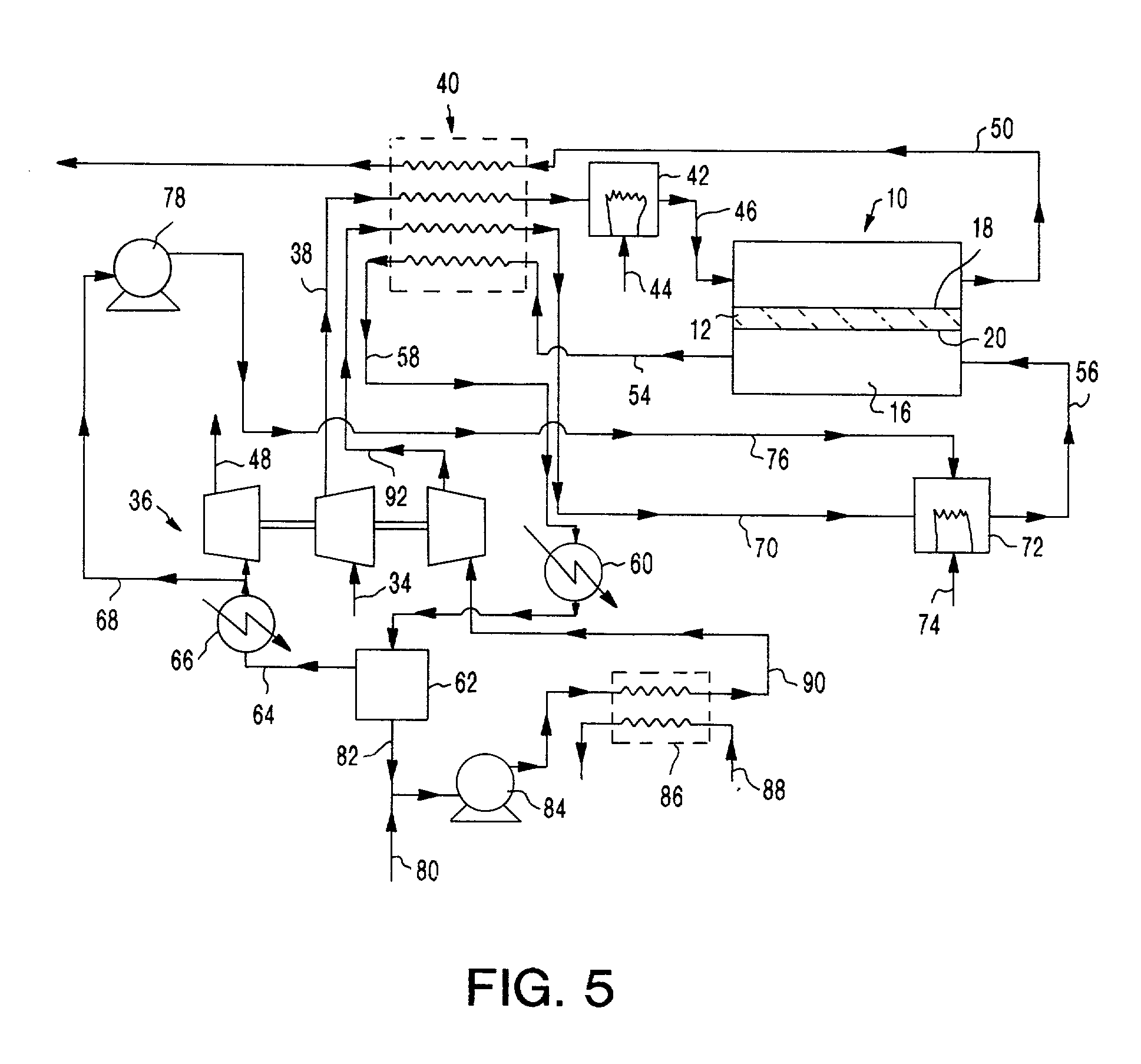

System and method for producing synthesis gas

ActiveUS20070124997A1Hydrogen separation using solid contactCatalyst regeneration/reactivationSteam reformingFluidized bed

A system for producing synthesis gas includes a regeneration zone. The regeneration zone includes a first fluidized bed configured to receive an oxidant for producing a regenerated oxygen transfer material. The system further includes a mixed reforming zone comprising a second fluidized bed configured to receive a first fuel and the regenerated oxygen transfer material to produce a first reformate stream and a steam reforming zone comprising a third fluidized bed configured to receive the first reformate stream, a second fuel and steam to produce the synthesis gas. The regeneration zone, mixed reforming zone and steam-reforming zone are in fluid communication with each other.

Owner:AIR PROD & CHEM INC

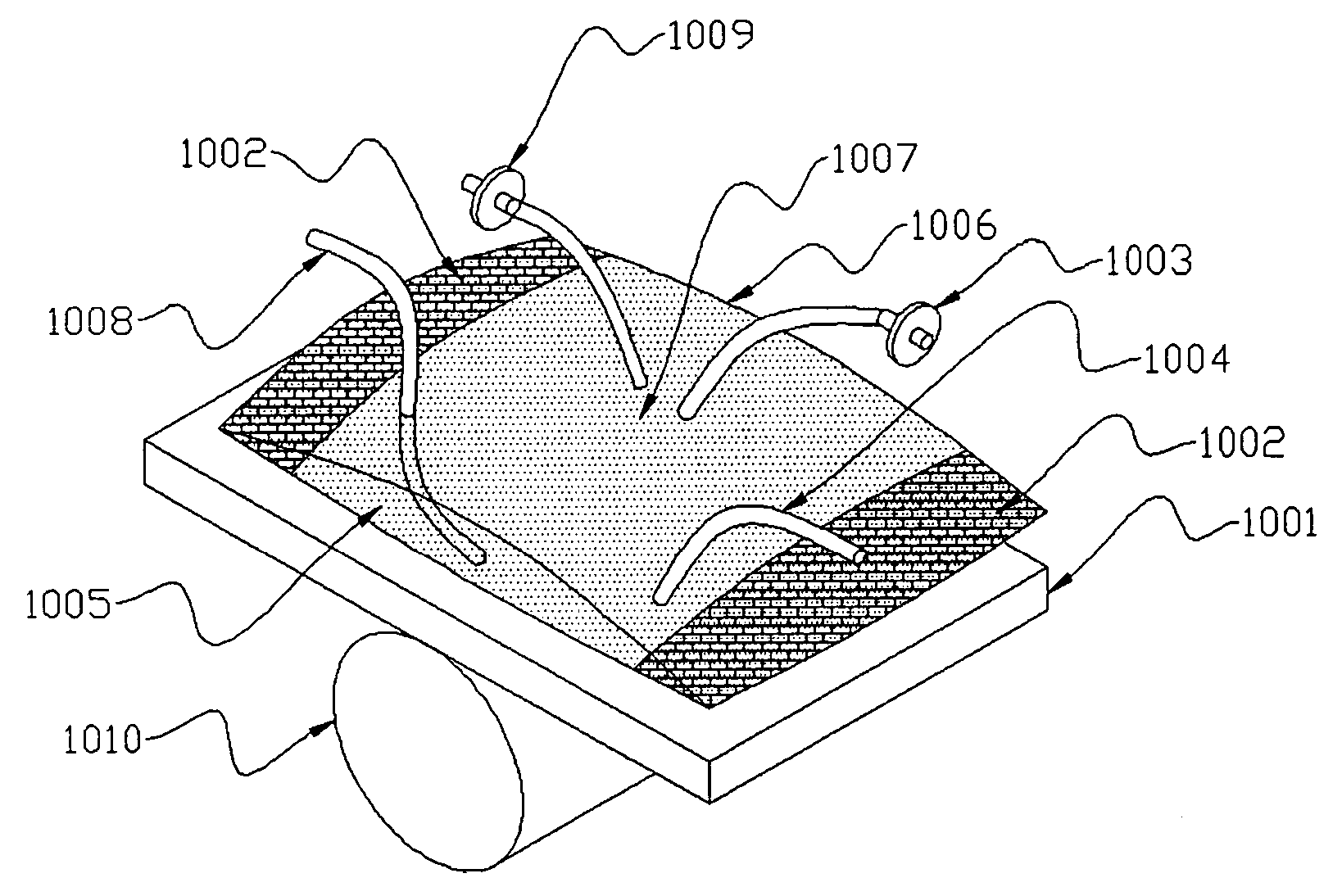

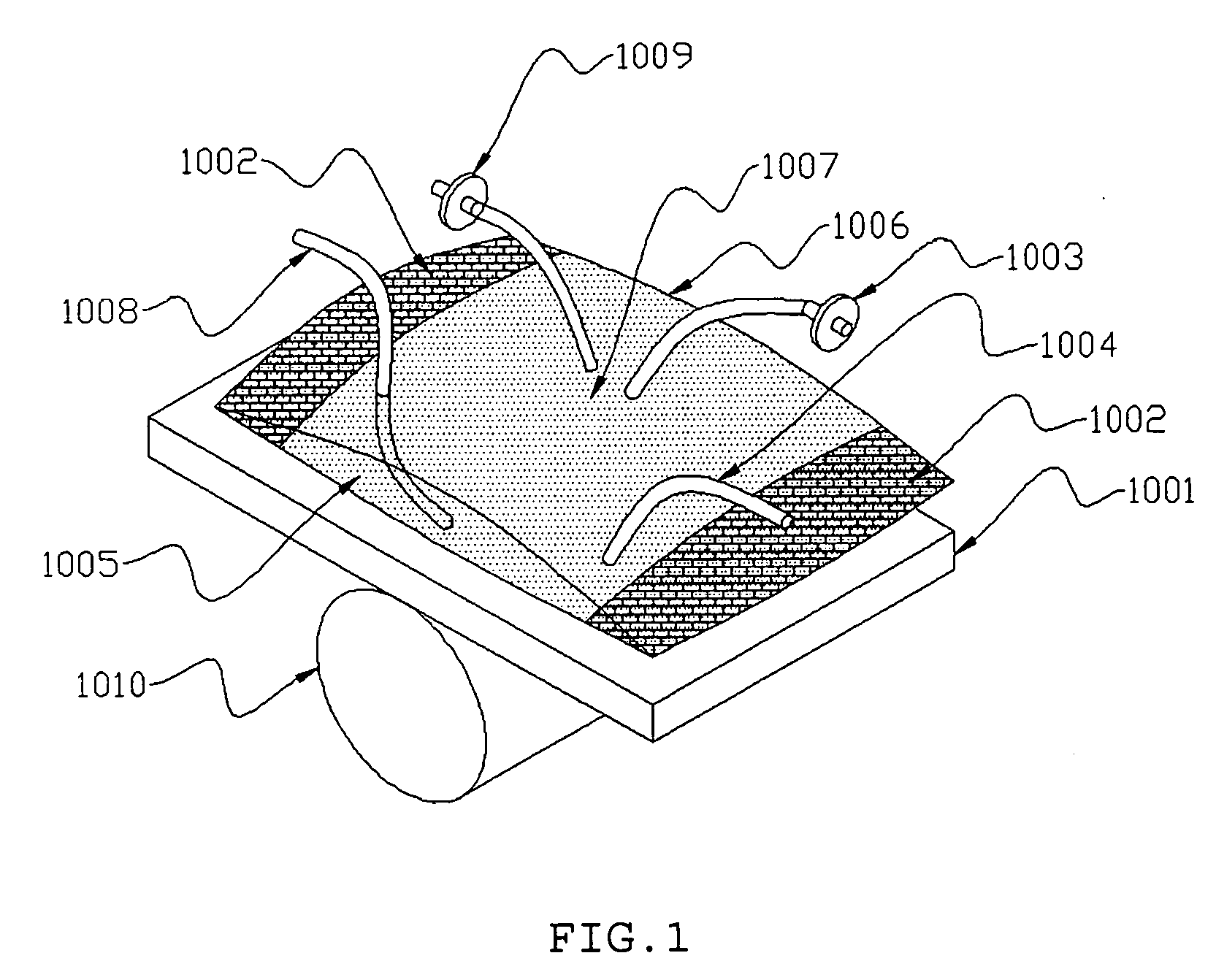

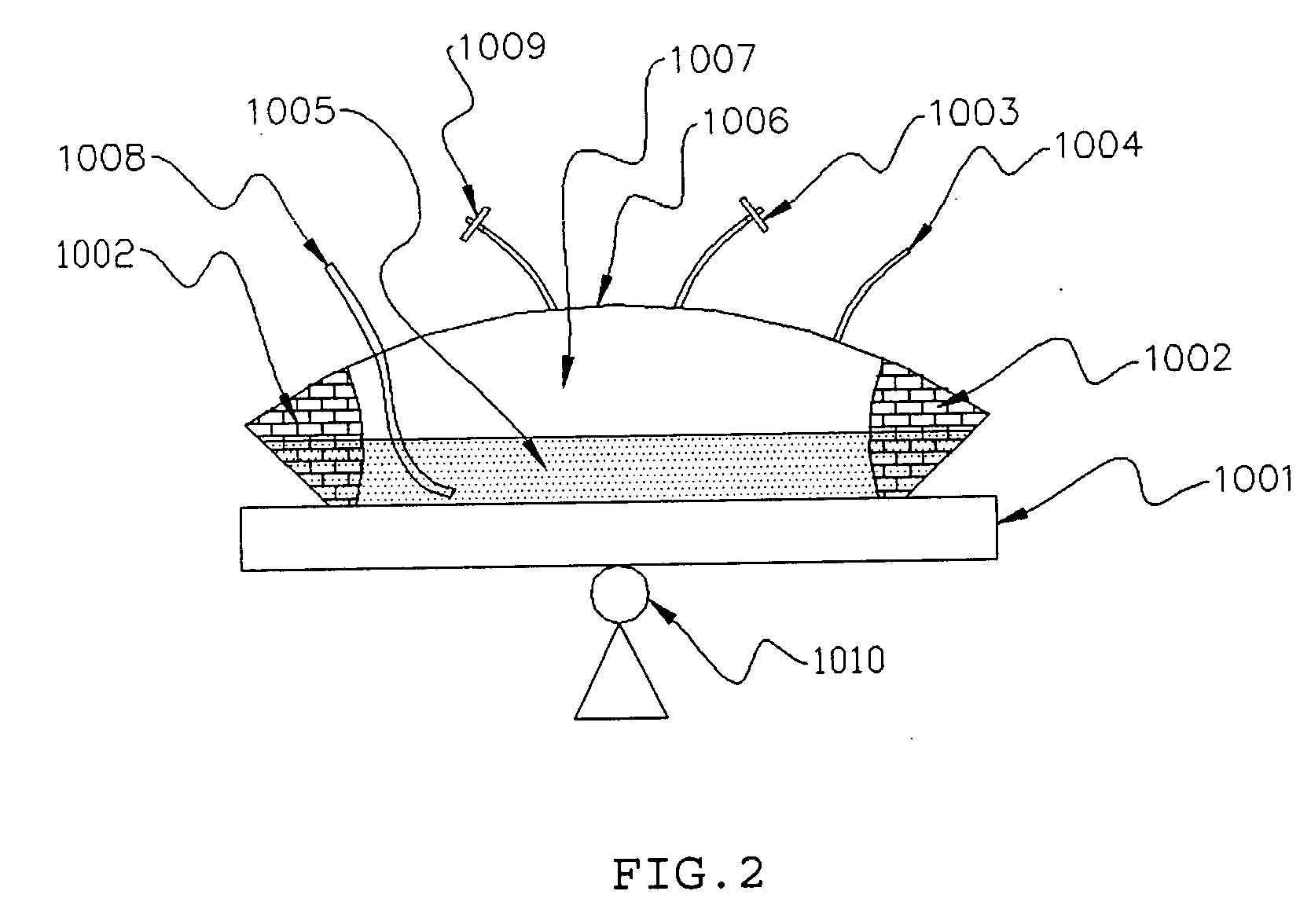

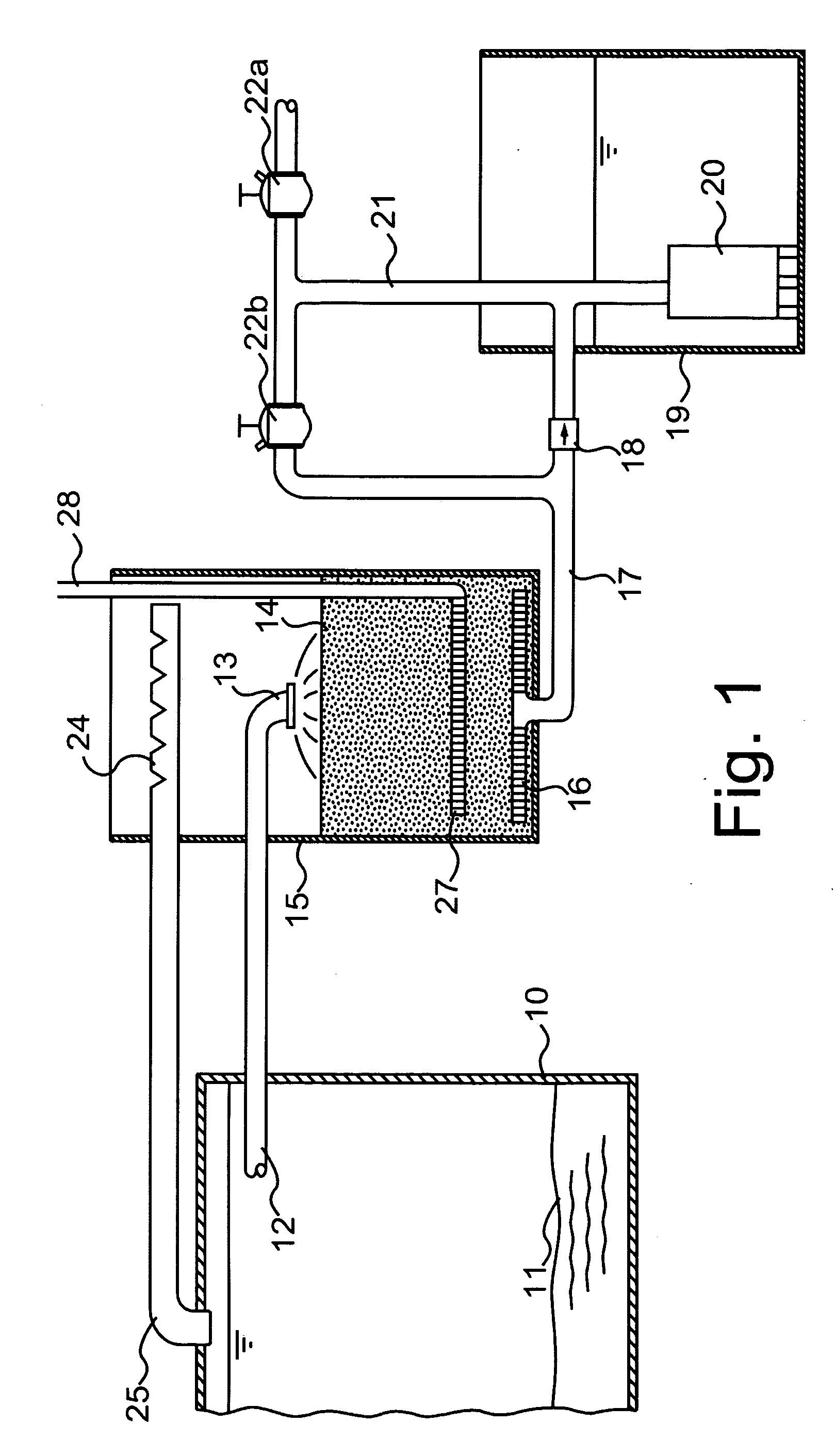

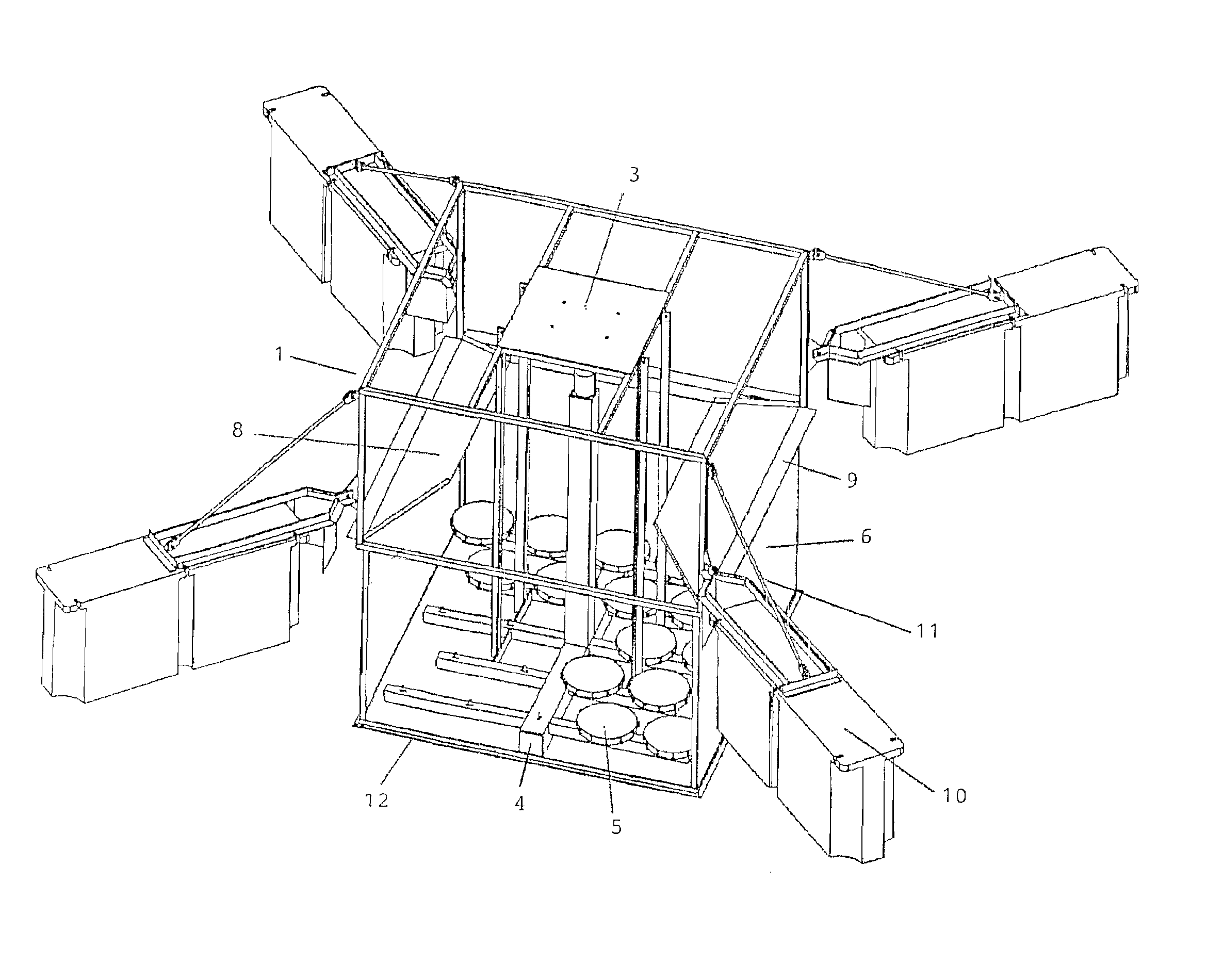

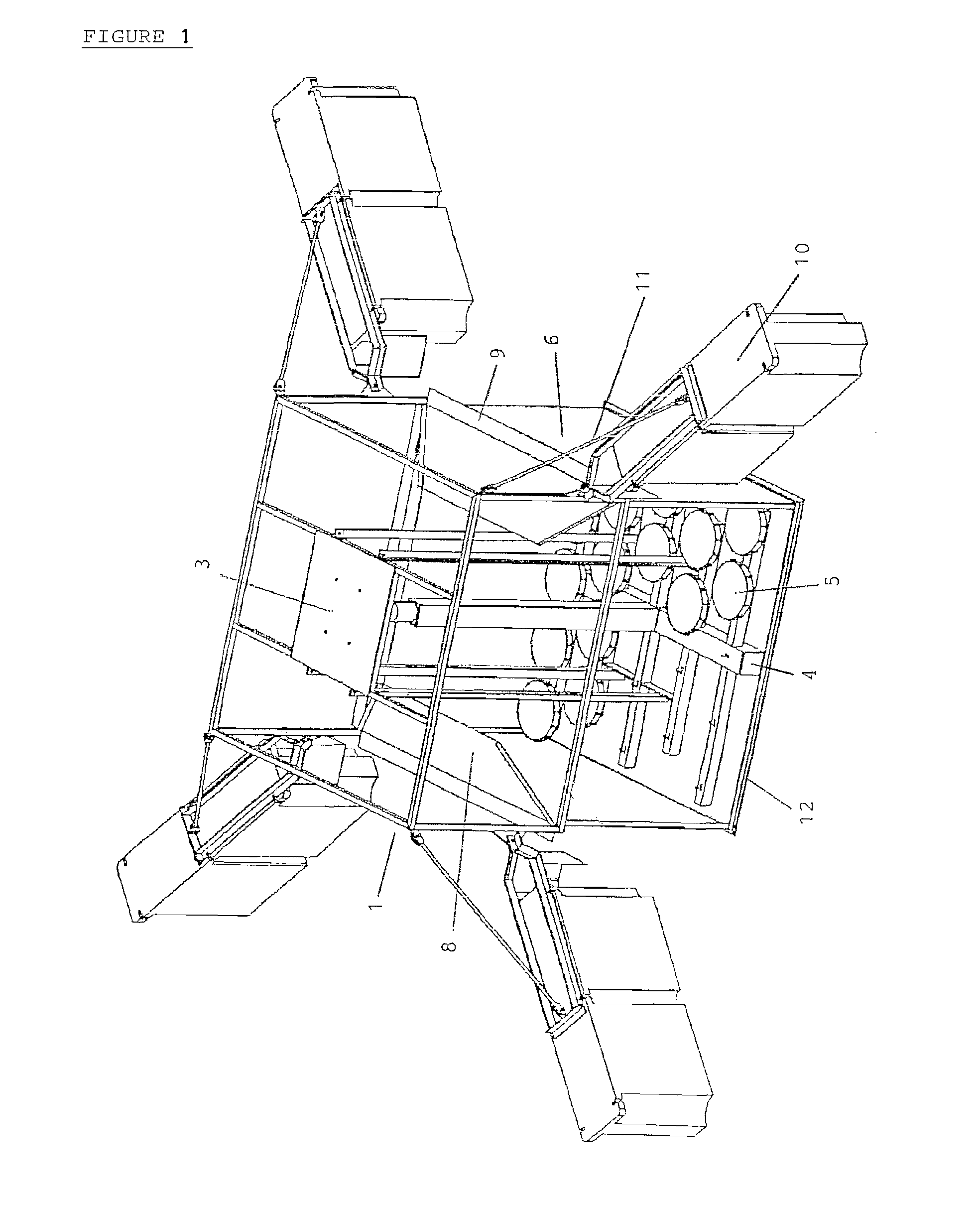

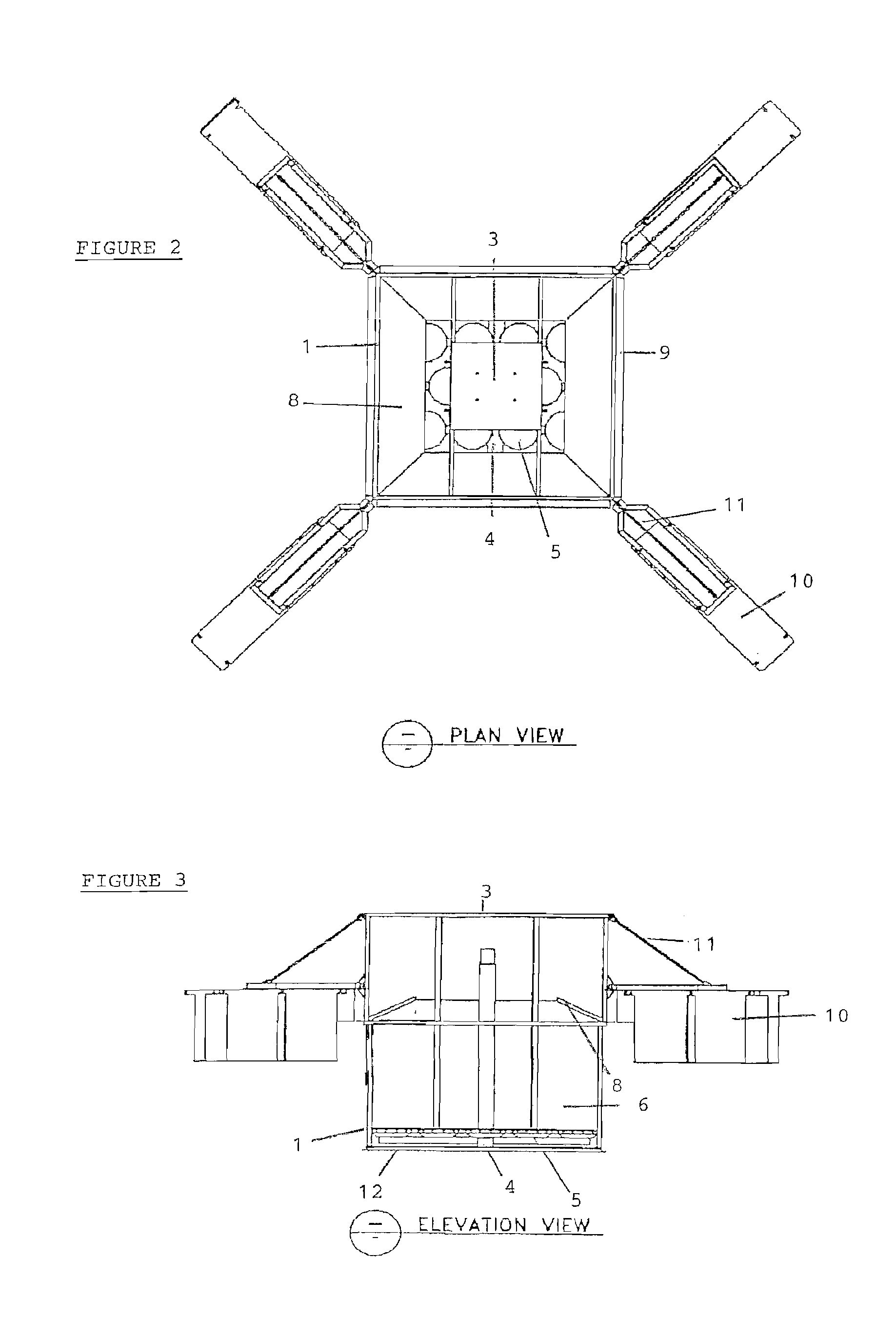

Apparatus and method for preparing and culturing cells

InactiveUS20050186669A1Maximizes cell adhesionIncrease surface areaBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyCulture cell

An apparatus and method for preparing and culturing cells includes a chamber having an inlet and an outlet for introducing culture medium and air. A cell growth substrate placed in the chamber for cells anchored or embedded. The preferred embodiment of invention claims a novel process for controlling the platform form to tilt at one end, to maintain the seesaw and rocking movement for cultured process. The seesaw movement or rocking movement efficiently the nutrition, carbon dioxide and oxygen transfer during cultured process for production of cellular protein products or harvesting the cells.

Owner:CESCO BIOENGINEERING CO LTD

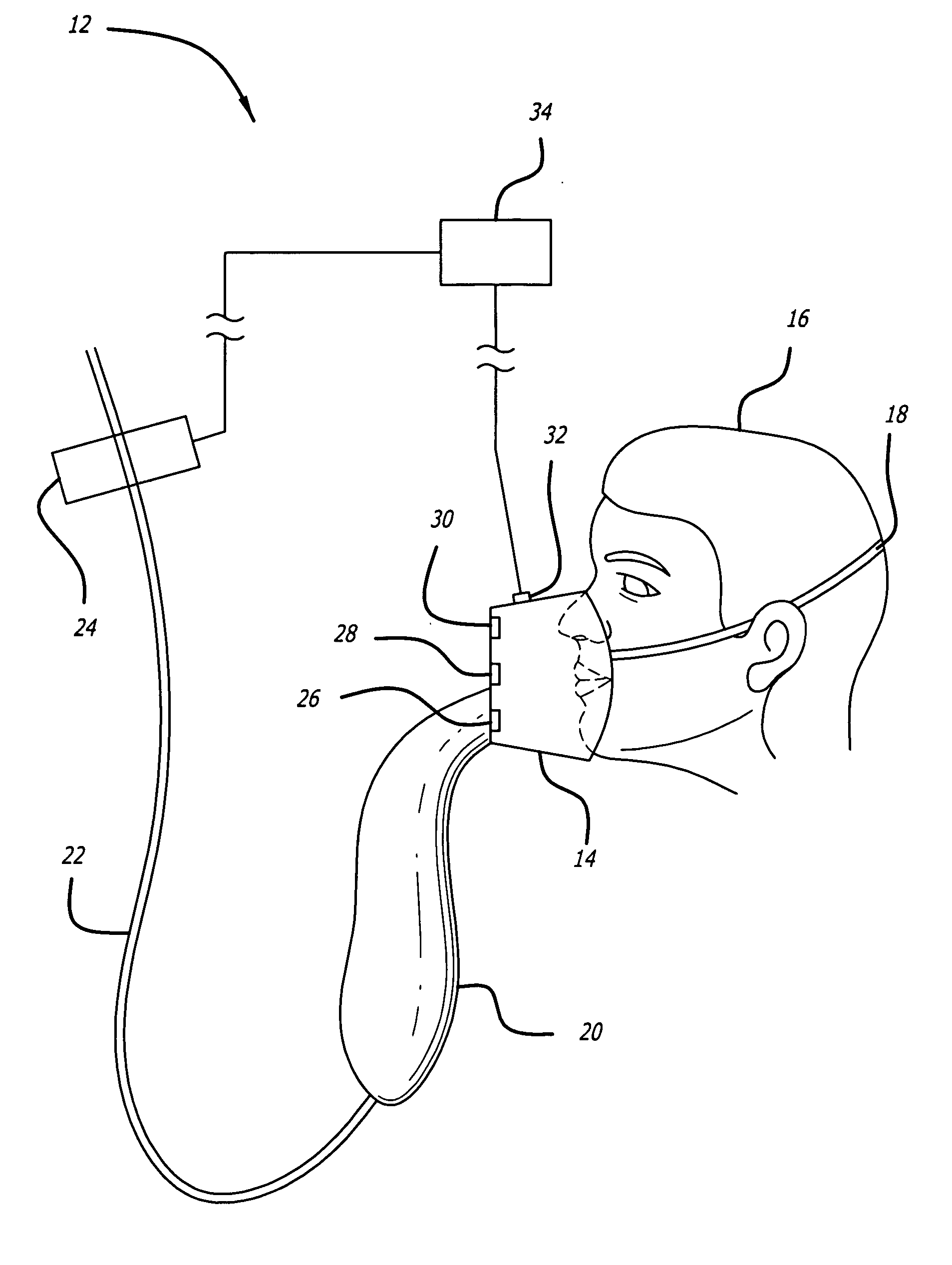

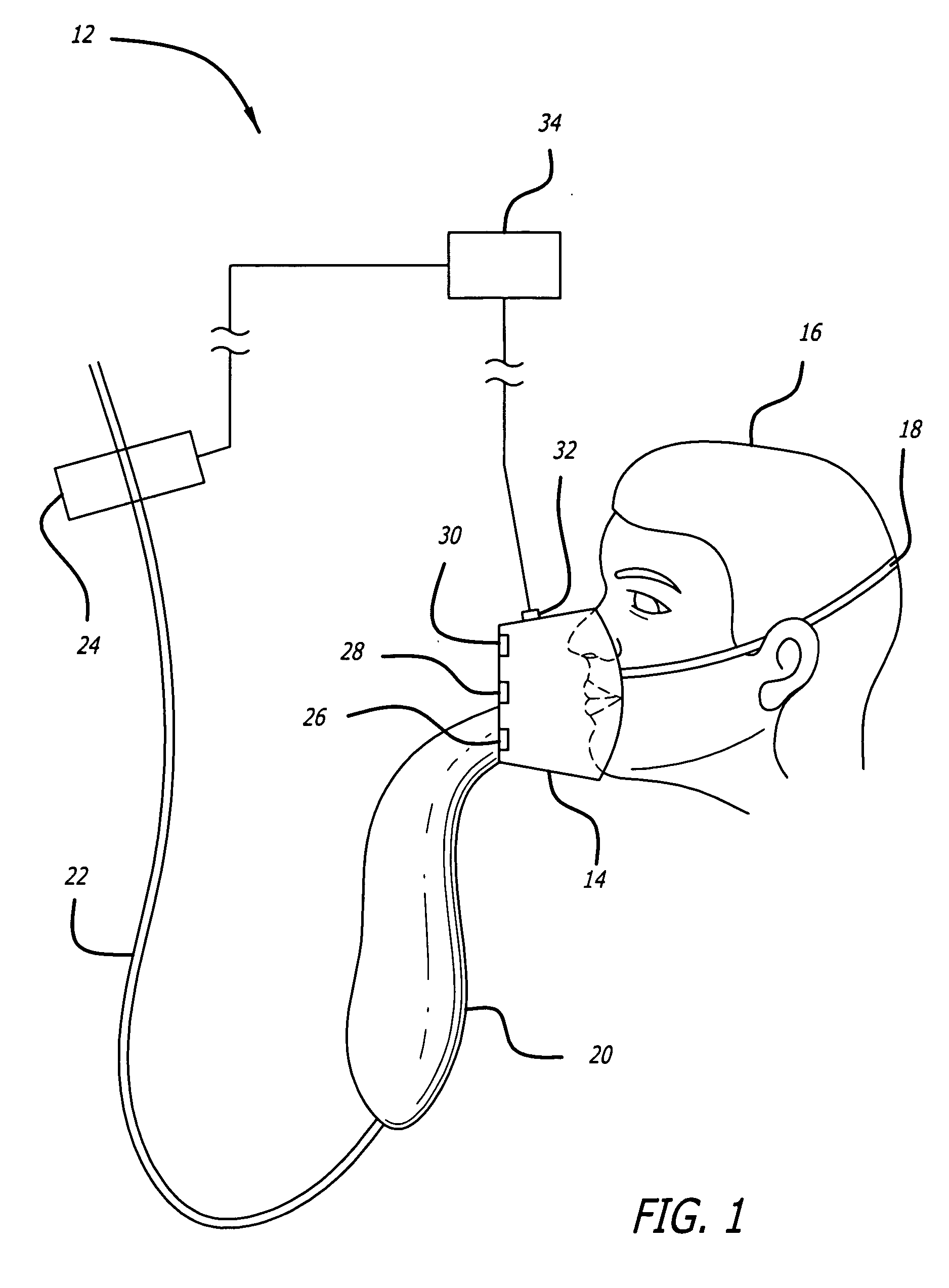

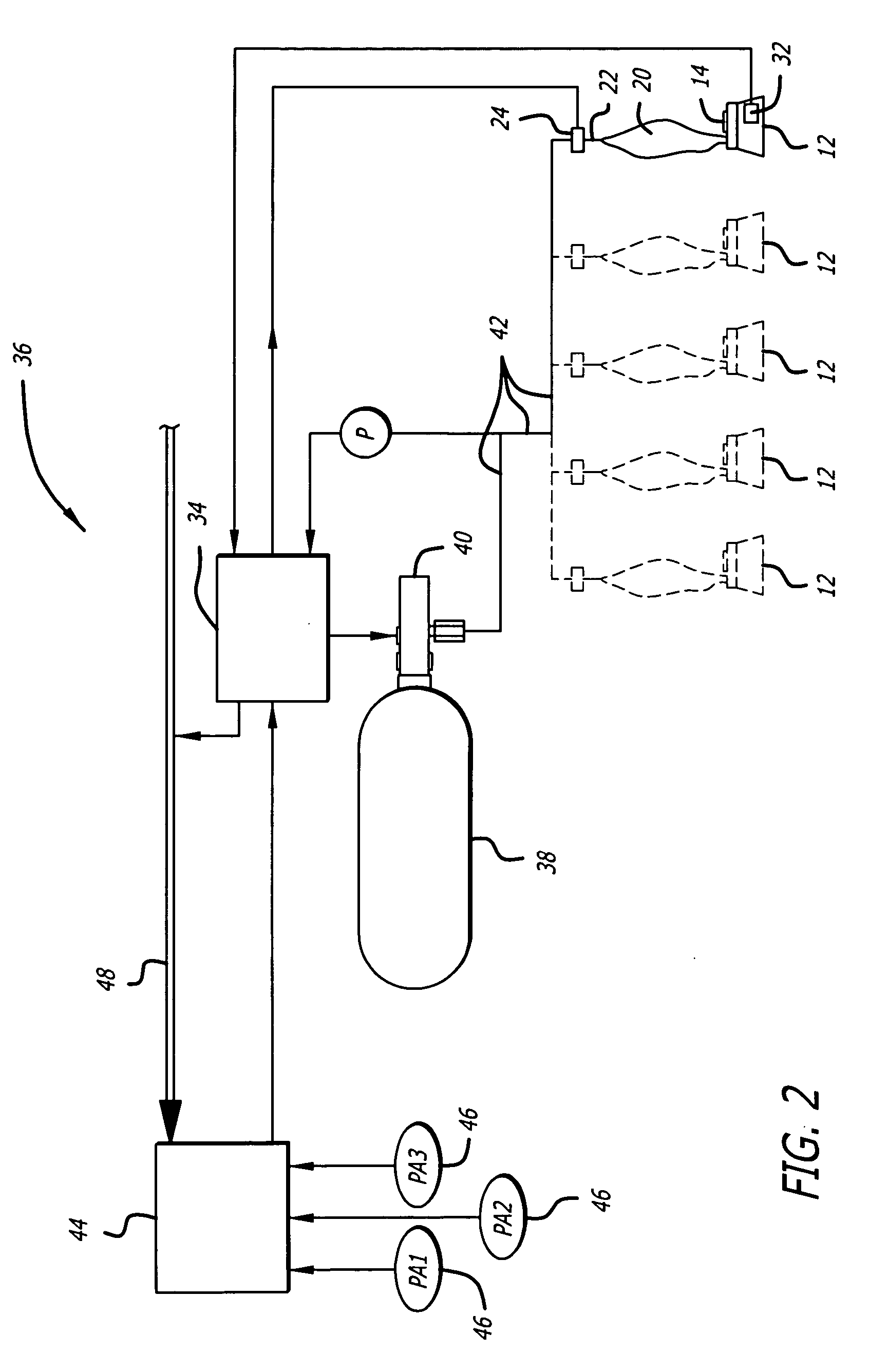

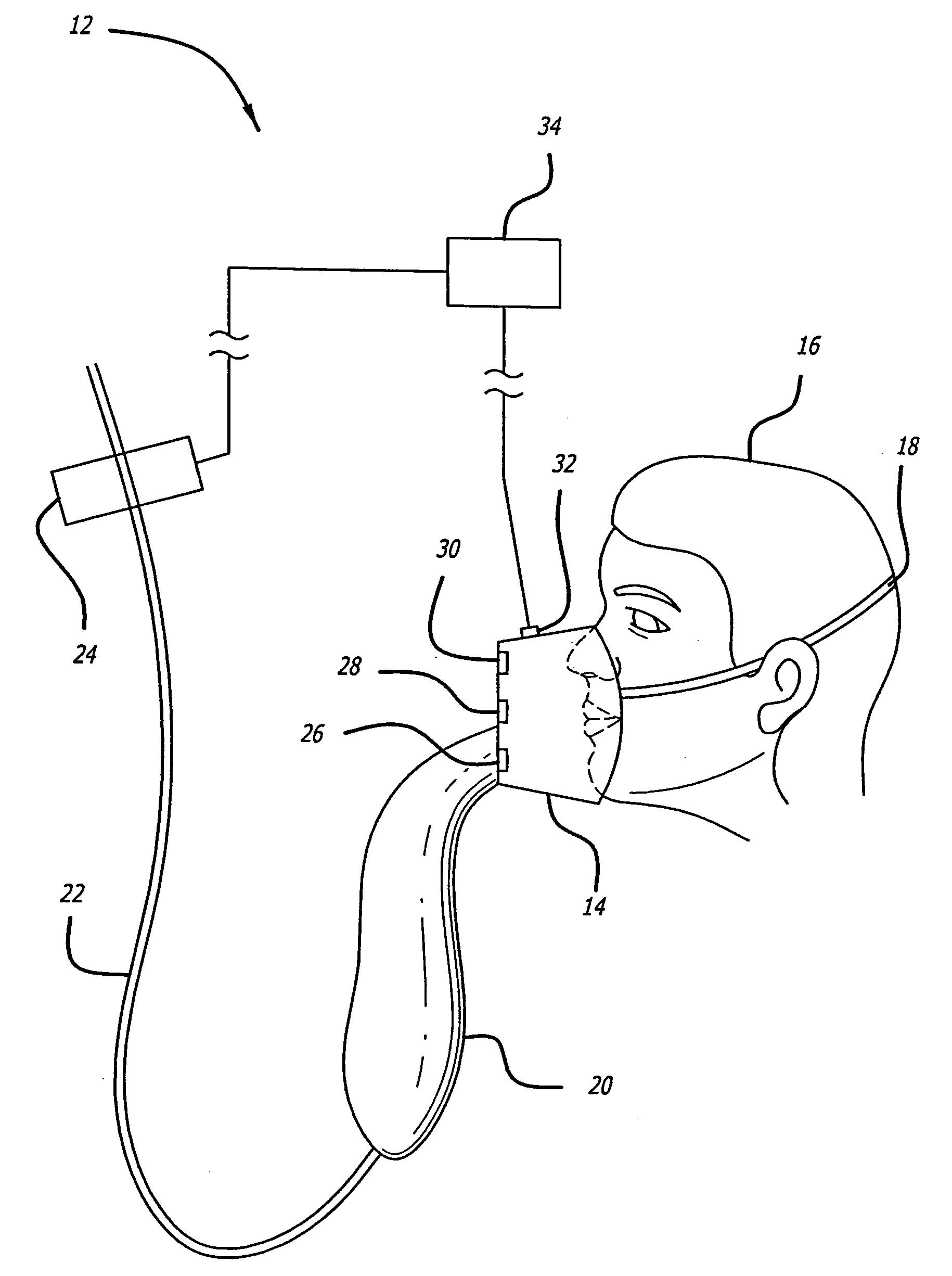

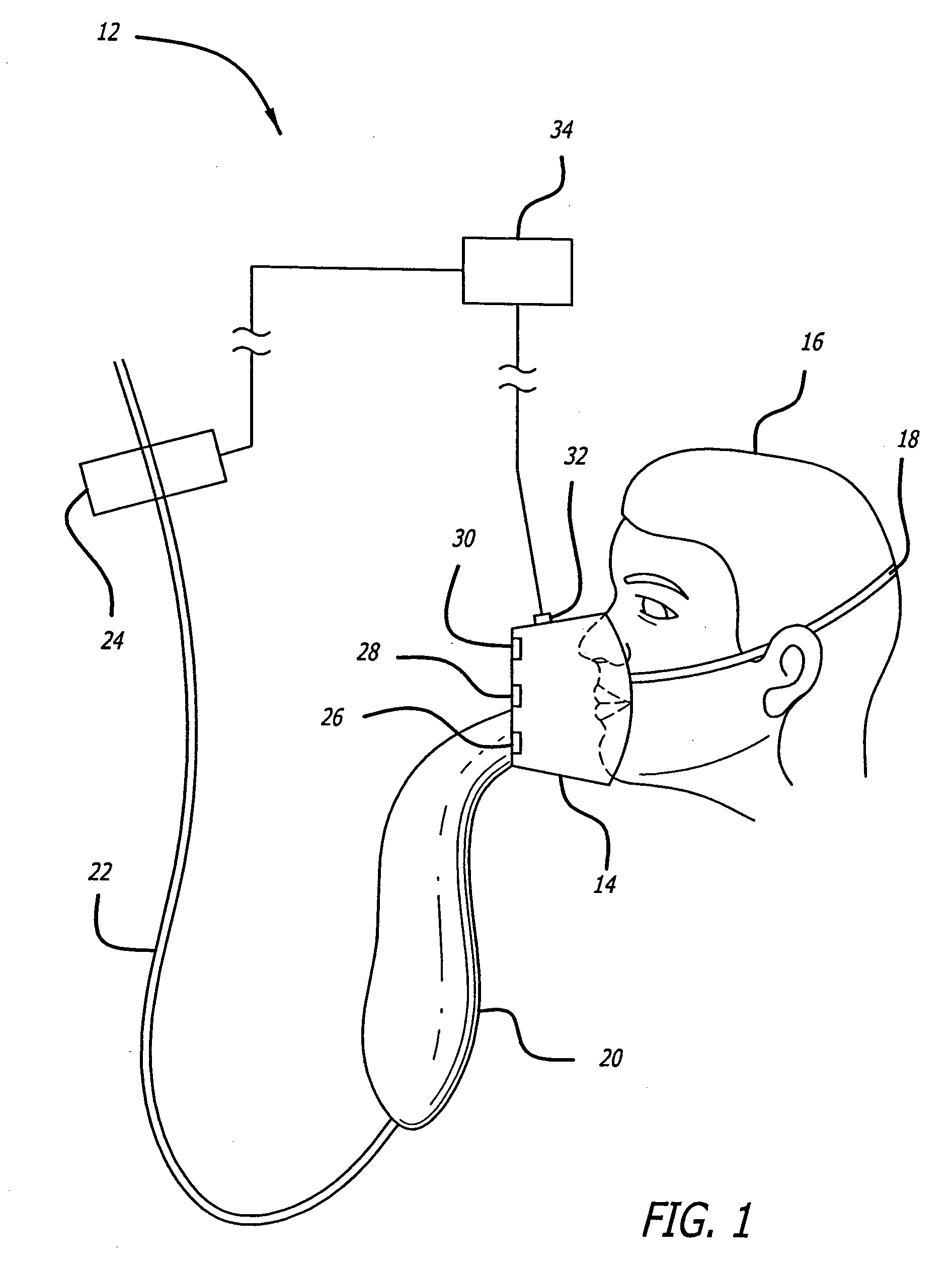

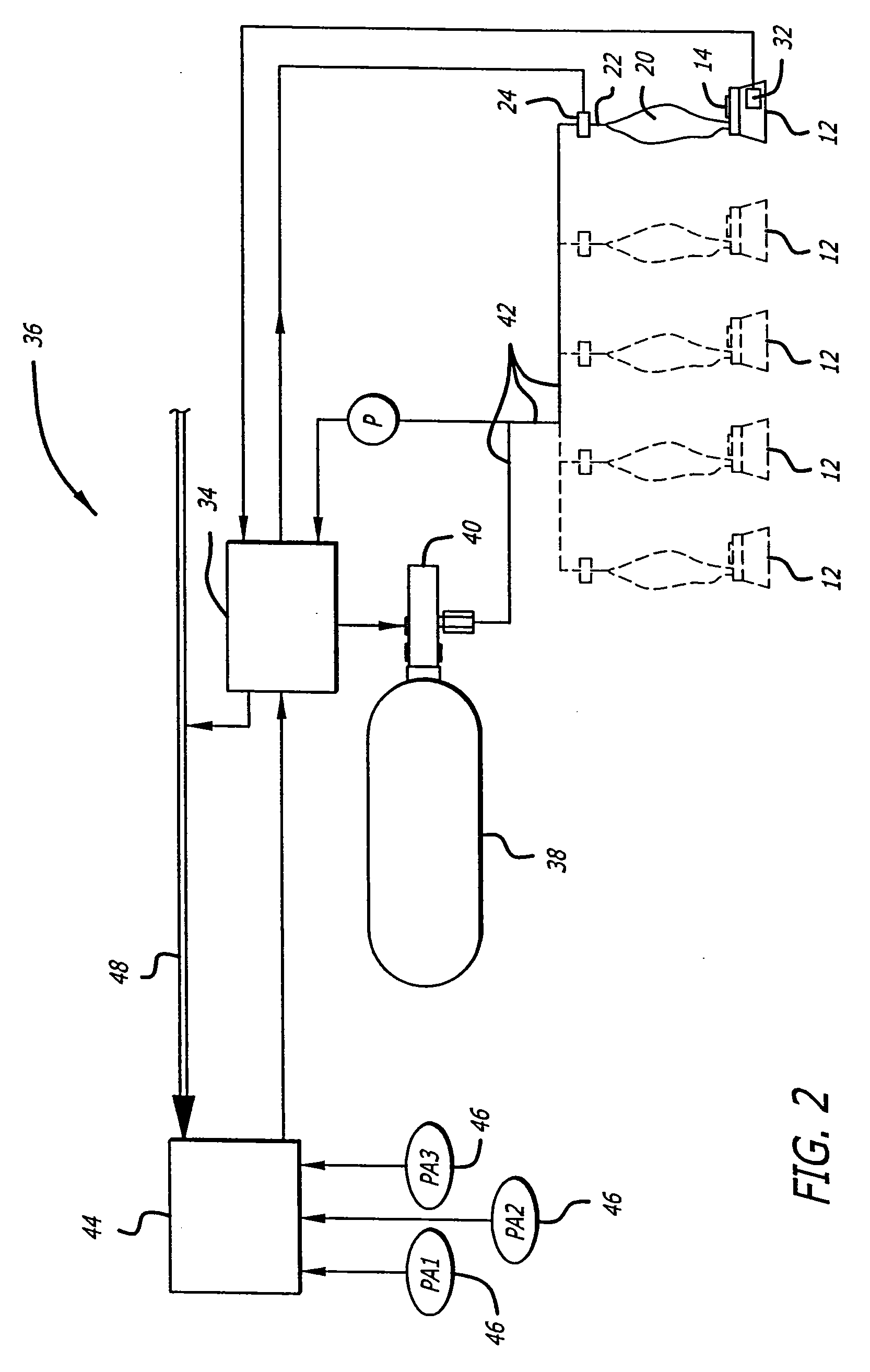

Oxygen conservation system for commercial aircraft

ActiveUS20060118115A1Reduce the amount requiredIncreased safety marginRespiratorsOperating means/releasing devices for valvesInhalationEngineering

An emergency oxygen supply system for use on aircraft in the event of a loss in cabin pressure is configured for delivering allotments of oxygen and timing the delivery such allotments to each passenger so as maximize the efficiency of the transfer of such oxygen into the passenger's bloodstream. The delivery of each allotment is selected so that the entire allotment is available for inhalation into the region of the lung most efficient at oxygen transfer while the volume of the allotment is selected to substantially coincide with the volume of such region of the lung.

Owner:BE INTPROP

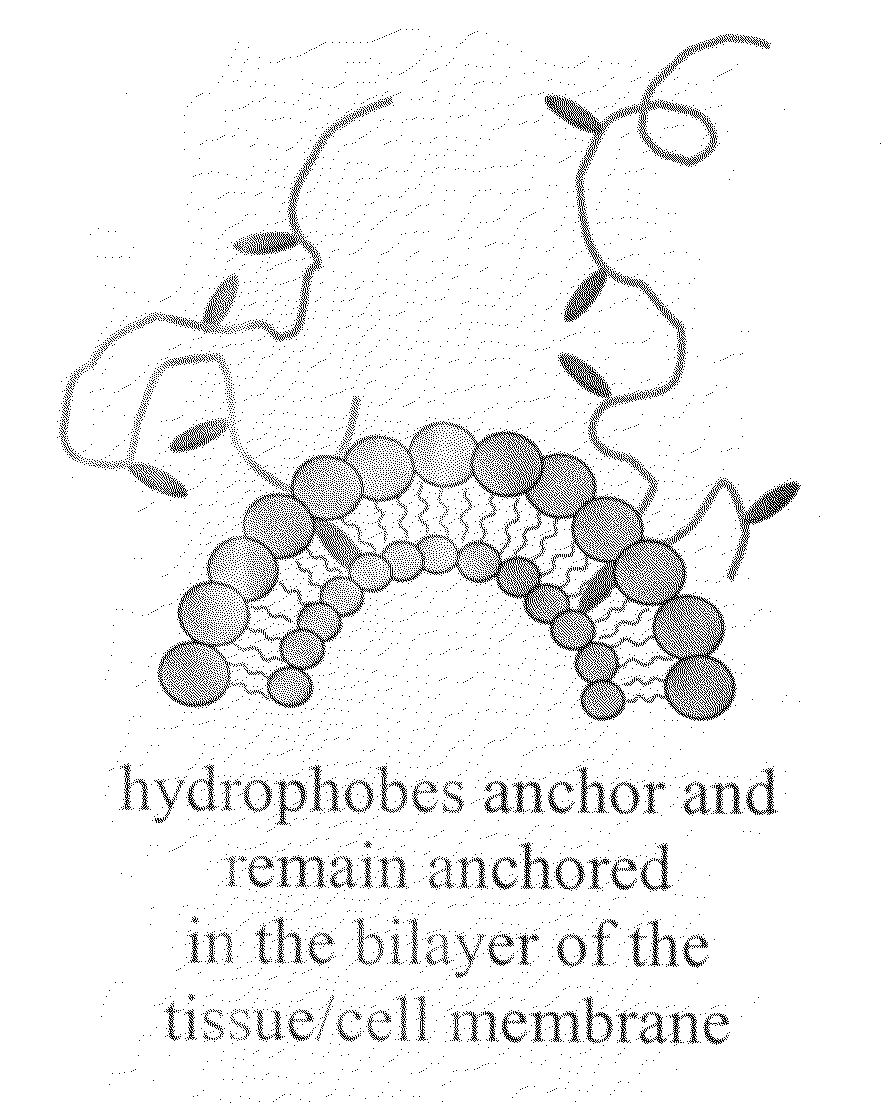

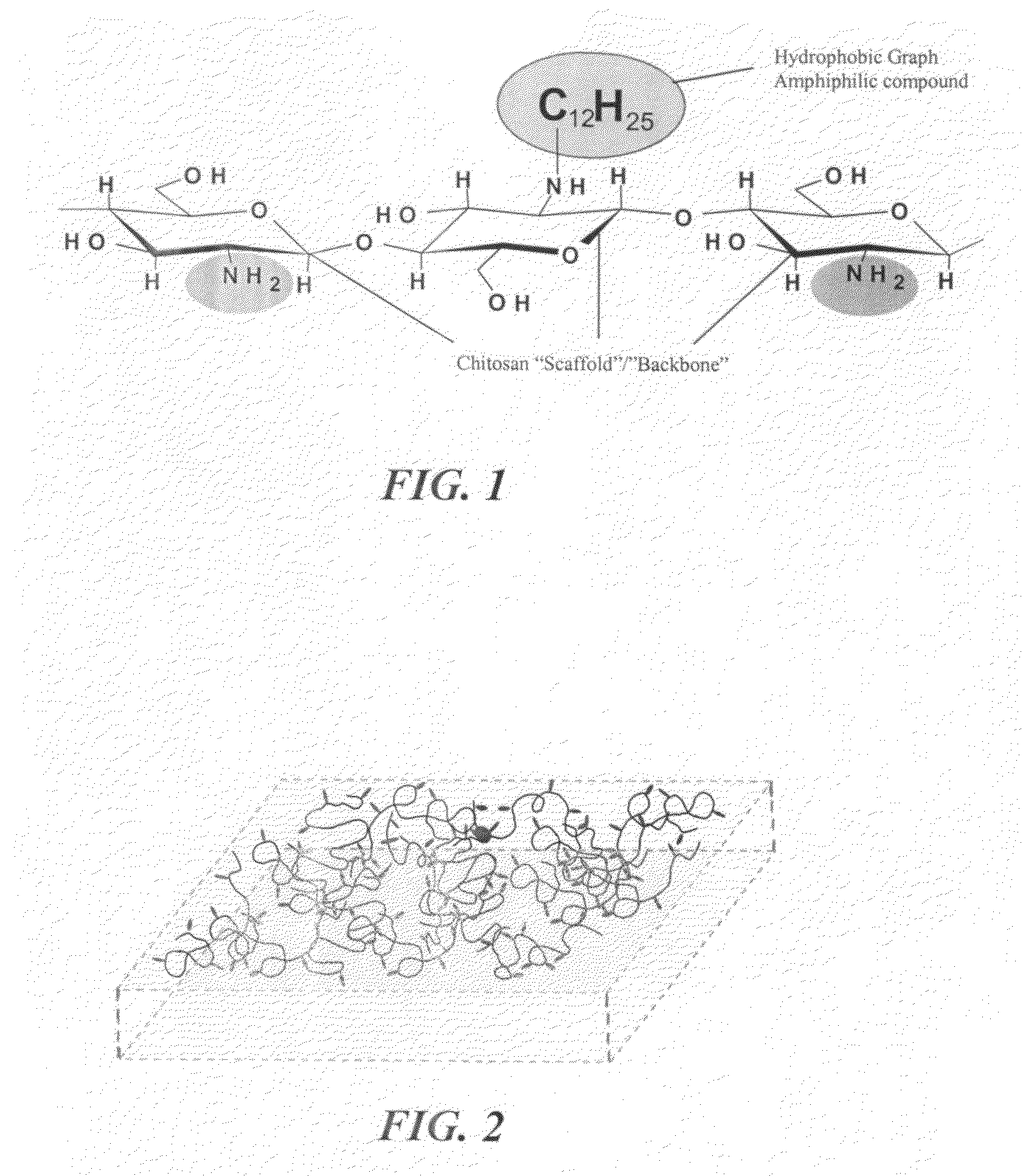

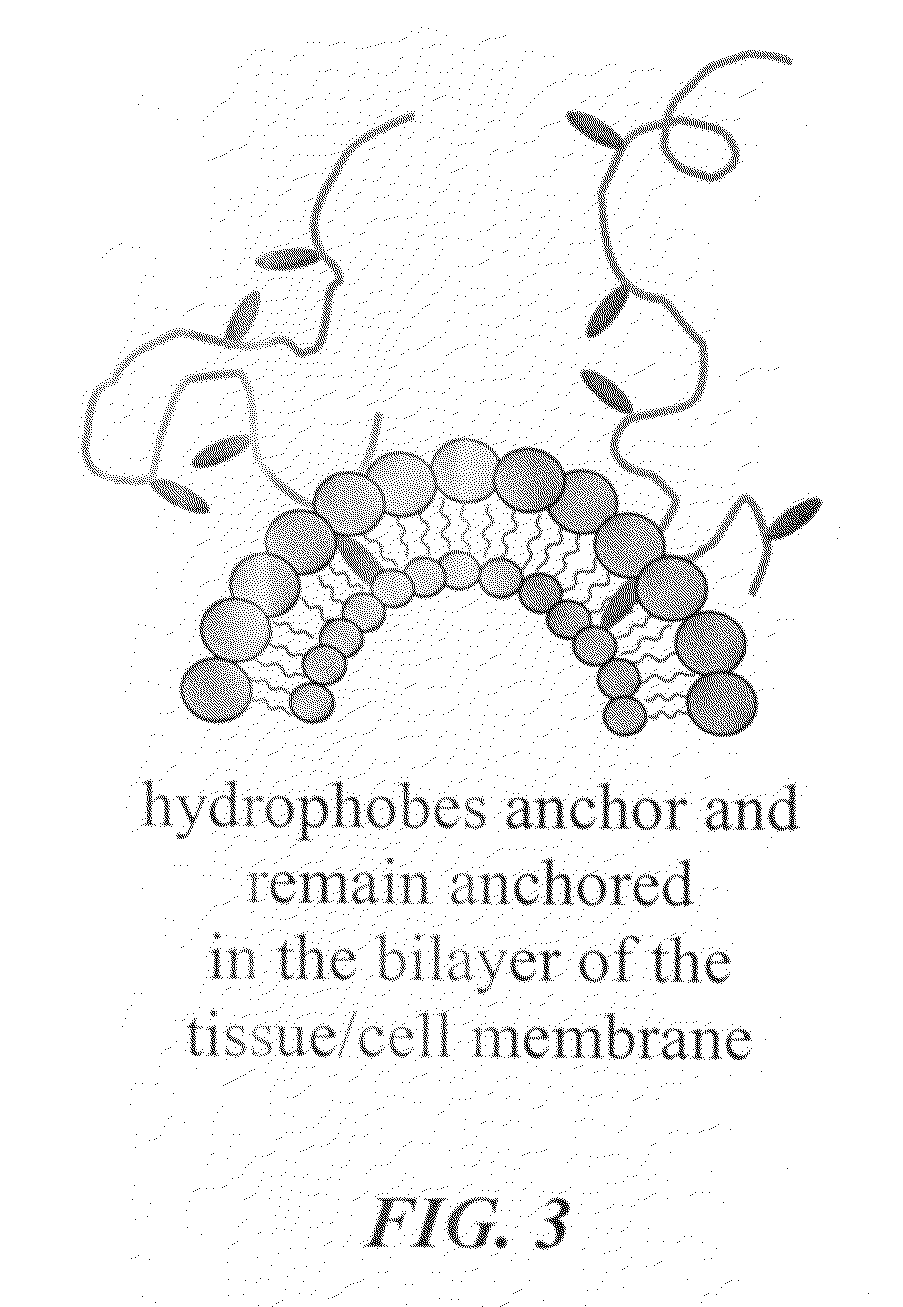

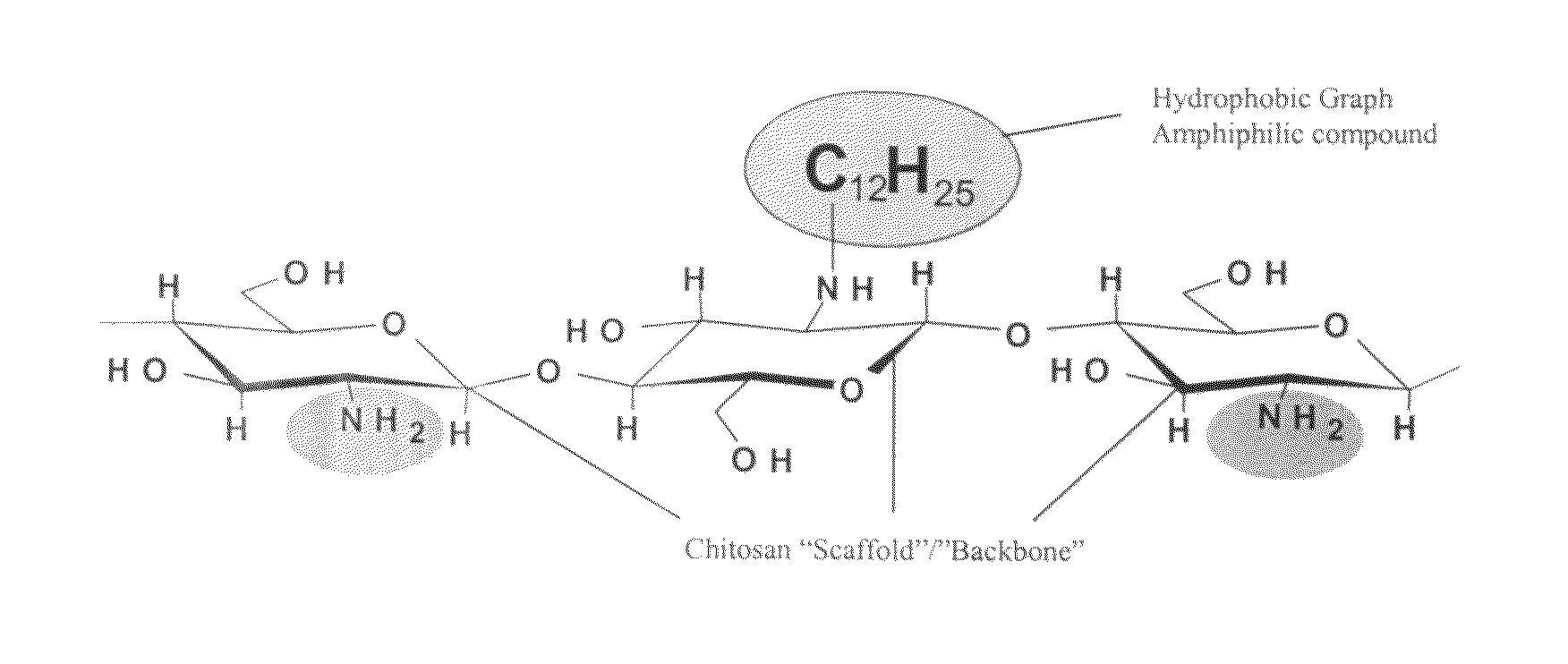

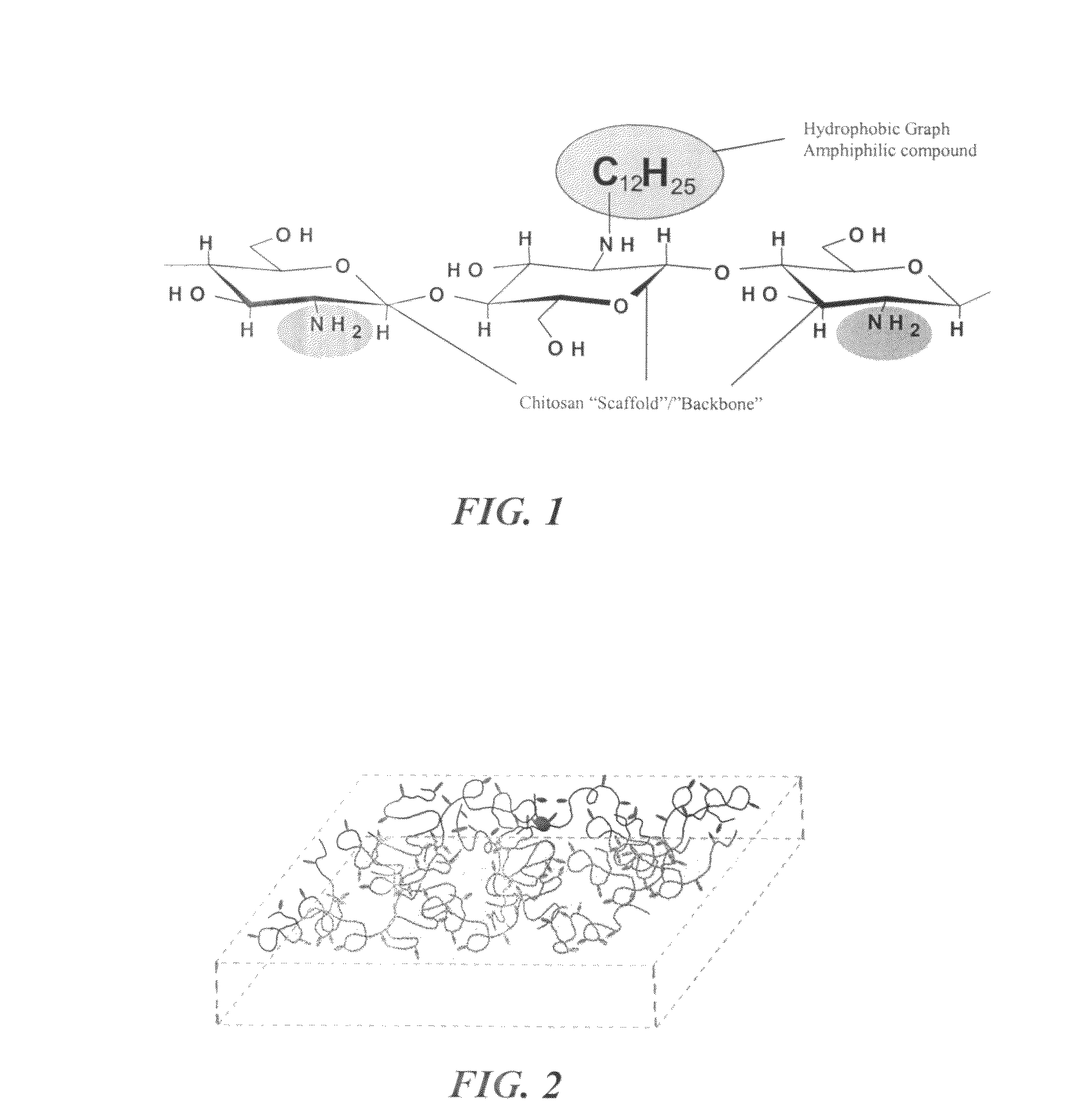

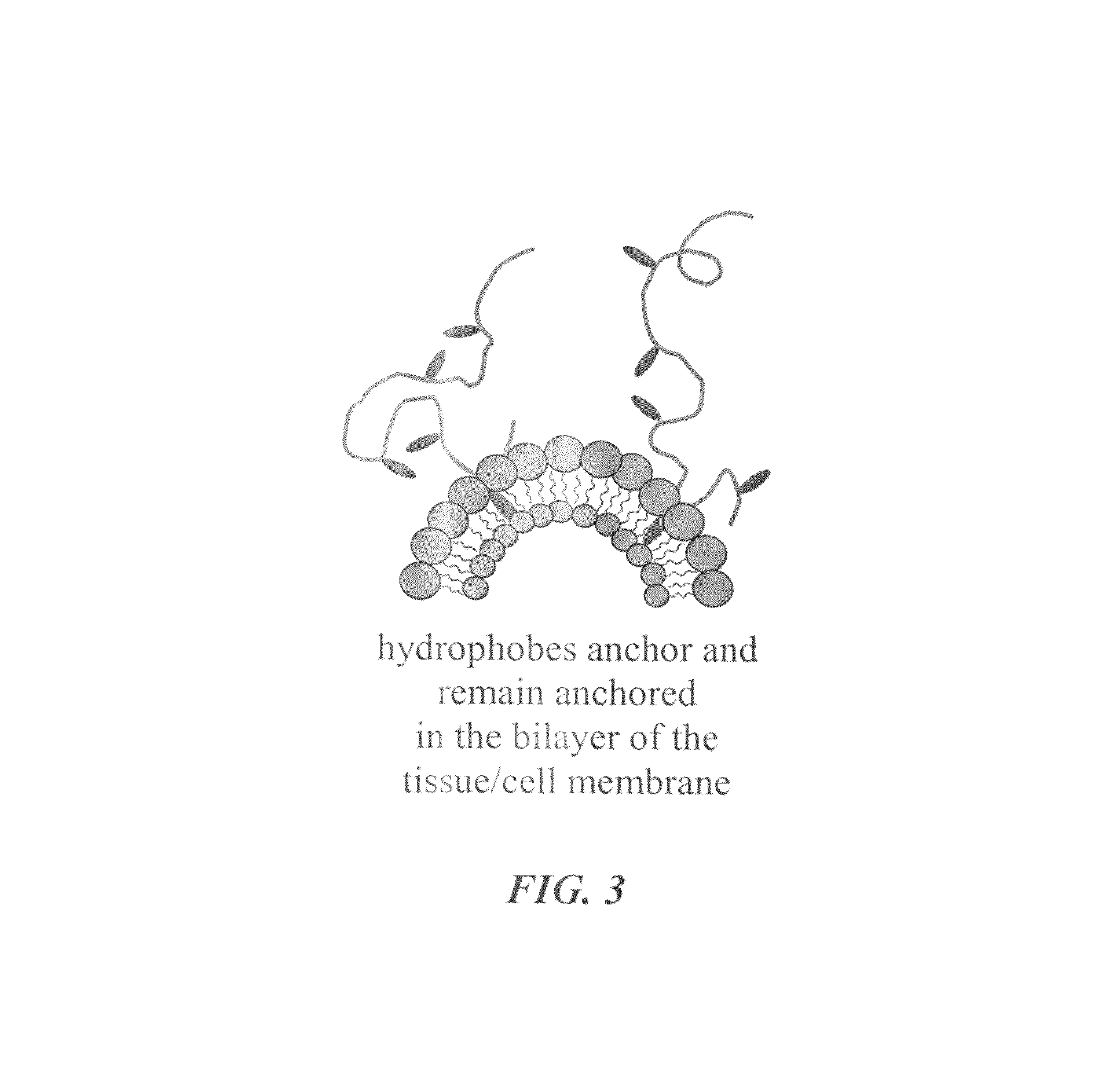

Advanced functional biocompatible polymeric matrix used as a hemostatic agent and system for damaged tissues and cells

A hemostatic tissue sealant sponge and a spray for acute wounds are disclosed. The sponge comprises hydrophobically modified polymers that anchor themselves within the membrane of cells in the vicinity of the wound. The seal is strong enough to substantially prevent the loss of blood inside the boundaries of the sponge, yet weak enough to substantially prevent damage to newly formed tissue upon recovery and subsequent removal of the sponge. In examples, the polymers inherently prevent microbial infections and are suitable for oxygen transfer required during normal wound metabolism. The spray comprises hydrophobically modified polymers that form solid gel networks with blood cells to create a physical clotting mechanism to prevent loss of blood. In an example, the spray further comprises at least one reagent that increases the mechanical integrity of the clot. In another example, the reagent prevents microbial infection of the wound.

Owner:UNIV OF MARYLAND

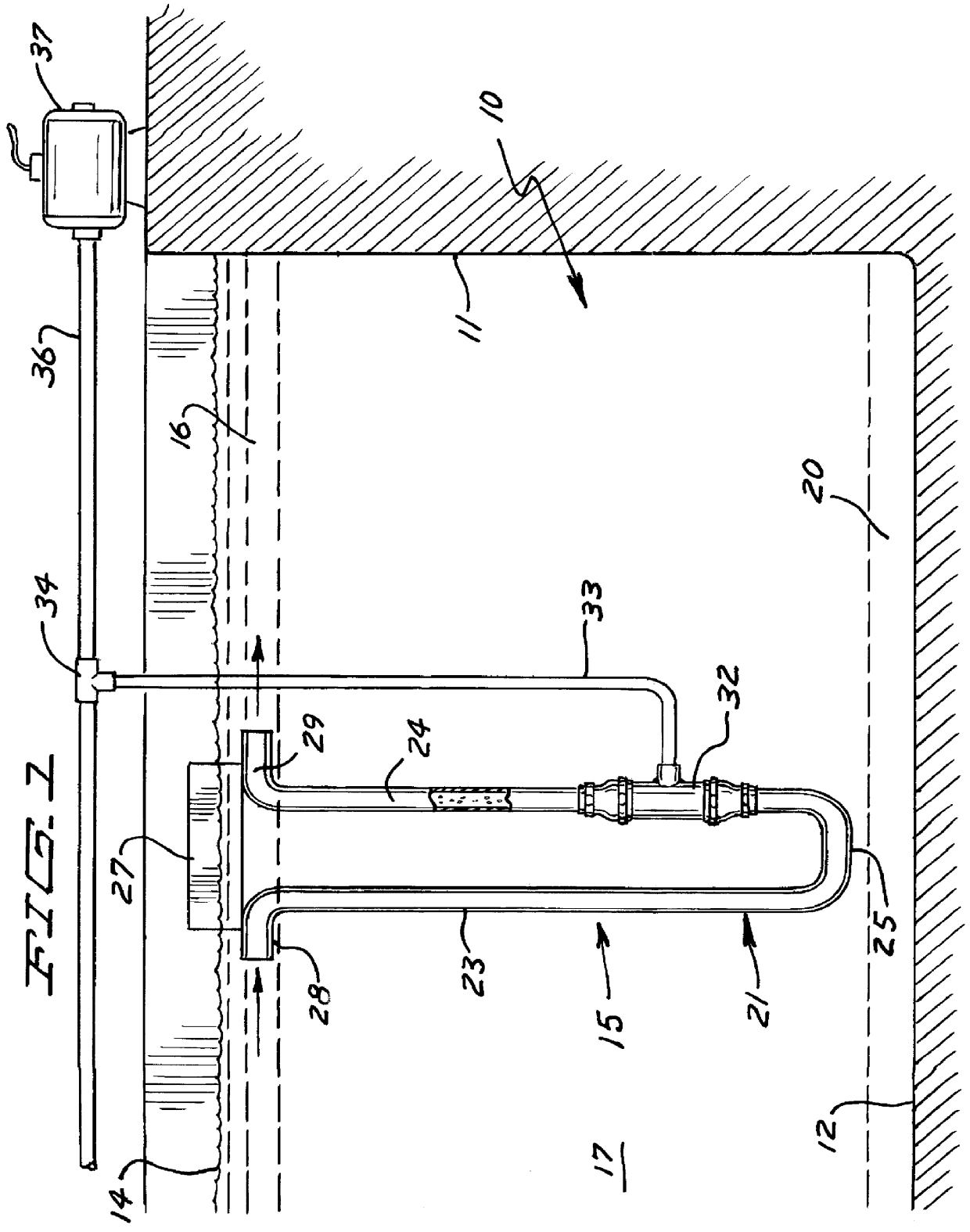

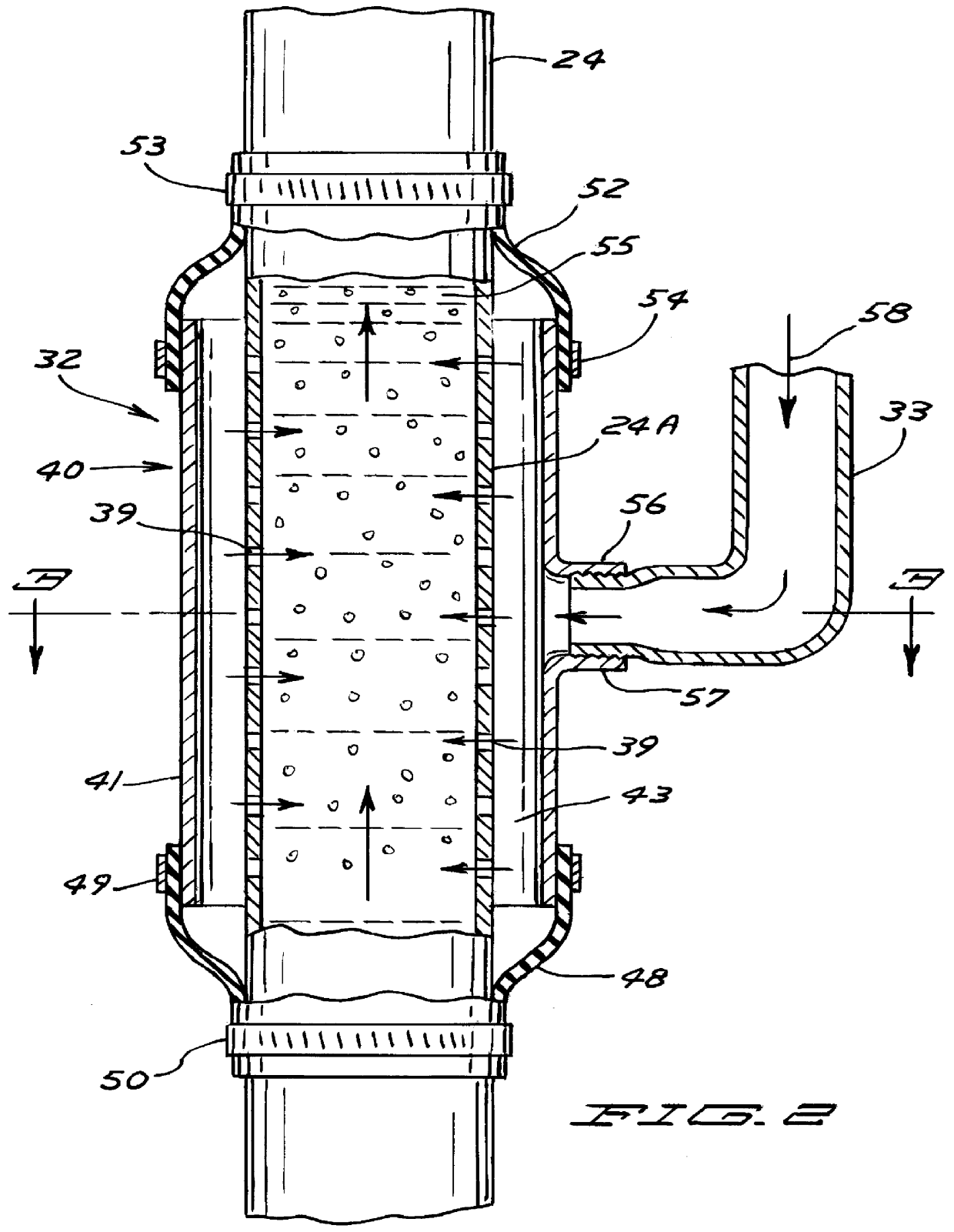

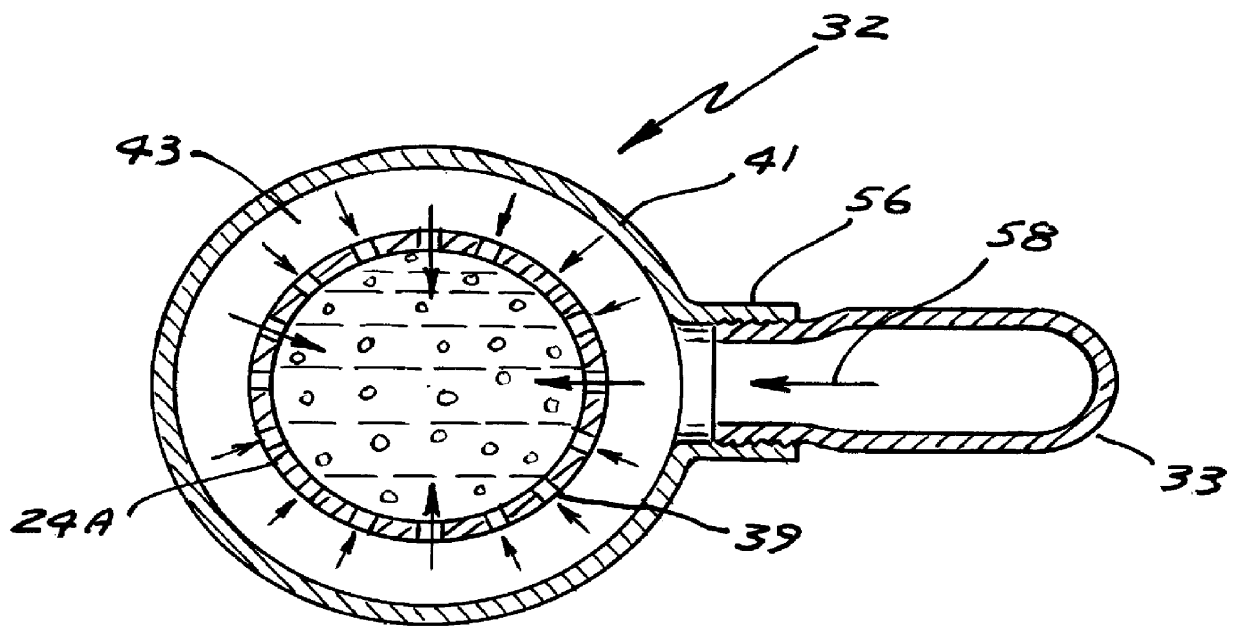

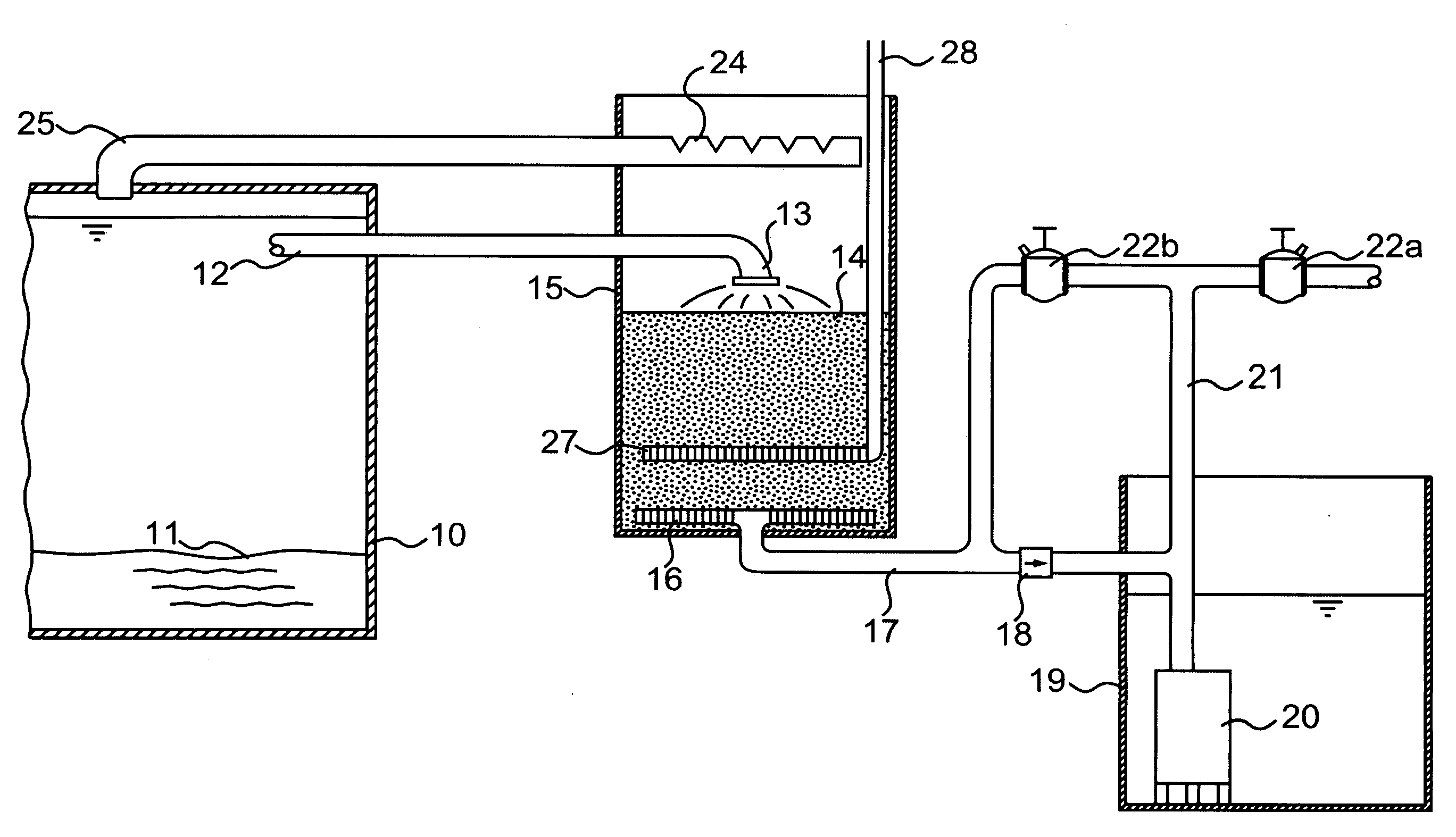

Aeration device and method for creating and maintaining facultative lagoon

InactiveUS6103123ATreatment using aerobic processesFlow mixersFacultative lagoonEnvironmental engineering

A facultative lagoon, an airlift aerator for such a lagoon, and a method of operating such a lagoon. The aerator includes a U-shaped body with a down flow leg and an airlift leg and a float. The float sustains the U-shaped body with respect to the surface of polluted material contained in the lagoon. The upper ends of the legs are submerged slightly beneath the surface of the material in the lagoon. The down flow leg has a water inlet and the airlift leg has the water outlet. A bubble generator is connected to a lower portion of the airlift leg. Air supplied under pressure to the bubble generator introduces bubbles into the airlift leg which establishes a water circulation through the U-shaped body. Bubbles transfer oxygen to the passing water which is disbursed through the water outlet. The dissolved oxygen is used in the biodegradation of the hazardous and odorous gases of the waste material that would otherwise be emitted into the atmosphere.

Owner:GANTZER CHARLES J

Backwashing unsaturated wastewater filter

ActiveUS20090294356A1Improve uniformityImprove efficiencyTreatment using aerobic processesSpecific water treatment objectivesWater sourceBiofilm growth

A compact high efficiency combined biological and physical unsaturated wastewater treatment filter configured for periodic backwashing is disclosed. The filter utilizes packed media and removes pollutants and pathogens from wastewater and other dirty water sources. The filter comprises a periodic backwashing means to less the chance that biofilm growth will clog the media pores. However, such backwashing still leaves sufficient biofilm attached to the media to maintain a very high level of treatment. In the preferred embodiment, the filter utilizes high frequency dosing to cause pore saturation at or near the surface during dosing and shortly thereafter in order to maximize distribution uniformity and to induce downward airflow into the media. The system provides a number of unexpected benefits; including allowing a very low distribution pressure and providing high oxygen transfer at low energy utilization into the filter media for aerobic biodegradation of pollutants.

Owner:BZAM LLC

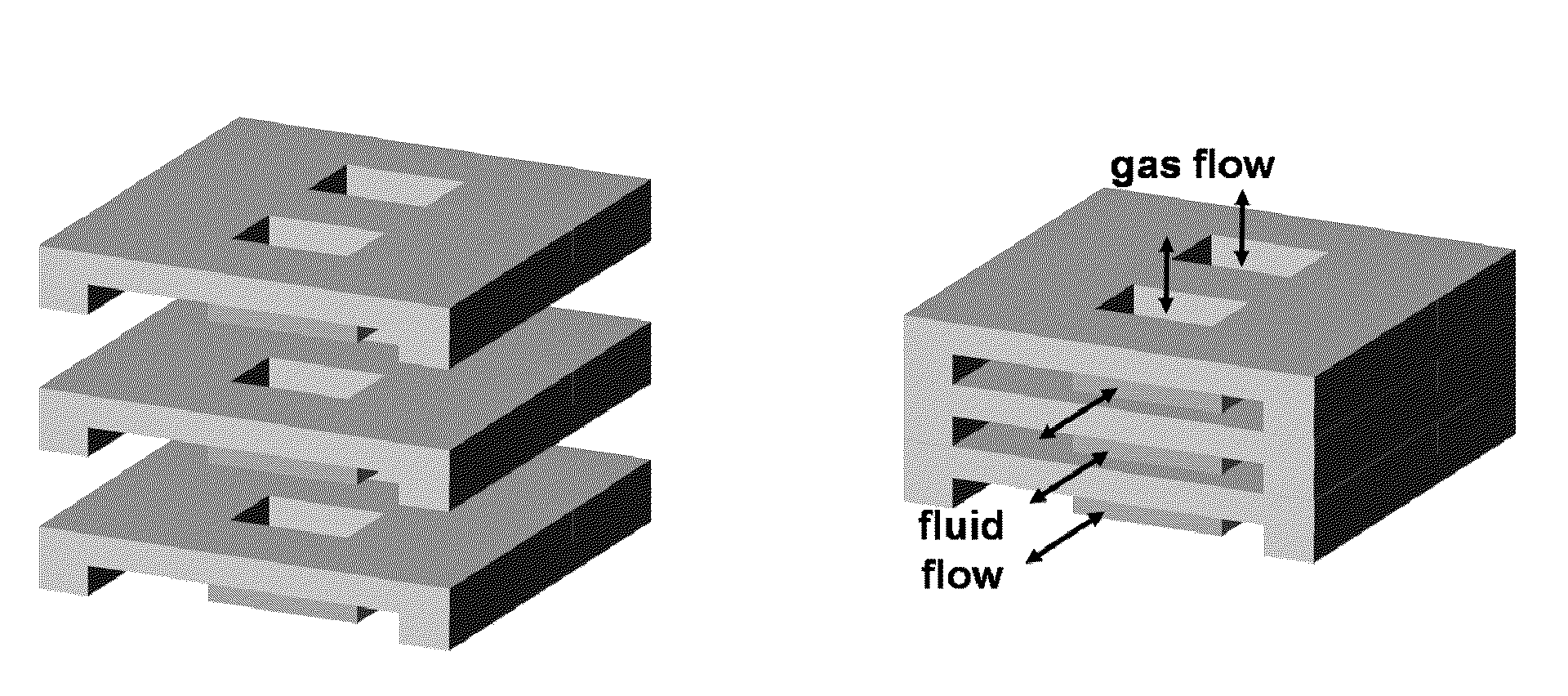

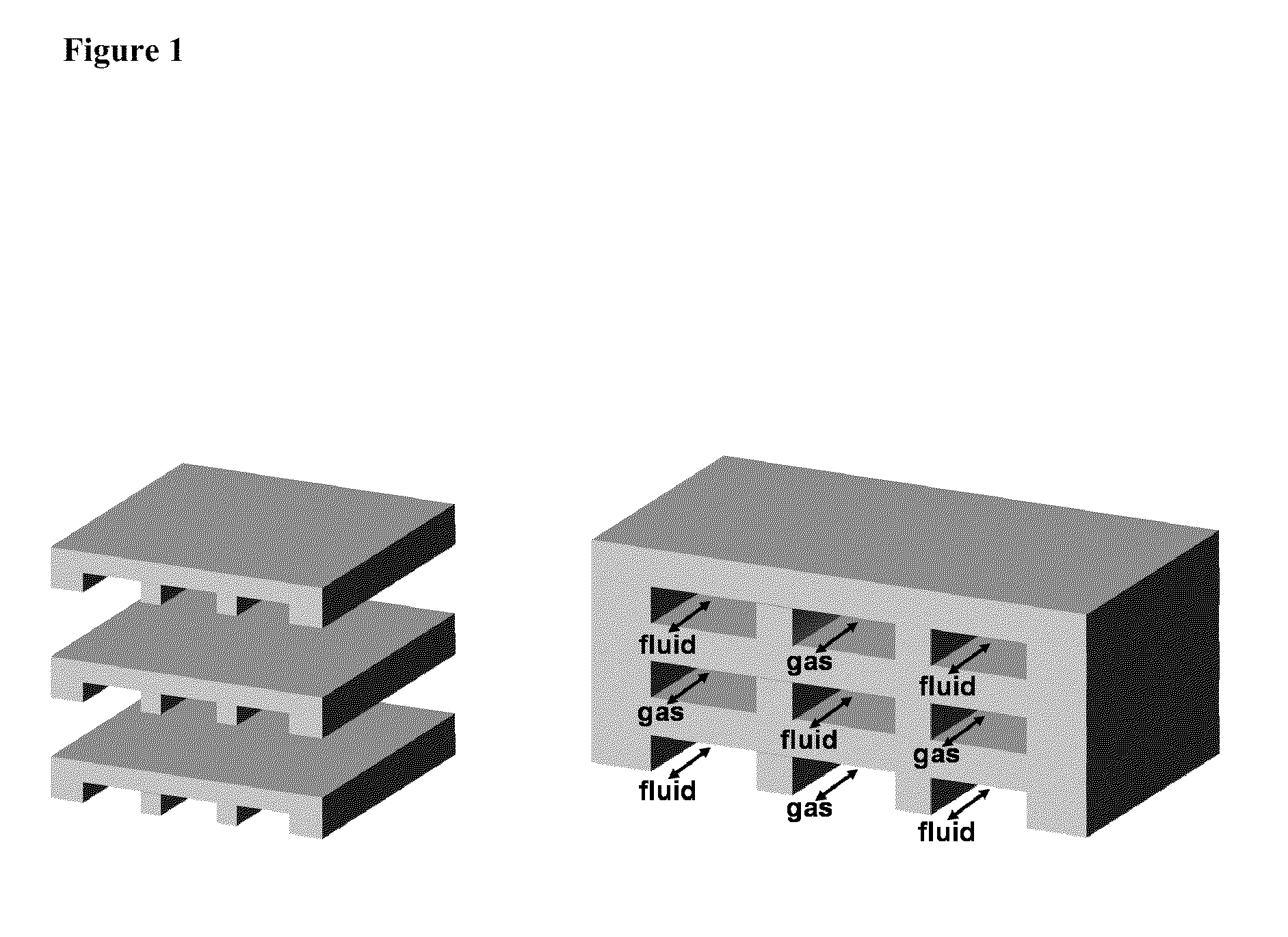

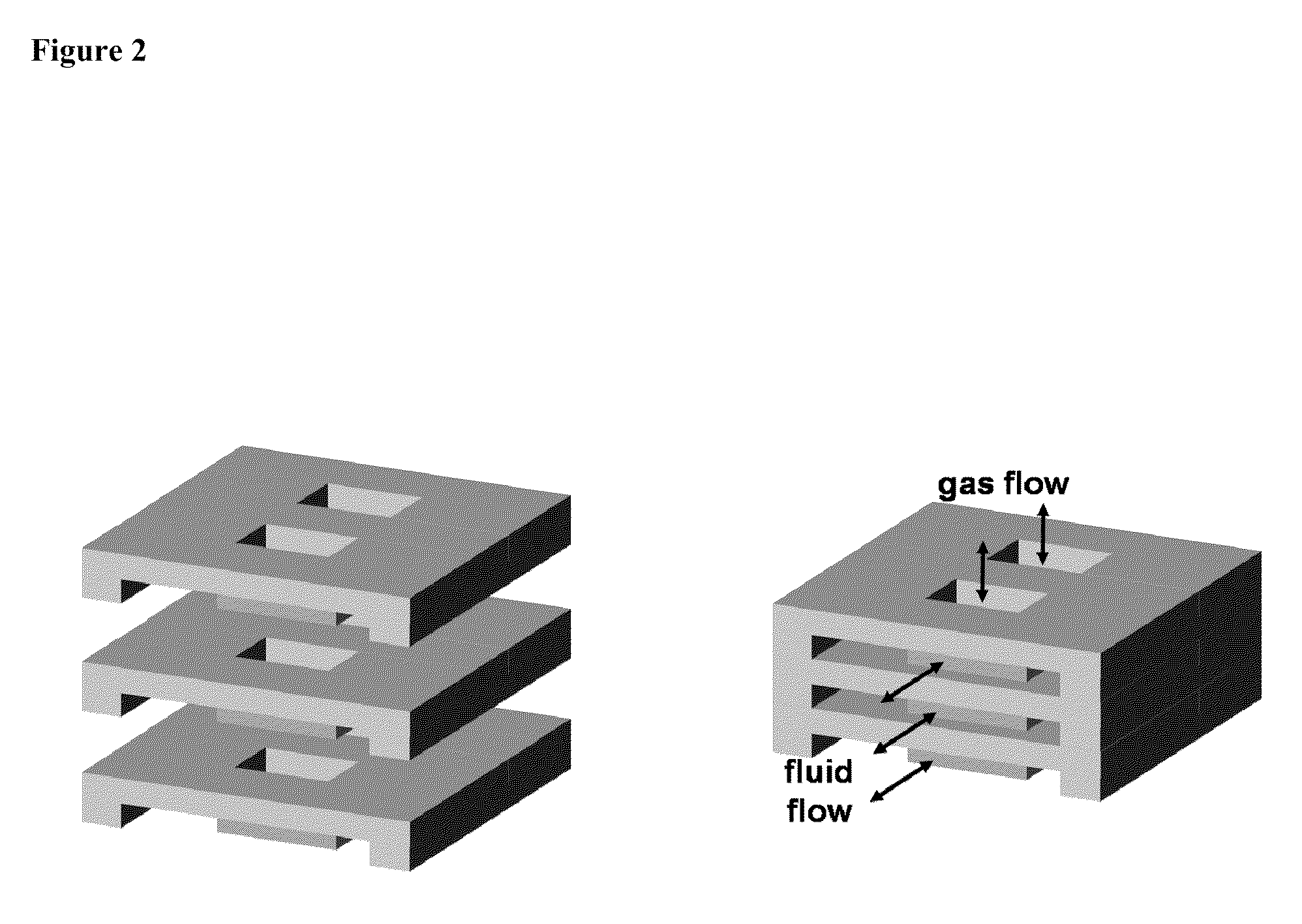

Microfluidic Device Facilitating Gas Exchange, and Methods of Use and Manufacture Thereof

ActiveUS20110158847A1Maximize transferSuperior fluid flow propertyOther blood circulation devicesFixed microstructural devicesGas exchangeBiomedical engineering

Owner:CHARLES STARK DRAPER LABORATORY

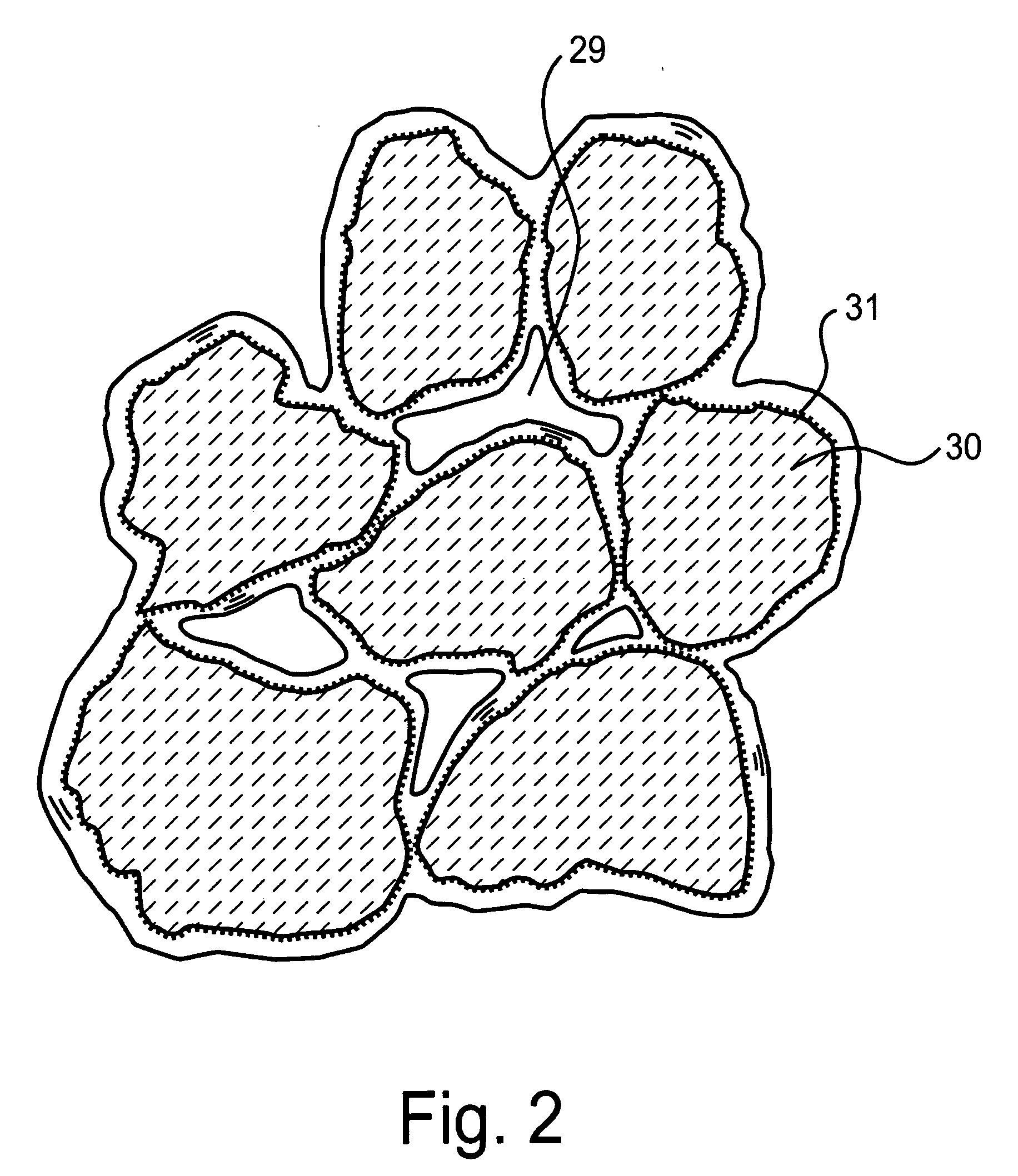

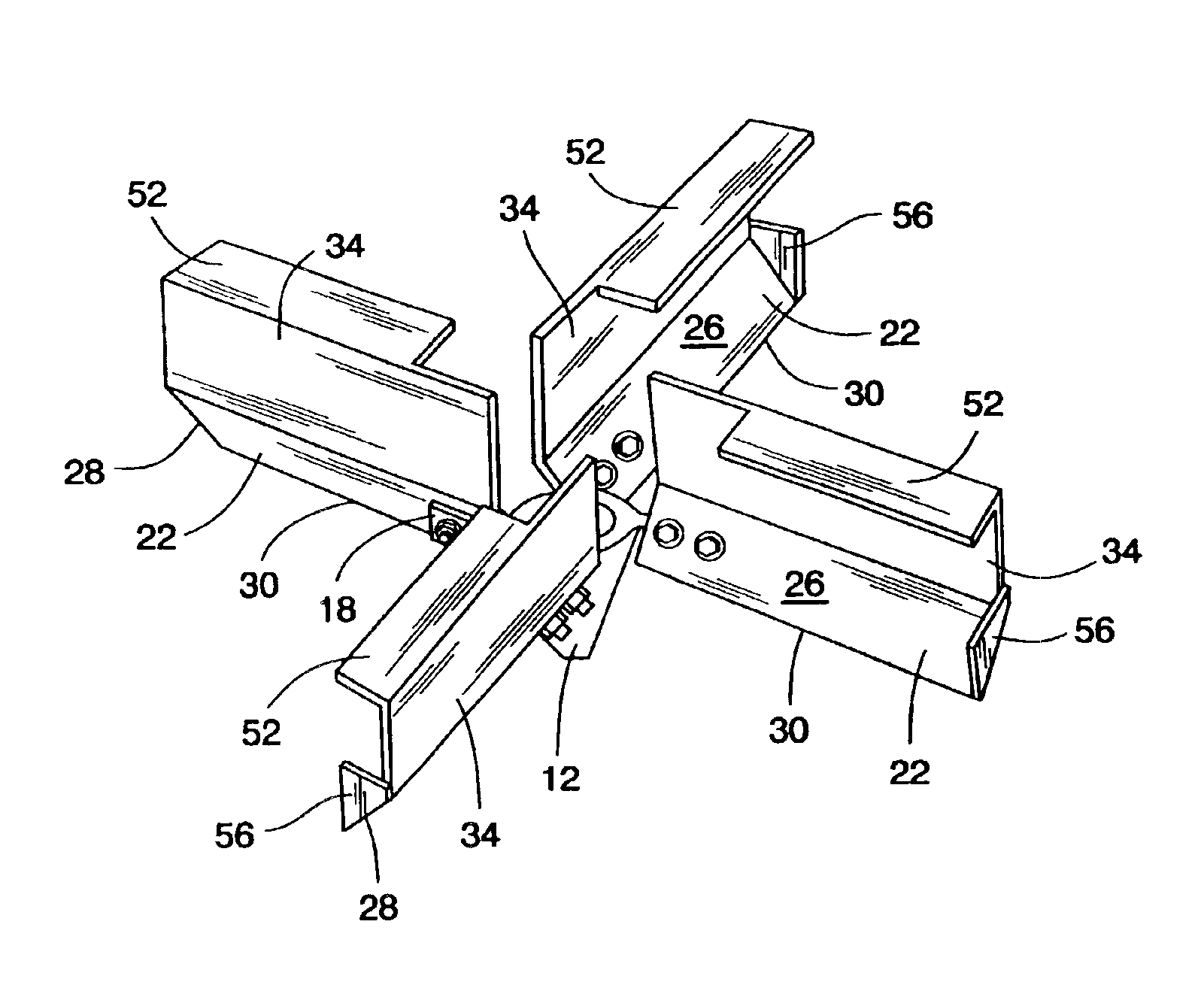

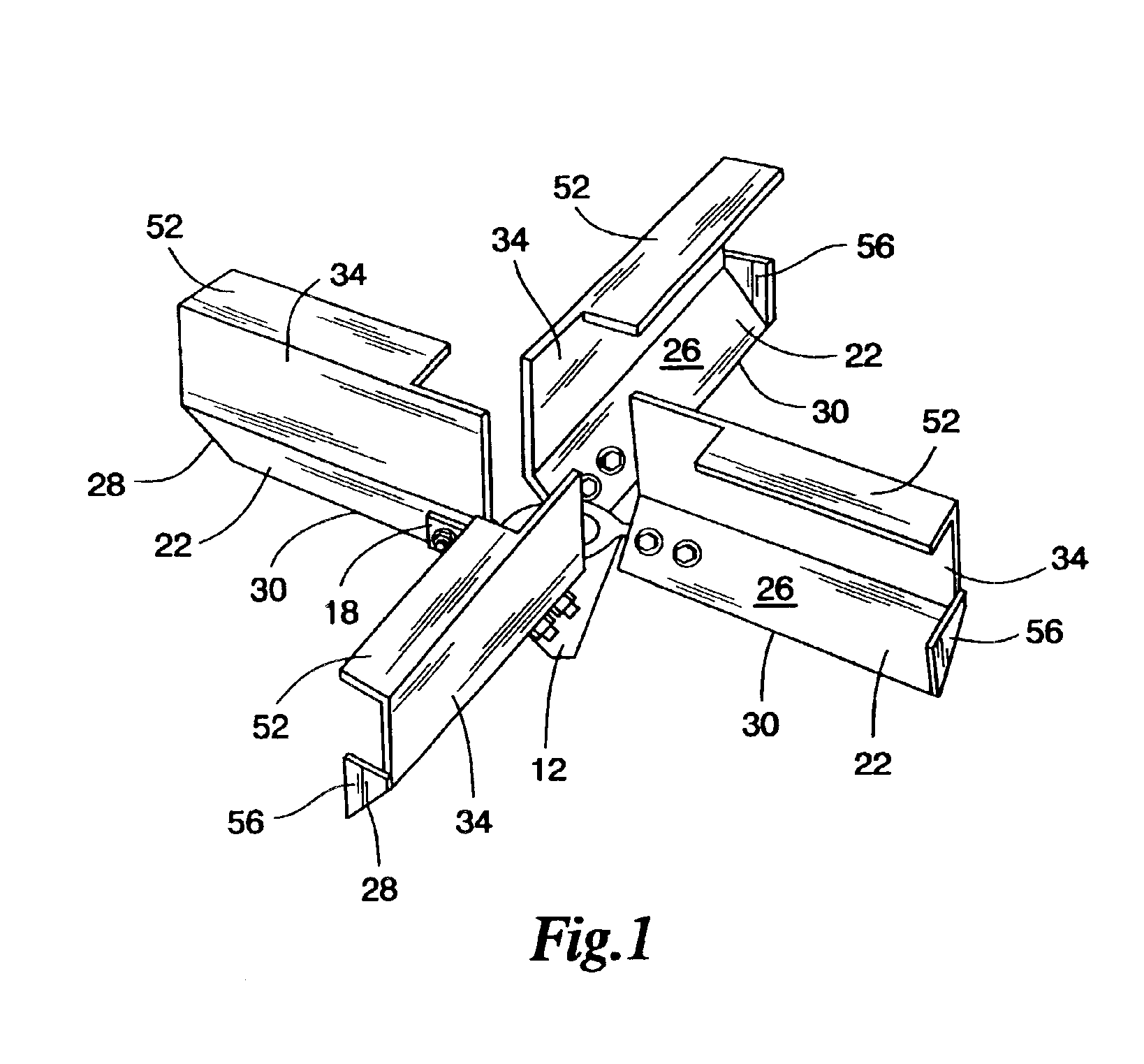

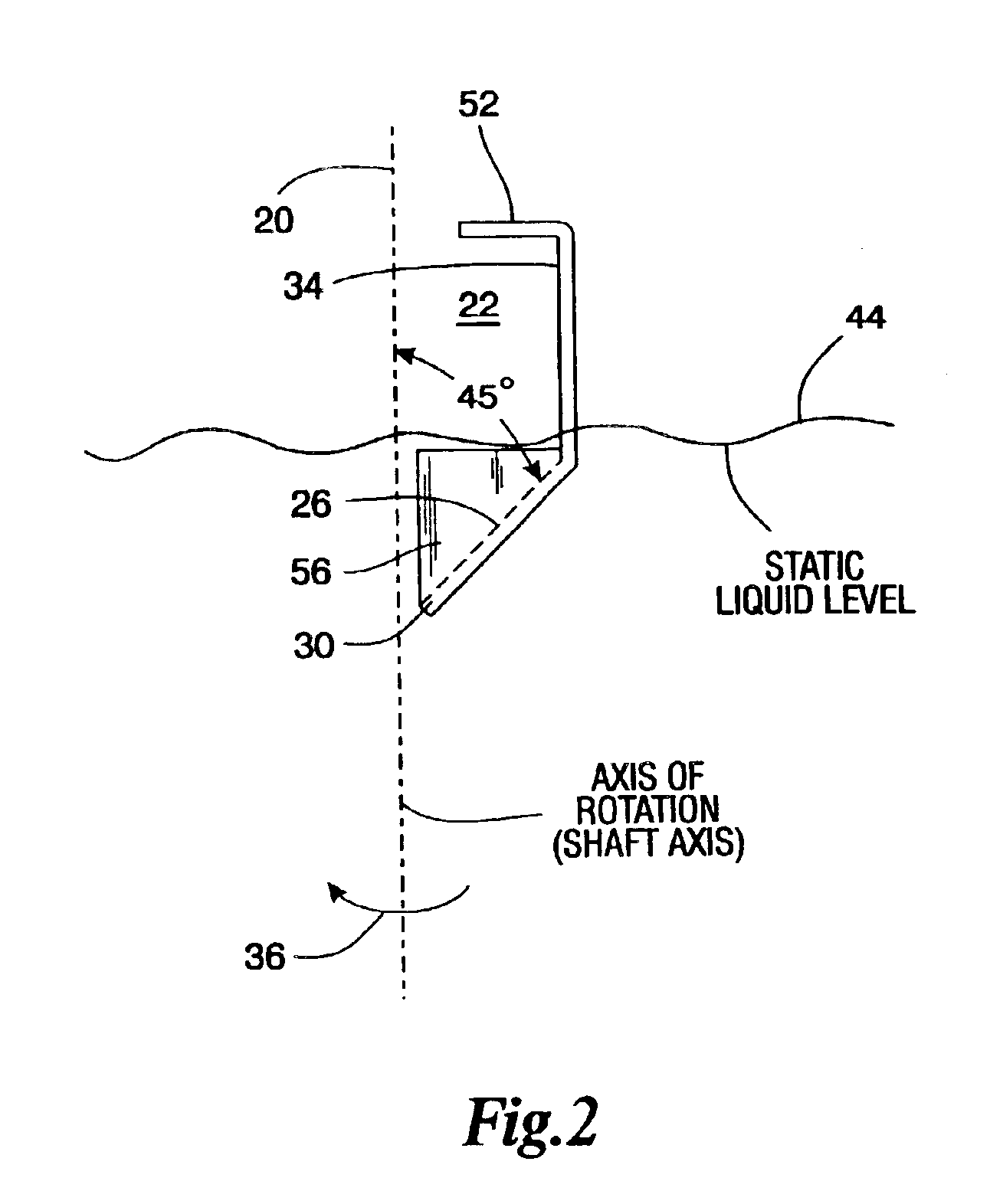

Surface aeration impellers

InactiveUS6877959B2Efficient sprayingImproves gas entrainmentPropellersFlow mixersImpellerEngineering

The invention is an improved surface aeration impeller for use in a liquid filled tank which particularly increases the surface turbulence and the entrainment of gas into the liquid surface. The impeller is an axial flow impeller and may be either a pitched blade turbine (PBT) or have airfoil shaped blades. In either case, the impeller has a portion which extends radially along an edge thereof which projects above the surface of the liquid being mixed in a vertical direction. The blades of the impeller are modified to include a top horizontal plate to lower the spray height of the liquid and an optional endcap, both of which can enhance and increase the standard aeration efficiency. Preferably, the impeller is rotated in an up-pumping direction and propels the liquid being aerated in a radially upward and outward direction. A sufficient upward surge of liquid is produced so that the liquid is observed to splash back onto the surface a plurality of times in the course of operation of the impeller. Such multiple splashing action enhances the contact between the air and the liquid itself to improve the oxygen transfer efficiency of the aeration impeller.

Owner:MIXING & MASS TRANSFER TECH

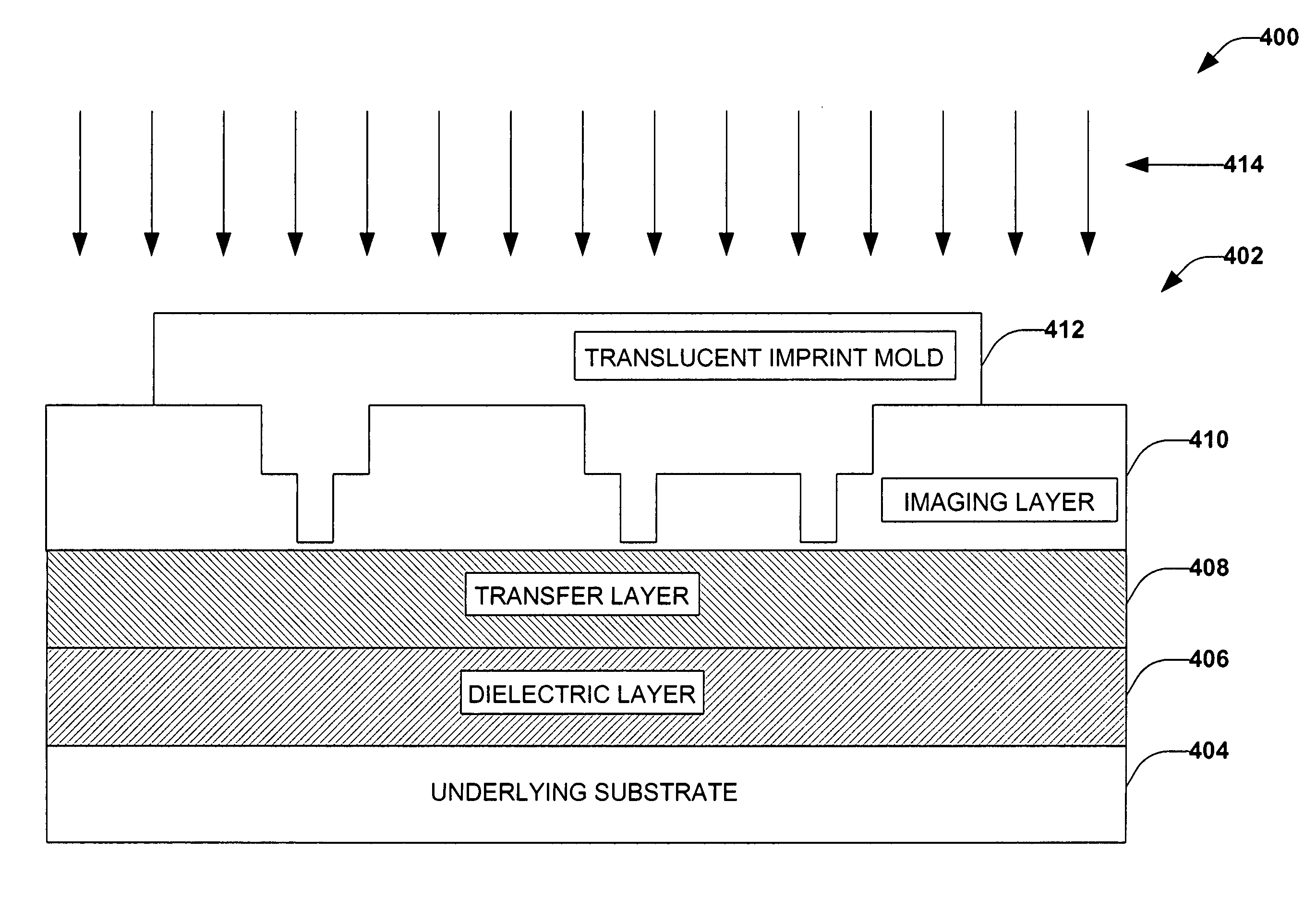

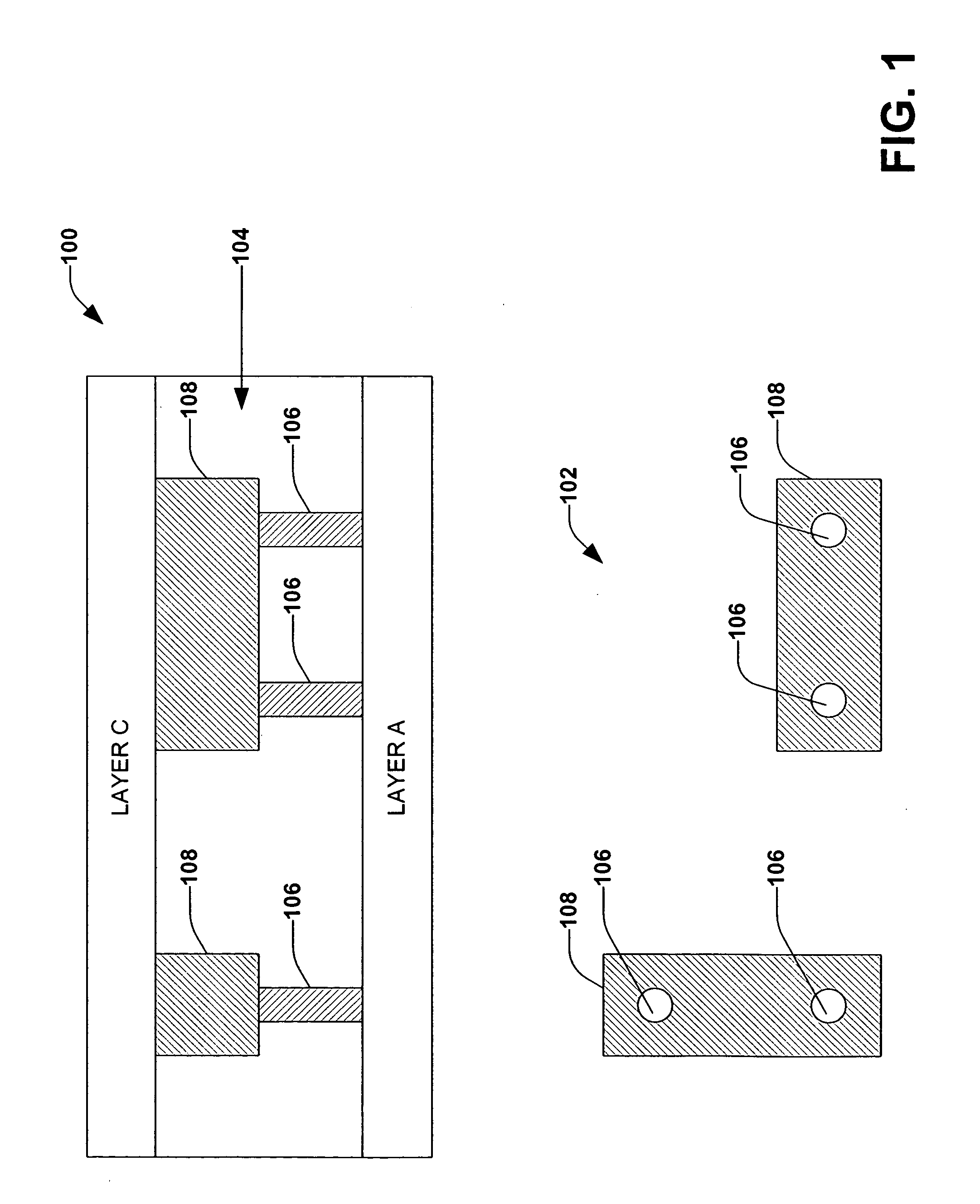

System and method for imprint lithography to facilitate dual damascene integration in a single imprint act

ActiveUS7148142B1Efficient transferEasy to integrateNanoinformaticsSolid-state devicesLithographic artistDielectric layer

A system and method are provided to facilitate dual damascene interconnect integration in a single imprint step. The method provides for creation of a translucent imprint mold with three-dimensional features comprising the dual damascene pattern to be imprinted. The imprint mold is brought into contact with a photopolymerizable organosilicon imaging layer deposited upon a transfer layer which is spin coated or otherwise deposited upon a dielectric layer of a substrate. When the photopolymerizable layer is exposed to a source of illumination, it cures with a structure matching the dual damascene pattern of the imprint mold. A halogen breakthrough etch followed by oxygen transfer etch transfer the vias from the imaging layer into the transfer layer. A second halogen breakthrough etch followed by a second oxygen transfer etch transfer the trenches from the imaging layer into the transfer layer. A dielectric etch transfers the pattern from the transfer layer into the dielectric layer. A metal fill process then fills the dual damascene openings of the dielectric layer with metal.

Owner:ADVANCED MICRO DEVICES INC

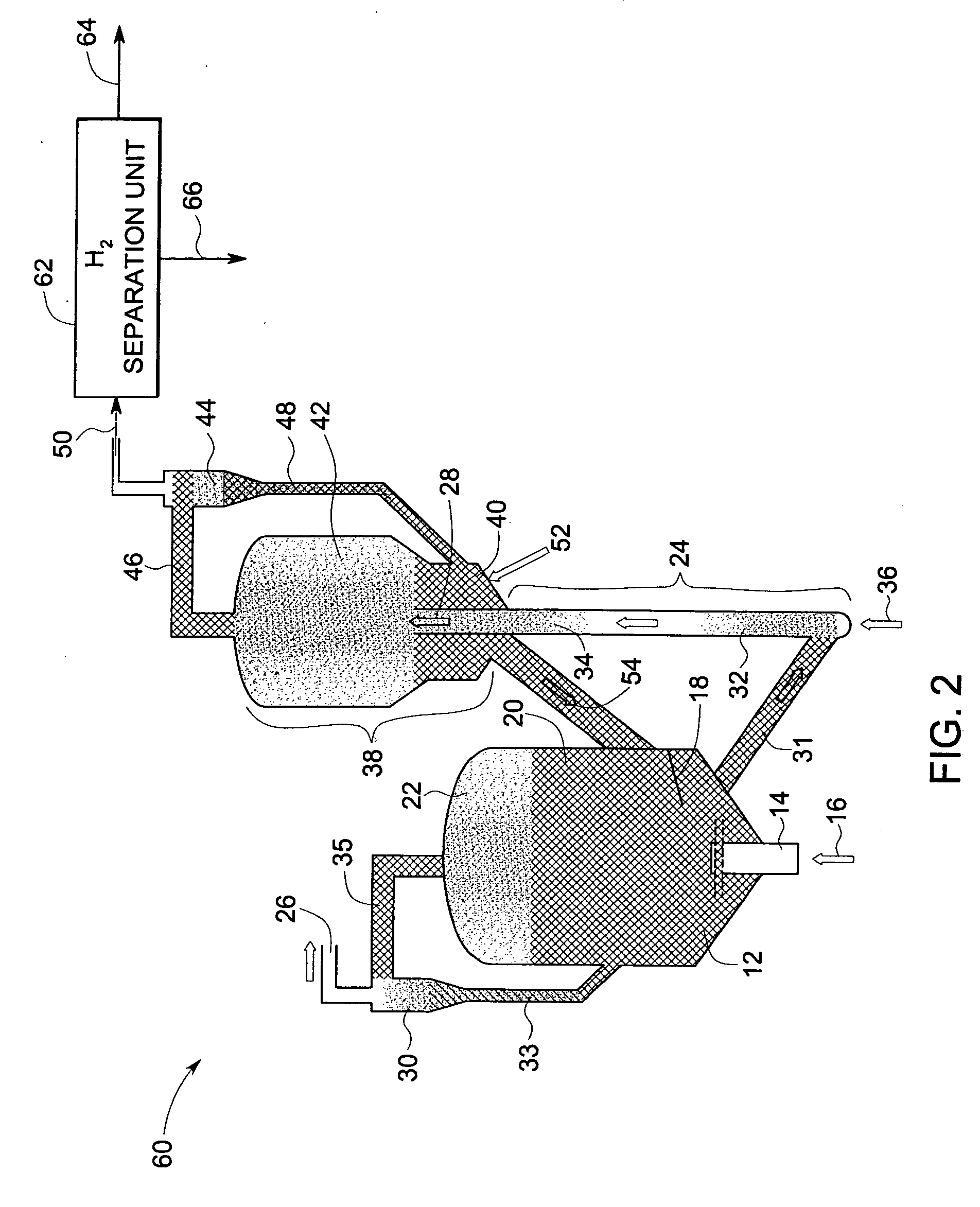

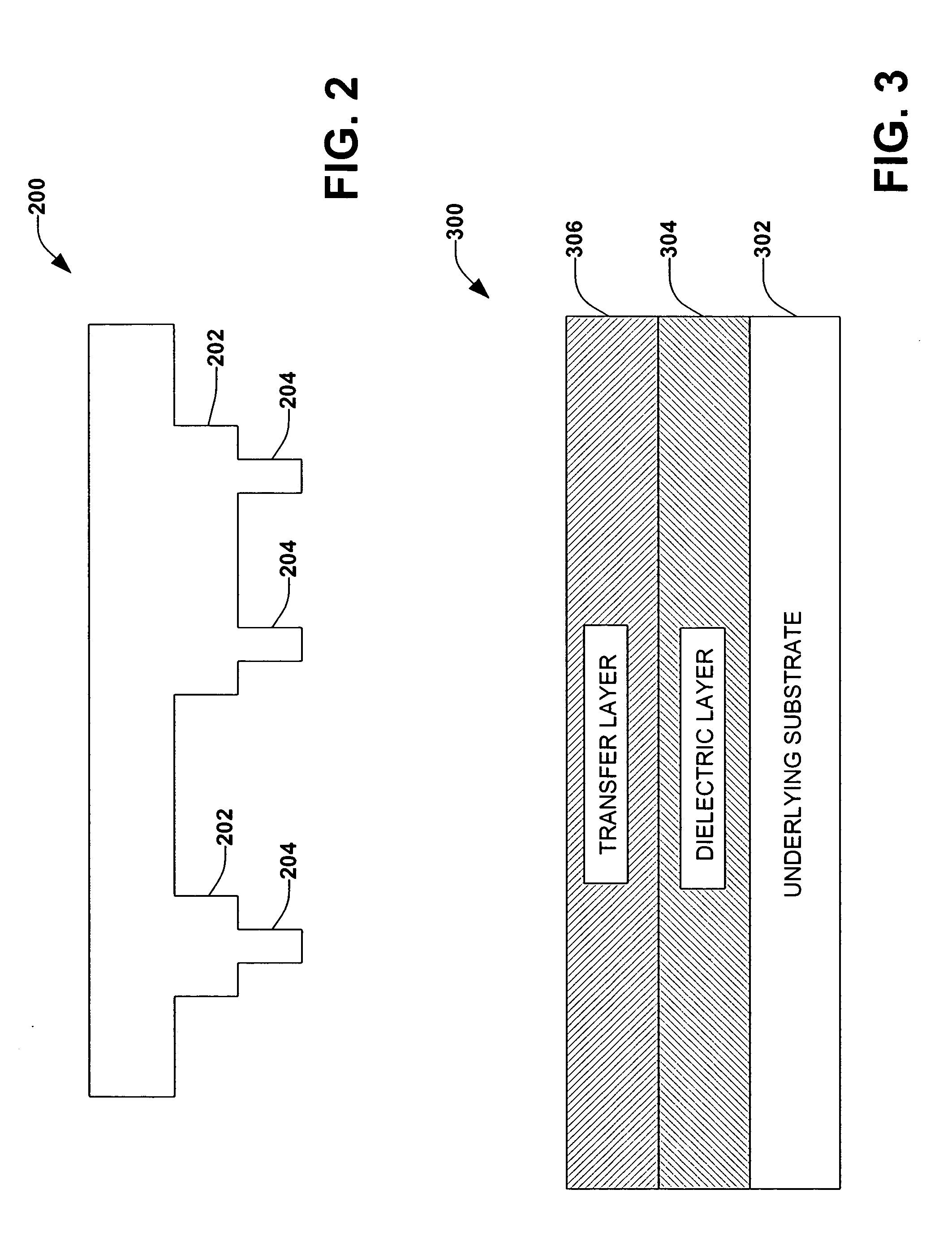

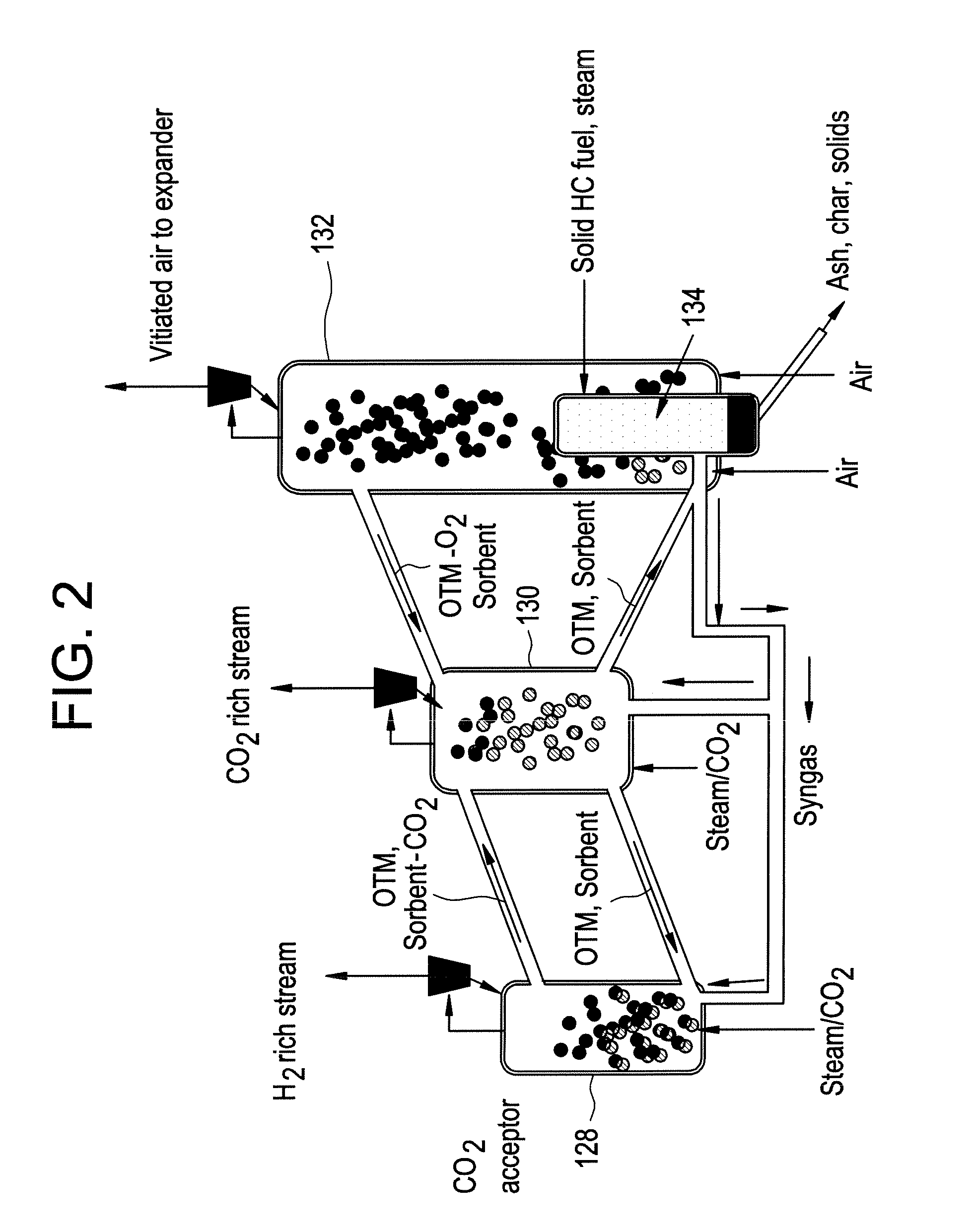

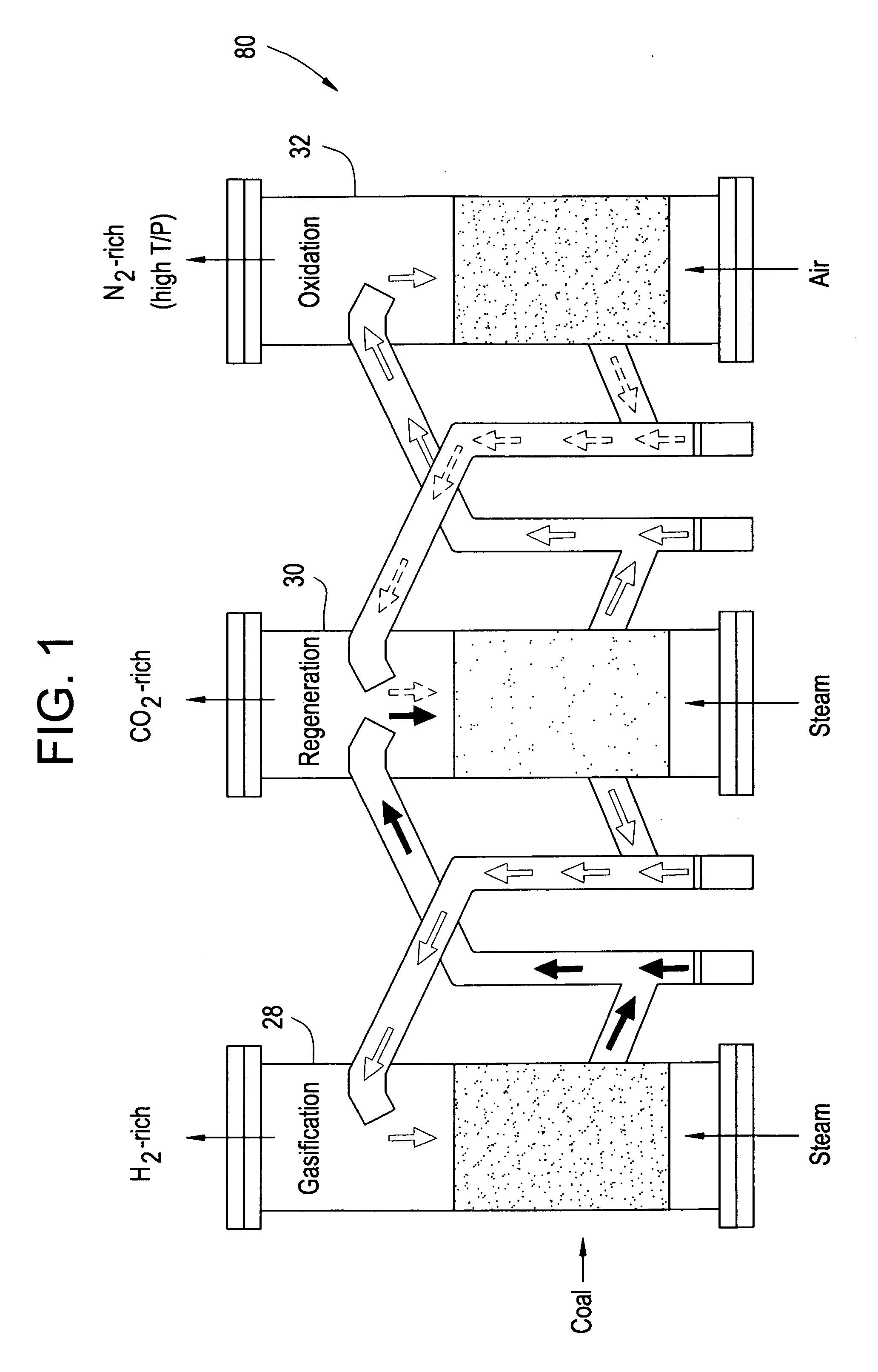

Unmixed Fuel Processors and Methods for Using the Same

Disclosed herein are unmixed fuel processors and methods for using the same. In one embodiment, an unmixed fuel processor comprises: an oxidation reactor comprising an oxidation portion and a gasifier, a CO2 acceptor reactor, and a regeneration reactor. The oxidation portion comprises an air inlet, effluent outlet, and an oxygen transfer material. The gasifier comprises a solid hydrocarbon fuel inlet, a solids outlet, and a syngas outlet. The CO2 acceptor reactor comprises a water inlet, a hydrogen outlet, and a CO2 sorbent, and is configured to receive syngas from the gasifier. The regeneration reactor comprises a water inlet and a CO2 stream outlet. The regeneration reactor is configured to receive spent CO2 adsorption material from the gasification reactor and to return regenerated CO2 adsorption material to the gasification reactor, and configured to receive oxidized oxygen transfer material from the oxidation reactor and to return reduced oxygen transfer material to the oxidation reactor.

Owner:AIR PROD & CHEM INC

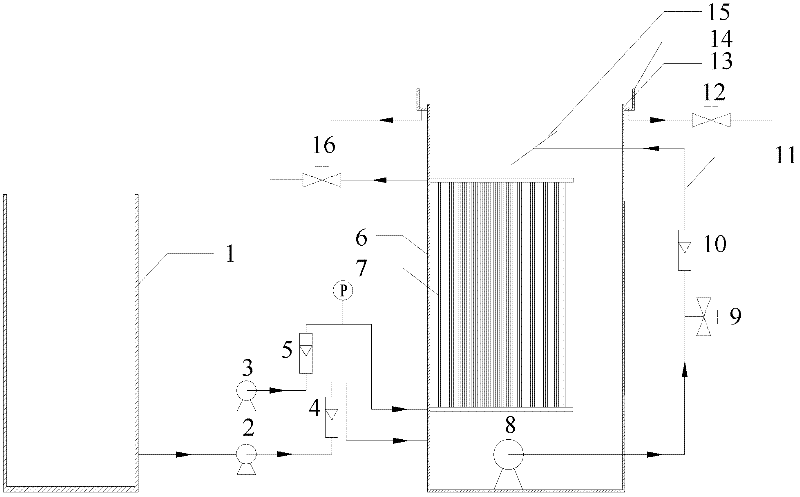

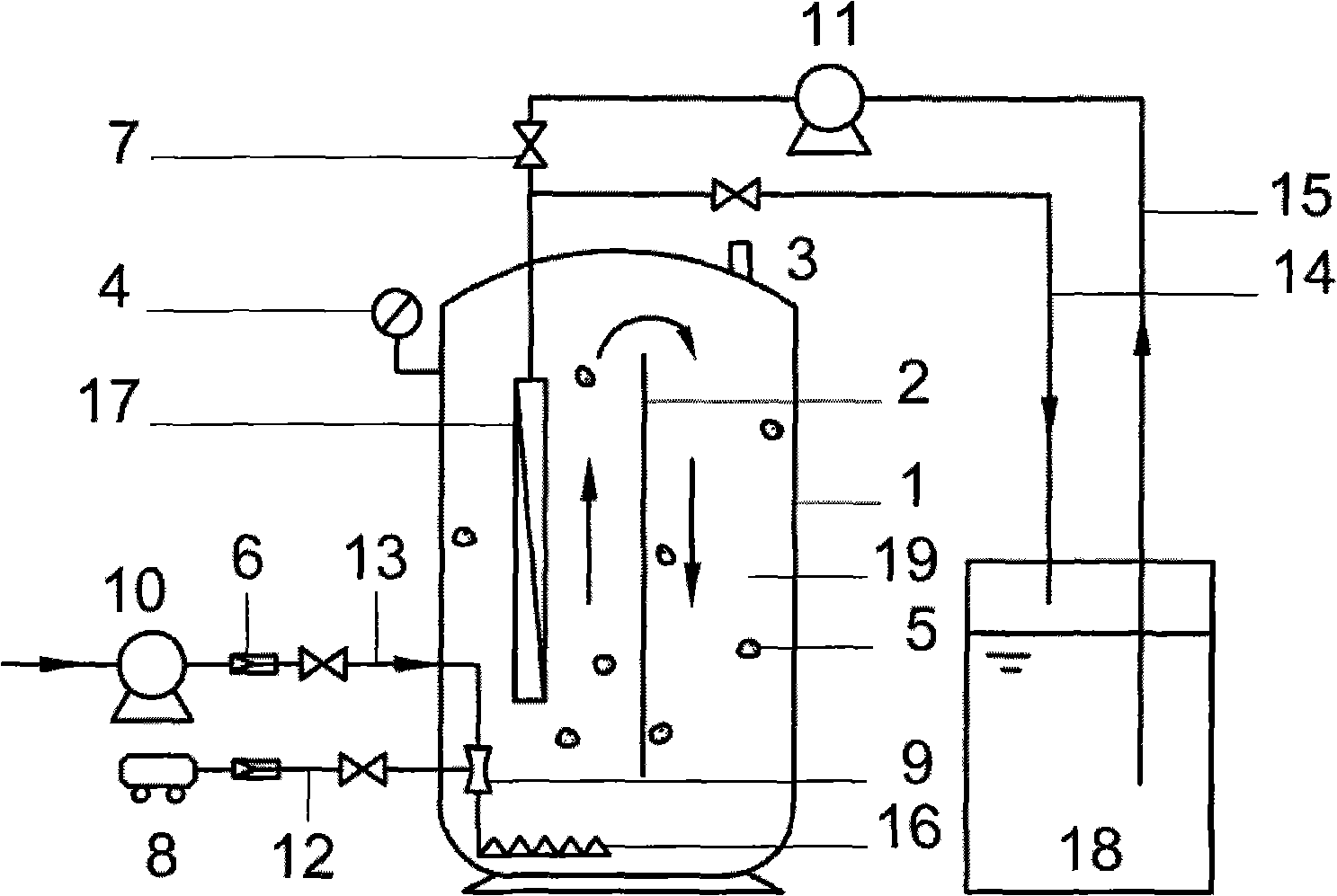

Integrated bubbleless aeration membrane bioreactor

InactiveCN102531153AMeet oxygen demandImprove oxygen transfer efficiencyTreatment using aerobic processesSustainable biological treatmentHollow fibreOxygen utilization rate

The invention discloses an integrated bubbleless aeration membrane bioreactor. A hollow-fiber curtain type membrane (7) is vertically placed in a biochemical reactor (6), the upper and the lower ends of the hollow-fiber curtain type membrane (7) are respectively fixed in the sidewalls of one-way PVC (polyvinyl chloride) tubes by resin, the PVC tube on the lower end of the hollow-fiber curtain type membrane (7) is connected with an intake tube, the PVC tube on the upper end of the hollow-fiber curtain type membrane (7) is connected with an exhaust tube, the intake tube is connected with an air compressor (3) through an air rotameter (5), and the exhaust tube leads into the air via a gas fine-regulating valve (16). Because the integrated bubbleless aeration membrane bioreactor adopts the hollow-fiber curtain type membrane structure, the oxygen utilization rate approximates 100 percent, the air is inputted from the air compressor via the lower end of the hollow-fiber curtain type membrane, and flows in the hollow-fiber membrane tube cavities, the oxygen in the tube cavities is pushed by the difference between the oxygen partial pressures of both sides of the membrane to directly disperse into the external biomembrane via the membrane wall or micropores on the membrane wall, consequently, the oxygen transfer efficiency is greatly increased, the requirement of the microbiological oxidative degradation of organic pollutants on oxygen consumption is met, and moreover, the gas fine-regulating valve after the exhaust tube can be utilized to effectively and stably control the pressure and flow velocity of gas, so that the aeration quantity can be conveniently and accurately controlled.

Owner:DALIAN UNIV

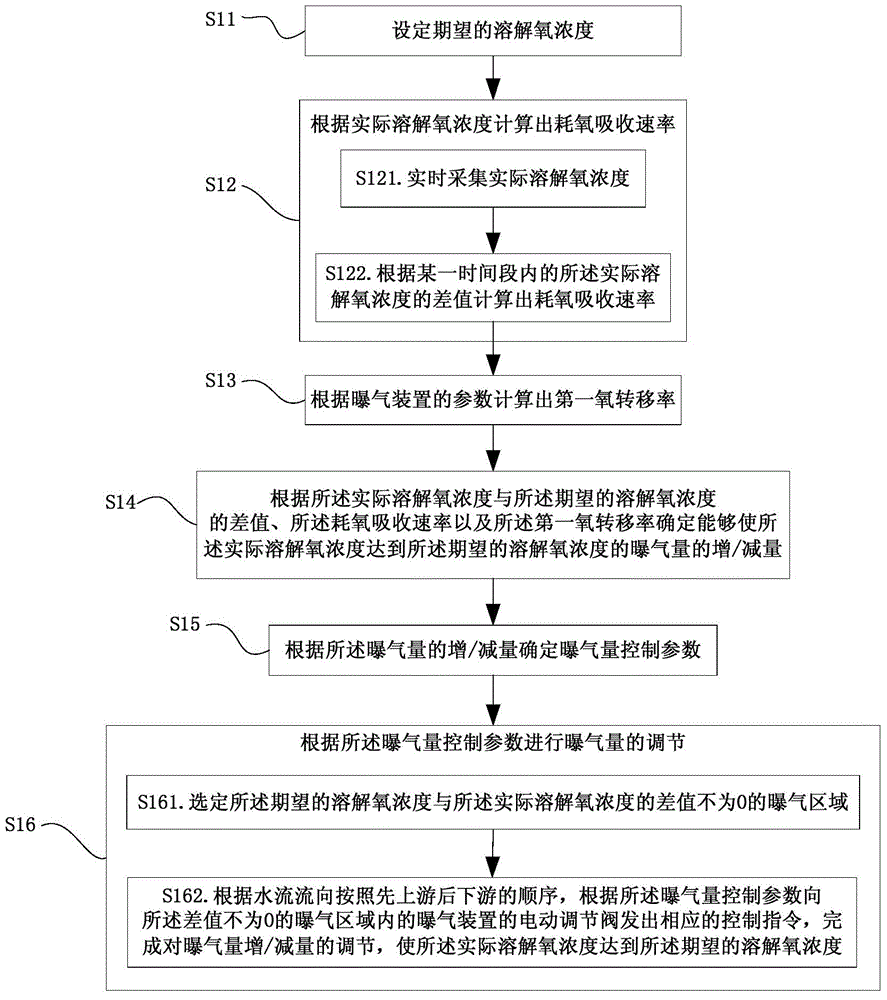

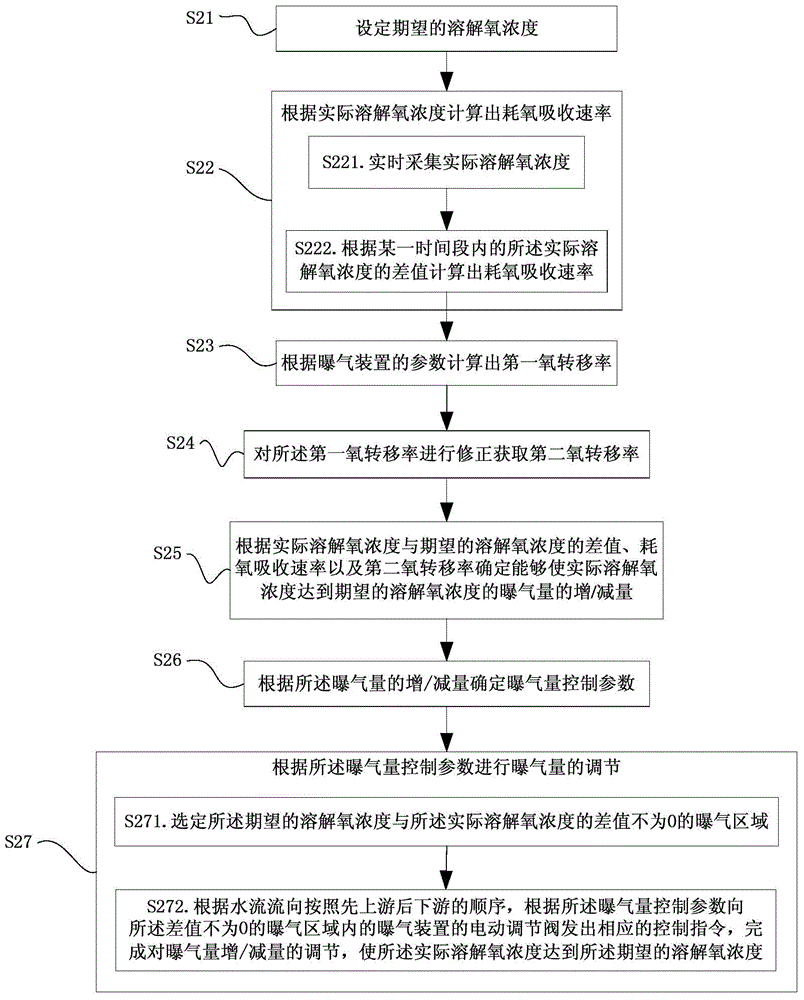

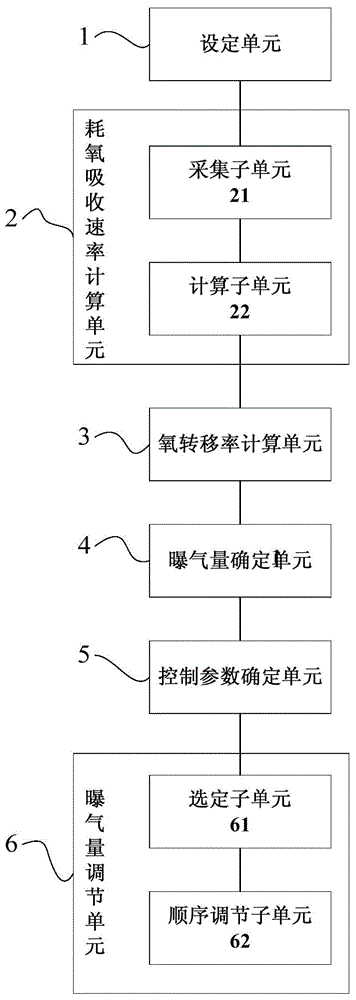

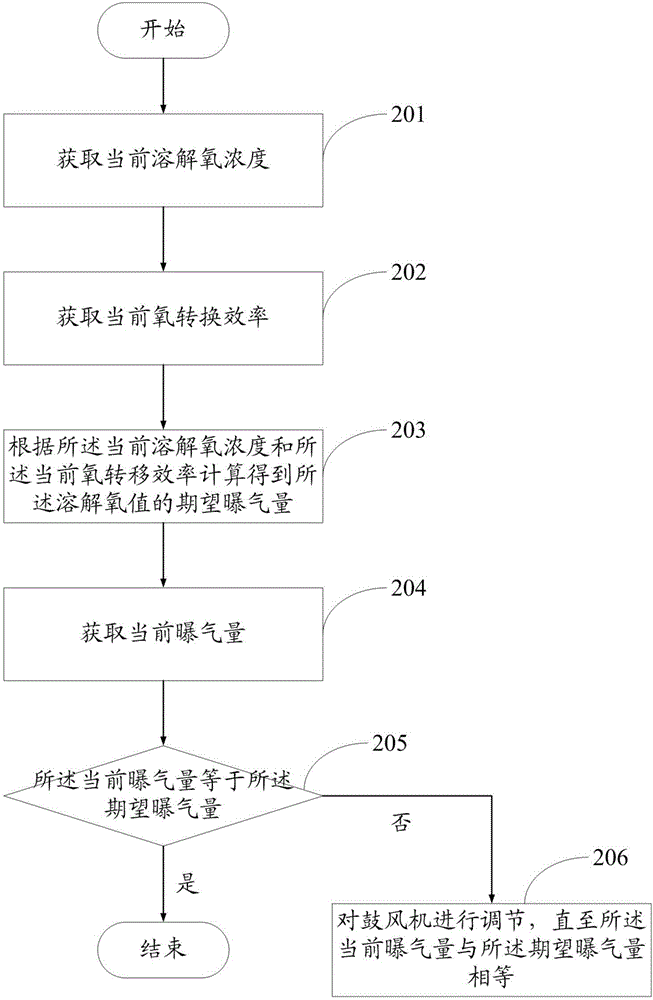

Aeration rate control method and system

ActiveCN104787872AAccurate adjustmentThe treatment effect is stable and effectiveTreatment using aerobic processesFlow control using electric meansAeration rateSewage treatment

The invention provides an aeration rate control method and system. The method comprises the following steps: setting an expected dissolved oxygen concentration, calculating first oxygen transfer ratio on the basis of parameters of the aeration device according to the difference between the actual dissolved oxygen concentration and expected dissolved oxygen concentration, determining the aeration rate increment / decrement capable of enabling the actual dissolved oxygen concentration to reach the expected dissolved oxygen concentration according to the difference between the expected dissolved oxygen concentration and actual dissolved oxygen concentration, the oxygen consumption absorption rate and the first oxygen transfer ratio, determining the aeration rate control parameters according to the aeration rate increment / decrement, and adjusting the aeration rate according to the aeration rate control parameters. Therefore, according to the aeration rate control method and system, the difference between the expected dissolved oxygen concentration and actual dissolved oxygen concentration, the oxygen consumption absorption rate and the first oxygen transfer ratio are utilized to determine the aeration rate increment / decrement capable of enabling the actual dissolved oxygen concentration to reach the expected dissolved oxygen concentration, thereby implementing the real-time accurate adjustment on the aeration rate. Thus, the sewage treatment effect is more stable and effective.

Owner:梁锐振

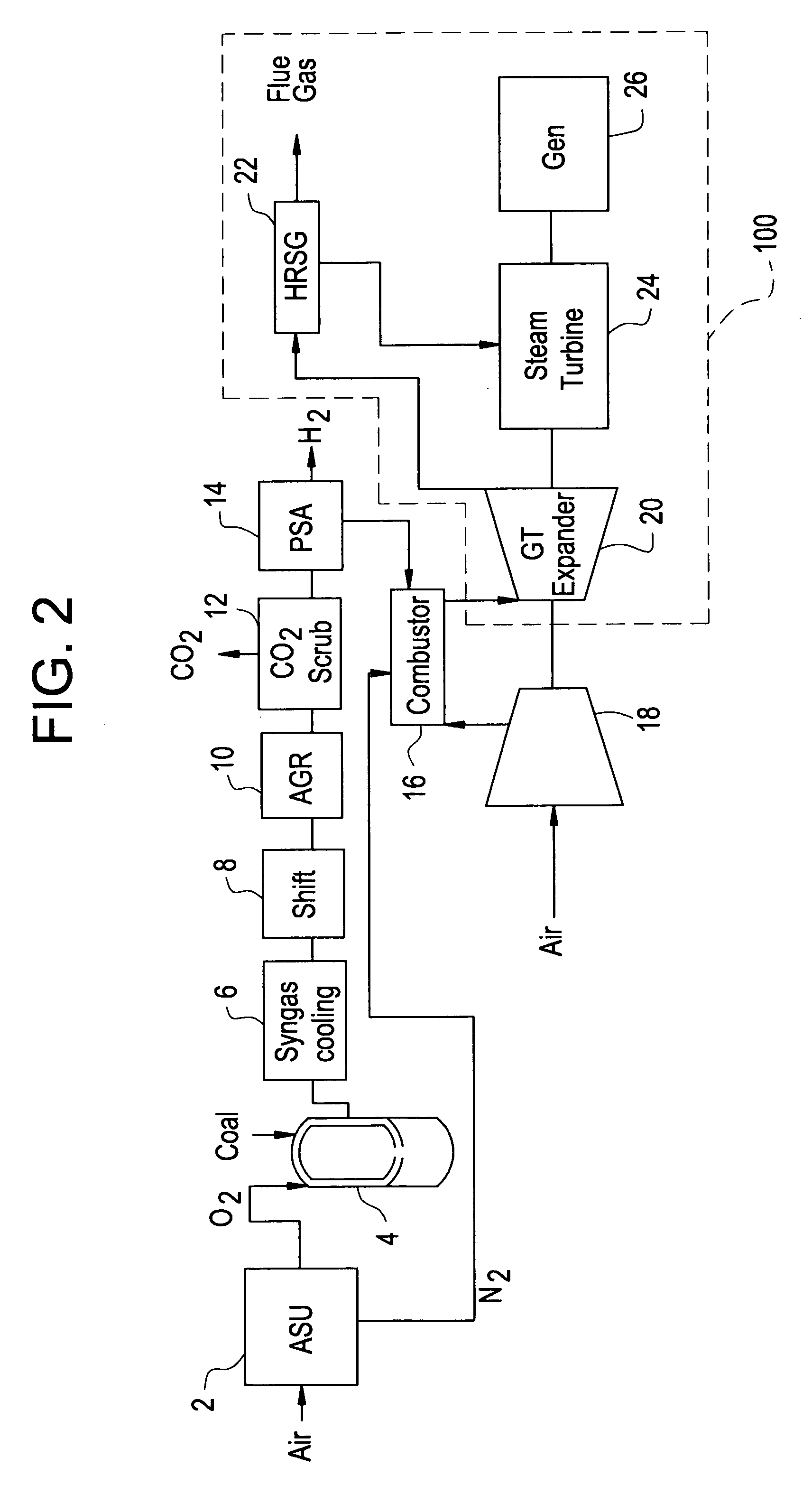

Systems and Methods Using an Unmixed Fuel Processor

InactiveUS20080134666A1Process environmental protectionFluidized bed combustionHydrogen/synthetic gas productionElectricitySorbent

Disclosed herein are systems and method for using unmixed fuel processors. In one embodiment, a system for using an unmixed fuel processor comprises: an unmixed fuel processor and a power generating unit. The unmixed fuel processor comprises: a gasification reactor, an oxidation reactor and a regeneration reactor. The gasification reactor comprises a CO2 sorbent material. The oxidation reactor comprises an oxygen transfer material. The regeneration reactor is configured to receive spent CO2 sorbent material from the gasification reactor and to return regenerated CO2 sorbent material to the gasification reactor, and configured to receive oxidized oxygen transfer material from the oxidation reactor and to return reduced oxygen transfer material to the oxidation reactor. The power generating unit configured to receive an oxygen depleted stream from the oxidation reactor and to produce electricity.

Owner:GENERAL ELECTRIC CO

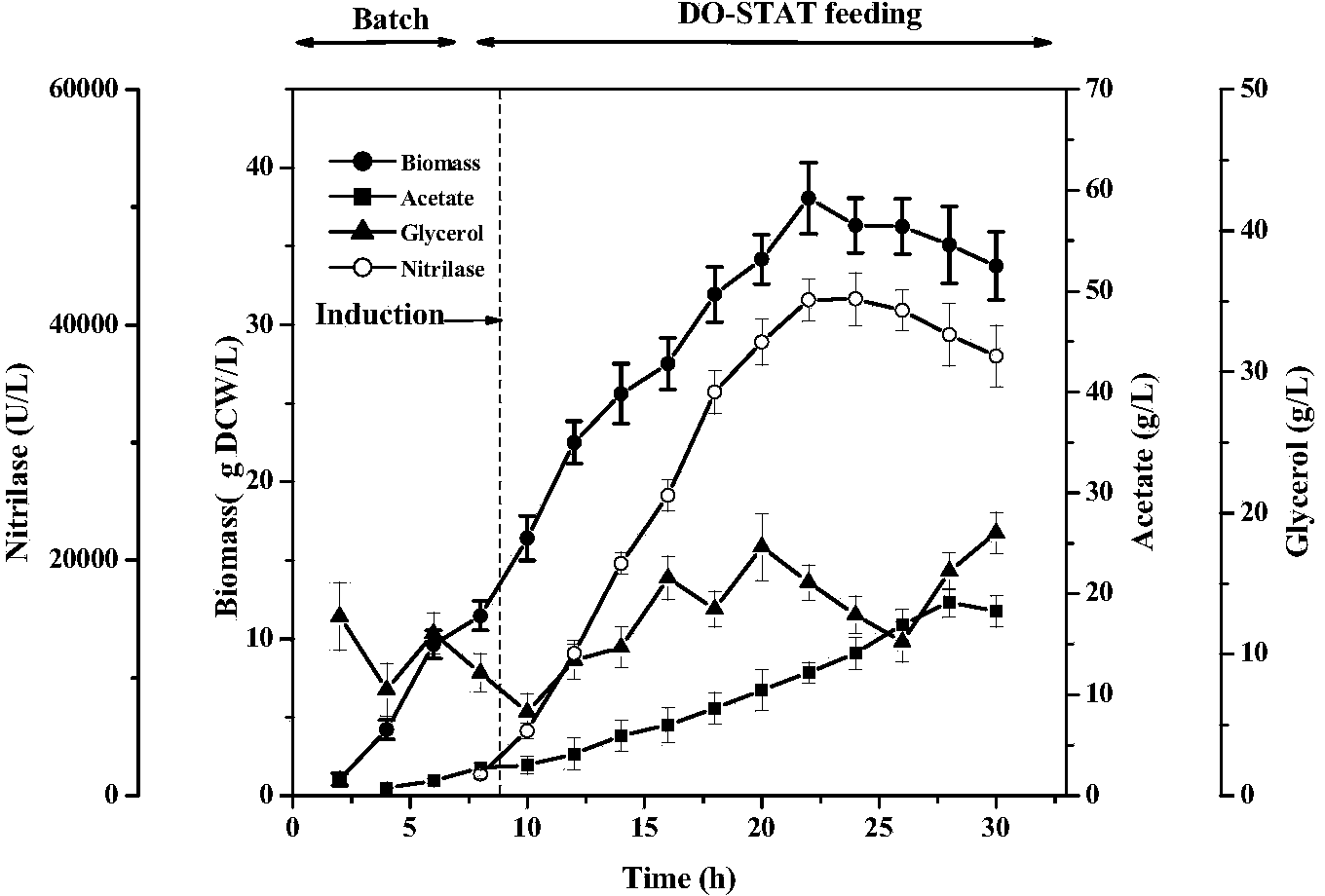

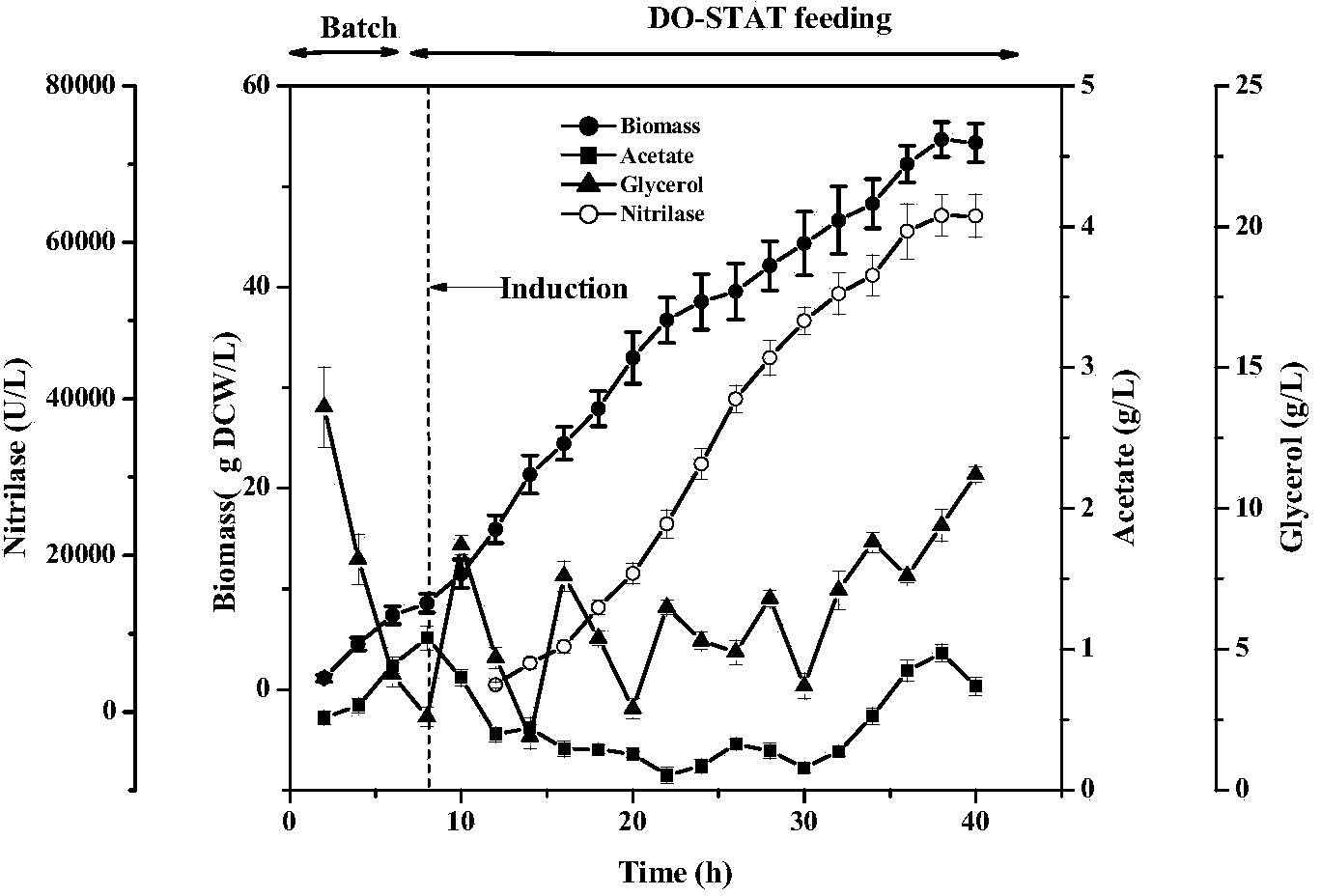

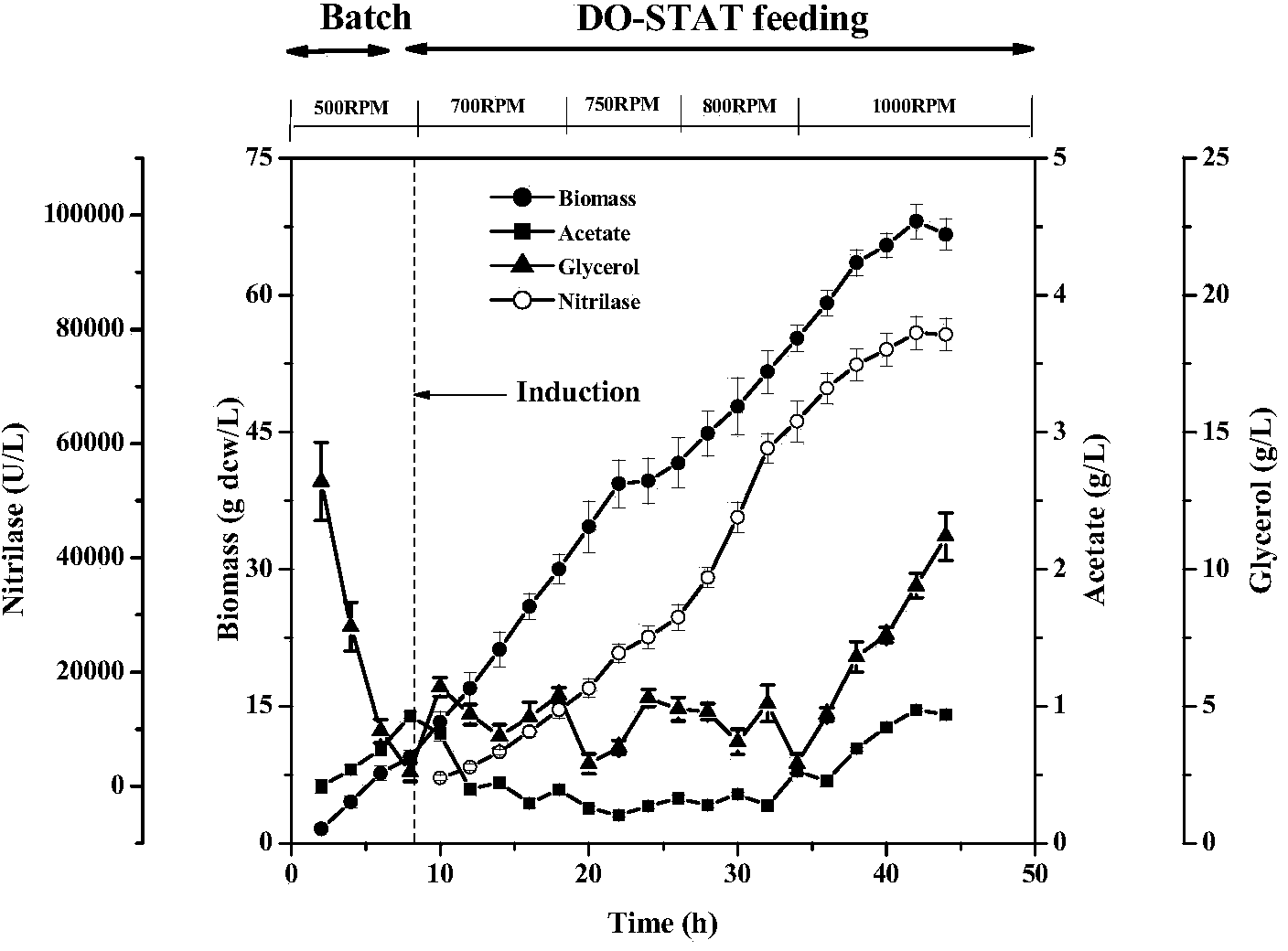

High-density fermentation method of engineering bacteria containing nitrilase

InactiveCN104212785APrevention of waste and other disadvantagesControl growth rateHydrolasesMicroorganism based processesEscherichia coliHigh concentration

The invention discloses a high-density fermentation method of engineering bacteria containing nitrilase. The method adopts a novel recombinant Escherichia coli fermentation and supplementary material culture medium formula, and uses a method of DO-STAT coupling step-by-step induction and gradual increase of the speed stage by stage. The method not only meets the need for mixing power in the culture process with biomass increase, effectively controls the growth rate of thalli, and prevents disadvantages of produced acid accumulation caused by fast growth of thalli, feedback inhibition and culture medium waste. In addition, the induced mode of batch-by-batch lactose supplement addition avoids the high viscosity of the fermentation broth caused by high concentration of lactose, resulting in resistance of oxygen transfer and mass transfer, but also improves the induction strength. The high-density fermentation technology of the invention increase the biomass of recombinant Escherichia coli from 10.35g DCW / L to 70g DCW / L, volume enzyme activity from 18205U / L to 103530U / L, and the fermentation level by 4.7 times.

Owner:ZHEJIANG UNIV OF TECH

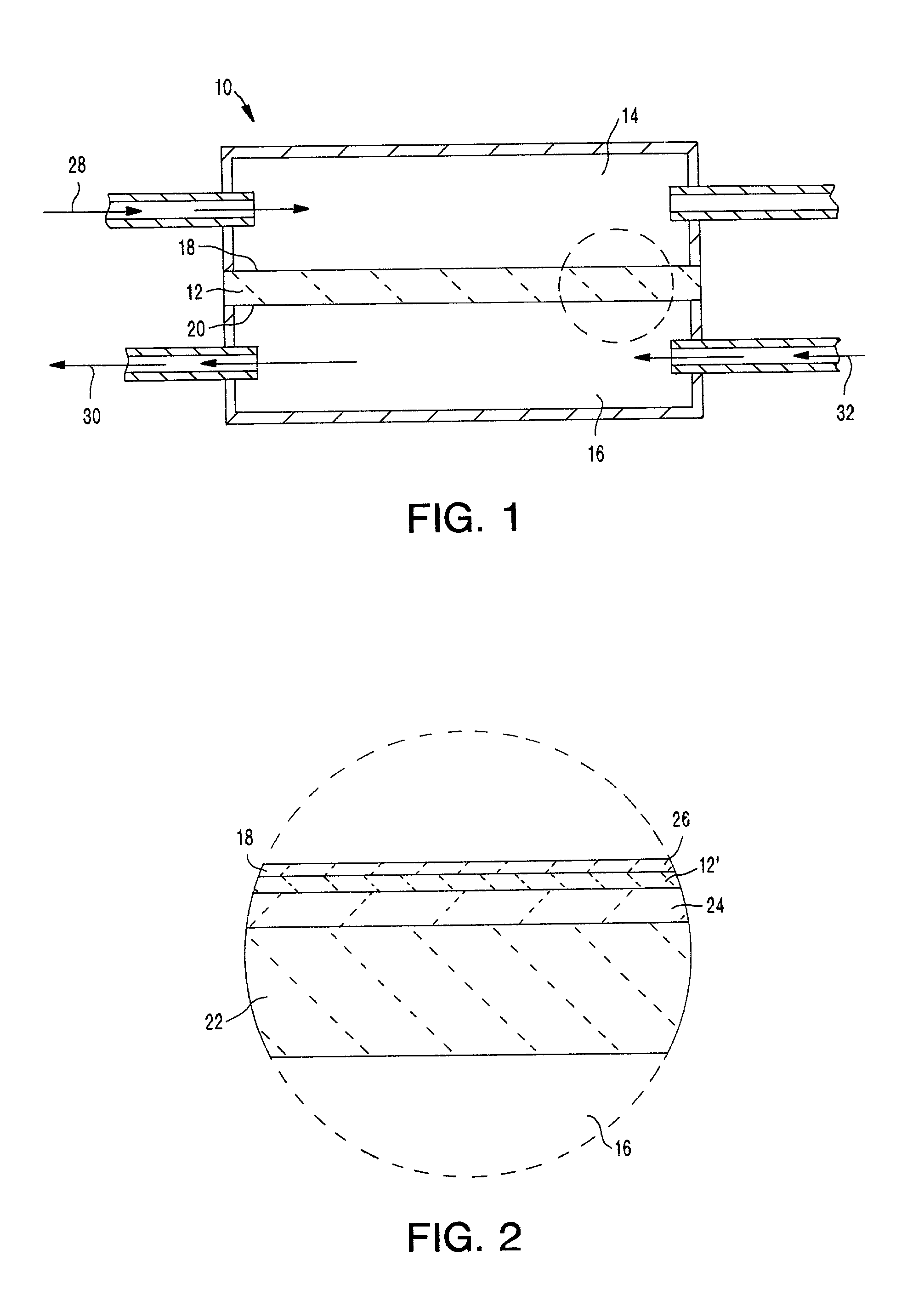

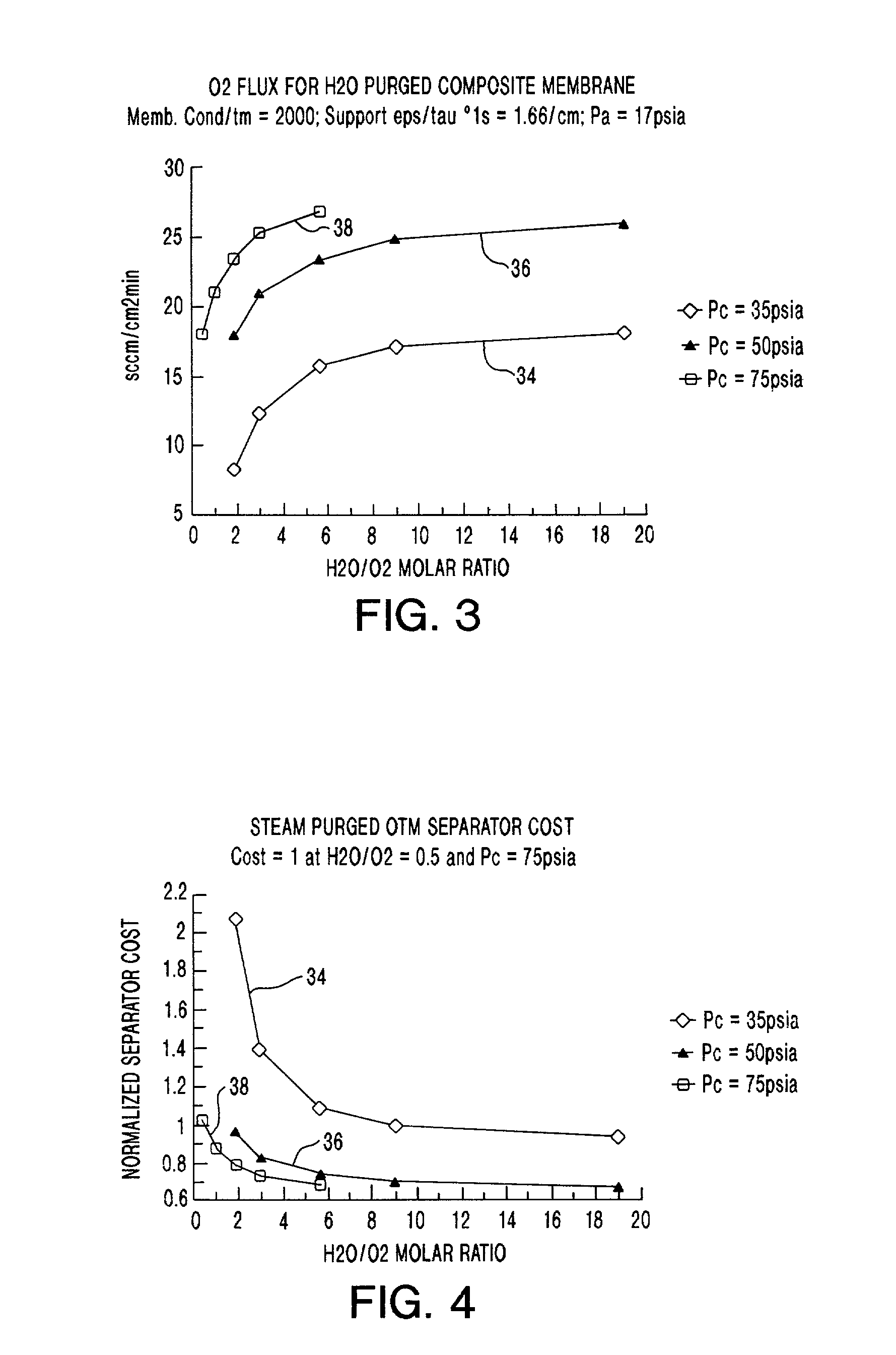

Low pressure steam purged chemical reactor including an oxygen transport membrane

InactiveUS20020127177A1Efficient transportHydrogenHydrocarbon from carbon oxidesSteam reformingPartial oxidation

Owner:PRAXAIR TECH INC

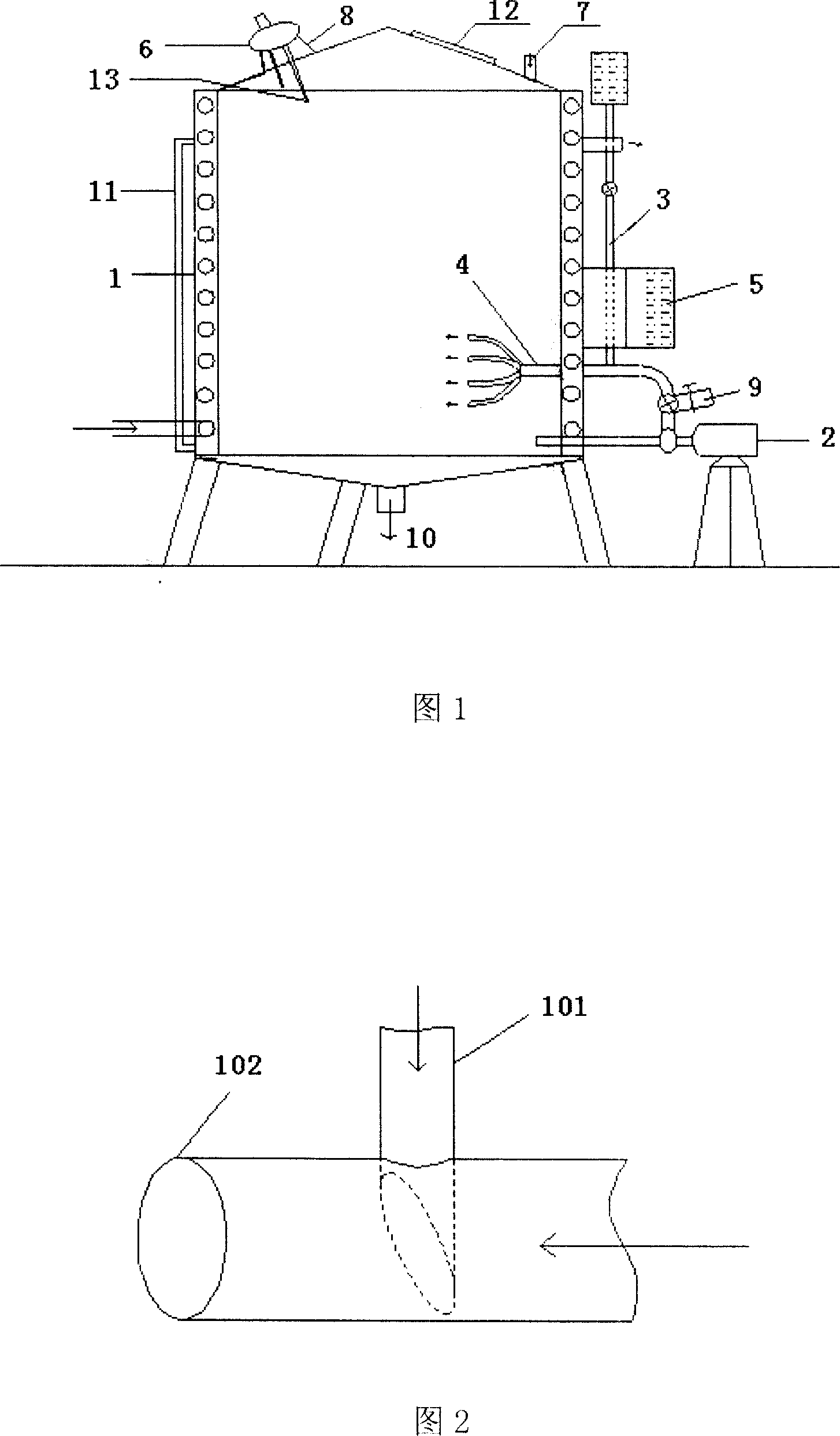

Fruit vinegar fermenting tank

InactiveCN101020887ASimple structureIncrease dissolved oxygenVinegar preparationAcetic acidTemperature control

The fruit vinegar fermenting tank includes a sandwiched tank body with a blow down port in the bottom, a material inlet port, an air exhaust port and an observation window; a coiler and a temperature controlling probe inside the tank; a centrifugal pump; a spraying system connected to the centrifugal pump; an air intake system comprising an air intake pipe, an air filter and an air flow rate regulator; and a discharge / sampling port. The fruit vinegar fermenting tank has the centrifugal pump for circulating the liquid and well combined air intake system and spraying system to complete air-liquid mixing and oxygen transfer. It has simple structure, easy sterilizing, great oxygen dissolving amount, high acetic acid producing efficiency, low cost and other features, and may be used for liquid acetic acid fermentation and other aerobic fermentation engineering.

Owner:NORTHWEST A & F UNIV +1

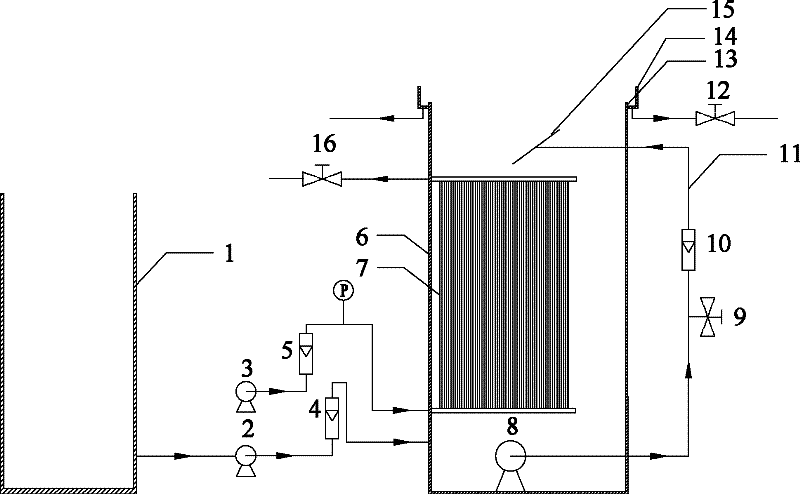

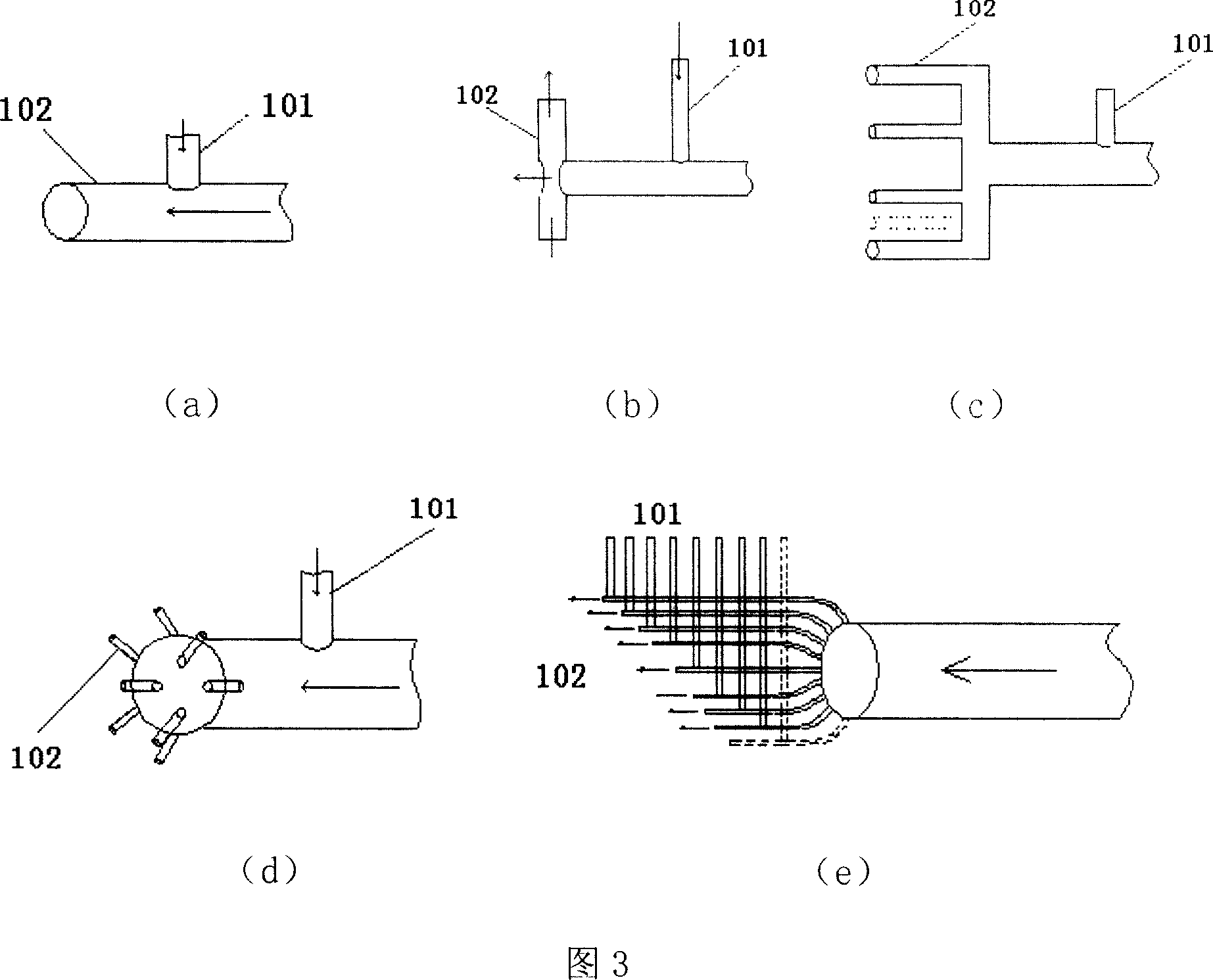

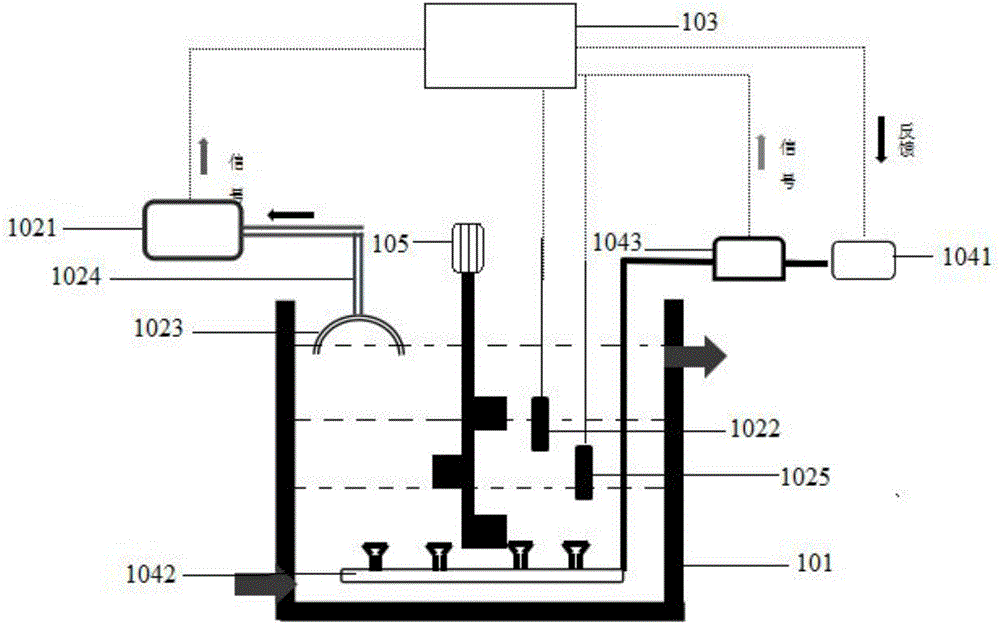

Aeration control system and aeration control method

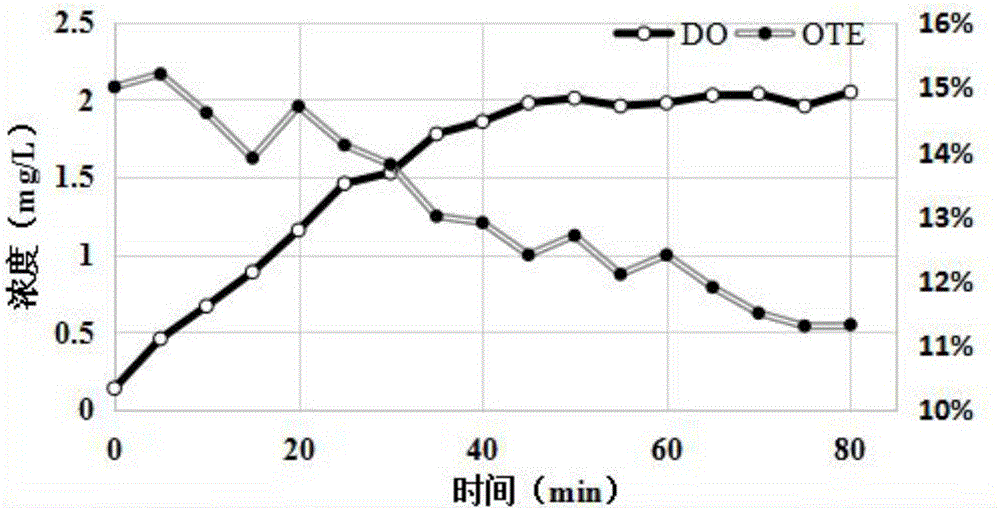

ActiveCN106430662AReal-time online precise aerationWater treatment parameter controlWater aerationAeration rateControl system

The invention discloses an aeration control system and an aeration control method. The aeration control system comprises an aeration tank, a data acquisition unit, a control unit and an aeration unit. The data acquisition unit comprises an oxygen transfer efficiency measuring instrument and a dissolved oxygen measuring instrument; the oxygen transfer efficiency measuring instrument comprises a gas collecting cover and a tail gas delivering tube; real-time oxygen transfer efficiency values can be transmitted to the control unit by the oxygen transfer efficiency measuring instrument via a signal wire; one end of the tail gas delivering tube is connected with the top of the gas collecting cover, and the other end of the tail gas delivering tube is connected with the oxygen transfer efficiency measuring instrument; the dissolved oxygen measuring instrument is connected with the control unit; the oxygen transfer efficiency measured by the oxygen transfer efficiency measuring instrument and the dissolved oxygen concentration measured by the dissolved oxygen measuring instrument can be transmitted to the control unit; a blower can be adjusted by the control unit according to the transmitted oxygen transfer efficiency and the transmitted dissolved oxygen concentration. The aeration control system and the aeration control method have the advantage that the internal aeration rate of the aeration tank can be precisely controlled by the aid of the aeration control system and the aeration control method.

Owner:尚川(北京)水务有限公司

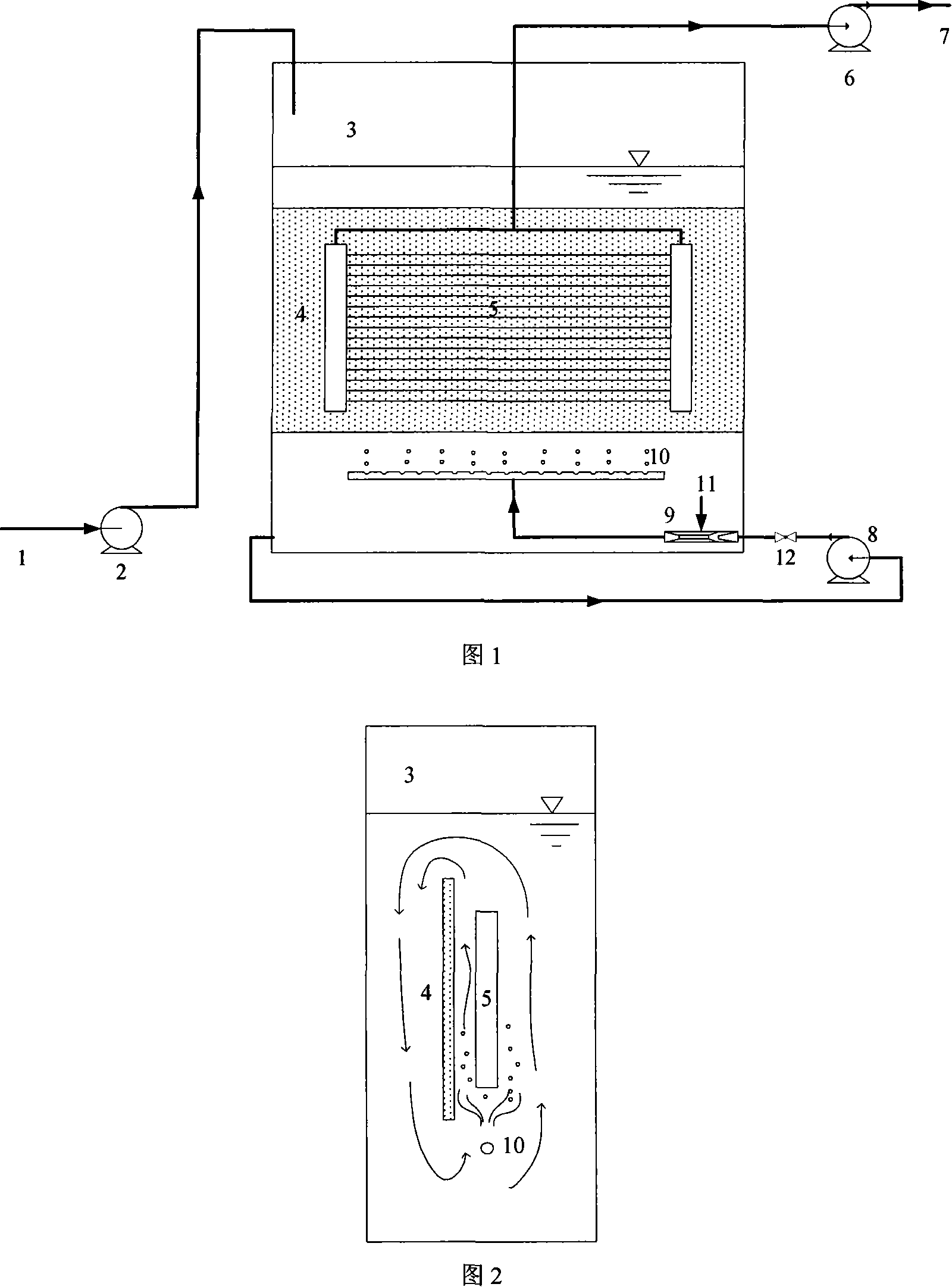

Shooting flow film-bioreactor method and device

ActiveCN101139135APromote circulationCirculating water pump for easy maintenanceTreatment using aerobic processesSustainable biological treatmentMixed flowWater flow

The present invention provides an operation method and device of jet membrane-bioreactor, namely that part of mud mixed liquor enters into a pipeline after pressured through a water pump to form high speed water flow by passing through a nozzle of a jet device to entrain surrounding air. Part of air is dissolved in the mixed liquor through the actions of mixing and cutting to form air-liquor spraying jet to oxygenize on the mud mixed liquor and scour on the membrane components through a diffusion air arrangement plate; simultaneously the air-liquor mixed flow drives the mud mixed liquor in a reactor to form inner recycle in the reactor which is helpful to mass and oxygen transfer, accelerate biochemical reaction and improve treatment efficiency. The device can realize membrane pollution control and improve oxygen utilization ratio simultaneously and has the advantages of low energy consumption, small noise, space saving, simple device structure and stable operation. The present invention is convenient for unmanned operation and control.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

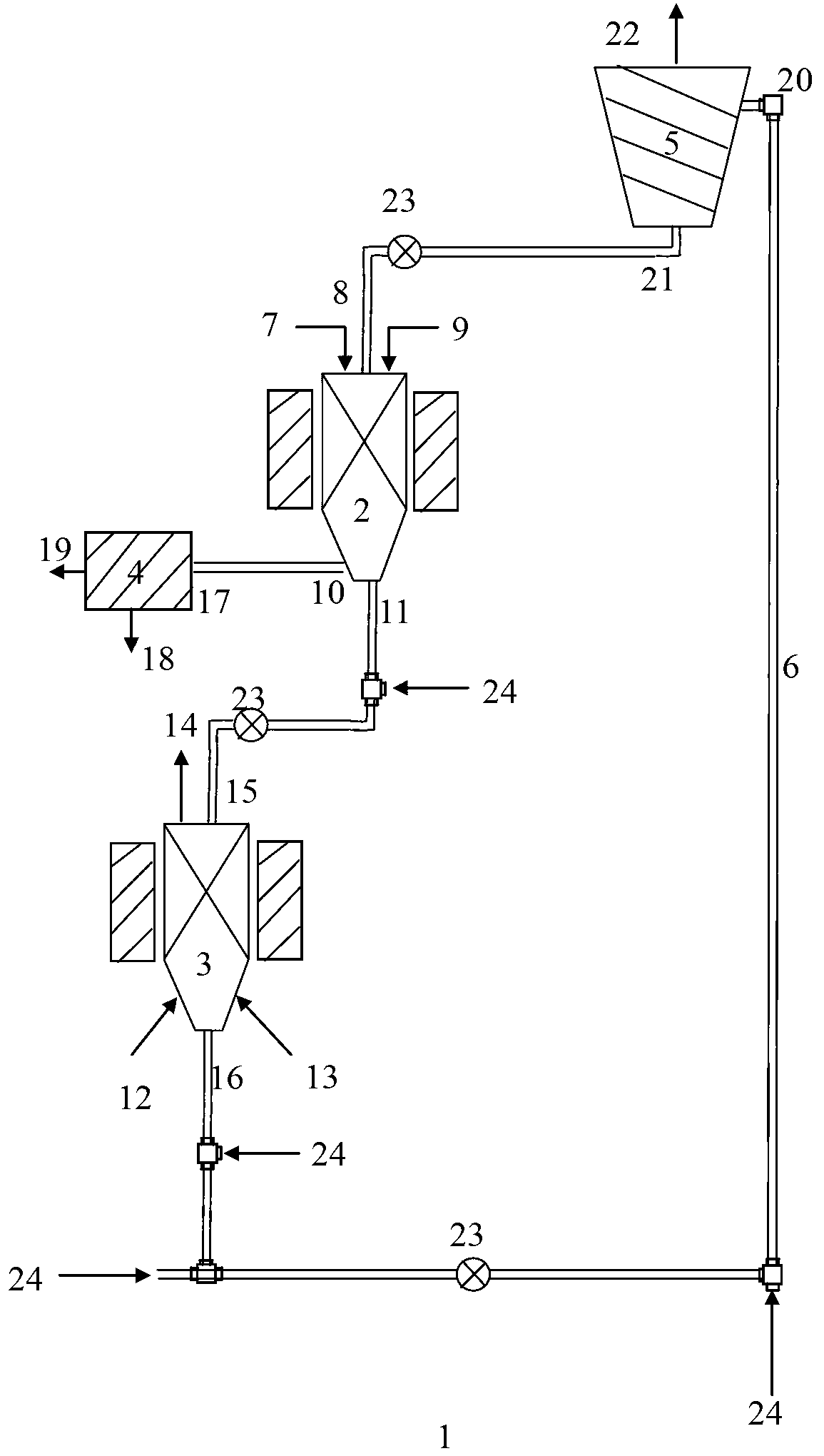

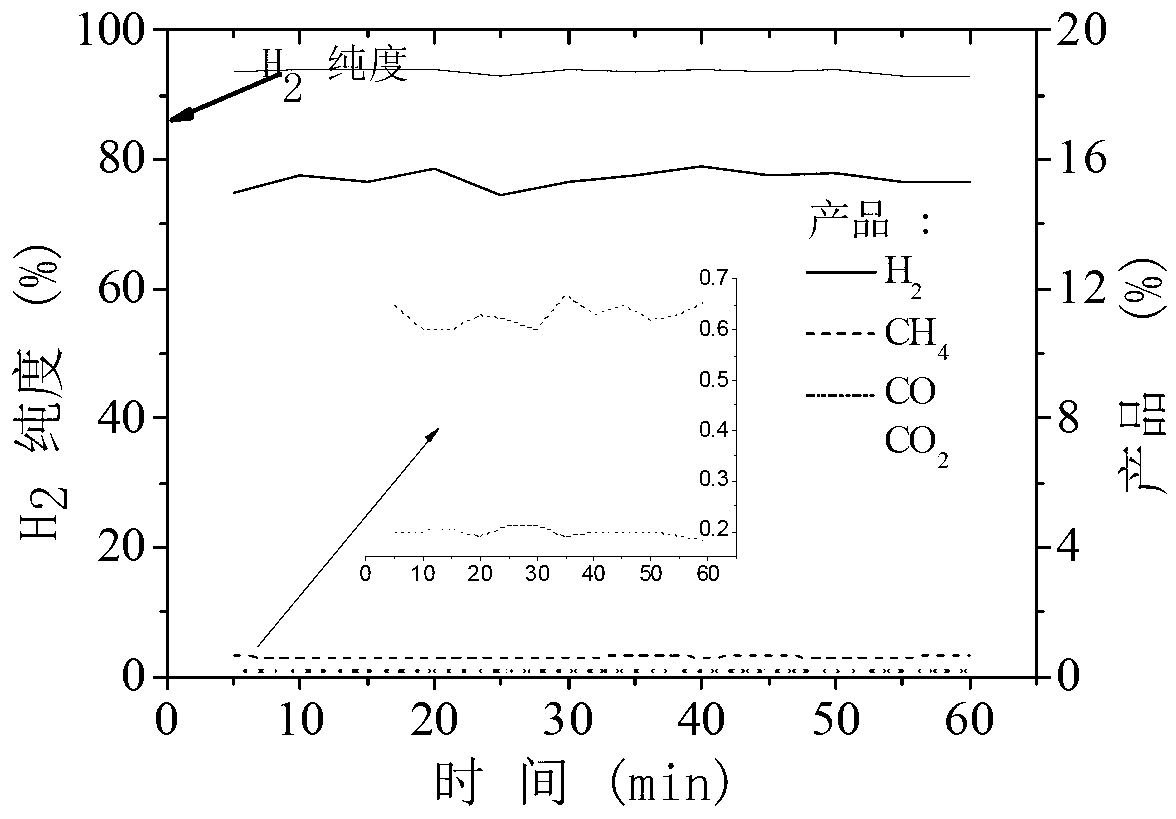

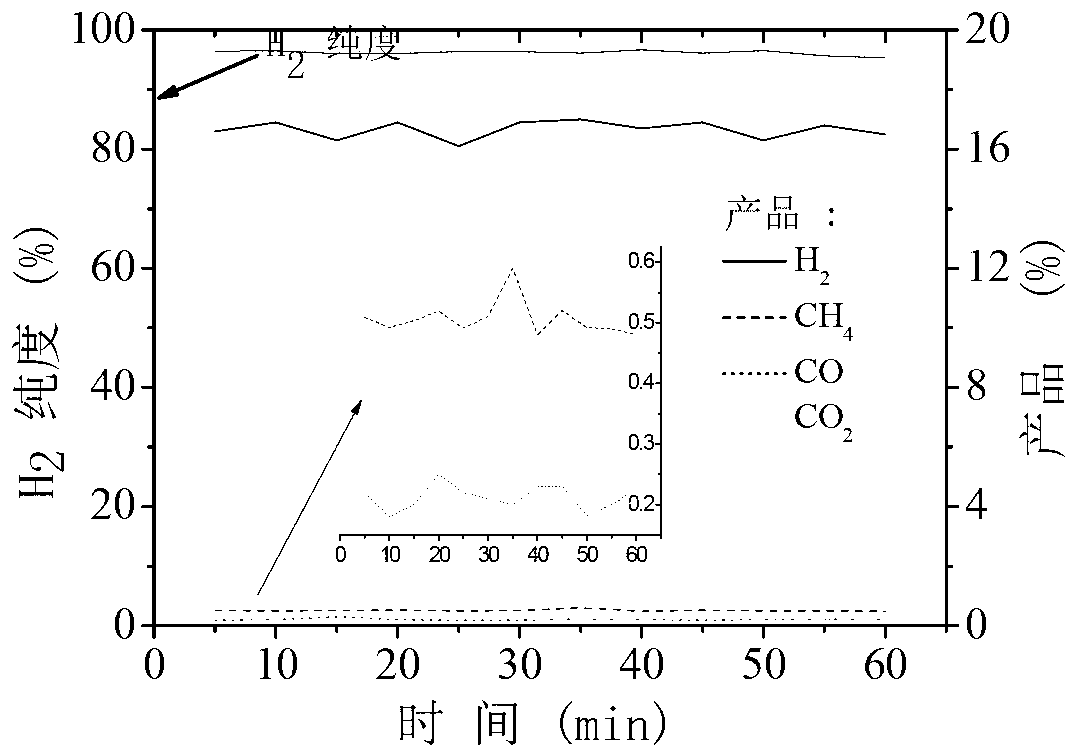

Process for preparing hydrogen by strengthening chemical chain reforming in continuous catalytic adsorption manner via moving bed

InactiveCN103288048AEfficient conversion and utilizationCondensation is convenientHydrogenChemical recyclingBiodieselPartial oxidation

The invention discloses a process method for preparing hydrogen by strengthening chemical chain reforming in a continuous catalytic adsorption manner via a moving bed. The process method is characterized by adopting a reformer, a regenerator, a condenser, a cyclone separator and a lifting pipe, wherein glycerinum which is a biodiesel byproduct serves as a raw material for preparing the hydrogen. According to the method, the oxygen transfer performance of the oxidation reduction of an NiO / AI2O3 catalyst is utilized fully, so that in-situ adsorption intensification of CO2 for hydrogen preparation is carried out by taking CaO as an adsorbent; the water vapor serves as a carrier gas of the reformer, so that the water vapor and the hydrogen of a product are separated conveniently; and the catalyst reduced in the reformer and an adsorbent mixture adsorbing the CO2 are simultaneously oxidated and regenerated in the regenerator. According to the process method, the partial oxidation, the water vapor reforming, the water-vapor transformation and the CO2 adsorption are carried out in the regenerator in a highly coupling manner; and the continuous movement, reaction and regeneration of the catalyst and the adsorbent are carried out by using the moving bed, so that an approximately fresh state is maintained always. Therefore, the hydrogen with high purity is continuously and stably produced at the low temperature under the normal pressure. As a result, the hydrogen preparing process is simplified; the hydrogen preparing cost is saved greatly; and the CO2 is continuously desorbed by the regenerator, which is favorable for CO2 reclamation.

Owner:DALIAN UNIV OF TECH

Pressure type membrane bioreactor technique of suspension bed and device

ActiveCN101525205AOvercoming the effects of stressPromote circulationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationInternal pressure

The invention discloses a pressure type membrane bioreactor technique of a suspension bed and a device, which relate to an equipment technique for treating organic wastewater with high concentration and difficult degradation. The invention is characterized in that the device comprises a pressure type membrane bioreactor, jet pressurized aeration equipment and a clean water tank. The pressure type membrane bioreactor is internally provided with particular suspended carriers which are in homogeneous fluidization in mixed liquor so as to enhance mass transfer of pollutants to a biomembrane; the suspended carriers have diverse microbial morphology and provide environment for growth of particular floras; the jet pressurized aeration equipment overcomes the influence of negative pressure of a jet device on the internal pressure of the bioreactor, improves oxygen transfer efficiency and accelerates degradation rate of microorganisms to organics; the membrane filtration is adopted for water yielding and a water pump is saved due to the difference of internal pressure and external pressure, thus saving cost and energy consumption and realizing good separation of solid and liquid. The bioreactor has compact structure, small occupied area, high efficiency and low energy consumption, has strong adaptability to load change of influent organics and toxic matters, is easy to operate and manage and is particularly applicable to treating organic wastewater with medium and high concentration and difficult degradation.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

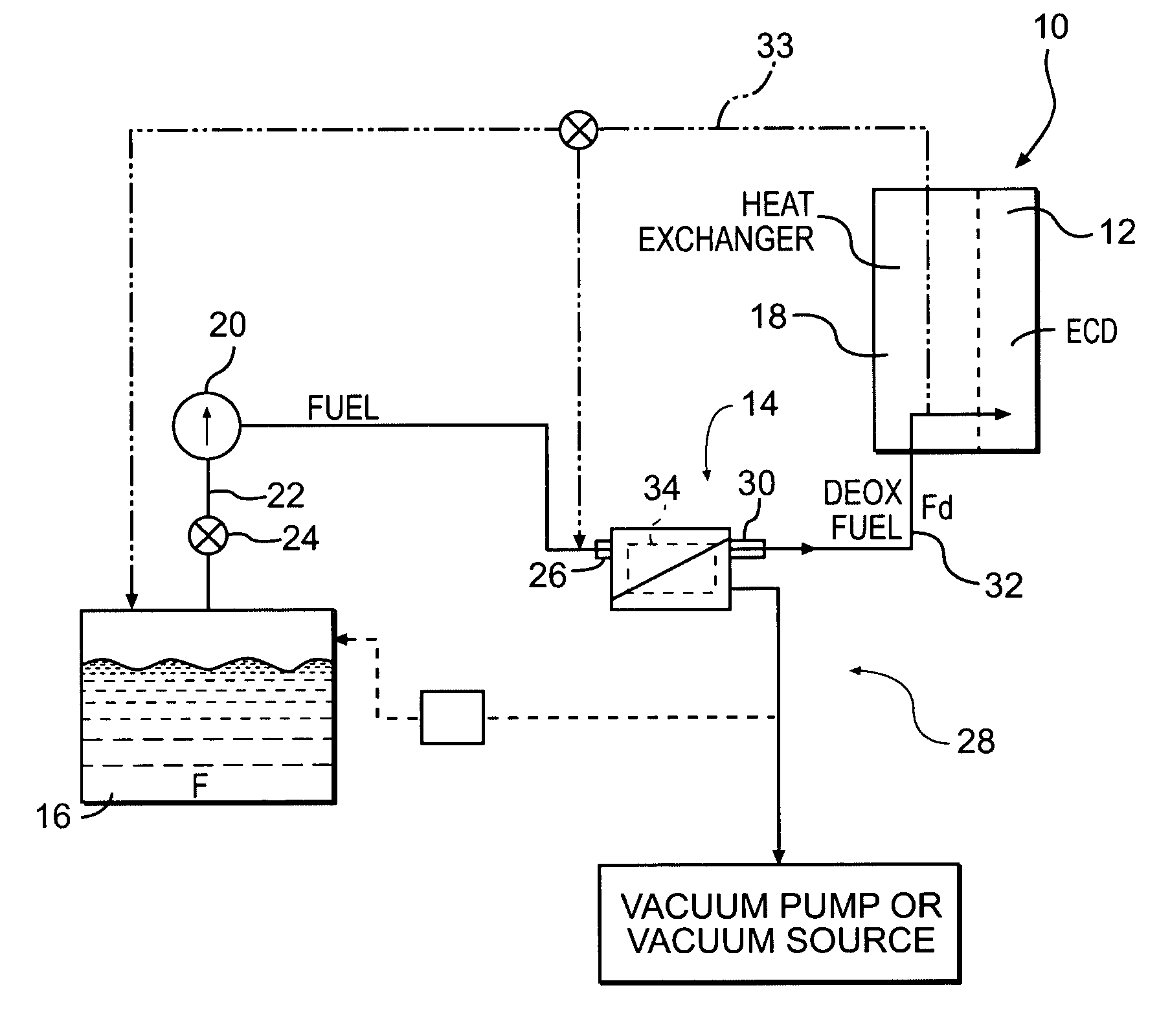

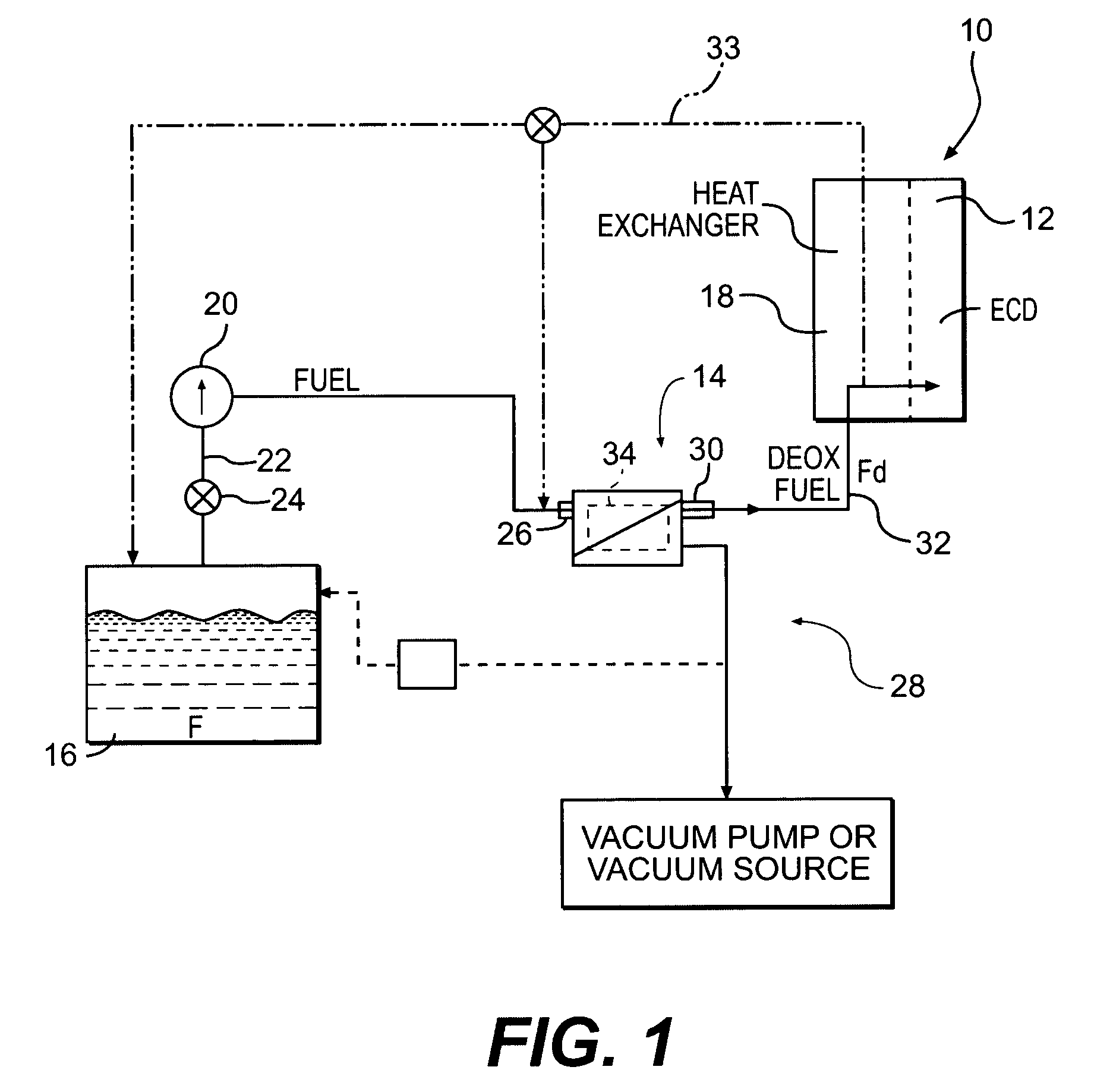

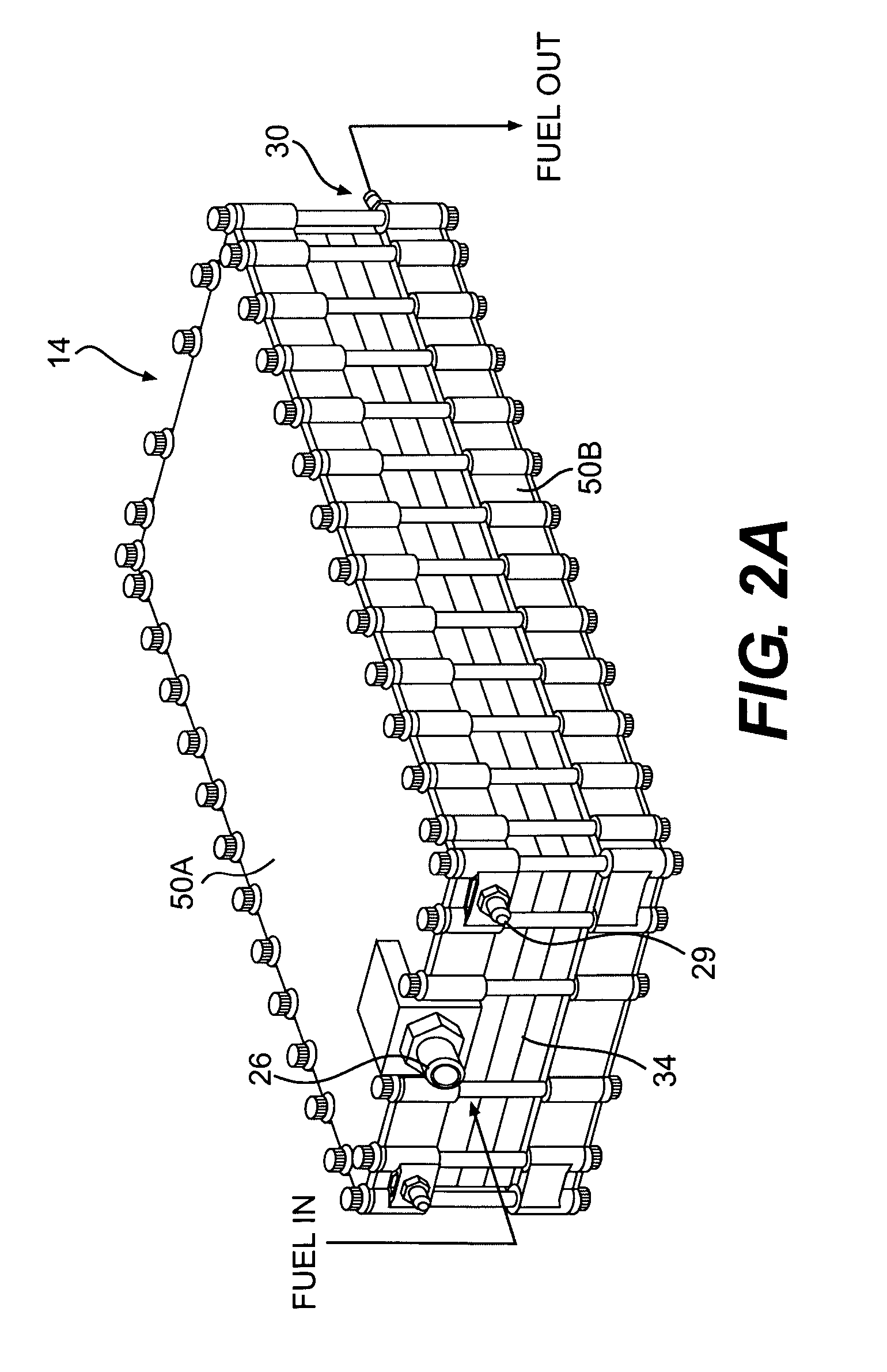

Fuel deoxygenation system with multi-layer oxygen permeable membrane

ActiveUS7615104B2Maximizes oxygen transfer rateLeakage rate is minimizedSemi-permeable membranesFuel tank safety measuresSealantDeoxygenation

A fuel system for an energy conversion device includes a deoxygenator system with an oxygen permeable membrane formed from a multiple of layers. The layers include a sealant layer, an oxygen permeability layer and a porous backing layer. The layered composite oxygen permeable membrane maximizes the oxygen transfer rate and minimizes the fuel leakage rate.

Owner:RTX CORP +1

Advanced functional biocompatible polymeric matrix used as a hemostatic agent and system for damaged tissues and cells

A hemostatic tissue sealant sponge and a spray for acute wounds are disclosed. The sponge comprises hydrophobically modified polymers that anchor themselves within the membrane of cells in the vicinity of the wound. The seal is strong enough to substantially prevent the loss of blood inside the boundaries of the sponge, yet weak enough to substantially prevent damage to newly formed tissue upon recovery and subsequent removal of the sponge. In examples, the polymers inherently prevent microbial infections and are suitable for oxygen transfer required during normal wound metabolism. The spray comprises hydrophobically modified polymers that form solid gel networks with blood cells to create a physical clotting mechanism to prevent loss of blood. In an example, the spray further comprises at least one reagent that increases the mechanical integrity of the clot. In another example, the reagent prevents microbial infection of the wound.

Owner:UNIV OF MARYLAND BALTIMORE +1

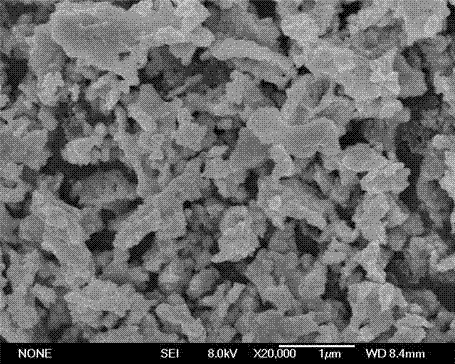

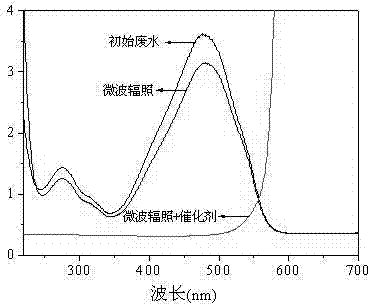

Method for catalytic degradation of high-concentrated organic wastewater by micro-wave cooperating with perovskite

InactiveCN102923811AAchieve degradationImprove oxygen storage capacityWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsAbsorbanceWave power

The invention provides a method for catalytic degradation of high-concentrated organic wastewater by micro-wave cooperating with perovskite. Cerium-doped La1-xCexBO3 perovskite prepared by the citric acid complexation method is adopted as a catalyst, wherein B is Fe, Co or Ni, and doping content of Ce is x which is from 0.1 to 0.9. The perovskite catalyst is added into organic wastewater, and additive amount of the perovskite is from 2.0g / L to 8.0g / L. Irradiation time is from 2 minutes to 10 minutes under the condition that a micro-wave power is from 200 to 700 watts. Rate of removal of the organic wastewater is calculated according to an absorbance. Aeration can be kept or air is continuously inflated in a catalytic degradation reaction and by means of oxygen transfer of the perovskite catalyst, a continuous reaction can be achieved. Various reactive oxygen species are generated in situ on the catalyst surface by using self oxygen storage performance and oxygen transfer performance of perovskite oxide instead of adding oxidants such as H2O2, and then degradation of organics can be achieved under the micro-wave cooperation effect.

Owner:QINGDAO UNIV OF SCI & TECH

Floating diffused air aerator

InactiveUS7520493B1Conserve energy inputImprove performanceCarburetting airWater cleaningLiquid wasteAtmospheric air

An aerator for mechanically inducing near laminar flow and controlled turbulence in a liquid waste treatment lagoon or pond. A blower, blower mount platform, diffuser modules, aeration manifold, aeration chamber, an adjustable, telescoping aeration chamber extension, baffles, and buoyancy apparatuses attach to a frame. The diffusers are located beneath the surface of the body of liquid at a predetermined, fixed depth. The blower supplies air to the diffusers and liquid-bubble mixture is released into an aeration chamber where artificial aeration is maximized. The mixture then rises through the aeration chamber. Bubble dissipation and flow conditioning baffles force bubbles to coalesce and vertically dissipate into the atmosphere. The liquid flows over the top of the baffles and a flow manipulation rim to radiate outward and parallel to the pond surface with minimum turbulence at an optimum flow discharge rate. The aerator provides optimized oxygen transfer at low energy costs.

Owner:HALDANE WILLIAM J

Oxygen conservation system for commercial aircraft

ActiveUS20080000480A1Reduce the amount requiredOvercomes shortcomings inherentBreathing masksEmergency oxygen systemsInhalationEngineering

An emergency oxygen supply system for use on aircraft in the event of a loss in cabin pressure is configured for delivering allotments of oxygen and timing the delivery such allotments to each passenger so as maximize the efficiency of the transfer of such oxygen into the passenger's bloodstream. The delivery of each allotment is selected so that the entire allotment is available for inhalation into the region of the lung most efficient at oxygen transfer while the volume of the allotment is selected to substantially coincide with the volume of such region of the lung.

Owner:BE INTPROP

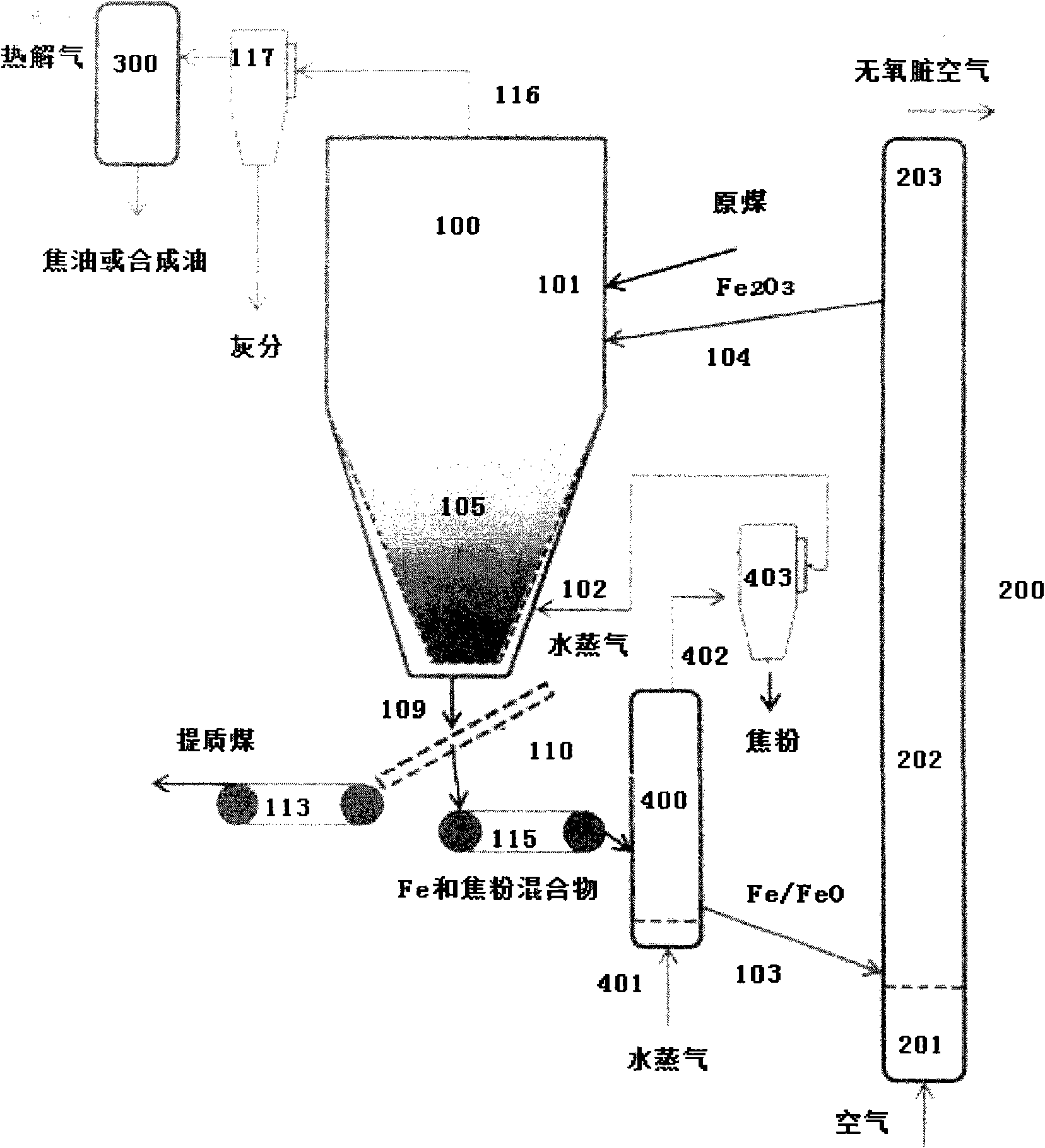

Coal or biomass medium low temperature pyrolysis quality improving system and method for producing quality improved coal, high calorific value pyrolysis gas and tar or liquefied synthetic oil by utilizing same

The invention relates to a coal or biomass medium low temperature pyrolysis quality improving system and a method for producing quality improved coal, high calorific value pyrolysis gas and tar or liquefied synthetic oil by utilizing the system. By utilizing the system and the method, effective capture of carbon dioxide can be realized. The system comprises a medium low temperature pyrolyzing furnace in a moving bed type preferably, at least one catalysis-heat carrier-oxygen transfer material regenerator communicated with the medium low temperature pyrolyzing furnace, a solid-solid separator and a condenser. In the medium low temperature pyrolyzing furnace, raw coal is subject to medium low temperature pyrolysis, and the quality improved coal, the high calorific value pyrolysis gas and the tar or liquefied synthetic oil gas are produced, wherein the tar or liquefied synthetic oil gas is condensed into jar or liquefied synthetic oil; and in the catalysis-heat carrier-oxygen transfer material regenerator, a saturated waste catalysis-heat carrier-oxygen transfer material is regenerated by oxidation and enters into the medium low temperature pyrolyzing furnace again, thus realizing regenerating cycle of catalysis-heat carrier-oxygen transfer materials.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Microfabricated artificial lung assist device, and methods of use and manufacture thereof

ActiveUS8647410B2Facilitates gas exchangeRisk minimizationSemi-permeable membranesAdditive manufacturing apparatusOxygenatorsIntensive care medicine

The invention provides systems and methods for exchanging gas in an oxygenator device, and methods for preparing and using such oxygenator devices. The systems and methods can be used to transfer oxygen to blood to assist lung function in a patient.

Owner:CHARLES STARK DRAPER LABORATORY

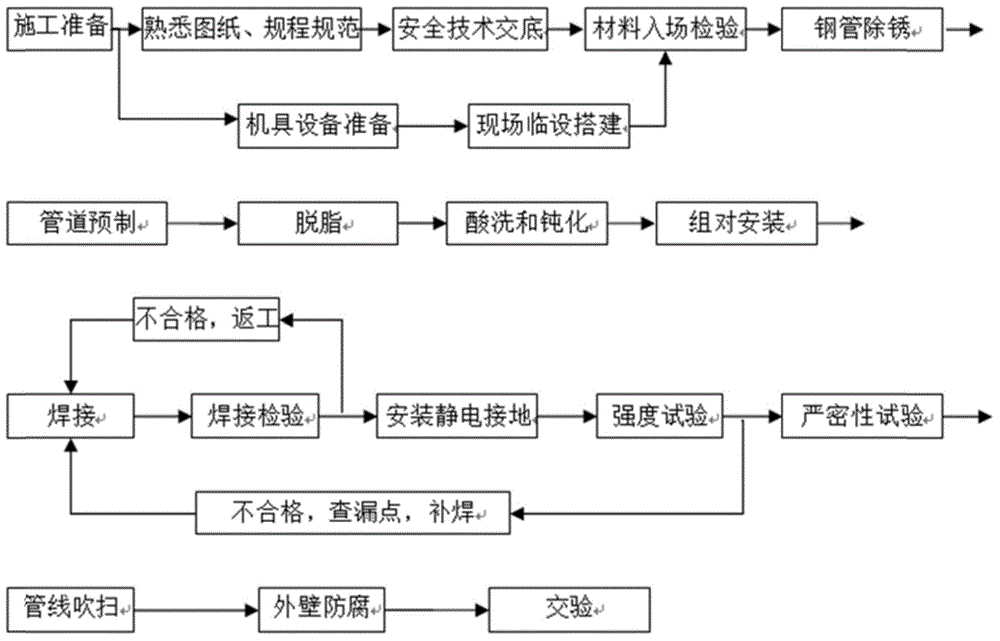

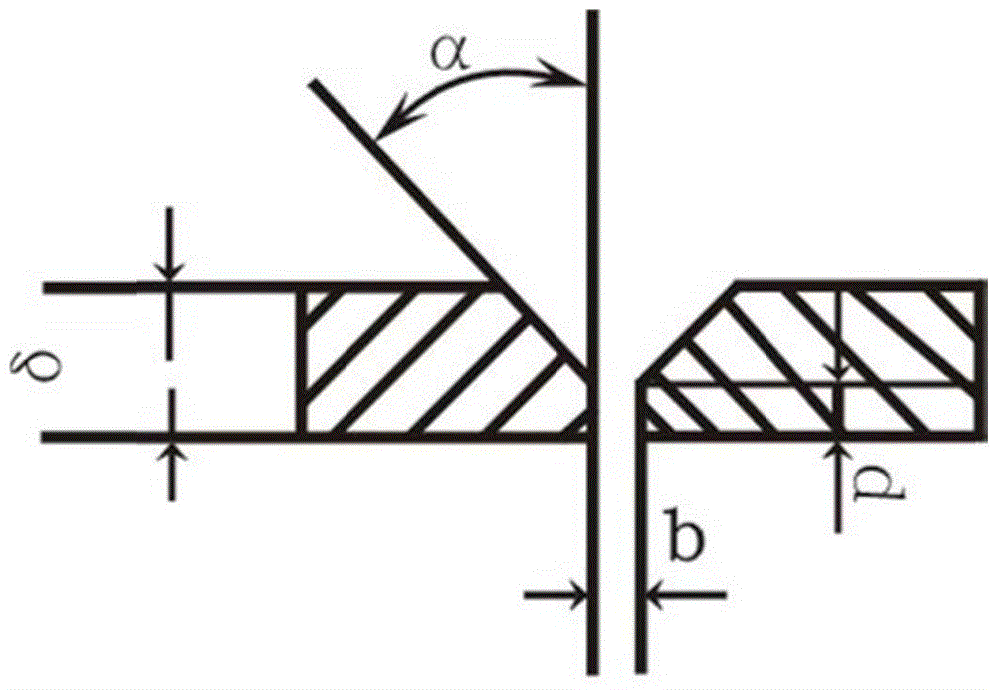

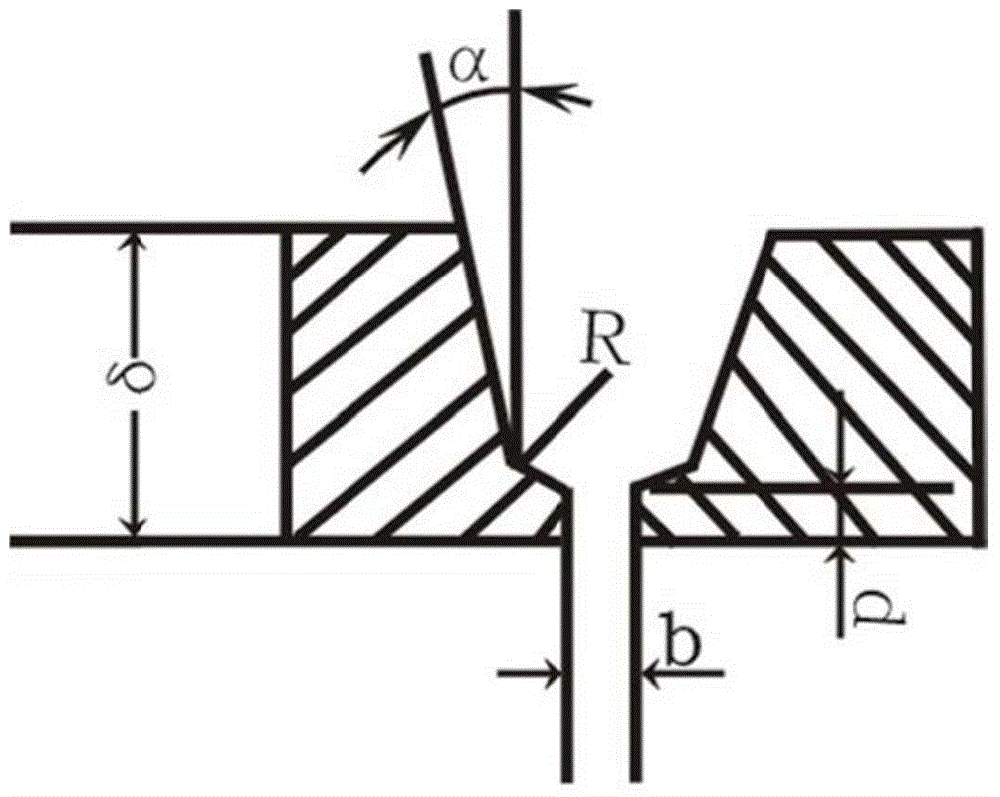

Installation method of outdoor carbon steel oxygen transferring pipeline

InactiveCN104907673AReduce labor intensityGuarantee processing qualityMetal working apparatusTubular articlesEngineeringUltimate tensile strength

The invention provides an installation method of an outdoor carbon steel oxygen transferring pipeline. The installation method comprises a pipeline prefabrication step, a cleaning step and a pair installation step. The pipeline prefabrication step comprises following steps: adopting a mechanical cutting method to discharge pipe material in order to obtain multiple pipe segments, polishing and flattening two ends of multiple pipe segments, and bevelling two ends of the multiple pipe segments by adoption of a bevelling machine. The cleaning step comprises steps of carrying out degreasing, acid pickling, neutralizing and passivating treatment to the pipeline in order. The pair installation step comprises the step of adopting a pairing device to pair pipe sections with pipe sections on a pairing platform. An internal-opening pairing device is adopted by pipe sections with external diameters above 426 mm. An external-opening pairing device is adopted by pipe sections with external diameters below 426 mm. After pairing operation is finished on an assembly platform, tack welding is performed. Then, combined pipe segments are obtained by welding counter-opening seams. The combined pipe segments are hoisted at an installation position as required. Pairing welding is carried out among the combined pipe segments and installed fixing pipe segments. The installation method of the outdoor carbon steel oxygen transferring pipeline is low in labor intensity and high in production efficiency.

Owner:湖北省建工工业设备安装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com