Aeration rate control method and system

A control method and aeration rate technology, applied in the direction of using electric device flow control, sustainable biological treatment, aerobic process treatment, etc., can solve the problem of DO stability and control, and the accuracy cannot properly solve the influence of DO signal time lag , The effect of sewage treatment is difficult to meet expectations, etc., to achieve stable dissolved oxygen concentration, real-time precise adjustment, and stable and effective sewage treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

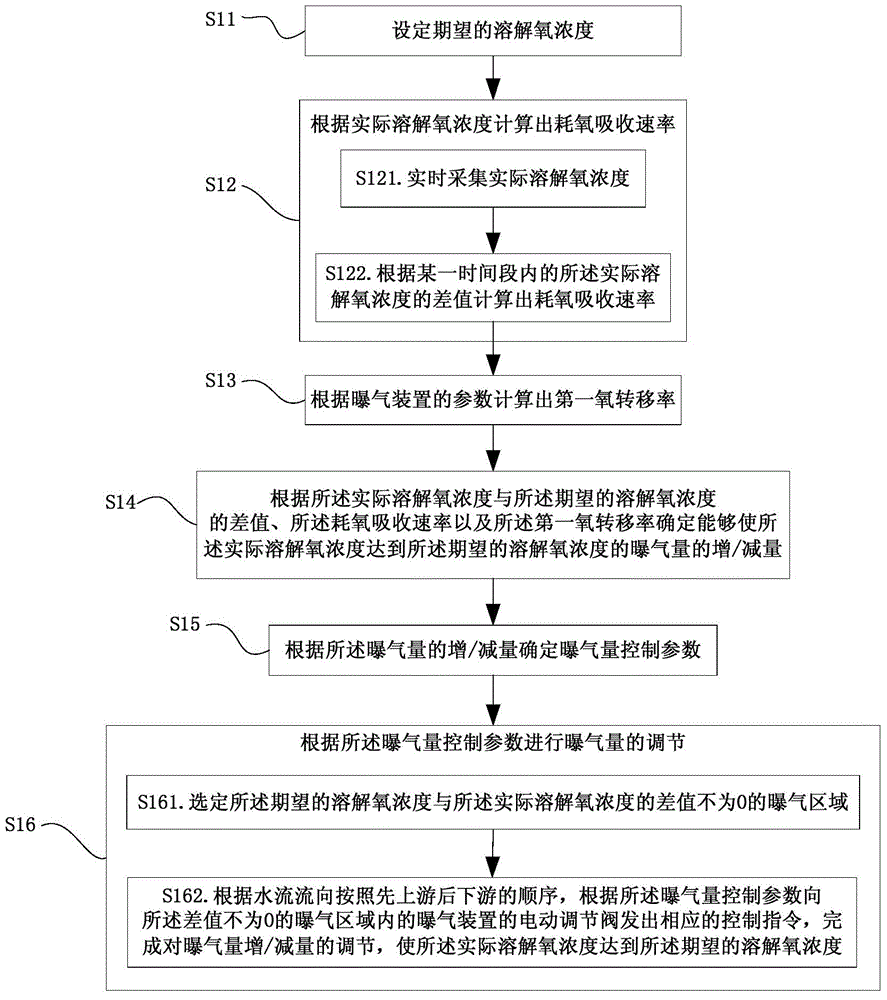

[0053] This embodiment provides a method for controlling the amount of aeration, such as figure 1 shown, including:

[0054] S11. Set the desired dissolved oxygen concentration.

[0055] S12. Calculate the oxygen consumption absorption rate according to the actual dissolved oxygen concentration.

[0056] S13. Calculate the first oxygen transfer rate according to the parameters of the aeration device.

[0057] S14. According to the difference between the actual dissolved oxygen concentration and the expected dissolved oxygen concentration, the oxygen consumption absorption rate and the first oxygen transfer rate, determine that the actual dissolved oxygen concentration can reach the expected dissolved oxygen concentration. The increase / decrease of the aeration rate of the oxygen concentration.

[0058] S15. Determine an aeration rate control parameter according to the increase / decrease of the aeration rate.

[0059] S16. Adjust the aeration amount according to the aeration ...

Embodiment 2

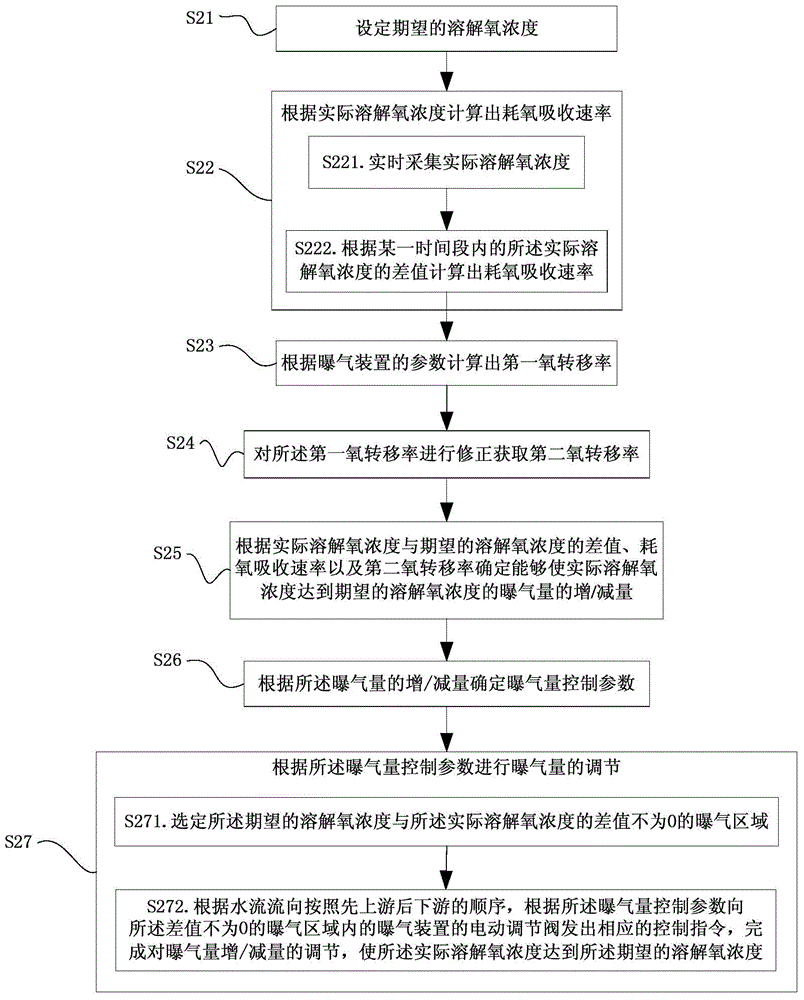

[0089] On the basis of Example 1, this example optimizes the aeration rate control method, such as figure 2 shown, including:

[0090] S21. Setting a desired dissolved oxygen concentration.

[0091] S22. Calculate the oxygen consumption absorption rate according to the actual dissolved oxygen concentration.

[0092] S23. Calculate the first oxygen transfer rate according to the parameters of the aeration device.

[0093] S24. Correcting the first oxygen transfer rate to obtain a second oxygen transfer rate.

[0094] S25. According to the difference between the actual dissolved oxygen concentration and the expected dissolved oxygen concentration, the oxygen consumption absorption rate and the second oxygen transfer rate, determine that the actual dissolved oxygen concentration can reach the expected dissolved oxygen concentration. The increase / decrease of the aeration rate of the oxygen concentration. Specifically, when the difference is positive and not within the preset ...

Embodiment 3

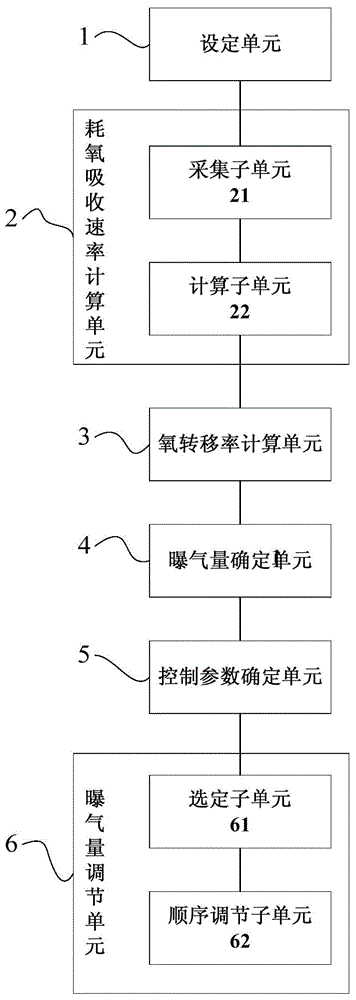

[0105] This embodiment provides an aeration volume control system, such as image 3 shown, including:

[0106] The setting unit 1 is used to set the desired dissolved oxygen concentration.

[0107] The oxygen consumption absorption rate calculation unit 2 is used to calculate the oxygen consumption absorption rate according to the actual dissolved oxygen concentration.

[0108] The oxygen transfer rate calculation unit 3 is used to calculate the first oxygen transfer rate according to the parameters of the aeration device.

[0109] The aeration rate determination unit 4 is configured to determine the actual dissolved oxygen concentration according to the difference between the actual dissolved oxygen concentration and the expected dissolved oxygen concentration, the oxygen consumption absorption rate and the first oxygen transfer rate. The increase / decrease of the aeration rate for the concentration to reach the desired dissolved oxygen concentration.

[0110] The control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com