Inclinable drilling machine used for machining furniture

A drilling machine and furniture technology, which is applied in wood processing equipment, manufacturing tools, fixed drilling machines, etc., can solve the problems of small application range and achieve the effects of wide application range, precise adjustment, and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

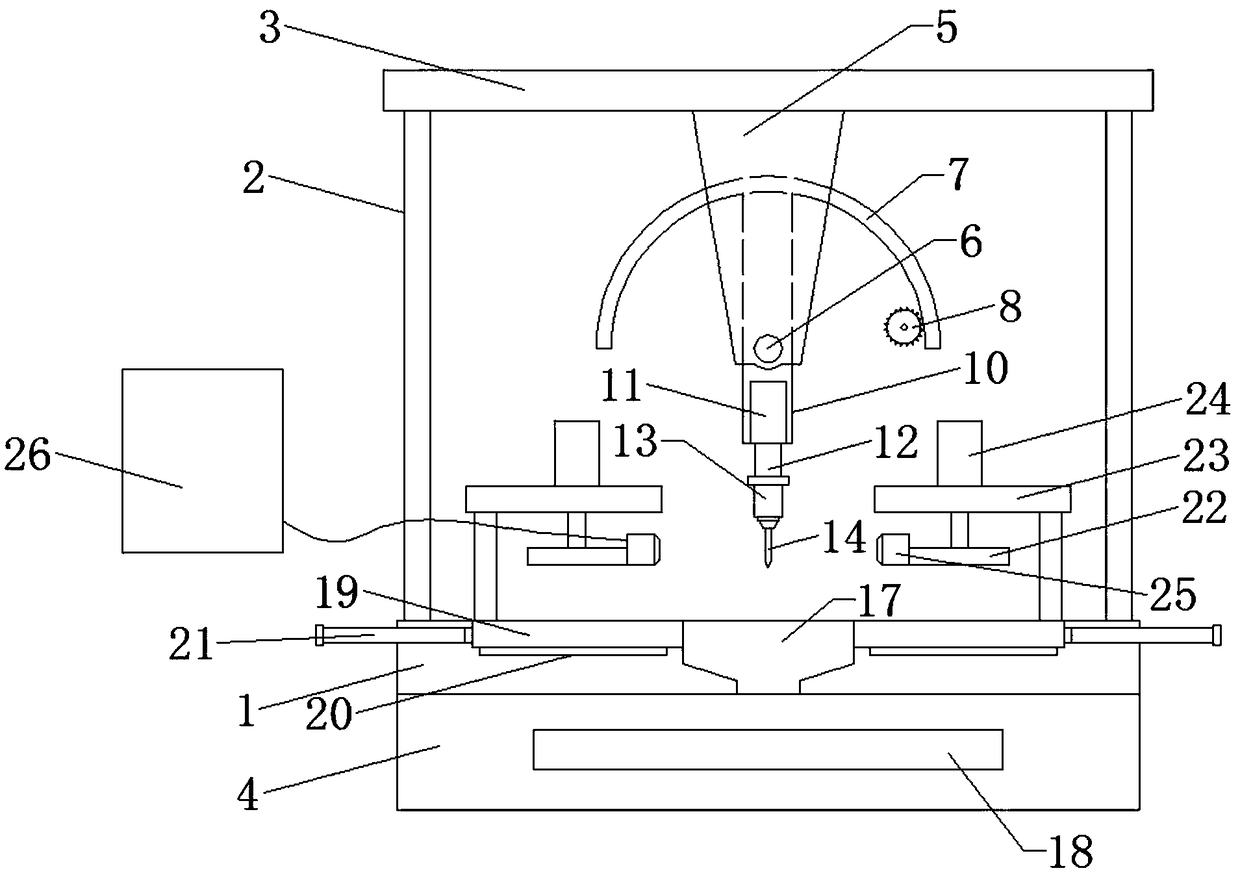

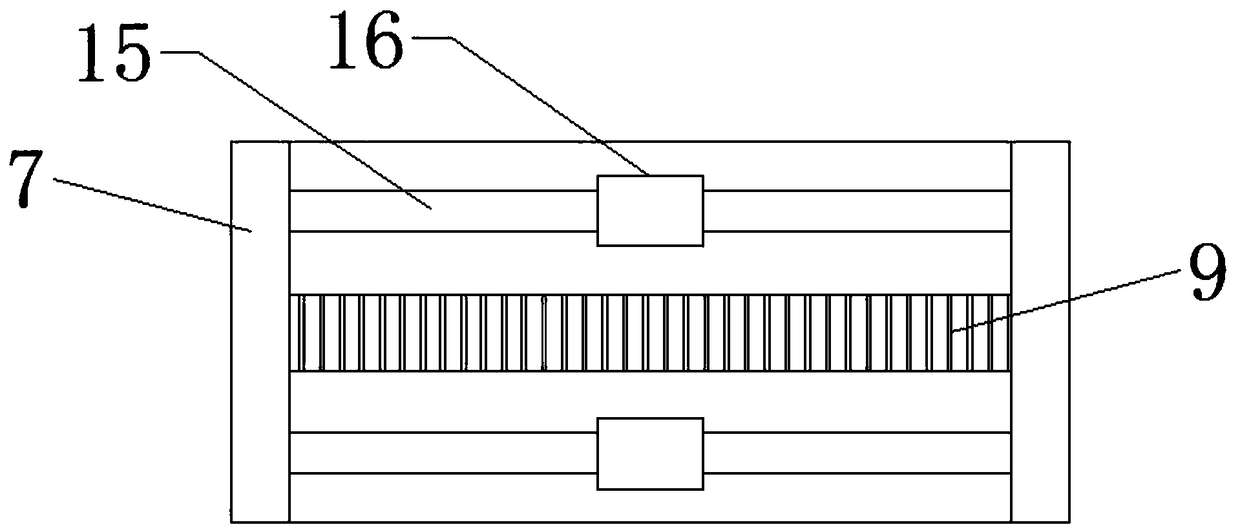

[0019] Please refer to the figure, in an embodiment of the present invention, a tiltable drilling machine for furniture processing includes a workbench 1, a support rod 2, a top plate 3, a base 4 and a support base 5; the workbench 1 is fixedly installed on the base 4, vertical support rods 2 are fixed on the left and right sides of the upper surface of the workbench 1, and the upper end of the support rod 2 is fixedly connected with a horizontal top plate 3, and the support seat 5 is welded on the lower surface of the top plate 3, and the support seat 5. There are two front and back, and a horizontal rotating shaft 6 is fixed between the lower ends of the two support seats 5; an upwardly curved arc plate 7 is arranged above the rotating shaft 6, and the central axis of the arc plate 7 is connected to the rotating shaft. 6 overlap, preferably, the arc-shaped plate 7 adopts a semi-circular arc, and the angle of inclination to be adjusted is relatively large, between the rotating...

Embodiment 2

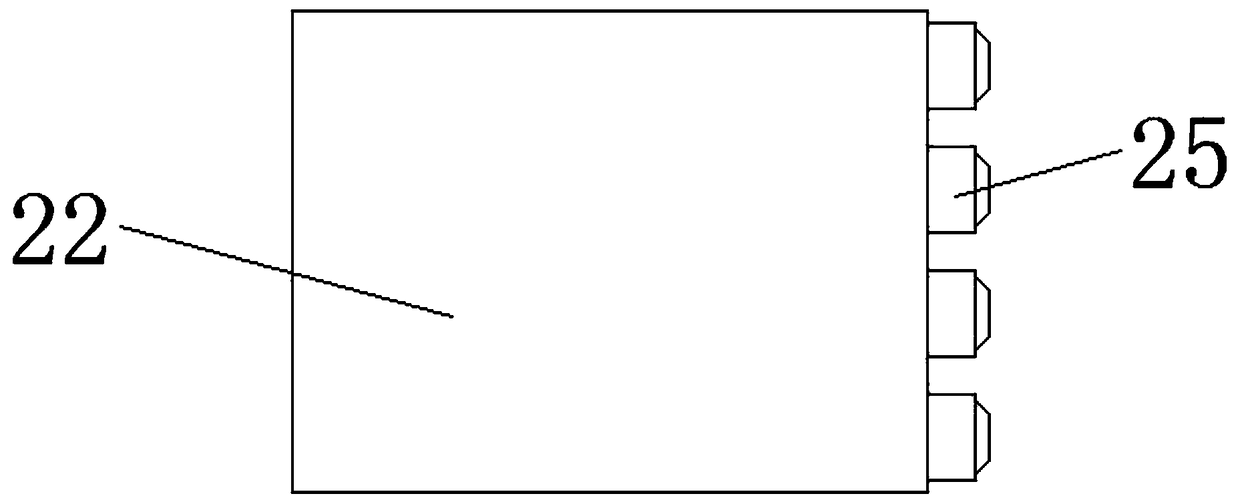

[0023] Both sides of the tank body 17 are provided with adjustment boards 19 that can extend horizontally into the tank body 17, and the distance between the adjustment boards 19 on both sides changes so that smaller volumes of planks can be placed on it. At the same time, the mounting plate 23 is also fixed on the adjusting plate 19, and moves synchronously to realize the compression of the plank; the bottom of the adjusting plate 19 is slidably connected to the workbench 1 through the chute 20, and the outer end of the adjusting plate 19 is rotated and connected with a horizontal adjustment The bolt 21 and the adjusting bolt 21 are screwed out of the workbench 1, and the length extending into the workbench 1 is adjusted by turning the adjusting bolt 21, thereby changing the horizontal position of the adjusting plate 19.

[0024] During use, according to the inclination angle of punching as required, the inclination of the arc-shaped plate 7 is adjusted through the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com