Self-angle-changing hydraulic-climbing formwork system

A self-variable angle, hydraulic technology, applied in the direction of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problem of inability to meet the changes in the size of the outer frame cylinder, limited application scope, poor structural versatility, etc. problems, to achieve the effect of high construction efficiency, wide application range and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

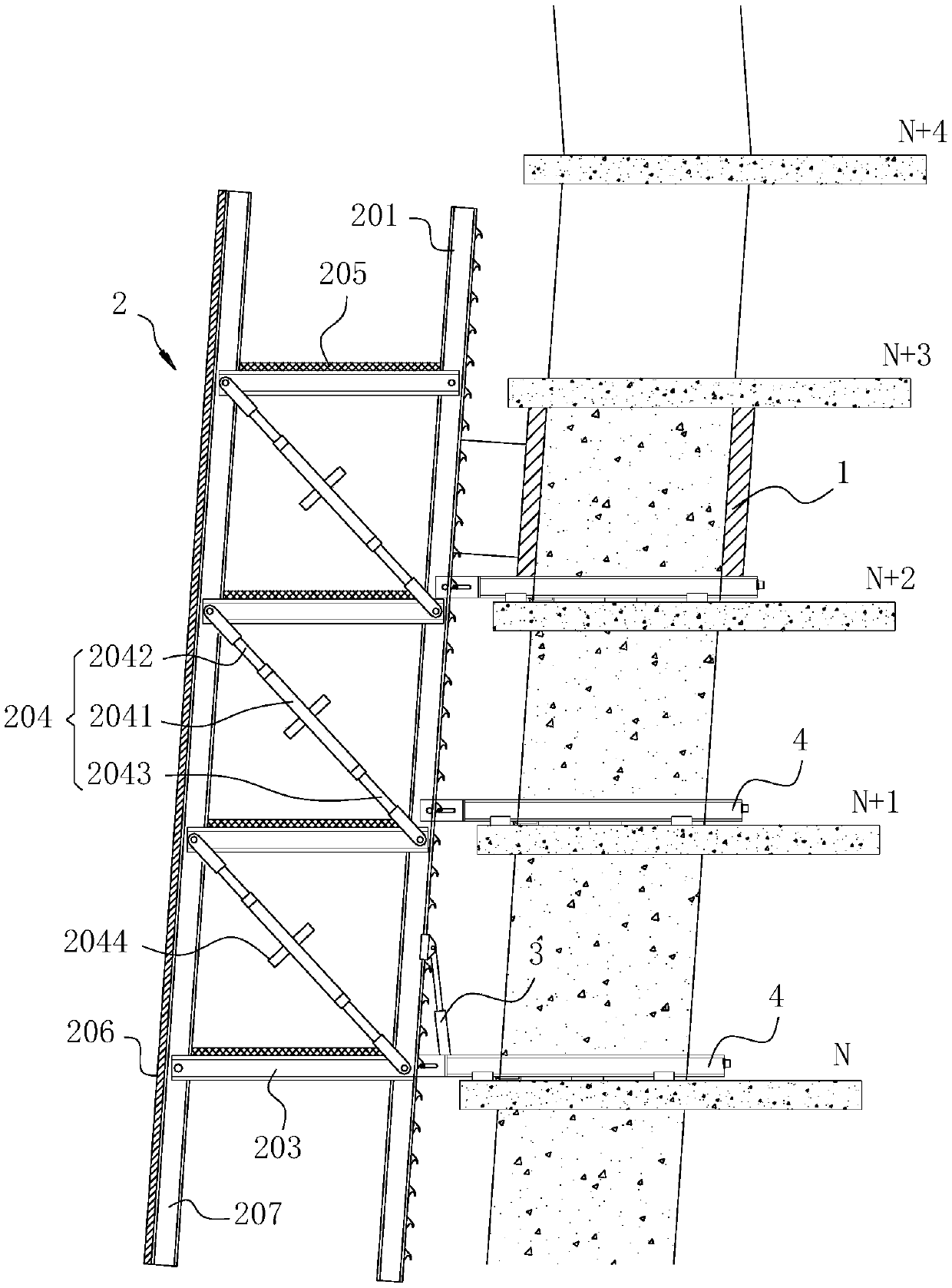

[0045] figure 1 The cylindrical section of the outer frame shown is an inwardly inclined section, and the construction process of this section of cylinder is as follows:

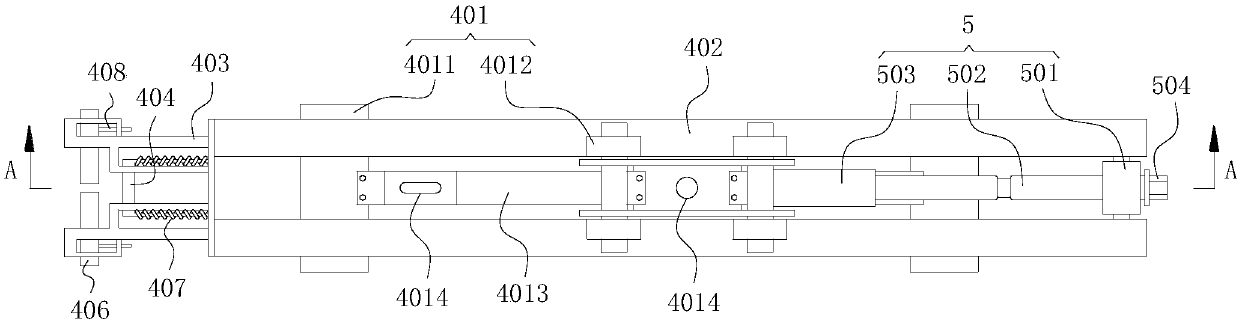

[0046] 1. Fix the floor support 4 on the N floor, N+1 floor, and N+2 floor, and then support the assembled climbing frame system 2 on the hanging seat 403 of the floor support 4; The formwork system 1 between the layers is fixed on the climbing frame system 2; on the N+2th floor, the screw head 504 is rotated by a wrench to drive the first screw 502 to rotate, and then the slider 402 moves to the right on the mounting base 401 , so that the climbing guide rail 201 is inclined to the right, and finally the inclination rate of the formwork system 1 is the same as the inclination rate of the outer frame column of the inwardly inclined section; The length of the strut 204 is used to level the operating platform 205, and then construction personnel can construct on the operating platform 203 and pour concrete in...

Embodiment 2

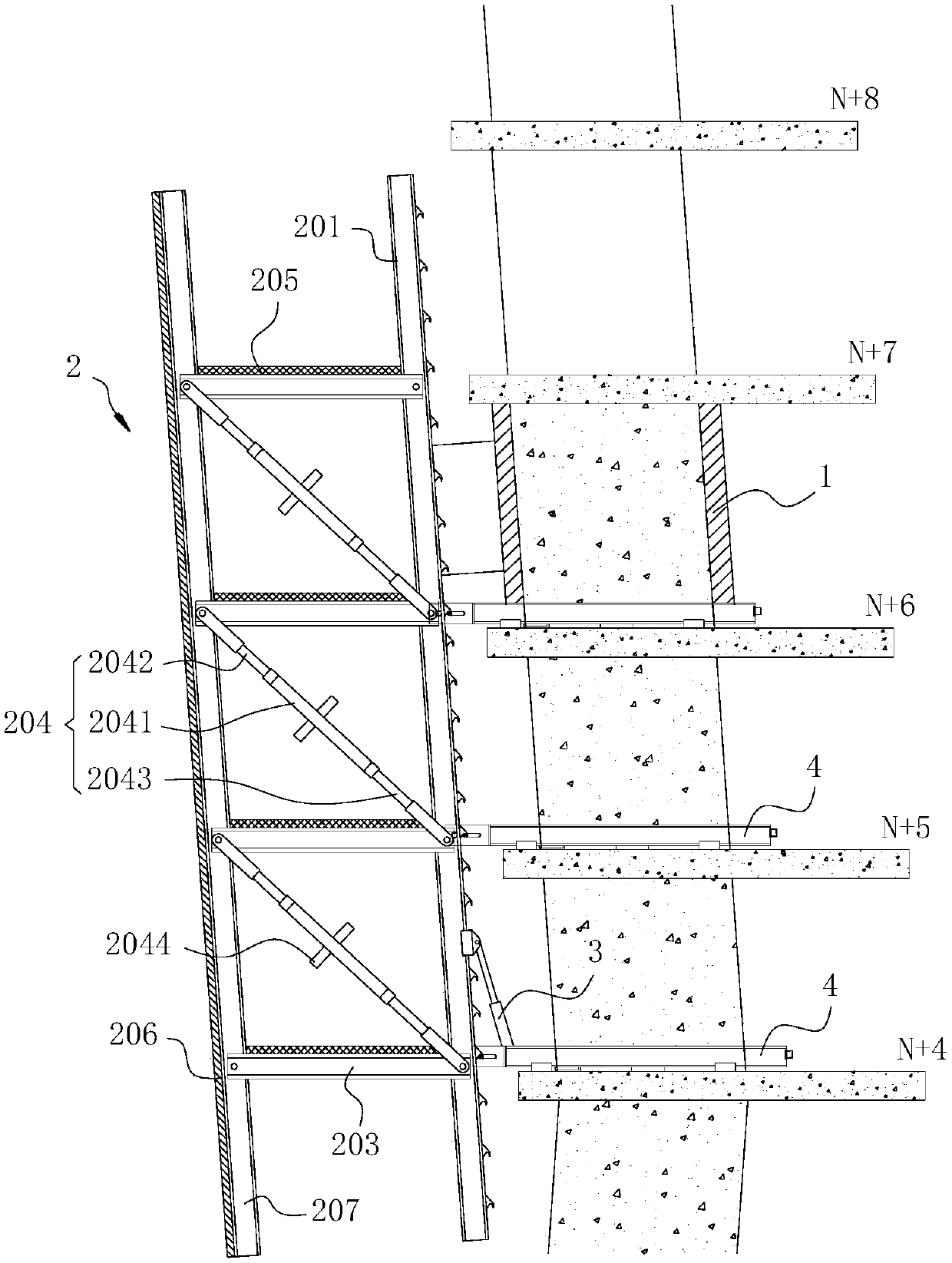

[0050] figure 2 The cylindrical section of the outer frame shown is an outwardly inclined section, the cylinder below the N+4th floor is an inwardly inclined section, and the cylinder above the N+4th floor is an outwardly inclined section. The construction process of the outward inclined column is as follows:

[0051] 1. After the columns between the N+2 and N+4 floors have been poured, the formwork system 1 is separated from the climbing frame system 2, and then the climbing frame system 2 is lifted to the N+4th floor by the hydraulic climbing system 3 To the working position on the N+6 floor, the formwork system 1 between the N+4 and N+6 floors is installed on the climbing frame system 2, and on the N+6 floor, the screw head 504 is rotated by a wrench to drive The first screw 502 rotates, and then the sliding member 402 moves to the left on the mounting seat 401, so that the climbing guide rail 201 is inclined to the left, and finally the inclination rate of the formwork s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com