Conveyor device with negative pressure suction

A conveying equipment and negative pressure technology, which is applied in the field of conveying equipment using negative pressure suction, can solve problems such as air pollution, achieve precise adjustment, and avoid the effect of mass distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

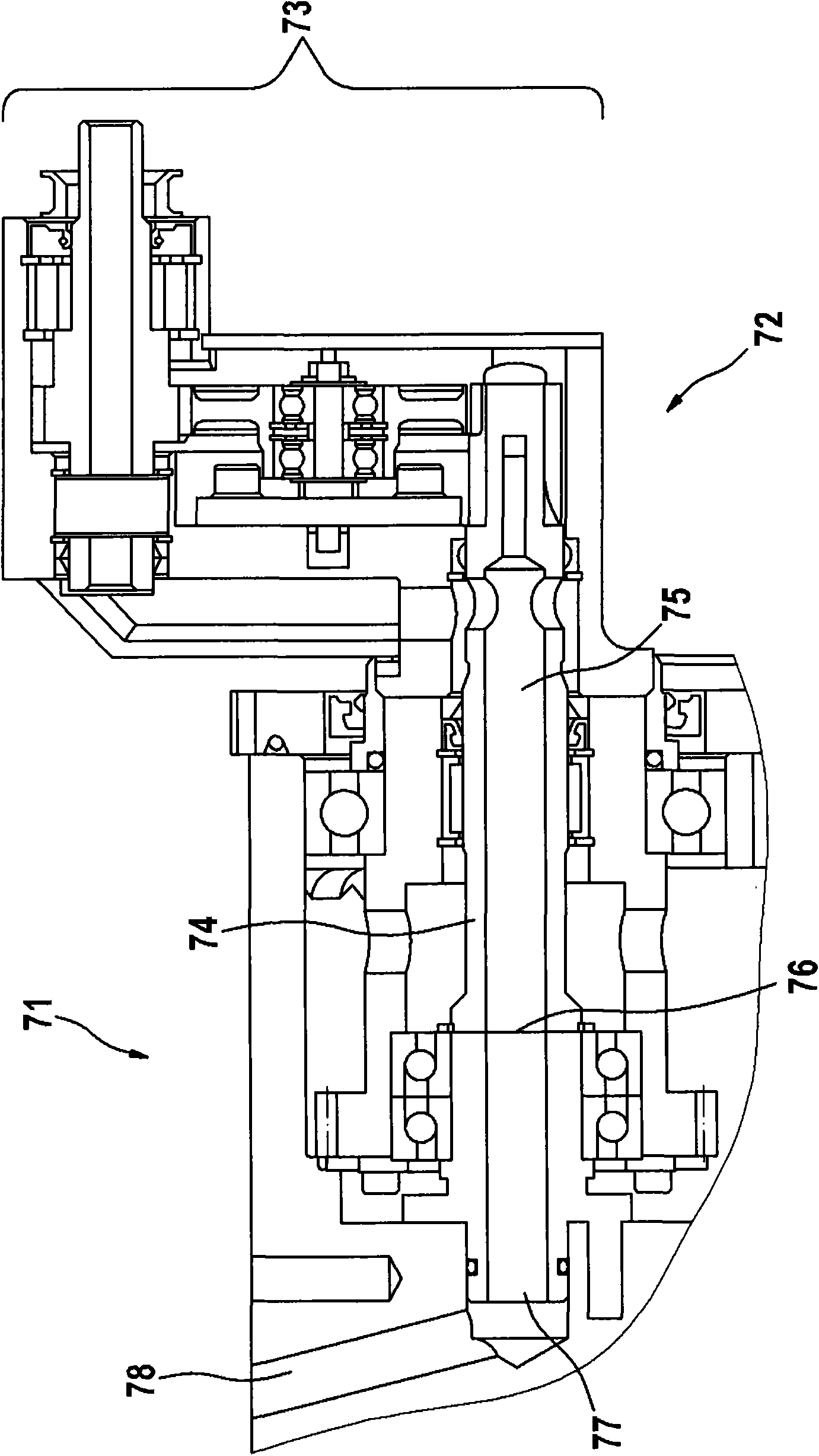

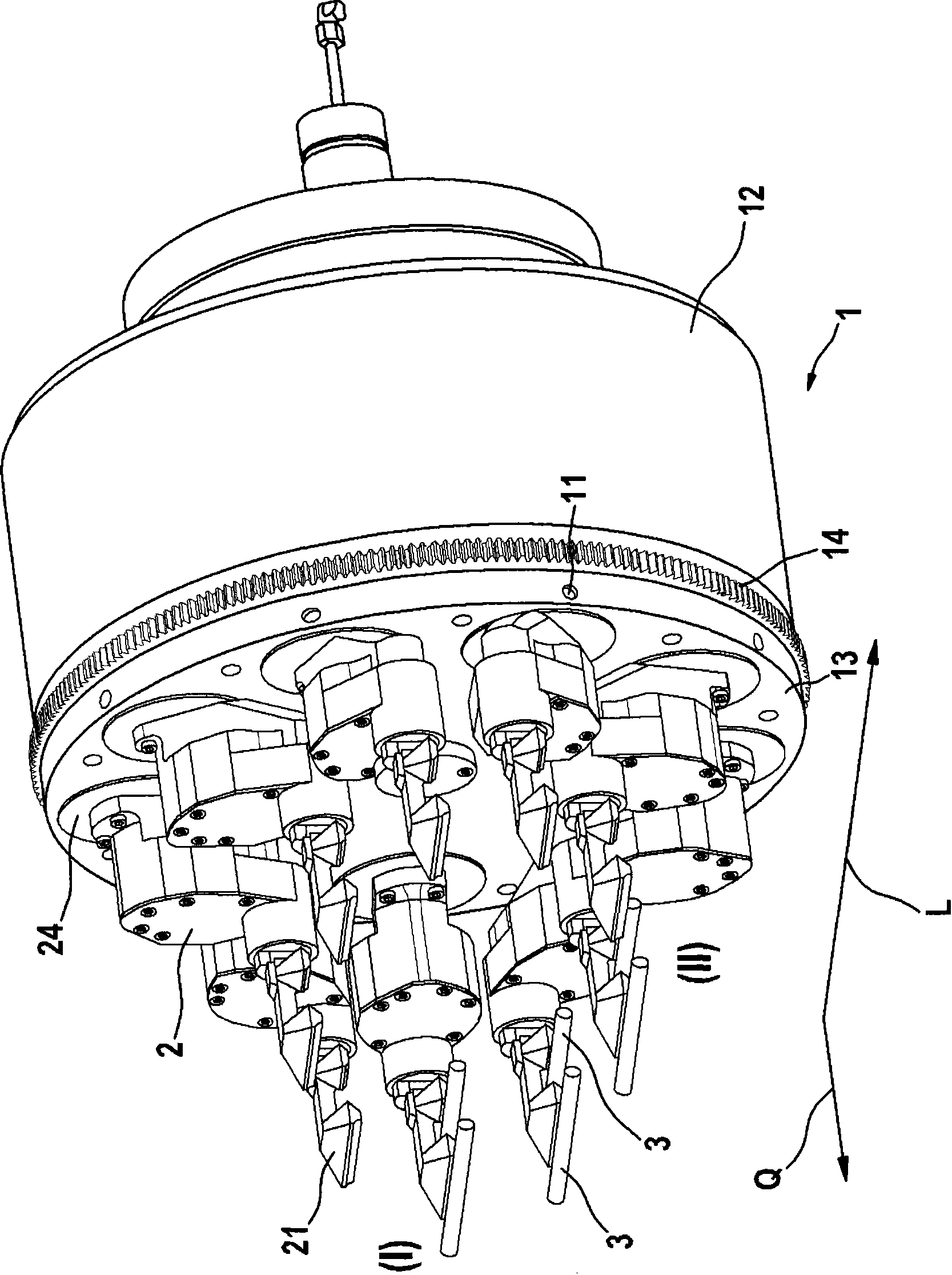

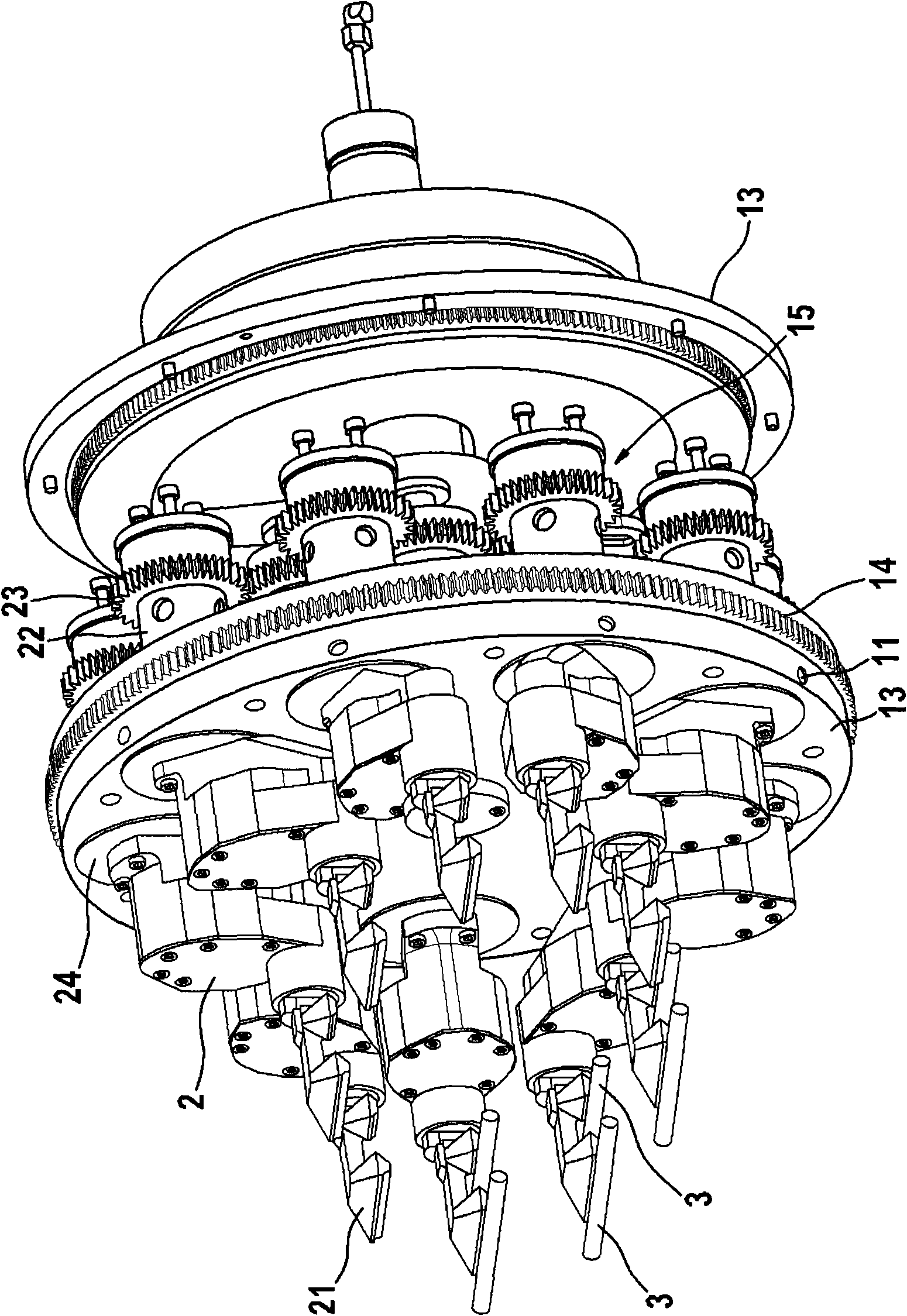

[0086] In Figure 2 to Figure 5 A device according to a first embodiment of the invention is described in . Figure 6 to Figure 1 1 shows a device according to a second embodiment of the invention. For more clarity, in image 3 ,Figure 4, Image 6 , Figure 7 And the retaining head is not shown in Fig. 11. For the same reason, in Figure 7 , Figure 10 , Figure 11A with Figure 11B The hatching of the section is omitted in , and in Figure 7 The revolutions are not shown in and 11, which are located behind the cutting plane and are partially covered by the cutting revolutions. Unless otherwise stated, the same reference numerals denote the same elements or regions herein.

[0087] exist Figure 2A In , a longitudinal conveyor according to a first embodiment of the invention is shown. The base body 1 is designed as a drum roller mounted rotatably about its central axis, which is driven via a central shaft during normal operation (that is to say for conveying rod-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com