Pressure type membrane bioreactor technique of suspension bed and device

A membrane bioreactor, pressure-type technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high concentration of organic matter in wastewater, difficulty in obtaining satisfactory results, and difficulty in wastewater treatment , to achieve stable effluent water quality, good solid-liquid separation effect, and improved oxygen transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

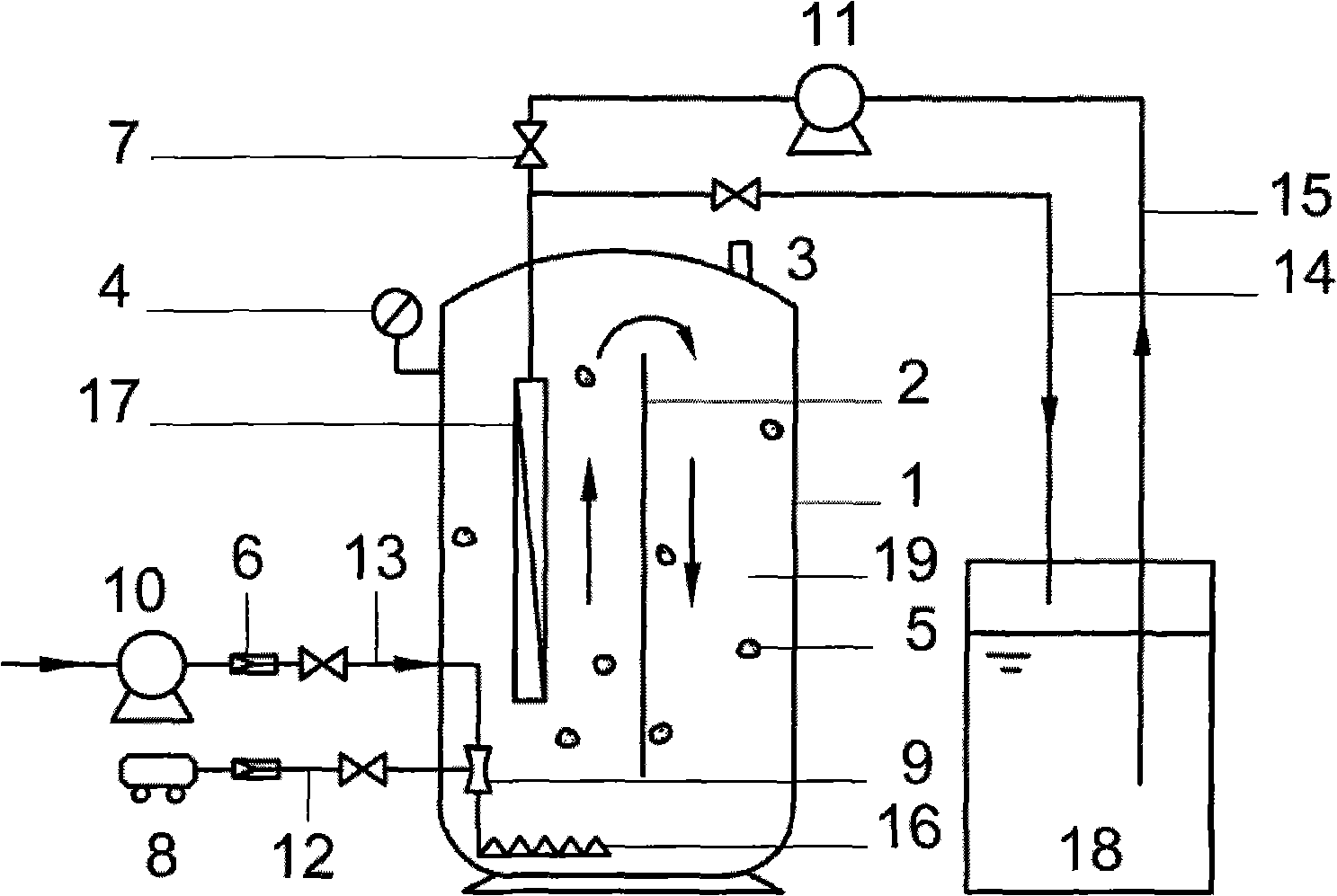

[0017] Example 1: The source of sewage is wastewater from a pharmaceutical factory, and the water quality condition is: COD Cr Content 4000~5000mg / L, methanol 8~10mg / L, benzene 3.0~3.5mg / L, SS 250~400mg / L. Control the pressure P=0.3MPa, adjust the air intake of the ejector to control the dissolved oxygen in the reactor at 5.0-6.0mg / L. After being treated by a pressure membrane bioreactor, the final effluent reaches the national reuse water standard, of which COD Cr The concentration is less than 30mg / L, and the turbidity of the effluent is less than 0.5mg / L.

example 2

[0018] Example 2: The source of sewage is monosodium glutamate wastewater, and the water quality condition is: COD Cr Content 2000~3000mg / L, BOD 5 The content is 800~1200mg / L, and the ammonia nitrogen is 200~320mg / L. Control the pressure P=0.2MPa, adjust the air intake of the ejector to control the dissolved oxygen in the reactor at 2.0-4.0mg / L. After being treated by a pressure membrane bioreactor, the final effluent COD Cr The concentration is less than 40mg / L, and the turbidity of the effluent is less than 0.6mg / L. The effluent water quality meets the national standard for reused water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com