Coal or biomass medium low temperature pyrolysis quality improving system and method for producing quality improved coal, high calorific value pyrolysis gas and tar or liquefied synthetic oil by utilizing same

A technology for low-temperature pyrolysis and upgrading of coal, which is applied in the fields of production of upgraded coal, high calorific value pyrolysis gas and coal tar or liquefied synthetic oil, chemical cycle reaction system, low-temperature pyrolysis and upgrading system of coal or biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

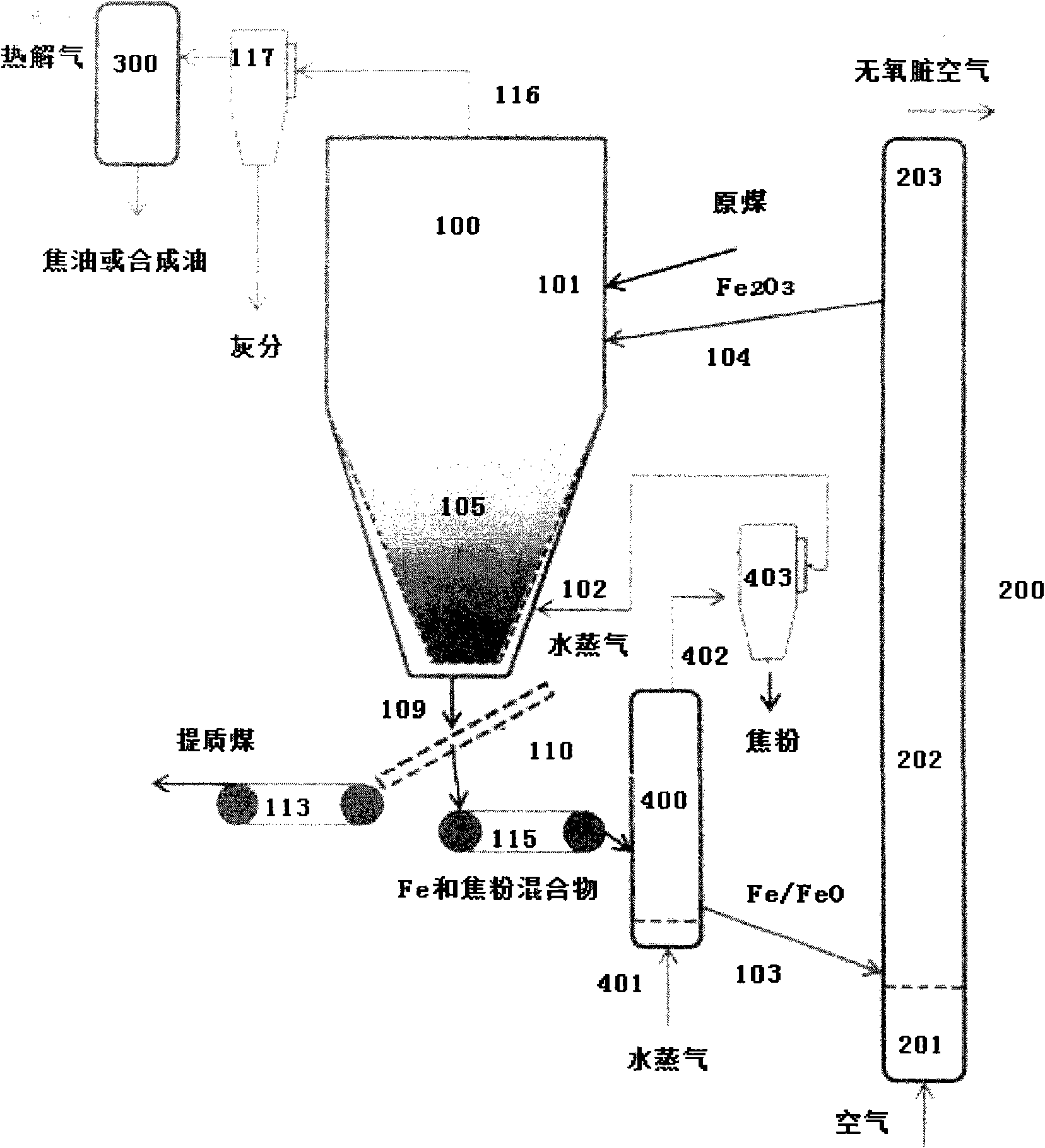

[0107] take as figure 1 The shown coal pyrolysis upgrading system implements the method for producing upgraded coal, high calorific value pyrolysis gas and coal tar or liquefied synthetic oil of the present invention

[0108] First, lignite of the following chemical composition was crushed into particles having the following particle size distribution using conventional crushing equipment.

[0109] 15 cm > 100 wt% bituminous coal particle size > 5 cm

[0110] Catalytic-heat carrier-oxygen transfer material is Fe 2 o 3 , which has the following particle size distribution:

[0111] 1 mm > 100% by weight catalytic-heat carrier-oxygen transfer material > 1 micron

[0112] 100 microns > 95% by weight catalytic-heat carrier-oxygen transfer material > 10 microns

[0113] The particle size of the above-mentioned particles is determined by a sieving method or a specific surface area method.

[0114] In weight %, the chemical composition of lignite is as follows (dry basis):

[0...

Embodiment 2

[0140] The lignite particle of crushing among the above-mentioned embodiment 1 is equal to or similar pyrrhotite (Fe (1-x) S) (wherein (1-x) is generally about 0.8) after mixing with a weight ratio of 99:1, the resulting mixture is injected into the medium and low temperature pyrolysis furnace (100) with the same method as in Example 1. Under the catalysis of pyrrhotite and FeS produced in the coal pyrolysis process, the coal or the tar produced by coal pyrolysis will be cracked and hydrogenated with the hydrogen in the pyrolysis gas to form low molecular weight liquefied synthetic oil.

[0141] Finally, in mol%, the chemical composition of coal pyrolysis gas is as follows:

[0142] Table 6

[0143] CO

[0144] The calorific value of the above-mentioned pyrolysis gas after dehydration is about 15900 kJ / m3, so it can be seen that it is still a gaseous fuel with a relatively high calorific value.

[0145] In weight %, the chemical composition of the synthetic oil is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com