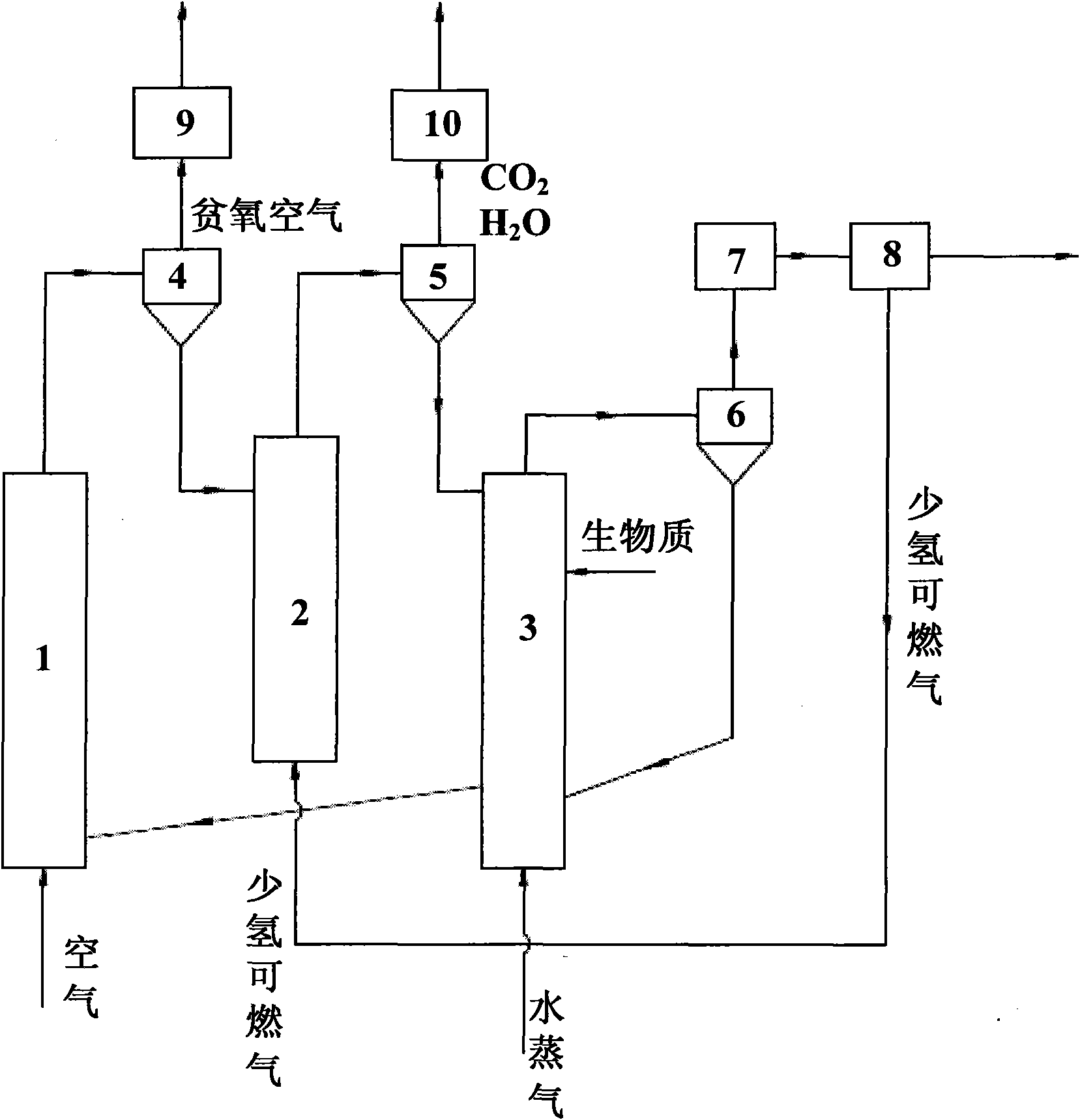

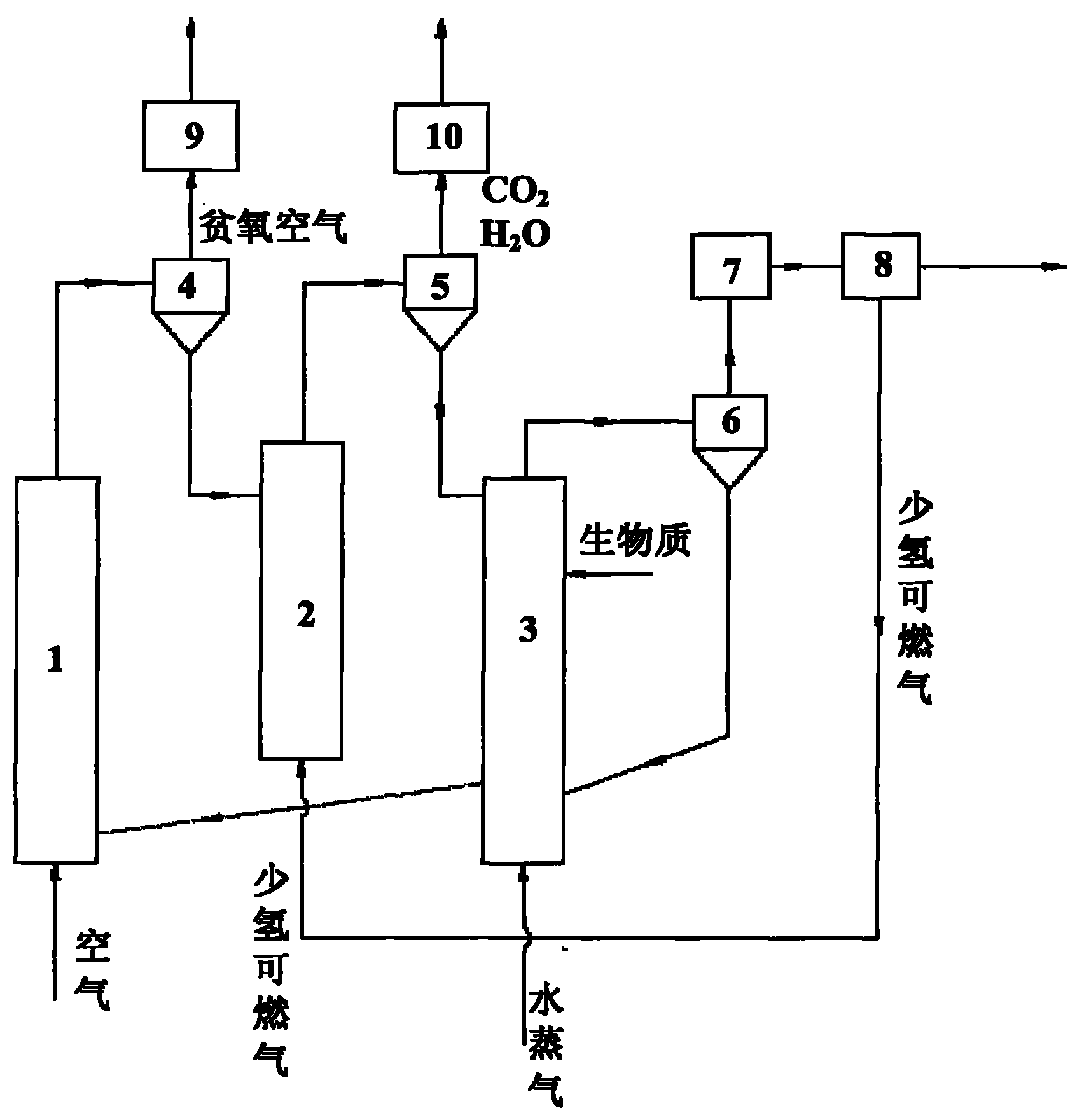

Biomass gasification hydrogen-producing system and method

A hydrogen production system and biomass technology, which is applied in the field of hydrogen production, can solve problems such as system complexity, and achieve the effect of energy efficiency and economical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use metal oxide Fe 2 o 3 As an oxygen carrier and heat carrier, it is oxidized in the air reactor 1 to obtain oxygen. Due to the high reaction temperature and its exothermic oxidation reaction, Fe 2 o 3 When leaving the air reactor 1, it carries a large amount of heat, and enters the fuel reactor 2 as a heat carrier and oxygen carrier to provide heat and oxygen for the reaction. Since the temperature of the moving bed gasifier 3 is lower than that of the fuel reactor 2, the Fe provided by the fuel reactor 2 3 o 4 Entering the moving bed gasifier 3 can still provide heat for gasification.

[0031] The main reactions in the moving bed gasifier are as follows:

[0032] Biomass Volatile Reactions:

[0033] CO+H 2 O→CO 2 +H 2

[0034] CH 4 +H 2 O→CO+3H 2

[0035] Biomass gasification: C+H 2 O→CO+H 2

[0036] Biomass (the biomass is particles with a water content lower than 15wt% after crushing) is added to the moving bed gasifier 3, and steam is fed into the g...

Embodiment 2

[0049] The metal oxide NiO is selected as the oxygen carrier and heat carrier. Ni is oxidized in the air reactor 1 to obtain oxygen. Because the reaction temperature is high and it is an exothermic oxidation reaction, NiO carries a large amount of heat when it leaves the air reactor 1, and is used as the heat carrier. And the oxygen carrier enters the fuel reactor 2 to provide heat and oxygen for the reaction. Since the temperature of the moving bed gasifier 3 is lower than that of the fuel reactor 2, the Ni provided by the fuel reactor 2 enters the moving bed gasifier 3 and can still provide heat for gasification.

[0050] Biomass (the biomass is particles with a water content lower than 15wt% after crushing) is added to the moving bed gasifier 3, and steam is fed into the gasification at 550°C. The main component of the combustible gas obtained from the gasification is h 2 , CO, CH 4 , CO 2 、H 2 O and a small amount of hydrocarbons, the combustible gas obtained by gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com