Patents

Literature

252results about How to "Improve gasification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

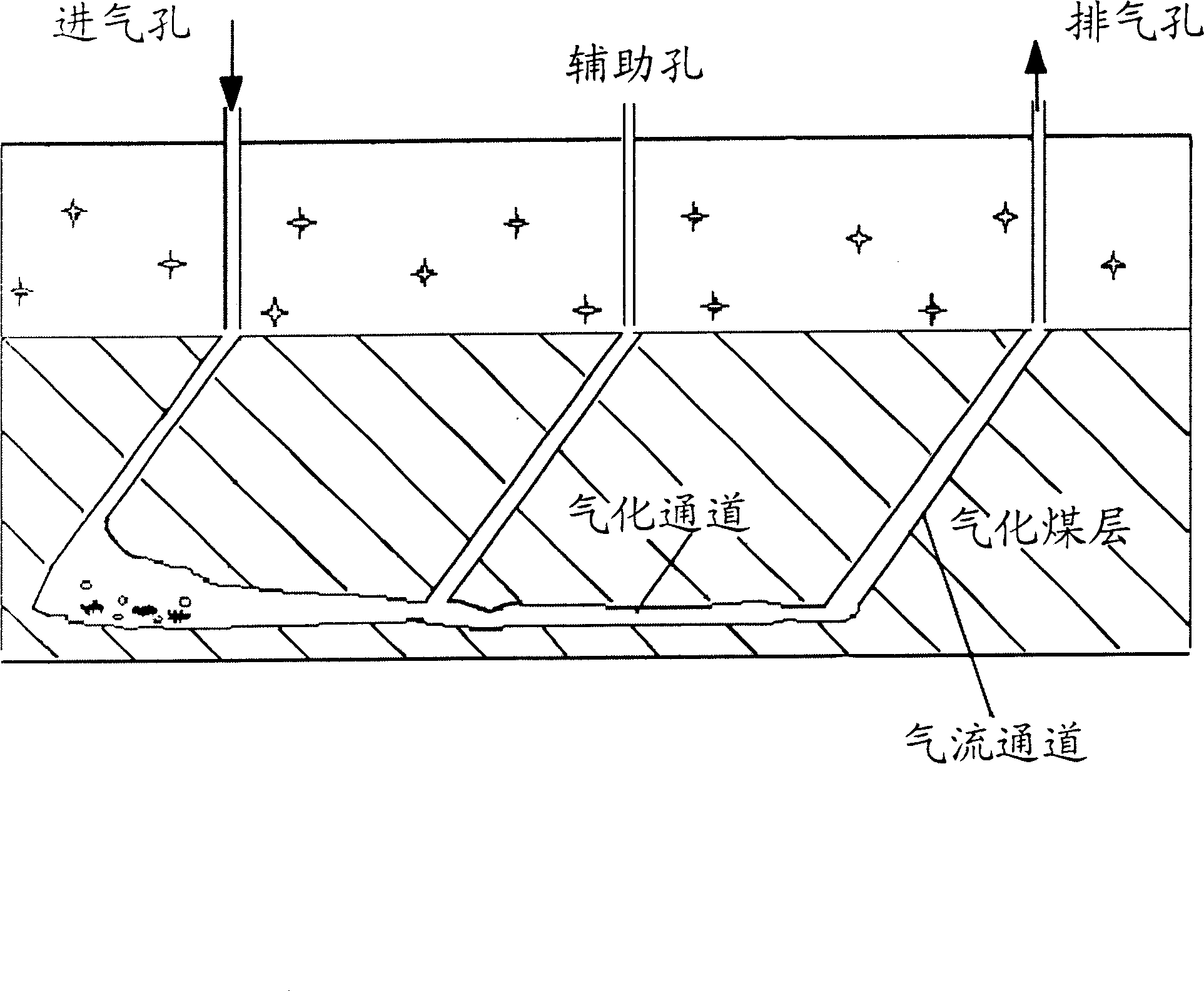

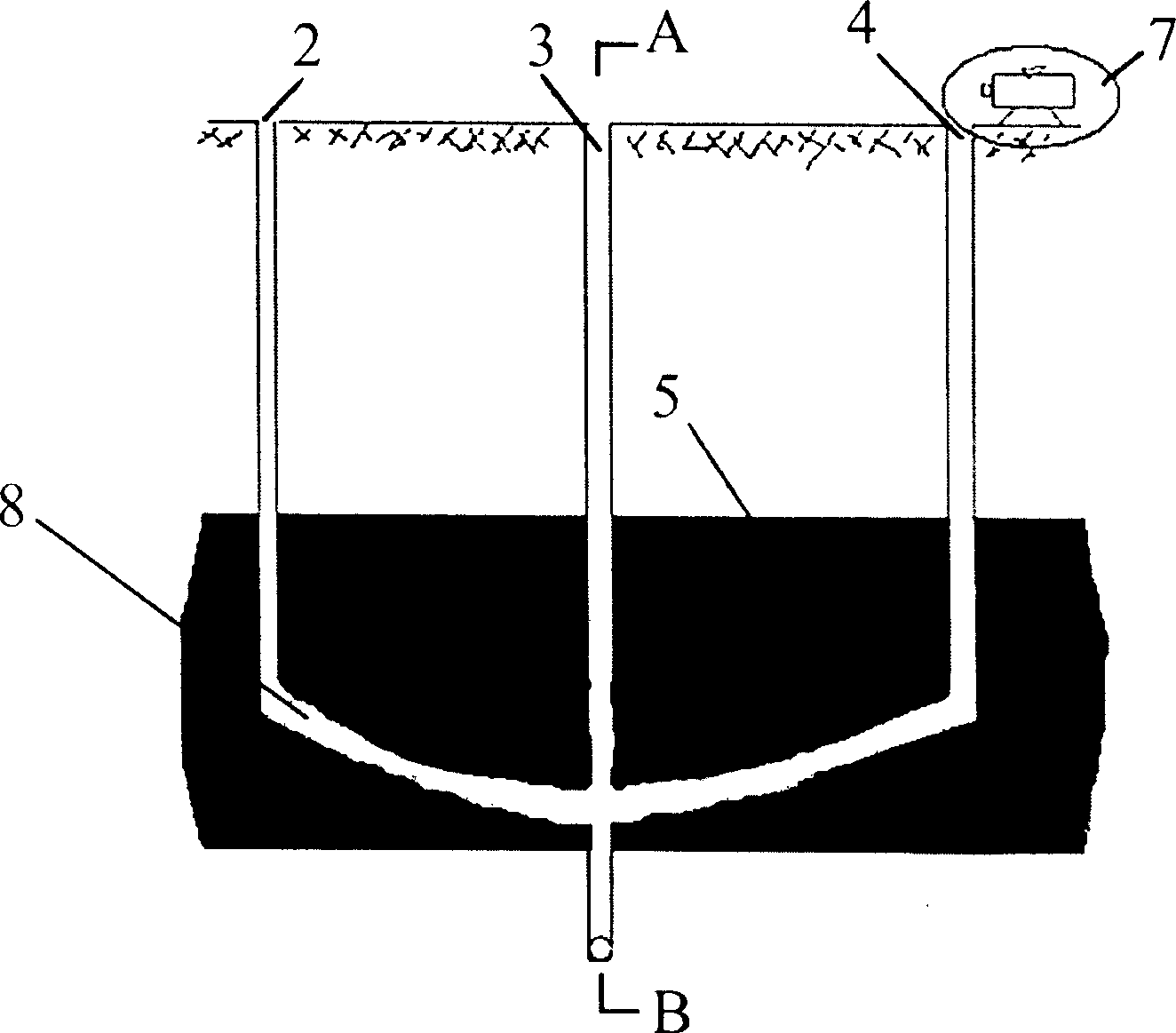

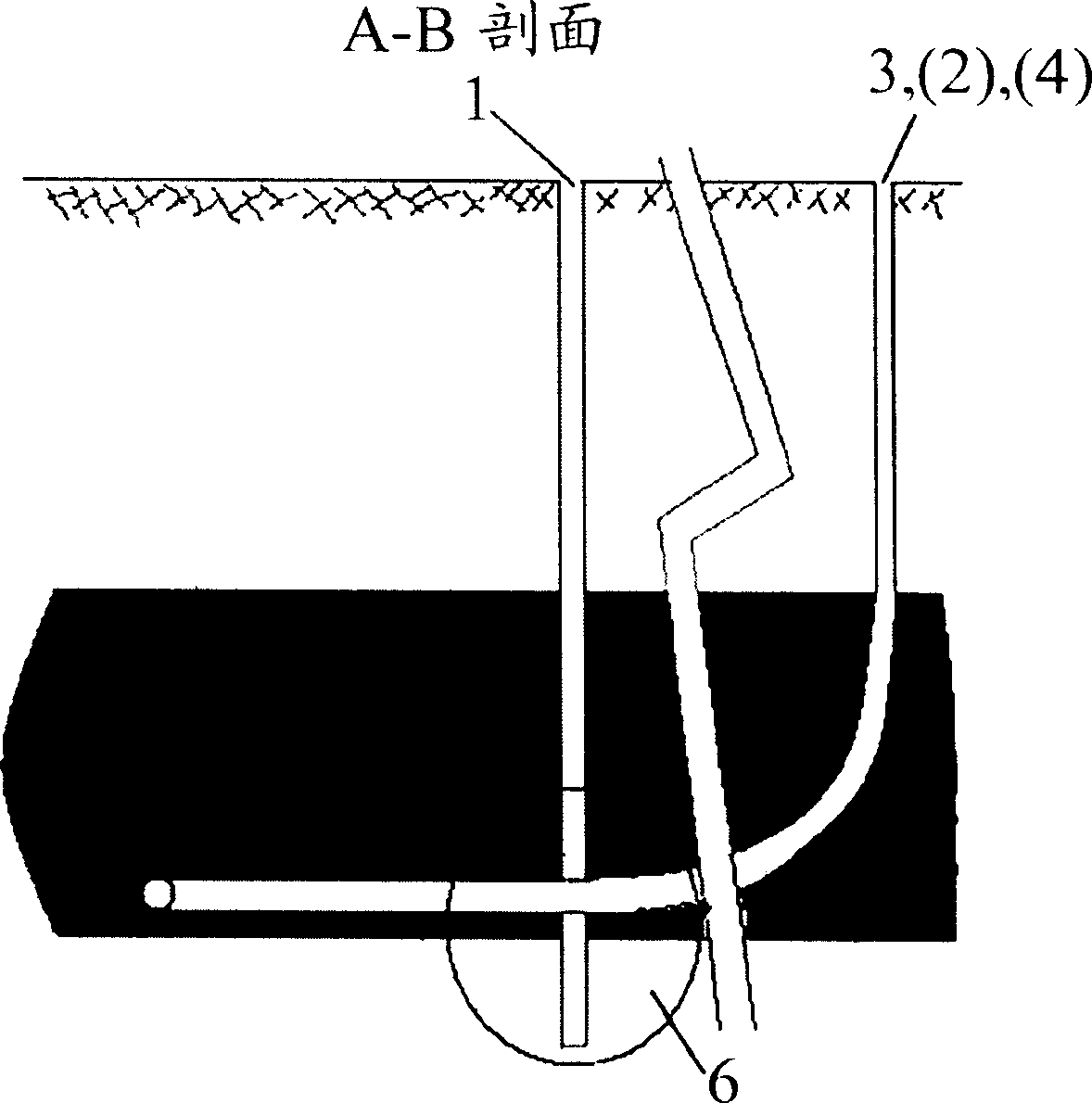

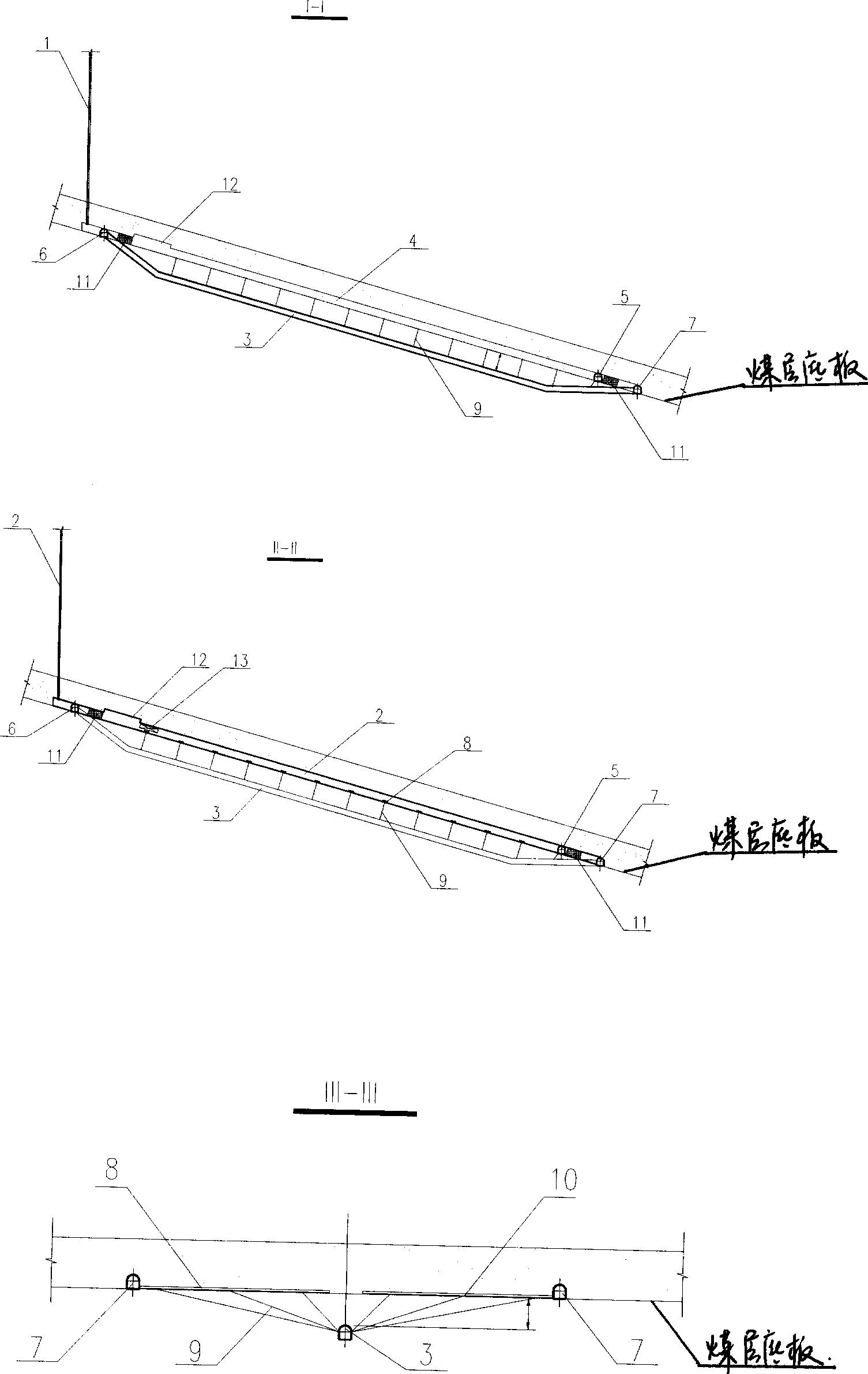

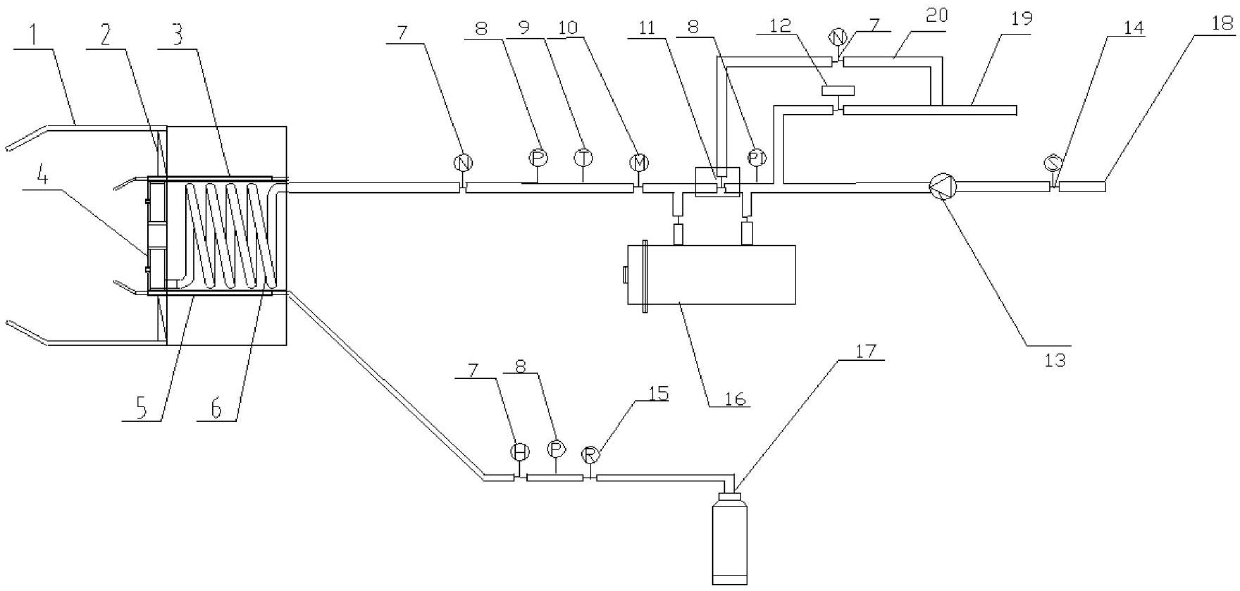

Underground coal gasification

ActiveCN1854459AImprove drainage efficiencyImprove gasification effectConstructionsCoal gasificationProcess engineeringCoal fired

A coal gasification process of coal bed deep underneath includes a gasification furnace in the coal bed, a gas let in canal linking one end of the furnace to ground, a gas let out canal linking the other end of the furnace to ground. Gas generated by coal burning in the furnace is collected. A drain system links a drain outlet over 10 meters below the furnace to the ground.

Owner:ENN SCI & TECH DEV

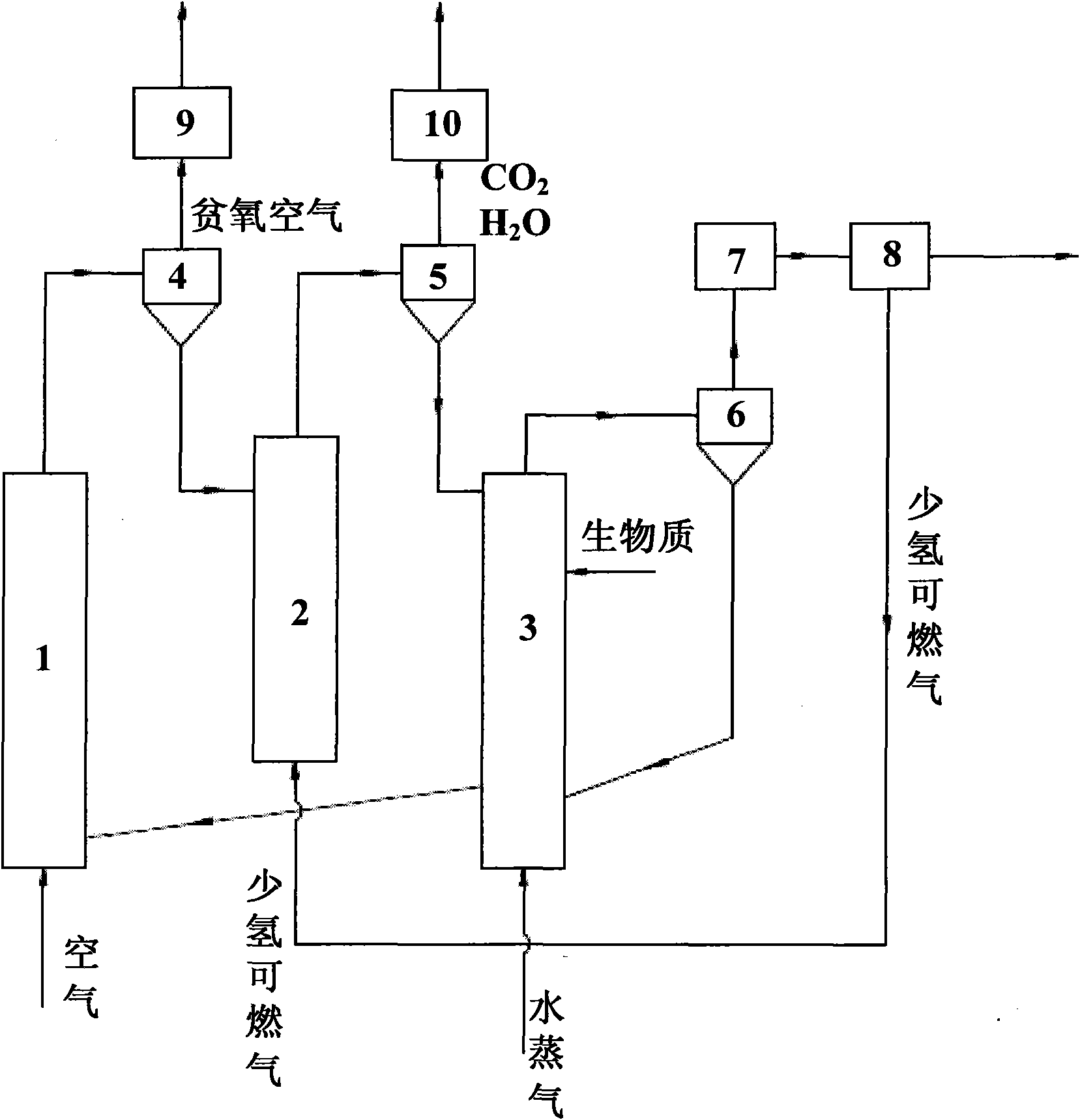

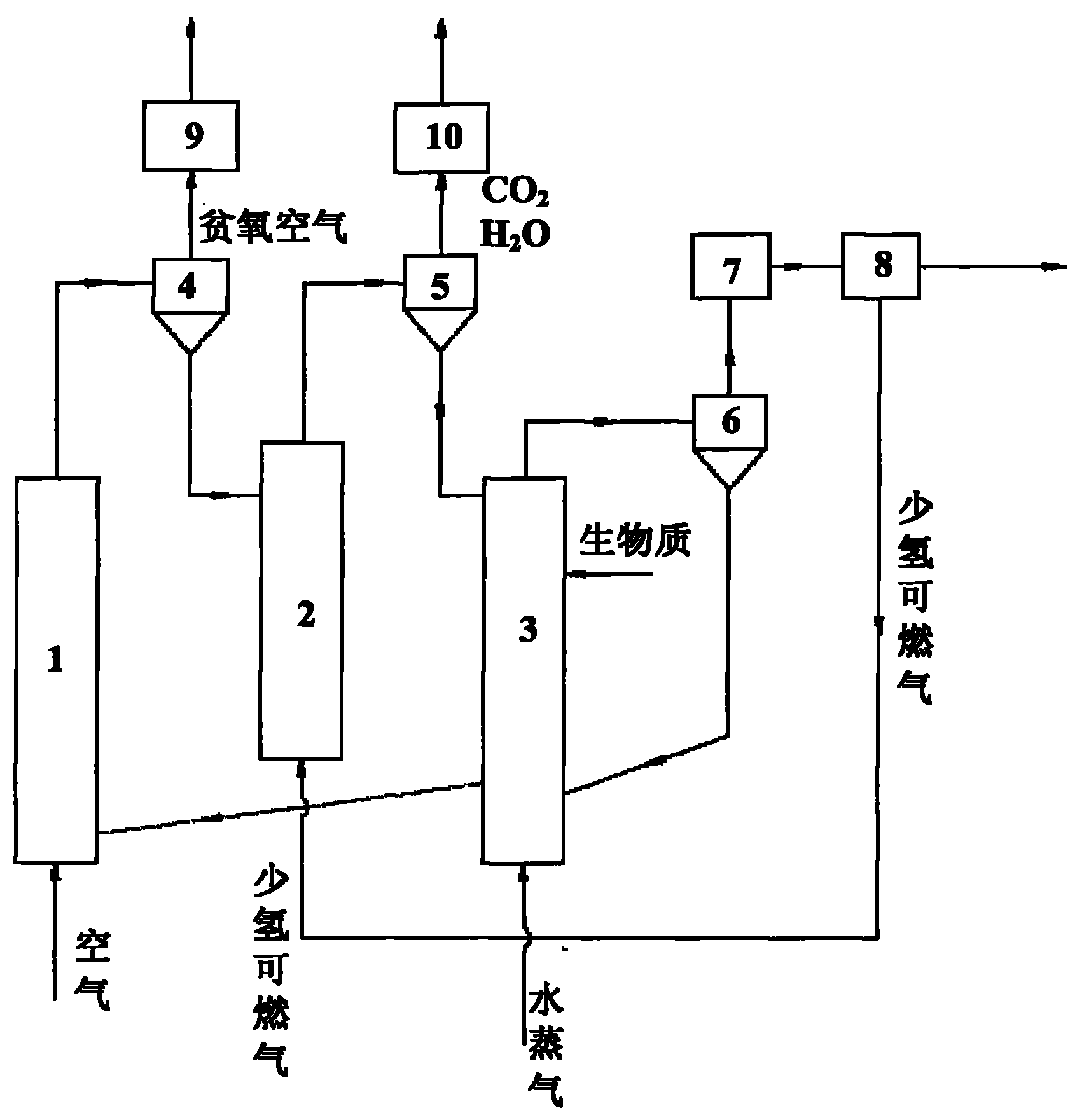

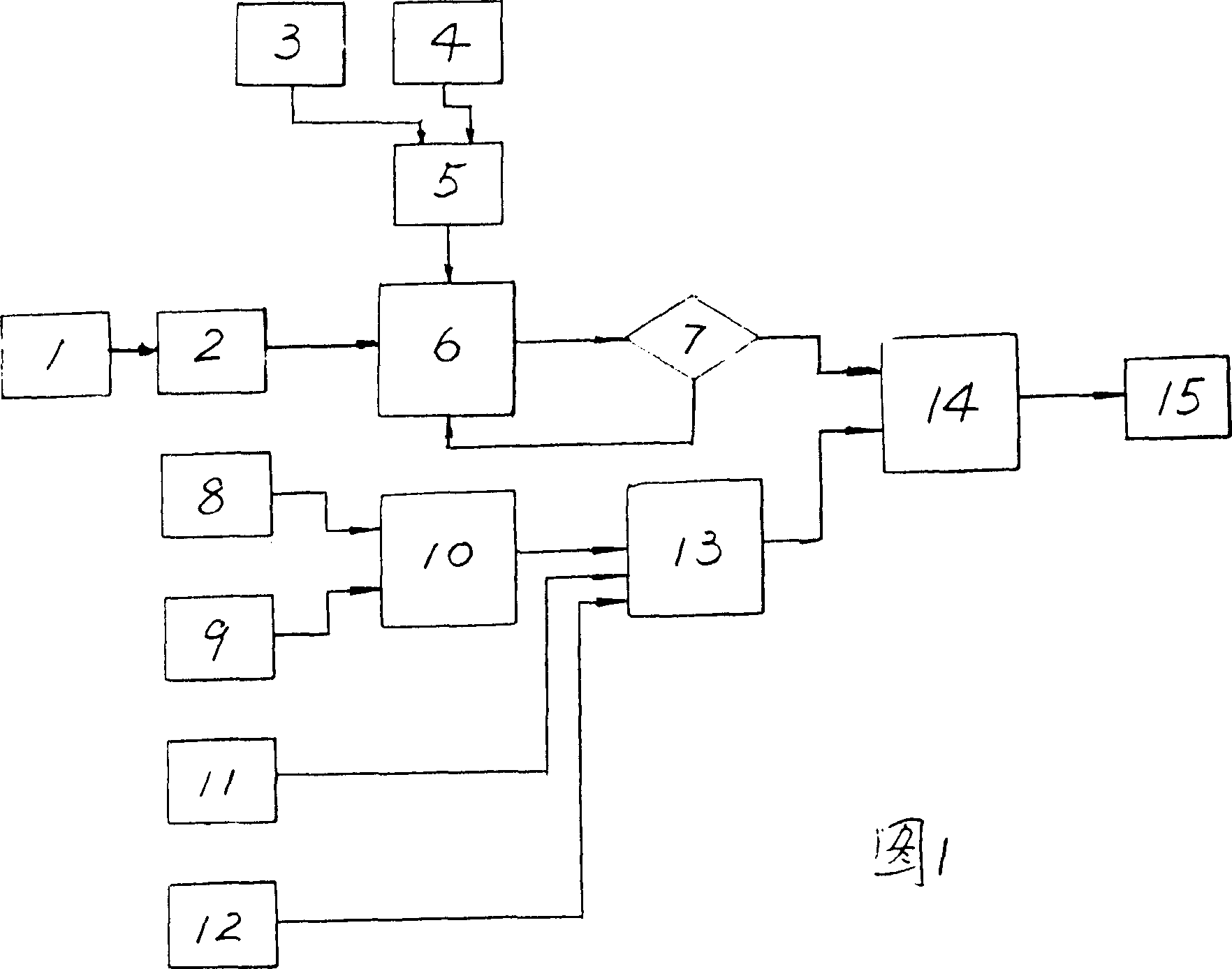

Biomass gasification hydrogen-producing system and method

InactiveCN101774542AReduce utilizationTo achieve hierarchical utilizationHydrogen productionGas solidHeat carrier

The invention discloses a biomass gasification hydrogen-producing system and a method, which belongs to the technical field of hydrogen production. Biomass gasification hydrogen production and chemical-looping combustion are combined to realize low-cost separation of carbon dioxide; and the fractional utilization of matter and energy is realized via the circulation among three beds with metal oxide as a heat carrier and an oxygen carrier. The system mainly comprises an air reactor, a fuel reactor, a moving bed gasifier, a gas-solid separation device, a gas purification device, a hydrogen separation device and a follow-up hydrogen-producing device. The system not only can realize hydrogen production, but also can realize hydrogen production with near zero emission of CO2, thereby realizing efficient cleaning and utilization of biomass.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

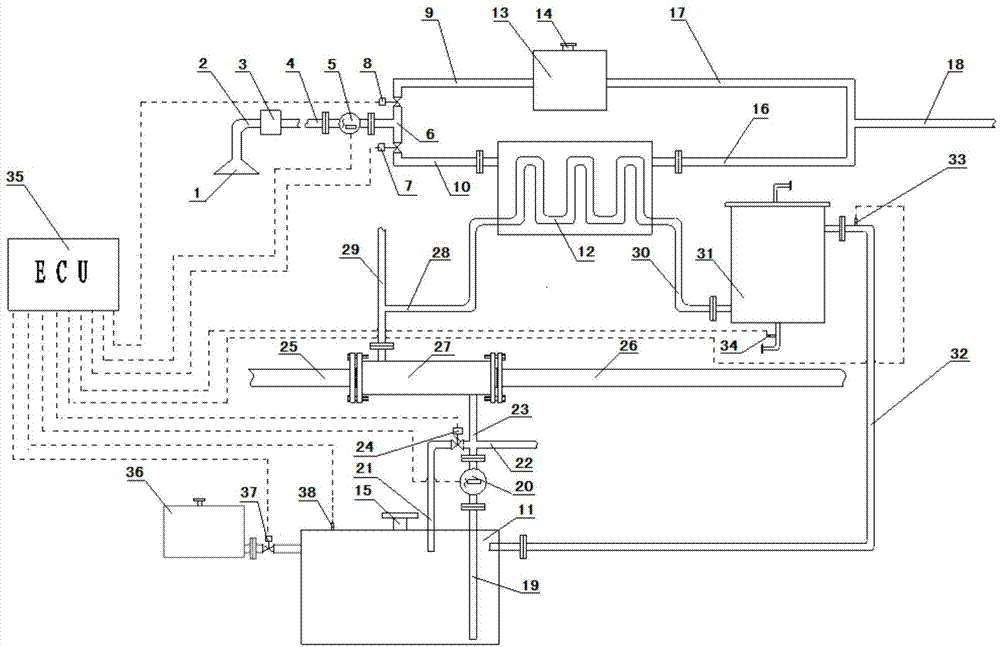

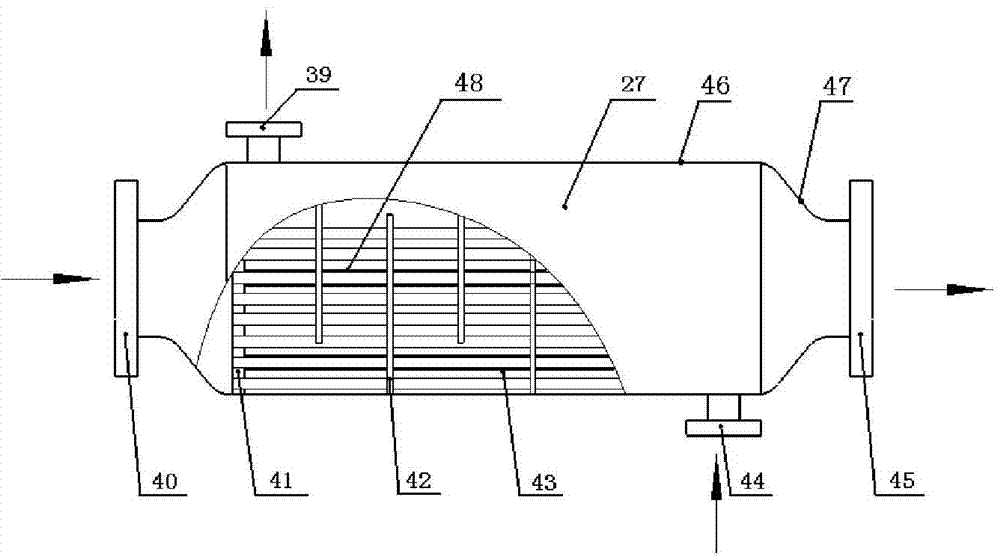

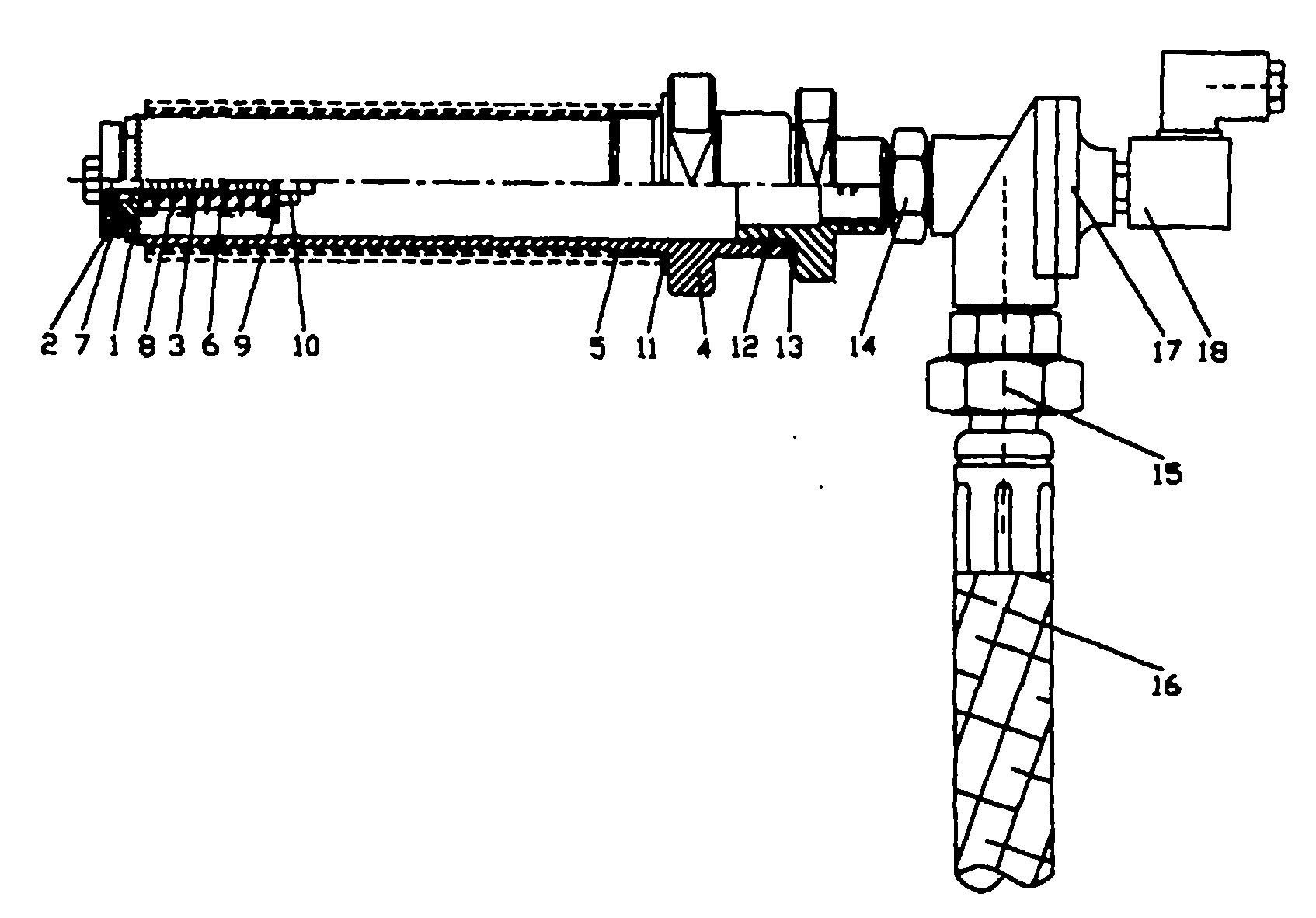

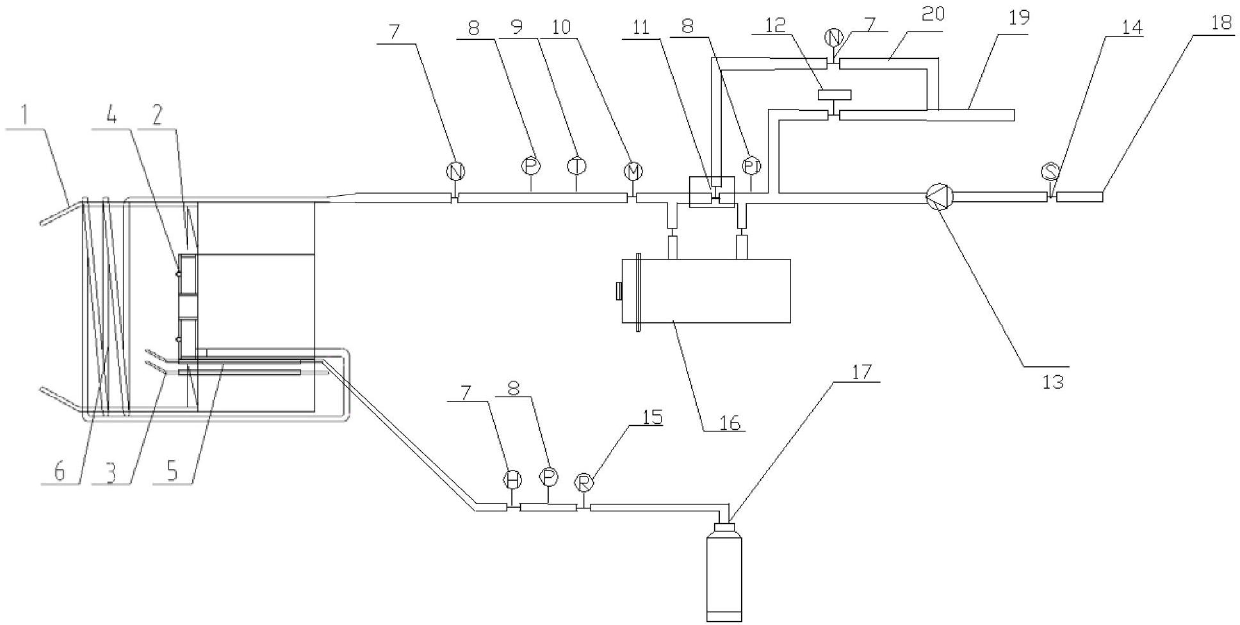

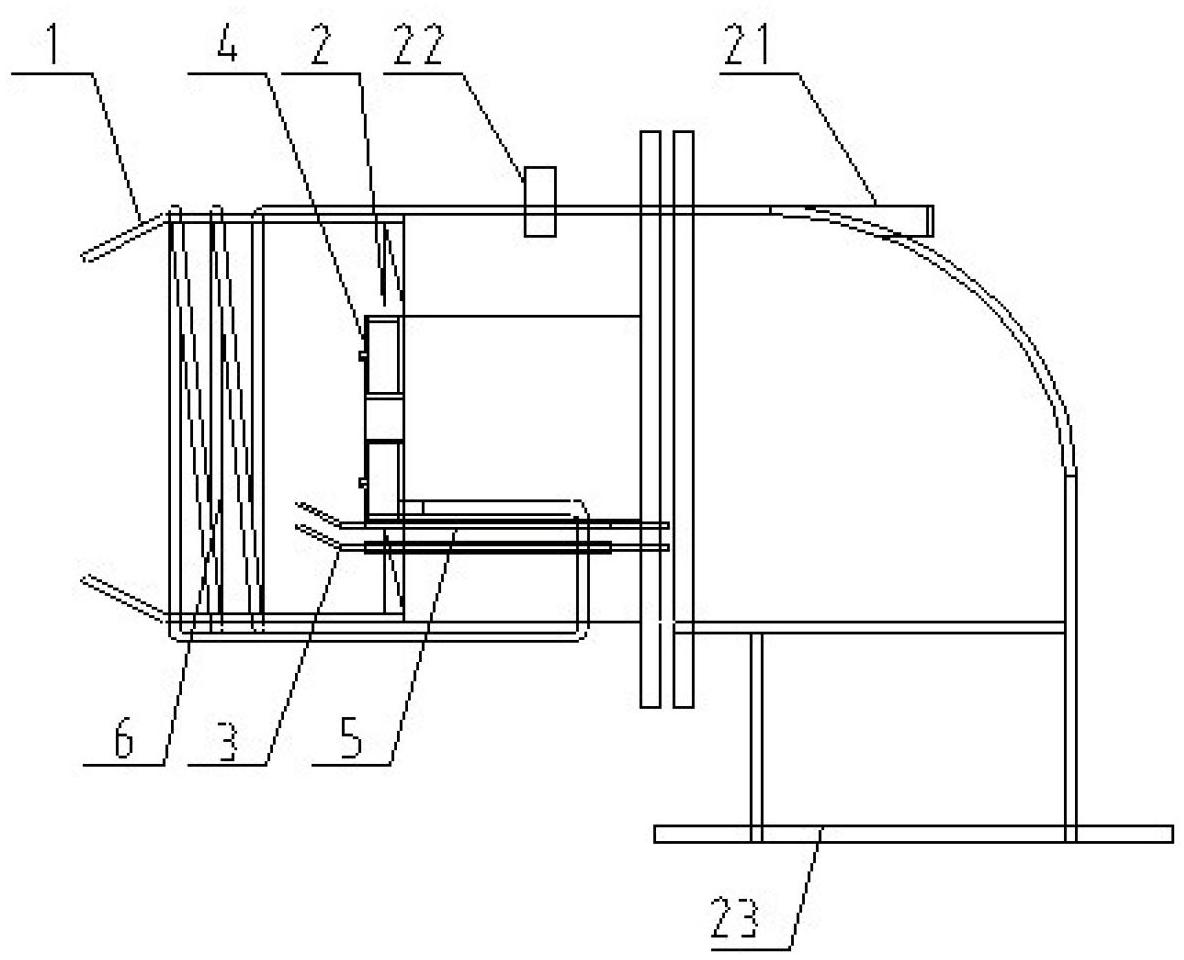

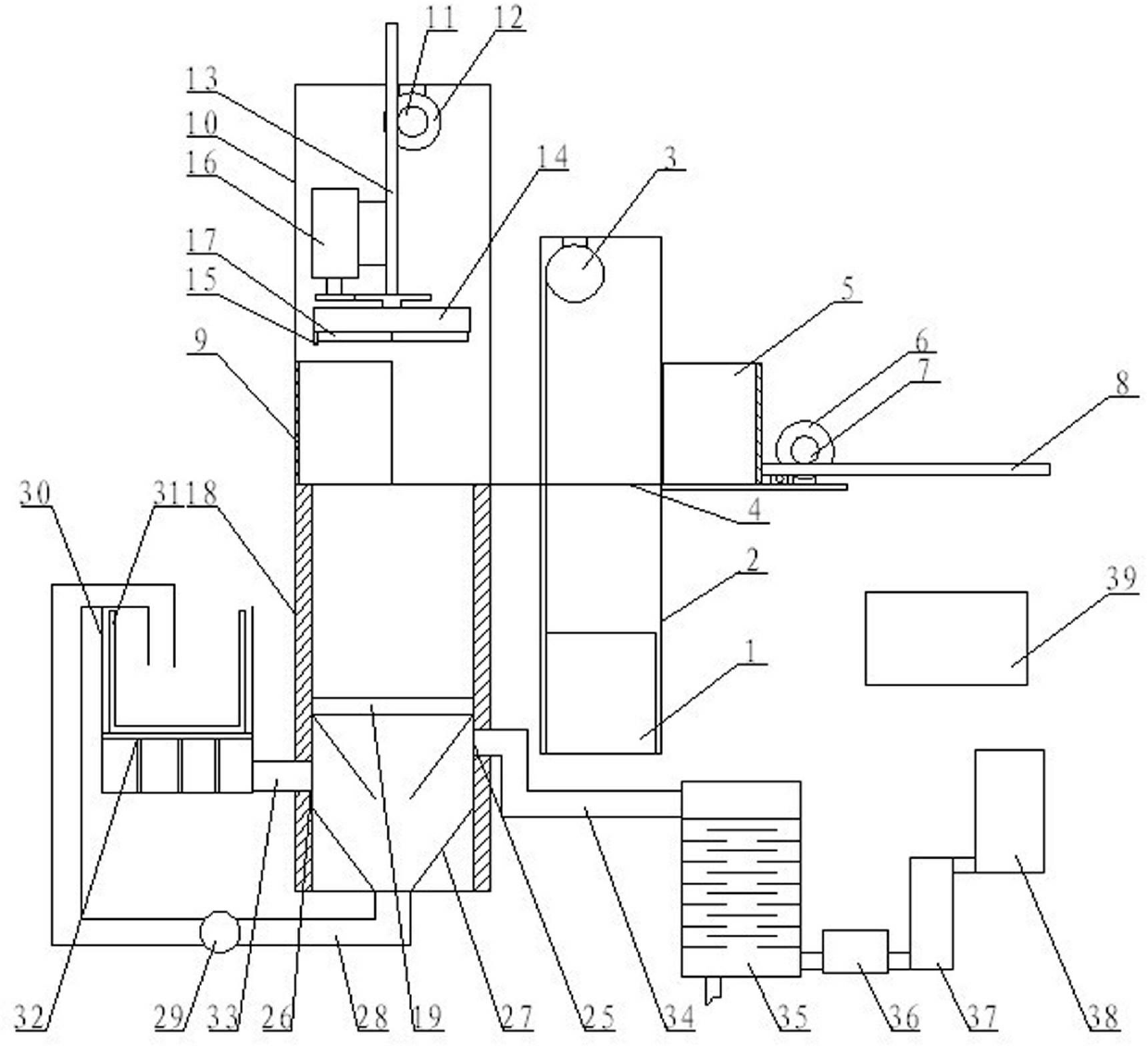

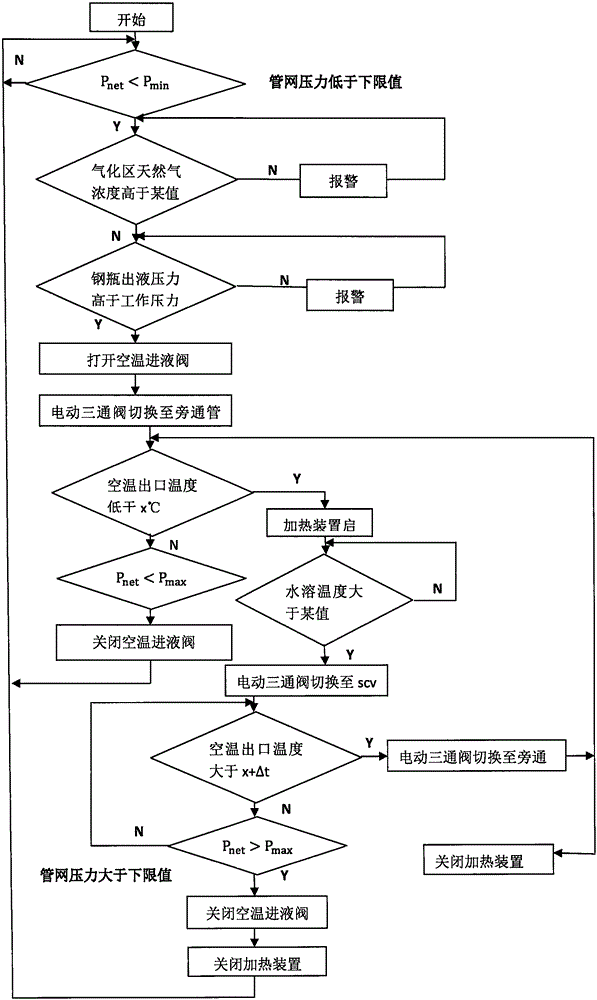

Ship gas/dual fuel engine LNG gasifying system based on exhaust energy recycling and control method thereof

ActiveCN103899440AImprove gasification effectImprove utilization efficiencyInternal combustion piston enginesFuel supply apparatusExpansion tankPlate heat exchanger

The invention aims at providing a ship gas / dual fuel engine LNG gasifying system based on exhaust energy recycling and a control method thereof. The ship gas / dual fuel engine LNG gasifying system comprises a heat transfer medium box, an exhaust heat exchanger, a heat dissipating device, an engine expansion water tank, an LNG gasifier and a liquid collecting plate. A heat transfer medium in the heat transfer medium box enters the exhaust heat exchanger through a first adjustable flow pump, enters the LNG gasifier after flowing through the heat dissipating device and then flows back to the heat transfer medium box, an external water source enters the engine expansion water tank and the heat dissipating device respectively through the liquid collecting plate and a three-way valve and then is drained, the external water source entering the heat dissipating device and the heat transfer medium are not mixed, and in other words, the external water source and the heat transfer medium flow in corresponding pipelines. The ship gas / dual fuel engine LNG gasifying system is high in heat dissipating capability and good in LNG gasifying effect, the engine exhaust emission heat can be recycled fully, the fuel utilization efficiency of an engine is improved, and the working environment of cabin marine engine operators can be obviously improved.

Owner:HARBIN ENG UNIV

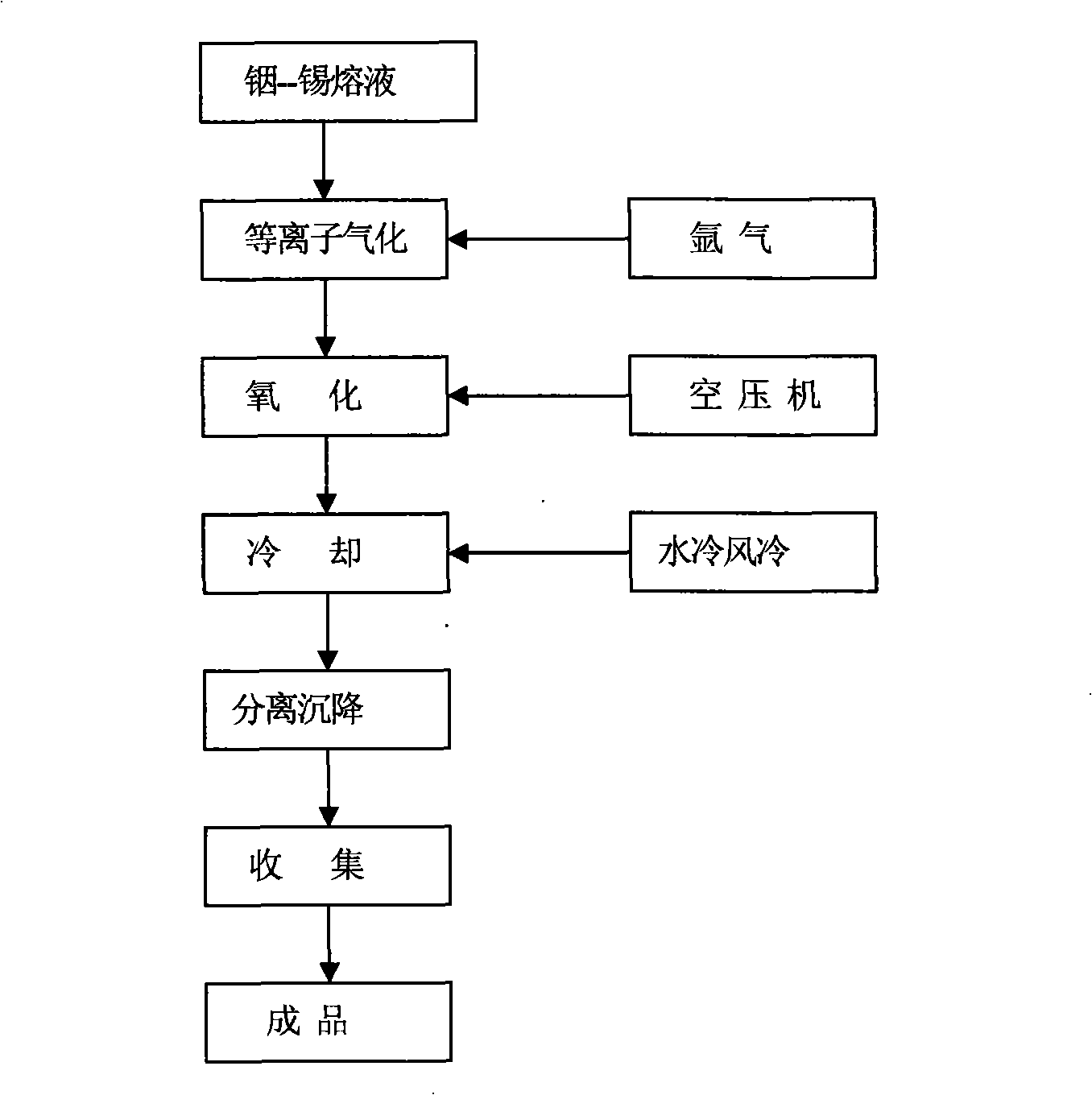

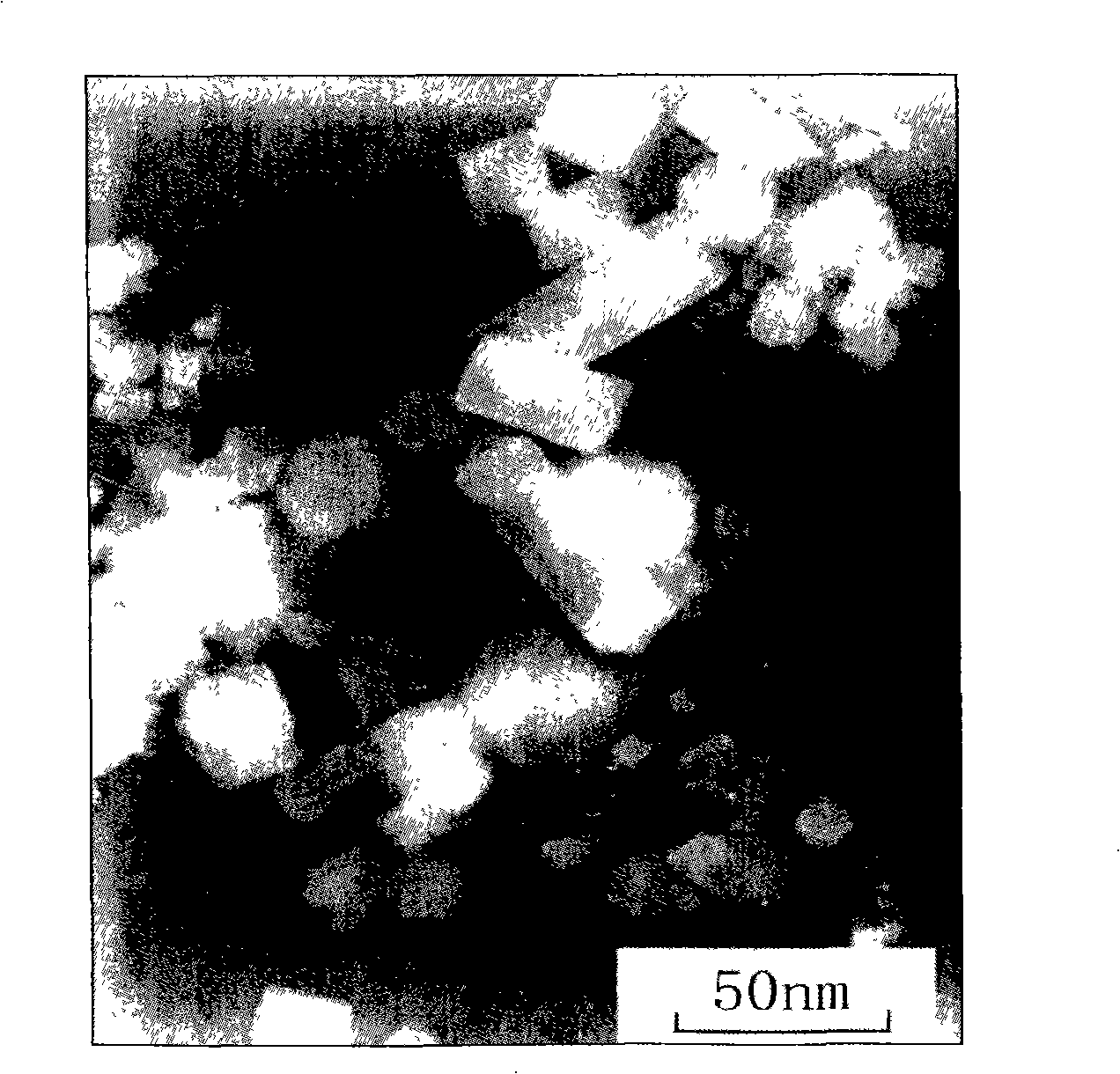

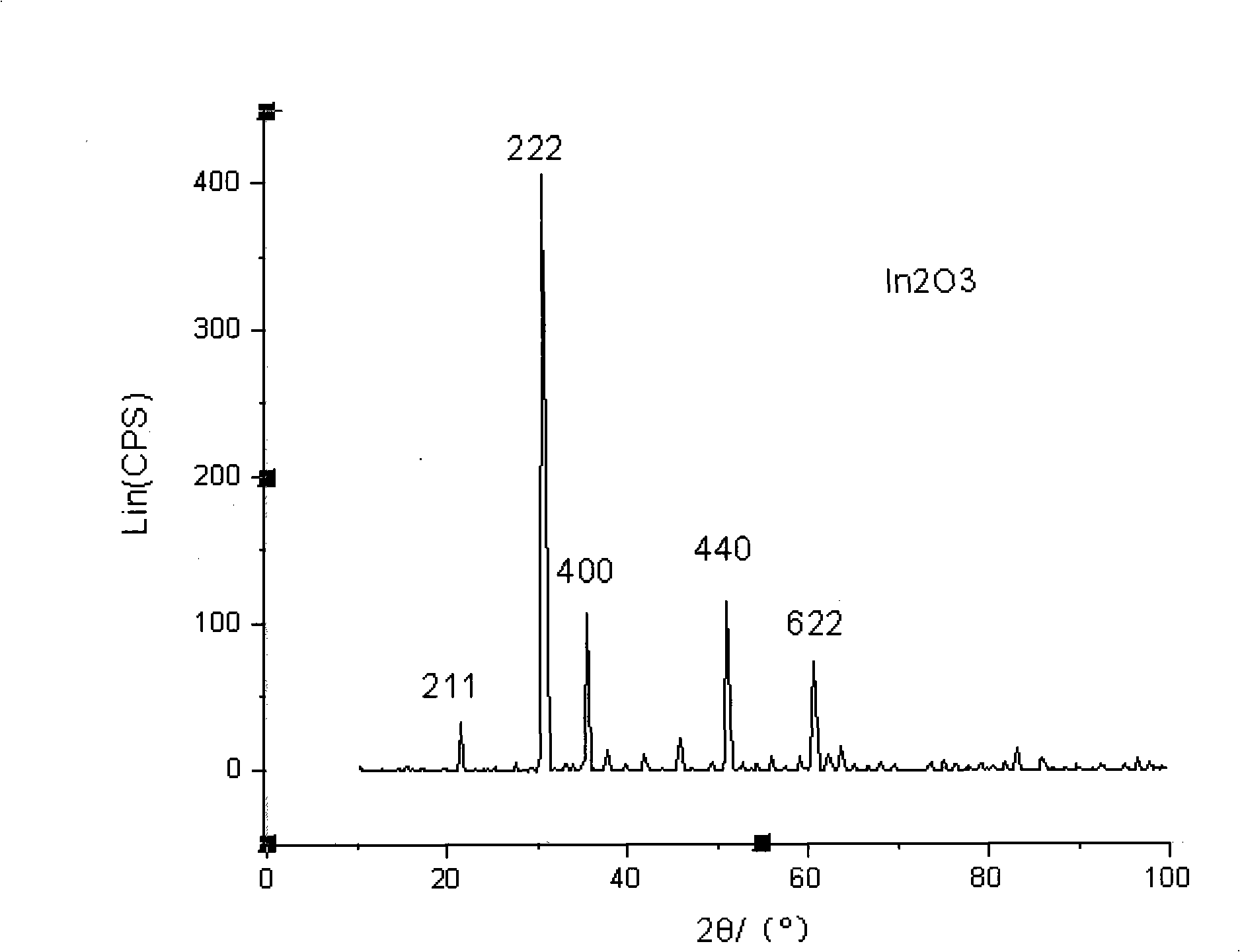

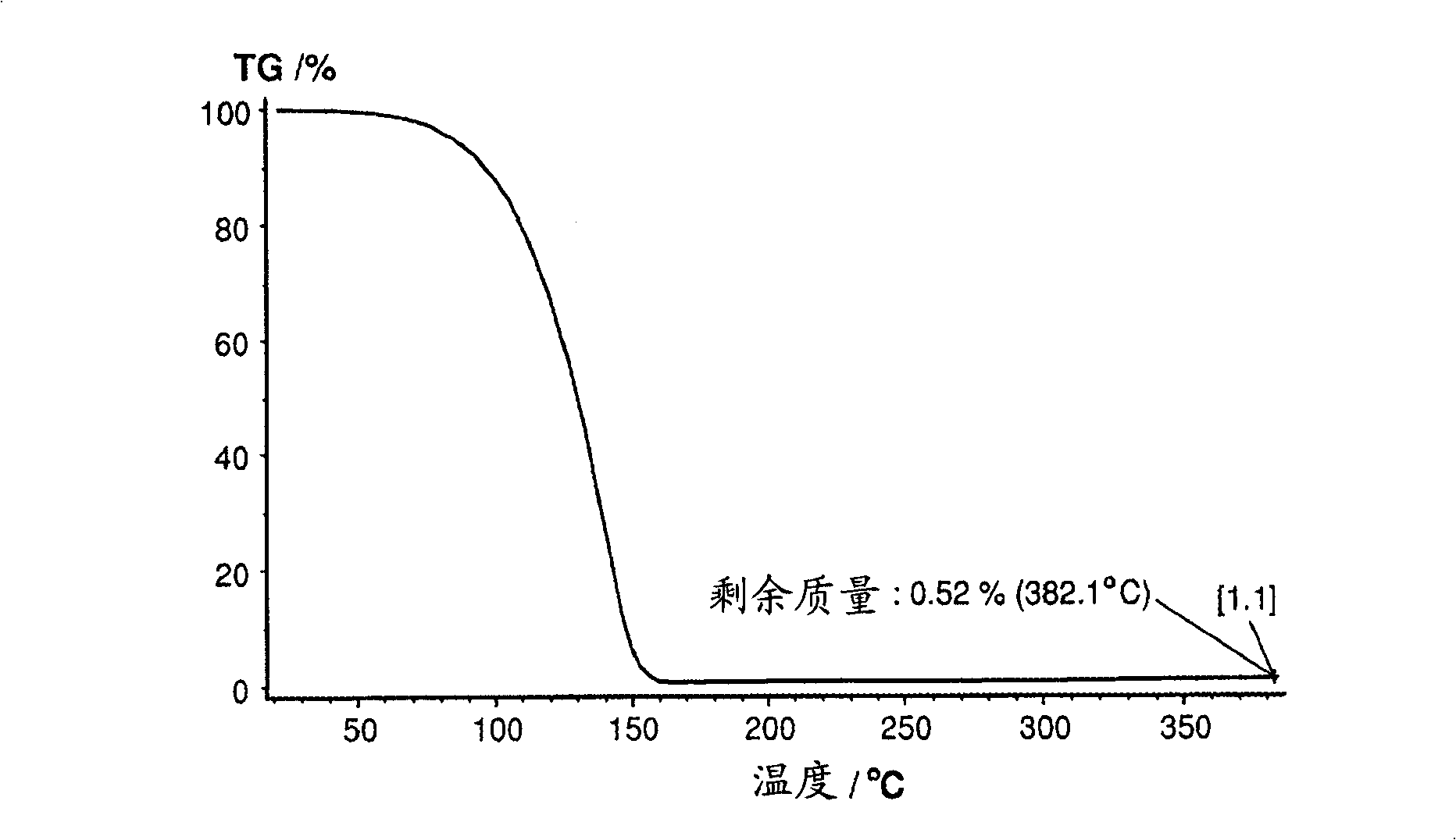

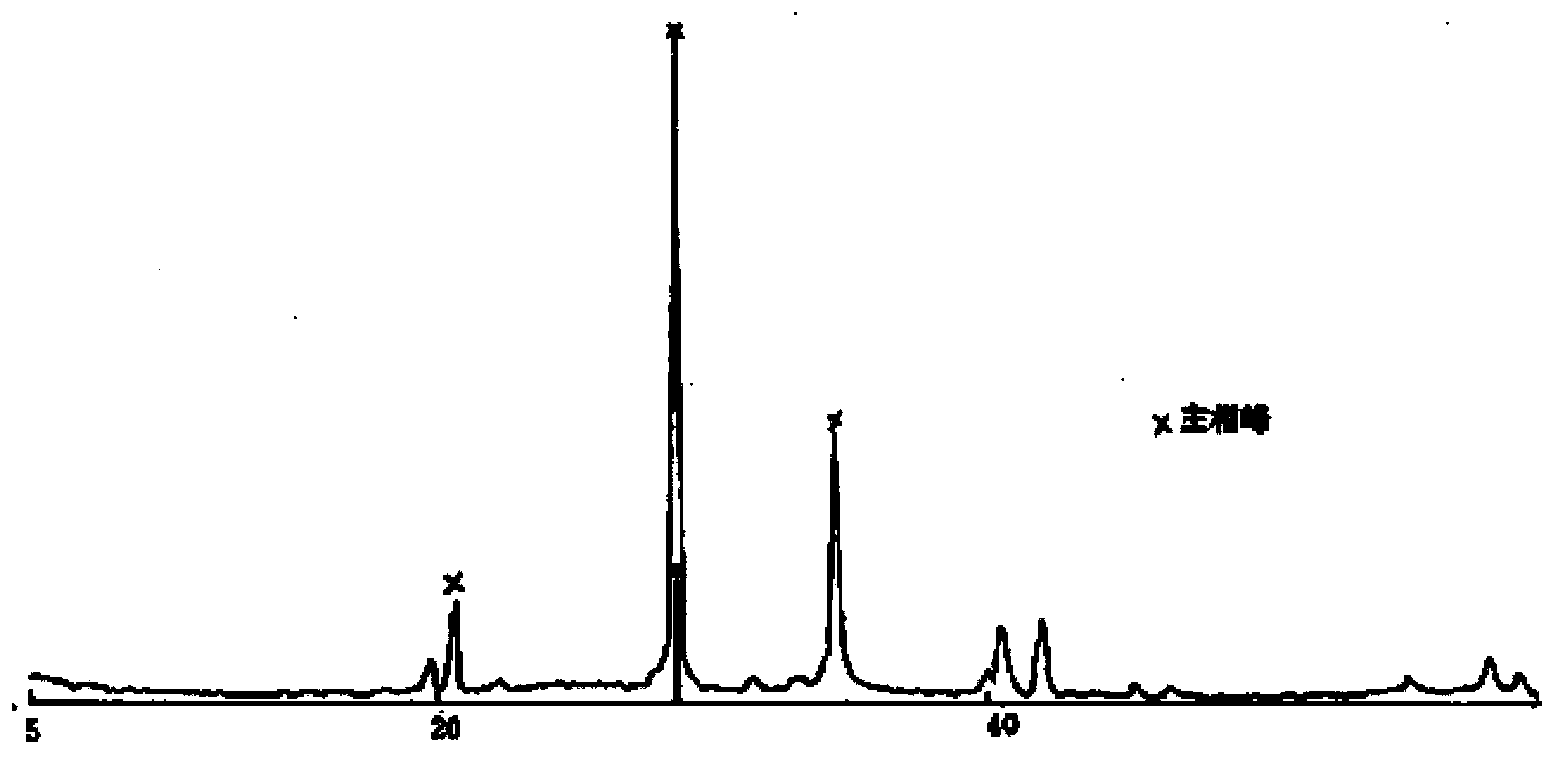

Method for producing nano-ITO powder with plasma electrical arc one-step method

InactiveCN101269834AGood dispersionGrowth inhibitionGallium/indium/thallium compoundsTin oxidesNano sizeGas phase

The invention relates to a method using a plasma arc one step method to prepare nano-size ITO powder. The method is characterized in that In-Sn alloy is continuously sent into a pot of a plasma reaction chamber by a feeding fixed point and fixed amount method, and the plasma reaction chamber uses Ar as a plasma gas, wherein, the working voltage ranges from 30 to 60 V, and the working current ranges from 100 to 400 A; alloyed material is used as a positive pole in the plasma reaction chamber, and a high igniter inflames between the positive pole and the negative pole of a nozzle to form an electric arc; inert gas around ionization forms stable plasma; raw materials are heated and melted by high temperature plasma to evaporate to form metal vapor which reacts with oxygen, and a great temperature grade is formed under the function of flowing water cooling of an inter layer of a reactor, thereby resulting in a high supersaturated zone in the metal vapor; through self nucleation, condensation and growth in a gas phase, nano-size to particle is formed. The nano-size ITO powder made by the method has the advantages of regular grain shape and high powder purity, and the method can realize continuous feeding, continuous reaction, and continuous milling. The efficiency is high, and compared with other methods, the method is easier to realize mass production.

Owner:KUNMING UNIV OF SCI & TECH

Metal precursor solutions for chemical vapor deposition

InactiveCN101343732AImprove gasification effectEasy to transportCopper organic compoundsChemical vapor deposition coatingArylGas phase

The present invention describes a metal precursor solution and metal source containing precursor liquid solutions for chemical vapor deposition processes, including atomic layer deposition, for fabricating conformal metal-containing films on substrates. More specifically, the metal source precursor liquid solutions are comprised of (i) at least one metal complex selected from -diketonates, -ketoiminates, -diiminates, alkyl metal, metal carbonyl, alkyl metal carbonyl, aryl metal, aryl metal carbonyl, cyclopentadienyl metal, cyclopentadienyl metal isonitrile, cyclopentadienyl metal nitrile, cyclopentadienyl metal carbonyl, metal alkoxide, metal ether alkoxide, and metal amides wherein the ligand can be monodentate, bidentate and multidentate coordinating to the metal atom and the metal is selected from group 2 to 14 elements, and (ii) a solvent selected from organic amides including linear amides and cyclic amides for such metal source containing precursors.

Owner:AIR PROD & CHEM INC

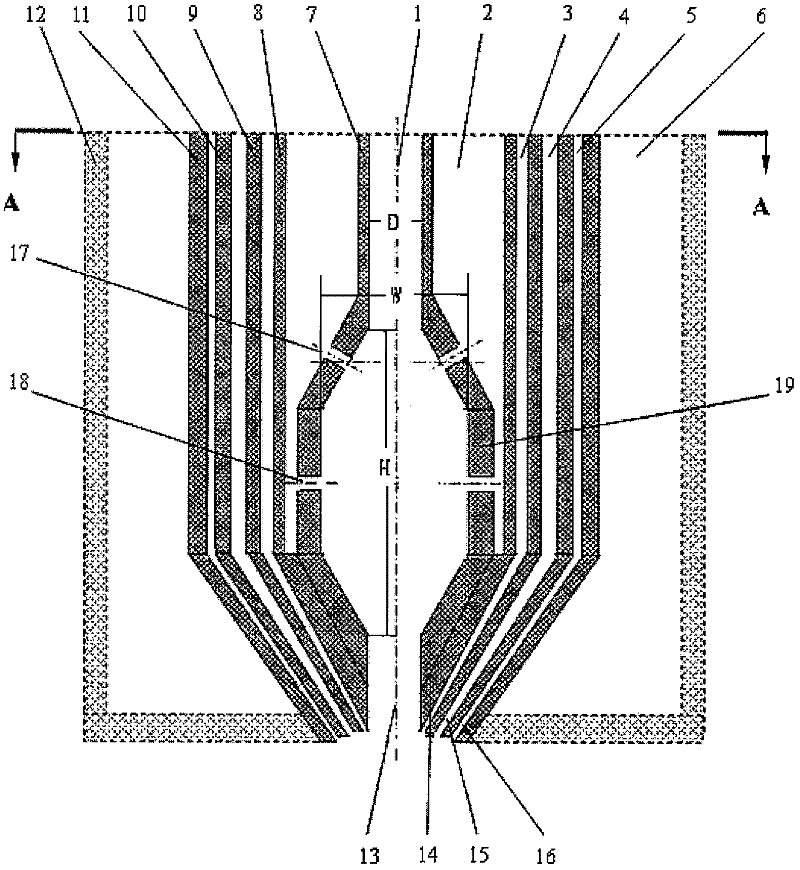

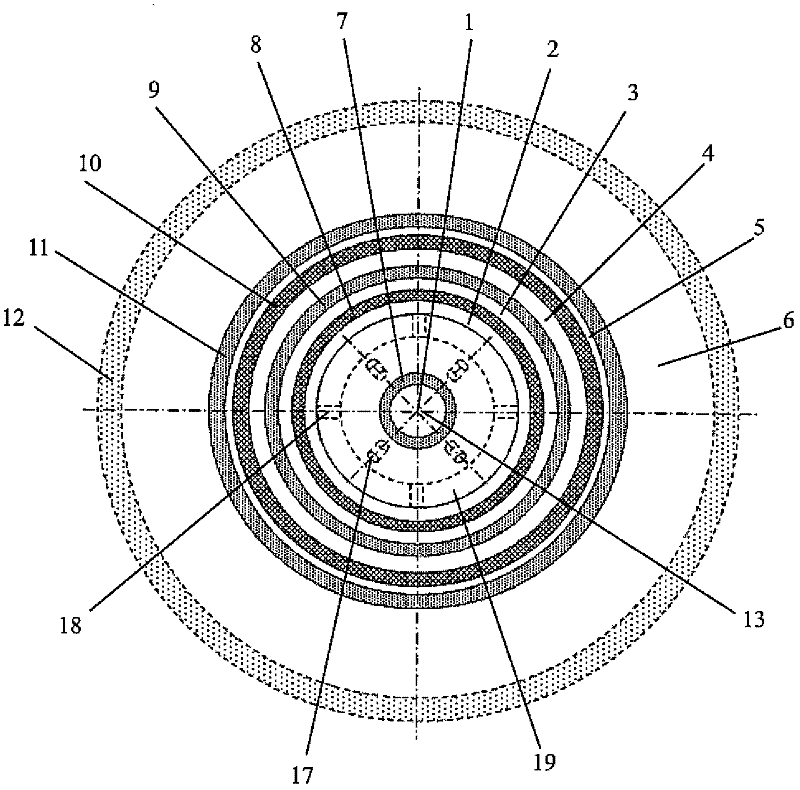

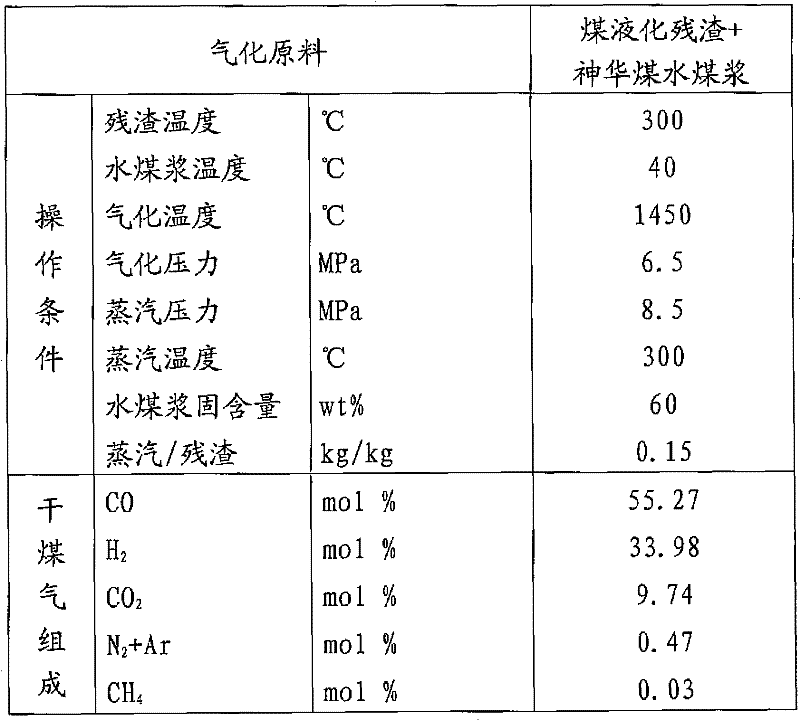

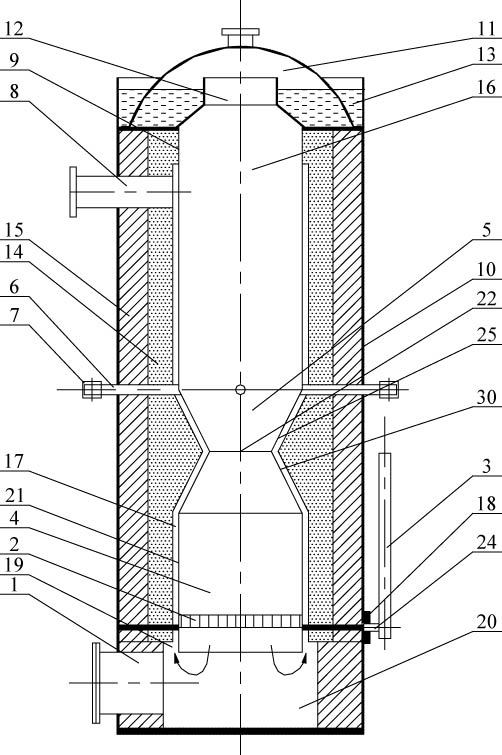

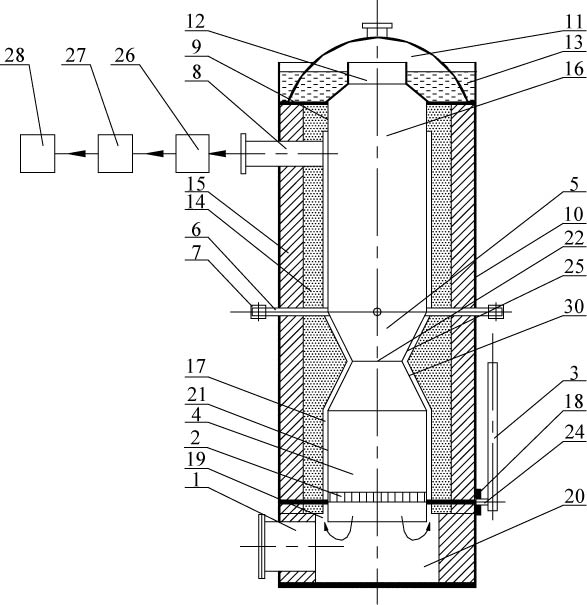

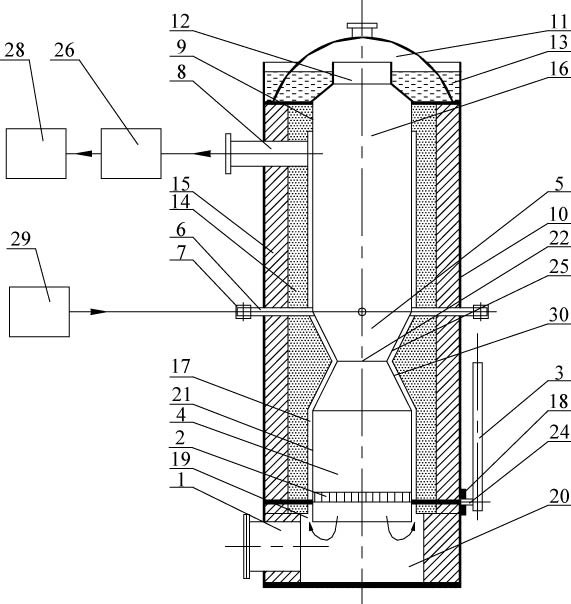

A joint gasification nozzle of coal liquefaction residue and coal water slurry and its application

ActiveCN102268300AImprove atomization effectCompact structureLiquid spraying apparatusGranular/pulverulent flues gasificationCoal waterLiquid state

The invention discloses a coal liquefaction residue and coal water slurry combined gasification nozzle which comprises a coal liquefaction residue pipe, a steam circular pipe, an inner circular oxygen pipe, a coal water slurry circular pipe, an outer circular oxygen pipe, a water-cooling circular pipe and a coal liquefaction residue and steam mixing chamber, wherein the coal liquefaction residue pipe, the steam circular pipe, the inner circular oxygen pipe, the coal water slurry circular pipe, the outer circular oxygen pipe and the water-cooling circular pipe are coaxially arranged from inside to outside in sequence; one end of the coal liquefaction residue and steam mixing chamber is communicated with the tail end of the coal liquefaction residue pipe, and the other end of the mixing chamber is communicated with a coal liquefaction residue and steam nozzle orifice; the wall of the mixing chamber is provided with a steam nozzle orifice which is communicated with the steam circular pipe; the tail end of the steam circular pipe is closed; the tail end of the coal water slurry circular pipe is communicated with the coal water slurry nozzle orifice; the tail end of the inner circular oxygen pipe is communicated with the inner circular oxygen nozzle orifice; and the tail end of the outer circular oxygen pipe is communicated with the outer circular oxygen nozzle orifice. By using the gasification nozzle, combined gasification of viscous heavy fuels such as molten coal liquefaction residues, high-temperature liquid-state heavy oil, residual oil and the like and coal water slurry can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

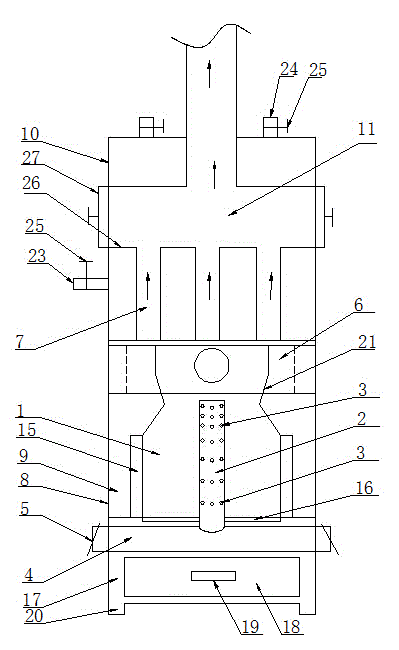

Down-draught type biomass gasifier for secondarily cracking tar

ActiveCN101812327AGuaranteed uptimeImprove energy efficiencyCombustible gas productionTarEngineering

The invention relates to a down-draught type biomass gasifier for secondarily cracking tar and aims at the problems that tar in the down-draught type biomass gasifier has high content and blocks a pipeline after being combined with water, ash, carbon and the like so as to influence the stable running of the gasifier. The lower end of an inner gasifier tube is arranged in an ash bin; a movable gassifier gate is arranged below the inside of a reduction chamber; a fuel gas secondary cracking chamber is arranged between a flame-retardant coating and the inner gasifier tube; a fuel gas secondary cracking chamber inlet is arranged between the outer wall at the lower end of the inner gasifier tube and the inner wall of the flame-retardant coating; one end of an air inlet pipe passes through the side wall of an outer gasifier tube which is arranged above a hearth necking, a heat-insulating layer, a flame-retardant coating and a fuel gas secondary cracking chamber and the side wall of the inner gasifier tube as well as is communicated with a hearth; the other end of the air inlet pipe is in threaded connection with a plug; the side wall of the plug is provided with a plurality of air inlet holes; and an air exhaust pipe passes through the side wall of the outer gasifier tube, the heat-insulating layer and the flame-retardant coating and is communicated with the fuel gas secondary cracking chamber. The invention can realize that tar in the fuel gas is secondarily cracked in a high-temperature area, greatly reduce the content of the tar in combustible gas and meet the requirement of rural residents on gas application.

Owner:湖南哈工机器人研究院有限公司

Multifunctional catalysis composition

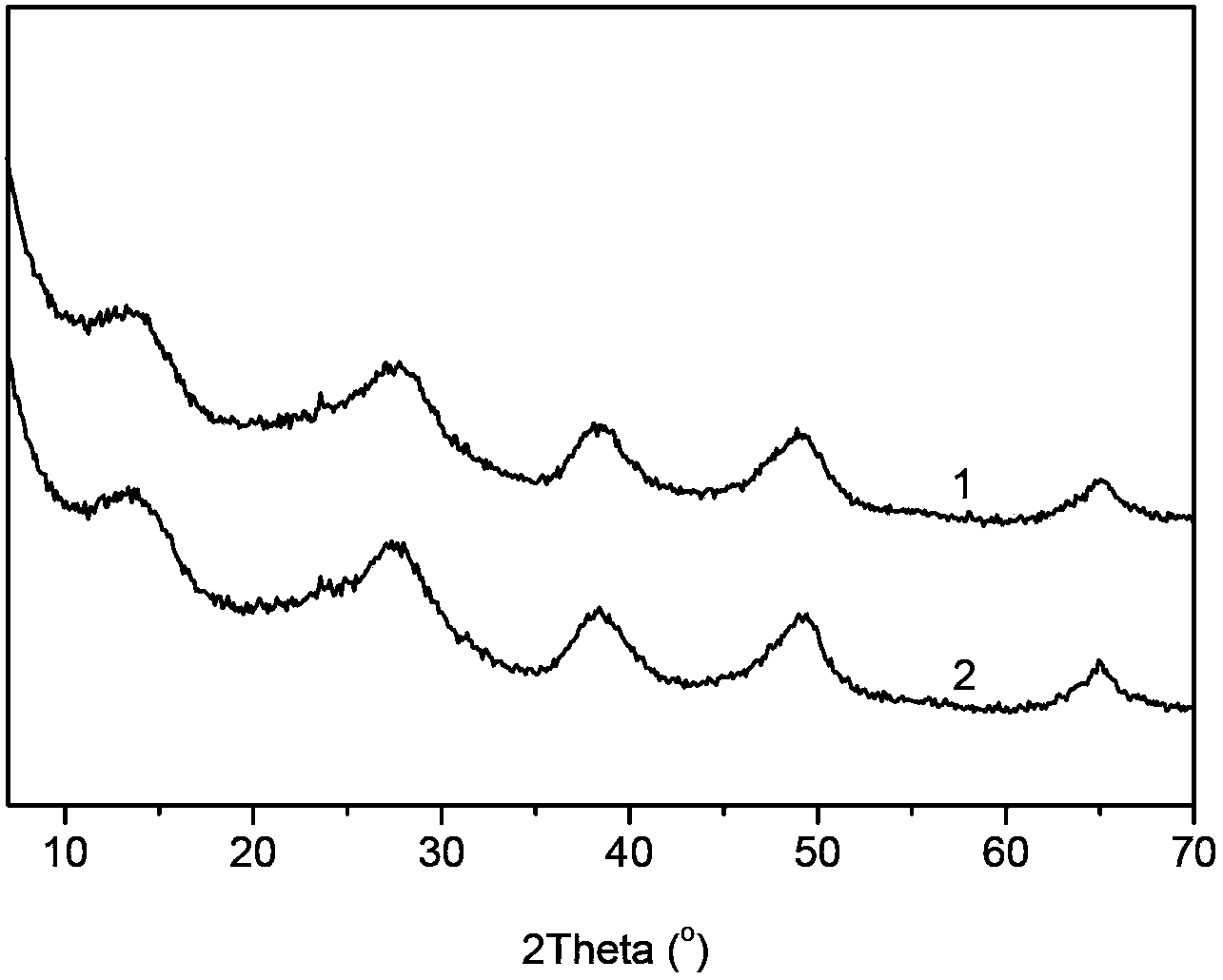

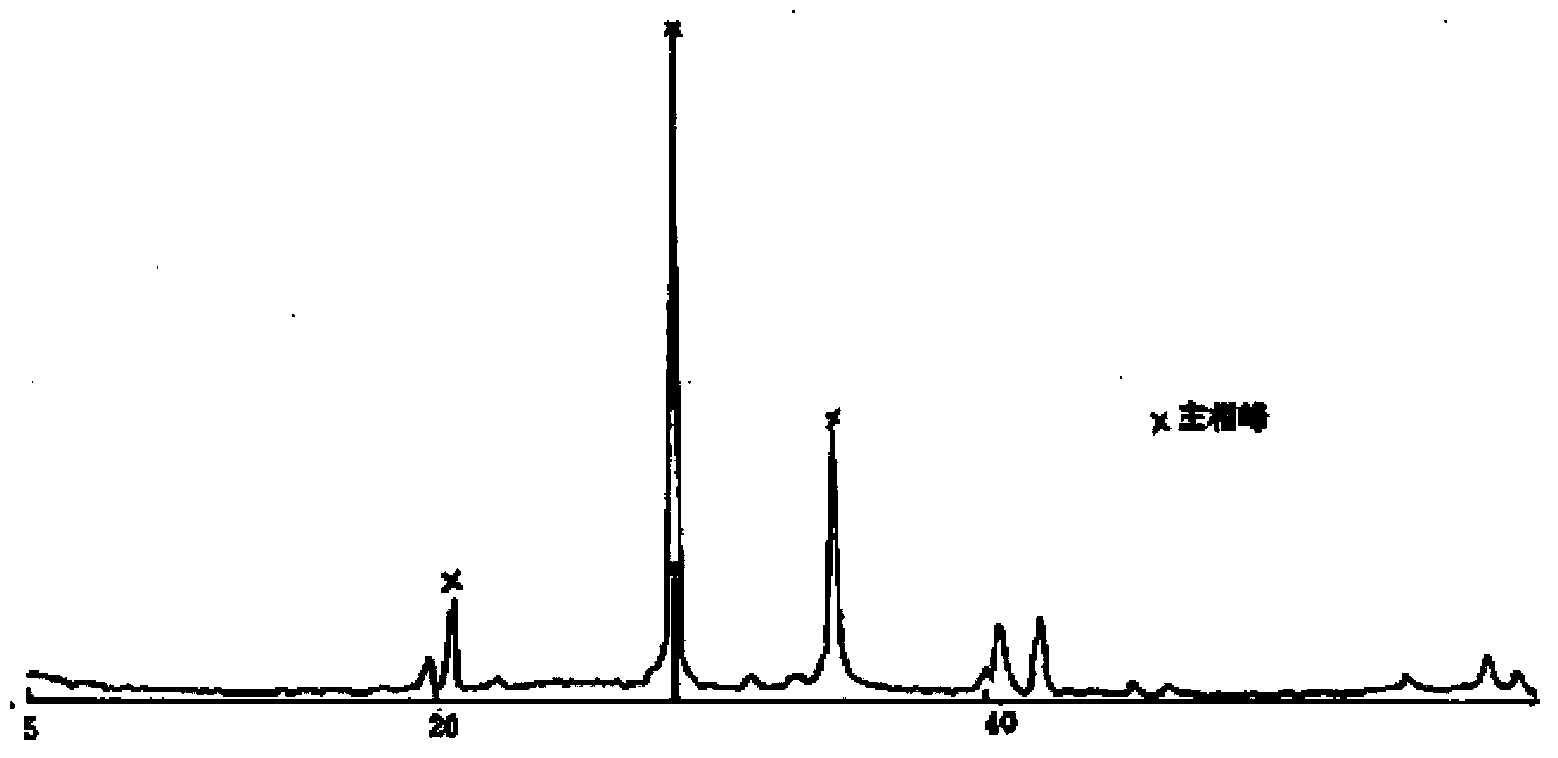

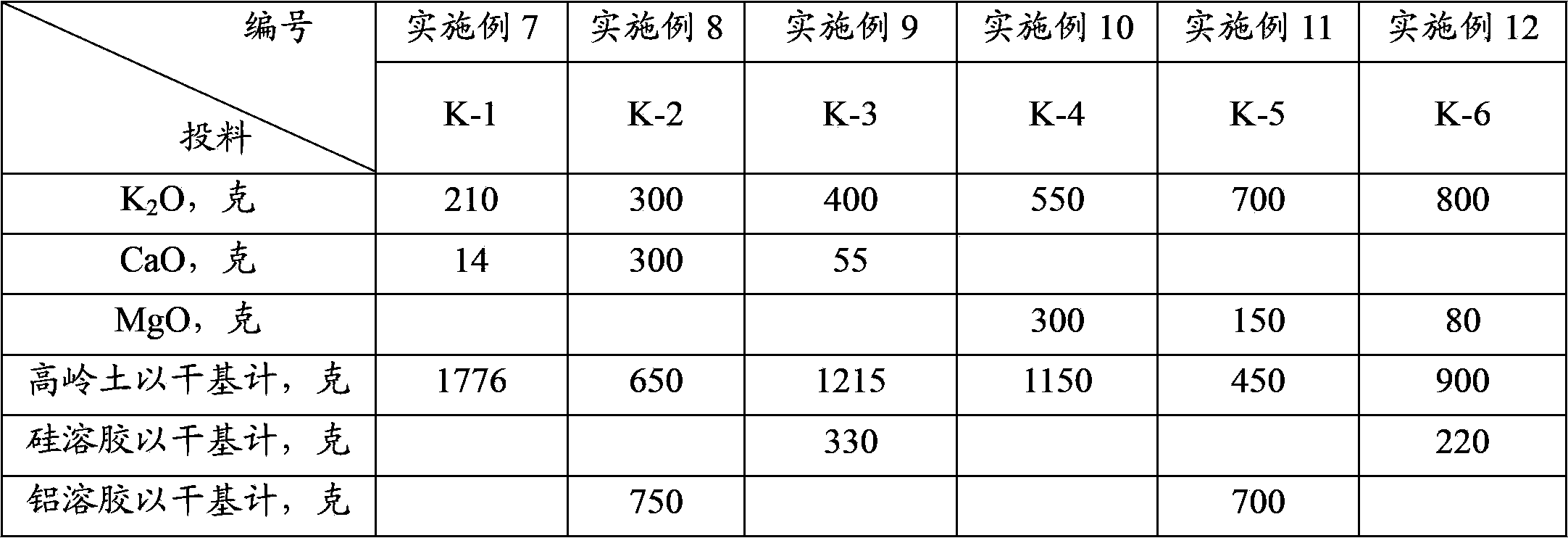

ActiveCN103566962AGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMolecular sieve catalystsBoehmiteOxide

A multifunctional catalysis composition comprises 1-50wt% of a mesoporous aluminosilicate material, 1-40wt% of a gasification active component, 1-60wt% of a cracking active component, 0-70wt% of clay and 5-97wt% of a heatproof inorganic oxide matrix, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm The catalysis composition can reduce the gasification temperature of the cracking gasification conversion of hydrocarbon oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

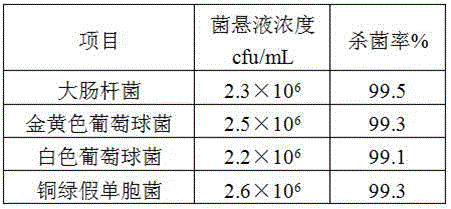

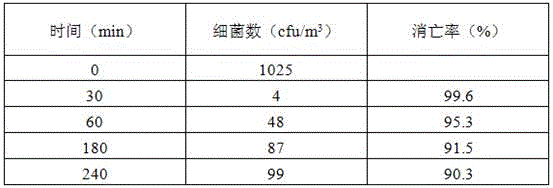

Traditional Chinese medicine sanitizer and preparation method thereof

InactiveCN106538638AEliminate bad smellNo bad smellBiocideDead animal preservationEscherichia coliChlorogenic acid

The invention belongs to the technical field of sanitizers, and particularly relates to a traditional Chinese medicine sanitizer and a preparation method thereof. The sanitizer is prepared from the following Chinese herbal medicine raw materials including, by weight, 10-30 parts of wormwood, 1-5 parts of garlic, 10-30 parts of honeysuckles, 5-21 parts of myrcia, 10-30 parts of cordate houttuynia and 2-15 parts of astragalus membranaceus. The garlic is table vinegar extractive liquid of garlic, and the weight ratio of the garlic to the table vinegar is 1:(3-10); and the sanitizer prepared from the Chinese herbal medicine raw materials comprises, by weight, 10-30% of chlorogenic acid. The prepared sanitizer has an obvious bactericidal effect on common germs such as staphylococcus aureus, escherichia coli, staphylococcus albus and pseudomonas aeruginosa in air; and the sanitizer has the advantages of being quick in effect initiating, long in duration time, low in cost, simple in preparation technique and the like.

Owner:李湘钰

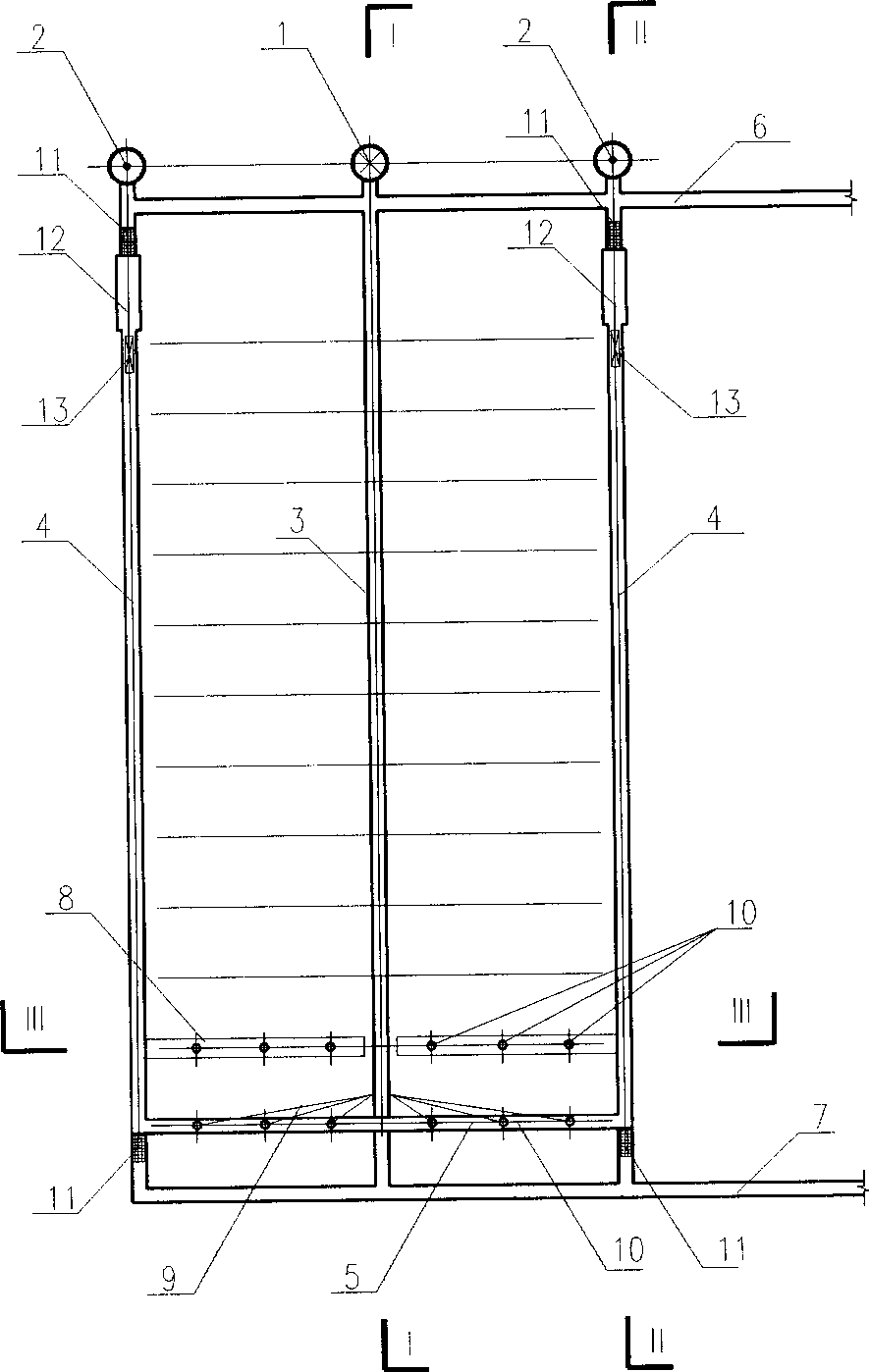

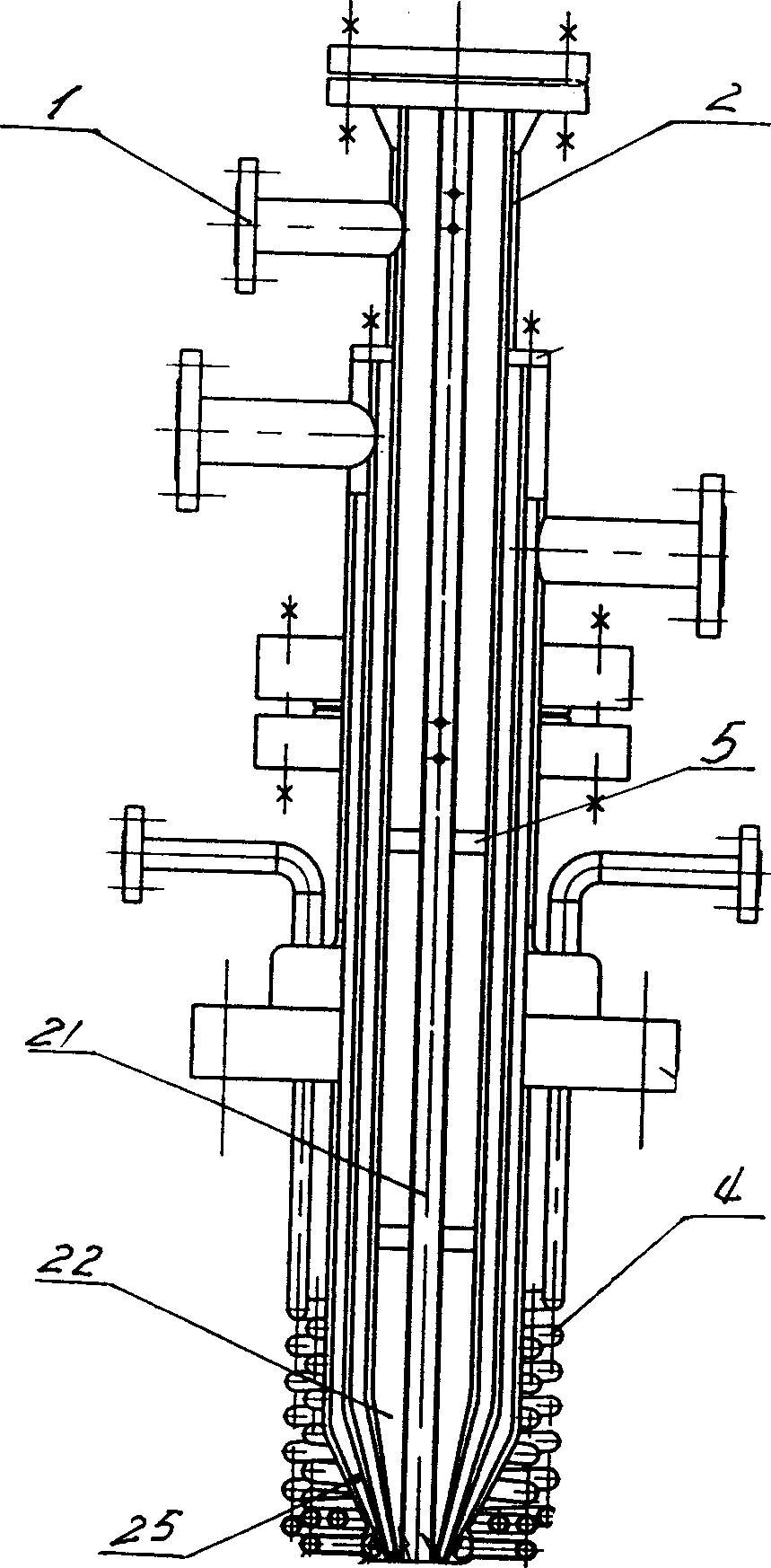

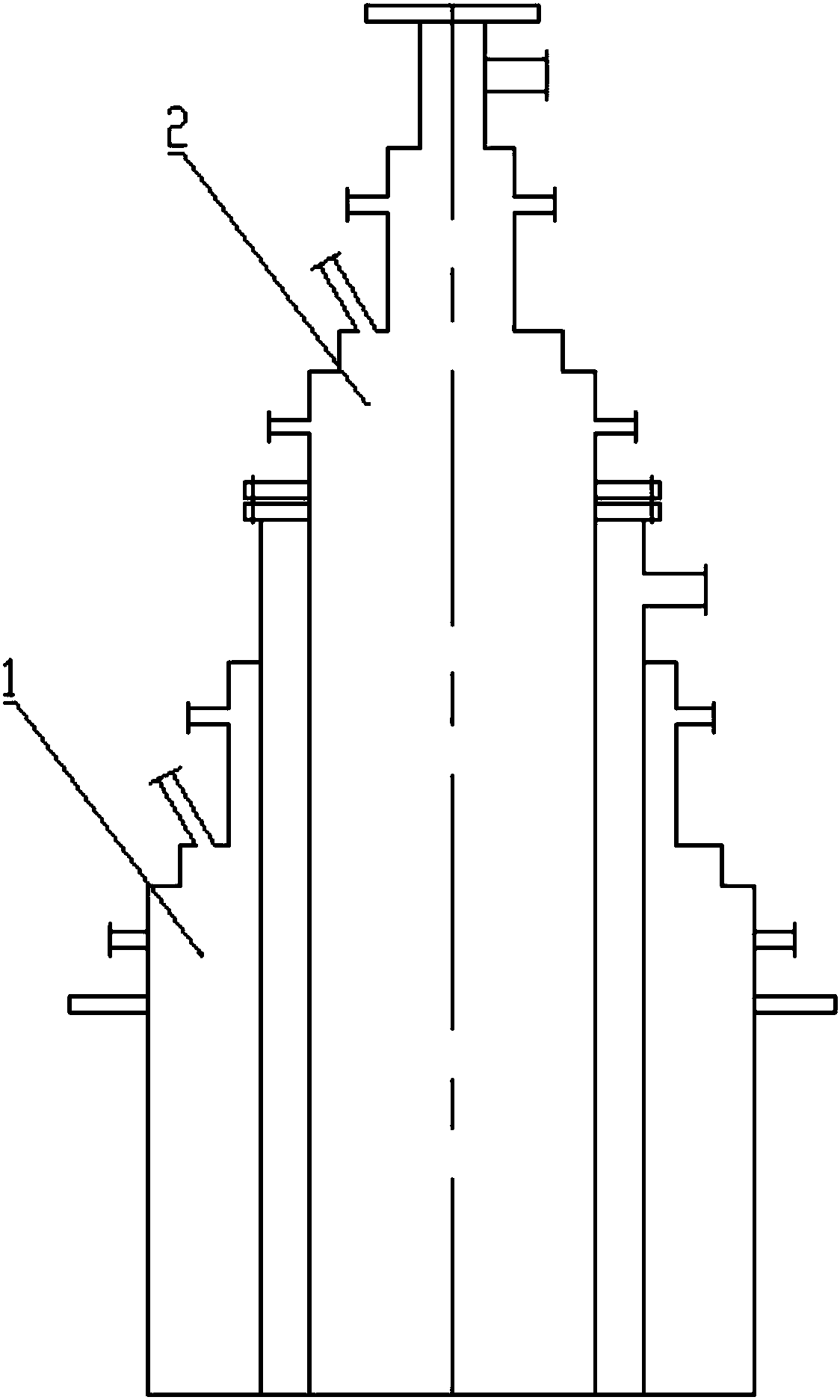

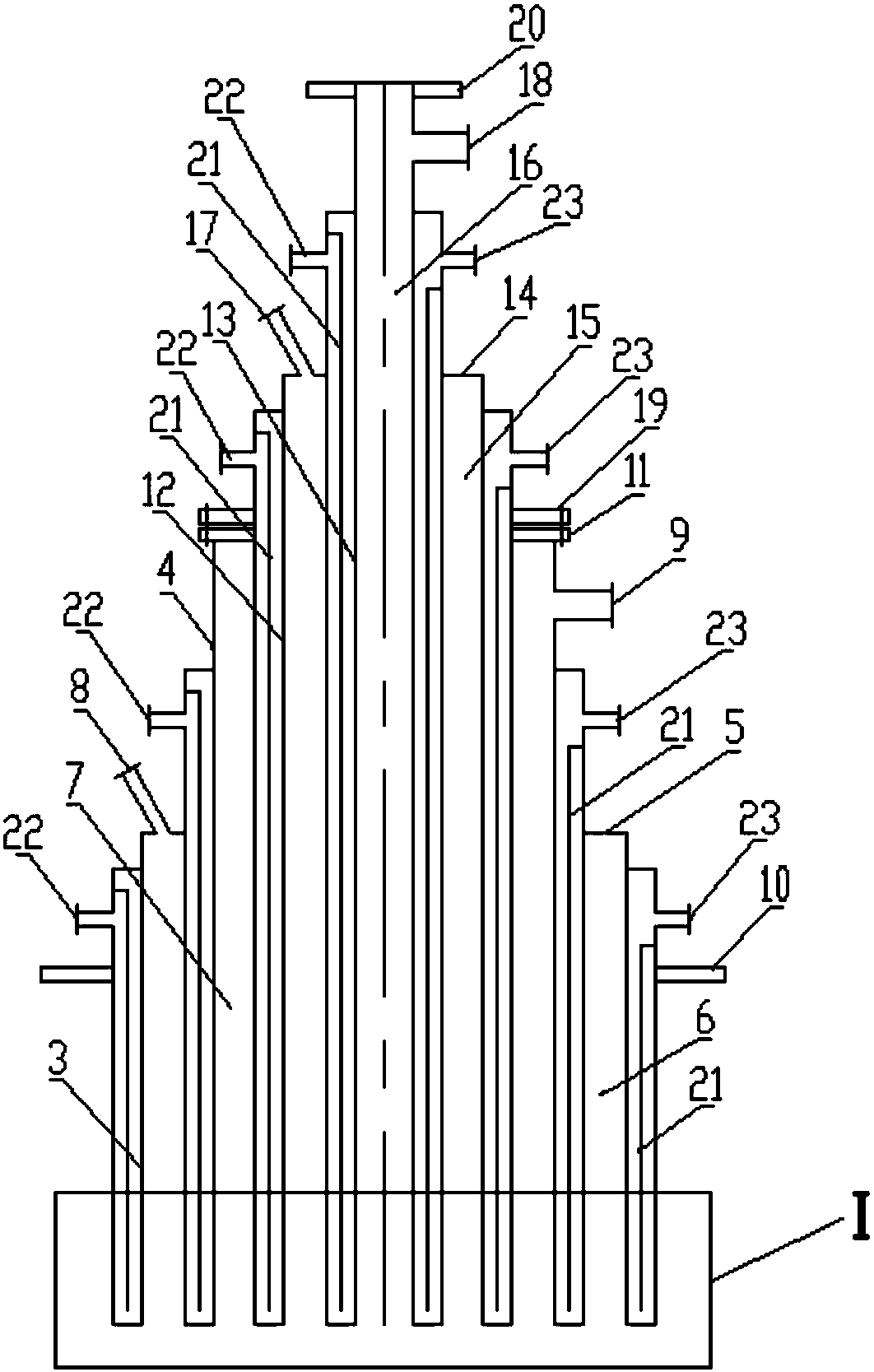

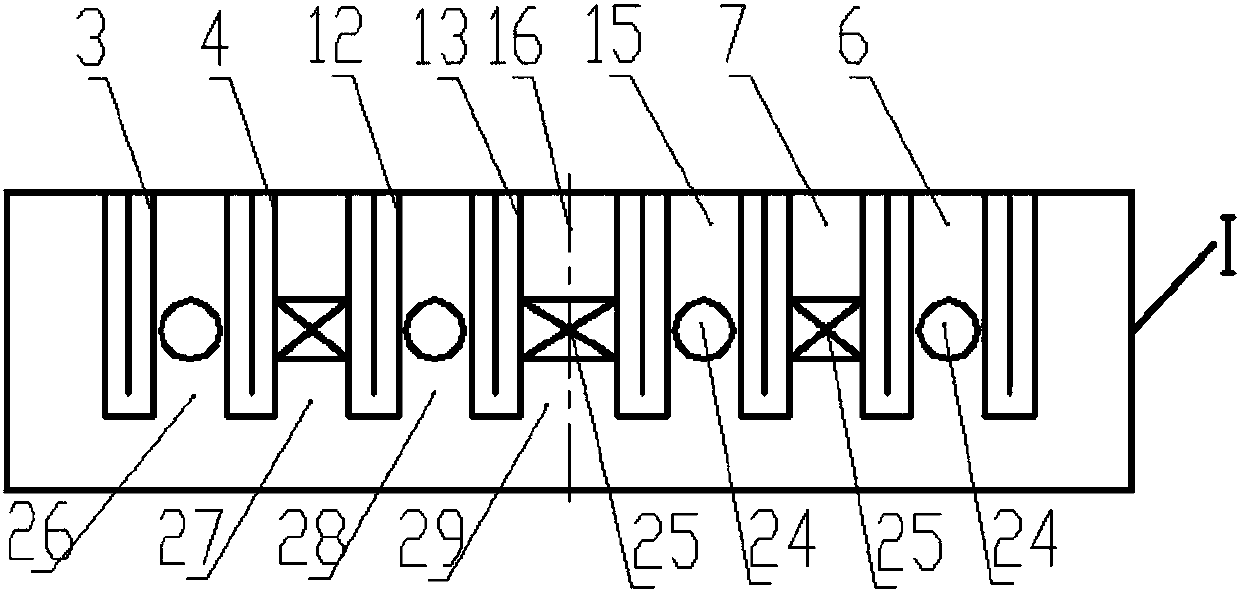

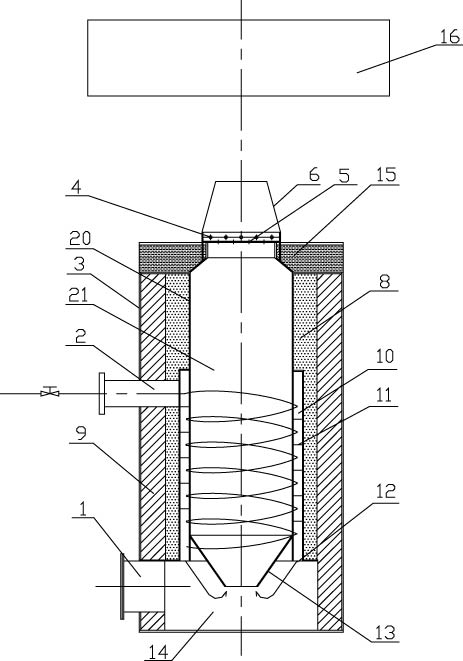

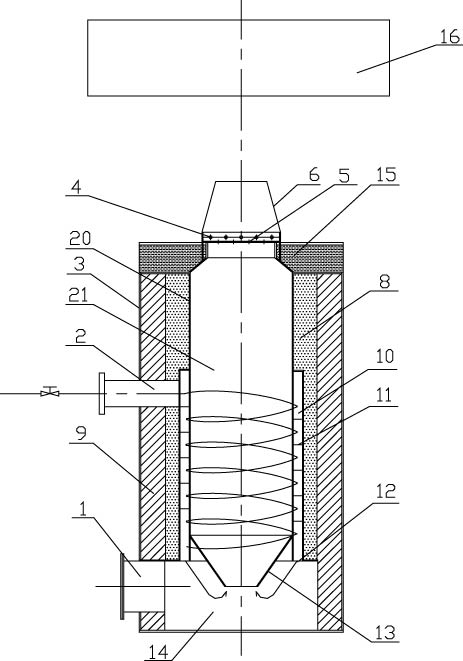

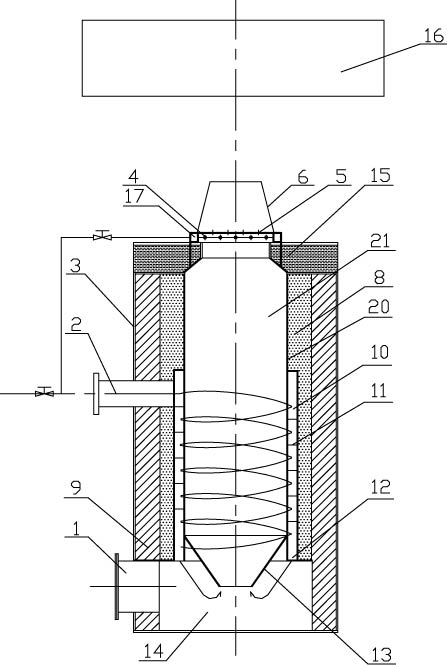

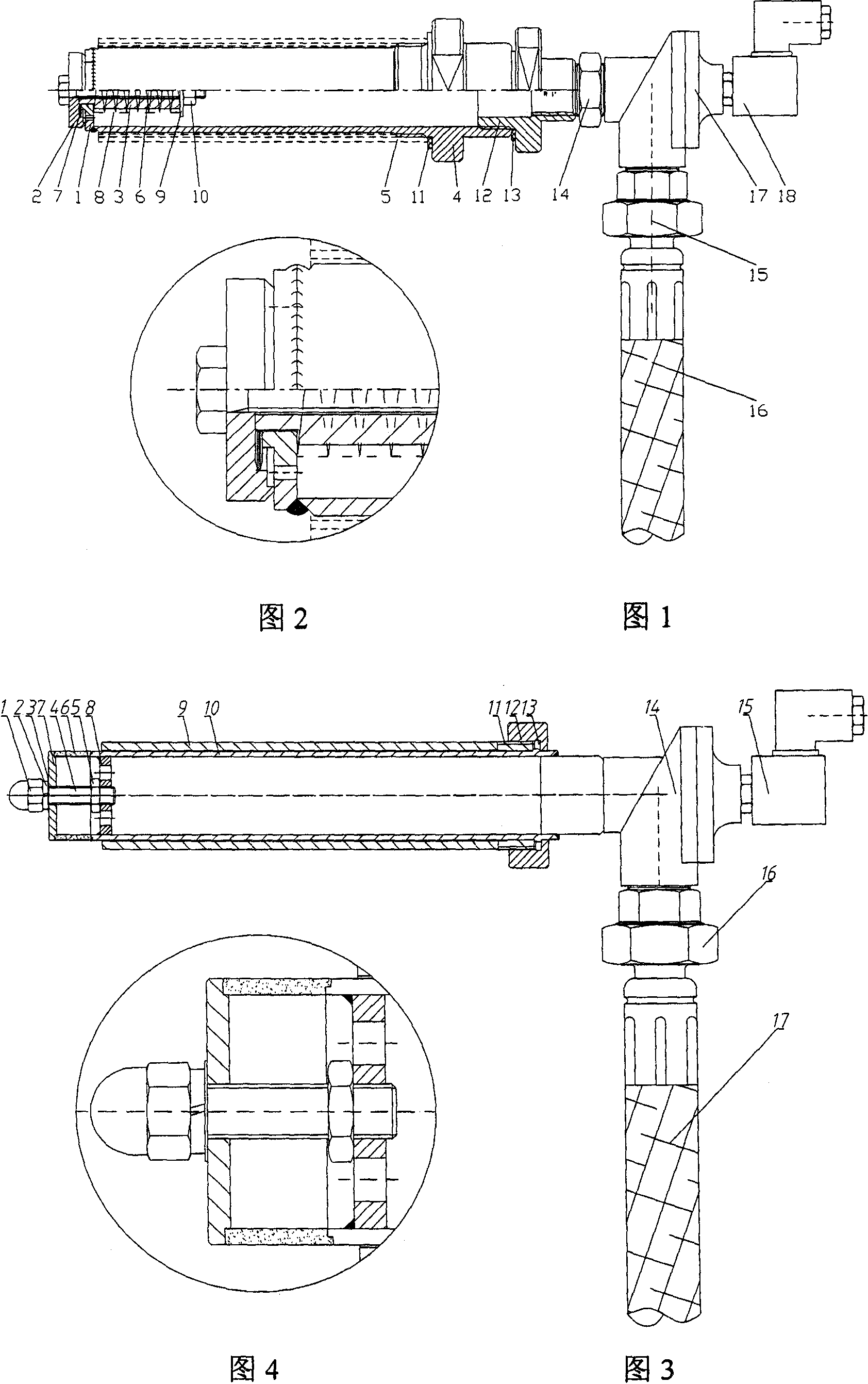

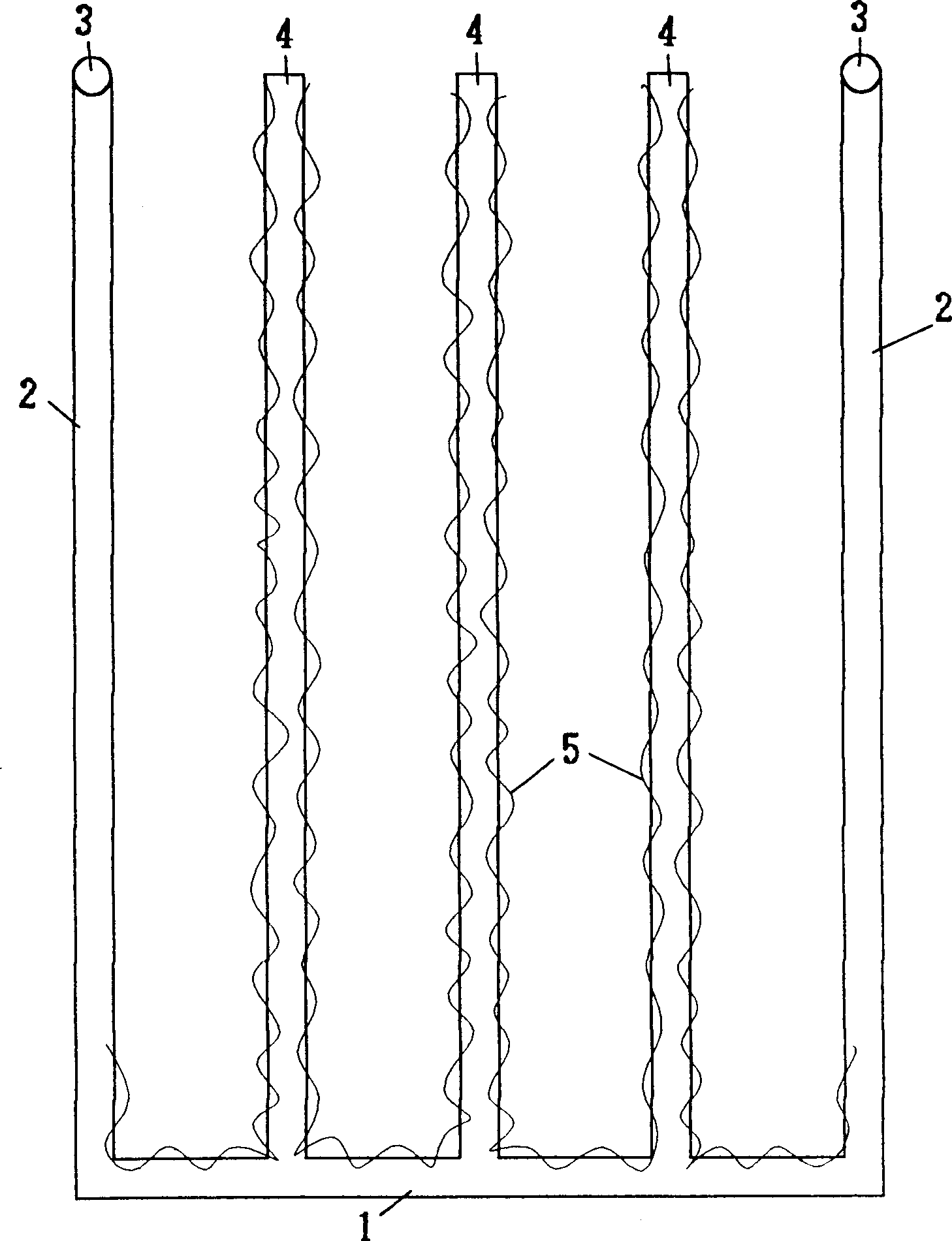

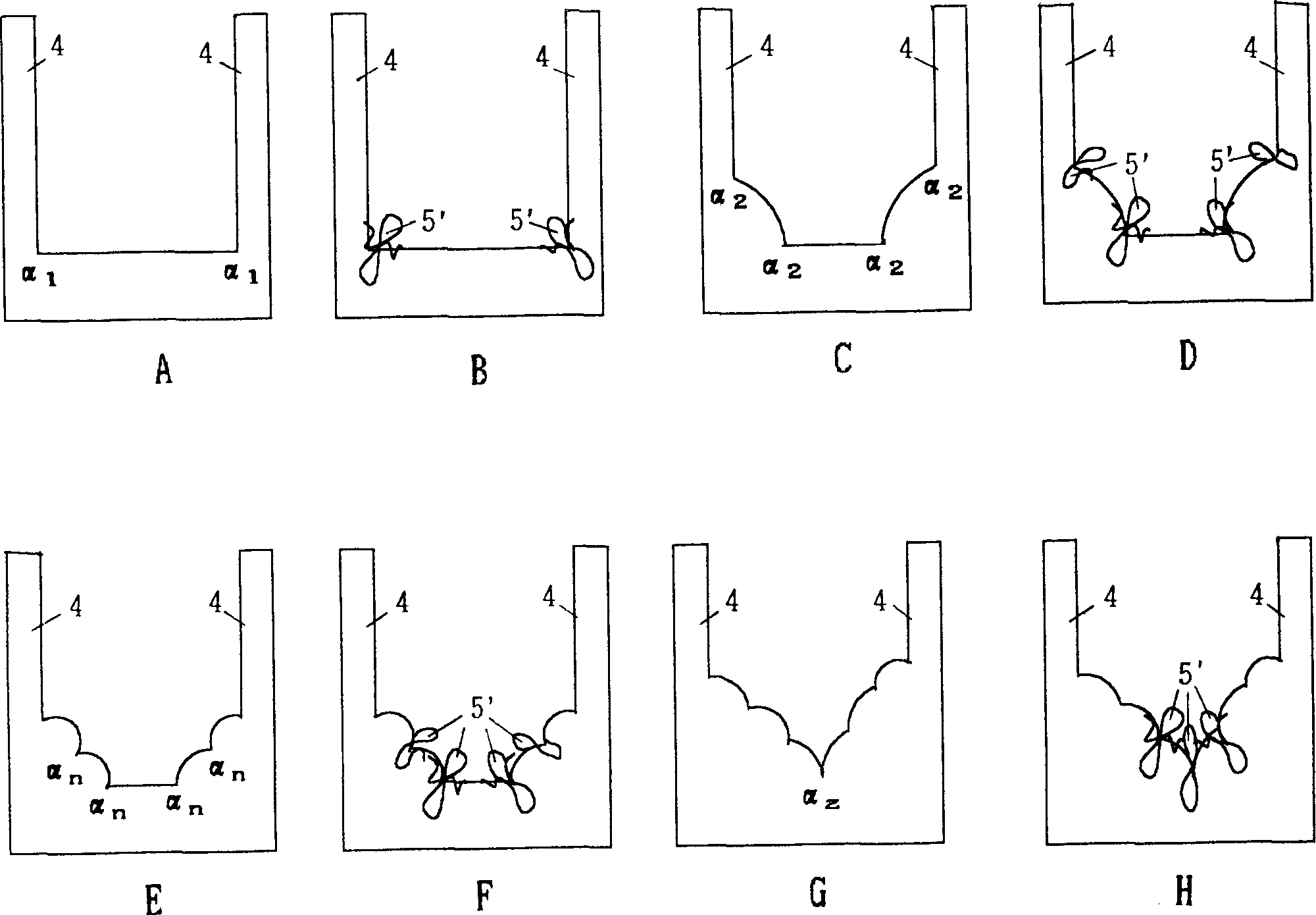

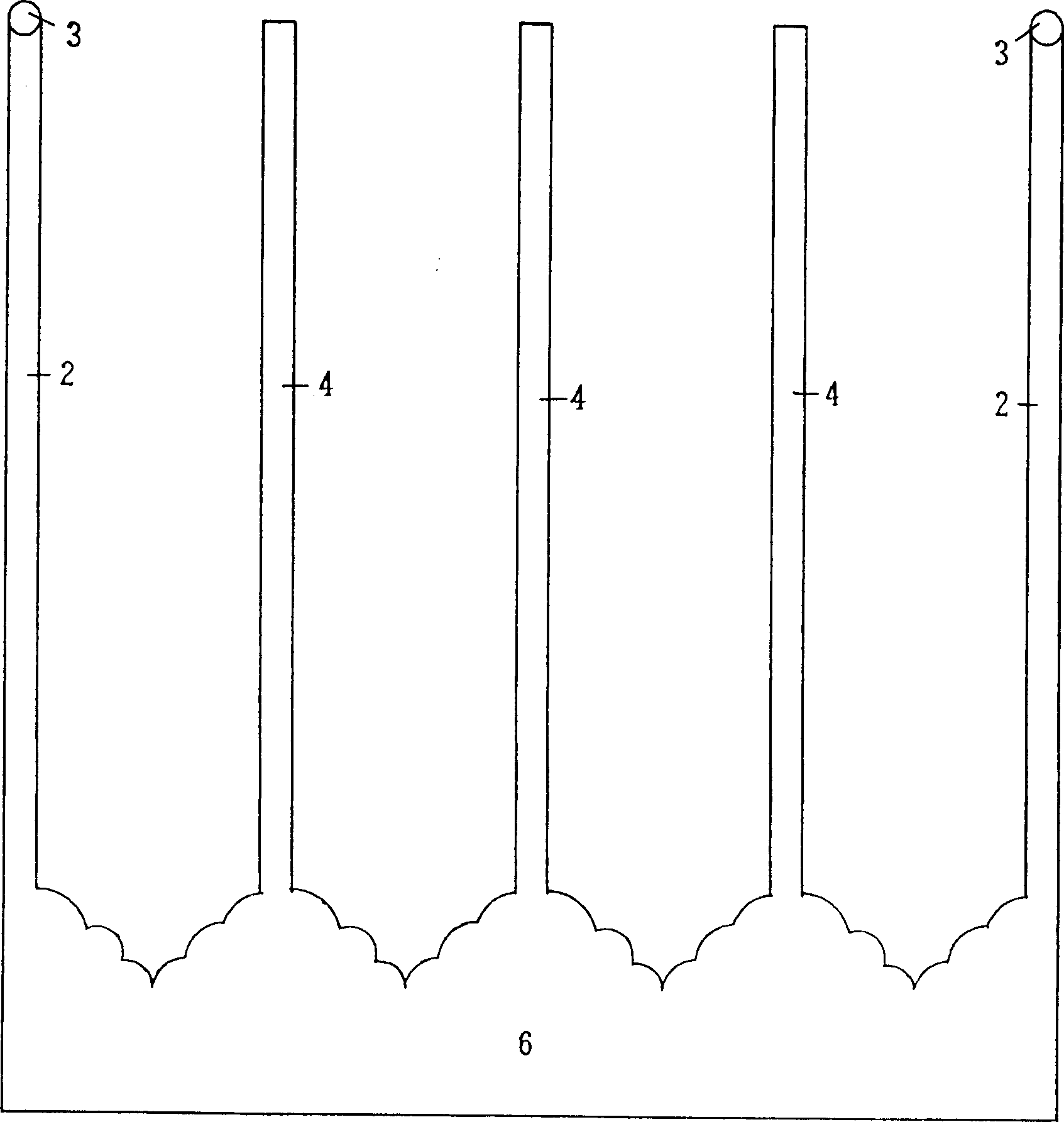

Lane control gas supply side line underground gasification furnace

InactiveCN101382062AControllable gas supply pointIncrease gasification strengthConstructionsCoal gasificationProcess engineeringEngineering

The invention provides an underground lane control gas supply side line gasification furnace. The furnace comprises a coal gas passage, multi-drill holes which are drilled directionally on the bottom of a coalbed in the coal gas passage, a gas supply lane, a gas supply pipe and a plurality of temperature pressure and flow testing instrument valves arranged in a base plate rock of the coalbed, and a gas supply branch pipe between the gas supply lane and the multi-drill holes. The system has a simple structure, easy configuration and reliable operation. The furnace capable of carrying out simultaneous multi-point gasification has the advantages of higher output, gas supply protection, controllability, adjustment as required, and the like. The furnace can solve a plurality of problems of poor gasification effect, discontinuous and unstable gas production, small gas output, low gasification rate, and the like.

Owner:ENN SCI & TECH DEV

Multifunctional catalysis composition

ActiveCN103566918AGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsActive componentPetroleum

A multifunctional catalysis composition comprises 1-70wt% of a mesoporous aluminosilicate material, 1-60wt% of a gasification active component, 0-70wt% of clay and 5-98wt% of a heatproof inorganic oxide by oxide, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm. The catalysis composition is used for the cracking gasification of heavy petroleum hydrocarbons, and realizes a low gasification temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas phase medium gasifying nozzle and using method

ActiveCN1648525AExtended operating lifeSolve the short service lifeHydrogenGas-gas reaction processesSpray nozzleClerestory

The gas phase medium gasifying nozzle includes gasified medium inlet pipe with flange and corresponding fixed multiple flow channel spray tube with integrated nozzle, and features the equal wall thickness connection between the spray tube and the nozzle with smooth transition, the nozzle with conic outer and inner walls, and nozzle end wall thickness of 1-4 mm. The reasonable arrangement of gasifying nozzles, arced gasifying furnace top and furnace mouth structure forms the optimal flow field and temperature field matching reaching best gasifying effect with effective gas component over 95.5 % and up to 96.3 %. The present invention has prolonged gasifying nozzle life.

Owner:SINOPEC NINGBO ENG +1

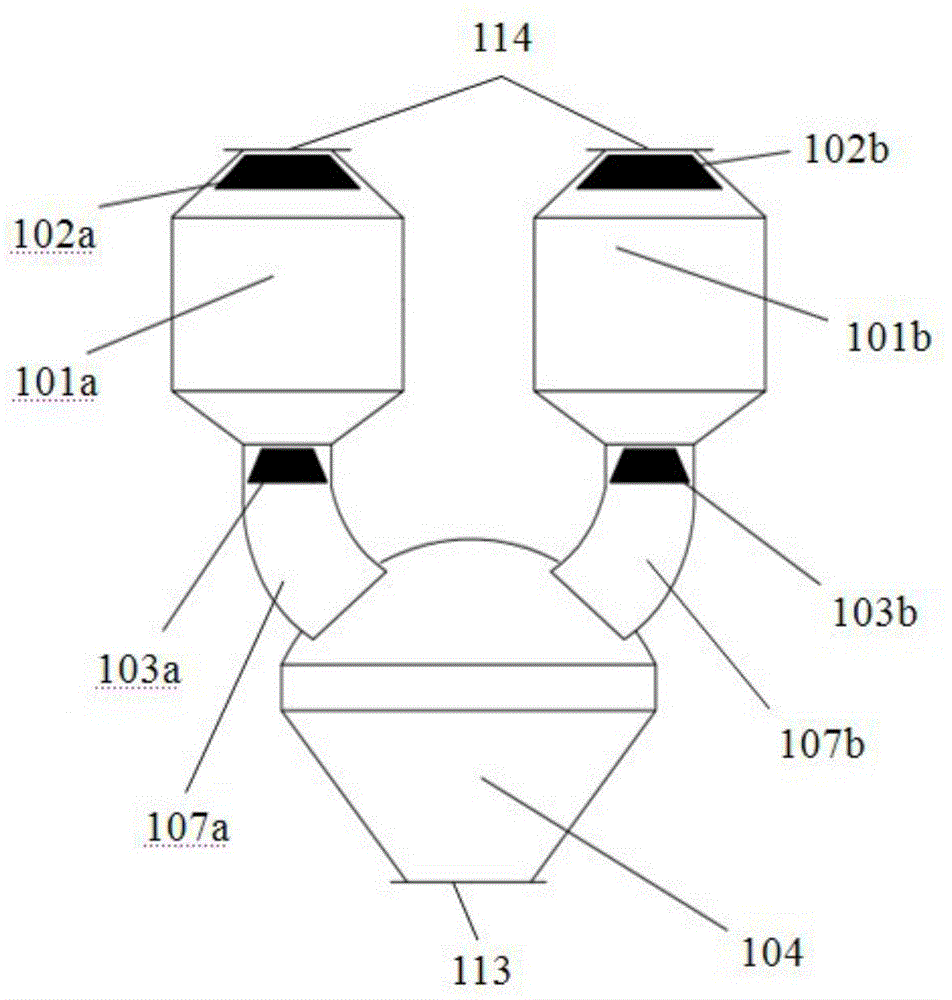

Gasification burner

PendingCN108728168AAdjust operating loadImprove conversion rateGasifier mechanical detailsGasification processes detailsCombustionReaction rate

The invention relates to a gasification burner. The gasification burner comprises a mother burner, N levels of sub-burners are arranged on the inner side of the mother burner, wherein N is an integergreater than or equal to 1, the mother burner and the sub-burners of each level are equipped with independent fuel channels and oxidant channels respectively, and the mother burner and the sub-burnersof each level are arranged to be a coaxial suit structure from the outside to the inside; the inner diameter of the mother burner is larger than the outer diameter of a first level sub-burner, and the inner diameter of the sub-burner of each level is larger than the outer diameter of the sub-burner of a next level; in a limited reaction space and residence time, the sufficient and uniform mixingof a fuel and an oxidant can be ensured, and the combustion reaction rate is accelerated, so that the fuel conversion rate and the gasification performance of a device are improved; in addition, through the adjustment of the load of the mother burner and the sub-burners of each level, the flame shape can be flexibly adjusted without reducing the load of a gasifier, so that the overheating of a gasifier furnace is effectively avoided, and different production load requirements of a project site can be met.

Owner:CHANGZHENG ENG

Family-size updraught tar-free biomass gasification direct burn type furnace

ActiveCN101813327ASimple structureHigh gasification temperatureDomestic stoves or rangesLighting and heating apparatusTarHearth

The invention discloses a family-size updraught tar-free biomass gasification direct burn type furnace which relates to a family-size updraught biomass direct burn type furnace for thoroughly solving the problem that a biomass gasification furnace generates tar. The lower end of a gas stove is arranged in an annular water tank; the lateral wall of the gas stove is provided with a plurality of secondary air inlet holes along the circumferential direction; the bottom end face of the gas stove is provided with a plurality of gas outlet holes; a hearth is communicated with the plurality of gas outlet holes through a central hole of the annular water tank; an air preheating chamber is arranged between a flame retardant coating and an inner furnace cylinder and is formed into a spiral air preheating chamber through a spiral clapboard arranged therein, and the lower end of the spiral air preheating chamber is a preheating air outlet; the upper edge of an ash hopper tightly clings to the inner wall at the lower end of the inner furnace cylinder, and the lower end of the ash hopper is arranged in an ash chamber. Air participates in gasification after heated by the spiral air preheating chamber, and the generated gas directly burns through the gas stove for cooking without a gas output process, and tar in the gas is directly burnt, thereby solving the problem of tar treatment.

Owner:湖南哈工机器人研究院有限公司

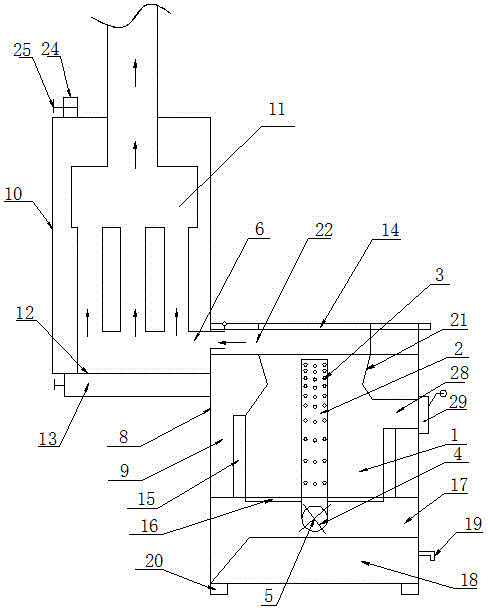

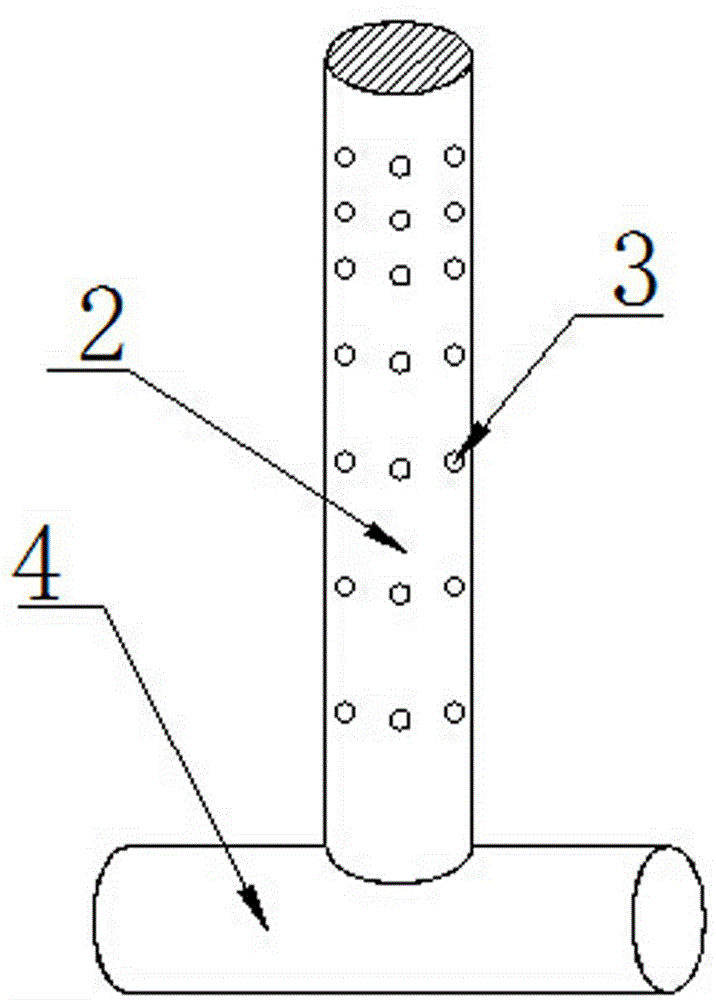

Heating gasifying furnace

InactiveCN103982918AIncrease profitBurn fullyLighting and heating apparatusStove/ranges for heating waterCombustionCoal

The invention provides a heating gasifying furnace. The heating gasifying furnace comprises a furnace chamber; a gasifying pipe is arranged inside the furnace chamber; the bottom of the gasifying pipe is open and the top is closed; the surface of the gasifying pipe is provided with gasifying holes which are communicated with the interior; the gasifying holes are uniformly formed in the gasifying pipe or the number of the gasifying holes which are formed in the top is larger than the number of the gasifying holes which are formed in the bottom; an opening at the bottom of the gasifying pipe is connected with a ventilation pipeline; a valve which can control the ventilation quantity is arranged on the ventilation pipeline; the number of the gasifying pipe is at least one; the gasifying pipe is vertically or obliquely arranged inside the furnace chamber; the furnace chamber is connected with a flue; a water tank is arranged outside the flue; the flue comprises a heat source concentration box which is arranged at the bottom of the water tank and a heat collection pipe which is perpendicular to the heat source concentration box; the top of the heat source collection pipe is connected with a chimney. The heating gasifying furnace has the advantages of being high in energy utilization rate, good in gasifying effect and full in coal combustion, well utilizing heat and being low in manufacturing cost, simple in technology, convenient to operate and high in environmental performance.

Owner:徐万友

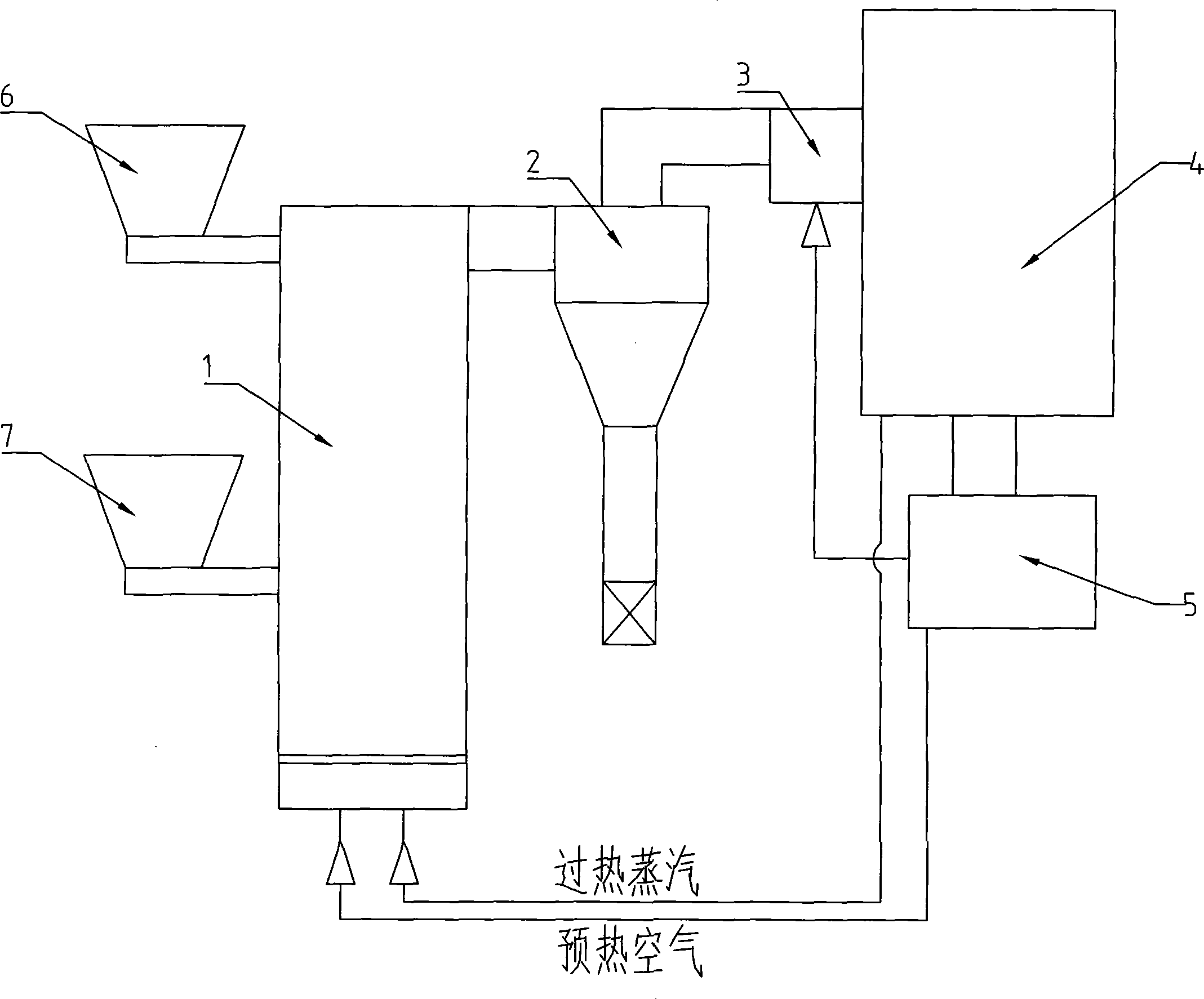

Biomass gasification mixed-combustion system of coal-fired power station boiler

InactiveCN103074117ALarge thermal inertiaImprove gasification effectBurnersEnergy inputCombustion systemFluidized bed gasifier

The invention relates to a biomass gasification mixed-combustion system of a coal-fired power station boiler. Preheated air and superheated steam of the boiler are adopted as a gasifying agent together to react with biomass in a fluidized bed gasifier adding bed materials to generate high-temperature biomass gas, most of the dust in the gas is removed in the high-temperature environment, and the gas is fed into the power station boiler for mixed combustion. The biomass gasification mixed-combustion system realizes clean biomass gas and fire coal mixed-combustion, eliminates the influence of alkali metal in the biomass dust on the coal-fired power station boiler, and realizes the efficient utilization of biomass.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

Clean coal burning catalyst

The clean coal burning catalyst consists of composite hydrogen-storing alloy, alkali metal chloride, alkali earth metal chloride, boride, alkali metal oxidant, iron and manganese oxidant and other additive. The production process includes preparation of composite hydrogen-storing alloy, and the composition of coal burning catalyst. The clean coal burning catalyst can coal burning efficiency and reduce pollution, and its use makes it possible to use high-sulfur and low-heat value coal in producing briquette, leading in low coal burning cost.

Owner:SHANGHAI JIENENG SCI TECH

Gas making and poly-generation apparatus by using environmental friendly clean fuel gas

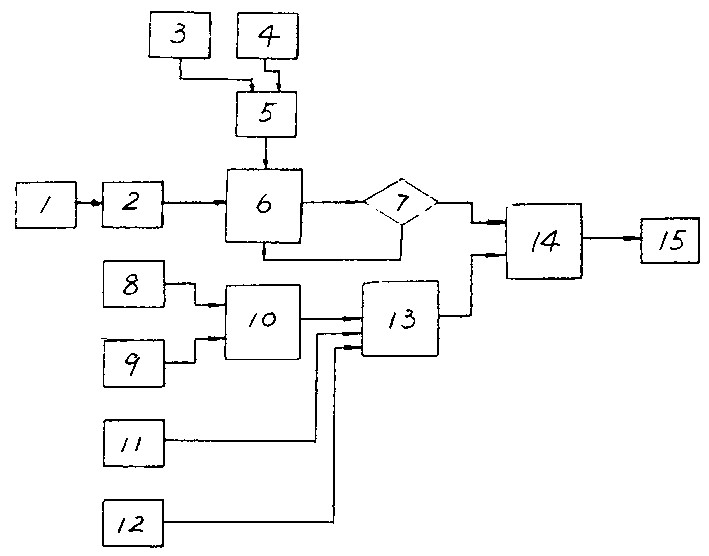

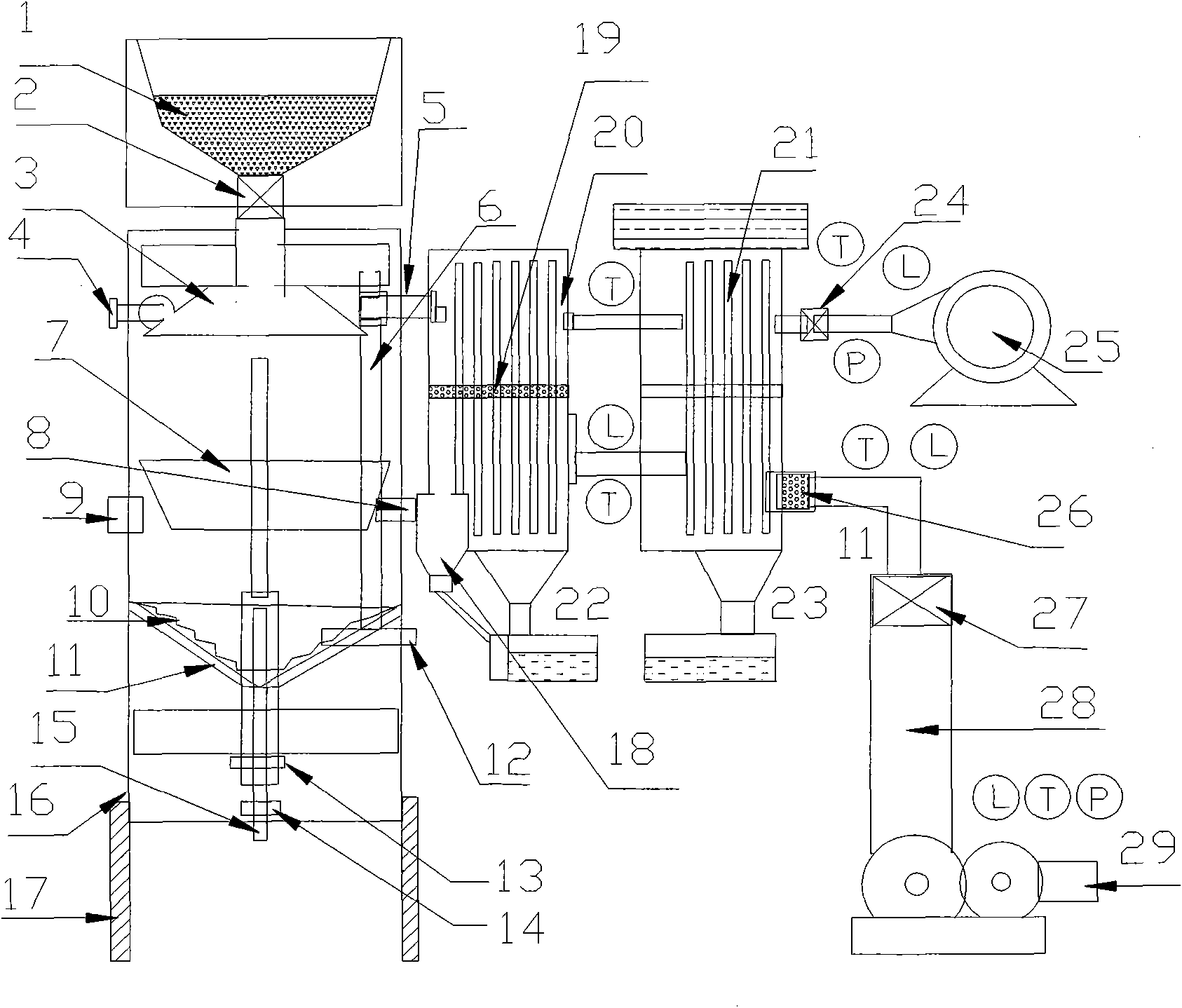

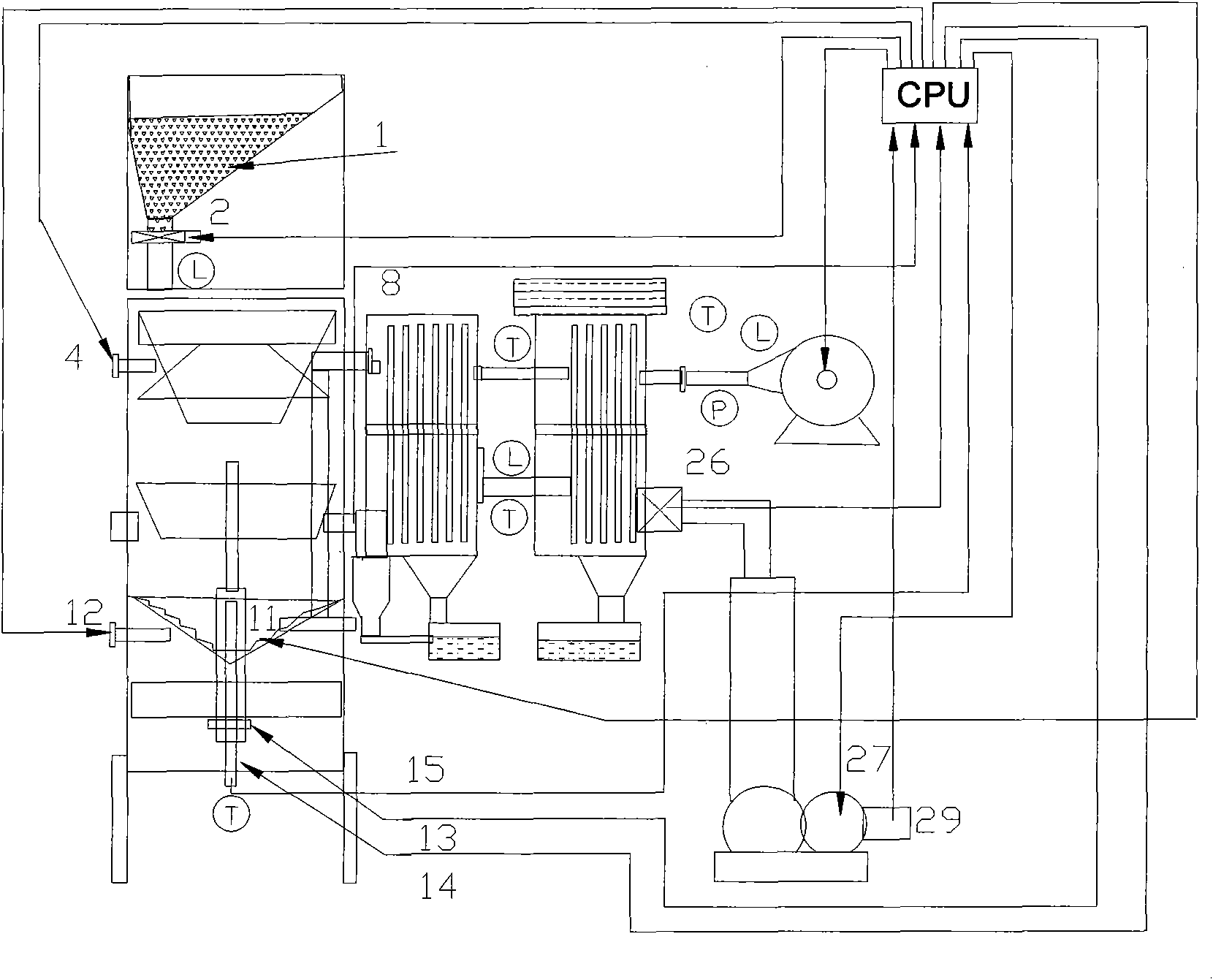

InactiveCN101586039ARelaxationWide adaptabilityOrganic chemistryLiquid hydrocarbon mixture productionAutomatic controlPollution

The invention discloses a gas making and poly-generation apparatus by using environmental friendly clean fuel gas. The apparatus is composed of a main furnace of a gasification furnace and a heat exchange and separator equipped with an automatic control system, which realizes automatic intellectualized operation. The apparatus can gasify any coal, for instance, soft coal, anthracite, coke, stone coal; and gasify (carbonize) biomass for instance, wood, bamboo, cotton stalk, rice hull and rubbish rod. When gasifying coal, by-products in gas making and purifying process can be recycled in the apparatus. Coal tar in the by-products can be pyrolyzed and gasified to make gas, residual heat making vapor for power generation of steam turbine, which realizes poly-generation and recycling. When gasify (carbonize) biomass, biomass diesel oil, acetic acid in coal producing, gas making and purifying process can be recycled in the apparatus, , residual heat making vapor for power generation of steam turbine, which realizes poly-generation and recycling. The poly-generation apparatus ensures environmental protection of whole gas making process in structure. The invention, except clinker, is of zero emission and pollution.

Owner:浙江华尚新能源股份有限公司

Novel nano scarfing gas

The invention provides a novel nanometer scarfing gas, including liquid mother solution composed by hydrocarbons or alkane compound, is characterized in: also including one or several adjuvant mixed in the mother solution. The scarfing gas has advantages of high burning value, complete burning, quickly cutting, and regular shape of flame easy controlling, good efffect of cutting or soldering.

Owner:李华

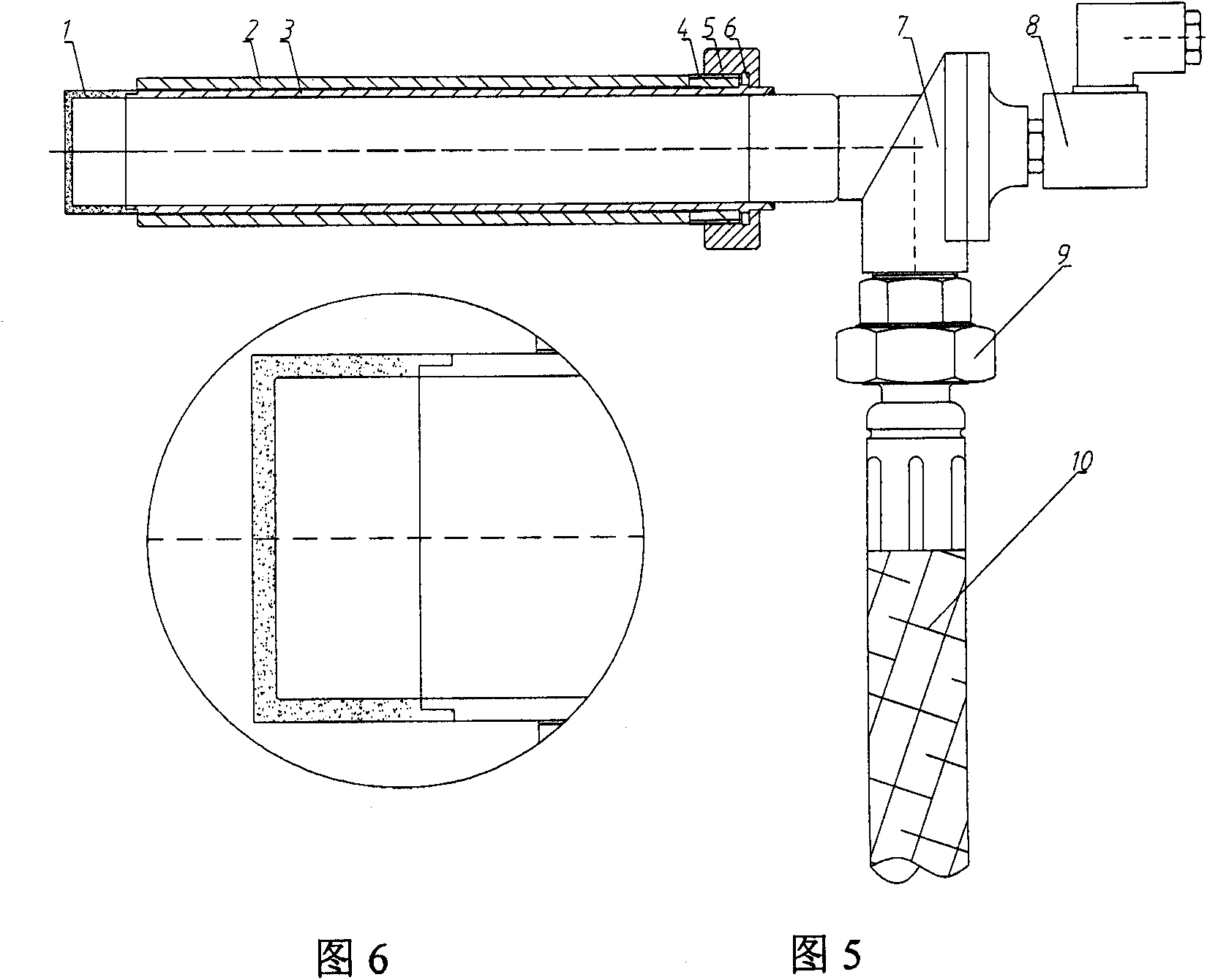

Gasification nozzle

ActiveCN101773889ABlowing forceGood gasification effectSpray nozzlesLiquid spraying apparatusFly ashElectromagnetic valve

The invention relates to a gasification nozzle in a gasification system of containers for storing powdery materials. A spray head (1) is welded at the front end of a nozzle body (4); a pressing plate (2) is connected with the spray head (1); a polytetrafluoroethylene gasket (11) is arranged between a connecting cylinder (5) outside the gasification nozzle and the nozzle body (4) for sealing and the connecting cylinder and the nozzle body are connected through internal threads; a polytetrafluoroethylene gasket (13) is arranged between a reducing connector (14) and the nozzle body (4) for sealing and the reducing connector and the nozzle body are connected through internal threads; the reducing connector (12) is connected with the air outlet end of a pulse electromagnetic valve body (17) through a short thread (14); a pulse electromagnetic valve coil (18) is arranged on the pulse electromagnetic valve body (17); and an air inlet rubber pipe (16) is connected to the air inlet of the pulse electromagnetic valve body (17) through a rubber pipe movable joint (15). The invention can be used in the gasification places of storage devices (transit warehouses, ash buckets and the like) of the powdery materials and the like generated by coal fired power plants (fly ash), cement plants (clinker), iron and steel companies (sintering machines) and the like.

Owner:岳波

Burner specific for gasifying biological alcohol base fuel and burning method thereof

InactiveCN102635849AIncrease temperatureImprove one-time burnout rateCombustion using gaseous and pulverulent fuelBurnersCombustion chamberAlcohol

The invention discloses a burner specific for gasifying biological alcohol base fuel, which comprises a combustion chamber and an oil supplying system. The combustion chamber comprises a flame shield with a cyclone plate, and a combustion nozzle; the combustion nozzle and a gasifying pipe are installed in the flame shield; one end of the gasifying pipe is connected with the combustion nozzle; the other end of the gasifying pipe is connected with an oil supplying pipe; an ignition rod and a liquefied gas ignition nozzle are further installed in the flame shield; the oil supplying system comprises an oil supplying pipe and an oil return pipe, wherein the oil return pipe comprises a primary oil return pipe and a secondary oil return pipe; the primary oil return pipe is connected with the oil supplying pipe; one end of the secondary oil return pipe is connected with the oil supplying pipe via a flow regulation valve; and the other end of the secondary oil return pipe is connected with the primary oil return pipe. The burner provided by the invention takes the biological alcohol base fuel as the fuel, and therefore the burner has the characteristics of high burn-off rate, high thermal conversion efficiency and the like. Waste gases emitted by burning are mainly CO2 and H2O, no NOx gas or smoke is generated, and each index can reach the relevant standard of the clean energy.

Owner:中天新能源农业科技投资有限公司

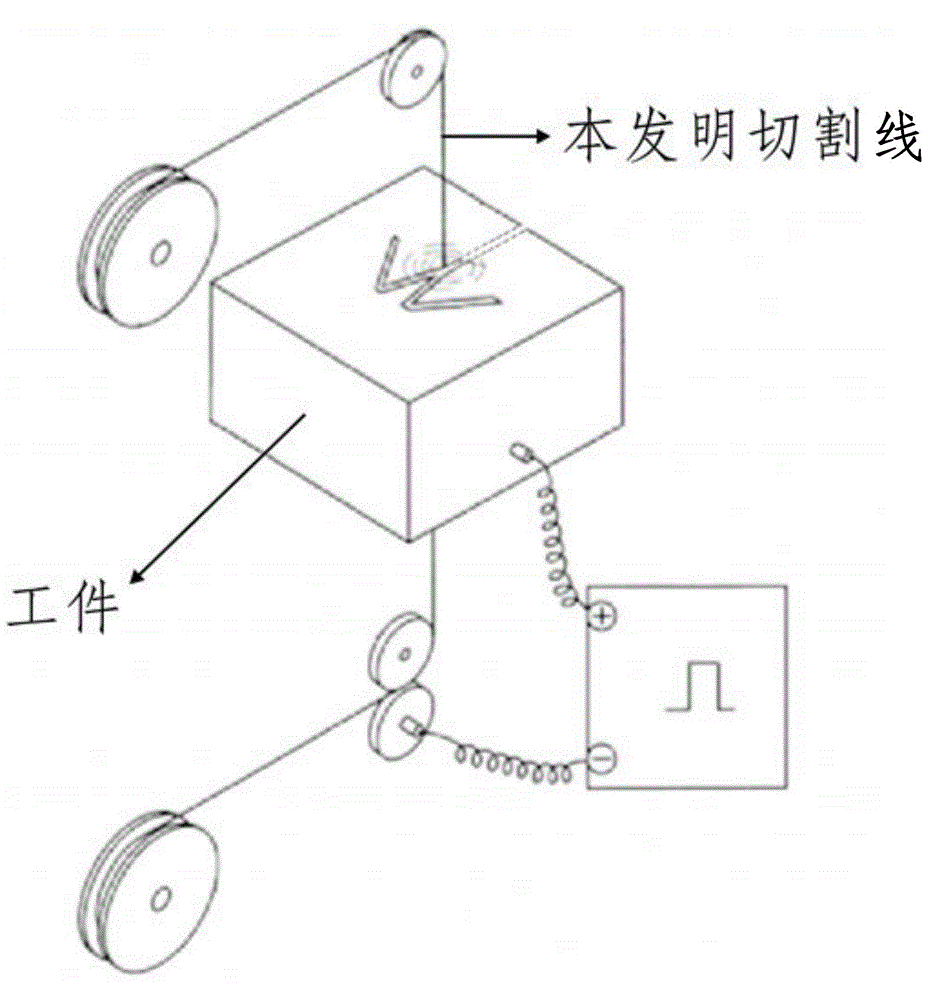

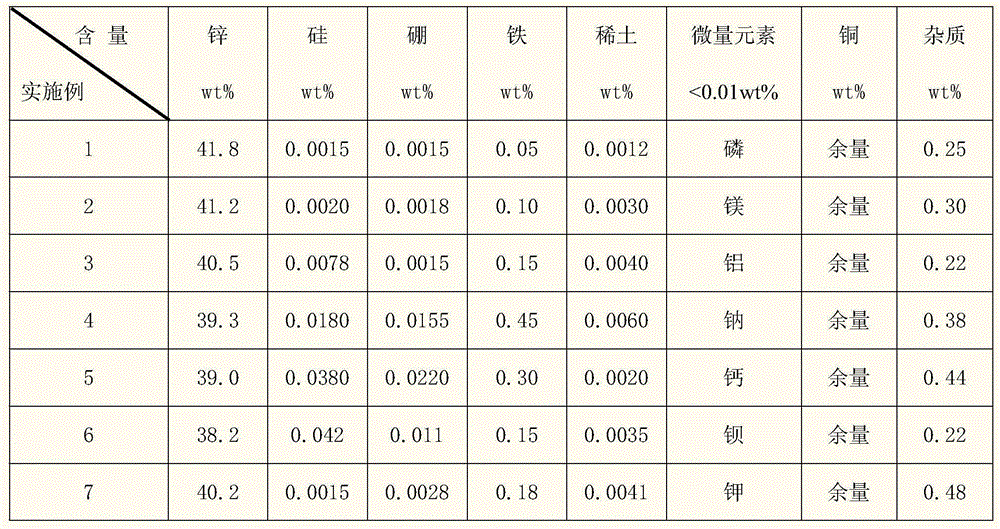

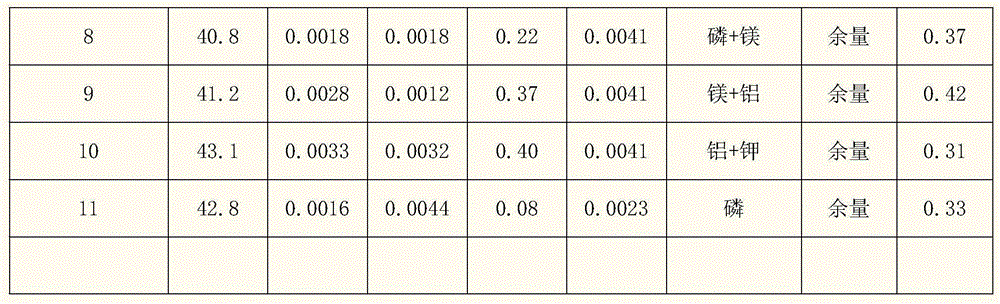

High zinc-silicon-boron-ferro copper alloy

The invention discloses a high zinc-silicon-boron-ferro-copper alloy. The copper alloy is characterized by comprising the components in percentage by weight: 38.0-44.0 percent of zinc, 0.001-0.5 percent of silicon, 0.001-0.025 percent of boron, 0.005-0.5 percent of ferro, 0.001-0.01 percent of rare earth, 0.0005-0.1 percent of other element including at least one of phosphorus, magnesium, potassium, calcium, sodium, aluminum and barium, and the balance of copper and inevitable impurity elements. The copper alloy is used for manufacturing a cutting line for one-way wiring; compared with the prior art, the copper alloy has the advantages that the manufactured cutting line for one-way wiring is high in mechanical performance, stable in discharging performance and high in cutting speed; the cutting line is simple in processing procedures, wide in application and low in cost and has wide market prospect.

Owner:NINGBO BODE HIGHTECH CO LTD

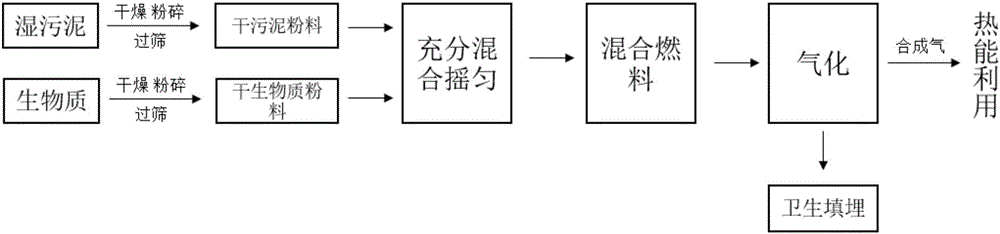

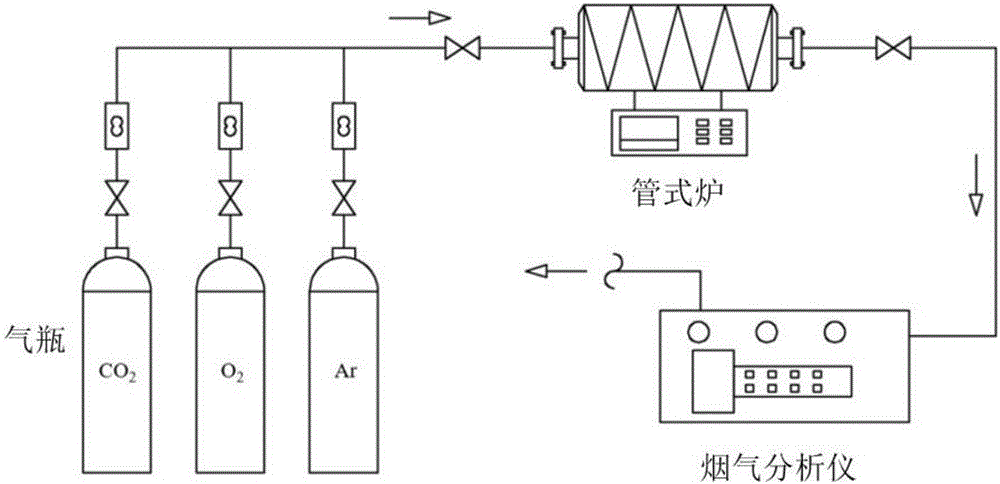

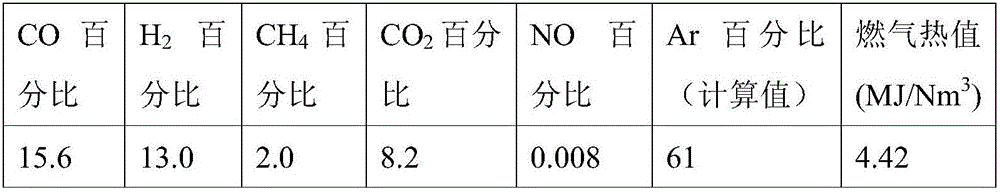

Method for preparing biomass synthesis gas low in nitric oxide content by mixed gasification of biomass and sludge

InactiveCN106350115AEmission reductionHigh energySludge treatmentGasification processes detailsSyngasSludge

The invention discloses a method for preparing biomass synthesis gas low in nitric oxide content by mixed gasification of biomass and sludge. The method comprises the following steps: respectively putting untreated sludge and biomass raw material into an oven, drying, crushing and mixing, thereby acquiring mixed grains of biomass and sludge; putting the mixed grains into a gasifying furnace, taking 300-400mL / min argon or nitrogen as carrier gas and taking O2 or CO2 as an auxiliary agent; performing gasifying reaction under the conditions of final temperature at 600-800 DEG C, heating rate at 10-25 DEG C / min and pressure at 0.1Mpa, thereby acquiring the synthesis gas. The method provided by the invention adopted for preparing the synthesis gas, compared with the independent gasification of the biomass or the sludge, has the advantage that the nitric oxide discharge in the gas preparation process can be effectively reduced; the reduction utilization of the sludge can be effectively realized; the treating cost of the sludge and the secondary pollution to the environment in the treating process can be greatly reduced.

Owner:TIANJIN UNIV

Coal layer loosening technology for underground gasified furnace

InactiveCN1419036AIncrease the lengthIncrease the areaConstructionsCoal gasificationRedoxEngineering

The present invention relates to an underground gasification furnace coalbed loosening process, belonging to the field of coal underground gasification technology. It is characterized by that in the interior of the furnace body of underground gasification furnace several loose-guiding channels which are parallel or approximately parallel to gas tream channel are excavated according to a certain spaced distance in the gasification channel, and the back-off shooting can be made on the both sides of loose-guiding channel so as to form artificial loose coal, and then form mine ground pressure loose coal by utilizing mine ground pressure change so as to raise gasification reaction area to raise yield of underground gasification furnace and its stability.

Owner:XINWEN MINING GROUP

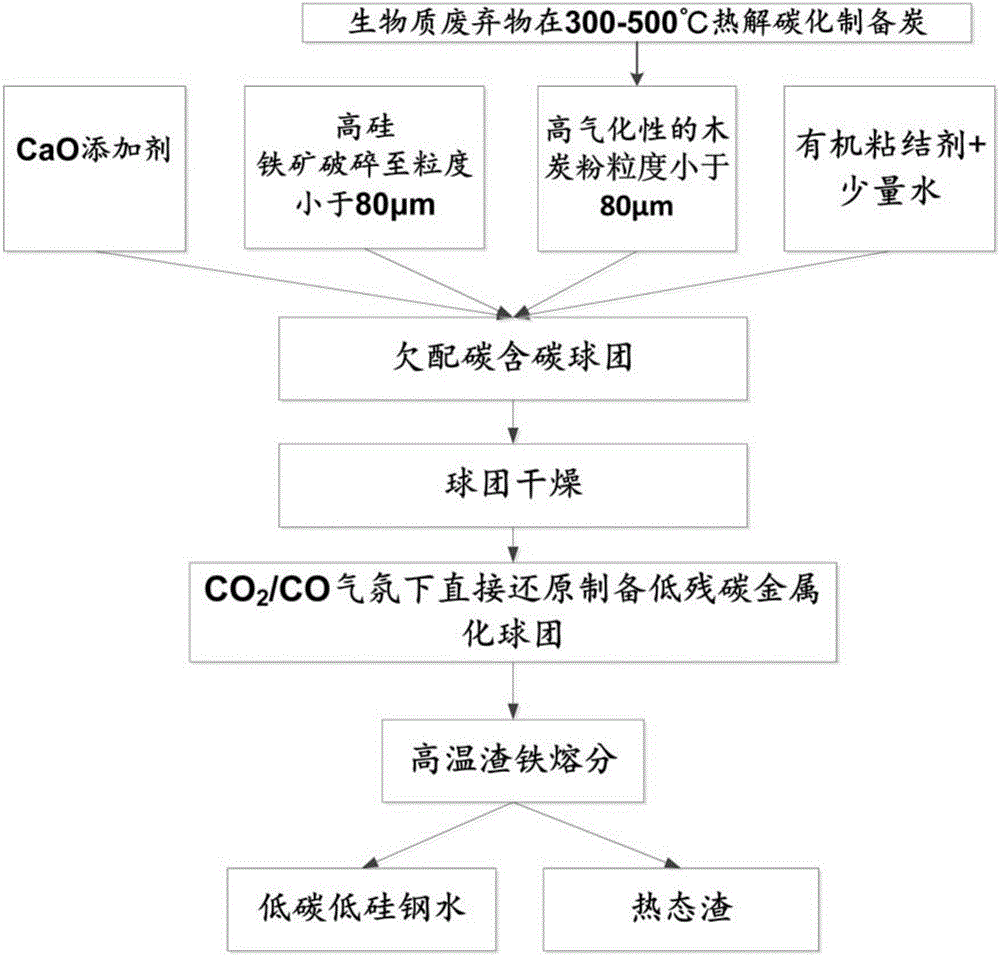

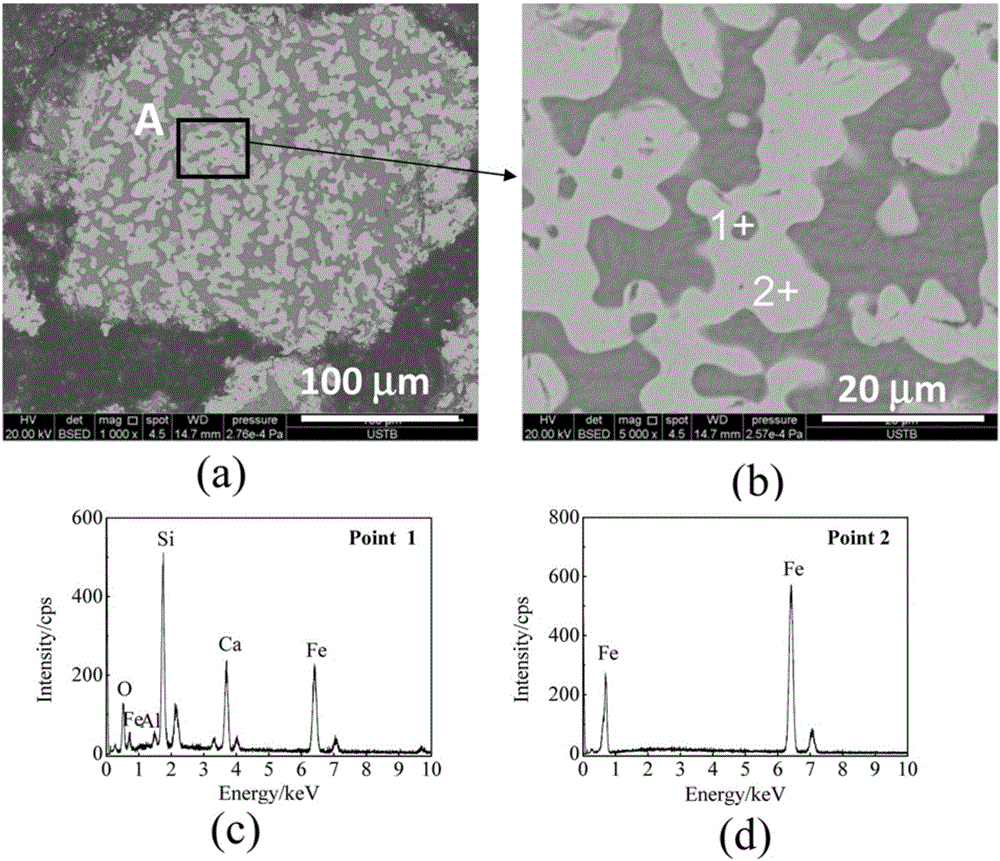

Method for directly preparing molten steel from high-silicon iron ores

ActiveCN105755195AShorten the production cycleImprove efficiencyElectric furnaceHearth type furnacesSlagReducing agent

The invention discloses a method for directly preparing molten steel from high-silicon iron ores. The method comprises the following steps of: preparation and grinding of biomass charcoal, grinding and ball milling of the high-silicon iron ores, preparation of carbon-containing pellets, direct reduction, and separation of high-temperature iron slag. Compared with existing methods for processing the high-silicon iron ores, the method has the advantages that biomass charcoal is prepared from wide-source agricultural biomass waste and is utilized as a reducer for preparing the carbon-containing pellets, and the carbon-containing pellets are subjected to direct reduction and electric furnace high-temperature melting by virtue of a commercial FASTMELT process; by controlling reduction conditions, high metallized pellets with extremely carbon residue are obtained in a direct reduction stage; and the molten steel with the quality directly reaching or exceeding converter tapping standards is directly obtained in a high-temperature melting stage. The method has the advantages that the recovery rate of iron is high, the quality of the obtained liquid-state low-carbon and low-silicon molten steel is good, and the like. According to the method, the conventional sintering-blast furnace-converter flow for iron-making and steel-making is avoided, so that the flow of processing the high-silicon iron ores is greatly simplified.

Owner:UNIV OF SCI & TECH BEIJING

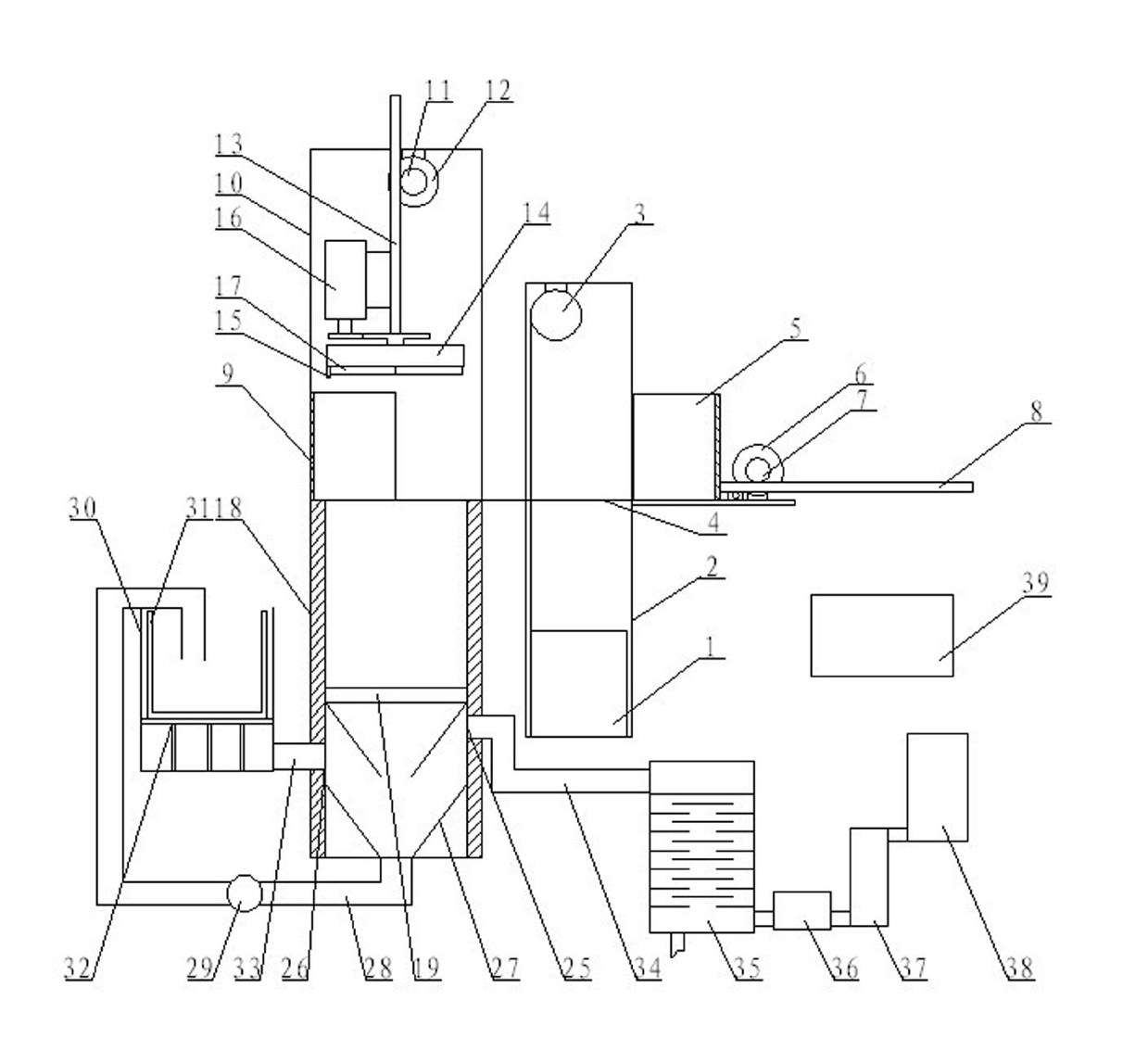

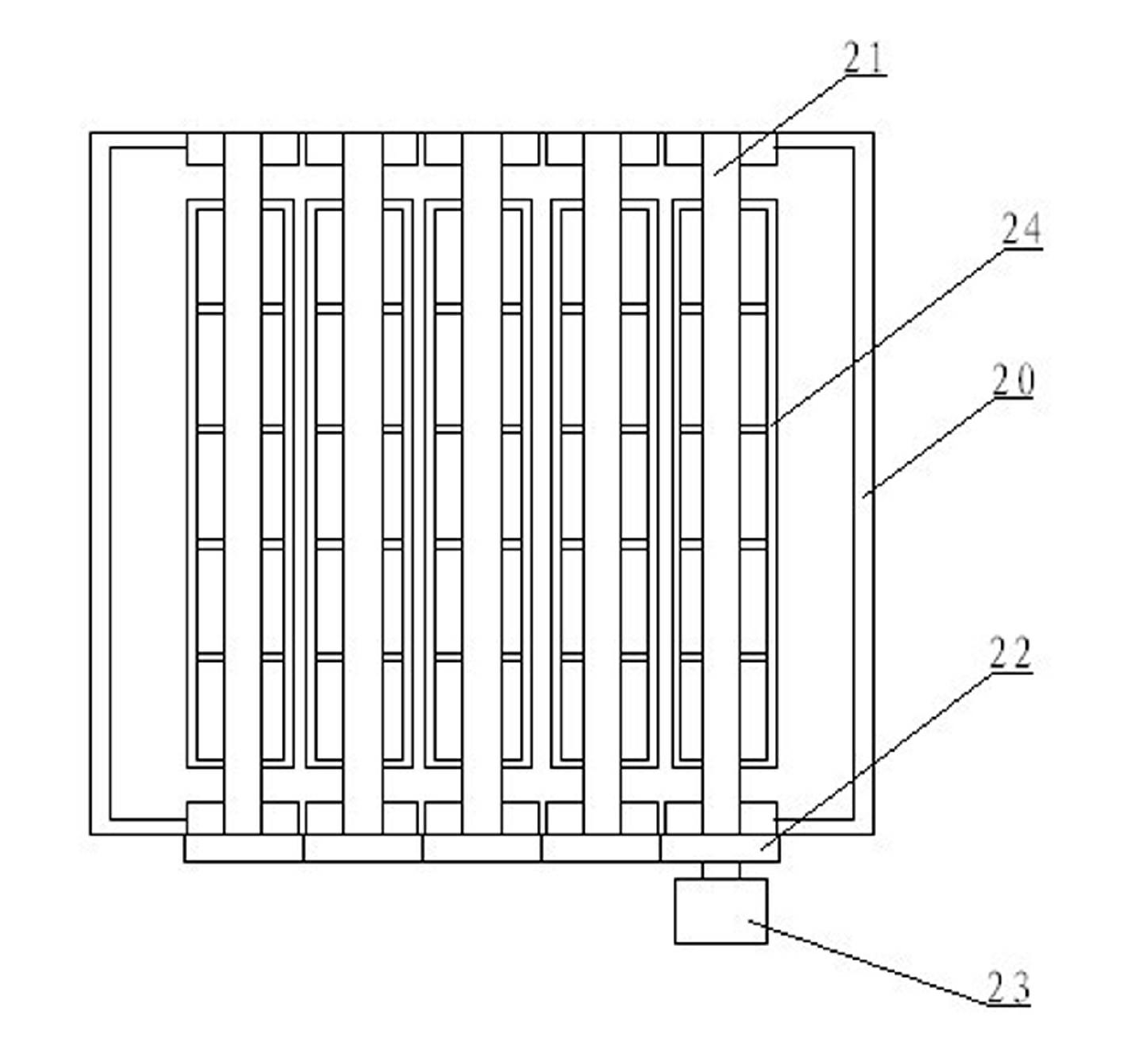

Novel straw direct gasification and poly-cogeneration device and preparation process

InactiveCN102329650AImprove gasification efficiencyUniform densitySpecial form destructive distillationFixed-bed gasificationFiltrationCogeneration

The invention relates to a novel straw direct gasification and poly-cogeneration device and preparation process. The device comprises a gasification furnace, a loading device, a pushing device, a pressing device, a distributing device, a carbon discharging device, a washing device, a fan, a water seal filtration device, a gas storage cabinet and a control cabinet. According to the invention, straw which does not need to be processed is directly fed into the gasification furnace for gasification through the loading, pushing, pressing and distributing devices, thereby effectively controlling straw cogenerated straw carbon and straw gas, matching a carbon shaving grate and the carbon discharging device to collect the straw carbon, carrying out labyrinth spraying and washing and separating the straw gas from straw extract, and filtering and collecting the straw gas in the water seal filtration device. The device has high reliability, good safety, strong practicability, simple gasification process, good gasification effect, high straw utilization ratio and low operation cost.

Owner:顾云江

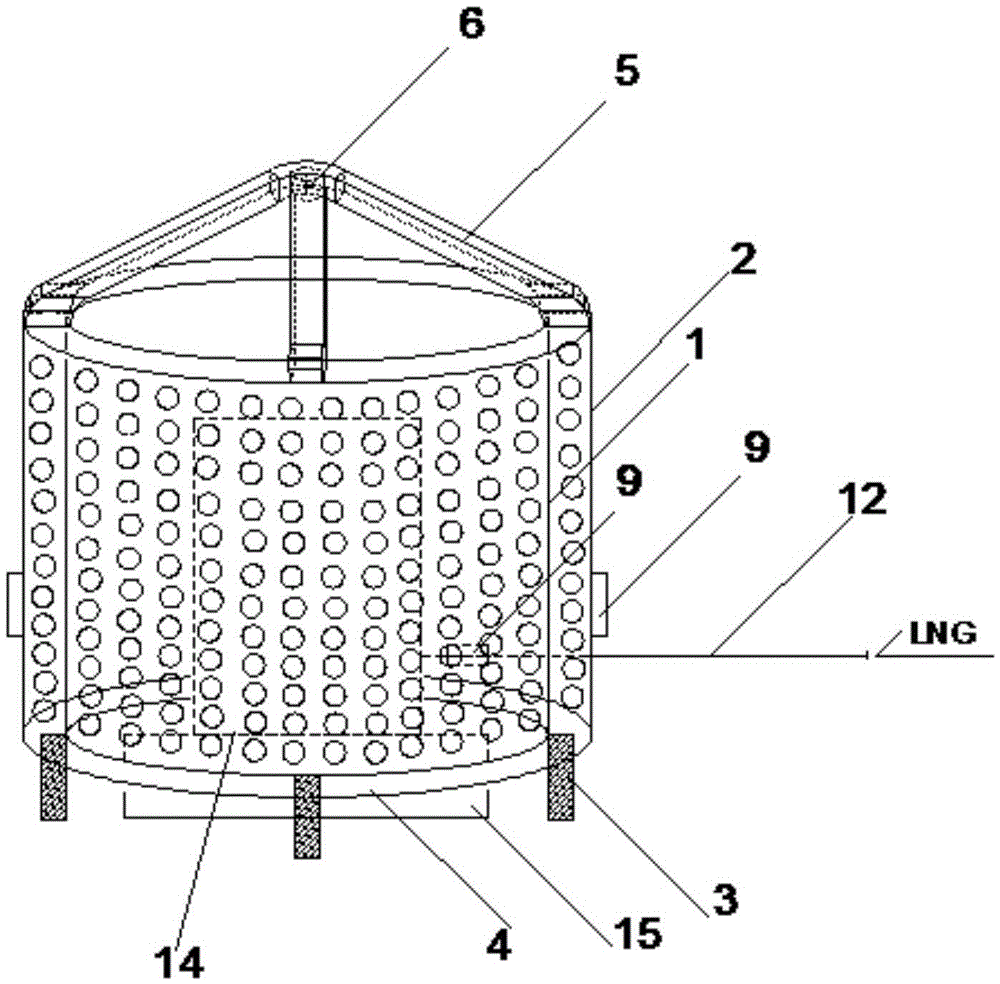

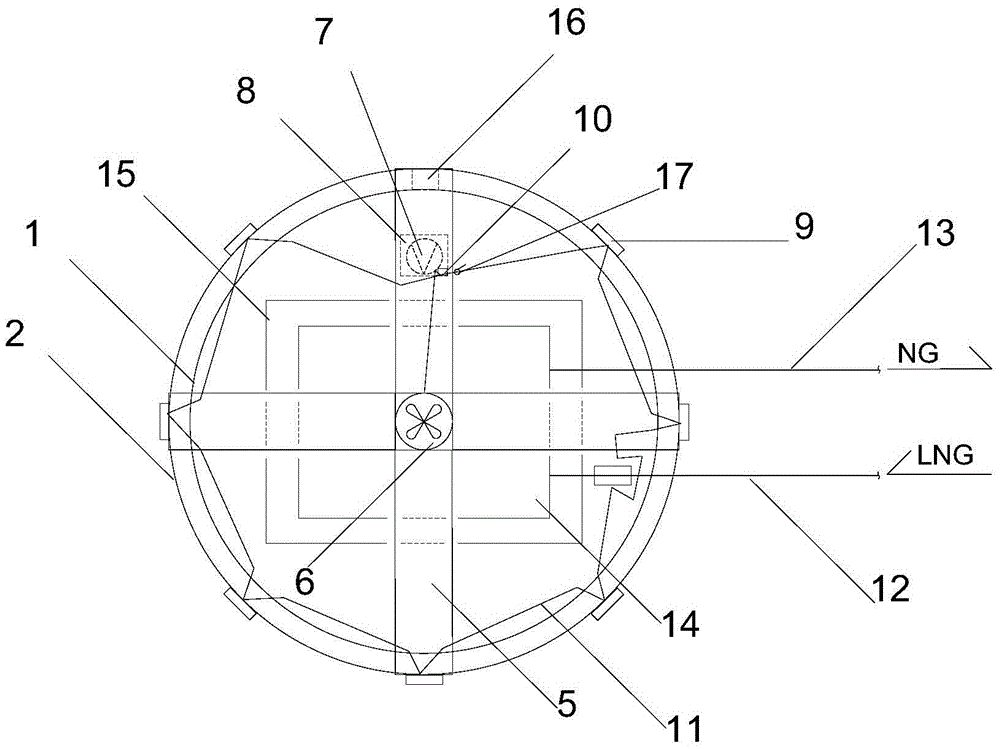

LNG air temperature type gasification device and method for generating electricity by using sun wall and temperature difference

ActiveCN105570669AImprove gasification effectAlleviate or eliminate the problem of frost accumulation and icingSolar heating energySolar heat devicesEngineeringTemperature difference

The invention relates to a LNG air temperature type gasification device and a method for generating electricity by using a sun wall and a temperature difference. A LNG air temperature type gasifier is positioned in the sun wall; air in an environment enters a sun wall cavity consisting of a sun wall inner plate and a sun wall heat collecting plate through small holes on the sun wall heat collecting plate and an air inlet in the bottom; the sun wall heat collecting plate absorbs solar radiation to heat the air; the air is heated to upwards flow, is gathered to an inlet of a fan through an air pipe, and is pressurized by the fan to send to the LNG air temperature type gasifier for gasifying LNG; when no solar radiation exists at night, the air is heated through self heat accumulating function of the sun wall for gasifying the LNG; and electric energy needed by the fan is supplied by a power supply formed by a temperature difference power generation chip. The device is simple in structure, uses a power generation technology of combining the solar radiation with the temperature difference, fully uses solar energy, air energy and LNG cold energy, is free of additional consumption of once energy, is environment-friendly and energy-saved, and is convenient for modularization and commercialization.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

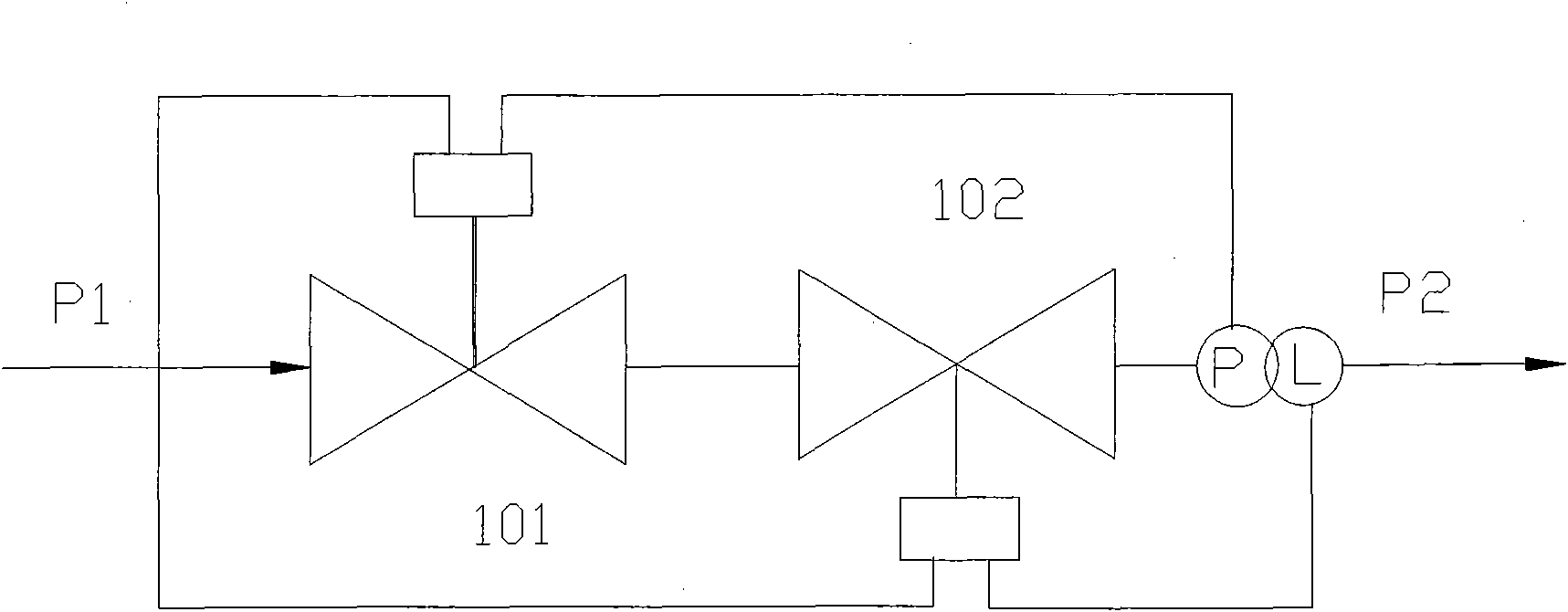

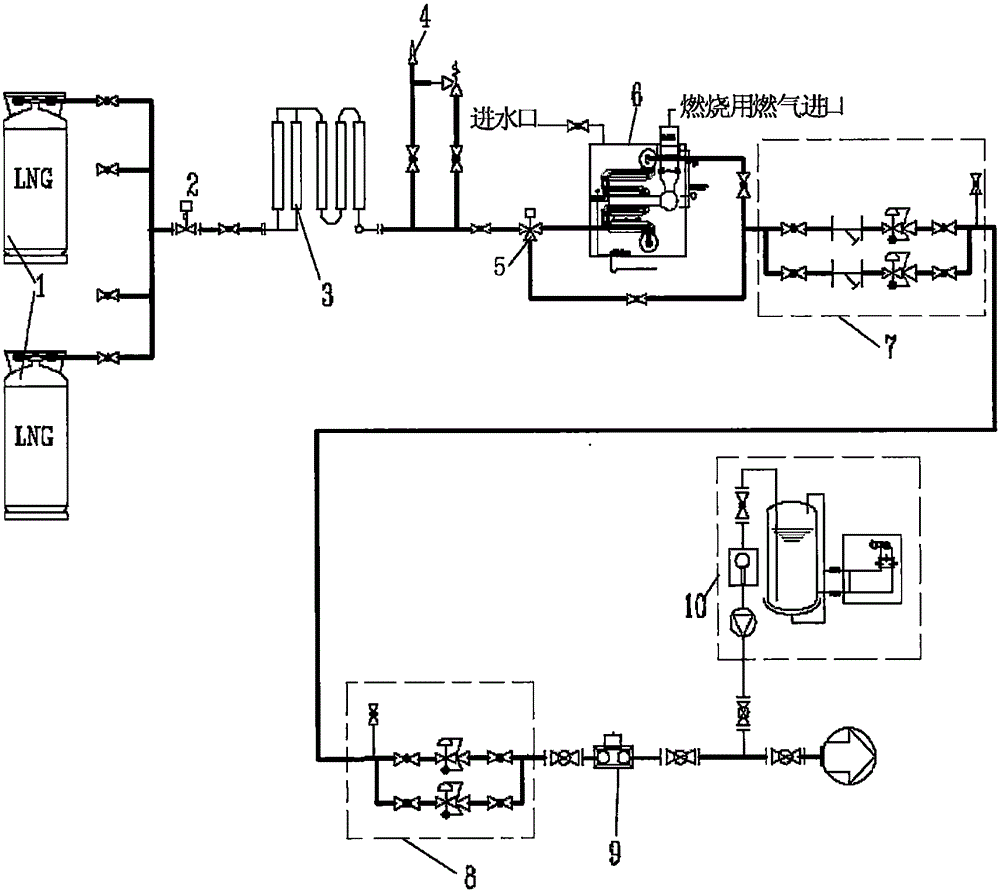

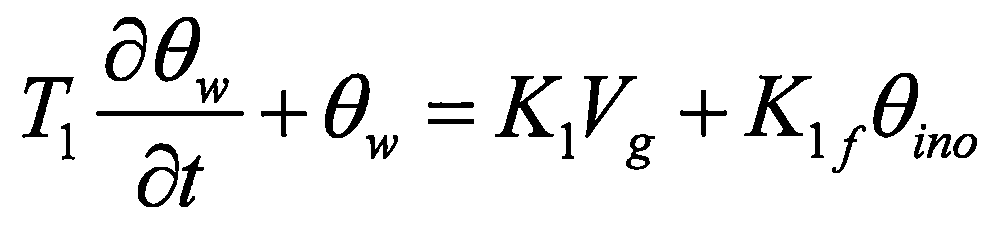

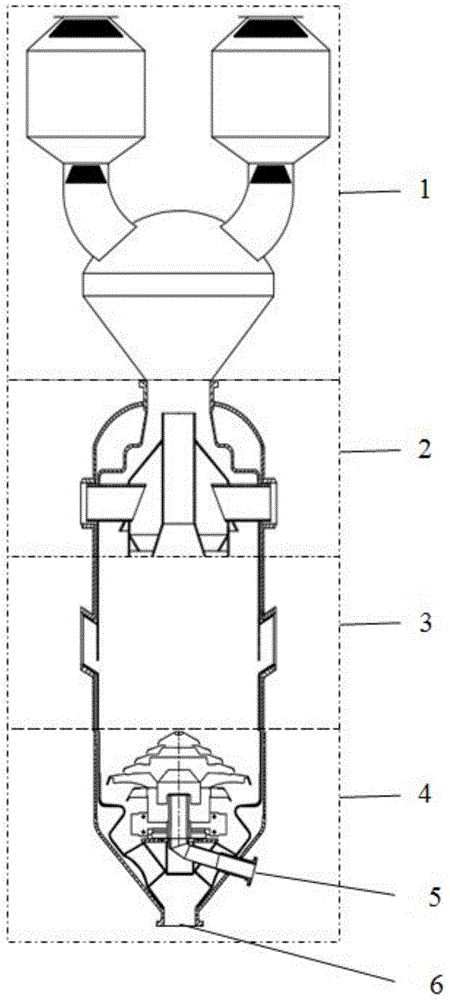

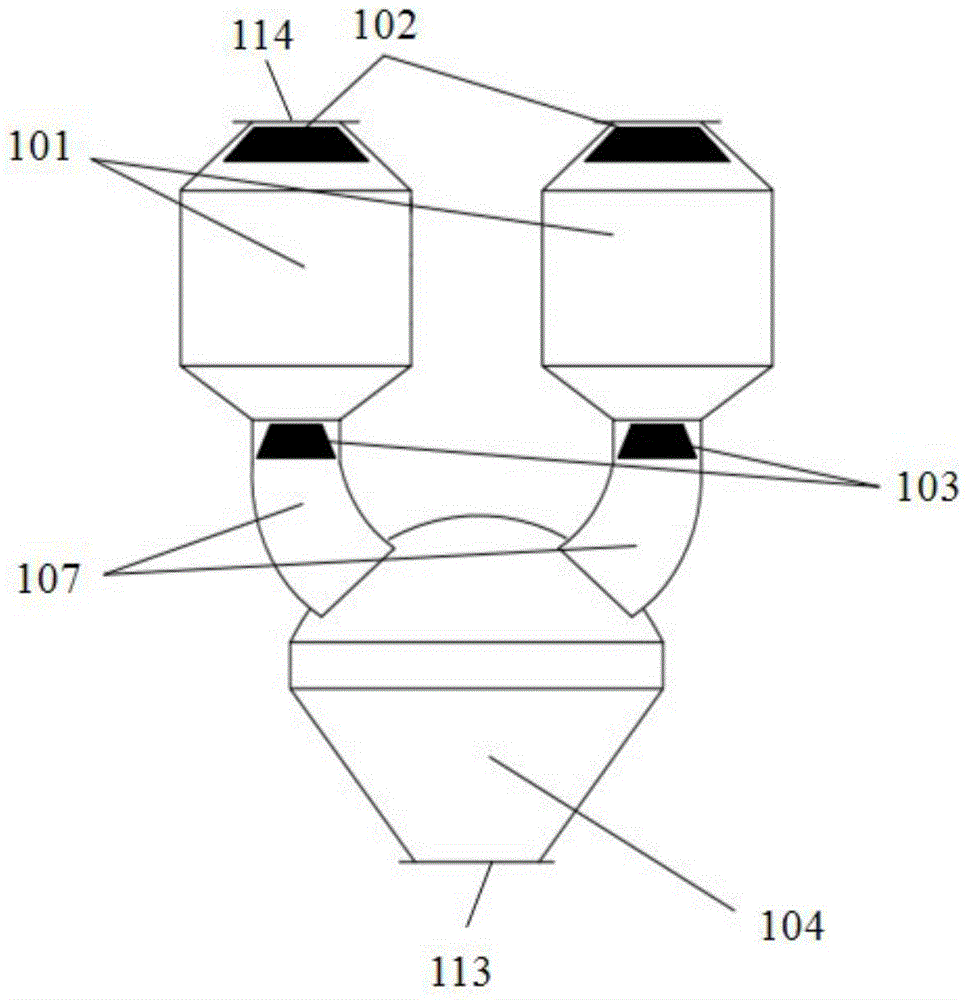

LNG vaporizer with fuel heating function and heating control method thereof

InactiveCN105221931AImprove efficiencyMeet different gas loadsStorage heatersNon-pressured vesselsCompressed natural gasProcess engineering

The invention discloses an LNG vaporizer with a fuel heating function. The LNG vaporizer comprises n LNG steel bottles (1), an emergency cut-off valve (2), an air-heated vaporizer body (3), a three-way valve (5), a fuel heating device (6) and a pressure regulating system, wherein n is larger than or equal to 1. The pressure regulating system is used for decompressing gasified medium-pressure natural gas to the pressure required by a user and comprises a first-stage pressure regulating device (7), a second-stage pressure regulating device (8), a metering device (9) and an odorizing device (10). The invention further discloses a heating control method of the LNG vaporizer with the fuel heating function. Through the safe, efficient and energy-saving auxiliary heating structure, efficiency is high, the requirement for different gas use loads can be met, the amount of fuel gas for combustion can be adjusted according to the gas use loads, and the requirements for gas use in different regions in different seasons can be met, and the better gasification effect is achieved.

Owner:BEIJING GAS GRP +1

Double-coal lock coal crushing, pressurizing and dry ash discharging gasification furnace

ActiveCN104479745AEvenly arrangedReduce flow rateGasifier feeding meansFixed-bed gasificationTarCoal dust

The invention relates to a double-coal lock coal crushing, pressurizing and dry ash discharging gasification furnace. The double-coal lock coal crushing, pressurizing and dry ash discharging gasification furnace comprises a communicated double-coal lock feeding device (1) and a furnace body. The double-coal lock coal crushing, pressurizing and dry ash discharging gasification furnace is characterized in that the communicated double-coal lock feeding device (1) is arranged on the furnace body, a double-channel static coal distributor (2) is arranged at the upper part of the furnace body, a gasification chamber is arranged in the furnace body, a crude coal gas discharging device (3) is arranged at the middle part of the gasification chamber, a rotary furnace grate (4) is arranged at the lower part of the furnace body, a gasifying agent inlet (5) and an ash discharging hole (6) are formed in the bottom of the furnace body, the gasifying agent inlet (5) is arranged between the rotary furnace grate (4) and the ash discharging hole (6), and the gasifying agent inlet (5) is connected with a gas distribution drum (412) in the rotary furnace grate (4). The double-coal lock coal crushing, pressurizing and dry ash discharging gasification furnace has the advantages that little coal dust is carried away and water content of tar-containing coal gas is low.

Owner:SEDIN ENG

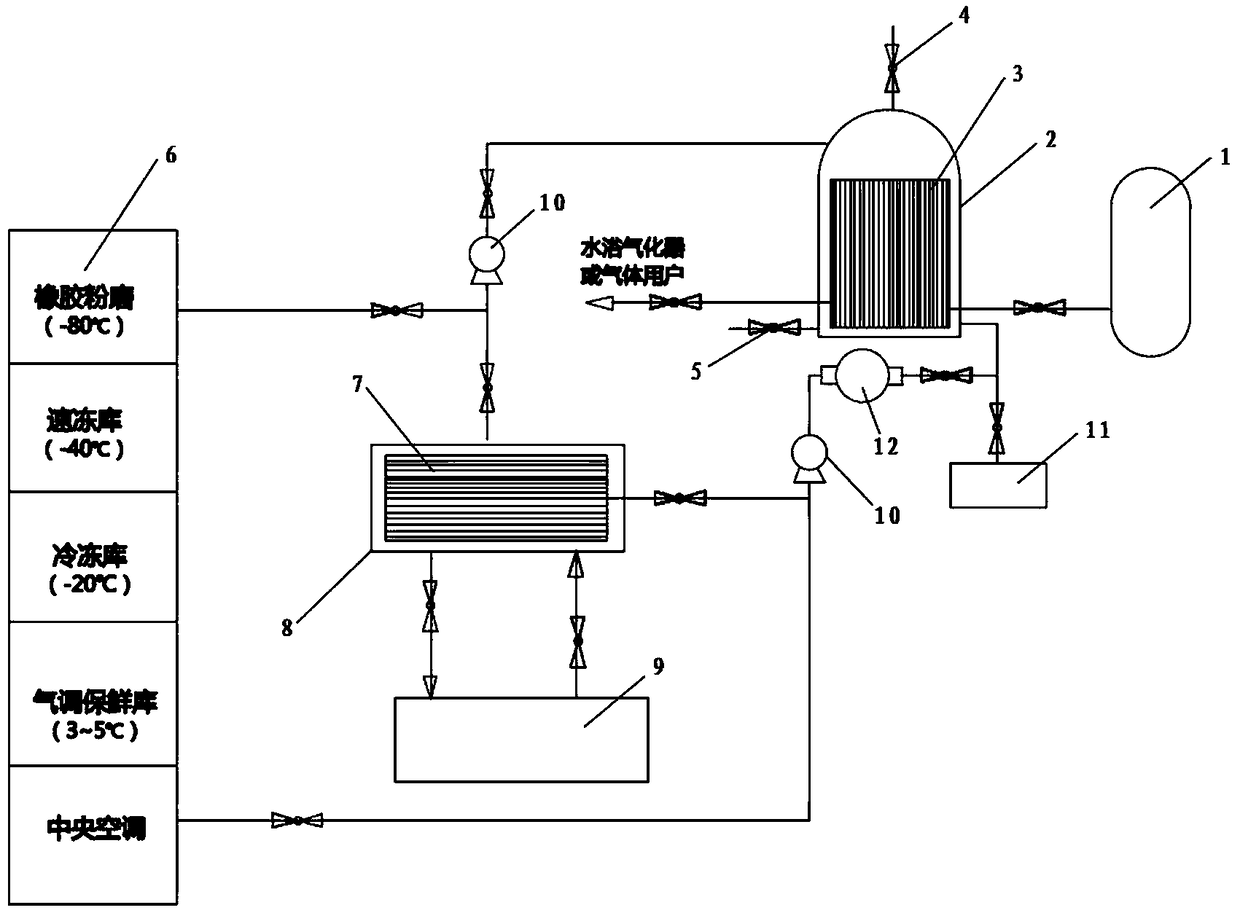

Cryogenic liquid gasification cold energy recycling device

PendingCN108759303AConducive to cascading utilizationIncrease profitSolidificationLiquefactionNitrogen generatorControl system

A cryogenic liquid gasification cold energy recycling device comprises a cryogenic liquid storage tank (1), a nitrogen generator or a nitrogen storage container (11) and a closed nitrogen refrigerantgasifier; the closed nitrogen refrigerant gasifier comprises an insulation shell (2) and a heat exchanger (3) arranged in the insulation shell (2), and cryogenic liquid is conveyed to a downstream secondary gasification system or directly conveyed to gas users through the heat exchanger (3) after being gasified; in this process, the heat exchanger (3) releases cold energy to nitrogen in the insulation shell (2) through heat exchange with the cryogenic liquid, and the closed nitrogen refrigerant gasifier is an assembly composed of one or more sets; the insulation shell (2) can be provided witha safety release valve (4) and a blow-down valve (5), and the output end of the insulation shell (2) is connected to a cascade cold energy user (6) and / or a liquid refrigerant system; and a nitrogen loop is used for providing circulating pressure under the control of a control system through a circulating pump (10) automatically.

Owner:丁斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com