Burner specific for gasifying biological alcohol base fuel and burning method thereof

A technology of fuel gasification and bio-alcohol, which is applied in the combustion of various fuels, combustion methods, and combustion of lump fuel and gaseous fuel, etc., can solve the problem of long burner startup time, unsatisfactory energy saving effect and low thermal efficiency. and other problems, to achieve the effect of improving safety and operability, improving one-time burnout rate, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

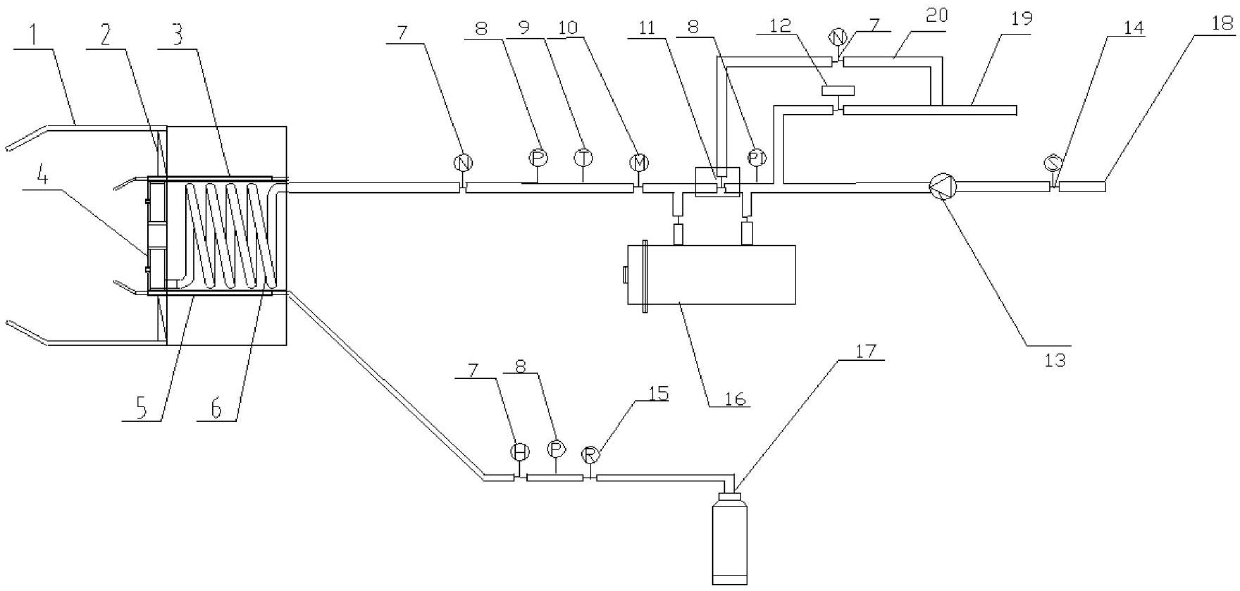

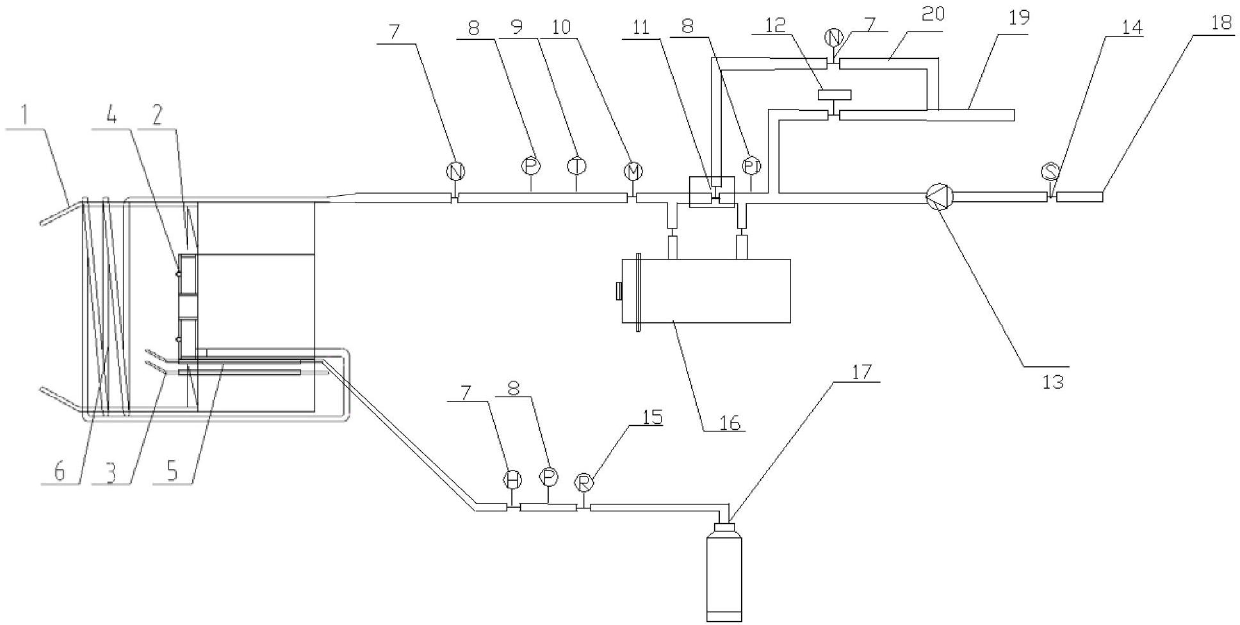

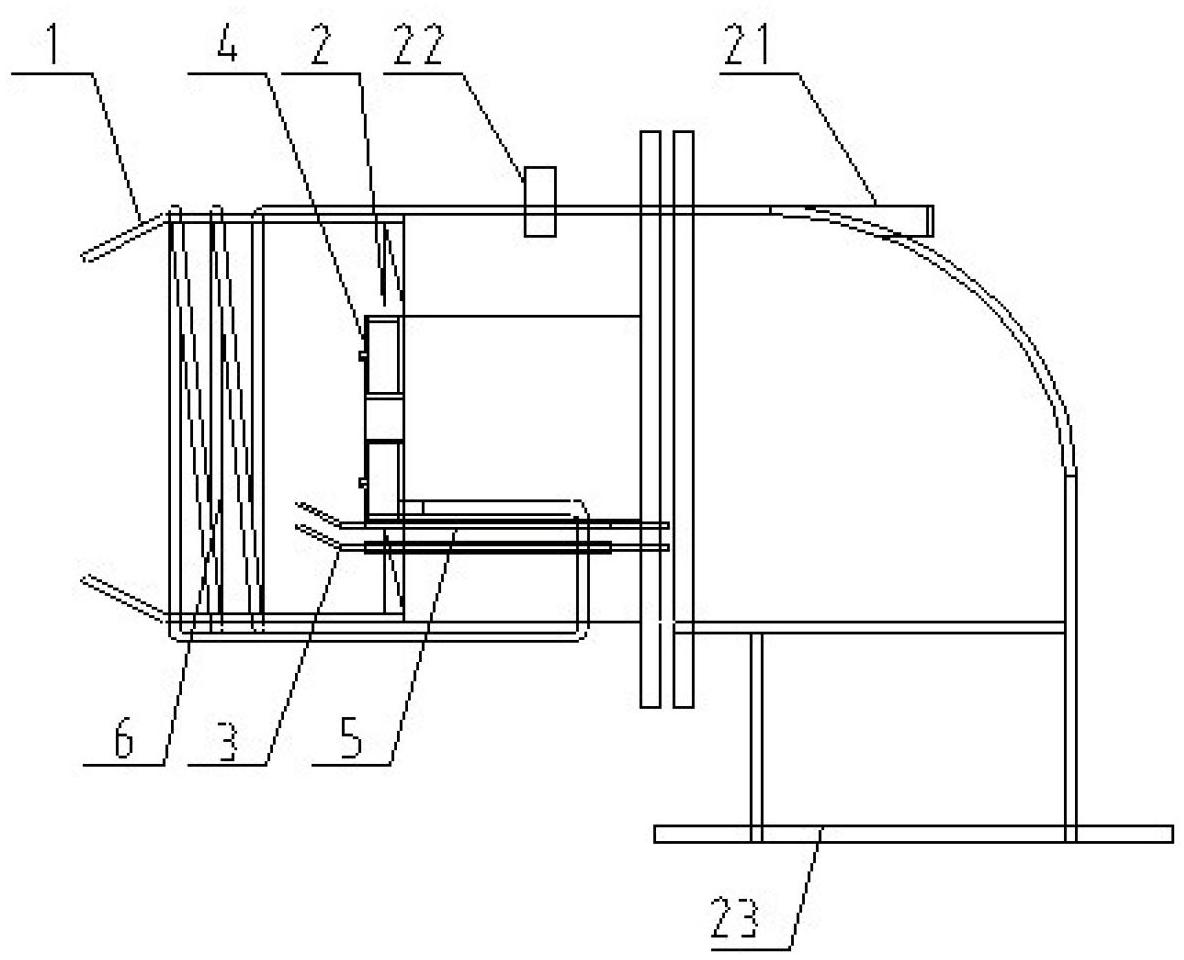

[0036] Mix the bioalcohol-based fuel and oxygen at a ratio of 6:1, turn on the fuel supply pump 13, input the mixed fuel to the heater 16 through the filter valve 14 on the fuel supply pipe 18, and control the heating of the fuel through the thermometer 9 temperature, so that the temperature of the fuel heated by the heater 16 is controlled at 95°C, and at the same time, the flow regulating valve 11 on the oil supply pipe 18, the manual control valve 10 and the solenoid valve 7, and the constant pressure on the first-stage oil return pipe 19 are respectively adjusted. The solenoid valve 7 on the valve 12, the secondary oil return pipe 20, and the pressure valve 8 keep the fuel supply pressure at 0.6Mpa. Open the liquefied gas cylinder 17, adjust the pressure of the liquefied gas ejection through the pressure reducing valve 15, ignite the ignition rod 3, and heat the gasification pipe 6 with the heat generated by the combustion of the liquefied gas ejected from the ignition nozz...

Embodiment 2

[0041] Mix the bioalcohol-based fuel and oxygen in a ratio of 7:1, turn on the fuel supply pump 13, input the mixed fuel to the heater 16 through the filter valve 14 on the fuel supply pipe 18, and control the heating of the fuel through the thermometer 9 temperature, so that the temperature of the fuel after being heated by the heater 16 is controlled at 100°C. At the same time, the flow regulating valve 11, the manual control valve 10 and the solenoid valve 7 on the fuel supply pipe 18 are adjusted respectively, and the constant pressure on the first-stage oil return pipe 19 is adjusted. The pressure valve 12 and the electromagnetic valve 7 on the secondary oil return pipe 20, and the pressure valve 8 keeps the fuel supply pressure at 0.7Mpa. Open the liquefied gas cylinder 17, adjust the pressure of the liquefied gas ejection through the pressure reducing valve 15, ignite the ignition rod 3, and heat the gasification pipe 6 with the heat generated by the combustion of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com