Patents

Literature

1016 results about "Mixed fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

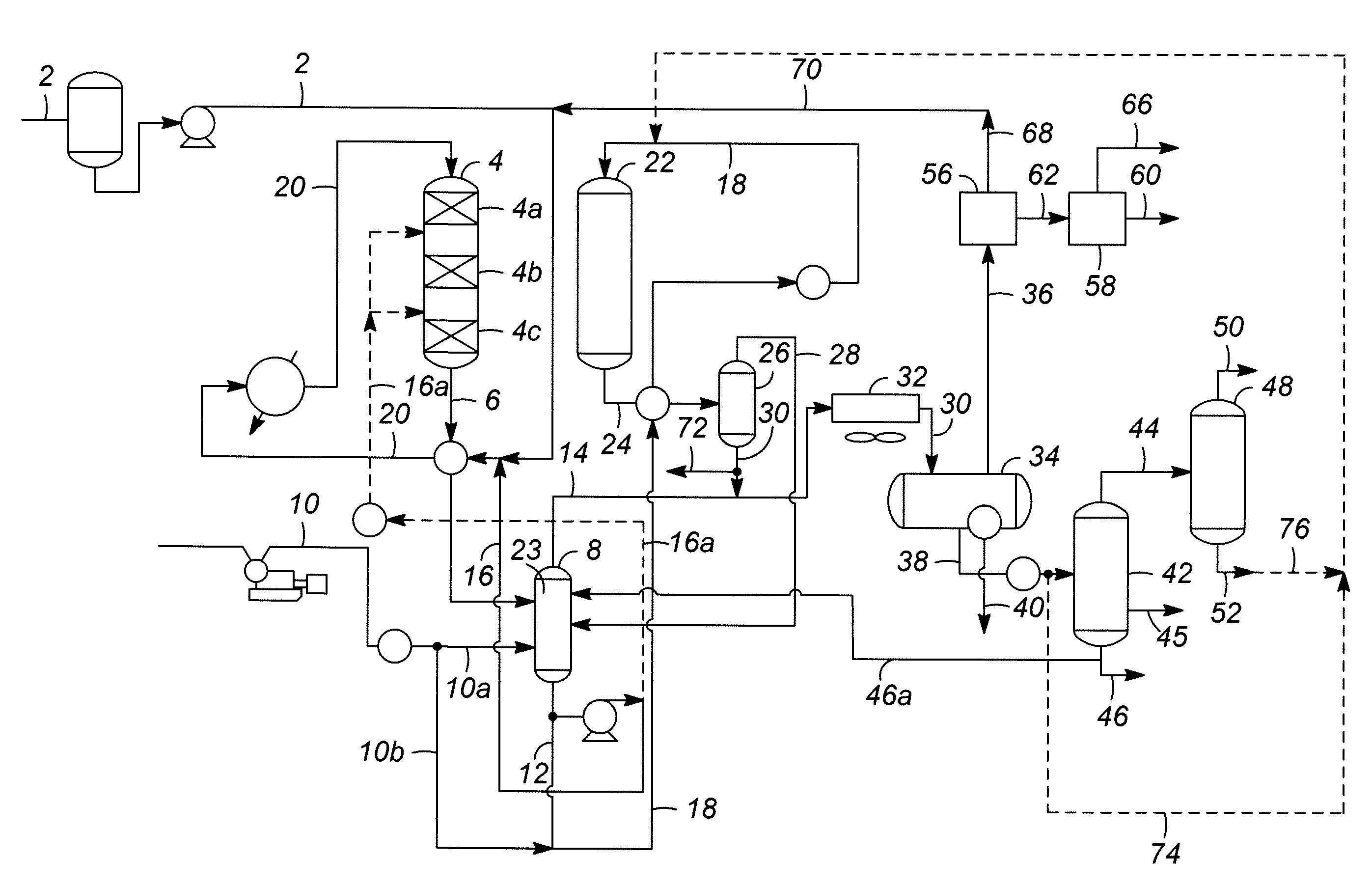

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

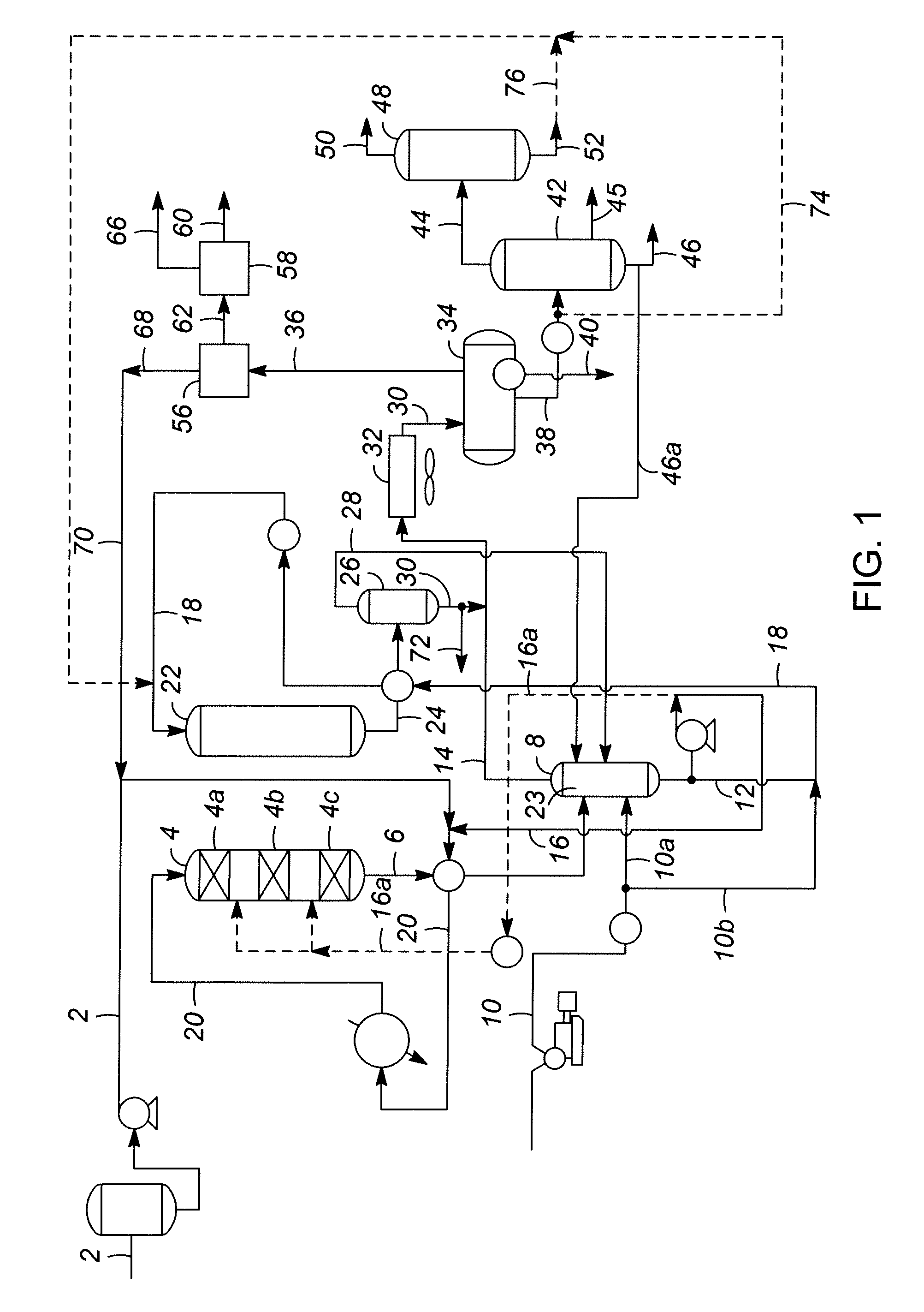

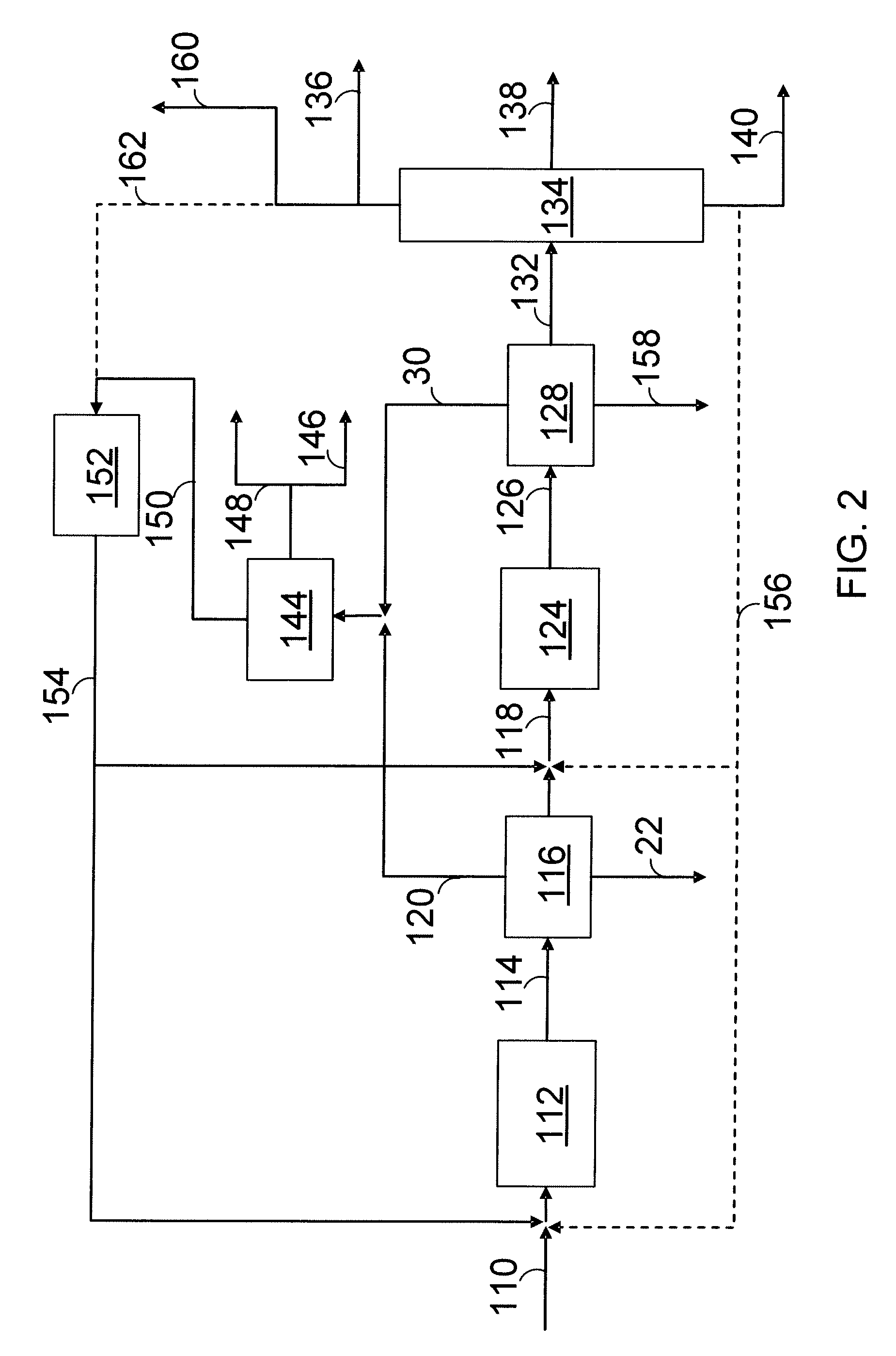

Reforming system for combined cycle plant with partial CO2 capture

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

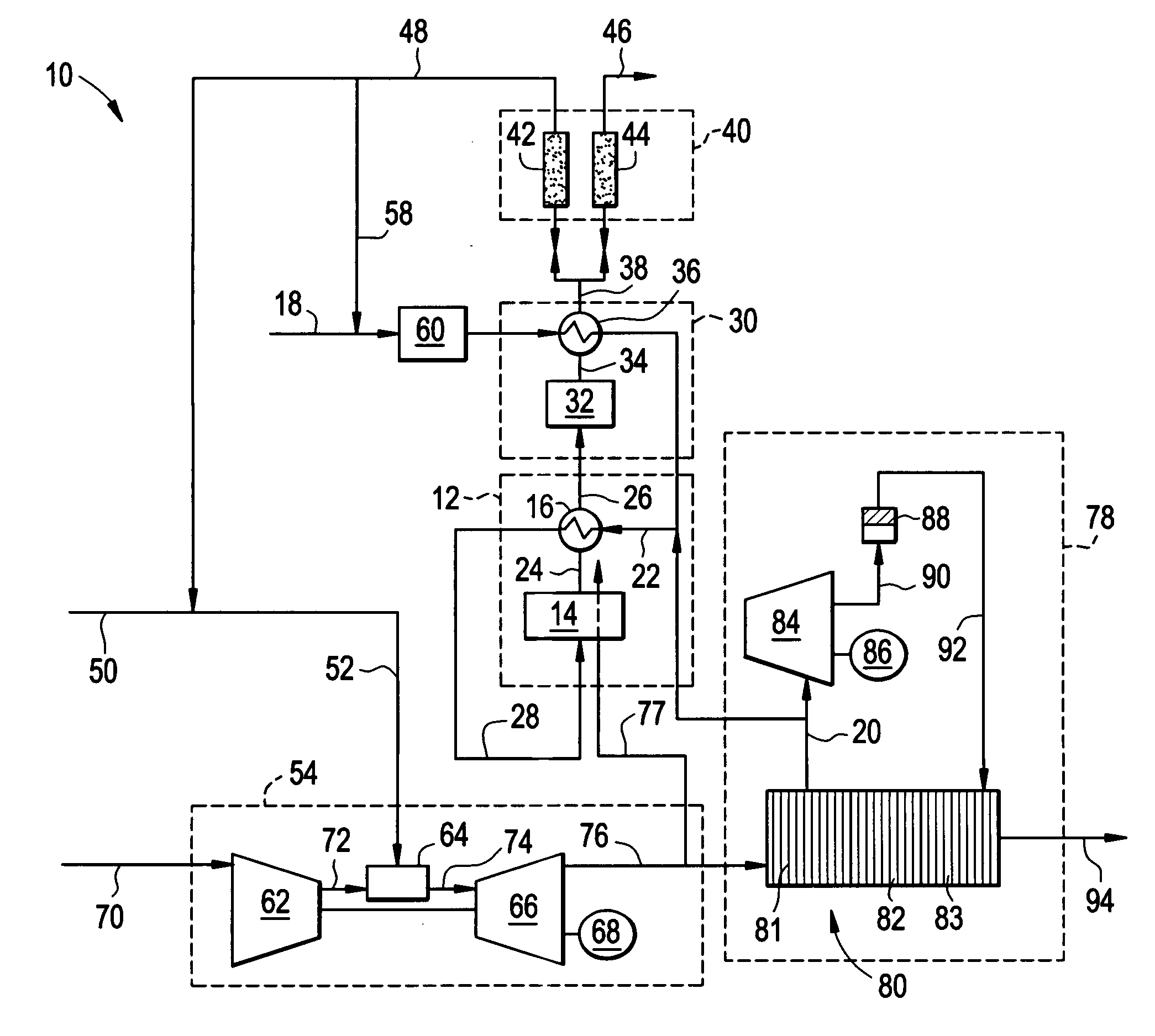

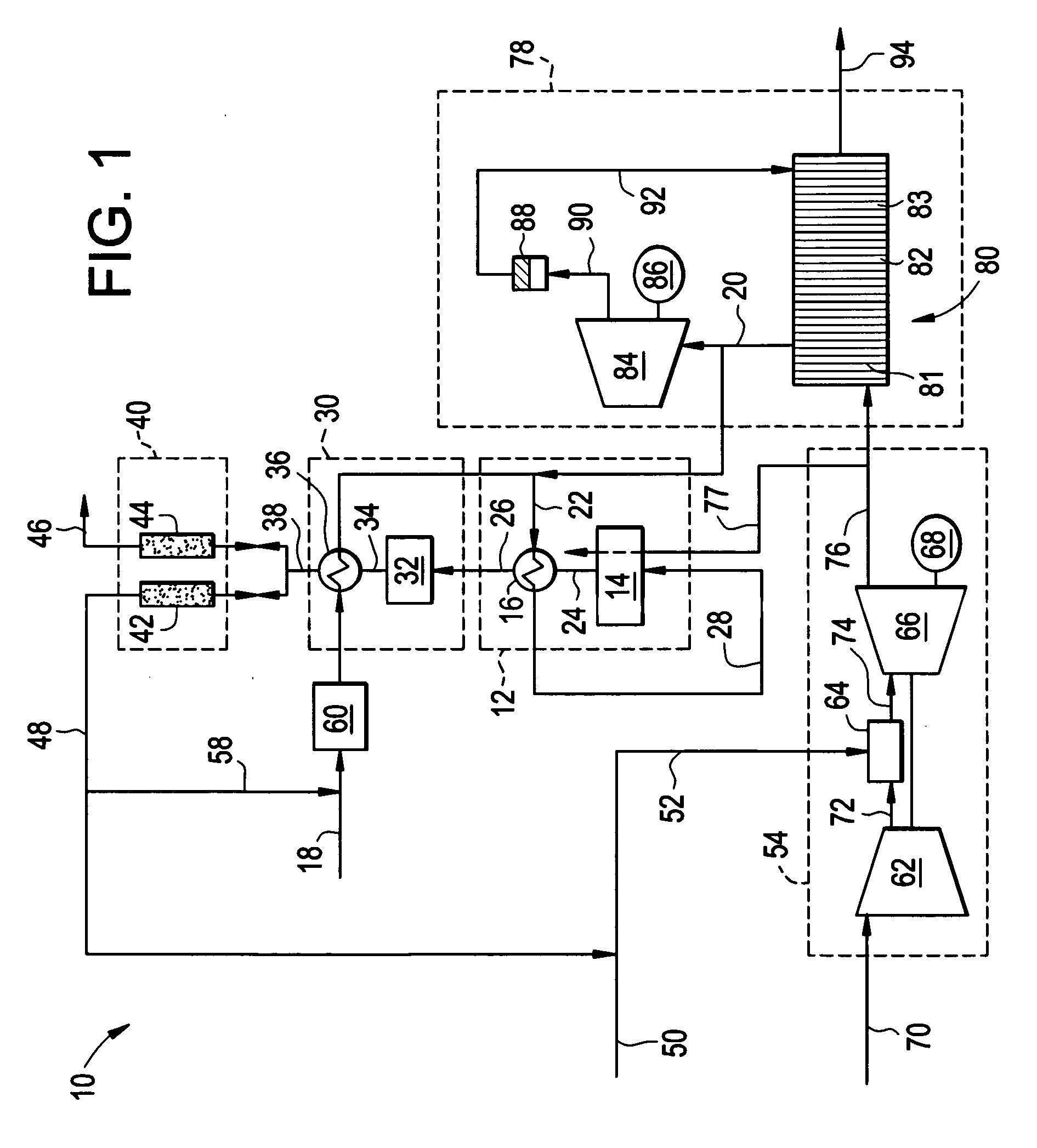

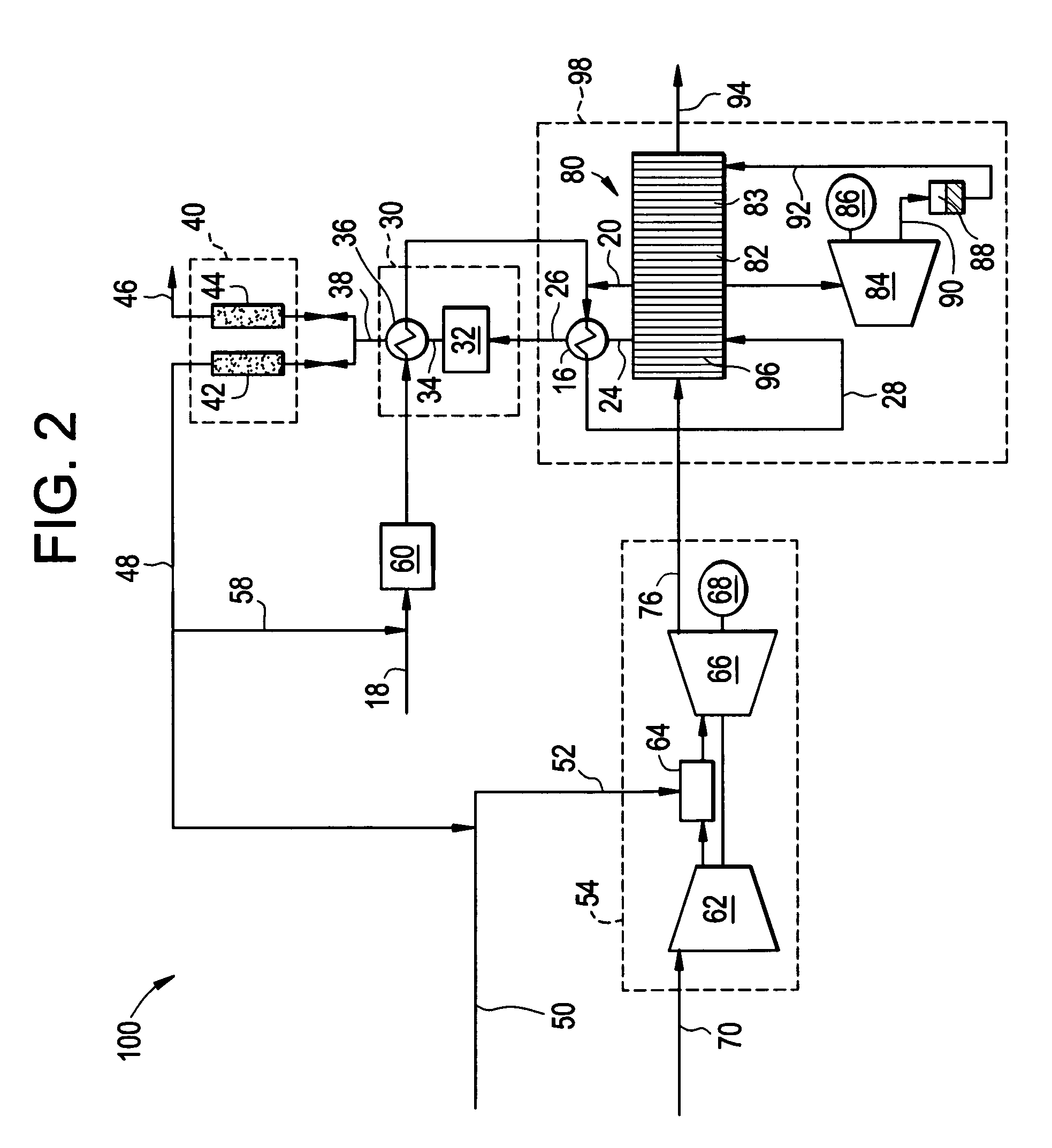

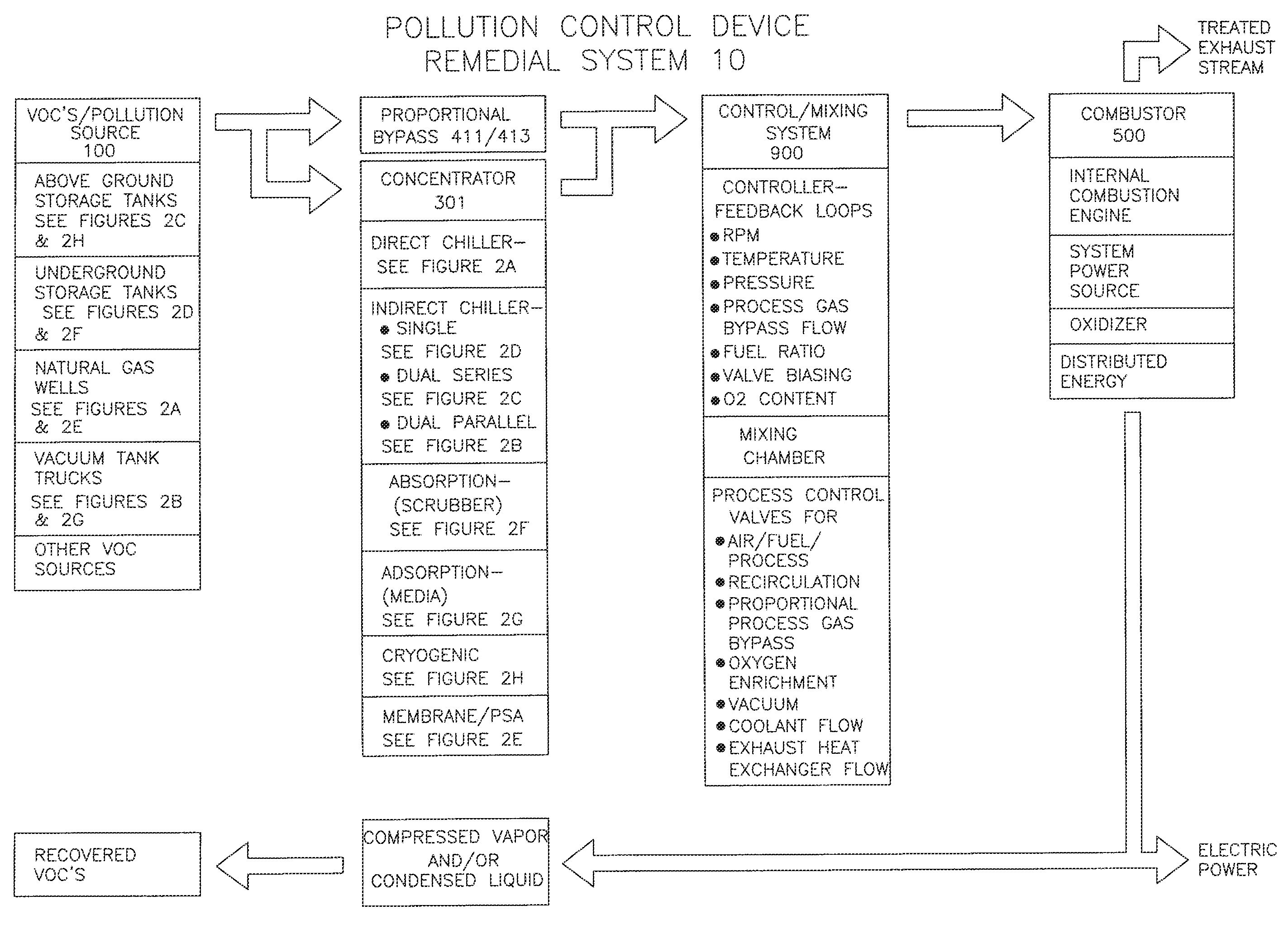

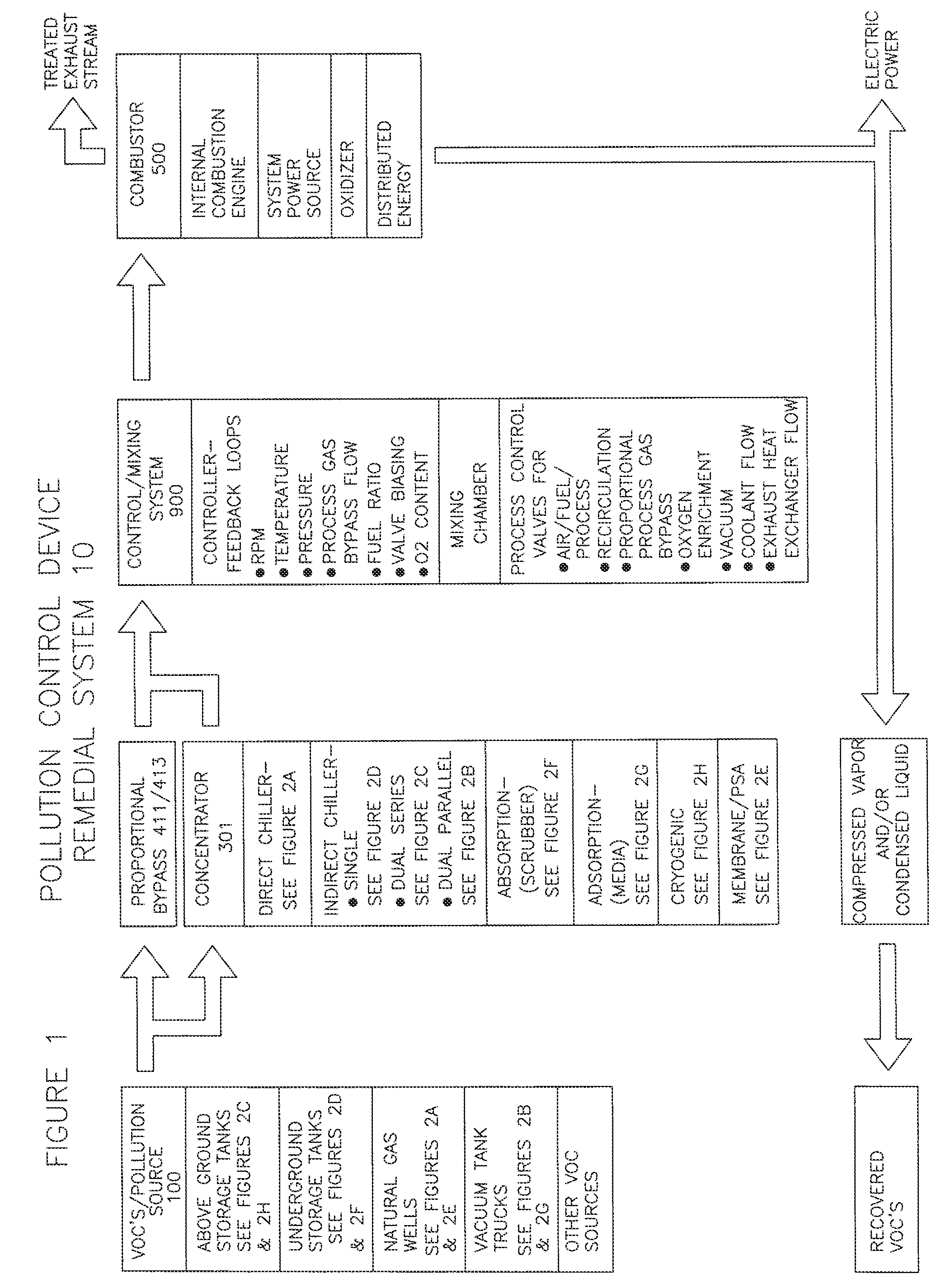

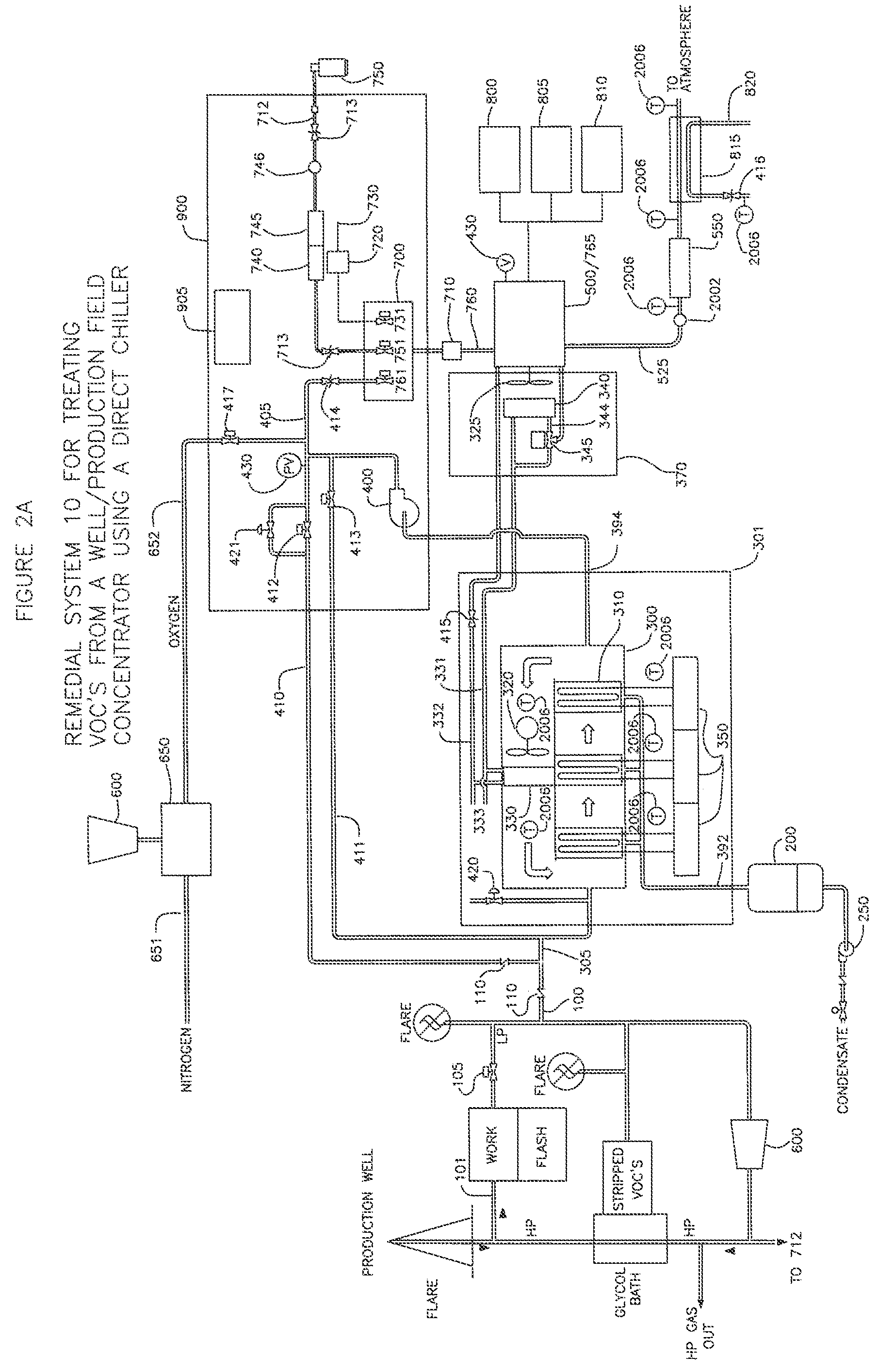

Remedial system: a pollution control device for utilizing and abating volatile organic compounds

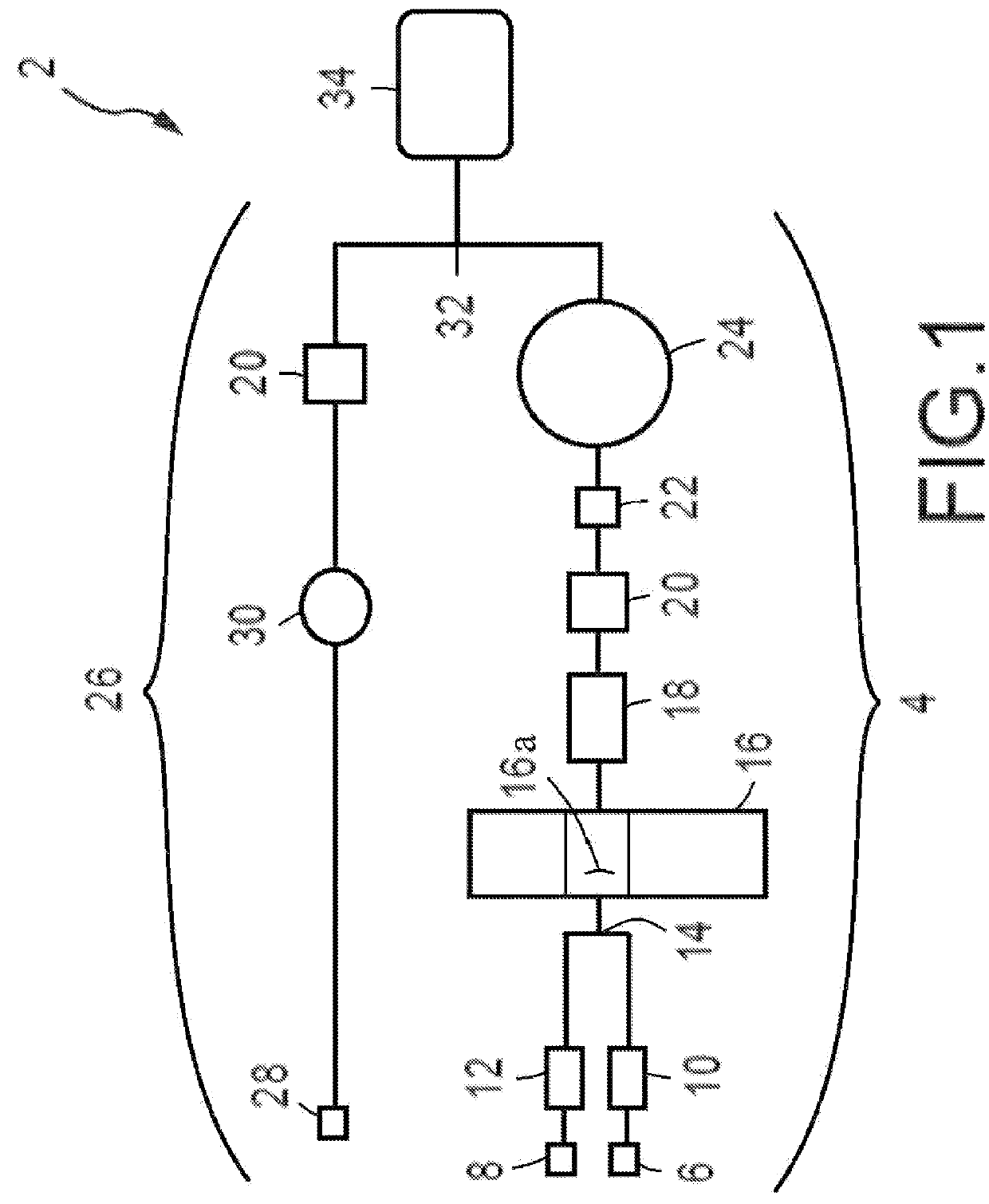

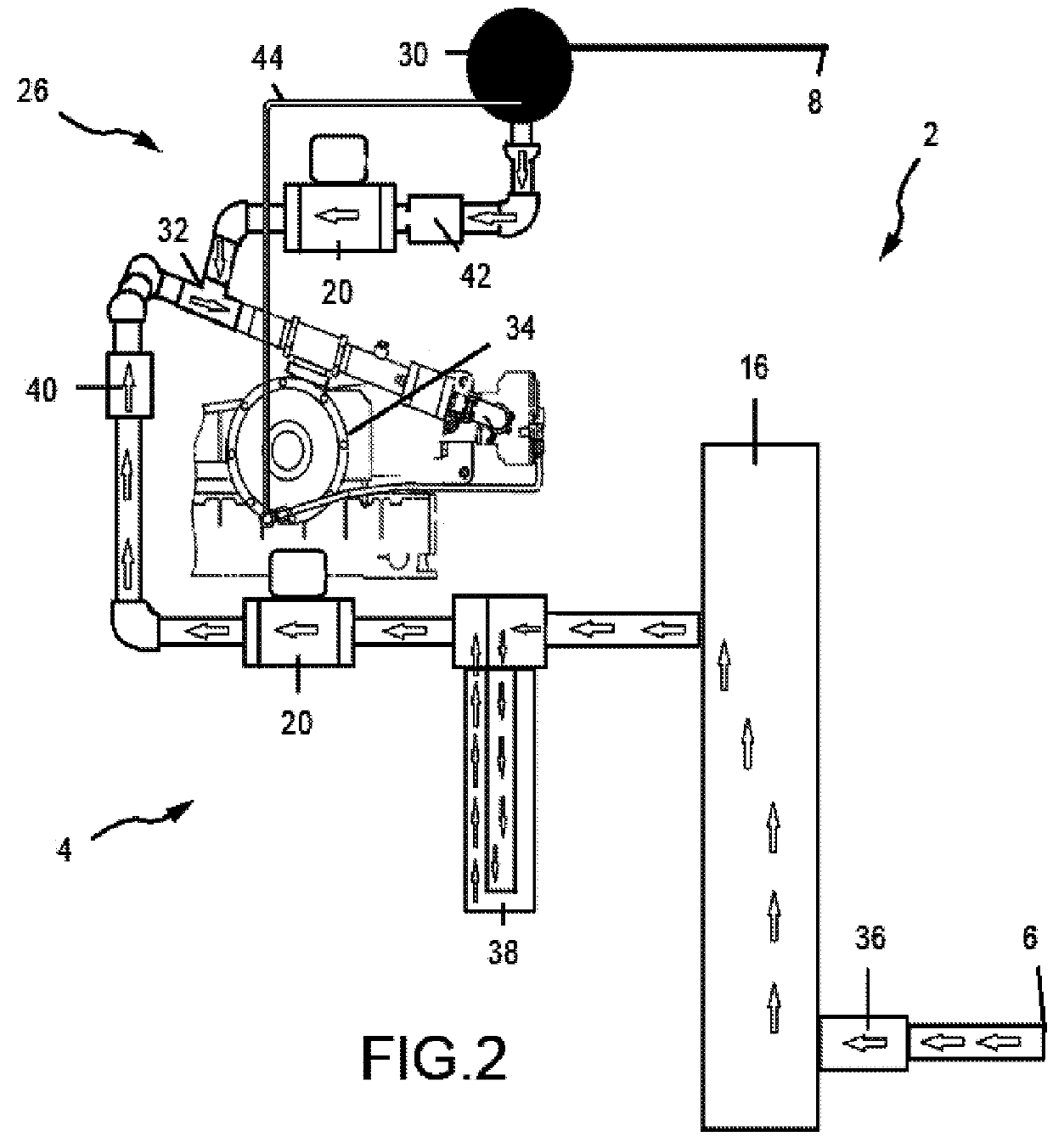

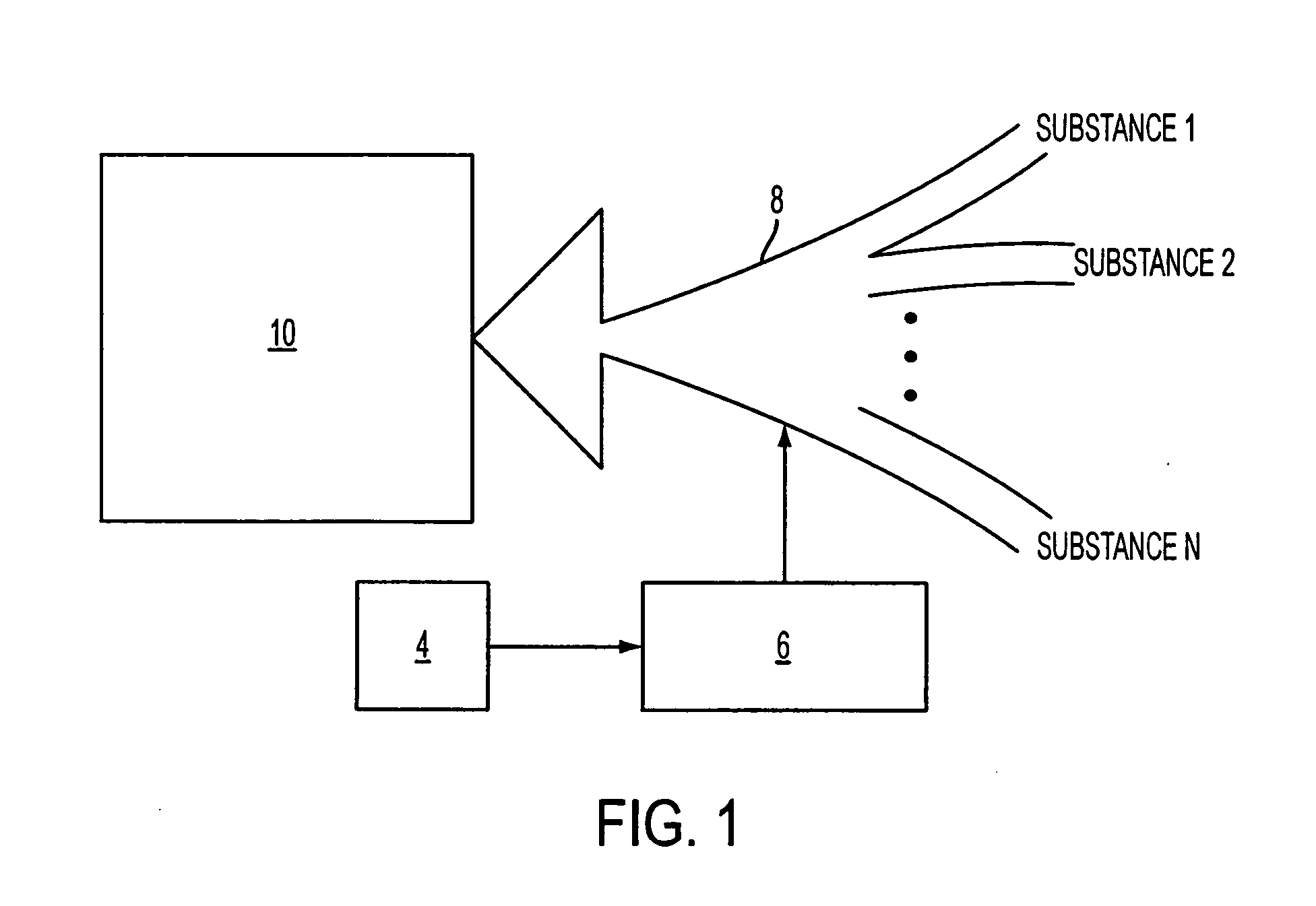

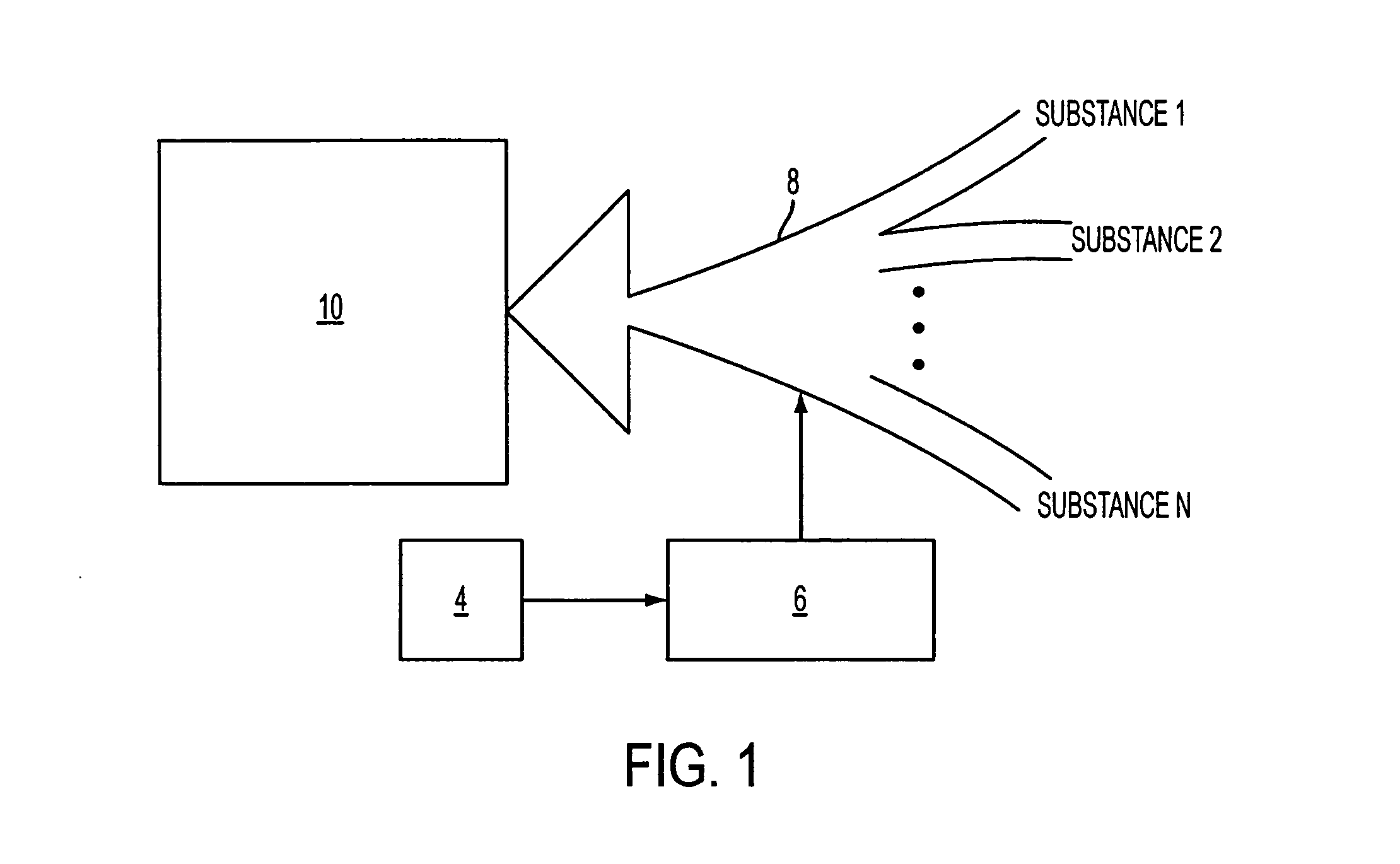

ActiveUS8776734B1Easy to useTreatment safetyGas treatmentNon-fuel substance addition to fuelHybrid systemControl system

A remedial pollution control system for treating volatile organic compounds that may include a vapor concentrator connected to a line that is laden with volatile organic compounds, the concentrator has an organic condensate output line and a vapor output line; a mixing chamber adapted to receive air provided from an air supply line, combustible fuel from an alternate fuel supply line, and a vapor stream from the vapor output line to produce a mixed fuel supplied to an internal combustion engine, a control mixing system with a controller for producing a proper air to fuel ratio in the mixed fuel supply, and power generated to operate other devices used to more efficiently abate volatile organic compounds and reduce greenhouse gas emissions.

Owner:INNOVATIVE ENVIRONMENTAL SOLUTIONS LLC DBA REMEDIATION SERVICE INTL

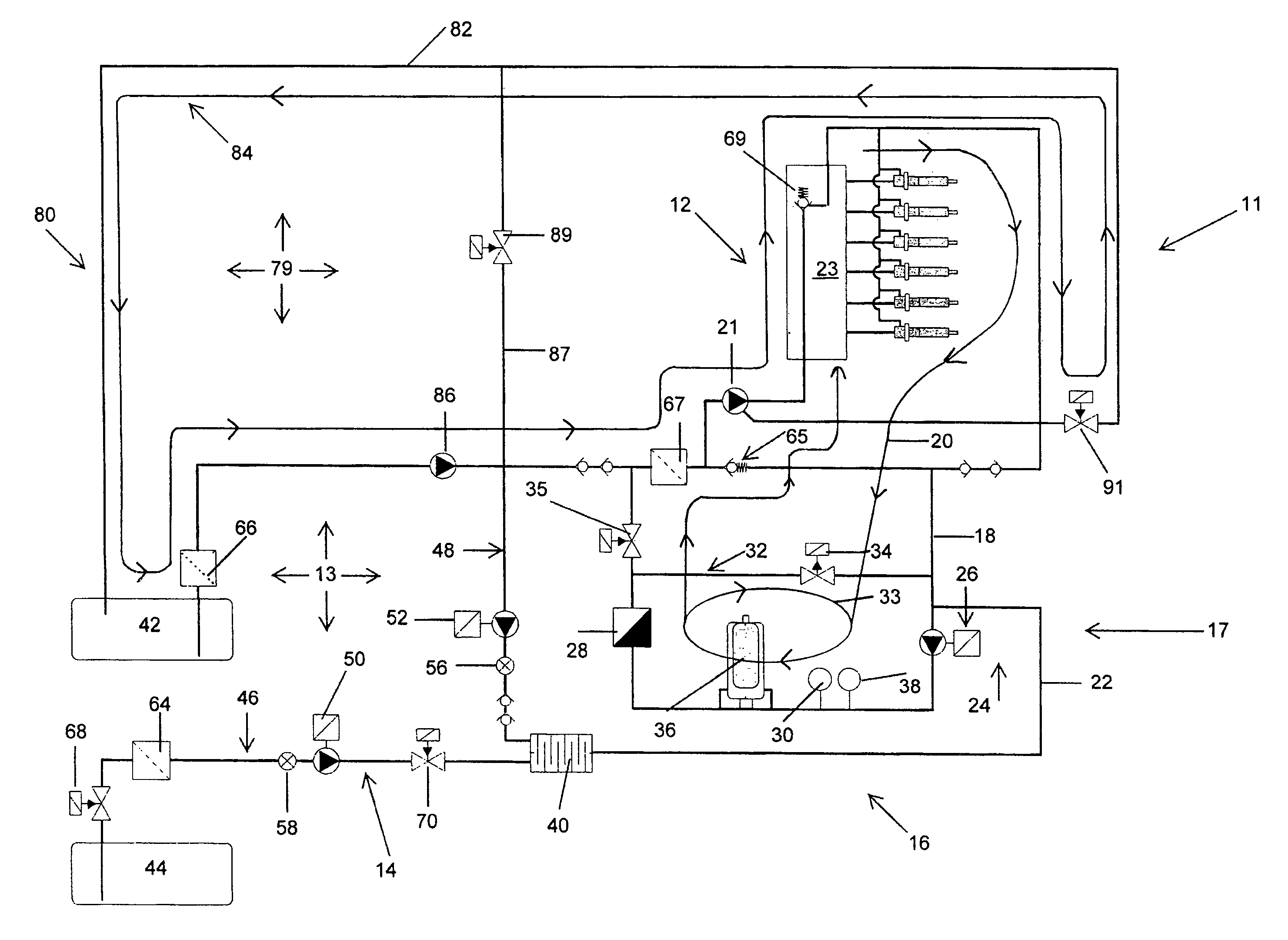

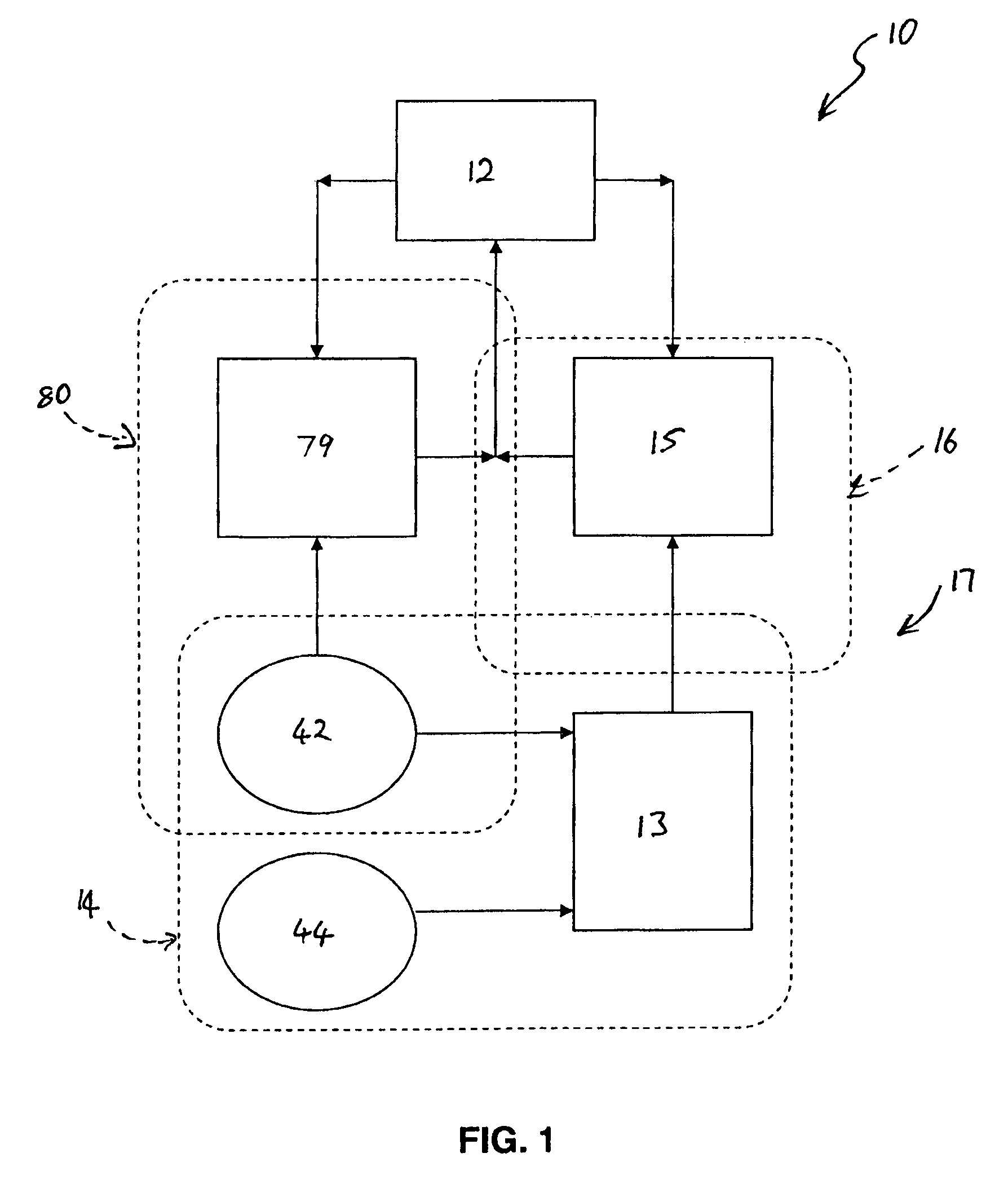

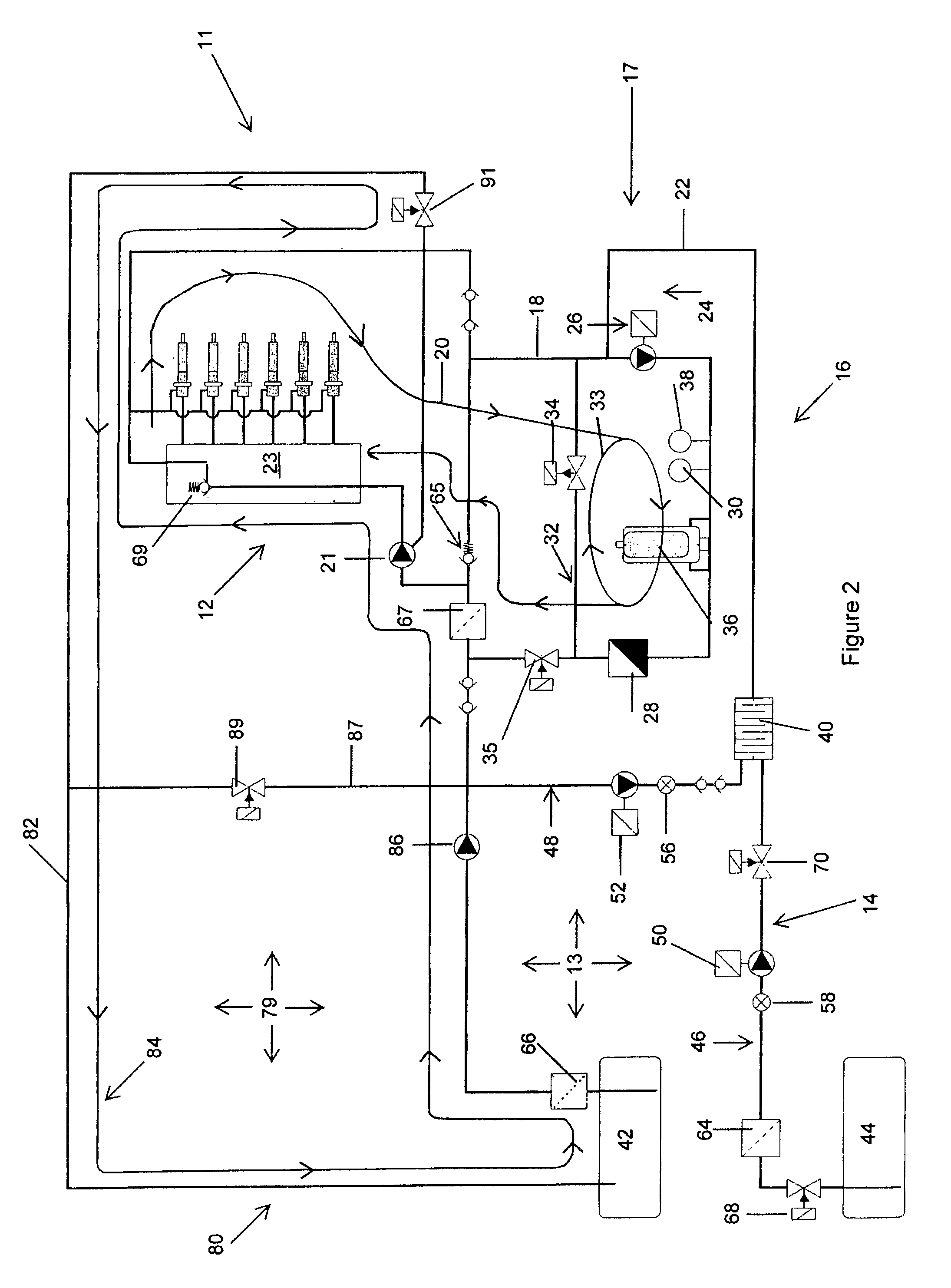

Dual fuel supply system for a direct-injection system of a diesel engine with on-board mixing

InactiveUS8973560B2Non-fuel substance addition to fuelInternal combustion piston enginesOn boardEngineering

The present invention is directed to a dual fuel supply system for supplying fuel to a direct-injection system of a diesel engine. The dual fuel supply system includes a diesel supply system to supply diesel to the direct-injection system; and a mixed fuel supply system that is operatively able to supply a liquid fuel premixture of diesel and liquefied gaseous fuel to the direct-injection system at a supply pressure within a fuel demand pressure range of the direct-injection system and at a corresponding temperature range that retains the fuel premixture below its vapor temperature as it flows through the fuel path of the direct-injection system and the diesel engine. The dual fuel supply system is configured to permit selective change over between the diesel supply system and the mixed fuel system to supply the direct-injection system selectively with either diesel or liquid fuel premixture respectively.

Owner:DGC IND

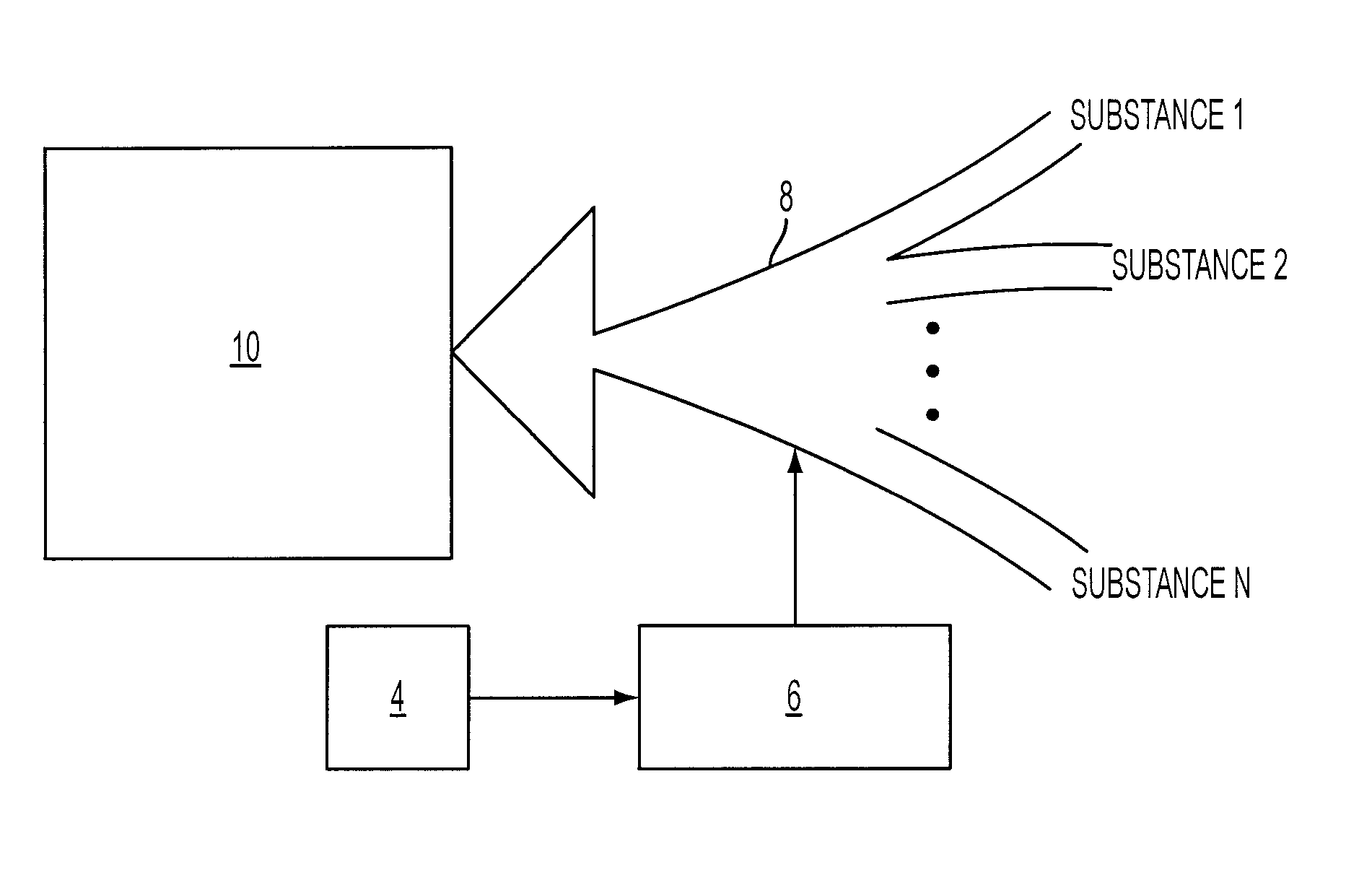

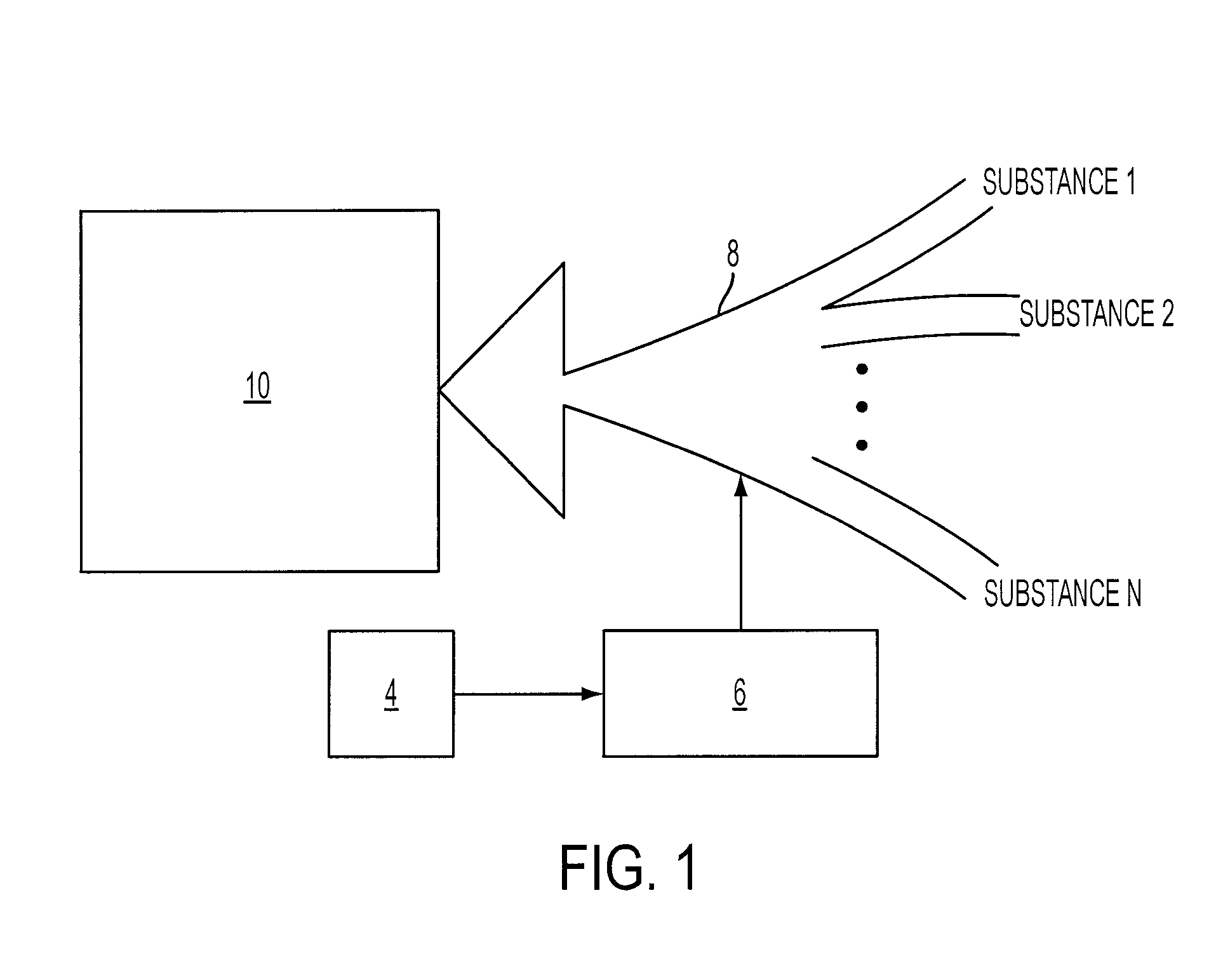

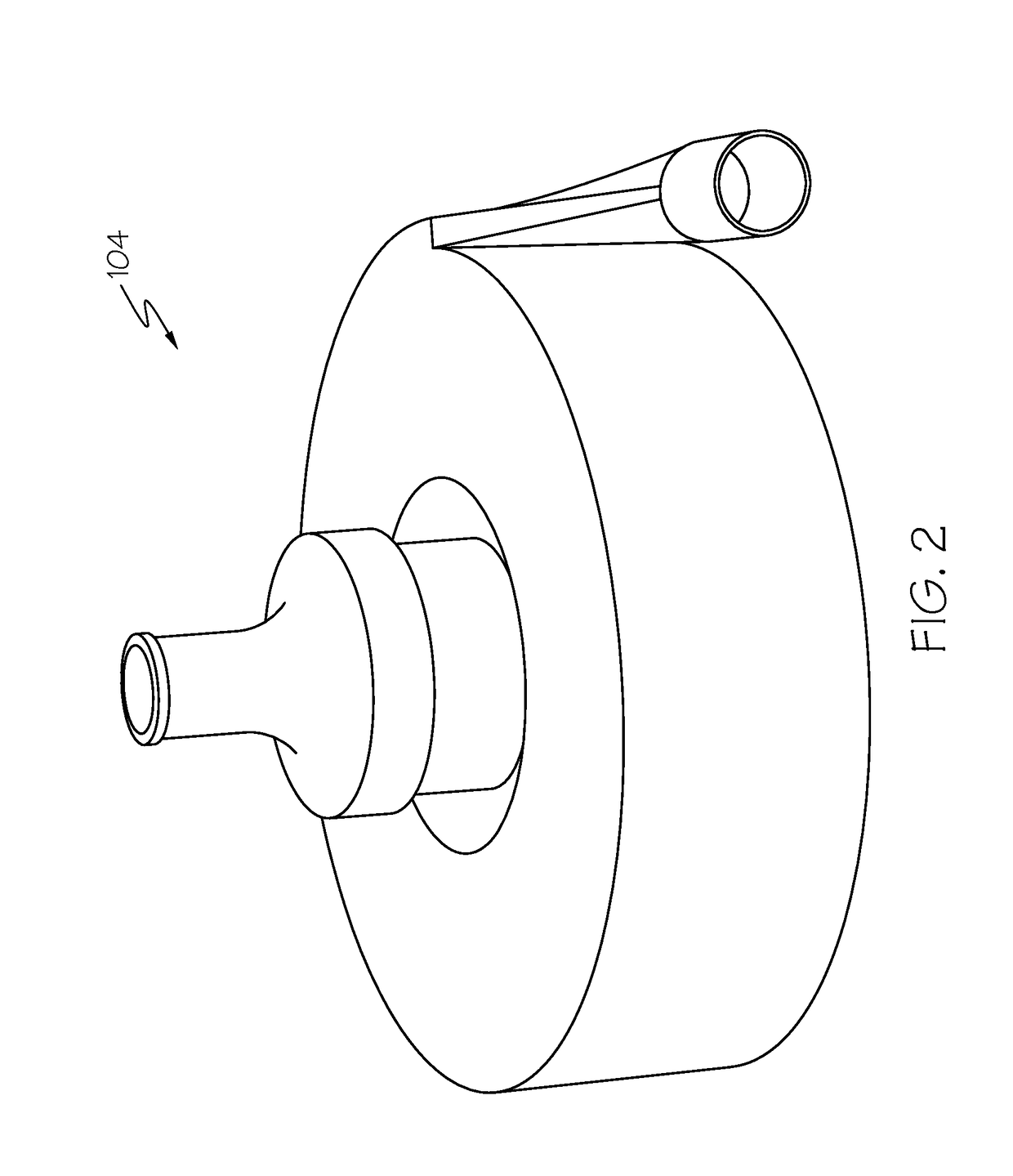

Multi-source gaseous fuel blending manifold

InactiveUS9964052B2Maintain continuityMaintain performanceInternal combustion piston enginesEngine controllersAutomotive engineeringMixed fuel

A device, system, and method are provided for blending multiple fuels in multiple states and optimizing the blended fuel for parameters including cost, energy content, pressure, etc. In a primary fuel / supplemental fuel system, the present invention allows a user to consume as much primary fuel as possible even if the primary fuel is hampered by inconsistent pressure or quality issue, thus ensuring a downstream engine runs continuously.

Owner:BM GRP

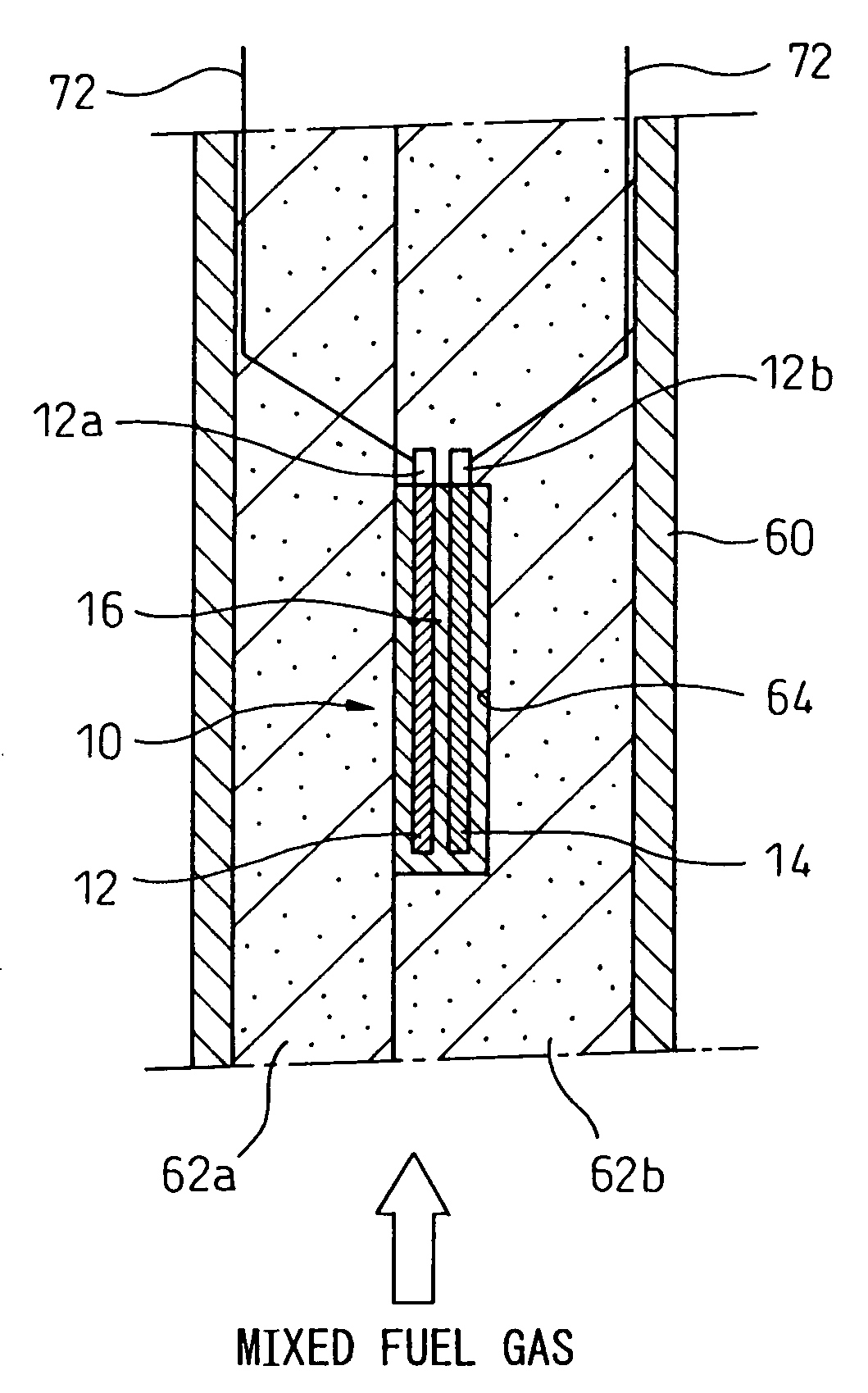

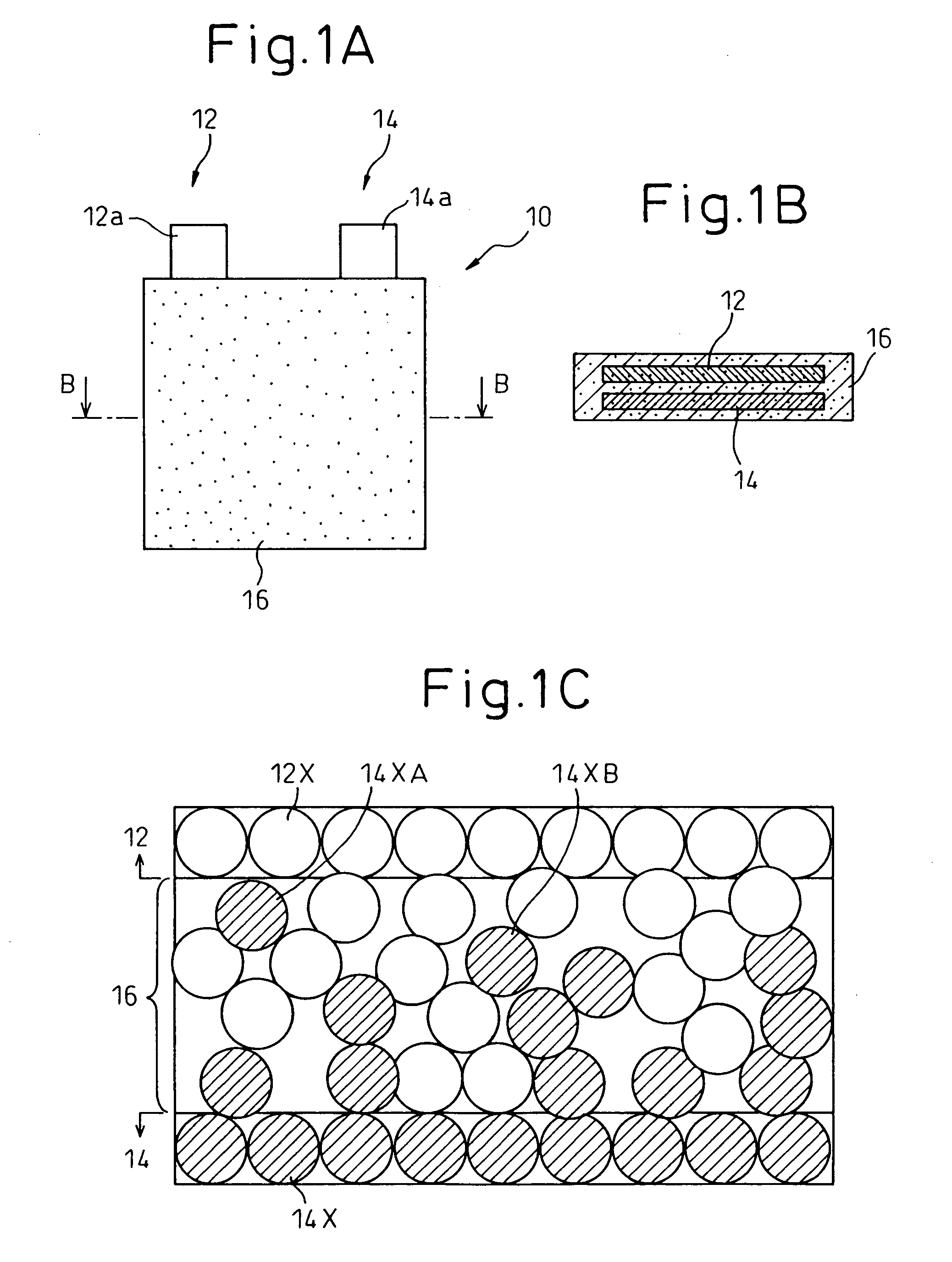

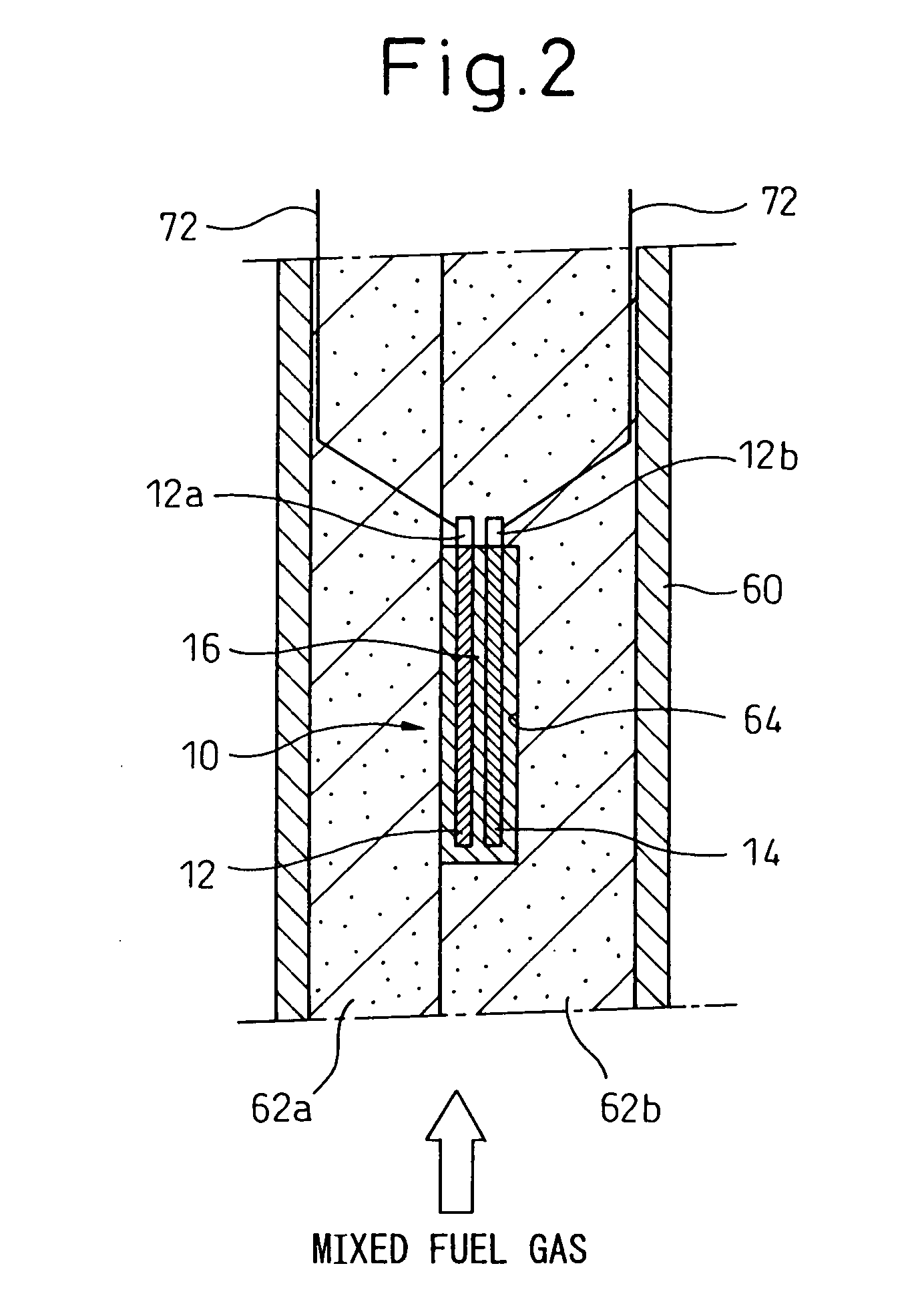

Fuel cell

A single chamber fuel cell comprised of a cell arranged in a mixed fuel gas comprised of hydrogen or another fuel gas and oxygen, wherein the cell used is a pn junction type semiconductor having electrodes of a p-type semiconductor with carriers of holes and an n-type semiconductor with carriers of electrons connected to ends of electrical takeout wires, and each of the p-type semiconductor and n-type semiconductor is formed porous to an extent enabling the mixed fuel gas to pass.

Owner:SHINKO ELECTRIC IND CO LTD

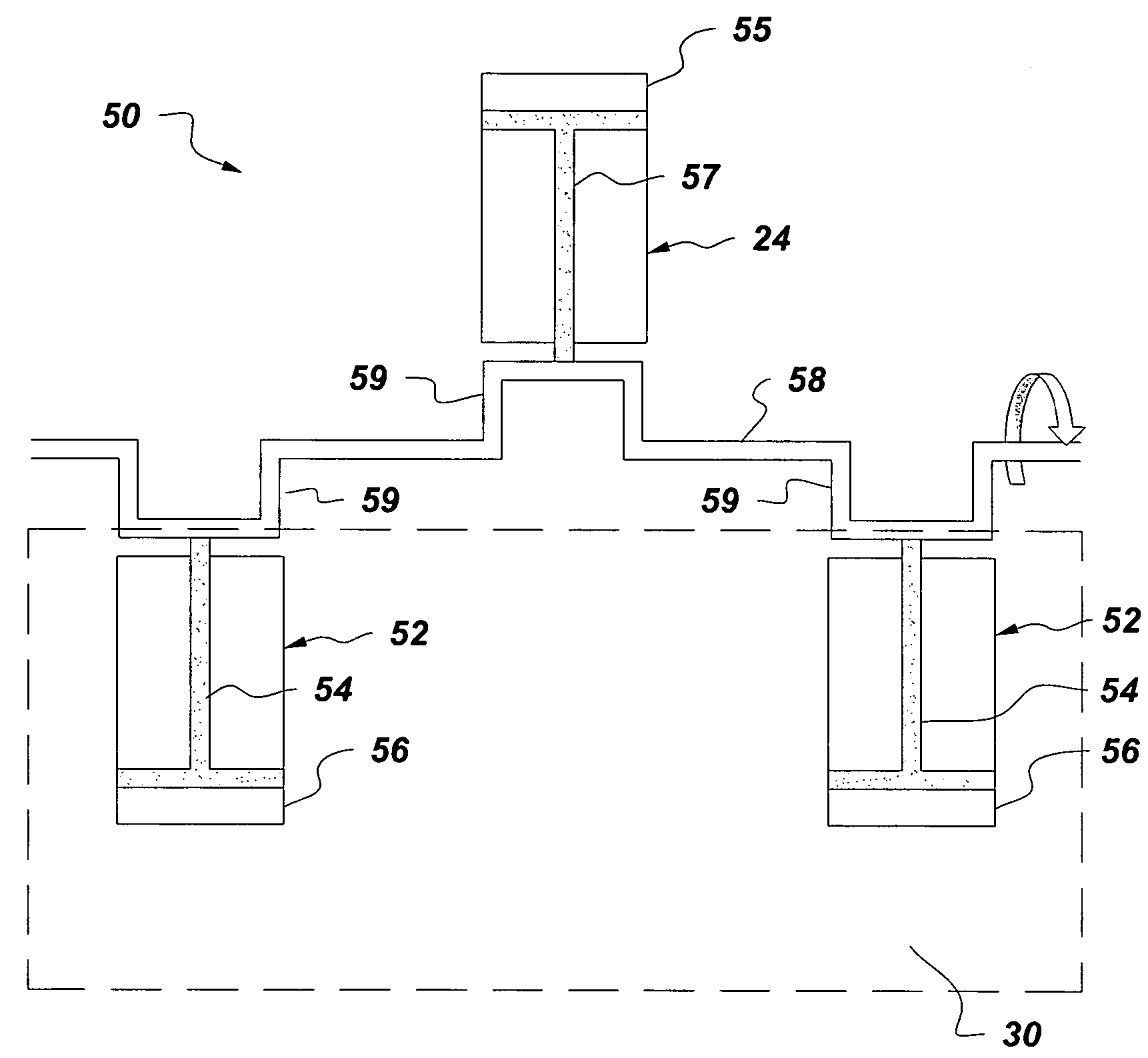

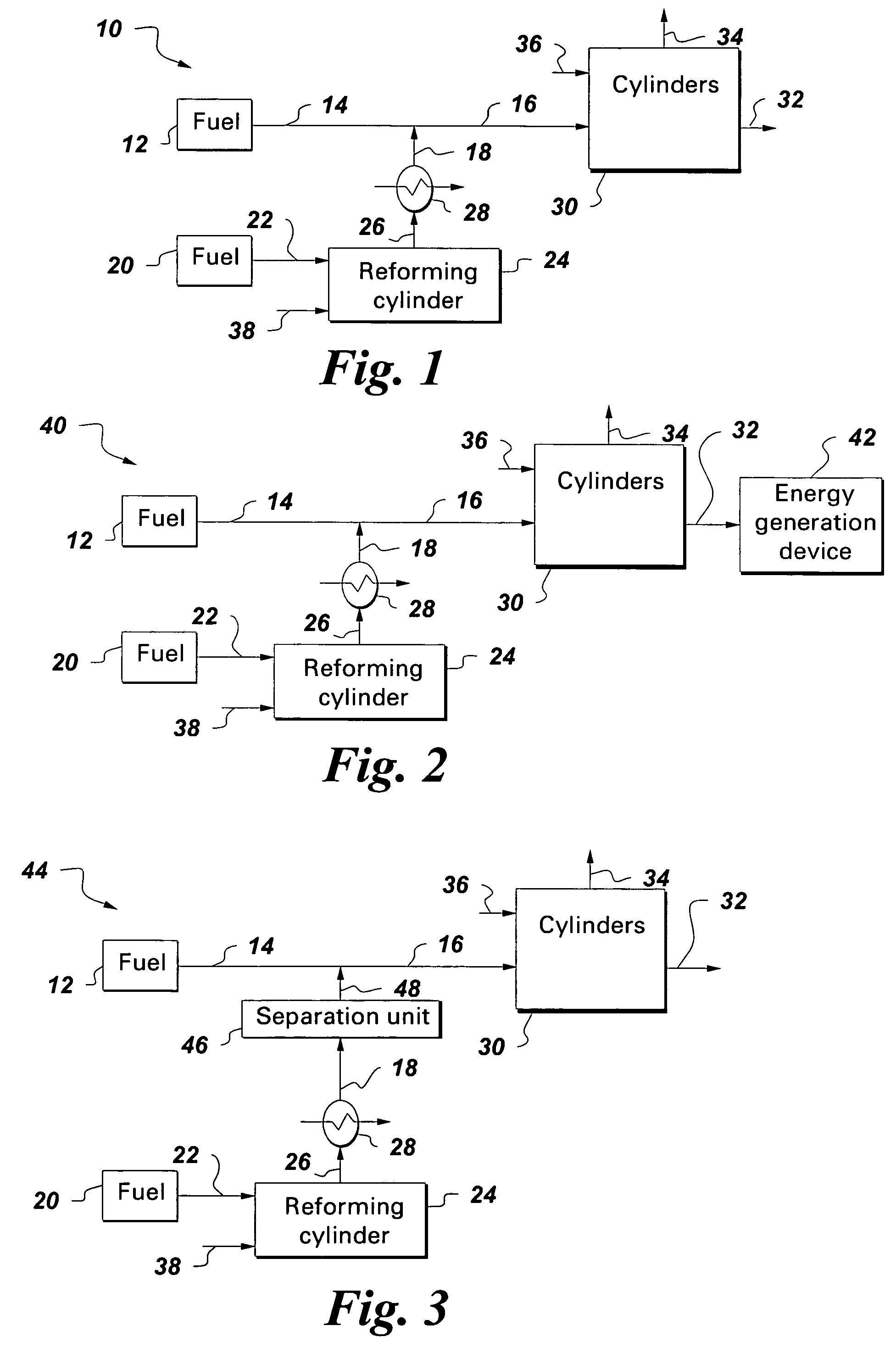

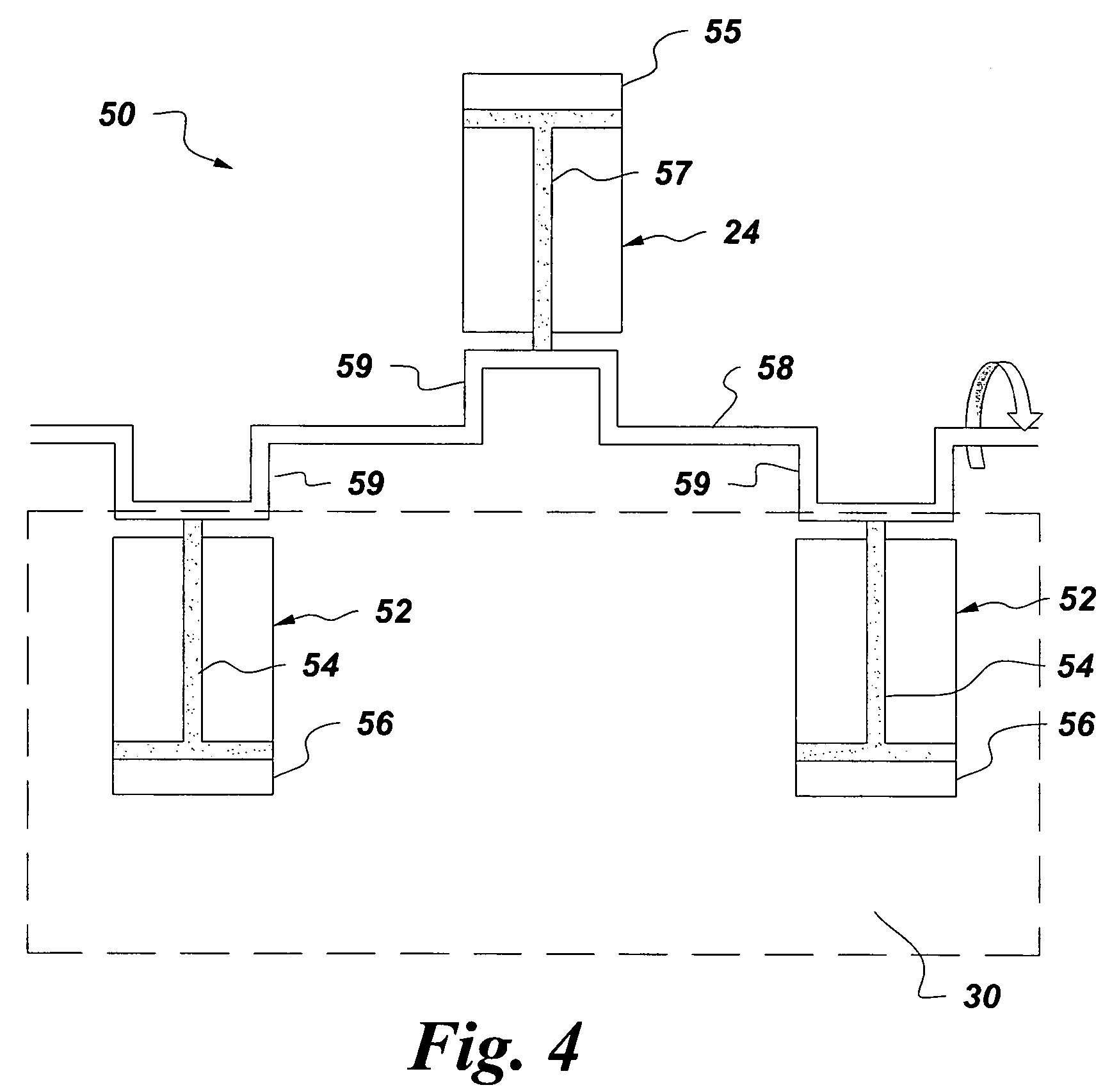

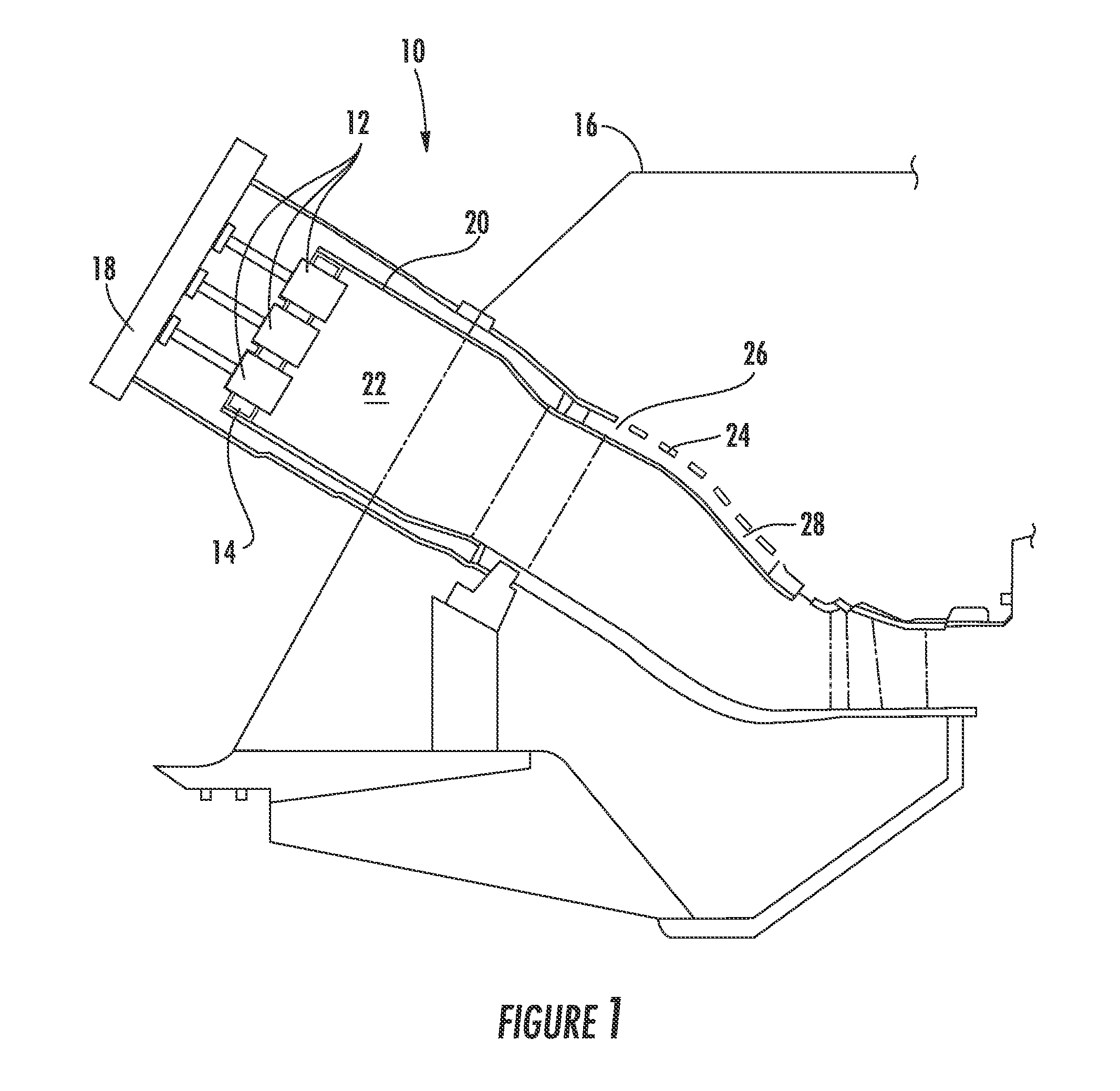

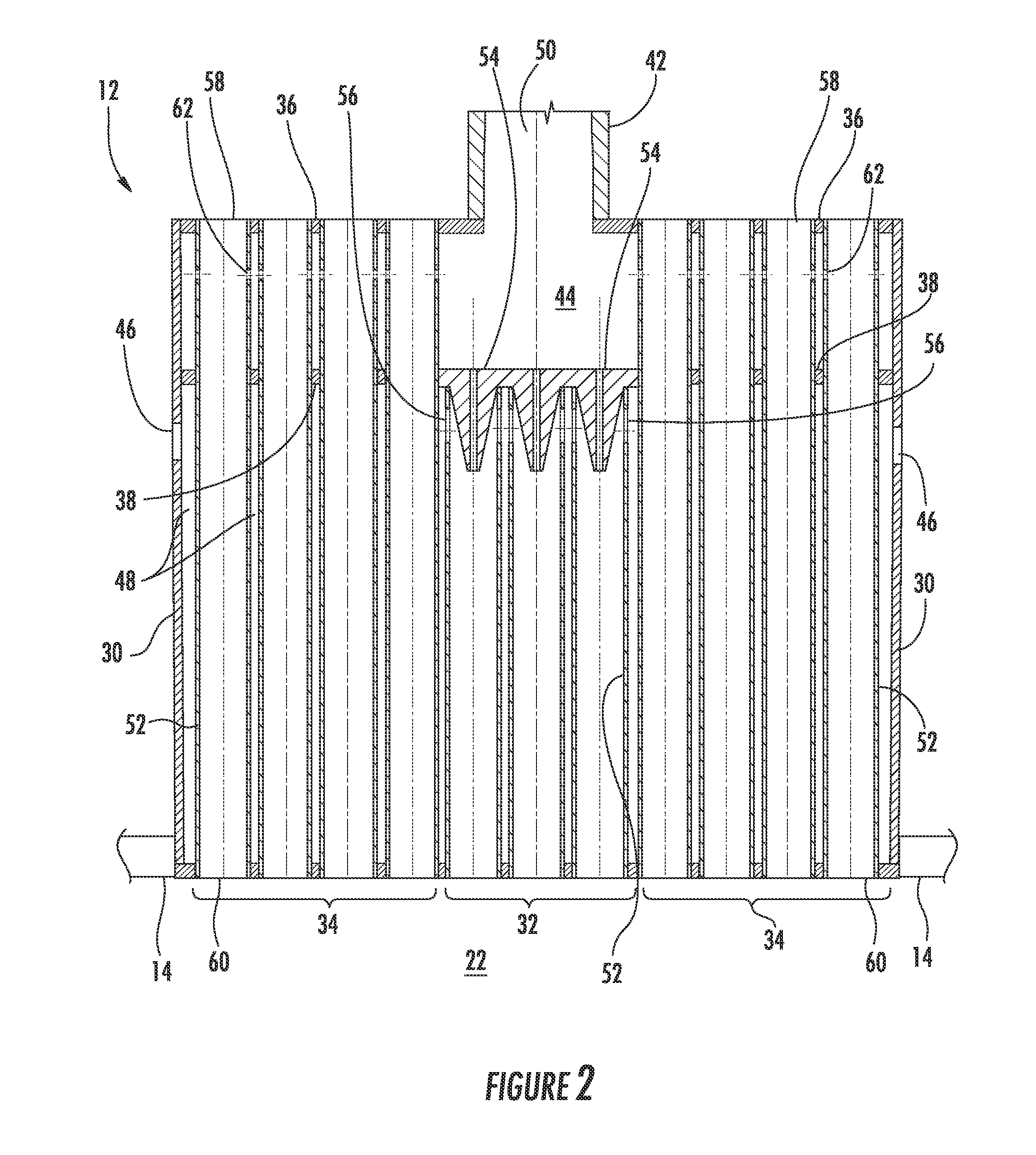

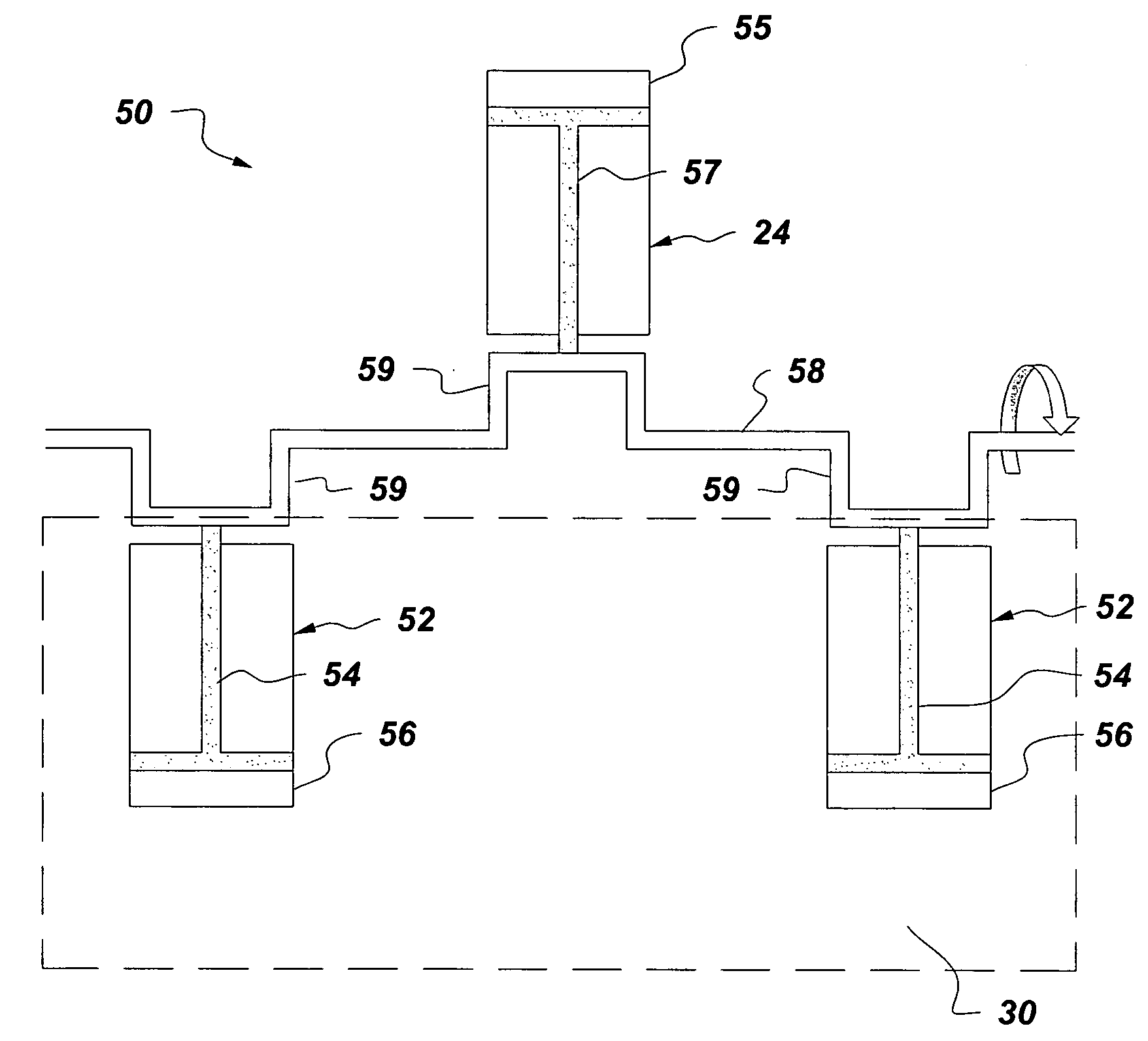

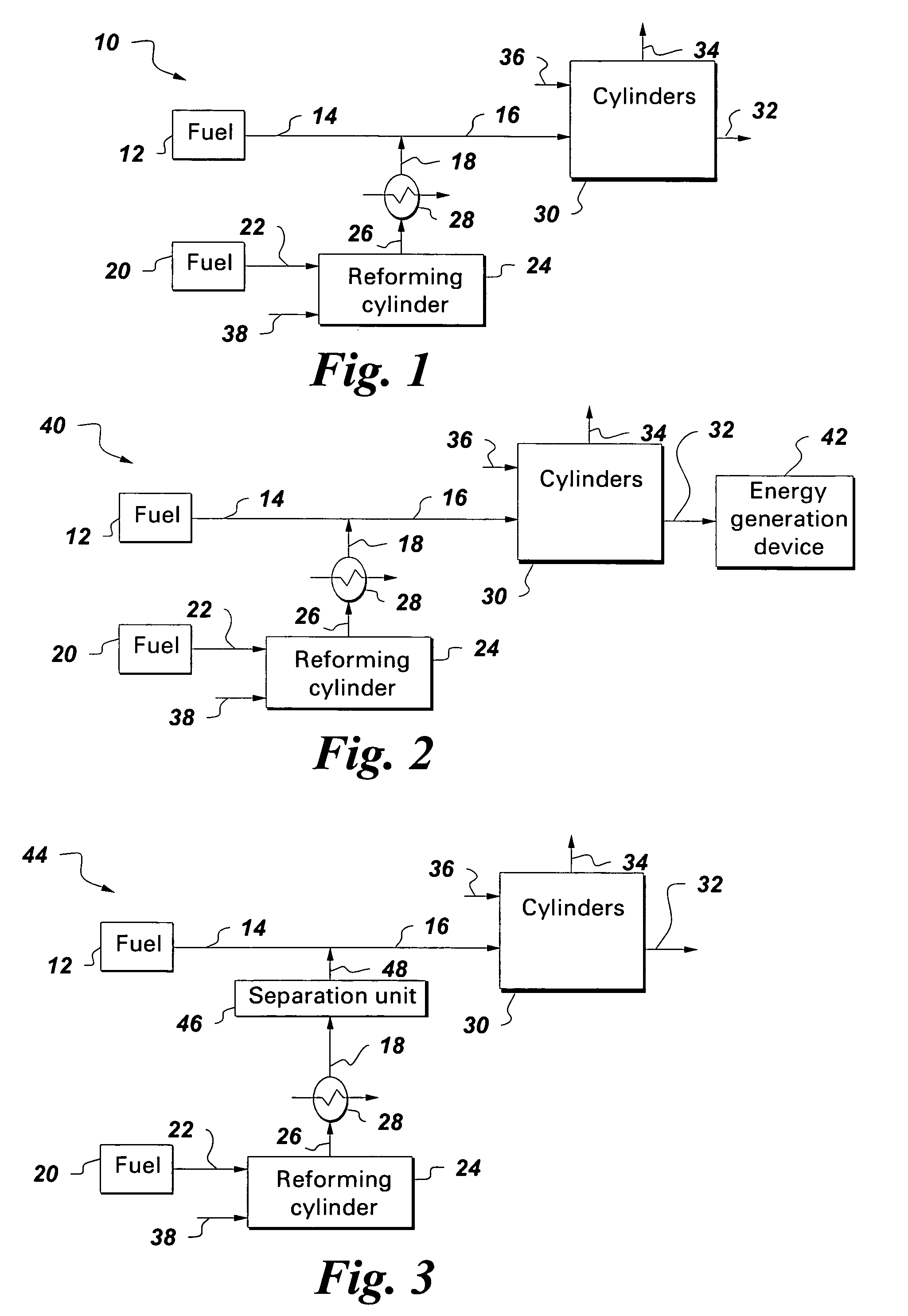

System and method for reducing emission from a combustion engine

InactiveUS7261064B2Emission reductionHydrogenNon-fuel substance addition to fuelHydrogenExhaust fumes

A combustion engine system comprises a plurality of cylinders configured to combust a mixed fuel to produce an exhaust gas and at least one reforming cylinder configured to receive a first portion of a fuel and deliver a reformed hydrogen-containing gas. The hydrogen-containing gas is introduced into a second portion of the fuel to form the mixed fuel to reduce emission from the combustion engine system.

Owner:GENERAL ELECTRIC CO

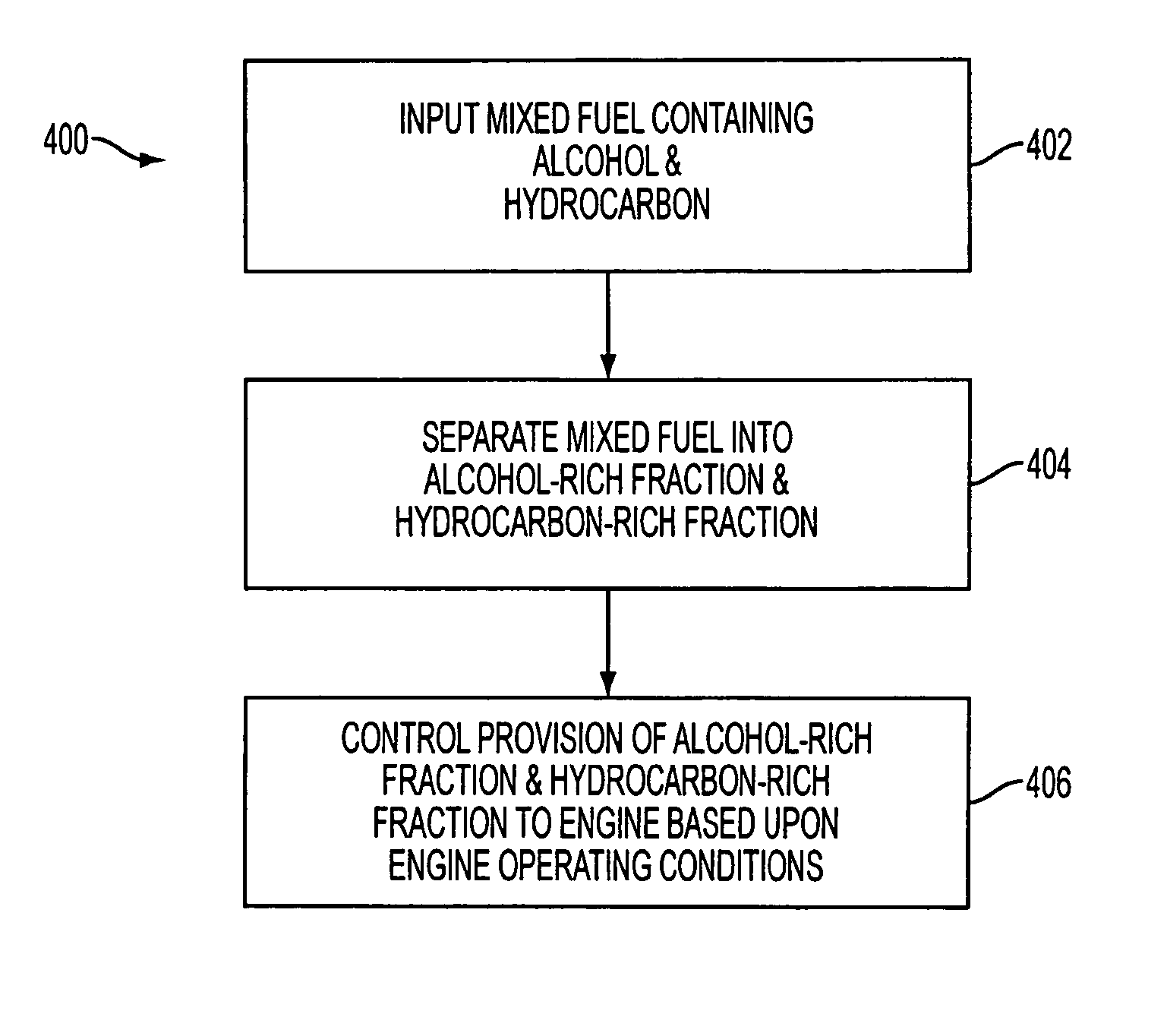

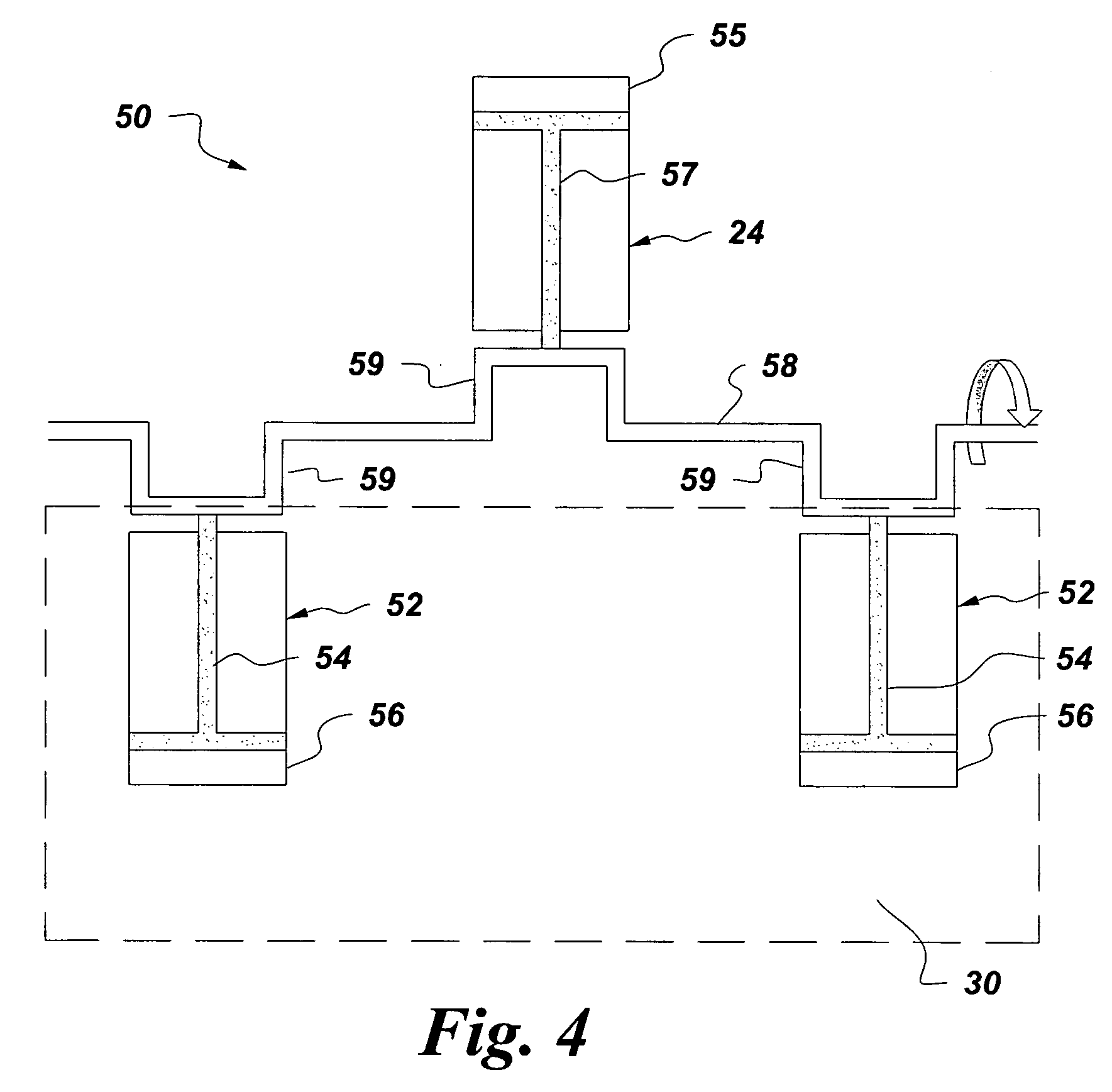

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215072A1Low costImprove charge cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelFuel tankElectrical polarity

In an apparatus having an internal combustion engine, a fuel tank, and an extractor disposed fluidically between the fuel tank and the engine, a method of operating the apparatus is disclosed, wherein the method comprises adding a volume of a mixed fuel into the extractor from the fuel tank, wherein the mixed fuel contains at least one substantially nonpolar fuel component and at least one polar fuel component, adding a volume of a polar solvent to the extractor, extracting at least a portion of the polar fuel from the mixed fuel into the polar solvent, thereby forming a first fuel mixture with an enriched concentration of the polar fuel and a second fuel mixture with an enriched concentration of the substantially nonpolar fuel, and providing the first fuel mixture and the second fuel mixture to the engine in a ratio selected based upon engine operating condition.

Owner:FORD GLOBAL TECH LLC

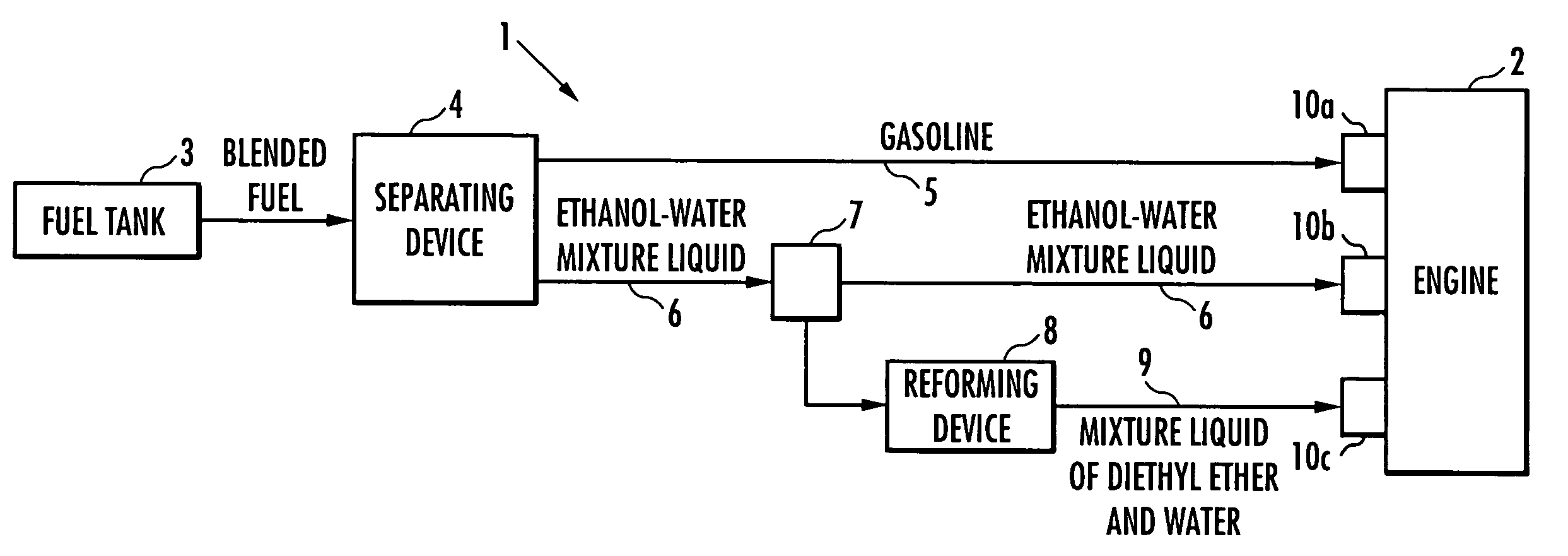

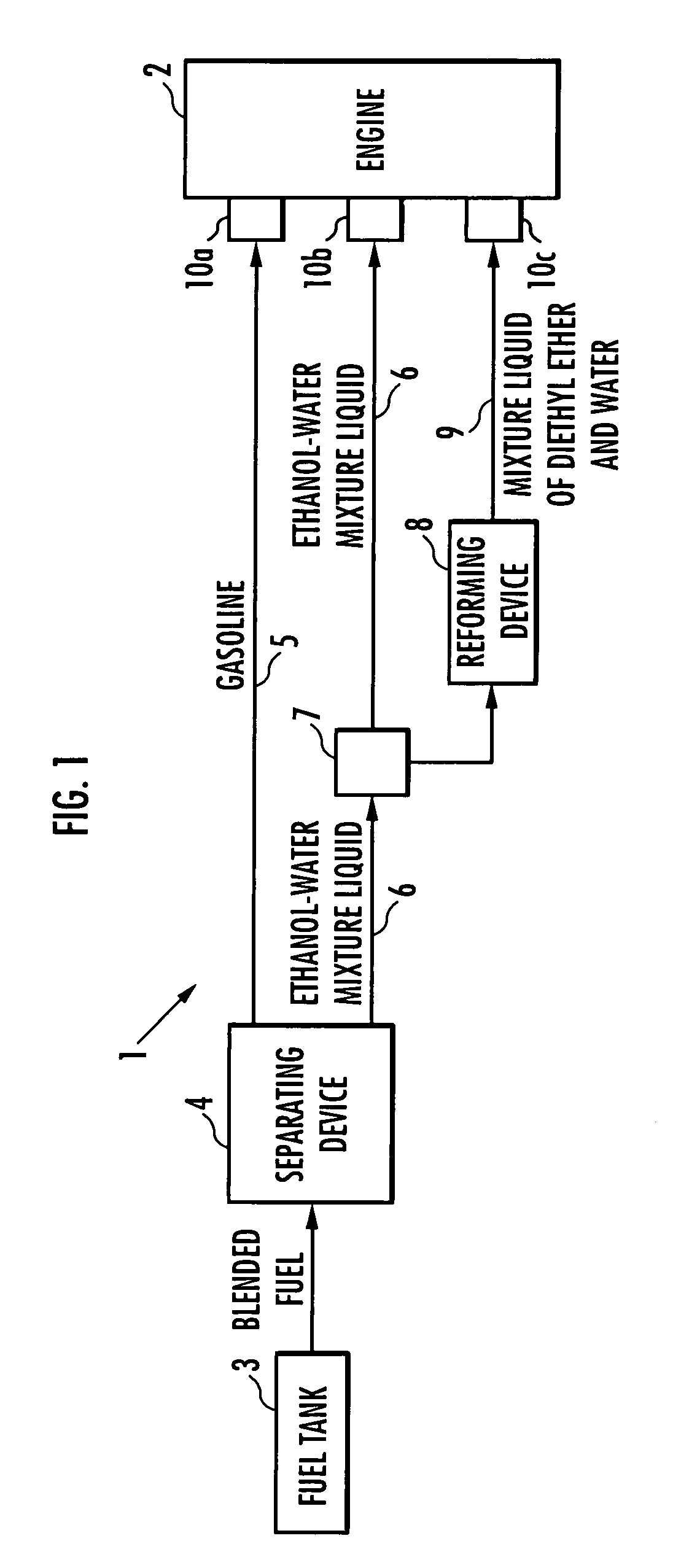

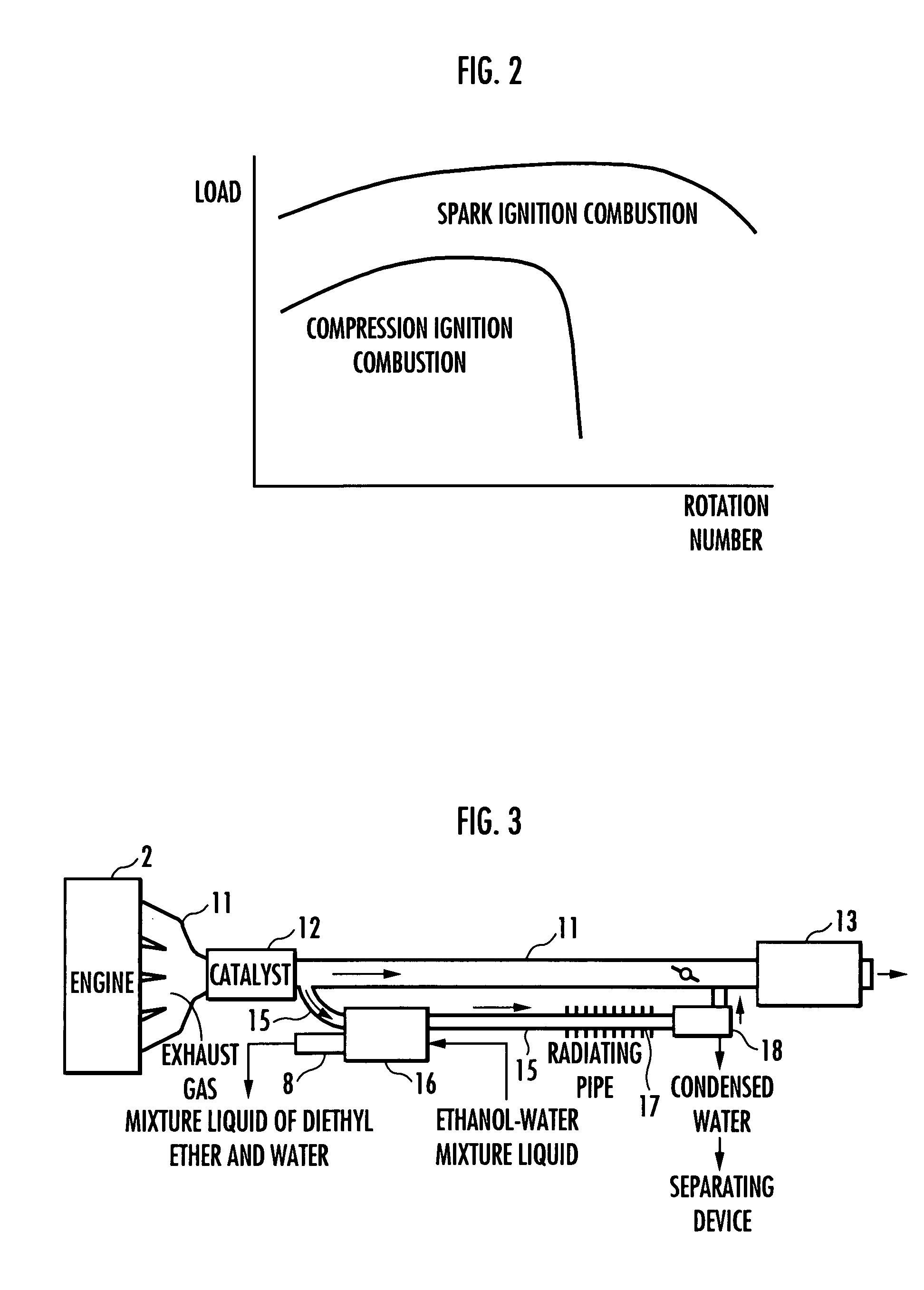

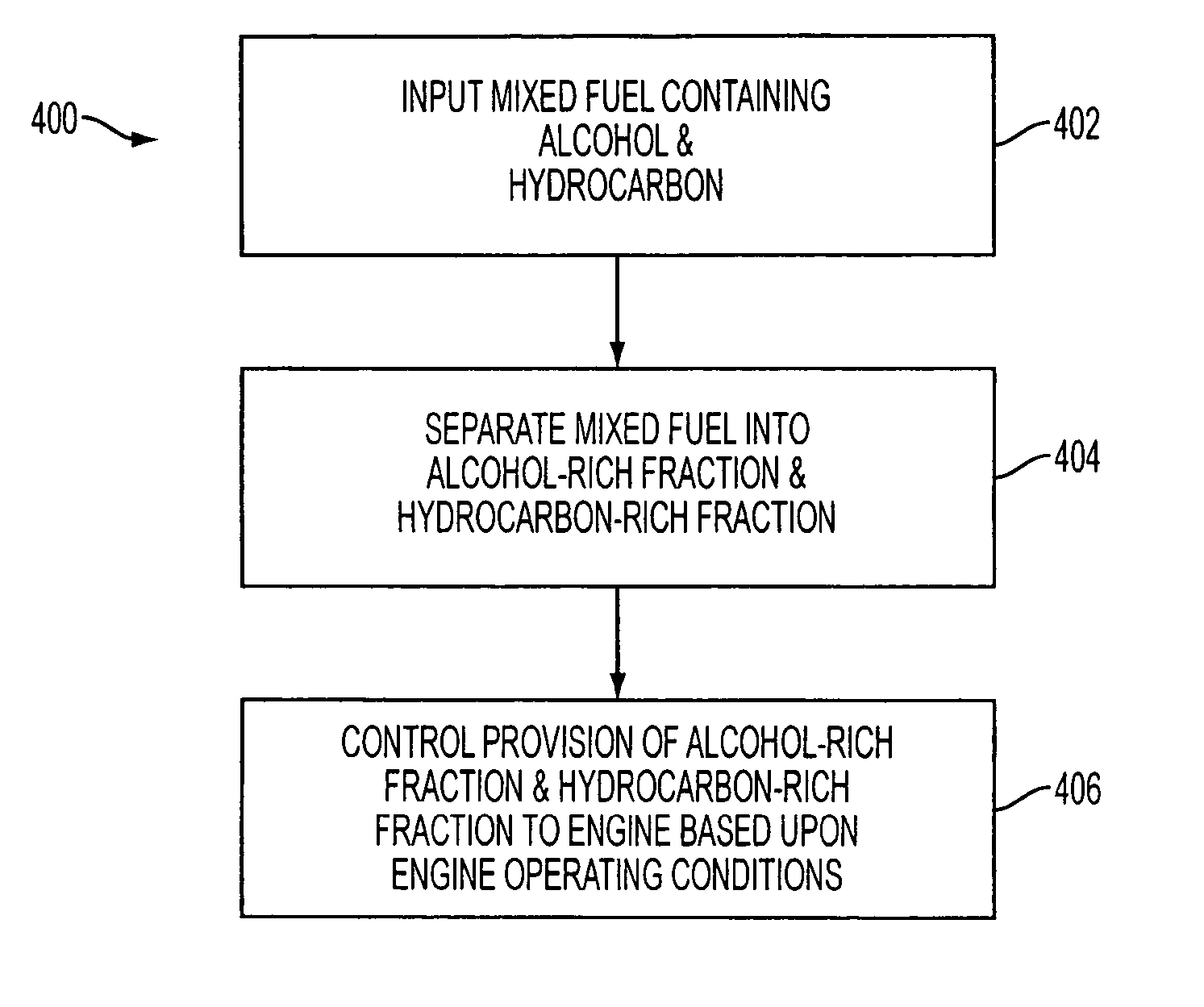

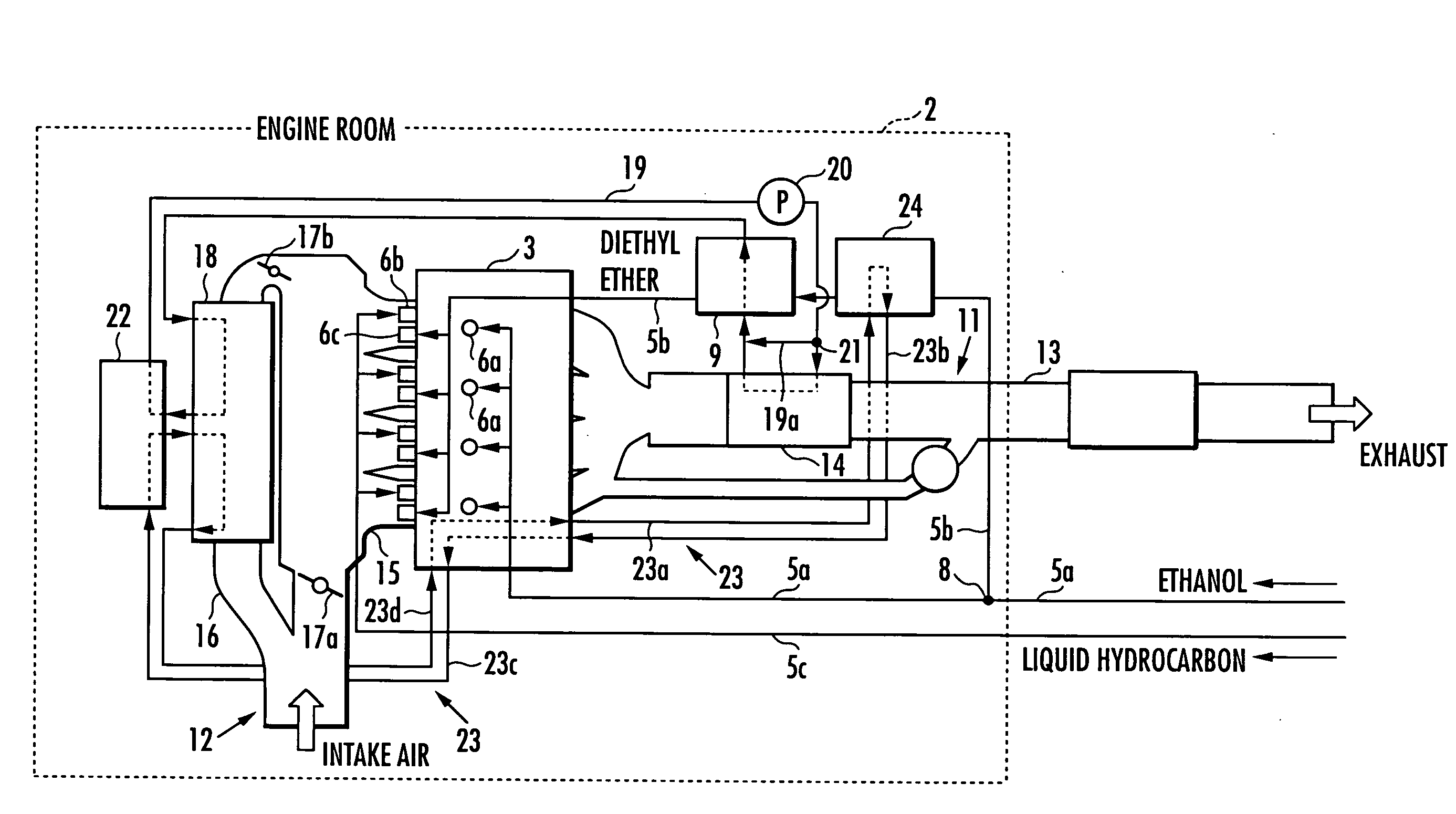

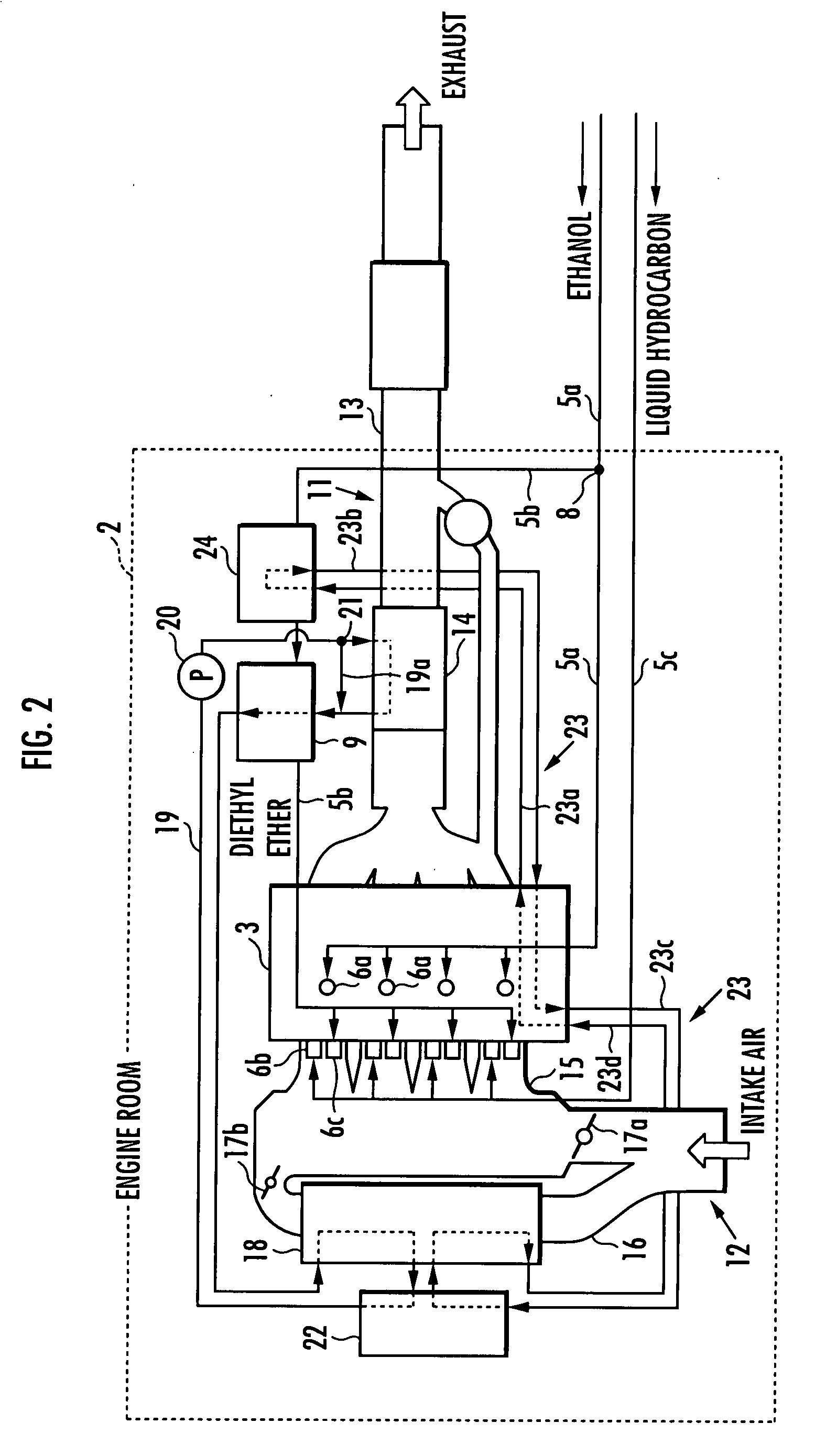

Internal combustion engine system

InactiveUS7370609B2Improve efficiencyEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesFuel tankNitrogen oxide

An internal combustion engine system uses a blended fuel of gasoline and ethanol, operates with high efficiency, and can inhibit nitrogen oxide and the like from being discharged. The internal combustion engine system includes: a fuel tank 3 that accommodates a blended fuel having an octane number of 80 to 100, which has been prepared by blending gasoline having the octane number of 30 to 85 and ethanol into a weight ratio between 9:1 and 6:4; A separating device for adding water to the blended fuel to separate the blended fuel into the gasoline and an ethanol-water mixture liquid; A reforming device for reforming one part of the ethanol-water mixture liquid to produce a mixture liquid of diethyl ether and water; and fuel injectors which independently inject each of the gasoline, the ethanol-water mixture liquid and the mixture liquid of diethyl ether and water.

Owner:HONDA MOTOR CO LTD

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215127A1Low costImprove charge cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesHigh rateFuel tank

An apparatus comprising an internal combustion engine, a fuel tank, a fuel separator disposed fluidically between the fuel tank and the engine, wherein the fuel separator comprises first and second passageways separated at least partially by a selective barrier that selectively transports a first fuel in a fuel mixture at a higher rate than a second fuel in the fuel mixture, and wherein the first passageway is configured to receive an input of fuel from the fuel tank, and an extraction fluid source in fluid communication with the second passageway of the fuel separator.

Owner:FORD GLOBAL TECH LLC

Apparatus with Mixed Fuel Separator and Method of Separating a Mixed Fuel

InactiveUS20070234976A1Increase heatIncrease profitElectrical controlNon-fuel substance addition to fuelInternal combustion engineMixed fuel

A method of operating a vehicle system including an internal combustion engine is disclosed, the method comprises separating a second fuel from a first fuel, the second fuel having a greater concentration of at least one component than the first fuel; combusting at least the first fuel at least during a first engine load; and combusting at least the second fuel at least during a second engine load higher than the first engine load.

Owner:FORD GLOBAL TECH LLC

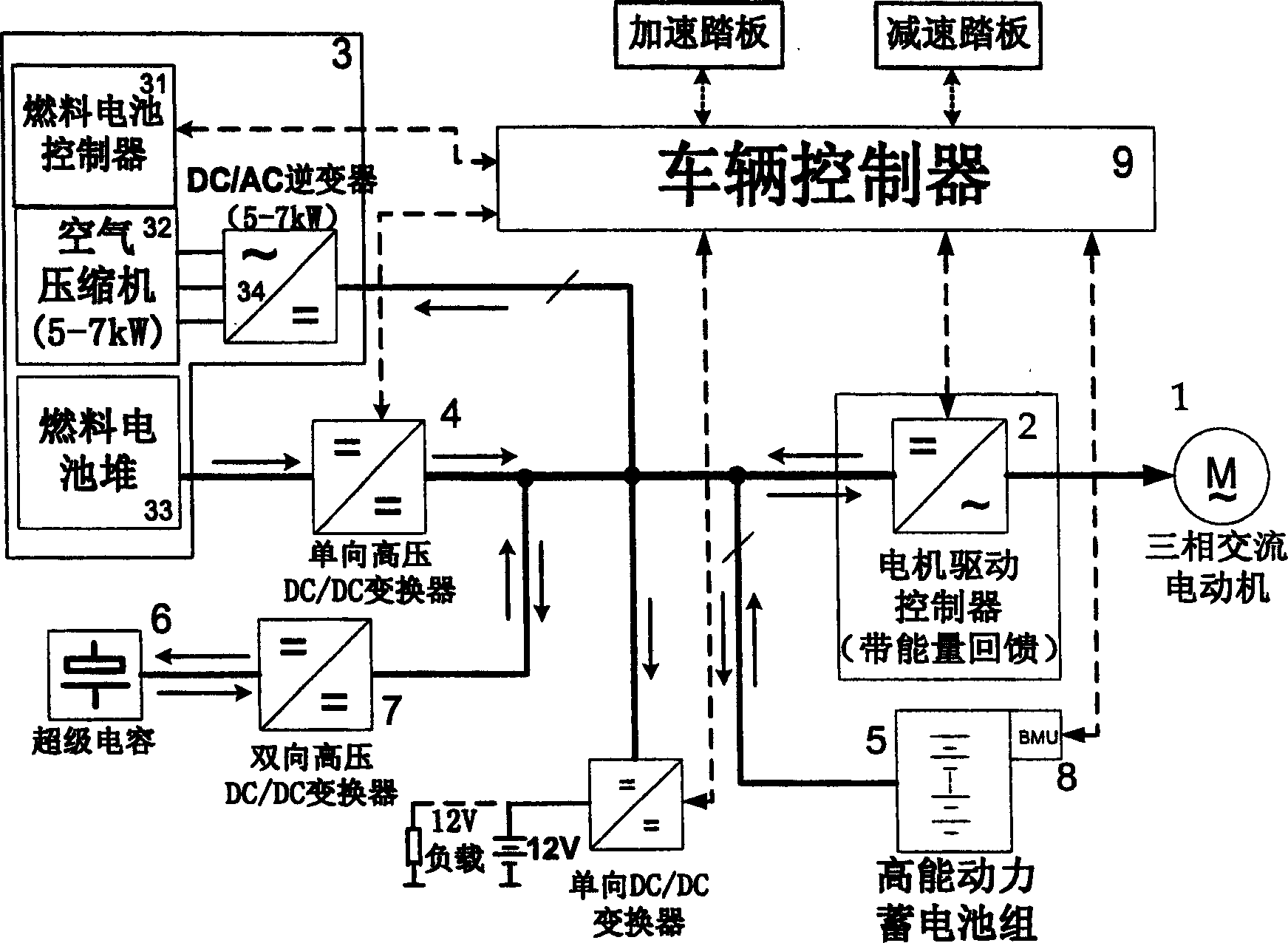

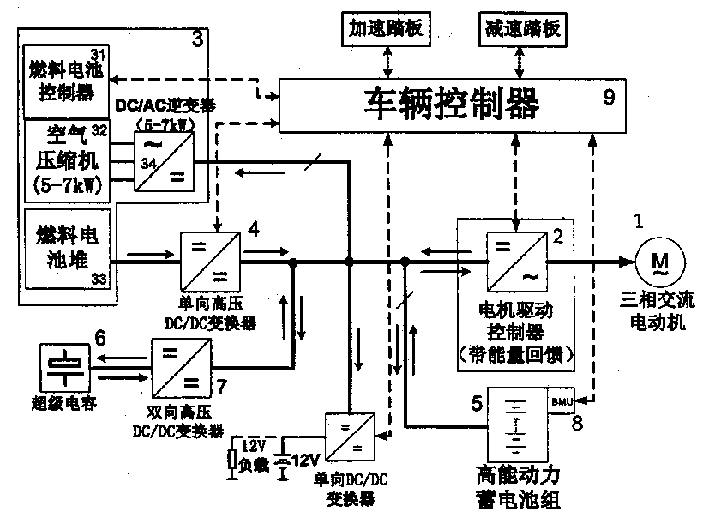

Power system of electric-electric mixed fuel battery automobile

InactiveCN1475378ARealize torque closed-loop controlReduce output voltageGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingCapacitanceHigh energy

A power system for car is composed of drive motor, motor drive controller, fuel battery, unidirectional high-voltage DC / DC converter, vehicle controller, high-energy power accumulator set and its management unit, super capacitor, and bidirectional DC / DC converter. Its advantages are high power performance and safety, and low cost.

Owner:SHANGHAI FUEL CELL VEHICLE POWERTRAIN +1

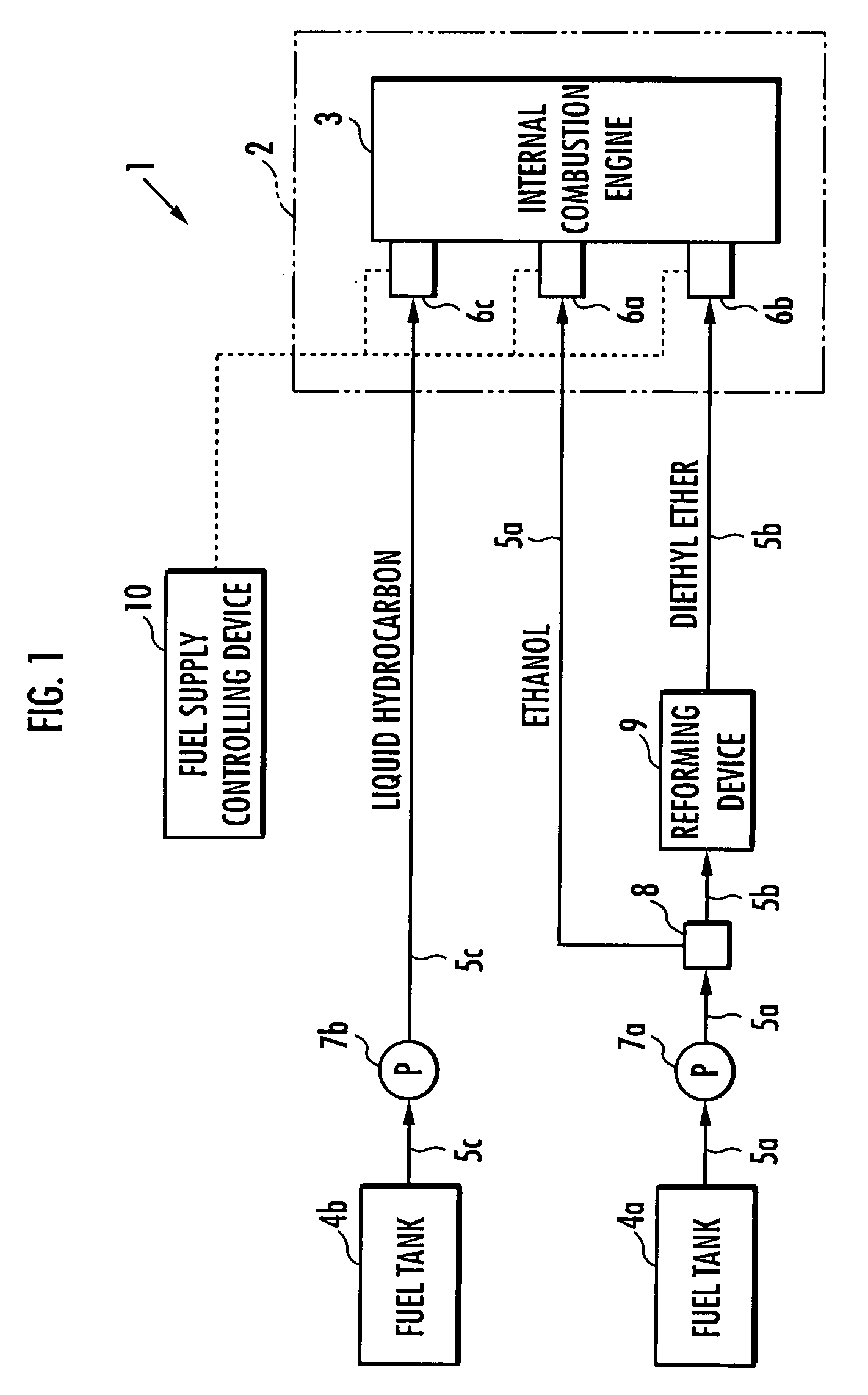

Internal combustion engine system

InactiveUS20080098985A1Accurate timingElectrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionNaphtha

The present invention provides an internal combustion engine system that can precisely control ignition timing on homogeneous charge compression ignition. The internal combustion engine system includes a fuel tank 4a containing ethanol, a fuel tank 4b containing at least one of gasoline and GTL naphtha, a reforming device 9 for reforming ethanol to obtain diethyl ether, a heat exchange device 14 for heating a heating medium, an ethanol heater 9b for heating ethanol with the heating medium, and a fuel supply controlling device 10 for controlling a mixture ratio of the fuel. The internal combustion engine system further includes an intake air heater 18 for heating intake air with the heating medium. The internal combustion engine system further comprises an adiabatic storage container 29 for storing the heating medium during a halt of an internal combustion engine 3. The internal combustion engine system further comprises a flow controlling device 27 for flowing the heating medium to the adiabatic storage container 29 only when a temperature detected by a thermal detector 30a is higher than a temperature detected by a thermal detector 30b during an operation of the internal combustion engine 3. The internal combustion engine system further comprises a fuel tank 42 containing a mixed fuel, and a separating device 43 for separating the mixed fuel into an ethanol-water mixture, gasoline and GTL naphtha by adding water to the mixed fuel.

Owner:HONDA MOTOR CO LTD

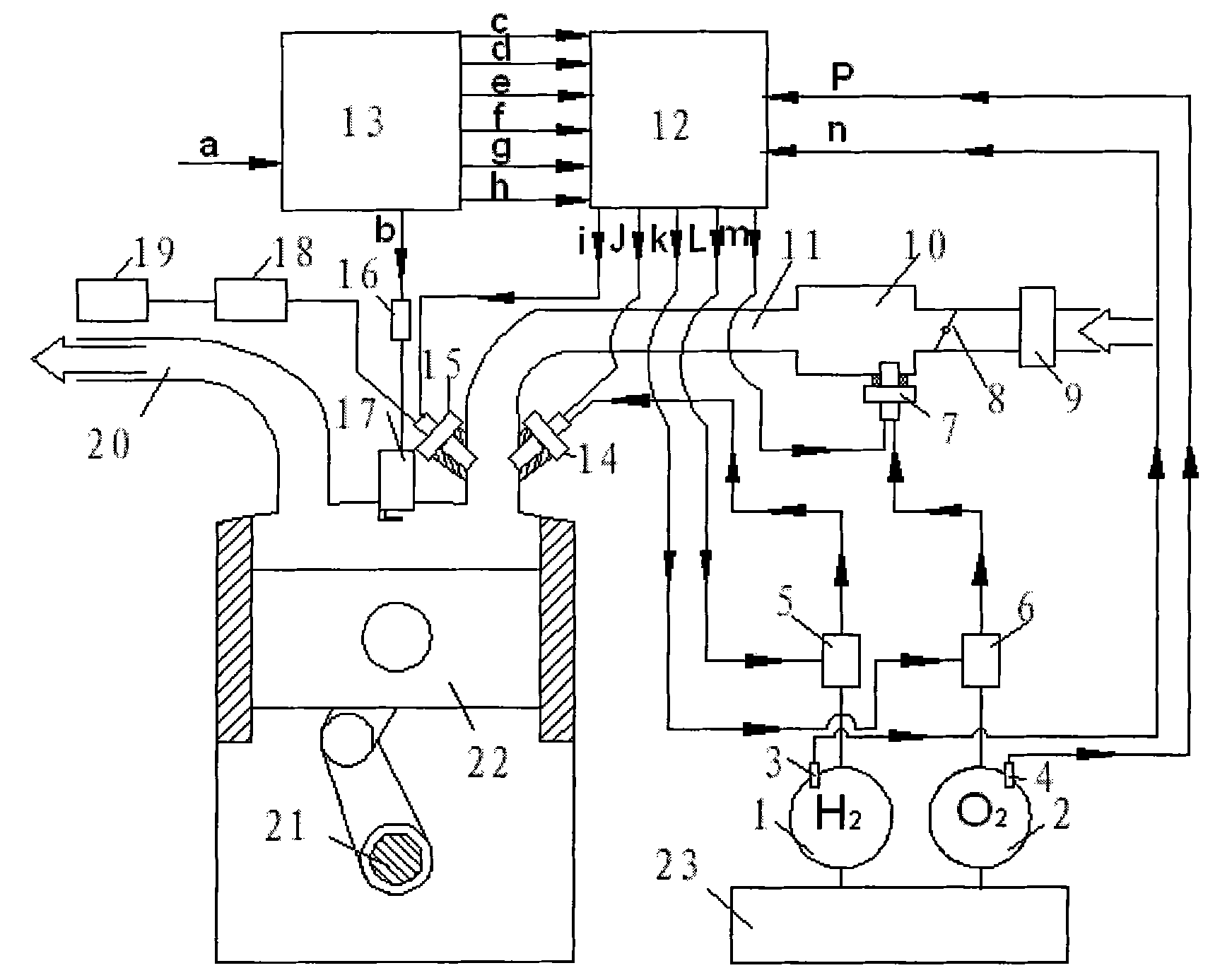

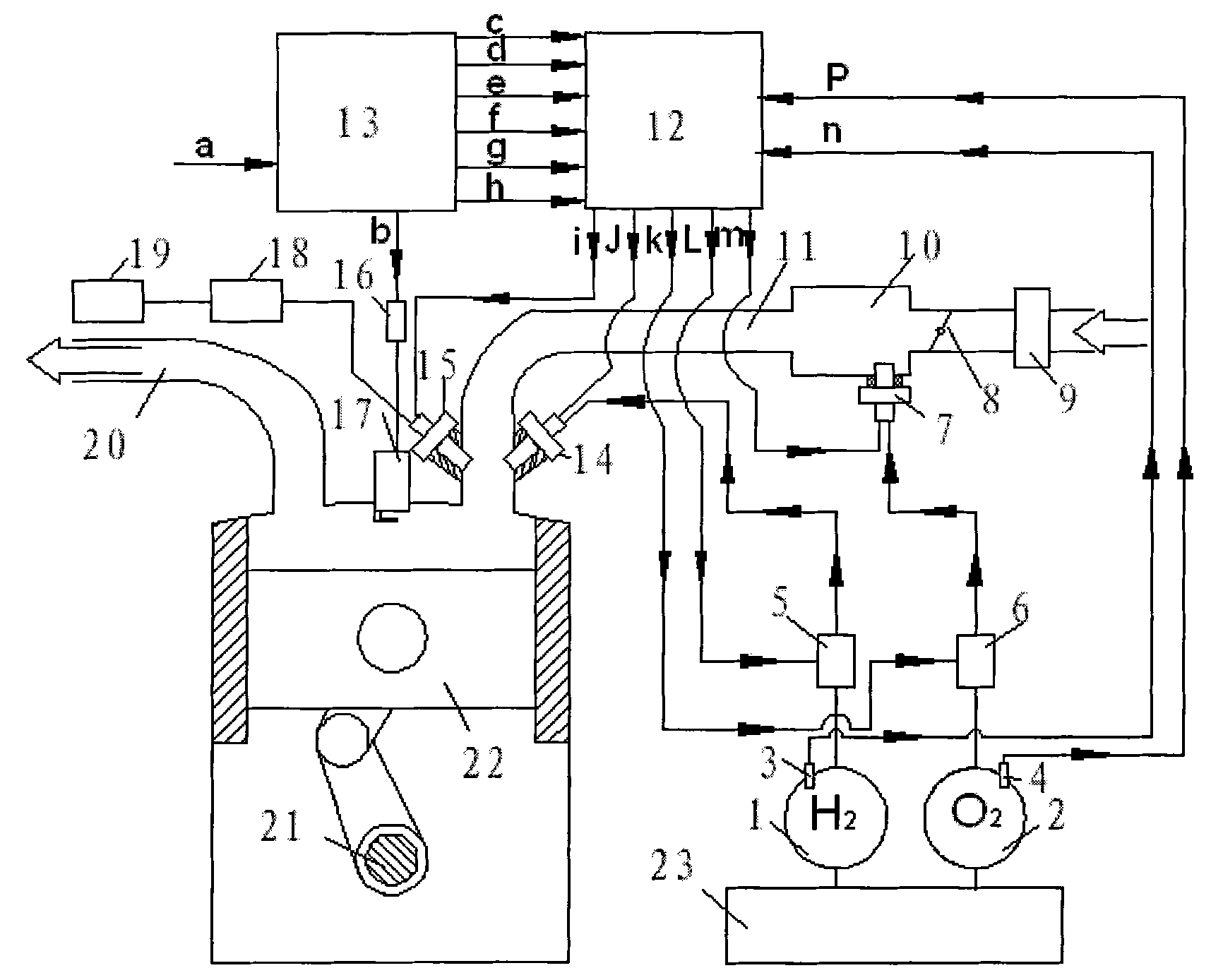

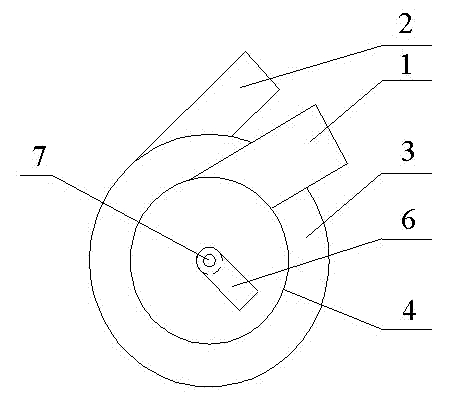

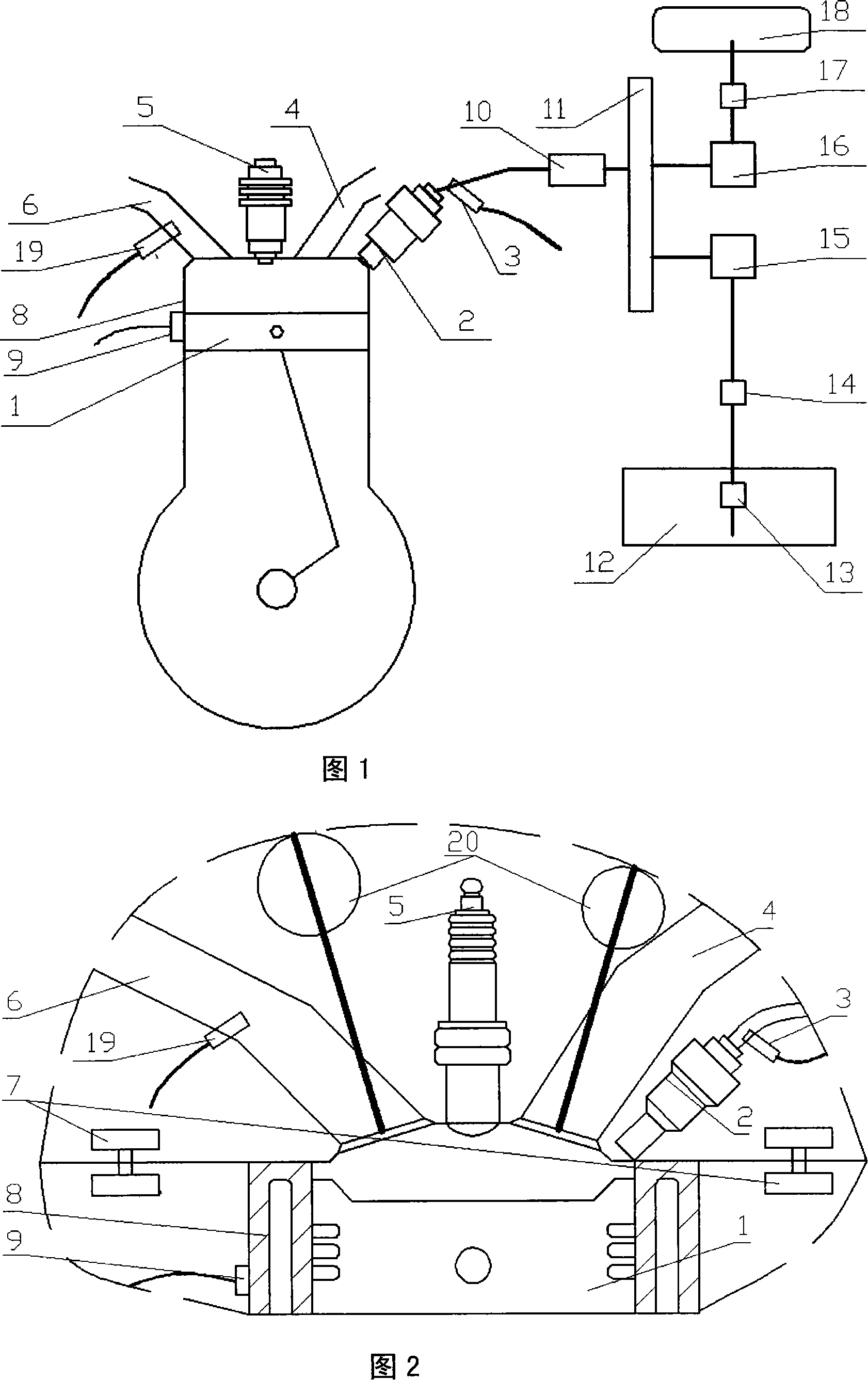

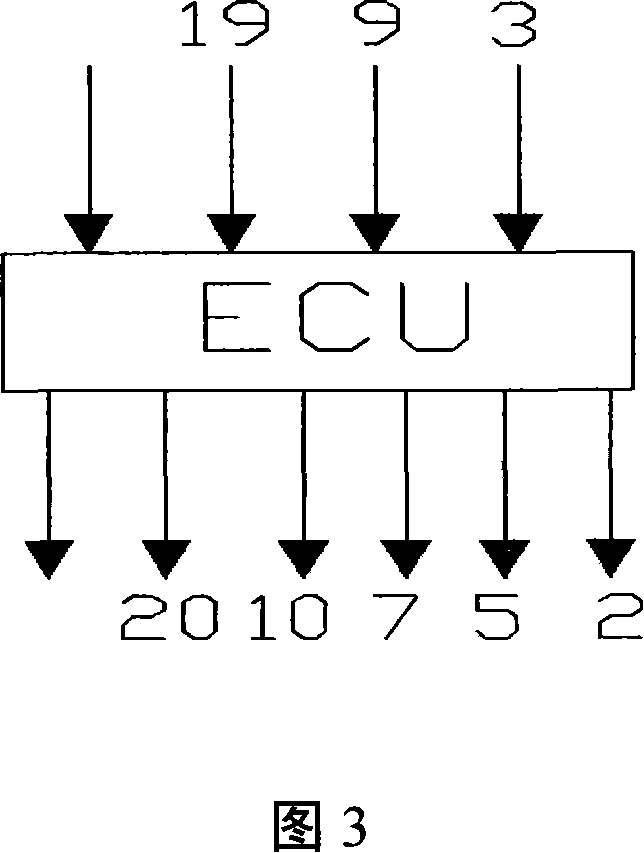

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108AReduce consumptionImprove economyElectrical controlInternal combustion piston enginesOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

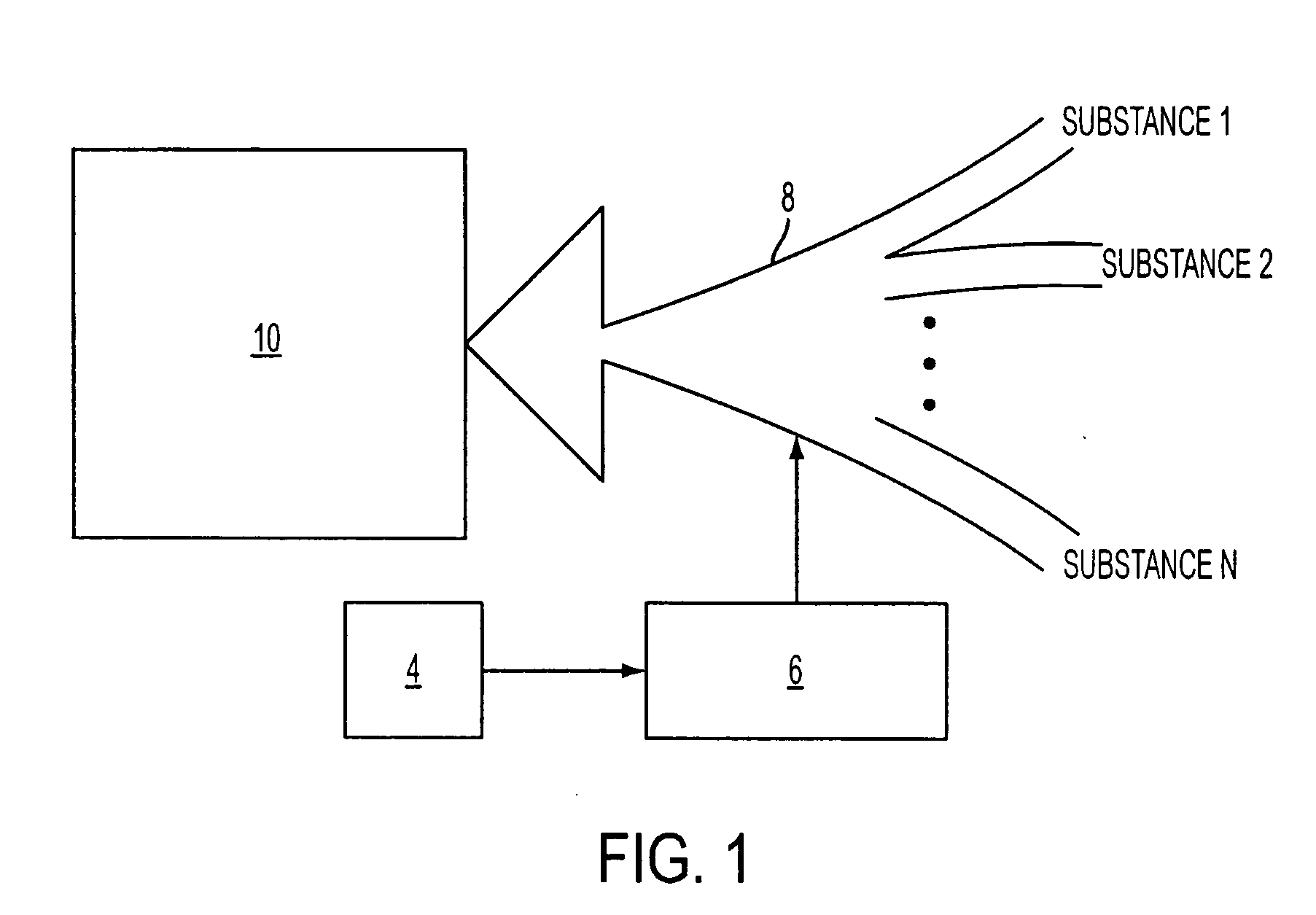

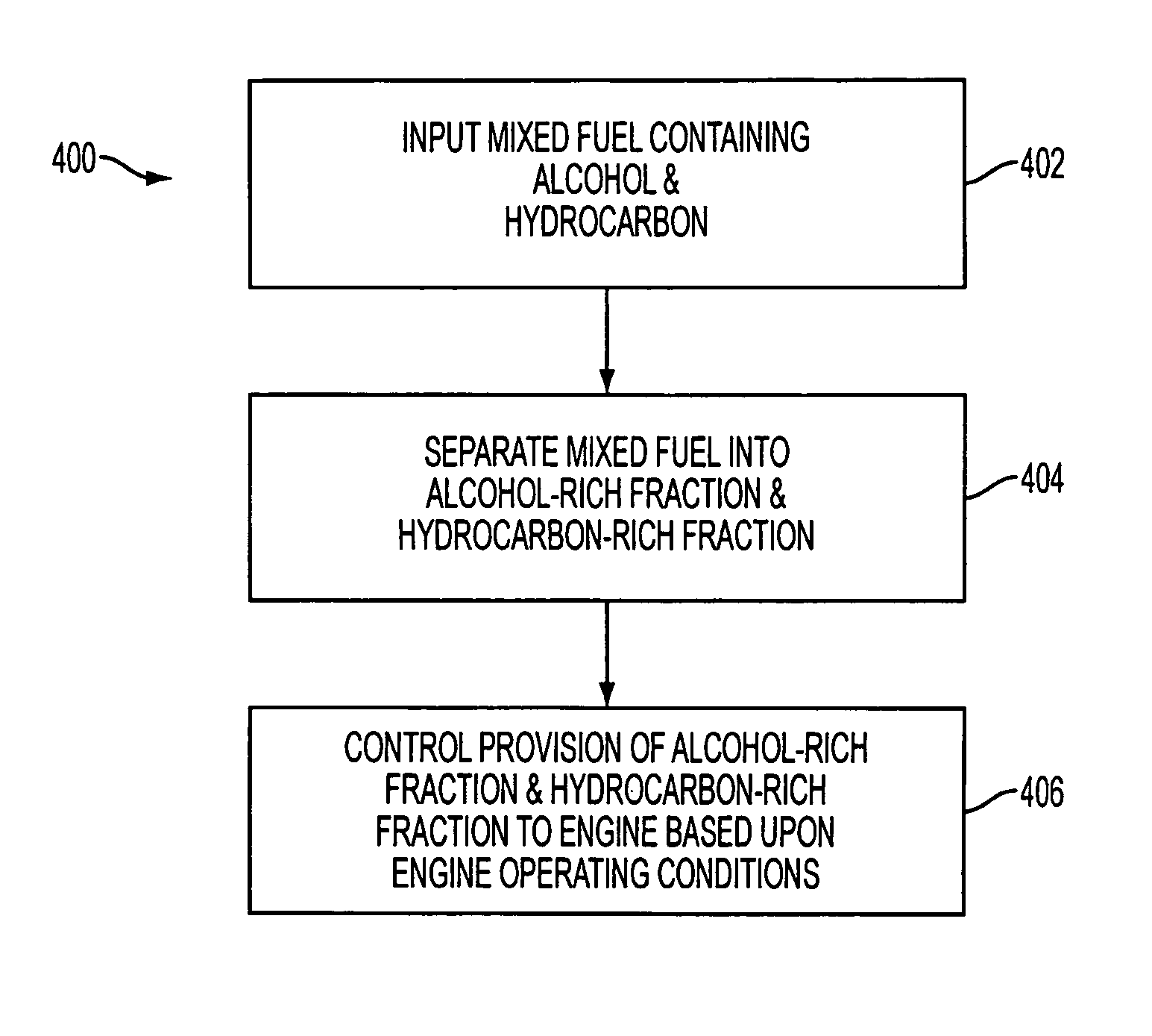

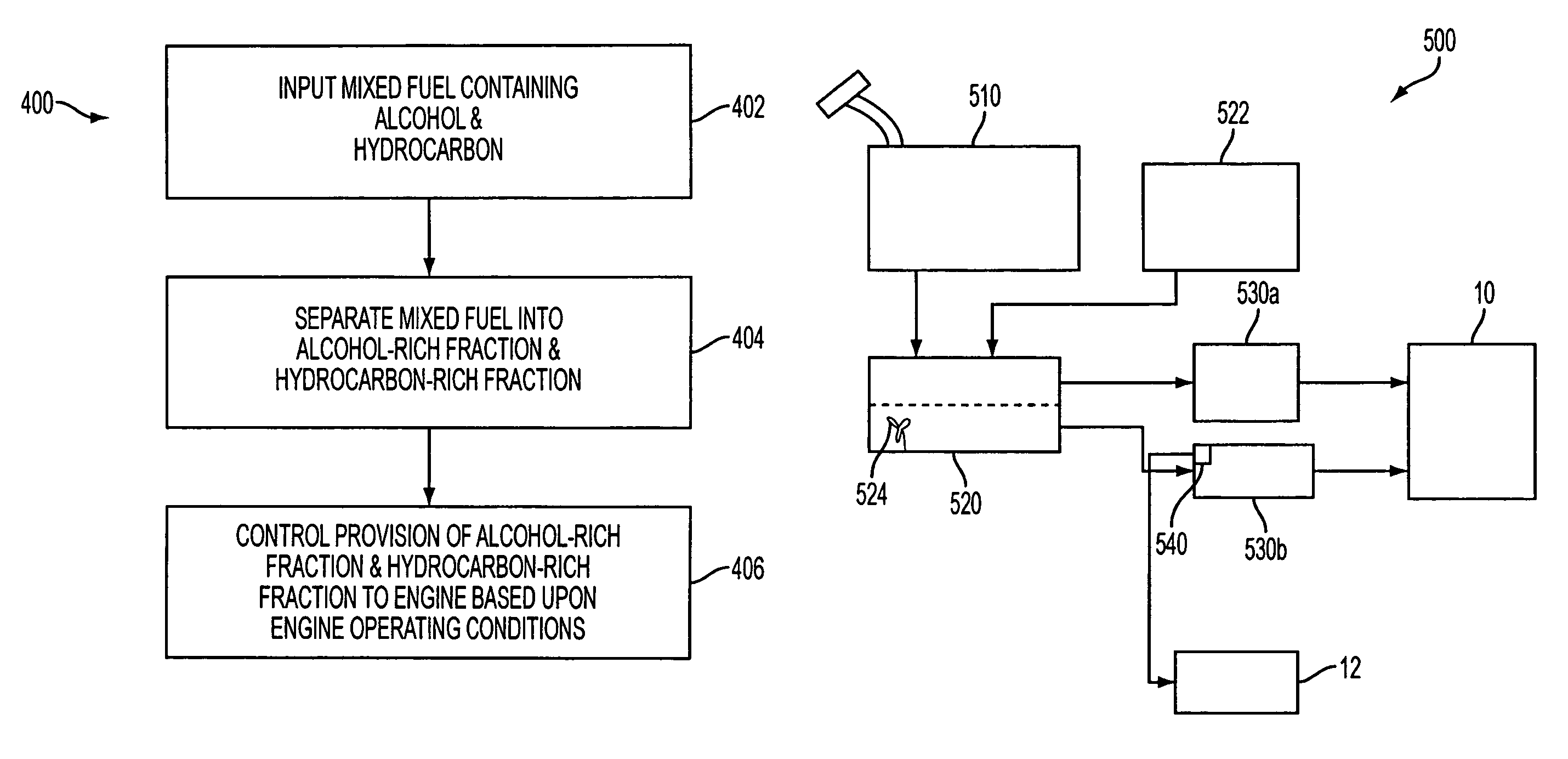

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215071A1Low costImprove charge cooling effectElectrical controlNon-fuel substance addition to fuelHydrocotyle bowlesioidesFuel tank

In an apparatus comprising a fuel tank, an internal combustion engine, and a separator positioned fluidically between the fuel tank and the internal combustion engine, a method of operating the apparatus is disclosed, wherein the method comprises inputting a mixed fuel containing a hydrocarbon component and an oxygenated component into the separator, separating the fuel in the separator into a hydrocarbon-enriched fuel fraction and an oxygenated fuel component-enriched fuel fraction, and controlling an amount of the hydrocarbon-enriched fuel fraction and an amount of the oxygenated fuel component-enriched fuel fraction provided to the engine based upon an engine operating condition.

Owner:FORD GLOBAL TECH LLC

Fuel products from plant or animal lipids

A novel method for producing fuel products from plant or animal lipids is provided. The carbon-carbon bonds in the molecules of plant or animal lipids are cracked into the molecules with smaller molecular weights. The mixed fuel is formed after chemical treatments. Then the mixed fuel (biopetroleum) is processed by a distillation process to produce fuel products according to their boiling points. The method is particularly advantageous to produce the energy source from agricultural products, which provides a solution for energy crisis with a significant potential.

Owner:LEE JOHN H

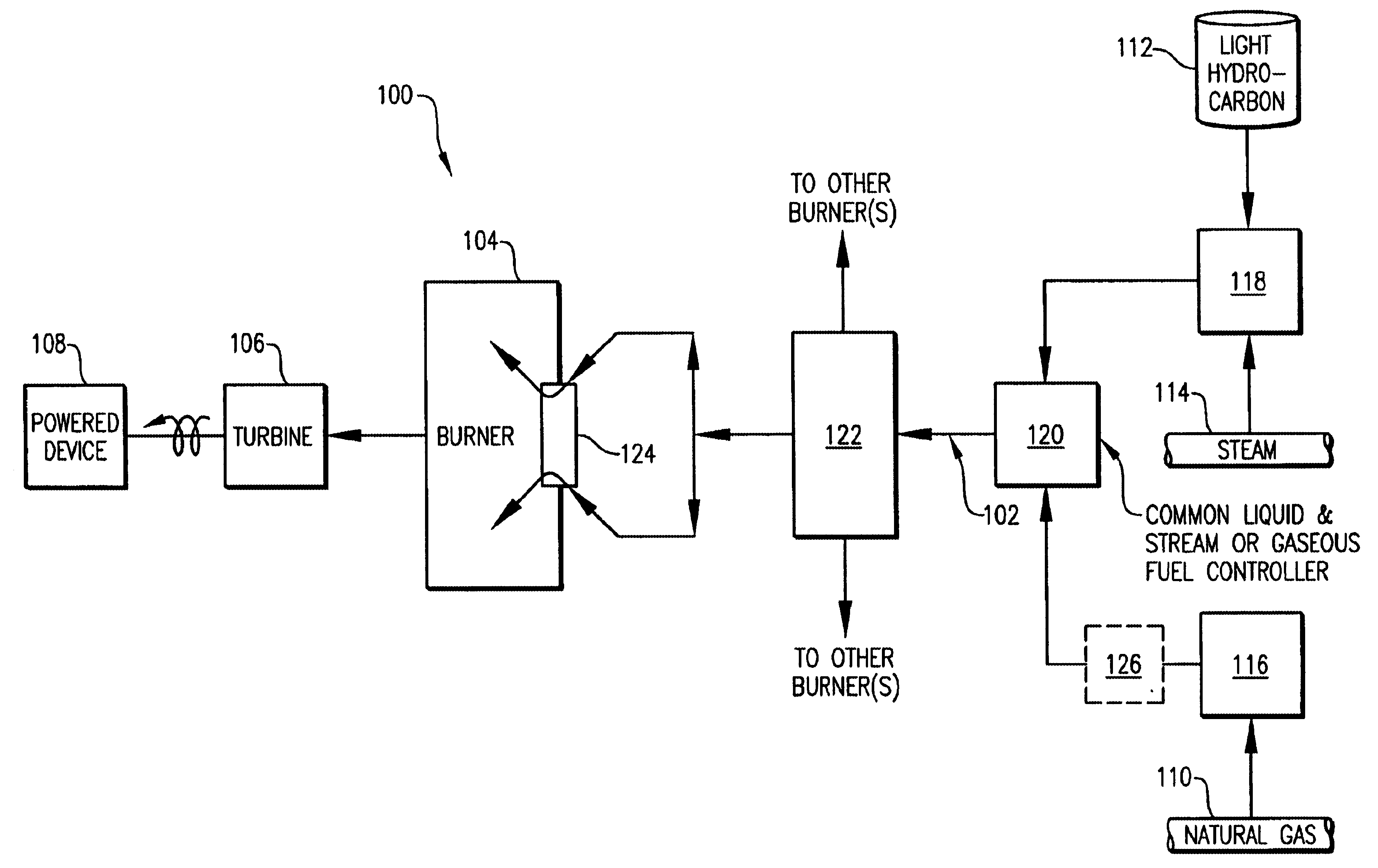

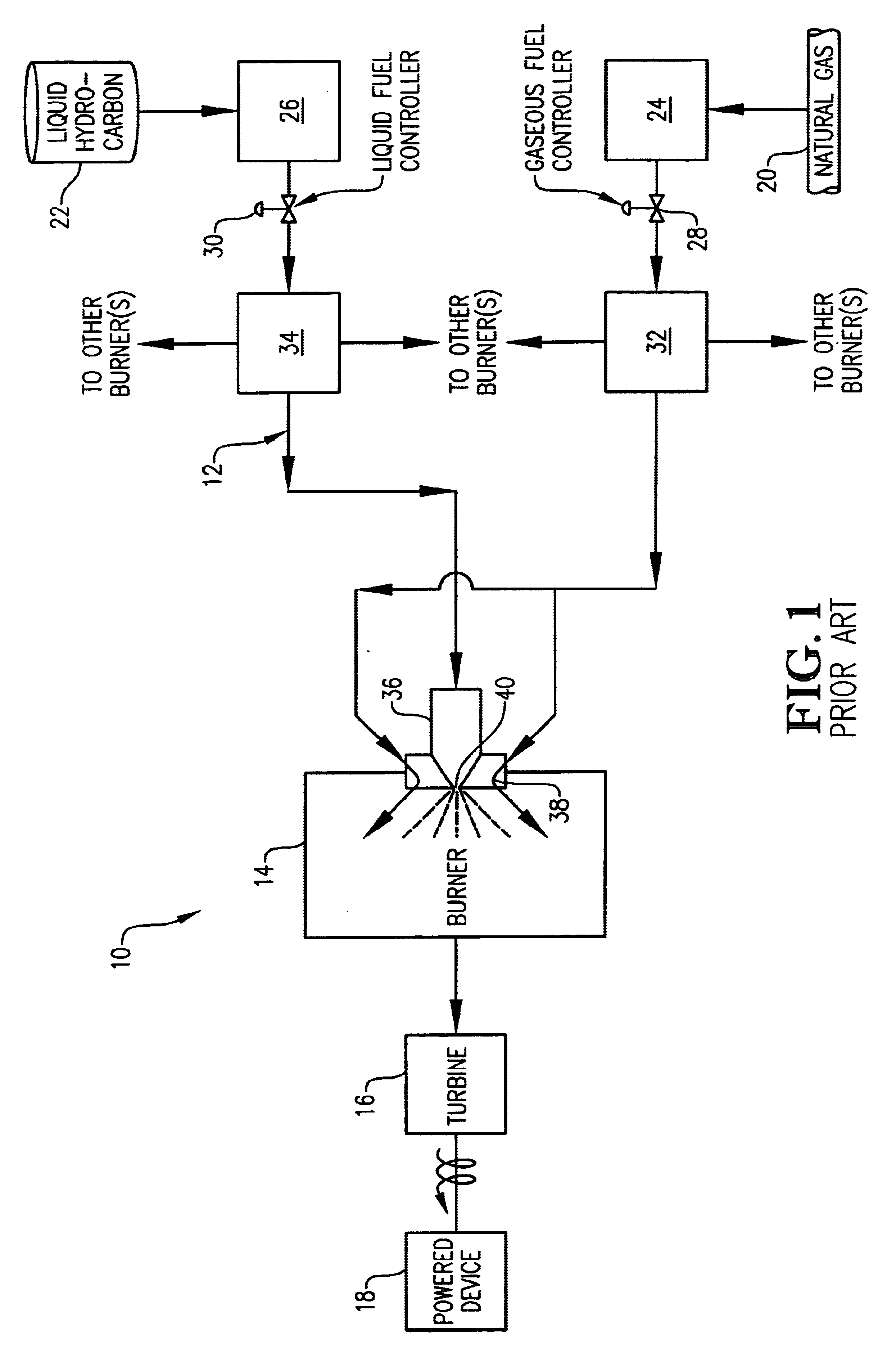

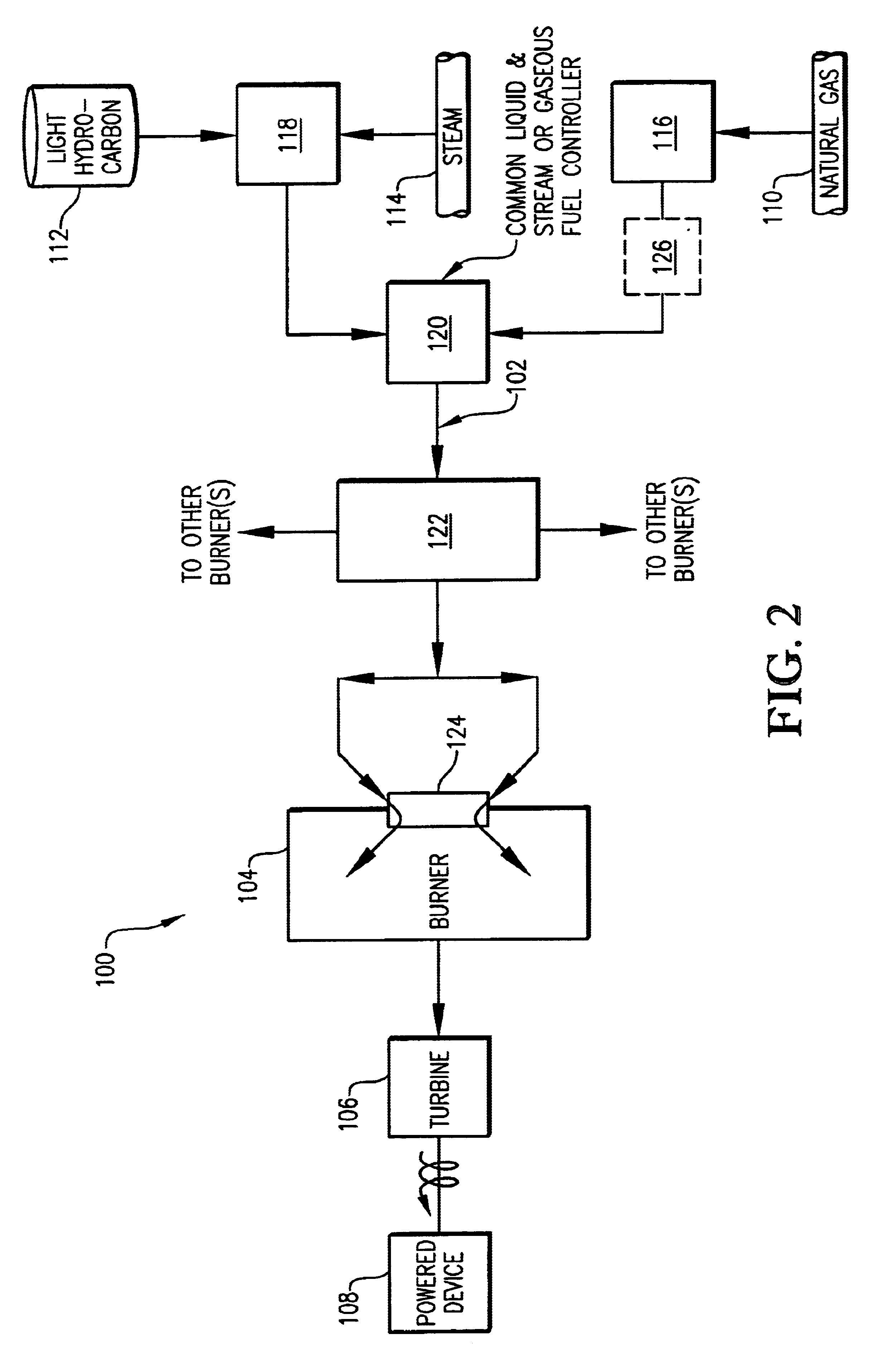

Dual fuel power generation system

InactiveUS6779333B2Easy to switchMinimal operationalTurbine/propulsion engine ignitionTurbine/propulsion engine startersTurbineMotive power

A dual fuel power generation system employing a steam-mixed fuel and / or a gaseous fuel to power a turbine engine. The steam-mixed fuel is a gaseous mixture of a light hydrocarbon and steam. The steam-mixed fuel and gaseous fuel are delivered to the turbine engine (either individually or mixed) via a common fuel controller, a common fuel distribution system, and a common gas-only fuel nozzle.

Owner:PHILLIPS 66 CO

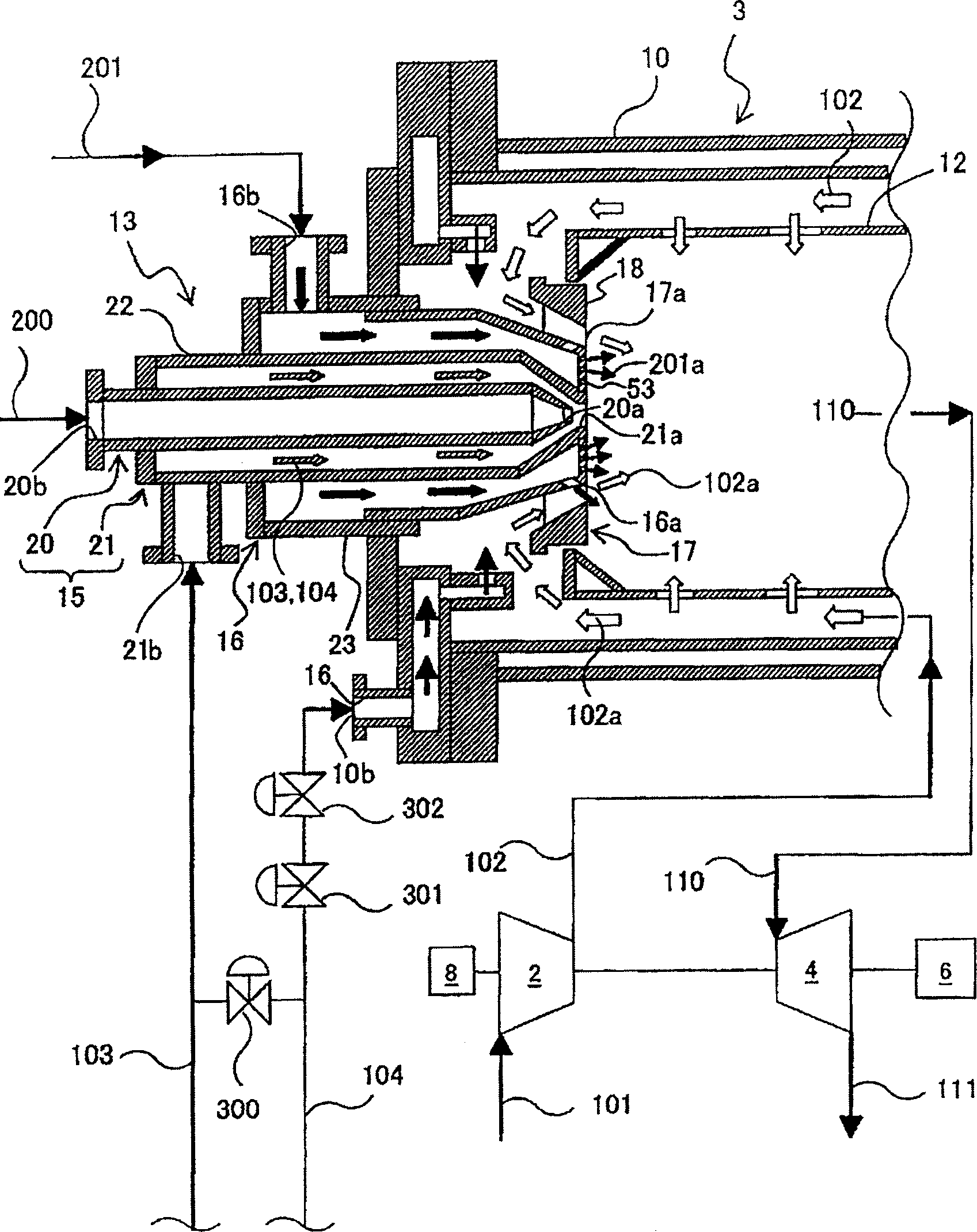

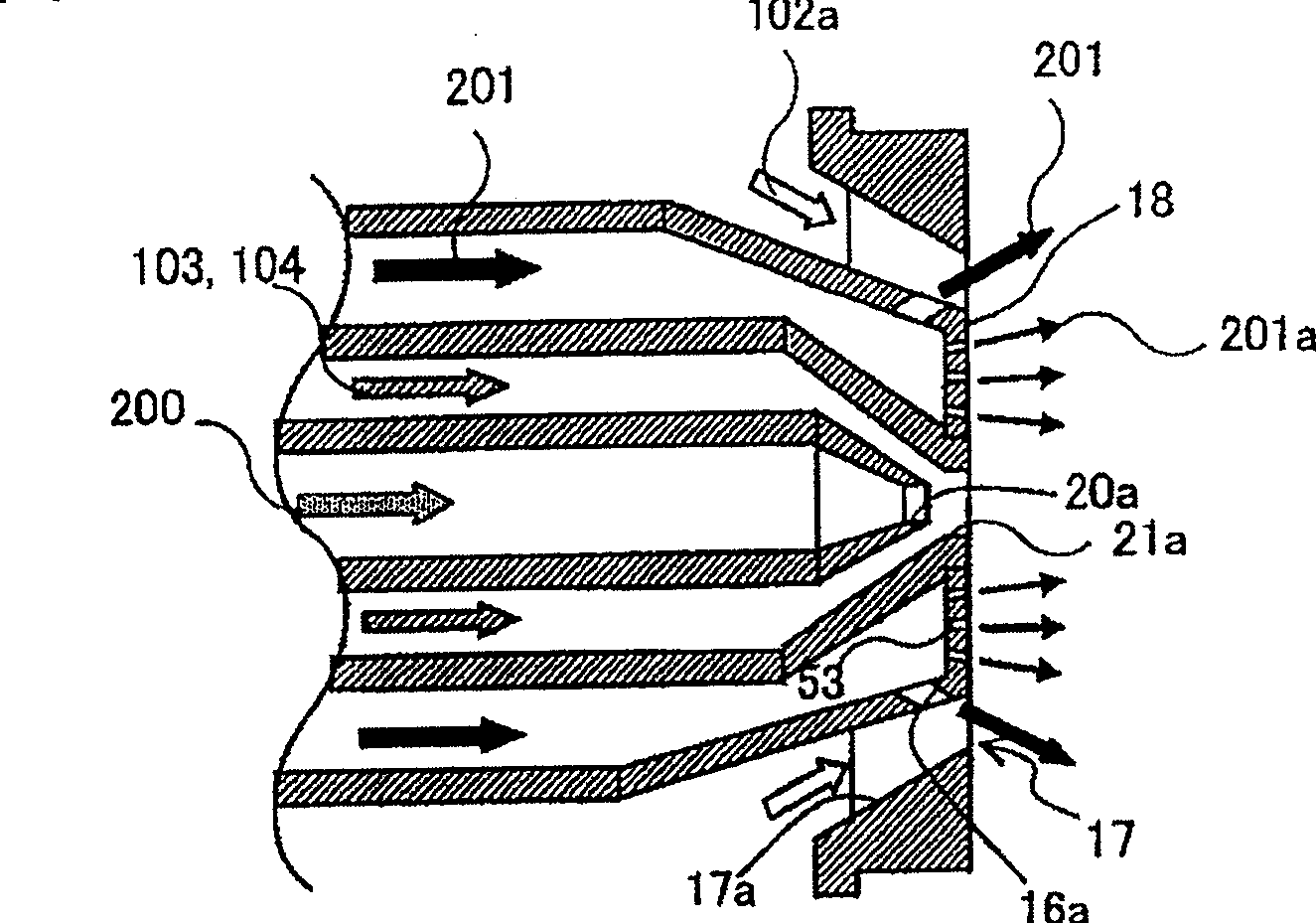

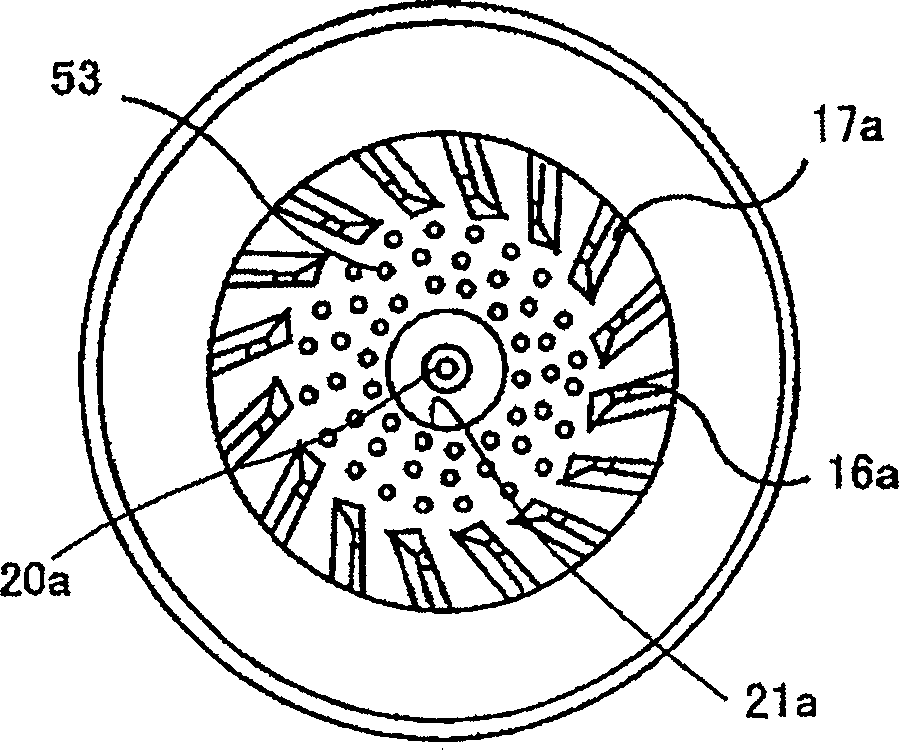

Burner, gas turbine combustor, burner cooling method, and burner modifying method

ActiveCN1884910AIncrease fuel concentrationImprove reliabilityGaseous fuel burnerMixed fuelGas turbines

Owner:MITSUBISHI POWER LTD

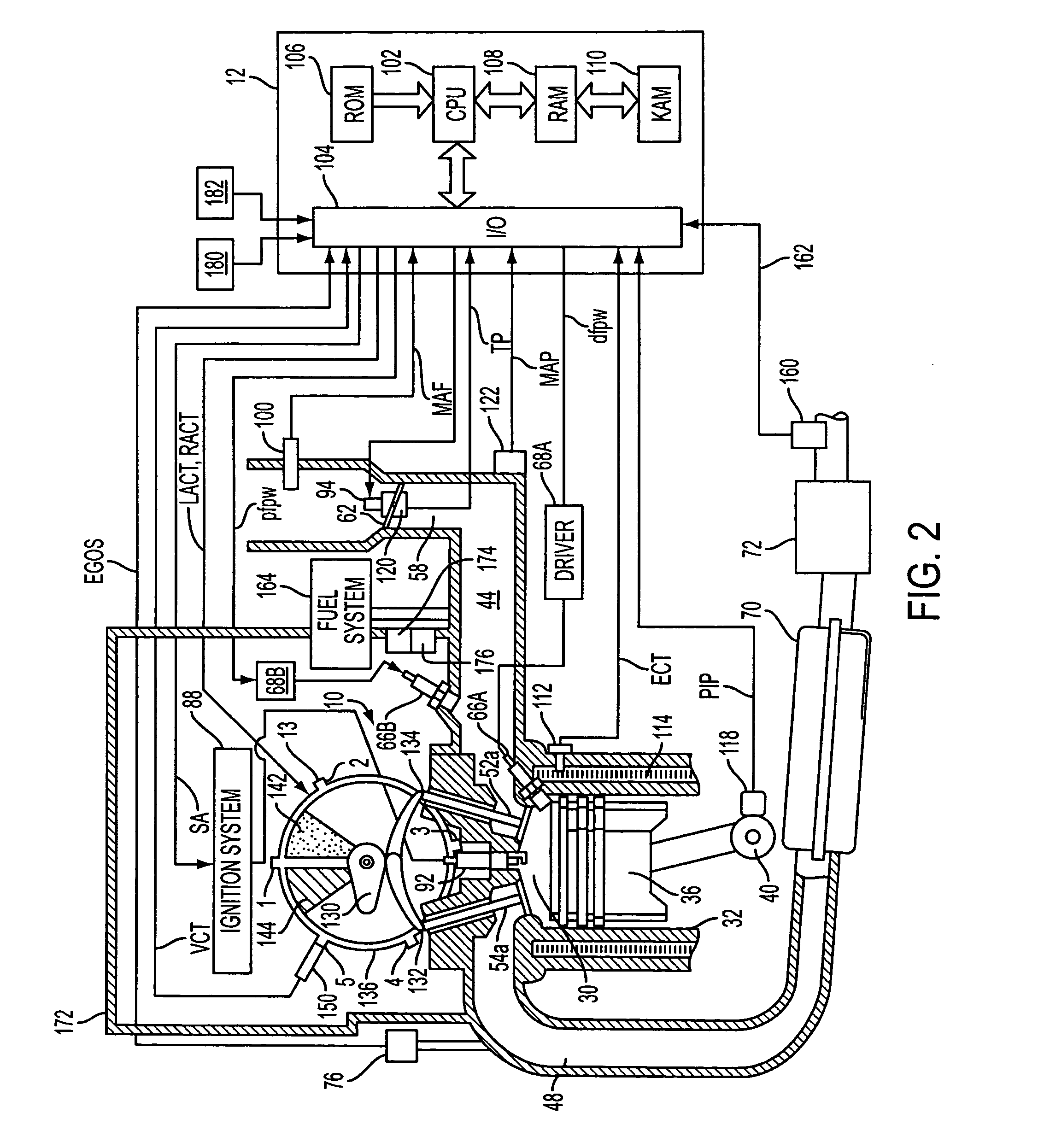

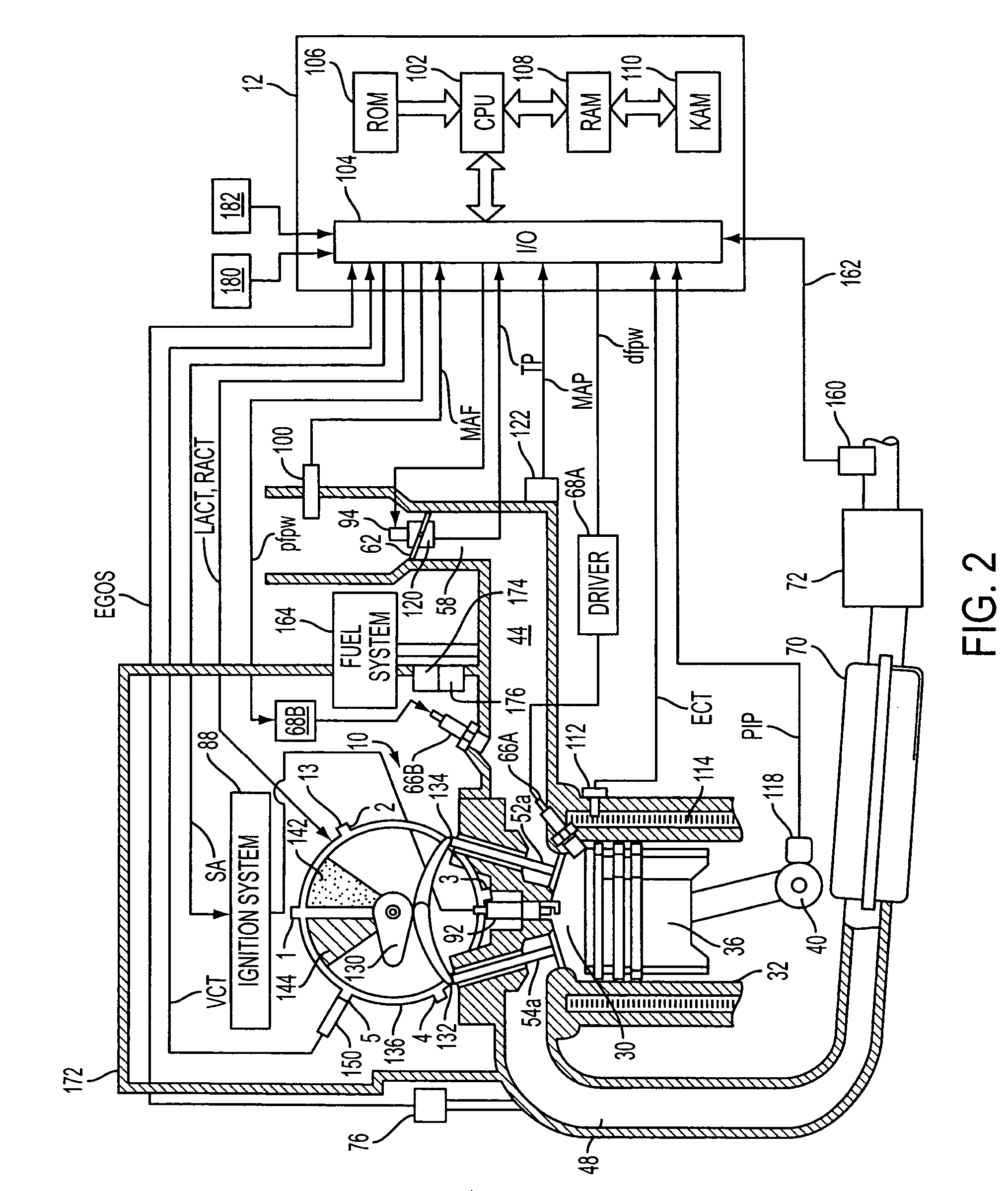

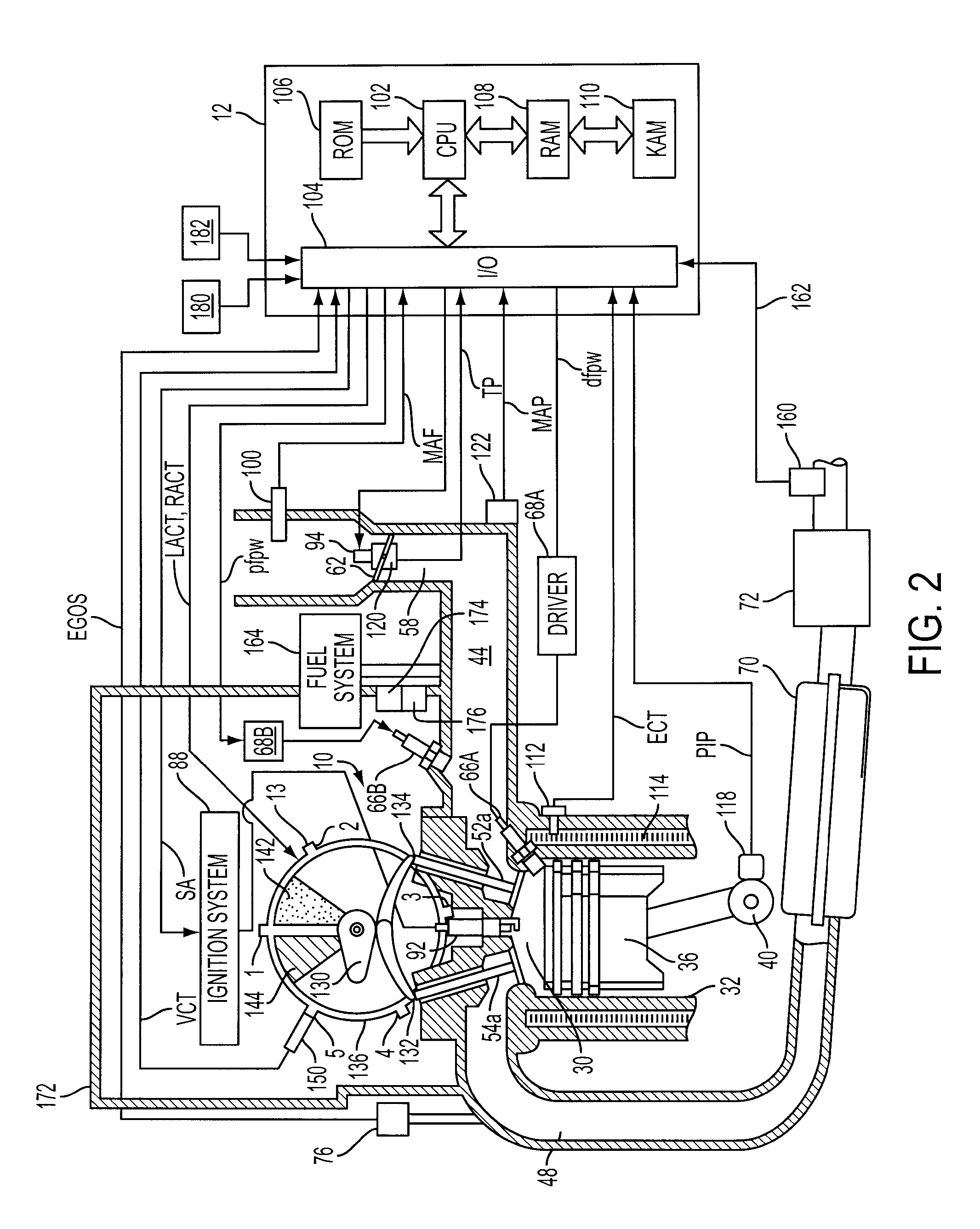

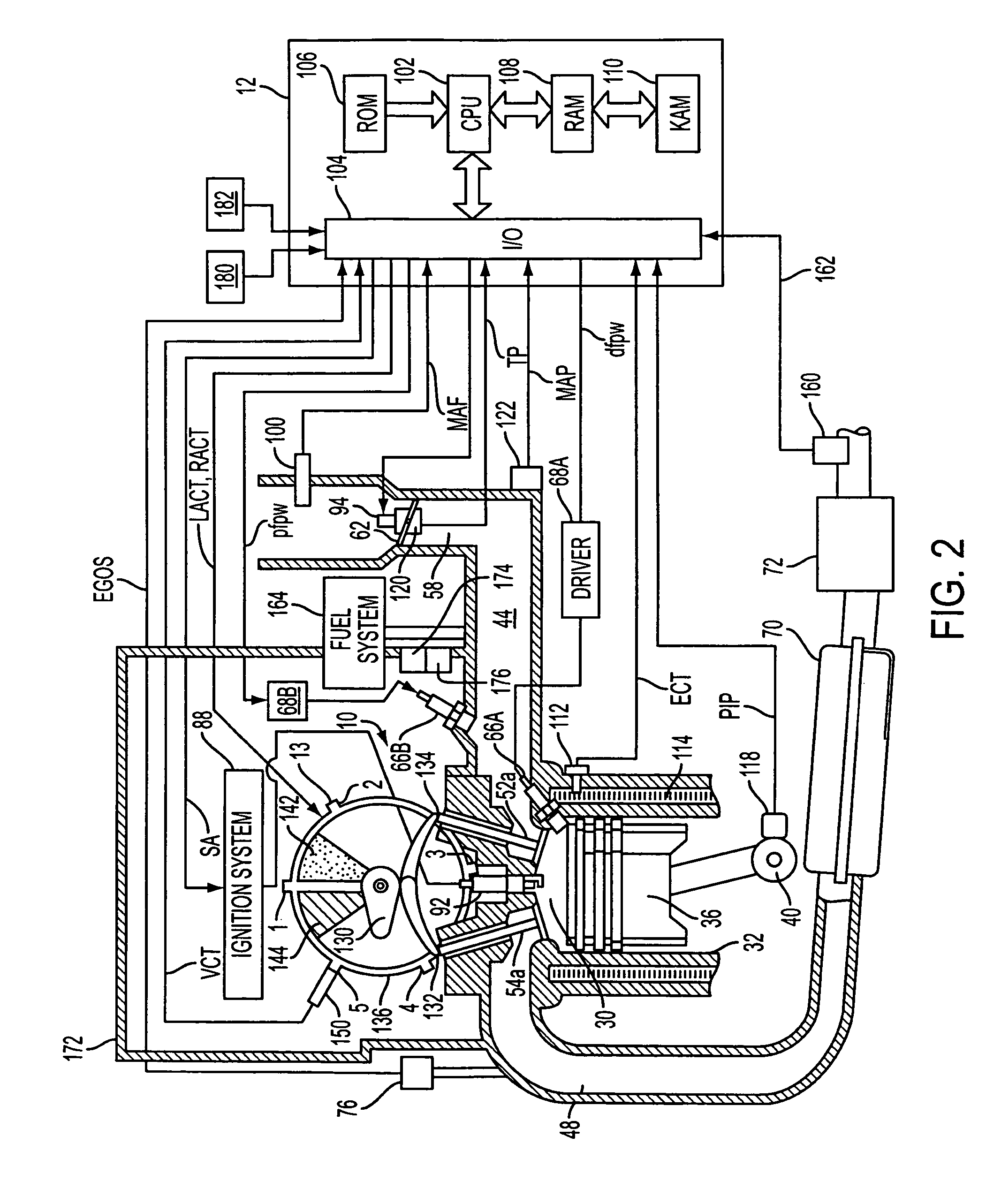

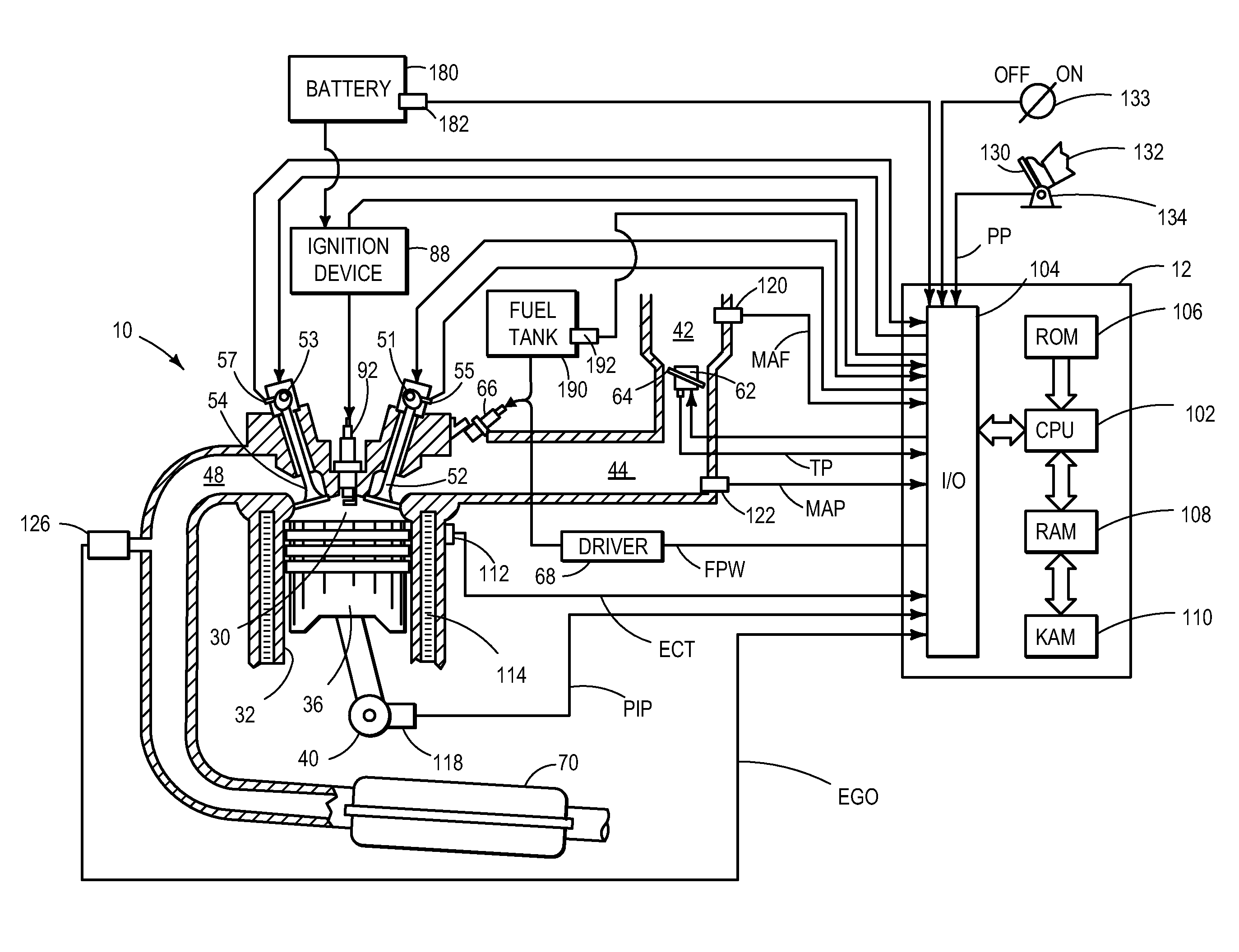

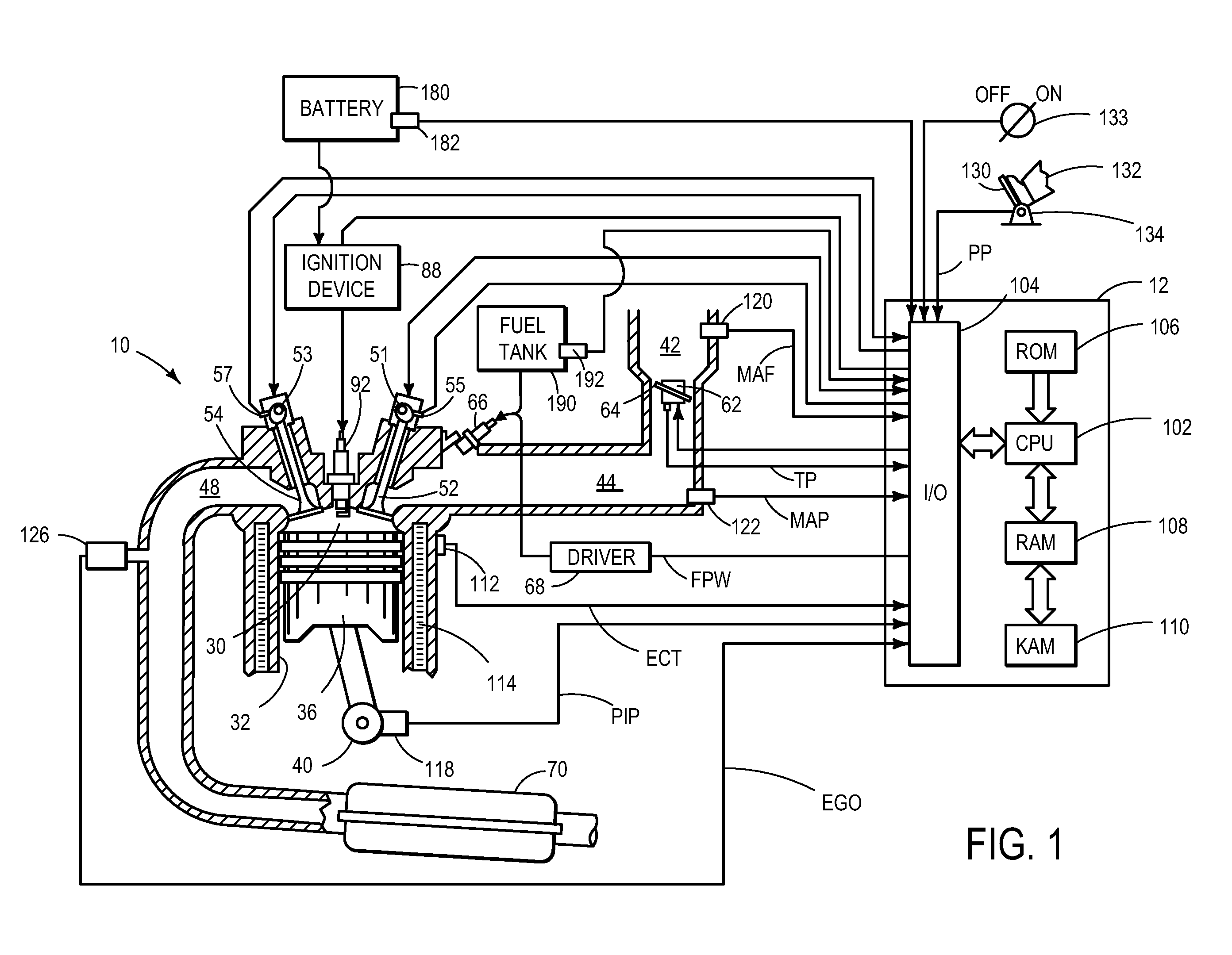

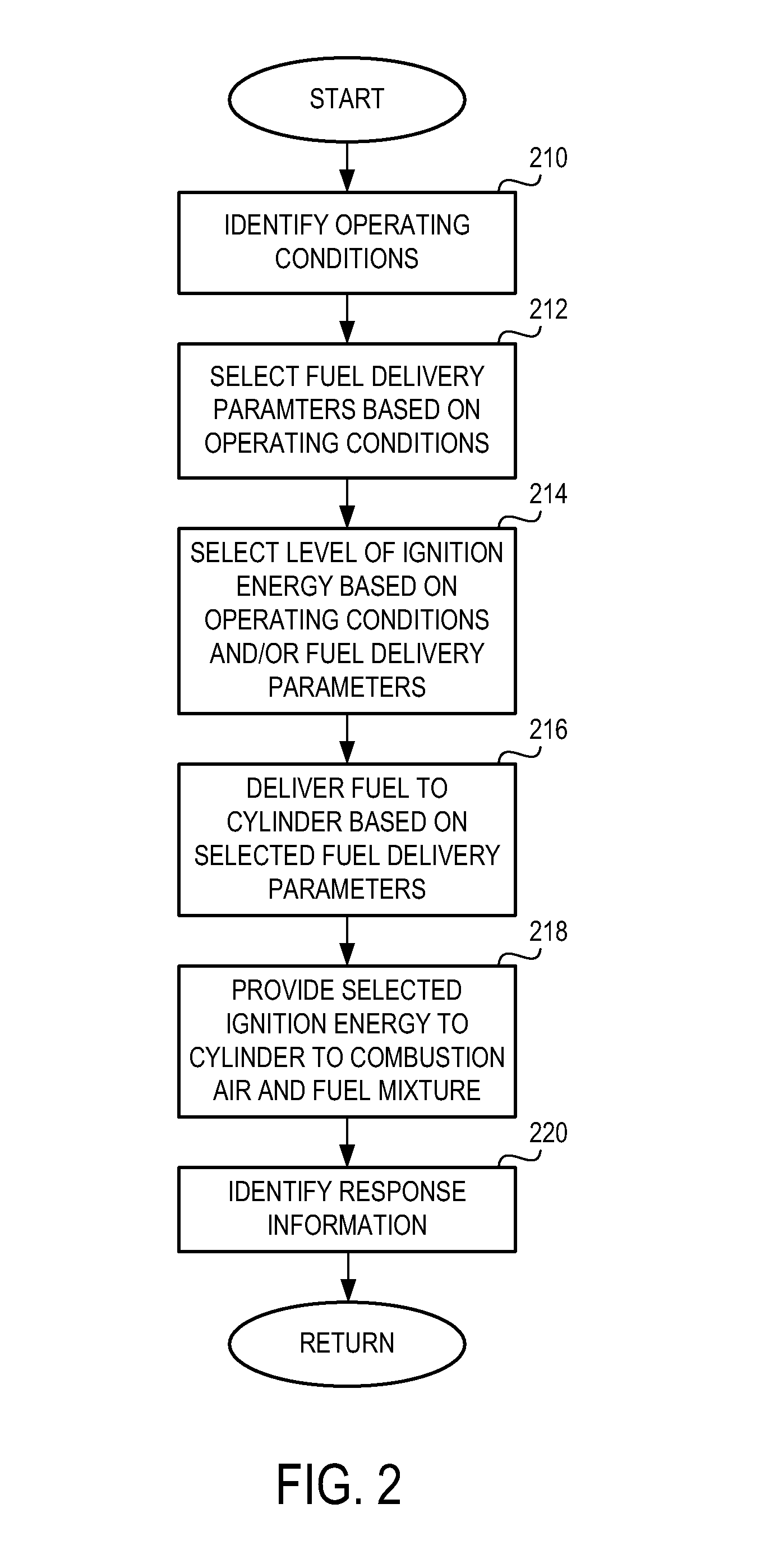

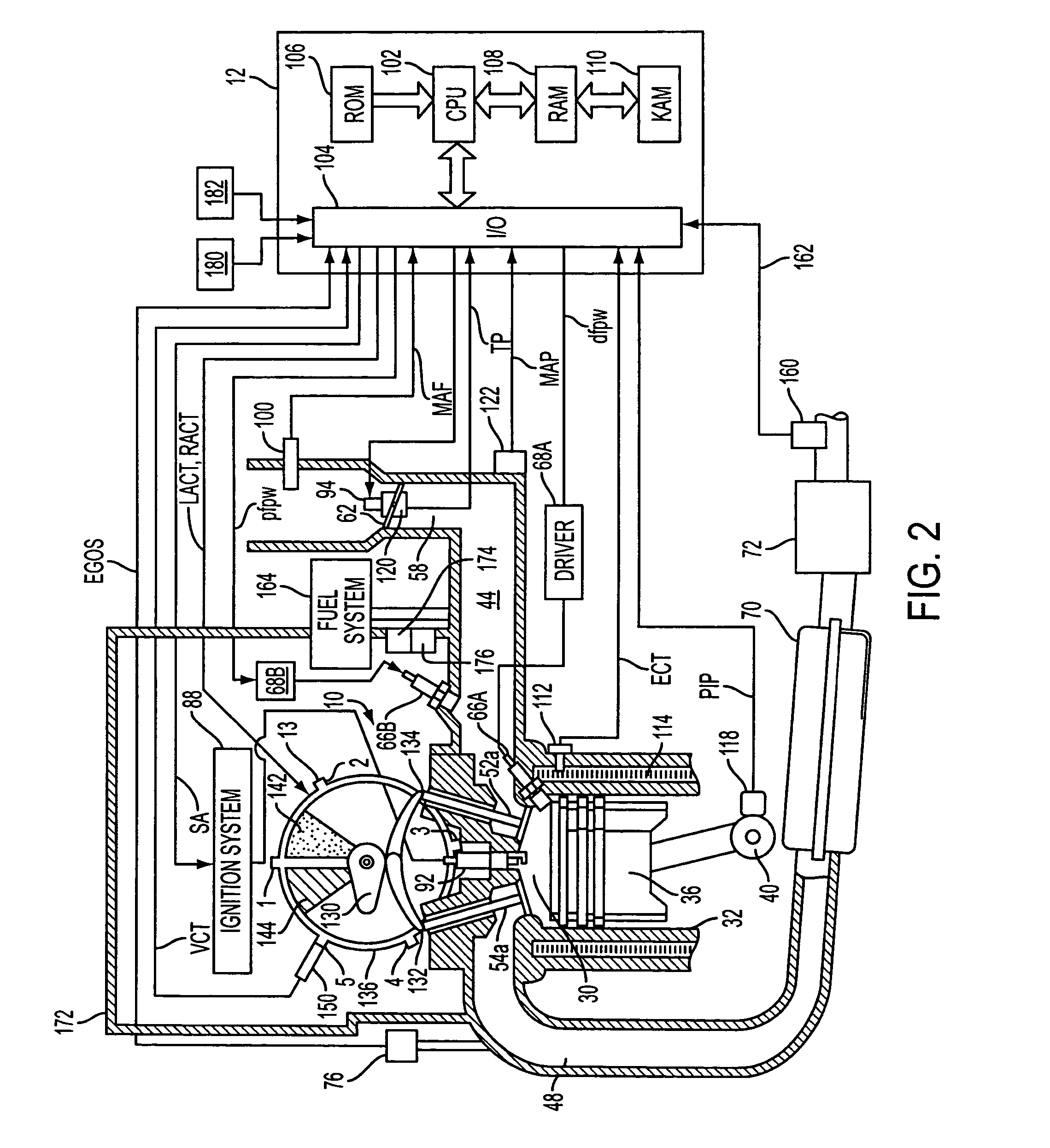

Ignition Energy Control for Mixed Fuel Engine

InactiveUS20090114188A1Improve combustion qualityImprove the level ofElectrical controlOther installationsEnergy controlControl system

As one example, an engine system for a vehicle is provided, including an internal combustion engine having at least one cylinder; a fuel system configured to provide a fuel to the cylinder; an ignition system including at least a spark plug; a control system configured to vary a level of ignition energy provided to the cylinder via the spark plug in response to a composition of the fuel provided to the cylinder by the fuel system. A method of operating the engine system by varying a level of ignition energy provided to the engine after a start-up is also provided.

Owner:FORD GLOBAL TECH LLC

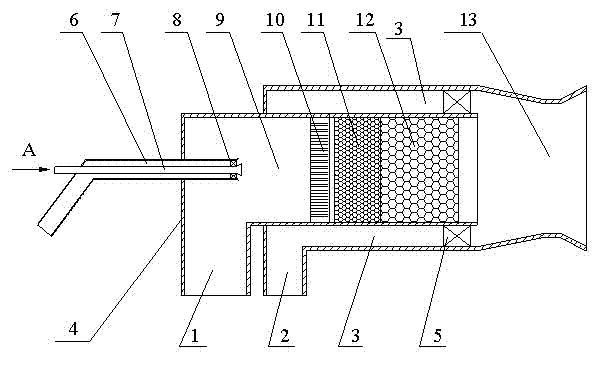

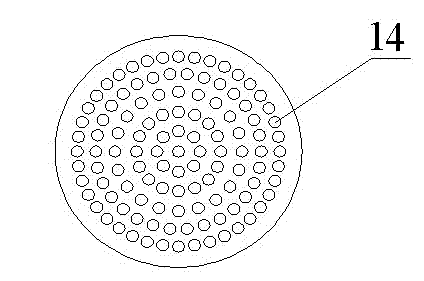

A Porous Media Burner Using Low Calorific Value Gas Fuel

InactiveCN102287819AImprove stabilityImprove combustion intensityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberPorous medium

The invention discloses a porous medium combustor for a low-caloric-value gas fuel. The porous medium combustor comprises an oxygen-enriched conduit, an ignition air gun, a premixed combustion chamber, secondary air pipes and a combustor nozzle of which the central axes are coincident; the secondary air pipes are coaxially sleeved outside the premixed combustion chamber; air pipelines and fuel pipelines which circumferentially incline are correspondingly arranged on respective pipe walls of the secondary air pipes and the premixed combustion chamber; a mixing chamber, a mixed fuel gas uniformdistributor, a small porous medium and a large porous medium are sequentially arranged in the premixed combustion chamber along an airflow direction; air holes of the small porous medium and the large porous medium adopt a honeycomb arrangement structure; the oxygen-enriched conduit is coaxially sleeved outside the ignition air gun; and outlet ends of the oxygen-enriched conduit and the ignition air gun pass through a wall surface of the premixed combustion chamber and extend into the mixing chamber. By adopting the segmental type porous medium, the combustion stability of the low-caloric-value gas fuel can be obviously improved, the combustion intensity of the low-caloric-value gas fuel is enhanced, the combustion volume is reduced, the combustion efficiency is improved, and the discharge of pollutant can be effectively reduced.

Owner:CHINA JILIANG UNIV

Flexible fuel engine with alterable compression ratio and control method thereof

InactiveCN101131126AValve arrangementsInternal combustion piston enginesCombustion systemVariable valve timing

The present invention discloses one kind of engine with changeable compression ratio and changeable fuel and its control method. The engine includes one combustion system, one fuel pressure regulating system, one liquid fuel providing system, one gas fuel providing system, one changeable gas valve timing mechanism, one electronic control unit and one sensor module. According to the acquired signal, the electronic control unit determines the current fuel type, regulates the compression ratio, combustion controlling strategy and gas distribution phase of the engine and regulates the pressure of the fuel injector, so as to fit the fuel. The engine of the present invention can burn gas fuel, liquid fuel and mixed fuel, and has compression ratio adjustable in 8-18 and high dynamic performance and economic performance in burning different types of fuel.

Owner:CHERY AUTOMOBILE CO LTD

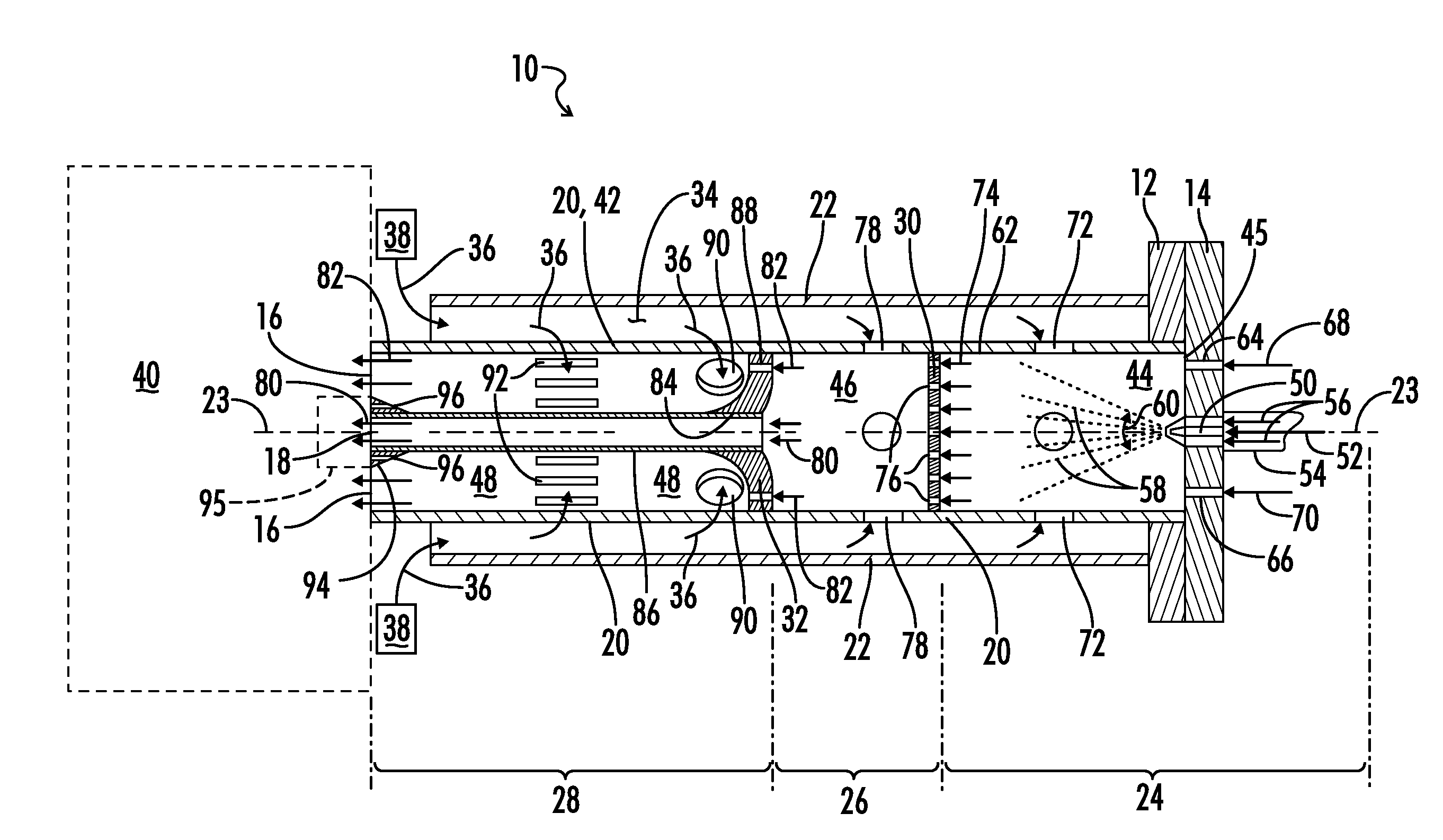

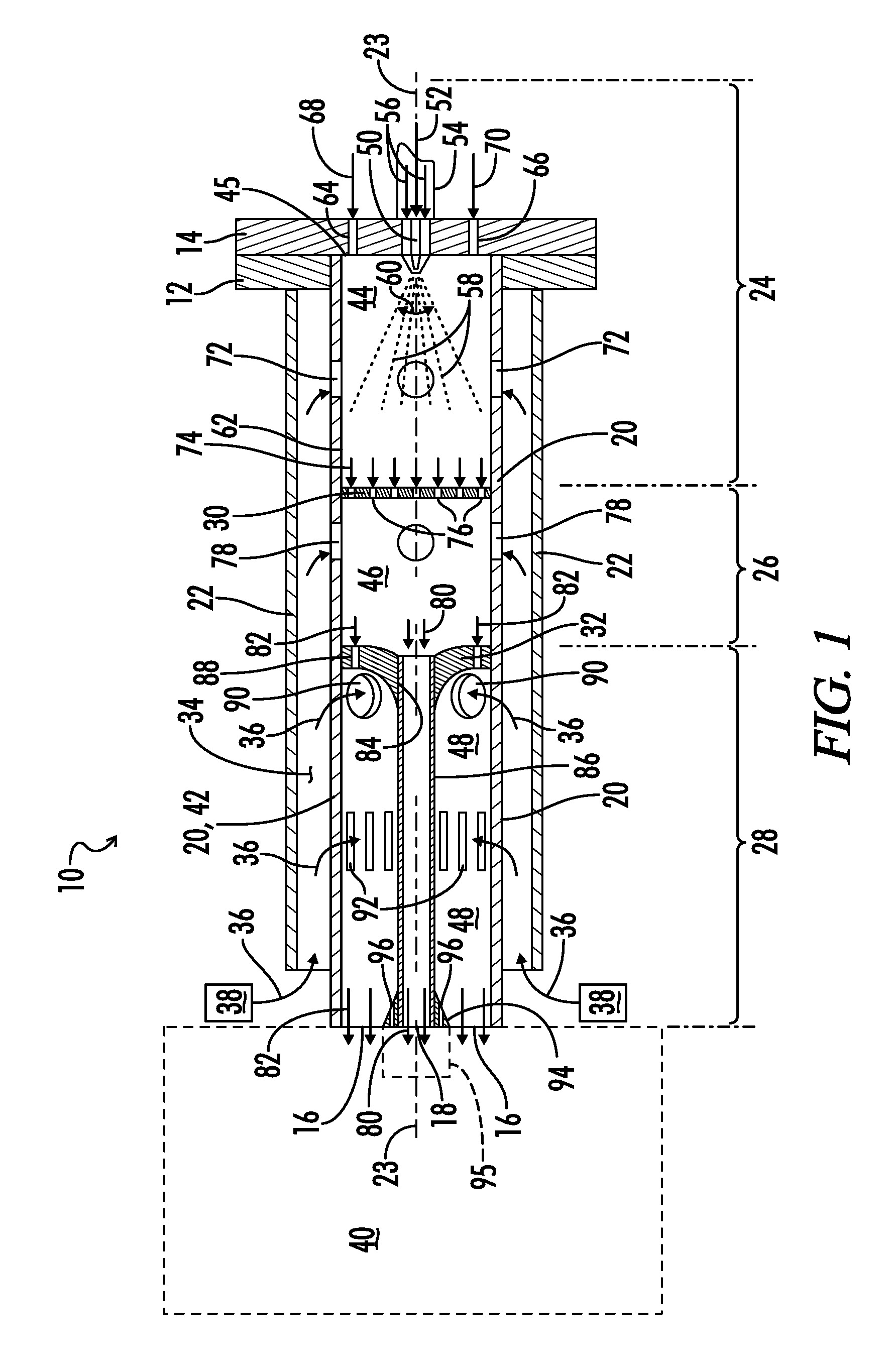

Multistaged Lean Prevaporizing Premixing Fuel Injector

ActiveUS20130306181A1Emission reductionReduce system complexityBurnersContinuous combustion chamberLiquid fuelDistributor

A multistaged lean prevaporizing premixing fuel injector apparatus is provided. The fuel injector may be utilized with a turbogenerator. Preheated combustion air from the turbogenerator's recuperator may be utilized by the fuel injector to prevaporize liquid fuel. The injector may provide for premixing of multiple fuel streams and include multiple stages with a flow distributor plate separating adjacent stages. The injector may include multiple stages, with a pilot tube located in a final stage splitting the fuel stream into a premixed pilot stream and a premixed final fuel and air mixture stream.

Owner:CAPSTONE TURBINE

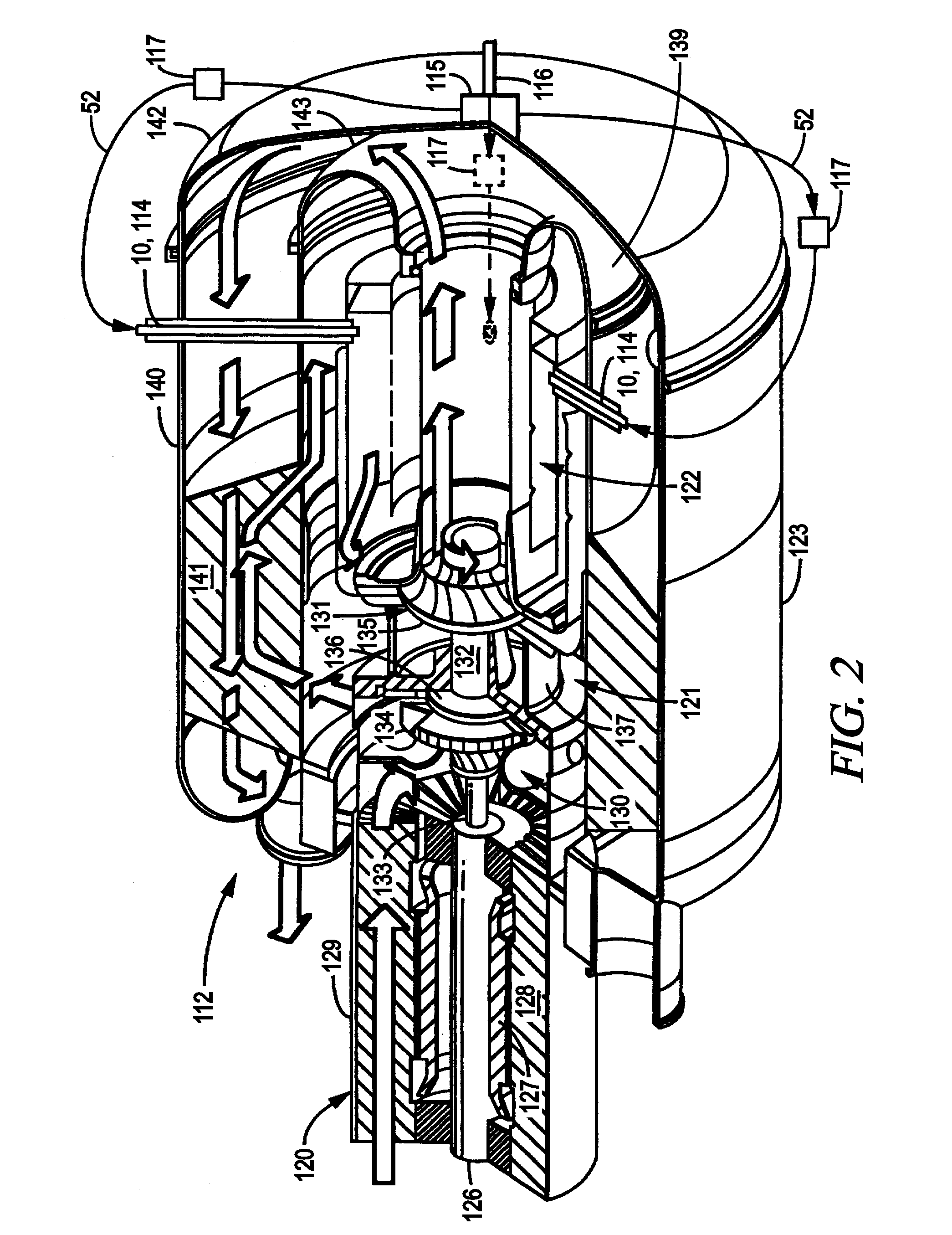

Apparatus and method for mixing fuel in a gas turbine nozzle

ActiveUS20120055167A1Turbine/propulsion fuel supply systemsContinuous combustion chamberEngineeringPlenum chamber

A nozzle includes a fuel plenum and an air plenum downstream of the fuel plenum. A primary fuel channel includes an inlet in fluid communication with the fuel plenum and a primary air port in fluid communication with the air plenum. Secondary fuel channels radially outward of the primary fuel channel include a secondary fuel port in fluid communication with the fuel plenum. A shroud circumferentially surrounds the secondary fuel channels. A method for mixing fuel and air in a nozzle prior to combustion includes flowing fuel to a fuel plenum and flowing air to an air plenum downstream of the fuel plenum. The method further includes injecting fuel from the fuel plenum through a primary fuel passage, injecting fuel from the fuel plenum through secondary fuel passages, and injecting air from the air plenum through the primary fuel passage.

Owner:GENERAL ELECTRIC CO

System and method for reducing emission from a combustion engine

InactiveUS20060070587A1Emission reductionHydrogenInternal combustion piston enginesHydrogenExhaust fumes

A combustion engine system comprises a plurality of cylinders configured to combust a mixed fuel to produce an exhaust gas and at least one reforming cylinder configured to receive a first portion of a fuel and deliver a reformed hydrogen-containing gas. The hydrogen-containing gas is introduced into a second portion of the fuel to form the mixed fuel to reduce emission from the combustion engine system.

Owner:GENERAL ELECTRIC CO

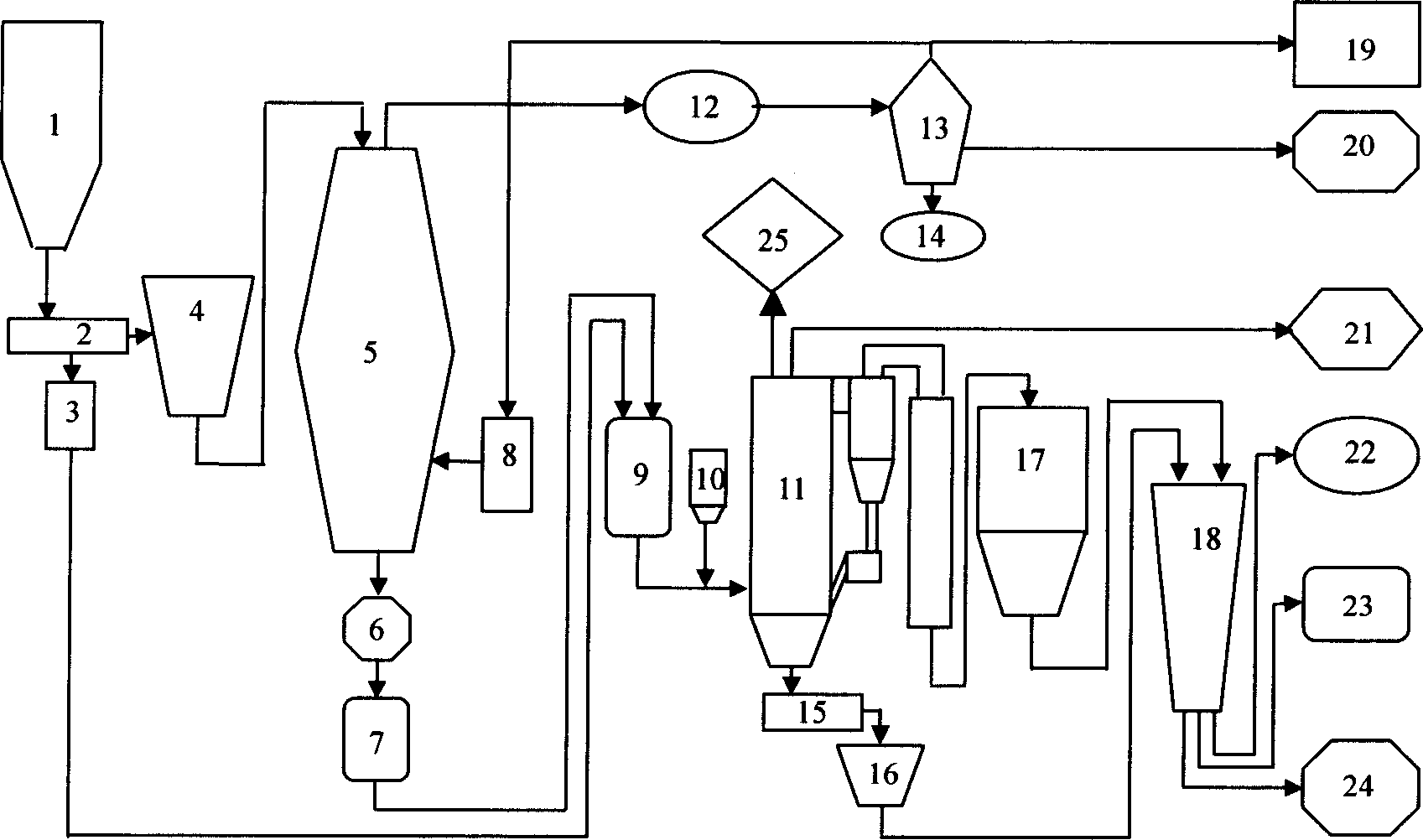

Method for complex optimum using oil shale

InactiveCN1683472AAchieve optimal utilizationIncrease profitLiquid hydrocarbon mixture productionSpecial form destructive distillationFluidized bedOil shale gas

The comprehensive optimized oil shale utilizing method includes crushing and sieving oil shale ore, dry distilling the 8-80 mm size component in retort furnace to produce shale oil and fuel gas, crushing the semicoke waste into 8 mm below size, mixing the crushed semicoke waste and 8 mm below size waste grain from oil refining to form mixed fuel for the circulating fluidized bed boiler, using the produced steam partially for externally supplying and partially to drive turbine generator, and using the cinder in producing cement, haydite and building block. The present invention provides one new way for comprehensive utilization of giant oil shale resource.

Owner:SHANGHAI JIAO TONG UNIV

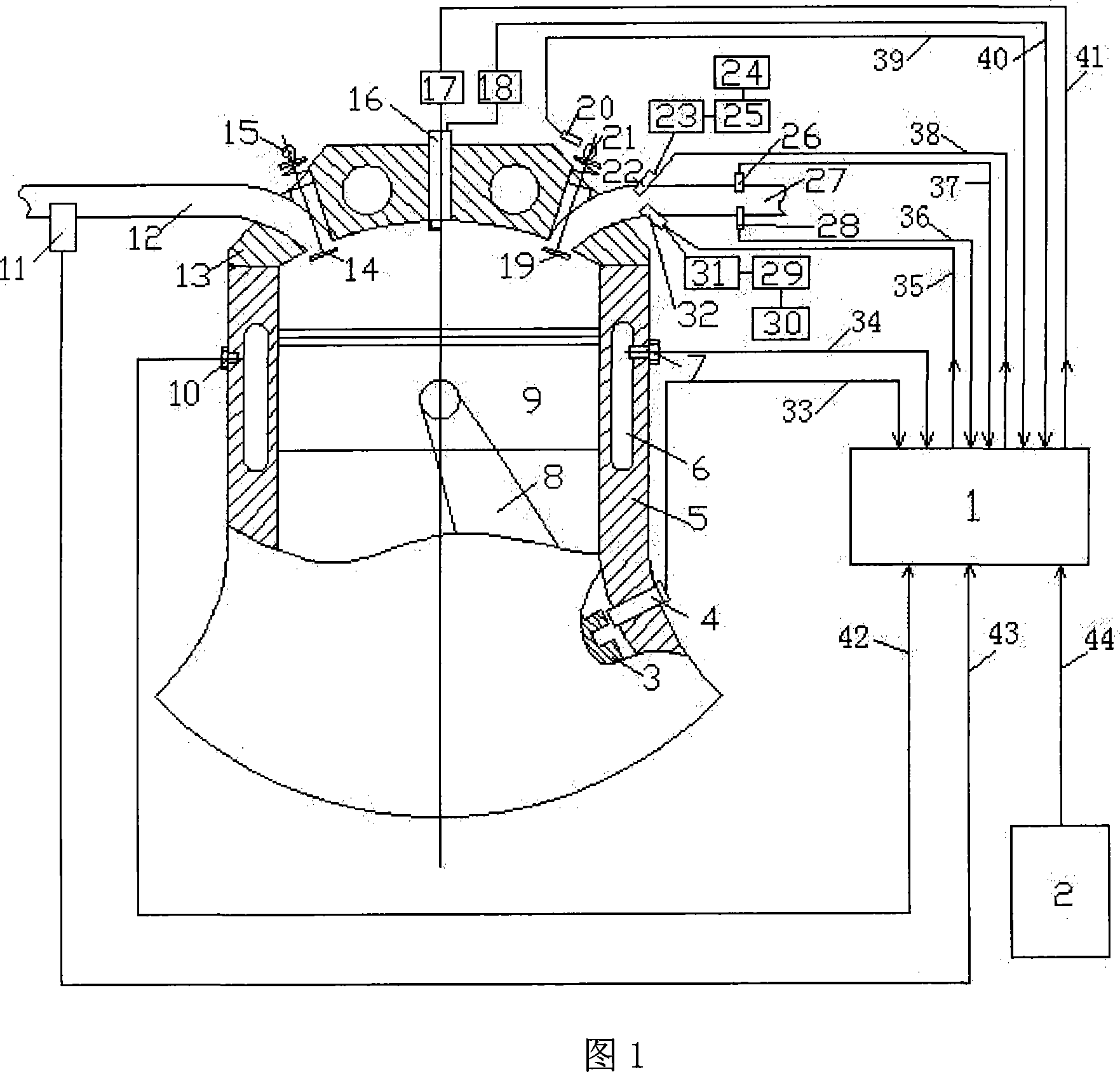

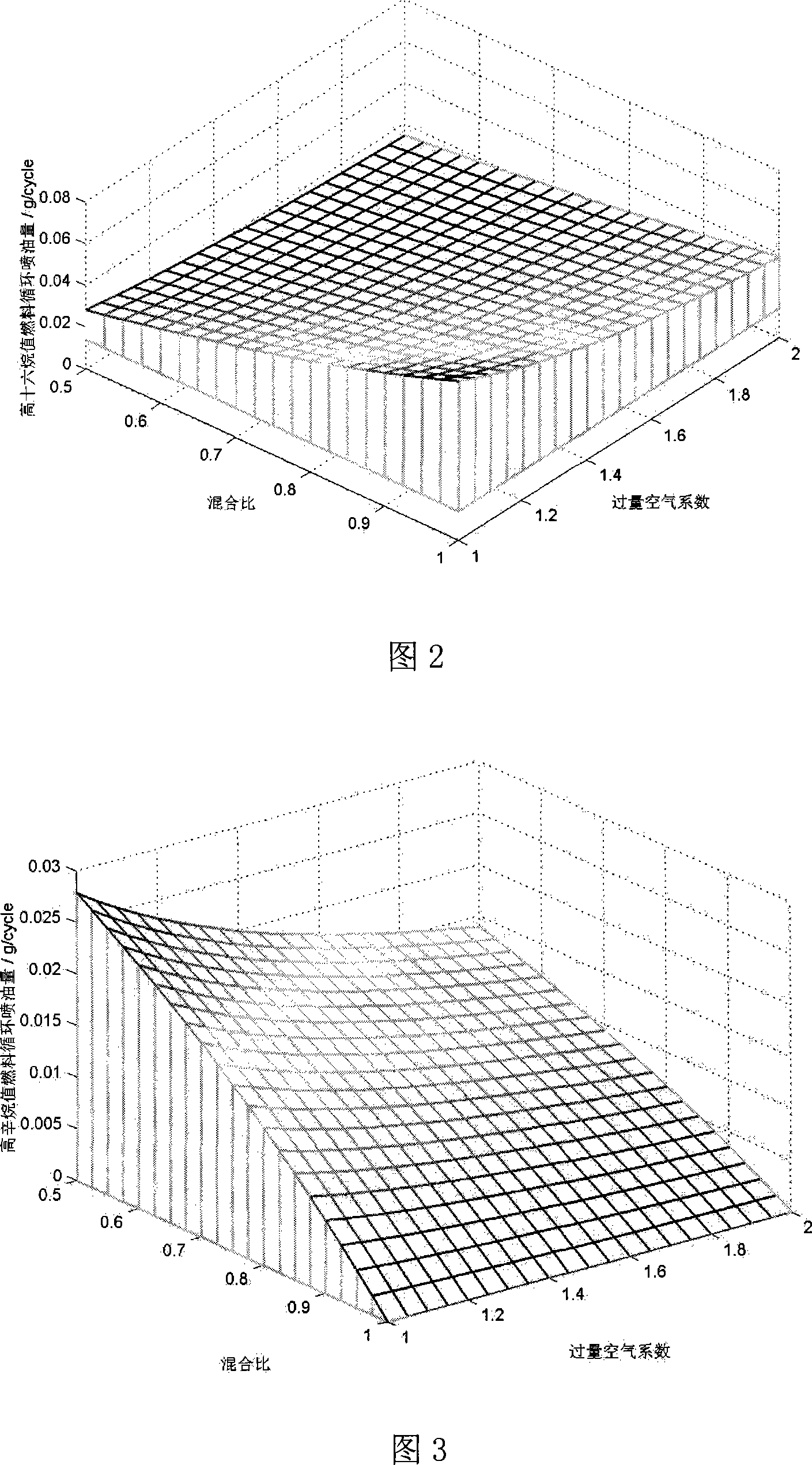

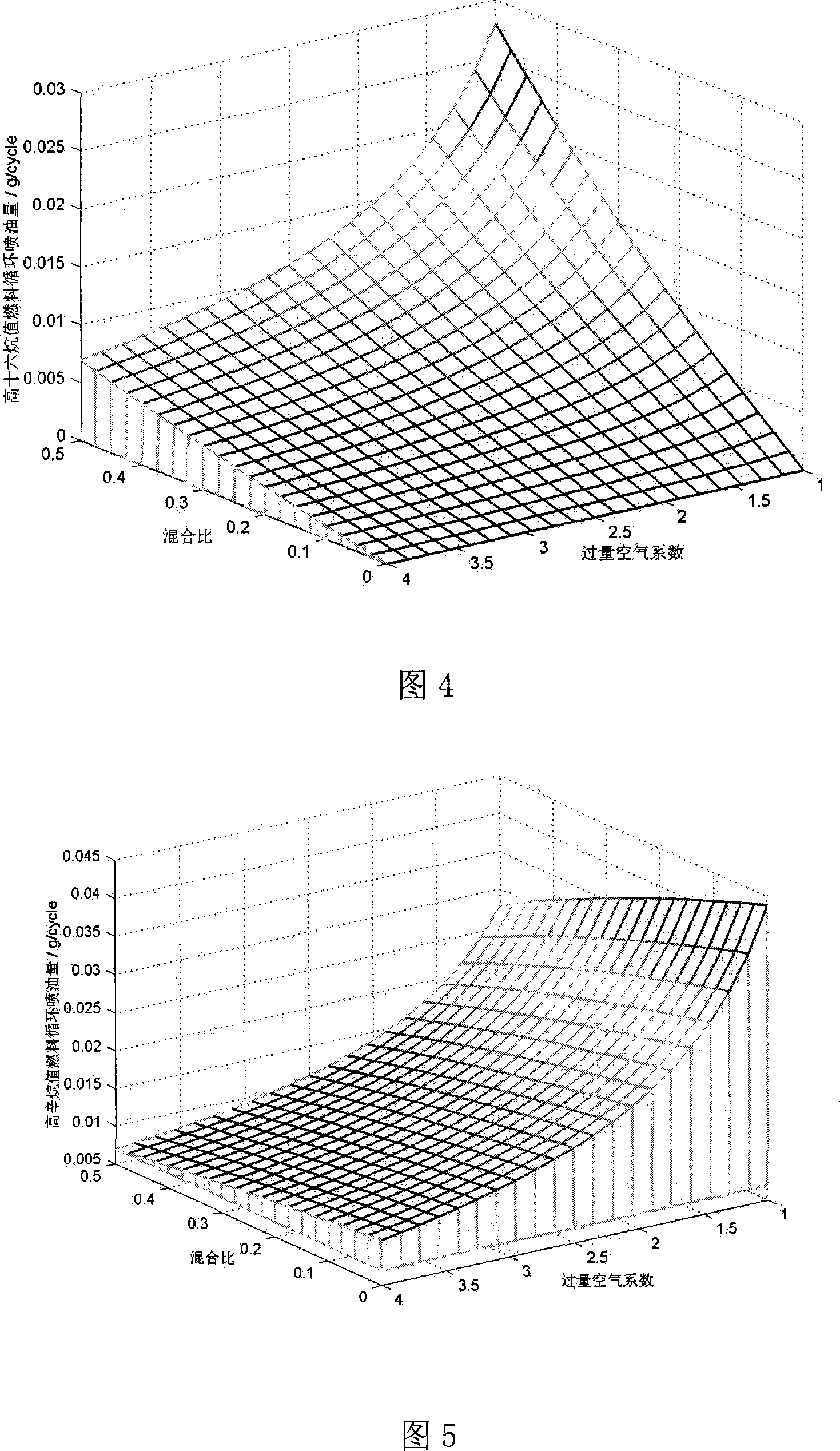

Fuel on-site mixing and compressed ignition internal combustion engine and control method

InactiveCN101215996AWide adaptabilityExpand the range of working conditionsElectrical controlMachines/enginesMixed fuelPower performance

The invention provides a fuel field mixing compression ignition internal combustion engine and a control method thereof, in particular relates to fuel preparation, supply and combustion control of a combustion engine. The invention adopts a high-octane and high-cetane fuel field mixing and auxiliary ignition technology, and can meet the requirement that the internal combustion engine makes use of the fuel of different octane numbers under different loads, namely, more high-cetane fuel is mixed in the high-octane fuel under low load or ignition is assisted in, to improve the ignition property of the mixed fuel so that the mixed fuel can be fired reliably under low load and temperature with the firing time controllable. The quantity of high-cetane fuel to be mixed in is reduced under medium load; a signal high-octane fuel is adopted under large load to avoid engine detonation. By adopting the fuel field mixing compression ignition combustion mode, not only an even premixing compression ignition engine is prevented from being on fire under low load, but also the working condition range under large load can be widened. In addition, the power performance of the engine is improved. In this way, the even premixing compression ignition engine is practical.

Owner:BEIJING UNIV OF TECH

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS8015951B2Increase heatIncrease profitNon-fuel substance addition to fuelInternal combustion piston enginesSolventOperant conditioning

Systems and methods are provided for extracting components of a mixed fuel into at least one substantially non-polar component and at least one polar fuel component. In one example approach, a volume of a mixed fuel is added to an extractor and a polar solvent is used to extract components of the mixed fuel. The extracted components may be selectively provided to an engine in a ratio based upon engine operating conditions.

Owner:FORD GLOBAL TECH LLC

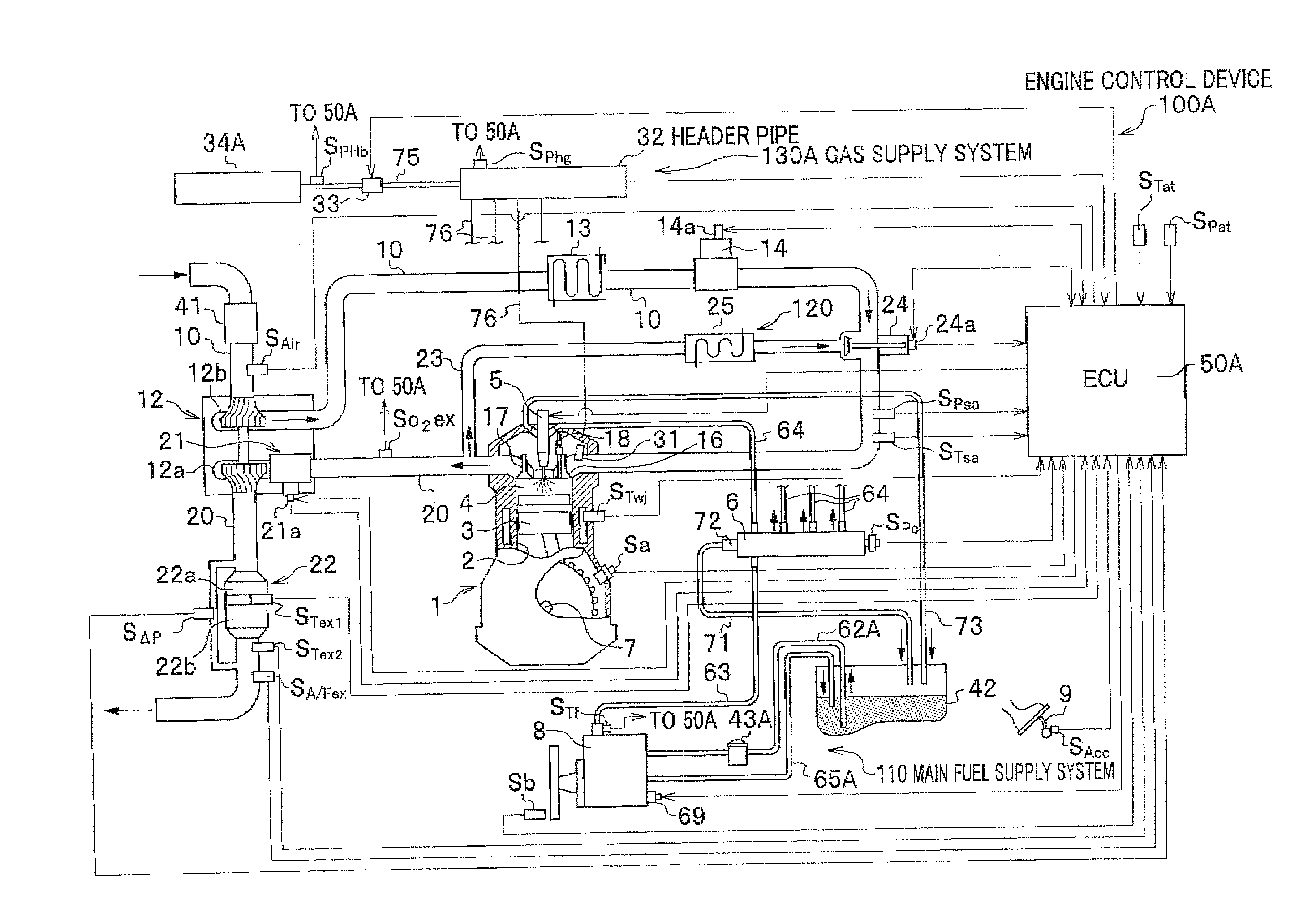

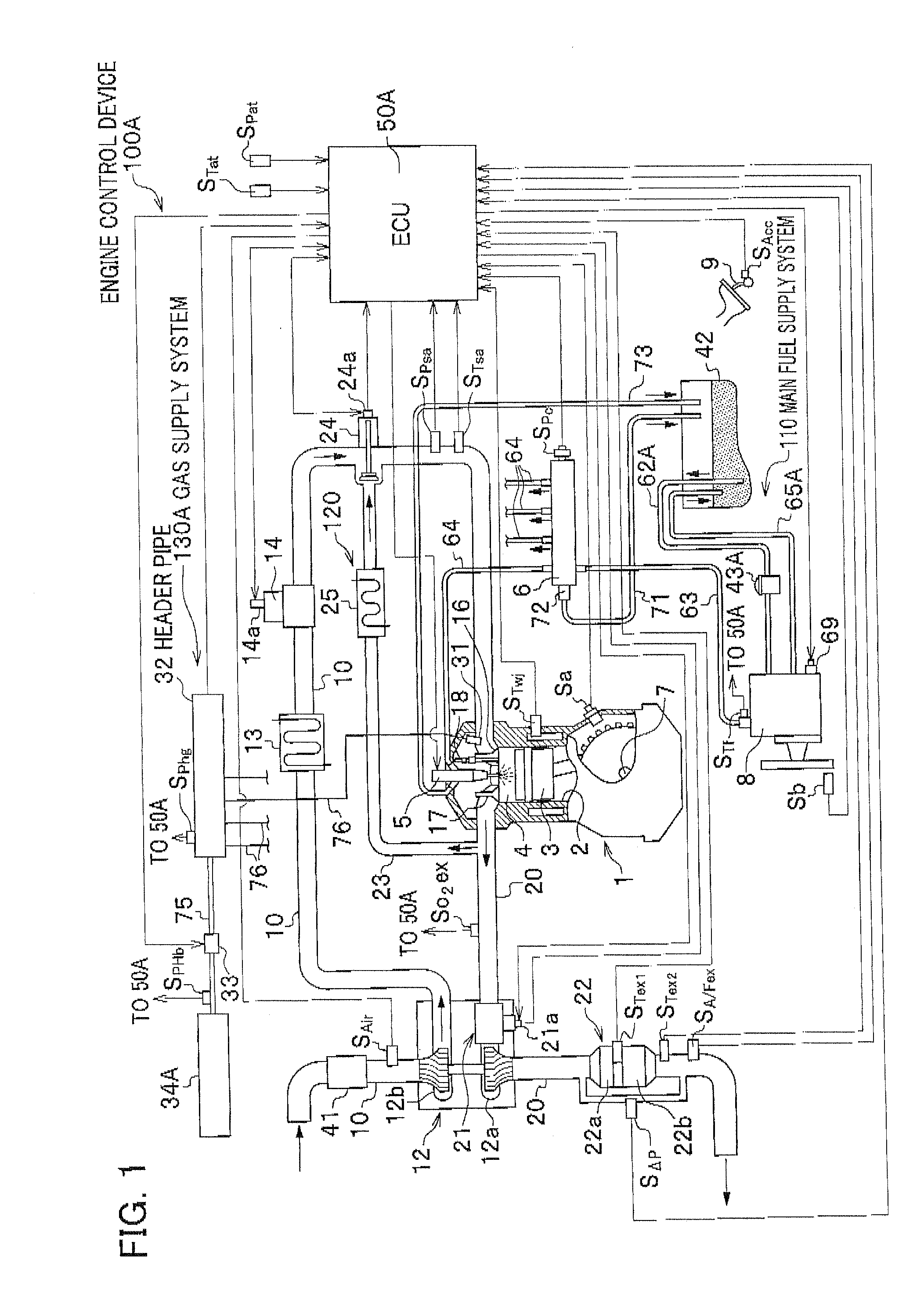

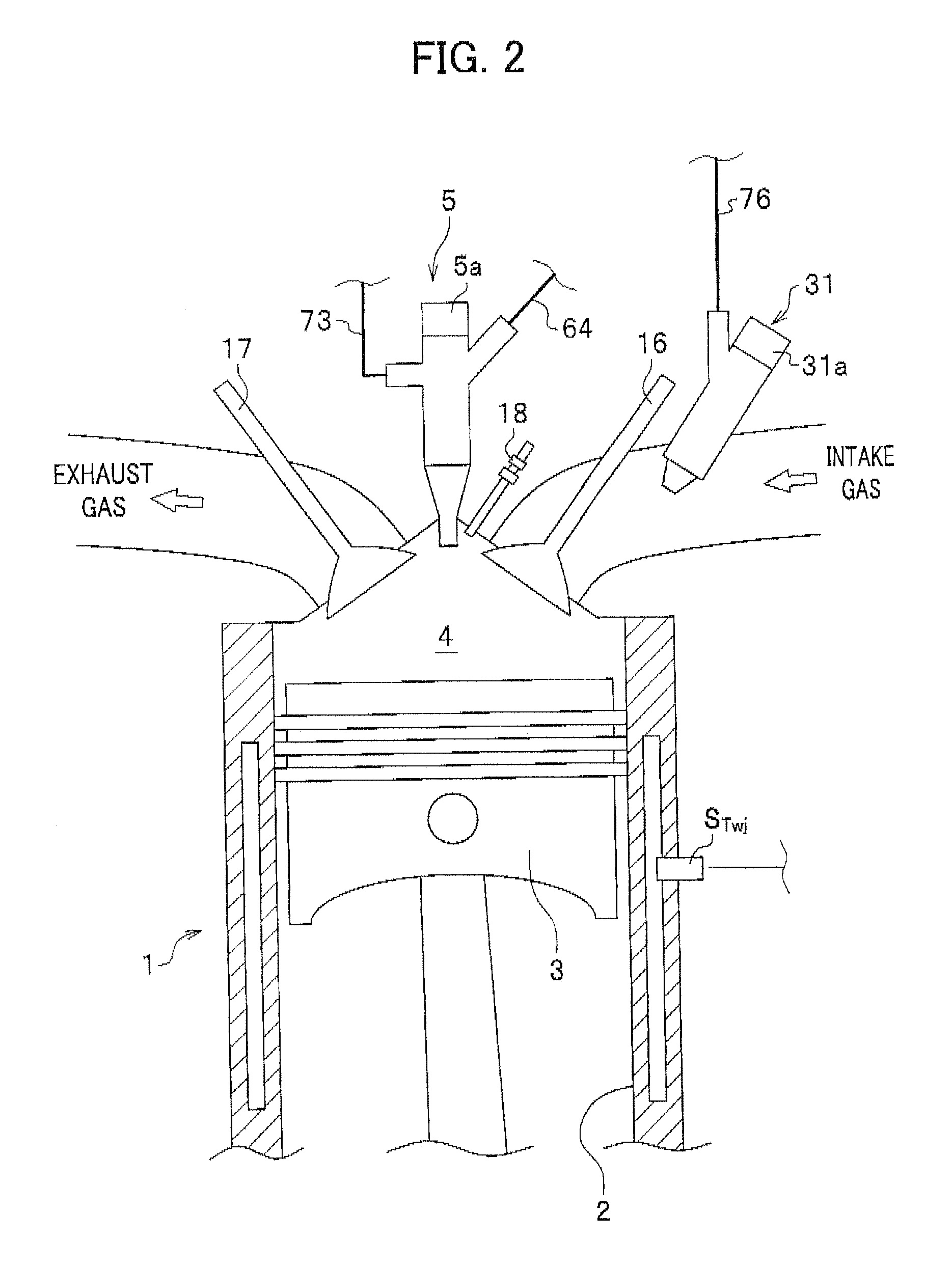

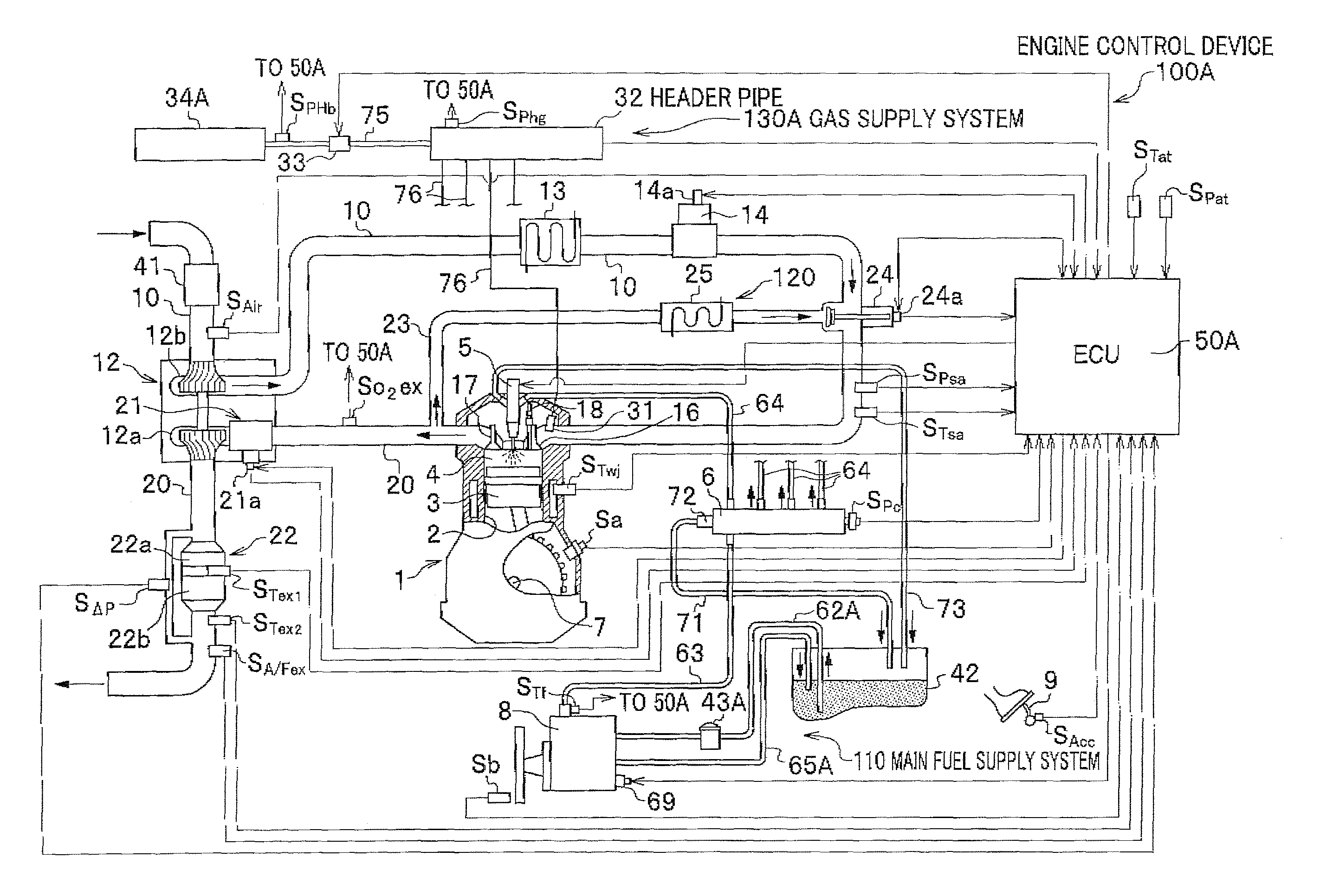

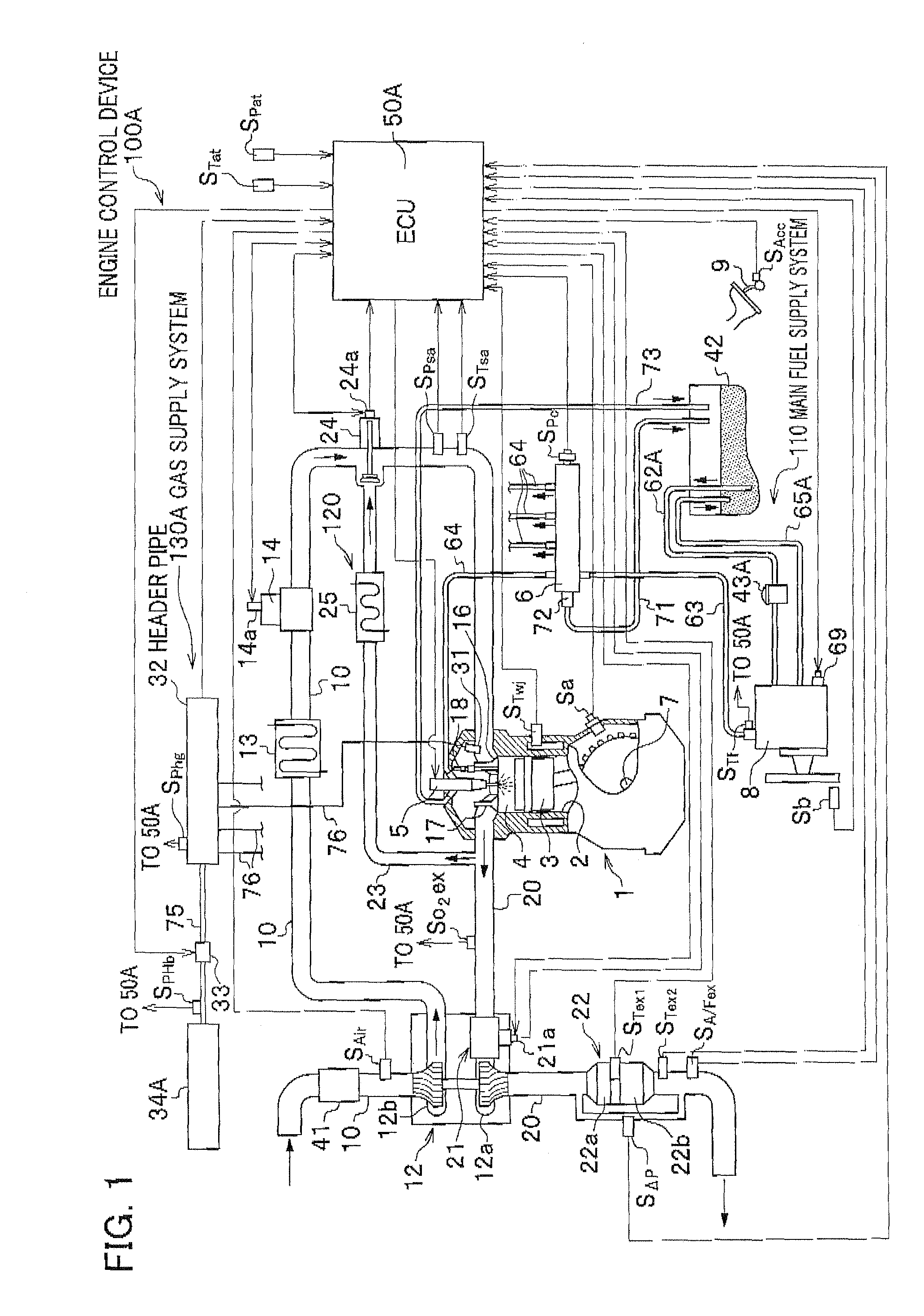

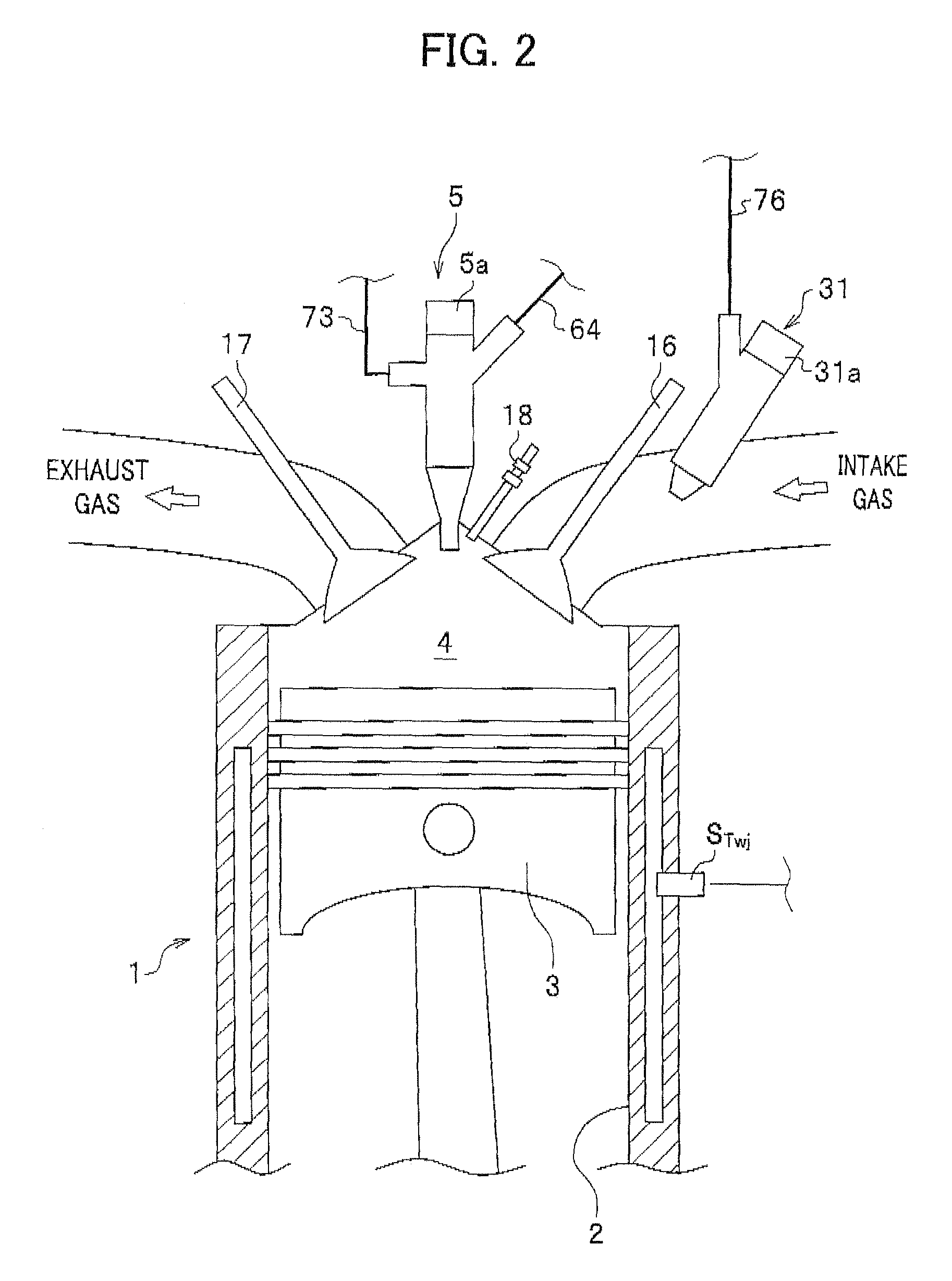

Control device for internal combustion engine

InactiveUS20100268442A1Guaranteed uptimeLarge operating areaAnalogue computers for vehiclesElectrical controlHydrogenExternal combustion engine

A control device for an internal combustion engine employing PCCI combustion, capable of realizing high-stability operation of the engine throughout a large operation area, is provided. The engine control device comprises a fuel supply system which supplies light oil or mixed fuel containing light oil to the engine, a gas supply system which supplies hydrogen to the engine, and a required premixed gas calculating unit which previously stores and uses multiple combustion waveforms (changing depending on hydrogen addition concentration) as data. The required premixed gas calculating unit selects one of the combustion waveforms so as to achieve high thermal efficiency depending on the status of the engine and determines the hydrogen addition concentration (addition concentration of the hydrogen to be supplied to the engine) corresponding to the selected combustion waveform, by which the generation of PM and NOx can be reduced while also improving the thermal efficiency of the engine.

Owner:HONDA MOTOR CO LTD

Control device for internal combustion engine

InactiveUS8396644B2Guaranteed uptimeLarge operating areaAnalogue computers for vehiclesElectrical controlHydrogenExternal combustion engine

A control device for an internal combustion engine employing PCCI combustion, capable of realizing high-stability operation of the engine throughout a large operation area, is provided. The engine control device comprises a fuel supply system which supplies light oil or mixed fuel containing light oil to the engine, a gas supply system which supplies hydrogen to the engine, and a required premixed gas calculating unit which previously stores and uses multiple combustion waveforms (changing depending on hydrogen addition concentration) as data. The required premixed gas calculating unit selects one of the combustion waveforms so as to achieve high thermal efficiency depending on the status of the engine and determines the hydrogen addition concentration (addition concentration of the hydrogen to be supplied to the engine) corresponding to the selected combustion waveform, by which the generation of PM and NOx can be reduced while also improving the thermal efficiency of the engine.

Owner:HONDA MOTOR CO LTD

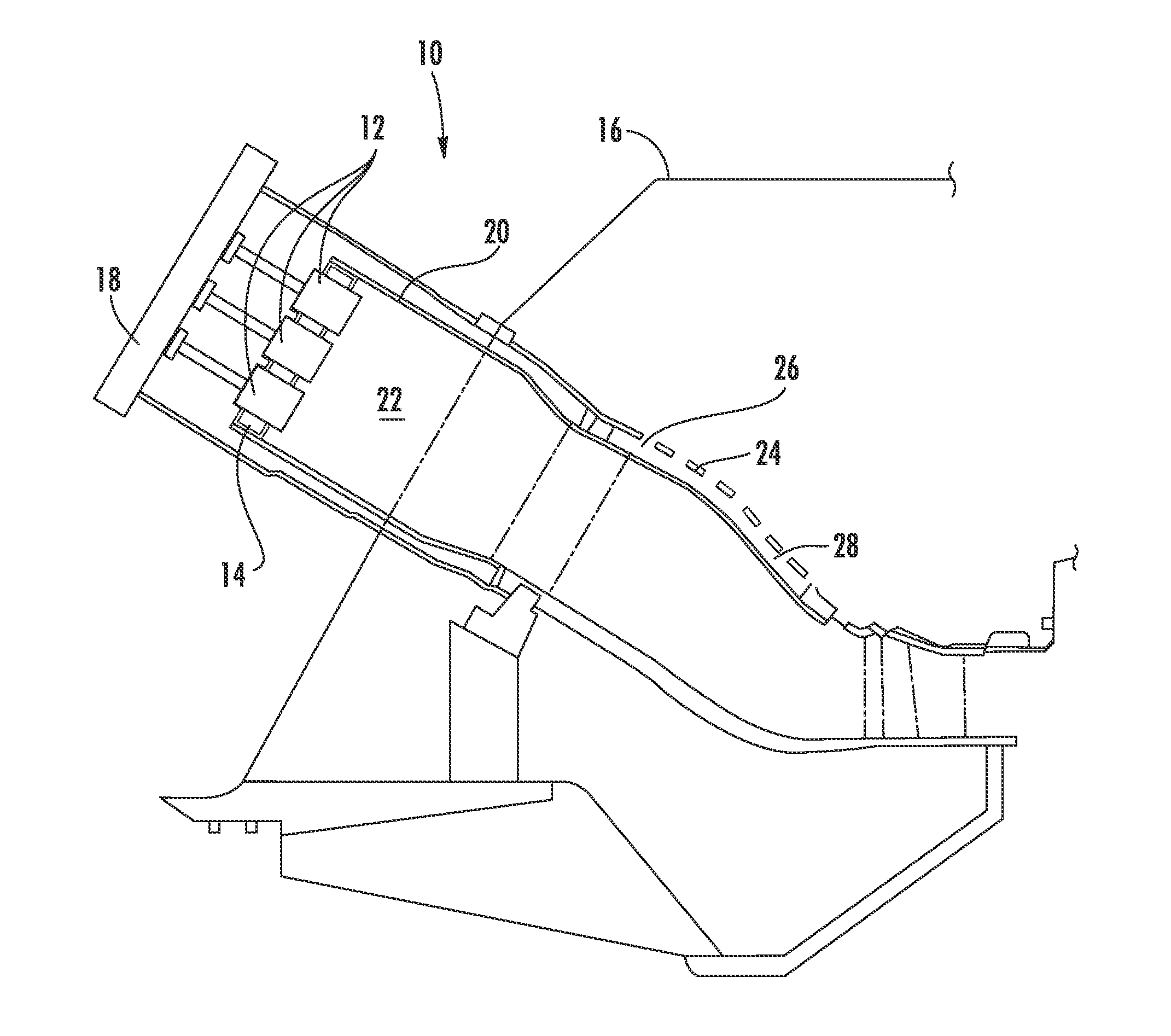

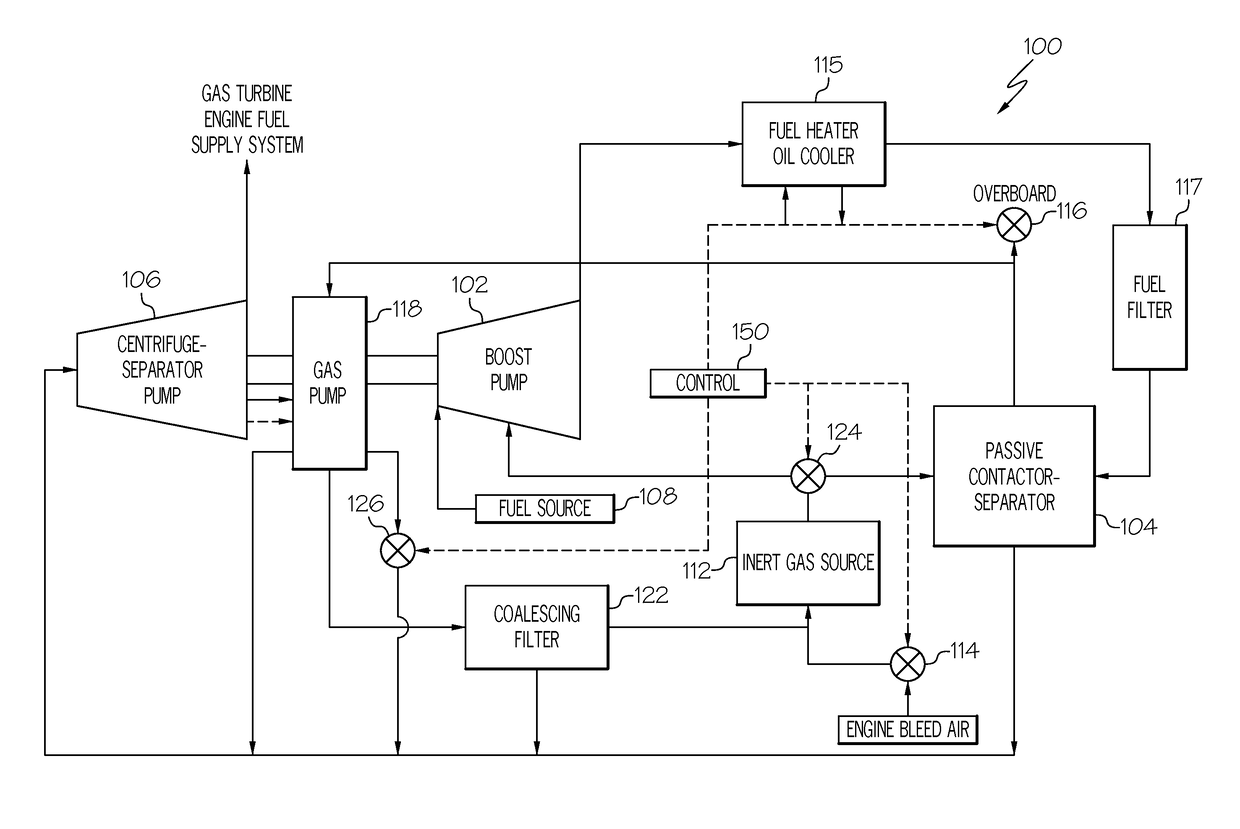

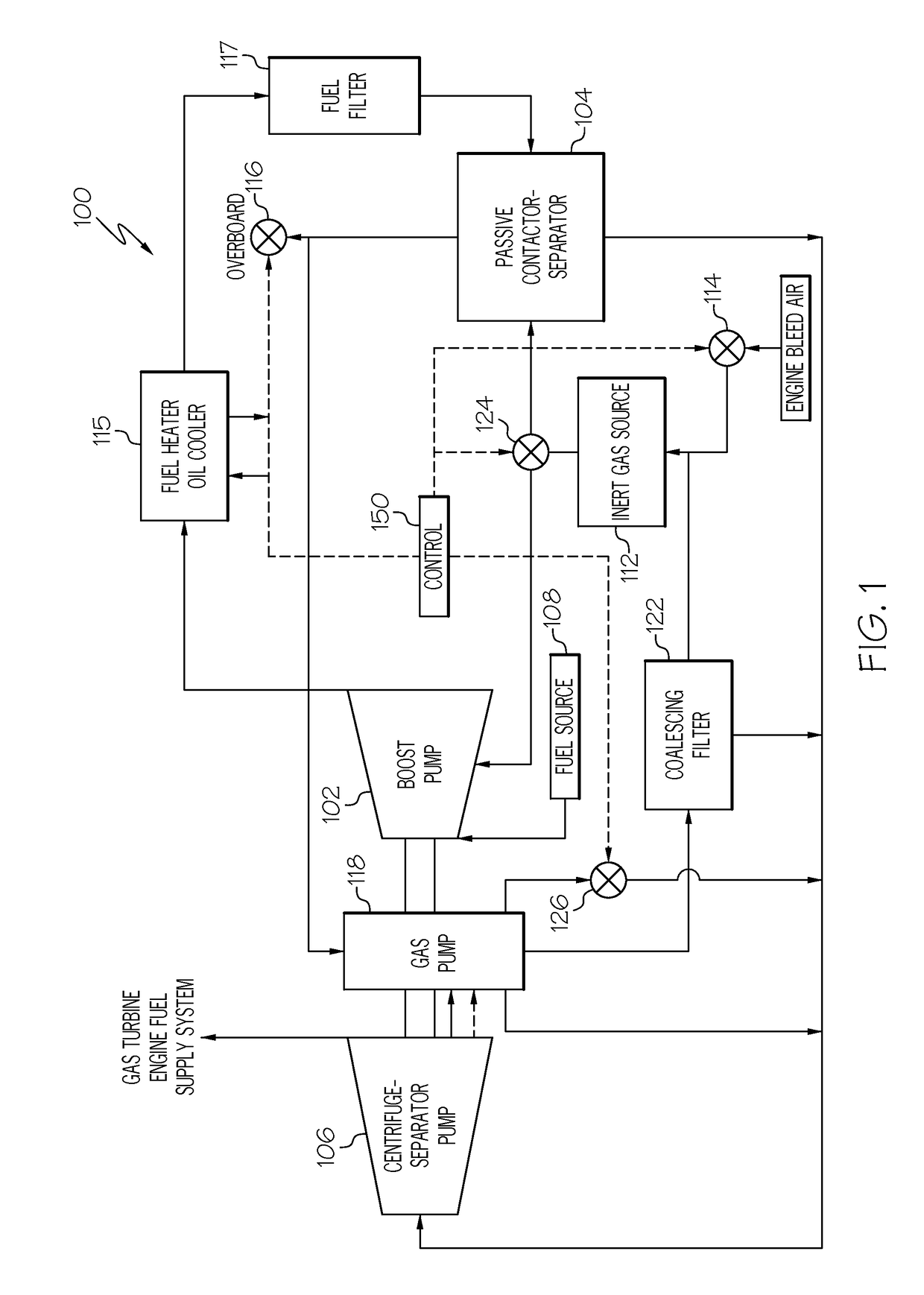

Aircraft fuel deoxygenation system

ActiveUS9834315B2Liquid degasification with auxillary substancesDispersed particle filtrationDeoxygenationMechanical engineering

An aircraft fuel deoxygenation system includes a boost pump, a contactor-separator, and a centrifuge-separator pump. The boost pump is adapted to receive fuel from a fuel source and inert gas from an inert gas source, and is configured to mix the fuel and inert gas and supply a fuel / gas mixture. The contactor-separator is coupled to receive the fuel / gas mixture and is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel with entrained purge gas and separated purge gas. The centrifuge-separator pump is coupled to receive the deoxygenated fuel with entrained purge gas and is configured to separate and remove the entrained purge gas from the deoxygenated fuel and supply the deoxygenated fuel and additional purge gas.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com