Burner, gas turbine combustor, burner cooling method, and burner modifying method

A gas turbine and burner technology, which is applied in the fields of burner, gas turbine burner, burner cooling and burner modification, can solve the problems of high flame temperature, high burning speed, and rising metal temperature on the nozzle end face, and achieves the The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

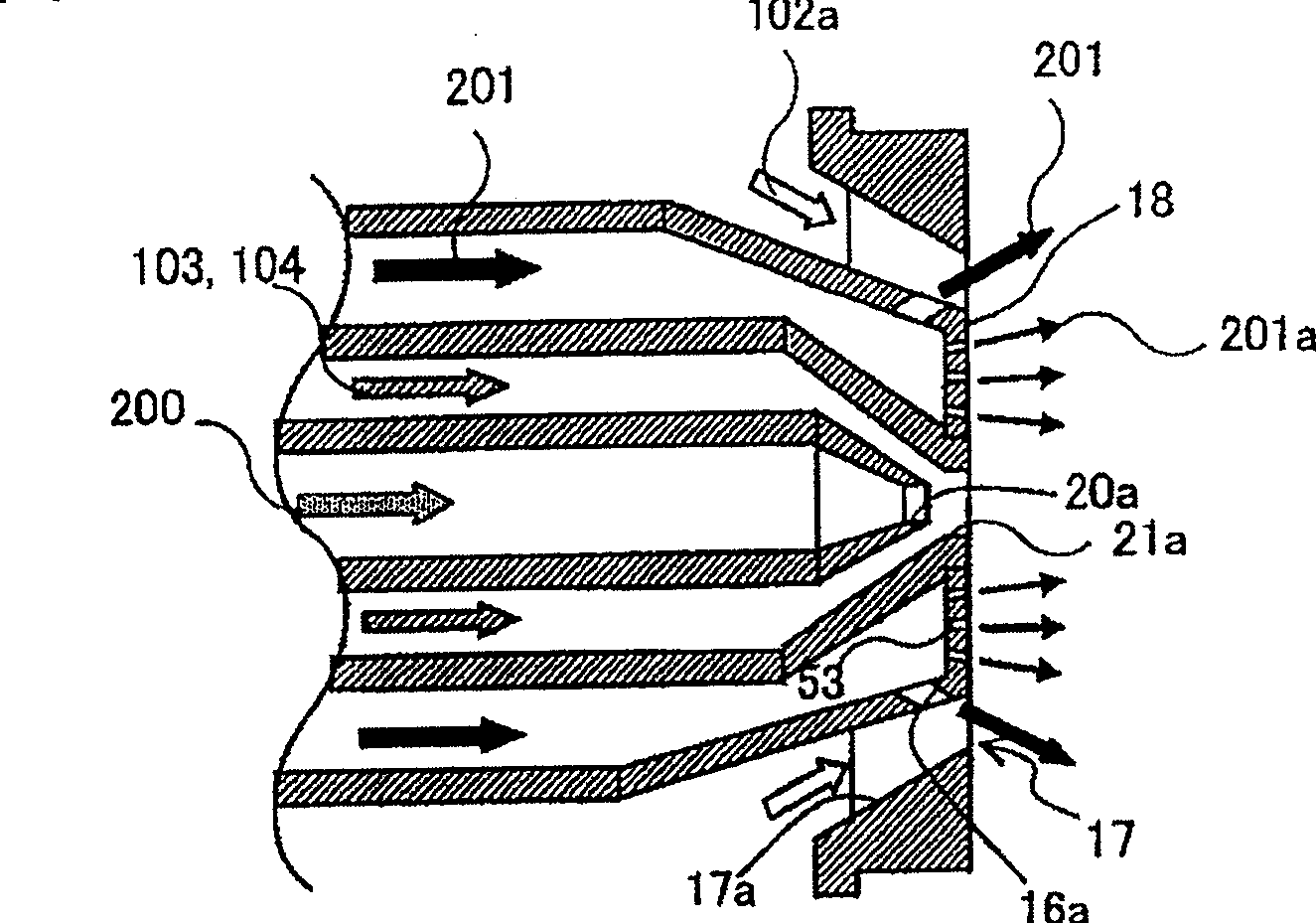

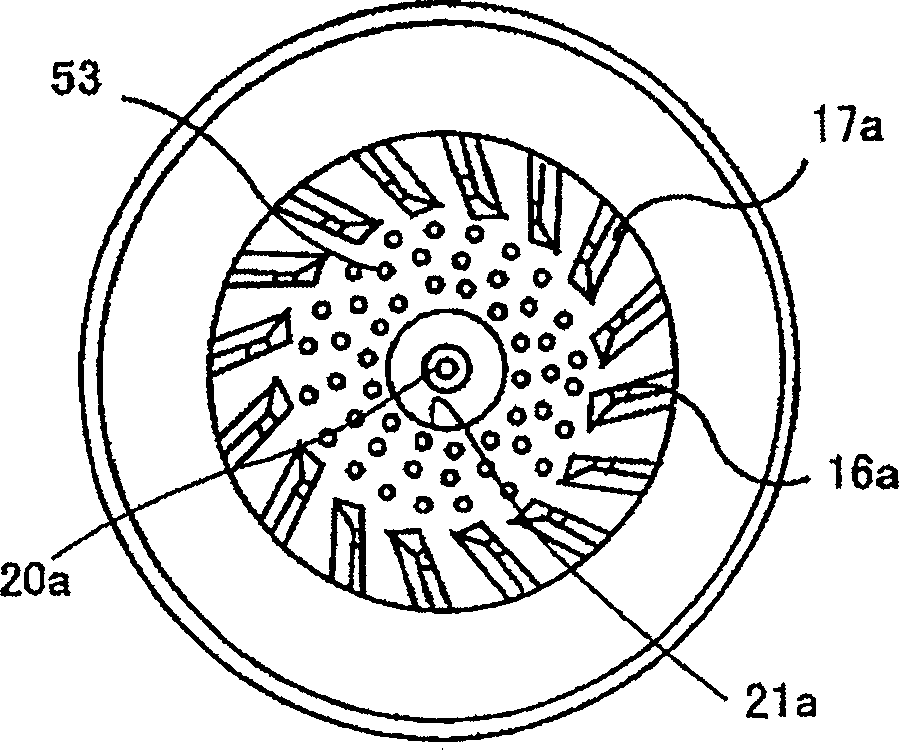

[0032] Embodiments of the present invention will be described below using the drawings.

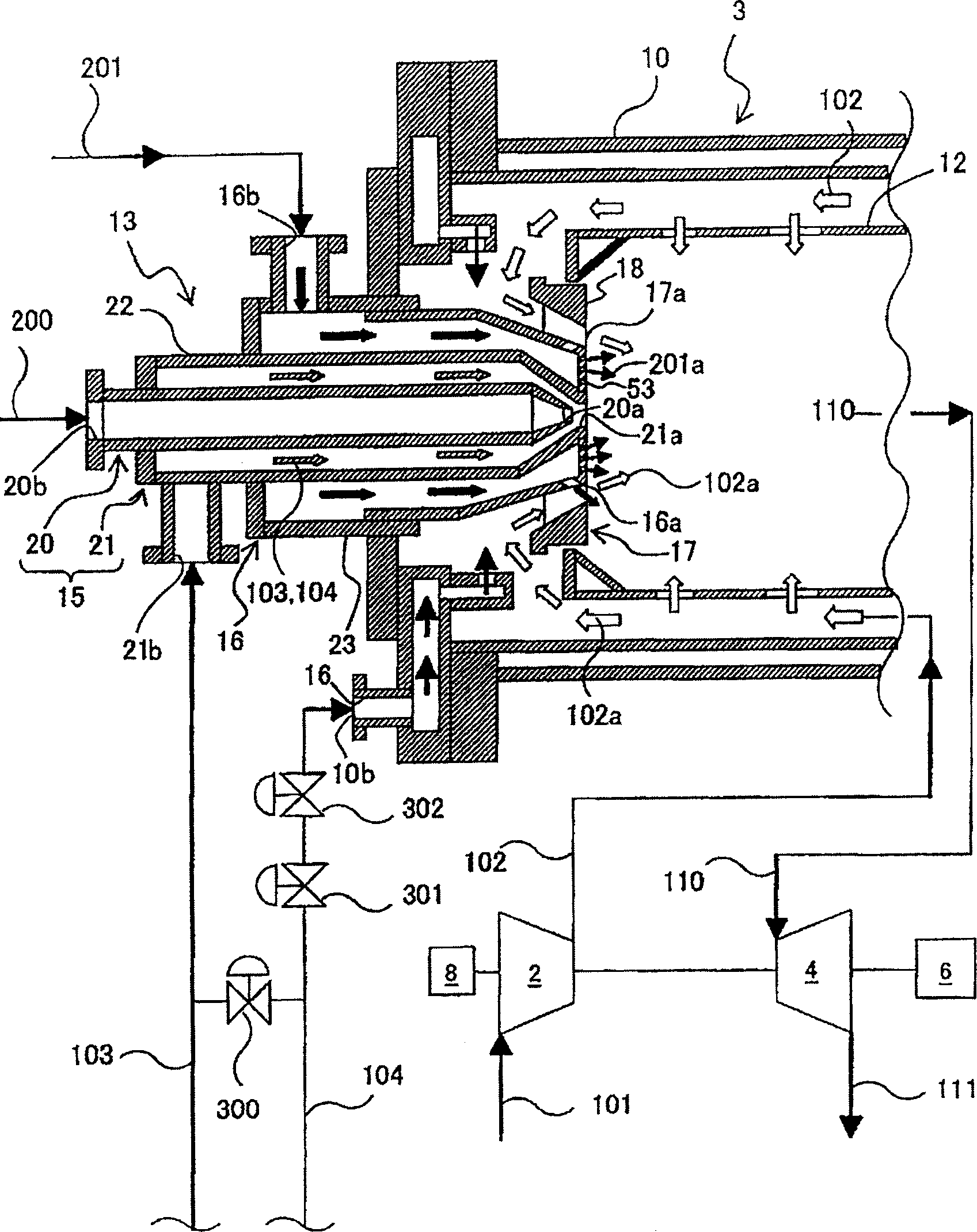

[0033] figure 1 It is a schematic diagram of a gas turbine plant including a burner according to a first embodiment of the present invention.

[0034] The gas turbine plant of the present embodiment includes an air compressor 2, a combustor 3, a turbine 4, a generator 6, a starter motor 8 for driving the gas turbine, and the like. In the air compressor 2 , the sucked air 101 is compressed, and the compressed air 102 from the air compressor 2 is burned by the combustor 3 together with fuels 200 and 201 . When the combustion gas 110 from the combustor 3 is supplied to the turbine 4 , the turbine 4 can obtain rotational power from the combustion gas 110 , and the rotational power of the turbine 4 is transmitted to the air compressor 2 and the generator 6 . The rotational power transmitted to the air compressor 2 is used as compression power, and the rotational power transmitted to the gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com