Fuel cell-turbocharged internal combustion engine hybrid power generation system

A fuel cell and hybrid power generation technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems that are not suitable for the field of distributed power generation, poor performance under variable working conditions, and long response time, etc., to achieve Efficiency improvement, CO emission reduction, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

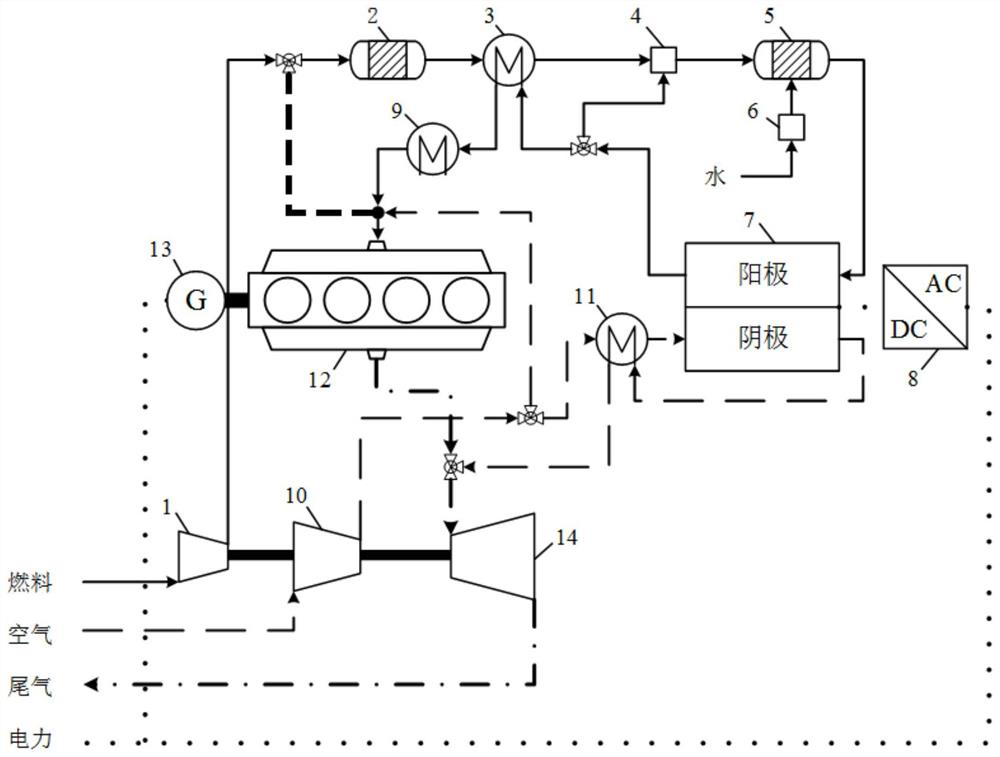

[0021] Specific implementation mode one: see figure 1 This embodiment will be described. The fuel cell-turbocharged internal combustion engine hybrid power generation system described in this embodiment includes a fuel compressor 1, a desulfurizer 2, a fuel heat exchanger 3, a mixer 4, a reformer 5, a water vaporizer 6, and a solid oxide fuel battery 7, inverter 8, cooler 9, air compressor 10, air heat exchanger 11, internal combustion engine 12, engine 13 and turbine 14, the fuel compressor 1, desulfurizer 2, fuel heat exchanger 3 and mixing The air compressor 10 is connected to the air heat exchanger 11, the gaseous water input end of the reformer 5 is connected to the gaseous water output end of the water vaporizer 6, and the fuel input of the reformer 5 end is connected with the output end of the mixer 4, the reformed gas output end of the reformer 5 is connected with the anode channel input end of the solid oxide fuel cell 7, and the cathode channel input end of the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com