Absorption and jet type super low temperature generation refrigeration and heating device

A refrigeration and heating device, ultra-low temperature technology, applied in refrigerators, steam engine devices, adsorption machines, etc., can solve the problems of ineffective use of environmental heat sources and low conversion rate, and achieve significant social and economic benefits and meet the needs of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

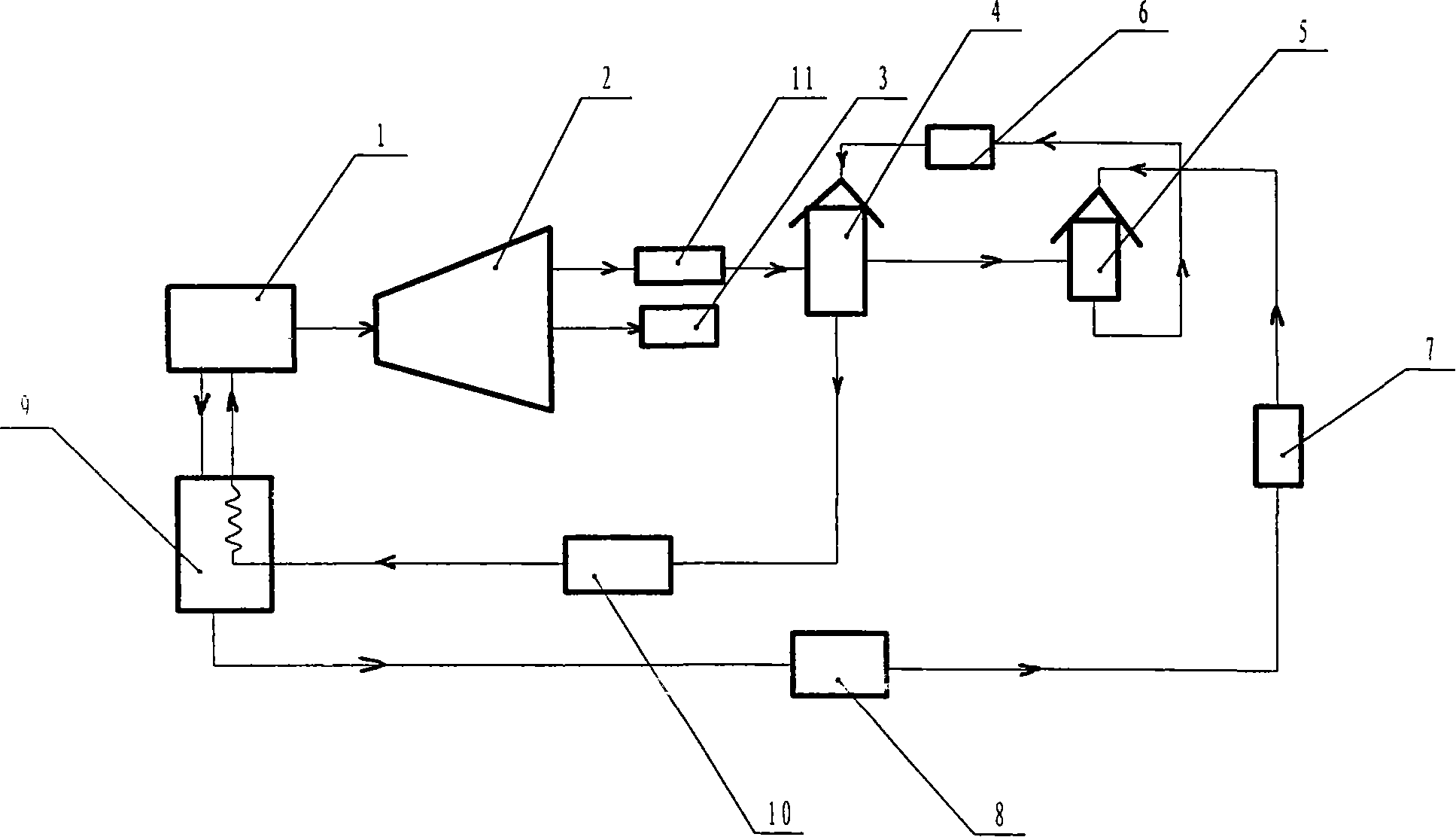

[0015] Embodiment 1: This example is an absorption-desorption device type, and now carbon dioxide and propylene carbonate are used as working fluids to describe the operation process.

[0016] Heat the 60-90°C driving heat source to heat the carbon dioxide-rich propylene carbonate absorption liquid in the desorber 1, desorb the carbon dioxide under a relatively high pressure (below 4MP), enter the steam turbine to expand and do work, and drive the generator I3 to generate electricity, and the carbon dioxide Exhausted gas enters the cold source heat exchanger 11 at low temperature (can be reduced to -45 to -60°C), absorbs ambient heat energy or outputs cold energy to the outside, makes carbon dioxide initially warm up and enters the absorption tower 4, and is absorbed by the second absorption tower 5 The semi-lean liquid is absorbed, and then enters the second collection tower to be fully absorbed by the lean liquid. After the rich absorption liquid is pressurized by the booster...

example 2

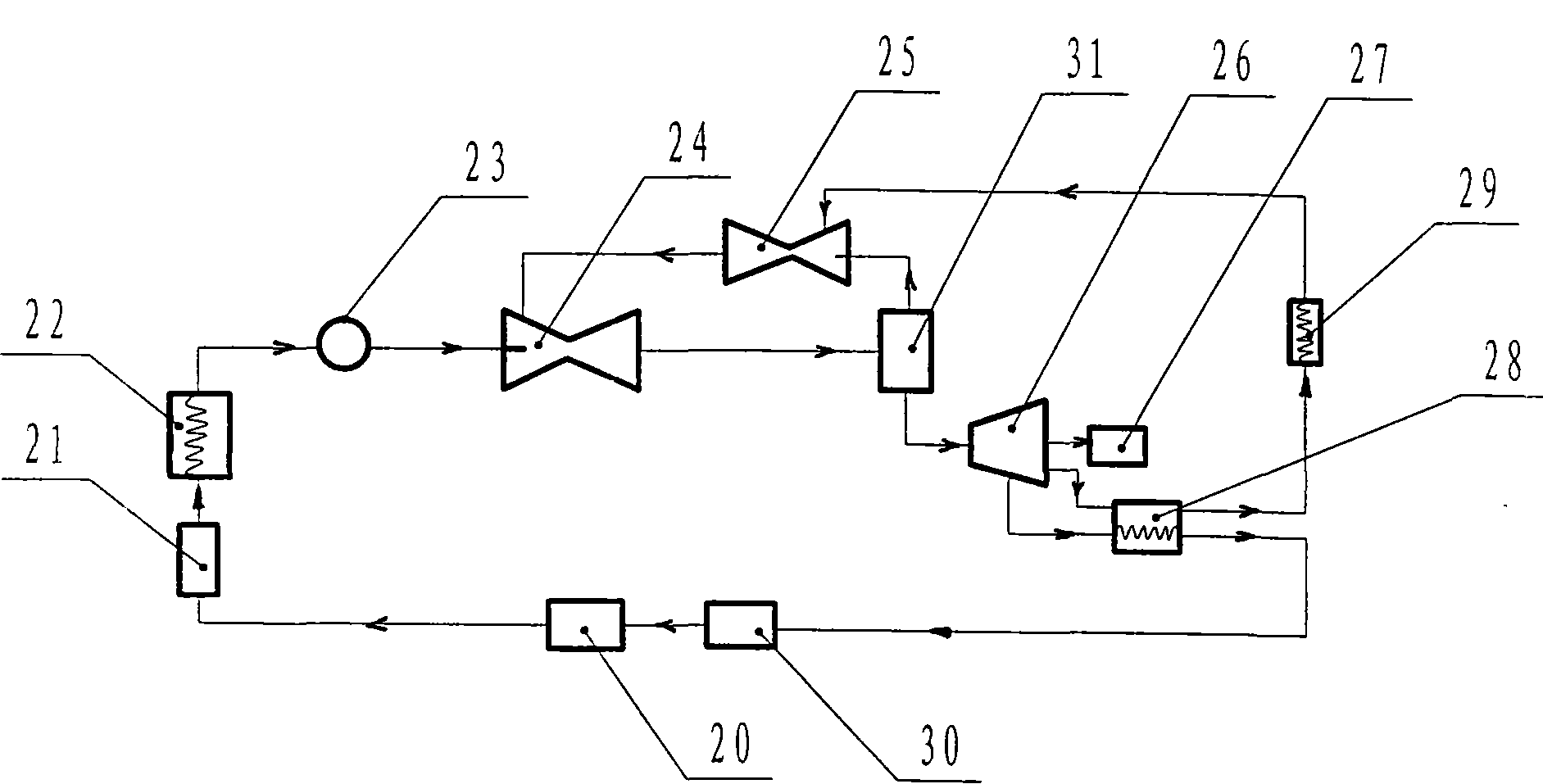

[0018] Example 2: This example is an injection-introduction type, in which 20 is a medium-pressure working medium storage tank, 21 is a high-pressure metering pump, and 22 is a heat exchanger that can distinguish between low and high temperature and has corresponding functions of vaporization and temperature increase and implements metering control , 23 is a supercritical high-pressure gas bag with a voltage stabilizing function. The combination of the above-mentioned devices is called a controllable supercritical device, which can freely determine and control the temperature and pressure of the working medium under supercritical conditions.

[0019] Taking perfluoroethane, which is excellent in power generation and refrigeration, as an example, its operation will be described.

[0020] The 25--45°C, 8-20MP perfluoroethane gas emitted by the controllable supercritical device enters the high-pressure injector 24, injects the low-medium pressure gas from the low-pressure injector...

Embodiment 3

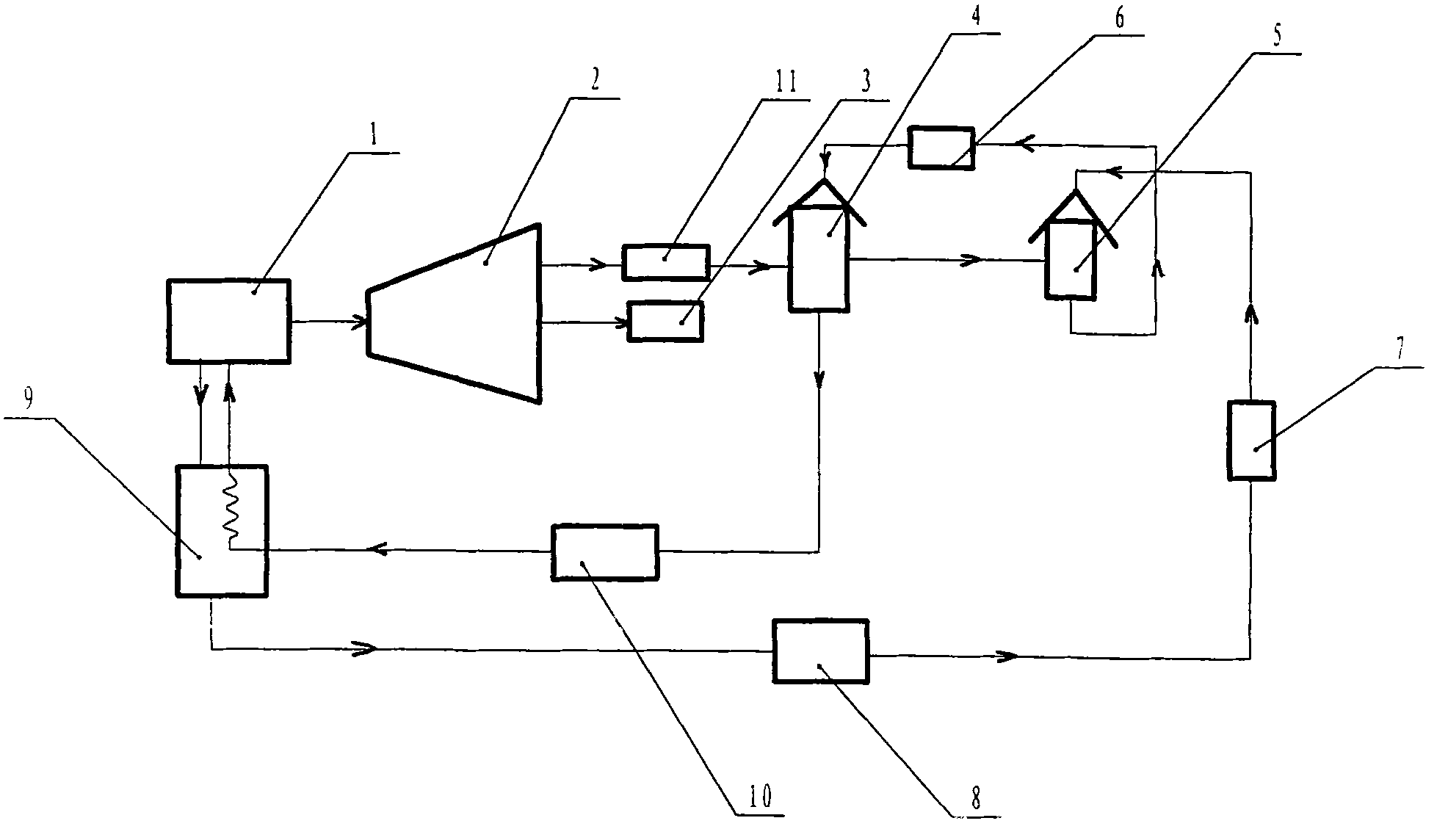

[0025] Embodiment 3: Combining the above two devices systematically can produce better effects, that is, the heat source at about 45°C in the heat exchanger II8 and heat exchanger III6 in Embodiment 1 is used as the driving heat source in Embodiment 2, Cool the semi-poor liquid from the heat exchanger III6 in Example 1 at an ultra-low temperature of about -50°C in the environmental heat absorber 29 in Example 2, so that the semi-poor absorption liquid has more absorption capacity at low temperatures, and the environment The heat absorber 29 is connected to the heat exchanger in the absorption tower 4, and the heat exchanger 22 is connected to the heat exchanger II8 and the high-temperature heat exchanger in the absorption tower 4 respectively, and the remaining links can be carried out with reference to Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com