Patents

Literature

584results about How to "Achieve self-sufficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

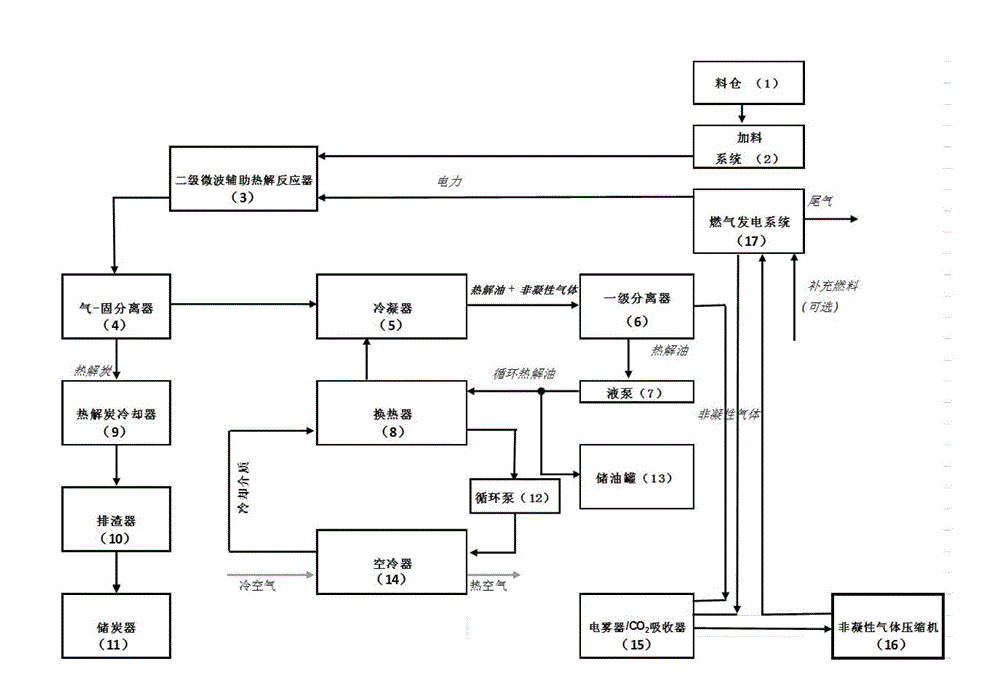

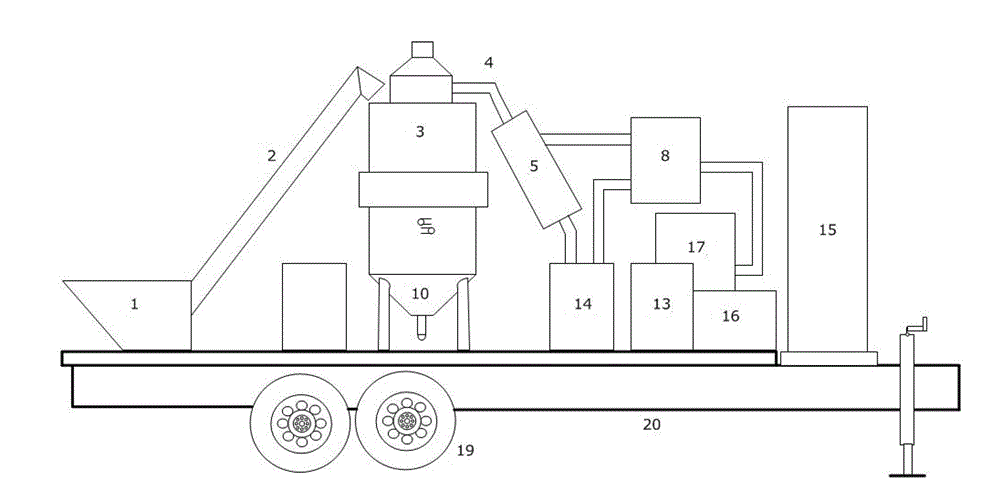

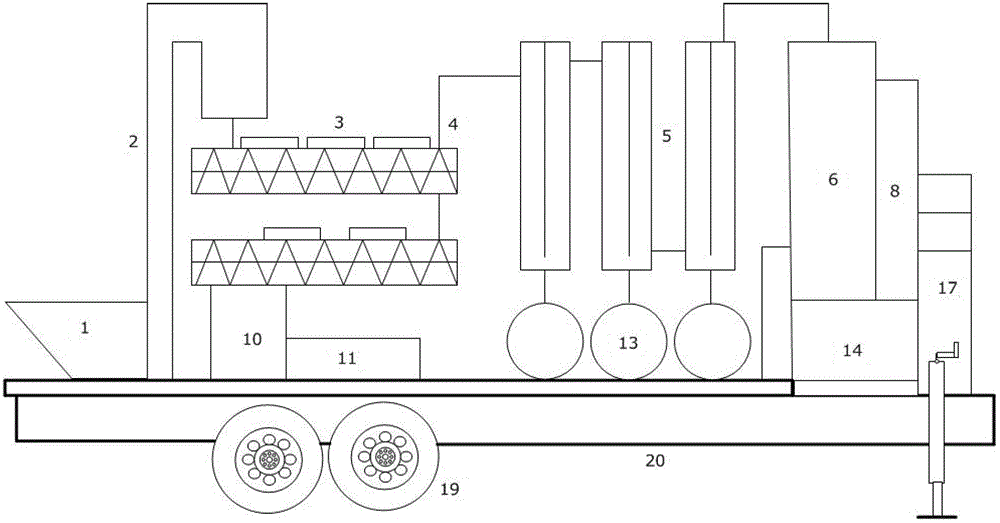

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

ActiveCN102718383ASolve the difficulty of large-scale collectionSolve the inconvenience of storage and transportationSludge treatment by pyrolysisByproduct vaporizationSlagChar

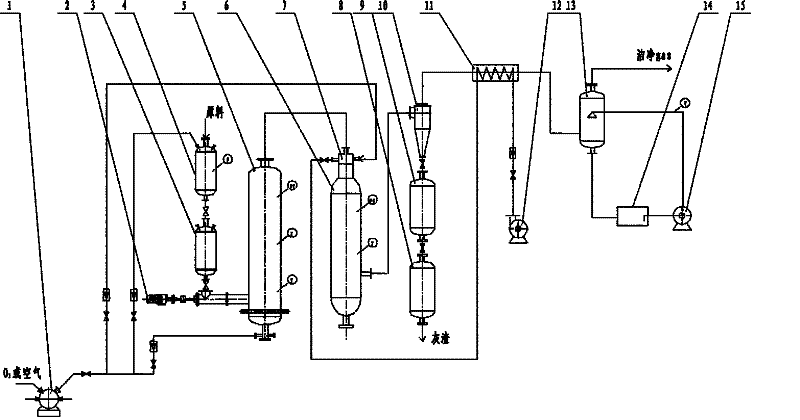

The invention discloses a pyrolysis device for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis. The device comprises a microwave-assisted pyrolysis reactor, a solid outlet of the reactor is connected with an inlet of a pyrolytic carbon cooler, an outlet of the pyrolytic carbon cooler is connected with a slag storer through a deslagging machine, a gas outlet of the reactor is connected with an inlet of a condenser through a pipeline, the condenser is provided with a gas-liquid separator, a gas outlet of the condenser is connected with a gas purifier, an outlet of the gas purifier is connected with a gas compressor, a liquid outlet of the condenser is connected with a liquid circulating pump, then one branch of the condenser is connected with an oil storage tank, and the other branch of the condenser is connected back to the condenser through a cooling medium circulating system. The invention further discloses a method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis. By the pyrolysis device and the method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis, various low-grade carbon-containing resources can be collected, stored and continuously produced at an economic scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

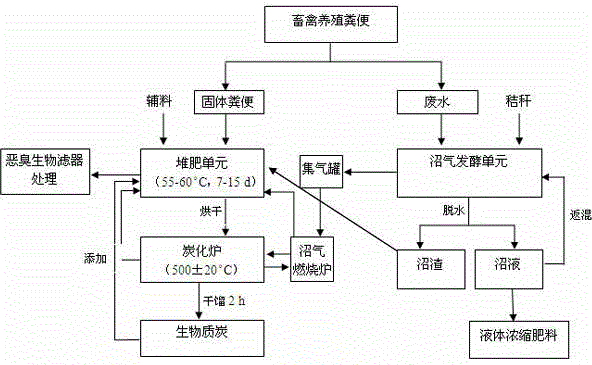

Resource utilization method of livestock and poultry breeding wastes

ActiveCN104150987AHigh calorific valueReduce moisture contentBio-organic fraction processingClimate change adaptationFecesResource utilization

The invention discloses a resource utilization method of livestock and poultry breeding wastes. The method comprises the following steps of carrying out solid-liquid separation on livestock and poultry breeding wastes to obtain solid manures and breeding wastewater, composting solid manures at a high temperature and carbonizing to prepare biomass carbon and carrying out biogas fermentation on the breeding wastewater and concentrating to obtain a liquid fertilizer. By adopting the method disclosed by the invention, livestock and poultry breeding wastes are subjected to optimal utilization in form of material and energy to obtain biomass carbon and the concentrated liquid fertilizer capable of being applied to the agricultural production and thus the resource utilization of wastes is achieved, and the recycling of resources can be realized inside a livestock and poultry breeding wastes treatment region to achieve the purposes of reducing energy consumption and pollutant emission.

Owner:ZHEJIANG UNIV

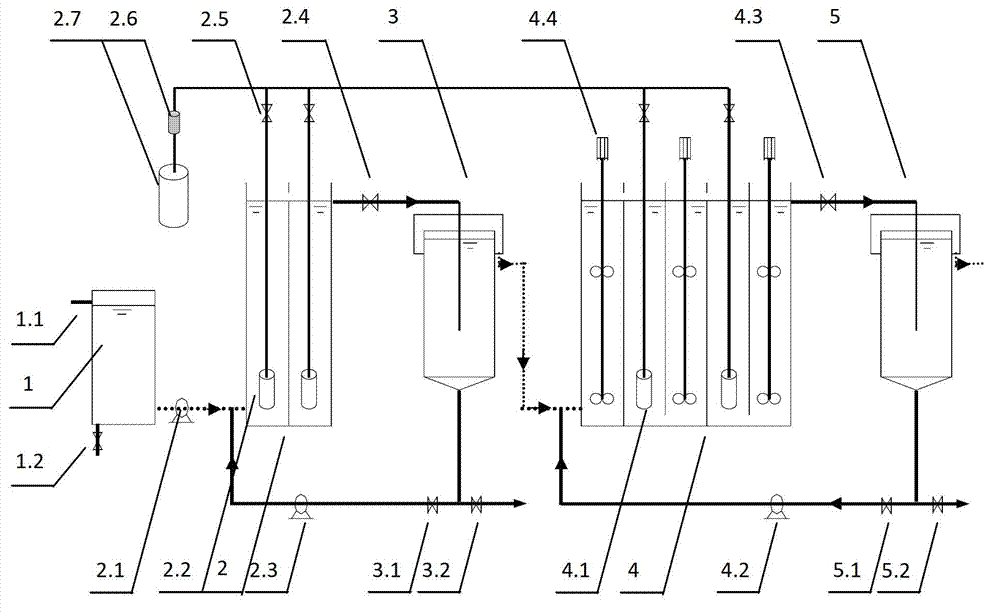

Continuous flow urban sewage partial nitrification and anaerobic ammonia oxidation denitrification method

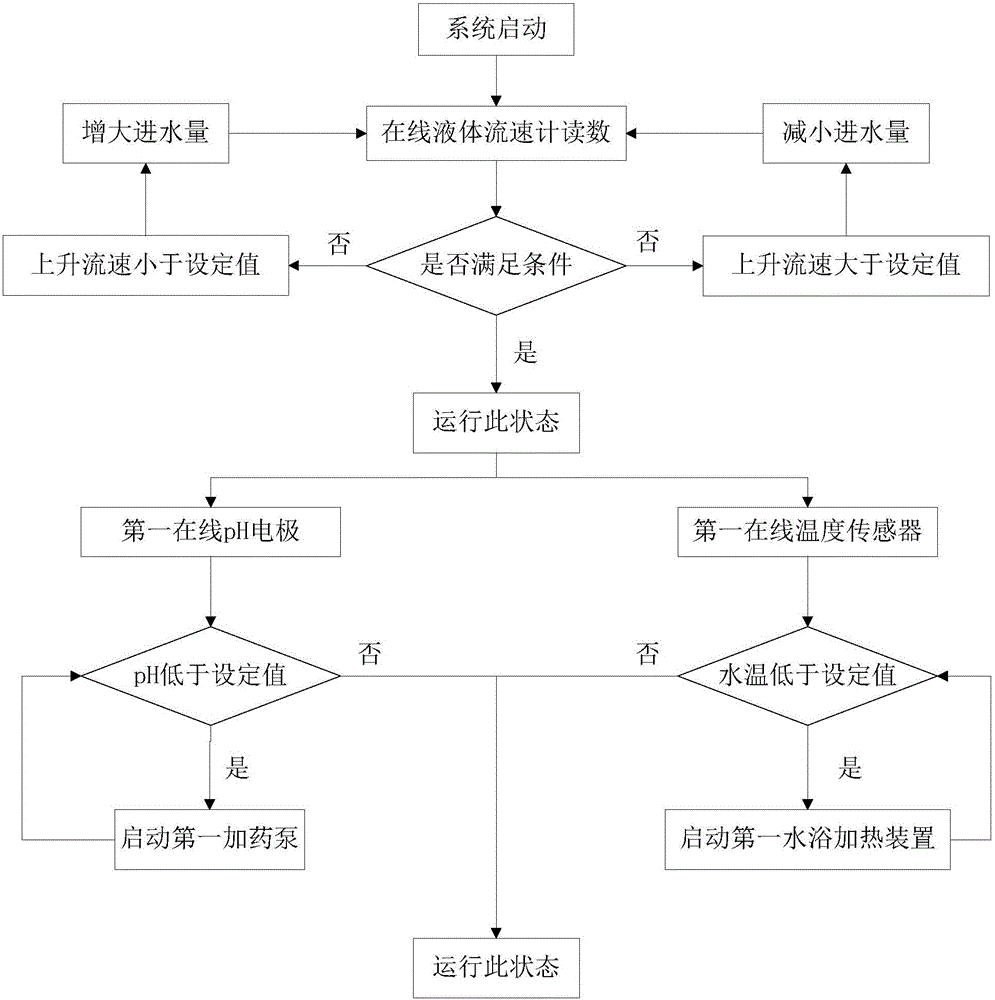

ActiveCN103086568AHigh recovery rateImprove realized recovery rateMultistage water/sewage treatmentActivated sludgeNitrate nitrogen

The invention discloses a continuous flow urban sewage partial nitrification and anaerobic ammonia oxidation denitrification method and belongs to the field of sewage. The method comprises the following steps of: allowing urban sewage to enter a biological adsorption reactor, adsorbing organic matters in water to activated sludge through the adsorption action of the activated sludge, and carrying out denitrification and anaerobic ammonia oxidation in an anoxic area of a partial nitrification anaerobic ammonia oxidation reactor to remove residual organic matters in water and nitrate nitrogen in return sludge; carrying out the partial nitrification in an aerobic area, and carrying out the anaerobic ammonia oxidation action in the anoxic area; repeating the actions in the aerobic area and the anoxic area; and finally, fulfilling the aim of removing nitrogen from the sludge.

Owner:上海立源生态工程有限公司

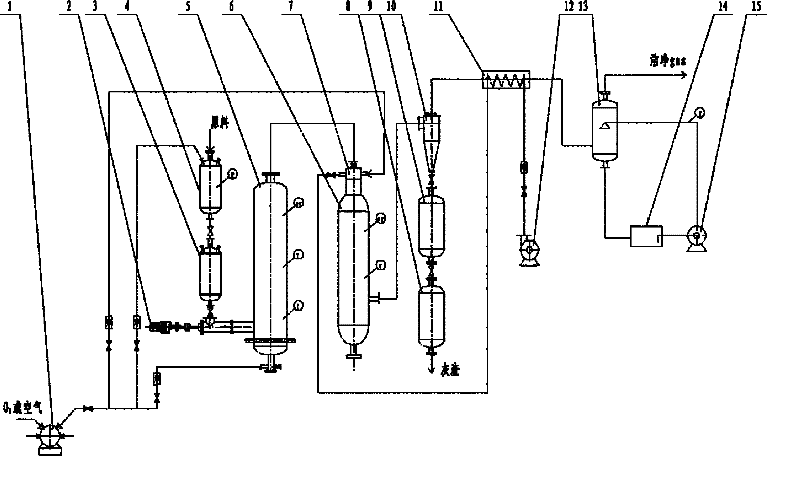

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

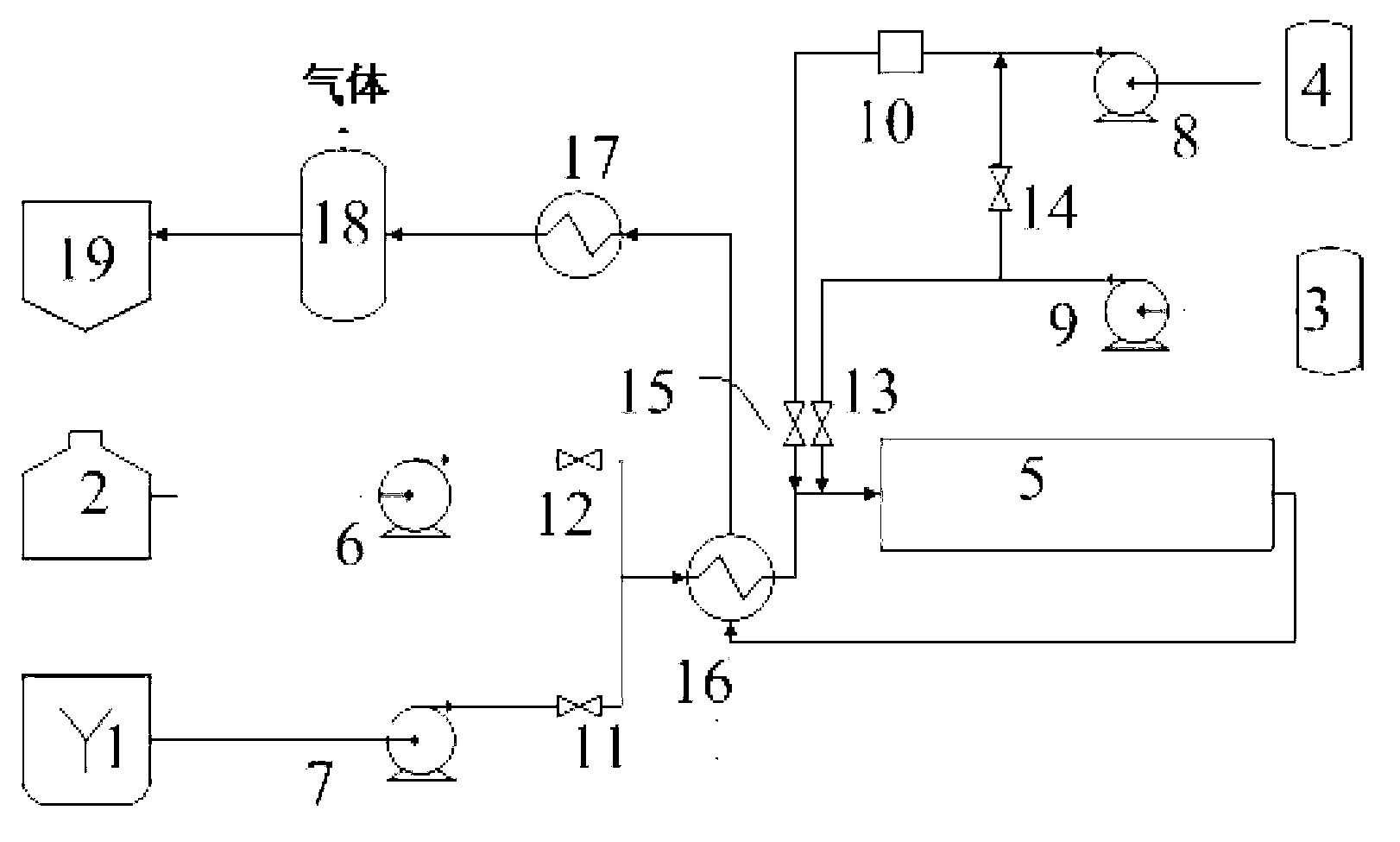

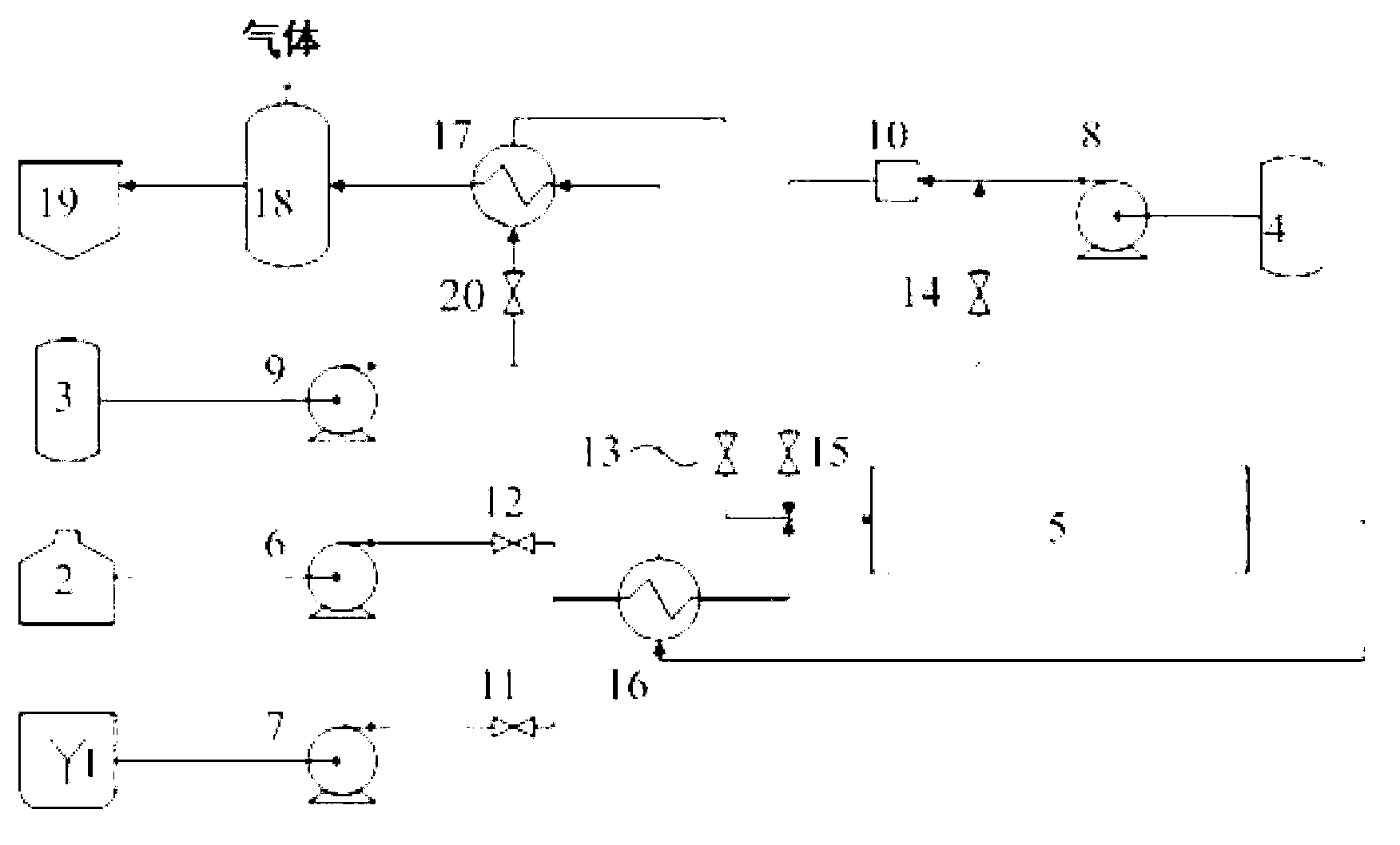

Method for treating carbon-containing organic matter by supercritical water oxidation

ActiveCN103073103AAchieve self-sufficiencyStart raw material without heatingWater/sewage treatment by oxidationDecompositionSupercritical water oxidation

The invention relates to a method for treating carbon-containing organic matter by supercritical water oxidation. The method comprises the step of obtaining oxidative decomposition product by oxidizing the carbon-containing organic matter in the supercritical state of water and under the effect of oxidant; heat released by the supercritical water oxidation treatment of the carbon-containing organic matter at least can satisfy the heat required by warming the carbon-containing organic matter to the supercritical state of the water, thereby energy is not required to be provided by the outside in the stable operation process, and the self-supply of reaction energy is completely achieved; and the cold start of the reaction is achieved by the cold start mode of low-temperature combustion catalysis.

Owner:ENN SCI & TECH DEV

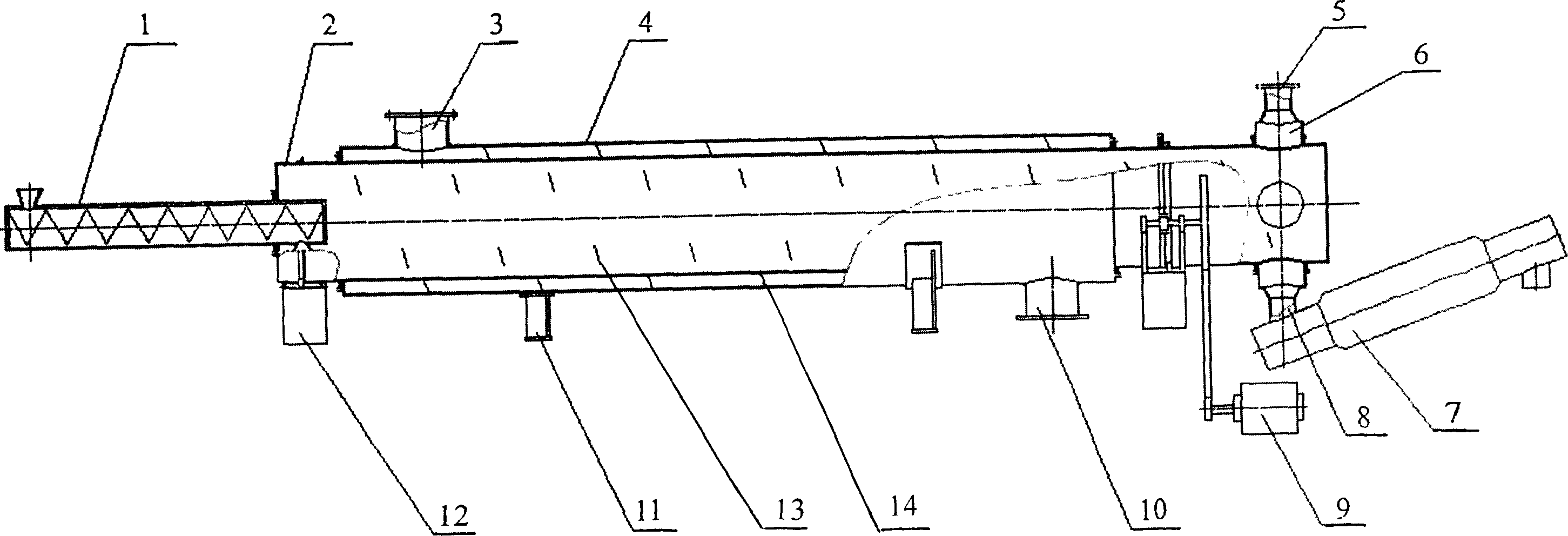

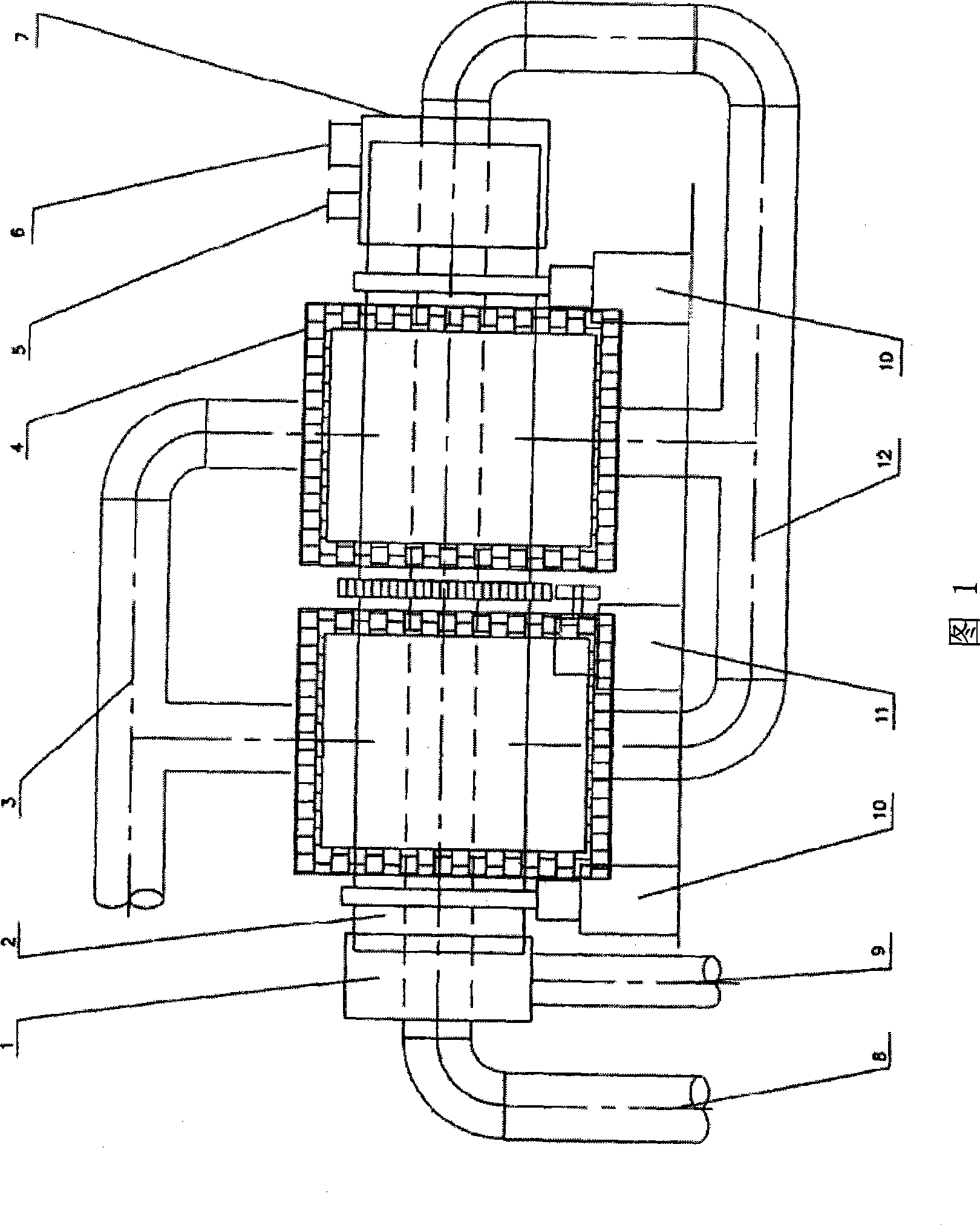

Horizontal type slew cylinder structure cracking furnace for waste steel wire blank continuous thermal cracking

InactiveCN1952045AAchieve self-sufficiencyThe cleavage reaction is fast and sufficientPigmenting treatmentLiquid hydrocarbon mixture productionEngineeringFlue

The invention disclosed a lying posture turnover cylinder cracking furnace which is used in the successive thermal cracking of a waste steel-wire tyre material. There's a below stack gas inlet and a top stack gas outlets on the outside tube of the cylinder; inside being positioned inner turning-over tube drived by transmission system; one side of the inner tube connects the tyre spiral feeder which can change the pitch, and the other side connects the static split product gathering trunk; on the top of the gathering trunk is the outlet of the gas hydrocracking product, while below the gathering trunk is outlet of the solid hydrocracking product, the gathering trunk also connects the spiral discharging device. The waste tyre material which is transferred by the spiral feeder is repeatedly grabbed by the grabbing plank located on the inner wall and pushed to the outlet. The high temperature stack gas counterflows in the passage between the outside and the inside tubes, during the process of the material's axial direction translation and circular direction rotation, the material absorbs the conducted calory from the tube wall to finish the splitting process. The gas product is pulped away by the blower while the solid product is discharged by the spiral discharging device through the bottom canal orifice.

Owner:ZHEJIANG UNIV

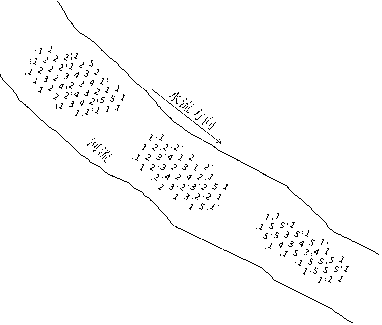

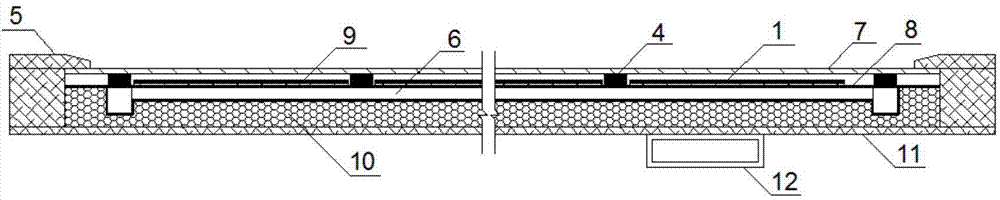

Multifunctional modularized floating island for in-situ restoration of polluted rivers and lakes

InactiveCN103058383AAchieve enhanced purificationSolve functionWater resource protectionEnergy based wastewater treatmentChemical oxygen demandWater quality

The invention relates to a multifunctional modularized floating island for in-situ restoration of polluted rivers and lakes. The floating island consists of five functional modules including a waterscape floating island module, a flexible filler floating island module, an aeration floating island module, a power supply floating island module and a functional floating island module. Each functional module is formed by floating beds in the same shape and size; different functional components are matched on the floating beds respectively so as to form the above functional modules. 2-5 different functional modules are selected in proportions according to the water quality difference and area load of the polluted river, and are optimally combined, thus various micro-environments are formed along the water flow direction, the self-cleaning ability of rivers and lakes are prompted, and the COD (chemical oxygen demand) and ammonia and nitrogen of the polluted water can all reach the V-type standard of surface water. With the adoption of the technology, the problems of single function, poor applicability and low water quality improving efficiency of the plant floating island structure in the prior art are solved, and the in-situ high-efficiency water quality improvement of water in polluted rivers and lakes is achieved.

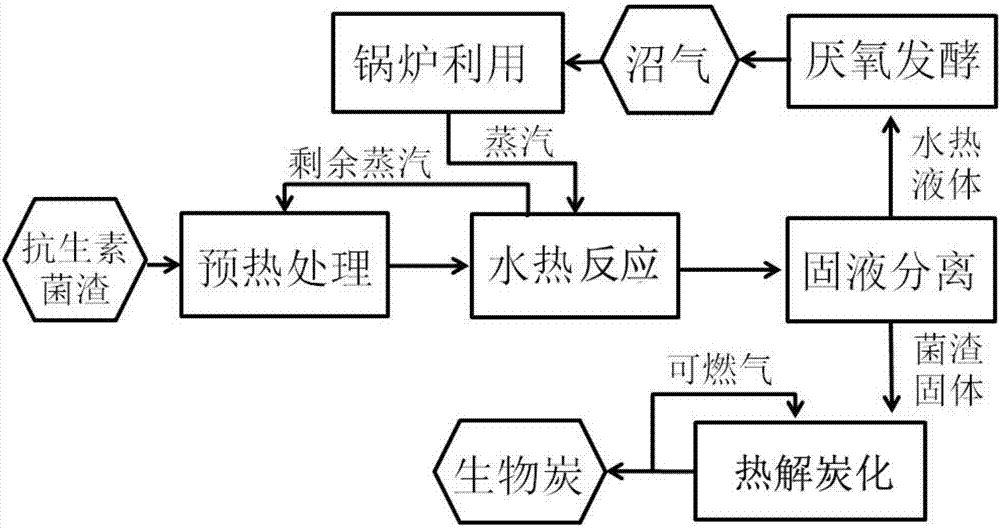

Method of preparing charcoal from antibiotic mushroom dregs

InactiveCN107365593APromote wall-breaking outflowImprove dehydration effectBiofuelsSpecial form destructive distillationCarbonizationCombustible gas

The invention discloses a method of preparing charcoal from antibiotic mushroom dregs. The method comprises the following steps: pre-heating treatment: feeding the antibiotic mushroom dregs into a pre-heating mixing tank for pre-heating treatment to obtain preheated mushroom dregs; hydrothermal reaction: feeding the pre-heated antibiotic mushroom dregs into a hydrothermal reaction kettle, introducing saturated steam into the hydrothermal reaction kettle to be directly contacted with the pre-heated antibiotic mushroom dregs to be heated for hydrothermal reaction, to obtain a hydrothermal mixture, and after discharging residual steam, feeding the mixture to the pre-heating mixing tank; solid-liquid separation: feeding the obtained hydrothermal mixture to mechanical dehydrating equipment for solid-liquid separation to obtain the mushroom dreg solids, the solid content rate of which is over 60% and a hydrothermal liquid; and pyrolysis carbonization: feeding the antibiotic mushroom dreg solids obtained by solid-liquid separation into a carbonization furnace for pyrolysis carbonization to obtain charcoal and combustible gas. According to the method disclosed by the invention, the high water content rate antibiotic mushroom dregs can be efficiently dehydrated, and meanwhile, byproducts in the mushroom dreg treatment process are utilized with high additional value, so that charcoal with high utilization value is output.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

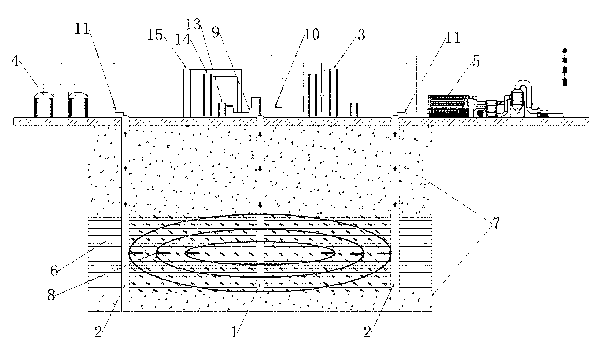

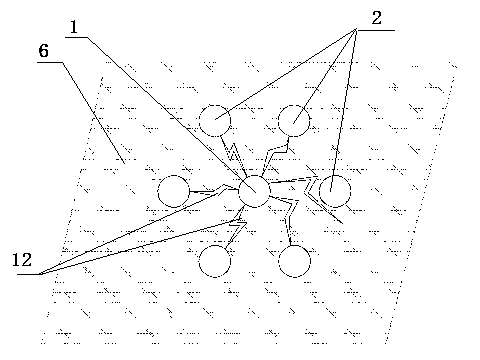

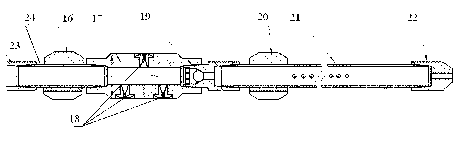

Method and process for extracting shale oil and gas by in-situ shaft fracturing chemical distillation of oil shale

ActiveCN103232852AAvoid pollutionPollution realizedFluid removalLiquid hydrocarbon mixture productionThermodynamicsDistillation

The invention provides a method and a process for extracting shale oil and gas by in-situ shaft fracturing chemical distillation of an oil shale. The method comprises the steps of drilling a shaft on an underground oil shale layer, injecting high-pressure medium (air, water and sand) into the oil shale layer; fracturing out a 1-3mm of crack on the oil shale layer by taking the shaft as a center; filling a crack support, and building an oil-gas channel; adding a heating device to the oil shale layer; heating the oil shale layer to 550 DEG C; initially distilling the oil shale, extracting the shale oil and gas, and leading the shale oil and gas out of the ground through the oil-gas channel; then leading in an oxidant to carry out oxidizing reaction on contained asphaltene and fixed carbon after the oil shale is distilled; and taking the generated heat energy as a heat source for subsequent distillation to achieve underground in-situ extraction of the shale oil. The world problems of large recovery cost, difficult tailings processing, a plurality of environmental protection problems and large land usage of ground dry distillation at present are solved.

Owner:JILIN ZHONGCHENG AUTOMOTIVE SERVICE CHAIN

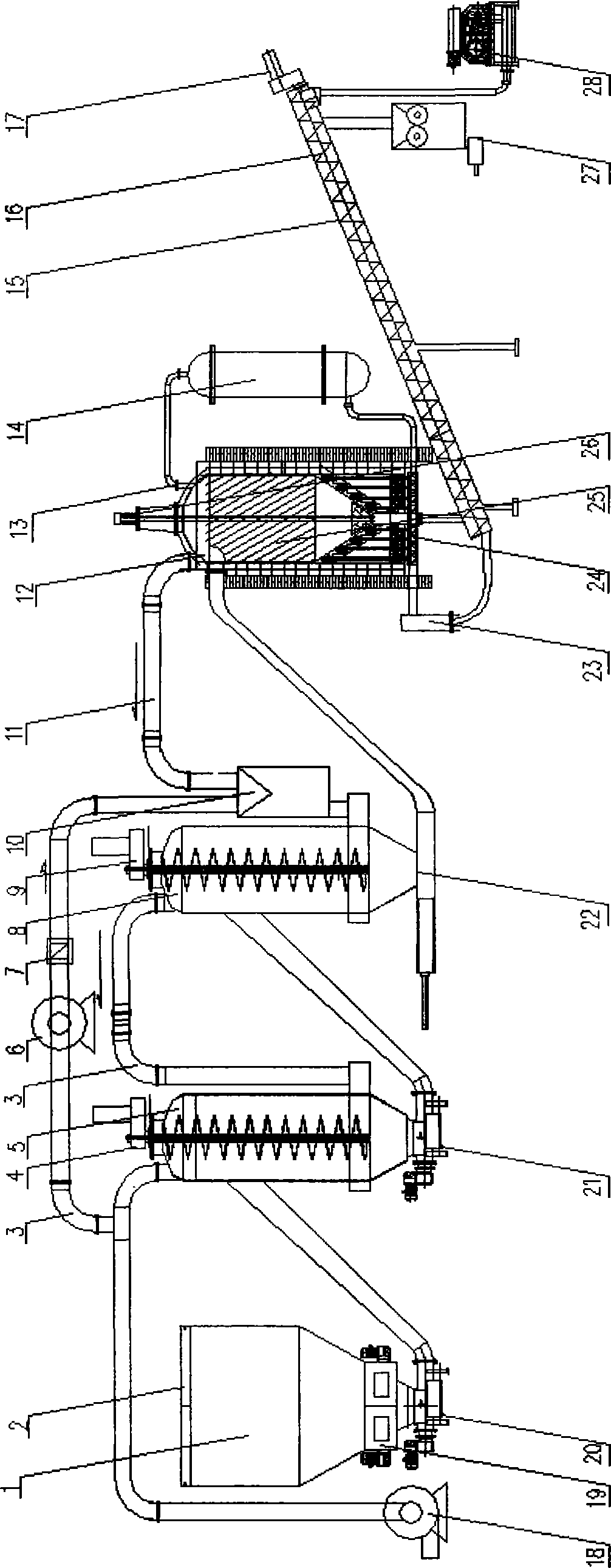

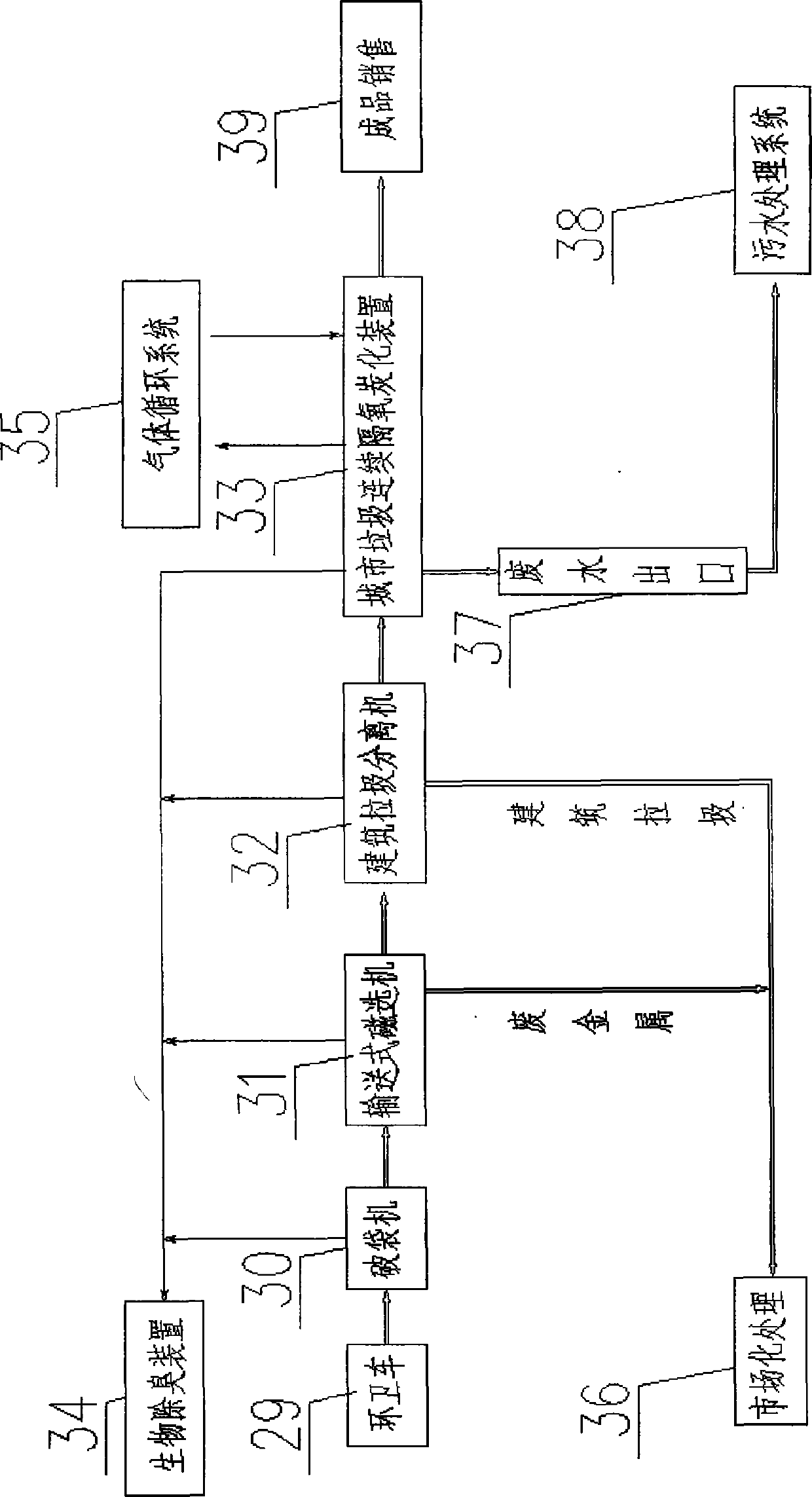

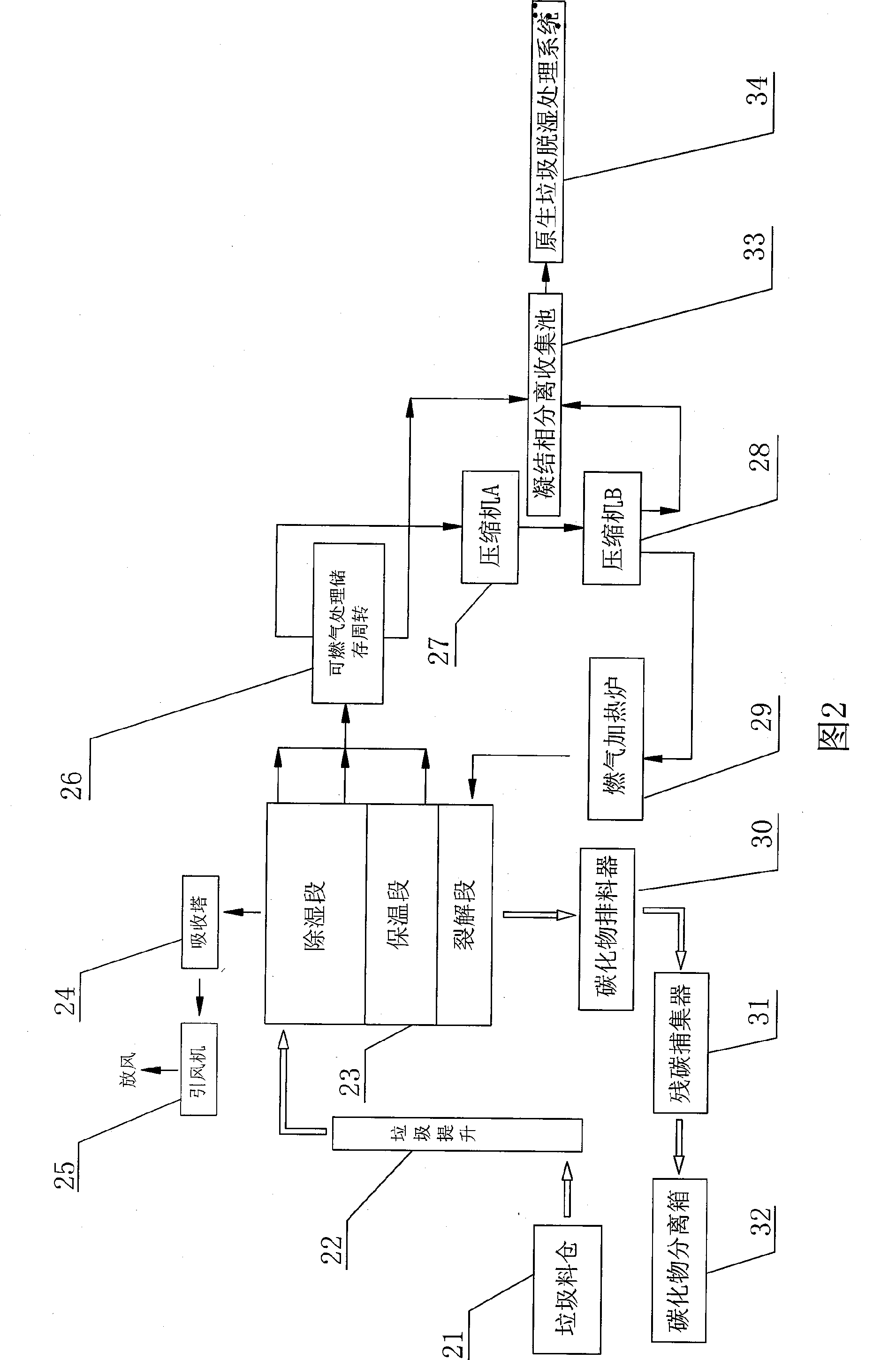

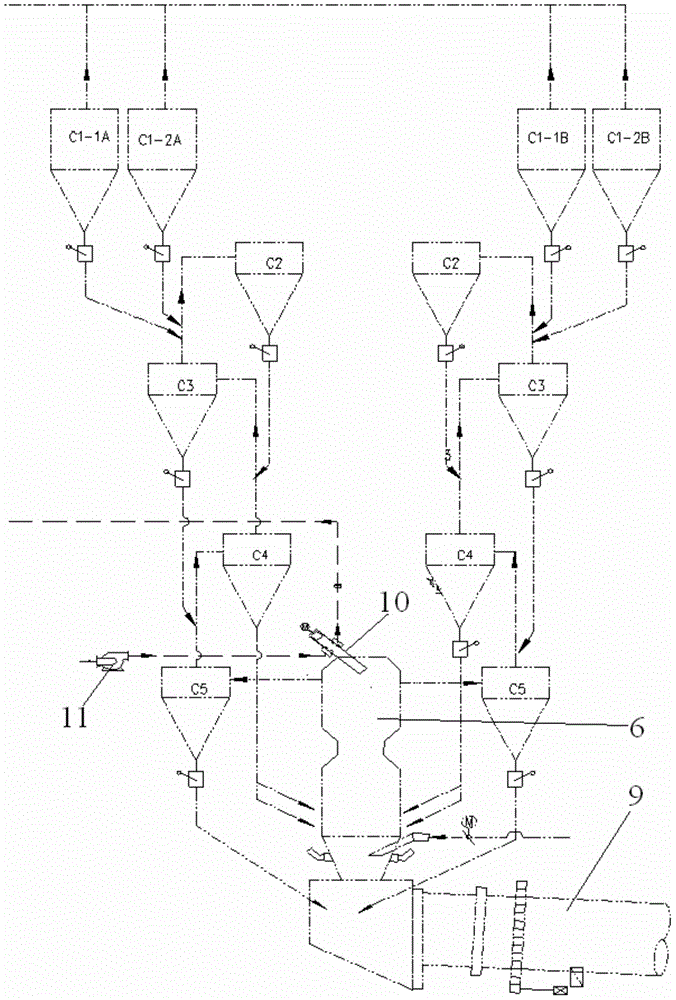

Continuous high-temperature oxygen-isolated carbonization process for treatment of municipal solid waste and apparatus used therein

ActiveCN103624060ASolve tough problemsAvoid it happening againConstruction waste recoverySolid waste disposalLitterCarbonization

The invention is a continuous carbonization process directed at municipal solid waste and an apparatus used therein. The process can mainly overcome problems occurred in treatment of municipal solid waste in the prior art, e.g., generation of oncogenic dioxin in burning of municipal solid waste. The process can realize pollution-free treatment of garbage. The invention has the following advantages: combustible gas produced in cracking and carbonization of municipal solid waste under high temperature and anaerobic conditions is used as an energy source for a system, thereby realizing self-sufficiency of energy; the anaerobic condition can well inhibit generation of dioxin; treating flow of the process is simple and stable, and long-time continuous treatment of municipal solid waste is realized; drying of municipal solid waste, deodorization of gas, circulation of heat and the like are realized.

Owner:宜兴市清泉水质处理设备有限公司

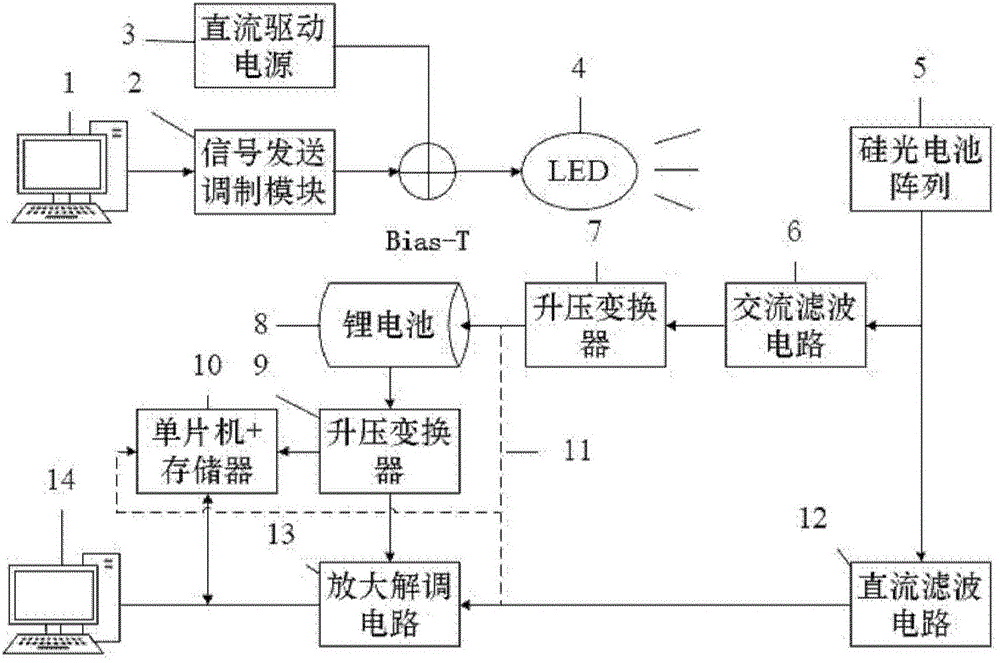

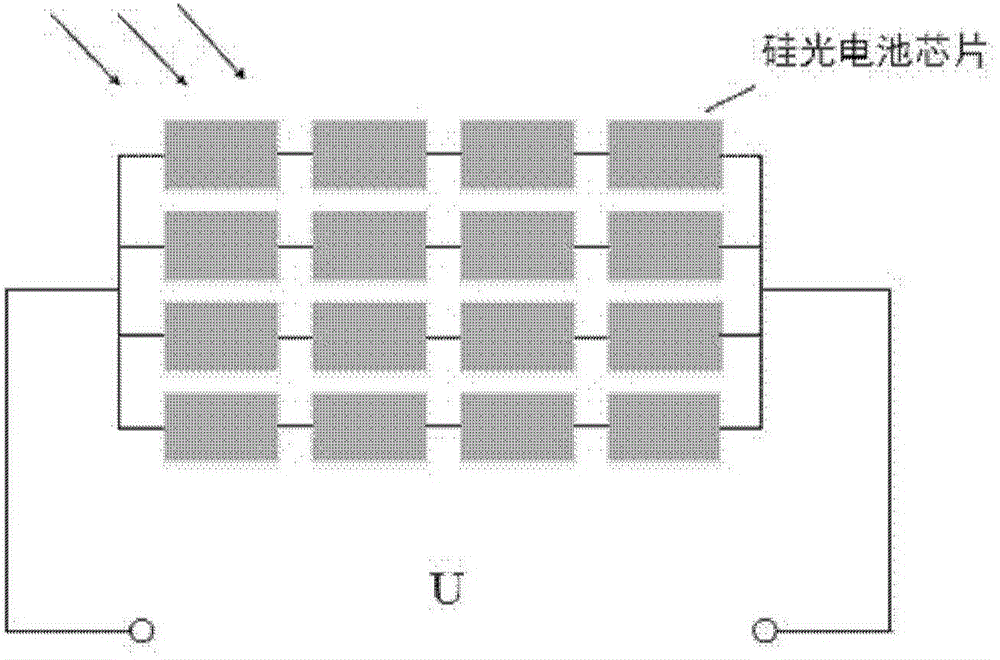

Energy-self-feeding visible light wireless communication system

InactiveCN104168062AAchieve energy self-sufficiencyRealize free mobile communicationPV power plantsEnergy storageData memoryLight source

The invention discloses an energy-self-feeding visible light wireless communication system. A computer sends signals to a signal sending modulation module which carries out modulation the signals and loads the signals to an LED direct-current driving power supply, so that the output current of the direct-current driving power supply comprises a direct-current component and a modulation current component. The direct-current component provides power for an LED light source. The modulation current component is correspondingly converted to changing of light intensity and is transmitted through free space. A silicon photocell array is used as a detector and receives light emitted by the LED light source, and light is converted into voltage. Silicon photocell array output voltage comprises a direct-current voltage component and an alternating voltage component. The direct-current voltage component provides power for a data storage and an amplifying demodulator circuit. The alternating voltage component carries out demodulation through the amplifying demodulator circuit, so that original signals are obtained in a restoring mode, and communication is completed. According to the energy-self-feeding visible light wireless communication system, an external power supply is of no need, light energy reusing and system self energy providing are achieved, and the practical application of visible light communication can be well achieved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for recycling surplus sludge hydrothermal carbonization solution

InactiveCN108558162AOvercoming the technical bottle diameter of low biological nitrogen removal efficiencyOvercoming the technical bottle diameter with low nitrogen removal efficiencyWater treatment compoundsSludge treatment by pyrolysisHigh concentrationChar

The invention provides a method for recycling a surplus sludge hydrothermal carbonization solution, which belongs to the technical field of environment engineering sludge treatment. The hydrothermal carbonization solution is appropriately circularly utilized in the hydrothermal carbonization process of the surplus sludge, so that while the yield of hydrothermal carbon is increased, the high-concentration hydrothermal carbonization solution which is easy to recycle is generated, nitrogen and phosphorus in the high-concentration hydrothermal carbonization solution are recycled through a struvitemethod, and a liquid phase part is used as a denitrification supplementary carbon source in the sewage biological denitrification. The method has the beneficial effects that the zero emission of thesurplus sludge in the sewage treatment can be realized, the technical bottleneck that the low-carbon-nitrogen-ratio waste water biological denitrification efficiency is low can be effectively overcome; and moreover, the hydrothermal carbon can be used as fuel for heating a hydrothermal carbonization reactor, so that the energy self-supply can be realized, and the application prospect in the aspectof recycling the surplus sludge in an urban sewage treatment factory is wide.

Owner:DALIAN UNIV OF TECH

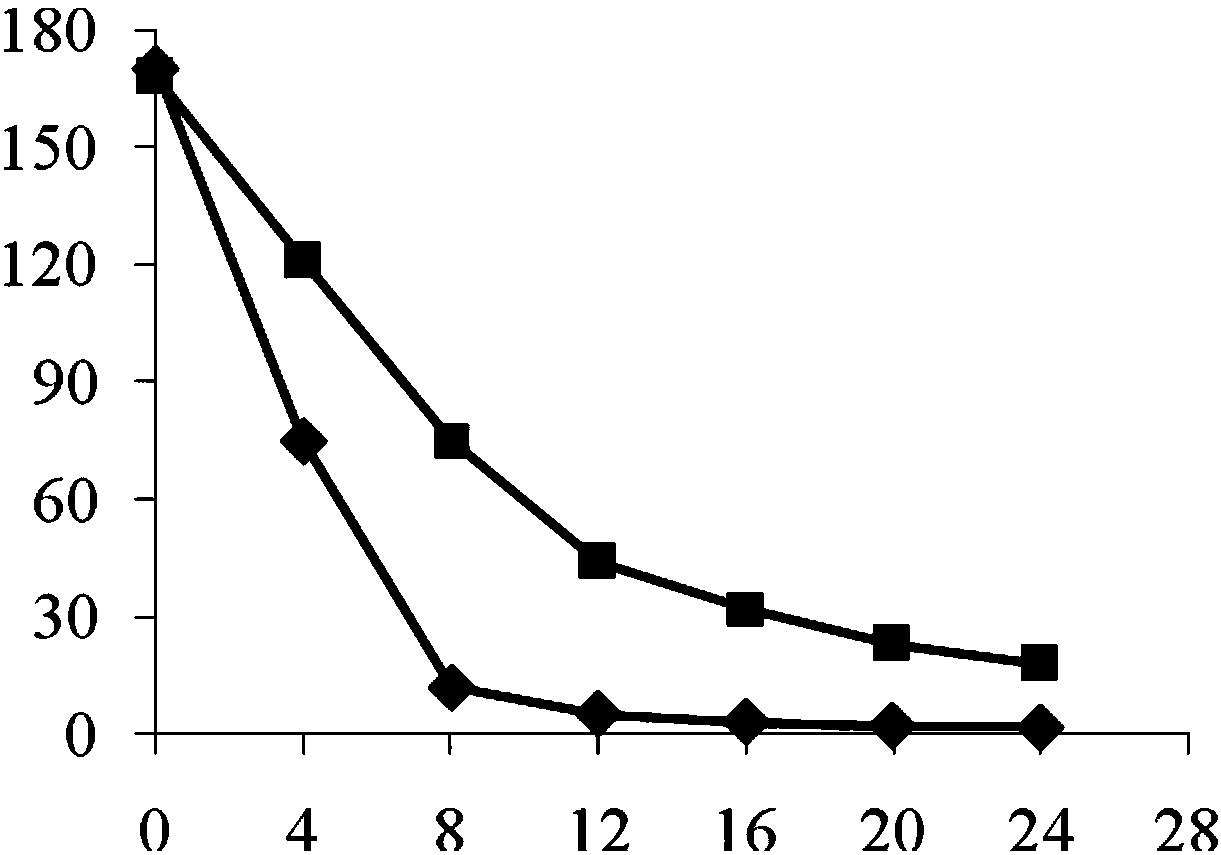

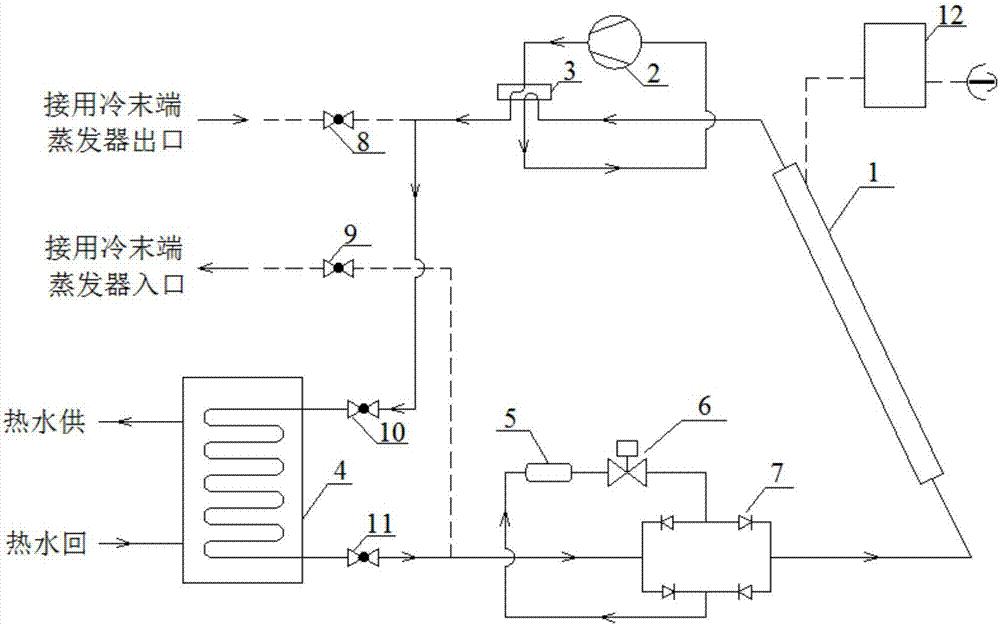

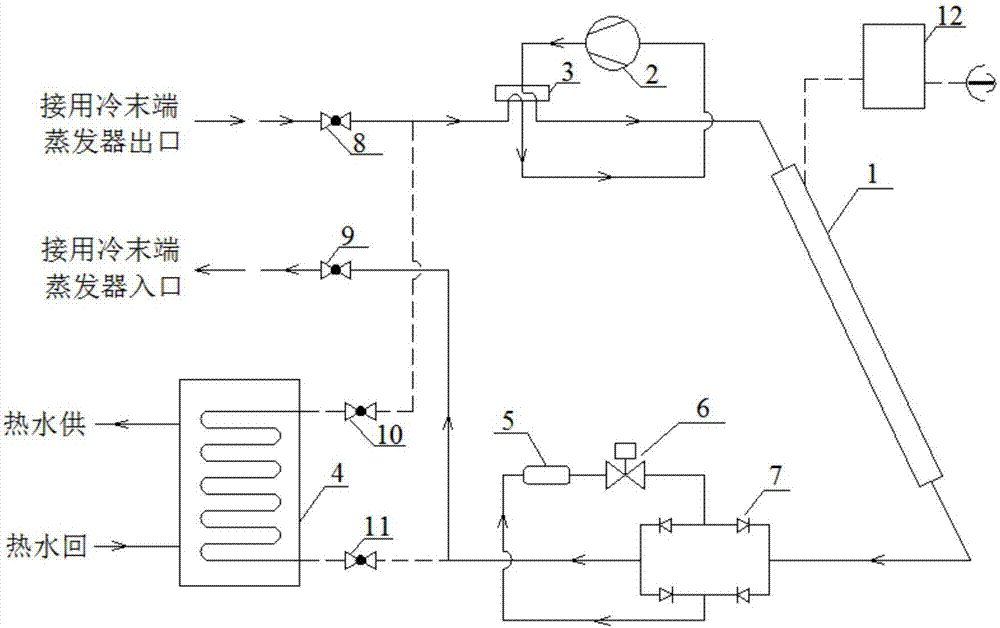

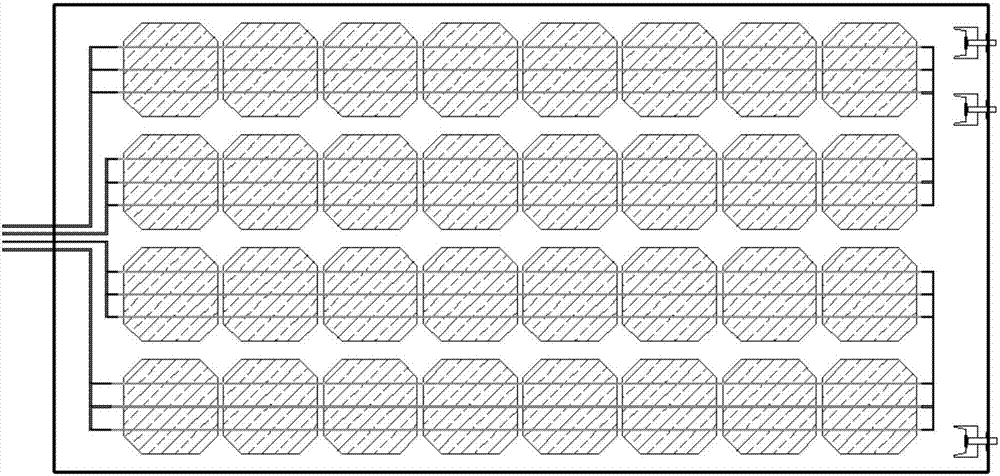

PVT heat pump system capable of achieving day and night time-division heat, power and cold supply through solar radiation and sky cold radiation

ActiveCN107401855ACombined heat and powerReduce power generation efficiencyPhotovoltaicsPhotovoltaic energy generationThermal energySky

The invention provides a PVT heat pump system capable of achieving day and night time-division heat, power and cold supply through solar radiation and sky cold radiation, and a photovoltaic power generation technology and a PVT heat pump technology which are relatively independent and mutually promoted in function are used simultaneously. Solar radiation energy and sky long-wave cold radiation energy are used as main energy resources of the system, and the energy is converted into electric energy, heat energy and cooling capacity through a PVT photoelectric-evaporation / condensation assembly in different modes at different times. The system integrates the various functions of power generation, heating, cooling and the like, equipment composition is simple, the equipment utilization rate is high, the energy saving effect is remarkable, the energy utilization rate is increased to the greatest extent, and the effects of achieving multiple purposes through the system and achieving day and night time-division heat, power and cold supply are achieved.

Owner:DALIAN UNIV OF TECH

No-oxygen pyrolysis gasification processing device of urban domestic garbage and technique thereof

The present invention discloses a city domestic rubbish anaerobic schizolysis gasification processing apparatus and technical skill thereof, wherein the apparatus is composed by a rubbish storage hopper, a converting kiln, a compressor, an organic matter converting kiln and a sewage disposal system etc. The technical skill includes no exogenous source low energy consumption dispose and system secondary pollution control technique etc. Technical problems like system oxygen exhaust technology, domestic rubbish dehumidifying technology, flowing technology of solid material inside the system, heating technology during the process etc. are solved through the invention. Harmlessness and zero discharge, energy self-supply and basic energy source and substance recirculation in the process of production, social low cost input and facilitating operation of rubbish treatment, and every saving, exhaust reducing and material cycle in natural world can be realized.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

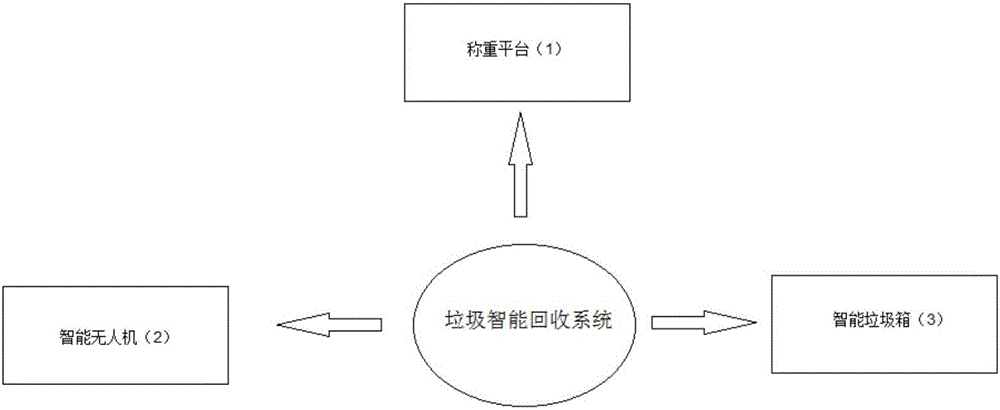

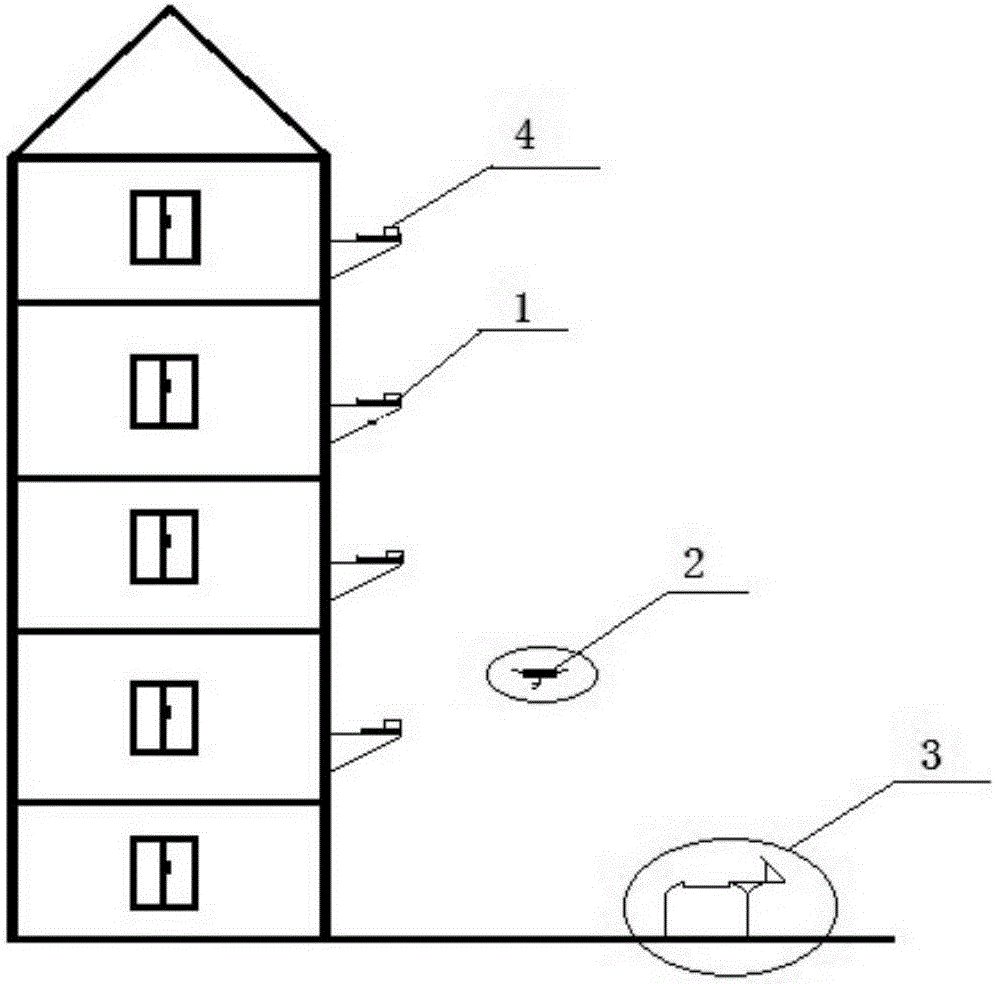

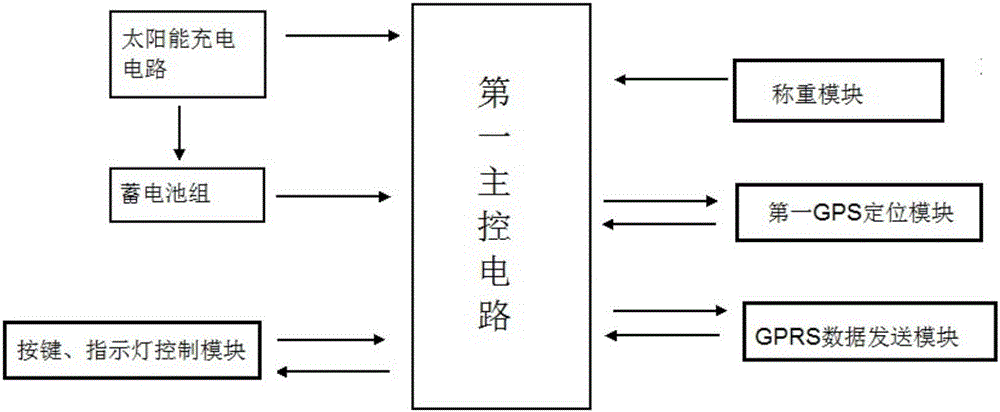

Intelligent community rubbish recovery system based on unmanned aerial vehicle and working method of intelligent community rubbish recovery system

ActiveCN106081426AEnvironmental AwarenessHigh precisionRefuse receptaclesRefuse cleaningRemote controlUncrewed vehicle

The invention discloses an intelligent community rubbish recovery system based on an unmanned aerial vehicle. The system comprises a weighing platform used for rubbish weighing, an intelligent unmanned aerial vehicle used for rubbish recovery, an intelligent rubbish can and a remote control device, wherein the intelligent rubbish weighing platform, the intelligent rubbish recovery unmanned aerial vehicle and the intelligent rubbish can are all connected through a wireless network to form the intelligent rubbish recovery system and are connected with the remote control device. The intelligent rubbish weighing platform is set by the aid of a user terminal, cooperates with the unmanned aerial vehicle and the intelligent rubbish can and cooperates with an altitude height sensor through a GPS positioning module, the intelligent community rubbish recovery system realizes route planning independently, rubbish from the user terminal is conveyed into the intelligent rubbish can through a manipulator, the rubbish treatment problem in a community is well solved, rubbish treatment is intelligent, the interest of a user in rubbish treatment is improved, and the environment-friendly awareness of the user is improved.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

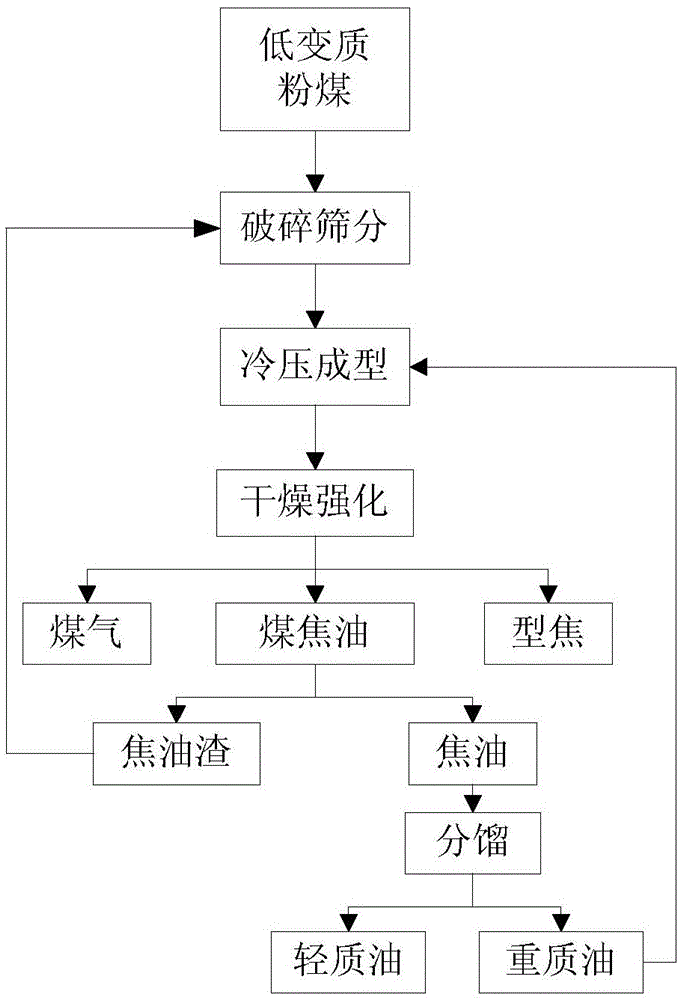

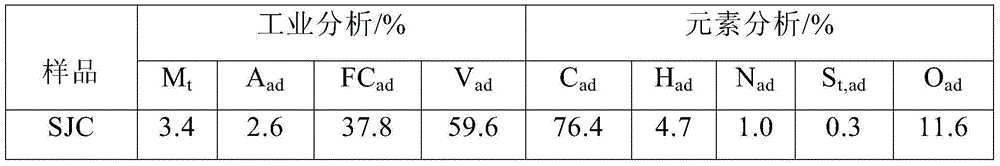

Method for preparing formed coke from low-metamorphic pulverized coal, heavy oil and tar residues as raw materials

InactiveCN104650937ASolve the problem of comprehensive utilization of resourcesSolve the key problems in the clean conversion processSpecial form destructive distillationCoking carbonaceous materialsHydrogenFractionation

The invention provides a method for preparing formed coke from low-metamorphic pulverized coal, heavy oil and tar residues as raw materials. The method comprises the following steps: firstly, grinding and sieving the low-metamorphic pulverized coal to obtain a raw material powder having a certain particle size, next, evenly mixing the low-metamorphic pulverized coal, the heavy oil and the tar residues together, performing pressure forming in a forming die, performing drying and strengthening treatment on the prepared briquette coal under a low temperature condition, and putting the treated briquette coal into a destructive distillation device for pyrolysis, thereby obtaining the formed coke, coal tar and gas, wherein the gas can be taken as a fuel gas or a chemical raw material gas; and the liquid oil is treated by fractionation to obtain a heavy oil and a light oil, the light oil is treated by hydrogenation for producing a fuel oil, and the heavy oil and the tar residues can be recycled to the briquette coal preparation process. The method is mainly applied to the medium-low temperature pyrolysis and upgrading and grading of the low-metamorphic pulverized coal, and is capable of recycling the tar and the hydrogen-enriched gas in the pulverized coal to the utmost extent while obtaining the formed coke product; and in short, the method has the characteristics of simple process, high production efficiency, high pyrolysis speed, good forked coke strength, good formed coke strength and high light oil yield.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

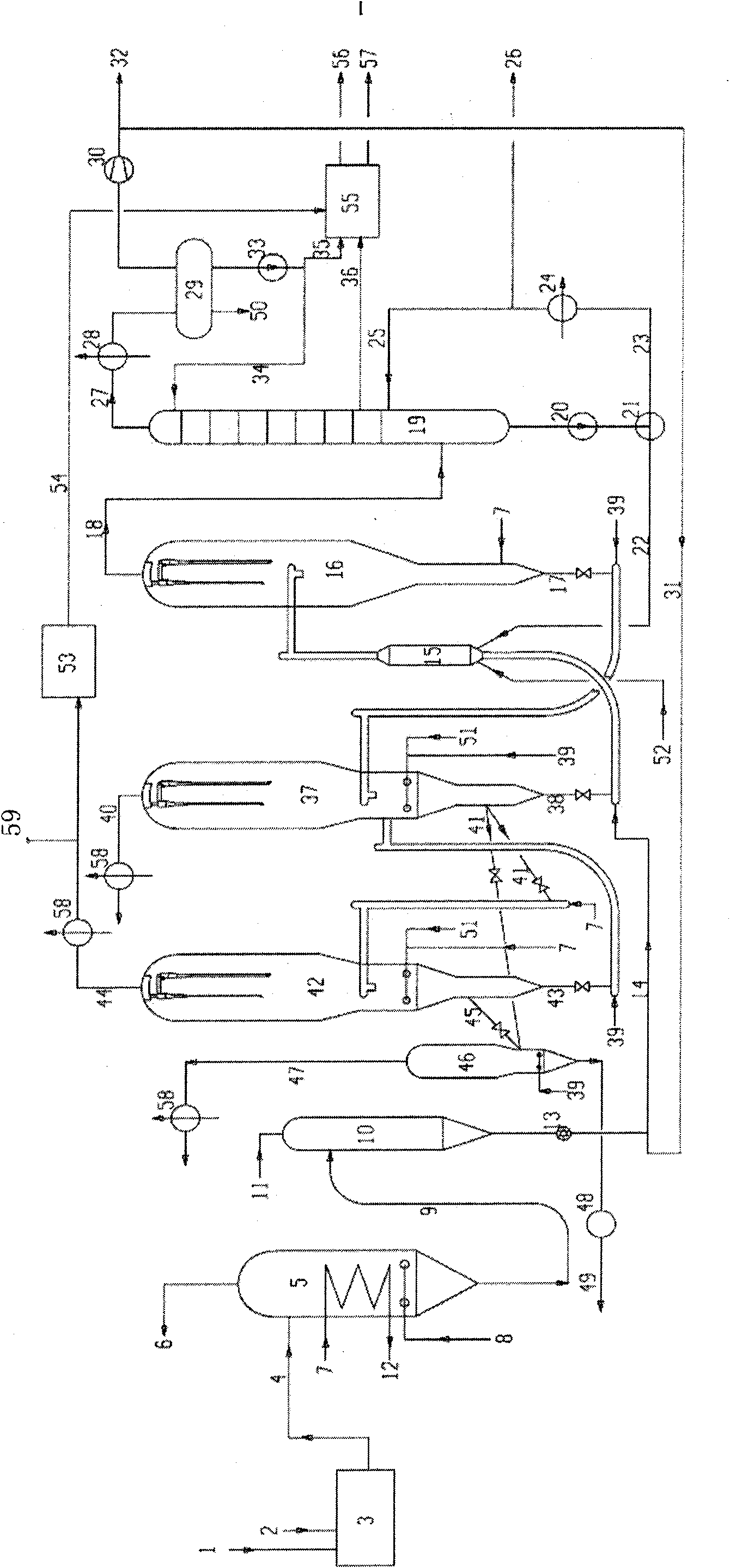

Technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification

InactiveCN102226107AImprove equipment production capacityHigh calorific valueProductsReagentsTarCoal tar

The invention relates to a technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification. Gasification in the technology is carried out in two stages, namely, primary gasification and high temperature gasification; biomass combustion gas, unreacted solids, tar and the like obtained in the primary gasification are directly delivered into a high temperature vapourizing furnace at high temperature and steam and air are also delivered into the vapourizing furnace so as to carry out high temperature gasification, thereby enhancing thermal efficiency, conversion rate of carbon and cracking rate of tar. In the process of the preparation, heat energy is self supplied, and heat is recovered to improve thermal efficiency; a thermal value of prepared synthetic gas can reach 7 to 8 MJ / m<3>. Equipment for realizing the technology comprises a biomass feed unit, gasification reactors, a dust collector, a heat reclaim unit, a washing unit, an air compressor, etc. The technology and equipment provided in the invention can be used to convert biomass raw materials like agricultural waste into synthetic gas with a high thermal value and low content of tar and are applicable to heat supply by biomass combustion gas, power generation by combustion gas or synthesis of liquid fuels.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

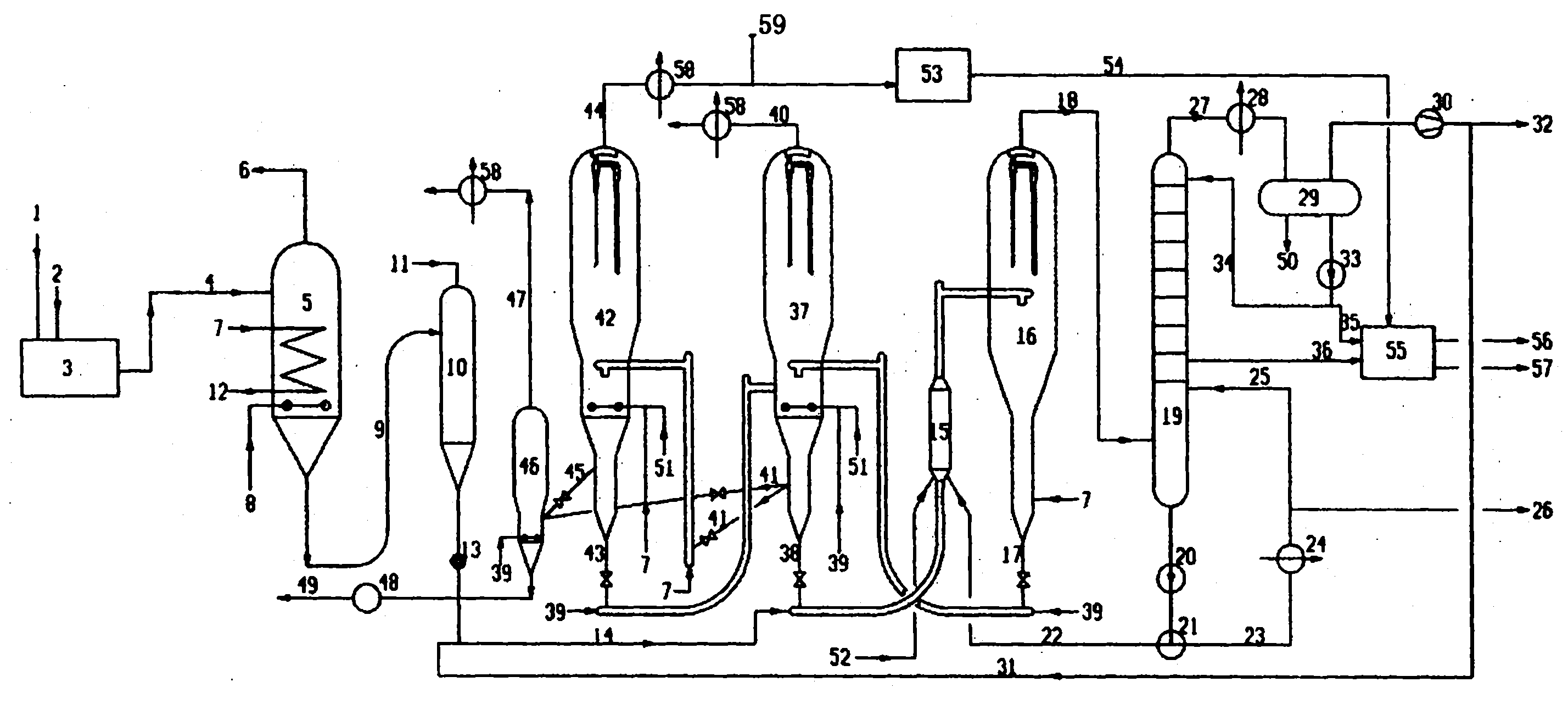

Comprehensive utilization method of oil shale

InactiveCN102031153AImprove light oil yieldSolve the problem of hydrogen sourceThermal non-catalytic crackingHydrogen separationSyngasHydrogenation process

The invention relates to the field of comprehensive utilization of oil shale, and provides a comprehensive utilization method of oil shale. Particularly, in the method, hydrogen production and oil hydrogenation processes of synthesis gas generated by oil shale dry distillation, dry distillation semicoke pre-charking, semicoke gasification after pre-charking, heavy oil recycle and gasification areorganically combined so as to obtain oil products from raw materials to the maximum extent, the oil products are hydrotreated to obtain high-quality clean oil products, the synthesis gas generated bygasification can be used as high-quality and cheap raw material for hydrogen production to provide a hydrogen source for oil product hydrogenation, and oil shale ash products obtained by cooling after gasification and complementary calcination are used as high-quality building materials. The invention provides a comprehensive utilization cleaner production process which can convert raw materials into high-quality products to the maximum extent and can fully utilize semicoke resources and rich production energy.

Owner:WISON ENG

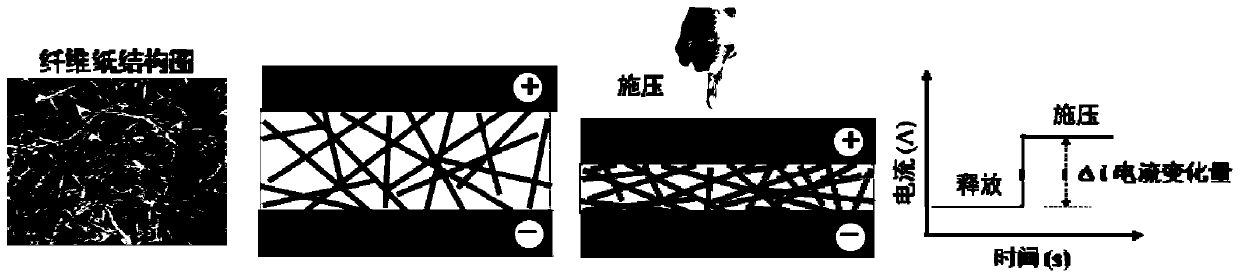

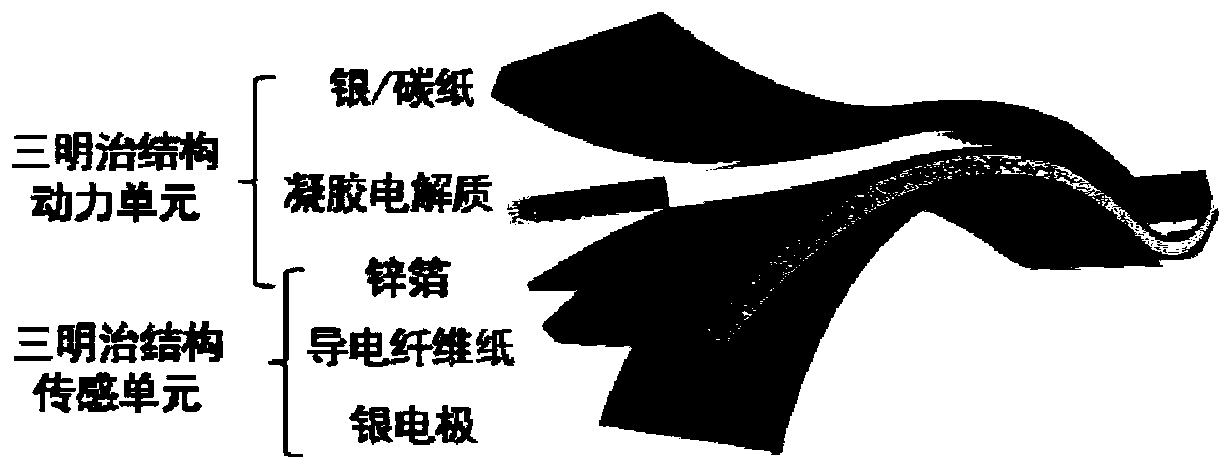

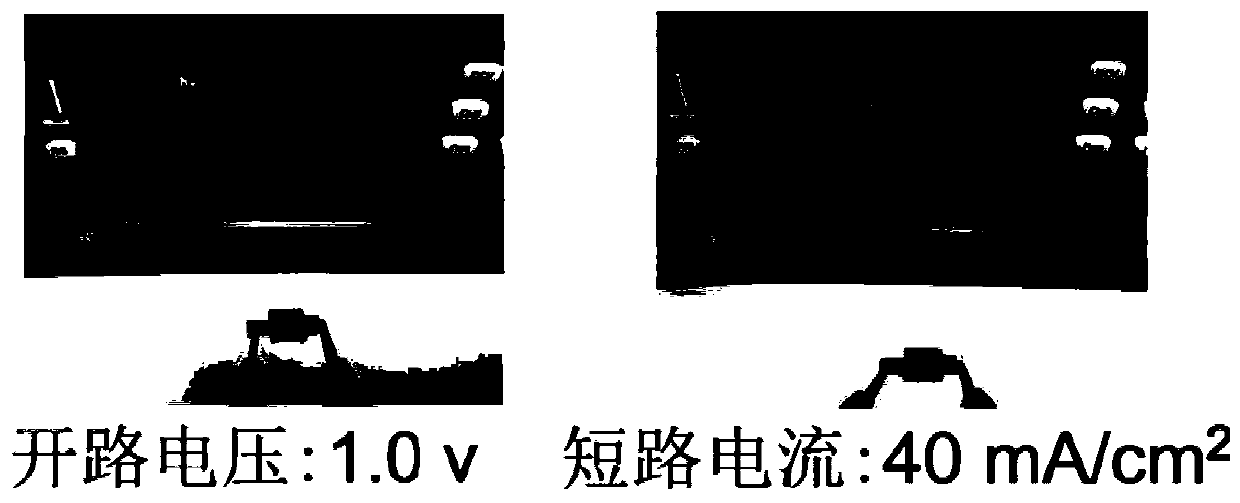

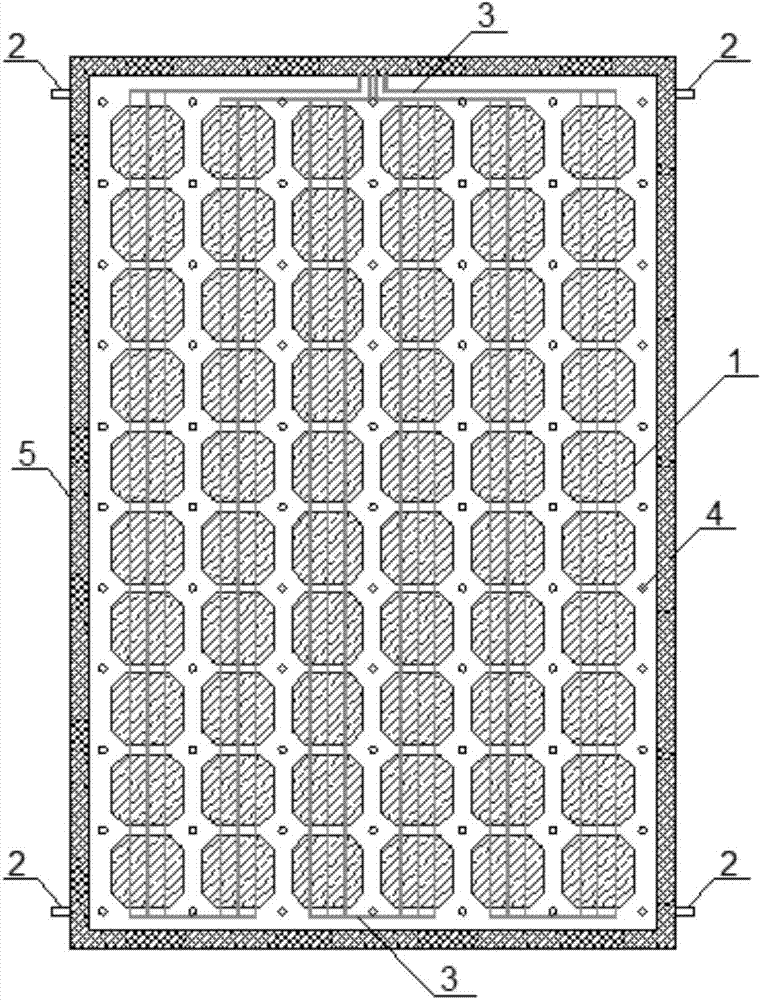

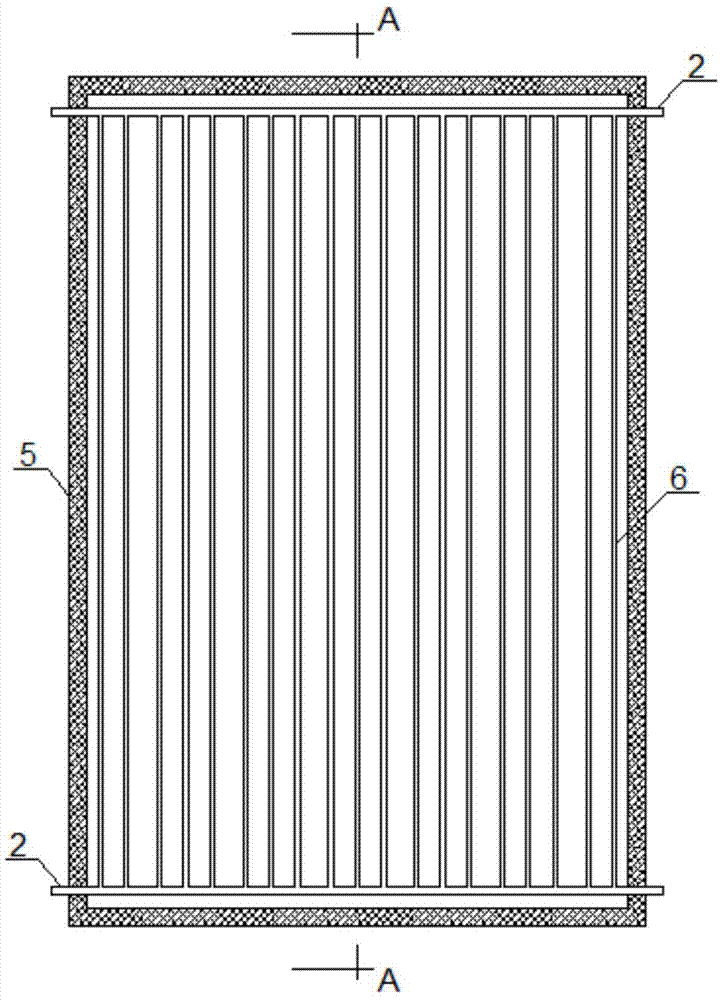

Integrated active power supply flexible pressure sensor

ActiveCN109974907ARealize integrated designPower optimizationFuel and primary cellsForce measurementFiberPhysical health

The invention provides an integrated active power supply flexible pressure sensor. The sensor comprises a sensing unit of a sandwich structure and a power unit which is arranged with the sensing unitin a cascading mode and is used for providing power for the sensing unit. The power unit is a zinc-air cell of the sandwich structure, and comprises an anode, a cathode and a gel electrolyte, whereinthe anode and the cathode are oppositely arranged, and the gel electrolyte is arranged between the cathode and the anode. The anode is a flexible zinc-containing electrode, and the cathode is a flexible air electrode. The sensing unit comprises a negative electrode, a positive electrode and conductive fiber paper or conductive woven cloth, wherein the negative electrode and the positive electrodeare arranged oppositely, and the conductive fiber paper or the conductive woven cloth are arranged between the positive electrode and the negative electrode. The sensing unit takes the flexible zinc-containing electrode of the power unit as the negative electrode. The integrated active power supply flexible pressure sensor realizes an integrated design of the power unit and the sensing unit, and can be applied to practical applications such as human physical health monitoring and the like.

Owner:TACSENSE SHENZHEN

Solar energy thermoelectricity co-generation and co-supply system

InactiveCN104748407AImprove utilization efficiencySolve the problem of using a single formSolar heating energySolar heat devicesThermal energyGlass cover

The invention discloses a solar energy thermoelectricity co-generation and co-supply system. The solar energy thermoelectricity co-generation and co-supply system is mainly composed of a water system and an electrical power system, which are relatively independent. The main component of the solar energy thermoelectricity co-generation and co-supply system is a solar energy thermoelectricity co-generation component. The structural materials of the component comprise a glass cover plate layer, an air insulation layer, a photovoltaic cell sheet, an EVA adhesive film, a metal absorber plate, a heat exchange tube liquid flow channel, an insulating layer and a packaging base plate from top to bottom. A silica gel spacer supports between the metal absorber plate and the glass cover plate to form the air insulation layer; a high-selectivity heat absorbing coating is sprayed on the metal absorber plate to improve the absorbing efficiency for sunlight. Under the shining of the sunlight, the outermost layer cell sheet uses a photovoltaic effect to transform light energy into electric energy and output to supply power to the outside; longitudinal heat exchange tubes in the metal absorber plate on the lower layer collect energy of the sunlight as solar energy heat collecting tubes and heat generated by the cell sheet heating and transforms the heat into heat of cycle fluid to output, therefore, the energy utilization efficiency is improved to the most extent, and the thermoelectricity co-generation is achieved.

Owner:DALIAN UNIV OF TECH

Heat energy recovery method for supercritical water oxidizing system

ActiveCN105152248AAchieve enrichmentRealized benefitsWater/sewage treatment by heatingWater heatersRecovery methodThermal energy

The invention relates to the technical field of energy and environments, in particular to a heat recovery method for a low-temperature multi-effect distillation united supercritical water oxidizing system. Supercritical water oxidizing reaction heat is recovered by three stages of heat recovery systems, wherein the heat of the first-stage recovery system is recovered to preheat condensed wastewater drained from a low-temperature multi-effect distiller and upper-branch evaporable water; the second-stage recovery system recovers the remaining heat recovered by the first-stage recovery system, and the heat is used for heating heat source water; the third-stage recovery system is used for recovering the remaining heat recovered by the second-stage recovery system and recovering heat generated at the bottom of the low-temperature multi-effect distiller, and the heat is used for heating cooling water. Through step-by-step heat recovery, the recovered heat is utilized stepwise, and the energy consumption of the system is greatly reduced.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

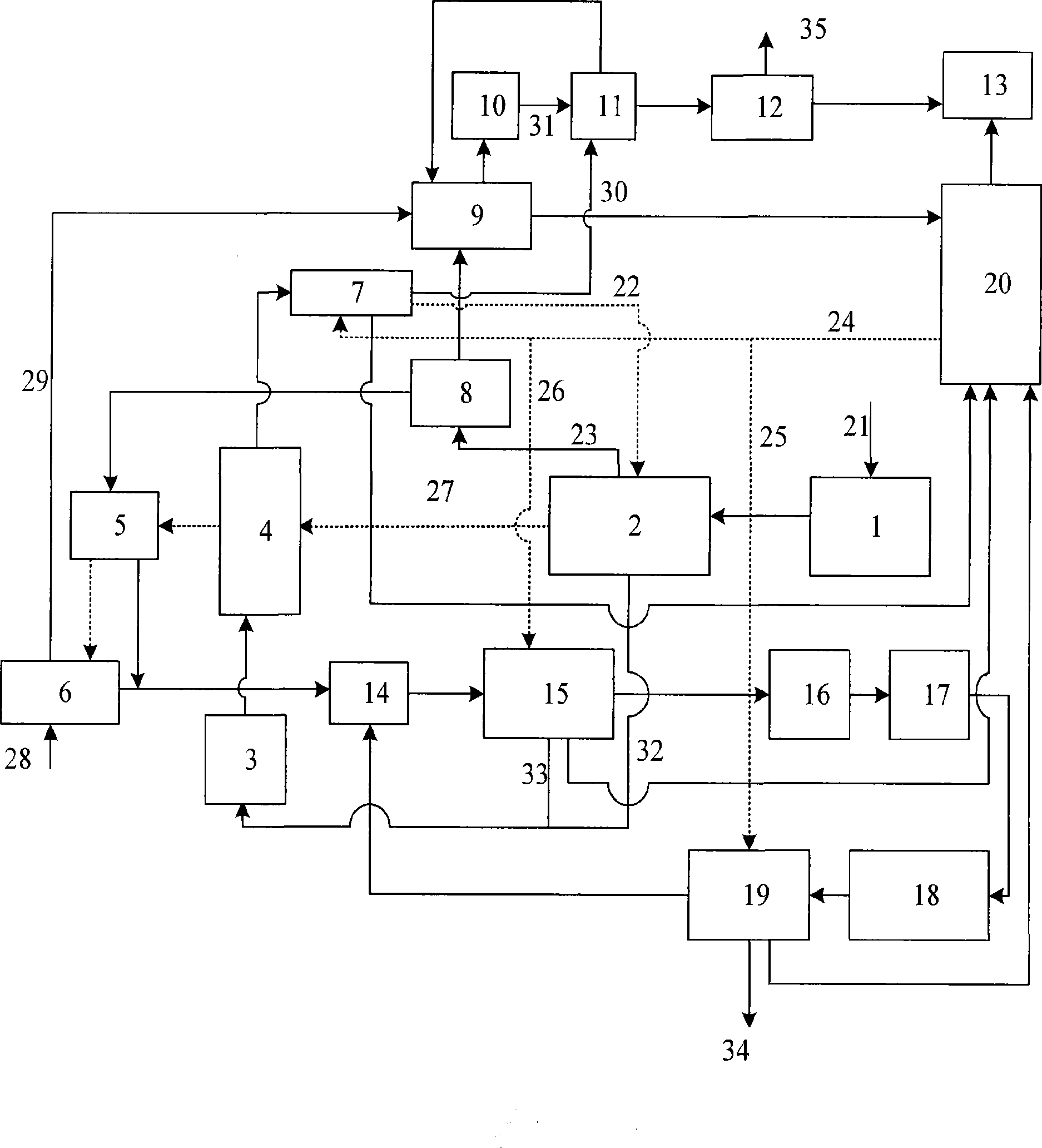

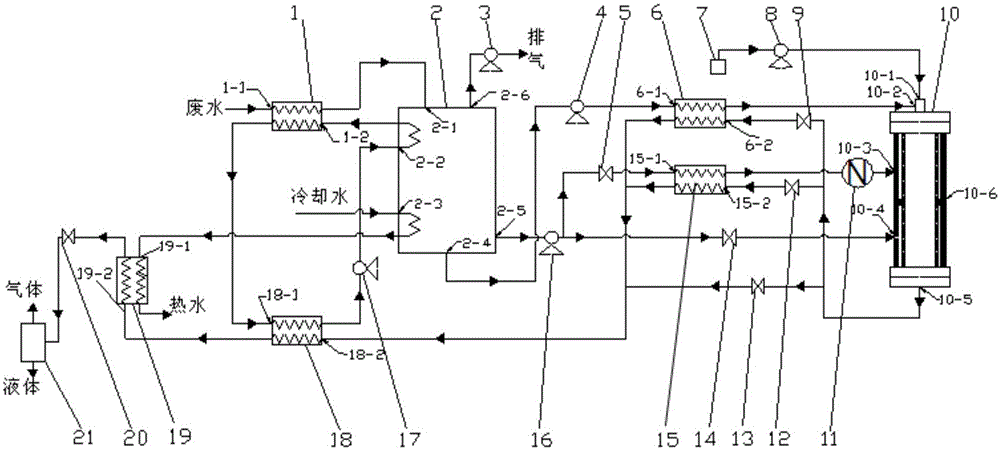

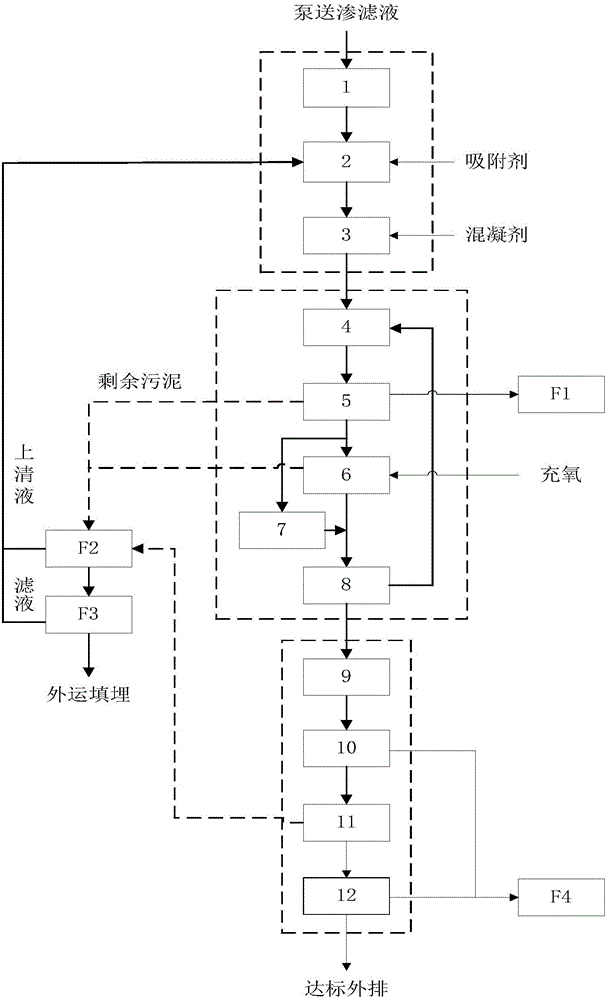

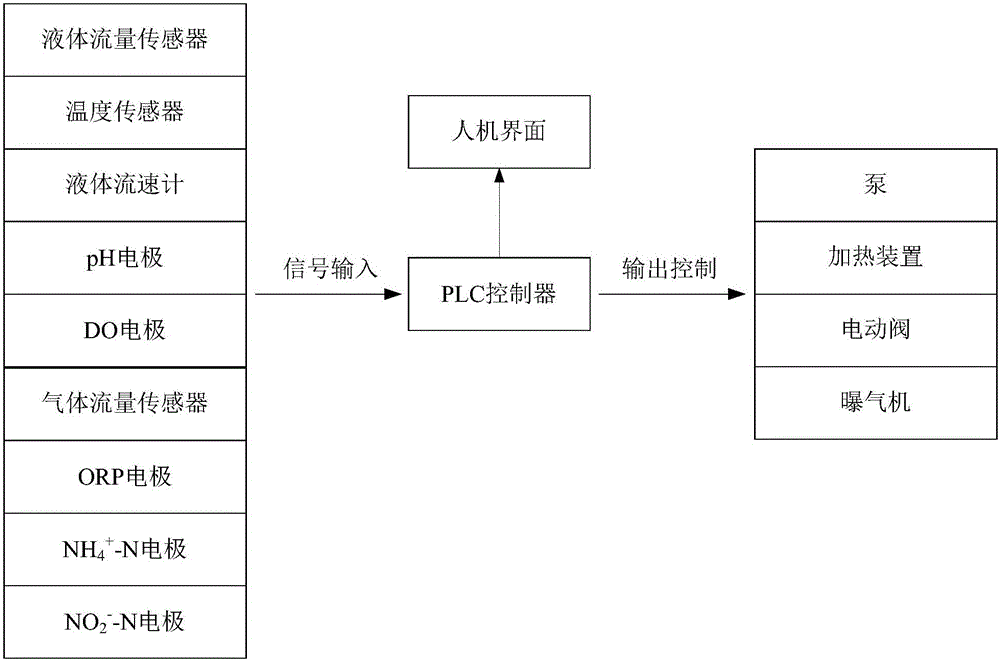

Anaerobic-autotrophic nitrogen removal-ozone oxidation coupling landfill leachate whole flow process zero emission processing process

ActiveCN105776775AReduce outputImprove nitrogen removal efficiencyWaste based fuelTreatment with anaerobic digestion processesNitrationTotal nitrogen

The invention provides a landfill leachate processing process. Landfill leachate sequentially passes through a pretreatment system, a main body biological treatment system and a deep treatment system; the pretreatment system consists of a regulating pool, an adsorption pool and a coagulating pool; wastewater is pretreated sequentially through the devices; outlet water enters the main body biological treatment system; the main body biological treatment system comprises an anaerobic EGSB (expanded granular sludge bed) reactor, an A / O short-range nitratlon reaction pool and an anaerobic ammonia oxidation UASB (upflow anaerobic sludge blanket) reactor; the treatment devices perform real-time regulation control through a PLC (programmable logic controller) control system for denitrification decarbonization reaction; the outlet water enters the deep treatment system for further treatment; the deep treatment system comprises a secondary coagulating pool, a primary homogeneous catalysis ozone oxidation reaction pool, a MBR (meane biological reactor) secondary biological reaction pool and a secondary homogeneous catalysis ozone oxidation reaction pool; finally, organic matters, total nitrogen and ammonia nitrogen of the outlet water reach the discharge standard. The landfill leachate processing process has the advantages that efficient denitrification and carbon removal are realized; the energy is saved; the consumption is reduced; the operation is stable; meanwhile, the goal of zero concentrated liquid generation is realized.

Owner:SHANGHAI BI ZONE ENVIRONMENTAL EQUIP & ENG

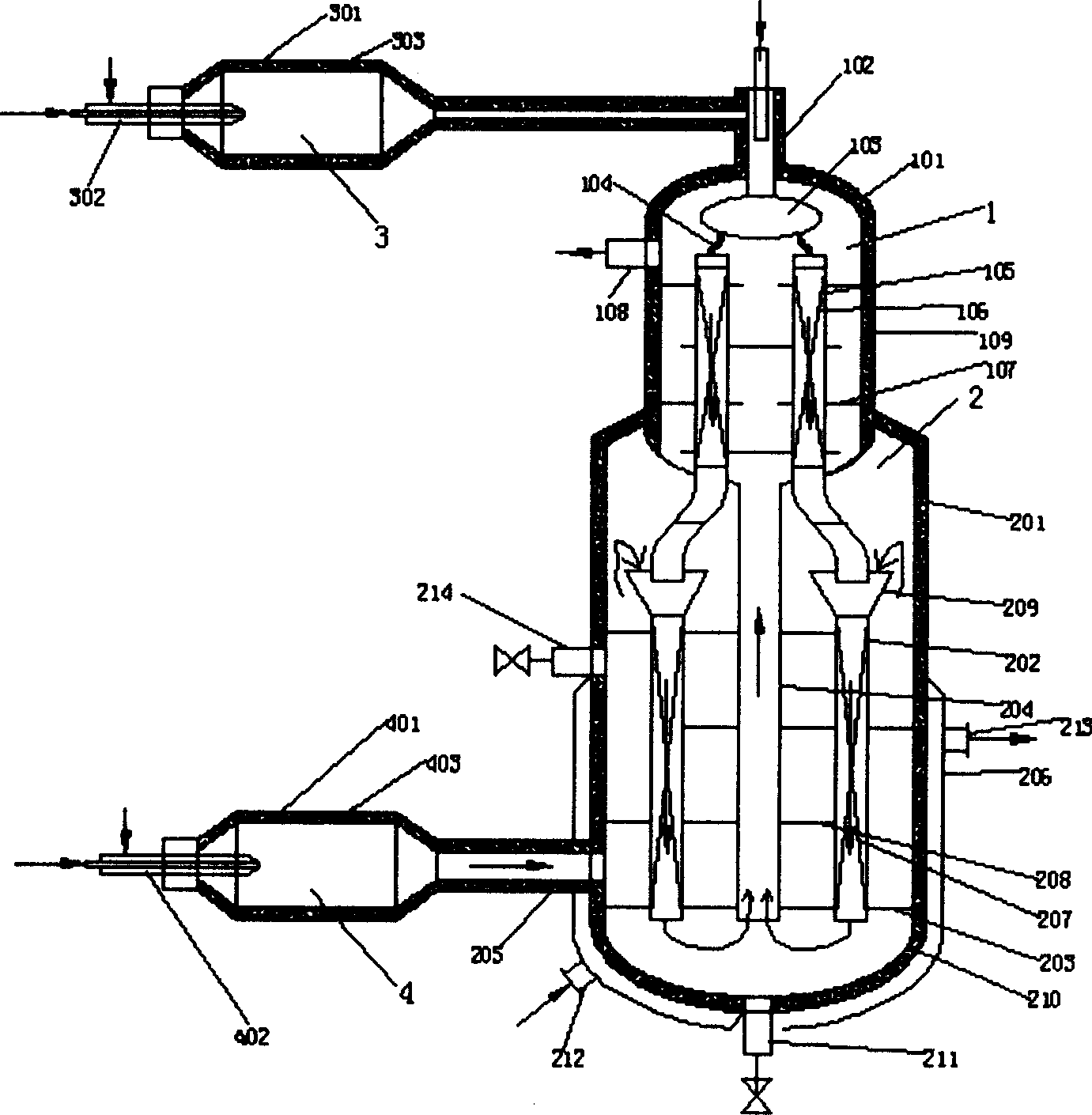

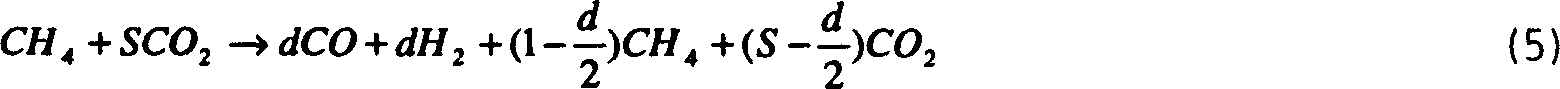

Hydrocarbon-converting synthetic gas producing apparatus and method

InactiveCN1636861AOptimizing Energy UtilizationReduce energy consumptionHydrogenChemical industrySyngasChemistry

The present invention relates to apparatus and method of producing synthetic gas with hydrocarbon. The hydrocarbon burning product or CO2 separated from the subsequent decarbonation process is led to hydrocarbon and water vapor converting reactor to replenish carbon to the system, to make the synthetic gas possess proper H2 / CO ratio for subsequent synthesis of liquid hydrocarbon fuel and to reach heat self feeding of the reactor. The apparatus includes two-section vapor converting furnace inside one container and two external hydrocarbon burner. The burning product of the external burner is made to exchange heat with gas inside the reactor or mix directly to supply heat and carbon source for the reaction. The present invention has the advantages of simultaneous completion of preparing synthetic gas and recovering heat, H2 / CO ratio adjustable in 1.5-2.7, high heat utilization, etc.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

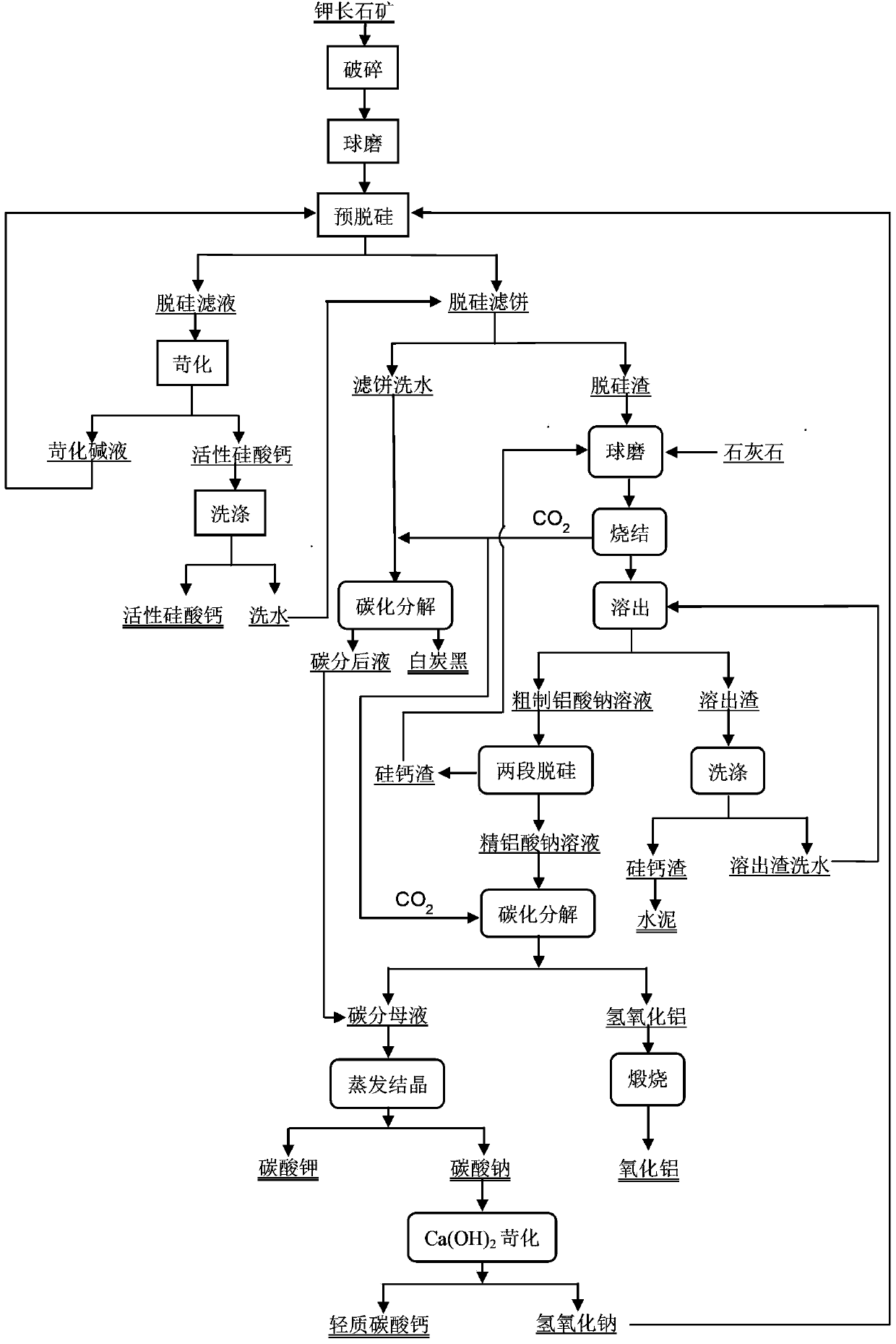

New technology using potash feldspar ore for production of potash, sodium carbonate and alumina

ActiveCN104211094AReasonable product planIncrease production costAlkali metal carbonatesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCalcium silicateSlag

The invention discloses a new technology using potash feldspar ore for production of potash, sodium carbonate and alumina, and a method comprising pre-desiliconization, soda-lime sintering dissolution, aluminum extraction by carbon and evaporation crystallization for separation of potassium and sodium is used for comprehensive recovery of aluminum, potassium and sodium resources. The new technology has the following advantages: the technical scheme of the new technology is reasonable, and active calcium silicate, white carbon black, sodium carbonate potassium carbonate and alumina can be produced. In carbonation decomposition process of the new technology, CO2 gas produced by sintering is used, the raw material cost is very low, and the greenhouse gas emissions can be reduced. During the sintering, the amount of a pre-desiliconization raw material is reduced by about 35%, the amount of silicon calcium slag is reduced by about 30%; desilicification slag needs no addition of sodium carbonate for raw material proportioning; washing water for washing active calcium silicate can be used for desiliconization slag washing, the amount of process water and waste water can be reduced, the silica product form can be enriched, the white carbon black and activated calcium silicate with the high added value can be outputted; by causticization regeneration of the sodium carbonate, alkali self-sufficiency and equilibrium cycle of the whole process can be realized.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

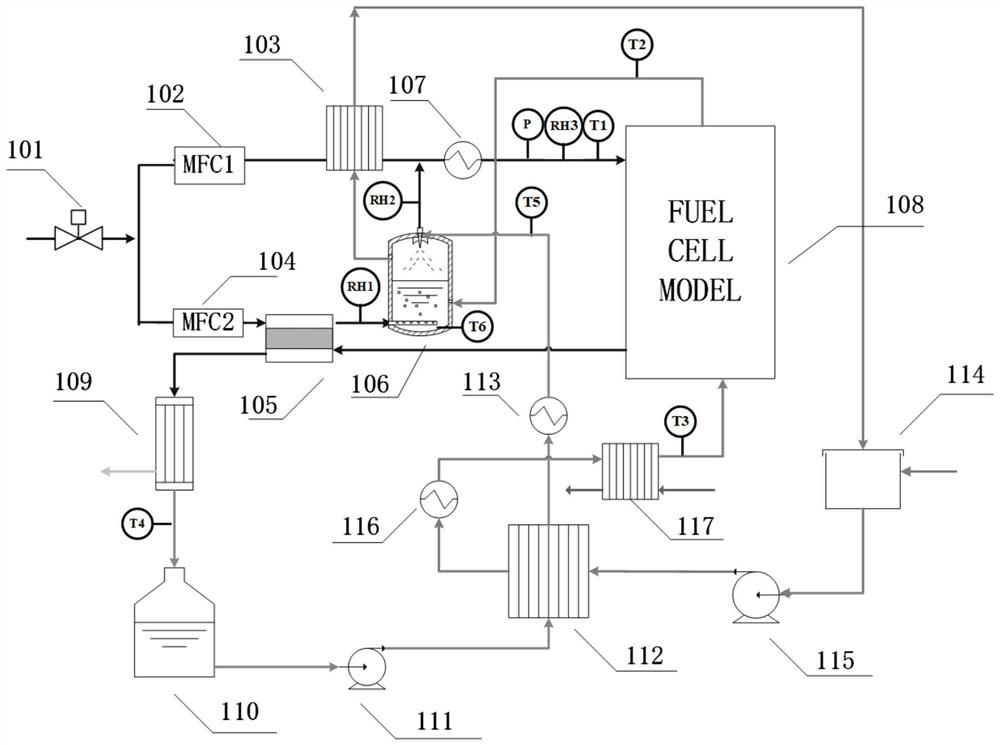

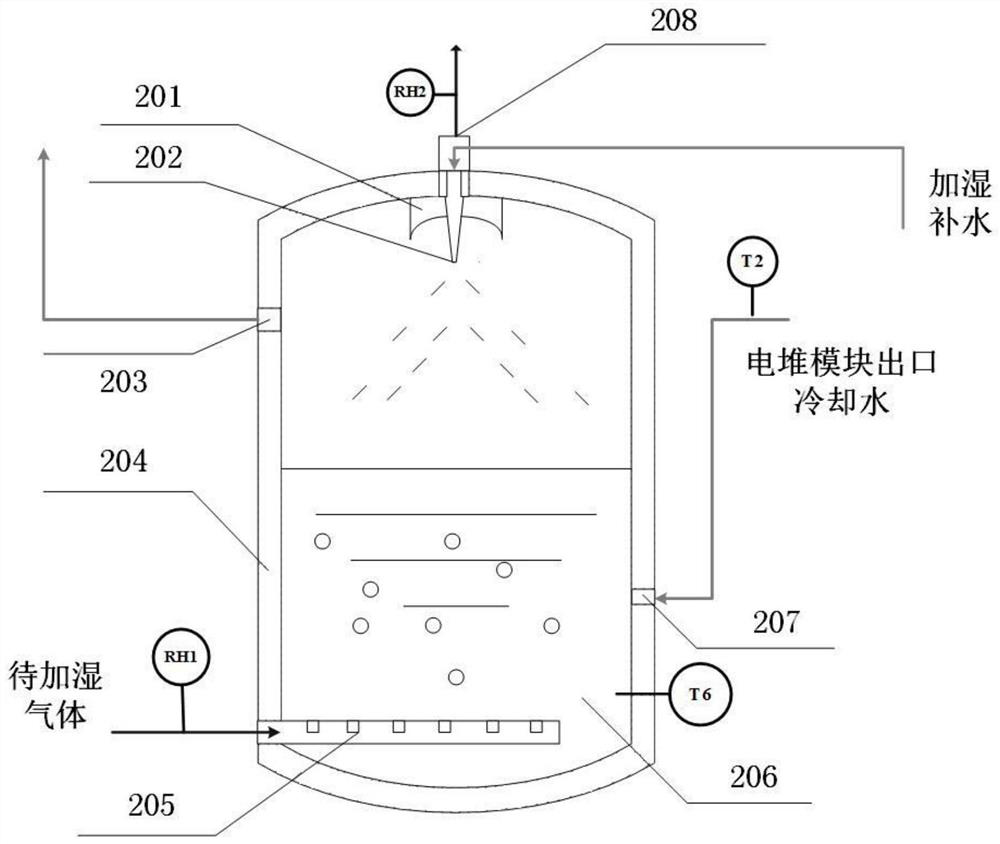

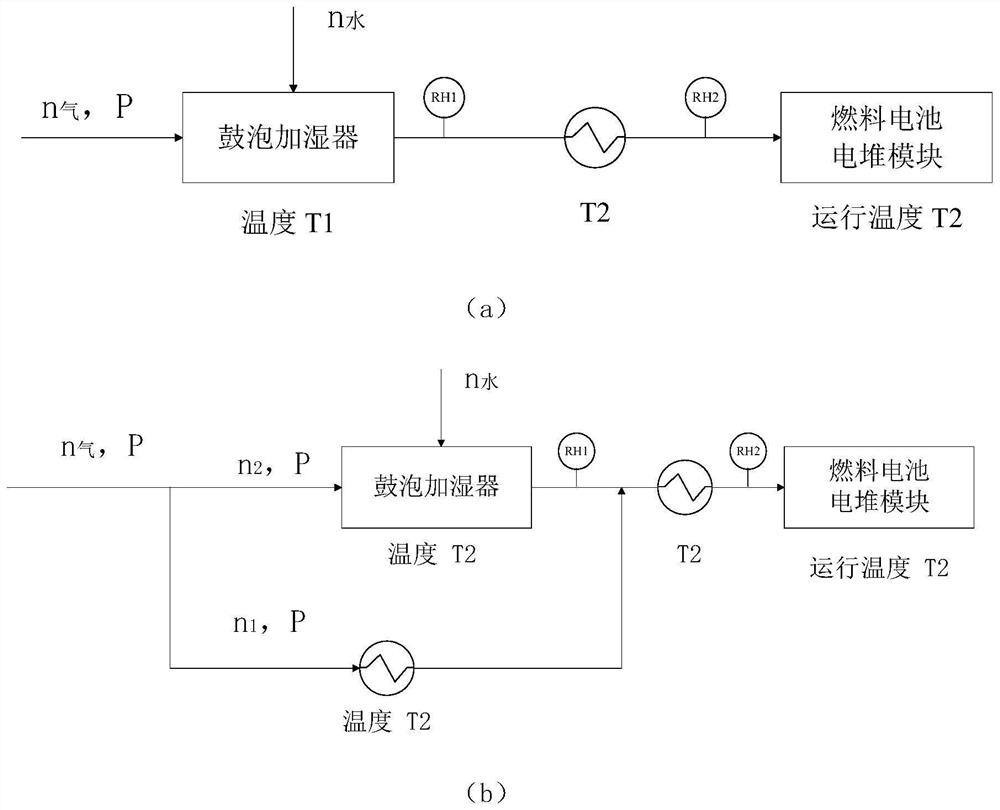

Bubbling and spraying combined humidifier and fuel cell humidifying system using same

ActiveCN111640968ARealize comprehensive utilizationGuaranteed uptimeFinal product manufactureFuel cellsFuel cellsProcess engineering

The invention discloses a bubbling and spraying combined humidifier and a fuel cell humidifying system using the same, and relates to the field of fuel cells, and particularly relates to the field ofhumidity control of the fuel cells. The system comprises a membrane humidifier and the bubbling and spraying combined humidifier, and outlet gas can be kept in a saturated state after the gas passes through the combined humidifying system. A stack module cooling system is connected into a humidifier heat exchange jacket, so that the temperature of a humidifier and the operating temperature of a stack module are kept consistent in real time, dry and wet mixed gas is heated to the operating temperature of the stack module through a stack mixed gas inlet heater, and finally the requirement for rapid humidity response is met through a dry and wet gas mixed humidity control method. Meanwhile, cyclic utilization of water produced by the fuel cell is achieved through a condensate water supplementing system, reaction gas is preheated through tail gas of the fuel cell and reaction heat production, comprehensive utilization of system energy is achieved, and efficient and low-energy-consumption operation of the humidifying system is guaranteed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

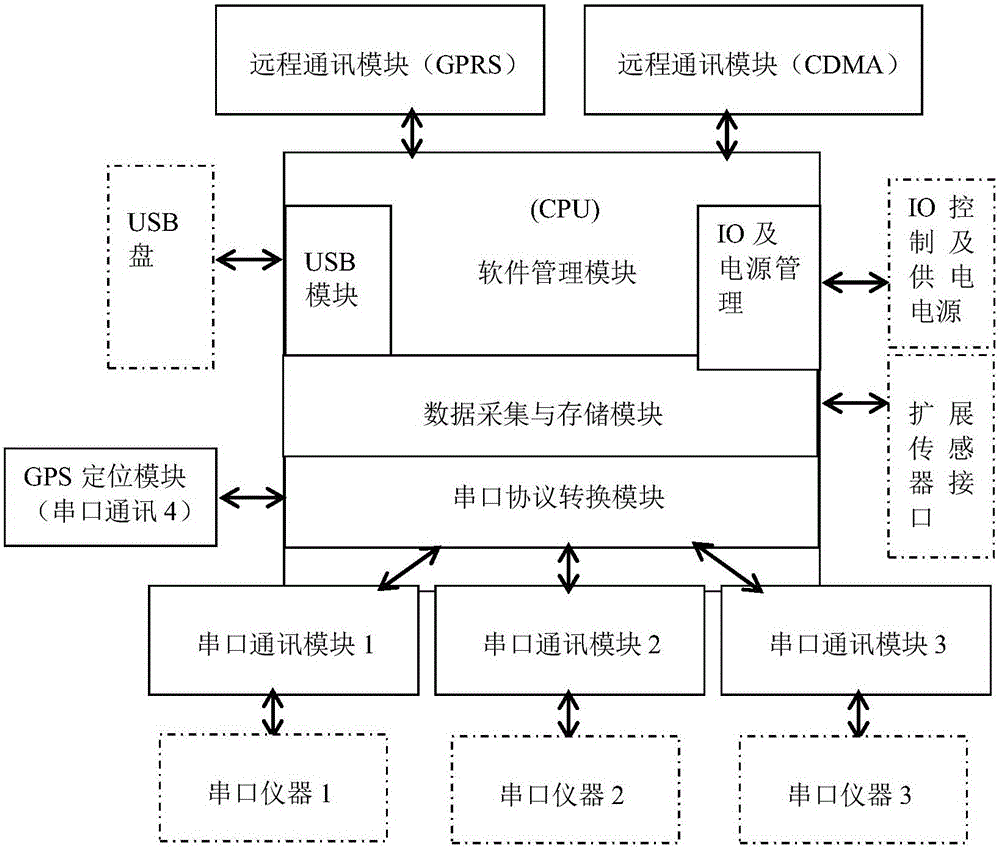

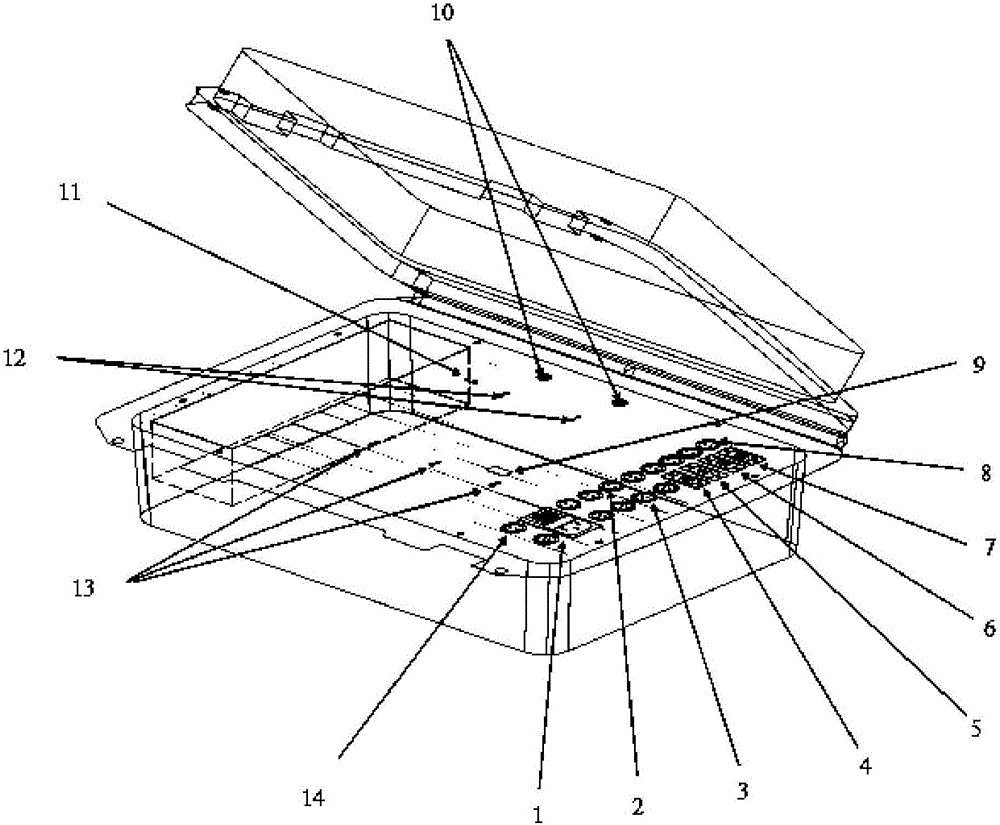

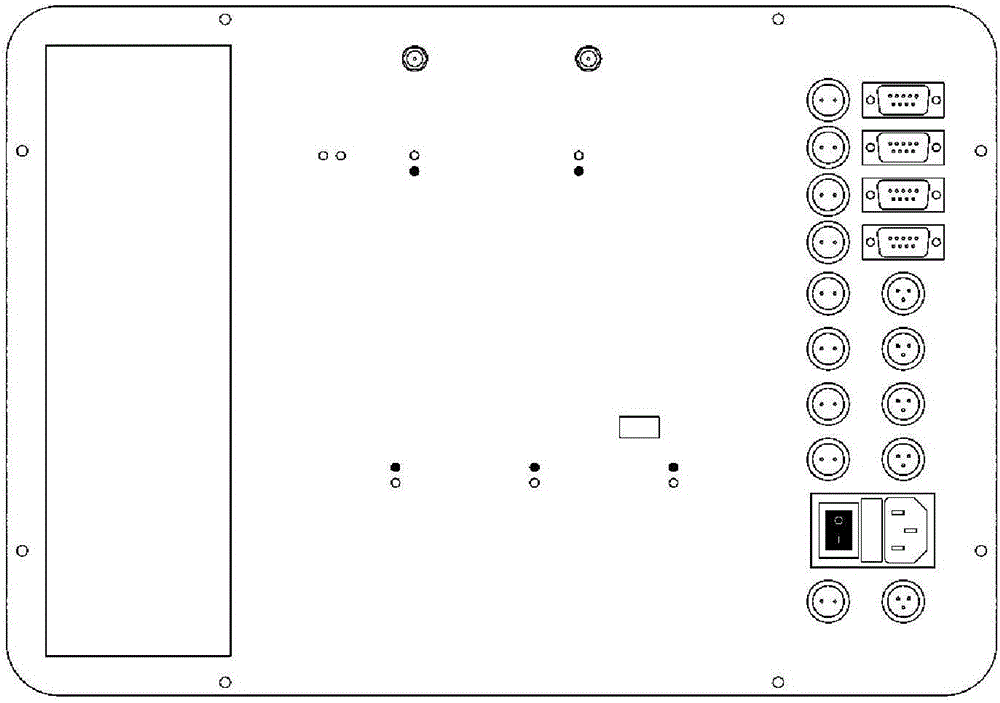

Portable positionable multi-interface data measuring, collecting and transmitting instrument

PendingCN105788211ACause confusionStrong lockTransmission systemsSatellite radio beaconingMicrocontrollerData stream

The invention provides a portable positionable multi-interface data measuring, collecting and transmitting instrument which comprises a box, a communication serial port module, a serial port protocol conversion module, a GPS positioning module, a data testing and storage module, a software management module, a remote communication module, a USB module and an environment parameter collecting module.A multi-serial-port instrument and a plurality of analog quantity sensor interfaces are controlled and managed with a single-chip microcomputer system to perform data collecting, storage, GPRS remote data transmission, GPS position positioning and other work, after effective GPS position information is bound, a positioning information mark is added into a measurement data stream, and thus measurement data is changed into new data with a time attribute and a position attribute.The portable positionable multi-interface data measuring, collecting and transmitting instrument solves the problem of data management caused by position changing due to the fact that mixing is likely to occur due to high repetition of measurement data; besides, an efficient remote measuring function is provided, and carrying and extension are convenient.

Owner:EAST CHINA NORMAL UNIV +1

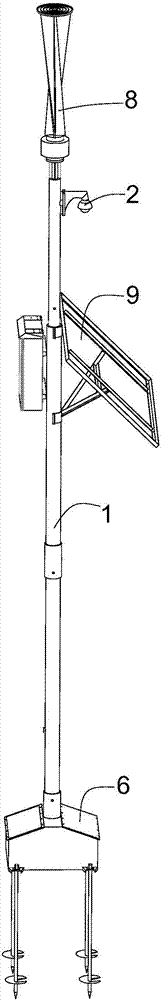

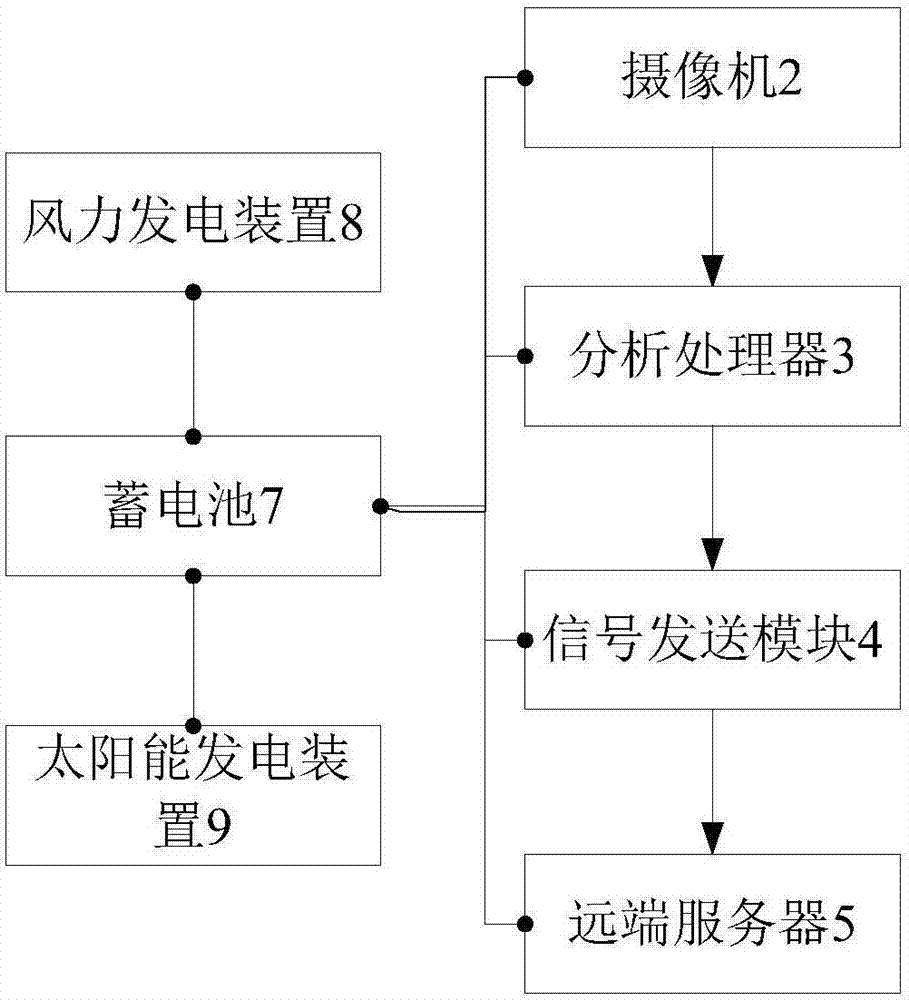

Oil and gas pipeline area intrusion detection device and method

PendingCN107578594AEfficient exclusionEffective swingBatteries circuit arrangementsClosed circuit television systemsControl signalThird generation

The invention provides an oil and gas pipeline area intrusion detection device and method. The method includes that whether a moving object belongs to human intrusion or not is judged through changesof the volume or contour of the moving object, swinging of grass and trees and the like due to wind can be effectively excluded, and false alarm rate is reduced; features that the embedding area of oil and gas pipelines is remote and is difficult to be connected to wired network are fully considered, and 3G, 4G or 5G networks are adopted; when an analysis processor determines that the moving object is not in the pipeline safety line, or the moving object does not belong to human intrusion, or duration of stay of the moving object in the pipeline safety line is within a set threshold value, theanalysis processor controls a signal transmission module not to transmit images, both flow rate and electricity are saved, and use cost is saved. The facts that the embedding area of the oil and gaspipelines is remote and has difficulty in power supply are fully considered, storage batteries are adopted in combination with wind and light power generation, and energy self sufficiency is realized;the oil and gas pipeline area intrusion detection device and method is low in false alarm rate, high in recognition rate, high in cost performance and suitable for large-scale application.

Owner:武汉阿卡瑞思光电自控有限公司

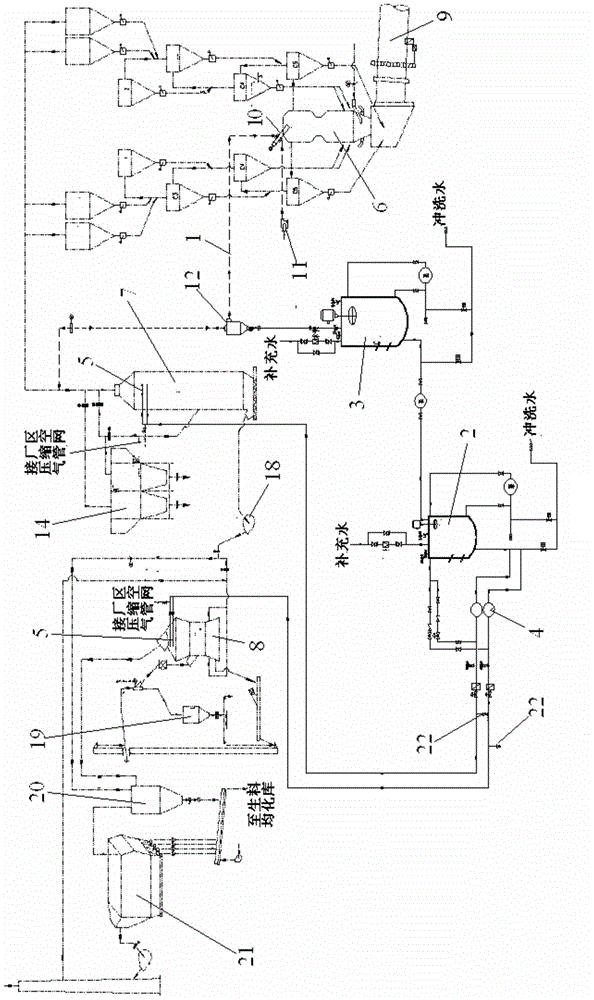

Device and method for recycling gasified and burned alkali for straw pulp papermaking black liquor circulating fluidized bed

ActiveCN102864674AEfficiently provideSolve processing problemsRegeneration of alkali lyeAir preheaterSlag

The invention provides a device and a method for recycling gasified and burned alkali for a straw pulp papermaking black liquor circulating fluidized bed and relates to the device and the method for recycling the alkali of papermaking black liquor. The device and the method are used for solving the problems that the prior art is difficult to be used for recycling the straw pulp papermaking black liquor, the auxiliary fuels are added to a recycling process and the running cost is increased. The device comprises a multi-effect evaporator, a disc evaporator, a thick black liquor tank, a pump, a spraying gun, a gasifying chamber, a feedback valve, a waste heat boiler, an air pre-heater, a bag-type dust collector, a draught fan, a cone valve, a heat exchange chamber, a dissolving tank, a causticizer, a chain plate type slag conveyor, a drier, a secondary air fan, a second gas-solid separator, a tar condensing tower, a spraying dehydrating tower, a sewage treatment plant, a water annular compressor, an air storage tank, a circulating ash distributing chamber and a circulating fluidized bed, wherein the dissolving tank is respectively communicated with the causticizer and the chain plate type slag conveyor and the chain plate type slag conveyor is communicated with the drier. The device provided by the invention is used for recycling the alkali of the straw pulp papermaking black liquor.

Owner:哈尔滨工大华实环保科技有限公司

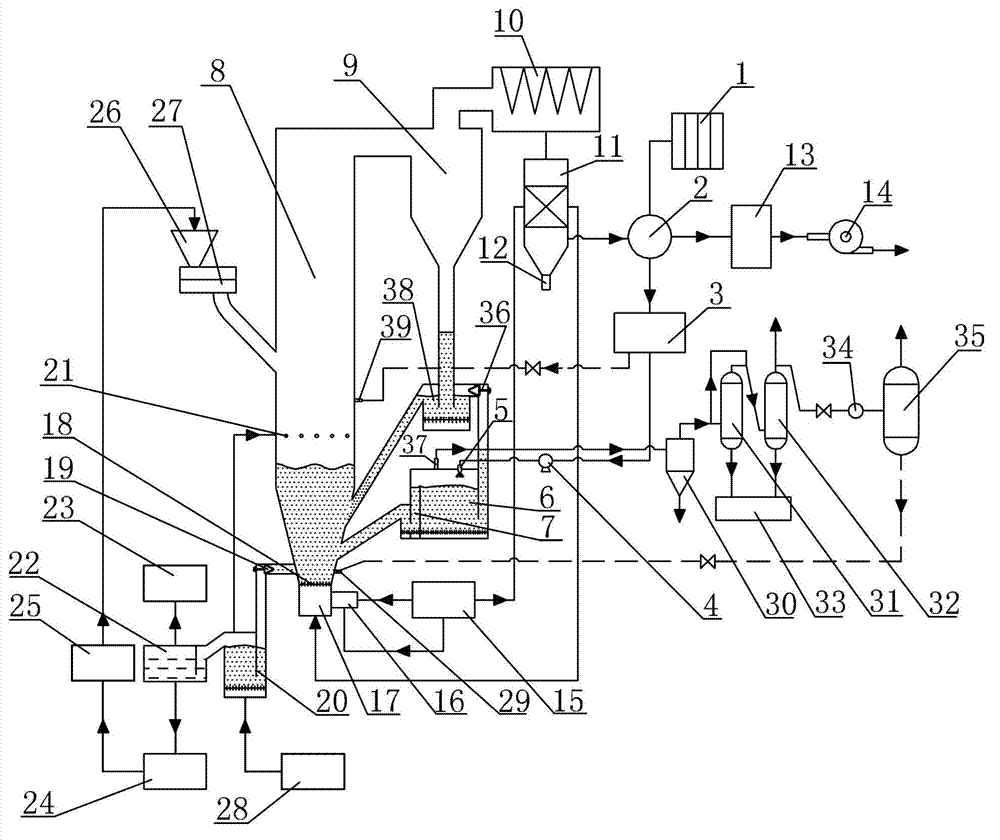

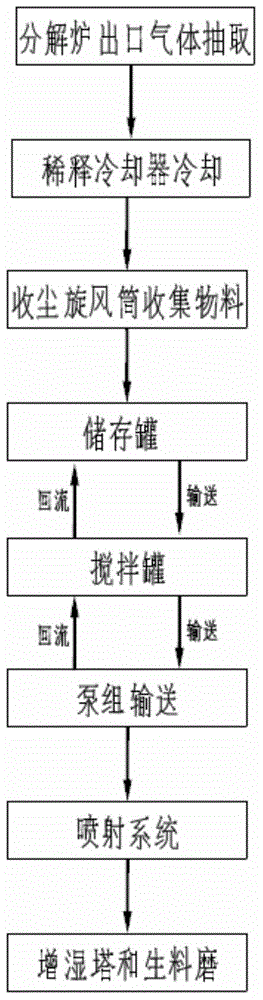

Novel dry-process cement kiln tail flue gas desulfurization system and desulfurization process thereof

InactiveCN104587826ADoes not affect normal productionAchieve self-sufficiencyDispersed particle separationWaste heat treatmentProduction lineProcess engineering

The invention discloses a novel dry-process cement kiln tail flue gas desulfurization system. A material taking device (1) is connected with an outlet of a decomposing furnace (6); the material taking device (1) is connected with a storage device (3); the storage device (3) is connected with a pulping device (2); and the pulping device (2) is respectively connected with a humidifier tower (7) and a raw mill (8) by virtue of a conveying device (4) and an injection device (5). The invention also discloses a desulfurization process for the system. With the adoption of the technical scheme, the desulfurization efficiency is high, and the desulfurization efficiency is more than 50 percent; the operation is convenient, and the degree of automation is high; the construction period is short, and normal production of the production line is not influenced by most of constructions of the desulfurization system; and moreover, an extra desulfurizing agent does not need to be purchased, and the investment cost and the operating cost are low.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

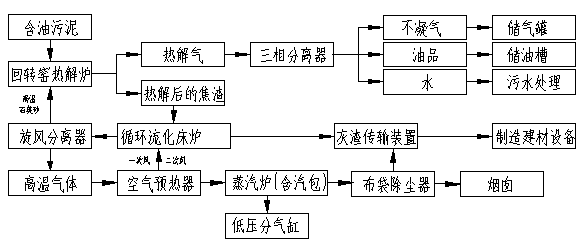

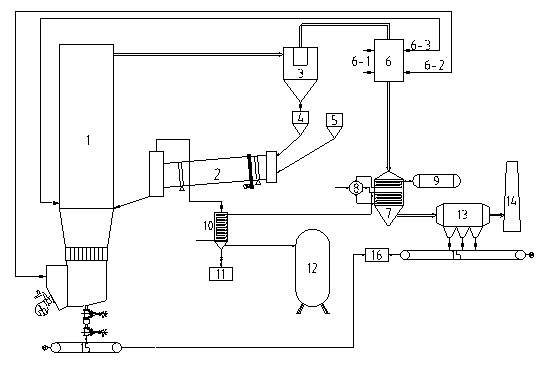

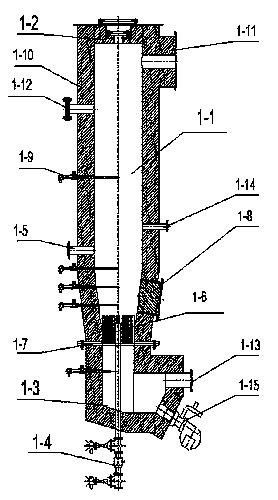

Resourceful treatment method of oil-containing sludge

ActiveCN103553290AHigh calorific valueAchieve self-sufficiencySludge treatment by pyrolysisDirect heating destructive distillationSludgeCyclonic separation

The invention relates to the technical field of high-temperature thermal analysis and particularly relates to an oil-containing sludge treatment method. The resource treatment method of the oil-containing sludge comprises the following steps that an incineration system heats up quartz sand; the heated quartz sand enters a thermal analysis system after cyclone separation; heat is transmitted to the oil-containing sludge by the high-temperature quartz sand, so that the oil-containing sludge reacts in a thermal analysis manner under a high-temperature anaerobic environment; the generated thermal analysis gas passes through a three-phase separator, so that oils, water and non-condensable gases are separated; coke bottom and the quartz sand in the thermal analysis residue are returned to the incineration system for being recycled. The resourceful treatment method disclosed by the invention has characteristics of high crude oil recovery, no secondary pollution and low energy consumption, so that various oil-containing sludge treatment and disposal problems generated in oil-field development and an oil refining process are effectively solved. The whole technical system is energy-saving and environment-friendly; meanwhile, resourceful, reduction and harmless treatment of the oil-containing sludge is realized.

Owner:DALIAN HUANZI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com