Method for treating carbon-containing organic matter by supercritical water oxidation

A technology of supercritical water oxidation and organic matter, applied in the direction of oxidized water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

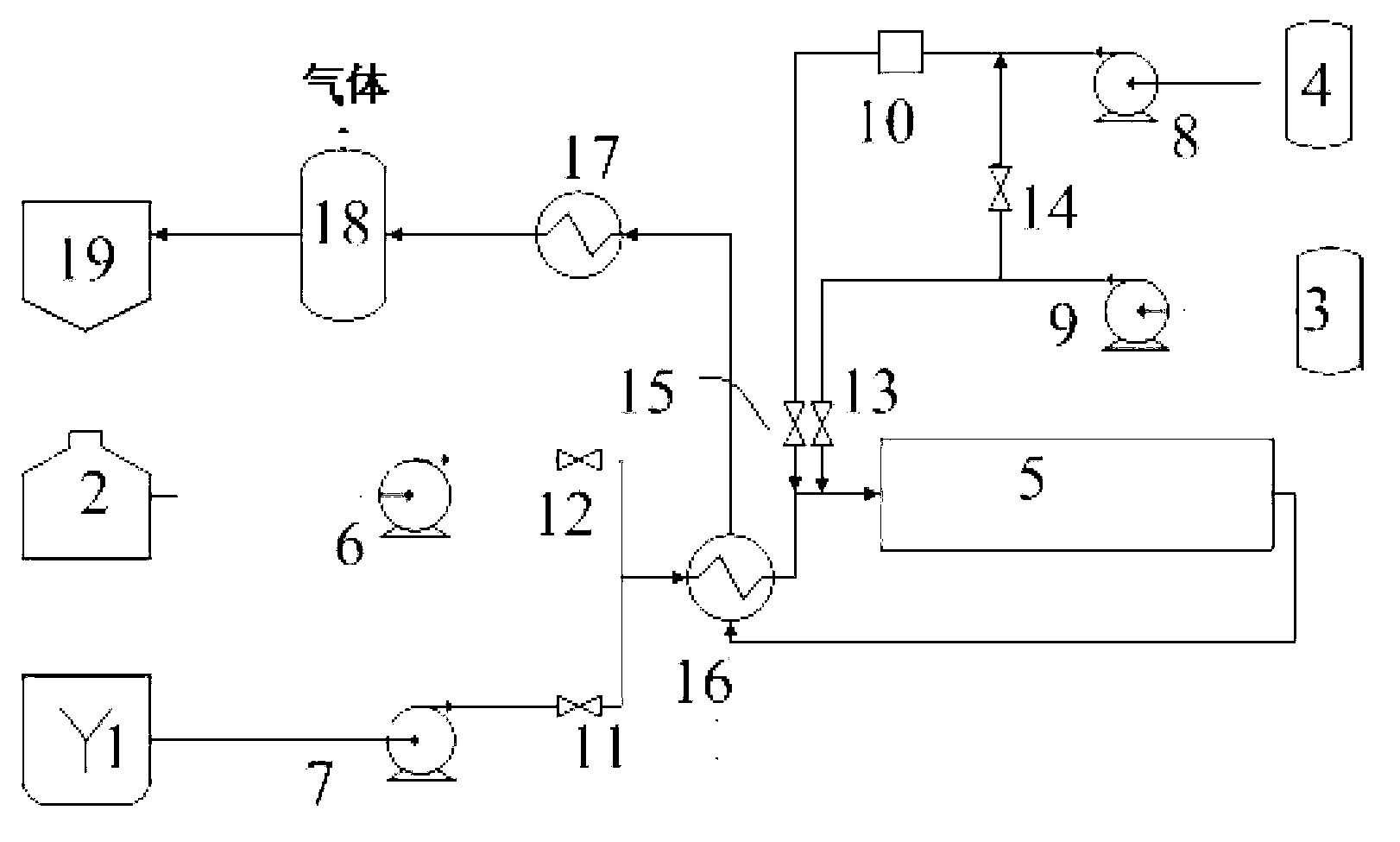

[0113] A method for supercritical water oxidation treatment of carbon-containing organic matter, such as figure 1 Carry out in the device of described supercritical water oxidation treatment carbonaceous organic matter, comprise the steps:

[0114] (1) Start the supercritical water oxidation reaction:

[0115] During the start-up process of the system, methanol is used as the auxiliary fuel, and the pressure of methanol reaches 22.5-23MPa through the auxiliary fuel pump, and the low-temperature combustion catalyst adopts PtO / Al 2 o 3 , the amount of methanol is 60% of the content of carbon-containing organic matter in the raw material, and the system oxidant uses O 2 , the pressure of the auxiliary fuel and oxidant passing through the oxidant pump is 23-24MPa, and the amount of auxiliary fuel oxidant is 120% of the oxygen demand for complete combustion of the auxiliary fuel;

[0116] (2) Stable operation of supercritical water oxidation reaction:

[0117] After the auxilia...

Embodiment 2

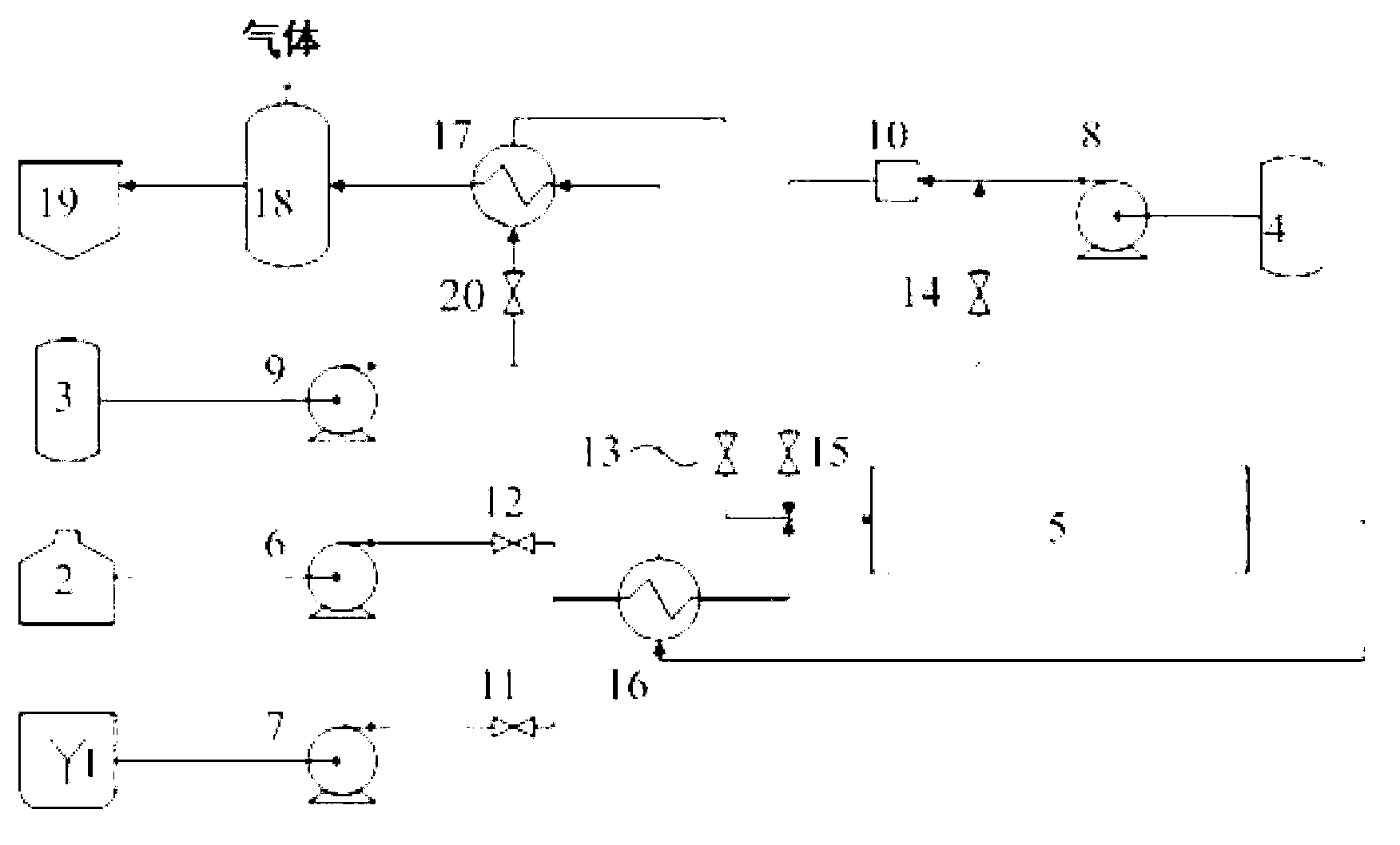

[0121] A method for supercritical water oxidation treatment of carbon-containing organic matter, such as figure 2 Carry out in the device of described supercritical water oxidation treatment carbonaceous organic matter, comprise the steps:

[0122] (1) Start the supercritical water oxidation reaction:

[0123] During the start-up process of the system, ethanol is used as the auxiliary fuel, and the ethanol is pressurized to 25-26MPa through the auxiliary fuel pump, and the low-temperature combustion catalyst adopts Pt / Al 2 o 3 , the amount of ethanol is 80% of the carbon-containing organic matter content of the raw material, and the system oxidant uses H 2 o 2 , the pressure of auxiliary fuel and oxidant reaches 26-27MPa through the oxidant pump, and the amount of auxiliary fuel is 130% of the oxygen demand for complete combustion of auxiliary fuel;

[0124](2) Stable operation of supercritical water oxidation reaction:

[0125] After the auxiliary fuel is burned, the te...

Embodiment 3

[0129] A method for supercritical water oxidation treatment of carbon-containing organic matter, such as figure 1 Carry out in the device of described supercritical water oxidation treatment carbonaceous organic matter, comprise the steps:

[0130] (1) Start the supercritical water oxidation reaction:

[0131] During the start-up process of the system, propanol is used as the auxiliary fuel, and the pressure of propanol is increased to 35-38MPa through the auxiliary fuel pump, and the low-temperature combustion catalyst adopts PdO / Al 2 o 3 , the amount of auxiliary fuel is 20% of the content of carbon-containing organic matter in the raw material, the oxidant of the system is air, the pressure of the auxiliary fuel flow oxidant is increased to 38-40MPa through the oxidant pump, and the amount of oxidant is 110% of the oxygen contained in the oxidant, which is the complete combustion oxygen demand of the auxiliary fuel %.

[0132] (2) Stable operation of supercritical water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com