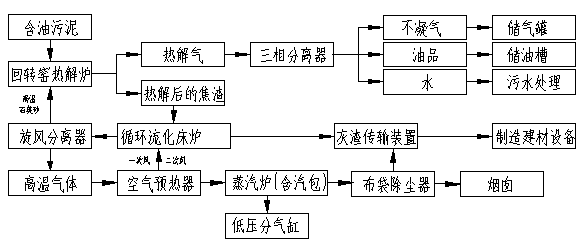

Resourceful treatment method of oil-containing sludge

A treatment method and resource-recycling technology, applied in the field of oily sludge resource-recycling treatment, achieves the effect of complete process route, solving environmental pollution and solving the problem of final outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

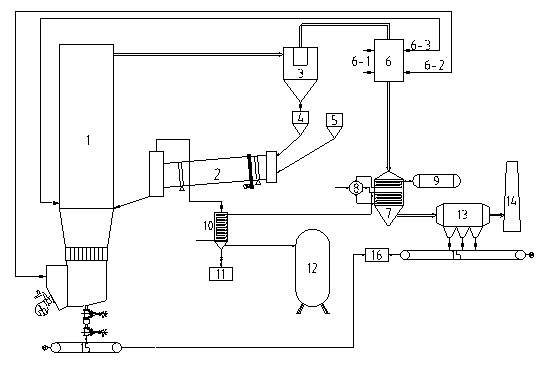

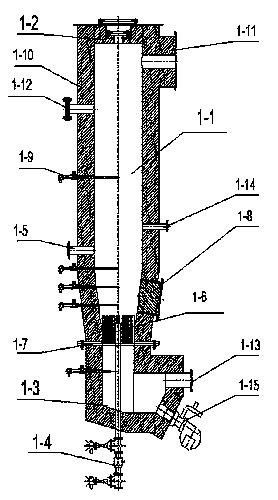

[0040] In conjunction with the accompanying drawings, the technical route and specific implementation process of the present invention will be described in detail, but the present invention is not limited to specific embodiments.

[0041] Refer to the specific process figure 1 , the first step of incineration: a high-temperature incineration reaction occurs in the circulating fluidized bed furnace 1, the temperature is 900-1200 ° C, the fluidization-heat-carrying medium quartz sand is heated to above 850 ° C, and the fuel is completely produced by pyrolysis. Provide; high temperature quartz sand (≧850℃) is carried by fluidized flue gas and discharged from the flue gas outlet of circulating fluidized bed furnace 1, enters cyclone separator 3 for gas-solid separation, high temperature quartz sand is separated and stored in the quartz sand silo 4. The high-temperature flue gas (800-900°C) enters the air preheater 6 and the steam furnace 7 to recover heat in multiple stages, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com