Patents

Literature

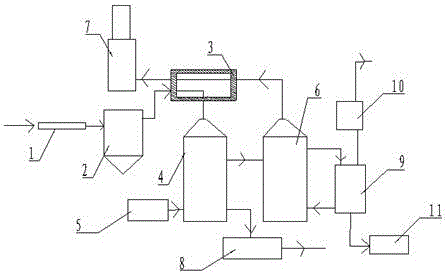

109results about How to "Complete desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

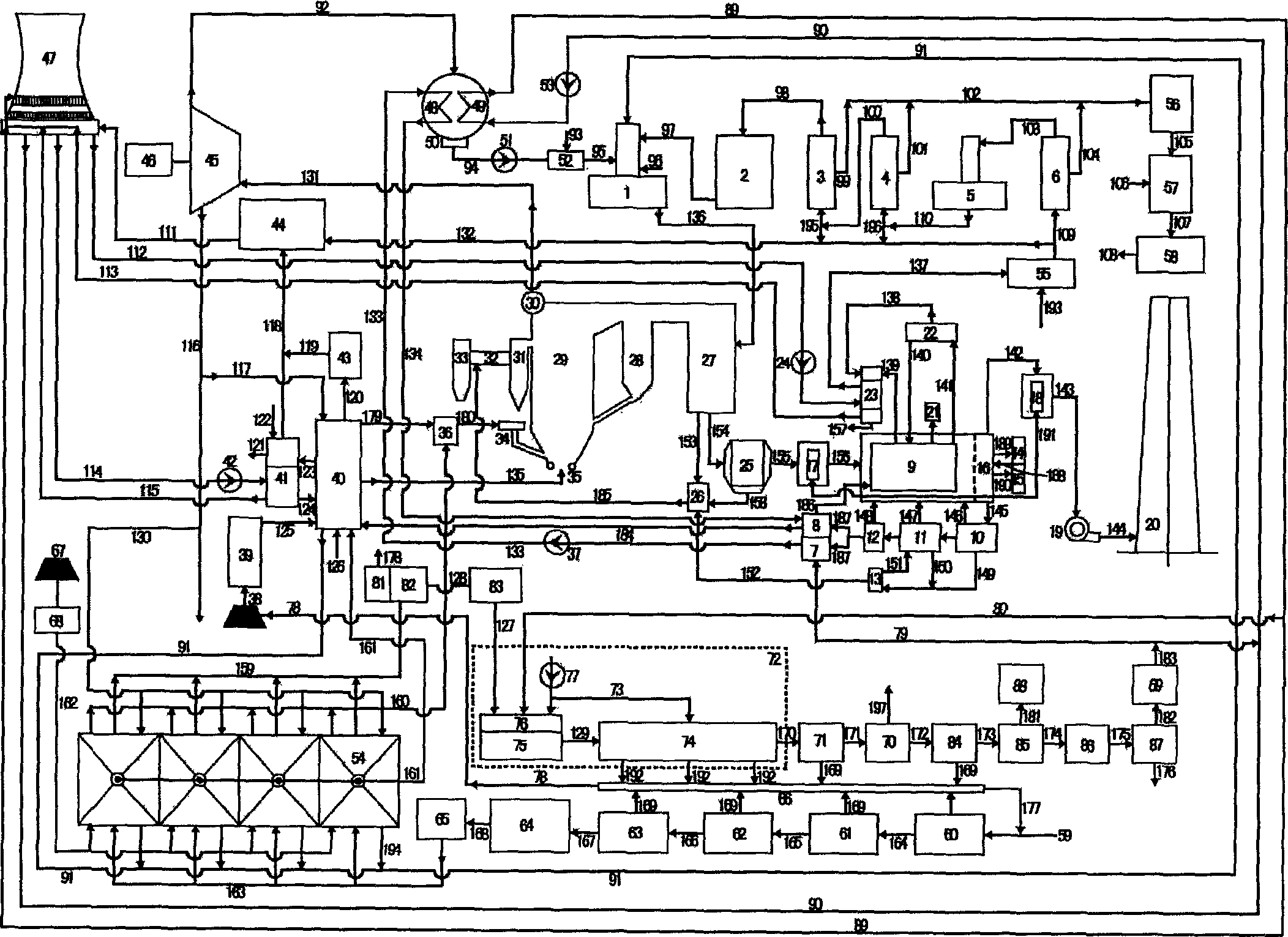

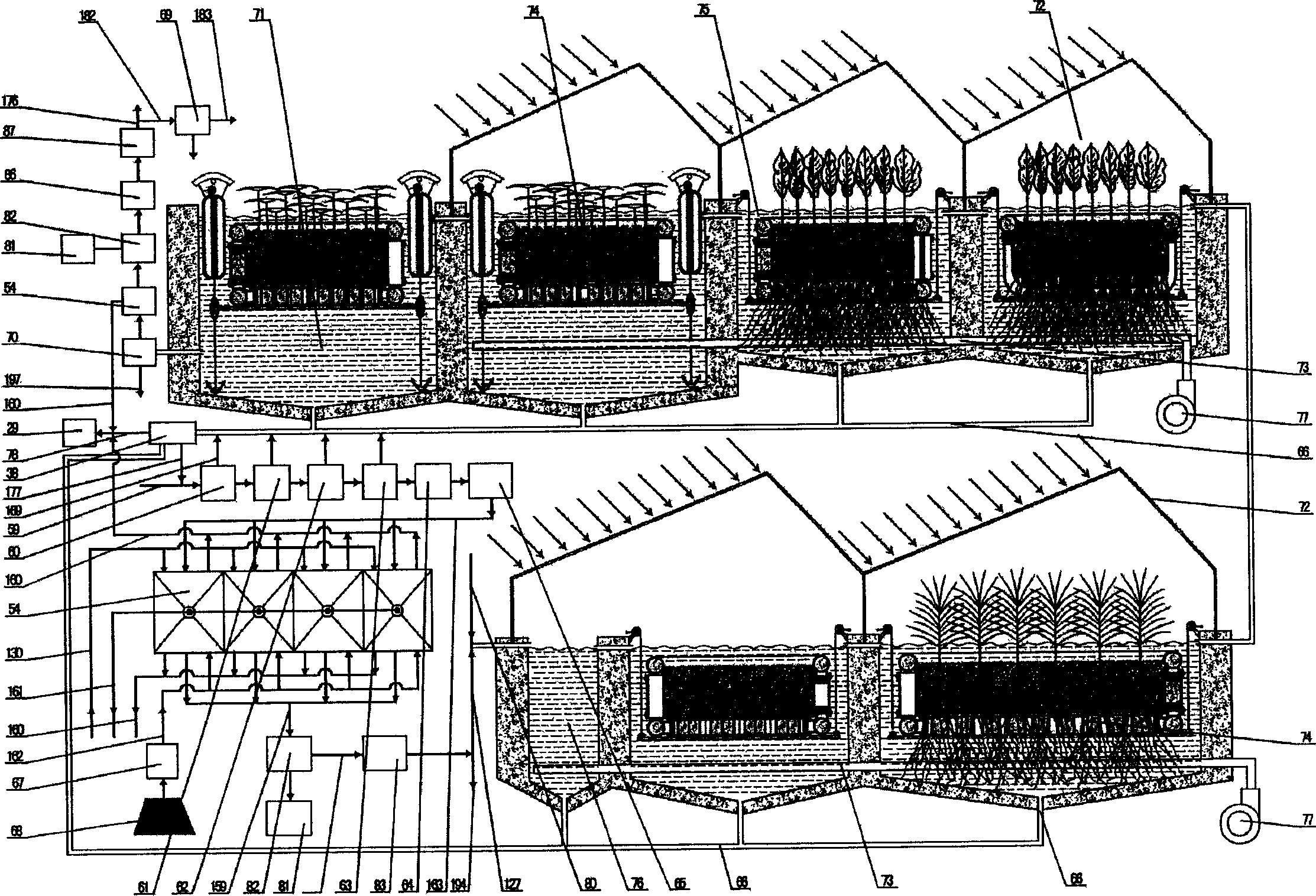

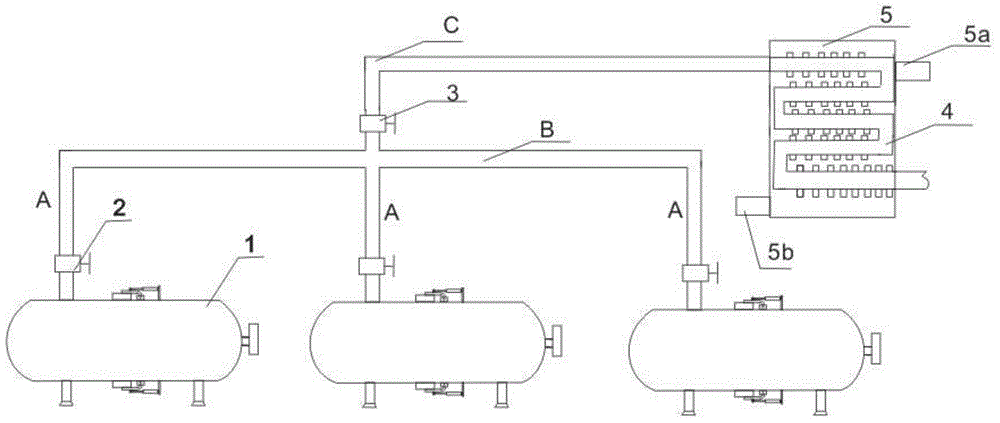

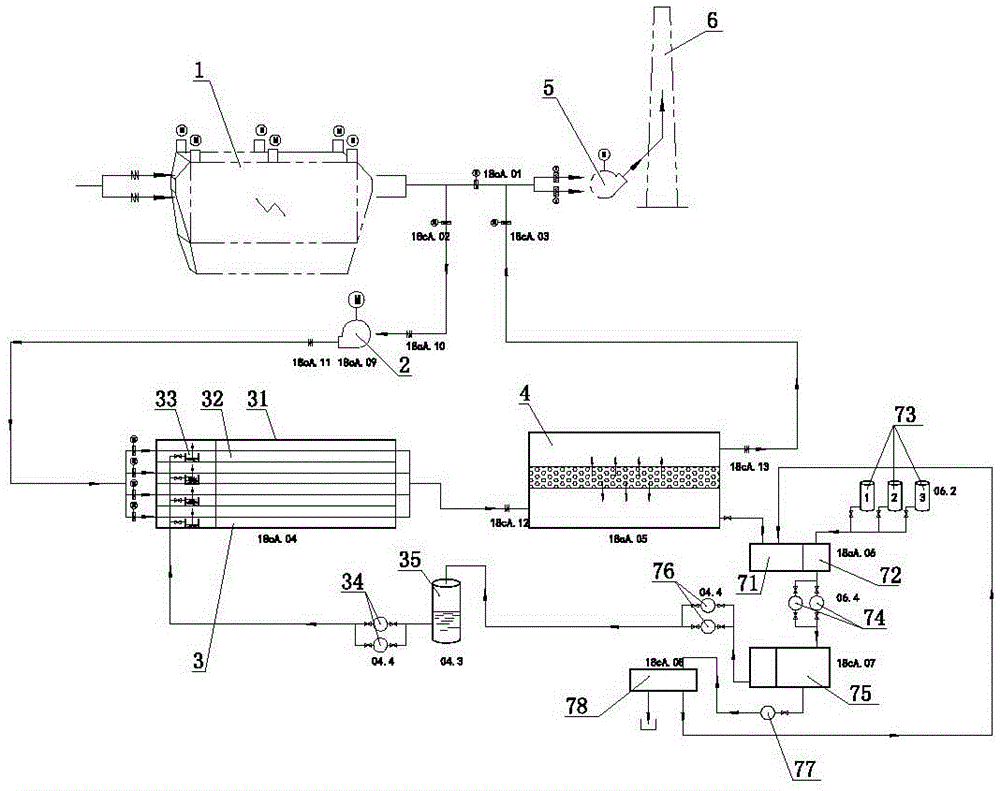

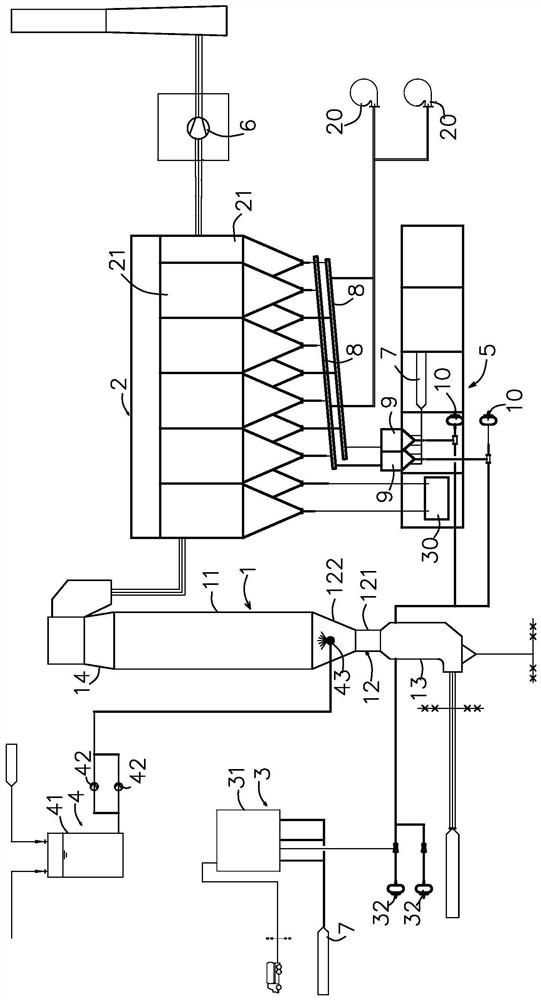

Sewage-refuse treatment clean-production system at the center of generating plant

InactiveCN1743284AImprove efficiencyComplete desulfurizationWater/sewage treatment by irradiationSolid waste disposalSteam condensationCoal

This sewage and garbage treatment system centrally designed for power plant includes sewage treatment unit, fuel processing unit, garbage combustion boiler, fly ash processing unit, smoke processing unit, the de-oxygenating draining steam of turbine steam-extraction heat-supply boiler and circulated water cooling unit. The effluent of sewage treatment unit with coal as filter is led into magnetic water strainer, and condensed water from the domestic garbage dehydration-drying condensed water-recovering combustion-supporting device is cleared by the coal filtration and normal water treatment system to feedback the circulated water-cooling system, the steam condensed water is heated and delivered into the de-oxygenating device. Treated sewage is introduced into multi-medium condenser and the distillation-desalination device; discharged smoke from fly ash incineration device is led into garbage combustion boiler; acid water discharged from distillation unit and alkaline water from coal filter are neutralized and discharged. Water distillation system and the circulation cooling water of the steam turbine condensator are led to the air- water cooling tower.

Owner:徐宝安

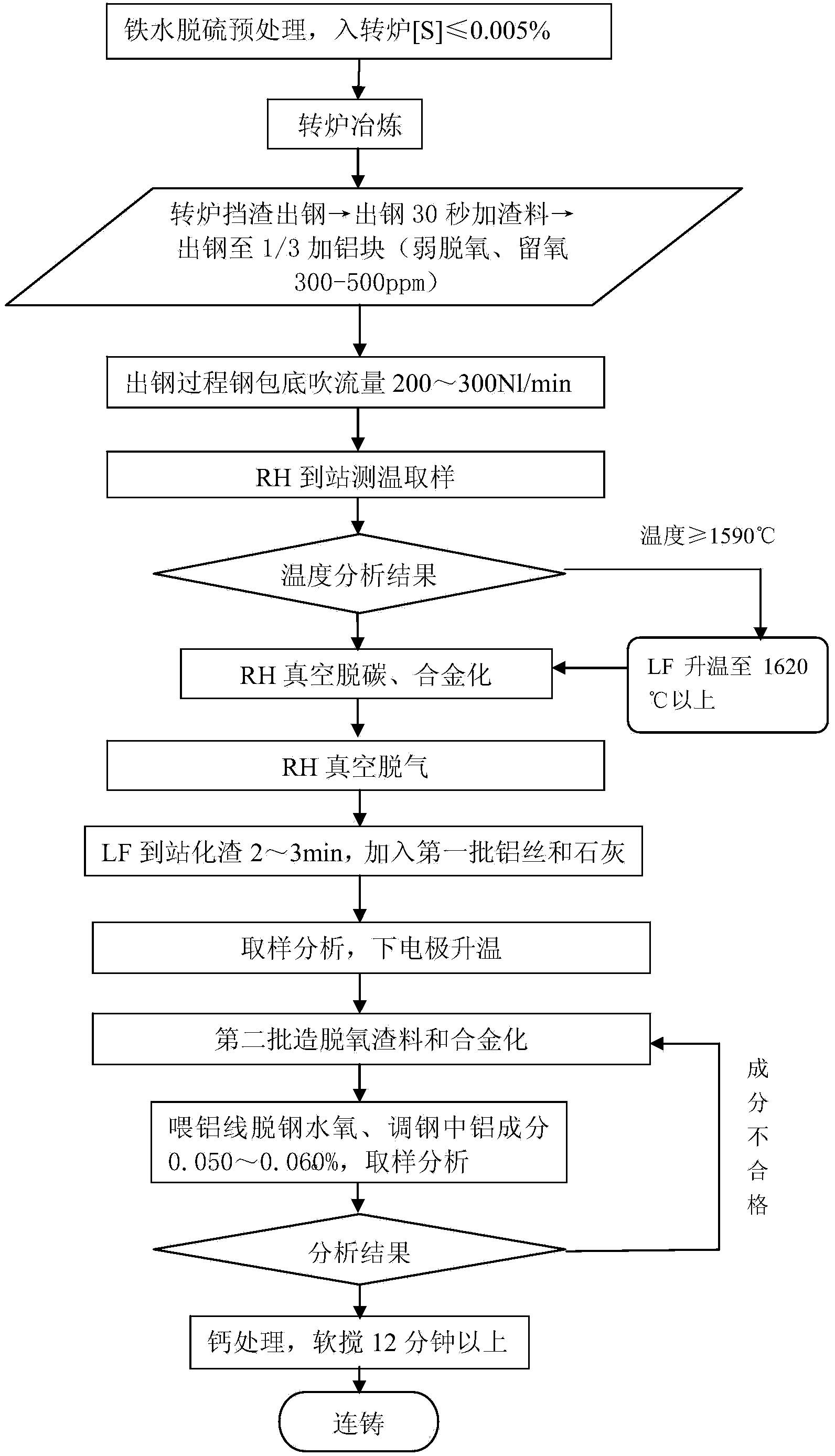

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

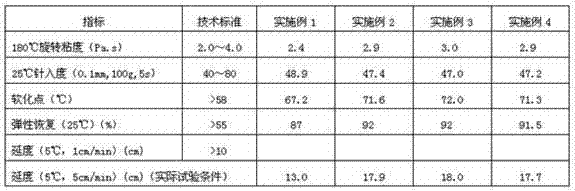

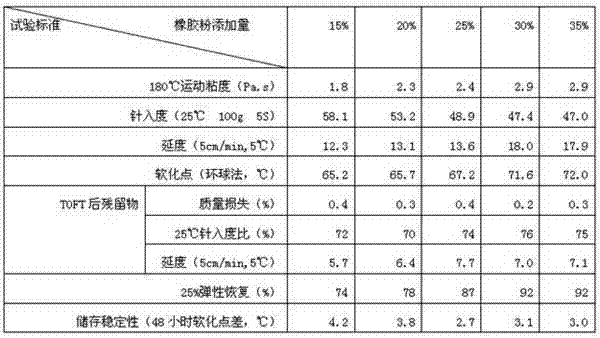

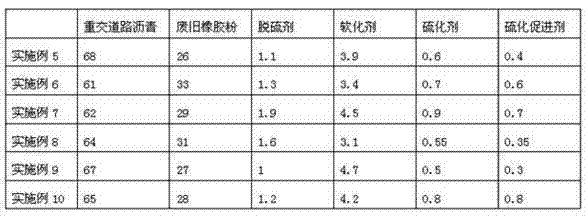

Waste rubber powder modified asphalt and preparation method thereof

ActiveCN103881405AHigh energy consumptionReduce production efficiencyPlastic recyclingBuilding insulationsAsphaltWaste rubber

The invention discloses a waste rubber powder modified asphalt relating to the technical field of asphalt compositions. Raw materials are composed of the following materials by weight ratio: asphalt, waste rubber powder, a desulfurizing agent, a softening agent, a vulcanizing agent and a vulcanization accelerator. A preparation method comprises the following steps of (1) pouring the asphalt into a reaction kettle, heating, adding the waste rubber powder, the desulfurizing agent and the softening agent into the reaction kettle to uniformly mix, and raising the temperature; and (2) smashing the waste rubber powder to 150-200 meshes to be added to a vulcanizing tank and adding the vulcanizing agent and the vulcanization accelerator. According to the preparation method, the waste rubber powder is directly added into the asphalt and then the desulfurizing agent is added so that the rubber powder is heated for swelling and desulfurized simultaneously in the reaction kettle, production equipment is saved, special rubber powder desulfurizing equipment is not used, the mixing amount of the waste rubber powder is large, the production cost is reduced, the production processes are reduced, the desulfurizing time is long, desulfurization is complete, and the production efficiency is high.

Owner:王国清

Forcible wet desulphurization process for lead plaster

The invention provides a forcible wet desulphurization process for lead plaster. The process comprises the following steps of adding water to stir the lead plaster in a lead plaster stirring tank to dilute the lead plaster into 10 to 30 mass percent ore pulp, pumping 20 cubic meters of ore pulp into a desulphurization stirring tank by using a slurry pump, simultaneously adding Na2CO3 into the desulphurization stirring tank according to the mass ratio of Na2CO3 to PbSO4 of (1-1.2):1, pumping the ore pulp out of the desulphurization stirring tank at the same time of desulphurization stirring, enabling the ore pulp to flow through a forcible desulphurizer, and circulating the ore pulp between the desulphurization stirring tank and the forcible desulphurizer. According to the process, PbCO3 product layers wrapped on the outer surfaces of PbSO4 particles can be crushed through the forcible desulphurizer in a desulphurization process to completely expose PbSO4 in a solution of Na2CO3, so that the efficiency of transformation of PbSO4 into PbCO3 is improved, and the aim of forcible desulphurization is fulfilled; rolling and grinding modes are adopted for crushing large PbSO4 crystalline particles through the forcible desulphurizer, and a supergravity stirring mode is adopted for crushing the large PbSO4 crystalline particles and stirring the ore pulp, so that the aims of crushing the large PbSO4 crystalline particles and accelerating desulphurization transformation are fulfilled.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

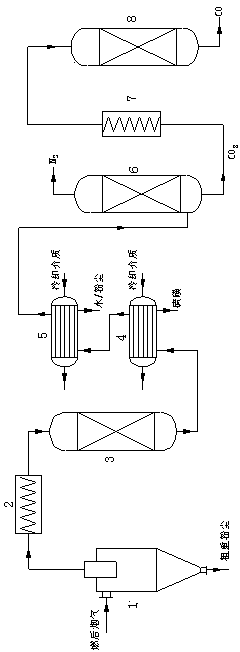

Method for synchronous desulphurization, denitration dedusting and emission reduction of carbon dioxide by fire coal and flue gas

InactiveCN104162358ALower capture costsIncrease concentrationCombination devicesProductsFlue gasEconomic benefits

The invention relates to a method for synchronous desulphurization, denitration dedusting and emission reduction of carbon dioxide by fire coal and flue gas, which comprises the following steps: cyclone dust collection, heating by flue gas, reduction by carbon for desulphurization and denitration, two-grade cooling for recovering sulphur, dedusting, collecting, heating of carbon dioxide and reduction. According to the invention, desulphurization and denitration treatment are simple and thoroughly, collection cost of carbon dioxide is reduced, and no secondary pollutant is generated, the byproduct has good market value, and zero discharge is realized. According to the invention, individual desulphurization and denitration treatment can be avoided, separating cost of carbon dioxide is reduced, cost and risk of transhipment and burying of carbon dioxide can be avoided, the produced CO is a C1 chemical important raw material, and the method has good economic benefit.

Owner:TIANJIN UNIV

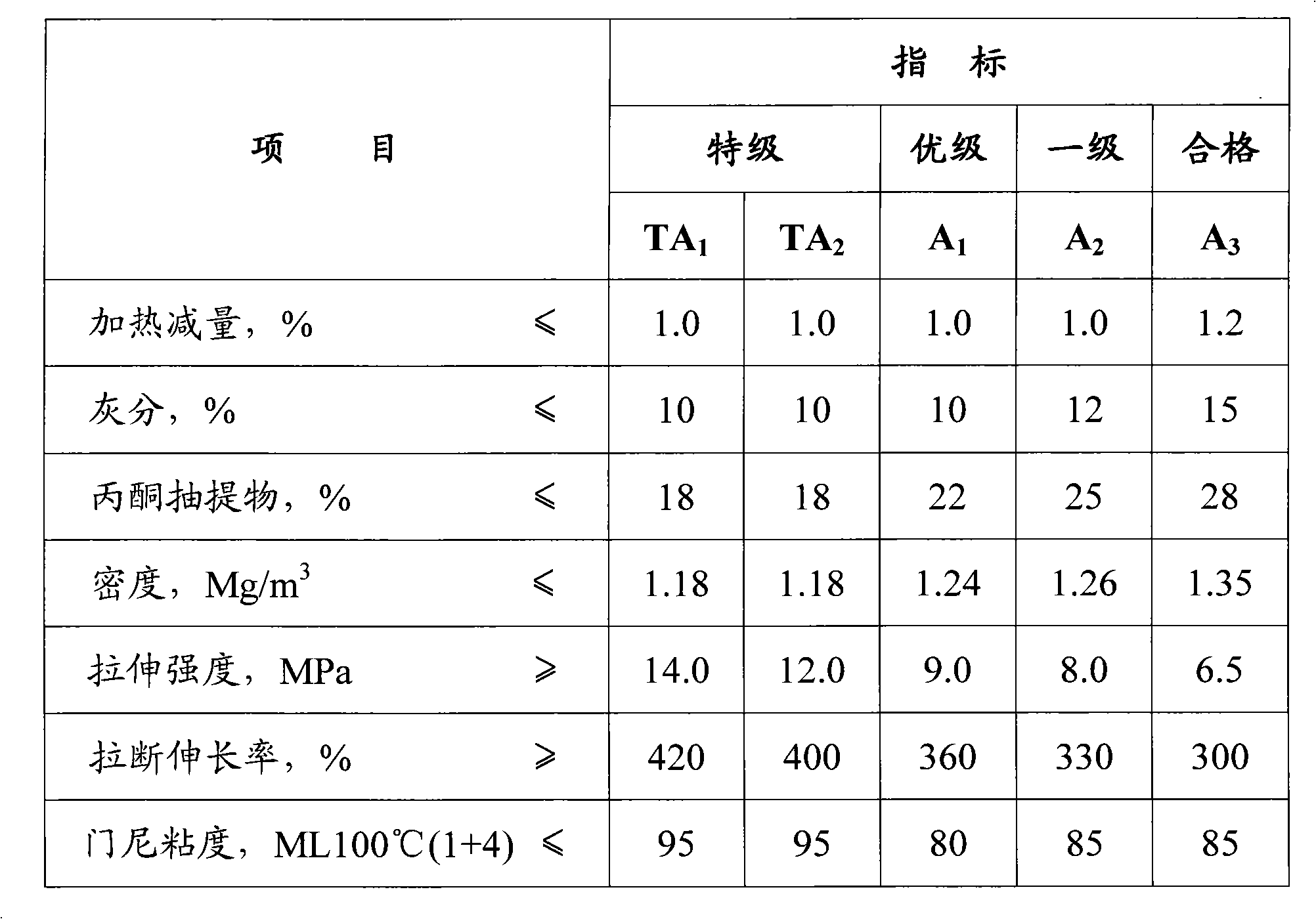

Preparation method for odorless regenerated rubber

ActiveCN104151660AGuaranteed high speed operationEffectively cut offPlastic recyclingVegetable oilPolymer science

The invention discloses a preparation method for odorless regenerated rubber. The preparation method is characterized in that tread rubber powder, an environment-friendly activator, a vegetable oil softener and water are added in the chemical desulfuration process; the environment-friendly activator is prepared from the following components in parts by weight: 3-3.5 parts of persulfate and 7-6.5 parts of aliphatic acid; the amount of the environment-friendly activator is 0.18%-0.29% of the mass of the tread rubber powder; the vegetable oil softener is prepared from cottonseed oil, colophony, pine tar oil, rap oil, drainage oil and olive oil; the amount of the cottonseed oil, the colophony, the pine tar oil, the rap oil, the drainage oil and the olive oil is 3.6%-4.6%, 0.6%-1%, 1.3%-1.9%, 1%-1.5%, 0.8%-1.4% and 0.7%-1.3% of the mass of the tread rubber powder respectively; the added quantity of water is 17%-20% of the mass of the tread rubber powder. According to the invention, products obtained through the preparation method are odorless without containing benzene compounds, are high in tensile strength, great in elongation and moderate in mooney point, and can reach the national-level standard of regenerated rubber; the products such as shoe soles produced from rubber prepared through the preparation method have no color migration.

Owner:普格三鑫环保资源科技利用开发有限公司

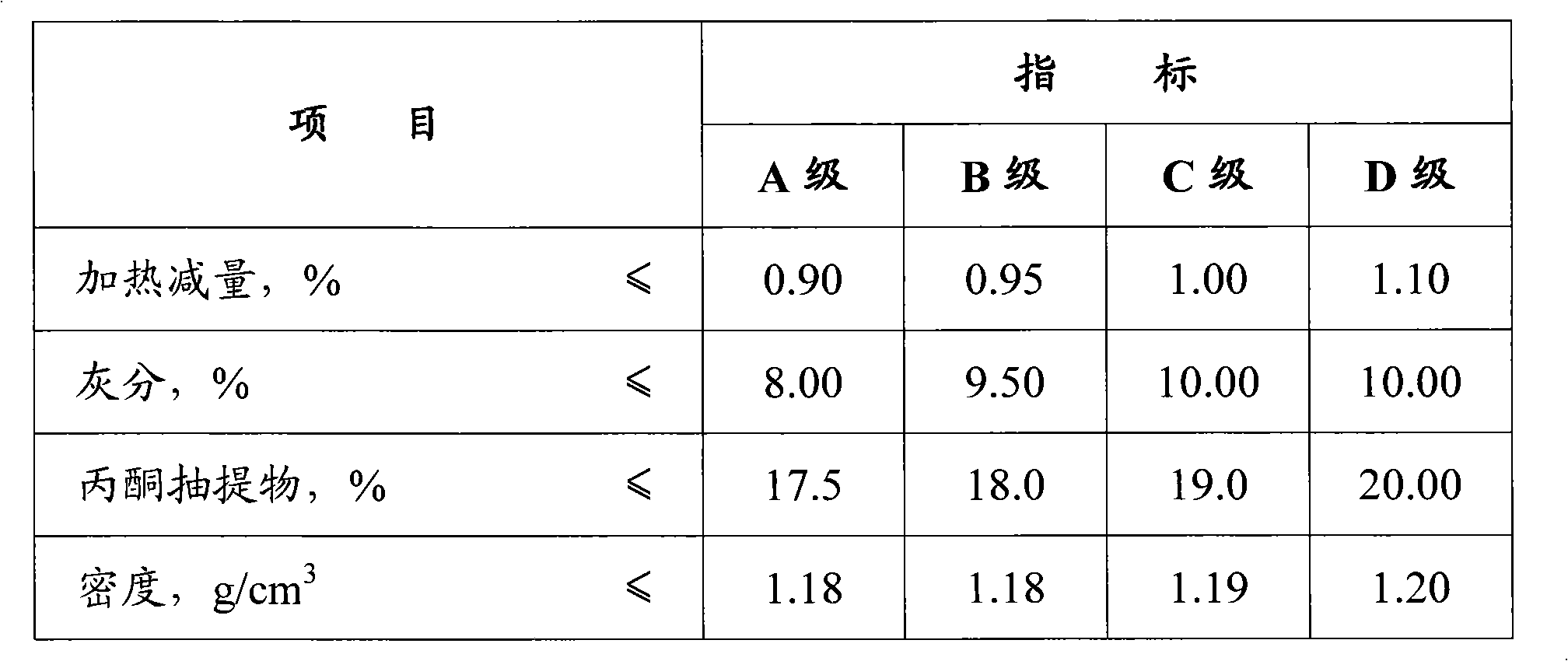

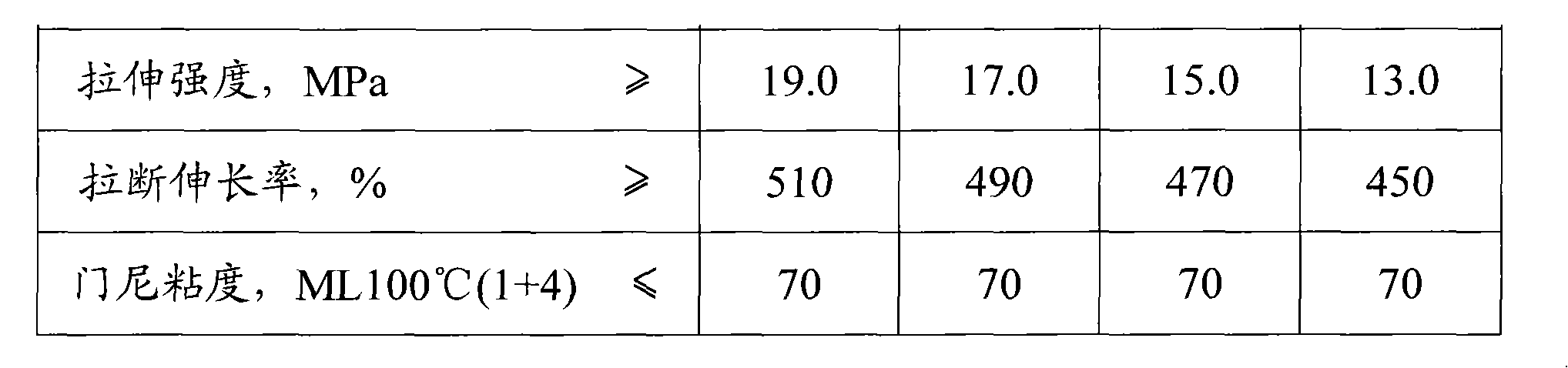

Environment-friendly high-quality tyre reclaimed rubber manufacturing method

InactiveCN101906217AReduce the presence of hazardous substancesConforms to EU standardsPlastic recyclingBuilding insulationsHazardous substanceTar

The invention relates to an environment-friendly high-quality tyre reclaimed rubber manufacturing method, comprising the following steps: selecting waste radial tyre crowns, pulverizing the selected waste radial tyre crowns, screening, and adding composition of rubber powder, vegetable pitch, odourless pine tar oil, starex, activating agent and water while blending, wherein the activating agent is activating agent580; and carrying out banburying after desulfurizing, and carrying out rubber filtering after refining. Since the vegetable pitch, the starex, the odourless pine tar oil and other softeners as well as the activating agent580 are adopted, no pollution exists; especially the activating agent580 substitutes for the activating agen420 with high pollution or the activating agent450 with pollution, desulfuration is more thorough, and the reclaimed rubber has improved quality and no harmful substance and accords with the European Union standards; and since the materials are reasonably selected, and the technologies such as refining, rubber filtering and the like are adopted, the manufacturing of the high-quality reclaimed rubber is realized.

Owner:福建环科集团三明市高科橡胶有限公司

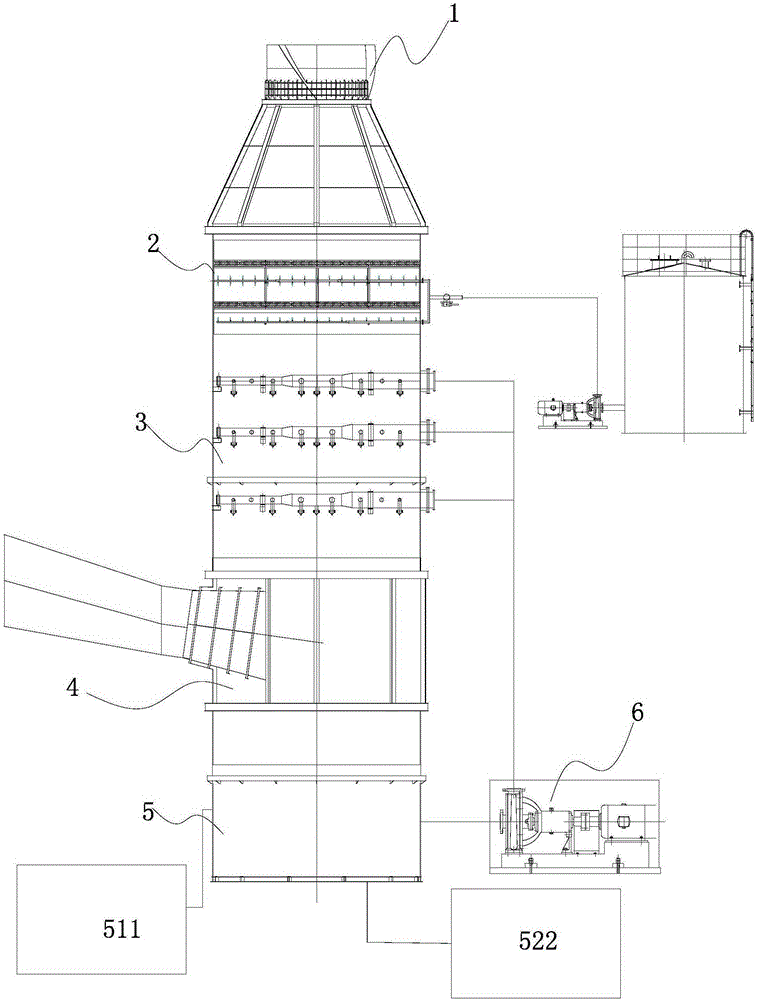

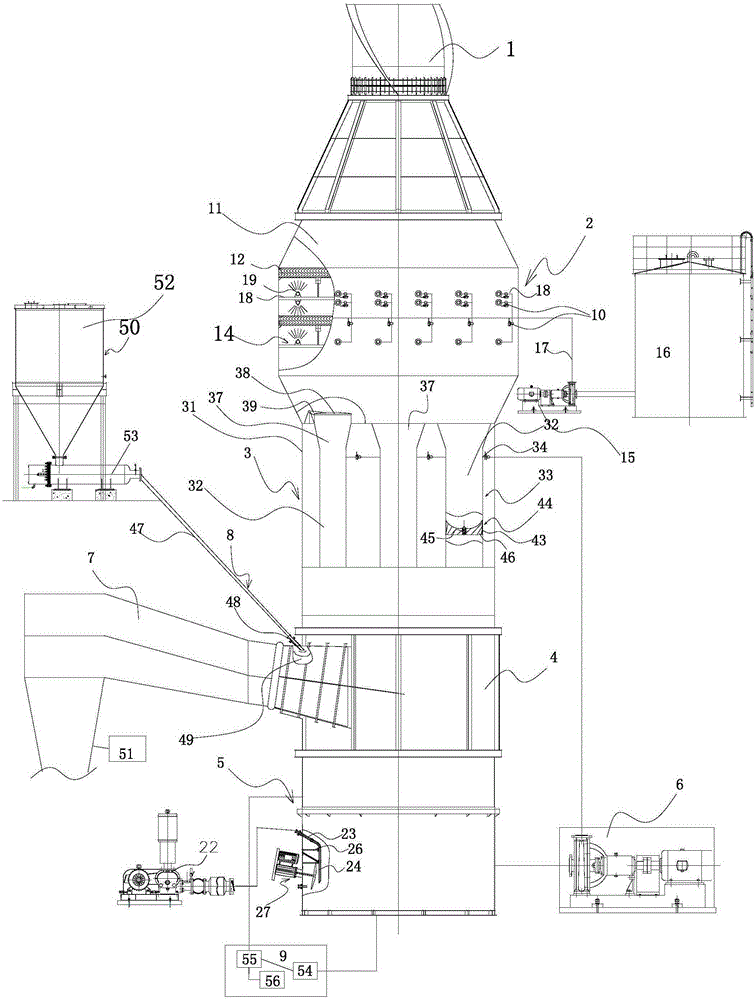

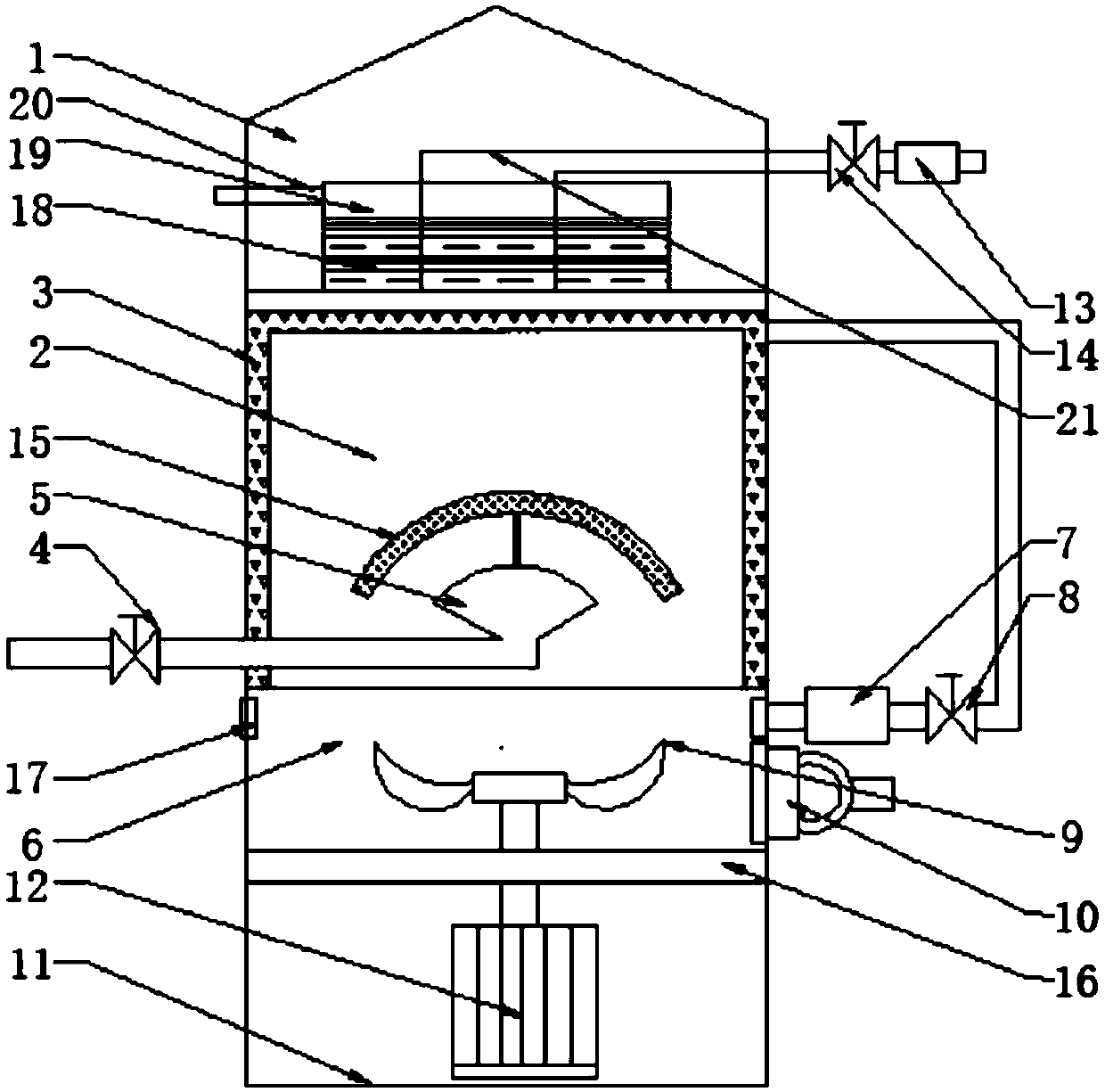

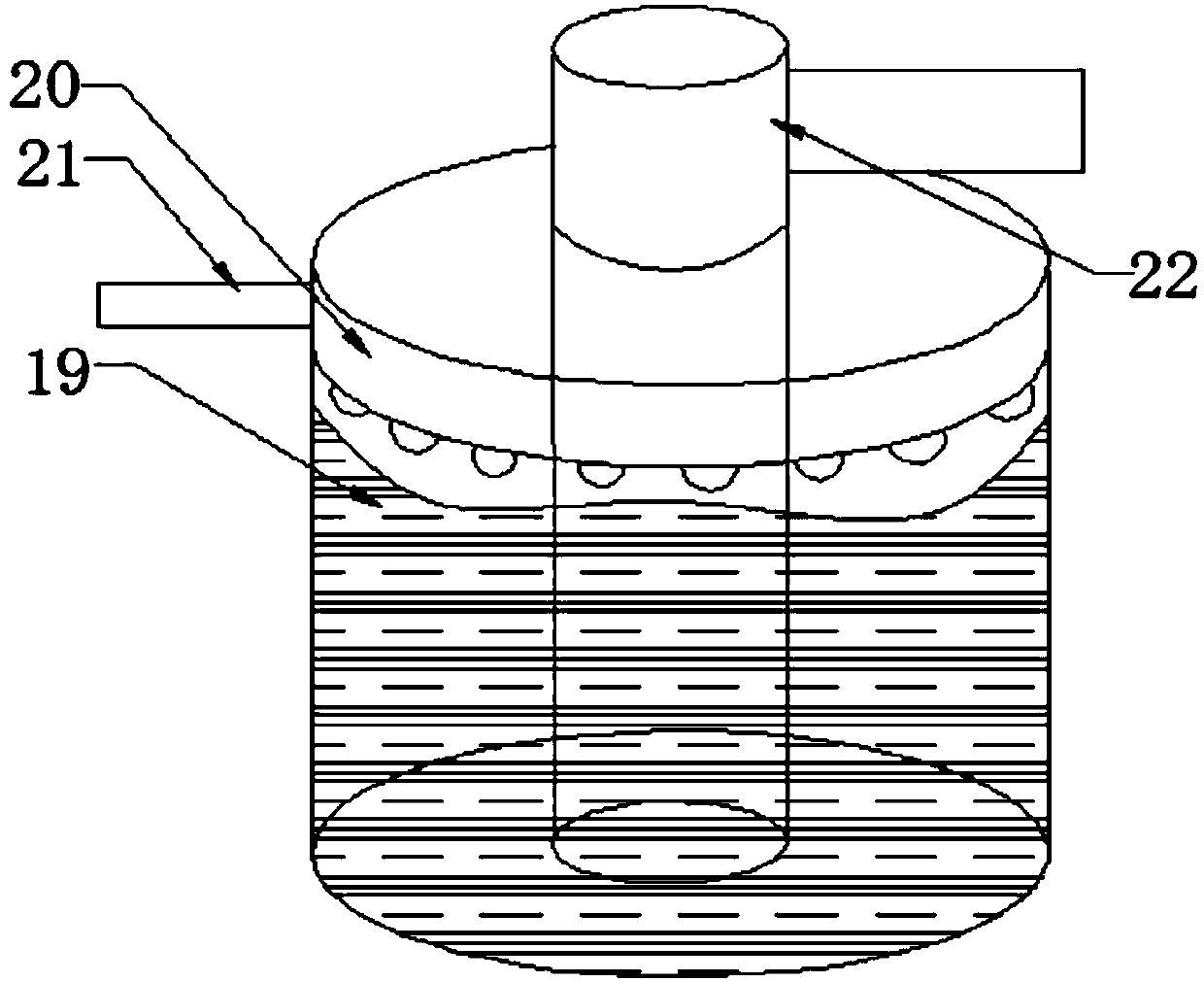

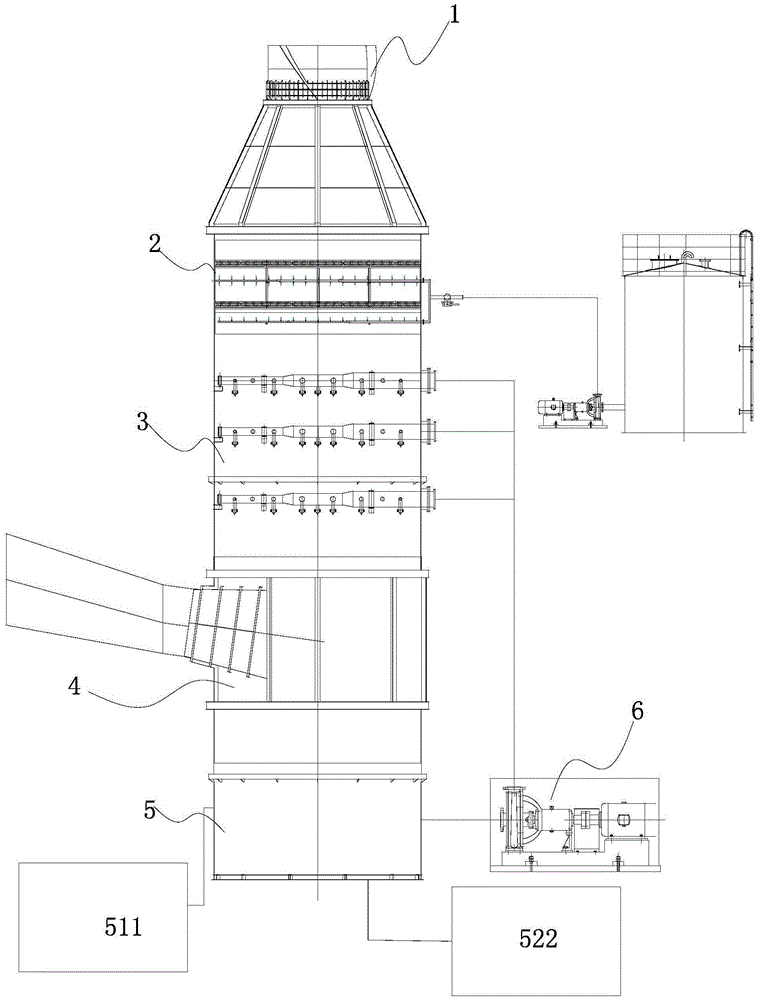

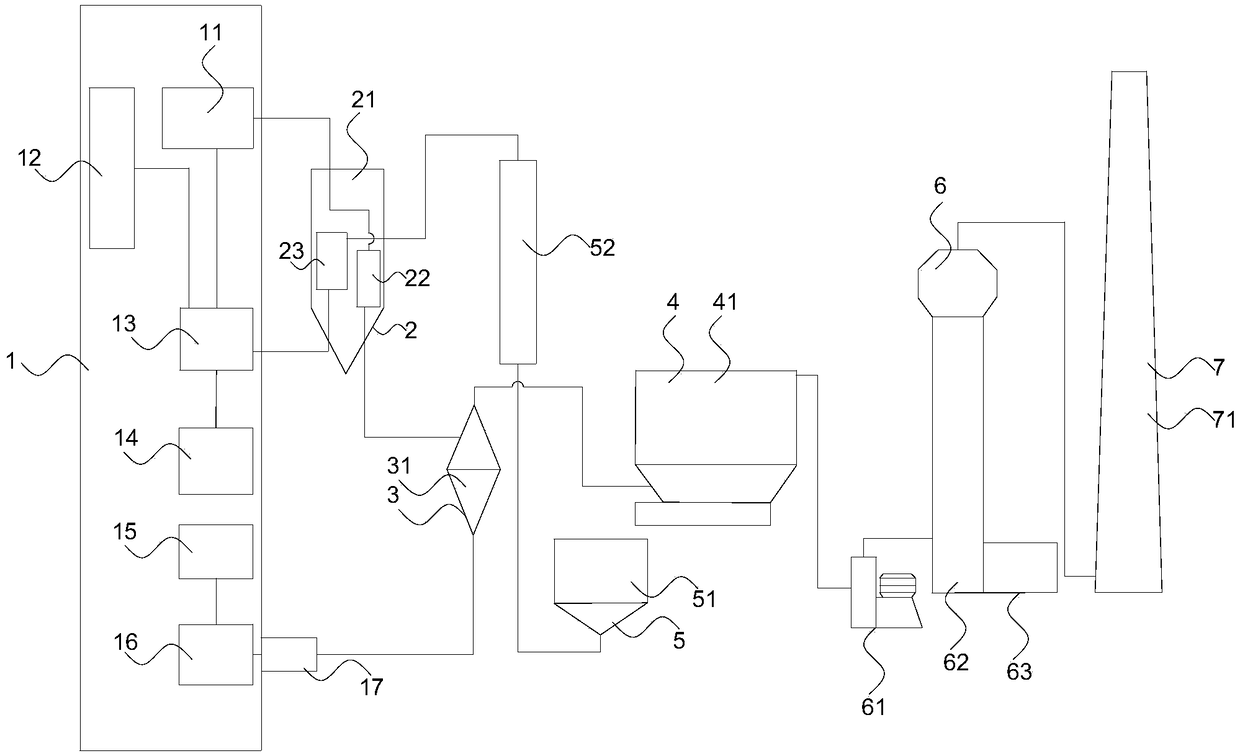

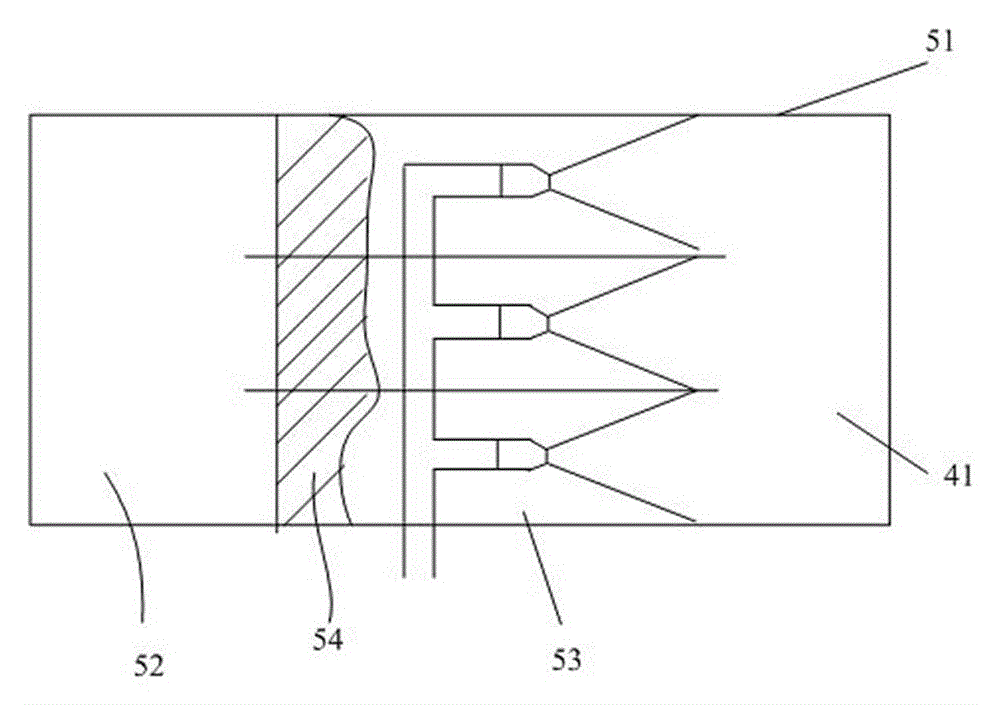

Flue gas desulphurization system and method for flue gas desulfurization by means of same

ActiveCN105169926APromote desulfurization reactionImprove desulfurization efficiencyDispersed particle separationImpellerFlue gas

The invention discloses a flue gas desulphurization system and a method for flue gas desulfurization. The system comprises a flue gas desulphurization tower, an ash storage device, a gypsum preparing device and an air induction device, wherein the flue gas desulphurization tower comprises a tower body, a fume extractor, a defrosting device, a rotational flow reaction device, a gas uniformizing device and a multi-functional collecting reservoir, the fume extractor, the defrosting device, the rotational flow reaction device, the gas uniformizing device and the multi-functional collecting reservoir are communicated from top to bottom in sequence, a flue is provided with a dry powder inlet communicated with a dry powder desulfurizing agent spraying device, the multi-functional collecting reservoir is arranged under the gas uniformizing device, the rotational flow reaction device comprises a rotational flow shell and at least one rotational flow chamber provided with at least one swirler inside, each rotational flow chamber is provided with a circular reaction slurry inlet and communicated with the gas uniformizing device, and each swirler comprises an impeller shell, an impeller center shaft and at least five swirl vanes surrounding the impeller center shaft. By the adoption of the system, flue gas desulphurization effect and degree can be improved, space can be saved, a slurrying pool and a slurry precipitation pool are not needed, maintenance is convenient, cost is low, energy is saved, and environment pollution is avoided.

Owner:龙创信恒(北京)科技有限公司

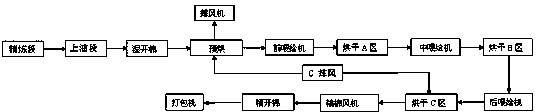

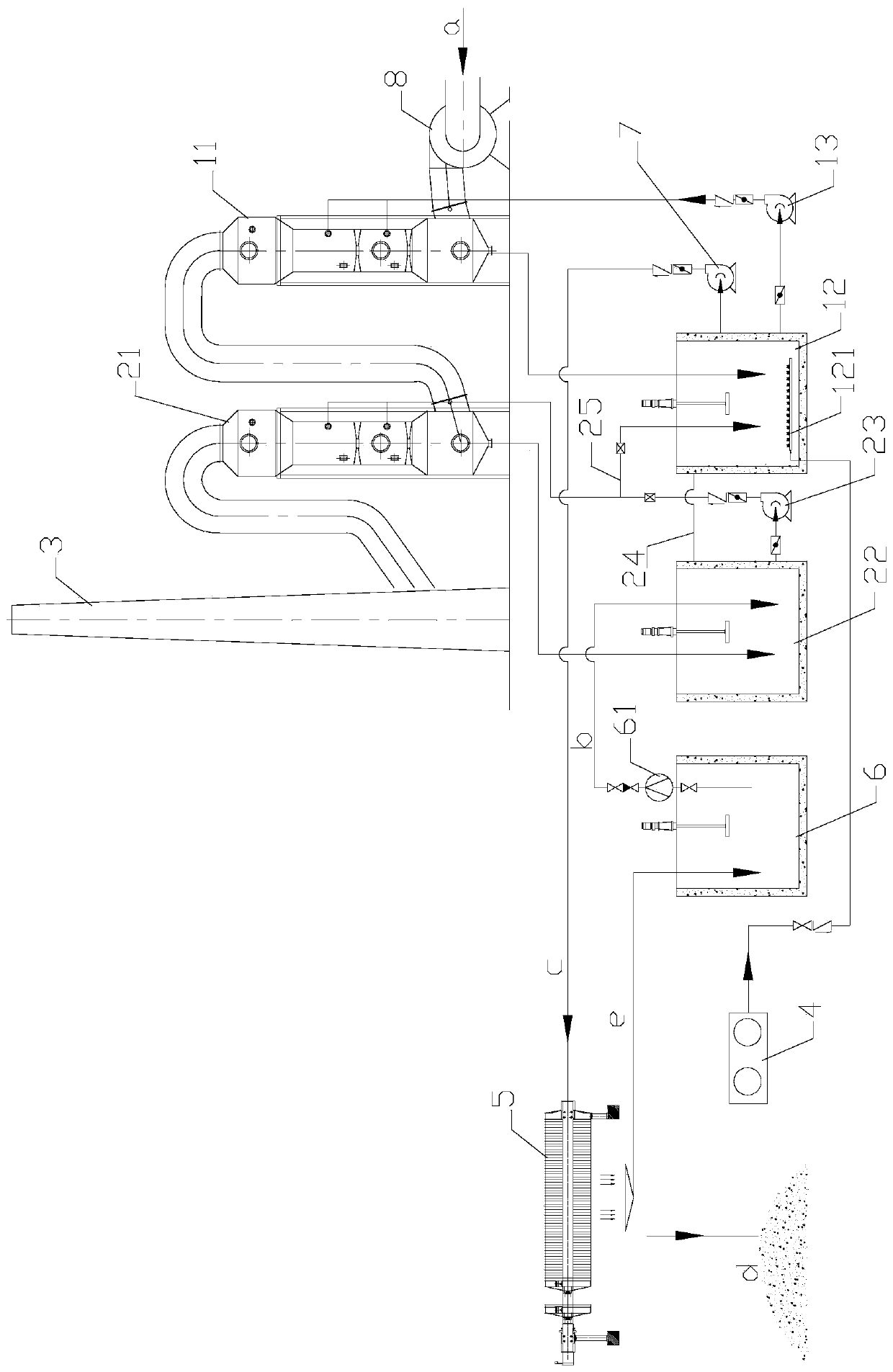

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290AIncrease washing timeWash Time GuaranteeSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

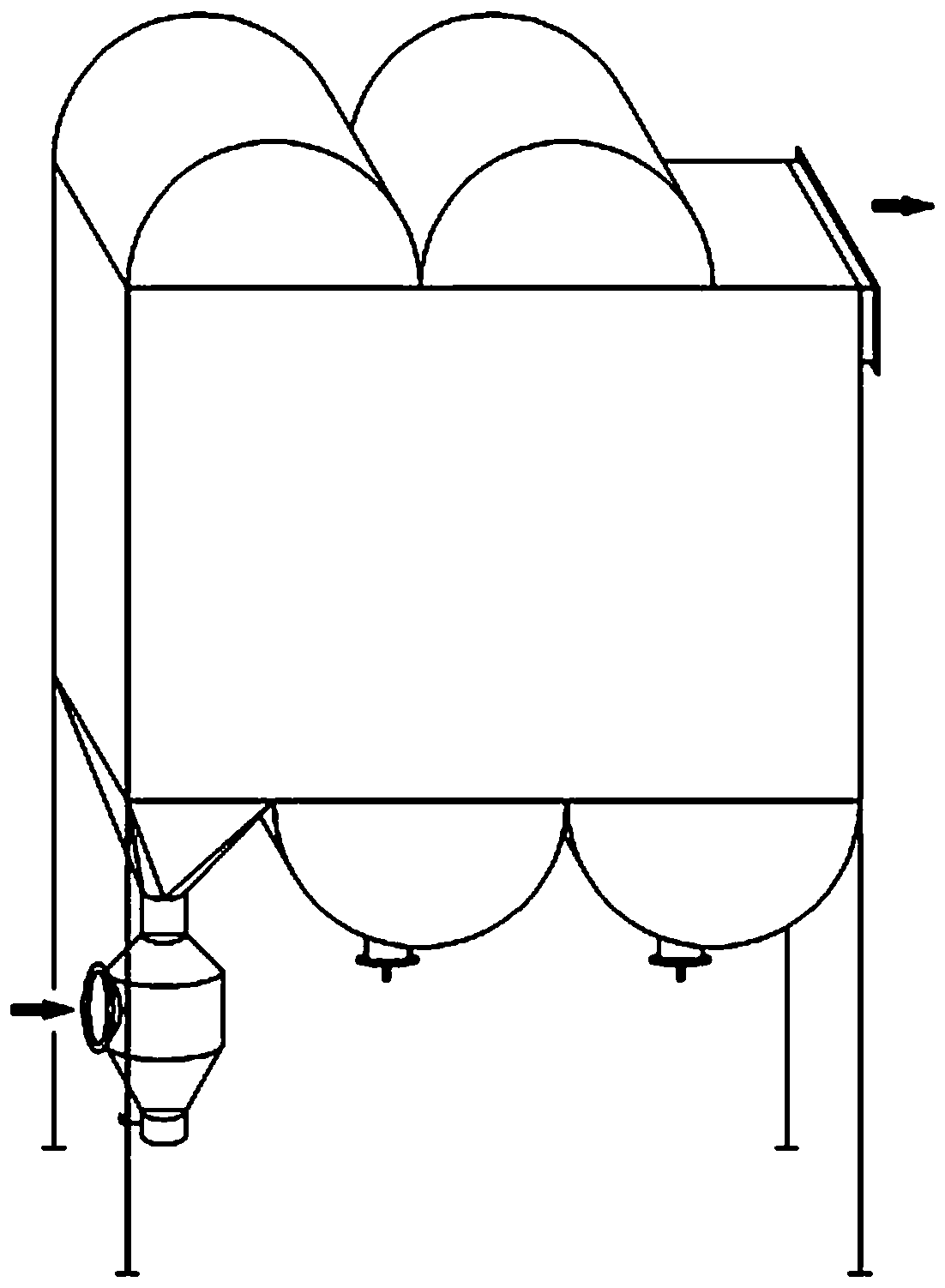

High-efficiency smoke desulfurizing, dedusting and purifying device

PendingCN108554151AWell mixedComplete contact reactionCombination devicesGas treatmentActivated carbonParticulates

The invention relates to a high-efficiency smoke desulfurizing, dedusting and purifying device. The device comprises a desulfurization tower, a dedusting box and a purifying box, smoke enters the desulfurization tower, the smoke and a chemical liquid flow in the desulfurization tower in the same direction and undergo a desulfurization reaction and rotation in order to achieve preliminary dedusting, radial interlacing mixing is performed on a stop channel, and a fluid infusion is obtained in the central area of the tower, so full air and liquid mixing, complete contact reaction and good desulfurizing and dedusting effects are achieved; the arrangement of a filter plate and an activated carbon adsorption layer makes waste gas filtered and adsorbed and some large particulate impurities in air filtered out, the waste gas in the dedusting box is conveyed into the purifying box through an exhaust fan and a conveying tube, the contact between an air filter screen and the chemical liquid makes the waste gas in full contact with the chemical liquid at the bottom of the inner chamber of the purifying box in order to chemically react the waste gas, and a stirrer in the purifying box can stir the chemical liquid to improve the reaction efficiency of the waste gas and the chemical liquid and improve the waste gas purifying effect.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

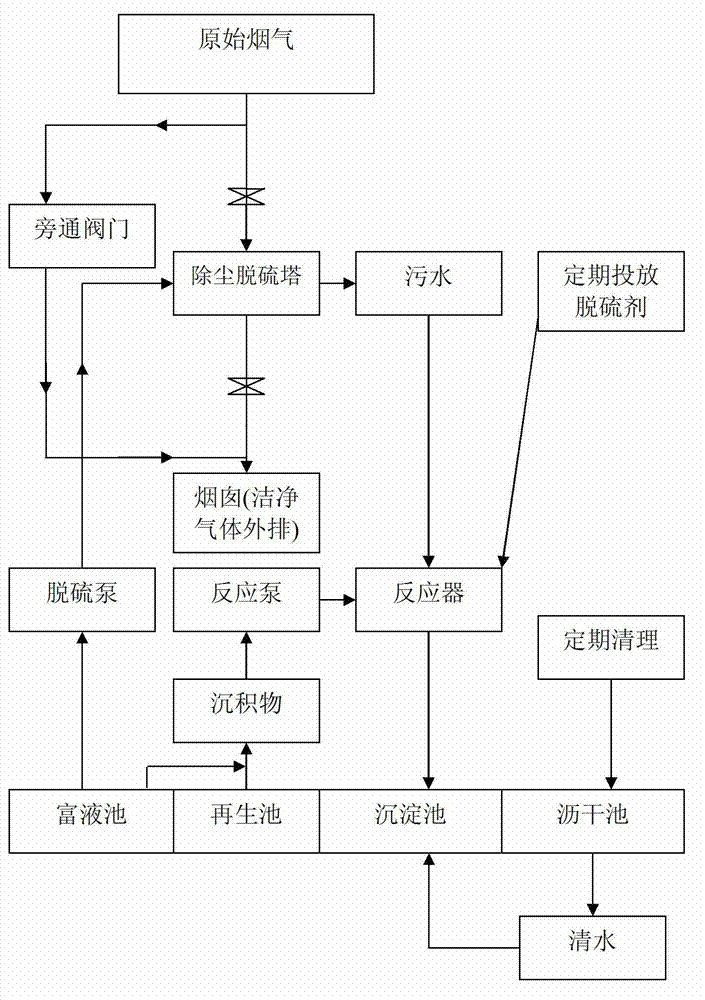

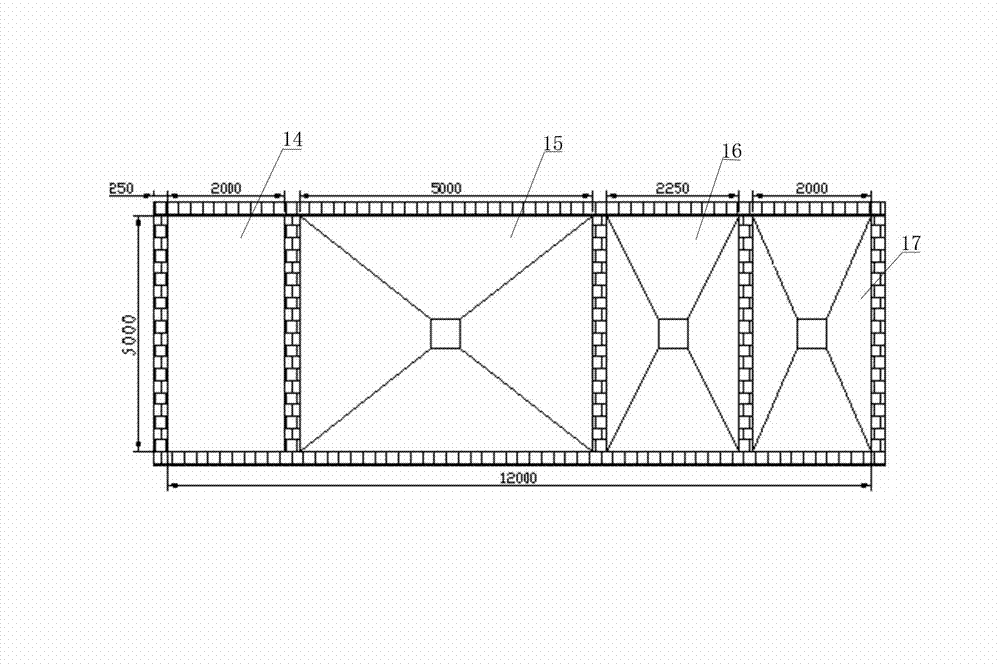

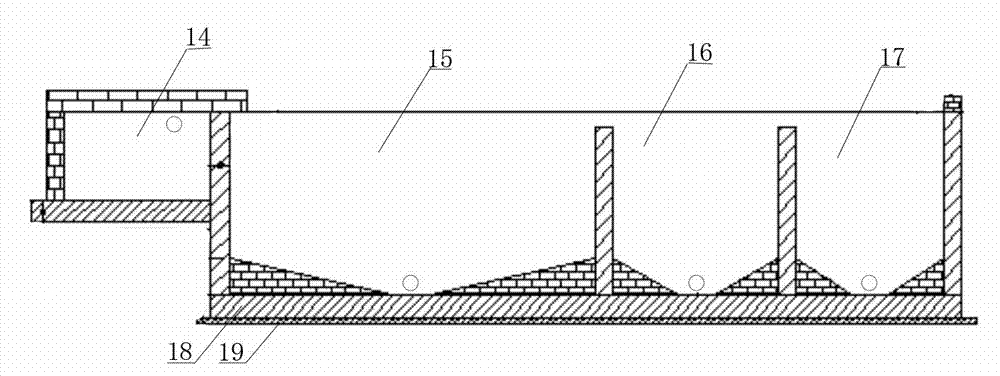

Catalytic double-alkali desulphurization and dust removal process

InactiveCN102847423AReduce surface tensionRapid precipitationUsing liquid separation agentPhysical chemistryDust control

The invention discloses a catalytic double-alkali desulphurization and dust removal process. NaOH is added into a rich liquor tank and one selected from or a mixture formed by two or three selected from the group consisting of washing powder, a washing agent and Na3PO4 is added at the same time, which enables surface tension of liquid to be reduced and rapid deposition of Ca(OH)2 or dust to be promoted; if Ca(OH)2 forms fouling in a dedusting desulfurization tower, normal operation of the dedusting desulfurization tower is affected. Meanwhile, after a foam layer is formed in the dedusting desulfurization tower, SO2 can be fully absorbed and fully reacts, thereby achieving the purpose of full desulphurization. The process provided by the invention has a remarkable effect, can ensure that equipment continuously runs for a long time and is substantially in a maintenance-free state, saves cost and is favorable for popularization and application.

Owner:GONGYI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY EQUIP FACTORY

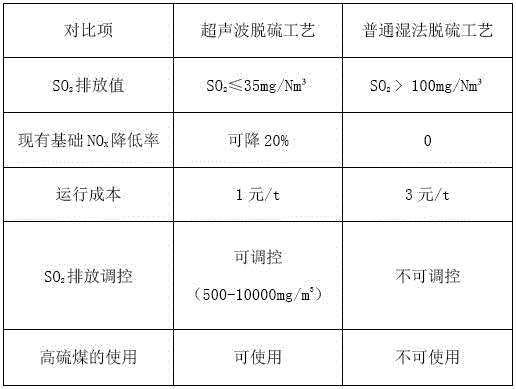

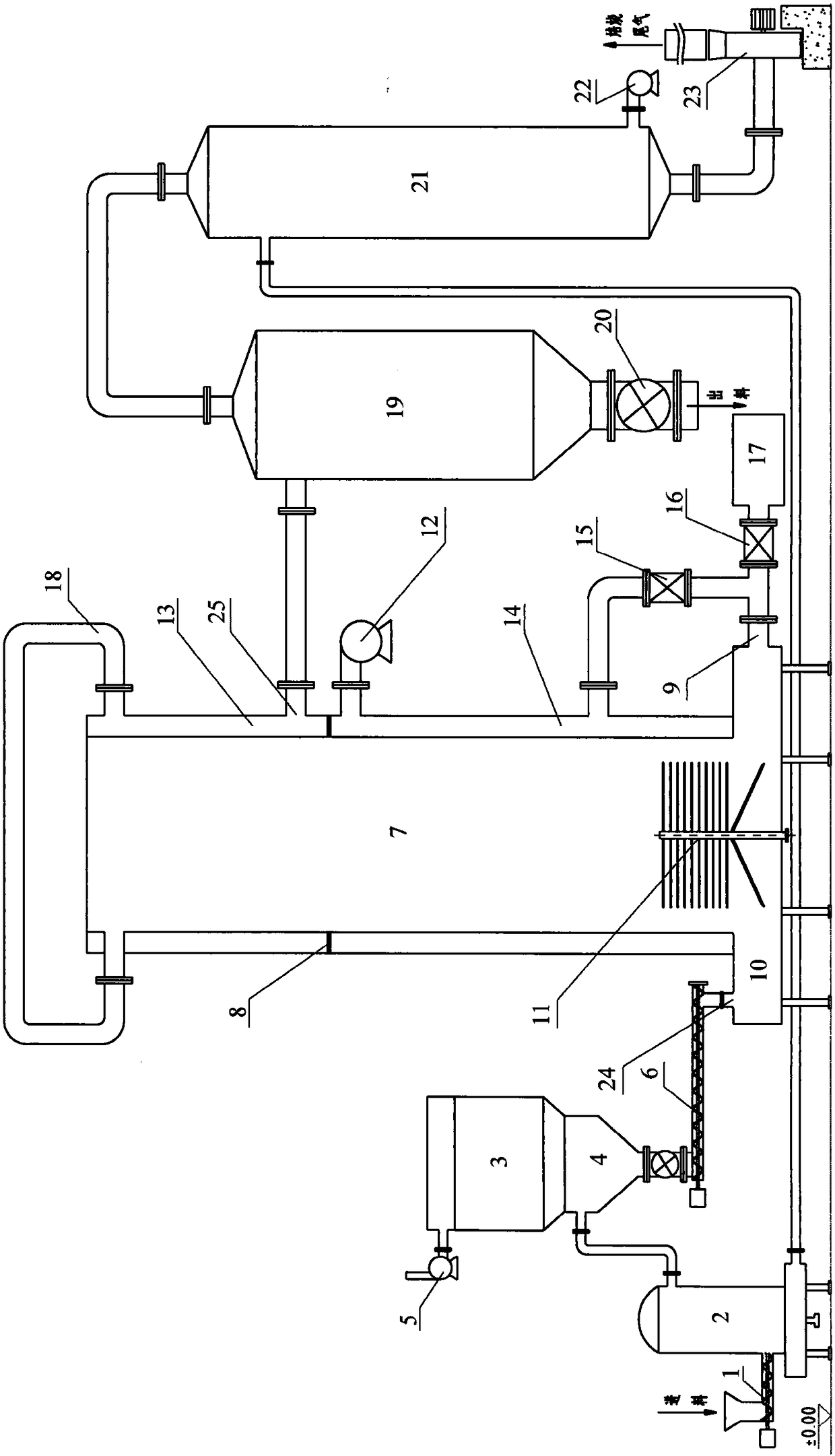

Ultrasonic desulfuration, denitration and dust removal method

InactiveCN105833696ATo achieve the purpose of desulfurizationComplete desulfurizationCombination devicesGas treatmentUltrasound deviceNitrogen oxide

The invention discloses an ultrasonic desulfuration, denitration and dust removal method .The method includes the steps that smoke enters an ultrasonic device; an ultrasonic generator in the ultrasonic device generates ultrasonic waves to atomize desulfuration liquid entering the ultrasonic device, SO2 in the smoke is catalyzed and oxidized by the atomized desulfuration liquid at high speed to generate SO3, and SO3 and a desulfuration medium in the desulfuration liquid react; the smoke processed by the ultrasonic device is sucked in under the action of an air draft fan and is conveyed back into a smoke exhaust pipeline .Desulfuration efficiency can reach 95% or above, the denitration effect is achieved, and nitrogen oxides are reduced by 20% or above.

Owner:陈佐会

Desulfurizing tower

InactiveCN107739637AIncrease contact areaExtension of timeGaseous fuelsDispersed particle separationContact timeEngineering

The invention discloses a desulfurizing tower which comprises a tower body, a spraying chamber and an alkali liquid tank, wherein a spraying chamber is formed inside the tower body; spraying heads arefixed at the top and on the side surface of the spraying chamber; a gas inlet tube is inserted into the bottom end of the spraying chamber; a first valve is fixed at one end of the gas inlet tube; afiltering plate is fixed at the other end of the gas inlet tube; the alkali liquid tank is fixed at the bottom of the spraying chamber; and the bottom of the alkali liquid tank is fixedly connected with the top of a residue collection tank. According to the desulfurizing tower disclosed by the invention, one end of the gas inlet tube takes the shape of an inverted funnel, the middle axis of the inverted funnel is overlapped with that of the spraying chamber, and then a fed gas is diffused around; as the spraying heads are arranged at the top end and the side surface of the spraying chamber, the gas-liquid contact area is increased, the gas-liquid contact time is prolonged, and relatively thorough desulfuration is achieved; an alkali liquid in the alkali liquid tank can be circulated, so that the purpose of environmental protection and emission reduction is achieved, and the consumption is reduced; and the alkali liquid can be stirred by stirring blades in the alkali liquid tank, so that the alkali liquid is uniform in concentration, and a stable desulfuration effect is ensured.

Owner:NANJING HONGBO ENVIRONMENTAL PROTECTION IND

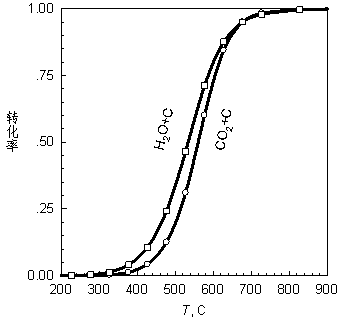

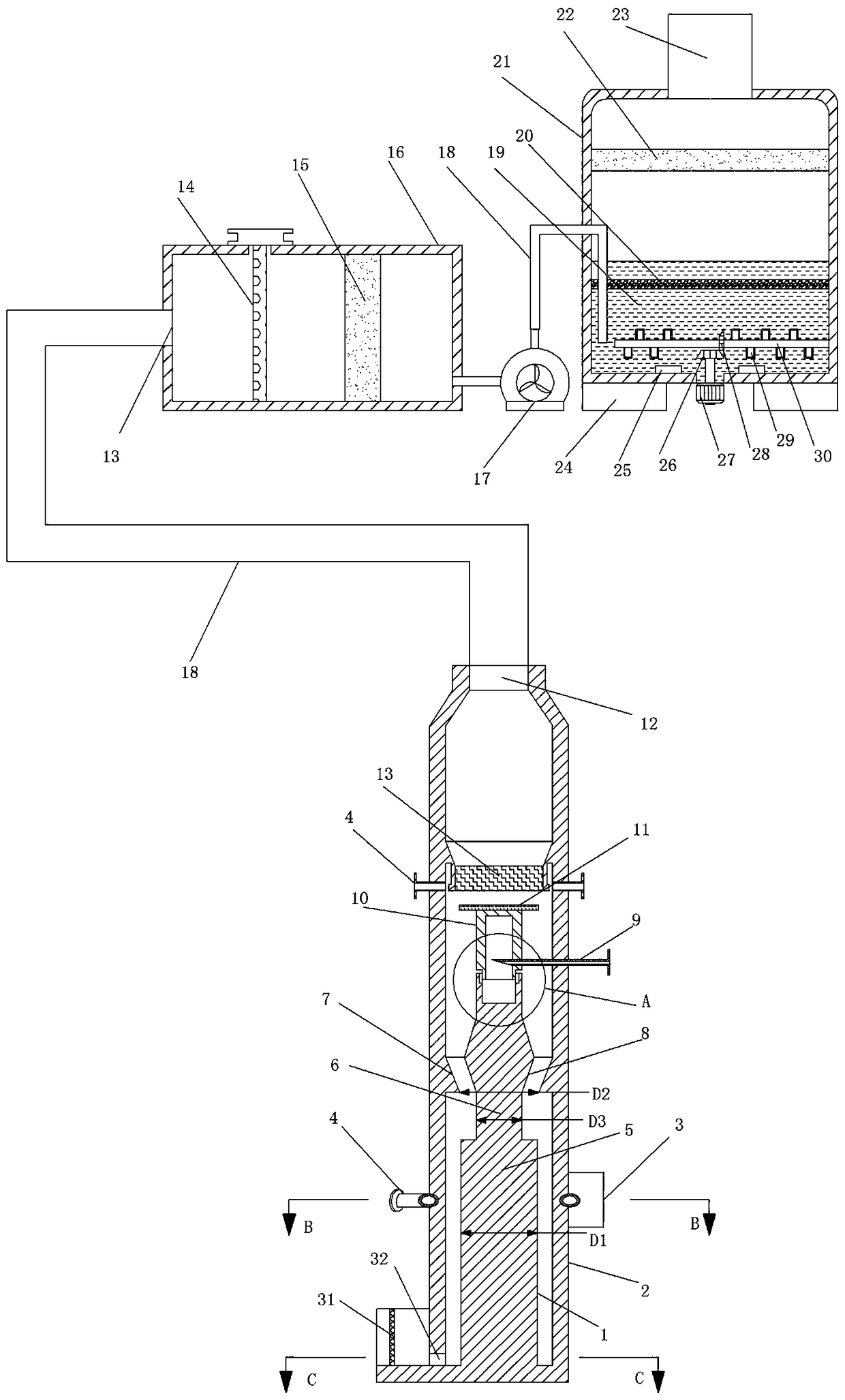

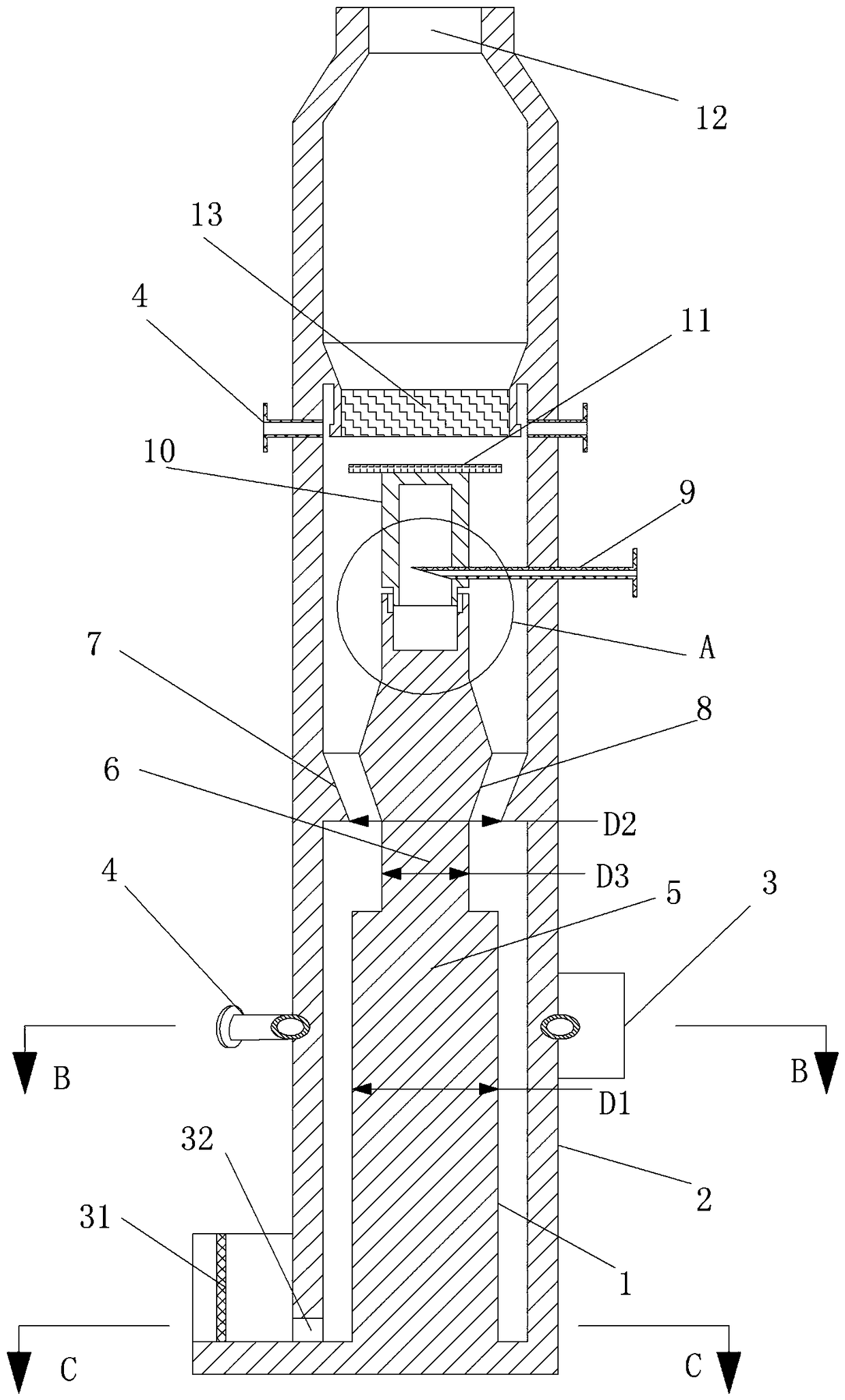

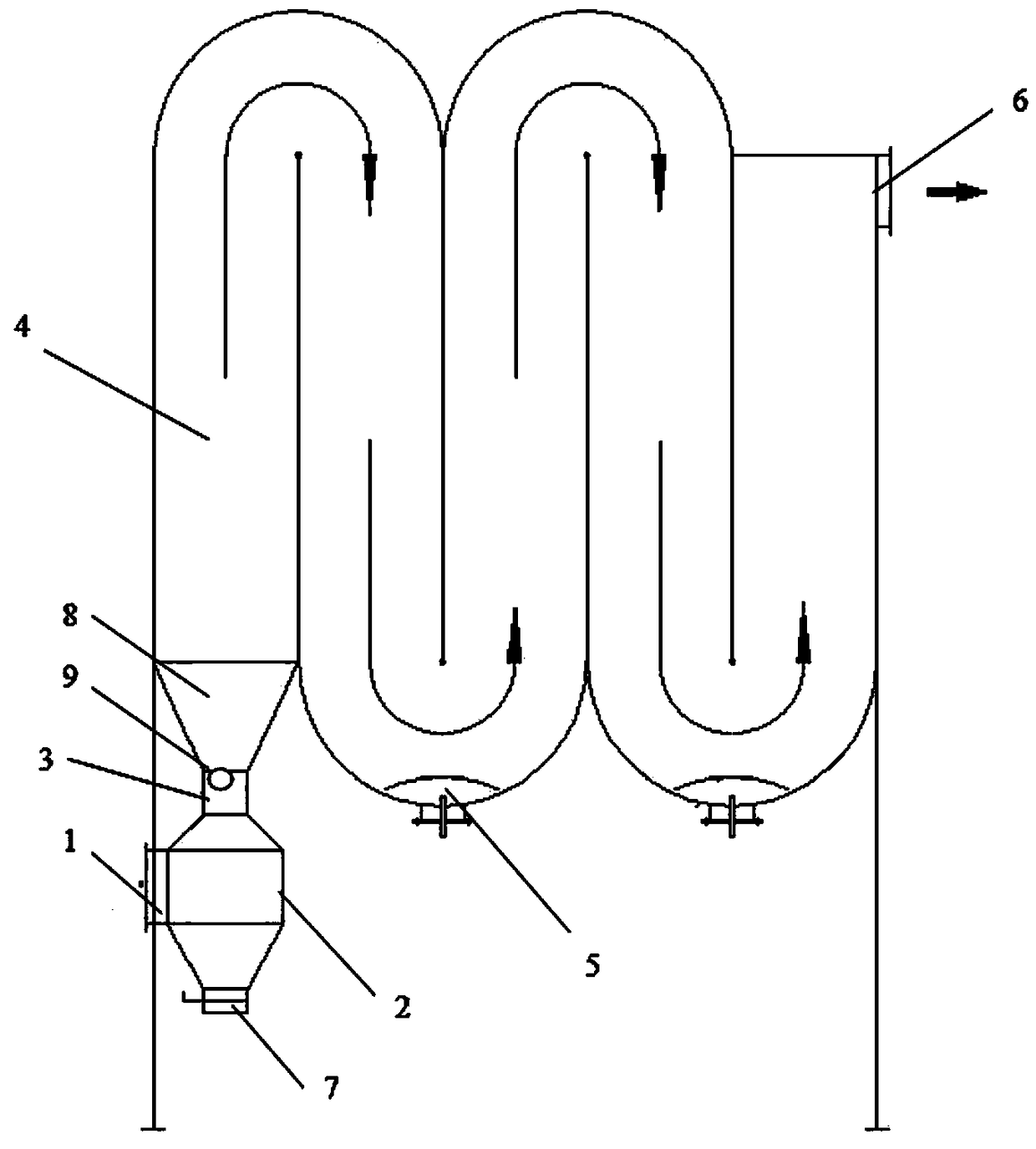

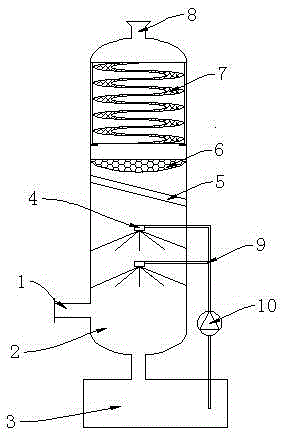

Bright molybdenum concentrate self-heating type rotational flow roasting technology and equipment

ActiveCN108149006AFully roasted oxidation reactionComplete desulfurizationMolybdenum oxides/hydroxidesWaste heat treatmentComing outGas solid

The invention relates to a bright molybdenum concentrate self-heating type rotational flow roasting technology and equipment. A rotational flow roasting furnace provided with a furnace body heat exchanging device is utilized to roast bright molybdenum concentrate so as to produce industrial molybdenum oxide. The heat emitted by a roasting reaction of the bright molybdenum concentrate is utilized to preheat air entering from an interlayer heat exchanging device of a lower furnace body in the roasting process, the preheated air is supplied into the rotational flow roasting furnace from the furnace bottom, a rotational flow wind distributing device makes the bright molybdenum concentrate be subjected to a roasting reaction under a rotational eddy state, a material coming out from the rotational flow roasting furnace enters an upper interlayer heat exchanging device of the rotational flow roasting furnace along with roasting eddy under the effect of negative pressure, a desulfurization reaction is completed in the interlayer heat exchanging device in the rotational advancing process, and a reacted gas-solid mixture enters a gas-solid separation discharging device to be subjected to gas-solid separation so that a solid roasted product and roasted smoke can be separated. The roasted smoke is sent to a SO2 recycling processing system under a draft effect of an induced draft fan afterentering a heat exchanger to exchange heat with the air, and the air after being subjected to heat exchanging is sent to a flash evaporation drying machine to dry the bright molybdenum concentrate.

Owner:NORTHEASTERN UNIV

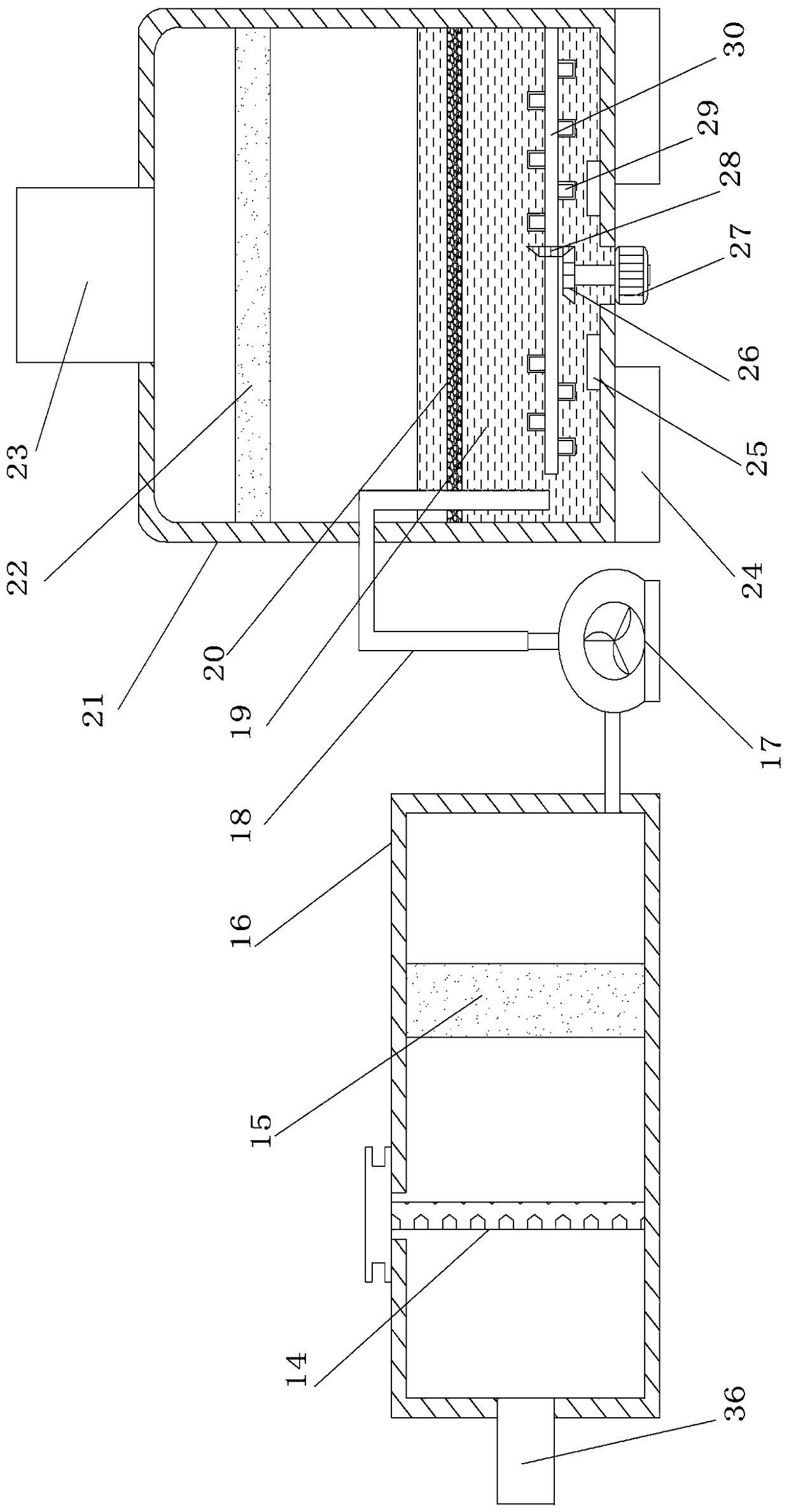

Horizontal semi-dry desulfurization box process technology

InactiveCN108126506AGuaranteed desulfurization efficiencyLess one-time investmentDispersed particle separationFluidized bedFlue gas

The invention discloses a horizontal semi-dry desulfurization box process technology. The technology comprises the following steps: flue gas goes through a flue gas inlet and then enters a desulfurization reactor, the outlet expansion section, externally connected with a Venturi throat, of the desulfurization reactor is provided with a water spray device, and atomized water sprayed by the water spray device reduces the smoke temperature in the desulfurization reactor; the flue gas carrying a desulfurization agent enters a desulfurization box, segment boxes are arranged in the desulfurization box, a fluidized bed is arranged at the bottom of every segment box body, the fluidized beds increase the conversion frequency of a reaction of SO2 and Ca(OH)2, greatly enhance the mass transfer and heat transfer between a gas and a solid, and greatly improve the desulfurization rate; and purified dust-containing flue gas is laterally discharged from the top of an absorption tower connected with aflue gas outlet, enters a desulfurization deduster, goes through a boiler fan and is discharged into a chimney. The design of the desulfurization tower becomes horizontal from horizontal, so the height of the desulfurization tower is greatly reduced, and the use amount of a material is reduced, thereby the production cost is reduced, and the technology has high practical values, and is worth promoting.

Owner:河南环碧环保工程设备有限公司

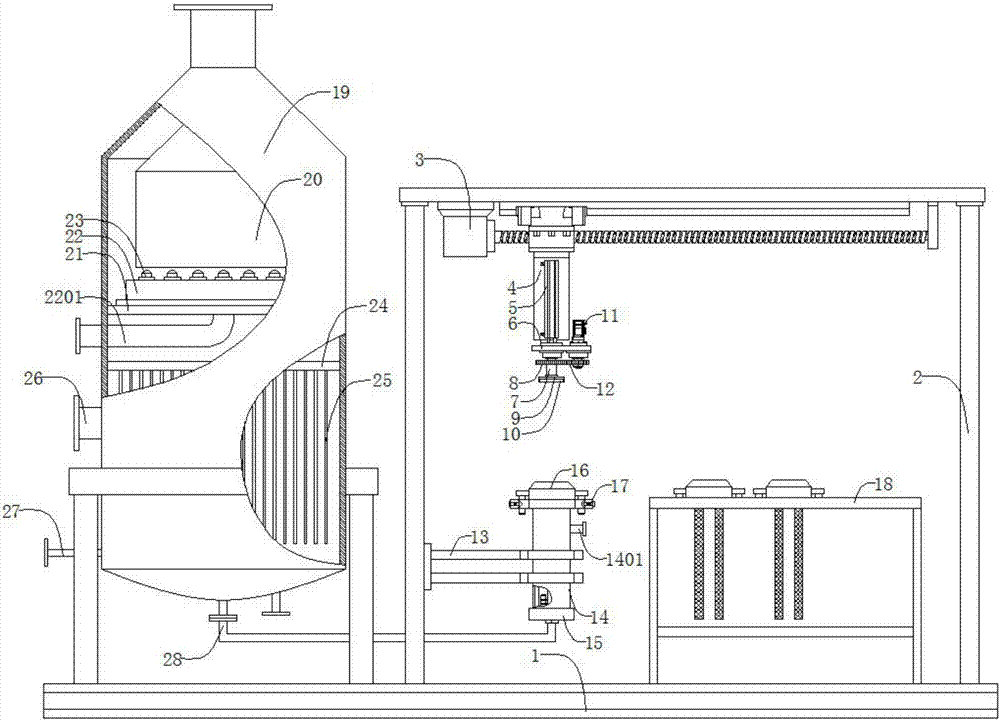

Automatic filter element replacement type flue gas desulfurization device

PendingCN107349777AReduce labor intensityAvoid damageDispersed particle separationToxic gasThermodynamics

The invention discloses an automatic filter element replacement type flue gas desulfurization device which comprises a base, a support, a feeding mechanism, a bracket, a cylinder, a push plate, a rotating shaft, a first gear, a lock head, a magnet, a first servo motor, a second gear, a fixing rack, a cylinder, a liquid separation mechanism, a filter element mechanism, a locking mechanism, a placement rack, a tank body, a diffusion pipe, a supporting plate, a water tank, an atomizing nozzle, a partition plate, an insertion pipe, an air outlet pipe, a liquid inlet pipe and a liquid outlet pipe. The device is simple in structure and is capable of automatically replacing the filter element mechanism, greatly reducing the labor intensity of an operator, improving the production efficiency and effectively preventing toxic gases from causing injuries to body health of the operator; meanwhile, the liquid medicine is atomized and subjected to primary desulfurization with flue gas, and the flue gas subjected to the primary desulfurization is introduced into the liquid medicine so as to be subjected to secondary desulfurization, so that the flue gas desulfurization is uniform and complete, and the desulfurization effect is excellent.

Owner:SUZHOU SBASOO AUTOMATION ENVIRONMENTAL PROTECTION EQUIP CO LTD

Zinc oxide slurry for flue gas desulfurization

The invention relates to zinc oxide slurry for flue gas desulfurization. The zinc oxide slurry contains an additive composed of alkanolamine, inorganic salt and a surfactant, wherein the weight of the additive in the zinc oxide slurry accounts for 0.05%-0.5% of the total weight of the zinc oxide slurry; the weight ratio of the alkanolamine to the inorganic salt to the surfactant in the additive is (1-2) to (0.2-0.5) to (0.5-1.5); the alkanolamine is one or the combination of two of triethanolamine and 2-amino-2-methyl-1-propanol; the inorganic salt is one or the combination of two of calcium chloride or sodium chloride; the surfactant is one or the combination of more of sodium dodecylbenzenesulphonate, Tween 80 and polyethylene glycol 20000. According to the slurry, the absorption effect on sulfur dioxide can be obviously improved and the viscosity of the zinc oxide slurry is reduced; the blocking in a production process is avoided and the pollution is further alleviated; resources are saved and the economic benefits are improved.

Owner:江苏蓝电环保股份有限公司

Double-circulation desulfurization device and desulfurization process

PendingCN110813046AComplete desulfurizationFully oxidizedGas treatmentCalcium/strontium/barium sulfatesSulfite saltProcess engineering

The invention discloses a double-circulation desulfurization device and a desulfurization process, and relates to the technical field of gas desulfurization. The device comprises a first-stage desulfurization tower, a second-stage desulfurization tower and a chimney which are sequentially communicated, the first-stage desulfurization tower, a first-stage circulating pool and a first circulating pump are sequentially communicated end to end to form first-stage desulfurization liquid circulation; the second-stage desulfurization tower, a second-stage circulating pool and a second circulating pump are sequentially communicated end to end to form second-stage desulfurization liquid circulation; an oxidation fan is communicated with a first-stage circulating pool; a filter pressing liquid outlet of the first-stage circulating pool is communicated with a filter press through a filter pressing pump; a pulping pool is communicated with a secondary circulating pool, and the secondary circulating pool is communicated with the first-stage circulating pool through an overflow pipe. The process comprises the following steps: respectively carrying out desulfurization treatment on sulfur-containing flue gas twice, and keeping the first-stage circulating pool to be weakly acidic to oxidize calcium sulfite slurry. The double-circulation desulfurization device provided by the invention has a good flue gas desulfurization effect, can fully convert the calcium sulfite slurry into gypsum, improves the conversion rate and quality of gypsum, and can effectively reduce the scaling and blocking phenomena of sulfite.

Owner:杨昆

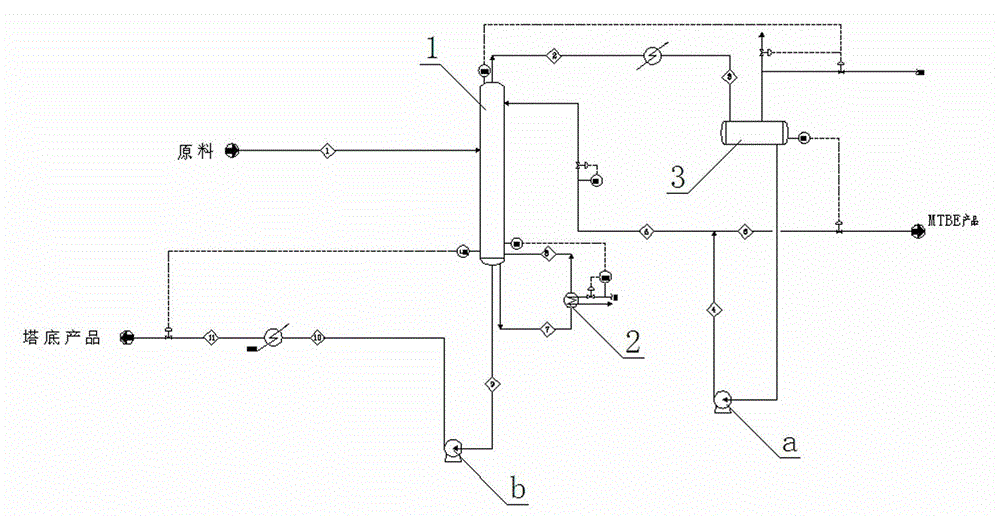

Desulfurization method for rectified MTBE (methyl tertiary butyl ethers)

The invention discloses a desulfurization method for rectified MTBE (methyl tertiary butyl ethers), which belongs to a desulfurization method for MTBE by using a desulfurization tower. The method comprises the following steps that: crude MTBE comprising 98.45-98.55% of MTBE, 0.37-0.39% of butene, 0.38-0.40% of carbon-8, 0.39-0.41% of butyl alcohol and 0.02-0.04% of sulfur-containing compounds are conveyed to a desulfurization tower; a gas phase at the top of the tower, after being condensed by a condenser of the desulfurization tower, enters a reflux tank of the desulfurization tower; condensed fluid is pressurized through a pump, then a part of the pressurized condensed fluid is extracted out and used as fine MTBE, and the other part of the pressurized condensed fluid is conveyed to the top of the tower and used as a reflux; and heavy components at the bottom of the tower are extracted intermittently, are pressurized through a pump, and cooled to 38-42 DEG C, and then the obtained product is conveyed to a drum area. Compared with the prior art, the desulfurization method disclosed by the invention has the following beneficial effects of relatively simple technological process, low investment, considerable yield, low energy consumption, small waste discharge; and the method has thorough desulfurization effect, the sulfur content of the finally produced fine MTBE is below 10ppm, the pure MTBE content is 99.1-99.3%, and the produced heavy components can be used as byproducts, thereby increasing both production and income.

Owner:HEILONGJIANG ANRUIJIA PETROLEUM CHEM

Preparation and applications of wet-process strong phosphoric acid desulfurizing agent

InactiveCN103539092ALow costGood environmental benefitsPhosphorus compoundsCalcium hydroxideSulfate radicals

The invention discloses a preparation and applications of a wet-process strong phosphoric acid desulfurizing agent. The desulfurizing agent comprises the following components in percentage by mass: 65%-80% of CaHPO4.2H2O.CaSO4, 3%-10% of Ca(H2PO4)2.H2O, 1%-10% of CaF2, 2%-10% of CaSO4.2H2O, 0.5%-5% of CaCO3, and the balance of impurities. The desulfurizing agent is prepared by the steps of: adding a certain amount of calcium hydroxide at normal temperature according to the quantity of fluorine in waste water, stirring for reacting, filtering, adding calcium hydroxide into a filtrate, drying the secondary filter cake to obtain the desulfurizing agent; mixing the desulfurizing agent and phosphoric acid with mass percentage concentration of P2O5 being15%-30% according to the mass of sulfate radical, forming slurry to be added into phosphoric acid with 40-54% ofP2O5 and 2.5%-6.5% of SO4<2->, carrying out desulfurization reaction at 50-80DEG C, and desulfurizing. The preparation has the characteristics of designing the treatment technology, changing waste water treatment process into a process of preparing a desulfurizing agent mainly containing phosphorus containing calcium salt precipitate, the desulfurizing agent can be used for removing sulfate radicals out of the wet-process strong phosphoric acid, is good in desulfurization effect, the phosphorous resource in the waste water can also be recovered, and the economic benefits and environment-friendly benefits are remarkable.

Owner:WENGFU (GRP) CO LTD

Spiral flue gas desulphurization apparatus

InactiveCN106512690AAvoid poisoningIncrease concentrationDispersed particle separationCeriumLanthanum

The invention discloses a spiral flue gas desulphurization apparatus. The spiral flue gas desulphurization apparatus comprises a gas inlet pipe and a desulphurization tank, wherein the gas inlet pipe is located at the lower part of the desulphurization tank; an ammonia water atomization nozzle is arranged at the central part of the desulphurization tank; a flue gas discharge outlet is formed in the top of the desulphurization tank; a demisting device and spiral wind guiding vanes are arranged in the desulphurization tank; the demisting device is arranged above the ammonia water atomization nozzle; the wind guiding vanes are located above the demisting device; and the wind guiding vanes are sprayed with at least one element selected from a group consisting of praseodymium, lanthanum, cerium, nickel, zinc and titanium or a compound of the elements selected from the group. The spiral flue gas desulphurization apparatus provided by the invention has the advantages of more thorough desulphurization, recoverable byproducts, no secondary pollution, etc.

Owner:CHONGQING HUAXU ENERGY TECH

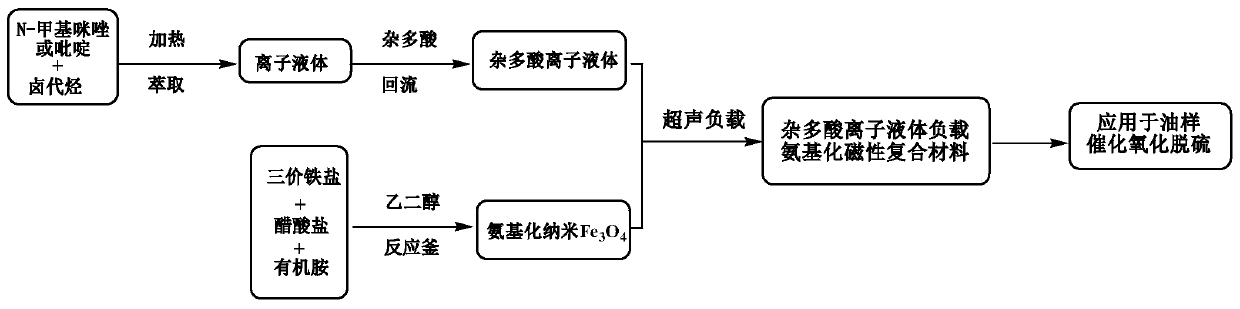

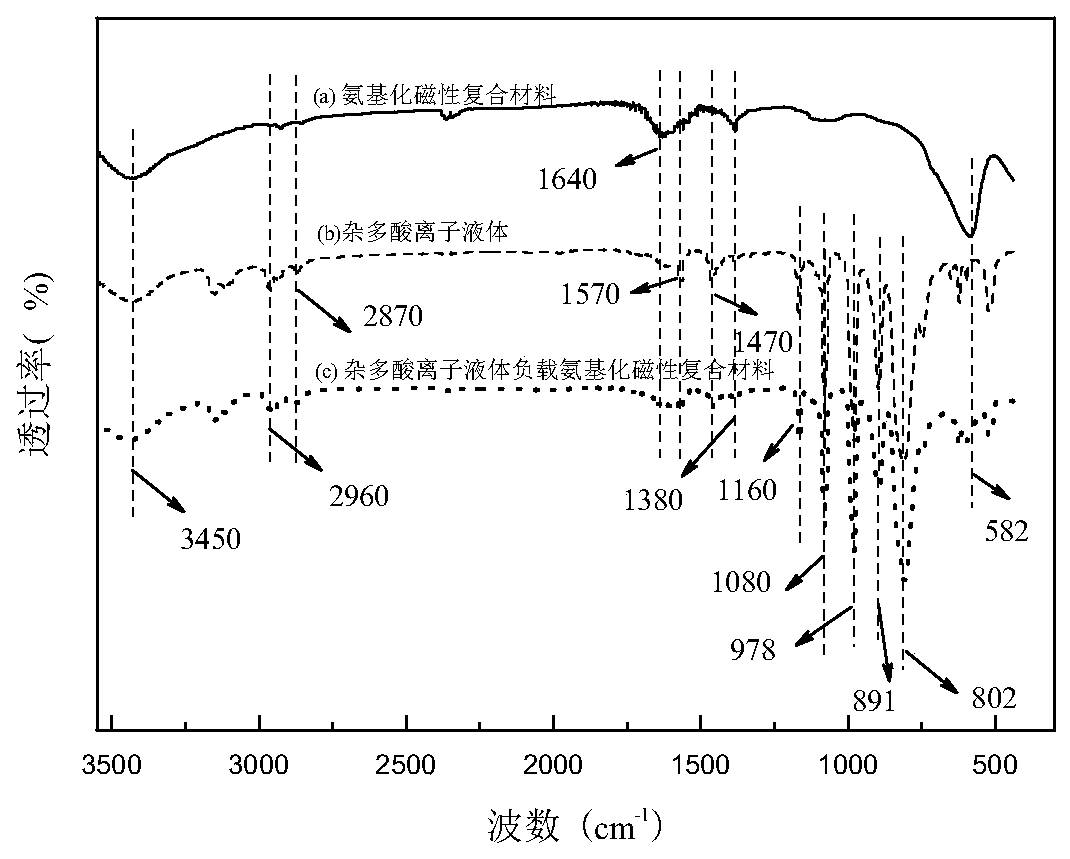

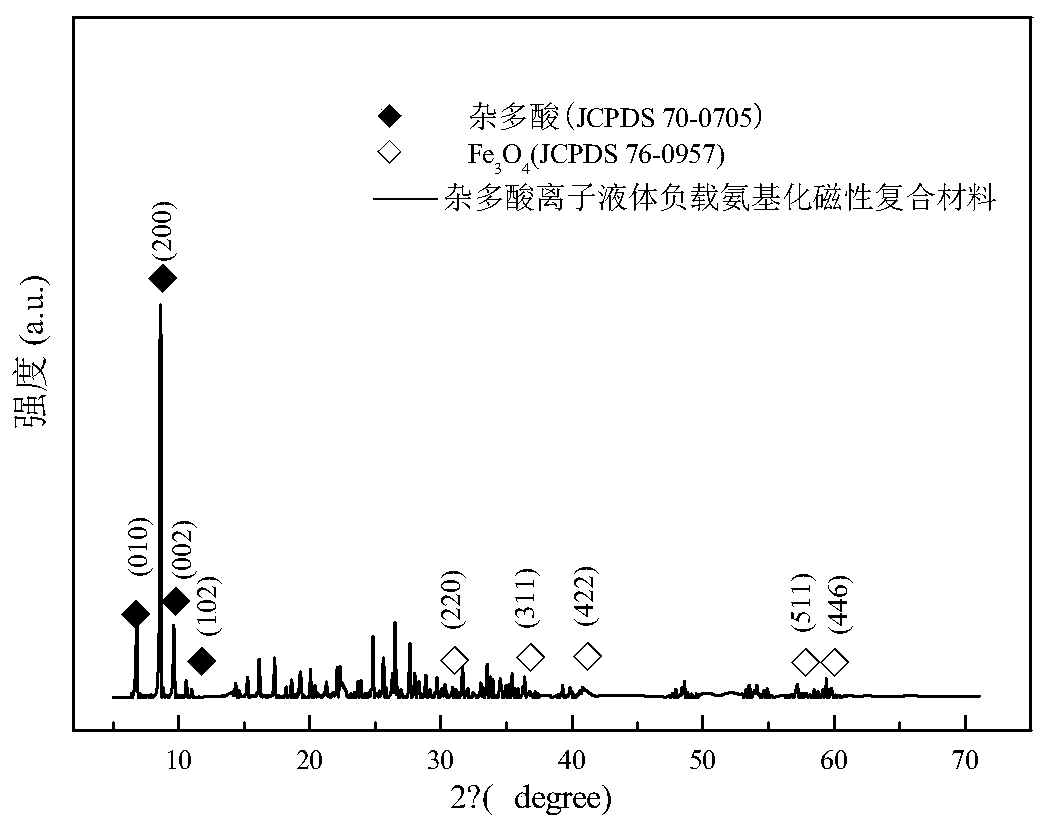

Heteropolyacid ionic liquid supported aminated magnetic composite of date cake structure, preparation method and application

ActiveCN109908962AEasy reunionSimplify operation stepsOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsChemistryPetroleum

The invention discloses a heteropolyacid ionic liquid supported aminated magnetic composite of a date cake structure, a preparation method and an application. The composite is prepared from raw materials including a heteropolyacid ionic liquid and an aminated magnetic composite by supporting the heteropolyacid ionic liquid on an aminated nano magnetic material with an ultrasonic immersing method.The preparation steps are shown as follows: firstly, the heteropolyacid ionic liquid is prepared through a substitution reaction, the aminated magnetic composite is prepared with a solvothermal method, and the heteropolyacid ionic liquid supported aminated magnetic composite is prepared with an ultrasonic supporting method. The product obtained with the method is powdery and brown, has uniform particle size distribution and has the date cake structure and stable properties. The defect of high probability of agglomeration of the magnetic materials is overcome, and the obtained material has gooddispersity, high magnetism and high yield, and raw materials are easy to obtain; the composite has magnetism and catalytic activity and can be effectively used for a catalyst for desulfuration of petroleum samples, and the catalyst can be separately recycled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

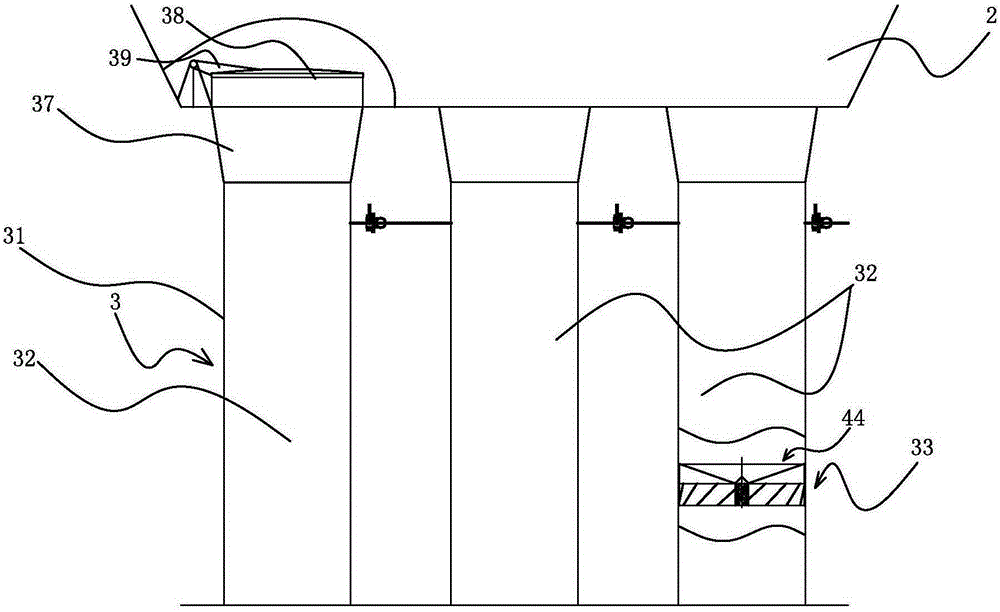

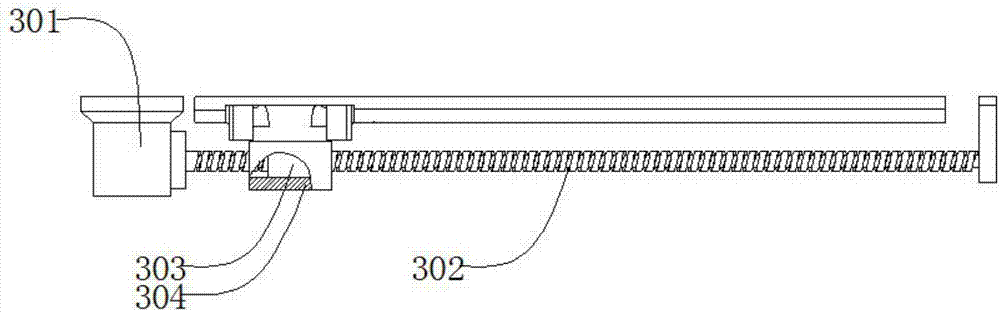

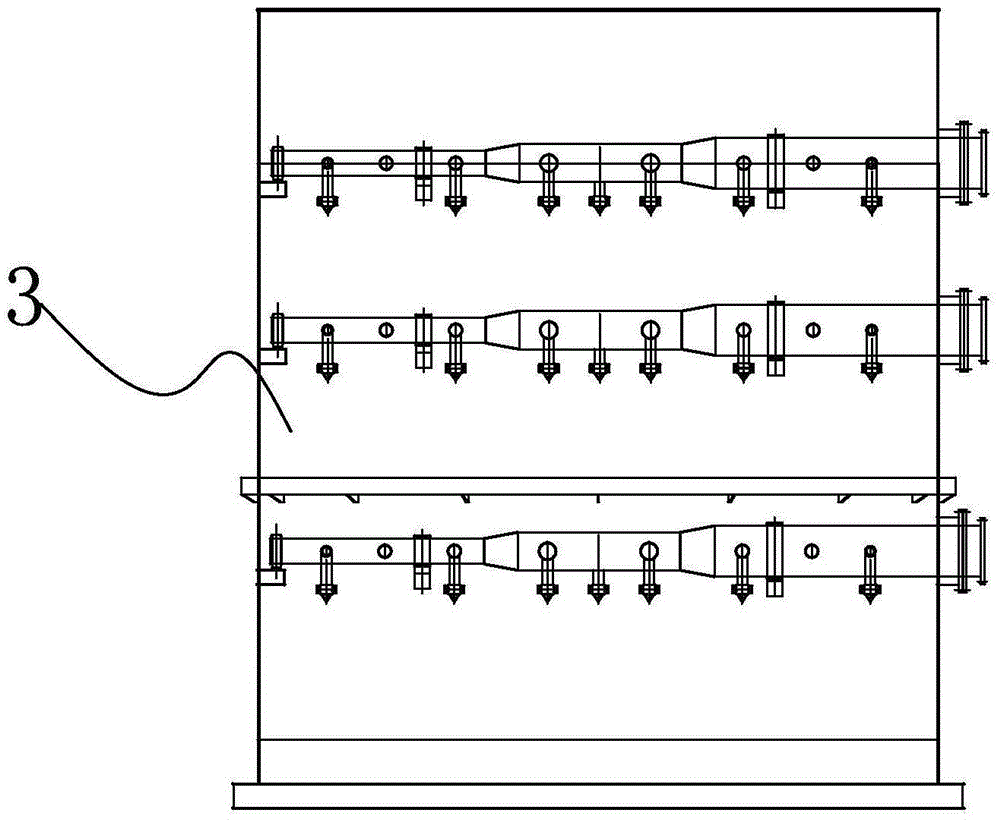

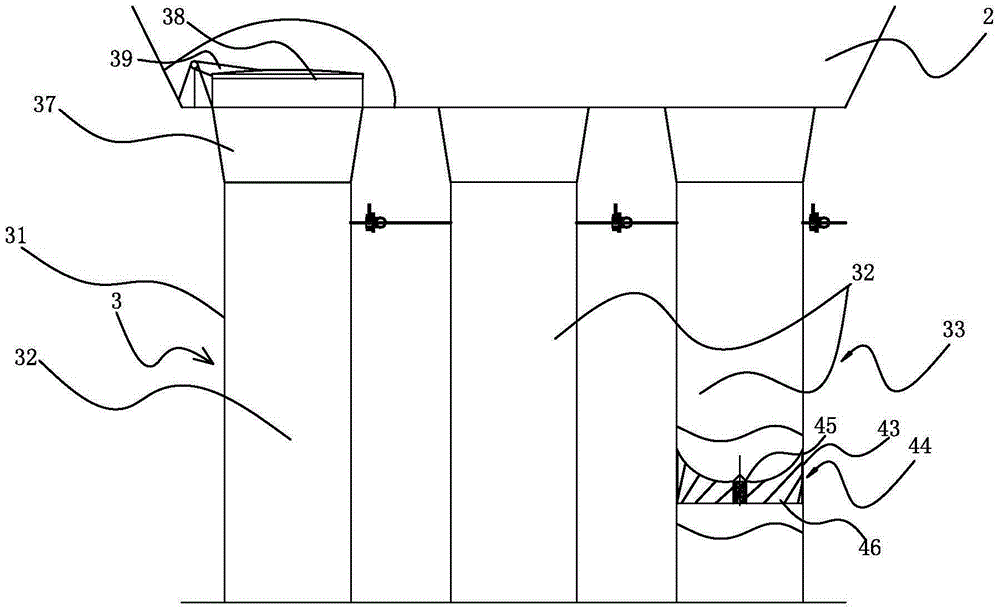

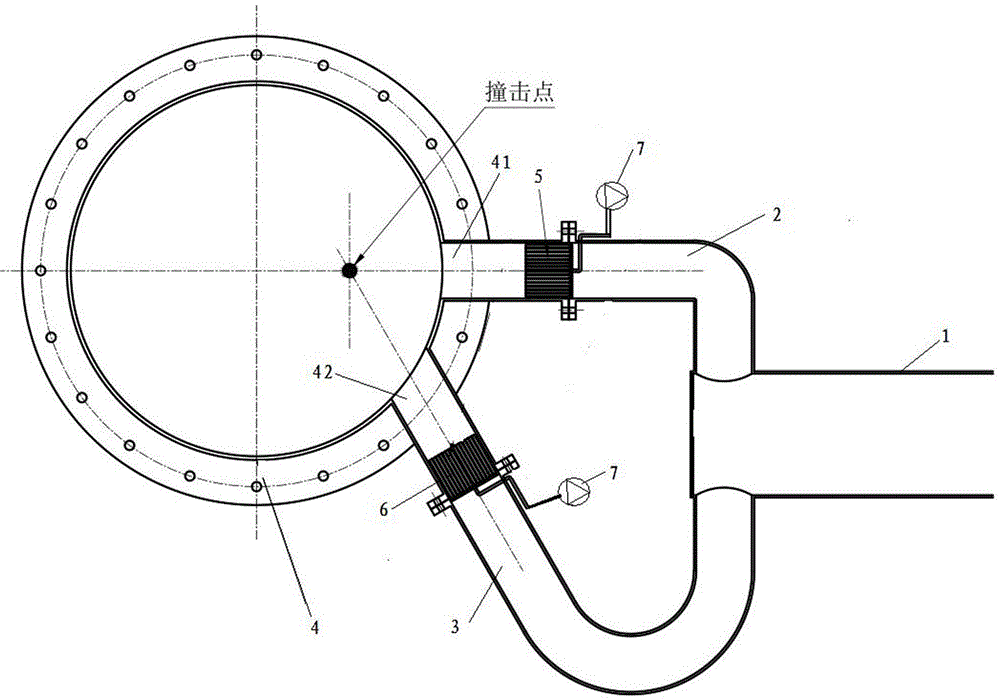

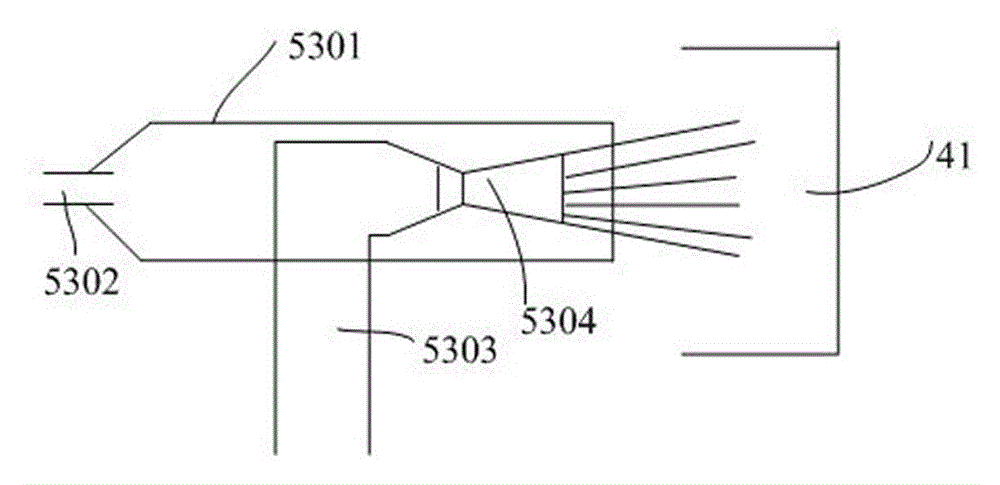

Rotational flow reaction device and flue gas desulfurization device

ActiveCN105169925AIncrease concentrationImprove desulfurization efficiencyDispersed particle separationImpellerFlue gas

The invention discloses a rotational flow reaction device and a flue gas desulfurization device. The rotational flow reaction device comprises a rotational flow shell and at least two rotational flow chambers, wherein each rotational flow chamber is provided with at least one swirler, a circular reaction slurry inlet is formed in the upper portion of each rotational flow chamber, and the lower side of each rotational flow chamber is communicated with a gas uniformizing chamber. Each swirler is a swirl impeller comprising an impeller shell, an impeller center shaft and at least five swirl vanes surrounding the impeller center shaft, wherein the impeller shell is fixed in the corresponding rotational flow chamber, the inner edge of each swirl vane is fixed to the impeller center shaft, and the outer edge of each swirl vane is fixed to the impeller shell. A flue gas flow regulating device is arranged on the top of each rotational flow chamber, can open and close the rotational flow chamber, and is connected with the top of the rotational flow chamber. The rotational flow reaction device is simple in structure, the number of the rotational flow chambers involved in reaction can be selected, the velocity of flue gas can be effectively controlled, flue gas desulfurization effect and degree can be guaranteed, energy can be saved, and environment pollution can be avoided.

Owner:龙创信恒(北京)科技有限公司

Purification system and purification method for asphalt smoke

PendingCN108744935AImprove purification effectImprove purification efficiencyGas treatmentDispersed particle filtrationParticulatesToxic gas

The invention discloses a purification system and a purification method for asphalt smoke. The purification system comprises a production system, a material storage device, a mixed adsorption device,a dust collection device, a material returning device, a desulfurizer and an output device, wherein the production system is used for producing a finished product and generating the asphalt smoke; thematerial storage device is used for storing and outputting sintered coke powder; the mixed adsorption device is used for using the sintered coke powder to adsorb volatile components inside the asphalt smoke and forming used coke powder, and forming sulfurous gas after the volatile components are adsorbed by the asphalt smoke; the dust collection device is used for separating the used coke powderand the sulfurous gas inside a low toxicity mixture; the material returning device is used for outputting the used coke powder to the material storage device; the desulfurizer is used for removing sulfur dioxide inside the sulfurous gas to generate non-toxic gas; and the output device is used for discharging the non-toxic gas to the outside. The purification system has the advantages and beneficial effects that various environmental protection output problems of the volatile components, sulfur dioxide and dust particulate matters inside the asphalt smoke can be solved at the same time, so thatthe purification effect and purification efficiency of the asphalt smoke are improved, secondary pollution is avoided from being generated, and the economic value is improved.

Owner:上海领津环境技术有限公司

External desulfurization method for molten iron by magnesium bar

InactiveCN100419091COvercome the disadvantages of desulfurization processQuick changeMaterials scienceMetal

The method comprises the following: fixing the magnesium stick on the desulfuration gun body; with the protection of cooling system and inactive gas, inserting the magnesium stick into iron water; when one magnesium stick disappearing, changing another one. The specific operation is following: installing magnesium stick in the desulfuration gun body, hydraulic heaver putting the desulfuration gun body into the iron water, carrying out desulfurization; changing the new magnesium stick when the last one used out; repeating the above steps until the desulfuration ending. The method overcomes the defects of conventional art, and has the advantages of low cost and simple operation.

Owner:NANJING NANGANG IND DEV CO LTD

Comprehensive flue gas synergistic treatment system for ceramic industry

PendingCN111744362AImprove the reaction environmentComplete desulfurizationGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention discloses a comprehensive flue gas synergistic treatment system for the ceramic industry. The system comprises a desulfurizing tower, a bag-type dust collector, a slaked lime supply device, a water spraying device, a recirculation device and an induced draft fan; a gas inlet is formed in the bottom end of the desulfurizing tower; an exhaust port is arranged at the top end of the desulfurizing tower; the slaked lime supply device and the water spraying device are communicated with the bottom of the desulfurizing tower; the communication position of the water spraying device and the desulfurizing tower is higher than the communication position of the slaked lime supply device and the desulfurizing tower, the bag-type dust collector is communicated with the exhaust port of the desulfurizing tower; the induced draft fan is communicated with the bag-type dust collector; one end of the recirculation device is connected with the bottom end of the bag-type dust collector, and theother end of the recirculation device is connected with the bottom of the desulfurizing tower, so that slaked lime can react with corresponding components of SO2 in flue gas, and therefore, desulfurization can be realized; the water spraying device is arranged, so that a good reaction environment in the desulfurizing tower is guaranteed; the recirculation device is arranged, particles are returned to the desulfurizing tower for continuous reaction, sufficient desulfurization of discharged materials is guaranteed, ultra-low emission without waste water and obvious plume is achieved, and the purpose of environmental protection is achieved.

Owner:佛山市普蓝环境工程有限公司

Flue gas desulphurization apparatus and flue gas desulphurization method

ActiveCN105013316AComplete desulfurizationRealize secondary desulfurization washingDispersed particle separationFlue gasProcess engineering

The invention provides a flue gas desulphurization apparatus, which comprises a flue capable of absorbing flue gas; a first channel and a second channel communicated with an outlet of the flue; a reaction tower; a first inlet of a tower body of the reaction tower arranged at outlet of the first channel, a second inlet of the tower body of the reaction tower arranged at outlet of the second channel, a first scrubber arranged on the first channel, performing desulphurization washing on the flue gas in the first channel from the flue, and spraying the high pressure gas-liquid mixing flow after washing from the first inlet; and a second scrubber arranged on the second channel, performing desulphurization washing on the flue gas in the second channel from the flue, and spraying the high pressure gas-liquid mixing flow after washing from the second inlet. The flue gas desulphurization apparatus can realize multitime desulphurization on flue gas, and flue gas desulphurization can be thoroughly completed.

Owner:HEBEI WEIWO ENVIRONMENT ENG TECH CO LTD

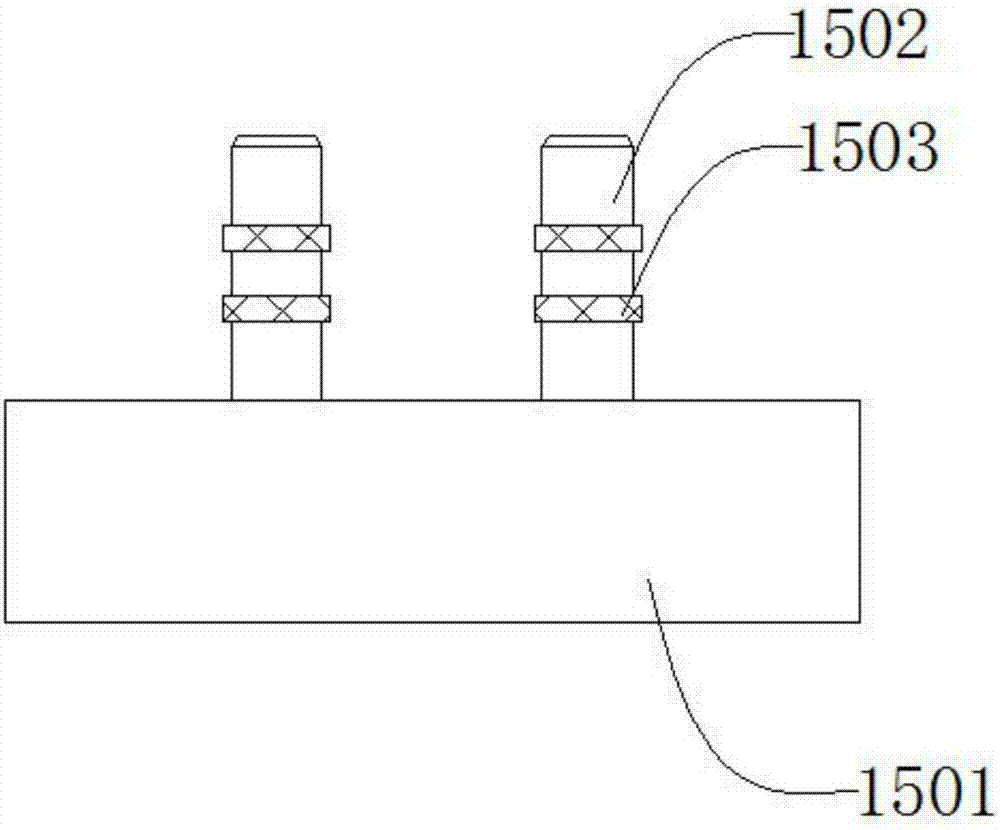

Desulfurization filter element

InactiveCN1718271AEasy to prepareLow costDispersed particle separationFiltration separationUranium carbideBarium peroxide

Owner:王涛 +1

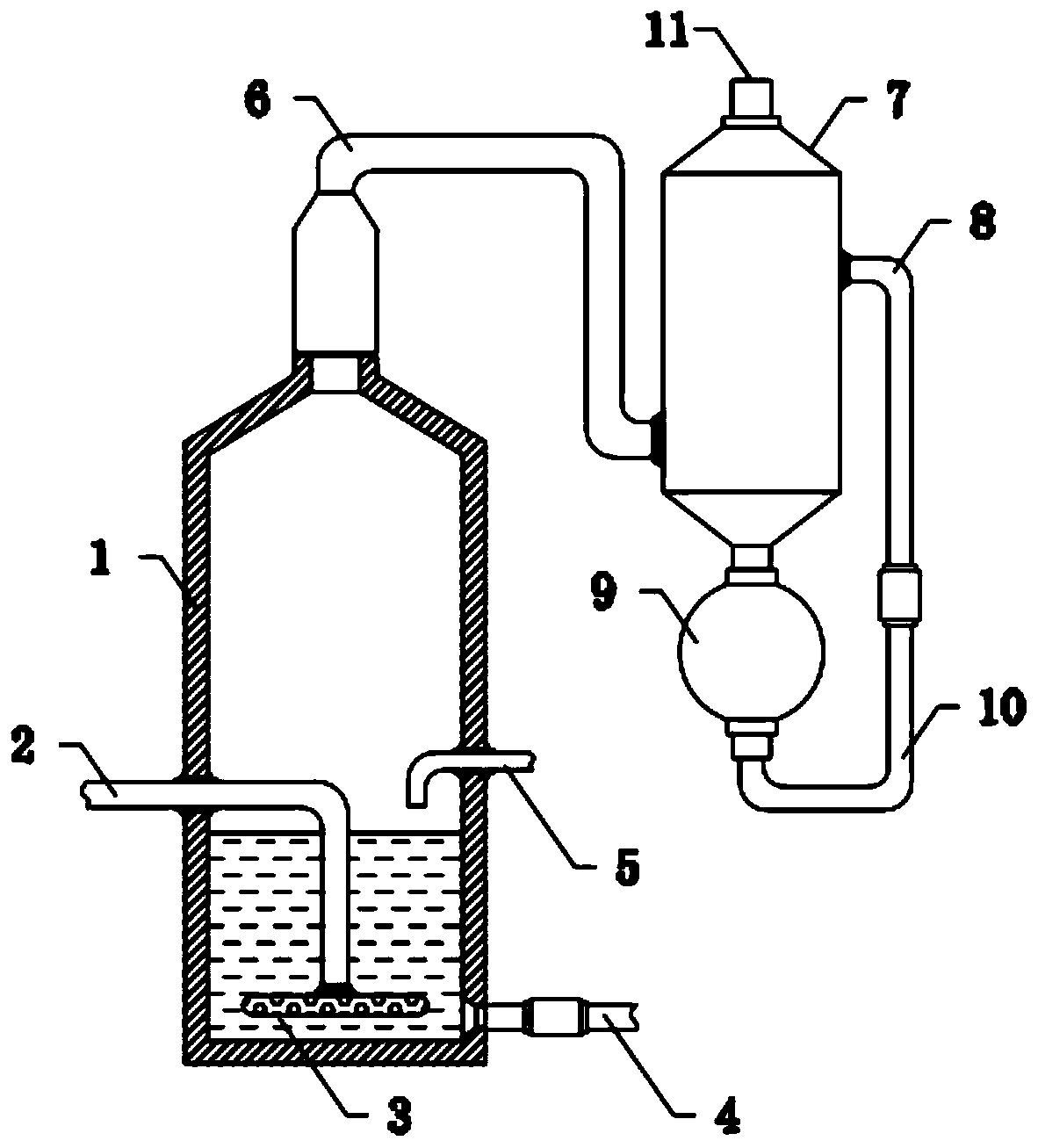

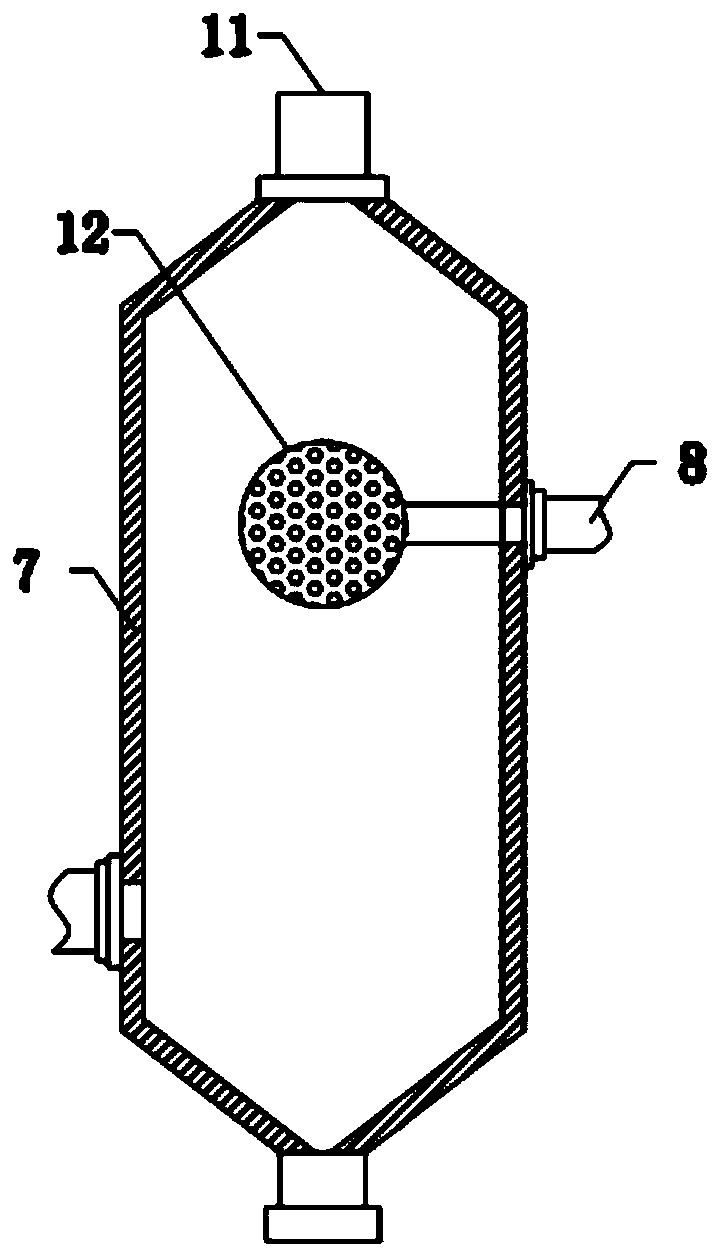

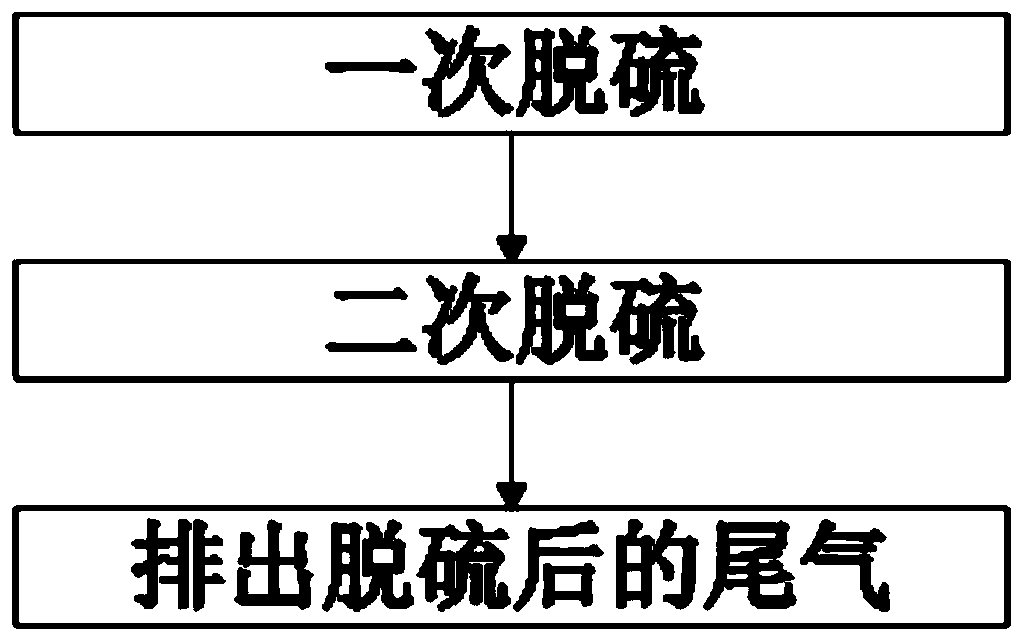

Ship tail gas high-efficiency desulfurization device and using method thereof

InactiveCN110252096AMeet emission standardsComplete desulfurizationDispersed particle separationMarine engineeringExhaust gas

The invention discloses a ship tail gas high-efficiency desulfurization device and a using method thereof, belonging to the technical field of ship desulfurization. The ship tail gas high-efficiency desulfurization device comprises a primary desulfurization cylinder, a ship tail gas inlet pipe and an extraction pipe, the ship tail gas inlet pipe is arranged in the middle of one side wall of the primary desulfurization cylinder; the bottom end of the ship tail gas inlet pipe is connected with a gas outlet pipe; the extraction pipe is connected with the bottom end of the side wall of the primary desulfurization cylinder; and the using method of the ship tail gas high-efficiency desulfurization device comprises the following specific using steps: S1, wet primary desulfurization; S2, drying secondary desulfurization; and S3, discharging of desulfurized tail gas; the tail gas can be directly outputted to a desulfurizing liquid at the bottom of the inner cavity of the primary desulfurization cylinder through the arrangement of the gas outlet pipe so as to directly contact the desulfurizing liquid and perform desulfurizing; desulfurization powder is sprayed out through the spraying action of a spraying pipe and a spraying head, so that desulfurization is directly carried out on the desulfurization powder and the ship tail gas, and the secondary desulfurization is more thorough in desulfurization.

Owner:上海蓝魂环保科技有限公司

A system for treating sulfur containing flue gas by utilizing sodium sulfite

InactiveCN106390704ACompact designComplete desulfurizationGas treatmentDispersed particle filtrationSulfite saltFlue gas

A system for treating sulfur containing flue gas by utilizing sodium sulfite is disclosed. The system includes a flue gas pipe containing sulfur containing flue gas from a power plant or a factory. The flue gas pipe is connected to a dust removal filter. A filter screen is disposed in the dust removal filter. The filtered sulfur containing flue gas is fed into a heat exchanger, and then fed into a pretreating column. An induced draft fan is connected to a top pipe outlet of a desulfurization column. Through power of the induced draft fan, gas is discharged from the top of the desulfurization column. The top gas is connected to the heat exchanger through a pipe so that the top gas is fed into a chimney through a pipe of the heat exchanger and is discharged into the air through the chimney. The system is compact in system design and good in absorption effects. A produced byproduct can be recovered for reutilization.

Owner:太仓市顺邦防腐设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com