Patents

Literature

60results about How to "Shorten desulfurization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid desulfurization refining method for ladle furnace

The invention discloses a rapid desulfurization refining method for a ladle furnace (LF). The method comprises the following steps of: 1) performing desulfurization refining in the LF, wherein the LF treatment starting temperature is between 1,570 and 1,605 DEG C; 2) after a ladle argon blowing device of the LF is turned on, blowing argon from the bottom of the ladle; 3) after finishing adjusting the temperature, inserting a desulfurization powder spraying gun into a molten steel liquid for spraying a desulfurizing agent; 4) after finishing spraying powder, switching the spraying gun to a functional stage of blowing the argon, blowing the argon from the top, simultaneously blowing the argon from the bottom of the ladle, and performing strong stirring desulfurization operation; 5) alloying, namely after desulfurization is finished, lifting the desulfurization powder spraying gun, adjusting a ladle bottom blowing flow, and performing alloy configuration to meet a target requirement on final components of a steel grade; and 6) after finishing adjusting components, performing soft stirring operation, measuring the temperature, sampling, and turning off the ladle argon blowing device to finish treating. The method realizes rapid desulfurization of the LF, and can shorten an overall melting cycle and improve the number of continuous casting furnaces and production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

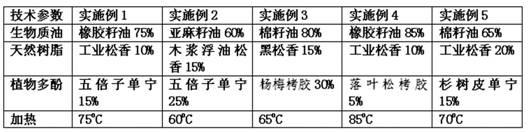

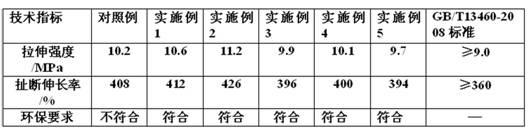

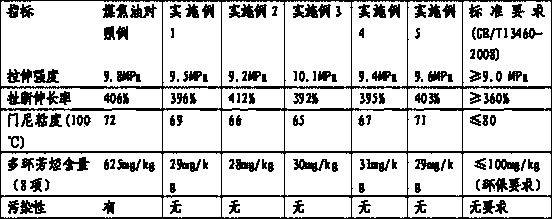

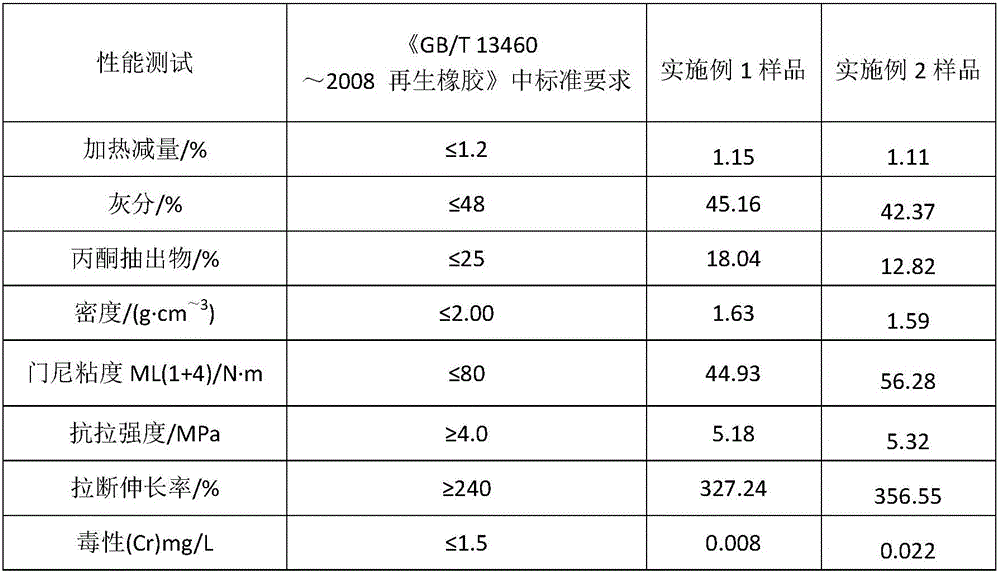

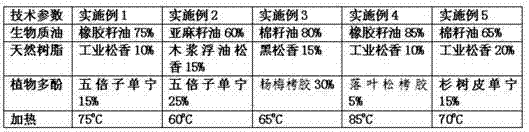

Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

The invention provides an environmentally-friendly biomass compound rubber regenerant. The regenerant is prepared from the following raw materials in mass percentage: 60-85% of bio-oil, 10-20% of natural resin and 5-30% of plant polyphenol. The preparation method of the regenerant comprises the following steps: (1) heating the bio-oil to 60-85 DEG C; (2) respectively adding the natural resins andthe plant polyphenol to the bio-oil and evenly mixing; and (3) naturally cooling the evenly mixed product to room temperature to finally obtain the environmentally-friendly biomass compound rubber regenerant product. In the invention, the bio-oil, the natural resins and the plant polyphenol which are extracted from plants are taken as raw materials, and the raw materials are renewable materials, which realizes maximum resource utilization and reduces dependence on petrochemical resource so as to achieve the purpose of green production of reclaimed rubber. The regenerant has the advantages of good rubber regeneration effect, high product quality, low production cost and no pollution and nuisance during the production process. The environmentally-friendly reclaimed rubber produced by the regenerant can be widely applied to various rubber products and can replace rubber materials, thus saving rubber resources.

Owner:KUNMING PHOENIX RUBBERS

Forcible wet desulphurization process for lead plaster

The invention provides a forcible wet desulphurization process for lead plaster. The process comprises the following steps of adding water to stir the lead plaster in a lead plaster stirring tank to dilute the lead plaster into 10 to 30 mass percent ore pulp, pumping 20 cubic meters of ore pulp into a desulphurization stirring tank by using a slurry pump, simultaneously adding Na2CO3 into the desulphurization stirring tank according to the mass ratio of Na2CO3 to PbSO4 of (1-1.2):1, pumping the ore pulp out of the desulphurization stirring tank at the same time of desulphurization stirring, enabling the ore pulp to flow through a forcible desulphurizer, and circulating the ore pulp between the desulphurization stirring tank and the forcible desulphurizer. According to the process, PbCO3 product layers wrapped on the outer surfaces of PbSO4 particles can be crushed through the forcible desulphurizer in a desulphurization process to completely expose PbSO4 in a solution of Na2CO3, so that the efficiency of transformation of PbSO4 into PbCO3 is improved, and the aim of forcible desulphurization is fulfilled; rolling and grinding modes are adopted for crushing large PbSO4 crystalline particles through the forcible desulphurizer, and a supergravity stirring mode is adopted for crushing the large PbSO4 crystalline particles and stirring the ore pulp, so that the aims of crushing the large PbSO4 crystalline particles and accelerating desulphurization transformation are fulfilled.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

Slag washing desulphurization method for molten iron utilizing residue thermal-state steel slag

InactiveCN102719588AShorten desulfurization timeEasy to handleRecycling and recovery technologiesProcess efficiency improvementThermal energyThermal state

The invention discloses a slag washing desulphurization method for molten iron utilizing residue thermal-state steel slag, and specifically relates to a slag washing desulphurization method for the molten iron by pouring the residue thermal-state steel slag of continuous casting into an empty hot-metal ladle when the molten iron is added. The method comprises pouring the residue thermal-state steel slag in a ladle into the empty hot-metal ladle by transport equipment such as a crane and the like, or by intermediate containers when the molten iron is added; carrying out slag washing desulphurization for the molten iron utilizing an impact of the molten iron; and then carrying out gas stirring or mechanical stirring for the molten iron followed by a slag removal operation. The method is advantaged by recycling thermal energy of the residue thermal-state steel slag, replacing molten iron desulphurizers or effectively reducing the consumption of the iron desulphurizers, shortening the desulphurization time of the molten iron, recycling the residue steel, improving the metal yield, realizing direct heat recovery of the residue thermal-state steel slag, simplifying the treatment process of the steel slag, and reducing the production cost of the steel.

Owner:ANGANG STEEL CO LTD

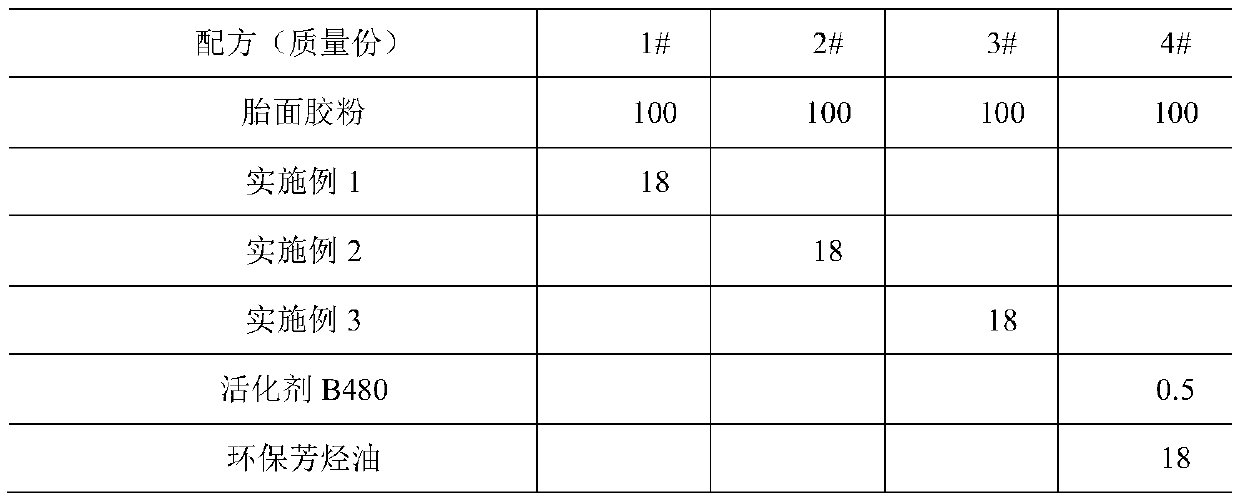

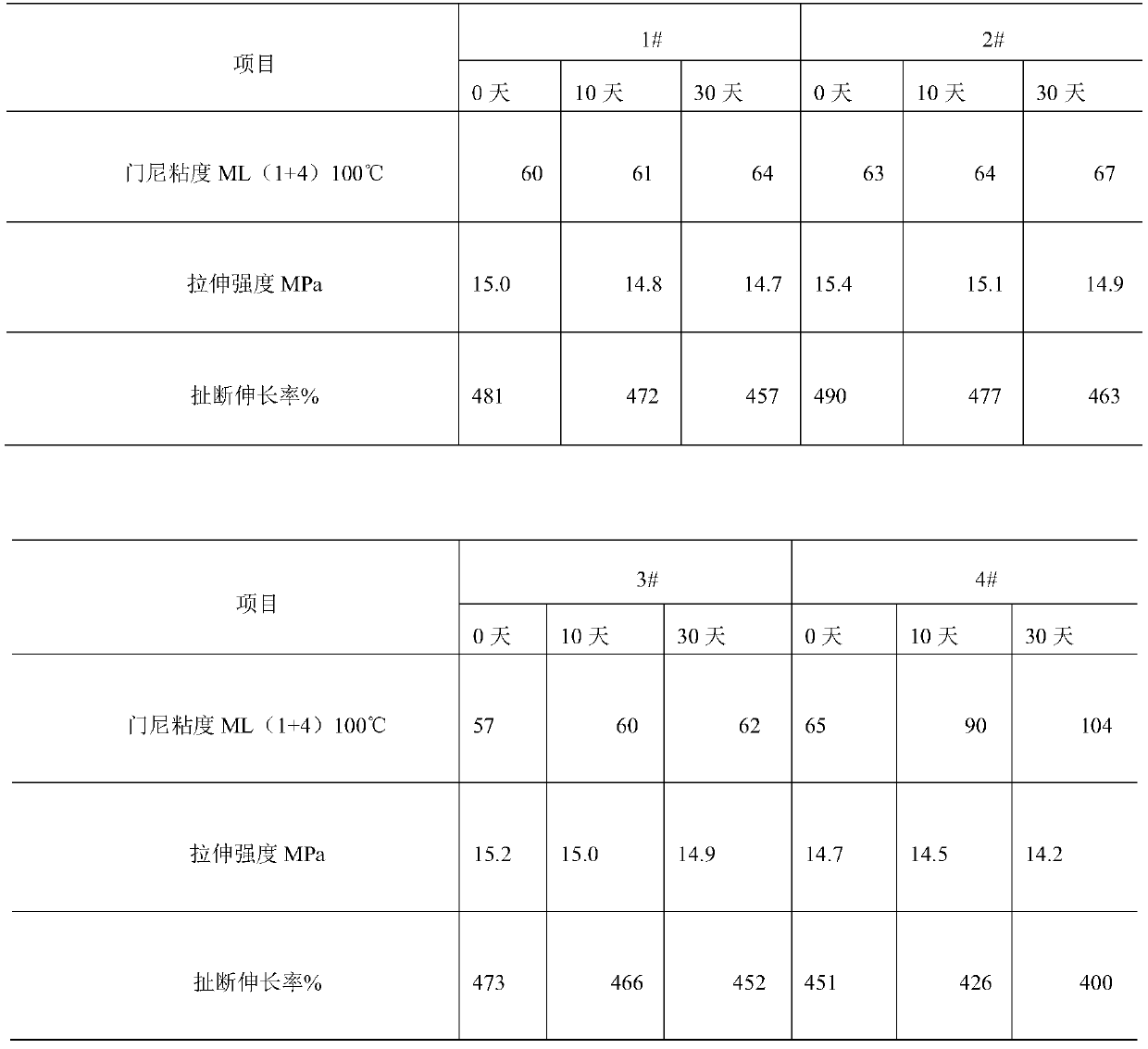

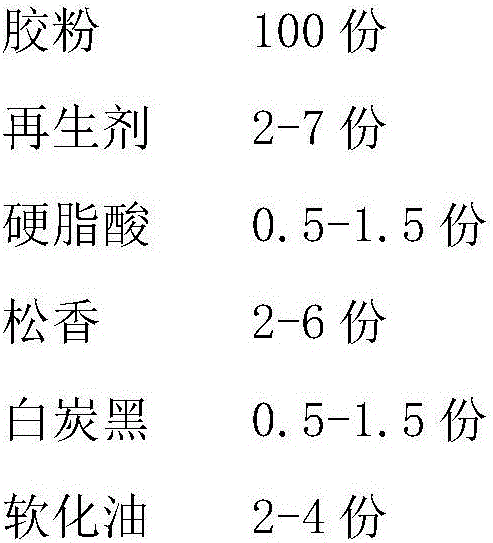

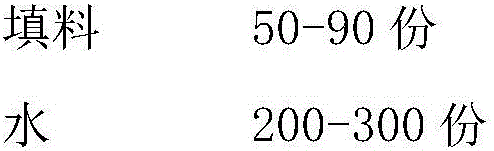

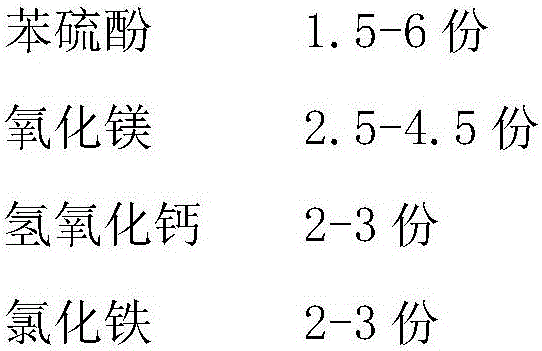

Environment-friendly reclaiming agent for rubber reclaiming and preparation method thereof

ActiveCN109796625AGood compatibilityImprove the activation effectPlastic recyclingPolymer scienceRoom temperature

The invention provides an environment-friendly reclaiming agent for rubber reclaiming and a preparation method thereof. The reclaiming agent is prepared from an activating agent, a catalyst and a softening agent through uniform mixing in a mass ratio of (0.5-5):(0.05-0.3):100. The preparation method comprises the steps that the softening agent is heated to 70-130 DEG C while stirred, and stirringis conducted for 3-5 minutes; the activating agent is added, and stirring is conducted for 5-10 minutes at the temperature of 80-120 DEG C; the catalyst is added, and stirring is conducted for 8-15 minutes at the temperature of 90-130 DEG C; after the materials are quickly cooled to the room temperature, the environment-friendly rubber reclaiming agent is obtained. By adjusting a formula, the reclaiming agents with different viscosities can be obtained, and an existing device can be used without being improved. The activating agent (the formula is shown in the description.) achieves efficientand environment-friendly desulfurization under the action of the catalyst, less energy is consumed in the desulfurated rubber powder refining process, the reclaimed rubber production cost is greatly reduced, the reclaimed rubber product prepared by using the method is excellent in performance and stable in Mooney viscosity.

Owner:NANJING L J R RUBBE & PLASTIC CO LTD +1

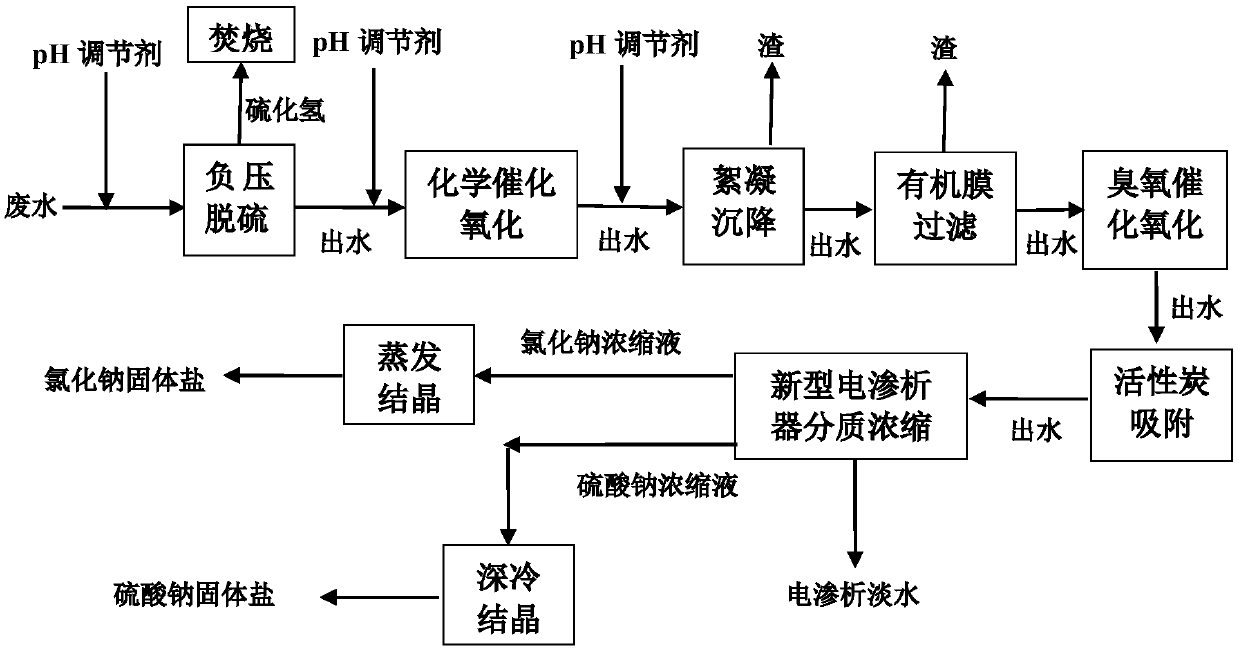

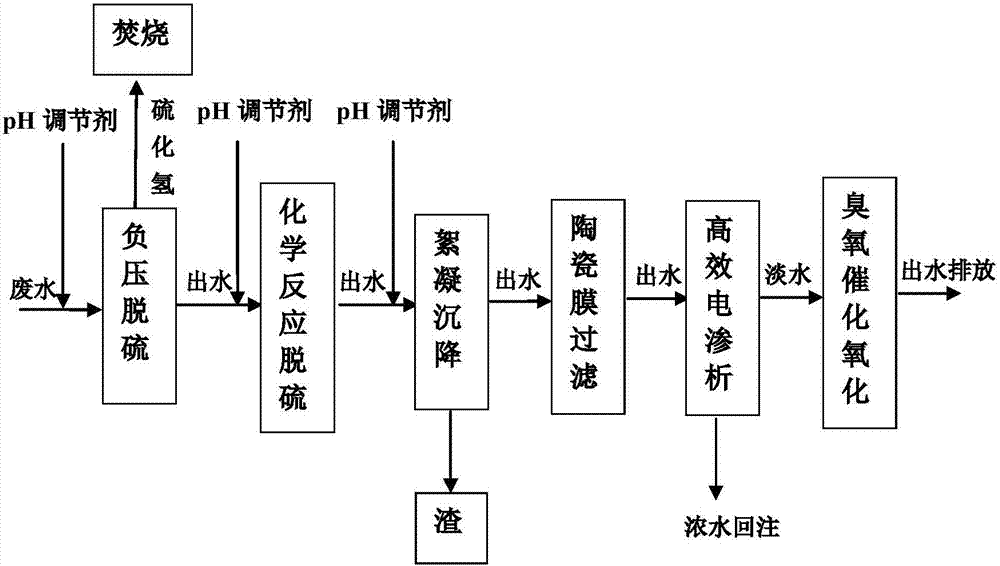

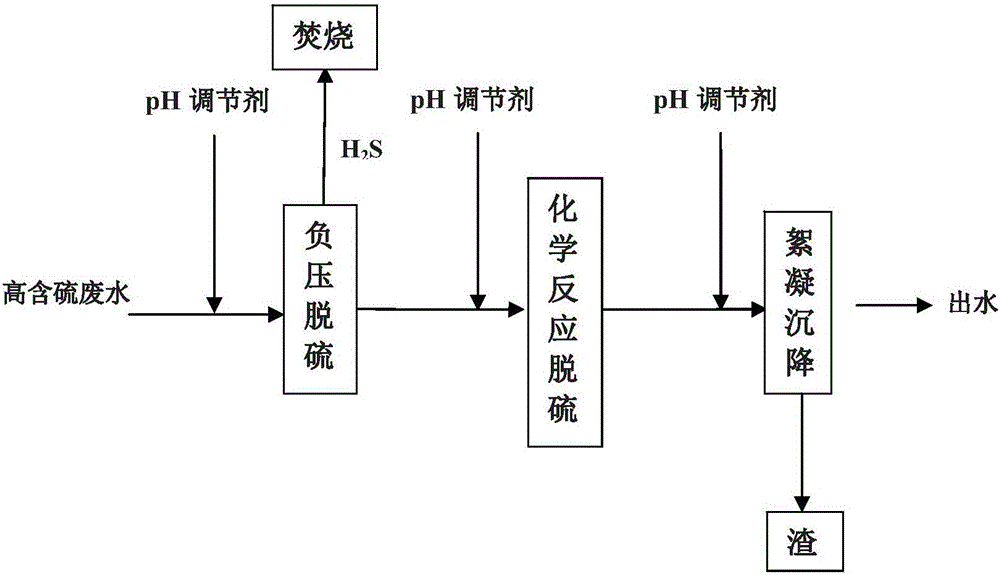

Resourceful treatment method for wastewater with high sulfur content of oil and gas field

ActiveCN107686196ARealize resourcesAddress sulfur contentWaste water treatment from quariesWater contaminantsFiltrationCatalytic oxidation

The invention relates to a resourceful treatment method for wastewater with high sulfur content of the oil and gas field. The resourceful treatment method adopts negative-pressure desulfuration, chemical catalytic oxidation, flocculation settlement, organic membrane filtration, ozone catalytic oxidization, active carbon adsorption, novel electrodialyzer electrolyte separation and concentration andcrystallization to treat wastewater with high sulfur content of the oil and gas field. The resourceful treatment method realizes electrolyte separation and crystallization of salts in wastewater on the basis of effectively removing sulfides, suspended solids, organic substances and oil in wastewater, solves the difficult treatment problem of the wastewater with high sulfur content of the oil andgas field, and realizes recycling of the wastewater with high sulfur content of the oil and gas field on the basis of up-to-standard discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

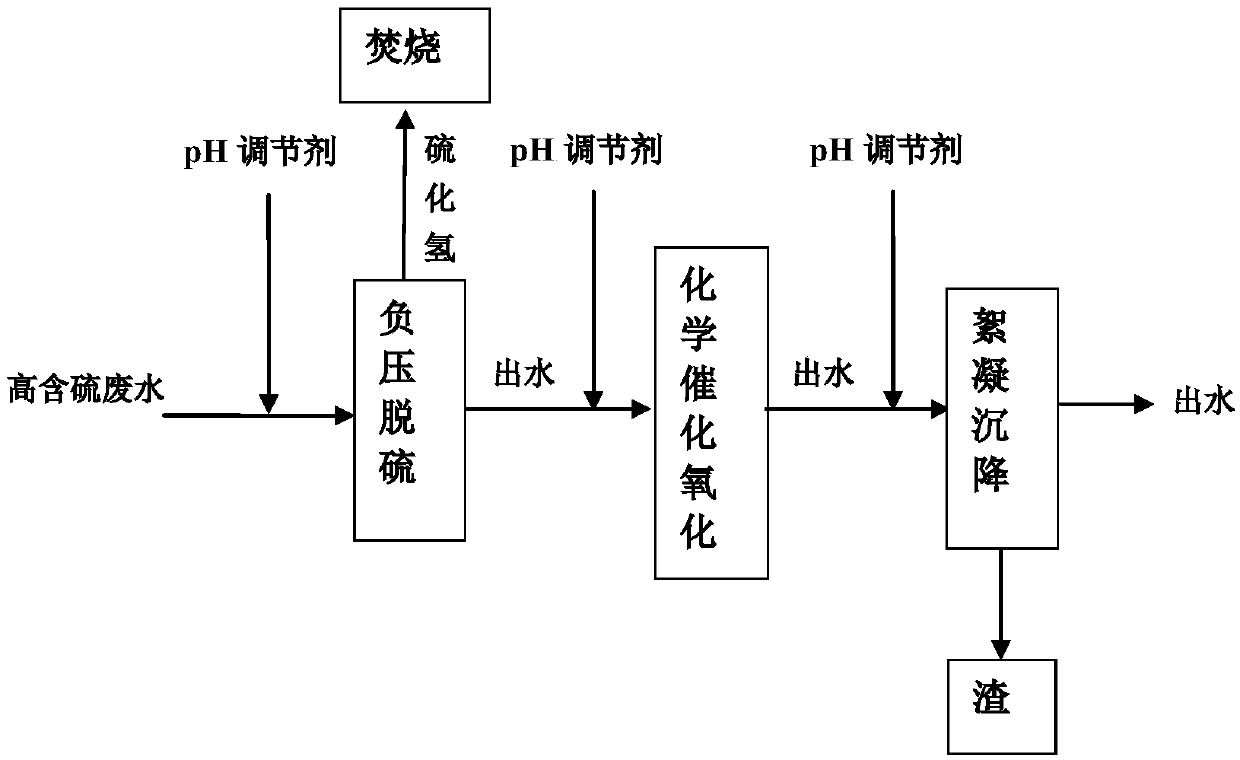

Deep desulfurization method for high-sulfur-containing wastewater of oil and gas field

InactiveCN106698733ATo achieve the purpose of deep removalMeet the reinjection water standardWaste water treatment from quariesMultistage water/sewage treatmentSulfideSulfur containing

The present invention relates to a deep desulfurization method of high-sulfur-containing wastewater of an oil and gas field, and the method comprises the following steps: according to the characteristic of a hydrogen sulfide presence form of sulfides in the high-sulfur-containing wastewater of the oil and gas field under acidic conditions, first, most of hydrogen sulfide in the wastewater is removed by a negative pressure desulfurization technology for centralized incineration; and secondly, residual hydrogen sulfide in negative pressure desulfurization unit effluent is oxidized by a chemical catalysis oxidation technology so as to finally realize the purpose of deep removal of the sulfides in the high-sulfur-containing wastewater of the oil and gas field, and the sulfur content of the effluent meets the reinjection water standard of the oil and gas field. The deep desulfurization method of the high-sulfur-containing wastewater of the oil and gas field can effectively remove the sulfides in the wastewater, solves the problem of too high sulfur content in the reinjection process of the high-sulfur-containing wastewater, and solves the disadvantages of huge equipment, complex process, low efficiency, poor environmental adaptability, high operation cost, difficulties in maintenance and the like in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

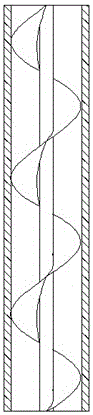

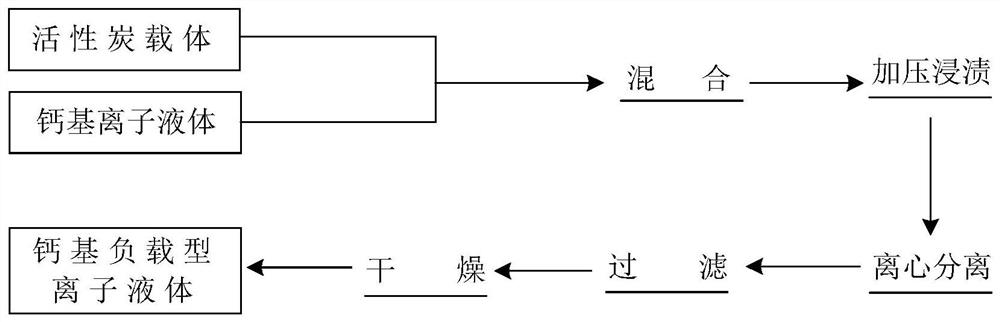

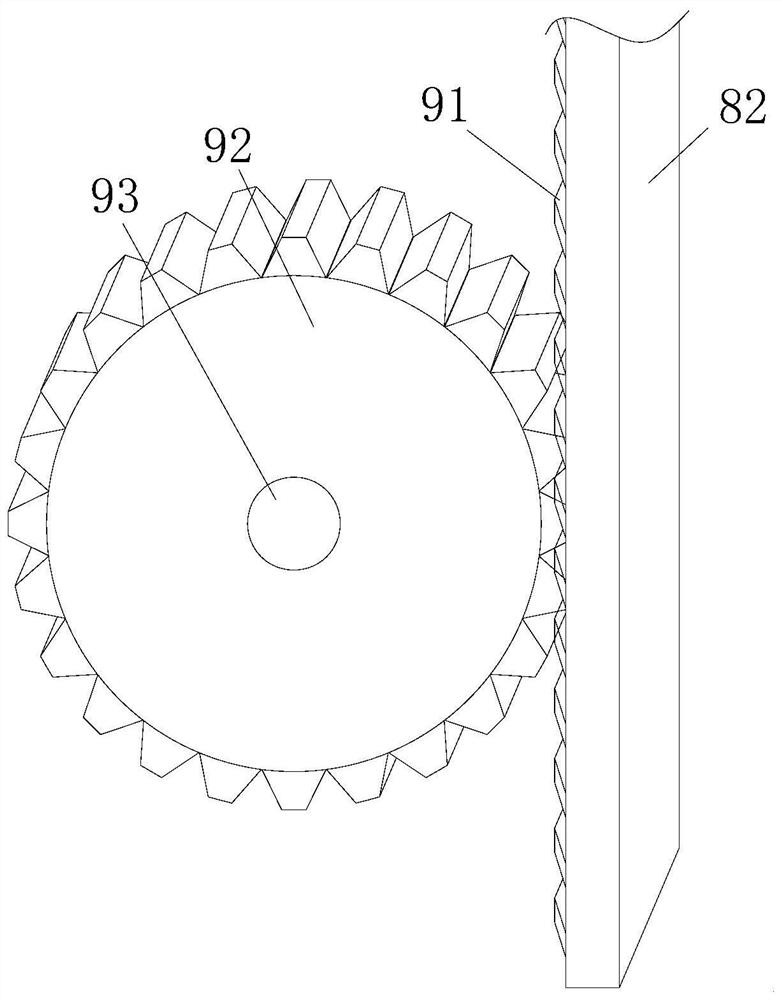

Novel desulfurization spray gun

The invention discloses a novel desulfurization spray gun. The novel desulfurization spray gun comprises an internal spray gun inner pipe, an external refractory material layer and a body arranged between the spray gun inner pipe and the refractory material layer, wherein a plurality of spray gun holes communicated with inner holes of the spray gun inner pipe are reserved on the lower part of the refractory material layer. The novel desulfurization spray gun is characterized by further comprising a swivel joint arranged between the body and an injection hose, wherein the swivel joint is a hollow stepped shaft; the upper part of the swivel joint is fixedly connected with the hose, while the lower part is connected with the body; and the swivel joint can rotate together with the body. The spray gun can freely move in a molten pool by means of spraying gas acting force of the spray gun when spraying by adding the swivel joint, so that the stirring function is added to the molten bath; a desulfurizing agent is more dispersedly sprayed into molten iron, the contact area of the desulfurizing agent and sulphur in the molten iron is increased, the desulfurization efficiency is greatly improved, the consumption of the desulfurizing agent is reduced, and the slopping iron loss is effectively reduced.

Owner:ANHUI XINHAI ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

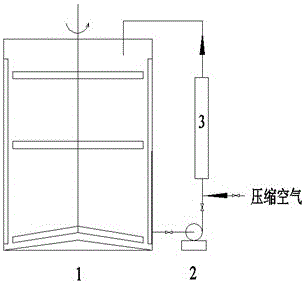

Lead plaster desulfurization method based on gas-liquid mixed flow

ActiveCN105734274AImprove desulfurization efficiencyReduce sulfur contentWaste accumulators reclaimingProcess efficiency improvementCirculator pumpSlurry

The invention discloses a lead plaster desulfurization method based on gas-liquid mixed flow and belongs to the field of waste lead-acid battery resource regeneration. The lead plaster desulfurization method comprises the specific steps that lead plaster is prepared to be lead plaster slurry with a certain concentration, then the lead plaster slurry is stored in a storage tank, and a desulfurizing agent is added into the storage tank; after being pressurized through a circulating pump, the lead plaster slurry is mixed with compressed air and then enters a desulfurizer which is internally provided with flow deflectors; and the lead plaster slurry and airflow form violent turbulent flow in the desulfurizer, and the surface of a reactant is instantaneously updated, so that efficient desulfurization is achieved. The lead plaster desulfurization method based on gas-liquid mixed flow is simple in process, rapid in response, high in production capacity and convenient to operate and maintain.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD +1

Reclaimed rubber process method special for high-temperature steam method

The invention relates to a reclaimed rubber process method special for a high-temperature steam method. The method is characterized by comprising the following steps of: filling waste vulcanized rubber powder with particle size of 20-40 meshes in a high-pressure reaction kettle; meanwhile, adding a softening agent, an activating agent, a thickening agent, a deodorant and an expanding agent; introducing steam with pressure of 0.8Mpa; adding a certain amount of water; and pressurizing and then keeping the temperature in the reaction kettle at 260-280 DEG C for 20-40 minutes, wherein the softening agent is 15-25 percent by weight of coal tar; the activating agent is 0.3-0.6 percent by weight of activating agent 450; the thickening agent is 3-5 percent by weight of rosin; the expanding agent is 2-6 percent by weight of dipentene; the deodorant is 0.3-0.6 percent by weight; and the balance is the waste vulcanized rubber powder. The method has the advantages of easily controlled desulphurization temperature and superior reclaimed rubber performance.

Owner:徐建雄

Environmentally-friendly composite rubber regenerant and preparation method thereof

ActiveCN103980720AEliminate environmental pollutionGood economic benefitsBuilding insulationsPetrochemicalRaw rubber

An environmentally-friendly composite rubber regenerant is prepared by using plant oil pitch, molasses and plant phenol. A preparation method of the environmentally-friendly composite rubber regenerant comprises the following steps: preparing raw materials, mixing the raw materials at a temperature of 25-75DEG C, uniformly stirring, and naturally cooling to room temperature in order to obtain the environmentally-friendly biomass composite rubber regenerant. Compared with regenerants produced by using petrochemical products comprising coal tar and the like, the regenerant prepared in the invention has the advantages of similar mechanical performances, high quality, low production cost, renewable raw material being inedible oil, and simple production method, and the regenerant prepared in the invention accords with environmental protection requirements, can be used for producing environmentally-friendly regenerated rubber, and provides a cheap and fine rubber regenerant for the production of environmentally-friendly rubber products. The environmentally-friendly regenerated rubber produced by using the environmentally-friendly composite rubber regenerant can be applied to substitute rubber materials in order to save the valuable rubber resource, and can be used to produce various rubber products as a raw material.

Owner:KUNMING PHOENIX RUBBERS

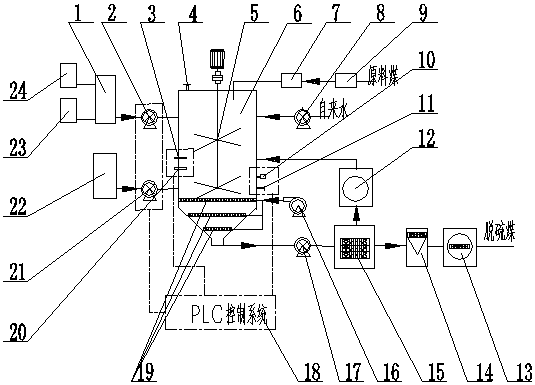

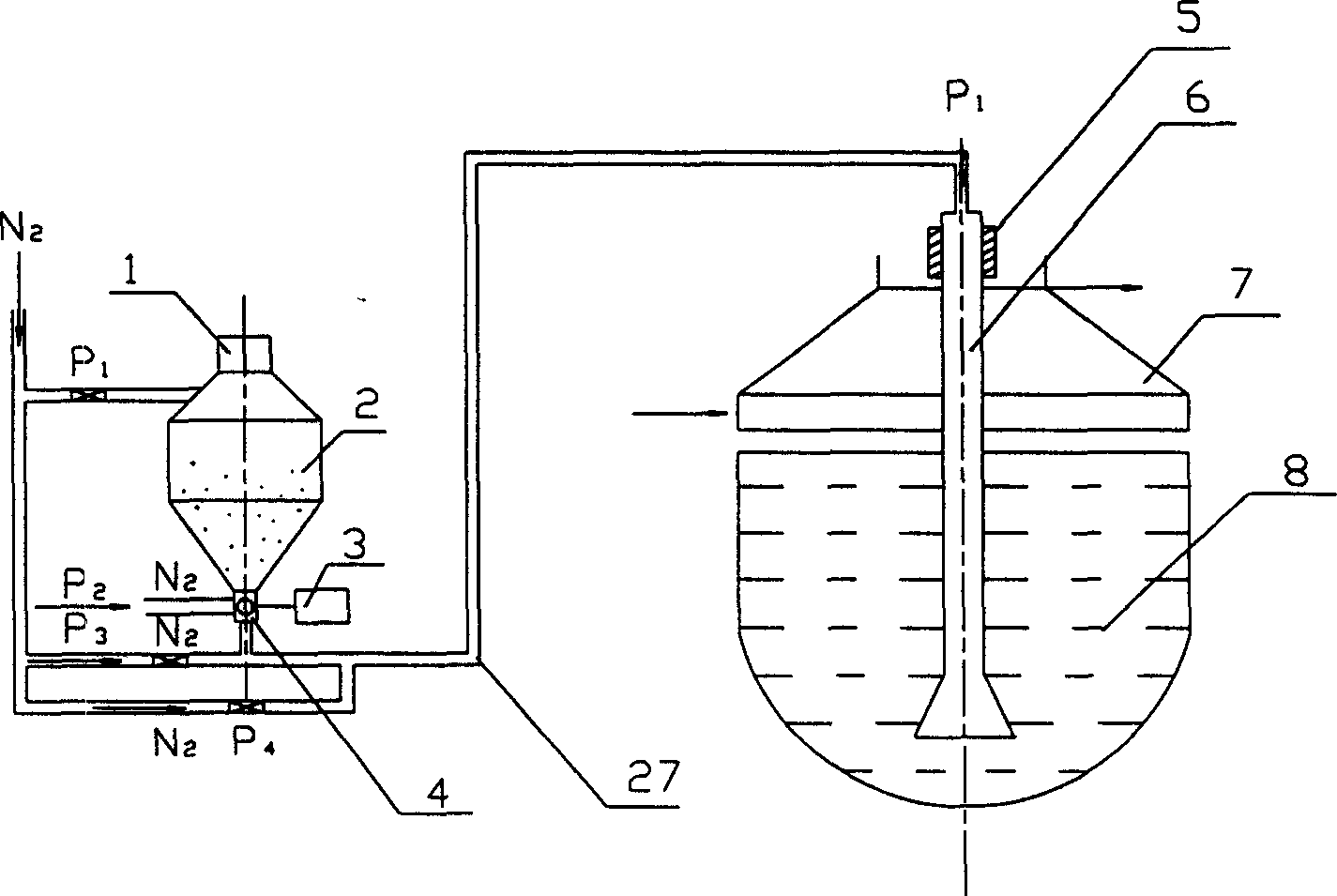

Biological coal desulfurization device and using method thereof

InactiveCN107557106AHigh priceCoal structure damageSolid fuelsThiobacillus ferrooxidansMeasuring instrument

The invention discloses a biological coal desulfurization device and a using method thereof. Rhodococcus erythropolis and thiobacillus ferrooxidans are mixed in a sulfuric acid environment at the pH value of 1-2, and inorganic sulfur in coal is removed by virtue of a biological reaction method. The biological coal desulfurization device mainly comprises a bacterium compound tank, a bacterium liquid metering pump, a pH value measuring instrument, a stirrer, a bio-reactor, a material delivery machine, a water delivery pump, a grinder, a liquid level transmitter, an acid and iron fetching tank, adrying machine, a washing machine, a filter, an air blower, a slurry pump, a PLC (Programmable Logic Controller) control system, an aeration coil pipe, a temperature transmitter, a sulfuric acid metering pump, a sulfuric acid storage tank, a rhodococcus erythropolis culture tank and a thiobacillus ferrooxidans culture tank. The operating steps and using method of the device are given. The desulfurization time is greatly shortened, the desulfurization efficiency is high, the coal slurry and coal-washing wastewater can be recycled, emission of three wastes is avoided, and the biological coal desulfurization device is suitable for industrialized treatment and production.

Owner:UNIV OF JINAN

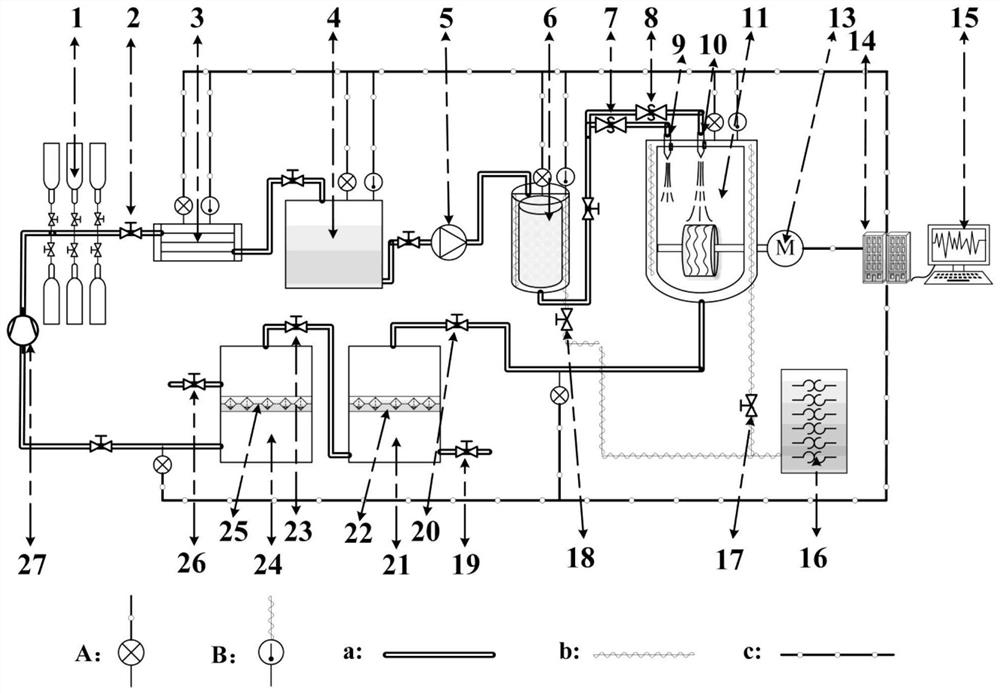

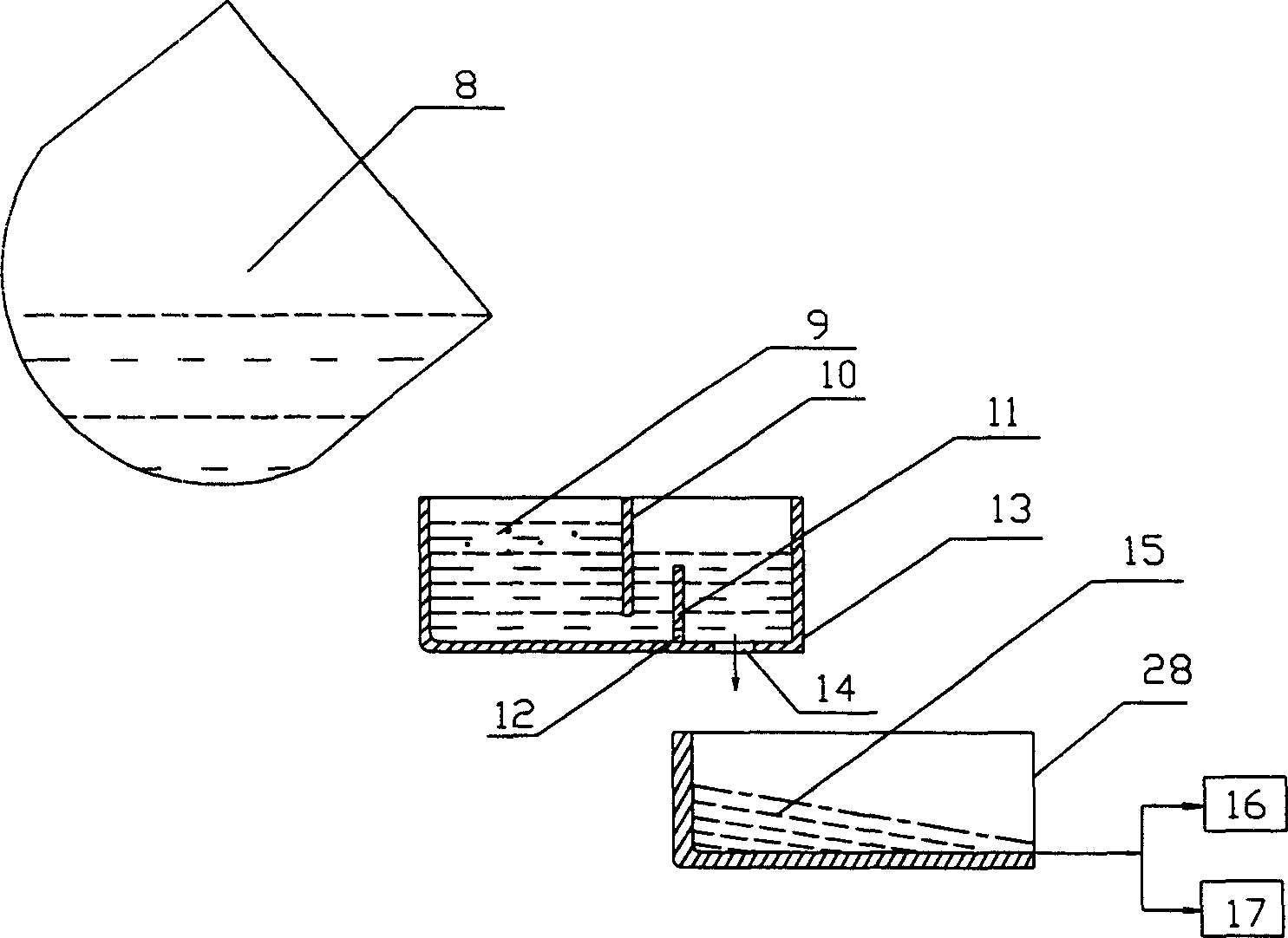

Waste tire crushing and desulfurization integrated device based on supercritical carbon dioxide jet flow and application method

ActiveCN111745860ACrushed fullyGive full play to the swelling effectSievingScreeningPlunger pumpSupercritical carbon dioxide

The invention discloses a waste tire crushing and desulfurization integrated device based on supercritical carbon dioxide jet flow and an application method. The application method comprises the following steps of: firstly, cooling gaseous carbon dioxide to a liquid state and temporarily storing the liquid carbon dioxide in a storage tank; pumping liquid carbon dioxide by a high-pressure plunger pump and pressurizing and storing the liquid carbon dioxide in a buffer tank; heating the liquid carbon dioxide in an oil bath, and converting the liquid carbon dioxide into a supercritical state; filling a tire crushing kettle with the supercritical carbon dioxide through a side nozzle and maintaining a supercritical state confining pressure environment; and forming the supercritical carbon dioxide jet flow through a central nozzle, and finishing recycling of waste tires under certain pressure. When one-time fine crushing of rubber is finished, the supercritical carbon dioxide has high heat and mass transfer characteristics, so that the desulfurization temperature of the rubber can be reduced and the desulfurization time is shortened; efficient desulfurization of rubber powder is synchronously realized and high-activity fine rubber powder is obtained; after the rubber is crushed, tire steel wires can be completely recycled and the gaseous carbon dioxide is circularly utilized; and thewaste tire crushing and desulfurization integrated device has the technical advantages of simple process, scientific principle, safety and high efficiency, energy saving and environment protection.

Owner:WUHAN UNIV OF SCI & TECH

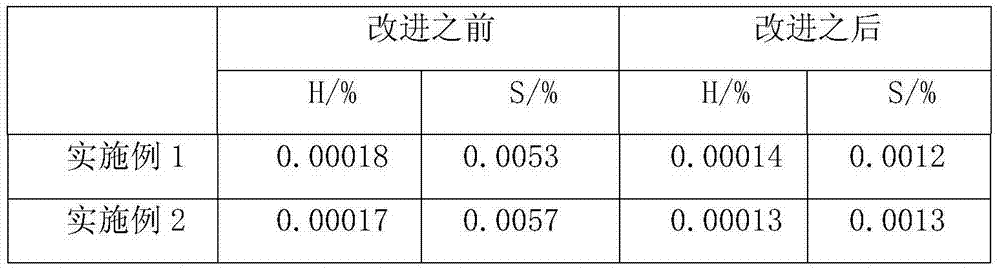

Production method of hydrogen induced cracking resistant steel

InactiveCN104762434AAchieve high volumeReduce consumptionManufacturing convertersAlkalinityTemperature control

The invention discloses a production method of hydrogen induced cracking resisting steel. The production method comprises the steps of molten iron pretreatment, converter blowing, CAS slag washing, LF furnace refining, RH furnace dehydrogenation and continuous casting. By adopting a refining slag synthetic technology, the initial refining slag alkalinity is controlled to be about 4.0, wherein the weight percentage of FeO and MnO is less than 1%, the weight percentage of Al2O3 is more than or equal to 20%, and the weight percentage of CaO is more than or equal to 45%; a large-flow argon blowing stirring technology is adopted; a temperature control technology is adopted, the temperature of molten steel before LF furnace slag washing is 1550-1570 DEG C, and the temperature of the slag washing process is 1580-1600 DEG C to ensure that the weight percentage of sulfur is effectively controlled within 0.0020%, the average weight percentage of sulfur is 0.0012%, and the lowest weight percentage of sulfur is 0.0003%; and the desulfurization rate of an LF refining furnace is improved from 60.53% to 83.66%, the furnace treatment with the unqualified sulfur content is reduced from 20% to 0, the consumption of desulfurization slag forming materials is reduced by 3.2kg / t steel, and the system desulfurization time is averagely shortened by 5-6 minutes. By adopting the production method, on the premise that the quality is ensured, large-batch, stable and low-cost production of the hydrogen induced cracking resisting steel is realized.

Owner:SHANDONG IRON & STEEL CO LTD

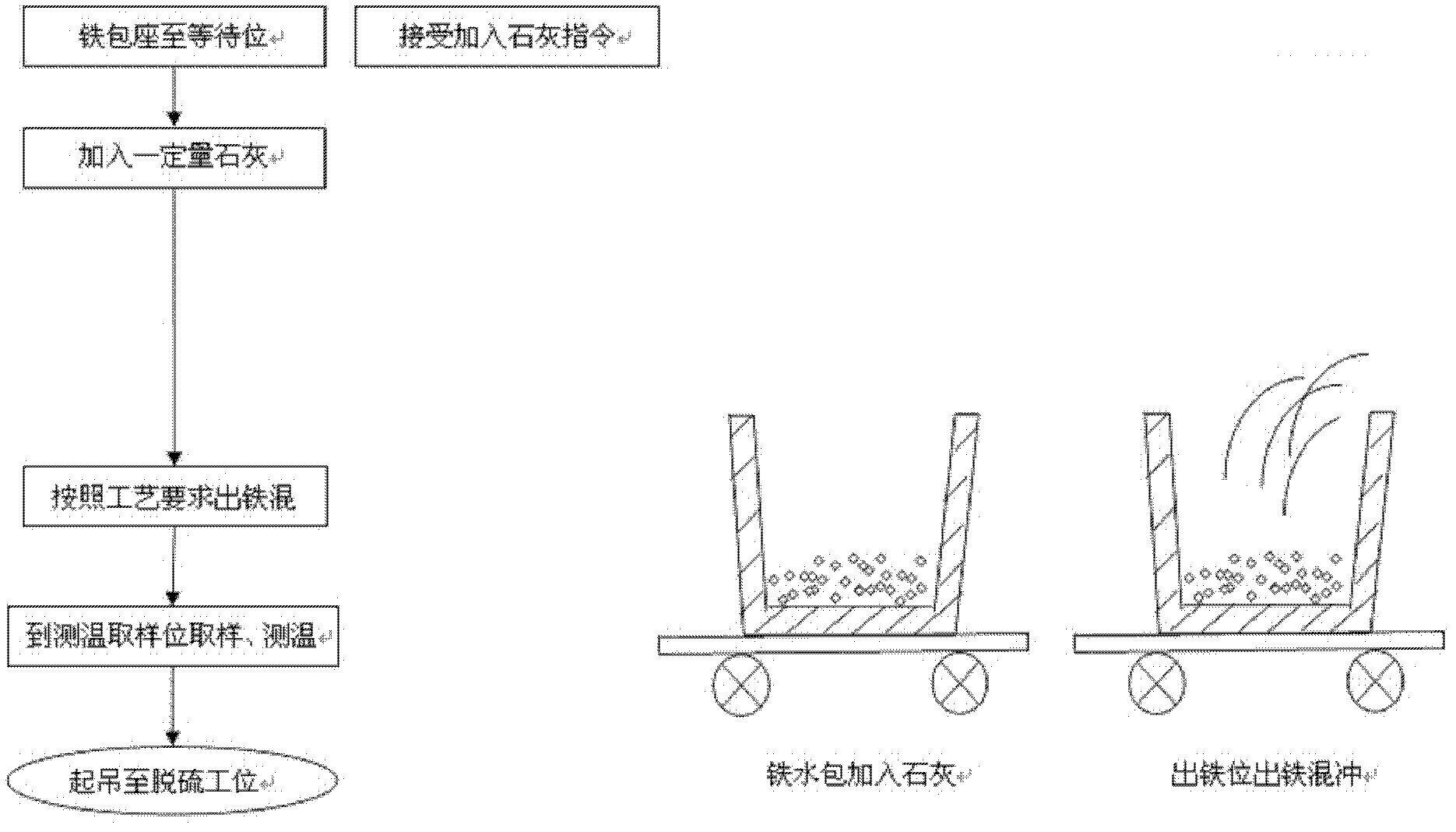

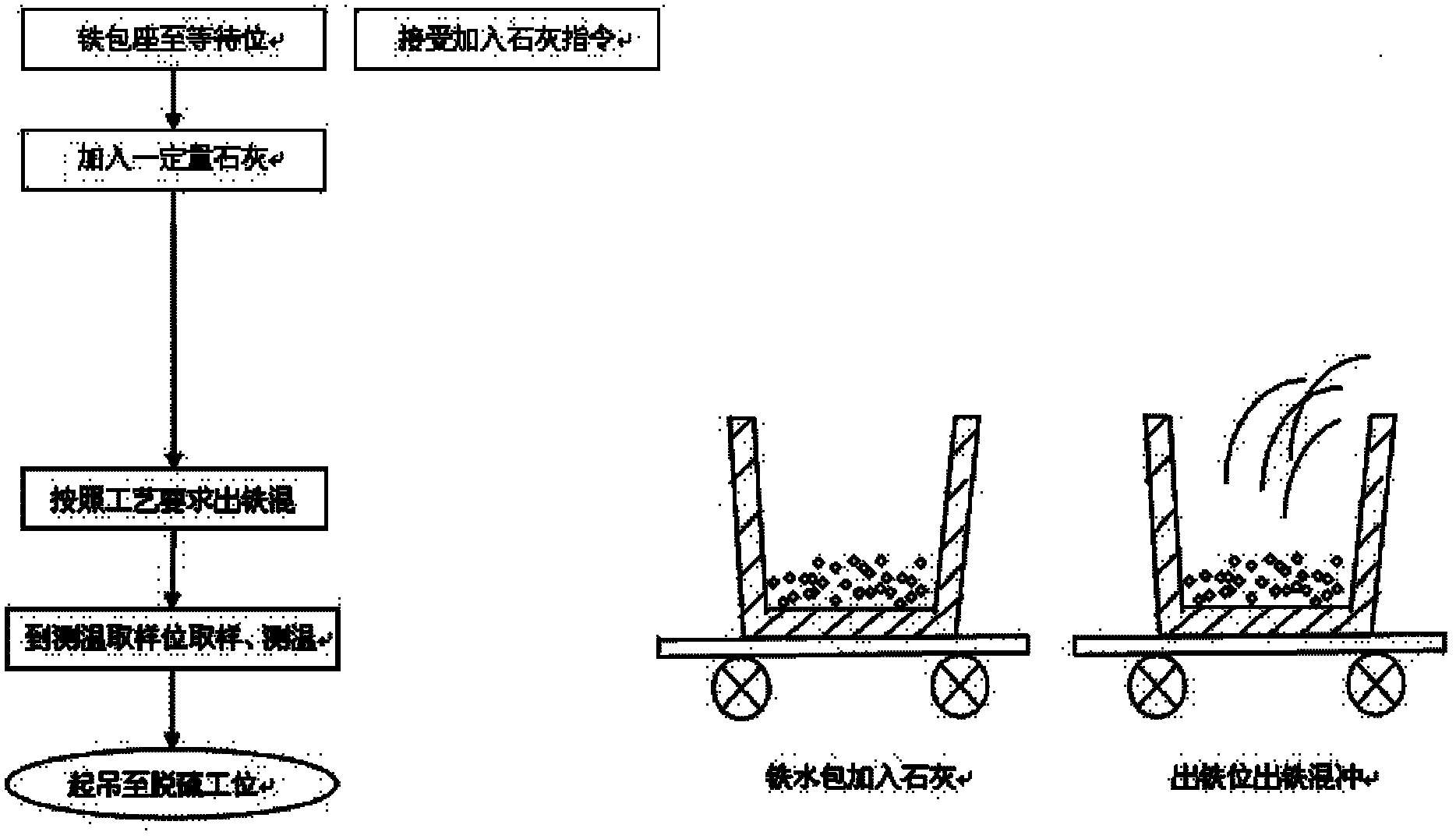

Method for two-step desulfurization of molten iron

InactiveCN102220447ADoes not occupy sky train timeGuaranteed continuous productionPre treatmentFerric

The invention relates to a method for two-step desulfurization of molten iron, which comprises the following steps: adding active lime into a molten iron ladle during reladling and tapping, then tapping, performing mixed flushing, and further entering a desulfurization station for blowing magnesium powder for pretreatment of the molten iron and desulfurization. In the method, no equipment is added, no fixed investment is involved, only a part of the bagged active lime needs to be artificially added into the bottom of the iron ladle, therefore, the method is simple and easy to operate, occupies no time of an overhead travelling crane and can ensure continuous production.

Owner:NINGBO IRON & STEEL

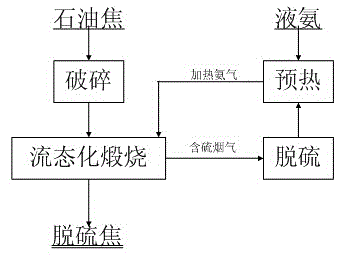

Technology for improving petroleum coke desulfurization efficiency in ammonia gas atmosphere

InactiveCN105060270AReduce pressure on environmental protectionImprove desulfurization efficiencyPetroleum cokePetroleum

The invention discloses a technology for improving the petroleum coke desulfurization efficiency in an ammonia gas atmosphere. The technology comprises the following steps: grinding petroleum cokes, then delivering the petroleum cokes to a high-temperature fluidized (ammonia gas) atmosphere furnace, wherein in the furnace, the petroleum coke particles are heated and are in a boiling state at the same time, so the petroleum coke particles have an enough contact surface with the desulfurizer (ammonia gas), taking out the petroleum cokes after the desulfurization; preheating the ammonia liquid to generate high-temperature ammonia gas with a temperature of 500 to 700 DEG C, and introducing the ammonia gas into fluidized equipment at a flow speed of 1 to 40 m / s. The petroleum cokes are grinded and sieved to form particles with a size smaller than 1 mm; then the particles are fed into high-temperature fluidized equipment with a temperature of 700 to 900 DEG C through a feeding device, and then ammonia gas is introduced into the equipment, and the petroleum coke is fluidized and desulfurized by the ammonia gas flows. After fluidized calcination within 30 minutes, the petroleum cokes are fed into a desulfurized coke tank. The technology and equipment are optimized on the basis of ammonia gas calcination and desulfurization so as to further shorten the desulfurization time and obtain a higher desulfuration rate.

Owner:CENT SOUTH UNIV

Reclaimed rubber prepared from oil field oil sludge and production method thereof

InactiveCN106188613AImprove qualityImprove vulcanization activityPlastic recyclingTarTherapeutic effect

The invention belongs to the field of oil field oil sludge resourceful treatment, especially discloses reclaimed rubber prepared from oil field oil sludge as a main raw material, and also discloses a production method. The reclaimed rubber prepared from the oil field oil sludge is composed of the raw materials by the mass percentage: 50%-65% of oily sludge, 5%-20% of a waste tire rubber powder, 20%-40% of clay, 0.1%-0.4% of an activator 420, 0.1%-0.3% of ethylene tar, and 0.1%-0.3% of alkyl phenol disulfide. According to the reclaimed rubber prepared with oil field oil sludge, through formula optimization design, the content of the oily sludge is increased significantly, the consumption of the oil field sludge is increased, and the oil field oil sludge resourceful treatment effect is increased by 20% or more; with use of the waste tire rubber powder, the use amount is only 5%-20% and is significantly reduced, and the production cost is saved; the reclaimed rubber has relatively short reclaiming reaction time and has high degree of desulfurization, and the reclaimed rubber properties all reach national corresponding reclaimed rubber standards.

Owner:青岛三聚猫环保能源科技有限公司

Gasoline desulfurization catalytic adsorbent, and preparation method and desulfurization method thereof

InactiveCN103585954AShorten desulfurization timeEliminate washing and extractionPhysical/chemical process catalystsOther chemical processesDecompositionCatalytic oxidation

The invention discloses a gasoline desulfurization catalytic adsorbent, and a preparation method and a desulfurization method thereof. The gasoline desulfurization catalytic adsorbent comprises the components by the weight percentage: 40%-60% of Ti3(PW12O40)4, 25%-40% of SiO2, and 15%-20% of Al2O3. Addition of Ti3(PW12O40)4 in the catalytic adsorbent can accelerate decomposition of tert-butyl hydroperoxide, oxygen obtained by decomposing tert-butyl hydroperoxide is increased, and thus an oxidative desulfurization reaction of dibenzothiophene is promoted; and at the same time, the gasoline desulfurization catalytic adsorbent has good catalytic oxidation and adsorption abilities. The gasoline desulfurization catalytic adsorbent can adopt adsorption to remove oxidation products while allowing an oxidation reaction of sulfides in gasoline to be carried out, does not need to adopt water washing extraction or water washing adsorption to remove the oxidation products, thereby omitting water washing extraction or water washing adsorption in the prior art, improving the work efficiency, and reducing the gasoline desulfurization time.

Owner:ANYANG INST OF TECH

Molten iron desulfurizing method

The improved molten iron desulfurizing process outside blast furnace includes spraying deactivated magnesia grains as desulfurizing agent via high-precision automatically regulating material feeding mode; desulfurizing in the molten iron ladle with water cooling hood to prevent adhesion of desulfurizing dross and molten iron; slag-iron separation in the same separator and feeding pure molten ironinto pig iron mixer or molten iron ladle. The said process has the features of less investment, simple process, low production cost and easy maintenance.

Owner:NANJING NANGANG IND DEV CO LTD

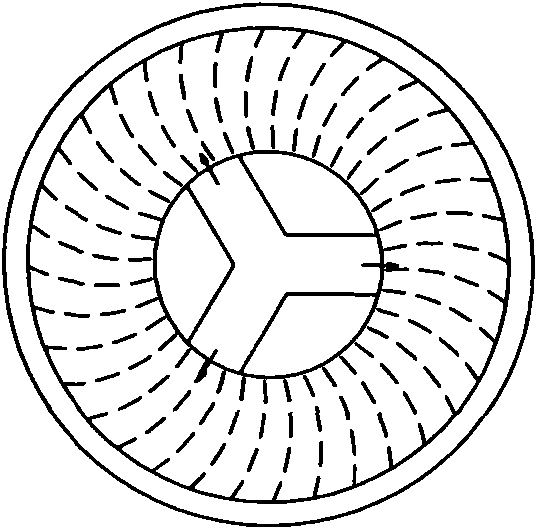

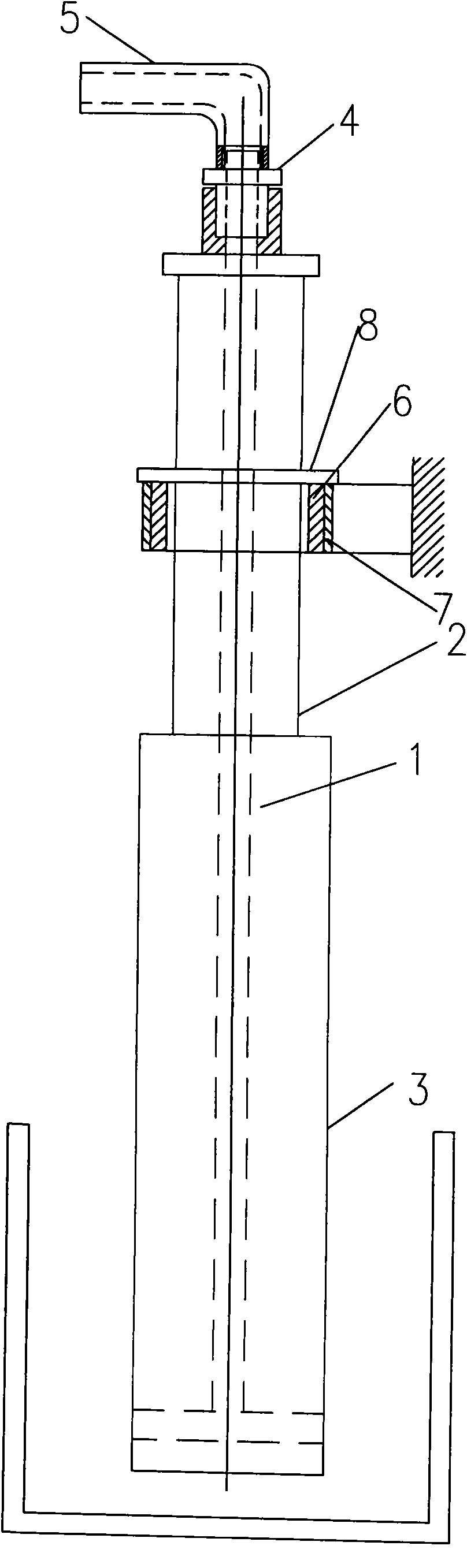

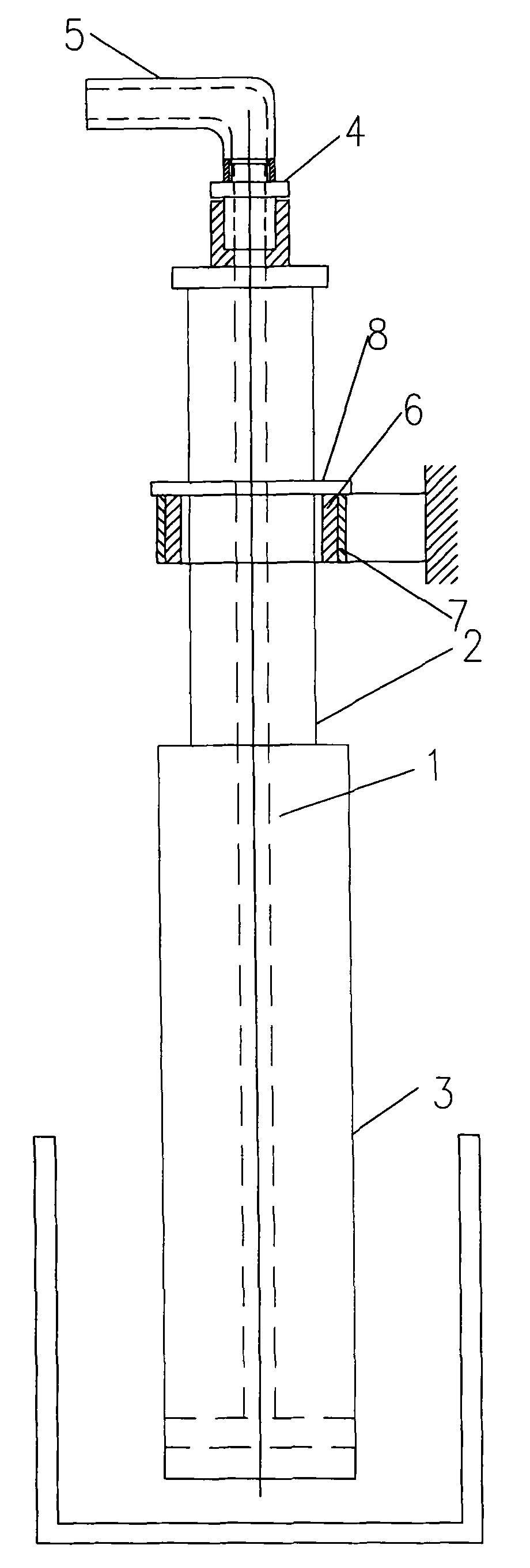

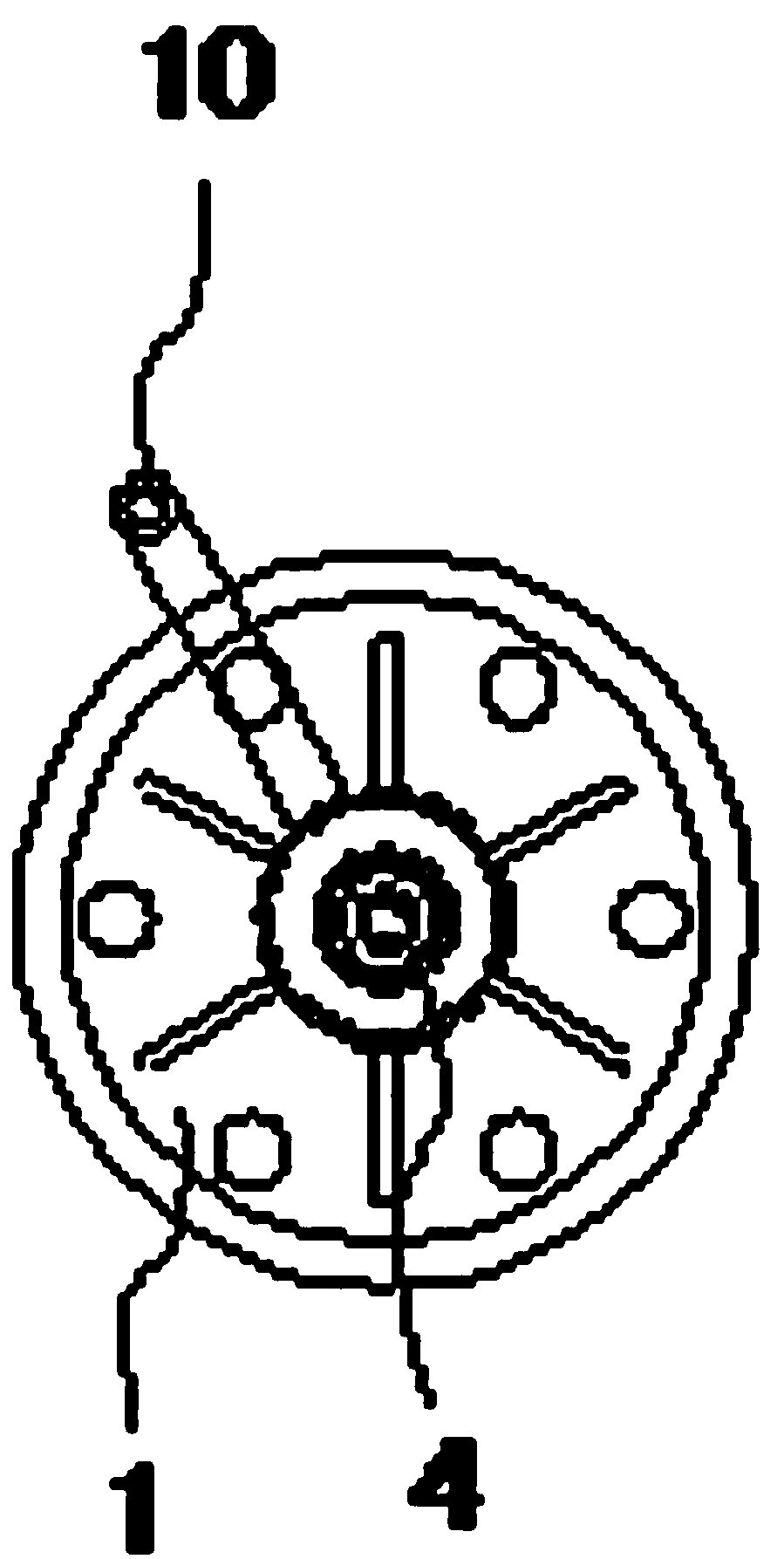

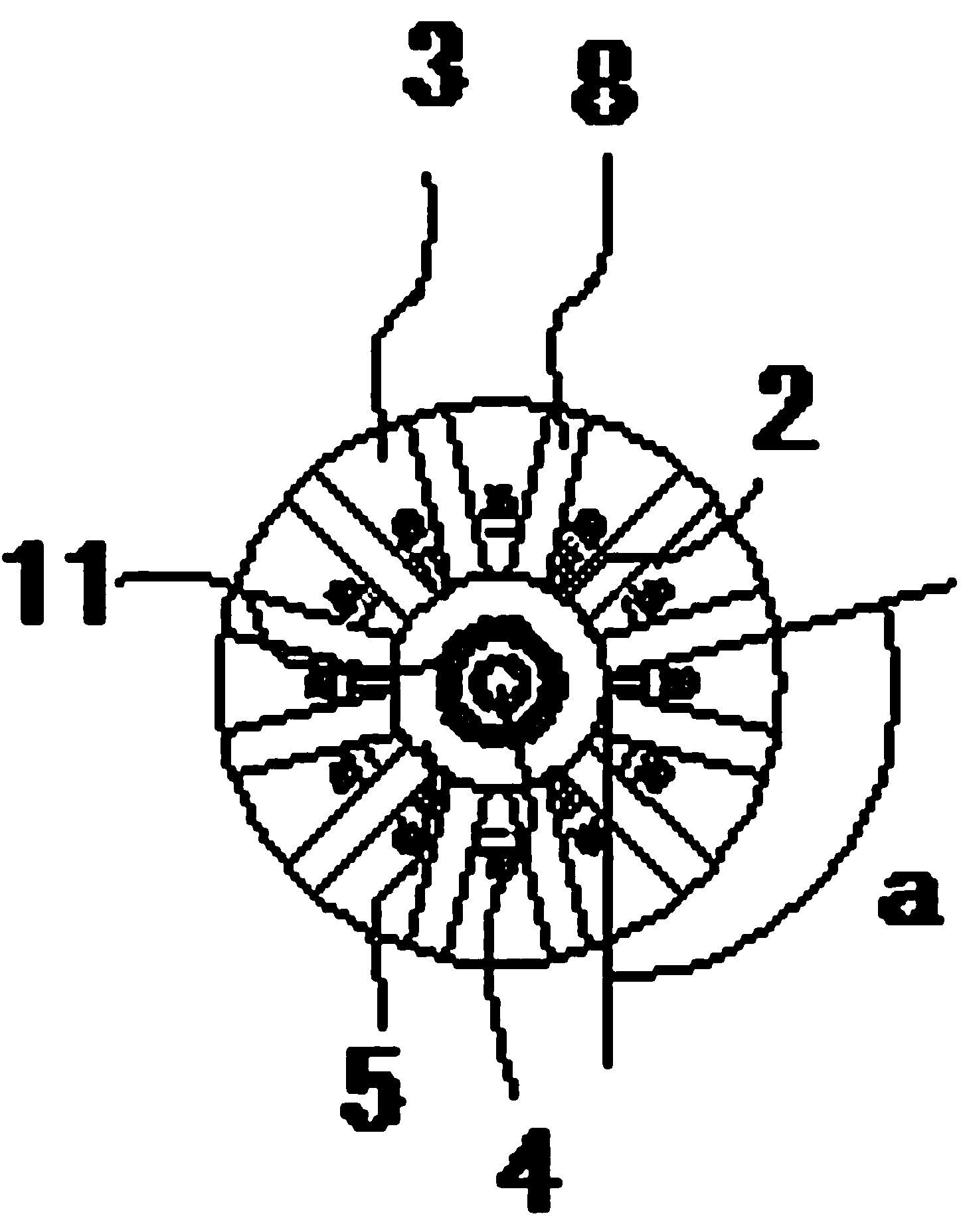

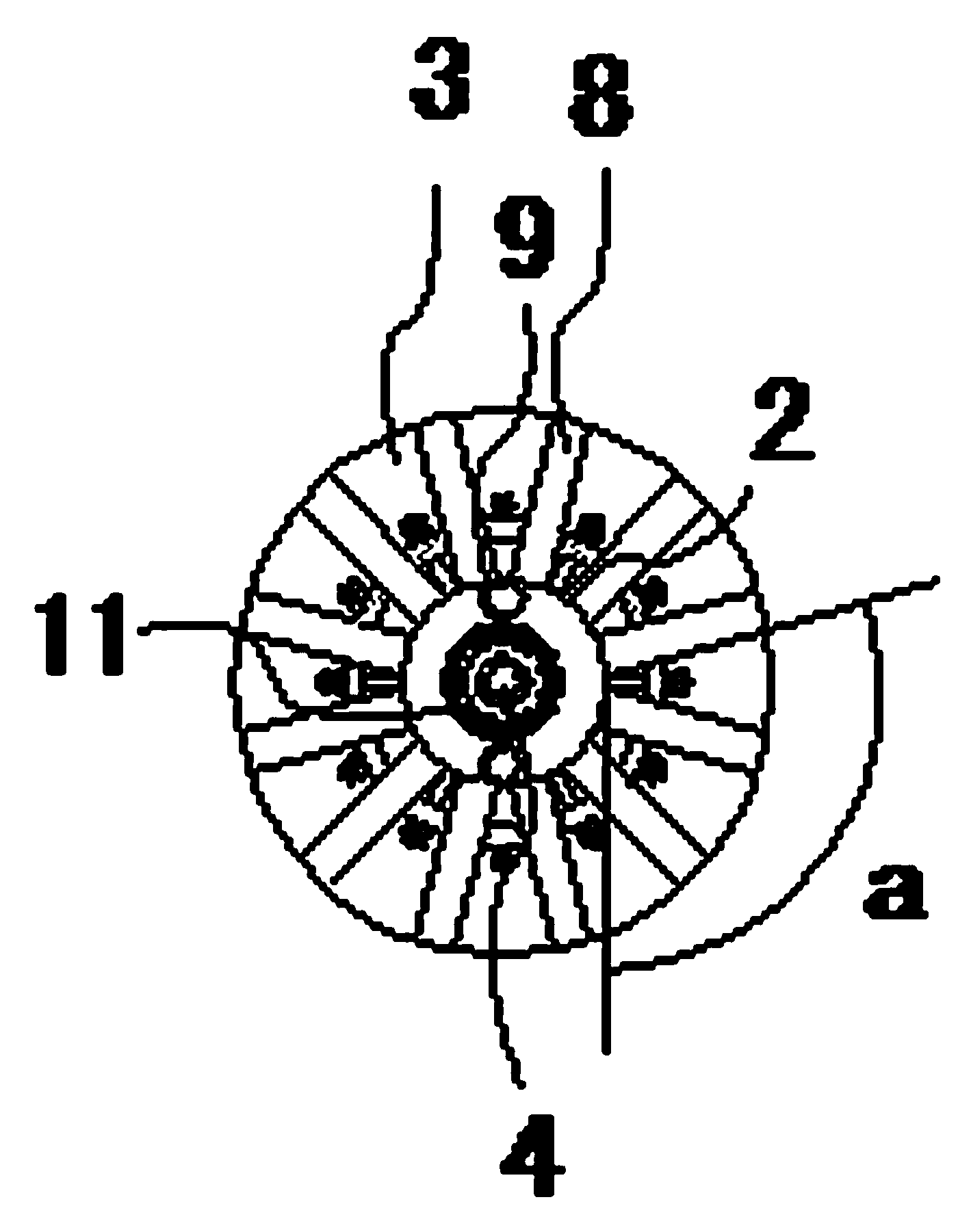

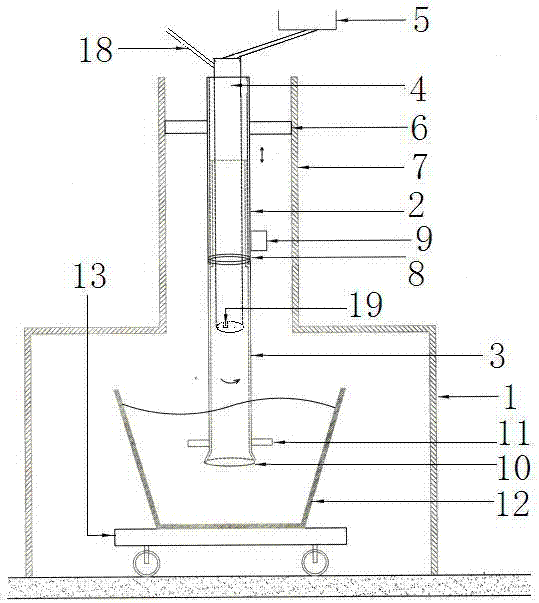

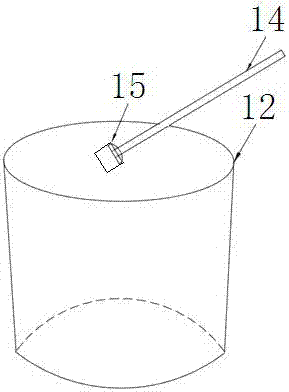

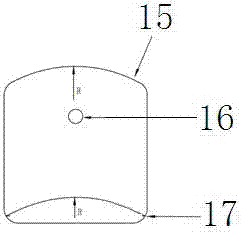

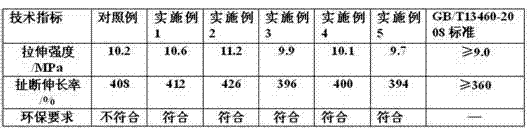

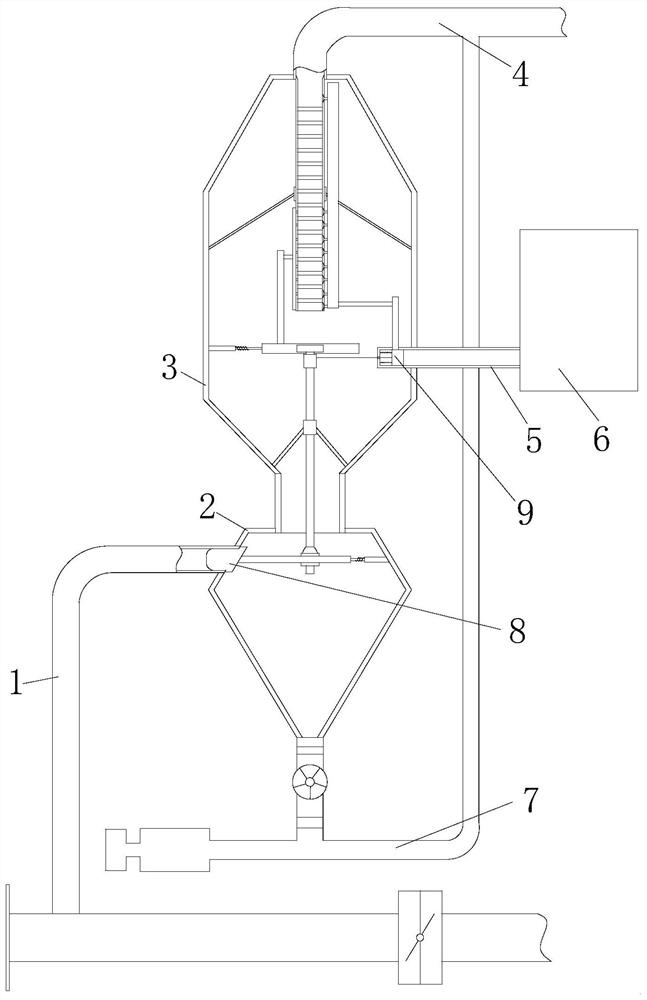

Efficient molten iron desulfurization spray gun

The invention belongs to the field of molten iron pretreatment desulfurization equipment, and particularly relates to an efficient molten iron desulfurization spray gun, which comprises a mounting flange (1), an outer protective pipe (2), a center desulfurizing agent nozzle pipe (4) and a refractory material protection layer (3); a blowing medium input pipe (10) is fixedly arranged in the mounting flange (1) region; a blowing medium gap (5) is arranged between the outer protective pipe (2) and the center desulfurizing agent nozzle pipe (4); one end port of the blowing medium input pipe (10) is communicated with the blowing medium gap (5) ; a blowing medium gas distribution mechanism (6) is horizontally fixedly arranged in the tail region of the outer protective pipe (2); the blowing medium gas distribution mechanism (6) comprises a gas supplying chamber (7) and a blowing medium nozzle (8); and the blowing medium gap (5) and the gas supplying chamber (7) are communicated. The efficient molten iron desulfurization spray gun is ideal in desulfurization effect, strong in stirring force, and fast in desulfurization reaction speed.

Owner:辽宁欣立耐火材料科技集团有限公司

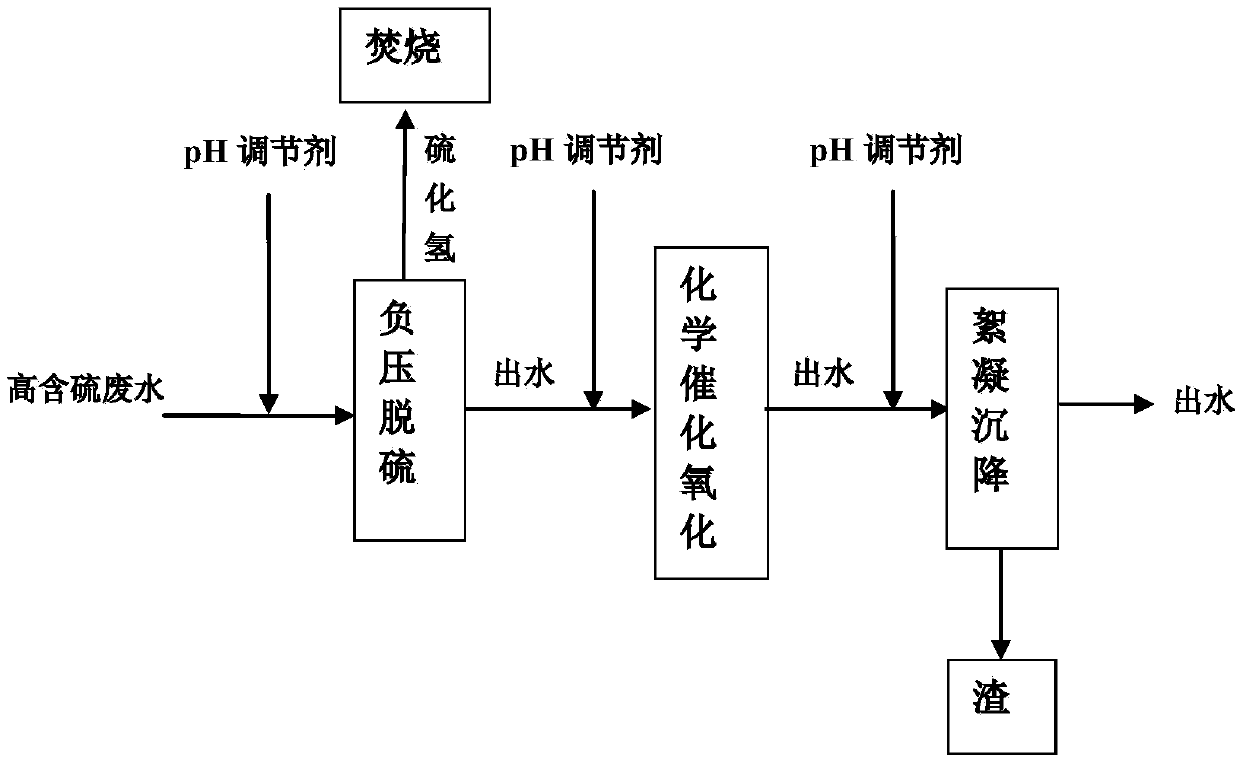

Reduced-injection standardized discharge method for high-sulfur wastewater in oil and gas fields

ActiveCN107417014ARealize the goal of reducing injection and meeting standardsSolve hugeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical reactionChemistry

The invention relates to a reduced-injection standardized discharge method for high-sulfur wastewater in oil and gas fields. The method includes the following steps: 1) removing majority of H2S in the high-sulfur wastewater through negative pressure desulfurization; 2) performing chemical reaction to residual H2S in the water generated through the negative pressure desulfurization to form precipitates; 3) performing flocculating settlement to the water generated through the chemical reaction desulfurization; 4) filtering the water generated by the flocculating settlement through a ceramic membrane filtration unit; 5) separating and concentrating the water generated through the ceramic membrane filtration in a high-effective electro-dialysis unit; and 6) performing ozone catalytic oxidization to the fresh water generated through the high-effective electro-dialysis, and discharging the water, which meets the standards, after the ozone catalytic oxidization. By means of the reduced-injection standardized discharge method, sulfides, suspension solids, organic matters, chlorides and oil in the high-sulfur wastewater are deeply removed, and the sulfur content, suspension solid content and oil content of eletro-dialyzed concentrated water satisfy standard of reinjection water of oil and gas fields. The water outputted after the ozone catalytic oxidization meets the standard and is discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of efficient composite molten iron desulfurizing agent

The invention discloses a preparation method of an efficient composite molten iron desulfurizing agent and belongs to the technical field of ferrous metallurgy auxiliary materials. The preparation method comprises the following steps: (1) burdening; (2) preparation process: a, performing passivation treatment on zinc chloride by virtue of a process which comprises spraying, namely spraying additives onto the surface of the zinc chloride powder in a container, and heat preservation, namely preserving heat for 4 minutes at a temperature ranging from 100 to 1050 DEG C so that the additives are boiled and completely volatilized to be absorbed by the cured zinc chloride to form a protective film; b, evenly mixing the materials with the material in the step a and performing drying pretreatment; pouring the passivation liquid into the materials, stirring, cooling naturally and grinding to obtain the powdery finished product; and (3) putting the powdery finished product into a damp-proof container or bag and sealing for later use. According to the preparation method of the efficient composite molten iron desulfurizing agent, high efficiency of molten iron desulfurization and energy conservation can be realized, the composite cost of molten iron desulfurization is not increased, the sulfur content in the desulfurized molten iron is less than 0.010%, and the desulfurization time is only 50% of the traditional desulfurization time.

Owner:WUHU JINLONG MOLD FORGING

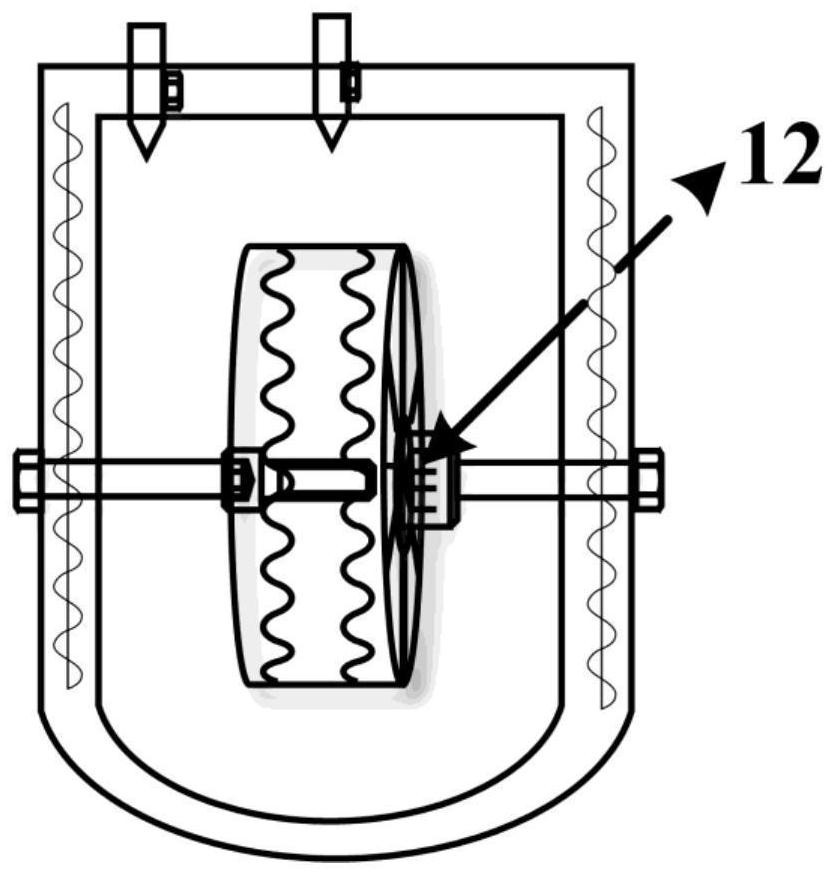

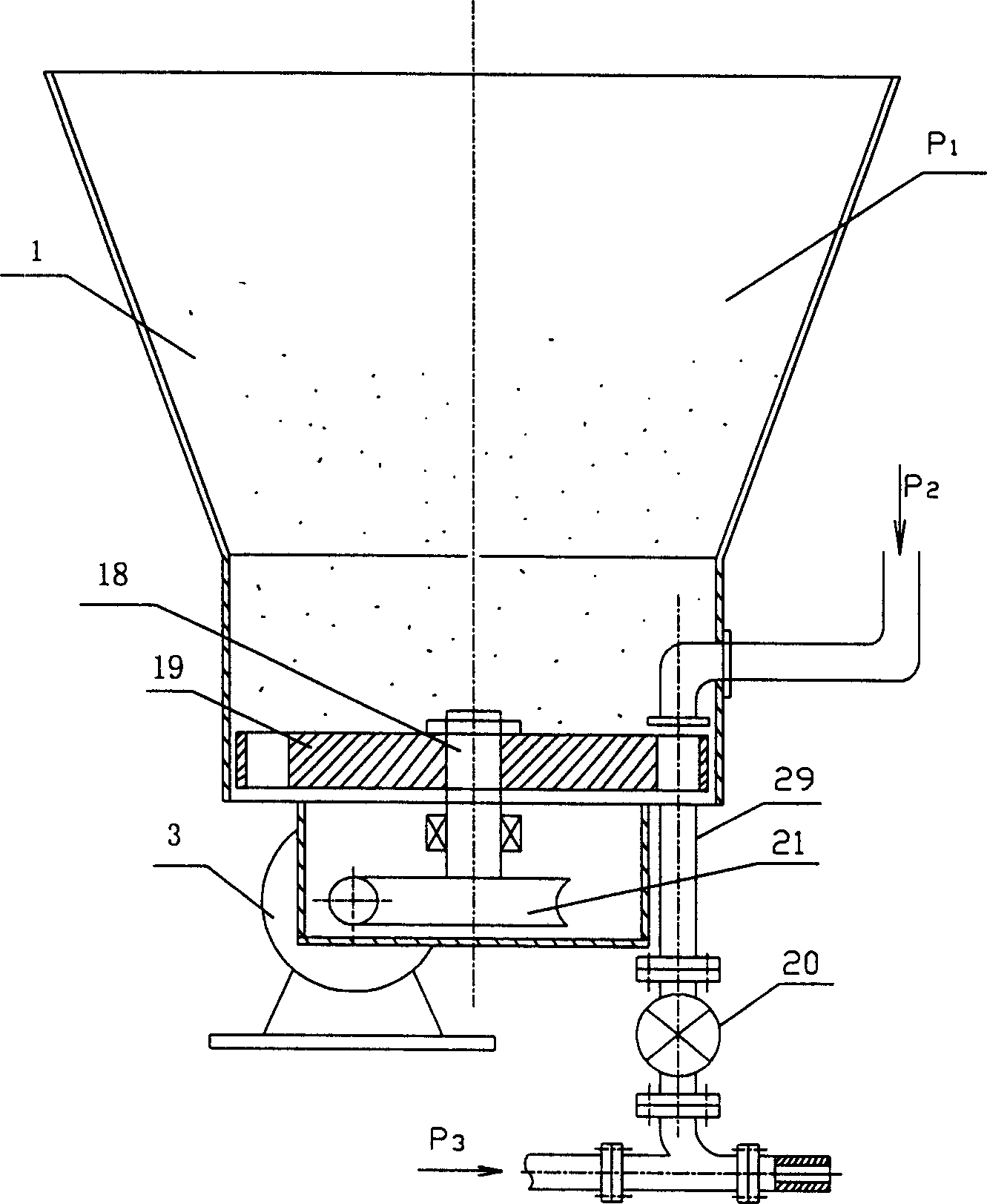

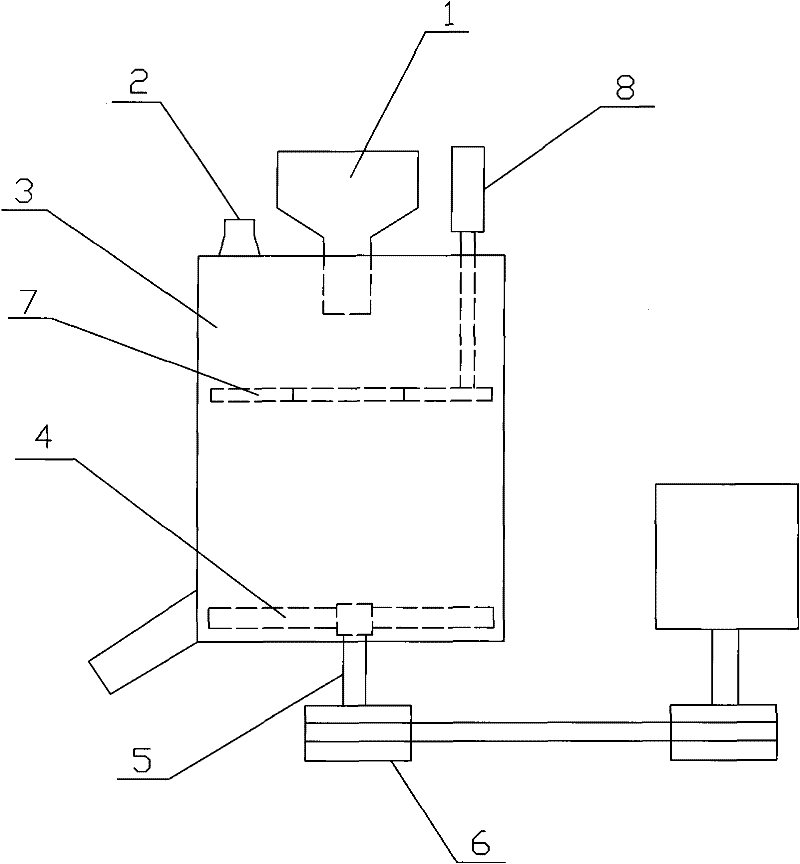

HG hot metal desulfurization device and desulfurization method thereof, and desulfurizer and slag remover

The invention discloses a HG hot metal desulfurization device and desulfurization method thereof, and a desulfurizer and a slag remover. A nozzle of the desulfurizer is formed in a support, the nozzle of the desulfurizer is fixed inside a sleeve, the sleeve is movably connected to the support in up and down direction, the lower part of the sleeve is rotationally connected with a stirred tube, one end of the nozzle of communicates with desulfurizer a stock bin of the desulfurizer, the other end of the nozzle of the desulfurizer communicates with the lower nozzle of the stirred tube, a nitrogen gas tube is in connection with the nozzle of the desulfurizer, the outlet direction of the nitrogen gas tube points to the lower nozzle of the stirred tube, a stirred tube is located at outside of the tube wall under the position of the lower part of the nozzle and fixed with a stirred rod , and the stirred tube is connected to a rotating motor fixed on the outside wall of the sleeve in a transmission mode. According to the structure of the HG hot metal desulfurization device, not only the dynamic property conditions of desulfurization is strengthened, but also a deep, complete, and full mixing of the desulfurizer with the hot mental can be made and desulfurization by reaction, thus utilization ratio of desulfurizer is improved, waste of desulfurizer is avoided, and in addition, nodulation of the stirring device is prevented.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Technology for producing ultralow-sulfur steel with steel ladle as refining furnace

A technology for producing ultralow-sulfur steel with steel ladle as refining furnace features that the efficient non-metal desulfurizing powder is used to make cored wire, and the cored wire is fed into molten steel while inertial gas is brown into it from the bottom of steel ladle to stir the molten steel for speeding up the desulfurizing reaction. Said desulfurizing powder contains BaO (5-40 mass%), CaO (50-80) and CaF2 (8-15). After refining the steel for 15-35 min, the sulfur content is reduced from 0.01% to 0.001%.

Owner:UNIV OF SCI & TECH BEIJING

Deep desulphurization method of high sulfur-containing waste water from oil and gas field

InactiveCN106256778ARealize deep desulfurizationHigh degree of automationMultistage water/sewage treatmentChemical reactionIndustrial waste water

The invention relates to the field of industrial waste water processing, and concretely relates to a deep desulphurization method of high sulfur-containing waste water from oil and gas field. The deep desulphurization method comprises the following steps: removing most hydrogen sulfide in waste water by employing a negative-pressure desulphurization technology for burning the hydrogen sulfide; forming precipitate on the residual hydrogen sulfide in a negative-pressure desulphurization effluent obtained by employing a chemical catalytic oxidation technology through a chemical reaction, removing the precipitate; and finally deeply removing sulfide in the high sulfur-containing waste water from oil and gas field. The deep desulphurization method can effectively remove the sulfide in the waste water, the problem of overhigh sulfur content during a high sulfur-containing waste water re-injection process of the oil and gas field is solved, and the disadvantages of large equipment, complex process, low efficiency, poor environment adaptability, high operation cost and difficult maintenance in the current processing technology can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regeneration production method of scrap rubber

ActiveCN105949504AIncreased probability of fractureImprove fracture efficiencyPlastic recyclingScrapDouble pass

The invention discloses a regeneration production method of scrap rubber. The method is characterized by comprising the following steps: cleaning, pulverizing, removing impurities, screening, stirring, desulfurizing, extracting, refining, and discharging and forming. The discharging and forming process sequentially comprises the steps of primary plate pressing and secondary rolling forming. The plate pressing and rolling are matched to implement the formation of the regenerated rubber; by using the plate pressing, the rubber powder primarily forms a plate, thereby enhancing the overall density and uniformity; and the double-pass rolling is performed to effectively enhance the mechanical properties and swelling degree of the plate rubber.

Owner:NANTONG HUILI RUBBER

Reclaiming agent and method and device for producing reclaimed rubber

The present invention discloses a reclaiming agent formula, a method for producing reclaimed rubber by utilizing the formula and a pre-reaction mixer cooperating with the method. The invention has the following advantages that: the disclosed reclaiming agent has the advantages of low cost, rich material source and easy production, and can produce high-performance, environment-friendly reclaimed rubber by means of a simple, low-cost production method; the disclosed reclaimed rubber production method has the advantages of little equipment investment, low cost, environment-friendly technique, simplicity, high produced reclaimed rubber quality and the like; the disclosed pre-reaction mixer can increase the desulfuration speed of the interior and exterior of waste rubber, increase the desulfuration degree and shortens the desulfuration time.

Owner:霍书光

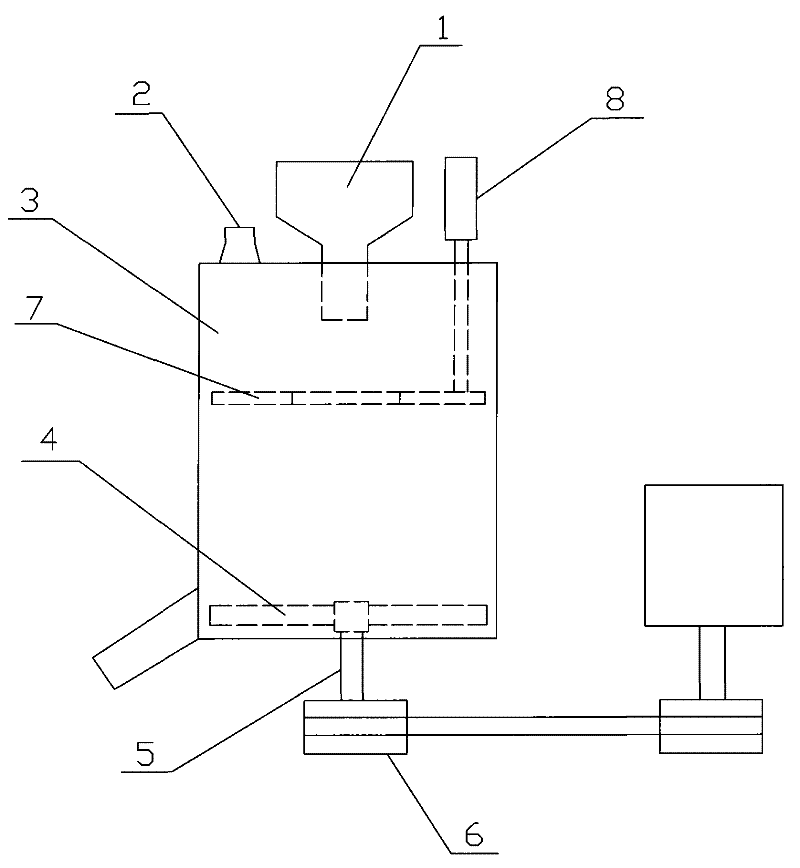

Calcium-based ionic liquid for flue gas desulfurization, desulfurizer and preparation method of desulfurizer

ActiveCN113041827AEasy to transportEnhanced mass transferGas treatmentDispersed particle separationActivated carbonPhysical chemistry

The invention discloses a calcium-based ionic liquid for flue gas desulfurization, a desulfurizer and a preparation method of the desulfurizer. The calcium-based ionic liquid for flue gas desulfurization is prepared from 1-butyl-3-methylimidazolium chloride ionic liquid, calcium chloride and a volatile solvent through a stirring reaction, centrifugal separation and drying. The desulfurizer for flue gas desulfurization is prepared from activated carbon and the calcium-based ionic liquid for flue gas desulfurization through a pressure impregnation method. The calcium-based ionic liquid is in a solid state at normal temperature and is convenient to transport; and meanwhile, the desulfurizer also overcomes the problems that existing ionic liquid for flue gas desulfurization is relatively high in viscosity and low in utilization rate during use.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

The invention provides an environmentally-friendly biomass compound rubber regenerant. The regenerant is prepared from the following raw materials in mass percentage: 60-85% of bio-oil, 10-20% of natural resin and 5-30% of plant polyphenol. The preparation method of the regenerant comprises the following steps: (1) heating the bio-oil to 60-85 DEG C; (2) respectively adding the natural resins andthe plant polyphenol to the bio-oil and evenly mixing; and (3) naturally cooling the evenly mixed product to room temperature to finally obtain the environmentally-friendly biomass compound rubber regenerant product. In the invention, the bio-oil, the natural resins and the plant polyphenol which are extracted from plants are taken as raw materials, and the raw materials are renewable materials, which realizes maximum resource utilization and reduces dependence on petrochemical resource so as to achieve the purpose of green production of reclaimed rubber. The regenerant has the advantages of good rubber regeneration effect, high product quality, low production cost and no pollution and nuisance during the production process. The environmentally-friendly reclaimed rubber produced by the regenerant can be widely applied to various rubber products and can replace rubber materials, thus saving rubber resources.

Owner:KUNMING PHOENIX RUBBERS

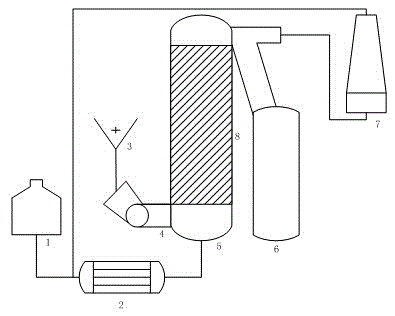

Energy-saving and efficiency-improving device of wet desulphurization spray tower

PendingCN113521999AShorten desulfurization timeImprove work efficiencyGas treatmentDispersed particle separationSpray towerFlue

The invention relates to an energy-saving and efficiency-improving device of a wet desulphurization spray tower. The device comprises a coke oven flue; the coke oven flue is communicated with an external induced draft fan; the free end of the coke oven flue is communicated with a first desulfurization tank, and the upper portion of the first desulfurization tank is communicated with a second desulfurization tank; the top end of the second desulfurization tank is communicated with a dust remover connecting pipe; and a desulfurizing agent connecting pipe is arranged on the side wall of the second desulfurization tank in a communicating manner. The structure of an existing wet desulphurization spray tower is improved, and in the using process of the improved wet desulphurization spray tower, the effects of saving energy and reducing consumption can be achieved through timely mixing and contact of flue gas and slurry; and meanwhile, the effect of efficient desulfurization of the flue gas can be achieved through multiple times of desulfurization of the flue gas.

Owner:JIANGSU MINSHENG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com