HG hot metal desulfurization device and desulfurization method thereof, and desulfurizer and slag remover

A technology of hot metal desulfurization and desulfurization agent, which is applied in the field of HG hot metal desulfurization device, desulfurizer and slag remover, can solve the problems of large consumption of desulfurizer, difficult removal of slag and easy resulfurization, difficult to reach deep desulfurization, etc., to reduce consumption and smelting time, strengthen dynamic conditions, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

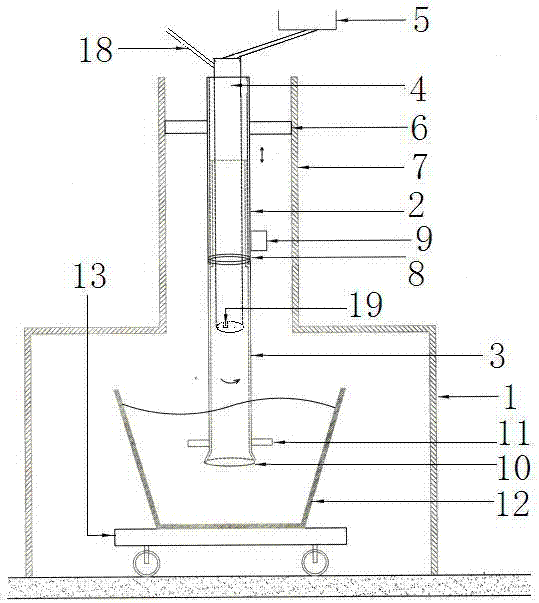

[0073] 1) After the molten iron ladle 12 to be desulfurized is advanced to the directly below the stirring tube 3, sampling and temperature measurement of the molten iron are carried out;

[0074] 2) After the temperature measurement is completed, the desulfurizer nozzle 4 moves down along the bracket 1 driven by the casing 2;

[0075] 3) When the lower nozzle 10 of the stirring tube 3 is about to contact the liquid surface of the molten iron in the ladle 12, open the gas valve of the nitrogen pipe 18, and the nitrogen flow rate is 100 Nm3 / h;

[0076] 3) The desulfurizing agent nozzle 4 continues to move downward along the support 1 under the drive of the casing 2 until the lower nozzle 10 of the stirring tube 3 and the stirring rod 11 extend into the molten iron in the ladle 12, and the insertion depth is 1.25 meters . Simultaneously start the rotary motor 9 to make the stirring tube 3 rotate, and rotate to the normal operating speed in the range of 70 to 100 r / min;

[0077...

Embodiment 2

[0089] 1) After the molten iron ladle 12 to be desulfurized is advanced to the directly below the stirring tube 3, sampling and temperature measurement of the molten iron are carried out;

[0090] 2) After the temperature measurement is completed, the desulfurizer nozzle 4 moves down along the bracket 1 driven by the casing 2;

[0091] 3) When the lower nozzle 10 of the stirring tube 3 is about to contact the liquid surface of the molten iron in the ladle 12, open the gas valve of the nitrogen pipe 18, and the nitrogen flow rate is 110 Nm3 / h;

[0092] 3) The desulfurizing agent nozzle 4 continues to move downward along the support 1 under the drive of the casing 2 until the lower nozzle 10 of the stirring tube 3 and the stirring rod 11 extend into the molten iron in the ladle 12, and the insertion depth is 1.35 meters . Simultaneously start the rotating motor 9 to make the stirring tube 3 rotate, and rotate to the normal operating speed in the range of 80 ~ 110 r / min;

[009...

Embodiment 3

[0105] 1) After the molten iron ladle 12 to be desulfurized is advanced to the directly below the stirring tube 3, sampling and temperature measurement of the molten iron are carried out;

[0106] 2) After the temperature measurement is completed, the desulfurizer nozzle 4 moves down along the bracket 1 driven by the casing 2;

[0107] 3) When the lower nozzle 10 of the stirring tube 3 is about to contact the liquid surface of the molten iron in the ladle 12, open the gas valve of the nitrogen pipe 18, and the nitrogen flow rate is 95 Nm3 / h;

[0108] 3) The desulfurizing agent nozzle 4 continues to move downward along the support 1 under the drive of the casing 2 until the lower nozzle 10 of the stirring tube 3 and the stirring rod 11 extend into the molten iron in the ladle 12, and the insertion depth is 1.3 meters . Simultaneously start the rotary motor 9 to make the stirring tube 3 rotate, and rotate to the normal operating speed in the range of 90 to 120 r / min;

[0109] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com