Solid biomass fuel boiler

A solid biomass and fuel technology, applied in the direction of solid fuel combustion, combustion equipment, fluid heaters, etc., can solve the problems of stopping the furnace for slag removal, coking of the grate, and inability to burn intermittently for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

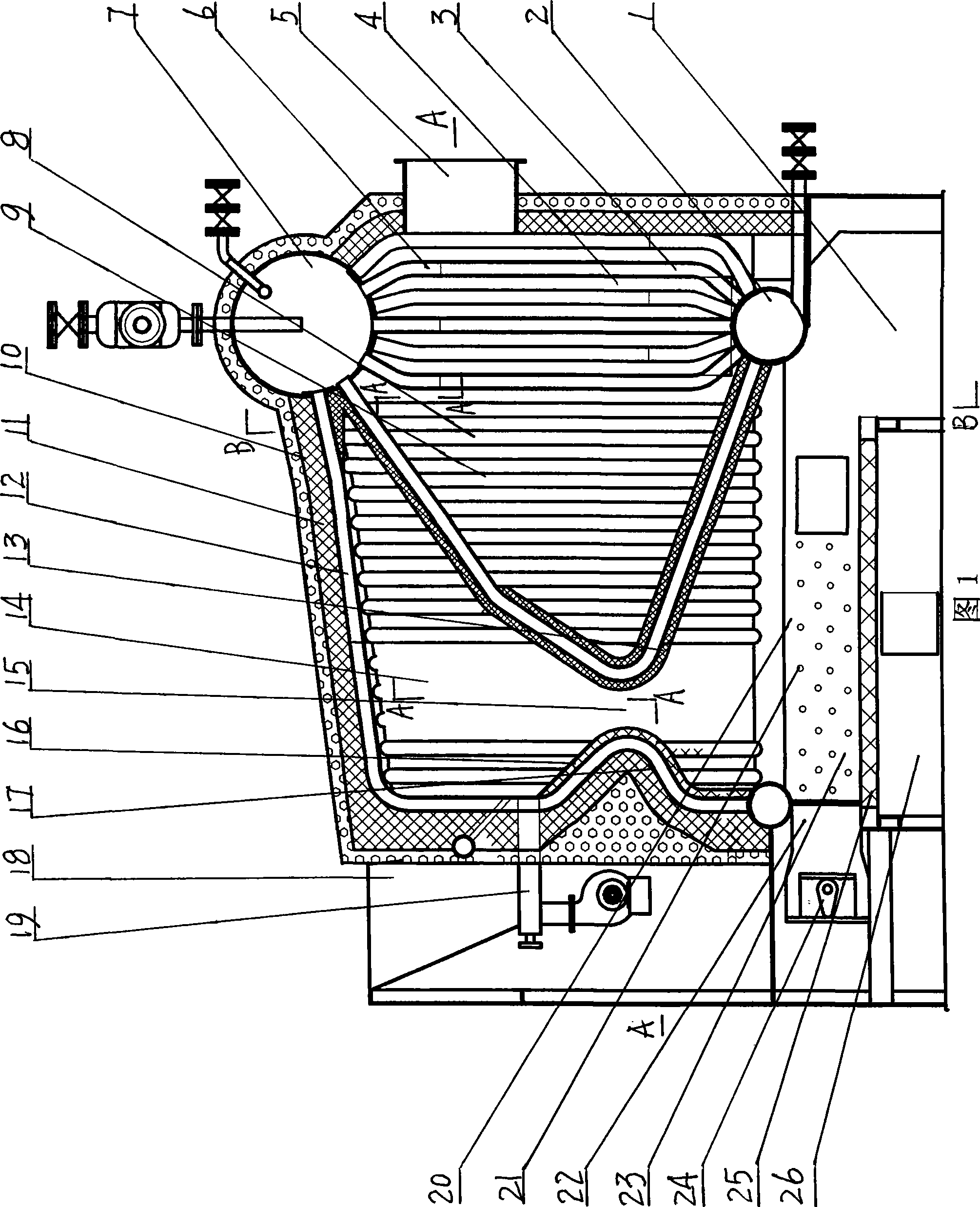

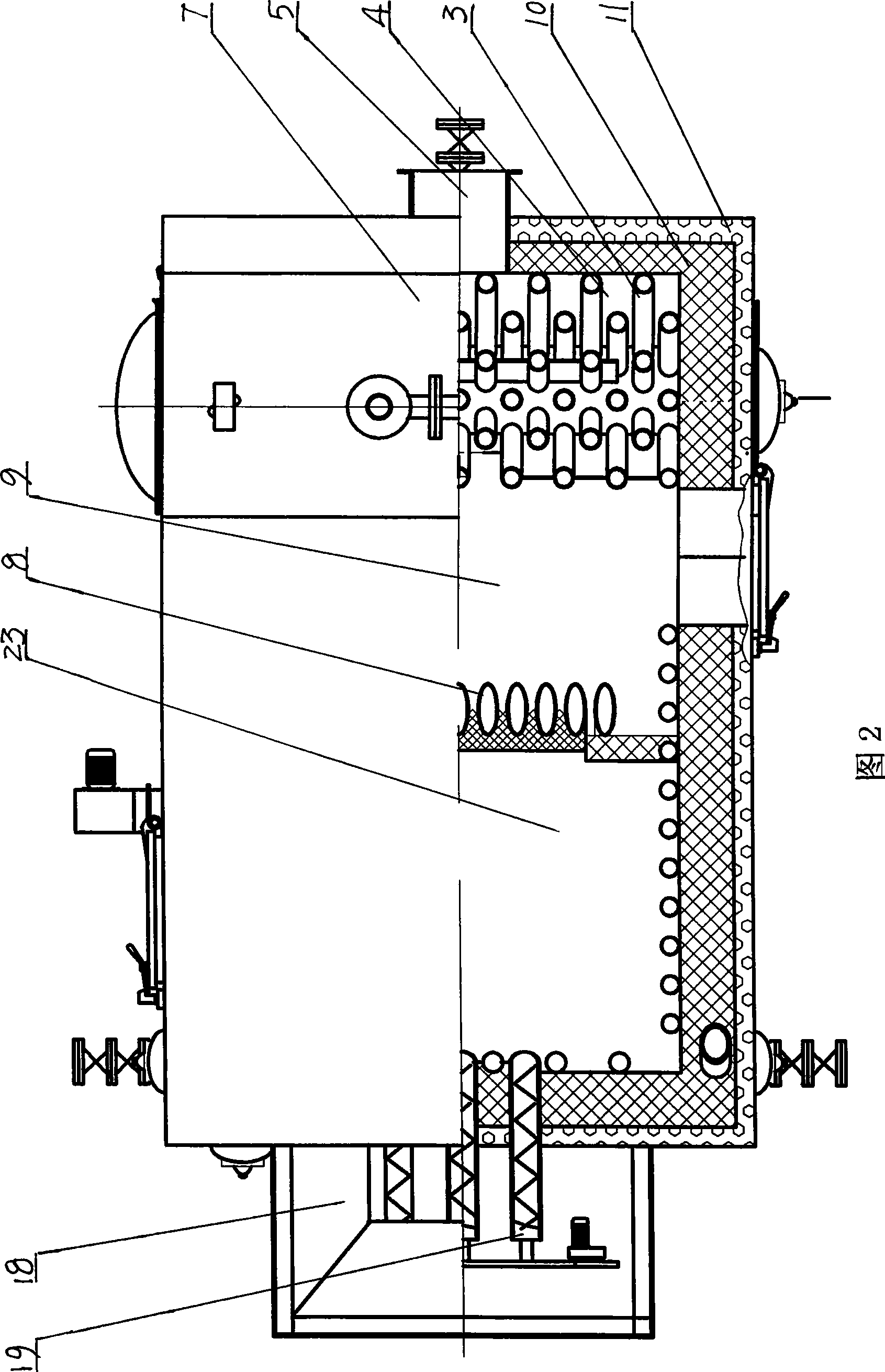

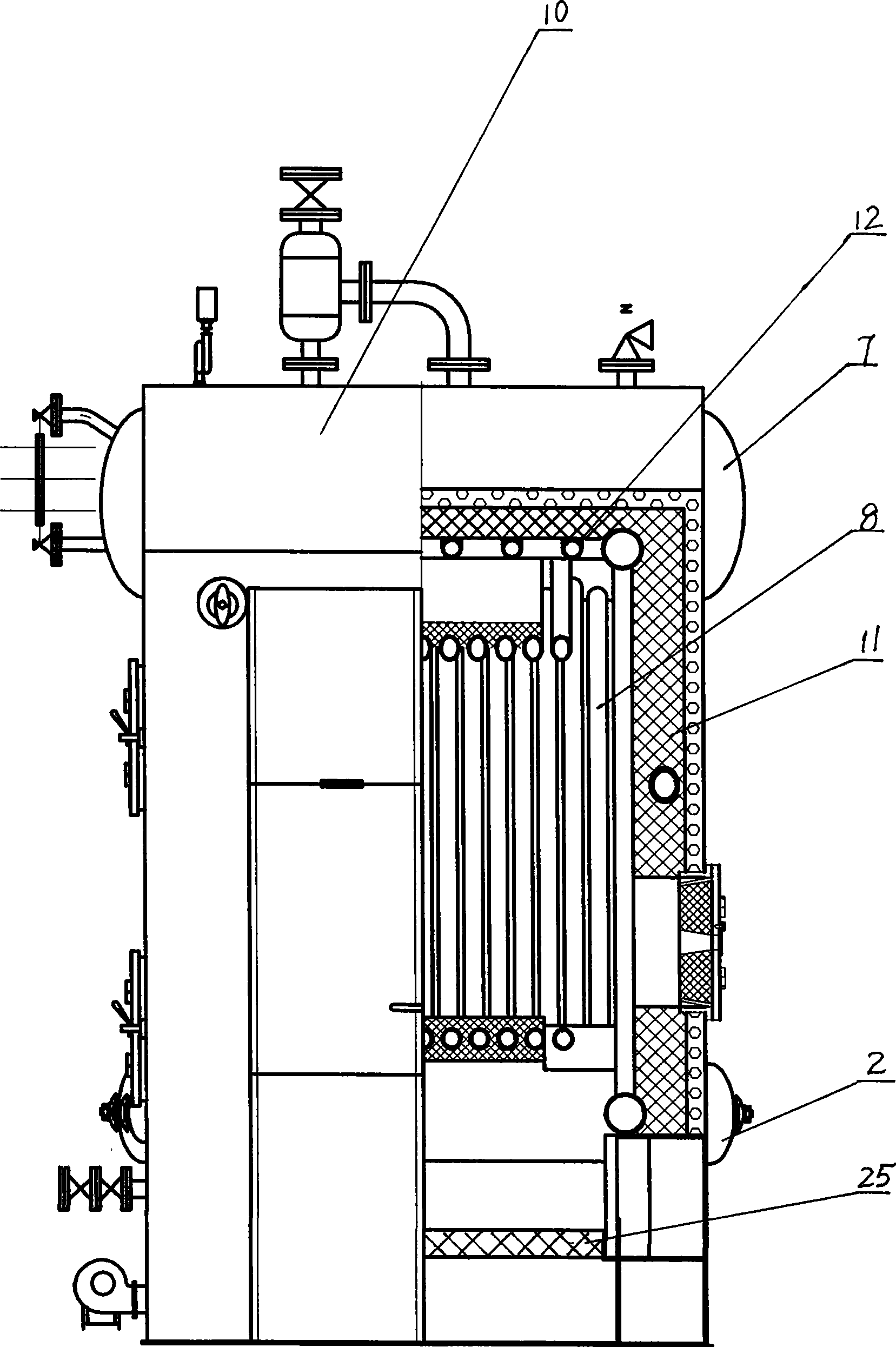

[0012] The present invention comprises the furnace body 10 that has insulating layer 11, and the bottom of furnace body 10 is combustion pool 23, and the inner wall of combustion pool 23 is the surface layer 20 of magnesium-carbon material, the fire grate 25 of magnesium-carbon material, the side of combustion pool 23 It is the air inlet 21; one end of the combustion pool 23 is the ash tank 1, and the other end of the combustion pool 23 is provided with a push block 22, and the push block 22 is connected with the motor by a cam mechanism 24.

[0013] Between the front arch 17 and the rear arch 13 of the body of heater 10 is a throat 15, and above the throat 15 is a combustion chamber 14;

[0014] In this way, the biomass fuel particles are evenly sent to the slope 16 of the front arch 17 of the throat 15 through the storage box 18 and a plurality of screw feeders 19, and slide down by their own weight, and then fall into the combustion pool 23 through the throat 15 . The effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com