Reclaiming agent and method and device for producing reclaimed rubber

A technology of rejuvenating agent and reclaimed rubber, applied in the direction of plastic recycling and recycling technology, can solve the problems of complex process, increased waste gas, environmental pollution, etc., and achieve the effect of wide source of raw materials, shortened desulfurization degree, and environmental protection of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

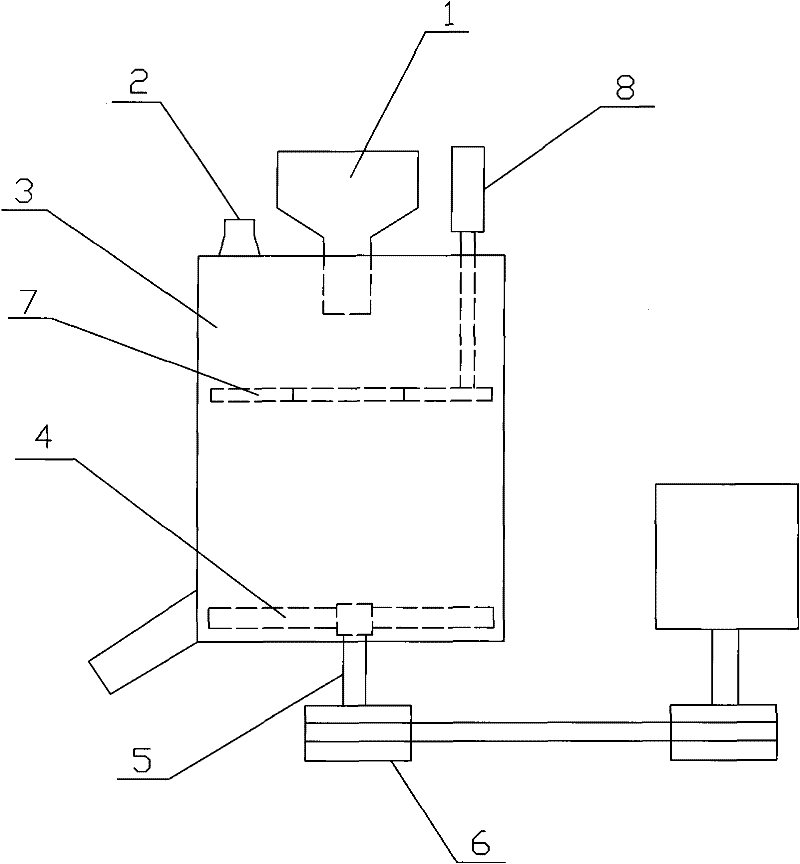

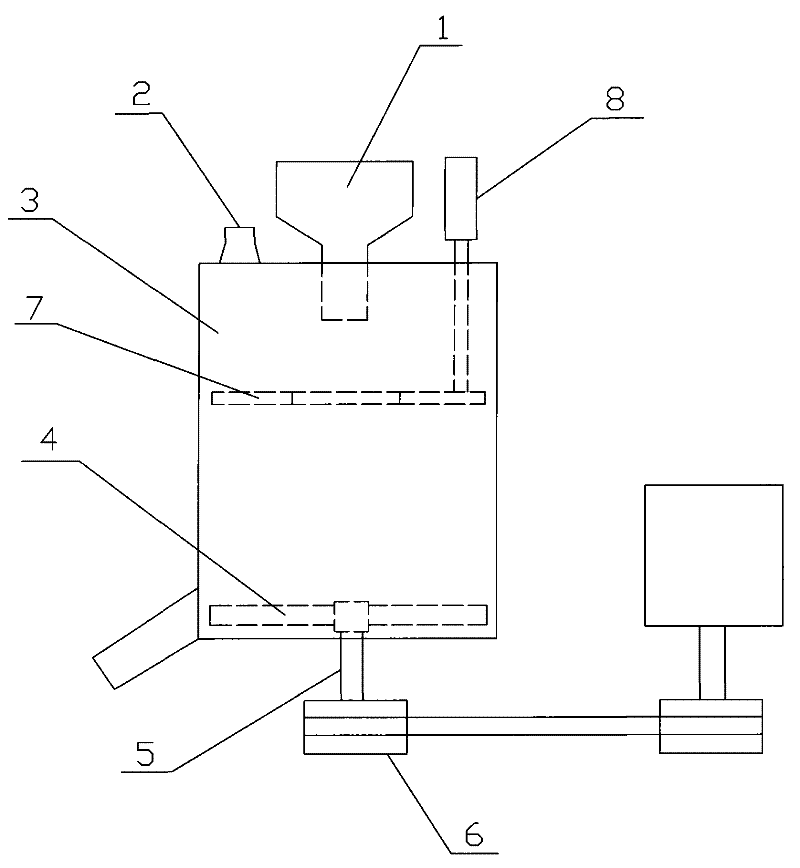

Image

Examples

Embodiment 1

[0034] A method for producing reclaimed rubber, comprising the following steps: crushing waste natural rubber into particles smaller than 5 mm, adding 3 parts of regenerant per 100 parts by weight, mixing to form a primary mixture, and putting it into an open mill Or on the refining machine, carry out thin pass, and become the reclaimed rubber in uniform flake shape. The regeneration agent is composed of the following parts by weight: 50 parts of triethanolamine; 20 parts of ferrous sulfate; 30 parts of zinc oxide; 10 parts of zinc stearate; 50 parts of zinc pentachlorothiophenate;

Embodiment 2

[0036] A method for producing reclaimed rubber, comprising the following steps: crushing waste synthetic rubber into particles smaller than 5 mm, adding 1 part of regenerant per 100 parts by weight, mixing to form a primary mixture, and putting it into an open mill or On the refining machine, carry out thin pass, and become the reclaimed rubber in uniform flake shape. The regeneration agent consists of the following parts by weight:

[0037] 100 parts of triethanolamine;

[0038] 100 parts of ferrous chloride;

[0040] Zinc stearate 30 parts;

[0041] 30 parts of zinc pentachlorothiophenate;

[0042] Split-22 50 parts;

[0043] 30 parts of white carbon black;

[0044] 40 parts of tall oil.

Embodiment 3

[0046] A method for producing regenerated rubber, comprising the following steps: the composite rubber composed of waste natural rubber and waste isoprene rubber is pulverized into particles smaller than 5 mm, wherein the weight ratio of waste natural rubber and waste isoprene rubber in the composite rubber can be 100:1, or 1:100, or 20:80, or 80:20, or 60:40, or 40:60, or 50:50 and other arbitrary weight ratios;

[0047] In terms of parts by weight, add 3 parts of regenerant to every 100 parts of compound glue, mix it to make primary mixture, put it into an open mill or refiner, and carry out thin pass to make a uniform sheet of regenerated rubber. The regeneration agent consists of the following parts by weight:

[0048] 70 parts of triethanolamine;

[0049] Any 60 parts of manganese naphthenate;

[0051] Zinc stearate 20 parts;

[0052] 100 parts of zinc pentachlorothiophenate;

[0053] Split-22 25 parts;

[0054] White carbon black 15 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com