Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

A technology for compounding rubber and biomass, which is applied in the field of environment-friendly biomass compound rubber rejuvenating agent and its preparation, can solve the problems of large environmental pollution, great smell and environmental protection, and does not meet the environmental protection technical requirements of recycled rubber, so as to reduce dependence and increase Friction coefficient, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings, but it is not limited to the embodiments.

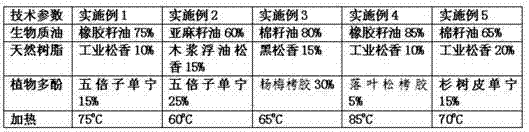

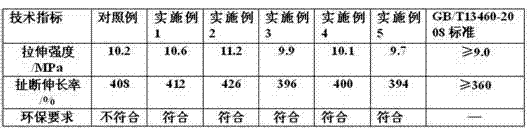

[0012] A production method of environmentally friendly biomass composite rubber regenerant. The parameters of each specific embodiment are shown in Table 1. The steps are:

[0013] (1) Material preparation

[0014] The environmentally friendly rubber regenerating agent is composed of three materials: biomass oil, natural resin and plant polyphenols, and their mass percentages are respectively 60-85:10-20:5-30. Among them, the biomass oil is natural rubber seed oil and cottonseed oil. Oil or linseed oil, the source is Yunnan Xishuangbanna Sanhuan Biological Technology Co., Ltd., the natural resin is industrial rosin processed from natural rosin or the by-product of the paper industry wood pulp high oil distillation rosin, the source is Yunnan Jinggu Forest Chemical ( Paper) Co., Ltd., plant polyphenols are pine bark tannin extract from Yunnan Moji...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com